PC-BASED WEIGHING SYSTEM

FlintWeigh II

T

EECCHHNNIICCAALL

T

M

AANNUUAAL

M

L

Flintec GmbH

Bemannsbruch 9

74909 Meckesheim

GERMANY

www.flintec.com

Table of Contents:

1. Safety Instructions ........................................................................................................................................ 3

2. Declaration of Conformity ............................................................................................................................ 4

3. Introduction and Block Diagrams ................................................................................................................ 5

3.1. Application Range .................................................................................................................................... 5

3.2. Block Diagrams ........................................................................................................................................ 5

3.3. Scope of Delivery ..................................................................................................................................... 6

3.4. Available Accessoires .............................................................................................................................. 6

4. System Components and Technical Characteristics ................................................................................ 7

4.1. Type FW-01 Scale Interface .................................................................................................................... 7

4.2. Technical Specifications ........................................................................................................................... 8

4.3. Important Information about the Operation of Digital Load Cells ............................................................. 9

4.4. Information about the Digital Inputs / Outputs .......................................................................................... 9

4.5. Operation of Standard Load Cells .......................................................................................................... 10

4.6. Sealing Details with Sticker .................................................................................................................... 10

4.7. Descriptive Plate .................................................................................................................................... 11

5. FlintWeigh II Software Installation ............................................................................................................. 12

5.1. Software Version .................................................................................................................................... 12

5.2. Installation .............................................................................................................................................. 12

5.3. FlintWeigh II Files ................................................................................................................................... 13

6. Weight Display and Control Buttons ......................................................................................................... 14

7. FlintWeigh II Configuration ........................................................................................................................ 15

7.1. Basic Setup during the Commissioning ................................................................................................. 15

7.1.1. Configure the Alibi Memory ............................................................................................................................ 16

7.2. Language and other Settings ................................................................................................................. 17

7.3. Scale with Standard Load Cells ............................................................................................................. 18

7.3.1. Define the Scale Parameters ......................................................................................................................... 18

7.4. Scale with Type RC3D Digital Load Cells .............................................................................................. 19

7.4.1. Preliminary Note ............................................................................................................................................. 19

7.4.2. Define the Scale Parameters ......................................................................................................................... 19

7.4.3. Digital Corner Correction ................................................................................................................................ 20

7.5. Calibrate the Scale ................................................................................................................................. 21

7.6. Optional Linearisation of the Scale Curve .............................................................................................. 22

7.7. Optional Use of Digital Outputs .............................................................................................................. 23

7.7.1. Setpoints and Limit Monitoring ....................................................................................................................... 23

7.7.2. Traffic Light Control ........................................................................................................................................ 24

8. Legal for Trade Operation .......................................................................................................................... 25

8.1. EC Type-approval and Test Certificate .................................................................................................. 25

8.2. Digital Descriptive Plate ......................................................................................................................... 25

8.3. Recording of Weight Values in the Alibi Memory ................................................................................... 25

8.4. Show Alibi Memory ................................................................................................................................ 26

8.5. Logbook .................................................................................................................................................. 26

8.6. Obligations with Legal for Trade Scales ................................................................................................ 27

8.7. Legal for Trade Data within the Scale Interface ..................................................................................... 27

9. Error Messages ........................................................................................................................................... 28

10. OLE Programming Interface ................................................................................................................... 29

10.1. OLE Functions .................................................................................................................................... 29

10.2. Application Example ........................................................................................................................... 32

FlintWeigh Technical Manual, Rev. 3.03 November 2011

Page 2 of 32

RIGHTS AND LIABILITIES

CAUTION

WARNING

WARNING

WARNING

WARNING

CAUTION

All rights reserved.

No part of this publication may be reproduced, stored in a retrieval system, or transmitted in any form or by any

means, mechanical, photocopying, recording, or otherwise, without the prior written permission of Flintec

GmbH

No patent liability is assumed with respect to the use of the information contained herein. While every

precaution has been taken in the preparation of this book, FLINTEC assumes no responsibility for errors or

omissions. Neither is any liability assumed for damages resulting from the use of the information contained

herein.

The information herein is believed to be both accurate and reliable. FLINTEC, however, would be obliged to be

informed if any errors occur. FLINTEC cannot accept any liability for direct or indirect damages resulting from

the use of this manual.

FLINTEC reserves the right to revise this manual and alter its content without notification at any time.

Neither FLINTEC nor its affiliates shall be liable to the purchaser of this product or third parties for damages,

losses, costs, or expenses incurred by purchaser or third parties as a result of: accident, misuse, or abuse of

this product or unauthorized modifications, repairs, or alterations to this product, or failure to strictly comply with

FLINTEC operating and maintenance instructions.

FLINTEC shall not be liable against any damages or problems arising from the use of any options or any

consumable products other than those designated as Original FLINTEC Products.

NOTICE: The contents of this manual are subject to change without notice.

Copyright © 2010-2011 by Flintec GmbH, 74909 Meckesheim, Bemannsbruch 9, Germany

1. Safety Instructions

READ this manual BEFORE operating or servicing this equipment. FOLLOW these

instructions carefully. SAVE this manual for future reference. DO NOT allow untrained personnel to

operate, clean, inspect, maintain, service, or tamper with this equipment. ALWAYS DISCONNECT

this equipment from the power source before cleaning or performing maintenance. CALL FLINTEC

ENGINEERING for parts, information, and service.

EXERCISE CARE WHEN MAKING CHECKS, TESTS AND ADJUSTMENTS THAT MUST BE

MADE WITH POWER ON. FAILING TO OBSERVE THESE PRECAUTIONS CAN RESULT IN

BODILY HARM.

PROPERLY GROUNDED OUTLET ONLY. DO NOT REMOVE THE GROUND PRONG.

SERVICING.

COMPONENTS OR INTERCONNECTING WIRING BETWEEN ELECTRONIC EQUIPMENT

ALWAYS REMOVE POWER AND WAIT AT LEAST THIRTY (30) SECONDS BEFORE ANY

CONNECTIONS OR DISCONNECTIONS ARE MADE. FAILURE TO OBSERVE THESE

PRECAUTIONS COULD RESULT IN DAMAGE TO OR DESTRUCTION OF THE EQUIPMENT OR

BODILY HARM.

DEVICES.

ONLY PERMIT QUALIFIED PERSONNEL TO SERVICE THIS EQUIPMENT.

FOR CONTINUED PROTECTION AGAINST SHOCK HAZARD CONNECT TO

DISCONNECT ALL POWER TO THIS UNIT BEFORE REMOVING THE FUSE OR

BEFORE CONNECTING/DISCONNECTING ANY INTERNAL ELECTRONIC

OBSERVE PRECAUTIONS FOR HANDLING ELECTROSTATIC SENSITIVE

FlintWeigh Technical Manual, Rev. 3.03 November 2011

Page 3 of 32

2. Declaration of Conformity

Richtlinie 2004/108/EG

Richtlinie 2006/95/EG

EG-Konformitätserklärung

0

Monat/Jahr: month/year:

Hersteller: Manufacturer:

Anschrift: Address:

Produktbezeichnung: Product name: FlintWeigh PC-Wägesystem / PC-based Weighing System

Das bezeichnete Produkt stimmt mit folgenden Vorschriften der Europäischen Richtlinien überein:

This product confirms with the following regulations of the Directives of the European Community

Parlaments und des Rates vom 15. Dezember 2004

zur Angleichung der Rechtsvorschriften der

Mitgliedstaaten über die elektromagnetische

Verträglichkeit und zur Aufhebung der Richtlinie

89/336/EWG

EC-Declaration of Conformity

12/2010

Flintec GmbH

Bemannsbruch 9

D-74909 Meckesheim

Deutschland / Germany

des Europäischen

Niederspannungs-Richtlinie

Directive 2004/108/EC of the European Parliament and of the

Council of 15th December 2004 on the approximation of the

laws of the Member States relating to electromagnetic

compatibility and repealing Directive 89/336/EEC

Directive 2006/95/EC Low Voltage Directive

Die Absicherung aller produktspezifischen

Qualitätsmerkmale erfolgt auf Basis eines zertifizierten

Qualitätsmanagement-Systems nach DIN ISO 9001.

Diese Erklärung bescheinigt die Übereinstimmung mit

den genannten Richtlinien, beinhaltet jedoch keine

Zusicherung von Eigenschaften.

Folgende Normen werden zum Nachweis der Übereinstimmung mit den Richtlinien eingehalten:

As a proof of conformity with the directives following standards are fulfilled:

EN 61326-1

EN 60950-1

Elektrische Mess-, Steuer-, Regel- und Laborgeräte - EMV-Anforderungen - Teil 1: Allgemeine

Anforderungen (IEC 61326-1:2005)

Electrical equipment for measurement, control and laboratory use - EMC requirements - Part 1: General

requirements (IEC 61326-1:2005)

Einrichtungen der Informationstechnik - Sicherheit - Teil 1: Allgemeine Anforderungen (IEC 609501:2005, modifiziert);

Information technology equipment - Safety - Part 1: General requirements (IEC 60950-1:2005 modified)

All product-related features are assured by a quality

system in accordance with ISO 9001.

