Page 1

GESTRA Steam Systems

NRGS 15-1

Installation Instructions 818479-00

Level Switch NRGS 15-1

Page 2

Contents

Page

Important notes

Usa ge for the intended purpose.......................................................................................8

Safety note.......................................................................................................................8

Danger .............................................. ...............................................................................8

Explan atory Notes

Scope of supply ...............................................................................................................9

Function............................................ ...............................................................................9

Technical data................................................................................................................10

Corrosion resistance......................................................................................................12

Establishing Functions

Select functio n ...............................................................................................................13

Factory setting ...............................................................................................................14

Cutting electrode ti ps to length ......................................................................................14

Adjust functio n ...............................................................................................................15

Set sensitivity range.......................................................................................................15

Tools ........................................................... ...................................................................15

Installation

Level switch NRGS 15-1................................................................................................16

Align terminal box ..........................................................................................................17

Remove terminal box.....................................................................................................17

Mount terminal box .......................................................... ..............................................18

Tools ........................................................... ...................................................................18

Wiring

Connec t level switch NRGS 15-1...................................................................................19

Tools ........................................................... ...................................................................19

Wir ing diagram............................................ ...................................................................20

Commissioning

Chec k wiring ..................................................................................................................21

Apply mains voltage.......................................................................................................21

Chec k switching functions..............................................................................................22

Malfunctions / Troubleshooting

Fault finding list..............................................................................................................24

Replace electronic circuit board.....................................................................................25

2

Page 3

Conte nts

Page

Annex

Adjust other functions ....................................................................................................26

Installation in non-metallic vessel ..................................................................................27

Revise d..........................................................................................................................27

Examples of Installation.................................................................................................28

