Page 1

GESTRA Steam Systems

NRA 1-3

Installation Instructions 818678-00

Test Station

NRA 1-3

1

Page 2

2

Contents

Page

Important Notes

Usage for the intended purpose ..............................................................................................................4

Safety note .............................................................................................................................................4

Danger ...................................................................................................................................................4

ATEX (Atmosphère Explosible) .................................................................................................................4

Explanatory Notes

Scope of supply ......................................................................................................................................5

Description .............................................................................................................................................5

Function .................................................................................................................................................5

System components ...............................................................................................................................5

Technical Data

NRA 1-3

Name plate / marking .............................................................................................................................7

Dimensions NRS 1-3

Installation

Test station NRA 1-3a .............................................................................................................................9

Test station NRA 1-3e .............................................................................................................................

Note .......................................................................................................................................................9

Tools .......................................................................................................................................................9

............................................................................................................................................. 6, 7

...............................................................................................................................8

9

Functional Elements

NRA 1-3................................................................................................................................................10

Key ....................................................................................................................................................... 11

Wiring

Connecting line of temperature sensor for detecting the temperature of the installation .......................12

Connecting line of measuring electrodes ..............................................................................................12

Wiring ..................................................................................................................................................12

Attention .............................................................................................................................................. 12

Tools ....................................................................................................................................................13

Wiring diagram for test station NRA 1-3 ............................................................................................... 13

Basic Settings

Factory setting .....................................................................................................................................14

Page 3

Contents – continued –

Page

Commissioning

Check wiring ........................................................................................................................................14

Set operating mode ..............................................................................................................................14

Note .....................................................................................................................................................15

Establishing the number of measuring channels ...................................................................................15

Note .....................................................................................................................................................15

Switching on supply voltage .................................................................................................................15

Operation, Alarm and Test

Specification of keys and display ..........................................................................................................16

Key to codes on seven-segment displays ..............................................................................................16

Start .....................................................................................................................................................17

Setting banking-up of condensate, mode 1 and 6 .................................................................................17

Setting banking-up of condensate, mode 2 and 7 .................................................................................18

Alarm messages ................................................................................................................................... 19

Alarm list, maintenance interval and test, mode 1 to 7 .................................................................... 19, 20

Note .....................................................................................................................................................20

Malfunctions .........................................................................................................................................20

Decommissioning

NRA 1-3................................................................................................................................................21

Danger .................................................................................................................................................21

Disposal

NRA 1-3................................................................................................................................................21

Annex

Declaration of Conformity CE ................................................................................................................22

3

Page 4

4

Important Notes

Usage for the intended purpose

Use the test station NRA 1-3 only in conjunction with the electrodes NRG 16-19, NRG 16-27 and

NRG 16-28 for monitoring steam traps for banking-up of condensate and loss of steam.

Safety note

The equipment must only be installed and commissioned by qualified and competent staff.

Retrofitting and maintenance work must only be performed by qualified personnel who – through

adequate training – have achieved a recognised level of competence.

Danger

The terminal strips of the test station NRA 1-3 are live during operation.

This presents the danger of electric shock.

Cut off power supply before mounting, removing or connecting the terminal strips.

ATEX (Atmosphère Explosible)

According to the European Directive 94/9/EC the equipment must not be used in explosion risk areas.

Page 5

Explanatory Notes

Scope of supply

NRA 1-3

1 Test station NRA 1-3

1 Installation manual

Description

The measuring electrode detects banking-up of condensate and steam loss either directly in the steam

trap or in separate test chambers.

The measuring electrodes NRG 16-27, NRG 16-28 feature an additional temperature sensor for

measuring the temperature of the condensate.

Up to 16 measuring electrodes and a temperature sensor for measuring the temperature of the installa

tion can be connected to the test station NRA 1-3.

Function

The following electrodes can be used for monitoring steam traps:

n Measuring electrode NRG 16-19 for detecting banking-up of condensate or steam loss (electrode

submerged or exposed)

n Measuring electrode NRG 16-27, NRG 16-28 for detecting steam loss and banking-up of conden-

sate, with the condensate temperature being measured by an integrated temperature sensor

Three LEDs indicate banking-up of condensate, steam loss and malfunction in measuring electrode

(cable disruption, short circuit) and a three-digit seven-segment display shows the number of the

faulty steam trap. If more than one steam trap are defective the numbers of the faulty traps are

indicated one after another.

