Page 1

NRR 2-40

Installation Instructions 810369-03

Level Controller Type NRR 2-40

1

Page 2

Contents

Page

Important Notes

Usage for the intended purpose ..................................................................................... 7

Safety note / Warning ...................................................................................................... 7

Explanatory Notes

Scope of supply ..............................................................................................................8

System description ......................................................................................................... 8

Function ..........................................................................................................................8

Technical data ................................................................................................................ 9

Installation

NRR 2-40 ......................................................................................................................10

Example of installation .................................................................................................35

Wiring

Wiring diagram............................................................................................... 3, 4, 10, 11

Basic Adjustments

CAN bus........................................................................................................................ 12

Node ID .........................................................................................................................12

Factory setting ..............................................................................................................13

Controller NRR 2-40 .....................................................................................................13

Commissioning

NRR 2-40 ......................................................................................................................14

Control range ................................................................................................................14

Adjusting the control range.................................................................................... 14, 15

Establishing switchpoints and proportional band .................................................. 16–19

Calibrating the feedback potentiometer of an external control valve .......................... 20

Operation

Normal operation ..........................................................................................................21

Alarm / High-level alarm / Low-level alarm .................................................................. 21

Relay test high/low level alarm ....................................................................................22

System Malfunctions

Systematic fault finding prodedure ...............................................................................23

System malfunctions 1 to 4 ................................................................................... 24–26

Operation Malfunctions

Fault-finding list for troubleshooting ...................................................................... 26–27

Annex

Factory set default node ID ................................................................................... 28, 29

Assigning/changing node ID......................................................................................... 28

Neutral band .................................................................................................................30

Establishing / changing neutral band .................................................................... 30–32

Declaration of conformity.............................................................................................. 34

