Flintec FT-12 User Manual

WEIGHT INDICATOR

FT-12

TECHNICAL MANUAL

For Firmware Version 2.07 and higher

Flintec GmbH Bemannsbruch 9 74909 Meckesheim GERMANY www.flintec.com

Table of Contents:

1 |

Safety Instructions ......................................................................................................................................... |

4 |

||

2 |

Declaration of Conformity ............................................................................................................................. |

5 |

||

3 |

Overview.......................................................................................................................................................... |

6 |

||

|

3.1 |

|

Key Features............................................................................................................................................. |

6 |

|

3.2 |

Available Options and Accessoires........................................................................................................... |

6 |

|

|

3.3 |

|

Technical Specifications............................................................................................................................ |

7 |

|

3.4 |

|

Housing Dimensions ................................................................................................................................. |

8 |

|

3.4.1 |

Desk Type Housing ........................................................................................................................................... |

8 |

|

|

3.4.2 |

Stainless Steel Housing .................................................................................................................................... |

8 |

|

|

3.4.3 |

Panel Type Housing .......................................................................................................................................... |

9 |

|

4 |

Installation and Commissioning................................................................................................................. |

10 |

||

|

4.1 |

|

Mechanical Installation............................................................................................................................ |

10 |

|

4.1.1 |

Jumpers........................................................................................................................................................... |

10 |

|

|

4.2 |

|

Electrical Connections............................................................................................................................. |

10 |

|

4.2.1 |

Power Supply and Grounding.......................................................................................................................... |

10 |

|

|

4.2.2 |

Standard Load Cell Connection....................................................................................................................... |

11 |

|

|

4.3 |

|

Commissioning........................................................................................................................................ |

11 |

5 Front Panel and Keypad .............................................................................................................................. |

12 |

|||

|

5.1 |

Weight Display and Status LEDs ............................................................................................................ |

12 |

|

|

5.2 |

|

Keypad .................................................................................................................................................... |

13 |

|

5.3 |

|

Key lock................................................................................................................................................... |

13 |

6 |

Setup and Calibration .................................................................................................................................. |

14 |

||

|

6.1 |

|

Basics...................................................................................................................................................... |

14 |

|

6.1.1 |

Basic Setup Keys on the Frontplate ................................................................................................................ |

14 |

|

|

6.1.2 |

Entering the Setup and Calibration Menu........................................................................................................ |

14 |

|

|

6.1.3 |

Exiting the Setup and Calibration Menu .......................................................................................................... |

14 |

|

|

6.2 |

|

Application Programmes ......................................................................................................................... |

15 |

|

6.2.1 |

Basic Weighing................................................................................................................................................ |

15 |

|

|

6.2.2 |

Check Weighing .............................................................................................................................................. |

15 |

|

|

6.2.3 |

Peak Hold........................................................................................................................................................ |

15 |

|

|

6.2.4 |

Dynamic Weighing .......................................................................................................................................... |

16 |

|

|

6.2.5 |

Filling............................................................................................................................................................... |

16 |

|

|

6.2.6 |

Setup............................................................................................................................................................... |

16 |

|

|

6.3 |

|

Configuration Parameters ....................................................................................................................... |

17 |

|

6.4 |

|

Scale Parameters.................................................................................................................................... |

17 |

|

6.5 |

|

Scale Calibration ..................................................................................................................................... |

19 |

7 |

Memory Operations...................................................................................................................................... |

20 |

||

|

7.1 |

|

ID Memory............................................................................................................................................... |

20 |

|

7.2 |

|

Preset Tare Memory ............................................................................................................................... |

20 |

|

7.3 |

|

Setpoint Memory ..................................................................................................................................... |

20 |

8 Alibi Memory and Legal Metrological Records ......................................................................................... |

21 |

|||

9 |

Communication ............................................................................................................................................ |

22 |

||

|

9.1 |

|

Overview about Communication ............................................................................................................. |

22 |

|

9.2 |

Serial Interface and Printer ..................................................................................................................... |

22 |

|

|

9.2.1 |

Standard Serial Interface Connector (RS232C) .............................................................................................. |

22 |

|

|

9.2.2 |

Optional Serial Interface Connector (RS232C, RS485, 20 mA TTY)............................................................... |