3

Page 4

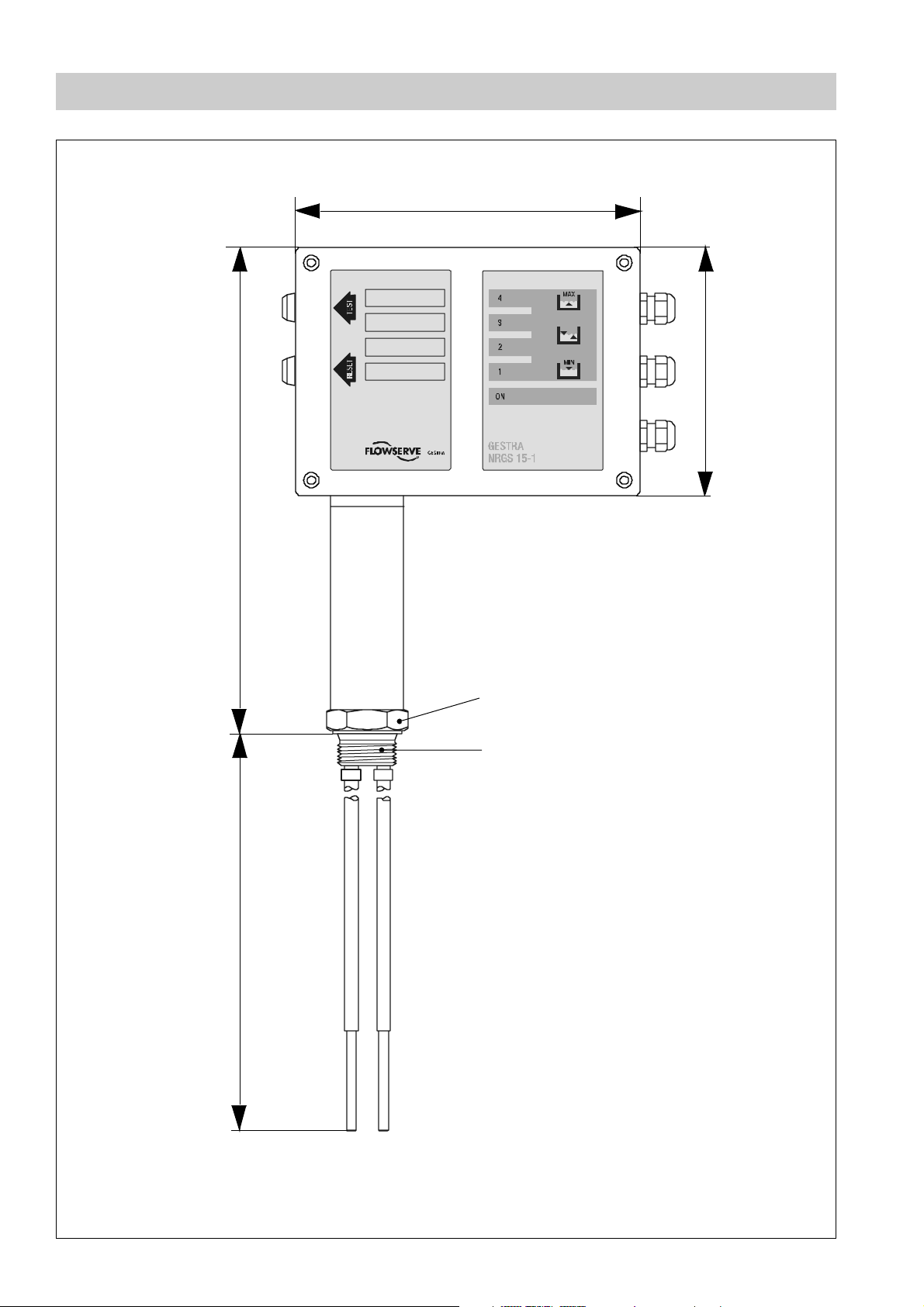

Dimensions

180

130

~355 1000

b = 60

12

A. F. 41

1" BSP to DIN ISO 228

Fig. 1

4

Page 5

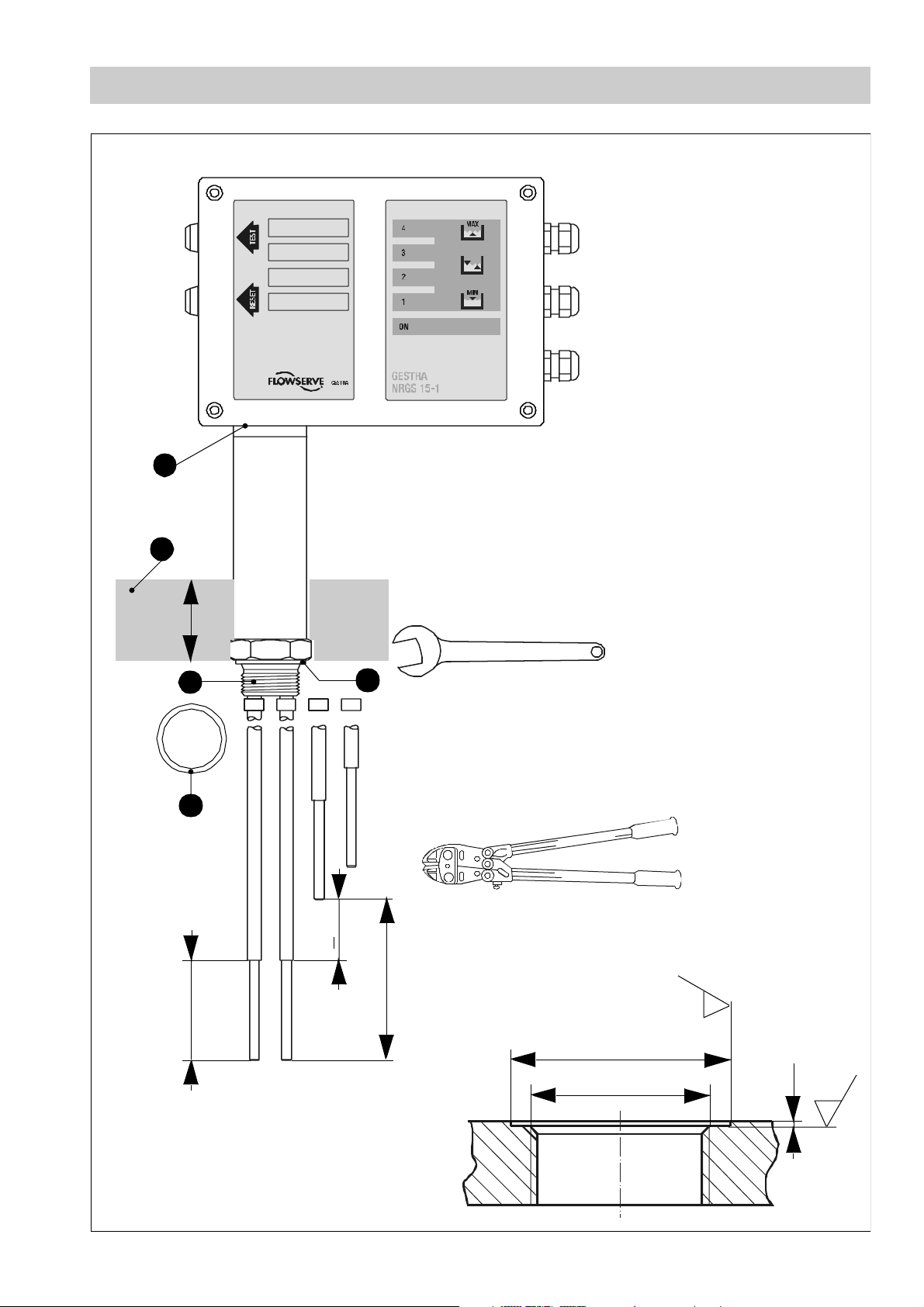

Func tio na l El eme nts

A

B

40

C

D

1

234

A. F. 41

E

>14

Fig. 2

50

65-70

Fig. 3

Ø 40

1" BSP to DIN

N10

0.5

N8

5

Page 6

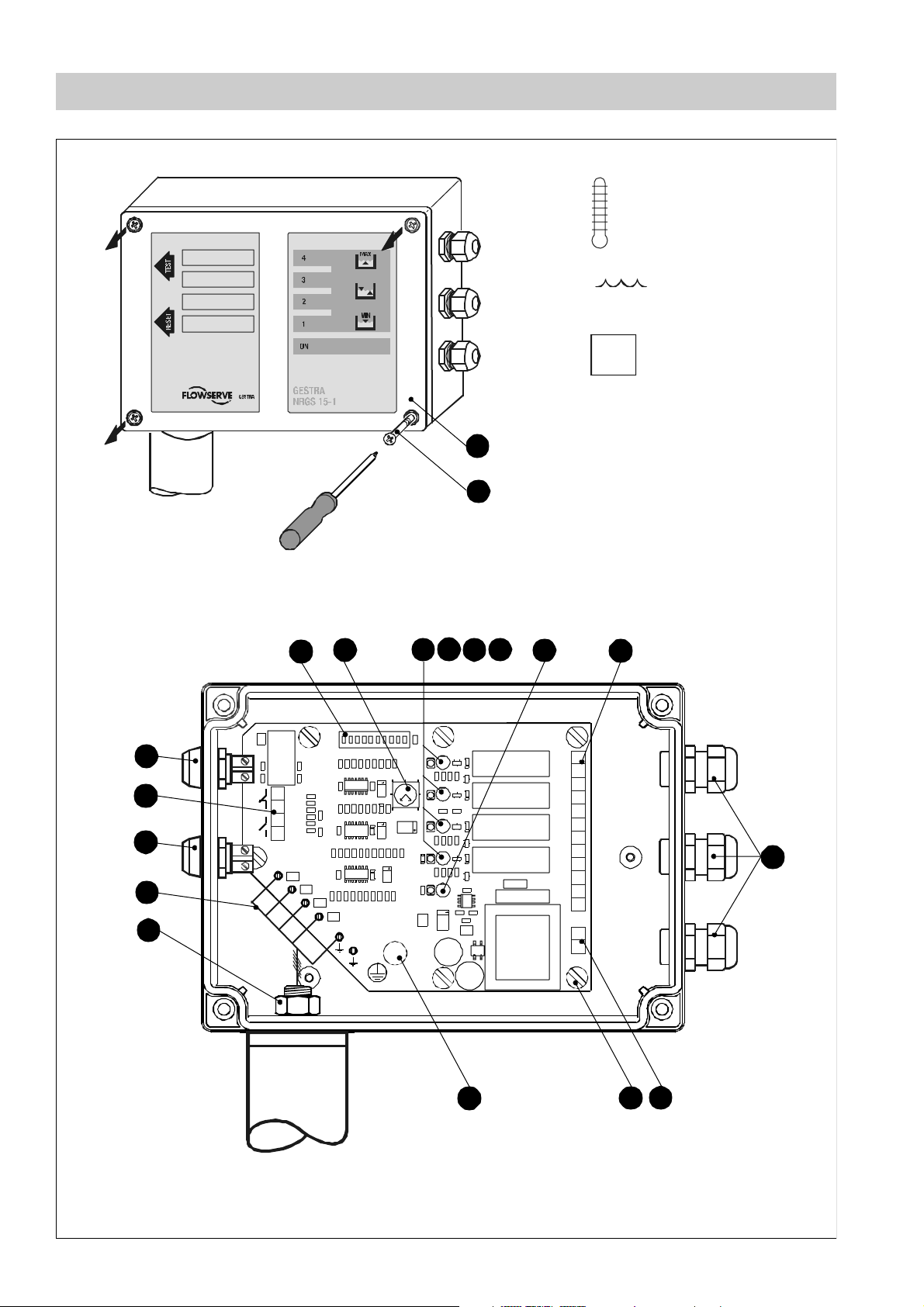

Functional Elements

Fig. 4

MAX 70 °C

%

MAX 95 %

IP 65

F

G

8

O

9

N

M

2

7

6

1

4

3

3 4

5

H

15

14

13

12

11

10

9

8

7

7

7

6

6

6

5

5

5

4

4

4

I

2

1

2

1

J

JKL

Fig. 5

6

Page 7

Key

1

LED 1 red

2

LED 2 red

3

LED 3 yellow

4

LED 4 red

5

LED "Mains supply ON" green

6

Code switch S1

7

Potentiometer for ti me delay (0 to 30 sec.)

8

TEST button

9

RESET button

A

Gasket

Therma l insulation

B

C

Electrode thread 1" BSP to DIN E N 228

Joint ring Ø33x39 to DIN 7603 made from 1.4301

D

E

Seating surface

F

Housing lid

G

Housing screws (cross recess head screws M4)

H

Terminal strip for control cable connection

Cable gland 3xM16x1.5

I

J

Terminal strip for mains supply

K

Fixing screws for electronics insert

L

PE connection

M

Fixing nut for terminal box

N

Term inal lugs for electrode wires, functional earth

O

Term inal strip for pushbuttons

7

Page 8

Important notes

Usage for the intended purpose

The level switch NRGS 15 - 1 is designed for detecting and signalling levels in liquids with

a mi nimum electrical conductivity.

The equipment must only be used within the admissible pressure and temperature ratings.

Any type of use differing from the usage described above must be considered as improper. The resulting risk will have to be borne by the user alone. The manufacturer hereby

expres sly rejects a ny claims for any damage resulting from improper usage.

Safety note

The equipment must only be installed and c ommissioned by qualified and competent

staff.

Retrofitting and maintenance work must only be performed by qualified staff who through adequate training - have achieved a recognised level of competence.