If banking-up of condensate, steam loss or malfunction in measuring electrode is indicated, an output

relay for the collective alarm will also be energised.

When using the measuring electrodes NRG 16-27, NRG 16-28 you can set the switchpoint for the

message “Banking-up of condensate” as a function of the separately detected temperature of the

installation or of the temperature measured in the steam trap.

The seven-segment display indicates every 6 months the maintenance interval of the measuring

electrodes in the form of an error code.

The seven-segment display indicates also status and error messages.

-

System components

TRG 5-63 (e. g.)

Temperature sensor with resistance thermometer Pt 100 for measuring the temperature of the

installation.

NRG 16-19

Measuring electrode for detecting banking-up of condensate or steam loss (electrode submerged or

exposed).

NRG 16-27, NRG 16-28

Measuring electrode for detecting banking-up of condensate or steam loss (electrode submerged or exposed) with integrated temperature sensor PT 1000 for measuring the temperature of the condensate.

5

Page 6

6

Technical Data

NRA 1-3

Supply voltage

230 V, 50 / 60 Hz

115 V, 50 / 60 Hz optional

Input

16 inputs for measuring electrodes NRG 16-19, NRG 16-27, NRG 16-28

1 input for temperature sensor, e. g. TRG 5-63, temperature sensing element Pt 100

Output

1 volt-free relay contact

Contact material: AgNi 0,15

Max. contact rating for switching voltages of 24 V AC/DC, 115 V AC and 230 V AC:

4 A resistive / inductive

Electrode voltage

12 V

Banking-up of condensate setting

Difference temperature condensate/installation dts 1 K to 100 K, adjustable in steps of 1 K

(mode 1 and 6)

Difference temperature condensate/switchpoint banking-up of condensate dtC 1 K to 100 K,

adjustable in steps of 1 K (mode 2 and 7)

Switchpoint banking-up of condensate 0 °C to 255 °C, adjustable in steps of 5 K (mode 2 and 7)

Indicators and adjustors

1 Three-digit seven-segment LED display, red, for indicating faulty steam traps and status and error

messages

3 LEDs for indicating banking-up of condensate, steam loss and malfunction in measuring electrode

3 Pushbuttons for parameter settings

1 Ten-pole code switch for system configuration

Delay of response

max. 5 sec.

Power consumption

max. 4 W

External fuse

63 mA

Design

NRA 1-3a: for wall mounting

NRA 1-3e: for panel mounting

Protection

NRA 1-3a: IP 65 to EN 60529

NRA 1-3e: Front: IP 65 to EN 60529, back: IP 00

Protection class

NRA 1-3a: 2 (completely insulated)

Max. admissible ambient temperature

55 °C

Enclosure

Material: ABS

Page 7

Technical Data – continued –

NRA 1-3 – continued –

Cable entry / Wiring

Cable gland with integral cable clamp, 8 x M 16 x 1.5, 17 five-pole screw-type terminals,

