Weight Indicator

FT-11(D)

Technical Manual

For FT-11 Firmware Version 2.13 and higher

For FT-11D Firmware Version 2.06 and higher

Flintec GmbH

Bemannsbruch 9

74909 Meckesheim

GERMANY

www.flintec.com

Table of Contents:

1. Safety Instructions .....................................................................................................................................4

2. Declaration of Conformity..........................................................................................................................5

3. Overview......................................................................................................................................................6

3.1 Key Features.............................................................................................................................................6

3.2 Available Options and Accessoires...........................................................................................................6

3.3 Technical Specifications............................................................................................................................7

3.4 Housing Dimensions .................................................................................................................................8

3.4.1 Desk Type Housing ...........................................................................................................................................8

3.4.2 Stainless Steel Housing ....................................................................................................................................8

3.4.3 Panel Type Housing (for FT-11 only) ................................................................................................................9

4. Installation and Commissioning .............................................................................................................10

4.1 Mechanical Installation............................................................................................................................10

4.1.1. Jumpers...........................................................................................................................................................10

4.2. Electrical Connections.............................................................................................................................10

4.2.1. Power Supply and Grounding..........................................................................................................................10

4.2.2. Standard Load Cell Connection (for FT-11 only) .............................................................................................11

4.2.3. Digital Load Cell Connection (for FT-11D only)...............................................................................................11

4.3. Commissioning........................................................................................................................................11

5. Front Panel and Keypad...........................................................................................................................12

5.1. Weight Display and Status LEDs ............................................................................................................12

5.2. Keypad ....................................................................................................................................................13

5.3. Key lock...................................................................................................................................................13

6. Setup and Calibration...............................................................................................................................14

6.1. Basics......................................................................................................................................................14

6.1.1. Basic Setup Keys on the Frontplate ................................................................................................................14

6.1.2. Entering the Setup and Calibration Menu........................................................................................................14

6.1.3. Exiting the Setup and Calibration Menu ..........................................................................................................14

6.2. Defining the Digital Load cells (for FT-11D only) ....................................................................................15

6.2.1. Digital Load Cell Addressing ...........................................................................................................................15

6.2.2. Eccentricity Adjustment ...................................................................................................................................16

6.3. Configuration Parameters .......................................................................................................................17

6.4. Scale Parameters....................................................................................................................................17

6.5. Scale Calibration .....................................................................................................................................19

7. Alibi Memory and Legal Metrological Records .....................................................................................21

8. Communication.........................................................................................................................................22

8.1. Overview about Communication .............................................................................................................22

8.2. Serial Interface and Printer .....................................................................................................................22

8.2.1. Standard Serial Interface Connector (RS232C) ..............................................................................................22

8.2.2. Optional Serial Interface Connector (RS232C, RS485, 20 mA TTY)...............................................................22

8.2.3. Continuous Output Mode ................................................................................................................................23

8.2.4. Host Mode (for FT-11 only) .............................................................................................................................23

8.2.5. Print Mode.......................................................................................................................................................23

8.2.6. Setup...............................................................................................................................................................24

8.3. Ethernet Option (for FT-11 only) .............................................................................................................26

8.3.1. Electrical Connections.....................................................................................................................................26

8.3.2. Setup...............................................................................................................................................................26

8.3.3. Data Structure .................................................................................................................................................28

8.4. Profibus Option (for FT-11 only)..............................................................................................................29

8.4.1. Electrical Connections.....................................................................................................................................29

8.4.2. Setup...............................................................................................................................................................29

8.4.3. Data Structure .................................................................................................................................................29

FT-11(D) Technical Manual, Rev. 1.35 November 2010

Page 2 of 52

8.5.

ProfiNet Option (for FT-11 only)..............................................................................................................30

8.5.1. Electrical Connections.....................................................................................................................................30

8.5.2. Setup...............................................................................................................................................................30

8.5.3. Data Structure .................................................................................................................................................30

8.6. CANopen Option (for FT-11 only) ...........................................................................................................31

8.6.1. Electrical Connections.....................................................................................................................................31

8.6.2. Setup...............................................................................................................................................................31

8.6.3. Data Structure .................................................................................................................................................31

9. Other I/O Options......................................................................................................................................32

9.1. Analogue Output Option (for FT-11 only)................................................................................................32

9.1.1. Electrical Connections.....................................................................................................................................32

9.1.2. Setup...............................................................................................................................................................32

9.2. Digital I/O Option.....................................................................................................................................33

9.2.1. Electrical Connections.....................................................................................................................................33

9.2.2. Setup...............................................................................................................................................................33

9.2.3. Entering Setpoints ...........................................................................................................................................34

9.3. Binary Output Option...............................................................................................................................34

10. Diagnostics ...............................................................................................................................................35

Appendix 1: Setup and Calibration Menus......................................................................................................36

Appendix 2: Continues Output Mode Data Structure.....................................................................................38

Appendix 3: Host Mode Data Structure............................................................................................................39

Appendix 4: Modbus RTU Data Structure........................................................................................................42

Appendix 5: Profibus DP / ProfiNet Data Structure (FT-11 only)...................................................................45

Appendix 6: CANopen Data Structure (for FT-11 only) ..................................................................................47

Appendix 7: Error Table.....................................................................................................................................49

Appendix 8: Parameter’s Default Table............................................................................................................50

Appendix 9: Calibration Table...........................................................................................................................52

FT-11(D) Technical Manual, Rev. 1.35 November 2010

Page 3 of 52

RIGHTS AND LIABILITIES

All rights reserved.

No part of this publication may be reproduced, stored in a retrieval system, or transmitted in any form or by any

means, mechanical, photocopying, recording, or otherwise, without the prior written permission of Flintec GmbH

No patent liability is assumed with respect to the use of the information contained herein. While every

precaution has been taken in the preparation of this book, FLINTEC assumes no responsibility for errors or

omissions. Neither is any liability assumed for damages resulting from the use of the information contained

herein.

The information herein is believed to be both accurate and reliable. FLINTEC, however, would be obliged to be

informed if any errors occur. FLINTEC cannot accept any liability for direct or indirect damages resulting from

the use of this manual.

FLINTEC reserves the right to revise this manual and alter its content without notification at any time.

Neither FLINTEC nor its affiliates shall be liable to the purchaser of this product or third parties for damages,

losses, costs, or expenses incurred by purchaser or third parties as a result of: accident, misuse, or abuse of

this product or unauthorized modifications, repairs, or alterations to this product, or failure to strictly comply with

FLINTEC operating and maintenance instructions.

FLINTEC shall not be liable against any damages or problems arising from the use of any options or any

consumable products other than those designated as Original FLINTEC Products.

NOTICE: The contents of this manual are subject to change without notice.

Copyright © 2008 – 2010 by Flintec GmbH, 74909 Meckesheim, Bemannsbruch 9, Germany

1. Safety Instructions

CAUTION READ this manual BEFORE operating or servicing this equipment. FOLLOW

these instructions carefully. SAVE this manual for future reference. DO NOT allow untrained

personnel to operate, clean, inspect, maintain, service, or tamper with this equipment.

ALWAYS DISCONNECT this equipment from the power source before cleaning or performing

maintenance. CALL FLINTEC ENGINEERING for parts, information, and service.

WARNING ONLY PERMIT QUALIFIED PERSONNEL TO SERVICE THIS EQUIPMENT.

EXERCISE CARE WHEN MAKING CHECKS, TESTS AND ADJUSTMENTS THAT MUST BE

MADE WITH POWER ON. FAILING TO OBSERVE THESE PRECAUTIONS CAN RESULT

IN BODILY HARM.

WARNING FOR CONTINUED PROTECTION AGAINST SHOCK HAZARD CONNECT

TO PROPERLY GROUNDED OUTLET ONLY. DO NOT REMOVE THE GROUND PRONG.

WARNING DISCONNECT ALL POWER TO THIS UNIT BEFORE REMOVING THE

FUSE OR SERVICING.

WARNING BEFORE CONNECTING/DISCONNECTING ANY INTERNAL ELECTRONIC

COMPONENTS OR INTERCONNECTING WIRING BETWEEN ELECTRONIC EQUIPMENT

ALWAYS REMOVE POWER AND WAIT AT LEAST THIRTY (30) SECONDS BEFORE ANY

CONNECTIONS OR DISCONNECTIONS ARE MADE. FAILURE TO OBSERVE THESE

PRECAUTIONS COULD RESULT IN DAMAGE TO OR DESTRUCTION OF THE

EQUIPMENT OR BODILY HARM.

CAUTION OBSERVE PRECAUTIONS FOR HANDLING ELECTROSTATIC SENSITIVE

DEVICES.

FT-11(D) Technical Manual, Rev. 1.35 November 2010

Page 4 of 52

2. Declaration of Conformity

EG-Konformitätserklärung

0

Monat/Jahr: month/year: 07/2010

Hersteller: Manufacturer: Flintec GmbH

Anschrift: Address:

Produktbezeichnung: Product name: FT-11 Weight Indicator

Das bezeichnete Produkt stimmt mit folgenden Vorschriften der Europäischen Richtlinien überein:

This product confirms with the following re gula tions o f the Directive s of the European Community

Richtlinie 2004/108/EG des Europäischen

Parlaments und des Rates vom 15. Dezember 2004

zur Angleichung der Rechtsvorschriften der

Mitgliedstaaten über die elektromagnetische

Verträglichkeit und zur Aufhebung der Richtlinie

89/336/EWG

Richtlinie 2006/95/EG Niederspannungs-Richtlinie

EC-Declaration of Conformity

Bemannsbruch 9

D-74909 Meckesheim

Deutschland / Germany

FT-11D Digital Weight Indicator

Directive 2004/108/EC of the European Parliament and of the

Council of 15th December 2004 on the approximation of the

laws of the Member States relating to electromagnetic

compatibility and repealing Directive 89/336/EEC

Directive 2006/95/EC Low Voltage Directive

Die Absicherung aller produktspezifischen

Qualitätsmerkmale erfolgt auf Basis eines zertifizierten

Qualitätsmanagement-Systems nach DIN ISO 9001.

Diese Erklärung bescheinigt die Übereinstimmung mit

den genannten Richtlinien, beinhaltet jedoch keine

Zusicherung von Eigenschaften.

Folgende Normen werden zum Nachweis der Übereinstimmung mit den Richtlinien eingehalten:

As a proof of conformity with the directives following standards are fulfilled:

EN 61326-1

EN 60950-1

Elektrische Mess-, Steuer-, Regel- und Laborgeräte - EMV-Anforderungen - Teil 1: Allgemeine

Anforderungen (IEC 61326-1:2005)

Electrical equipment for measurement, control and laboratory use - EMC requirements - Part 1: General

requirements (IEC 61326-1:2005)

Einrichtungen der Informationstechnik - Sicherheit - Teil 1: Allgemeine Anforderungen (IEC 609501:2005, modifiziert);

Information technology equipment - Safety - Part 1: General requirements (IEC 60950-1:2005 modified)

All product-related features are assured by a quality

system in accordance with ISO 9001.

This declaration certifies the conformity with the listed

directives, but it is no promise of characteristics.