This declaration certifies the conformity with the listed

directives, but it is no promise of characteristics.

FlintWeigh Technical Manual, Rev. 3.03 November 2011

Page 4 of 32

3. Introduction and Block Diagrams

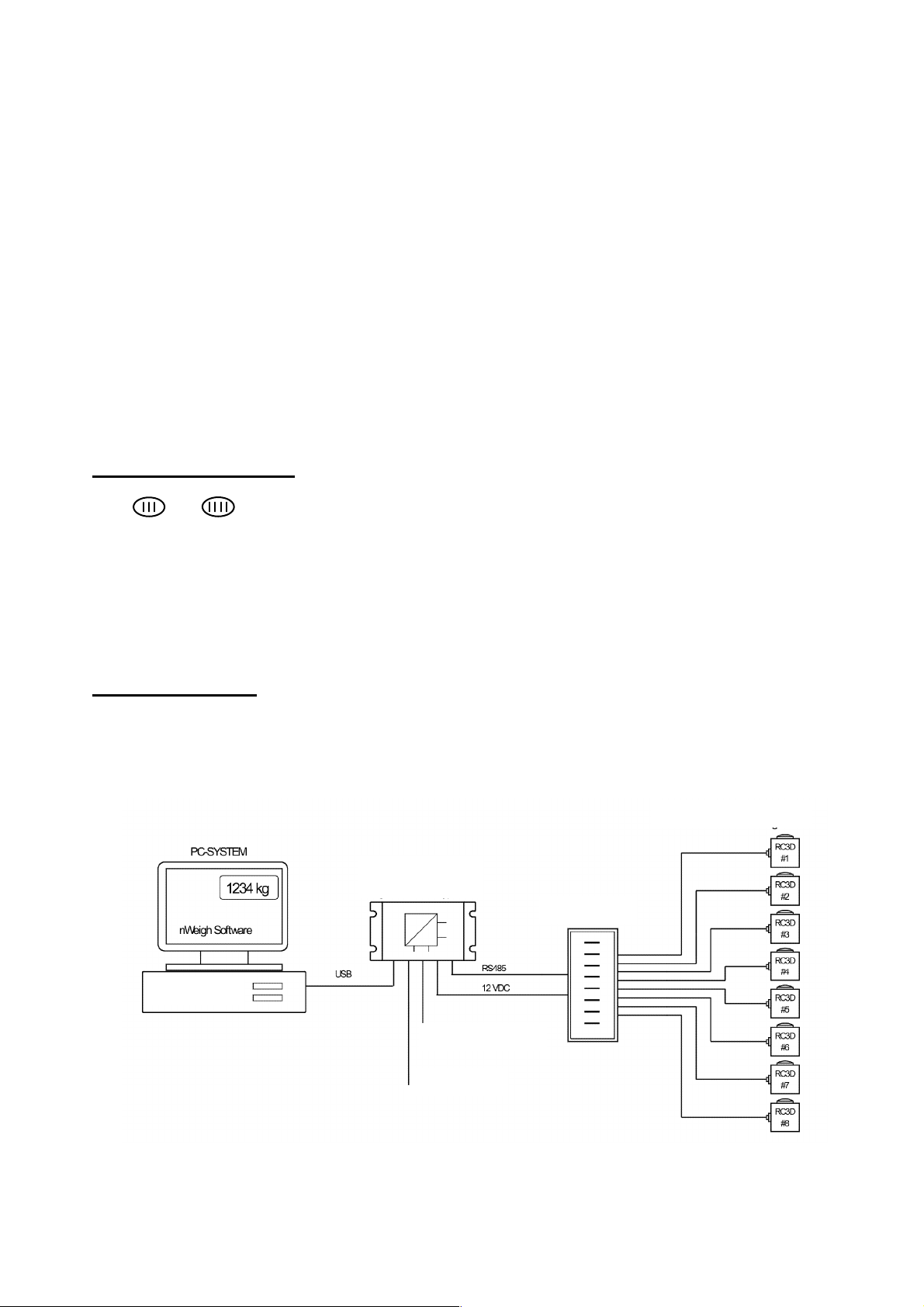

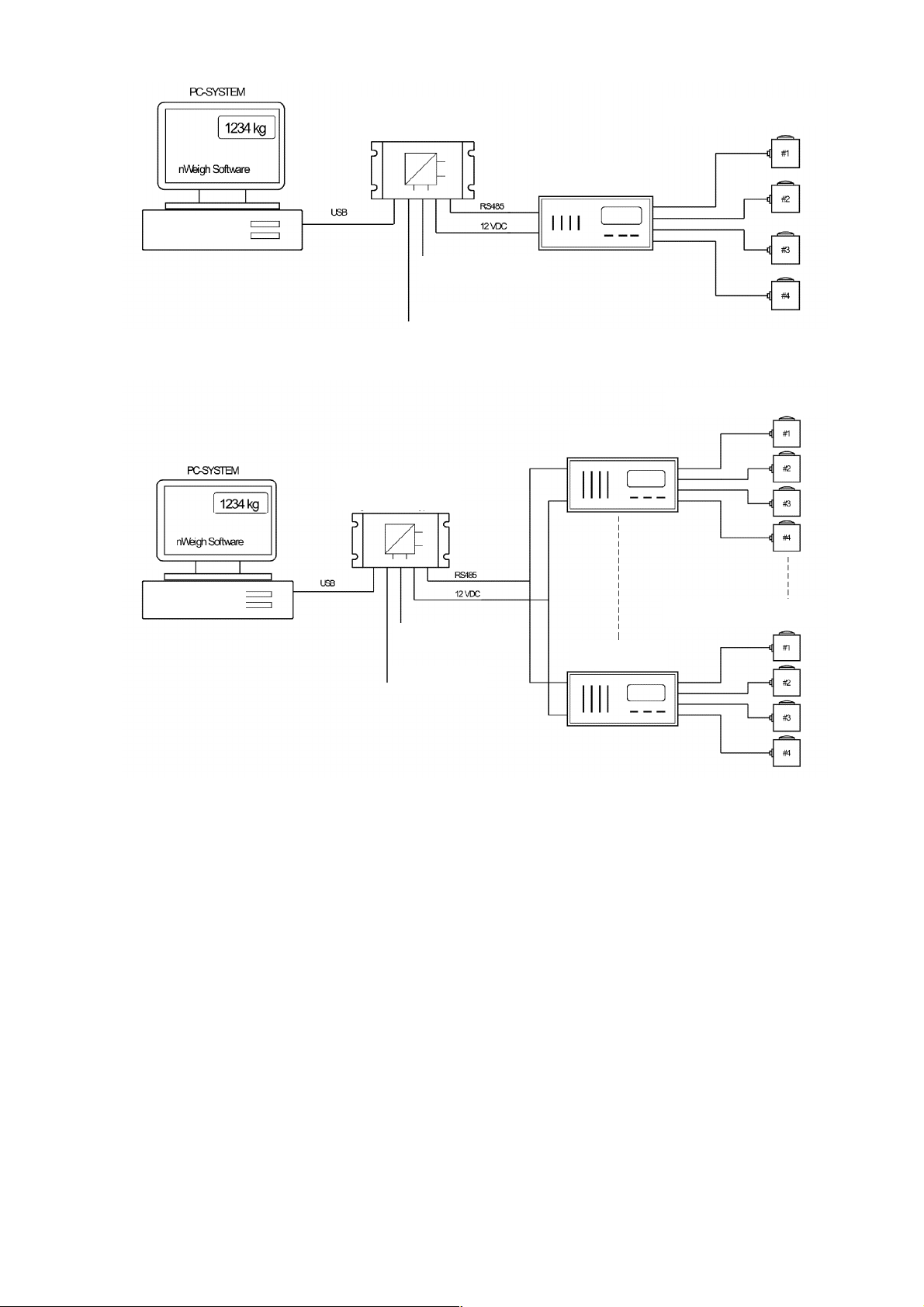

Fig. 3.1: Connection of RC3D digital load cells via KPFD

-

8 junctio

n box

Scale Interface

The W&M approved type FW-01 Scale Interface is the key component to integrate a Weighing System into your

PC. FlintWeigh does not require any separate weight display and the scale interface assures, that the weight

data will be reliably processed in the PC.

It is possible to connect up to 2 scales (up to 16x type RC3D digital load cells respective 2x type LDU digital

amplifiers) via RS485 to the scale interface, which will be connected to the PC via USB interface.

When the scales are based on standard load cells you can select among several LDU types which may be

plugged into socket within the KAL-4 junction box. The selection of the applied LDU will be defined by the

requirements for the weighing application. The technical characteristics of the LDU types and connection

details about digital and standard load cells you can find in chapter 4.

3.1. Application Range

For protecting the consumers all scales which are used for commercial transactions (legal for trade

applications) have to be calibrated in a standardized way. Typical legal for trade scales are retail scales in

shops. Privately used bathroom scales or kitchen scales are examples for scales which don’t require an

approved calibration.

