Page 1

GESTRA

GESTRA Steam Systems

NRG 16-42

Installation Instructions 810295-03

Level electrode NRG 16-42

1

Page 2

Contents

Page

Important Notes

Usage for the intended purpose ..............................................................................................................4

Safety note .............................................................................................................................................4

Danger ...................................................................................................................................................4

Attention .................................................................................................................................................4

ATEX (Atmosphère Explosible) .................................................................................................................4

Explanatory Notes

Scope of supply ...................................................................................................................................... 5

Description .............................................................................................................................................5

Function .................................................................................................................................................5

System components ...............................................................................................................................5

Design .................................................................................................................................................... 5

Technical data

NRG 16-42 .............................................................................................................................................

Corrosion resistance ............................................................................................................................... 7

Sizing .....................................................................................................................................................7

Name plate / marking .............................................................................................................................7

Dimensions NRG 16-42 ..........................................................................................................................

Design

NRG 16-42 .............................................................................................................................................9

Key .......................................................................................................................................................11

Functional Elements

NRG 16-42 ...........................................................................................................................................10

Key .......................................................................................................................................................11

Installation

NRG 16-42 ...........................................................................................................................................12

Attention ...............................................................................................................................................12

Note .....................................................................................................................................................12

Tools .....................................................................................................................................................12

Examples of installation NRG 16-42 ..................................................................................................... 13

Key .......................................................................................................................................................14

6

8

2

Page 3

Contents continued

Page

Wiring

NRG 16-42 ...........................................................................................................................................15

Aligning terminal box ............................................................................................................................ 15

Note .....................................................................................................................................................15

Wiring diagram ..................................................................................................................................... 16

Attention ...............................................................................................................................................17

Tools .....................................................................................................................................................17

Basic Settings

CAN Bus ...............................................................................................................................................18

Node ID ................................................................................................................................................18

Attention ...............................................................................................................................................18

Factory setting ......................................................................................................................................18

Factory set default node IDs .................................................................................................................. 19

Assigning / changing node ID ................................................................................................................ 19

Attention ...............................................................................................................................................19

Code switch settings for node ID / baud rate .........................................................................................20

Commissioning

Check wiring ........................................................................................................................................21

Apply mains voltage..............................................................................................................................21

Operation

Level electrode with CAN bus................................................................................................................21

Note .....................................................................................................................................................21

Malfunctions

Fault finding list for troubleshooting ................................................................................................ 21-22

Decommissioning

Danger .................................................................................................................................................23

Disposal................................................................................................................................................23

Annex

Declaration of conformity ......................................................................................................................23

3

Page 4

Important Notes

Usage for the intended purpose

Use level electrode NRG 16-42 only in conjunction with level switch NRS 1-42.

Safety note

The equipment must only be installed and commissioned by qualified and adequately trained

personnel.

Maintenance and retrofitting must only by performed by entrusted personnel who – through adequate

training – have achieved a recognised level of competence.

Danger

When loosening the electrode live steam or hot water might escape.

This presents the danger of severe scalding. It is therefore essential not to dismantle

the electrode unless the boiler pressure is verified to be zero.

The electrode is hot during operation. This presents the risk of severe burns to hands

and arms. Installation and maintenance work should only be carried out when the

system is cold.

If the internal ceramic insulation breaks, hot steam can escape through the lateral vent

hole on the electrode body. This presents the risk of severe scalding. Do not stay near

the electrode during operation.

Attention

The name plate indicates the technical specification on the equipment.

Do not commission or operate equipment without a name plate.

ATEX (Atmosphère Explosible)

According to the European Directive 94/9/EC the equipment must not be used in explosion-risk areas.

4

Page 5

Explanatory Notes

Scope of supply

NRG 16-42

1 Level electrode type NRG 16-42

1 Joint ring (of stainless steel 1.4301) D 33 x 39 to DIN 7603, bright annealed

1 Terminating resistor 120

1 Installation manual

Description

Ω

The level electrode NRG 16-42 works according to the conductivity measurement principle.

With the NRG 16-42 a maximum of 4 levels can be signalled in conductive liquids:

■4 levels with one switchpoint each.

■ High level (MAX) alarm, Low level (MIN) alarm, pump ON, pump OFF with one switchpoint each.

Use level electrode NRG 16-42 in combination with level switch type NRS 1-42 or further system

components. The level data are transferred to the level switch or another system component via

CAN data bus, using the CANopen protocol.