FT-11(D) Technical Manual, Rev. 1.35 November 2010

Page 5 of 52

3. Overview

The type FT-11(D) weight indicator is an economic and powerful state-of-the-art instrument. The accurate and

versatile instrument is available in different housings, meeting the industries demand for various environmental

conditions. FT-11(D) is approved by Weights & Measures Authorities for use in Accuracy Class III applications

with up to 10 000 intervals according to OIML R76. It has a large 6 digit LED weight display (red, 20 mm or 14

mm high) with weight status information. With a variety of interface options the FT-11(D) weight indicators are

the perfect fit to weighing systems and process control systems.

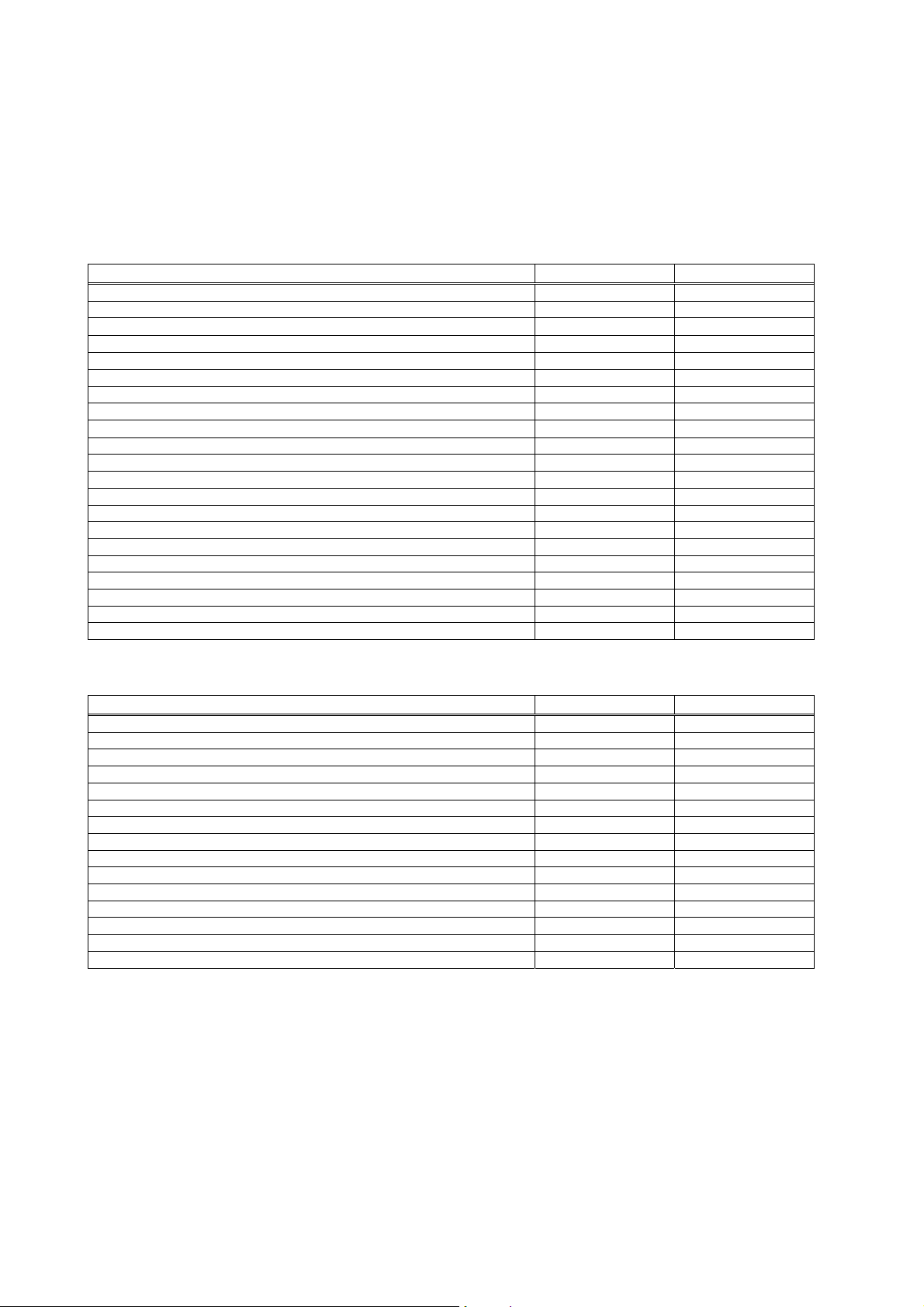

3.1 Key Features

FT-11D FT-11

EU Type approved for 10 000 intervals Yes Yes

Single or dual range Yes Yes

Approved sensitivity 0.4 V/e

High internal resolution up to 8 000 000 counts Yes Yes

Display resolution up to 60 000 counts Yes Yes

Maximum conversion rate of 100/s Yes

Adaptive digital filter for fast and stable reading Yes Yes

High resolution display mode Yes Yes

Up to 6 load cells (350 ) or 18 load cells (1100 )

Up to 10 digital load cells (DLC); 16 if externally powered Yes

Automatic eccentricity adjustment Yes

Realtime clock No No

Standard Serial interface RS232C Yes Yes

Integrated AC power supply Yes Yes

Zeroing with one button & Taring with one button Yes Yes

Auto-zero tracking and auto-zero at power-up Yes Yes

Motion detection Yes Yes

Printout in different formats incl. header and footer Yes Yes

Isolated digital inputs / outputs Option Option

Setpoint monitoring (3 setpoints, digital I/O required) Yes Yes

Key lock option to prevent unauthorized access Yes Yes

Yes

Yes

3.2 Available Options and Accessoires

FT-11D FT-11

Alibi memory for up to 149 764 weighing results Yes Yes

Additional serial interface RS232C Yes Yes

Additional serial interface RS232C / 20 mA TTY CL / RS485 Yes* Yes*

Modbus RTU No Yes

Ethernet TCP/IP and Modbus RTU over Ethernet No Yes

Profibus DP-V0 & DP-V1 No Yes

ProfiNet No Yes

CANopen No Yes

Analogue output 0 – 10 V and 4 – 20 mA No Yes

Binary data output (17-bit code) No Yes

Digital inputs / outputs 3x / 3x 3x / 3x

12 V DC (12…17 V DC) power inlet No Yes

24 V DC (20…27 V DC) power inlet No Yes

Rechargeable battery (for 230 V AC version only) No Yes

Flintec IndFace Software No Yes

* 20 mA TTY CL not for stainless steel housing

FT-11(D) Technical Manual, Rev. 1.35 November 2010

Page 6 of 52

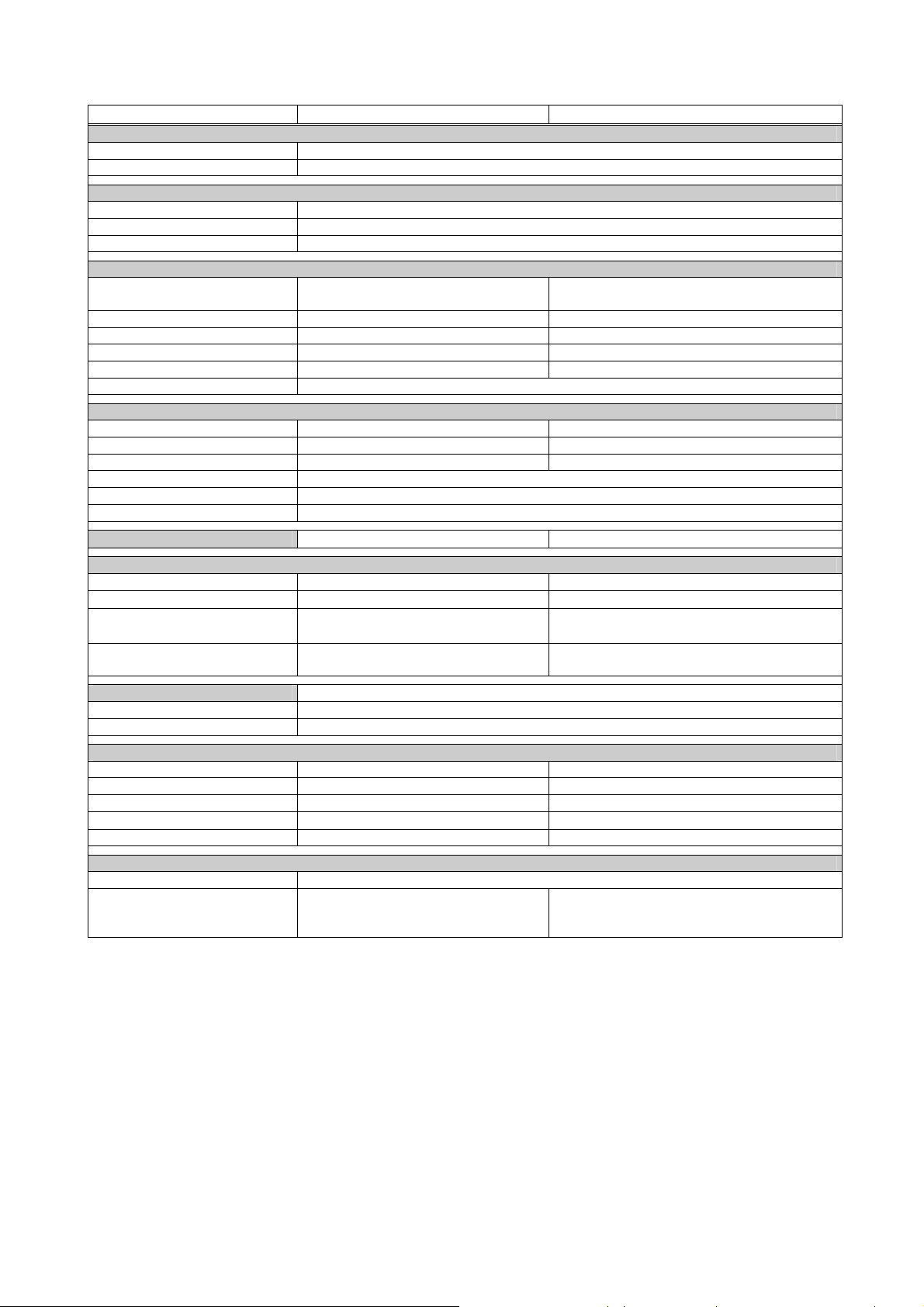

3.3 Technical Specifications

Accuracy

Accuracy class: III

EU Type approved: 10 000 intervals (single range); 2x 6 000 intervals (dual range)

Display and Keyboard

Display: 6 digits, 7 segments, LED red, 20 mm high (Panel type 14 mm high)

Display update rate: 250 ms

Keyboard: 8-keys; membran with tactile feedback

A/D Converter

A/D converter type:

Conversion rate: Max. 100 measurement values per second

Input sensitivity: 0.4 V/e (approved), 0.1 V/d (non approved)

Analogue input range: 0 to 20 mV

Internal resolution: Up to 8 000 000 counts

Display resolution: Up to 60 000 counts

Scale Calibration and Functions

Calibration: By application weights By application weights or in mV/V (eCal)

Corner adjustment: Automatic Only externally

Digital filter: 5 step adjustable 10 step adjustable

Weighing functions: Tare, zero, auto zero tracking, motion detection, auto zero at power up

Programmable setpoints: 3 setpoints, (needs digital I/O option)