Legal for trade applications

The weighing terminal has an EC type approval which covers standard load cells and scales of the accuracy

class and .

All load cells have to keep the tolerances according "OIML R60, Metrological regulation for load cells, Edition

2000".

For selecting the proper weighing module in legal for trade applications, it is required to verify the compatibility

of modules for the weighing instrument (see file KOMPMODENG.XLS on the Flintec CD-ROM).

For further information about software, alibi memory and legal for trade applications see chapter 4.

Industrial applications

All scale connections in industrial applications fall within the responsibility of the scale operator. In such

applications an approved alibi memory is not available.

3.2. Block Diagrams

Alibi memory

Digital Load Cells

Type FW-01

KPFD-8

12 V DC Supply

Digital I/O

FlintWeigh Technical Manual, Rev. 3.03 November 2011

Page 5 of 32

Fig. 3.2: Connection of standard load cells via KAL

-

4 junction box with integrated LDU

Fig. 3.3: Block diagram with standard load cells and 2 scales

Scale Interface

Scale Interface

Type FW-01

Standard Load Cells

KAL-4

Alibi memory

12 V DC Supply

Digital I/O

Standard Load Cells

KAL-4

Type FW-01

Alibi memory

Standard Load Cells

12 V DC Supply

KAL-4

Digital I/O

3.3. Scope of Delivery

► Type FW-01 Scale Interface

► Suitable plug connectors for the load cells and the digital I/O

► FlintWeigh II Software

► This manual

► A medium (CD-ROM) with the FlintWeigh II software, the technical manual, the test certificates of the

LDUs, the FlintWeigh II EC type approval, some examples for using the OLE functions and a template

for the scale’s descriptive plate in RTF format

3.4. Available Accessoires

► Type KPFD-8 junction box for type RC3D digital load cells

► Type LDU 68.1 / 68.2 / 69.1 / 78.1 digital amplifiers for standard load cells

► Type KAL-4 digital junction box

FlintWeigh Technical Manual, Rev. 3.03 November 2011

Page 6 of 32

4. System Components and Technical Characteristics

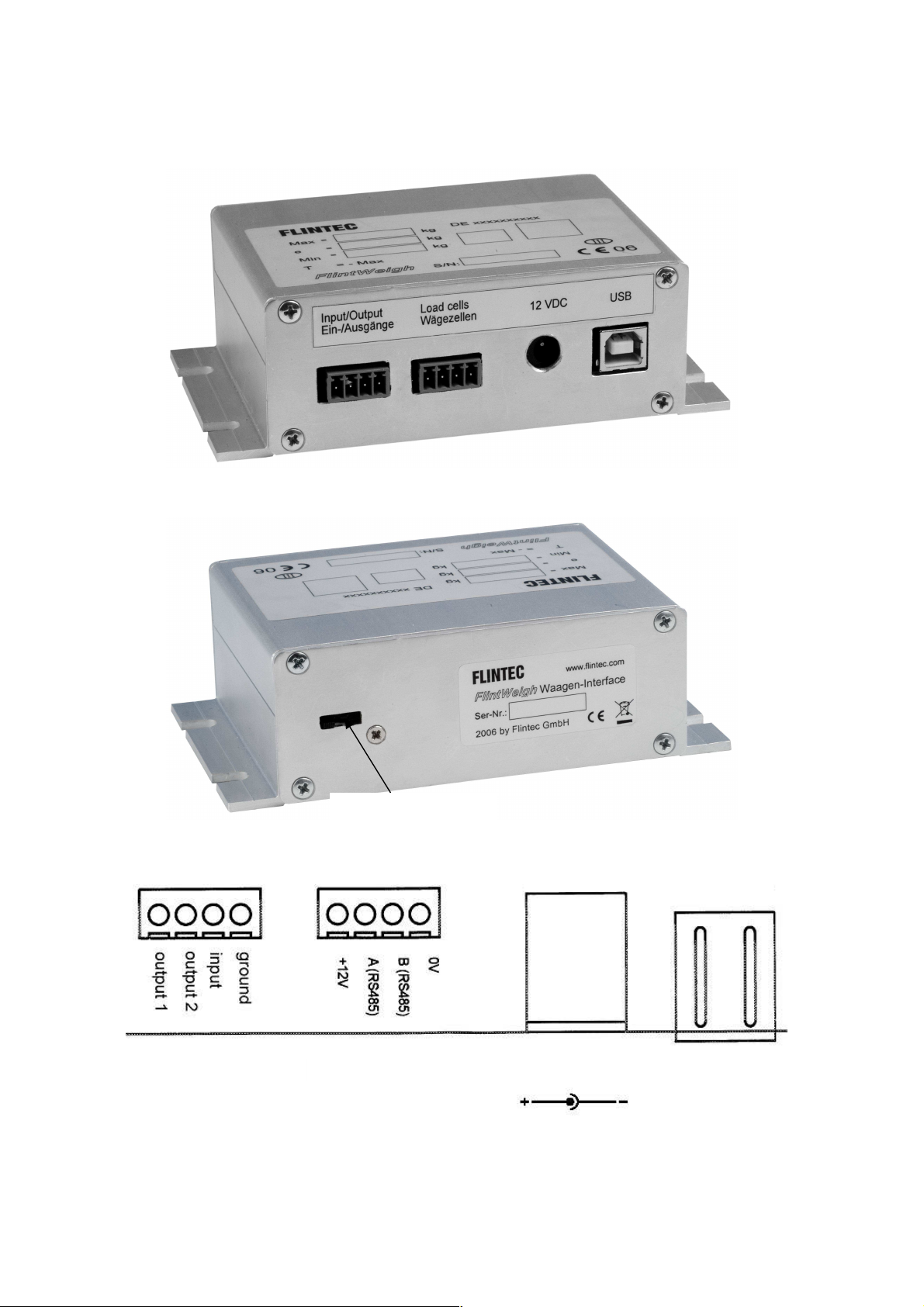

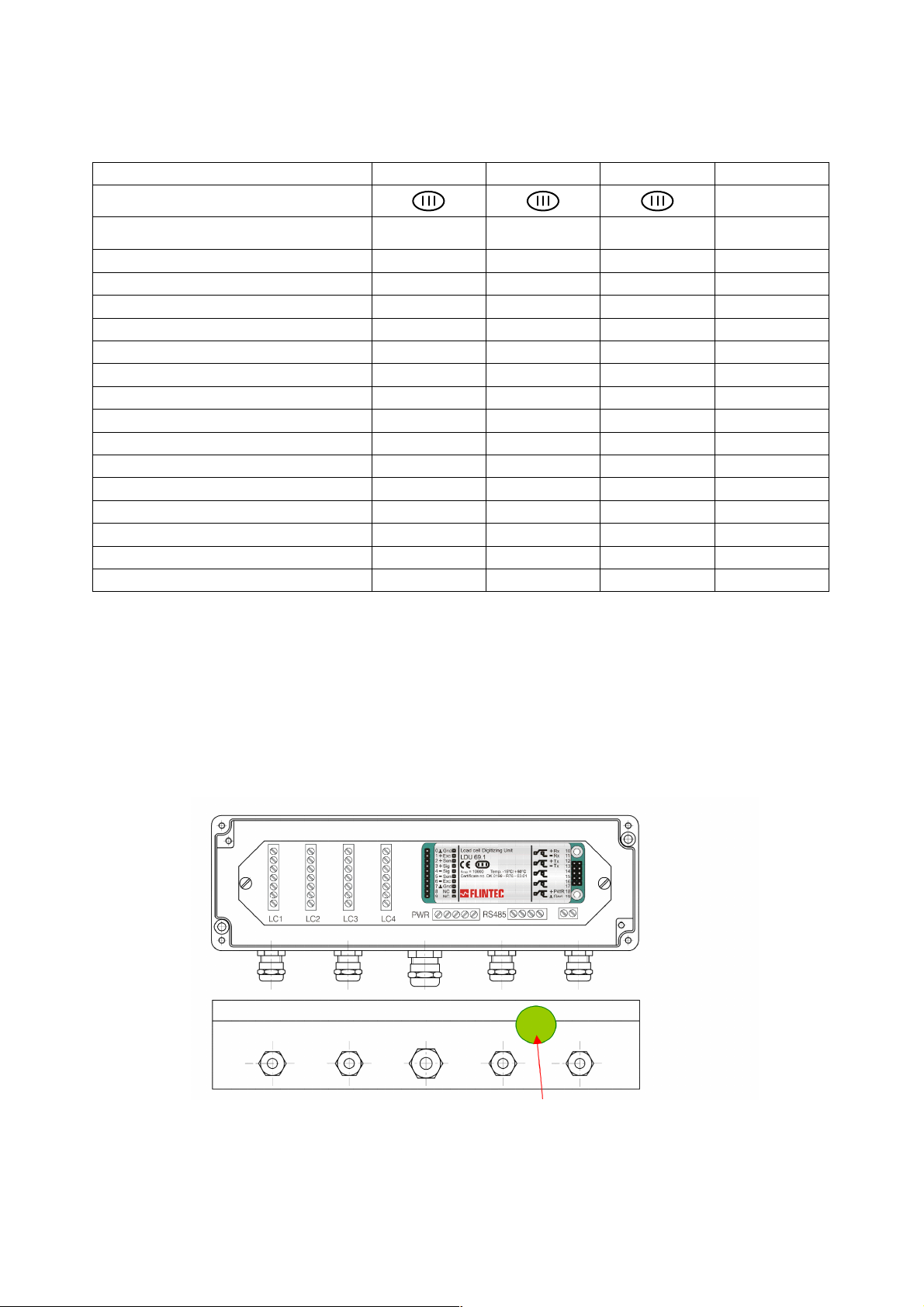

Fig.4.1 Scale interface, connector side

Fig.4.2 Scale Interface; calibration lock (will be sealed in legal for trade applications)