2

Page 3

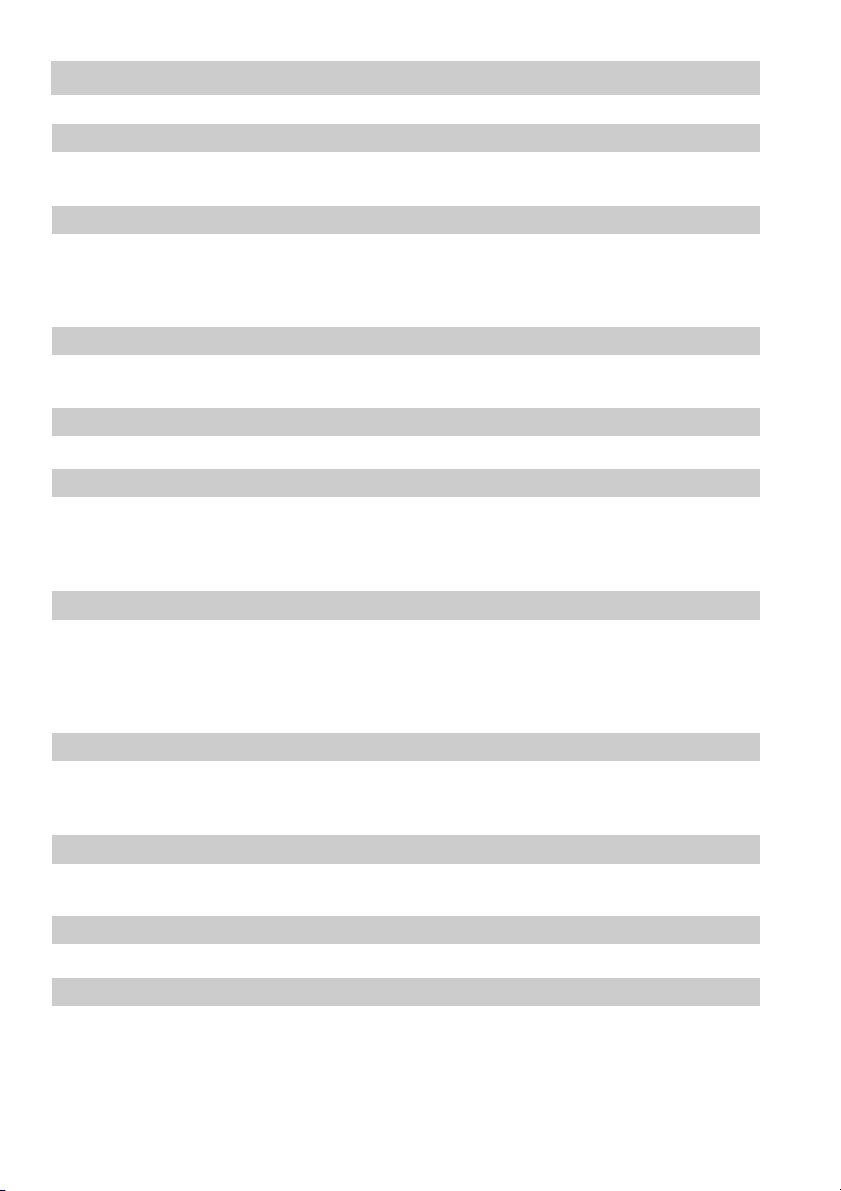

Wiring Diagram

NRR 2-40 as three-position stepping controller

Paired cable

Paired cable

Fig. 1

Fig. 2

3

Page 4

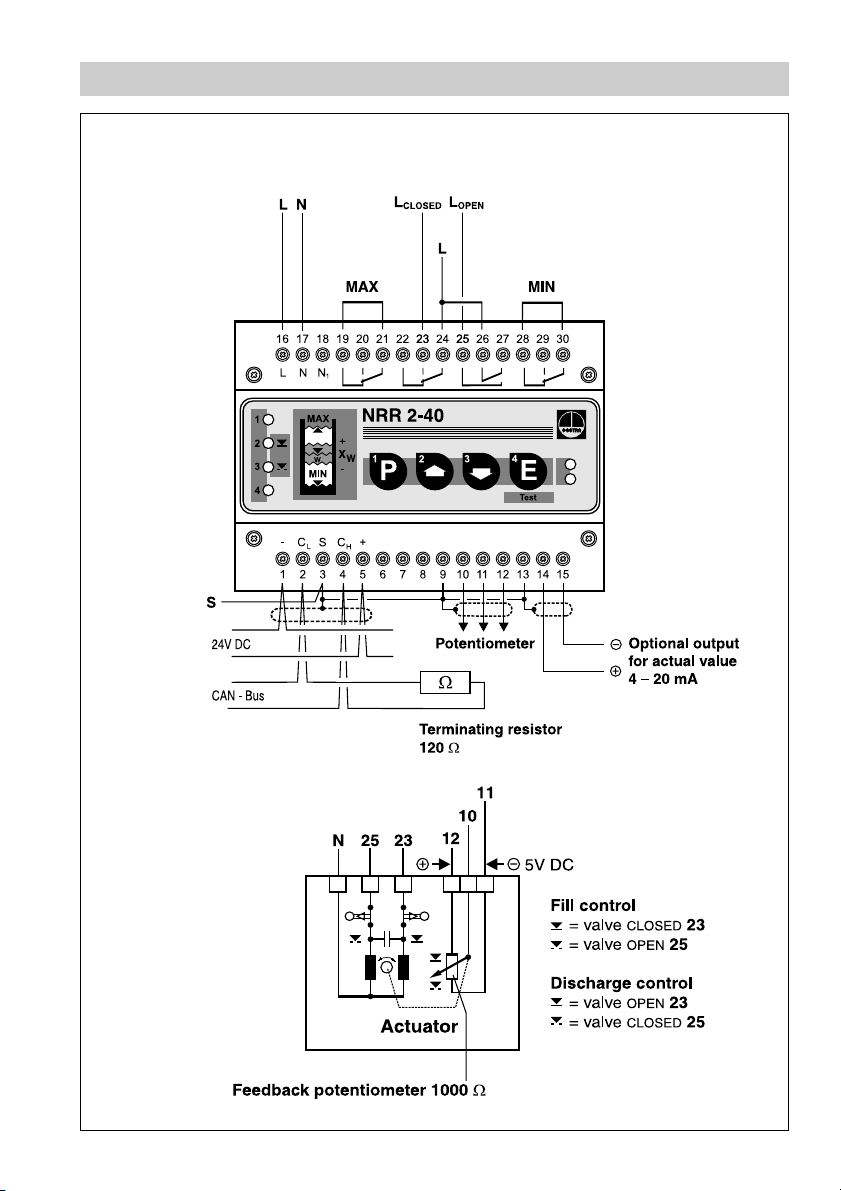

Wiring Diagram

NRR 2-40 as continuous controller

Paired cable

Paired cable

Fig. 3

Control terminal

and display unit

URB 1

Terminating resistor

120 Ω

*) CEP = central earthing point

Level switch

NRS 1-42

CEP*)

Voltage supply CAN data line

Fig. 4

4

Level controller

NRR 2-40

Level electrode

NRG16-42

Terminating resistor

120 Ω

Sensor

...

