FAD-4

ANALOGUE LOADCELL JUNCTION BOX

WITH TRANSDUCERS ELECTRONICS

REFERENCE MANUAL

Flintec GmbH

Bemannsbruch 9

74909 Meckesheim

Germany

Tel. +49 6226 92400

Fax. +49 6226 924099

www.flintec.net

germany@flintec.net

FLINTEC

Document

FAD - 4 DIGITAL LOADCELL JUNCTION BOX

Date

02.05.00 FAD4_2RM

Code

Rev.

2

Page

1 of 20

FLINTEC

TABLE OF CONTENTS

1 INTRODUCTION........................................................................................................................................... 3

2 HARDWARE DESCRIPTION – INSTALLATION ...................................................................................... 4

2.1 Mounting.................................................................................................................................................. 4

2.2 Wiring ...................................................................................................................................................... 4

2.3 Power........................................................................................................................................................ 4

2.4 Analogue output........................................................................................................................................ 4

2.5 Setpoint outputs........................................................................................................................................ 4

2.6 Tilt switch................................................................................................................................................. 4

3 FUNCTIONAL DESCRIPTION..................................................................................................................... 5

4 SETUP & CALIBRATION SEQUENCE..................................................................................................... 14

5 CALIBRATION EXAMPLES ...................................................................................................................... 15

5.1 STANDARD (WEIGHTS)..................................................................................................................... 15

5.2 ELECTRONIC (mV/V). ........................................................................................................................ 16

6 OPERATION ................................................................................................................................................ 17

7 ERRORS ....................................................................................................................................................... 18

8 SPECIFICATIONS - MAINTENANCE....................................................................................................... 19

8.1 TECHNICAL SPECIFICATIONS......................................................................................................... 19

8.2 ENVIRONMENTAL CONSIDERATIONS.......................................................................................... 20

8.3 MAINTENANCE................................................................................................................................... 20

8.4 SERVICE ............................................................................................................................................... 20

This manual contains proprietary information, protected by international copyright lows. No part of this

document may be reproduced without the written agreement of the publisher, Flintec GmbH.

The information herein is believed to be both accurate and reliable. Flintec GmbH however, would

be obliged to be informed if any errors occur. Flintec GmbH cannot accept any liability for direct or

indirect damages resulting from the use of this manual.

Flintec GmbH reserves the right to revise this manual and alter its content without notification at any time.

Document

FAD - 4 DIGITAL LOADCELL JUNCTION BOX

Date

02.05.00 FAD4_2RM

Code

Rev.

2

Page

2 of 20

FLINTEC

1 INTRODUCTION

The FAD-4 is a junction board for connection of up to 4 analogue loadcells. It contains all transducer

electronics to excite the strain gauges, amplify, filter and convert the analogue signal of each loadcell to a

digital form. The outputs from each loadcell are corner corrected and summed to form the scale weight

output. If one loadcell is connected only it should be connected to LC.1 input, two loadcells to inputs 1

and 2 etc.

The weight is output in digital form via an RS485A serial interface or in analogue form via a

0 , 4 – 20mA optional interface.The RS485 interface may be used in multidrop applications where each

FAD-4 has itsown unique address.

All weighing functions necessary for operation of weighing system such as Zero, Tare, No motion

detection, error monitoring are performed by the FAD-4.

An ASCII standard serial interface command set allows FAD-4 to be connected with personal computers,

PLCs ,intelligent peripherals, etc.

The calibration of each corner and of the scale is handled by the FAD-4 through a calibration sequence

initiated via the serial interface. Calibration constants are stored in EEPROM on board.

Calibration sequrity is effected by a CALLOCK hardware inside the DJB which may be sealed and a

PINLOCK software device that once activated inhibits access to calibration constants if the PIN code is

not entered. The unit is also provided with an Audit Trail Counter which is incremented every time the

calibration parameters and / or constants are modified.

The weight data rate is setup selectable to cater for high accuracy static weighing (2-5 conversions/sec) or

medium accuracy dynamic weighing (10-20-40 conversions/sec) applications with computers or other

systems.

The unit has been designed for use in industrial environments and is EMC compliant to EN 45501 standards.

The FAD-4 has two optoisolated setpoint outputs and one optoisolated input. It also has a serial display

and keyboard interface plus a multiprocessor interface at TTL level.

A potential free Tilt switch may be connected to inhibit weighing while the scale is not level.