conductor size 1.5 mm

Max. cable length

50 m

Weight

Approx. 2 kg

Name plate / marking

Admissible ambient temperature

2

Safety note

Equipment designation

Electrical rating

Protection

Fig. 1

Manufacturer

Disposal note

CE marking

Specification for ordering

spare parts

7

Page 8

8

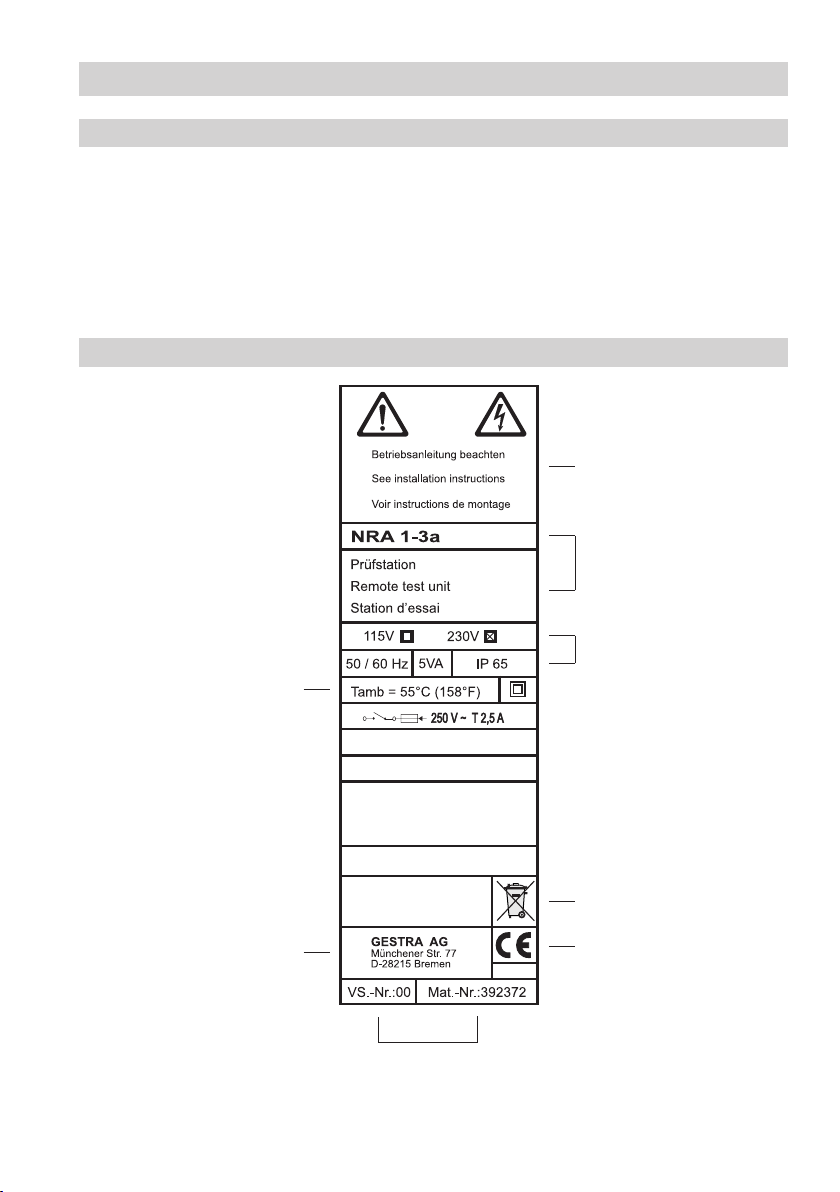

Technical Data – continued –

Dimensions NRA 1-3

Fig. 2

Test station NRA 1-3 a

137

146.7

226.5

Fig. 3

Test station NRA 1-3 e

Front panel cut-out 236x151

105

146.7

226.5

Page 9

Installation

Test station NRA 1-3a

The enclosure of the test station NRA 1-3a is designed for wall mounting. The four fixing holes are

accessible after opening the base part. For this purpose use a screwdriver with a broad blade to lever

the hinge out of the slot on the left side, see Fig. 2.

Then use suitable screws and wall plugs to fix the rear cover.

Test station NRA 1-3e

The enclosure of the test station NRA 1-3e is designed for panel mounting, panel cut-out:

236 x 151 mm. Place the equipment into the cut-out of the panel.

To unlock the hinge and swing the front panel open use a broad blade screwdriver to lever the front

panel out of the frame. Then turn the four screws for the tensioning clamps to the right until the

casing is firmly fixed in the panel cut-out, Fig. 3.

Note

Test station NRS 1-3a

After mounting the equipment you can

n connect the measuring electrodes / temperature sensor and

n set the operating mode and the number of the measuring channels (see “Commissioning”)

in a single operation with the base part open. Then close the base part and lock the left hinge.

Tools

n Screwdriver (5.5/100)

9

Page 10

10

1 2 3 4 5 1 2 3 4 5

1 2 3 4 5 1 2 3 4 5

1 2 3 4 5 1 2 3 4 5

1 2 3 4 5 1 2 3 4 5

1 2 3 4 5 1 2 3 4 5

1 2 3 4 5 1 2 3 4 5

1 2 3 4 5 1 2 3 4 5

1 2 3 4 5

1 2 3 4 5

1 2 3 4 5

1 2 3 1 2

1

0

9

8

7

6

5

4

3

2

NO

Functional Elements

E

NRA 1-3

6

5

1

2 3 4

Fig. 4

E

F

G

H

I

J

K

L

A

NRA 1-3

(Connecting side)