22 |

|

|

9.2.3 |

Continuous Output Mode ................................................................................................................................ |

23 |

|

|

9.2.4 |

Host Mode ....................................................................................................................................................... |

23 |

|

|

9.2.5 |

Print Mode ....................................................................................................................................................... |

23 |

|

|

9.2.6 |

Setup............................................................................................................................................................... |

24 |

|

FT-12 Technical Manual, Rev. 1.35 November 2010 |

Page 2 of 44 |

9.3 |

Ethernet Option ....................................................................................................................................... |

27 |

|

9.3.1 |

Electrical Connections..................................................................................................................................... |

27 |

|

9.3.2 |

Setup............................................................................................................................................................... |

27 |

|

9.3.3 |

Data Structure ................................................................................................................................................. |

29 |

|

10 |

Other I/O Options...................................................................................................................................... |

30 |

|

10.1 |

|

Analogue Output Option ...................................................................................................................... |

30 |

10.1.1 |

Electrical Connections..................................................................................................................................... |

30 |

|

10.1.2 |

Setup............................................................................................................................................................... |

30 |

|

10.2 |

|

Digital I/O Option ................................................................................................................................. |

31 |

10.2.1 |

Electrical Connections..................................................................................................................................... |

31 |

|

10.2.2 |

Setup............................................................................................................................................................... |

31 |

|

10.2.3 |

Entering Setpoints ........................................................................................................................................... |

32 |

|

10.3 |

|

Binary Output Option ........................................................................................................................... |

32 |

11 |

Diagnostics ............................................................................................................................................... |

33 |

|

Appendix 1: Setup and Calibration Menus ...................................................................................................... |

34 |

||

Appendix 2: Continues Output Mode Data Structure ..................................................................................... |

35 |

||

Appendix 3: Host Mode Data Structure............................................................................................................ |

36 |

||

Appendix 4: Modbus RTU Data Structure........................................................................................................ |

39 |

||

Appendix 5: Error Table..................................................................................................................................... |

42 |

||

Appendix 6: Parameter’s Default Table............................................................................................................ |

43 |

||

Appendix 7: Calibration Table........................................................................................................................... |

44 |

||

FT-12 Technical Manual, Rev. 1.35 November 2010 |

Page 3 of 44 |

RIGHTS AND LIABILITIES

All rights reserved.

No part of this publication may be reproduced, stored in a retrieval system, or transmitted in any form or by any means, mechanical, photocopying, recording, or otherwise, without the prior written permission of Flintec GmbH

No patent liability is assumed with respect to the use of the information contained herein. While every precaution has been taken in the preparation of this book, FLINTEC assumes no responsibility for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained herein.

The information herein is believed to be both accurate and reliable. FLINTEC, however, would be obliged to be informed if any errors occur. FLINTEC cannot accept any liability for direct or indirect damages resulting from the use of this manual.

FLINTEC reserves the right to revise this manual and alter its content without notification at any time.

Neither FLINTEC nor its affiliates shall be liable to the purchaser of this product or third parties for damages, losses, costs, or expenses incurred by purchaser or third parties as a result of: accident, misuse, or abuse of this product or unauthorized modifications, repairs, or alterations to this product, or failure to strictly comply with FLINTEC operating and maintenance instructions.

FLINTEC shall not be liable against any damages or problems arising from the use of any options or any consumable products other than those designated as Original FLINTEC Products.

NOTICE: The contents of this manual are subject to change without notice.

Copyright © 2008 – 2010 by Flintec GmbH, 74909 Meckesheim, Bemannsbruch 9, Germany

1 SAFETY INSTRUCTIONS

CAUTION READ this manual BEFORE operating or servicing this equipment. FOLLOW these instructions carefully. SAVE this manual for future reference. DO NOT allow untrained personnel to operate, clean, inspect, maintain, service, or tamper with this equipment. ALWAYS DISCONNECT this equipment from the power source before cleaning or performing maintenance. CALL FLINTEC ENGINEERING for parts, information, and service.

WARNING ONLY PERMIT QUALIFIED PERSONNEL TO SERVICE THIS EQUIPMENT. EXERCISE CARE WHEN MAKING CHECKS, TESTS AND ADJUSTMENTS THAT MUST BE MADE WITH POWER ON. FAILING TO OBSERVE THESE PRECAUTIONS CAN RESULT IN BODILY HARM.