Function

The conductivity of the liquid is used to signal the liquid level. Some liquids are conductive, which

means that they allow an electric current to flow through them.

For the safe functioning of this device a minimum conductivity of the liquid to be measured is required.

The conductivity measurement method can detect two conditions: electrode rod submerged or

exposed, meaning switchpoint reached (or exceeded) or not yet reached. Before installation, the

length of the electrode rod must be cut to the required switching levels, e. g. for max./min. alarm,

controlling of a valve or pump.

At regular intervals the level electrode NRG 16-42 sends a data telegram to the level switch NRS 1-42.

The data are transferred via a CAN bus to DIN ISO 11898 using the CANopen protocol.

System components

NRS 1-42

Data exchange: CAN bus to DIN ISO 11898, using CANopen protocol.

URB 1, URB 2

Control terminal & display unit.

Functions: Parameterization and visual display (LCD).

Data exchange: CAN bus to DIN ISO 11898, using CANopen protocol.

Design

NRG 16-42:

Screwed design 1" BSP, EN ISO 228-1. Fig. 2

5

Page 6

Technical data

NRG 16-42

Type Approval Nº

TÜV · WR · 04-399

Max. service pressure

32 bar g at 238°C

Connections

Screwed 1" BSP, DIN ISO 228-1

Flanged DN 50, PN 40, DIN 2635

Materials

Case: Die cast aluminium 3.2161 (G AlSi8Cu3)

Stem: S. S. 1.4571 (X6CrNiMoTi17-12-2)

Measuring electrodes: S. S. 1.4401 (X5CrNiMo17-12-2)

Electrode insulation: PEEK

Spacer disc: PTFE

Lengths supplied

500 mm

1000 mm

1500 mm

Supply voltage

18 – 36 V DC

Current consumption

65 mA

Fuse

Thermal fuse T

= 85°C

max

Hysteresis

-2 K

Electrode voltage

10 V

ss

Data exchange

CAN bus to DIN ISO 11898, CANopen protocol

Indicators and adjustors

1 green LED “C

1 red LED “b

an bus CommuniCation”

us fault”