OPTIONS

OP.1 Analogue output 20mA optoisolated.

OP.2 Automatic Tilt correction device (Two directional).

OP.3 PCLINK software to link to higher level software (DOS or WINDOWS environment).

OP.4 Stainless steel housing 200 x 105 x 45 mm with cable glands or DB9F connector.

OP.5 Mains power adapter 230 VAC to 9 VAC/ 500mA.

OP.6 Remote Display Terminal RDT-52.

OP.7 RS232C/RS485A converter including power adapter 230 VAC to 9 VAC/ 500mA.

OP.9 Custom software on request.

Document

FAD - 4 DIGITAL LOADCELL JUNCTION BOX

Date

02.05.00 FAD4_2RM

Code

Rev.

2

Page

3 of 20

FLINTEC

2 HARDWARE DESCRIPTION – INSTALLATION

Normally FAD-4 comes in a sealed stainless steel enclosure, suitable for wash down environment.

Entry of connecting cable is through sealed cable glands. Refer to Annex A for details of the enclosure and

main PCB 703.2. In addition an analogue output (PCB 760) and a tilt switch may be connected.

2.1 Mounting

The mounting location should be such that the unit is not subject to excessive vibrations or heat.

The top panel should be accessible.

2.2 Wiring

Remove the lid by undoing the four screws.

Insert cables via the cable glands. Strip the cables and connect the loadcells 1 to 4 to connectors ST6 to ST9

respectively. If the loadcell cables are 6 wire connect together the excitation and sense leads or cut off the sense

leads.

Connect the shields of the cables on SHLD terminal or directly on the chassis screws using eyelet terminals.

Power and communication cable is connected via cable gland s. See Annex A connector diagram for details.

Connect serial communication cable according to the drawing “FAD-4/703.2/88”.

When wiring is completed pull out any excessive cable and tighten the cable glands to ensure a firm grip

on the cables. Re-Install the lid and tighten the screws until the side edges are recessed 2mm from the lid edges.

FOR OPTIMUM EMC PERFORMANCE KEEP THE LENGTH OF THE SHIELD INSIDE THE

ENCLOSURE AS SHORT AS POSSIBLE.

2.3 Power

As the instrument is computer controlled it requires clean power for reliable operation.

Power supplied should come from a source that is isolated from other process equipment.

A mains adapter of 7,5 – 10 VAC / 500 mA is recommended for operation of both the RDT-52 and

FAD-4. Connect a power supply 7 - 10 VAC or 7.5 - 12 VDC (150mA min.) to ST1 or to Pin 8, 9 of

DB9 female connector (polarity independent).

2.4 Analogue output

Connect to ST2 of analogue output pcb760 according to drawing “FAD-4/760/040”.

2.5 Setpoint outputs

Connect isolated input / output to ST5 (if used) according to drawing “FAD-4/703.2/040”.

2.6 Tilt switch

Connect a dry contact to Pins 1 & 2 of ST3 directly or to Pins 2, 3 of D9 connector.

The tilt switch wires must be contained in the power and communications cable.

N.O or N.C contact and debounce timer are set in SETUP 1.

CAUTION : Do not run signal cables together with power cables.

Connect the shielding where indicated on the drawing only.

Never use a meg ger to check wiring.

Document

FAD - 4 DIGITAL LOADCELL JUNCTION BOX

Date

02.05.00 FAD4_2RM

Code

Rev.

2

Page

4 of 20

FLINTEC

3 FUNCTIONAL DESCRIPTION

All FAD-4 operations are performed via the serial interface, through the use of LESIP Master/Slave serial

interface protocol . The communication standards and timing are described in the LESIP manual. The file types

specific to FAD-4 will be described here. The FAD-4 is always a slave. In principle a number of FAD`s

may be connected in a network microprocessor controlled device.

The communication buffer size is 13 bytes max for Transmitter and Receiver (Half duplex).

Detailed description of the file types and sequences is given in the following pages .

