Page 1

®

FBM 550 A1

Petrol Lawnmower

Translation of original operation manual

6

Page 2

Before reading, unfold the page containing the illustrations and familiarise yourself with all functions of the

device.

GB / IE Translation of original operation manual Page 5

Page 3

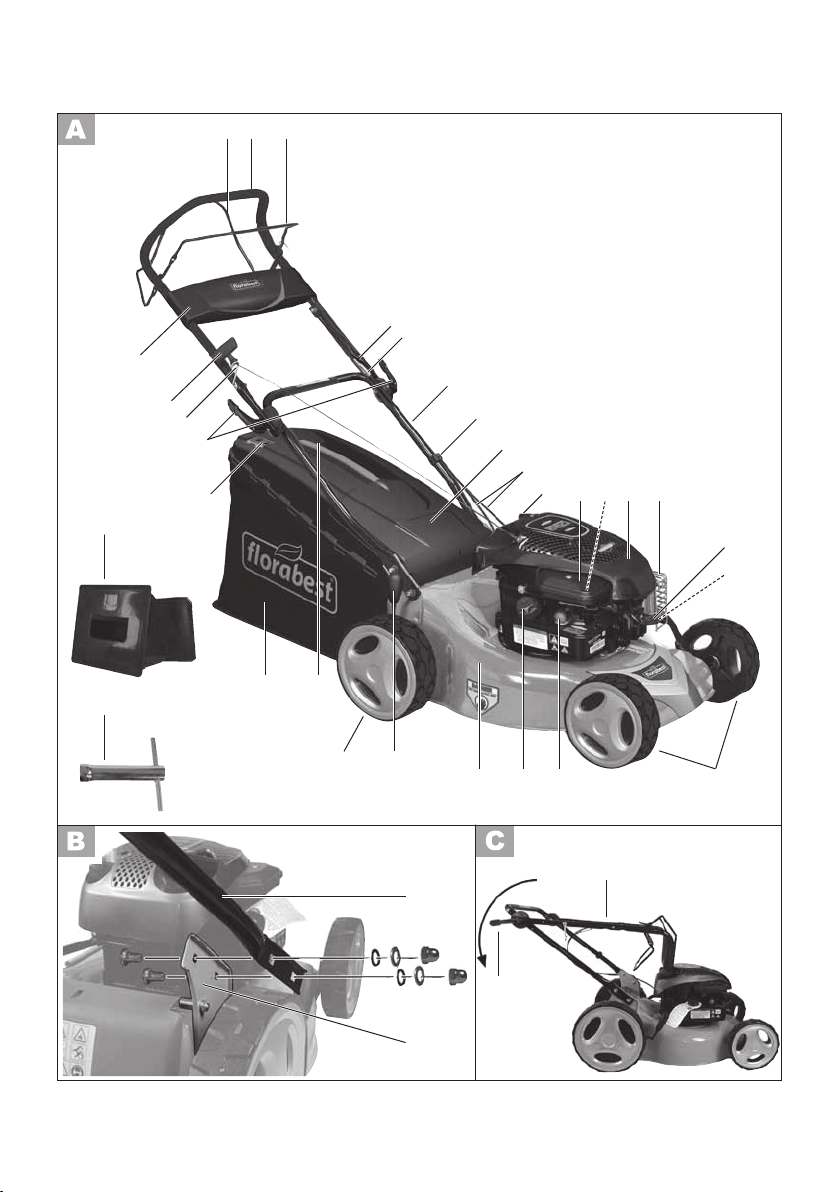

29

30

28

27

26

25

24

12

23

3

4a

4b

5

6

7

8

9

101112 13

14

15

22

21

20

16171819

2

5

25

31

Page 4

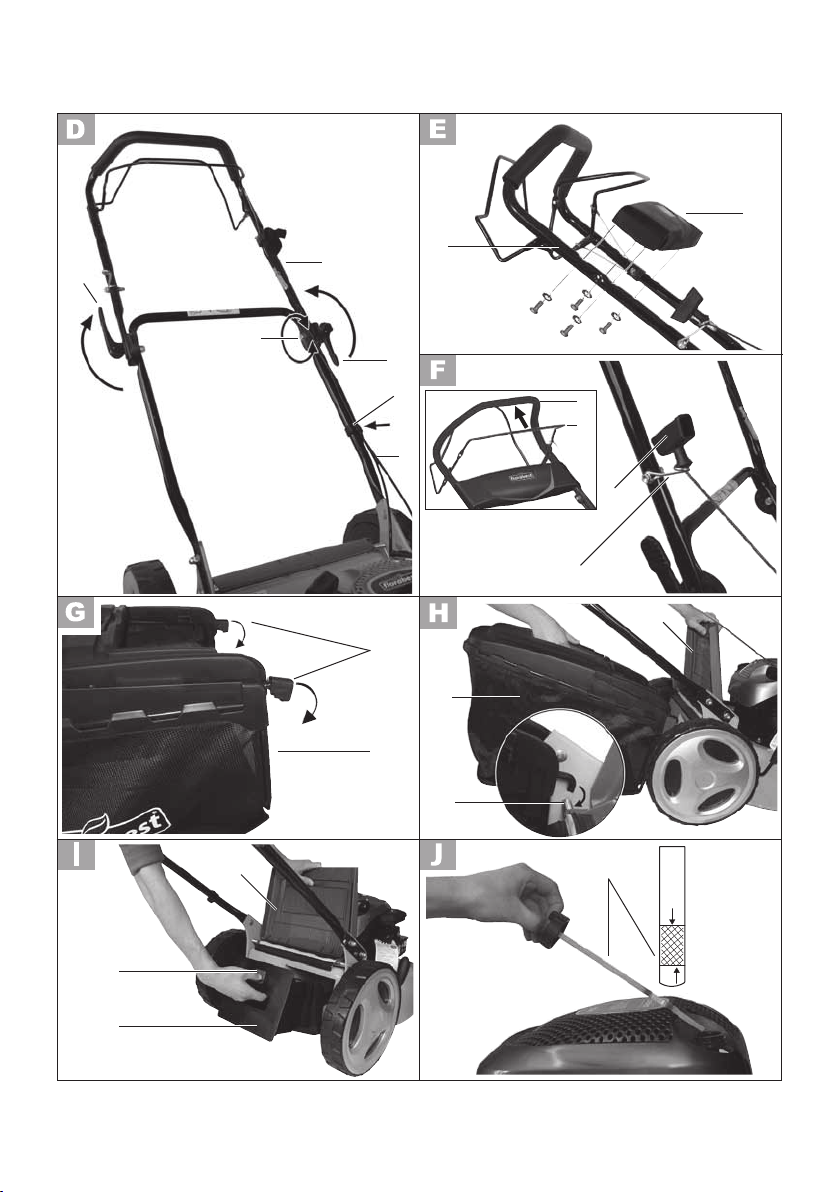

25

32

28

2

2

25

6

2

3

8

27

26

7

33

23

23

35

29

34

7

9

FULL

ADD

Page 5

Content

GB IE

Symbols and icons ................................6

Symbols on the device ........................6

Symbols in the manual ........................7

Safety Instructions ................................7

Intended Use ..........................................9

General Description ............................10

Summary ...........................................10

Functional Description ......................10

Safety Equipment ..............................10

Delivery Contents .............................. 11

Initial Operation ................................... 11

Installing the Handle Bar ...................11

Installing the Starter Cord ................. 11

Installing the Grass Collection Box ...12

Installing the Mulch Kit ......................12

Filling with Engine Oil and Checking

the Oil Level ......................................12

Filling with Petrol ...............................13

Operation ..............................................13

Starting and Stopping the Engine .....13

Mowing ..............................................14

Working Instructions ...........................14