1 10-pole code switch for node ID and baud rate settings

Electric connection

M 12 sensor connector, 5 poles, A-coded,

M 12 sensor jack, 5 poles, A-coded

Protection

IP 65 to DIN EN 60529

Max. admissible ambient temperature

70 °C

Weight

approx. 2.5 kg

6

Page 7

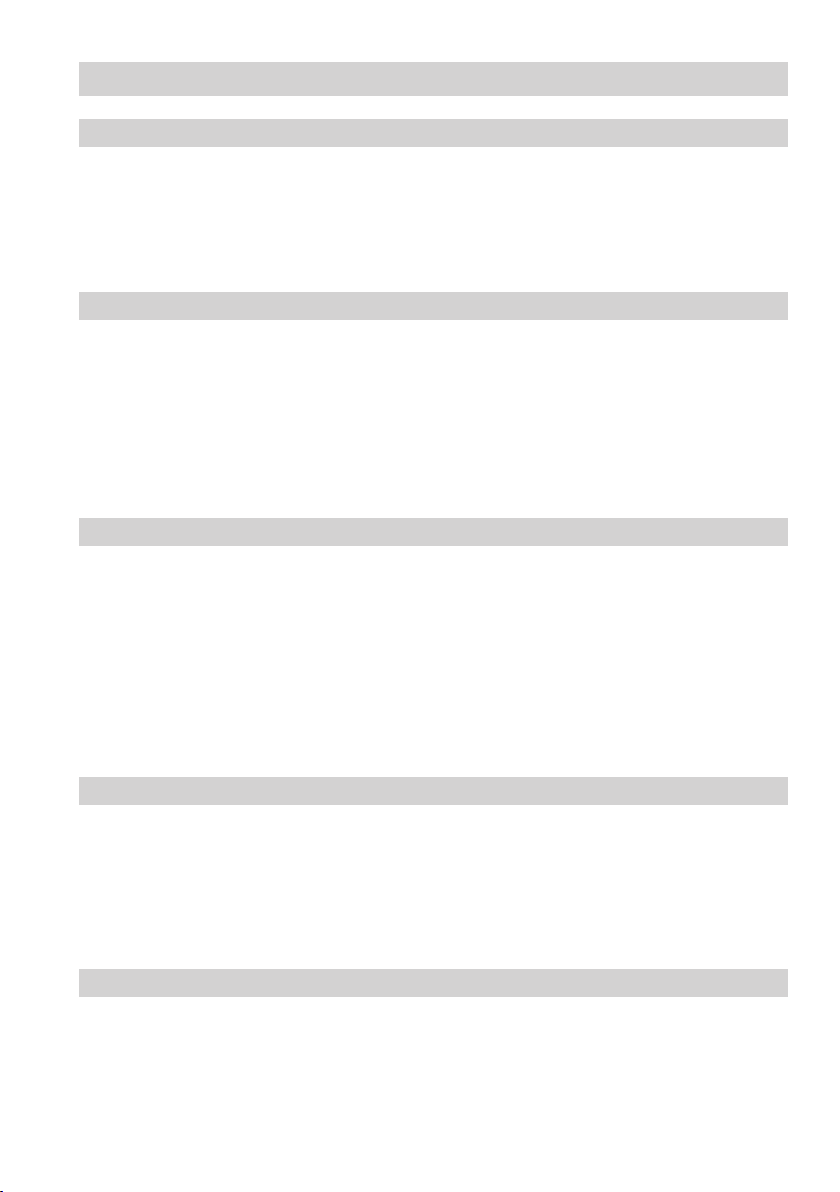

Technical Data continued

NRG 16-42

PN 40 G1 1.4571 IP 65

0,5 / 10µS/cm

Betriebsanleitung

beachten

See installation instructions

Voir instructions de

montage

32 bar ( 464 psi)

238 °C ( 453 °F)

Tmax = 70°C (133 °F)

Pmax

Tmax

IN/OUT: CAN-Bus

Münchener Str. 77,D-28215 Bremen

GB Reg. Design 2 053 113

US Pat. 5 719 342, 5 805 052,

Design 383 403

18-36 V DC

Node ID:__ __ __

TÜV.WR.99-399

GESTRA AG

SER Nr.:

Corrosion resistance

When used for its intended purpose the safe functioning of the electrode will not be impaired by

corrosion.

Sizing

The electrode body must not be subjected to sharp increases in pressure. Welds and flanges of the

electrode are designed to withstand dynamic loading (bending and alternating stress). The dimensional

allowances for corrosion reflect the latest state of technology.