WARNING FOR CONTINUED PROTECTION AGAINST SHOCK HAZARD CONNECT TO PROPERLY GROUNDED OUTLET ONLY. DO NOT REMOVE THE GROUND PRONG.

WARNING DISCONNECT ALL POWER TO THIS UNIT BEFORE REMOVING THE FUSE OR SERVICING.

WARNING BEFORE CONNECTING/DISCONNECTING ANY INTERNAL ELECTRONIC COMPONENTS OR INTERCONNECTING WIRING BETWEEN ELECTRONIC EQUIPMENT ALWAYS REMOVE POWER AND WAIT AT LEAST THIRTY (30) SECONDS BEFORE ANY CONNECTIONS OR DISCONNECTIONS ARE MADE. FAILURE TO OBSERVE THESE PRECAUTIONS COULD RESULT IN DAMAGE TO OR DESTRUCTION OF THE EQUIPMENT OR BODILY HARM.

CAUTION OBSERVE PRECAUTIONS FOR HANDLING ELECTROSTATIC SENSITIVE DEVICES.

FT-12 Technical Manual, Rev. 1.35 November 2010 |

Page 4 of 44 |

2 DECLARATION OF CONFORMITY

0 |

EG-Konformitätserklärung |

|

EC-Declaration of Conformity |

||

Monat/Jahr: month/year: |

07/2010 |

|

Hersteller: Manufacturer: |

Flintec GmbH |

|

Anschrift: Address: |

|

Bemannsbruch 9 |

|

|

D-74909 Meckesheim |

|

|

Deutschland / Germany |

Produktbezeichnung: Product name: |

FT-12 Wäge-Indikator / FT-12 Weight Indicator |

|

Das bezeichnete Produkt stimmt mit folgenden Vorschriften der Europäischen Richtlinien überein:

This product confirms with the following regulations of the Directives of the European Community

Richtlinie 2004/108/EG des Europäischen Parlaments und des Rates vom 15. Dezember 2004 zur Angleichung der Rechtsvorschriften der Mitgliedstaaten über die elektromagnetische Verträglichkeit und zur Aufhebung der Richtlinie 89/336/EWG

Richtlinie 2006/95/EG Niederspannungs-Richtlinie

Die Absicherung aller produktspezifischen Qualitätsmerkmale erfolgt auf Basis eines zertifizierten Qualitätsmanagement-Systems nach DIN ISO 9001.

Diese Erklärung bescheinigt die Übereinstimmung mit den genannten Richtlinien, beinhaltet jedoch keine Zusicherung von Eigenschaften.

Directive 2004/108/EC of the European Parliament and of the Council of 15th December 2004 on the approximation of the laws of the Member States relating to electromagnetic compatibility and repealing Directive 89/336/EEC

Directive 2006/95/EC Low Voltage Directive

All product-related features are assured by a quality system in accordance with ISO 9001.

This declaration certifies the conformity with the listed directives, but it is no promise of characteristics.

Folgende Normen werden zum Nachweis der Übereinstimmung mit den Richtlinien eingehalten:

As a proof of conformity with the directives following standards are fulfilled:

EN 61326-1

EN 60950-1

Elektrische Mess-, Steuer-, Regelund Laborgeräte - EMV-Anforderungen - Teil 1: Allgemeine Anforderungen (IEC 61326-1:2005)

Electrical equipment for measurement, control and laboratory use - EMC requirements - Part 1: General requirements (IEC 61326-1:2005)

Einrichtungen der Informationstechnik - Sicherheit - Teil 1: Allgemeine Anforderungen (IEC 60950- 1:2005, modifiziert);

Information technology equipment - Safety - Part 1: General requirements (IEC 60950-1:2005 modified)

FT-12 Technical Manual, Rev. 1.35 November 2010 |

Page 5 of 44 |

3 OVERVIEW

The type FT-12 weight indicator is an economic and powerful state-of-the-art instrument. Its application covers any type of standard weighing process including dynamic weighing, check weighing and filling.

The accurate and versatile instrument is available in different housings, meeting the industries demand for various environmental conditions.