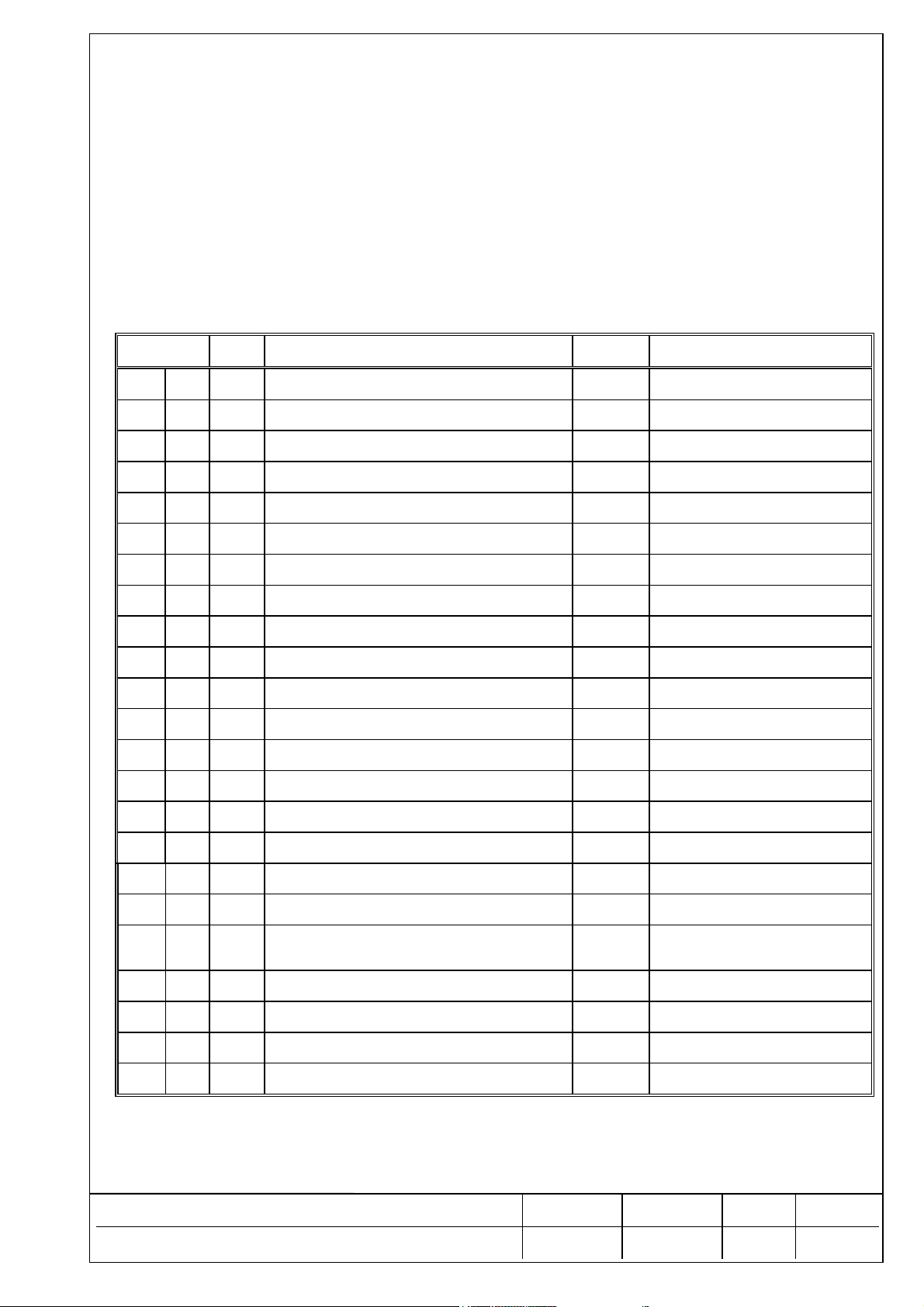

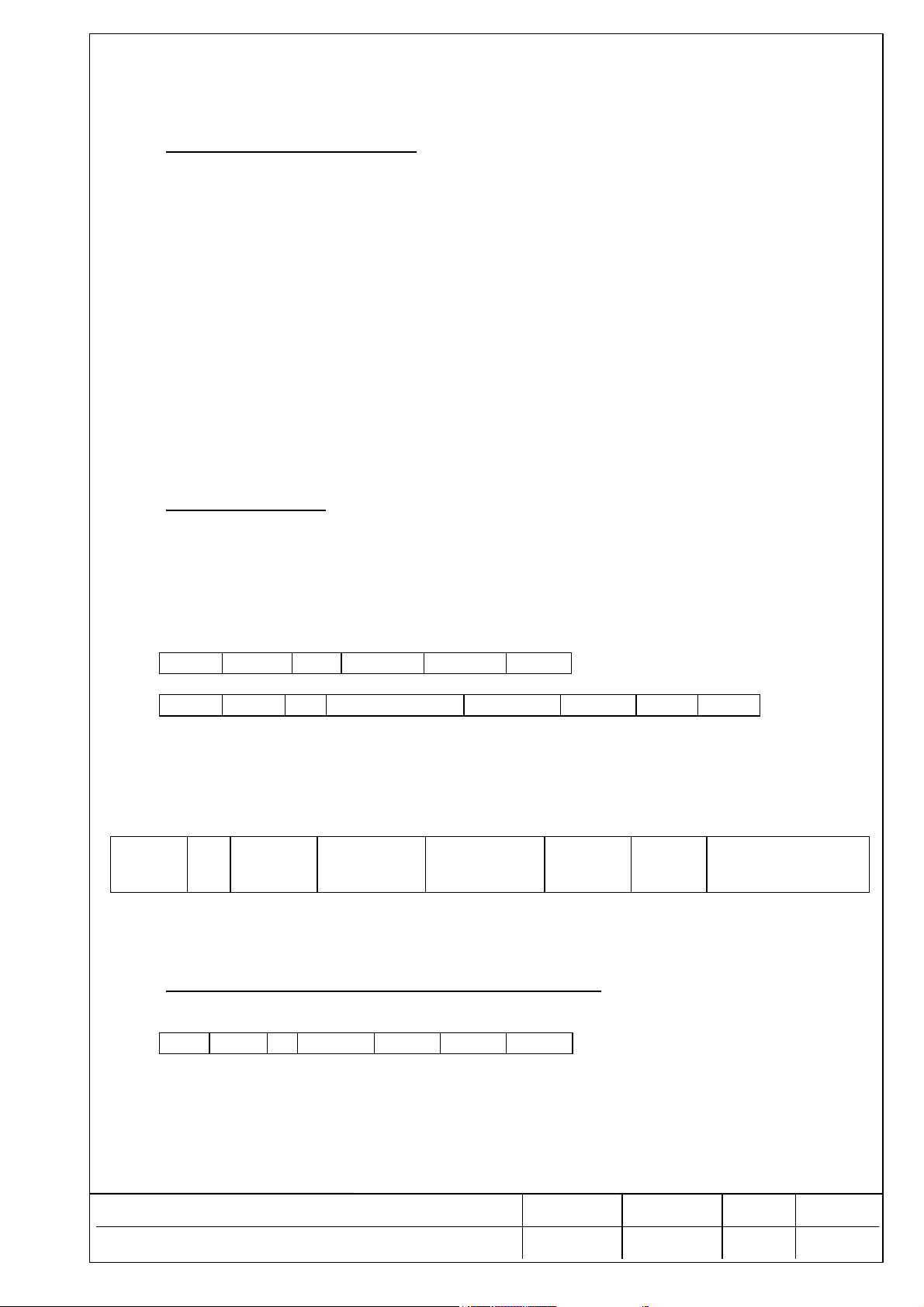

LIST OF FILE TYPES (COMMANDS)

TYPE HEX DESCRIPTION TIME RESPONSE

? 3F UPLOAD WEIGHT & STATUS 50 ms STATUS + WEIGHT

A 41

a 61 DEADLOAD CAL(weights) 16 sec Poll slave by using command ‘?’

B 42 SPAN CAL (ELECTRONIC, mV/V input) 1.5 sec Poll slave by using command ‘?’

DEADLOAD CAL (ELECTRONIC mV/V)

1.5 sec Poll slave by using command ‘?’

b 62 SPAN CAL (weights) 16 sec Poll slave by using command ‘?’