Page 5

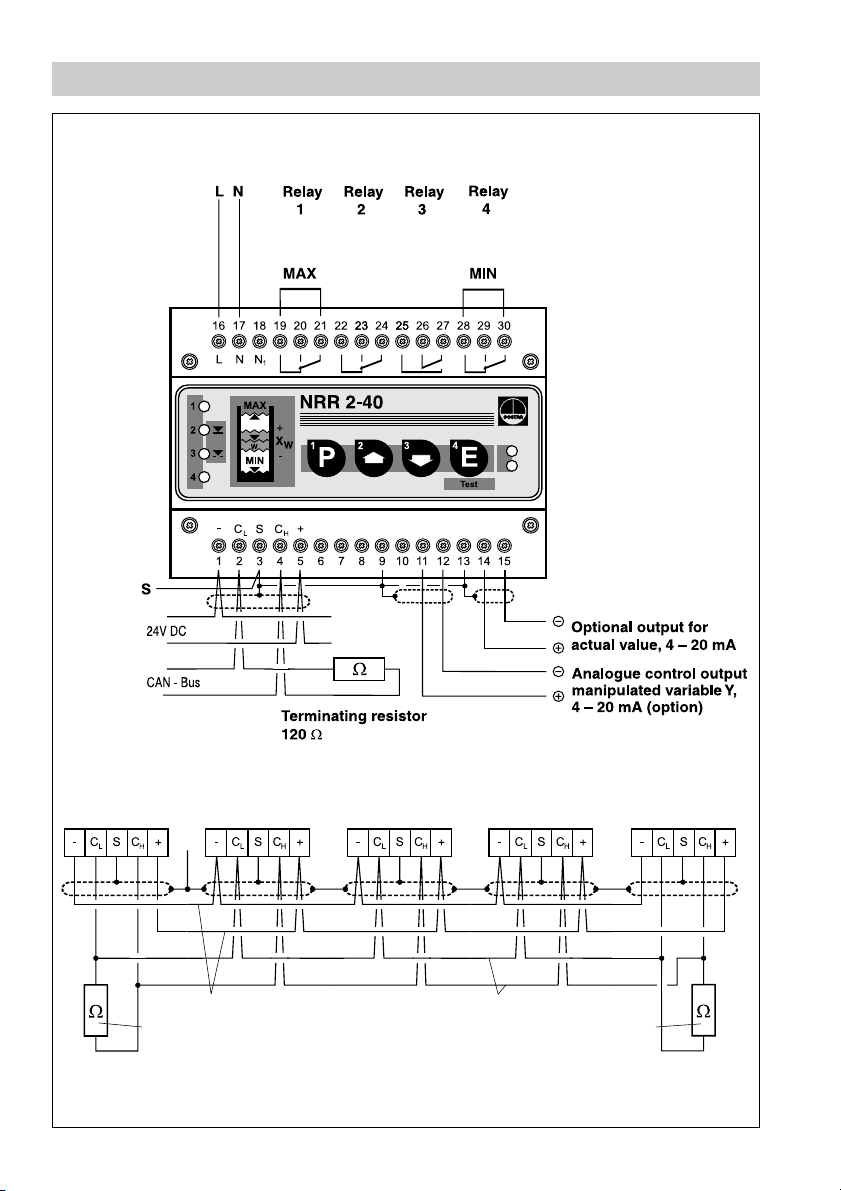

Parts Drawings

1

Fig. 5

7

6

A

A

B

8

5

234

Fig. 6

5

Page 6

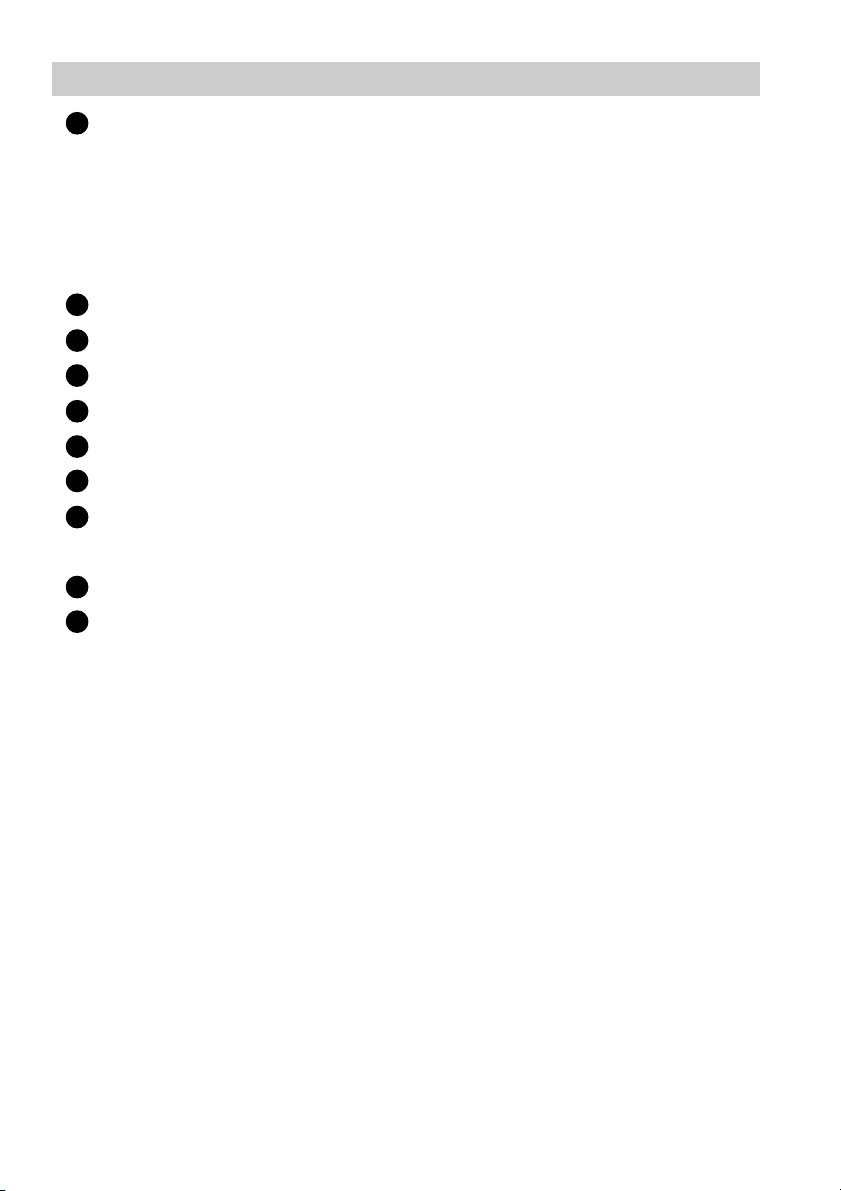

Key

Indicator LED

1

LED 1 – Switchpoint 1

LED 2 – Control valve closing

LED 3 – Control valve opening

LED 4 – Switchpoint 4

LED “Bus status”

2

LED “Power”

3

Enter button / Test mode

4

Decrease button

5

Increase button

6

7

Program button

Code selector switch, 10 poles

8

A

Terminal strip

B

Screws for terminal strip

High-level

not allocated

not allocated

Low-level

MalfunctionAlarm

Multifunction

Multifunction

Multifunction

Multifunction

6

Page 7

Important Notes

Usage for the intended purpose

Use level controller NRR 2-40 in combination with level electrode NRG 26-40 only

for controlling the liquid level of conductive fluids.

Safety Note

The equipment must only be installed by qualified staff.

Qualified staff are those persons who – through adequate training in electrical

engineering, the use and application of safety equipment in accordance

with regulations concerning electrical safety systems, and first aid & accident

prevention – have achieved a recognised level of competence appropriate

to the installation and commissioning of this device.

Warning

The terminal strip of the NRR 2-40 is live during operation. This presents

the danger of electric shock. Cut off power supply before fixing or

removing the housing lid or terminal strips.

7

Page 8

Explanatory Notes

Scope of supply

NRR 2-40

1 Level controller type NRR 2-40 (plug-in unit in plastic case with box terminals)

1 Terminating resistor 120 Ω

1 Installation manual

System Description

Use level controller type NRR 2-40 in combination with level electrode type

NRG 26-40 for level control and monitoring. The level controller has the following

functions:

■

Two liquid level limits with one switchpoint each (HIGH-LEVEL alarm, LOW-LEVEL

alarm)

■

Three-position stepping or modulating control within a predefined proportional

band

■

Continuous level monitoring within the control band defined by two preset limits

The NRR 2-40 features an optional output for a standard signal 4 – 20 mA.

The level data are transferred from the electrode NRG 26-40 to the level controller

via a CAN data bus.

Function

At regular intervals the level electrode NRG 26-40 sends a data telegram to the level

controller NRR 2-40. The data are transferred via a CAN bus to DIN ISO 11898,

adopting the CANopen protocol. The transmitted data are then evaluated and

allocated to the manually adjusted switchpoints. Optionally a standard signal

4 – 20 mA is established for external level indication. A relay de-energizing delay

can be set manually with the control terminal and display unit URB 1.

To guarantee the correct functioning and safety of the system the data transmitting

cycle of the level controller is constantly monitored. When the CAN bus line is

interrupted the level controller sends a visual signal to indicate a malfunction and the

relays 1 and 4 will be instantaneously de-energized (alarm position).

GESTRA’s control terminal and display unit URB 1 enables advanced features such

as adjustable energizing and de-energizing delays of the output relays (1– 25 s).

8

Page 9

Technical Data

Type approval no.

NRR 2-40: TÜV

.

98-399

Input / Output

Interface for CAN bus to DIN ISO 11898 CANopen

Feedback potentiometer 1000Ω

Output – voltage supply for electrodes

Power supply 24V DC, short-circuit protected.

Analogue output 4– 20 mA, load 500Ω for display of actual value (option).

Analogue control output for manipulated variable 4– 20 mA, max. load 500Ω (option).

4 volt-free relay contacts.

Max. contact rating with switching voltages of 24V AC, 115V AC and 230 V AC:

4 A resistive, 0.75 A inductive at cos ϕ 0.5

Max. contact rating with a switching voltage of 24V DC: 4 A.