Danger

Danger

When loosening the level electrode steam or hot water might escape. This

presents the danger of severe s calds to the whole body.

It is essential not to mount or dismantle the electrode unless the boiler

pressure is verified to be zero!

The electrode becomes hot during operation. Touching the hot equipment

presents the risk of severe burns to hands and arms. All installation, removal

and maintenance work must only be performed when the system is cold.

Danger

The term inal strip of the level sw itch is live during operation. This presents

the danger of electric s hock!

Cut of f po we r s upp l y before opening the housing cover of the level switch!

After removing the housing cov e r check aga in that the system is deenergized.

To check the power supply or the correct functioning, switch the level switch

on again . This work must only be performed by qualified personnel.

8

Page 9

Explanatory Notes

Scope of supply

NRGS 15-1

■ 1 Level electrode with four tips

■ 1 Terminal box with integrated level switch

■ 1 Joint ring Ø33x39 to DIN 7603, made of 1. 4301 E8P

■ 1 Installation manual

or

NRGS 15-1

■ 1 Level electrode with four tips

■ 1 Terminal box with integrated level switch and built-in Test and Reset pushbutton

■ 1 Joint ring Ø33x39 to DIN 7603, made of 1. 4301 E8P

■ 1 Installation manual

Function

The level switch NRGS 15-1 is a compact-type system consisting of a level electrode

with four tips and an integrated level switch. For the correct functioning of the equipment

the water must have a minimum conductivity of >0.5µS/cm at 25°C.

In the inte grated level switch a time- delayed switching channel, an output relay and a

signal LED are assigned to each one of the four electrode tips.

The functions of the sw itching channels 1 and 4 are fixed, the switchting chan nels 2 and

3 can be adjusted via code switch to suit individual requirements. The tips of the electrode

are cut to l ength on site in order to establish the desired switchpoints of the associated

switching channels.

The following functions are possibl e:

■ Electrode rod 1 exposed / switching channel 1 energizes relay 1 = low level 1 with

optional performance test and lock-out function

■ Electrode rod 2 exposed / switching channel 2 energizes relay 2 = low level 2

■ Electrode rod 3 exposed or submerged / switching channel 3 energizes relay 3 as a

function of time = timed pump control (fill/discharge control)

■ Electrode rod 3 exposed or submerged / switching channel 3 energizes relay 3

= on/off pump control (fill/discharge control)

■ Electrode rod 4 submerged / switching channel 4 energizes relay 4 = high level

9

Page 10

Expl an ato ry No tes – continued –

Technical data

Service pressure

25 barg at 224 °C

Connection

Screwed 1" BSP, DIN ISO 228

Materials

Screw-in housing: 1.4571, CrNiMoTi 17 12 2

Electrode rods: 1.4571, CrNiMoTi 17 1 2 2

Electrode insulati on: PTFE

Spacer disc: PTFE

Terminal box: polycarbonate

Electrode rods

Length supplied : 1000 mm

Diameter: 5 mm

Mains supply

220–240V +10/-15%, 50/60 Hz

110–120V +10/-15%, 50/60 Hz

24 V +10 /-15%, 50/60 Hz (opti onal)

Power consumption

3VA

Se nsitivity (at 25 °C)

Range 1: 0.5 µS/cm

Range 2: 10 µS/c m

The selection of the above range is done via a code switch.

Electrode voltage

20 Vss

Output

Four volt-free rel ay contacts.

Max. contact rating with a s witching voltage of 24 V A C/DC, 115 V AC and 230 V AC:

resistive / inductive 4 A.

Ensure interference suppression by providing contactor with an arc suppressor RC combina tion.

Contact material AgNi 0.15.

Energizing/de-energizing delay

Relay 1 and 2: 1 sec., factory set

Relay 3: 0-30 sec., adjustable via potentiometer

Relay 4: 3 sec., factory set

10

Page 11

Expl an ato ry No tes – conti nued –

Technical data - continued -

Indicators and adjustors

3 red LEDs to indicate "Low leve l alarm 1 + 2 / Hi gh level".

1 yellow LED to indica te "Pump ON".

1 green LED to indicate "Mains supply ON".

1 ten-pole c ode switch to select the sensitivity r ange and to establish the functions.

1 test but ton in the terminal box to c heck the function of switching channel 1

(connec ted to terminals).

1 reset button in the terminal box to reset the lock-out function (connec ted to terminals).

Cable entry / Wiring

3 cable glands with in tegral cable clamps (M 16).

1 two-pole terminal str ip for power supply.

1 twelve-pole terminal strip for connecting the control cables.

1 four-pole terminal strip for test and reset button.

Screw-type terminal strips, conductor size <1.5 mm2.

Protection

IP 65 to DIN EN 60529

Max. admissible ambient temperature

70 °C

Weight

NRGS 15-1: approx. 1.4 kg

11

Page 12

Expl an ato ry No tes – continued –

Technical data - continue d -

Name Plate 110-120 and 220-240 VAC

Vor Öffnen des Deckels. Gerät

freischal ten! Betriebsanl eitung

beachten

Before removing cover isolate from

power supplies . See install ation

instructions

Avant d'ouvrir le couverc le

dèconnecter complètement l'apparei l.