M

N

O

P

Q

R

S

T

C

D

Page 11

Functional Elements – continued –

Key

1 Seven-segment display

2 LED indicating steam loss

3 LED indicating banking-up of condensate

4 LED indicating malfunction in measuring electrode

5 Pushbutton for settings

6 Code switch

A Terminal for temperature sensor for system temperature

C Terminal for collective alarm

D Terminal for mains voltage

E – T Terminals for measuring electrodes

Mode 1, 2, 4 – 7

E – T Channel 1 – 16

Mode 3

E + M Channel 1

F + N Channel 2

G + O Channel 3

H + P Channel 4

I + Q Channel 5

J + R Channel 6

K + S Channel 7

L + T Channel 8

11

Page 12

12

Wiring

Connecting line of temperature sensor for detecting the temperature of the installation

Use screened three-core cable (e. g. Ölflex 110 CH, manufactured by LAPP, 3 x 0.5 mm²) for connecting

the sensor. Max. cable length between temperature sensor and test station NRA 1-3: 50 m. Connect

screen to the sensor.

Connecting line of measuring electrodes

NRG 16-19

The measuring electrode comes with a 2 m long connecting line and can be directly plugged into

the test station NRA 1-3. An extension is possible with screened two-core cable, e. g. Ölflex 110 CH,

manufactured by LAPP, 2 x 0.5 mm². Max. cable length between temperature sensor and test station

NRA 1-3: 50 m. Connect screen to the distribution substation.

NRG 16-27, NRG 16-28

Use screened five-core cable (e. g. Ölflex 110 CH, manufactured by LAPP, 5 x 0.5 mm²) for connecting

the electrode. Max. cable length between measuring electrode and test station NRA 1-3: 50 m.

Connect screen to the connecting coupler.

Wiring

NRA 1-3a

With the base part taken off:

1. Loosen the cable glands and pull the connecting lines through the glands.

2. Remove approx. 32 cm of the end insulation of the cable and the screen.

3. Connect the wires to the terminal strips (rear of base part) according to the wiring diagram and use

a cable tie for securing the cable bundle to prevent misalignment.

4. Tighten cable glands to achieve a good seal. Use sealing plugs to seal off cable glands that are not

used.

NRA 1-3e

1. Remove approx. 30 mm of the cable end insulation.

2. Connect the wires to the terminal strips (rear of base part) according to the wiring diagram.

Attention

n To protect the output relays provide the circuit with a T 2.5 A (slow blow) fuse.

n To suppress interferences provide connected contactors with RC combinations as

specified by the manufacturer.

n Install an easily accessible disconnector that serves as means of isolation from the

electrical supply near the test station (EN 61010-1).

n Label this disconnector as means of isolation for the test station.

Page 13

Wiring – continued –

1 2 3 4 5 1 2 3 4 5

1 2 3 4 5 1 2 3 4 5

1 2 3 4 5 1 2 3 4 5

1 2 3 4 5 1 2 3 4 5

1 2 3 4 5 1 2 3 4 5

1 2 3 4 5 1 2 3 4 5

1 2 3 4 5 1 2 3 4 5

1 2 3 4 5 1 2 3 4 5

1 2 3 4 5

1 2 3 1 2

1

0

9

8

7

6

5

4

3

2

NO

L

N

1 2 3 4

Tools

n Screwdriver for cross-recess head screws, size 1 and 2

n Screwdriver for slotted screws, size 2.5, completely insulated to VDE 0680

Wiring diagram for test station NRA 1-3

Class 4 (NRA 1-3)

Class 5 (NRA 1-3)

NRG 16-27/-28

Distribution

substation

Condensate

NRG 16-19

Condensate

NRA 1-3

Code switch,

white

e. g. TRG 5-63

Malfunction

*) Cable tie

Disconnector

Fig. 5

13

Page 14

14

Basic Settings

1 098765432

NO

Factory setting

Test station NRA 1-3

The test station features the following factory set default values:

n Difference of condensate temperature / plant temperature or switchpoint “Banking-up of conden-

sate”: 40 K

n Maintenance interval: 6 months (not adjustable)

n Code switch 6 Fig. 4: All switches are set to OFF.

Commissioning

Check wiring

Before commissioning please check:

Are the measuring electrodes /temperature sensor correctly wired in accordance with the wiring

diagram?

Set operating mode

Use code switch 6, Fig. 4, switches S1 – S3 to set one of the following seven operating modes.