Contact material: silver, hard-gold plated

Interference suppression

Provide contactor with an external RC combination (100 Ω / 47 nF)

Relay de-energizing delay

Output “

MIN”, “MAX” 3s

Indicators and adjustors

1 red LED for switchpoint “

1 red LED for switchpoint “

2 green LEDs for “

1 green LED “

1 red LED “

CONTROL VALVE OPENING” and “CONTROL VALVE CLOSING”

OPERATION”

BUS MALFUNCTION”

MAX”

MIN”

1 ten-pole code selector switch for setting node ID and baud rate

4 pushbuttons

Proportional band X

p

1 % to 100%

Valve position feedback

0 Ω to 1000 Ω (only when used as three-position stepping controller)

Switching range (dead band) X

Sh

0 % (factory setting) up to 15 %

Supply voltage

230 V ± 10 %, 50/60 Hz

115 V ± 10 %, 50/60 Hz (option)

Power consumption

10 VA

Protection

Case: IP 40 to DIN ISO 60529

Terminal strip: IP 20 to DIN ISO 60529

Admissible ambient temperature

0 °C to 55 °C

Case material

Front panel: polycarbonate, grey

Enclosure: polycarbonate, black

Weight

Approx. 0.8 kg

9

Page 10

Installation

NRR 2-40

Installation on mounting rail

1. Clip level controller onto mounting rail 35x 15 mm (DIN EN 50022).

2. Align level controller, fig. 19, 20.

Tool

■ Screwdriver (5.5/100)

Wiring

Note that screened multi-core twisted-pair control cable is required, e. g.

UNITRONIC

®

BUS CAN 2 x 2 x ... 2 or RE-2YCYV-fl 2 x 2 x ... 2.

The baud rate (data transfer rate) dictates the cable length between the bus nodes

and the total current consumption of the measuring sensors dictates the conductor

size.

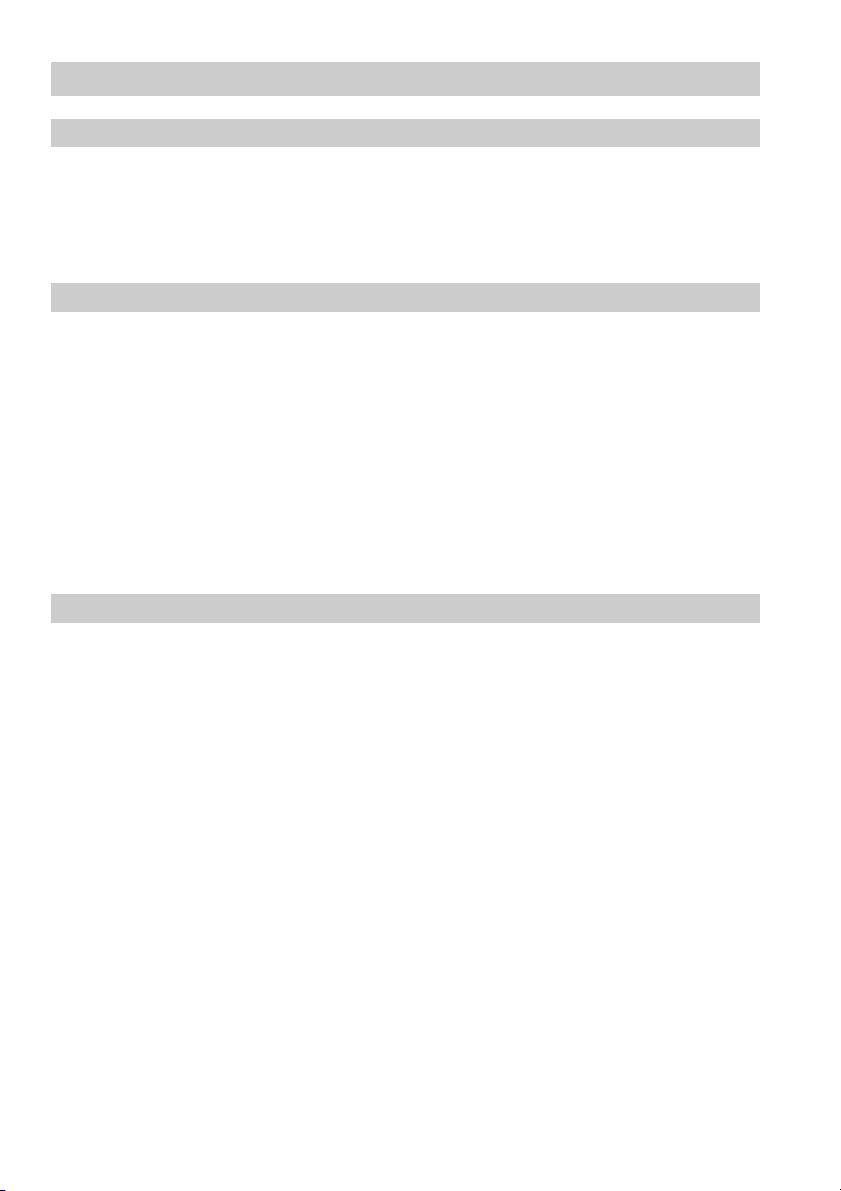

8S9S01SetarduaBhtgnelelbaC

FFO NO FFO s/tiBk052 m521

gnittesyrotcaF

NONOFFOs/tiBk521m0525.0x2x2

FFOFFONOs/tiBk001m53357.0x2x2

NOFFONOs/tiBk05m005

FFONONOs/tiBk02m0001

NONONOs/tiBk01m0001

sriapforebmuN

2

mm[ezisrotcudnocdna

]

43.0x2x2

notnedneped,tseuqerno

noitarugifnocsub

The baud rate is set via a code switch. Reduce baud rate if cable is longer than

specified in the table. Make sure that all bus nodes have the same settings.

To protect the switching contacts fuse circuit with 2.5 A (anti-surge fuse) or according

to TRD regulations (1.0 A for 72 hrs operation).

When a max. cable length of 1000 m is desired, make sure to modify the baud

rate accordingly. Refer to pages 28 and 29 for more details.

Wiring diagram

See wiring diagrams on pages 3 and 4.

UNITRONIC® is a registered trademark of LAPP Kabelwerke GmbH, Stuttgart

10

Page 11

Wiring – continued –

Attention

■

Wire equipment in series. Star-type wiring is not permitted.

■

Interlink screens of control cables such that electrical continuity is

ensured and connect them once to the central earthing point (CEP).