FT-12 is approved by Weights & Measures Authorities for use in Accuracy Class III applications with up to 10 000 intervals according to OIML R76. It has a large 6 digit LED weight display (red, 20 mm or 14 mm high) with weight status information. With a variety of interface options the FT-12 weight indicator is the perfect fit to weighing systems and process control systems.

3.1Key Features

EU Type approved for 10 000 intervalsSingle or dual range

Approved sensitivity 0.4 mV/e

High internal resolution up to 8 000 000 countsDisplay resolution up to 60 000 counts

Maximum conversion rate of 100/s

Adaptive digital filter for fast and stable readingHigh resolution display mode

Up to 6 load cells (350 ) or 18 load cells (1100 )Realtime clock

Standard Serial interface RS232CIntegrated AC power supply

Zeroing with one button & Taring with one buttonAuto-zero tracking and auto-zero at power-up

99 preset tare values & auto tare clear optionMotion detection

Printout in different formats incl. header and footer

Totalizing and printing of consequential weighing resultsSetpoint monitoring (3 setpoints, digital I/O required)

9 set point groups with 3 setpoints each

5 standard application modes incl. check weighing, dynamic weighing, filling, and peak holdKey lock option to prevent unauthorized access

3.2Available Options and Accessoires

Alibi memory for up to 149 764 weighing resultsAdditional serial interface RS232C

Additional serial interface RS232C / 20 mA TTY CL* / RS485 (* not for stainless steel housing)Modbus RTU

Ethernet TCP/IP and Modbus RTU over EthernetAnalogue output 0 – 10 V and 4 – 20 mA