General Working Instructions ............14

Setting the Cutting Height .................14

Emptying the Grass Collection Box ... 14

Mowing with the Mulch Kit ................15

Cleaning and Maintenance .................15

Cleaning and General Maintenance

Work ..................................................15

Cleaning / Replacing the Air Filter .....16

Maintaining the Spark Plug ...............16

Changing the Engine Oil ...................16

Adjusting the Bowden Cable .............17

Maintenance Intervals .......................17

Checking/Sharpening/Replacing the

Blade .................................................18

Adjusting the Carburettor ..................18

Storage .................................................18

General Storage Instructions ............18

Storage During Longer Breaks from

Operation ..........................................18

Technical Specications .....................19

Disposal / Environmental Protection .. 19

Replacement parts ..............................20

Guarantee .............................................20

Troubleshooting ..................................21

Translation of the original

EC declaration of conformity .............22

Exploded Drawings ............................23

Grizzly Service-Center ........................25

Before initial use, please read these operating instructions and the Briggs & Strat-

ton instruction manual carefully in order to avoid incorrect handling. Keep the

instructions in a safe place and pass them on to any subsequent user, so the information is available at all times.

5

Page 6

GB IE

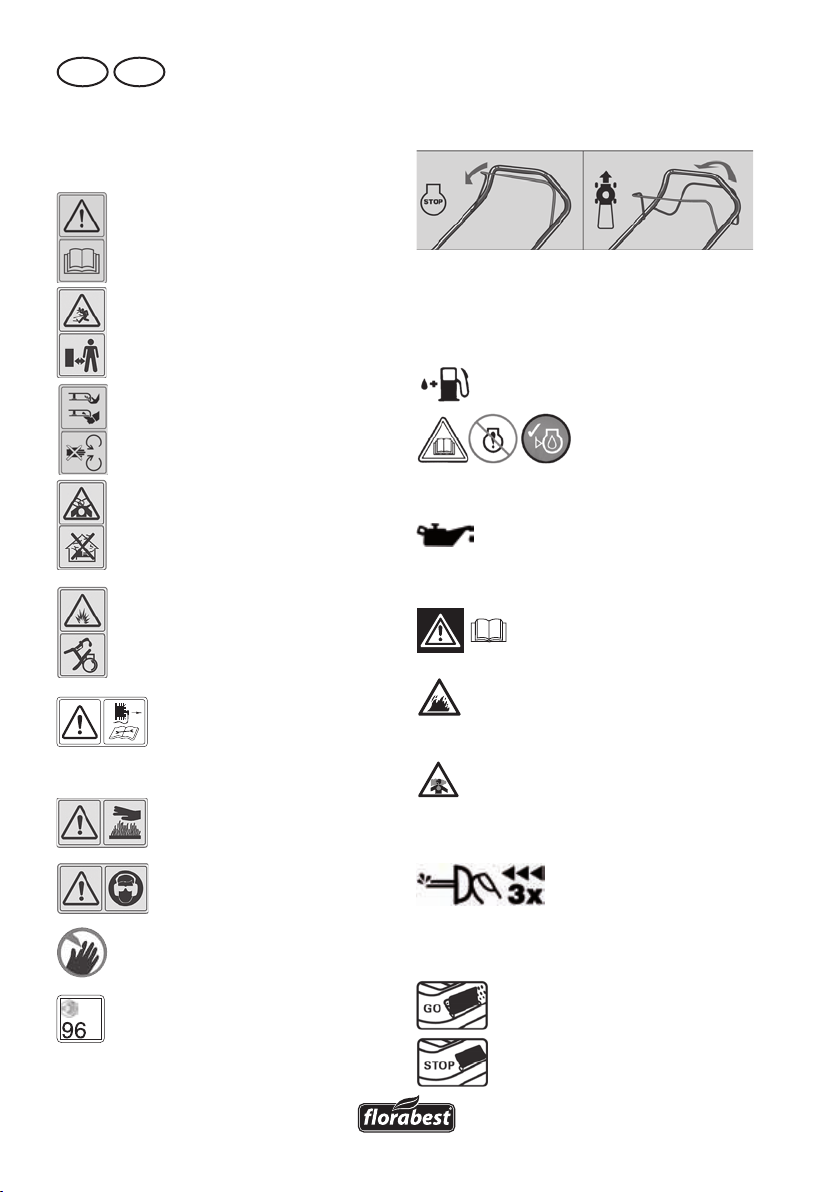

Symbols and icons

Symbols on the device

Attention!