■

To protect the switching contacts fuse circuit with 2.5 A (slow blow) or

according to TRD regulations.

■

If more than one system components are connected to a CAN bus

network provide the first and last equipment with a terminating

resistor of 120 Ω. Fig. 4

■

The CAN bus network must not be interrupted while operating.

Any interruption will result in

If the level controller must be replaced, remove terminal

strip Fig. 6.

Before removing the CAN-bus line from the terminal strip disconnect all

relevant system components to avoid malfunction alarms.

Note

■

Connect screen only to designated terminals.

■

The loop resistance must be under 10 Ω.

■

The rated voltage is stated on the name plate.

■

When switching off inductive loads, voltage spikes are produced that

may impair the operation of control and measuring systems. Inductive

loads should therefore be provided with commercial arc suppressor

RC combinations.

■

In spite of correct wiring H.F. interference caused by the installation

may lead to system breakdowns and malfunction messages. If

necessary refer to the “Fault finding list for troubleshooting” on

pages 26 and 27.

HIGH/LOW level alarm!

A

Tool

■ Screwdriver for slotted screws, size 2.5, completely insulated according to

VDE 0680.

11

Page 12

Basic Adjustments

CAN bus

All level and conductivity controllers and associated electrodes are interconnected

by means of a CAN bus using the CANopen protocol. Every item of equipment

features an electronic address (node ID). The four-core bus cable serves as power

supply and data highway for high-speed data exchange.

The CAN address (node ID) can be set between 1 and 123.

The NRR 2-40 is configured at our works and ready for service with other GESTRA

system components without having to set the node ID.

If several systems of the same kind are to communicate in one CAN bus

network, be sure to assign one node ID for each individual system component.

Refer to pages 28 and 29 for more details.

Node ID

12

Page 13

Basic Adjustments – continued –

Factory setting

The level controller features the following factory set default values:

■ Baud rate: 250 kb/s

■ Proportional band X

■ Node ID: 040

■ Switchpoint 1: 80 %

■ Switchpoint 4: 20 %

: 20%

P

■ Relay with de-energizing delay switchpoint 1: 3s

■ Relay with de-energizing delay switchpoint 4: 3s

80 %

60%

40 %

20 %

100%

20 %

0%

Fig. 7

Controller NRR 2-40

The controller type NRR 2-40 is specially designed for level control in steam boilers

and feedwater deaerators. The NRR 2-40 is a proportional controller with steadystate deviation. The positive and negative deviation lies within the proportional band

(Xp) preselected by the user.

It is possible to control electric and pneumatic actuators. The control of electric

actuators is accomplished by an analogue signal which, in combination with an

active position feedback coming from the valve, is converted in the controller into a

three-position stepping signal. The control pulses for the electric actuator are

transmitted by a relay incorporated in the controller.

The control of pneumatic actuators is effected by an analogue signal 4– 20 mA.

The analogue signal is transmitted directly from the proportional controller to the

positioner of the pneumatic control valve, which means that an active position

acknowledgement is not possible.

X

values:

P

X

> large permanent deviation, valve reacts sluggishly

P

X

< no permanent deviation, valve may be hunting

P

recommended X

value 30 % – 100 %.

P

13

Page 14

Commissioning

NRR 2-40

Apply power to the unit.

The four indicator LEDs flash rapidly.

The LED “Power” lights up.

The test cycle takes about two seconds.

Control Range

Desired control range [mm]

Max. control range

Indicator LEDs flash rapidly

LED “Power” illuminated.

Determine the appropriate level

control range for your

system.

Fig. 8

Adjusting the control range

Press button for 3 sec.

Lower liquid level until the lower limit of

the control range is reached.

If necessary first use button to

adjust the upper limit of the control

range.

Press button briefly.

Note:

In the event of a system malfunction, the

LED(s) “Bus status” and/or “Power” will

be flashing rapidly when in program

mode. Quit program mode and

analyse the system malfunction

(see pages 22 – 26).

14

NRG 26-40

37

Lower measuring point

26

LEDs illuminated LEDs flash slowly

3 sec.

LEDs flash LEDs flash rapidly

briefly

LED “Power”

Page 15

Commissioning – continued –

Adjusting the control range – continued –

Press button briefly.

The lower limit of the desired control

range is now saved.

LEDs illuminated LEDs flash slowly

briefly

Press button briefly.

Raise liquid level until the desired upper

limit of the control range is reached.

Press button briefly.

Press button twice briefly.

The upper limit of the desired control

range is now saved.

The NRR 2-40 is now again in operating

mode.

LEDs illuminated LEDs flash slowly

briefly

LEDs illuminated LEDs flash slowly

briefly

twice briefly

15

Page 16

Commissioning – continued –

Switchpoints and proportional band

Switchpoint 1

Switchpoint 2

Switchpoint 3

Switchpoint 4

Selected control range

You can establish two switchpoints and a proportional band Xp within the control

range.

X

P

NRG 26-40

Fig. 9

16

80 %

70%

50 %

20 %

20%

90 %

45%

35 %

10 %

Fig. 10 (example) Fig. 11 (example)

10%

Page 17

Commissioning – continued –

Establishing switchpoints and proportional band

Press button briefly.

Raise or lower the liquid level in the

vessel until the desired value is reached.

Use button if you first want to

establish the proportional band or a

different switchpoint.

LED illuminated LEDs flash slowly

briefly

Press button briefly.

Lower the liquid level until switchpoint 4

within the desired control range is reached.

Note:

In the event of a system malfunction,

the LED(s) “Bus status” and/or “Power”

will be flashing rapidly when in program

mode.

Press button briefly.

Switchpoint 4 is now saved.

Press button briefly.

The lower limit of the proportional band

X

is now selected (switchpoint 3).

p

LED flashes LEDs flash slowly

briefly

LED illuminated LEDs flash slowly

briefly

LED illuminated LEDs flash slowly

briefly

Press button slowly.

Raise the liquid level until switchpoint 3

within the desired control range is reached.

Example:

Liquid level switchpoint 3 = 40% and

liquid level switchpoint 2 = 60% make a

proportional band X

The setpoint is at approx. 50%.

(60% – 40 %) = 20 %

p

LED flashes LEDs flash slowly

briefly

17

Page 18

Commissioning – continued –

Establishing switchpoints and proportional band – continued –

Press button briefly.

Switchpoint 3 is now saved.