Alibi memory: Optionally available: 74 880 records or 149 760 records

Linearity:

Load cells

Communication & protocol: RS485, compatible to RC3D

Excitation: 12 V DC, max. 450 mA

Number of load cells:

Connection:

Communication:

Continuous mode update rate: 100 ms

Option board update rate: 40 ms

Power supply:

200...240 V AC , 50/60 Hz Yes Yes

12...17 V DC, max. 12 VA No Optionally

20...27 V DC, max. 12 VA No Optionally

Battery runtime:

Battery charging time: 6 h

Environment and Enclosure

Operation temperature: -10 °C to +40 °C legal for trade; max. 85% RH, non-condensing

Enclosure

Up to 10 (directly powered) or

up to 16 (externally powered)

4-wire technique, 2 wires for digital

interface and 2 wires for power supply

Standard serial interface RS232C; 1 200 to 57 600 baud; programmable

Aluminium cast desk type (IP30) or

FT-11D FT-11

24 bit Delta-Sigma ratiometric

with integral analog and digital filters

stainless steel (IP65)

Within 0.0015% FS, 2 ppm/°C

5 V DC at 58...1200 max. 100 mA

Up to 6 load cells (350 ) or

18 load cells (1 100 ) connected in parallel

4- or 6-wire technique. Cable length is

274 m/mm² for 6-wire connection

5 h (with 93 LC) to 7 h (with 410 LC)

Aluminium cast desk type (IP30) or

panel type (front panel IP65) or

stainless steel (IP65)

FT-11(D) Technical Manual, Rev. 1.35 November 2010

Page 7 of 52

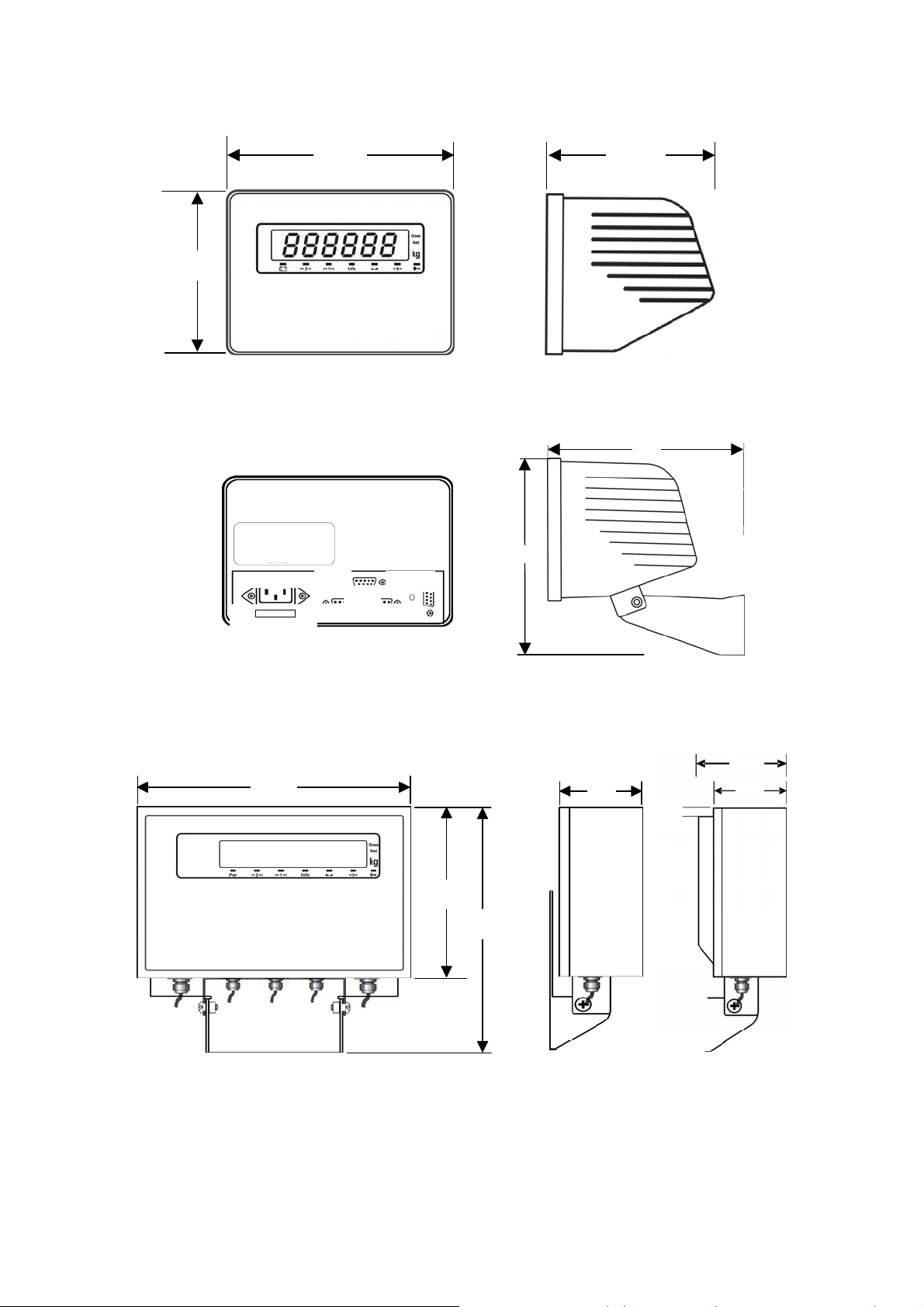

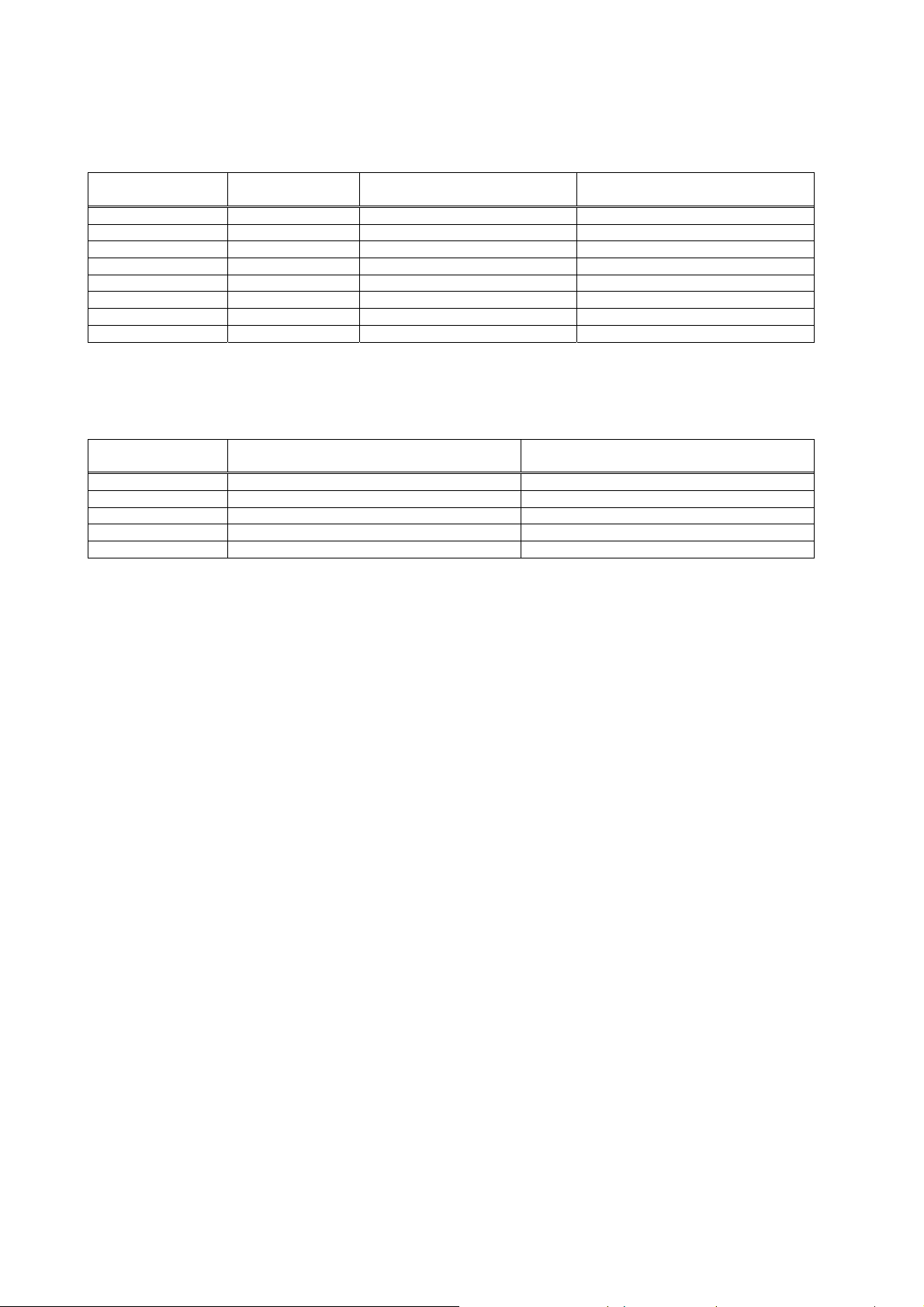

3.4 Housing Dimensions

3.4.1 Desk Type Housing

140

Desk type front view Desk type side view

RS232

OPTIO

S/N

Desk type rear view Dimensions of Desk type housing with wall mount kit

155195

187

179

LOAD CELL

3.4.2 Stainless Steel Housing

220

220

220

Stainless steel housing front view Stainless steel housing side view

160

160

160

70

70

15

15

15

230

230

230

100 mm deep with big backplane option

100

100

100

70

70

70

FT-11(D) Technical Manual, Rev. 1.35 November 2010

Page 8 of 52

3.4.3 Panel Type Housing (for FT-11 only)

90

Panel type front view Panel type side view

174

5,5

5,5

5,5

69

69

69

175

144

144

144

80

80

80

68

9

9

9

164

164

164

Sticker

Sticker

5, mounting with 4x M4

Panel type rear view The hole dimensions for mounting on a panel

FT-11(D) Technical Manual, Rev. 1.35 November 2010

Page 9 of 52

4. Installation and Commissioning

PRECAUTION: Please read this manual carefully before energizing the indicator. Perform the commissioning

operation according the procedure given here. Use trained personnel for cleaning, commissioning, checking and

service of the indicator. The interference of untrained personnel may cause some unwanted damages or injures.

Note: In this manual the term “Digital Load Cell“ will be refered to “DLC“.

4.1 Mechanical Installation

First of all please determine the place where your indicator can operate safely. This place should be clean, not

getting direct sun light if possible, with a temperature between -10 ºC and +40 ºC, humidity not exceeding 85%

non-condensing. Take care to the housing dimensions and the suggested panel hole dimensions given in

chapter 3.4. All the cables should be installed safely to avoid mechanical damages.

To avoid electrical noise protect your indicator which has very low input signal level from the equipment that

produces electrical noise, especially in panel mounting.

4.1.1. Jumpers

There are three jumpers on the instrument’s main board/weighing board for calibration and for switching on/off.

To change the position of this jumpers, open the housing and perform the necessary changes before energizing

the indicator.