Read the instruction manual.

Risk of injury from parts being

ung out.

Keep bystanders away from the

equipment.

Risk of injury from sharp blades.

Keep feet and hands away.

Caution – toxic fumes!

Do not operate the equipment in

enclosed areas.

Caution – petrol is ammable!

Do not smoke and keep away

from heat sources.

Caution – risk of injury!

Before maintenance work,

switch off the engine and take

out the spark plug connector.

Caution – hot surfaces!

Risk of burning.

Symbols on the handle bar:

Stop the equipment:

Release the safety

catch

Wheel drive on:

Pull up the drive

catch

Symbols on the ller cap:

Note on the petrol ller

Caution! Before start-

ing, check the oil level.

Symbols on the oil ller cap:

Note on the oil ller

Symbols on the Tank:

Attention!

Read the instruction manual.

Caution – petrol is ammable!

Allow the engine to cool for at least

2 min. before refuelling.

Caution – toxic CO fumes! Do not

operate the equipment in enclosed

areas.

Pictorial Symbols on the Petrol Pump:

Caution – risk of injury!

Wear eye and ear protection.

Danger!

Keep hands and feet away.

L

WA

Information of the acoustic power

level L

dB

in dB.

wa

6

Press the petrol pump

(primer) 3x before starting.

Fill Level Indicator on the Grass Collection Box:

Fill level indicator open:

Grass collection box empty

Fill level indicator closed:

Grass collection box full

Page 7

GB IE

Symbols in the manual

Warning symbols with informa-

tion on damage and injury prevention.

Instruction symbols (the instruc-

tion is explained at the place of the

exclamation mark) with information

on preventing damage.

Help symbols with information on

improving tool handling.

Safety Instructions

This section deals with the basic safety

procedures when working with the equipment.

WARNING! Read all of the safety

instructions and directions. Failure

to observe the safety instructions

and directions may result in electric

shock, re and/or serious injury.

Instructions:

• This appliance is not intended for use

by persons (including children) with

reduced physical, sensory or mental

capabilities, or lack of experience and

knowledge, unless they have been given supervision or instruction concerning use of the appliance by a person

responsible for their safety.

• Children should be supervised to ensure that they do not play with the appliance.

• Read the operating instructions carefully. Familiarise yourself with the

controls and with the correct use of the

equipment.

• Do not allow children or other people

who are unfamiliar with the operating

instructions to use the equipment. Local regulations may set a minimum age

for the user.

• Do not mow whilst people – especially

children – or animals are nearby. If

distracted, you may lose control of the

equipment.

• The operator or user is responsible for

accidents or damage to other persons

or their property.

• Observe noise control and local regulations.

Preparatory Measures:

• When mowing, always wear sturdy

shoes and long trousers. Do not mow

barefoot or in light sandals. Loose

clothing, jewellery or long hair can become caught in moving parts. Wearing

suitable clothing reduces the risk of

injury.

• Check the area on which the equipment is to be used and remove all objects (stones, sticks, wires) that could

be caught and ung out.

• Warning: Petrol is highly ammable.

Fire or explosions can result in serious

burns:

- Keep petrol only in containers in-

tended for this purpose;

- Only refuel outdoors and do not

smoke whilst refuelling;

- Fill with petrol before starting the

engine. Do not open the ller cap or

rell with petrol whilst the engine is

running or the equipment is hot:

- If petrol is spilled, do not attempt to

start the engine. Instead, remove the

equipment from the surface on which

the petrol has been spilled. Avoid

any ignition attempt until the petrol

fumes have evaporated;

7

Page 8

GB IE

- For reasons of safety, replace petrol

and other ller caps in the event of

damage.

• Replace defective silencers.

• Before use, always carry out a visual

inspection to check whether the cutting

tools, mounting bolts and entire cutting

unit are worn or damaged. To avoid

imbalance, only replace worn or damaged tools and bolts in sets.

• Take care with equipment that has

several cutting tools, as the movement

of one blade may result in rotation of

other blades.

• Use only replacement parts and accessories supplied and recommended

by the manufacturer. The use of parts

from other manufacturers may result

in injuries and will result in immediate

invalidation of the guarantee.

Handling:

• Do not run the combustion engine in

enclosed spaces, in which dangerous

carbon monoxide can collect.

• Mow only in daylight or with good articial lighting. An unlit working area can

result in accidents.

• If possible, avoid using the equipment

on wet grass.

• Always ensure a safe stance, particularly on slopes. This will give you better

control of the equipment in unexpected

situations.

- Always work across the slope, never

upwards or downwards.

- Take particular care when changing

the direction of travel on the slope.

- Do not mow on excessively steep

slopes.

• Run the equipment only at walking

speed.

• Take particular care when turning the

equipment around or pulling it towards

you.

• Stop the cutting tool if the equipment

has to be tipped up for transportation

over a surface other than grass and

when moving the equipment from and

to the surface to be mown.

• Do not use the equipment with damaged safety equipment or guards or

with no safety equipment attached, e.g.

impact protection and/or grass catchers. This ensures that the equipment

remains safe.

• Do not change the engine regulator

setting and do not over-rev it. This may

damage the equipment.