Voir instructions de montage.

PN 25 G 1 1.4571

PmaxPmax

Tmax Tmax

Tamb ( )133°F 70°C

362psi 25 bar ()

435°F (224°C)

IP 65

110 - 120 VAC 50 / 60 Hz

0 - 30s

3VA

0, 5 / 10 µS /cm

Vor Öffnen des Deckels. Gerät

freischal ten! Betriebsanl eitung

beachten

Before removing cover isolate from

power supplies . See install ation

instructions

Avant d'ouvrir le couverc le

dèconnecter complètement l'apparei l.

Voir instructions de montage.

PN 25 G 1 1.4571

PmaxPmax

Tmax Tmax

Tamb ( )133°F 70°C

362psi 25 bar ()

435°F (224°C)

IP 65

220 - 240 VAC 50 / 60 Hz

0 - 30s

3VA

0, 5 / 10 µS /cm

GESTRA GmbH

Münchener Straße 77

D-28215 Bremen

Phone: +49 (0) 421 / 3503-0

gestra.gmbh@flowserve.com

GESTRA GmbH

Münchener Straße 77

D-28215 Bremen

Phone: +49 (0) 421 / 3503-0

gestra.gmbh@flowserve.com

Co rro s ion re si stan ce

If the NRGS 15-1 is used fo r its intended purpose, its safety is not impaired by corrosion.

12

Page 13

Establ ishi ng Func tio ns

Select function

Before installing and commissionin g the NRGS 15-1 ascertain the settings for the

required functions.

Five functions are available:

ON

Function 1

Electrode rod 1 Low level 1 / bu rner off

Electrode rod 2 Low level 2

Electrode rod 3 Timed pump control (fill control) tv=0 – 30 sec.

Electrode rod 4 High level

Function 2

1

2354 678910

ON

1

23 54 678910

Electrode rod 1 Low level 1 / bu rner off with test an d reset button

Electrode rod 2 Low level 2

Electrode rod 3 Timed pump control (fill control) tv=0 – 30 sec.

Electrode rod 4 High level

Function 3

Electrode rod 1 Low level alarm 1 / burner off

Electrode rod 2 Feed pump on (fill control)

Electrode rod 3 Feed pump off (tv=0 sec.)

Electrode rod 4 High level

Function 4

Electrode rod 1 Low level alarm 1 / burner off with test and reset button

ON

123 54 678910

ON

123 54 678910

Electrode rod 2 Feed pump on (fill control)

Electrode rod 3 Feed pump off (tv=0 sec.)

Electrode rod 4 High level

13

Page 14

Establishing Functions – cont inued –

Select function - continu ed -

ON

Function 5

Electrode rod 1 Low level alarm 1

Elec t r od e ro d 2 Pum p of f

Elec t r od e ro d 3 Pum p on (d i sch arg e co nt ro l ) tv=0 sec .

Electrode rod 4 High level

Fa ctory se ttin g

The factory setting of level switch NRGS 15-1 without pushbuttons is function 1 and with

pushbuttons is function 2.

123 54678910

The preset time delay for pump control is 5 sec. and the preset sensi tivity range is

10 µS/cm.

Cutting electrode tips to length

1. Determine the lengths of the electrode rods as a function of the level-dependent

switchpoints (measured from the gasket face ) and enter the data in the table blow.

E

2. Then cut all electrode tips (see Fig. 2) to the required lengths by using a bolt cutter.

3. Deburr faces of electrode tip ends.

4. Strip off 50mm of PTFE ins ulation from the ends of the electrode tips (see Fig. 2).

Make sure that there is an electrical resistance path of >14mm between the electrode tips.

5. Arrange PTFE spacer discs so that the electrode tips cannot com e into contact with

each other.

Electrode

Function

tip

Ca ble /

Connector

Length

[mm]

1 1

2 2

3 3

4 4

14

Page 15

Establishing Functions – continu ed –

Adjust function

1. Undo the housing screws and remove the housing lid.

2. Set the code switch to the desired function (see “Select function“). To set the code

switch located on the electronics insert (see Fig. 5) use a screwdriver with a thin

6

6

G F

blade.

3. Use a waterproof marker to enter the established functions in the labelling boxes on

the lid (see Fig. 4).

4. After adjusting the functions replace housing lid and fasten the housing screws .

F G

Set sensitivity range

The sensitivity is set at our works to > 10µS/c m.

If the electrical conductivity of the boiler water is below 10µS/cm at 25°C you have to

change the sensitivity range.

1. Undo the housing screws and remove the housing lid .

2. Set the code switch such that the desired function is established. To set the c ode

switch located on the electronics insert (see Fig. 5) use a screwdriver with a thin

6

6

G F

blade.

The following functions can be adjus ted via code switch:

Code switch S1 Setting

ON

123 54 678910

Sensitivity >

ON

Sensitivity >

123 54 678910

3. After adjusting the functions replace housing lid and fasten the housing screws .

0.5µS/c m at 25 °C

10µS/cm at 25°C

F G

Tools

■ Bolt cutter

■ Hacksaw

■ Flat file, medium cut

■ Screwdriver for cross head screws, s ize 2

■ Screwdriver for slotted screws, siz e 2.5, completely insulated according to VDE 0680

15

Page 16

Installation

Le ve l s wit c h N RG S 15-1

We highly recommend that only qualified staff should carry out installation work in accordance with these installation instructions. The manufacturer expressly rejects any claims

for damage caused by improper installation.