Name plate / marking

Designation of

the equipment

Fig. 1

7

Page 8

4

3

GESTRAS teamSystems

GESTRA

NRG 16-42

4

3

1

2

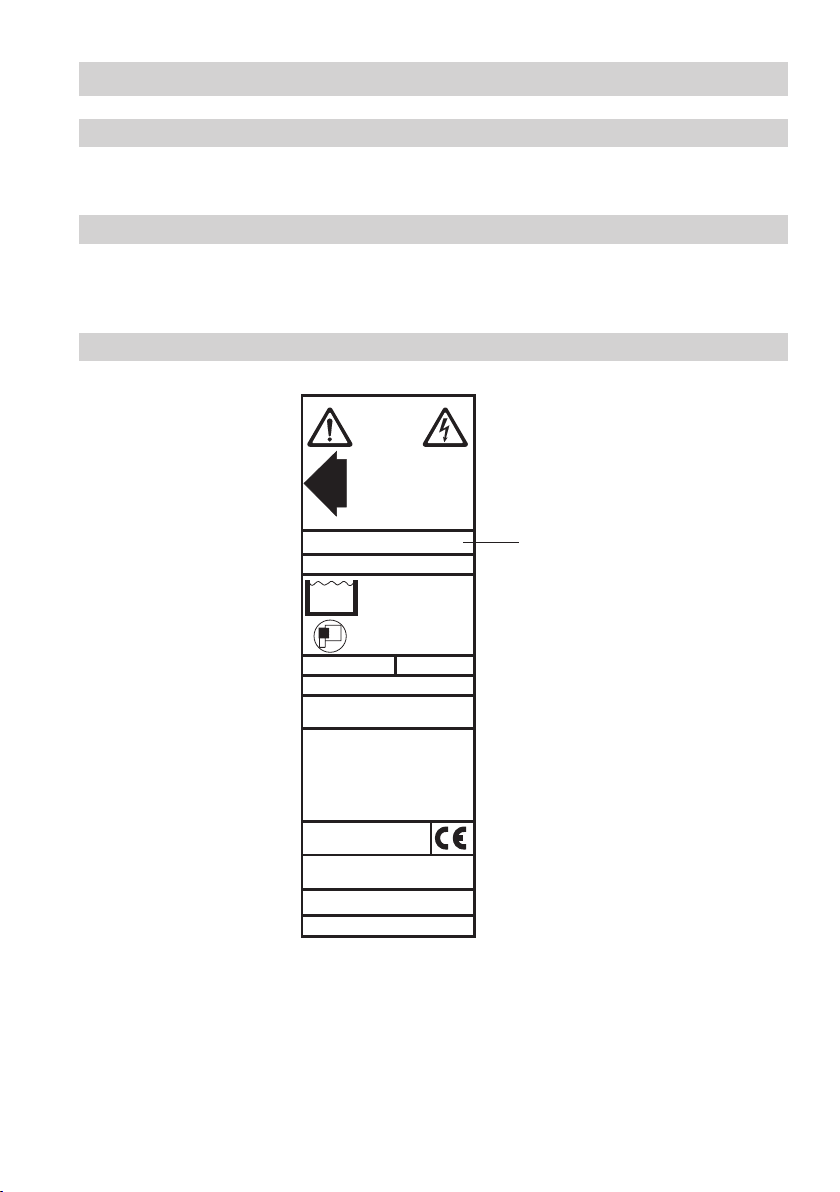

Technical Data continued

Dimensions NRG 16-42

175

140

337.5

Depth: 70mm

500, 1000, 1500

Fig. 2

8

Page 9

Design

2

1

4

3

GESTRASt eamSystems

GESTRA

NRG 16-42

NRG 16-42

A

D

B

C

≥14

50

Fig. 3 Fig. 4

65-70

∅ 40

1" BSP, ISO 228-1

N 10

0.5

9

Page 10

Functional Elements

1

2

3

4

5

1 098765432

NO

MAX 70°C

MAX 95%

%

IP 65

GESTRA Steam Systems

GESTRA

NRG 16-42

NRG 16-42

MAX 70 °C

MAX 95 %

Fig. 5

M

E

Fig. 6

F

F

G

H

I

J

L K

10

Page 11

Design / Functional Elements continued

Key

A Thermal insulation, provided on site, d = 20 mm (outside of thermal insulation of the steam boiler)

B Seating surface

C Joint ring (of stainless steel 1.4301) D 33 x 39 to DIN 7603, bright annealed

D Electrode thread 1" BSP, EN ISO 228-1

E Housing screws M4

F M 12 sensor connector, 5 poles, A-coded

M 12 sensor jack, 5 poles, A-coded

G Housing cover

H 10-pole code switch (for setting node ID and baud rate)

I LED “Can bus CommuniCation” (flashes during data exchange), green

J LED “bus fault”, red

K Terminal strip

L PE connection

M Plug

11

Page 12

Installation

NRG 16-42

1. Determine required measuring lengths of electrode rods and enter data in table “Functions”.

2. Cut electrode rods , , and accordingly, Fig. 3

2

1

3. Deburr faces of electrode tips.

4. Strip off 50 mm of PTFE insulation from the ends of electrode tips.

5. Check seating surfaces of threads or flange provided on vessel or boiler standpipe, Fig. 4

6. Place joint ring

C onto seating surface B of electrode, Fig. 3. Use only joint ring

(of stainless steel 1.4301) D 33 x 39 to DIN 7603 supplied with electrode.

7. Apply a light smear of silicone grease (e. g. Molykote

8. Screw level electrode into threads or flange provided on vessel or boiler standpipe and tighten with a

41 mm open-end spanner. The torque required is 140 Nm

Function Function Electrode rod Length [mm]

e.g. High level alarm 1

e.g. Feed pump ON 2

e.g. Feed pump OFF 3

e.g. First low-level alarm 4

Attention

■ The seating surfaces of the threads or flange provided on the vessel or boiler standpipe

must be accurately machined. Fig. 4

■ Do not bend electrode rod when mounting.

■ Use only the supplied joint ring D 33x 39 (of stainless steel 1.4301) to DIN 7603.

■ Do not lag electrode body.

■ Do not insulate electrode thread with hemp or PTFE tape.

4

3

Please enter data.

®

111) to electrode thread D.

when cold.

Please enter data.

Note

■ For the approval of the boiler standpipe with connecting flange the relevant local and

national regulations must be considered.

■ See four examples of installation on page 13.

Tools

■ Open-end spanner 17 mm A. F.

■ Open-end spanner 41 mm A. F.