6

Code switch, white

Mode S1 S2 S3

1 ON OFF OFF Yes

2 OFF ON OFF No

3 ON ON OFF No

4 OFF OFF ON No Steam loss 16 No temperature measurements

5 ON OFF ON No

6 OFF ON ON Yes

7 ON ON ON No

Plant

temperature

OFF OFF OFF Test

Function Channels Remark

Steam loss

Banking-up of

condensate

Steam loss

Banking-up of

condensate

Steam loss

Banking-up of

condensate

Banking-up of

condensate

Banking-up of

condensate

Banking-up of

condensate

Comparison of condensate temp.

16

and plant temperature

Only condensate temperature is

16

measured

8 No temperature measurements

No temperature measurements

16

Comparison of condensate temp.

16

and plant temperature

Only condensate temperature is

16

measured

Page 15

Commissioning – continued –

1 098765432

NO

Note

In mode 3 two measuring electrodes NRG 16-19 (one for banking-up of condensate and

one for steam loss) per measuring channel are connected together so that e. g. a float trap

can be monitored. For more information see the installation instructions for NRG 16-19,

NRG 16-27, NRG 16-28.

In mode 6 and 7 the measuring electrodes NRG 16-27, NRG 16-28 receive the measure

ments of the condensate temperature only from the integrated temperature sensor.

Establishing the number of measuring channels

Use code switch 6 Fig. 4, switches S4 – S7 to set the number of measuring channels.

The switches S8 – S0 must remain in the OFF position.

6

Code switch, white

S4 S5 S6 S7 Channels S4 S5 S6 S7 Channels

OFF OFF OFF OFF 1 OFF OFF OFF ON 9

ON OFF OFF OFF 2 ON OFF OFF ON 10

OFF ON OFF OFF 3 OFF ON OFF ON 11

ON ON OFF OFF 4 ON ON OFF ON 12

OFF OFF ON OFF 5 OFF OFF ON ON 13

ON OFF ON OFF 6 ON OFF ON ON 14

OFF ON ON OFF 7 OFF ON ON ON 15

ON ON ON OFF 8 ON ON ON ON 16

-

Note

If the settings of S1 – S7 are changed during operation, the new settings will only be

accepted by the test station after the supply voltage has been switched off and on.

Switching on supply voltage

Switch on supply voltage. The seven-segment display and the LEDs will be tested, i. e. all segments

and LEDs will be illuminated/flashing.

15

Page 16

16

Operation, Alarm and Test

E

Specification of keys and displays

Fig. 6

Function of keys

Key 1: Reduce value –, browse

Key 3: Increase value +, browse

Key 2 (E): Press briefly: Call up/Execute menu // Continue / Save settings

Key 2 (E): Press longer: Return to menu, cancel input

Key 1 + 3: Press longer: Reset/Delete values (e. g. alarm list + maintenance interval)

LEDs 1 – 3

LED 1: Steam loss

LED 2: Banking-up of condensate

LED 3: Measuring electrode NRG 16-27 defective (short circuits, parting of a cable).

Measuring electrodes NRG 16-19 are not monitored.

Key to codes on seven-segment display

Code Meaning

The following codes can appear on the seven-segment display even if no key is being pressed:

SYS System SYS changes with plant temperature in °C

E.01

E.02

E.03 Error Maintenance interval (6 months) elapsed

C.01 – C.16 Channels 1 - 16

If the E key is pressed:

HIS History Alarm list detailing old alarms

InT Interval Remaining time of maintenance interval

CAL Calibration Channel calibration in mode 2

dtC (mode 2, 7)

dtS (mode 1, 6)

tSt Test LEDs and all segments are illuminated

ALL All channels Channel selection when calibrating / setting

C.01 – C.16 Channels 1 - 16

don Done Confirmation of input when setting parameters

clr Clear Confirmation of clear command (interval, alarm)

Error Incorrect configuration due to inadmissible code switch setting

Error In mode 2 and 7 the settings for banking-up of condensate is not finished

Indication of measuring channel

Delta TC Admissible deviation from condensate temperature in steam trap

Delta TS Admissible deviation from plant temperature

Indication of measuring channel

Page 17

Operation, Alarm and Test – continued –

Start

Mode 1, 6: After the mains voltage has been switched on and the display test has been finished the

system temperature, error messages and current alarms will be indicated.

Mode 2 to 5 and 7: After the mains voltage has been switched on and the display test has been finished

error messages and current alarms will be indicated.