Binary data output (17-bit code)Digital inputs / outputs

12 V DC (12…17 V DC) power inlet24 V DC (20…27 V DC) power inlet

Rechargeable battery (for 230 V AC version only)Flintec IndFace Software

FT-12 Technical Manual, Rev. 1.35 November 2010 |

Page 6 of 44 |

3.3Technical Specifications

|

Accuracy |

|

|

|||

|

Accuracy class: |

|

III |

|

||

|

EU Type approved: |

|

10 000 intervals (single range); 2x 6 000 intervals (dual range) |

|

||

|

|

|

|

|

|

|

|

Display and Keyboard |

|

|

|||

|

Display: |

|

6 digits, 7 segments, LED red, 20 mm high (Panel type 14 mm high) |

|

||

|

Display update rate: |

|

250 ms |

|

||

|

Keyboard: |

|

18-keys; membran with tactile feedback |

|

||

|

|

|

|

|

|

|

|

A/D Converter |

|

|

|||

|

A/D converter type: |

|

24 bit Delta-Sigma ratiometric with integral analog and digital filters |

|

||

|

Conversion rate: |

|

Max. 100 measurement values per second |

|

||

|

Input sensitivity: |

|

0.4 μV/e (approved), 0.1 μV/d (non approved) |

|

||

|

Analogue input range: |

|

0 to 20 mV |

|

||

|

Internal resolution: |

|

Up to 8 000 000 counts |

|

||

|

Display resolution: |

|

Up to 60 000 counts |

|

||

|

|

|

|

|

|

|

|

Scale Calibration and Functions |

|

|

|||

|

Calibration: |

|

Calibration is performed by application weights |

|

||

|

Corner adjustment: |

|

Only externally |

|

||

|

Digital filter: |

|

In 10 step adjustable |

|

||

|

Application modes: |

|

Basic weighing, filling, check weighing, dynamic weighing and peak hold |

|

||

|

Weighing functions: |

|

Tare, zero, auto zero tracking, motion detection, auto zero at power up |

|

||

|

Programmable setpoints: |

|

9 groups with 3 setpoints each (needs digital I/O option) |

|

||

|

Alibi memory: |

|

Optionally available: 74 880 records or 149 760 records |

|

||

|

|

|

|

|

|

|

|

Linearity: |

|

|

|

Within 0.0015% FS, 2 ppm/°C |

|

|

|

|

|

|||

|

Load cells |

|

|

|||

|

Excitation: |

|

5 V DC at 58...1200 max. 100 mA |

|

||

|

Number of load cells: |

|

Up to 6 load cells (350 ) or 18 load cells (1 100 ) connected in parallel |

|

||

|

Connection: |

|

4- or 6-wire technique. Cable length 274 m/mm² for 6-wire connection |

|

||

|

|

|

|

|

||

|

Communication: |

|

|

|

Standard serial interface RS232C; 1 200 to 57 600 baud; programmable |

|

|

Continuous mode update rate: |

|

|

|

100 ms |

|

|

Option board update rate: |

|

40 ms |

|

||

|

|

|

|

|||

|

Power supply: |

|

|

|||

|

AC Power supply |

|

200…240 V AC, 50/60 Hz |

|

||

|

DC Power supply |

|

optionally 12…17 V DC, max. 12 VA or optionally 20…27 V DC, max. 12 VA |

|

||

|

Battery runtime: |

|

5 h (with 93 LC) to 7 h (with 410 LC) |

|

||

|

Battery charging time: |

|

6 h |

|

||

|

|

|

|

|||

|

Environment and Enclosure |

|

|

|||

|

Operation temperature: |

|

-10 °C to +40 °C legal for trade; max. 85% RH, non-condensing |

|

||

|

|

|

|

|

Aluminium cast desk type (IP30) or |

|

|

Enclosure |

|

panel type (front panel IP65) or |

|

||

|

|

|

|

|

stainless steel (IP65) |

|

FT-12 Technical Manual, Rev. 1.35 November 2010 |

Page 7 of 44 |

3.4Housing Dimensions

3.4.1 Desk Type Housing

195 |

|

|

|

|

|

155 |

|

|

|

|

|

||

|

|

|

|

|

|

|

140

Desk type front view |

Desk type side view |

187

|

|

|

|

|

179 |

|

|

POWER 230 VAC, 50Hz, |

RS232 |

LOAD CELL |

|

|

|

||

|

|

|

C |

|

|

|

|

|

|

|

|

OPTIO |

|

|

|

|

|

|

|

N |

|

|

|

S/N |

|

|

ANA □BIN □ETH □INT □MOD □I/O3 3 □I/O4 8 |

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|||

|

|

|

|

|

|||

|

Desk type rear view |

Dimensions of Desk type housing with wall mount kit |

|||||

3.4.2 Stainless Steel Housing

|

|

|

|

|

|

|

|

|

100 |

|||

220 |

|

|

|

|

|

|

|

70 |

|

|

|

70 |

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|||

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

15 |

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

160

230

Stainless steel housing front view |

Stainless steel housing side view |

|

100 mm deep with big backplane option |

FT-12 Technical Manual, Rev. 1.35 November 2010 |

Page 8 of 44 |

3.4.3 Panel Type Housing

174 |

|

|

|

|

|

175 |

|

|

|

|

|

||

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

90 |

68 |

Panel type front view |

Panel type side view |

5,5 |

9 |

144 |

|

69 |

80 |

|

|

164 |

Sticker |

|

5, mounting with 4x M4 |

Panel type rear view |

The hole dimensions for mounting on a panel |

|

FT-12 Technical Manual, Rev. 1.35 November 2010 |

Page 9 of 44 |

4 INSTALLATION AND COMMISSIONING

PRECAUTION: Please read this manual carefully before energizing the indicator. Perform the commissioning operation according the procedure given here. Use trained personnel for cleaning, commissioning, checking and service of the indicator. The interference of untrained personnel may cause some unwanted damages or injures. Note: In this manual the term “Digital Load Cell“ will be refered to “DLC“.

4.1Mechanical Installation

First of all please determine the place where your indicator can operate safely. This place should be clean, not getting direct sun light if possible, with a temperature between -10 ºC and +40 ºC, humidity not exceeding 85% non-condensing. Take care to the housing dimensions and the suggested panel hole dimensions given in chapter 3.5. All the cables should be installed safely to avoid mechanical damages.

To avoid electrical noise protect your indicator which has very low input signal level from the equipment that produces electrical noise, especially in panel mounting.

4.1.1 Jumpers

There are three jumpers on the instrument’s main board/weighing board for calibration and for switching on/off. To change the position of this jumpers, open the housing and perform the necessary changes before energizing the indicator.

J8 On/Off Switch

(always short circuit at the Panel type)

J2 Calibration

(short circuit for calibration)

J17 short circuit for on/off key function

Figure 4.1 FT-12 Main board

4.2Electrical Connections

4.2.1 Power Supply and Grounding

FT-12 is available with 230 V AC power supply or 24 V DC or 12 V DC power inlet. The 230 V AC indicators are supplied with a power cable; the DC indicators are supplied with a special connector for the power inlet. Prepare your power voltage according to your instrument’s power inlet. The DC connector pin configuration can be found in Figure 4.2 below.