Figure 4.1 FT-11(D) Main board

J8 On/Off Switch

(always short circuit at the Panel type)

J2 Calibration

(short circuit for calibration)

Only for FT-11(D) & FT-12

J17 short circuit for on/off key function

4.2. Electrical Connections

4.2.1. Power Supply and Grounding

FT-11(D) is available with 230 V AC power supply or 24 V DC or 12 V DC power inlet. The 230 V AC indicators

are supplied with a power cable; the DC indicators are supplied with a special connector for the power inlet.

Prepare your power voltage according to your instrument’s power inlet. The DC connector pin configuration can

be found in Figure 4.2 below.

Definition

12 V / 24 V 1 3

0 V 2 2

Housing Gnd 3 1

Desk / Panel

The quality of the instrument’s ground will determine the accuracy and the safety of your indicator. A poor

ground can result in an unsafe condition if an electrical short cuircuit happens. A good ground connection is

needed to minimize extraneous electrical noise pulses. It is important that the instrument does not share power

lines with noise-generating equipment such as heavy load switching, motor control equipments, inductive loads,

etc. If the condition of the power line in the plant is bad, prepare a special power line and grounding.

If you have to service the indicator, turn off the power and wait at least for 30 seconds before interfering.

All connectors are at the rear side of the housings of desk and panel types. The stainless steel housings must

be opened to make the required connections. These connections must be done as described below.

Figure 4.2 The pin layout of the DC DC connector

for desk and panel type

Pin no.

for stainless steel housing

Pin no.

FT-11(D) Technical Manual, Rev. 1.35 November 2010

Page 10 of 52

4.2.2. Standard Load Cell Connection (for FT-11 only)

The load cell wiring should be made carefully before energizing to avoid damages to the weight indicator and

the load cells. The input resistance of the load cells that you want to connect should be more than 58 .

The sense pins of the instrument should be connected. In 4-wire installations the sense and excitation pins with

the same polarity should be short circuited at the connector side.

6-wire Load Cell

Connection

+ Excitation + Excitation 1 1

+ Sense + Excitation 2 2

Shield Shield 3 4

- Sense - Excitation 4 6

- Excitation - Excitation 5 7

+ Signal + Signal 7 3

- Signal - Signal 8 5

Shield Shield Connector body 4

4-wire Load Cell

Connection

Pin no. for desk type & panel

type (D-Sub, 9-pin, female)

Pin no. for stainless steel

housing (J12 connector)

4.2.3. Digital Load Cell Connection (for FT-11D only)

The signal cable between the instrument and the junction box must be suitable for high speed RS485. The

cable must have a common shield. Please also take care for the correct termination of the RS485 bus (see also

manual of type KPFD junction box).

Definition

+ Power 5 5

- Power 3 6

COM A 9 2

COM B 7 3

Shielding Connector body 4

Pin no. for desk type housing

(D-Sub, 9-pin, female)

Pin no. for stainless steel housing

(J12 connector)

4.3. Commissioning

After making the required installations and connections to your indicator, turn the power on and perform

following steps:

Get familiar with the instrument’s setup mode (see chapter 6.1)

For FT-11D only: Define the digital load cells (see chapter 6.2)

Define the configuration parameters (see chapter 6.3)*

Define the scale parameters (see chapter 6.4)

Calibrate the scale (see chapter 6.5)

* Note: Most of the parameters can be skipped for later setup. Please take care for the parameters which may

be locked by the J2 calibration jumper in legal for trade applications (see Appendix 1: Setup and Calibration

Menu of the instrument).

If you want to use the Flintec IndFace Software (for FT-11 only) then you have to set up the instrument’s

standard serial interface to host mode (see chapter 9.2) before you adjust all the configuration parameters.

After checking the performance of your weighing instrument you can begin to use the indicator.

If there are peripheral connections, first you should turn the power off; make the peripheral connections, perform

the required safety checks and energize the indicator. Then set the related parameters and check if the

peripheral devices are operating properly.

If required perform following additional steps:

Set up the serial interfaces (see chapter 8.2)

Printer setup (see chapter 8.2)

Set up other optional inputs and outputs (see chapter 8.3ff and 9)

FT-11(D) Technical Manual, Rev. 1.35 November 2010

Page 11 of 52

5. Front Panel and Keypad

5.1. Weight Display and Status LEDs

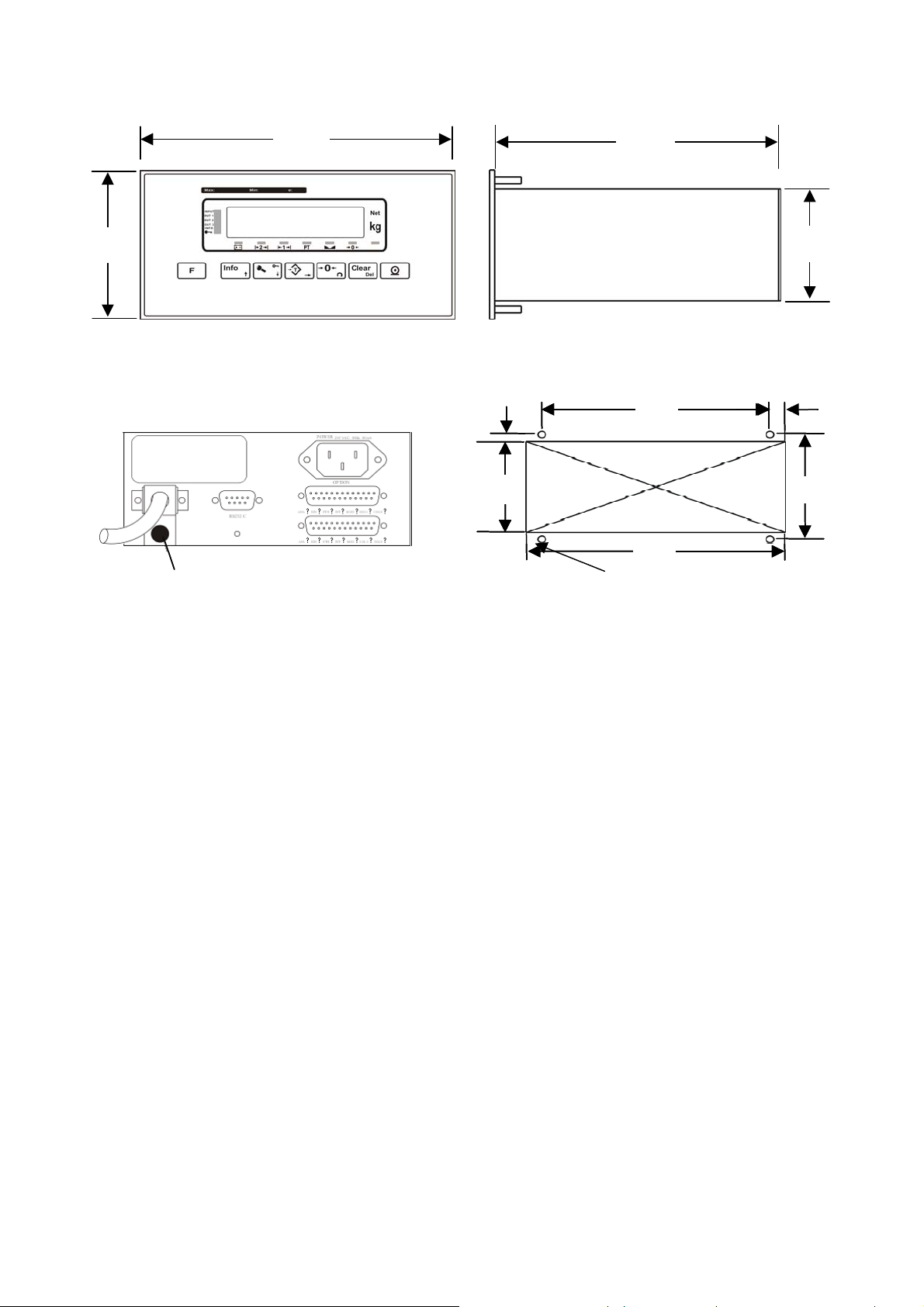

Figure 5.1 Front panel view of FT-11(D)

The weight display of FT-11(D) is a 6 digit LED with 14 mm or 20 mm height.

At the right side of the display there are three status LEDs for indicating “Gross”, “Net” and the standard unit

“kg”.

Below the weight display there are several status LEDs. The meanings of these are:

Status LEDs related to the weighing process

LED Meaning

Info: The instrument displays information different from the weight

Range: With multi range scales these LED indicates the current operating range. For single range scales

only the first range LED is lit.

Stable: The weight value on the display is stable

Center of zero: The weight is in the center of zero (see param. [203] in chap.6.4)

Key lock: is active

Power: This LED will flash in case of supply voltage decrease. If the voltage decreases too much the

indicator will automatically shut off.

FT-11(D) Technical Manual, Rev. 1.35 November 2010

Page 12 of 52

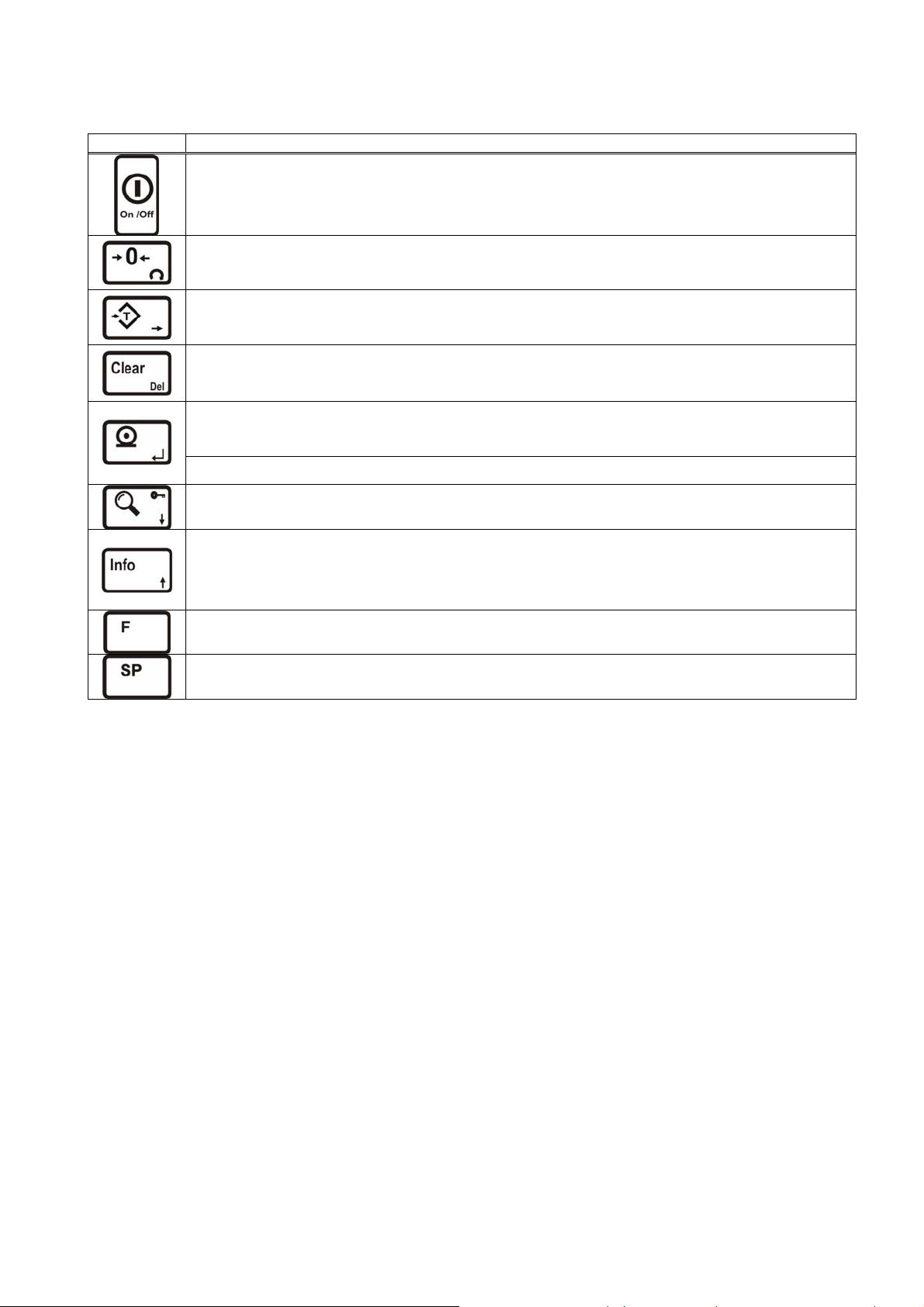

5.2. Keypad

The meaning of the front panel keys and the key functions are:

Key Meaning

Power On/Off: This key is used for turning the instrument on or off.