For more information on the codes HIS, Int and tSt see section “Alarm list, Maintenance interval and

Test”, mode 1 to 7.

Setting banking-up of condensate, mode 1 and 6

Key E

SYS / °C

briefly →

← longer

(1)

(1)

HIS

Keys

↓ (3) ↑

InT

Keys

↓ (3) ↑

dtS

Key E

briefly →

← longer

(1)

ALL

Keys

↓ (3) ↑

C.xx

Key E

briefly →

← longer

Key E

briefly →

← longer

Change

temperature

Keys (1),(3)

Change

temperature

Keys (1),(3)

Key E

briefly →

Key E

briefly →

don

←

dtS

don

←

C.xx

The precondition for this operating mode is:

n the use of the measuring electrodes NRG 16-27, NRG 16-28 (with integrated condensate

temperature measurement at the steam trap)

n the use of a separate temperature sensor for the measurement of the system/(plant) temperature

With the parameter dtS the difference between the condensate temperature in the steam trap and the

plant temperature can be modified either globally for all steam traps (ALL) or for each individual trap

(C.xx). The factory set default value is 40 K. The value can be changed in increments of 1 K up to a max.

limit of 100 K.

17

Page 18

18

Operation, Alarm and Test – continued –

Setting banking-up of condensate, mode 2 and 7

y y y

Serial

poll

The precondition for this operating mode is:

n the use of the measuring electrodes NRG 16-27, NRG 16-28 (with integrated condensate

temperature measurement at the steam trap)

With the parameter dtC the factory set difference of 40 K between the temperature measured at the

steam trap and the switchpoint “Banking-up of condensate”. The value can be changed in increments

of 1 K up to a max. limit of 100 K.

In the parameter mode CAL the condensate temperature from all steam traps is polled, the difference

dtC is subtracted and the result saved.

Starting from the parameter mode ALL, the switchpoint “banking-up of condensate” can be adjusted in

increments of 5 K for each individual steam trap (C.xx) in order to match the settings optimally to the

operating conditions.

Key E

briefly →

← longer

(1)

(1)

(1)

HIS

Keys

↓ (3) ↑

InT

Keys

↓ (3) ↑

CAL

Keys

↓ (3) ↑

dtC

Key E

briefly →

← longer

Key E

briefly →

← longer

ALL

Keys

(1)

↓ (3) ↑

C.xx

Change

tempera-

ture

Keys (1), (3)

Key E

briefly →

Key E

briefly →

← longer

Key E

briefly →

Temperature

auto poll

Change

temperature

Keys (1), (3)

don

←

dtC

auto →

Key E

briefly →

don

←

CAL

don

←

C.xx

Page 19

Operation, Alarm and Test – continued –

E

Alarm messages

Fig. 7

The alarm messages “Banking-up of condensate”, “Steam loss” and “Malfunction in electrode” (short

circuit, parting of cable) will be indicated in the particular operating mode by the LEDs 1 – 3 and the

output relay for the collective alarm is energized.

In addition, the seven-segment display shows the number of the faulty steam trap (C.xx). If more than

one steam trap are faulty the numbers are indicated one after the other.

Once the cause for the alarm is eliminated, the message is entered into the alarm list.

Alarm list, maintenance interval and test, mode 1 to 7

SYS /

y y y

Serial

poll

Alarm list HIS

Use keys 1 and 3 to browse through the list. The respective alarm messages are indicated by the

associated LEDs 1 – 3. If you want to delete a list entry press and hold down the keys 1 and 3, the

message clr appears, the entry is deleted and the cursor goes to the next entry.

Key E

briefly →

← longer

(1)

(1)

HIS

Keys

↓ (3) ↑

InT

Keys

↓ (3) ↑

tSt

Key E

briefly →

← longer

Key E

briefly →

← longer

Key E

briefly →

← longer

Display,

keys (1),(3)

=

browse

Display

Display

LEDs +

segments

Keys

(1) + (3)

longer →

← auto

Keys

(1) + (3)

longer →

← auto

Key E

briefly →

clr

clr

don

←

tSt

19

Page 20

20

Operation, Alarm and Test – continued –

Alarm list, maintenance interval and test, mode 1 to 7 – continued –

Maintenance interval InT

The paramter mode InT shows the remaining time of the maintenance interval in days. Hold down the

keys 1 and 3 to reset the maintenance interval, the message

previous display.