Fig.4.3 Scale Interface;

connectors

4.1. Type FW-01 Scale Interface

Calibration lock

Digital

Digital

Input/Output

Input/Output

-

Digital load cell connector suitable for connecting RC3D load cells or one/two units of LDU xx.x in

half-duplex mode, see LDU xx.x manual

-

External 12 V supply required for powering the digital load cells / LDU units

FlintWeigh Technical Manual, Rev. 3.03 November 2011

Digital

Digital

Load cells

Load cells

USBSupply 12 V DC

USBSupply 12 V DC

Page 7 of 32

4.2. Technical Specifications

GENERAL

Scale interface

ACCURACY

Accuracy Class III

EU Type approved

DISPLAY AND KEYBOARD

Display

Resolution Selectable up to 99 000 counts (in accordance with the regulations)

Status annunciators Net mode, No Motion, Max. and Min, e, Scale no.

Keyboard The standard PC keyboard is used

INTERFACE TO DIGITAL LOAD CELLS

Communication & Protocol

Excitation 12 V DC, max. 450 mA

No. of load cells / load cell

digitizing units

Load cell connection

SCALE CALIBRATION AND FUNCTIONS

No. of scales

Calibration Calibration performed by FlintWeigh II software

Corner correction Digital corner correction (only with type RC3D load cells)

Weighing functions Zero, tare, gross, motion detection, automatic zero tracking (Active-X-Control)

COMMUNICATION

To PC USB 2.0

DIGITAL INPUTS / OUTPUTS

Output 2x opto-isolated for setpoints (Open collector, 24 V DC, 50 mA)

Input 1x opto-isolated, 24 V DC

POWER

Power requirements

ENVIRONMENT AND ENCLOSURE

Operating temperature -10…+40 °C

Storage temperature -10…+70 °C

Humidity 40 to 90% RH (non-condensing)

EMC According to OIML R 76 and EN 45501 requirements

Enclosure Aluminium housing (IP 40), installed in the direct vincinity of the PC system

PC SYSTEM

Requirements

Intelligent interface with non-volatile memory for system parameters and

calibration data

10 000 intervals (single interval) or n x 3 000 intervals (multi range / multi

interval)

Approval no. D-10-09-024 from 09th August 2010

Approved PC-based weighing system with weight display on PC monitor

(Active-X-Control)

RS485 half-duplex, baud rate 9 600…38 400; E7,1 OR 8N,1; compatible with

type RC3D load cell respective type LDU xx.x load cell digitizing unit

Up to 10 pieces directly powered type RC3D digital load cells OR

up to 16 pieces externally powered type RC3D digital load cells OR

up to 2 pieces directly powered type LDU xx.x load cell digitizing units

(valid for one scale interface)

4-wire technique,

2 wires for the digitale interface and 2 wires for the sensor supply

Up to 2 scales per scale interface

With type RC3D it’s possible to have a 2-deck weighbridge system

12 V DC / max. 1.5 A; power consumption depends on number of connected

load cells / load cell digitizing units

Windows XP; 1024 x 768 or higher graphic resolution; 128 MB or more RAM,

512 MB or more harddisk memory, USB 2.0 Interface

FlintWeigh Technical Manual, Rev. 3.03 November 2011

Page 8 of 32

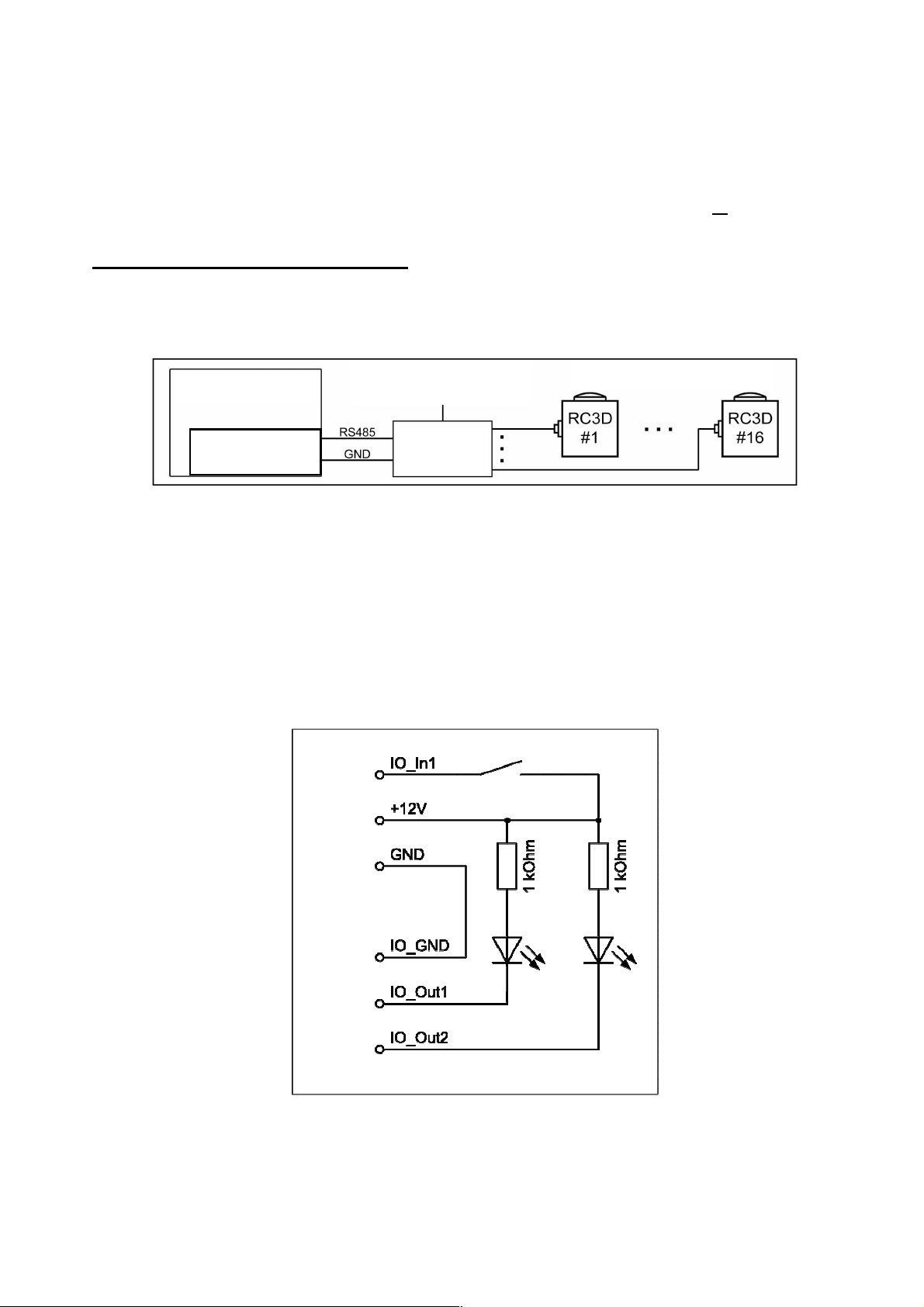

4.3. Important Information about the Operation of Digital Load Cells

Fig. 4.4: Schematic of the external power supply to the digital load cells

Fig. 4.5 : Wiring example for the digital I/O

Pin 6

Pin 2

Pin 1

Pin 5

Pin 7

Pin 8

box

+12V DC / 1.5 A

The connection of the digital load cells has to be done according the description in the KPFD-8 manual (see

Flintec-CD, technical documents, manuals).

It is allowed to connect up to 16 digital load cells (e.g. type RC3D) to the scale interface.

IMPORTANT: If you connect more than 10 digital load cells, then it is mandatory to power all load cells from an

external power supply.

External power supply for digital load cells

The external power supply has to provide a stabilized +12 V DC / ±5% with at least 1.5 A current. The input

goes directly to the connection cable of the digital load cells. Only the pins "RS485 A", "RS485 B" and "GND"

will be connected with the scale interface.

Weighing terminal

External power supply

Digital load cells

Weighing

system controller

Junction

4.4. Information about the Digital Inputs / Outputs

The digital I/O connections (one input, two outputs) can be used connecting e.g. a traffic light, a gate or a

switch-key.