• Before starting, the engine, disengage

all cutting tools and drives.

• Start or operate the start switch with

care and in accordance with the manufacturer’s instructions. Ensure sufcient

space between feet and the cutting

tool. Risk of injury.

• When starting or activating the engine,

do not tip the equipment unless the

equipment has to be lifted for this procedure. In this case, tip the equipment

only as far as is absolutely necessary

and lift only the side that is away from

the user.

• Do not start the engine when standing

in front of the ejection channel.

• Switch on the engine in accordance

with the instructions and only if your

feet are a safe distance away from the

cutting tools.

• Do not place hands or feet under rotating parts. Always keep away from the

ejection opening. A moment of carelessness when using the equipment

may result in serious injury.

• Do not leave or carry the equipment

when the engine is running.

• Switch off the engine, take out the

spark plug connector and ensure that

8

Page 9

GB IE

all moving parts are still:

- Before releasing blockages or removing obstructions in the ejection

channel;

- Before checking, cleaning or working

on the equipment;

- If a foreign body is struck. Look for

damage to the equipment and carry

out the necessary repairs before restarting and working with the equipment;

- If the equipment starts to vibrate unusually strongly, an immediate check

is required.

• Switch off the engine

- When leaving the equipment;

- Before refuelling;

• Close the throttle valve when stopping

the engine.

• Do not leave the equipment unattended in the workplace.

• Do not work with equipment that is

damaged or incomplete or has been

converted without the approval of the

manufacturer.

Using machines for applications other

than those intended may result in dangerous situations.

Maintenance and Storage:

• Ensure that all nuts, bolts and screws

are tightened rmly and the equipment

is in safe working condition. Many accidents are caused by poorly maintained

equipment.

• Do not keep the equipment with petrol

in the tank inside a building in which

petrol fumes could potentially come

into contact with open re or sparks.

• Allow the engine to cool before placing the equipment in enclosed spaces.

Risk of re.

• To avoid the risk of re, keep the engine, exhaust and area around the fuel

tank free of grass, leaves or leaking

grease (oil).

• Check the grass catcher regularly for

wear or loss of function.

• For reasons of safety, replace worn

or damaged parts. Replace defective

silencers.

• If the fuel tank is to be drained, do this

outdoors.

• Handle your equipment with care.

Keep the tools sharp and clean to enable you to work better and more safely.

Follow the maintenance directions.

• Do not attempt to repair the equipment

yourself unless you are trained to do

so. Any work not specied in these

instructions is to be carried out only by

customer service centres authorised

by us.

• Keep the equipment in a dry place and

out of reach of children. Machines are

dangerous if used by inexperienced

people.

Intended Use

The equipment is intended only for mowing lawns and grass areas up to 1200 m

domestic use.

This equipment is not suitable for commercial use. Commercial use will invalidate the

guarantee.

Any use other than specically permitted in

these instructions may result in damage to

the equipment and represent a serious risk

to the user.

The equipment is intended for use by

adults. Children or other people who are unfamiliar with the operating instructions must

not use the equipment.

The operator or user is responsible for

accidents or damage to other persons or

their property.

2

in

9

Page 10

GB IE

General Description

The illustration of the princi-

pal functioning parts can be

found on the front and back

foldout pages.

Summary

1 Drive catch

2 Upper handle bar

3 Safety catch

4a Bowden cable lock nut

4b Bowden cable adjusting nut

5 Lower handle bar

6 Cable clamp

7 Rear impact protection

8 Bowden cables

9 Oil ller cap with dipstick

10 Air lter box with

11 Air lter (no illustration)

12 Engine cover (nger protection)

13 Exhaust guard

14 Spark plug connector with

15 spark plug (no illustration)

16 2 front wheels

17 Petrol pump (primer)

18 Filler cap

19 Sheet steel housing

20 Lever for cutting height adjust-

ment

21 2 rear wheels

22 Grass collection box carrying

handle

23 Grass collection box

24 Fill level indicator

25 2 quick-release levers for xing

the bar

26 Starter cord guide

27 Starter handle with starter cord

28 Screen

29 Mulch kit

30 Spark plug wrench

31 Bar slot

32 Nut on tensioning lever

33 Grass collection box protective

caps

34 Grass collection box suspension

bracket

35 Mulch kit button

36 Cut height position

37 Ventilations holes

Functional Description

The equipment is driven by a powerful

four-stroke engine (Briggs & Stratton 550

series). The ball bearing mounted wheels,

the rear wheel drive and the blade braking function make the equipment easier to

operate.

The equipment is tted with a high quality

sheet steel housing and collapsible handle bar. There are two modes of operation

available to the user: mowing with the

grass collection box or mulch mowing.

Refer to the following descriptions for a

functional description of the controls.

Safety Equipment

3 Safety catch

The equipment stops when the

safety catch is released.

7 Rear and side impact protec-

tion

protect the operator from parts

that are ung out and from accidentally touching the blades

when mowing with no grass collection box.

10

Page 11

GB IE

13 Exhaust guard

prevents hands or combustible

materials from coming into contact with a hot exhaust.

Delivery Contents

Carefully unpack the appliance and check

that it is complete:

- Petrol lawn mower (pre-assembled)

- Collapsed handle bar

- Grass collection box

- Mulch kit (already mounted)

- Cable clamp

- Assembly accessories for xing the

bar

- 5l transport can

- Spare spark plug

- Spark plug wrench

- Quick guide

- Operating instructions

- Briggs & Stratton operating instructions

- Briggs & Stratton dealer list

Initial Operation

Caution! Risk of injury from

rotating blades. Carry out work

on the equipment only when the

blade is switched off and stationary.

Installing the Handle Bar

Caution! When installing the

handle bar, ensure that the

Bowden cables (

squashed.

1. Position the ends of the bottom

handle bar (5) in the two bar

slots (31) on the lawnmower.