Test tSt

The parameter tSt checks the segments of the seven-segment display and the LEDs 1 – 3. After the

test the system returns to the parameter tSt.

Note

If the key E is used to select a parameter but then no key is pressed, the test station

returns to the start window after 10 seconds.

Malfunctions

The following malfunctions can be indicated by the seven-segment display:

Error code Error Remedy

E.01 Incorrect configuration set by code switch

E.02

E.03 Maintenance interval elapsed

E.04 Temperature in test station is too high Check installation of test station

In mode 2, 7 the setting “Banking-up of

condensate” has not been finished

clr appears and the system returns to the

Check and correct configuration.

The test station accepts the new settings only after

switching the supply voltage off and on again

Finish the setting “Banking-up of condensate”

Remove and clean measuring electrodes.

Reset the maintenance interval in the parameter

mode InT

If faults occur that are not listed above or cannot be corrected, please contact our service centre or

authorized agency in your country.

Page 21

Decommissioning

NRA 1-3

First disconnect the supply voltage and pull the cable out of the cable gland. Then disconnect the

measuring electrodes and pull the electrode cables out of the cable glands.

De-install the test station.

Danger

The terminal strips of the test station NRA 1-3 are live during operation.

This presents the danger of electric shock.

Always cut off power supply before mounting, removing or connecting the terminal

strips!

Disposal

NRA 1-3

De-install the test station NRA 1-3 and separate the waste materials, using the materials

specifications.

Dispose of electronic components (boards) separately.

For the disposal of the test station observe the pertinent legal regulations concerning waste disposal.

21

Page 22

22

Annex23For your Notes

Declaration of Conformity

We hereby declare that the test station NRA 1-3 conforms to the following European Directive:

n

LV guideline 73/23/eec version 93/68/eec

n

EMC guideline 93/68/eec

This declaration is no longer valid if modifications are made to the equipment without consultation

with us.

Bremen, 7th July 2006

GESTRA AG

Head of Design Dept

Dipl. Ing. Uwe Bledschun

(Academically qualified engineer)

Quality Assurance Manager

Dipl. Ing. Lars Bohl

(Academically qualified engineer)

Page 23

Page 24

Agencies all over the world:

www.gestra.de

GESTRA

España

GESTRA ESPAÑOLA S.A.

Luis Cabrera, 86-88

E-28002 Madrid

Tel. 00 34 91 / 5 15 20 32

Fax 00 34 91 / 4 13 67 47; 5 15 20 36

E-mail: aromero@flowserve.com

Great Britain

Flowserve Flow Control (UK) Ltd.

Burrel Road, Haywards Heath

West Sussex RH 16 1TL

Tel. 00 44 14 44 / 31 44 00

Fax 00 44 14 44 / 31 45 57

E-mail: gestraukinfo@flowserve.com

Italia

Flowserve S.p.A.

Flow Control Division

Via Prealpi, 30

l-20032 Cormano (MI)

Tel. 00 39 02 / 66 32 51

Fax 00 39 02 / 66 32 55 60

E-mail: infoitaly@flowserve.com

Polska

GESTRA POLONIA Spolka z.o.o.

Ul. Schuberta 104

PL - 80-172 Gdansk

Tel. 00 48 58 / 3 06 10 -02 od 10

Fax 00 48 58 / 3 06 33 00

E-mail: gestra@gestra.pl

Portugal

Flowserve Portuguesa, Lda.

Av. Dr. Antunes Guimarães, 1159

Porto 4100-082

Tel. 0 03 51 22 / 6 19 87 70

Fax 0 03 51 22 / 6 10 75 75

E-mail: jtavares@flowserve.com

USA

Flowserve GESTRA U.S.

2341 Ampere Drive

Louisville, KY 40299

Tel.: 00 15 02 / 502 267 2205

Fax: 00 15 02 / 502 266 5397

E-mail: dgoodwin@flowserve.com

GESTRA AG

P. O. Box 10 54 60, D-28054 Bremen

Münchener Str. 77, D-28215 Bremen

Telephone +49 (0) 421 35 03 - 0

Fax +49 (0) 421 35 03 - 393

E-Mail gestra.ag@flowserve.com

Internet www.gestra.de

818678-00/806cm · 2006 GESTRA AG · Bremen · Printed in Germany

24

Loading...

Loading...