C 43 DOWNLOAD mV/V for each corner 0.1 sec Poll slave by using command ‘?’

c 63 CALIBRATE CORNERS 16 sec Poll slave by using command ‘?’

d 64 UPLOAD AUDIT TRAIL CNT,CALLOCK 0.1sec 6 Digit counter, status Callock

f 66 UPLOAD CORNER FACTORS 0.1 sec FACTOR 1,2,3 ,4

G 47 GROSS 0.1sec NONE

H 48 RESERVED

i 69 UPLOAD INTERNAL RESOLUTION 0.1 sec INTERNAL DIVIDIONS

J 4A LOCK / UNLOCK CALIBRATION 0.1sec 6 Digit PIN or NAK

P 50 DOWNLOAD PAR 1/ PAR 2/ PAR 3 0.1 sec ACK or NAK

p 70 UPLOAD PAR 1/ PAR 2/ PAR 3 0.1 sec PAR 1/2/3

Q 51 DOWNLOAD SETPOINT 1 / SETPOINT 2 0.1 sec ACK or NAK

q 71 UPLOAD SETPOINT 1 / SETPOINT 2 0.1 sec SETPOINT 1/ SETPOINT 2

R 52 RESET SLAVE 16 sec NONE

S 53 DOWNLOAD SETUP : SETUP 1 / SETUP 2 0.1 sec ACK or NAK

s 73 UPLOAD SETUP1 0.1sec Setup1

T 54 TARE 0.1 sec NONE

W 57 WRITE TO EEPROM 16 sec NONE

Z 5A ZERO 3 sec NONE

Document

FAD - 4 DIGITAL LOADCELL JUNCTION BOX

Date

02.05.00 FAD4_2RM

Code

Rev.

2

Page

5 of 20

FLINTEC

FILE TYPE DESCRIPTION

Calibration and weight parameters are protected by calibration lock devices hardware and software.

If the CALIBRATION LOCK is activated, weight parameter/ calibration file types are not accessible.

The “CAL LOCK” is a hardware jumper inside the DJB required by Weights & Measures authorities

so that calibration can be sealed (jumper inserted).

The “PINLOCK” is a software Personal Identification Number, which ensures that no accidental

scale calibration is attempted. The “PIN LOCK” and the “CAL LOCK” are logically connected.

In addition to the “CAL LOCK” an A.T.CNT (Audit Trail Counter) is provided for use by

Weights and Measures Authorities.

The A.T.CNT (6 digits) is incremented when a weight parameter is changed, or a corner / scale

calibration is attempted, regardless if the changes are saved in EEPROM or not.

The position of the “CAL LOCK” jumper and the A. T. CNT number may be inspected with

Fn 48 (chapter 6).

The A.T.CNT may be viewed by the Weight & Measures to verify that no calibration constants have

been altered since the inspection/stamping date .

To avoid wait time in certain commands, (especially when units are connected in a network), the

DJB will not respond to the command issued but on subsequent polls by command “?”.

? UPLOAD STATUS

It is the main command used to poll the FAD(s), which reply with the current weight being

measured or with a message if bit0 of status byte is ‘1’. In the normal state the FAD-4 will respond

within 3-4 character time. (e.g. with 9600baud, the character time ≈ 1 msec, the master should

expect reception of STX from the FAD-4 within 5 msec after the ETX was transmitted from the

master).

Master transmission

STX ADD ? BCS2 BCS1 ETX

Slave response

STX ADD X STATUS BYTE WEIGHT BCS2 BCS1 ETX

where X= ‘?’ if there is new A/D conversion since the last weight value transmission.

X=’ ’ if there is no new A/D conversion since the last weight value transmission.

and WEIGHT: 5 digits + decimal point if any.(ASCII,MSD FIRST)

STATUS BYTE

b7 b6 b5 b4 b3 b2 b1 b0

Zero or

Parity

1 Sign of

weight

0=+ 1=-

The WEIGHT field will contain a message if b0 of the status byte is high.

A . DEAD LOAD CALIBRATION (ELECTRONIC mV/V)

Downloads the total mV/V output of the empty scale for dead load calibration.

Master transmission :

STX ADD A yyyyyy BCS2 BCS1 ETX

yyyyyy : 6 digits of mV/V multiplied by 10000 (ASCII decimal).

Poll the slave by using command ‘?’. Possible response messages: ‘WAIT..’ or ‘ERR 91’.

Slave returns to normal Weight output after the command is completed.

THE VALUE IS NOT SAVED IN EEPROM UNTIL A STORE COMMAND IS ISSUED.

No Motion

0=NO,

1=YES

Out of Range

0=NO

1=YES

Autozero

0=NO

1=YES

0=Gross

1=Net

0=Normal Weight

1=No Weight Display

Document

FAD - 4 DIGITAL LOADCELL JUNCTION BOX

Date

02.05.00 FAD4_2RM

Code

Rev.