Digital output: 2x, open collector (max. 24 V DC, max. 50 mA)

Digital input: 1x, opto-isolated, 3...24 V DC, max. 20 mA; min. switching current = 1,5 mA

FlintWeigh Technical Manual, Rev. 3.03 November 2011

Page 9 of 32

4.5. Operation of Standard Load Cells

Fig. 4.6: Sealing details with sticker

The scale interface can be connected with up to two LDU amplifiers. Depending on the application – legal for

trade scale or industrial application – it can be selected among various weighing modules.

Weighing module type LDU 68.1 LDU 69.1 LDU 78.1 LDU 68.2

Accuracy class

Certificate no.

Intervals "n" acc. Kompmodeng: n

ind

DK0199-R76-

10.04 Rev.1

DK0199-R76-

11.08 Rev.1

DK0199-R76-

10.08 Rev. 1

10.000 10.000 10.000

Internal resolution ± 130 000 > ± 1 000 000 ± 260 000 ± 130 000

Approved single range scale

Approved multi range scale no

Approved multi interval scale no

Load cell excitation U

Minimum input voltage U

Approved min. input per vsi ∆U

EXC

MIN

min

yes yes yes

yes yes

yes yes

5 V DC 5 V AC 5 V DC 5 V DC

0 V 0 V 0 V 0 V

1.0 µV 0.1 µV 0.3 µV

Input sensitivity 0.05 µV/d 0.02 µV/d 0.05 µV/d 0.1 µV/d

Min. load cell impedance R

Max. load cell impedance R

Min. operation temperature T

Max. operation temperature T

Fractional error limit P

ind

Load cell connection 4-/6- wire technique

Tab. 4.3: Technical characteristics of LDU amplifiers

Lmin

Lmax

min

max

87.5 Ω 87 Ω 87.5 Ω 87.5 Ω

1150 Ω 1200 Ω 1150 Ω 1150 Ω

-15 °C -15 °C -15 °C -15 °C

+55 °C +55 °C +55°C +55 °C

0.5 0.5 0.5

4/6 4/6 4/6 4/6

The connection of the standard load cells has to be done as described in the manual of the KAL-4 digital

junction box (see Flintec-CD, technical documents, manuals).

Not approved

no

no

no

4.6. Sealing Details with Sticker

The legal for trade operation requires a sealing of the junction boxes. The following figure shows a possible

positioning of the sticker for KAL-4

FlintWeigh Technical Manual, Rev. 3.03 November 2011

Page 10 of 32

4.7. Descriptive Plate

Fig. 4.7: Descriptive plate of the weighing terminal

The descriptive plate has to be placed on the weighing terminal’s enclosure. It must coincide with the digital

descriptive plate within the FlintWeigh II software.

The descriptive plate supplies following information:

► Owner and number of the EC type approval

► Version no. of the software incl. revision no./ check sum

► Serial no. of the built-in weighing system controller

► Type and serial no of the LDUs

► Year of manufacture

► Traceable access counter (TAC)

► Metrological symbol “M”

► Interval, min.load and max. load of the scale

Hint: You can find a template for the scale’s descriptive plate in RTF format on the Flintec CD-ROM.

FlintWeigh Technical Manual, Rev. 3.03 November 2011

Page 11 of 32

5. FlintWeigh II Software Installation

Fig. 5.1 : Software source directory on the Flintec CD

Fig. 5.2 : Software target directory on the installation PC

The FlintWeigh II software displays the continuously measured weight value of the weighing system controller

within a graphical window in a legal for trade quality.

FlintWeigh II also provides an OLE interface. External programmes can access the data and information within

FlintWeigh II by using OLE functions. All windows and control buttons are part of the OLE interface.

By configuring two digital outputs and one digital input it is possible to implement a simple limit monitoring or

traffic light control.

5.1. Software Version

The software version is defined as follows:

NWxyF.exe with x = Main version no.

and y = Revision no.

5.2. Installation

It is not required to install the FlintWeigh II software in the conventional way. Just copy from the Flintec-CD to a

directory of your choice on a target PC of your choice:

► The directory “USB Driver 2008“ (Windows 7 / Vista) respective “USB Driver 2006“ (Windows XP);

these driver files are required to install the scale interface via USB connection

► the files "NW11F.exe" and " nxWeigh.dll"

e.g.: NW11F.exe Main version no. 1, Rev. no. 1

Hint: Your profile as a Windows user requires writing preferences for this installation directory. In this directory

further configuration files will be created (see chapter 5.3).

Then you connect the scale interface to an USB port of the installation PC. Hereby the installation PC

automatically detects the scale interface and the operating system will search for a suitable device driver, which

you can find in the directory “USB Driver 2008“ (Windows 7 / Vista) resp. “USB Driver 2006“ (Windows XP).

After the successful driver installation the Windows device manager should list the FlintWeigh scale interface in

the section “Connections (COM & LPT)“ listen. Please note the assigned COM port no. for further use during

the commissioning.

When started for the first time FlintWeigh II should start with the language setting "English" (see chapter 8.2).

FlintWeigh Technical Manual, Rev. 3.03 November 2011

Page 12 of 32

5.3. FlintWeigh II Files

In the FlintWeigh II software directory you can find the following files (some files may be hidden or protected

and therefore not visible):

NW11F.EXE

NW10.KEY

NW10.INI

NW10.LIM

NW10xx.CFG

Following files may be located in the FlintWeigh II software directory or somewhere else (see data memory

Server):

NW10.CNT

FlintWeigh II main programme; can be used directly (EXE file) as weight display or for

service and calibration purposes. In weighing mode the main programme can communicate

to application programmes via its integrated OLE interface. If the OLE interface is in use the

FlintWeigh II software automatically starts in the weighing mode.

This file will be created during the commissioning. It contains non-approved parameters and

settings like COM port, baud rate, remote display, language, filter settings, zero tracking,

etc.

This file will be created during the commissioning. It contains the path information to the

storage location of the alibi data.

This file will be created during the commissioning. It contains the manual settings of the

digital outputs (setpoints).

This file will be created during the commissioning. For diagnosis purposes it contains copies

of the calibration data, which are stored in the approved memory of the weighing system

controller.

Record counter (for multi scale systems), protected by CRC16 checksum

NWmmjj.MEM

Alibi memory files, divided by month (mm = month, yy = year), protected by CRC16

checksum

FlintWeigh Technical Manual, Rev. 3.03 November 2011

Page 13 of 32

6. Weight Display and Control Buttons

Fig. 7.1 : Weight display and control but

tons

Service functions: the win

dow

FlintWeigh II

opens (6)

Displayed scale (no.) and select scale (7)

Zeroing the selected scale (8)

Taring the selected scale (9)

Operation mode of the selected scale (10)

(1) Display window FlintWeigh II

(2) Logo

(3) Software version and checksum

(4) Weight value

(5) Weight unit*

(6) Service functions

(7) Displayed scale (no.) and select scale

(8) Zeroing the selected scale

(9) Taring the selected scale

(10) Operation mode of the selected scale

(11) “Print” (record) to alibi memory

(12) Alibi memory

*Unit in black letters: scale is calibrated

Unit in grey letters: scale has no valid calibration

The various functions will be described below.

In the weighing mode via the OLE interface only the window “Information“ will be opened.

It’s not possible to set up anything.

Currently scale no. 1 is displayed.

Other options are:

Scale no. 2 is displayed

Dual scale function, sum of scale no. 1 and no. 2

Zeroing is only allowed for the empty scale. The current load must fall within the defined

zeroing range ( -1% to +2% off max. load in legal for trade applications; user-defined range

in industrial applications)

Taring is only allowed, if the current gros weight is positive and the scale is in no-motion

condition. When clicking this button the scale will be tared (gros net). The next click on

this button will delete the tare weight (net gros).

A tared scale will display the additional info “NET“.

The next click on this button will delete the tare weight (net gros).

Scale is stable (no-motion condition)

Scale is within the zero setting range

Active weighing range (1, 2 or 3)

“Print” (record) to alibi memory (11)

Performs a weighing and saves the corresponding data to the alibi memory

Alibi memory (12)

Here you can view and print the contents of the alibi memory

FlintWeigh Technical Manual, Rev. 3.03 November 2011

Page 14 of 32

7. FlintWeigh II Configuration

Fig. 8.1 Weight dis

play before commissioning

Fig.8.2 Register „Communication“

Sensor interface:

Sensor type:

Scale system:

Data memory:

Remote display:

Gravitational factor:

7.1. Basic Setup during the Commissioning

When you commission FlintWeigh II for the first time, following basic setup has to be done:

• Sensor interface and Sensor type ( standard load cells OR digital load cells)

• Scale system

• Data memory

• Interface to remote display and remote display type

• Gravitational factor, if applicable

These basic settings will be described in this chapter.

Start the main programme ”NW11F.EXE“

A click on this button will open the service functions

(window FlintWeigh II Settings).