2. Use the enclosed assembly accessories to screw the bottom

handle bar (5) to the bar slot

(31).

3. Fold out the top handle bar (2).

4. Lock the quick release tensioning levers (25) by pressing them

towards the top handle bar (2).

The tensioning levers must be

tightened and in contact with

the bar such that tensioning is

possible with average force.

To loosen the tensioning lever,

turn the nut (32) on the tensioning lever anticlockwise.

To tighten the tensioning lever,

turn the nut (32) on the tensioning lever clockwise.

5. Fix the Bowden cables (8) to the

bar using the cable clamp (6).

6. Use the enclosed assembly accessories to screw the screen

(28) onto the top handle bar (2).

8) are not

Observe the Briggs & Stratton in-

struction manual supplied.

Before starting the equipment, you must

- Install the handle bar

- Install the grass collection box / mulch

kit

- Install the starter cord

- Fill with engine oil

- Fill with petrol

Installing the Starter Cord

1. Pull the safety catch (3) towards

the handle bar (2) and hold it.

2. Slowly pull the starter cord on

the starter handle (27) towards

the bar and hook the starter

cord into the starter cord guide

(26).

3. Release the safety catch (3).

11

Page 12

GB IE

Installing the Grass Collection

Box

Caution: Do not operate the

equipment with the grass collection box or impact protection

installed incompletely. Risk of

injury!

The mulch kit must be removed

before using the grass collection

box (see

Remove the Protective Caps:

1. Remove the protective caps

(33) on the grass collection box

(23).

Fixing the Grass Collection

Box onto the Equipment:

2. Lift the rear impact protection

(7).

3. Remove the mulch kit (

it is plugged in.

4. Hook the grass collection box

(23) into the mounting provided

for this (34) on the rear of the

equipment.

5. Release the impact protection

(7). It holds the grass collection

box in position.

Dismantling the Grass Collec-

tion Box:

6. Lift the impact protection (7) and

remove the grass collection box

(23).

).

29) if

Fixing the Mulch Kit:

1. Lift the impact protection (7).

2. Remove the grass collection

box (

3. Push down the button (35) on

the mulch kit and plug in the

mulch kit (29). The button clicks

into place.

Removing the Mulch Kit:

4. Lift the impact protection (7).

5. Push down the button (35) and

remove the mulch kit (29).

23) if it is installed.

Filling with Engine Oil and

Checking the Oil Level

Place the equipment on a level

base.

1. Unscrew the oil ller cap and

dipstick (9) and pour oil into the

tank. The oil tank holds 0.6 l oil.

Use brand oil (e.g. SAE 30).

2. To check the oil level, wipe the

dipstick (9) on a clean cloth

and replace it in the tank until it

stops.

3. After pulling it out, read off

the oil level on the dipstick.

The oil level should be in

the marked area between

the minimum and maximum marks.

4. Wipe off any spilt oil and

close the oil ller cap (9).

FULL

ADD

Installing the Mulch Kit

The grass collection box must be

removed before using the mulch kit

(see

)

12

Check the oil level every time be-

fore mowing and add oil when the

lower marking point is reached.

Page 13

GB IE

Filling with Petrol

Warning! Petrol is ammable and hazardous to health:

- Keep petrol in containers intended for

this purpose;

- Only refuel outdoors and never with

the engine running or when the machine is hot;

- Open the ller cap carefully to allow

excess pressure to escape;

- Do not smoke whilst refuelling;

- Avoid skin contact and inhalation of

the fumes;

- Remove spilt petrol;

- Keep petrol away from sparks, open

ames and other ignition sources;

- Dispose of leftover petrol in an environmentally friendly way (see “Disposal / Environmental Protection”).

- Do not use petrol/oil mixtures;

- Use normal or super unleaded

petrol;

- Only use clean, fresh petrol;

- Do not store petrol for longer

than one month, as its quality

deteriorates.

1. Unscrew the ller cap (

pour in the petrol to the lower edge of

the ller.

Do not ll the tank entirely, to allow

the petrol room to expand.

2. Wipe away petrol residues around the

ller cap and close the ller cap.

18) and

Operation

Observe the noise protection and

local regulations.

Starting and Stopping the Engine

Warning! Petrol is ammable.

Start the engine at least 3 m

away from the lling location.

Check the petrol and oil levels

regularly (see “initial operation”)

and rell in time.

Start the equipment on a sturdy,

level base, if possible not in long

grass. Ensure that the cutting tool

is touching neither objects nor the

ground.

Start the Engine:

1. For a cold start,

press the petrol

pump (

2. Pull the safety catch (3) towards

the handle bar and hold it.

3. Pull the starter cord (23) and the

engine starts.

4. When the engine starts, allow

the starter handle (27) to slowly

slide back into the starter cable

guide (26).

Stopping the Engine:

5. Release the safety catch (3),

the engine stops and the blade

is slowed.

17) (primer) 3x.

13

Page 14

GB IE

Mowing

1. Start the engine (see ).

2. Wheel drive on: pull the drive

catch (1) towards the handle

bar (2). The mower moves forwards.

3. Wheel drive off: release the

drive catch (1). The equipment

stops.

Working Instructions

General Working Instructions

• As far as possible, mow the lawn when

it is dry in order to protect the turf.

• Set the cutting height such that the

equipment is not overloaded.

• Run the equipment at walking speed

in lines that are as straight as possible. For uninterrupted mowing, the

lines should always overlap by a few

centimetres.

• Do not move backwards.

• On slopes, always work across the

slope.

• If the blade comes into contact with

a foreign body, switch off the engine

immediately. Wait until the blade is

stationary and check the equipment

for damage. Restart work only if the

equipment is undamaged.

• Switch off the equipment during long-

er breaks and for transportation and

wait until the blade is stationary.