2

Page

6 of 20

FLINTEC

EXAMPLE: For a 0,1234 mV/V loadcell deadload output the data downloaded must be 001234.

Master transmission :

STX A A 001234 0 0 ETX

Master transmission:

STX A ? = 3 ETX

Slave response:

STX A ? E WAIT.. 2 3 ETX

a. DEADLOAD CALIBRATION (WEIGHT)

When this command is received the FAD-4 will measure the weight of the empty scale by

averaging 32 conversions. This DEADLOAD average will be held in the ZERO CALIBRATION

memory.

Master transmission:

STX ADD a BCS2 BCS1 ETX

Poll the slave by using command ‘?’. Possible response messages: ‘WAIT..’ or ‘ERR 91’ .

Slave returns to normal weight output mode after the command is completed.

THE VALUE IS NOT SAVED IN EEPROM UNTIL A STORE COMMAND IS ISSUED.

B. SPAN CALIBRATION (ELECTRONIC, mV/V)

Used to download the capacity of each loadcell for SPAN factor computation .

The command must be preceded by command “C”.

Master transmission:

STX ADD B yyyyy BCS2 BCS1 ETX

yyyyy: 5 digits without decimal point (ASCII decimal)

Poll the slave with command ‘?’. Possible responses: “WAIT..” or “ERR 90” or “ERR 91”.

Slave returns to normal weight output mode after the command is completed.

THE VALUE IS NOT SAVED IN EEPROM UNTIL A STORE COMMAND IS ISSUED.

b. SPAN CALIBRATION (WEIGHTS)

Used to download the known WEIGHT already placed on the scale for Span factor computation.

Master transmission:

STX ADD b yyyyy BCS2 BCS1 ETX

yyyyy: 5 digits without decimal point (ASCII decimal)

Poll the slave with command ‘?’. Possible responses: “WAIT..” or “ERR 90” or “ERR 91”.

Slave returns to normal weight output mode after the command is completed.

THE VALUE IS NOT SAVED IN EEPROM UNTIL A STORE COMMAND IS ISSUED.

C. DOWNLOAD mV/V OF EACH CORNER

Used to download mV/V output at rated capacity of each loadcell. The loadcells must be of the

same rated capacity. The FAD-4 will expect the data for the number of loadcells stated in P1

command.

Master transmission:

STX ADD C 1 yyyyyy BCS2 BCS1 ETX

yyyyyy : 6 digits (ASCII decimal) of rated mV/V multiplied by 10000 for CORNER 1.

Poll the slave by using command ‘?’. Possible response messages: “ERR 91” or “CORN.2”

Master transmission:

STX ADD C 2 yyyyyy BCS2 BCS1 ETX

yyyyyy : 6 digits (ASCII decimal) of rated mV/V multiplied by 10000 for CORNER 2.

Document

FAD - 4 DIGITAL LOADCELL JUNCTION BOX

Date

02.05.00 FAD4_2RM

Code

Rev.

2

Page

7 of 20

FLINTEC

Poll the slave by using command ‘?’. Possible response messages: “ERR 91” or “CORN.3”

Master transmission:

STX ADD C 3 yyyyyy BCS2 BCS1 ETX

yyyyyy : 6 digits (ASCII decimal) of rated mV/V multiplied by 10000 for CORNER 3.

Poll the slave by using command ‘?’. Possible response messages: “ERR 91” or “CORN.4”

Master transmission:

STX ADD C 4 yyyyyy BCS2 BCS1 ETX

yyyyyy : 6 digits (ASCII decimal) of rated mV/V multiplied by 10000 for CORNER 4.

Poll the slave with command ‘?’.

Slave returns to normal Weight output after command is completed.

c. CALIBRATE CORNERS (WEIGHT)

It is used to compute correction factors for the corners by using weight equal to 10 - 30% of each

loadcell capacity. This command is in fact a procedure having a number of steps equal to the stated

number of loadcells. Empty the scale and send command:

Master transmission:

STX ADD c 0 BCS2 BCS1 ETX

Poll the slave by using command ‘?’.

Possible response messages: “WAIT..” or “ERR 91” or “CORN.1”.

Place the test weight on scale CORNER 1,wait to stabilise and send command:

Master transmission:

STX ADD c 1 BCS2 BCS1 ETX

Poll the slave by using command ‘?’.

Possible response messages: “WAIT..” then “CORN.2” if corner 1 was ok,

or “CORN.1” if something is wrong. If the same corner is returned repeat the procedure.