LED illuminated LEDs flash slowly

briefly

Press button briefly.

The upper limit of the proportional band

X

is now selected (switchpoint 2).

p

Press button briefly.

Raise liquid level until switchpoint 2

within the desired control range is

reached.

Example:

Liquid level switchpoint 3 = 40% and

liquid level switchpoint 2 = 60% make a

proportional band X

of 20%.

p

Press button briefly.

Switchpoint 2 is now saved.

LED illuminated LEDs flash slowly

briefly

LED flashes LED flash slowly

briefly

LED illuminated LEDs flash slowly

briefly

Press button briefly.

Switchpoint 1 is now selected.

18

LED illuminated LEDs flash slowly

briefly

Page 19

Commissioning – continued –

Establishing switchpoints and proportional band – continued –

Press button briefly.

Raise liquid level until switchpoint 1

within the desired control range is

reached.

LED flashes LEDs flash slowly

briefly

Press button twice briefly.

Switchpoint 1 is now saved.

The NRR 2-40 is now again in operating

mode.

LED illuminated

twice briefly

19

Page 20

Commissioning – continued –

Calibrating the feedback potentiometer of an external control valve

The feedback potentiometer of an external control valve with electric actuator has to

be manually calibrated before commissioning.

1. Ascertain the total resistance of the feedback potentiometer.

2. Set the control valve manually into mid-position.

3. Adjust manually the position of the feedback potentiometer until the partial

resistance values of the measured total resistance are equal.

Fig. 12

Attention

20

■ The GESTRA level controller type NRR 2-40 requires a 1000

feedback potentiometer.

■ The NRR 2-40 works as two-position controller when the terminals for

the feedback potentiometer are not wired or the feedback potentiometer

is defective.

■ Use the control and display unit URB 1 for semi-automatic calibration of

the feedback potentiometer of an external control valve without

measurement of the resistance value. For more details see the

installation instructions of the URB 1.

ΩΩ

Ω

ΩΩ

Page 21

Operation

Normal operation

Normal operation, controller is working.

The green LEDs 2 and 3 flash when the

external control valve is opened or

closed.

All LEDs go out when the setpoint is

reached.

The LED “Power” is illuminated.

Alarm

There are two types of alarm:

■ High-level alarm

■ Low-level alarm

High-level alarm

LED 1 changes after the de-energizing

delay from rapid flashing to lighting.

Low-level alarm

LEDs flash when the control valve is motored

LED “Power” illuminated

illuminatedflashes

LED 4 changes after the de-energizing

delay from rapid flashing to lighting.

flashes illuminated

21

Page 22

Operation – continued –

Relay test high/low-level alarm

Press button briefly.

The test mode is active for 5 seconds.

LEDs illuminated

briefly

Hold down button .

Indicator LED 4 goes out

LED 4 goes out.

A low-level alarm is simulated for

switchpoint 4.

Hold down button .

Indicator LED 1 goes out

LED 1 goes out.

A high-level alarm is simulated for

switchpoint 1.

System Malfunctions

There are four types of system malfunctions that might occur in the level electrode

and the level controller:

■ Max. admissible temperature in electrode terminal box exceeded

■ No or faulty communication between controller and electrode

■ Malfunction in CAN bus

■ Failure of 24 V power supply unit built in level controller NRR 2-40

22

Attention

The terminal strip of the NRR 2-40 is live during operation.

This presents the danger of electric shock.

Cut off power supply before mounting or removing the equipment.

Page 23

System Malfunctions – continued –

Systematic Malfunction Analysis

The sources of malfunctions occurring in CAN bus systems operating with several

bus-based stations must be analysed systematically since faulty components or

incorrect settings can give rise to negative interactions with intact bus devices in

the CAN bus system. These unwanted interactions can cause error messages in

fully functional bus devices, which will make fault detection even more difficult.

We recommend the following systematic fault finding procedure:

Step 1 (Start)

Detach terminal strips

in all sensing units of

bus nodes.

Level electrode

Conductivity electrode

Pressure sensor

Temperature sensor

Check

Use fault-finding

list to correct

fault(s).

Final test:

have all faults

been eliminated?

System

Malfunction

Use fault-finding list

to identify the

fault(s).

Cut off power supply

to the equipment.

Step 2

Plug in terminal strips

of the bus nodes

e. g.

NRS ...

and

NRG ...

(sensing unit)

Step 3

Apply mains voltage

to bus nodes,

e. g.

NRS ...

and

NRG ...

Check next system

System O.K.

Detach terminal

strips between

bus nodes

e. g.

NRS ...

and

NRG ...

23

Page 24

System Malfunctions – continued –

System malfunction 1

The four indicator LEDs flash slowly.

High/low-level alarm

LEDs flash slowly

Fault:

Remedy:

The max. admissible temperature in the electrode terminal box is exceeded.

Insulate electrode flange to protect the equipment against heat radiation.

As soon as the temperature drops below the max. admissible limit the equipment

automatically returns to normal operation.

System malfunction 2

LEDs flash rapidly

The four indicator LEDs flash rapidly.

High/low-level alarm

Fault:

Remedy:

Fault:

Remedy:

The CAN bus line between the bus-based devices is interrupted.

Check wiring and terminals. Restart system.

Incorrect node ID(s).

Set correct nodes ID(s), referring to section “Annex - assigning and

changing the node IDs”. Disconnect the system from its power supply.

After 5 sec. apply power and restart system.

24

Page 25

System Malfunctions – continued –

System malfunction 3

LED “Bus status” flashes slowly.

Fault

: Malfunction in CAN bus.

Remedy:

LED “Bus status” flashes slowly.

High/low-level alarm

Restart system.

LED flashes slowly

LED flashes slowly

Fault:

Remedy:

Fault:

Remedy:

Fault

Remedy:

Data transfer in CAN bus interrupted.

The bus cables have to be correctly connected according to the wiring

diagram (observe polarity!). Make sure that all end-of-line devices are

provided with 120 Ω terminating resistors, see wiring diagram.

Disconnect the system from its power supply. After 5 sec. apply power

and restart system.

The baud rate of one or more bus-based devices is not set correctly.

Check baud rate settings of all bus devices. The baud rates must be

identical. Refer to section “Annex” for more details.

Disconnect the system from its power supply. After 5 sec. apply power

and restart system.

The overall length of the bus cable does not correspond to the selected

baud rate.

Change baud rate settings of all bus-based devices according to the

indications specified in “Annex”.