Molykote® 111 is a registered trademark of DOW Corning Corp., Midland Michigan, USA

■ Hacksaw

■ Flat file, medium cut

12

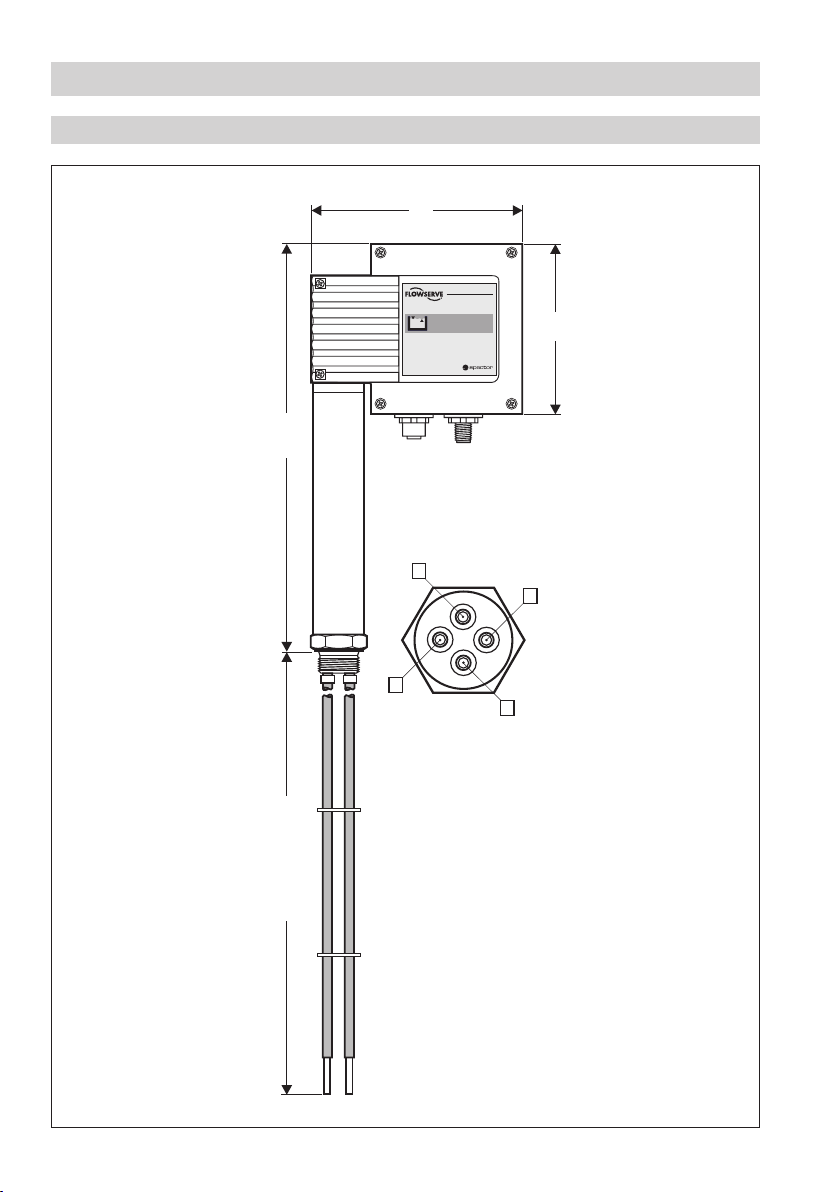

Page 13

12

Installation continued

9

Examples of installation NRG 16-42

1" BSP

DN 50

4

8

≤90°

∅20

Fig. 7

1" BSP ¾" BSP

1" BSP

1

2

∅ 20

3

20

≤1500

DN

50

4

5

6

8

≥10

9

0

∅20

≥10

≤90°

1

2

∅ 20

3

20

5

6

9

0

Fig. 8

1" BSP

1

1

2

DN 20

≥20

4

3

Fig. 9

≤1500

DN 100

24,5 24,5

∅20

20

4

> 40

≥10

≤90°

∅20

5

7

8

9

!

DN 20

Fig. 10

ME

5

9

DN 20

13

Page 14

Installation continued

Key

1 Flange PN 40, DN 50 (2"), DIN 2527

Flange PN 40, DN 100 (4"), DIN 2527

2 For the approval of the boiler standpipe with connecting flange the

relevant regulations must be considered.