To switch off the key must be pressed and hold at least for 2 seconds.

There is no On/Off key on panel type housings.

Manual Zero: In Gross mode, if the scale doesn’t show zero while there is no load on the pan, you can

zero the scale by pressing this key.

Manual Tare: Pressing this key tares the scale and gets into the Net mode.

Clear: Pressing this key clears the tare and the scale and returns to Gross mode.

Print: By pressing this key weight data and other information depending on the instrument setup are sent

to a printer or a PC via serial port.

Enter: This key is used for confirming an entered value and to get to the next parameter in setup mode.

High Resolution: By pressing this key the weight value will be shown with a higher resolution for a short

period.

Info: This key is being used to view Total and CN information. To toggle between these infos you have to

press this key repeatedly and finally you will return to weighing mode again. To clear the total weight, you

have to press the <Clear> key while the total value is seen on the display. [All C ] will appear on the

display. You can confirm the deletion by pressing <Enter> or cancel by pressing the <F> key.

Function : This key is used in combination with other keys to enter any function or to quit without saving.

Setpoint: These keys are being used to view or to enter setpoint values.

5.3. Key lock

The instrument has the capability to lock the keys to avoid unauthorized person’s interference. You can activate

or deactivate this function by pressing the <F> and <Key Lock> keys sequentially. The LED with the key sign

(below the display) indicates the keys are locked.

For FT-11: The key(s) which would be locked are set in parameter [115].

FT-11(D) Technical Manual, Rev. 1.35 November 2010

Page 13 of 52

6. Setup and Calibration

6.1. Basics

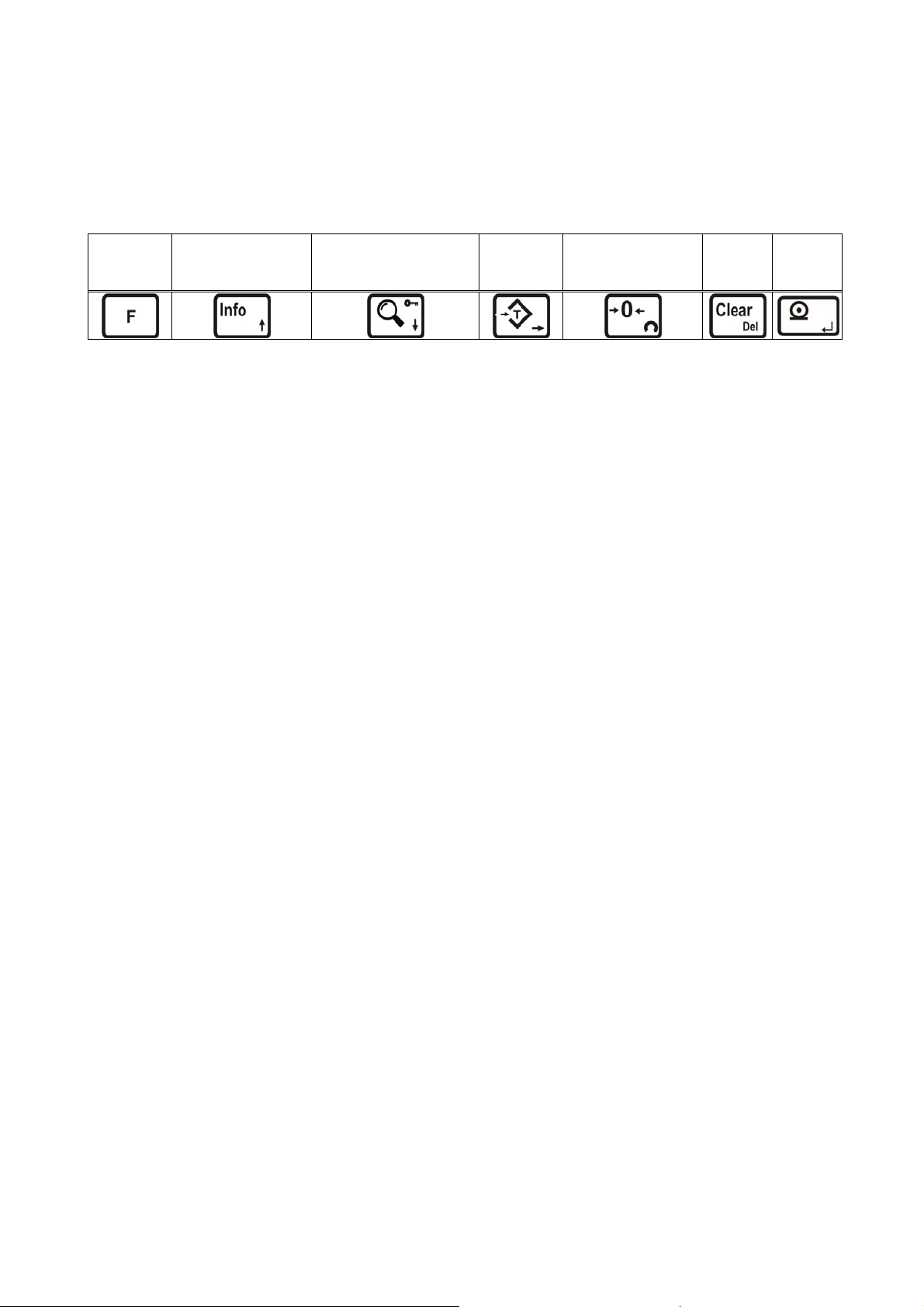

6.1.1. Basic Setup Keys on the Frontplate

The symbols located on the lower right corner of each key indicate the function of the keys in the setup menu.

The basic meanings of these keys are given in the table below.

Exit without

saving

Stepping forwards to

the next parameter

Stepping backwards to

the previous parameter

Changing

the digit

If you use a PC the Flintec IndFace software can be used for the setup and the calibration (for FT-11 only).

6.1.2. Entering the Setup and Calibration Menu

To enter the Setup and Calibration Menu: Press <F> and <Info> keys sequentially

First [FunC ] and then [PASSWr ] prompts will be displayed sequentially.

Here you can enter the parameter block by using:

the service password: Press <Zero> and <Info> and <Enter>

or the operator password: Press <Tare> and <Enter>

The calibration jumper (see chapter 4.1) should be short circuit to change the legal metrological parameters in

the service mode (there is black box on the top right corner of the grey coloured boxes in the calibration menu

flowcharts, see Appendix 1).

The Setup and Calibration menu consists of main blocks which are displayed as [X-- ] and sub-blocks.

By using <> and <> keys you can reach previous or next main blocks. After reaching the desired main block

you can get in by pressing the <Enter> key. As you enter the block you will reach the first sub-block in that main

block. The sub-block address will be seen on the display as [X0- ].

You can also search between the sub-blocks by using <> and <> keys and reach the first parameter of the

displayed sub-block by pressing the <Enter> key. The number of the parameter is displayed as [XY0 ]. Again

you can search between parameters by <> and <> keys.

For entering numerical values in the parameters press the <Tare> key to select the digit and press the <Zero>

key to change the value.

Changing the value

or increasing the

flashing digit

Clear

(delete)

Enter

6.1.3. Exiting the Setup and Calibration Menu

Whatever parameter block you are in – if you press the <F> key, you will get out of the active sub-block and

reach the next sub-block. If you press the <F> key again you will get out of the active block and reach the next

main block. If you press the <F> key once again, the [SAvE ] message appears on the display.

Here you can press

the <Enter> key to save the changes into the memory or

you can press the <Tare> key to store the changes temporarily until the power goes off or

you can press the <F> key to abort any changes.

The [Waıt] message will be displayed for a few seconds and afterwards the weighing mode will restart

automatically. Especially for legal metrological usage, please don’t forget to turn the power off and remove the

calibration jumper before you start the operation.

FT-11(D) Technical Manual, Rev. 1.35 November 2010

Page 14 of 52

6.2. Defining the Digital Load cells (for FT-11D only)

8

6.2.1. Digital Load Cell Addressing

The parameter group [22-] is used for defining and addressing the DLCs.

[22-] DLC Configuration Block

In this section the DLCs are introduced to the indicator.

[220 X] DLC Type

0 = RC3D This parameter must be set to “0” for type RC3D digital load cell.

[221 XX] Quantity of DLC

Enter the quantity of DLCs used in the scale. The quantity can be selected between 1 and 16.

[222 ] DLC Addressing

The following diagram shows the addressing principles of the DLCs in a weighbridge / truck scale. The

numbers in the diagram show the DLC addressing principle for easy eccentricity adjustment.

Entrance Exit

1

3

5

For addressing of DLCs, press the <Tare> key.

The messages [222 YY] and [ XXXXXX ] will be displayed alternately.

Here: “YY” DLC number /address

“X” Last 6 digits of the DLC’s serial number

If you press <Enter> the next load cell will be shown, the <F> key is used to return the parameter group

[20-].

You can enter the S/N, by pressing the <Tare> key. The serial numbering system of the indicator is 9

digits. First you will see the first 3 digits of the S/N. Enter this digits by pressing the <Tare> and <Zero>

keys. If the serial number of the DLC is less than 9 digits, the unused digits on the left must be set to “0”.

For example, if the serial number is “1234567” then “001234567” must be entered. After entering the first

3 digits, the following 6 digits are entered by pressing <Enter>.

Important hint: When addressing the connected Type RC3D load cells, the load cells should always be

loaded. If the load cells are unloaded, FT-11D may show a DLC input error.

After entering all serial numbers sequentialy, the display goes to parameter group [20-]. This means all

load cells are addressed and ready to work in the scale.

For replacing any load cell, you have to re-address the new load cell in parameter [222]. After installing

the new load cell, turn on the indicator. Enter parameter [222] and then access the load cell address of

the replaced DLC. Enter the serial number of the new load cell as described in the previous paragraph.