• Clean the equipment after each use,

as described in the “cleaning and

maintenance“ chapter.

Setting the Cutting Height

The equipment has 10 positions for setting the cutting height (30-75 mm):

1. Pull the lever (20) outwards and

push it to the desired position

(36).

2. Push the lever (20) back in.

The correct cutting height is around

30 – 45 mm for an ornamental lawn and

around 40 – 65 mm for a utility lawn.

Select a greater cutting height for

the rst cut of the season.

Emptying the Grass Collection

Box

Fill Level Indicator:

The ll level indicator (

the side of the grass collection box (

23) shows when the grass collection box

is full.

Fill level indicator open:

Grass collection box empty

Fill level indicator closed:

Grass collection box full

1. Stop the engine and wait until

the blade is stationary.

2. Lift the rear impact protection

(7) and remove the grass collection box (23).

3. Empty (see “disposal / environmental protection“) and reassemble the grass collection box

(23).

24) attached to

14

Page 15

GB IE

Mowing with the Mulch Kit

When mulch mowing, the grass is cut,

chaffed and spread on the lawn all in one

go. The cut grass serves as a natural fertiliser.

Tips for Mulch Mowing:

• Cut the grass back by 2 cm from a

grass height of 4-6 cm.

• Use sharp cutting blades.

• Do not mow wet grass.

Cleaning and Maintenance

Have any repair and mainte-

nance work not described in

these instructions carried out by

a specialist workshop. Use only

original Grizzly replacement

parts. Risk of accidents!

Carry out maintenance and

cleaning work strictly with the

engine switched off and spark

plug connectors removed. Risk

of injury!

Allow the equipment to cool

before any maintenance and

cleaning work. Elements of the

engine are hot. Risk of burning!

Wear gloves when handling the

blade.

For cleaning and maintenance

work, also observe the Briggs &

Stratton instruction manual supplied.

We recommend contacting an au-

thorised Briggs & Stratton dealer for

maintenance work on the engine.

Cleaning and General Maintenance Work

Tip the Equipment

(Service Position):

To clean the underside of the equipment,

tip the equipment backwards on the upper

handle bar (2).

To prevent the equipment from tipping

back,

- remove the grass collection box (

23) if it is installed.

- set the cut height to the highest position (36),

- loosen the quick release tensioning

levers (25) and fold the top handle bar

(2) towards the equipment (see “Assembling the Handle Bar”).

The Bowden cables (9) must not be

caught when doing this.

Ensure that the quick release

tensioning levers (25) come to a

stop on the side.

When cleaning or servicing the

appliance, ask someone to hold

the tilted appliance.

Risk of injury if the equipment

tilts back.

Do not tilt the equipment sideways

or forwards. Operating uids could

leak out and the engine could be

damaged.

• Always keep the equipment clean. To

clean, use a toothbrush or cloth but no

corrosive cleaning agents or solvents.

Do not use water to clean the engine as

it could contaminate the fuel system.

• After mowing, remove plant remains

that are stuck to the equipment by using a piece of wood or plastic. Clean

the vent holes (

37), ejection hole

15

Page 16

GB IE

and blade area especially. Do not use

hard or pointed objects, which could

damage the equipment.

• Oil the wheels from time to time.

• Before each use, check the lawnmower for obvious defects such as loose,

worn or damaged parts. Check that

all nuts bolts and screws are sitting

rmly.

• Check covers and guards (

12, 13) for damage and that they are

sitting correctly. Replace if necessary.

3, 7,

Cleaning / Replacing the Air

Filter

Do not operate the equipment

without the air lter otherwise dust

and dirt will get into the engine and

result in damage to the machine.

1. Loosen the screw on the air

lter box (10) and remove the

box.

2. Open the air lter box and remove the air lter (11).

3. Clean the air lter (11) in soap

solution and allow it to dry.

Knead a few drops of fresh oil

into the air lter.

4. Replace a defective air lter

with a new lter (see “Spare

Parts”).

5. To install, place the air lter (11)

in the air lter box (10) and reclose it.

6. Screw the air lter box back

onto the equipment.

Maintaining the Spark Plug

A worn spark plug or a spark gap

that is too large will result in a reduction of engine performance.

1. Disconnect the spark plug connector (14) from the spark plug

by simultaneously pulling and

turning.

2. Unscrew the spark plug (15) an-

ticlockwise using the enclosed

spark plug wrench (

3. Check the spark gap using a

feeler gauge (available from

specialist shops). The spark gap

must be at least 0.76 mm.

4. If necessary, adjust the gap by

carefully bending the ground

electrode on the spark plug.

5. Clean the spark plug with a wire

brush.

6. Insert the cleaned and adjusted

spark plug or replace a damaged

spark plug with a new one (recommended torque 20 Nm, determined with a torque wrench)

(see “replacement parts“).

30).

Changing the Engine Oil

Change the engine oil with the

petrol tank empty and the engine

warm.

• Change the engine oil for the

rst time after around 5 operating hours then every 50 operating hours or annually.

• Change the engine oil when the

engine is warm.

• Dispose of the used oil in an

ecofriendly manner (see “disposal / environmental protection“).

16

Page 17

GB IE

1. Remove the spark plug terminal (

Adjusting the Bowden Cable

14).

2. - Lay the mower on its side, open the

oil tank cap (

9) and drain the

engine oil into a suitable collecting

If the Bowden cable becomes misplaced

for the drive and has too much play, it can

be adjusted.

vessel;

- Or open the oil tank cap (

pump out the engine oil with an oil

pump.

3. Rell with engine oil (see “Initial Opera-

tion”).

9) and

1. Loosen the small lock nut (4a).

2. - Turn the adjusting nut (4b)

anticlockwise:

TheBowdencableshortens.

- Turn the adjusting nut (4b)

clockwise:

TheBowdencablelengthens.