3 Vent hole Provide vent hole as close as possible to the boiler wall.

4 High water (HW)

5 Electrode rod d = 5 mm

6 Protection tube DN 80

7 Protection tube DN 100

8 Electrode distance ≥ 14 mm

9 Low water (LW)

0 Reducer K-88.9 x 3.2 – 42.4 x 2.6 W to DIN 2616, part 2

! Reducer K-114.3 x 3.6 – 48.3 x 2.9 W to DIN 2616, part 2

14

Page 15

Wiring

NRG 16-42

Note that screened multi-core twisted-pair control cable is required, e. g. UNITRONIC®

BUS CAN 2 x 2 x ... mm2 or RE-2YCYV-fl 2 x 2 x ... mm2.

Prefabricated control cables (with connector and coupler) of various lengths for connecting the

equipment are available as accessories.

The baud rate (data transfer rate) dictates the cable length between the bus nodes and the total power

consumption of the sensor dictates the conductor size.

S 8 S 9 S 10 Baud rate Cable length

OFF ON OFF 250 kBit/s 125 m

Factory setting

ON ON OFF 125 kBit/s 250 m 2 x 2 x 0.5

OFF OFF ON 100 kBit/s 335 m 2 x 2 x 0.75

ON OFF ON 50 kBit/s 500 m

OFF ON ON 20 kBit/s 1000 m

ON ON ON 10 kBit/s 1000 m

Number of pairs

and conductor size [mm2]

2 x 2 x 0.34

on request, dependent on

bus configuration

The baud rate is set via a code switch. Reduce baud if cable is longer than specified in the table above.

Make sure that all bus nodes feature the same settings.

To protect the switching contacts fuse circuit with 2.5 A (anti-surge fuse) or according to TRD

regulations (1.0 A for 72 hrs operation).

When a max. cable length of more than 125 m (up to 1000 m) is desired, make sure to modify

the baud rate accordingly. Refer to pages 19 and 20 for more details.

Aligning terminal box

1. Unscrew screws E, remove housing cover G. Fig. 5

2. Loosen screw M with 17 mm spanner but do not remove. Fig. 6

The electrode terminal can be turned through +/– 180°.

3. Turn electrode terminal into desired direction (+/–180°).

4. Tighten plug

M with a torque of 25 Nm.

5. Set node ID (see “Basic Settings”, “Configure level electrode”).

6. Replace housing cover G and fasten screws E.

Note

■ Wire the control cable according to the wiring diagram with connector and coupler.

UNITRONIC® is a registered trademark of LAPP Kabelwerke GmbH, Stuttgart

15

Page 16

1

2

3

4

NRG 16-42

_

1

2

3

4

5

S

+

C

L

H

C

24V DC

CAN - Bus

S

1 098765432

NO

C

L

C

H

Wiring continued

5 5 5 555

+

-

LCH

C

S

Wiring diagram

Electrode rod

Electrode rod

Electrode rod

Electrode rod

Terminating resistor 120 Ω, paired cable.

3

2 1 5 46 3 4 1 52

Code switch

e.g. UNITRONIC® BUS CAN 2 x 2 x...

e.g. UNITRONIC® BUS CAN 2 x 2 x...

1 Screen

2 Voltage supply 24V DC+

3 Voltage supply 24V DC-

4 CAN Data line C

5 CAN Data line C

6 Terminating resistor 120 Ω

2

2

H

L

Controller

NRS ...

LRR ...

TRS ...

Operating

device URB 1

Coupler with terminating

resistor 120

Fig. 11

UNITRONIC® is a registered trademark of LAPP Kabelwerke GmbH, Stuttgart

Ω

CEP

Central

earthing

point

16

Level electrode

Conductivity electrode

NRG ...

LRG ...

Temperature transmitter

TRV ...

Connector with terminating

resistor 120

Ω

Page 17

Wiring continued

Attention

■ Wire equipment in series. Star-type wiring is not permitted!

■ Interlink screens of control cables such that electrical continuity is ensured and

connect them once to central earthing point (CEP).

■ In a CAN bus network the first and the last equipment must be provided with a

terminating resistor of 120

■ The CAN bus network mut not be interrupted while operating.

An interruption will result in high/low level alarm!

Tools

■ Screwdriver for cross head screws, size 1

■ Screwdriver for slotted screws, size 2.5, completely insulated according to VDE 0680

■ Open-end spanner 17 mm A. F.

Ω. Fig. 11

17

Page 18

Basic Settings

CAN bus

All level and conductivity controllers and associated electrodes are interconnected by means of a CAN

bus adopting the CANopen protocol. Every item of equipment features an electronic address (Node ID).

The four-core bus cable serves as power supply and data highway for high-speed data exchange.