Select the serial interface, which has been assigned to the weighing system

controller (see chapter 5.3) and set up the baud rate to „9600“

Defines, if standar or digital load cells will be connected

(LDU = standard load cells; RC3D,= digital load cells)

Defines, if there will be “1 scale“, “2 scales“ (independend from each other) or a

“Dual scale”

(Dual scale = sum of scale no.1 and scale no.2)

Location for the alibi memory (see chapter 8.1.1)

Define interface and type as required

Is only used, if the calibration location and the installation location are not

identical. Otherwise this parameter remains untouched.

Default setting: 9.8075656

FlintWeigh Technical Manual, Rev. 3.03 November 2011

Page 15 of 32

7.1.1. Configure the Alibi Memory

Fig.8.3 Configure the alibi memory

Fig.8.4 Alibi memory in a local dir

ectory

Fig.8.5 Alibi memory on a network drive

In legal for trade applications the recorded weighing results will be stored to an approved data memory, the so

called alibi memory.

In the standard installation the data memory will be

automatically created in the FlintWeigh II

programme directory.

Generally the location for the data memory can be

selected freely, e.g. it is allowed to choose another

local directory or any network drive.

For changing the memory location click on the

folder sign in the Data memory area.

FlintWeigh Technical Manual, Rev. 3.03 November 2011

Page 16 of 32

7.2. Language and other Settings

Fig. 8.6 Register „Parameters“

Filter characteristics:

Language:

Zero tracking:

Zero after power on:

Frameless:

Record lock:

Input (tilt)

Zero crossing

Changing > 20e

Passcode:

Output 1:

FlintWeigh II has some setup parameters, which can be set up before or after the commissioning. If you have

configured a multi scale system, then first select the wished scale (“1” or “2”) in the weight display (Fig. 7.1).

Selected scale

Filter characteristics for the digital signal processing: Depending on the application the

settling characteristics can be set to “fast“ (shortest settling time), „medium“ (factory

setting) or „slow“ (best averaging)

(the record lock is

active, if the weight unit

shows a grey

background)

Select as necessary, the selected language will be activated immediately

Enables / disables the automatic zero tracking in normal weighing mode

(automatic zeroing of the display, if the scale is stable and the current weight value

falls within the zero setting range)

Enables / disables the automatic zeroing after software start

(automatic zeroing of the display, if the scale is stable and the current weight value

falls within the zero setting rang)

Enables / disables the frameless operation of the software

If "Frameless" is enabled, the window will be displayed without title bar and frame in

the operation via OLE communication.

Enables the digital input as a recording criteria, e.g. tilt sensor

(closed = recording allowed; open = recording locked)

If enabled, the scale must be unloaded before a new weighing

result can be recorded

If enabled, the displayed weight has to change by at least 20 e

before a new weighing result can be recorded

Here you can define an alphanumeric user-defined password (1 to 8 characters) for

protecting the FlintWeigh II settings from any unauthorized access.

If this field is empty, no password will be asked.

Attention: Please note your password! If a password is defined you will never get

access to the scale settings without this password.

Output 2:

FlintWeigh Technical Manual, Rev. 3.03 November 2011

The functionality of the digital outputs, e.g. setpoint outputs, normally will be defined

after the scale calibration (see chapter 8.7).

Page 17 of 32

7.3. Scale with Standard Load Cells

Fig. 8.7 Register ”Calibration“

Sensor address:

LDU

-

Typ Sensor address

Comment

Scale type:

Setting

Comment

Scale interval 1/2/3:

Decimals:

Unit:

No-motion range /

Max. capacity:

Important: The sensor type already has been set to “LDU” (see Fig. 8.2; Register “Communication“).

If you have to configure a multi scale system, then select the wished scale no. ("1" or "2") within the weight

display (Fig. 7.1).

7.3.1. Define the Scale Parameters

For sensor type “LDU“ and

single-interval scale

Selected scale

Defines the address for the LDU (see table below for the factory settings) and enables

the LDU (by activating the check box besides the input field)

Note: The address in parentheses will be used for the second LDU, if two LDUs of the

same type will be used.

68.1 1 (2) Legal for trade

69.1 3 (4) Legal for trade

78.1 5 (6) Legal for trade (see chapter 4.4)

68.2 7 (8) Not approved

Single-interval The scale has exactly one weighing range with a constant scale

interval

Multi-range The scale has 2 or 3 weighing ranges with different scale intervals. If

the current gros value of the measured weight falls within the next

weighing range and larger scale interval (changeover threshold 1 and

2), then the larger scale interval remains active until the scale will be

unloaded and will return to the zero point.

Multi-interval The scale has 2 or 3 weighing ranges with different scale intervals.

The current gros value of the measured weight determines the active

weighing range and the active scale interval at any time.

Step size of the display resolution for the scale respective the weighing range

period:

FlintWeigh Technical Manual, Rev. 3.03 November 2011

Number of digits after the decimal point

Weight unit for the displayed weight: g, kg, t or lb

Condition for a stable scale (no. of scale intervals, no. of measured values);

Default: 2d and 10 values in legal for trade applications; in industrial applications these

criteria may be modified

Maximum load of the scale (as a multiple of the scale interval e1)

Page 18 of 32

Min. capacity:

Minimum load of the scale (as a multiple of the scale interval e1)

Test weight:

Changeover

Fig. 8.8 Addressing load cells in a weighbridge / vehicle scale

Fig.8.9 Register ”Calibration“

Fig.8.10 RC3D Load cells

Sensor

-

Adresse:

Weight of the calibration weight (as a multiple of the scale interval e1)

Only for multi-range / multi-interval scales:

threshold 1/2:

Transition points for range or interval (as a multiple of the scale interval e1)

Important: For saving all scale parameter settings you have to close the window FlintWeigh II Settings

afterwards.

Now the weight display (Fig. 7.1) should show a random value.

The next step is the calibration of the scale (see chapter 8.5).

7.4. Scale with Type RC3D Digital Load Cells

Important: The sensor type already has been set to “RC3D” (see Fig. 8.2; Register “Communication“).

If you have to configure a multi scale system, then select the wished scale no. ("1" or "2") within the weight

display (Fig. 7.1).

7.4.1. Preliminary Note

The next figure shows the basic principles of addressing the load cells in a weighbridge / vehicle scale. The

shown numbering simplifies the corner correction (chapter 8.4.3).

7.4.2. Define the Scale Parameters

for sensor type “RC3D“ and Single-interval scale

After activating the check box “enable” and clicking the button “RC3D“ the window

“RC3D Load Cells“ will be opened (see Fig. 8.10).

Here you select the load cells by their addresses (A, B, C, etc.). The serial numbers will

be read and displayed automatically.

If one or more address fields should have a red background, then the communication to

this/these load cell(s) is not OK. The corresponding load cells have to be checked

(address, protocoll, load etc.)

FlintWeigh Technical Manual, Rev. 3.03 November 2011

Page 19 of 32

Scale type:

Setting

Comment

Scale interval 1/2/3:

Decimals:

Unit:

No-motion range /

period:

Max. capacity:

Min. capacity:

Test weight:

Changeover

Fig.8.11 RC3D Load cells

Single-interval The scale has exactly one weighing range with a constant

scale interval

Multi-range The scale has 2 or 3 weighing ranges with different scale

intervals. If the current gros value of the measured weight falls

within the next weighing range and larger scale interval

(changeover threshold 1 and 2), then the larger scale interval

remains active until the scale will be unloaded and will return to

the zero point.

Multi-interval The scale has 2 or 3 weighing ranges with different scale

intervals. The current gros value of the measured weight

determines the active weighing range and the active scale

interval at any time.

Step size of the display resolution for the scale respective the weighing range

Number of digits after the decimal point

Weight unit for the displayed weight: g, kg, t or lb

Condition for a stable scale (no. of scale intervals, no. of measured values);

Default: 2d and 10 values in legal for trade applications; in industrial applications these

criteria may be modified

Maximum load of the scale (as a multiple of the scale interval e1)

Minimum load of the scale (as a multiple of the scale interval e1)

Weight of the calibration weight (as a multiple of the scale interval e1)

Only for multi-range / multi-interval scales:

threshold 1/2:

Transition points for range or interval (as a multiple of the scale interval e1)

Important: For saving all scale parameter settings you have to close the window FlintWeigh II Settings

afterwards.

Now the weight display (Fig. 7.1) should show a random value.

The next step is the digital corner correction (see chapter 8.4.3).

7.4.3. Digital Corner Correction

Important: After the digital corner correction the scale always requires a new calibration.

Each corner (load cell) will be loaded one after the other with a

calibration weight (the calibration weight should be at least 10%

of max. capacity; better is 30% of max.capacity).

Using the slider the display value of the loaded load cell will be

corrected until the displayed value equals the calibration

weight.

The corner correction doesn’t depend on the sequence of the

loaded load cell, but a systematic course may spare time and

minimises the risk for errors (see chapter 8.4.1).

Hint: It may be meaningful to perform a calibration of the scale

and save the calibration data before the corner correction. This

optimises the display characteristics already before the corner

correction.