Maintenance Intervals

Regularly carry out the maintenance work listed in the “maintenance intervals” table.

Regular maintenance prolongs the life of the equipment. It also gives optimum cutting

performance and avoids accidents.

Maintenance Work

(See “cleaning and maintenance“)

Check and tighten screws,

nuts and bolts

Check the engine oil level /

petrol level and rell with engine oil / petrol if required

Clean operating elements / the

area around the silencer

Clean the nger protection

b

Before After

Work

After

1

Hrs.

After

st

5

8 Hrs.

After

50 Hrs.

Annual

Change the engine oil

Replace the air lter

a

Clean/adjust the spark plug

Replace the spark plug

Check the silencer and spark

b

catcher

Clean the air cooling system

a

Clean more often if there is a high level of dust or heavy dirt

b

See Briggs & Stratton instruction manual

a,b

17

Page 18

GB IE

Checking/Sharpening/Replacing the Blade

• Take off the spark plug (14) and check

the blade for wear and damage.

• Always have a blunt blade resharpened by a specialist workshop, as an

imbalance check can be carried out

there.

• Always have a specialist workshop

change a damaged or imbalanced

blade.

Incorrect installation can result

in serious injury.

Adjusting the Carburettor

The carburettor has been preset in the

factory for optimum performance. If readjustments are required, have the adjustments made by a specialist workshop.

Storage

General Storage Instructions

Do not store the equipment

with a full collection box. In hot

weather, the grass begins to ferment when heat is generated.

Risk of re.

• Clean and service the equipment before storage.

• Allow the engine to cool before storing the equipment in enclosed areas.

• Use suitable and authorised containers for storing fuel.

• Keep the equipment in a dry place

that is protected from dust and out of

reach of children.

• Do not wrap the equipment in nylon

bags as damp and mould could form.

For space-saving storage, the up-

per handle bar (2) can be folded

down (see small image). Release

the quick-release lever (25) and

fold down the handle bar so the

equipment takes up less space.

The Bowden cables (8) must not

be squashed when doing this.

Storage During Longer Breaks

from Operation

Non-observance of the storage

instructions may cause starting

problems or permanent damage

as a result of fuel residues in the

carburettor.

• Start the engine and allow it to run until it stops due to running out of petrol.

• Change the oil (see “changing the engine oil “).

• Preserve the engine:

- Unscrew the spark plug (

(see “cleaning and maintenance“);

- Pour a tablespoon of engine oil

through the spark plug hole into the

engine compartment;

- Pull the starter cord (

several times with the safety catch

(

3) pulled in order to distribute

the oil inside the engine;

- Screw the spark plug (

• Dispose of used oil and petrol residues in an ecofriendly manner (see

“disposal / environmental protection“).

There is no need to drain the petrol

tank if a fuel stabiliser is added to

the petrol (see “replacement parts”

and Briggs & Stratton instruction

manual).

15)

27) slowly

15) tight.

18

Page 19

GB IE

Technical Specications

Engine ................4-stroke Briggs&Stratton

........................................550 Series (XHQ)

B&S Engine design number .. 10T8020201H1

Engine size ...................................158 cm

Power input ...................................... 1,83 kW

Blade rotation speed................. 2800 min

Blade torque ................................... 45 Nm

Wheel drive......................... max. 3.3 km/h

Petrol tank volume ..............................0.8 l

Octane rating ....................................95-98

Engine oil tank volume .......................0.6 l

Spark plug ..................Champion RJ19LM

Cutting circle .................................460 mm

Cutting height ............10-stage, 30-75 mm

Grass collection box volume................65 l

Weight (inc. collection box) ............ 30.3 kg

Sound pressure level

(L

pA) ..................82.2 dB(A); K=3.0 dB(A)

Sound power level (L

measured ......... 93.4 dB(A); K=2.14 dB(A)

guaranteed ...............................96 dB(A)

Vibration at the handle

(a

n) .................... 4.644 m/s

The stated vibration emission value was

measured in accordance with a standard

testing procedure and may be used to

compare one power tool to another.

The stated vibration emission value may

also be used for a preliminary exposure

assessment.

Warning:

The vibration emission value may

differ during actual use of the

power tool from the stated value

depending on the manner in which

the power tool is used.

Safety precautions aimed at protecting

the user should be based on estimated

WA)

2

; K=1.5 m/s

exposure under actual usage conditions

(all parts of the operating cycle are to be

considered, including, for example, times

during which the power tool is turned off

and times when the tool is turned on but is

3

running idle).

-1

Noise and vibration values were determined according to the standards and

stipulations mentioned in the declaration

of conformity.

Technical and optical changes can be carried out in the course of further development without notice. All dimensions, references and information of this instruction

manual are therefore without guarantee.

Legal claims, which are made on the basis of the instruction manual, cannot thus

be considered as valid.

Disposal / Environmental

Protection

• Return the tool, accessories and

2

packaging to a recycling centre when

you have nished with them.

- Carefully drain the petrol and oil

tanks and take your equipment to

a recycling centre. The plastic and

metal parts that are used can be

separated by type and thus recycled.

- Take used oil and petrol residues

to a disposal point and do not pour

them into the sewer system or down

the drain.

- Ask our Service-Center for details.

• Defective units returned to us will be

disposed of for free.

• Do not throw cut grass in the dustbin but rather compost it or spread it

under bushes and trees as a mulch

layer.

19

Page 20

GB IE

Replacement parts

Replacement parts can be ordered directly from our service centre. Please indicate

the machine type and the number of the

spare part with your order.

Replacement blade....................91099462

Blade screw ...............................91099460

Grass collection box ...................91099561

Air lter ......................................30250011

Spark plug .................................30220210

B&S fuel stabiliser, 125 ml ..........30230028

B&S Engine oil, 600 ml ..............30230029

Maintenance set

(air lter, 30 ml fuel stabiliser,

600 ml engine oil, spark plug) ......30270001

Replacement parts and accessories for

the engine (e.g. air lters and spark plugs)

can also be ordered directly from Briggs &

Stratton.