Note: It is always assumed that the RS485 load cell bus system is correctly terminated, please see the

manual of the installed junction box.

Figure 6.1 The addressing principles of the DLC’s in a weighbridge / truck scale

2

4

6

7

9

10

FT-11(D) Technical Manual, Rev. 1.35 November 2010

Page 15 of 52

6.2.2. Eccentricity Adjustment

The eccentricity adjustment must be done in parameter group [32-] before the calibration of the scale. The

adjustment can be done for each load cell independently or for sectional pairs. The selection is done by

parameter [320]. After selection of the adjustment method , the adjustment is performed automatically as

described in parameter [321].

[32-] DLC Eccentricity Adjustment Block

In this parameter group the eccentricity correction is performed automatically or manually. This

adjustment must be performed automatically before calibration.

[320 X] Adjustment Method

The scale eccentricity can be adjusted in corners (each DLC individually) or in sectional pairs.

0 = Independent DLC (factory default) 1 = Sectional pair

[321 ] Auto Adjustment

After entering parameter [321] by pressing the <Tare> key, you will see [Zero CA] on the display. Unload

the scale and press the <Enter> key. Do not interfere the scale during the period the [Waıt] message is

displayed. Next the instrument will display [321 01]. Place a weight of at least 10% of the DLC capacity

as close as possible to the independent load cell or sectional pair 1. Then press <Enter>. After some

period [321 02] appears on the display. Apply the same load to the other places in sequence.

After loading all load cells / sections the message [322 ] will be shown on the display. This means the

eccentricity error correction is performed automatically.

[322 ] Manual Adjustment

If needed the eccentricity error can get modified manually. You can change the error correction

coefficients of the DLCs in this parameter. For entering this parameter press the <Tare> key. You can

change the load cell number by the <Enter> key. For changing the coefficient of any DLC select the

number of the DLC and press the <Tare> key to view and edit the coefficient. Use <Tare> and <Zero>

keys for changing the value and then press the <Enter> key.

To exit this parameter press the <F> key and save the changes you applied by pressing <Enter>. The

<F> key is used to quit without saving the manual corrections.

[323 X] Service mode: Set Shift Coefficients manually to 1

This parameter allows you to view the weighbridge’s performance with disabled eccentricity correction for

service purposes. Using this function does not change any stored coefficient but all coefficients are

“temporarily” set to value 1.

0 = Normal operation (factory default) 1 = Service mode

Attention: After the eccentricity adjustment a scale calibration has to be done.

FT-11(D) Technical Manual, Rev. 1.35 November 2010

Page 16 of 52

6.3. Configuration Parameters

[1--] Configuration Block

[11-] Start Up

[111 X] Auto Power Off

0 : Auto power off disabled (default) 1 : Power off after 3 minutes of stability or no key function

2 : Power off after 10 minutes of stability or no key function

[112 X] Store Tare at Power Off

0 : Disabled (factory default) 1 : Enabled

[113 X] Auto Clear Tare

0 : Disabled (factory default) 1 : The scale returns to gross mode after unloading

[115 ] Key lock (for FT-11 only)

[ ABCDE] When the key lock function is activated, all key(s) set to “1” in this parameter are

locked.

A : On/Off B : Setpoint C : Zeroing D : Taring / Clear E : Print

[12-] Filter

In this block the proper filter values according to the operating conditions can be entered. One of the most

important features of the indicator is viewing the filter characteristics on the display and with the help of this

option, you can select the most suitable filter without leaving the setup mode.

[120 X ] Filter

For FT-11 the filter value can be set from 0 to 9, for FT-11D the value range is from 0 to 4. When you

enter this parameter and press the <Enter> key while [120 X] is shown on the display, the weight

variation can be seen on the display. The value of the filter can be changed by using the <> and <>

keys and the weight variation for each value is shown on the display. After finalising the filter selection

you can go to the next step by pressing the <F> key.

[14-] Entries

In this block you can enter the initial CN (consecutive number).

[142 ] Label No. (CN)

[ XXXXXX ] The desired value is entered via <Tare> and <Zero> keys and saved by pressing

<Enter>. If the number exceeds 65 535 it will automatically restart at 1.

6.4. Scale Parameters

[2--] Scale Block

The parameters related to the weighing operation are located here.

[20-] Set Up

[200 X] Approved

0 = No 1 = Yes

[201 X] Increased Indication

0 = by pressing key 1 = Always increased indication

[202 X] Power On Zero

This parameter setting controls if after power-on the scale will get automatically zeroed if the weight is in

the percentage of the zeroing range. If the weight is not in the zeroing range the display will show [E E E

] message until you press the <Enter>.

0 = disable 1 = ± 2% 2 = ± 10%

[203 X] Zeroing Range

0 = disable 1 = ± 2% 2 = ± 20%

FT-11(D) Technical Manual, Rev. 1.35 November 2010

Page 17 of 52

[204 X] Auto Zero Tracking

AZT automatically re-adjusts the scale to zero for compensating defined small deviations around the

centre of zero.

0 = disable 1 = ± 0,5e 2 = ± 1e 3 = ± 3e

[205 X] Tare

0 = Disabled 1 = Multi tare via key 2 = Tare via key in gross mode

[206 X] Motion Detector

This parameter defines the sensitivity level which will determine what is considered as stable.

0 = ± 0.3e 1= ± 0.5e 2= ± 1e 3= ± 2e 4 = No motion detector

[207 X] Tilt Switch (for FT-11 only)

The tilt switch is being used to prevent wrong weighing results in mobile scales due to the slope of the

floor. If this parameter is enabled the digital input 1 must be connected to the tilt switch.

0 = Disabled 1 = Normally Open contact 2 = Normally Closed contact

[208 X] Stability Time

This parameter defines the time period (up to 9.9 s) which will determine what is considered as stable.

[21-] Scale Build

The capacity and the resolution of the scale will be defined here.

[210 X] Scale Type

The capacity and resolution parameters will vary according to the selection here.

0 = Single Range 1 = Dual Range

You will reach the next parameter by pressing <Enter>. Please note that the following parameters will

vary according to this selection.

If single range has been selected:

[212 ] Capacity

Press the <Tare> key to reach this parameter.

[CAP ]

[ XXXXXX ]

[d ]

[ XXXXXX ]

The capacity of the scale will be entered here by <Tare> and <Zero> keys.

The value will be confirmed by pressing <Enter>.

Display resolution of the scale will be selected by <Zero> key.

The selection will be confirmed by pressing <Enter>.

If dual range has been selected:

[211 ] 1. Capacity

Press the <Tare> key to reach this parameter.

[CAP1 ]

[ XXXXXX ]

[d1 ]

[ XXXXXX ]

The capacity of the first weighing range (Select from Appendix 6) will be entered

here by <Tare> and <Zero> keys and confirmed with <Enter>.

Display resolution of the first weighing range will be selected by <Zero> key and

confirmed with <Enter>.

[212 ] 2. Capacity

Press the <Tare> key to reach this parameter.

[CAP2 ]

[ XXXXXX ]

[d2 ]

[ XXXXXX ]

Attention: After the scale parameters have been changed the scale has to be calibrated.

FT-11(D) Technical Manual, Rev. 1.35 November 2010

The capacity of the second weighing range (Select from Appendix 7) will be entered

here by <Tare> and <Zero> keys and confirmed with <Enter>.

Display resolution of the second weighing range will be selected by <Zero> key and

confirmed with <Enter>.

Page 18 of 52

6.5. Scale Calibration

[3--] Calibration Block

The calibration of the scale will be performed here.

[30-] Calibration

[300 ] Gravity

This parameter should be used in the scale that will be verified in two stages by gravity adjustment (in

legal metrologic applications). This parameter should not be touched in other applications.

If you enter a value in this parameter before calibration (as six decimal digits, e.g. enter “798564” for

“9.798564”), this value will be assumed as the reference gravity acceleration where the initial calibration

has been performed. After the initial calibration this parameter will be automatically set to “0”.

If the value of this parameter is “0” this means no gravity adjustment has been performed after the initial

calibration.

In the second stage of the verification the gravity acceleration of the place where the weighing indicator

will be used should be entered (as six decimal digits, e.g. enter “800065” for “9.800065”).

Exit setup by saving the changes without entering the calibration (parameter [301]).

[301 ] Calibration with Test Weights

Begin the calibration by pressing <Enter>.

Unload the scale when the displays shows [ZEro.CA] message and press <Enter>.

The display will show the [WAıt ] message during the zero calibration. In this period the scale must be

unloaded and stable.

Approximately 10 seconds later the display will show [LoAd ] and then [ XXXXXX ].

The value shown on the display is the weight that should be used for the span calibration. If the value of

the test weight which will be used is different from the value shown on the display, type the new value by

<Tare> and <Zero> keys, place the test weights on the scale and press <Enter>. Any test weight should

be at least 10% of the scale capacity or higher.

The display will show the [WAıt ] message during the span calibration. Approximately 10 seconds later

the display will show the [SAvE ] message. You can save the calibration by pressing <Enter> or quit

without saving by pressing the <F> key.

[31-] Adjustment

In this sub-block you can only perform zero adjustment or span adjustment without doing a full calibration.

[310 ] Zero Adjustment

This parameter is only used for refreshing the zero level of the scale to prevent wrong weighings due to

zero drifts. Begin the zero adjustment by pressing <Enter>. Unload the scale when the displays shows

the [ZEro.CA] message and press <Enter> again.

The display will show the [WAıt ] message during the zero adjustment. In this period the scale must be

unloaded and stable. Approximately 10 seconds later the display will show the [SAvE ] message. You can

confirm the “Save zero adjustment” by pressing <Enter> or cancel it by pressing the <F> key.

[311 ] Span Adjustment

This parameter lets you perform the span adjustment. By pressing the <Enter> key [XXXXXX] appears on

the display. The displayed value is the weight that should be used for the span adjustment. If the value of

the test weight that will be used is different from the value shown on the display, then type the new value

by <Tare> and <Zero> keys, place the test weights on the scale and press <Enter>.

The display will show the [WAıt ] message during the span adjustment. Approximately 10 seconds later

the display will show the [SAvE ] message. You can confirm the “Save span adjustment” by pressing

<Enter> or cancel it by pressing the <F> key.

[312 ] Span Adjustment Under Load (for FT-11 only)

This parameter is being used to perform span adjustment of a scale without lifting the load from it. This

operation is especially used for span adjustment of filled tanks. You can make span adjustment without

removing the load in the tank.

When you press the <Enter> key the [P.ZEro ] message appears on the display. This means the scale

will take the current load as a temporary zero. After getting ready for this level, which means temporary

zero adjustment, the <Enter> key should be pressed. The display will show the [WAıt ] message during

the temporary zero adjustment. After this step the display will show [LoAd ] for a certain period and then [

XXXXXX ]. The value shown on the display is the weight that should be used for the span adjustment. If

the value of the test weight which will be used is different from the value shown on the display, type the

FT-11(D) Technical Manual, Rev. 1.35 November 2010

Page 19 of 52

new value by <Tare> and <Zero> keys, place the test weight on the scale and press <Enter>. The display

will show the [WAıt ] message during the span adjustment under load. Approximately 10 seconds later

the display will show the [SAvE ] message. You can confirm the “Save span adjustment under load” by

pressing <Enter> or cancel it by pressing the <F> key.