The next step is always the calibration of the scale (see chapter 8.5)

FlintWeigh Technical Manual, Rev. 3.03 November 2011

Page 20 of 32

7.5. Calibrate the Scale

Important: Before you can calibrate the scale you have to define the basic setup (see chapter 8.1) and the

scale parameters (see chapter 8.3 respective 8.4). If you have to configure a multi scale system, then select the

wished scale no. ("1" or "2") within the weight display (Fig. 7.1).

1. Open the window “nWweigh Settings“

2. Open the register “Calibration”

3. Unload the scale

4. Click the button “Dead load“; this defines the

current load status of the scale as the zero

point. The weight display should show now the

value “0”.

5. The calibration weight will be put on the centre

of the scale. The true applied weight (at least

10% of max. capacity) has to be entered into

the field “Test weight” (here 2500e = 5 kg).

6. Click the button “Gain“; now the correct gain

for the selected scale will be calculated. The

weight display should show now the value of

the calibration weight.

7. For saving the calibration data click the button

“Save calibration data”. Now a warning

appears which describes the consequences in

legal for trade applications. (“Attention! After

saving the claibration data, the internal

calibration counter (TAC) is still counted

forward. Afterwards the scale has to be reapproved by the Calibration Authority!”)

8. For confirming the saving click the button

“Save”. If you want to keep an existing

approval click the button “Cancel”.

9. After the calibration the window FlintWeigh II

Settings has to be closed. This will save all

setup changes.

10. The weight display will now show the weight of

the calibration weight, if the calibration weight

still loads the scale.

Hint: After the calibration you have to close the window FlintWeigh II Settings by clicking the button “X“ (upper

right window corner). In multi scale applications you may select and calibrate the second scale now.

FlintWeigh Technical Manual, Rev. 3.03 November 2011

Page 21 of 32

7.6. Optional Linearisation of the Scale Curve

The standard scale calibration may be supplemented by a linearisation with up to 5 correction points. Hereby

the correction points have to be in a stricly increasing order, which is:

Min. capacity < Point 1 < Point 2 < Point 3< Point 4 < Point 5 < Max. capacity of the scale

Important: Before any linearisation you have to define the basic setup (see chapter 8.1), the scale parameters

(see chapter 8.3 respective 8.4) and you have to calibrate the scale (see chapter 8.5). If you have to configure

a multi scale system, then select the wished scale no. ("1" or "2") within the weight display (Fig. 7.1).

1. Open the window “nWweigh Settings“

2. Open the register “Linearisation“

3. Correction point 1: A calibration weight will be

put on the centre of the scale. The true applied

weight as a multiple of the scale interval e has

to be entered. Then you use the slider to correct

the display value until it equals the calibration

weight

4. Define correction point 2, if applicable (this is

done like correction point 1 but uses a higher

weight)

5. Define further correction points, if applicable

6. 7. For saving the calibration data click the

button “Save calibration data”. Now a warning

appears which describes the consequences in

legal for trade applications. (“Attention! After

saving the claibration data, the internal

calibration counter (TAC) is still counted

forward. Afterwards the scale has to be reapproved by the Calibration Authority!”)

7. For confirming the saving click the button

“Save”.

.

Hint: After the linearisation you have to close the window FlintWeigh II Settings by clicking the button “X“ (upper

right window corner). In multi scale applications you may select and correct the second scale now.

FlintWeigh Technical Manual, Rev. 3.03 November 2011

Page 22 of 32

7.7. Optional Use of Digital Outputs

Fig.8.11 Re

gister “Parameters“

Setting

Function

Fig.8.12 Example for the limit monitoring

After opening the service functions (window FlintWeigh II Settings) and selecting the register “Parameters“, you

can assign a functionality to the digital outputs:

for defining the digital outputs

Step 1: Select the source to control the output

Allowed settings are Scale 1, Scale 2 and

Combination.

Step 2: Assign a functionality to the output

Allowed settings are:

7.7.1. Setpoints and Limit Monitoring

“Off“ Without

“Limit“ Limit monitoring (see chapter 8.7.1)

“Traffic light“ Traffic light control (see chapter

8.7.2)

1. Select the scale as the source

2. Select the function “Limit“

3. Define the weight value as a multiple of interval

e; if the output shall follow the “Net value”, then

activate the associated check box

4. The output will be switched, if the “weight value

< Limit“. If the output shall show an inverse

logic, then activate the associated check box

“Exceeded”

5. By activating the check box “Input” you may use

the digital input as an additional switching

criteria for the limit monitoring: the setpoint

output will only be activated, if the digital input is

active, too

FlintWeigh Technical Manual, Rev. 3.03 November 2011

Page 23 of 32

7.7.2. Traffic Light Control

The implementation of a traffic light control requires following setup:

1. Define the function “Limit“ for digital output 1

2. Define the function “Traffic Light” for digital output 2

3. The setpoint values for both outputs have to be defined to the same value in such a way, that the

system can reliably detect an “Empty scale”

A functional setup switches the outputs as follows (vehicle scale example):

Action/Status

Output 1

(“Empty”)

Entrance Exit

Empty scale A1 = 1 Green Red

Vehicle is on the scale A1 = 0 Red

Red

Weight recorded A1 = 0 Red Green A2 = 1

Empty scale A1 = 1 Green Red

Output 2

(Weighing finalised)

A2 = 0

A2 = 0

A2 = 0

FlintWeigh Technical Manual, Rev. 3.03 November 2011

Page 24 of 32

8. Legal for Trade Operation

Fig. 9.1 Digital descriptive plate

Fig. 9.2 Successful recording of weight values

Fig. 9.3 Prevented recording of weight values

8.1. EC Type-approval and Test Certificate

See documents on the Flintec CD.

8.2. Digital Descriptive Plate

The digital descriptive plate will be displayed after opening the service functions (window FlintWeigh II Settings)

and selecting the register „Information“:

The digital descriptive plate must conform to the physical

descriptive plate.

(1) Version and revision of the software, checksum in

legal for trade applications in parentheses

(2) Hint area in non-approved applications

(3) Metrological symbol "M": green = approved, red = not

approved

(4) No. of EC type-approval

(5) Electronic calibration counter "TAC"

(6) Logo and address of the owner of the EC typeapproval

(7) Parameters of the selected scale

(8) Parameters of the weighing system controller and the

LDUs

Here you can also enable the 10-times higher resolution

display mode.

8.3. Recording of Weight Values in the Alibi Memory

Click the button within the weight display

The window „Information“ will be opened:

Here the record no. and the weight value to record will be

displayed.

For transfering them into the alibi memory click the “OK“ button.

If the error message „Recording is not possible“ appears, then

the scale was in motion or any of the enabled record locks (see

register „Parameters“) has prevented the successful recording.

FlintWeigh Technical Manual, Rev. 3.03 November 2011

Page 25 of 32

8.4. Show Alibi Memory

Fig. 9.4 Show alibi memory

Figure 9.5 Main window of the alibi memory

Fig. 9.6 Show logbook

Fig. 9.7 Main window of the Logbook

Click the button within the weight display

The window FlintWeigh II long-time memory will be

opened.

First select the month and year of the time period to

display

If necessary it is also possible to display archived

alibi data: search for the path to the file

(“NWxxxx.MEM”*) and afterwards click the button

“Show long-time memory”.

Contents of the long-time memory: COM port no.,

scale no., record no., date and time, weight, scale

status and tare weight where applicable.

If you click the button “Print” the contents of the

long-time memory will be printed.

*incl. path and file name e.g.

C:\FlintWeigh_II\NW0510.MEM

8.5. Logbook

Open service functions

Select register “Logbook”

Here you can view all changes which are relevant

for the legal for trade operation (e.g. calibrations,

updated software version, etc.).

Hint:

The amount of logbook entries is limited to 200.

FlintWeigh Technical Manual, Rev. 3.03 November 2011

Page 26 of 32

8.6. Obligations with Legal for Trade Scales

Structure

of the general scale data

Structure of the individual scales (3x for Scale 1, Scale 2 and Dual scale)

Logbook

The operator is responsible for the first and all regularly recurrent official calibrations.

Important: The official seal may only be broken by authorized qualified staff.

If one or more of the following changes has happened, the operater has to send a written note to the assigned

public authority and a new official calibration is mandatory:

► Broken seals

► Replaced load cells

► Replaced load carrier

► Replaced wiring

► Replaced LDUs

► Replaced weighing system controller

► Replaced descriptive plate

► Calibration of the scale

► Changes to the approved software settings

Hint: The user is responsible for the correct performance of any official calibration.

8.7. Legal for Trade Data within the Scale Interface

In legal for trade and industrial applications all calibration data will be stored in a flash memory in the scale

interface. These data can only be accessed, if the authentification of the FlintWeigh II Software to the scale

interface is valid. If these data will be saved during a calibration, the electronic calibration counter (TAC) will

automatically increased by one. The stored data is the following:

Serial no. Up to 17x per controller; up to 16x type RC3D digital load cell respective LDU

Gravitational factor Default value: 9.8075656

Calibration counter

Programme version x._

Programme revision _.x

Corner correction Max. 16 data records for up to 16x type RC3D digital load cell

Checksum EXE CRC16 for complete programme code

Checksum CRC16 for general scale data

Scale interval 3x for up to three ranges

Decimals

Unit

Min. capacity Default value: 20e

No-motion

Calibration weight

Max. capacity Max. capacity + 9e = overload

Changeover threshold 2x per scale (up to 3 ranges per scale)

Curve linearisation Up to 5 points per scale

Zero point (Dead load pt.)