Before installing the electrode cut the electrode rods to length, make sure that 50mm of

the PTFE insulation are stripped off (see Fig. 2) and establish the functions.

The supplied spacer discs must be slipped ov er the electrode tips and distributed uniformly to ensure sufficient spacing between the tips.

1. Check that seating surfaces of threads or mounting flange provided on vessel or boiler standpipe (see Fig. 3) are accurately machined. If necessary rework the surfaces

according to the specifications indicated in the drawing.

2. Place joint ring (supplied with the electrode) onto the seating surface of the elec-

D E

trode.

3. Apply a light smear of silicone grease to the electrode thread.

4. Screw electrode into threads or flange provided on v e sssel (see Fig. 3) and tighten

with a 41 mm open-end spanner. The torque required when cold is 160 Nm.

5. Provide a max. thermal insulation of boiler of 40mm at electrode (see Fig. 2).

Attention

Do not s ubject the electrode tips to shocks and do not bend the electrode

tips when mounting.

Use only joint ring Ø33x39 DIN 7603 made from 1.4301 E8P. Do not in-

D

sulate the threads with hemp or PTFE tape!

Do not lag the electrode body above the hexgonal part.

The electrode must only be installed i n a vertical position.

The specified torques must be strictly observed.

16

Note

For the approval of the boiler standpipe (see Fig. 3) the relevant regulations

must be considered.

Carry out the installation work in co mpliance with the installation examples

given in this installation manual.

Page 17

Installation – c ontinued –

Align terminal box

Align the terminal box s uch that the LEDs , , , , can be seen by the oper ator.

1. Undo the housing screws and remove the housing lid .

G

2. Use open-end spanner A. F. 18 (19)mm to loosen the fixing nut and turn the ter -

1 2 3 4 5

F

M

minal box into the desi red direction (cable gland).

3. Re-tighten the fixing nut with a torque of 25 Nm.

4. Replace the housing lid and tighten the housing screws firmly .

M

F

G

If necessary you can take off the terminal box in order to align the electrode part. The terminal box must be re-installed after alignment.

Rem ove t erm i nal b ox

1. Undo the housing screws and remove the housing lid .

2. Unplug the electrode wires from terminal lugs for electrode wires, functional earth

G F

N

and mark them.

3. Use open-end spanner A. F. 18 (19)mm to unscrew the fixing nut . Pull electrode

wires through fixing nut .

M

M

4. Remove terminal box. R un all electrode wires through the hole for the fixing s crew

(see Fig. 5).

5. Remove the gasket between the electrode part and the housing.

A

17

Page 18

Installation – cont inued –

Mount terminal box

1. Put gasket onto electrode part.

A

2. Run all electrode wires through the hole for the fixing screw (see Fig. 5) in the

terminal box.

3. Place the terminal box onto the electrode part and turn it into the desired direction

(cable gland). Make sure that the gasket is properly placed between the electrode

part and the housing.

4. Pull al l electrode wires through fixing nut . Use an open-end spanner A. F. 18

M

(19)mm to fasten the hexagon nut to the fixing screw, applying a torque of 25 Nm.

5. Connect the electrode wires according to the wiring diagram (see Fig. 6) to the terminal lugs for electrode wires, functional earth .

6. Replace the housing lid and tighten the housing screws .

F G

N

Attention

Close the lid of the housing whenever interrupting the installation or re-

F

moval work of the terminal box.

Check the gasket for signs of damage. Re-use only undamaged gas-

A

kets.

Tools

■ Open-e nd spanner 41 mm A. F.

■ Open-end spanner 18 (19) mm A. F.

■ Screwdriver for cross-recess head screws, size 2.5, completely insulated according to

VDE 0680

18

Page 19

Wir ing

Connect level switch NRGS 1 5-1

Use multi-core flexible control cable with a min. conductor size of 0.75 mm² as mains and

control cables.

1. Undo the housing screws and remove the housing lid .

2. Unplug the two-pole terminal strip and the twelve-pole terminal strip from the

G F

J H

electron ics insert.

3. Strip off approx. 40 mm of cable insulation coating and remove approx. 5 mm of conductor end insulation.

4. Loosen cable glands and run the mains cables through the lower cable gland

and the control cables through the upper cable glands .

I I

I

5. Connect mains and control cables according to the wiring diagram (inside of housing

lid) to te rmi nal strips , .

6. Plug terminal strips , to electronics insert.

7. Seal cable entries by tightenting cable glands . Use sealing plugs for cable

H J

H J

I I

glands that are not used.

8. Replace the housing lid and tighten the housing screws firmly .

F G

Attention

The following relocations of cables with basic insulation are not permissible: Mains and control cables in low voltage areas

Provide level switch and control circuit with a slow-blow 2.5A fuse.

Provide connected contactors with RC combinations according to manu-

facturer's specification to ensure interference suppression.

Note that the sealing plugs are not scope of the supply.