[313 ] eCal (electronic calibration)

Warning: The scale capacity and the resolution must be entered before performing eCal.

This parameter allows to calibrate the scale without using test weights. Based on scale capacity, total

load cell capacity, load cell rated output and estimated preload FT-1x calculates the calibration

coefficients. If the conditions are convenient for zero calibration, you may perform automatic zero

adjustment instead of entering estimated preload.

For maximized eCal accuracy the A/D coefficients of the instrument are adjusted in the factory.

Press the <Tare> key to enter eCal.

[LC.CAP ]

[ XXXXXX ]

[LC.oUt ]

[ XXXXXX ]

[rt.oUt ]

[ZEr.AdJ]

[ XXXXXX ]

[PrE-Ld]

[ XXXXXX ]

[ SAvE ]

Enter the total load cell capacity in [kg] via <Tare> and <Zero> keys and press

<Enter> to go to the next step.

Example : If the scale uses 4 load cells with 1000 kg maximum capacity for each,

then enter 4000.

Enter load cell’s rated output in [mV/V] via <Tare> and <Zero> keys. If the scale

uses more than one load cell, then calculate the mean value of all load cells’ rated

output as indicated in their certificates. Press <Enter> to go to the next step.

Example: If the load cell’s rated outputs are LC1: 2.0010, LC2: 1.9998, LC3:1.9986

and LC4:2.0002, then the mean value will be

Mean LC output = ( 2.0010 + 1.9998 + 1.9986 + 2.0002 ) ÷ 4 = 1.9999 mV/V.

Enter load cell’s rated output in [counts] via <Tare> and <Zero> keys (200 000 is

default setting). Press <Enter> to go to the next step.

If the scale is empty and you want to make an automatic zero adjustment instead of

entering the estimated preload (see next step), press the <Enter> key.

When the message [Zero.CA] appears then press the <Enter> key for starting the

zero calibration. The display will show the [WAıt ] message during zero adjustment.

In this while the scale must be unloaded and stable. Approximately 10 seconds

later the display will prompt you to save the calibration by the [SAvE ] message

(see below). If the scale is not empty or you prefer to enter the estimated preload

value, press the the <> or <> key.

Enter the scale’s dead load value in [kg] by using <Tare> and <Zero> keys.

Press <Enter> to go to the next step.

Hint: Is the deadload not exactly known, then you should enter „0“ for this

parameter. After save and restart of the weighing function the following weighing

result is identical to the real deadload value of the scale. Note this value and repeat

the eCal procedure with a known deadload value.

Save this eCal calibration by pressing <Enter> OR

press the <F> key to quit without saving this eCal calibration.

Note: If you want to make a zero adjustment after entering the estimated preload value, empty the scale,

change the preload value to (estimated value + display value at zero load) or enter parameter 310 for

zero adjustment.

FT-11(D) Technical Manual, Rev. 1.35 November 2010

Page 20 of 52

7. Alibi Memory and Legal Metrological Records

If the alibi memory is installed and activated, the indicator keeps the latest 149 764 weighing records in this

memory. The recorded data can be viewed on the indicator’s display or exported via serial port.

To find a definite record you have to enter parameter [802]. After reaching the desired record, the recorded data

can be viewed in the display. If needed you can print this record together with the following 9 records by

pressing the <Print> key. If you press the <Print> key in parameter [803], all recorded data will be sent via serial

port. The <F> key cancels the print job.

Empty fields will be printed as “------“ , corrupted records as “xxxxx” . For the records for which weighing

results cannot be given, the message “no rec” will be shown on the display.

If the alibi memory is activated, the alibi record number is also found on the print out data.

After installing the alibi board or changing the main board “Error 41” or “Error 42” will be shown on the display

after power on because the activation of the alibi memory is required.

If the calibration jumper is short circuited, you can activate the alibi board by pressing the <Enter> key after

power on. Otherwise the alibi errors will disappear by pressing the <Enter> key, but you cannot export any data

(Error “43” will be shown after pressing the <Print> key ).

[8--] Metrological Data Block

The parameters about Metrological Registry are being entered in this section.

[80-] Legal Metrological Records

In this block edit the parameters with <> key and use the <Enter> key according to the parameter’s

description.

[800] Counter

This counter increases automatically by 1 after starting the setup mode with enabled calibration jumper

and service password. This counter cannot be changed manually.

[801] Alibi Memory)

0 = Disabled 1 = Enabled

[802] Finding any record from Alibi Memory

You can call any record from the Alibi Memory by <Tare> and <Zero> keys. If the <Print> key is pressed

while an alibi record is on the display, this and the 9 previous records will be printed.

[803] Print all Alibi Memory records

All data from the Alibi Memory can be printed by pressing the <Print> key. You can stop printing with the

<F> key.

[804] Alibi Info

You can get some basic information about the alibi memory board and the records by pressing the

<Print> key. These data are:

SN : Pin code of the alibi memory card

SA : The alibi record start number within this indicator

LA : The alibi record number of the next weighing with this indicator

CN : Calibration counter number

CS : Check sum status

AS : Capacity of the alibi memory

LD : Firmware date of the alibi memory

FT-11(D) Technical Manual, Rev. 1.35 November 2010

Page 21 of 52

8. Communication

8.1. Overview about Communication

Application Hardware channel

Data export to PC (non-approved);

Remote display;

Remote control with ASCII entries

(Z, T, C)*

IndFace-Software (FT-11 only);

Process control (PLC, DCS,

SCADA...)

Data export to PC (legal for trade

with alibi memory);

Output to printer;

Remote control with ASCII entries

(P, Z, T, C)*

Process control (PLC, DCS,

SCADA...)

* Z = Zero; T = Tare; C = Clear; P = Print

Option Profibus (for FT-11 only; see Chap. 8.4 + Appendix 5) Profibus DP

Option ProfiNet (for FT-11 only; see Chap. 8.5 + Appendix 5) ProfiNet

Option Serial Interface 3 (RS232C, RS485, 20 mA TTY)

Option CANopen (for FT-11 only, see Chap. 8.6 + App. 6) CANopen

Standard Serial Interface (RS232C)

Option Serial Interface 2 (RS232C)

Option Ethernet (for FT-11 only; see Chap. 8.3)

Option Serial Interface 2 (RS485)

Option Ethernet (for FT-11 only; see Chap. 8.3)

OR

OR

OR

OR

Operation

mode of the

interface

Continuous output

mode;

see Chap. 8.2.3

and Appendix 2

Host mode (for

FT-11 only);

see Chap. 8.2.4 &

Appendix 3

Print mode;

see Chap. 8.2.5

Modbus RTU (for

FT-11 only);

see Appendix 4

8.2. Serial Interface and Printer

The instrument has a standard serial port for connecting peripheral equipment.

The serial port is suitable for bi-directional communication. If you transmit ASCII codes of P, Z, T or C letters to

the serial port, the indicator will behave like the related keys have been pressed. If optional serial interfaces are

installed, only continuous data output can be programmed for more than one interface (see chapter 8.2.7 for

setup details).

8.2.1. Standard Serial Interface Connector (RS232C)

The instrument has a standard serial port for connecting to peripherals.

Standard Serial interface; Parameter group [00-]

Baudrate 1200, 2400, 4800, 9600, 19 200, 38 400 or 57 600 baud

Data format 8 bit no parity OR 7 bit even parity OR 7 bit odd parity

Start / Stop bit 1 start bit and 1stop bit

The connection of the standard RS232C of the instrument should be made as given in the table below.

Definition

TXD 2 3 3

RXD 3 4 2

GND 7 2 5

Shield Connector body 1

You have to connect each TXD (output) with RXD (input) at the other end.

Desk type housing, panel type

housing; Pin no. (D-Sub, 9-pin, male)

Stainless steel housing

Pin no. (J11 connector)

RS232C;

typical PC allocation

8.2.2. Optional Serial Interface Connector (RS232C, RS485, 20 mA TTY)

Additional serial interfaces can be added in addition to the standard RS232C port.

2nd Serial interface Optional RS232C; Parameter group [01-]

3nd Serial interface Optional RS232C / RS485 / 20 mA TTY current loop* (field changeable); Parameter group [02-]

* 20 mA TTY current loop not available with stainless steel housing

If parameter [012] is set to 2 (= hardware handshake), the second serial interface cannot be used as RS232C

port. Up to 32 instruments can be connected with enabled RS485 port.

FT-11(D) Technical Manual, Rev. 1.35 November 2010

Page 22 of 52

The pin configuration of the optional D-Sub 25-pin female connector is given below.

Parameter [012] Pin no. for stainless steel housing

is set to

“0” or “1”

is set to “2”

for desk and panel types

(D-Sub, 25-pin, female)

Pin no.

J10 connector

(Option 1)

JR1 / JR2 connector

(Option 2 or 3)

TxD1; Par. [01-] 2 8 15

RxD1; Par. [01-] 3 7 14

TxD2; Par. [02-] RTS1; Par. [01-] 4 3 10

RxD2; Par. [02-] CTS1; Par. [01-] 5 2 9

GND (RS 232C) 7 6-9 13

R-; Par. [02-] 8 Not used

R+; Par. [02-] 9 Not used

T+; Par. [02-] 10 Not used

+V; Par. [02-] 11 Not used

Termination (RS 485) 19 Not used

Termination (RS 485) 20 Not used

A; Par. [02-] 21 5 12

B; Par. [02-] 22 4 11

T-; Par. [02-] 24 Not used

+24V; 20 mA CL 25 Not used

Shield D25 body 1 1

The RS485 interface termination can be done by short circuiting pin no. 19 and 20 at the desk and panel type

enclosures or by jumper JP4 on the interface board within the stainless steel housing . These short circuits

terminate the line with an internal termination resistor of 100 .

25

11

20 mA CL ASCII interface connection:

The 20mA CL ASCII output is disabled by

default. For enabling this output the

10

connections should be made as given in figure

shown on the left.

(Enabled output is not available for 12 V DC

24

instruments and stainless steel housings).

9

FT-13

8

8.2.3. Continuous Output Mode

The continuous output mode allows for a fast and continuous data export to connected peripheral devices. The

output data structure is described in Appendix 2.

8.2.4. Host Mode (for FT-11 only)

The indicator can communicate with a PC in host mode. You can upload or download data to the indicator by

adjusting the related interface parameters within the FLINTEC IndFace software (for FT-11 only) or using the

command sets described in Appendix 3. This mode is convenient for process control applications which need

not only the weight data, but also require some uploads / downloads and status control.

8.2.5. Print Mode

In the print mode you can select the print formats (parameter group [04-], see chapter 8.2.6). This format –

preferably the single line – is convenient to use as weight data interface in legal for trade applications which

require recording to the Alibi memory. The print mode is not available for more than one interface (see also

overview in chapter 8.1).

1. Single Line

You can send the data in single lines as shown below by pressing the <Print> key.

Example from FT-11(D):

CN: 21 G: 3.000kg T: 1.000kg N: 2.000kg

CN GROSS TARE NET

MSD LSD SP MSD LSD SP MSD LSD SP MSD LSD LF CR

9 3 13 3 13 3 13 1 1

FT-11(D) Technical Manual, Rev. 1.35 November 2010

Page 23 of 52

2. Multi Line

Flintec GmbH

Flintec GmbH

www.flintec.com

www.flintec.com

Germany

Germany

By pressing the <Print> key you can send the data in multiple lines as shown

in the labels at the left.