Gain value

Scale type Single-interval, Multi-range, Multi-interval

Checksum CRC16 for scale data

Logbook entries Up to 200; 8 bytes incl. CRC for each

FlintWeigh Technical Manual, Rev. 3.03 November 2011

Page 27 of 32

9. Error Messages

Warnings

Software

Calibration

Important note: If a warning appears, the calibration data have to be saved again. Thereby the internal

calibration counter will be incremented by one which is especially relevant in legal for trade applications.

A new software version is used.

Elements of the calibration data have been changed.

FlintWeigh Technical Manual, Rev. 3.03 November 2011

Page 28 of 32

10. OLE Programming Interface

Function

Description

The programming interface to an application programme is executed as an automation (OLE-) server for 32-bit

Windows programmes (OLE = Object Linking and Embedding).

The communication between any application programme and FlintWeigh II will be done exclusively by the

following functions which are described below.

10.1. OLE Functions

Position (x,y) Position the weight display on the desktop ("0,0" belongs to top left corner)

Parameter Type Use

x Integer Horizontal position

y Integer Vertical position

Attention: It is mandatory to call this function exactly once during the initialisation of the

application software!

Stop() Stops communication

Attention: It is recommended to call this function once just before closing the application

software. This will stop the communication to the weight system controller clearly!

Switch(w) Select scale (only for multi scale systems)

Parameter Type Use

w Integer w = 1 (scale 1); w = 2 (scale 2)

w = 3 (dual scale)

Zero() Zeroing the selected scale

SetTare() Taring the selected scale

ClrTare() Delete the tare weight of the selected scale

PreTare(v) Set the tare weight for the selected scale manually

Parameter Type Use

v 32-bit

Integer

Tare value including all decimal places but without

decimal point ( e.g. 13.25 kg v = 1325)

Value Read the current weight value

Return value Format

String, 9 digits „nnnnnnndd“ with

nnnnnnn = weight value including decimal point, 7 digits

dd = weight unit, 2 digits

Hint: Unused places within the weight value will be filled with spaces.

Ten(t) Weight display with 10-times increased resolution (zoom)

Parameter Type Use

t Integer zoom off (t = 0) / zoom on (t= 1)

FlintWeigh Technical Manual, Rev. 3.03 November 2011

Page 29 of 32

Function

Description

Regist Register the current weight value – Format 1

Return value Value range

Format: string, 16 digits:

“rrrrrr nnnnnnn dd w” with

rrrrrr Record no., 6 digits 000001, 000002, 000003...

nnnnnnn

Weight value including

decimal point, 7 digits

0...800 000

dd Weight unit, 2 digits g, kg, t, lb

w Scale no., 1 digit 1 (scale 1); 2 (scale 2); 3 (dual scale)

Hint: Unused places within the weight value will be filled with spaces.

Attention: In legal for trade operation an entry to the alibi memory will be created and the

record counter will be incremented by one.

If a recording is not possible, a 2-digit error code will be notified:

E1 Scale in motion E4 No zero crossing

E2 Weight value ≤ 0 E5 Open input (tilt)

E3 Gros weight < minimum load E6 Overload, etc.

Regist2 Register the current weight value – Format 2

Return value Value range

Format: string, 30 digits:

“w_rrrrrr_nnnnnnn_kk_ttttttt_dd“ with

w Scale no., 1 digit 1 (scale 1); 2 (scale 2); 3 (dual scale)

rrrrrr Record no., 6 digits 000001, 000002, 000003...

nnnnnnn

kk Tare indication

ttttttt

Weight value including

decimal point, 7 digits

Tare value including

decimal point, 7 digits

0...800 000

„ “ (no tare); „ T“ (normal tare);

„PT“ (manual tare entry)

0...800 000

dd Weight unit, 2 digits g, kg, t, lb

Hint: Unused places within the weight value will be filled with spaces.

Attention: In legal for trade operation an entry to the alibi memory will be created and the

record counter will be incremented by one.

If a recording is not possible, a 2-digit error code will be notified:

E1 Scale in motion E4 No zero crossing

E2 Weight value ≤ 0 E5 Open input (tilt)

E3 Gros weight < minimum load E6 Overload, etc.

Param(w) Read scale parameters

Parameter Type Use

w Integer w = 1 (scale 1); w = 2 (scale 2); w = 3 (dual scale)

Return value Value range

Format: string, 17 digits:

"w_t_z1_z2_z3_k_dd" with

w Scale no., 1 digit 1 (scale 1); 2 (scale 2); 3 (dual scale)

t Scale type, 1 digit 1 (single-interval), 2 (multi-range), 3 (multi-interval)

z1 Scale interval 1, 2 digits 01, 02, 05, 10, 20, 50

z2 Scale interval 2, 2 digits 02, 05, 10, 20, 50 (at single-interval: 01)

Z3 Scale interval 3, 2 digits 05, 10, 20, 50 (at single-interval: 01)

k Decimal places, 1 digit 1, 2, 3, 4, 5

dd Weight unit, 2 digits g, kg, t, lb

FlintWeigh Technical Manual, Rev. 3.03 November 2011

Page 30 of 32

Function

Description

Status(w) Read scale status

Parameter Type Use

w Integer w = 1 (scale 1); w = 2 (scale 2); w = 3 (dual scale)

Return value Value range

Format: string, 31 digits:

"AB_gggggggdd_tttttttdd_nnnnnndd" with

A Status bit 1

B Status bit 2

gggggggdd Gros value and unit 0...800 000 / g, kg, t, lb

tttttttdd Tare value and unit 0...800 000 / g, kg, t, lb

nnnnnnndd Net value and unit 0...800 000 / g, kg, t, lb

Hint: Unused places within the weight value will be filled with spaces.

SetOutput(o,w,f,v) Configure digital outputs and setpoints

Parameter Type Use

o 32-bit Integer o = 1 (output 1); o = 2 (output 2)

w 32-bit Integer w = 1 (scale 1); w = 2 (scale 2); w = 3 (dual scale)

f 32-bit Integer

Flag Operation

2

21

22 0 (= 0) Under-run

23 0 (= 0) Gros value

24 Status of fixed setting

25 Enabled by input

20 (= 1) = No motion

21 (= 2) = Active tare (net indication)

22 (= 4) = Zero setting range

23 (= 8) = Accurate zero

24 (= 16) = Error

20 (= 1) = Zero crossing

21 (= 2) = Minimum load

22 (= 4) = Tilt switch

00 Output not used

0

01 Fixed setting

02 Setpoint control

03 Traffic control

1 (= 1) Exceeded

1 (= 8) Net value

0 (= 0) Off

1 (= 16) On

0 (= 0) Off

1 (= 32) On

v 32-bit Integer Setpoint including all decimal places but without decimal

point ( e.g. 13.25 kg v = 1325)

All functions are characterised in the type library “NW10.TLB”, which may be included into the programming

environment of the application programme.

FlintWeigh Technical Manual, Rev. 3.03 November 2011

Page 31 of 32

10.2. Application Example

Example 1 – Visual Basic:

Call of OLE function "Regist" in VB

------------------------------------------------------ Dim scale As Object

'Create object and position the weight display

'(only once in the programme during initialisation)

Set scale = CreateObject("scale99.serv")

Call scale.Position(0,0)

'Recording

'(several times during normal operation)

print_str = scale.Regist

'Stop communication

'(only once in the programme before closing)

Call scale.Stop

-------------------------------------------------------

Example 2 - VisualBasicScript / Windows Scripting Host:

Call of OLE function "Regist2" in VBS

'-----------------------------------------------------------' Sample programme for use of OLE connection to FlintWeigh II

'----------------------------------------------------------- '## Create Shell-Object ##

Set ws = CreateObject("WScript.Shell")

'## Create OLE-Object for "FlintWeigh II" ##

Set scale = CreateObject("Scale99.Serv")

'## First neccesary command to "FlintWeigh II"=position(x,y) ##

scale.position 0,0

'## Info message and waiting till "FlintWeigh II" is ready ##

ws.popup "Wait for initialisation of OLE server" ,1

WScript.Sleep (10*1000)

'## Show FlintWeigh II window ***

scale.Show

'## Wait for scale is ready and do recording–format 2 ##

Do

regist2value = scale.regist2

Loop Until (left(regist2value,1)<>"E")

'## Show result of recording – format 2 ##

msgbox regist2value

'## Stop OLE-Server ##

scale.stop

'----- End of Sample programme -----

www.flintec.com

FlintWeigh Technical Manual, Rev. 3.03 November 2011

Page 32 of 32

Loading...

Loading...