Definition |

Pin no. |

Pin no. |

|

for desk and panel type |

for stainless steel housing |

||

|

|||

12 V / 24 V |

1 |

3 |

|

0 V |

2 |

2 |

|

Housing Gnd |

3 |

1 |

Desk / Panel |

Figure 4.2 The pin layout of the DC connector |

|

The quality of the instrument’s ground will determine the accuracy and the safety of your indicator. A poor ground can result in an unsafe condition if an electrical short cuircuit happens. A good ground connection is needed to minimize extraneous electrical noise pulses. It is important that the instrument does not share power lines with noise-generating equipment such as heavy load switching, motor control equipments, inductive loads, etc. If the condition of the power line in the plant is bad, prepare a special power line and grounding.

If you have to service the indicator, turn off the power and wait at least for 30 seconds before interfering.

All connectors are at the rear side of the housings of desk and panel types. The stainless steel housings must be opened to make the required connections. These connections must be done as described below.

FT-12 Technical Manual, Rev. 1.35 November 2010 |

Page 10 of 44 |

4.2.2 Standard Load Cell Connection

The load cell wiring should be made carefully before energizing to avoid damages to the weight indicator and the load cells. The input resistance of the load cells that you want to connect should be more than 58 Ω.

The sense pins of the instrument should be connected. In 4-wire installations the sense and excitation pins with the same polarity should be short circuited at the connector side.

6-wire Load Cell |

4-wire Load Cell |

Pin no. for desk type & panel |

Pin no. for Stainless steel |

Connection |

Connection |

type (D-Sub, 9-pin, female) |

housing (J12 connector) |

+ Excitation |

+ Excitation |

1 |

1 |

+ Sense |

+ Excitation |

2 |

2 |

Shield |

Shield |

3 |

4 |

- Sense |

- Excitation |

4 |

6 |

- Excitation |

- Excitation |

5 |

7 |

+ Signal |

+ Signal |

7 |

3 |

- Signal |

- Signal |

8 |

5 |

Shield |

Shield |

Connector body |

4 |

4.3Commissioning

After making the required installations and connections to your indicator, turn the power on and perform following steps:

Get familiar with the instrument’s setup mode (see chapter 6.1)Set up the application mode (see chapter 6.2)*

Define the configuration parameters (see chapter 6.3)*Define the scale parameters (see chapter 6.4)

Calibrate the scale (see chapter 6.5)

* Note: Most of the parameters can be skipped for later setup. Please take care for the parameters which may be locked by the J2 calibration jumper in legal for trade applications (see Appendix 1: Setup and Calibration Menu of the instrument).

If you want to use the Flintec IndFace Software for FT-12 then you have to set up the instrument’s standard serial interface to host mode (see chapter 9.2) before you adjust all the configuration parameters.

After checking the performance of your weighing instrument you can begin to use the indicator.

If there are peripheral connections, first you should turn the power off; make the peripheral connections, perform the required safety checks and energize the indicator. Then set the related parameters and check if the peripheral devices are operating properly.

If required perform following additional steps:

Set up the memory functions (see chapter 7)Set up the serial interfaces (see chapter 9.2)Printer setup (see chapter 9.2)

Set up other optional inputs and outputs (see chapter 9.3 and 10)