Disconnect the system from its power supply. After 5 sec. apply power

and restart system.

25

Page 26

System Malfunctions – continued –

System malfunction 4

LED “Power” flashes slowly.

LED flashes slowly

Fault:

Remedy:

Fault:

Remedy:

The power supply unit (PSU) is overloaded and may be misused for other

components.

Check load of power supply unit. Be sure to use the PSU only for the

voltage supply of bus-based network components.

Disconnect the system from its power supply. After 5 sec. apply power

and restart system.

Power supply unit defective.

Replace PSU.

Operation Malfunctions

Attention

The terminal strip of the NRR 2-40 is live during operation.

This presents the danger of electric shock.

Cut off power supply before mounting or removing the equipment.

Fault-finding list for troubleshooting

Device does not work – no function

Fault:

Remedy:

LED “Power” does not light up.

Apply power. Connect the equipment properly, referring to wiring

diagrams.

26

Page 27

Operation Malfunctions – continued –

Fault-finding list for troubleshooting – continued –

Device does not work – interference signal

Fault:

Remedy:

Device fails to function properly

In spite of correct wiring and commissioning of the equipment an

interference signal is indicated.

The interference signal is caused by high-frequency interferences coming

from the installation. For interference suppression we supply ferrite rings,

stock code # 147253. The 230 V supply lines should be looped five to ten

times through the ferrite ring. If several controllers are used in one

system, they can be fed from the interference suppressed supply lines.

For the interference suppression of the bus line we supply hinged-shell

ferrite rings, stock code # 147254. The hinged-shell ferrite rings are

clamped onto the bus line close to the terminal strip of the controller.

Fault:

Remedy:

Fault:

Remedy:

Fault

Remedy:

Fault:

Remedy:

Fault:

Remedy:

The device works as two-position controller

Fault:

Remedy:

Incorrect function at analogue output. The following actual value indicator

shows incorrect values.

Correct the switchpoint settings and the control range settings of the

electrode.

Switchpoints and actual value indication drift continuously towards 100%.

Deposits have accumulated on the electrode rod. Remove the level

electrode and clean the electrode rod.

A high-level alarm is raised although the liquid level is below high level.

Deposits have accumulated on the electrode rod. Clean the electrode rod.

Defective electrode insulation. Replace level electrode.

Liquid level below switchpoint “low level”, device fails to switch.

Check installation of level electrode and vent hole in the protection tube.

If an external measuring pot is used make sure to open the isolating

valves.

“High-level” switchpoint exceeded – no indication.

Level switch defective. Replace the equipment.

Feedback potentiometer defective or not connected.

Connect equipment according to wiring diagram. Check feedback

potentiometer.

If faults occur that are not listed above or cannot be corrected, please contact our

service center or authorized agency in your country.

27

Page 28

Annex

Warning

Ther terminal strip of the NRR 2-40 is live during operation. This presents

the danger of electric shock.

Cut off power supply before fixing or removing the housing lid or the

terminal strips.

Factory set default node IDs

Controller Level electrode

The node IDs of the individual units have to be adjusted manually.

For more information refer to the corresponding installations manuals.

Assigning/ changing node ID

If several systems of the same kind are to communicate in one CAN bus network, be

sure to assign one node ID for each individual system component (e. g. controller).

Detach terminal strip in order to set code switch .

Attention

■ Do not assign the same node ID twice within the CAN bus network.

A

8

Fig. 13

28

Page 29

Annex – continued –

Node ID

OFF

S1

OFFS2

OFFS3

ON

S4

OFFS5

ON

S6

OFFS7

Fig. 14 (Factory setting)

S8

OFF

S9 S0

ON

ONON

16

32

64

OFF

ON

ON

OFF 1000 m

ON

ONON

Fig. 16 (Factory setting 250 kBit/s)

ON

ON

ON

40

1

2

S1

S2

4

8

S4

S7

Fig. 15 (Example)

Baud rate

Cable length

250 kBit/s

125 kBit/s

100 kBit/sOFFOFF 335 m

50 kBit/sOFF

20 kBit/s

10 kBit/s

ON

ON

OFFS3

ON

OFFS5

OFFS6

ON

125 mOFF

250 m

500 m

1000 m

Node ID

1

2

4

8

16

32

64

75

29

Page 30

Annex – continued –

Warning

The terminal strip of the NRR 2-40 is live during operation.

This presents the danger of electric shock.

Cut off power supply before fixing or removing the housing lid or terminal

strips.

Neutral band

To guarantee a smooth controlled system you can establish a neutral band for the

setpoint W. The setpoint is defined by the proportional band which is determined by

switch point 2 and 3.

Detach terminal strip in order to set code switch .

A

Fig. 17 (Factory setting of neutral band)

Establishing/ changing neutral band

Note down current node ID and baud rate.

■ Node ID in this example “40”

■ Baud rate in this example

“

250 kBit/s”

8

Switch off mains voltage.

The four status LEDs go out.

The LED “Power” goes out.

30

LED “Power” extinguished

Page 31

Annex – continued –

Adjust neutral band according to fig. 18.

■ Neutral band in this example “2 %”

Apply mains voltage.

The four status LEDs flash rapidly. If the

LED “Power” is alight, the adjustment

was successful.

If the LED (“Bus status”) above the LED

“Power” is alight, repeat the adjustment

procedure.

Switch off mains voltage.

The four status LEDs go out.

The LED “Power” goes out.

Adjust current node ID and baud rate.

■ Node ID in this example “40”

■ Baud rate in this example

“

250 kBit/s”

Apply mains voltage.

The four status LEDs flash rapidly.

The LED “Power” is illuminated.

The system is ready for operation.

Status LEDs flash rapidly

LED “Power” illuminated

LED “Power” extinguished

Status LEDs flash rapidly

LED “Power” illuminated

31

Page 32

Annex – continued –

S1 S2 S3 S4 S5 S6 S7 S8 S9 S10 N-Zone

OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF 0 %

OFF OFF OFF OFF OFF OFF OFF

OFF OFF OFF OFF OFF OFF OFF OFF

OFF OFF OFF OFF OFF OFF OFF

OFF OFF OFF OFF OFF OFF OFF OFF OFF

OFF OFF OFF OFF OFF OFF OFF

OFF OFF OFF OFF OFF OFF OFF OFF

OFF OFF OFF OFF OFF OFF OFF

Fig. 18

ON

OFF OFF 1 %

ON

OFF 2 %

ON ON

OFF 3 %

ON

ON

OFF

ON

ON ON

ON ON ON

5 %

7 %

10 %

15 %

32

Page 33

For your notes

33

Page 34

Annex – continued –

Declaration of conformity

We hereby declare that the equipment NRR 2-40 conforms to the following European

guidelines:

■ LV guideline 73/23/eec version 93/68/eec

■ EMC guideline 89/336/eec version 93/68/eec

which are based on the following harmonised standards:

■ LV standard DIN EN 50178

■ EMC standard DIN EN 50 081-2, DIN EN 61 000-6-2

This declaration is no longer valid if modifications are made to the equipment without

consultation with us.