The CAN address (Node ID) can be set between 1 and 123.

The NRG 16-42 is configured at our works and ready for service with other GESTRA system

components without having to set the node ID.

If several systems of the same kind are to communicate in one CAN bus network, be sure to

assign one node ID for each individual system component (e. g. controller). Refer to the

following pages for more details.

Node-ID

Reserved NRS 1-42 NRG 16-42

X - 1

Attention

The node IDs of the individual units have to be adjusted manually.

For more information refer to the respective installation manuals.

Factory setting

The level electrode features the following factory set default values:

■ Baud rate: 250 kB/s

■ Sensitivity: 10 µS/cm

■Node ID: 021

X X + 1

20 21 Factory setting

Reserved area

18

Page 19

1

2

3

4

5

1 098765432

NO

Basic Settings continued

NRS 1-40 ID: 001

NRS 1-40.1 ID: 001

NRS 1-41 ID: 006

NRS 1-42 ID: 020

NRS 2-40 ID: 039

NRR 2-40 ID: 040

LRR 1-40 ID: 050

NRG 16-40 ID: 002

NRG 16-40 ID: 003

NRG 16-41.1 ID: 004

TRV 5-40 ID: 005

NRG 16-41 ID: 007

NRG 16-42 ID: 021

NRG 26-40 ID: 041

LRG 16-40 ID: 051

Factory set default node IDs

Switching Controller Level Electrode

Assigning / changing node ID

If several systems of the same kind are to communicate in one CAN bus network, be sure to establish

one node ID for each individual system component (e. g. controller).

1. Undo screws

2. Change code switch

3. Re-attach housing cover

E and remove housing cover G.

H settings as required. For more information refer to page 20.

G and fix it with screws E.

Attention

■ Do not assign the same node ID twice within the CAN bus network.

Fig. 12

H

19

Page 20

1 098765432

NO

1 098765432

NO

Basic Settings continued

Code switch settings for node ID / baud rate

H H

▲

S1

OFFS2

OFFS4

OFFS6

OFFS7

Fig. 13 (Factory setting)

S8

OFF

ON

OFF

ON

OFF

OFF

Node ID

ON

ONS3

ONS5

S9 S0

OFFON

OFF

ON

ON

ON

1

2

4

8

16

32

64

Baud rate

250 kBit/s

125 kBit/s

100 kBit/s

ON 20 kBit/sONOFF 1000 m

ON 10 kBit/sONON 1000 m

Fig. 15 (Factory setting 250 kBit/s)

21

50 kBit/s

▲

S1

ON

ONS2

ONS3

OFFS4

OFFS5

OFFS6

ONS7

Fig. 14 (Example)

Length of cable

Node ID

125 m

250 m

335 m

500 m

71

1

2

4

8

16

32

64

20

Page 21

Commissioning

Check wiring

Check whether the level electrode NRG 16-42 and the associated level switch NRS 1-42 have been

wired according to the wiring diagram. Fig. 11

Apply mains voltage

Turn on the power for level switch NRS 1-42.

Operation

Level electrode with CAN bus

During operation the level switch detects the level electrode via CAN bus.

The communication via CAN bus is faultless – there are no fault messages.

Note

■

To analyse and eliminate malfunctions refer to “Fault finding list for troubleshooting” on

pages 21 - 22.

Malfunctions

Fault finding list for troubleshooting

Equipment fails to work – Indication of a malfunction

Fault: In spite of correct wiring and commissioning of the equipment an interference signal

is indicated.

Remedy: The interference signal is caused by H. F. interferences coming from the installation. For

interference suppression of the voltage supply we supply ferrite rings, stock code 147253.

The 230 V supply lines should be looped through the ferrite ring five to ten times.

If several controllers are used in the system, they can be fed from the interference

suppressed supply lines. For the interference suppression of the bus line we supply

hinged-shell ferrite rings, stock code 147254. The hinged-shell ferrite rings are clamped

onto the bus line close to the terminal strip of the controller.

21

Page 22

Malfunctions continued

Fault finding list for troubleshooting continued

The equipment fails to work – no function

Fault: LED “Power” does not light up.

Remedy: Apply mains voltage. Wire equipment according to the wiring diagram.

Fault: The thermal fuse has been triggered.

Remedy: The ambient temperature must not exceed 70°C.

Fault: The LED I does not light up. No data exchange.

Remedy: Check level switch NRS 1-42. Connect electode according to the wiring diagram.