FT-12 Technical Manual, Rev. 1.35 November 2010 |

Page 11 of 44 |

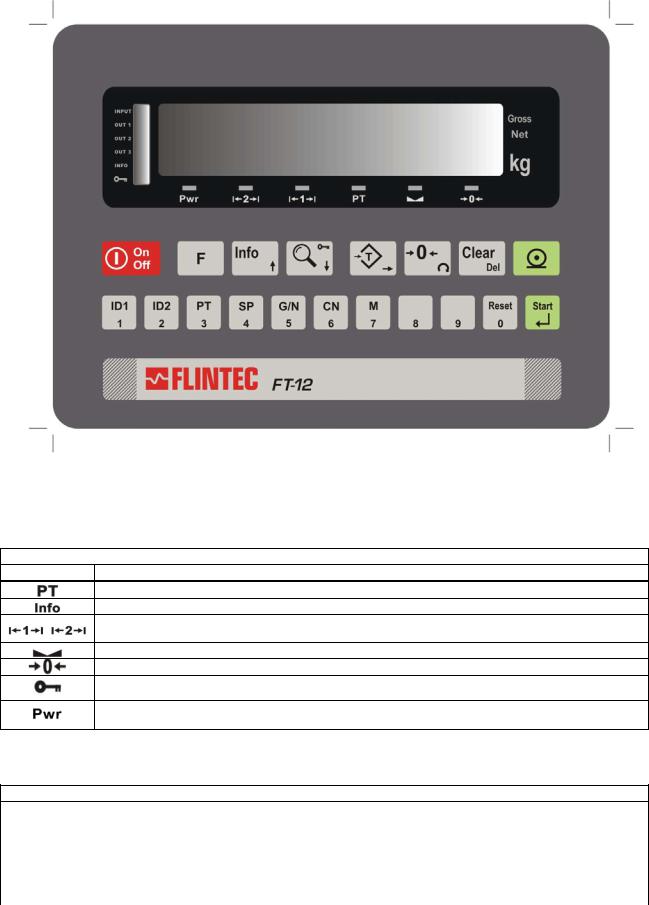

5 FRONT PANEL AND KEYPAD

5.1Weight Display and Status LEDs

Figure 5.1 Front panel view of FT-12

The weight display of FT-12 is a 6 digit LED with 14 mm or 20 mm height.

At the right side of the display there are 3 status LEDs for indicating “Gross”, “Net” and the standard unit “kg”.

Below the weight display there are 6 status LEDs related to the weighing process:

Status LEDs related to the weighing process |

|

LED |

Meaning |

Preset tare: Indicator works with a preset tare

Info: The instrument displays information different from the weight

Range: With multi range scales these LED indicates the current operating range. For single range scales only the first range LED is lit.

Stable: The weight value on the display is stable

Center of zero: The weight is in the center of zero (see param. [203] in chap.6.3)

Key lock: is active

Power: This LED will flash in case of supply voltage decrease. If the voltage decreases too much the indicator will automatically shut off.

At the left side of the weight display there is a group of 6 status LEDs that have different meanings according to the current application programme (for details refer to the relevant section in chapter 6.2.):

Status LEDs related to the application programme

Basic Weighing |

Check Weighing |

Peak Hold |

Dynamic Weighing |

Filling |

INPUT |

W + + |

Ready |

INPUT |

Start |

OUT 1 |

W + |

In Process |

OUT 1 |

Ready |

OUT 2 |

OK |

EOP |

OUT 2 |

Coarse |

OUT 3 |

W - |

Error |

OUT 3 |

Fine |

INFO |

W - - |

INFO |

INFO |

EOB |

Key Lock |

Key Lock |

Key Lock |

Key Lock |

Key Lock |

FT-12 Technical Manual, Rev. 1.35 November 2010 |

Page 12 of 44 |

5.2Keypad

The meaning of the front panel keys and the key functions are:

FT-12 |

Meaning |

Power On/Off: This key is used for turning the instrument on or off. To switch off the key must be pressed and hold at least for 2 seconds. There is no On/Off key on panel type housings.

Function : This key is used in combination with other keys to enter any function or to quit without saving.

Info: This key is being used to view Total and CN information. To toggle between these infos you have to press this key repeatedly and finally you will return to weighing mode again. To clear the total weight, you have to press the <Clear> key while the total value is seen on the display. [All C ] will appear on the display. You can confirm the deletion by pressing <Enter> or cancel by pressing the <F> key.

High Resolution: By pressing this key the weight value will be shown with a higher resolution for a short period.

Manual Tare: Pressing this key tares the scale and gets into the Net mode.

Manual Zero: In Gross mode, if the scale doesn’t show zero while there is no load on the pan, you can zero the scale by pressing this key.

Clear: Pressing this key clears the tare and the scale and returns to Gross mode.

Print: By pressing this key weight data and other information depending on the instrument setup are sent to a printer or a PC via serial port.