Bremen, 23rd July 2002

GESTRA GmbH

Head of the Design Dept.

Uwe Bledschun

(Academically qualified engineer)

Key

Terminal strips

Supporting rail 35 x 15 to DIN EN 50022

Quality Assurance Manager

Lars Bohl

(Academically qualified engineer)

34

Page 35

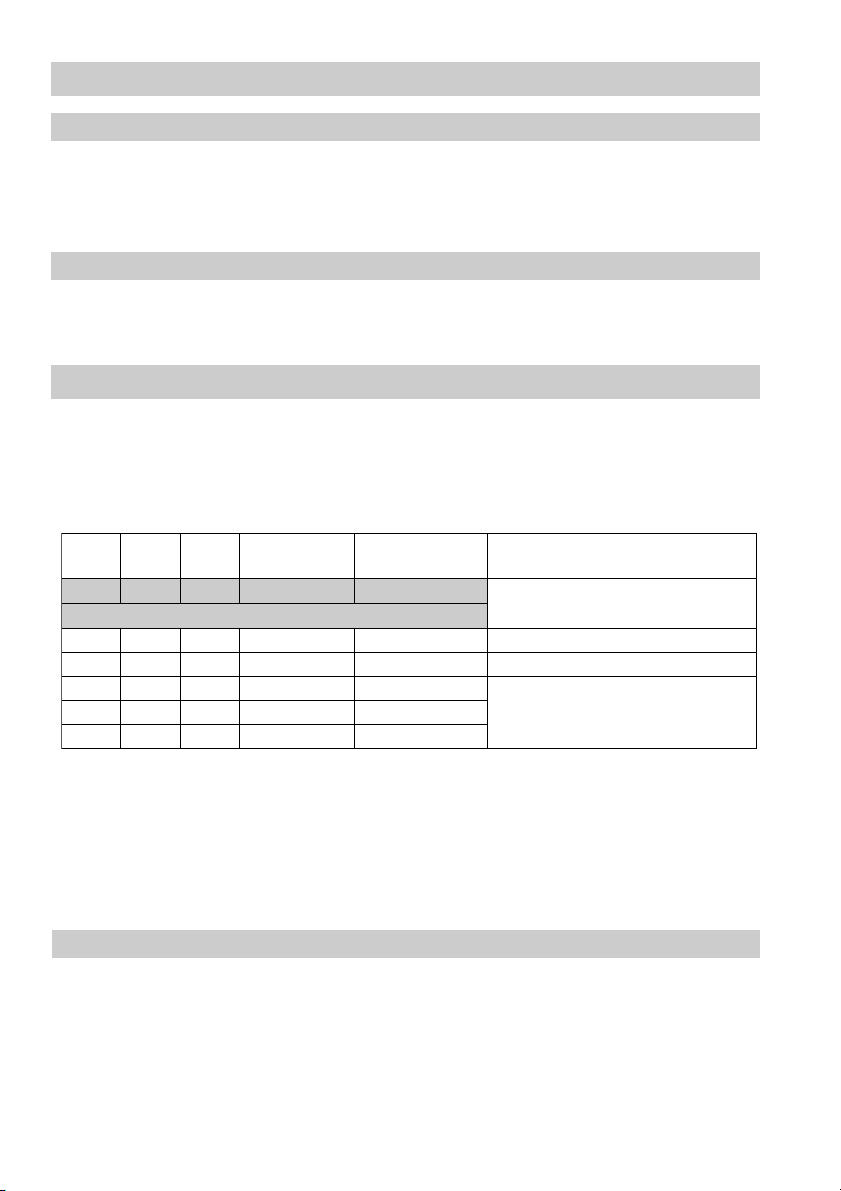

Example of Installation

Fig. 19

100

73

MAX 55 °C

118

MAX 95%

Fig. 20

20 20

35

Page 36

GESTRA Gesellschaften · GESTRA Companies · Sociétés GESTRA · Sociedades Gestra · Società GESTRA

Vertretungen weltweit · Agencies all over the world · Représentations dans le monde entier · Representaciones en todo el mundo · Agenzie in tutto il mondo

Great Britain

Flowserve Flow Control (UK) Ltd.

Burrel Road, Haywards Heath

West Sussex RH 16 1TL

Tel. 00 44 14 44 / 31 44 00

Fax 00 44 14 44 / 31 45 40

E-mail: sales@flowserve.com

France

Flowserve Flow Control S.A. S.

10 Avenue du Centaure, BP 8263

F-95801 CERGY PONTOISE CEDEX

Tél. 0 03 31/ 3443 26 60

Fax 00331/34432687

E-mail: gnation@flowserve.com

España

GESTRA ESPAÑOLA S.A.

Luis Cabrera, 86-88

E-28002 Madrid

Tel. 00 3491 /5 152 032

Fax 003491/4136747; 5152036

E-mail: gestra@gestra.es

Italia

Flowserve S.p. A

Divisione Italgestra

Via Prealpi, 30 – 20032 Cormano (MI)

Tel. 00 3902 /66 3251

Fax 00 39 02/ 66 32 55 60

E-mail: info@italgestra.it

Portugal

Flowserve Portuguesa, Lda.

Av. Dr. Antunes Guimarães, 1159

Porto 4100-082

Tel. 0035122/6198770

Fax 003 51 22/ 61075 75

E-mail: gestra@gestra.pt

®

GESTRA GmbH

Postfach 10 54 60, D-28054 Bremen, Münchener Str. 77, D-28215 Bremen

Telefon +49 (0) 421 35 03- 0, Telefax +49 (0) 421 35 03- 393

E-Mail gestra.gmbh@flowserve.com, Internet www.gestra.de

A Unit of Flowserve Corporation

810369-03/1103c · ©2000 GESTRA GmbH · Bremen · Printed in Germany

36

Loading...

Loading...