If further spare parts should be necessary, please nd the part number on the

exploded drawing.

Guarantee

• The guarantee period for this equipment is 3 years from the date of purchase and it is applicable only for the

initial buyer.

• Please note any different guarantee

conditions for the motor and read the

enclosed operating instructions from

motor manufacturer “Briggs & Stratton” carefully. This guarantee does not

affect your legal guarantee rights. The

responsible “Briggs & Stratton” service is responsible for motor problems

on your lawn mower in accordance

with the enclosed dealer list. Should

another problem occur, please contact

our central service points (see page

25 for tel. no., fax no., e-mail address).

• The guarantee does not include:

- Damage caused by natural wear,

overloading or improper use.

- Equipment employed for commercial use.

- Damages arising as the result of

non-compliance with the operating

instructions or if the cleaning intervals have not been observed.

- Equipment on which technical interventions have been undertaken.

• The following parts are subject to normal wear and therefore not covered

by the guarantee: cutter, spark plugs,

air lter, starter cord.

• Please do not send equipment to our

service points without prior agreement

by telephone, as you could otherwise

incur costs for non-acceptance.

• The repair or replacement of the

equipment will neither result in extension of the guarantee period nor the

commencement of a new guarantee

period for the equipment or any replacement parts installed as a result

of this work. This also applies if onsite service is used.

• Defective units returned to us will be

disposed of for free.

20

Page 21

Troubleshooting

Problem Possible Cause Fault Correction

Too little petrol in the tank Fill with petrol

Follow the instructions for starting the

engine (see ”operation“)

Attach the spark plug connector

14)

Clean, adjust or replace the spark plug

(see “cleaning and maintenance“)

Have the carburettor adjusted by a

specialist workshop

Replace the air lter (see “cleaning and

maintenance“)

Have the carburettor adjusted by a

specialist workshop

Have the carburettor adjusted by a

specialist workshop

Clean, adjust or replace the spark plugs

(see “cleaning and maintenance“)

Clean the ventilation slot

Change the spark plug

Fill with engine oil (see “initial opera-

tion”)

Replace the air lter (see “Cleaning

and Maintenance”)

Fill with engine oil (see “initial operation”)

Adjust the Bowden cables or have

them adjusted by a specialist workshop

Change the cutting height (see “setting

the cutting height“)

Have the blade sharpened or replaced

by a specialist workshop

Remove the grass (see “cleaning and

maintenance“)

Have the blade installed by a specialist

workshop

Have the blade installed by a specialist

workshop

Engine does not

start

Engine starts but

equipment does

not run at full

power

Engine splutters,

stops

Engine overheats

Engine smokes

Drive does not

switch on

Output unsatisfactory or engine

labouring

Blade does not

turn

Abnormal noises,

rattling or vibrations

Incorrect starting sequence

Spark plug connector (

not put on correctly

Sooted spark plug

Incorrectly adjusted carburettor mix

Dirty air lter (

Incorrectly adjusted carburet-

tor mix

Incorrectly adjusted carburettor mix

Sooted spark plug (

Ventilation holes (

blocked

Incorrect spark plug (

Too little engine oil in the en-

gine

Dirty air lter (

Too little engine oil in the engine

Bowden cables (

justed

Grass too short or too long

Blade blunt

Blade blocked with grass,

grass collection box full, ejection channel blocked

Blade blocked with grass Remove the grass

Blade not installed correctly

Blade not installed correctly

Blade damaged

11)

15)

37)

15)

11)

8) misad-

GB IE

21

Page 22

GB IE

Translation of the original

EC declaration of conformity

We herewith conrm that the

Petrol lawn mower

Series FBM 550 A1

Serial number 201112000001 - 201201020562

is compliant with the current versions of the following relevant EU guidelines:

2006/42/EC • 2004/108/EC • 2000/14/EC • 2005/88/EC

In order to guarantee compliance, the following harmonised standards, national standards and regulations have been applied:

EN 836/A3:2004 • EN ISO 14982:2009

The following are also conrmed as being compliant with Noise Emissions Directive

2000/14/EC:

Guaranteed sound power level: 96 dB(A);

Measured sound power level: 93.4 dB(A)

The conformity evaluation procedure employed is compliant with appendix VI of

2000/14/EC and 2005/88/EC.

Registered Ofce: TÜV Süd,

Industrie-Service GmbH, Westendstr. 199, 80686 München,

NB 0036

Grizzly Gartengeräte GmbH & Co. KG

Am Gewerbepark 2

64823 Groß-Umstadt, 10.2.2012

22

(Documentation Representative)

Oliver Christ

Page 23

Exploded Drawings

GB IE

informative

23

Page 24

GB IE

24

informative

Page 25

Grizzly Service-Center

Service Great Britain

GB

Tel.: 0871 5000 720

(£ 0.10/Min.)

E-Mail: grizzly@lidl.co.uk

IAN 71990

Service Ireland

IE

Tel.: 1890 930 034

(0,08 EUR/Min., (peak))

(0,06 EUR/Min., (off peak))

E-Mail: grizzly@lidl.ie

IAN 71990

GB IE

2010-12-14_rev02_gs

25

Page 26

2

3

27

26

1

20

36

10

37

4a

4b

11

36

25

2

8

0,76 mm

15

14

2

8

Page 27

Page 28

IAN 71990

Grizzly Gartengeräte GmbH & Co. KG

Am Gewerbepark 2

D-64823 Groß-Umstadt

Last Information Update: 11 / 2011

Ident.-No.: 89420203112011 - 6

6

Loading...

Loading...