ID1, ID2 : These keys are used for entering new ID codes or with <F> key for calling IDs from the memory. To enter a new ID, you have to press one of the ID keys (ID1 or ID2), then enter the value via numerical keypad and confirm with <Enter>. You can cancel the ID entry and return to the weighing mode by pressing the <F> key.

Numerical Keypads: These keys are used for entering numerical values in setup mode.

Preset Tare: After pressing this key you can manually enter a tare value via numerical key pad. After confirming with <Enter> key the indicator tares the scale with this value. If you do not want to change this value, quit with <F> key.

Setpoint: These keys are being used to view or to enter setpoint values.

Gross/Net: This key is being used to see the gross weight value without clearing the tare value while working in Net mode.

Label No: After pressing this key, first [CN ] message appears on the display then you can see the CN no. By pressing the <F> key or after a while automatically it returns to weighing mode.

Memory: This key is used for data entry to ID, PT and setpoint memories.

Numerische Tasten: Eingabe von numerischen Parameterwerten bei der Konfiguration.

Reset: This key is used to reset the process in Filling, Peak hold and Dynamic mode.

Enter: This key is used for confirming an entered value and to get to the next parameter in setup mode. This key is also used to start the process in Filling, Peak hold and Dynamic modes.

5.3Key lock

The instrument has the capability to lock the keys to avoid unauthorized person’s interference. You can activate or deactivate this function by pressing the <F> and <Key Lock> keys sequentially. The LED with the key sign (below the display) indicates the keys are locked.

FT-12 Technical Manual, Rev. 1.35 November 2010 |

Page 13 of 44 |

6 SETUP AND CALIBRATION

6.1Basics

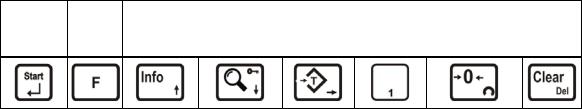

6.1.1 Basic Setup Keys on the Frontplate

The symbols located on the lower right corner of each key indicate the function of the keys in the setup menu. The basic meanings of these keys are given in the table below.

Exit Enter without

saving

Stepping |

Stepping |

Changing |

Entering |

Changing the |

Clear |

forwards to |

backwards to |

the |

value or |

||

the next |

the previous |

the digit |

parameter |

increasing the |

(delete) |

parameter |

parameter |

|

value |

flashing digit |

|

If you use a PC the Flintec IndFace software can be used for the setup and the calibration of FT-12.

6.1.2 Entering the Setup and Calibration Menu

To enter the Setup and Calibration Menu: Press <F> and <Info> keys sequentially First [FunC ] and then [PASSWr ] prompts will be displayed sequentially.

Here you can enter the parameter block by using:

the service password: |

Press <Zero> and <Info> and <Enter> |

or the operator password: |

Press <Tare> and <Enter> |

The calibration jumper (see chapter 4.1) should be short circuit to change the legal metrological parameters in the service mode (there is black box on the top right corner of the grey coloured boxes in the calibration menu flowcharts, see Appendix 1).

The Setup and Calibration menu consists of main blocks which are displayed as [X-- ] and sub-blocks.

By using < > and < > keys you can reach previous or next main blocks. After reaching the desired main block you can get in by pressing the <Enter> key. As you enter the block you will reach the first sub-block in that main block. The sub-block address will be seen on the display as [X0- ].

You can also search between the sub-blocks by using < > and < > keys and reach the first parameter of the displayed sub-block by pressing the <Enter> key. The number of the parameter is displayed as [XY0 ]. Again

you can search between parameters by < > and < > keys. FT-12 has numerical keys for entering parameter values.

6.1.3 Exiting the Setup and Calibration Menu

Whatever parameter block you are in – if you press the <F> key, you will get out of the active sub-block and reach the next sub-block. If you press the <F> key again you will get out of the active block and reach the next main block. If you press the <F> key once again, the [SAvE ] message appears on the display.

Here you can press

the <Enter> key to save the changes into the memory or

you can press the <Tare> key to store the changes temporarily until the power goes off oryou can press the <F> key to abort any changes.

The [Waıt] message will be displayed for a few seconds and afterwards the weighing mode will restart automatically. Especially for legal metrological usage, please don’t forget to turn the power off and remove the calibration jumper before you start the operation.

FT-12 Technical Manual, Rev. 1.35 November 2010 |

Page 14 of 44 |

Loading...

Loading...