Switchpoints reached / level below switchpoints – no function

Fault: The electric conductivity is too low.

Remedy: Set sensitivity of level switch NRS 1-42 to ≥ 0.5 µS/cm.

Fault: The electrode rods have earth contact.

Remedy: Change installation position.

Fault: The electrode housing does not have earth connection to the boiler.

Remedy: Clean seating surfaces and insert metal joint ring (of stainless steel 1.4301) 33 x 39 to

DIN 7603. Do not insulate compact system with hemp or PTFE tape!

Fault: The vent hole in the protection tube does not exist, is obstructed or flooded.

Remedy: Check protection tube and, if necessary, provide vent hole.

Fault: The isolating valves of the external measuring pot (optional) are closed.

Remedy: Open isolating valves.

Switchpoints reached / level below switchpoints – incorrect function

Fault: The switching function has not been correctly allocated. Electrode rods have been cut

to the wrong size.

Remedy: Identify electrode supply wire and reconnect the circuit board in the terminal box

accordingly.

Fault: The internal seal of the electrode rod is damaged.

Remedy: Replace level electrode.

If faults occur that are not listed above or cannot be corrected, please contact our service centre or

authorized agency in your country.

22

Page 23

Decommissioning

Danger

Risk of severe burns and scalds to the whole body!

Before removing the level electrode make sure that the vessel and the measuring pot are

depressurised (O bar) and cooled down to room temperature (20 °C).

Disposal

Remove the level electrode and separate the waste materials, using the material specifications as a

reference. Electronic components (circuit boards) must be disposed of properly.

For the disposal of the level electrode observe the pertinent legal regulations concerning waste disposal.

Annex

Declaration of conformity

We hereby declare that the equipment NRG 16-42 conforms to the following European guidelines:

■

LV guideline 73/23/eec version 93/68/eec

■

EMC guideline 89/336/eec version 93/68/eec

■ ATEX Directive 94/9/EC of 23 March 1994

This declaration is no longer valid if modifications are made to the equipment without consultation

with us.

Dipl.-Ing. Uwe Bledschun

(Academically qualified engineer)

Head of the Design Dept.

Bremen, 3rd January 2005

GESTRA AG

Dipl.-Ing. Lars Bohl

(Academically qualified engineer)

Quality Assurance Manager

23

Page 24

Agencies all over the world:

www.gestra.de

GESTRA

España

GESTRA ESPAÑOLA S.A.

Luis Cabrera, 86-88

E-28002 Madrid

Tel. 00 34 91 / 5 15 20 32

Fax 00 34 91 / 4 13 67 47; 5 15 20 36

E-mail: aromero@flowserve.com

Great Britain

Flowserve Flow Control (UK) Ltd.

Burrel Road, Haywards Heath

West Sussex RH 16 1TL

Tel. 00 44 14 44 / 31 44 00

Fax 00 44 14 44 / 31 45 57

E-mail: gestraukinfo@flowserve.com

Italia

Flowserve S.p.A.

Flow Control Division

Via Prealpi, 30

l-20032 Cormano (MI)

Tel. 00 39 02 / 66 32 51

Fax 00 39 02 / 66 32 55 60

E-mail: infoitaly@flowserve.com

Polska

GESTRA POLONIA Spolka z.o.o.

Ul. Schuberta 104

PL - 80-172 Gdansk

Tel. 00 48 58 / 3 06 10 -02 od 10

Fax 00 48 58 / 3 06 33 00

E-mail: gestra@gestra.pl

Portugal

Flowserve Portuguesa, Lda.

Av. Dr. Antunes Guimarães, 1159

Porto 4100-082

Tel. 0 03 51 22 / 6 19 87 70

Fax 0 03 51 22 / 6 10 75 75

E-mail: jtavares@flowserve.com

USA

Flowserve GESTRA U.S.

2341 Ampere Drive

Louisville, KY 40299

Tel.: 00 15 02 / 4 95 01 54, 4 95 17 88

Fax: 00 15 02 / 4 95 16 08

E-mail: dgoodwin@flowserve.com

GESTRA AG

P. O. Box 10 54 60, D-28054 Bremen

Münchener Str. 77, D-28215 Bremen

Telephone +49 (0) 421 35 03 - 0

Fax +49 (0) 421 35 03- 393

E-Mail gestra.ag@flowserve.com

Internet www.gestra.de

810295-03/206cm · © 1998 GESTRA AG · Bremen · Printed in Germany

24

Loading...

Loading...