3 lines of header and 1 line of footer can be downloaded to the instrument (in

host mode).

The data output structure is defined by the printer parameters.

3. Title and Footnote (for FT-11 only)

It is possible to load 3 lines of header and 1 line of footer to FT-11 and print a label with title and footnote in print

mode.

Title and footnote can be loaded to the indicator from a PC via the serial port in host mode. The FLINTEC

IndFace software can be used for this. The free of charge interface software can be downloaded from the

FLINTEC web site www.flintec.com

.

8.2.6. Setup

[0--] Interface Block

You can access the parameters of the instruments’s serial interface(s) in parameter section [0--].

The data output modes can be used only once per instrument except for continuous data output.

[00-] Serial Interface 1 (Standard serial interface)

[000 X ] Data Format

0 : No data transfer 1 : Continuous data output

2 : Print mode ( refer to parameter [040] ) 3 : Host mode

[001 X] Baud Rate

0 : 1 200 Baud 1 : 2 400 Baud 2 : 4 800 Baud 3 : 9 600 Baud

4 : 19 200 Baud 5 : 38 400 Baud 6 : 57 600 Baud

[002 X] Handshake

0 : No Handshake 1 : Xon/Xoff

[003 XX] Address

The address range is 1 to 99. If you enter 0, the indicator will operate without an address.

[004 X] Data Length and Parity

0 : 8 bit, no parity 1 : 7 bit, odd parity 2 : 7 bit, even parity

[005 X] Checksum

0 : Checksum byte disabled 1 : Checksum byte enabled

[01-] Serial Interface 2 (Optional serial interface)

[010 X ] Data Format

0 : No data transfer 1 : Continuous data output

2 : Print mode (refer to parameter [040]) 3 : Host mode

[011 X] Baud Rate

0 : 1 200 Baud 1 : 2 400 Baud 2 : 4 800 Baud 3 : 9 600 Baud

4 : 19 200 Baud 5 : 38 400 Baud 6 : 57 600 Baud

[012 X] Handshake

0 : No Handshake 1 : Xon/Xoff 2 : Hardware

Warning: If you choose hardware as handshake, the serial interface 3 can not be used as RS232C.

[013 XX] Address

The address range is 1 to 99. If you enter 0, the indicator will operate without an address.

FT-11(D) Technical Manual, Rev. 1.35 November 2010

Page 24 of 52

[014 X] Data Length and Parity

0 : 8 bit, no parity 1 : 7 bit, odd parity 2 : 7 bit, even parity

[015 X] Checksum

0 : Checksum byte disabled 1 : Checksum byte enabled

[02-] Serial Interface 3

The parameters of the 3rd serial interface.

[020 X ] Data Format

0 : No output 1 : Continuous data output 2 : Print mode (refer to parameter [040])

3 : Host mode 4 : Modbus RTU High-Low 5 : Modbus RTU Low-High

[021 X] Baud Rate

0 : 1 200 Baud 1 : 2 400 Baud 2 : 4 800 Baud 0 : 1 200 Baud

4 : 19 200 Baud 5 : 38 400 Baud 6 : 57 600 Baud

[022 X] Handshake

0 : No Handshake 1 : Xon/Xoff

[023 XX] Address

The address range is 1 to 99. If you enter 0, the indicator will operate without an address.

[024 X] Serial Mode

0 : Interface operates as RS232C (param. [012] 2) 1 : Interface operates as RS485

2 : Interface operates as 20 mA TTY Current Loop (not for 12 V DC powered instruments)

[025 X] Data Length and Parity

0 : 8 bit, no parity 1 : 7 bit, odd parity 2 : 7 bit, even parity

Note: The parameter [025] must be set to “0” for Modbus RTU output.

[026 X] Checksum

0 : Checksum byte disabled 1 : Checksum byte enabled

[04-] Printer

If one of the serial interfaces is selected as printer, the label settings will be made in this sub-block.

[040 X ] Print Out Format

1 : Single line 2 : Multi line

[042 X] Transfer of CN (Consecutive no.) via serial interface

0 : no 1 : yes

[045 ] Minimum Print

[XXXXXX]

[046 X] Print Control

0 : Printing with key 1 : Auto print 2 : Print interlock

Explanation: If set to “Auto print”, the data will automatically be printed when the value is stable and

higher than the minimum print value. The weight value should fall below the minimum print value to

reprint. If this parameter is set to “Print interlock”, after printing the weight must change for reprint.

[047 XY] Line Feed

X = 0, 1, 2…9 Number of empty lines at the top of the label (numerical key entry)

Y = 0, 1, 2…9 Number of empty lines at the bottom of the label (numerical key entry)

If the weight is less than the value entered here, the data will not be printed

[048 X] Form Feed

0 : No FF 1 : After printing the printer will go to the next page automatically

[049 X] Quantity of Copies

X = 0, 1, 2…9 Number of labels to print for each weighing

Note: This function is only valid for parameter [040] = 2.

FT-11(D) Technical Manual, Rev. 1.35 November 2010

Page 25 of 52

8.3. Ethernet Option (for FT-11 only)

FT-1x series indicators which are equipped with an Ethernet option can be connected to Ethernet TCP/IP or

Modbus RTU over Ethernet networks as described below.

8.3.1. Electrical Connections

The pin configuration of the RJ45 Ethernet connector is described below:

1212

1: Link LED

2 Activity LED Shield Chassis ground

State

Off No link No Activity

Amber 10 Mbit/s Half Duplex

Green 100 Mbit/s Full Duplex

Pin no. Signal Description

1 TX+ Differential Ethernet transmit data +

2 TX– Differential Ethernet transmit data –

3 RX+ Differential Ethernet receive data +

4 Not used, terminated

5 Not used, terminated

6 RX– Differential Ethernet receive data –

7 Not used, terminated

8 Not used, terminated

Link LED Activity LED

Connection to an Ethernet hub

Cabling is done using a standard

RJ-45 patch cable.

Direct connection to a PC

Cabling is done using a RJ-45

cross over cable.

8.3.2. Setup

There are several setup parameters for the Ethernet network as described below:

Host Name

IP Address

Local Port

Gateway

Subnet Mask

Primary DNS

Secondary DNS

DHCP

Remote

Connection

Remote IP

Remote Port

Important hint: During the setup the Ethernet output (weight value and status bits) will not be updated.

Device name on the network. Default is “ “

The numeric code that identifies all computers that are connected to the internet.

Default is “92.168.16.250”

Ethernet connection point of the device. Default is “10001”

Network point that acts as an entrance to other networks. Default is “192.168.16.254”

Defines a range of IP addresses in a network. Default is “255.255.255.0”

Primary DNS server IP address

Secondary DNS server IP address

The Dynamic Host Configuration Protocol provides dynamically allocated IP

addresses to computers on a network, if it is enabled.

Automatic connection to any device on the network

IP address of the PC or device which should be connected automatically

Ethernet connection point of the PC or device which should be connected

automatically

FT-11(D) Technical Manual, Rev. 1.35 November 2010

Page 26 of 52

The Ethernet setup can be done using the Ether X PC software.

Note: For older instruments the configuration will be done by the Ethernet Device Installer PC

software, see separate document on the Flintec Product-CD.

Setup by Ether X Software:

Step 1: Install the Ether X software from the Flintec Product-CD to any PC on the network

Step 2: Start the Ether X software

Step 3: After pressing the “Search” button the software lists the FT-1x devices on the network as shown in

the figure below

Step 4: The IP address of any device may be changed after clicking the “Assign IP” button

Step 5: Click the “Details“ button to open the parameter window as shown below.

Frequently Asked Questions (FAQ)

Question:

Answer:

The Ether X could not reach the FT-1x instrument.

1. Check the local network connection

2. Check if the IP address of the indicator is convenient for your network

3. Check the PC Ethernet output with other network instruments

4. Check the existence of the Ethernet related parameters in the instrument setup (see

chapter 8.3.3). If you cannot not see these parameters in the setup, please check the proper

installation of the Ethernet board.

5. Change the Ethernet option board.

The parameter window presents information like

Firmware Version of Ethernet option board and it helps

to edit resources like Host Name, Gateway, DNS

server etc.

After changing any parameter, enter the password and

click the “Save Settings” button.

The default Password is “123456”.

The “Load Defaults” button resets the device to the

default settings.

FT-11(D) Technical Manual, Rev. 1.35 November 2010

Page 27 of 52

Question:

The Ether X software could reach the FT-1x instrument, but you can’t communicate with the

instrument.

Answer:

Question:

Answer:

The port number of the indicator is not convenient for port numbers of your application

software. Check the port number of the indicator by using the Ether X software.

How can I check the communication?

You can use any communication program like HyperTerminal which is supplied with your

Windows operating system (Microsoft).

Example: HyperTerminal

1. Open the HyperTerminal and choose a name for the connection.

Press OK.

2. Then enter the Ethernet address of the indicator and the port

number as shown at the left. Also you need to set the connection

type to “TCP/IP (WinSock)”.

3. To test the connection now, you can set the Ethernet output of the

indicator to “continuous” (refer to chapter 8.3.3).

With an active HyperTerminal you should now be able to follow the

data stream.

8.3.3. Data Structure

[0--] Interface Block

[03-] Ethernet

This sub-block includes the parameters of the Ethernet port.

[030 X ] Data Format

0 : No Ethernet output 1 : Continuous data 2 : Print mode (refer to parameter [040])

3 : Host mode 4 : Modbus RTU High-Low* 5 : Modbus RTU Low-High**

* High word before low word at address 40001 and 40002

** Low word before high word at address 40001 and 40002

Note: In continuous data format of the Ethernet interface, the checksum byte is disabled.

The data structure depends on the selected data format (see parameter [030]):

Data format Data structure

Continuous output mode See Appendix 2

Print mode See Chapter 8.2.5 and 8.2.6 parameter [040]

Host mode See Appendix 3

Modbus RTU See Appendix 4

[031 XX] Address

The address of the instrument will be entered via numerical keypad in the range 01 to 99.

FT-11(D) Technical Manual, Rev. 1.35 November 2010

Page 28 of 52

8.4. Profibus Option (for FT-11 only)

FT-11 indicators which are equipped with the Profibus option can be connected to a PLC bus as described

below.

Profibus DP V0 & V1 Automatic (96 kbit/s to 12 Mbit/s)

Update rate Weight data will be updated each 40 ms

Response time on entries 5 ms to 25 ms

8.4.1. Electrical Connections

The pin configuration of the female 9-pol D-Sub Profibus connector (DB9F) is described in the table below:

Pin no. Signal Description

1

2

3 B-Line Positive RxD / TxD, RS485 level

4 RTS Request to send

5 GND Isolated GND

Operation mode LED

1

2 Status LED

3 Profibus Connector

Operation mode LED

State Indication Action / Comment

Off Not on-line /No power Check power and cable

Green On-line, data exchange

Flashing Green On-line, clear

Flashing Red (1 flash) Setup error Not supported

Flashing Red (2 flash) PROFIBUS configuration error Check GSD file

Status LED