Tools

■ Screwdriver for cross recess head screws, size 1 and 2

■ Screwdriver for slotted screws, siz e 2.5, completely insulated according to VDE 0680

19

Page 20

Wi r i ng – conti nued –

Wiring diagram

15

Electrode

cables

TEST

RESET

4

3

2

1

4

1

2

3

4

3

2

1

14

13

12

11

10

9

8

7

6

5

4

Mains supply

Fig. 6

PE connection

20

Page 21

Commissioning

Check wiring

1. Make sure that the level switch is correctly wired in accordance with the wiring

diagram (see Fig. 6).

2. Make sure that the mains voltage agrees with the specification on the name plate.

Apply m a in s vo lt age

1. Undo the housing screws and remove the housing lid .

2. Apply mains voltage. The green LED is illuminated. The other LEDs are lit as a

G F

5

function of the water level.

3. Check that al l functions of the respective switchpoints work correctly. The

LEDs , , , s erve as optical indicat ors of the asso ciated switchpoints.

1 2 3 4

(see “Check switching functions“).

4. After establishing the functions replace housing lid and tighten the housing

screws .

G

F

Danger

The term inal strip of the level sw itch is live during operation. This presents

the danger of electric s hock!

Cut of f po we r s upp l y before opening the housing cover of the level switch!

After removing the housing cov e r check aga in that the system is

de-energized.

To check the power supply or the correct functioning, switch the level switch

on again . This work must only be performed by qualified personnel.

21

Page 22

Commissioning – contin ued –

Check switching functions

Use the following table as reference when checking the individual switching functions.

Electrode rod1 = low level 1

Electrode rod1 emerges Relay1 is de-energized after 1sec.

Elec t r od e ro d1 ente rs th e

liquid

Press TEST button Relay1 is de-energized and locked out after 1sec.

Press RESET button for 3s Relay1 is energized after 1sec. LED1 off

Electrode rod1 emerges Relay1 is de-energized and locked out after 1sec.

Elec t r od e ro d1 ente rs th e

liquid

Press RESET button for

3sec.

Relay1 is energized after 1sec. LED1 off

Te st an d lock- ou t fu nc tio n

Relay1 is energized after 1sec. LED1 off

Electrode rod2 = low level 2

LED1

illuminated

LED1

illuminated

LED1

illuminated

Electrode rod2 emerges Relay2 is de-energized after 1sec.

Elec t r od e ro d2 ente rs th e

liquid

Elec t r od e ro d4 ente rs th e

liquid

Electrode rod4 emerges Relay4 is de-energized after 3sec. LED4 off

Relay2 is energized after 1sec. LED2 off

Electrode rod4 = high level

Relay4 is de-energized after 3sec.

LED2

illuminated

LED4

illuminated

22

Page 23

Commissioning – contin ued –

Check switching functions - continued -

Electrode rod3 = timed pump control (fill control)

Electrode rod3 em erges Relay3 is energized, p ump ON

Electrode rod3 enters the

liquid

Relay 3 is de-energized too early or too late: Increase or decrease time delay with the aid of the

potentio meter and let el ectrode ti p3 emerge or enter the liquid again. Repeat the process until

you have found the correct switchpoint for the pump. If 30sec. time delay is not enough for filling

the boiler, please select the operation mode "on-off pump control".

Electrode rod3 = on-off pump control (fill control)

Electrode rods2 and 3

exposed

Electrode rod2 enters the

liquid

Electrode rod3 enters the

liquid

Relay3 is de-energized after a preset time delay

(0–30 sec.) = pump OFF

Set potentiometer for time delay to 0 sec.

Relay3 is energized, pump ON

Relay3 is de-energized = pump OFF LED3 off

LED3

illuminated

LED3 of f

LE Ds2 and 3

illuminated

LED2 of f

Electrode rods2 and 3 = on-off pump control (discharge control)

Set potentiometer for time delay to 0 sec.

Electrode rods2 and 3

submerged

Electrode rod3 emerges LED3 off

Electrode rod2 emerges Relay3 is de-energized = pump OFF

Relay3 is energized, pump ON

LED2 of f and

LED3

illuminated

LED2

illuminated

23

Page 24

Ma lfu nct ions / Trou bl esho ot ing

Fault finding list

Switchpoint "Pump OFF" exceeded - no function

Fault: Mains voltage is not applied.

Remedy:Switch on mains voltage. Connect l evel switch according to wiring diagram

(Fig. 5).

Fault: The electrical conductivity is too low.

Remedy:Set code switch to 0.5 µS/cm.

Fault: The earth connection to the v essel is interrupted.

Remedy:Clean seating surfaces (see Fig. 3) and inser t metal joint ring Ø33x39

DIN 7603 (made from s. s. 1.4301). Do not insulate the level switch with

hemp or PTFE tape!

6

D

Fault: Electronic circuit board defective.

Remedy:Replace electronic circuit board.

Level below switchpoint "Low level" - no function

Fault: The electrode tips have earth contact.

Remedy:Check and, if necessary, change position of installation.

Fault: If the equipment is installed inside the boiler: The vent hole in the protection

tube does not exist or is obstructed.

Remedy:Check installation of level switch. Make sure that the level in the protection

tube corresponds to the actual water level (see Exa mples of Installation).

Switchpoint has been reached - incorrect function

Fault: The switching function has not been assigned correctly. The electrode tips

have been cut to the wrong length.

Remedy:Assign the electrode tips correctly and change connections on the electronic

circuit board correspondin gly.

N

Fault: The switching function does not correspond to the selected function. The

code switch has been set to the wrong value.

Remedy:Set code switch according to the selected function.

6

24

Page 25

Malfunctions / Troubleshooting – continued –

Rep lace el ectron ic cir cuit boa rd

1. Undo the housing screws and remove the housing lid .

2. Pull the electrode wires out of the terminal lugs on the electronic circuit board.

Unplug all terminal strips , , .

3. Undo the PE connection .

4. Unscrew the fixing screws of the electronic circuit board and take out the electronic

G F

N

H J O

L

K

circuit board. The electronic circuit board is available as spare part type NRV 1-47.

5. Install the new electronic circuit board in reverse order.

25

Page 26

Annex

Adjust other functions

The level switch assigns one switching channel to each electrode tip. The functions of the

switching channels 1 and 4 are fixed, the switchting channels 2 and 3 can be adjusted via

code switch to suit individual requirements.

The assigned electrode tip is cut to length on site in order to establish the level-dependent

switchpoint of each individual switching channel.

The code switch can also be used to establish other functions than the ones described in

section "Select function“.

Code switch Function

ON

123 54 678910

ON

123546

6

7 8 910

No TEST button

No RESET button

ON

123 54 678910

ON

1235467

ON

123 54 678910

ON

123 54 678910

8 910

On-off pump control switched on

Electrode tip separated from electrode tip

2 1

Pump fill control switched on

or

Pu mp disch arge control switched on

26

Page 27

Annex – contin ued –

Installation in non-metallic vessel

The level switch electrode can also be installed in non-metallic vessels.

Note that in this case the electrode tip cannot be used for high level alarm but must be

4

used as reference elec trode.

For this purpose plug the connection of the electrode tip into the free terminal lug for

the functional earth .

In addition, cut the electrode tip to the same length as electrode tip and strip off the

N

4 1

4

whole insul ation.

Revi se d

Index

00 New installation instructions 28 May 2004

Description Date

27

Page 28

Examp les of In stalla tion

NRG 1.-42

DN50

> Ø 80

1"BSP

Ø 20

1" BSP

1

2

1

2

DN50

4

5

3

4

5

6

Ø 20

Fig. 7

Key

1

Flange PN40, DN50, DIN 2527

or flange PN40, DN100, DIN 252 7

2

For the approval of the boiler standpipe with connecting flange the relevant

regulatio ns must be considered.

3

e. g. reducer K88.9x60.3x3.2 DIN 2616

Ø 20

< 90°

7

6

7

< 90°

Fig. 8

Ø 20

28

4

Boiler wall

5

Provide vent hole as c lose to the boiler wall as possible!

6

Protection tube >DN80

7

e. g. reducer K88.9x30x3.2 DIN 2616

Page 29

For your no tes

29

Page 30

www.gestra.de

España

GESTRA ESPAÑOLA S.A.

Luis Cabrera, 86-88

E-28002 Madrid

Tel. 00 34 91 / 51 52 032

Tel. 00 34 91 / 41 36 747; 51 52 036

E-mail: aromero@flowserve.com

Great Britain

Flowserve Flow Control (UK) Ltd.

Burrel Road, Haywards Heath

West Sussex RH 16 1TL

Tel. 00 44 14 44 / 31 44 00

Tel. 00 44 14 44 / 31 45 57

E-mail: gestraukinfo@flowserve.com

Italia

Flowserve S.p.A.

Flow Control Division

Via Prealpi, 30

I-20032 Cormano (MI)

Tel. 00 39 02 / 66 32 51

Fax 00 39 02 / 66 32 55 60

E-mail: infoitaly@flowserve.com

Poland

GESTRA POLONIA Spolka z.o.o.

UI. Schuberta 104

PL - 80-172 Gdansk

Tel. 00 48 58 /306 10-02 od 10

Fax 00 48 58 /306 33 00

E-mail: gestra@gestra.pl

Portugal

Flowserve Portuguesa, Lda.

Av. Dr. Antunes Guimarães, 1159

Porto 4100-082

Tel. 0 03 51 22 / 6 19 87 70

Fax 0 03 51 22 / 6 10 75 75

E-mail: jtavares@flowserve.com

USA

Flowserve DALCO Steam Products

2601 Grassland Drive

Louisville, KY 40299

Tel. 00 15 02 / 4 95 01 54, 4 95 17 88

Fax 00 15 02 / 4 95 16 08

E-mail: dgoodwin@flowserve.com

GESTRA AG

Postfach 10 54 60, D - 28054 Bremen

Münchener Str. 77, D -28215 Bremen

Telefon +49 (0) 421 35 03- 0

Telefax +49 (0) 421 35 03-393

E-Mail gestra.ag@flowserve.com

Internet www.gestra.de

808597-00/804agt ©2004 GESTRA AG Bremen Printed in Germany

Loading...

Loading...