Place the same test weight on scale CORNER 2, wait to stabilise and send command:

Master transmission:

STX ADD c 2 BCS2 BCS1 ETX

Poll the slave by using command ‘?’.

Possible response messages: “WAIT..” then “CORN.3” if corner 1 was ok,

or “CORN.2” if something is wrong. If the same corner is returned repeat the procedure.

Place the same test weight on scale CORNER 3, wait to stabilise and send command:

Master transmission:

STX ADD c 3 BCS2 BCS1 ETX

Poll the slave by using command ‘?’.

Possible response messages: “WAIT..” then “CORN.4” if corner 1 was ok,

or “CORN.3” if something is wrong. If the same corner is returned repeat the procedure.

Place the same test weight on scale CORNER 4, wait to stabilise and send command:

Master transmission:

STX ADD c 4 BCS2 BCS1 ETX

Poll the slave by using command ‘?’.

Possible response messages: ’WAIT..’ then ‘CORN.4’ if something is wrong else the slave

returns to normal weight output mode.

If the same corner is returned repeat the procedure .

THE VALUES ARE NOT SAVED IN EEPROM UNTIL A STORE COMMAND IS ISSUED.

Document

FAD - 4 DIGITAL LOADCELL JUNCTION BOX

Date

02.05.00 FAD4_2RM

Code

Rev.

2

Page

8 of 20

d. UPLOAD CALIBRATION SECURITY PARAMETERS

The command is used by the master to upload the current status of the hardware CAL LOCK

jumper, the software PIN LOCK state and the contents of the Audit Trail counter.

Master transmission:

STX ADD d BCS2 BCS1 ETX

Slave response:

STX ADD d x yyyyyy BCS2 BCS1 ETX

Where x = 0 CALLOCK = Not inserted, PINLOCK = Not active

x = 1 CALLOCK = Inserted, PINLOCK = Not active

x = 2 CALLOCK = Not inserted, PINLOCK = Active

x = 3 CALLOCK = Inserted, PINLOCK = Active

yyyyyy = 6 digit Audit Trail Counter MSD first.

f. UPLOAD CORNER FACTOR.

It is used to upload corner factors.

Master transmission:

STX ADD f x BCS2 BCS1 ETX

Slave response:

STX ADD f x yyyyyy BCS2 BCS1 ETX

x : One digit defining CORNER (1-4).

yyyyyy : 6 digits of the respective corner factor. (ASCII decimal)

G. GROSS

Clears any tare in use and returns slave to gross mode.

Master transmission:

STX ADD G BCS2 BCS1 ETX

Slave response : NONE. The master may check execution of the command by examining the next

status string.

J. LOCK / UNLOCK CALIBRATION (PINLOCK)

The command is used to activate or deactivate the software calibration lock.

UNLOCK : Deactivates the software lock and releases weight parameter and calibration changes.

Master transmission:

STX ADD J 0 xxxxxx BCS2 BCS1 ETX

xxxxxx = 6digit PIN

Slave response:

STX ADD J 0 xxxxxx BCS2 BCS1 ETX

if the PIN was correct or NAK block followed by reset.

LOCK: Activates the software lock and disables further weight parameter and calibration attempts.

FLINTEC

Document

FAD - 4 DIGITAL LOADCELL JUNCTION BOX

Date

02.05.00 FAD4_2RM

Code

Rev.

2

Page

9 of 20

FLINTEC

Master transmission:

STX ADD J 1 xxxxxx BCS2 BCS1 ETX

xxxxxx = 6digit PIN

Slave response:

STX ADD J 1 xxxxxx BCS2 BCS1 ETX

or NAK block if already locked.

THE VALUE IS NOT SAVED IN EEPROM UNTIL A STORE COMMAND IS ISSUED.

TO CHANGE PIN FIRST UNLOCK WITH THE OLD PIN THEN LOCK WITH THE NEW PIN.

BE CAREFUL WITH THE NEW PIN. IF IT IS LOST THE UNIT MUST BE RETURNED TO THE

FACTORY TO RECLAIM IT.

i. UPLOAD INTERNAL RESOLUTION

Uploads internal resolution of slave FAD-4.

Master transmission:

STX ADD i x BCS2 BCS1 ETX

where x : One digit defining the corner number (0-4). 0 = Sum of the corners.

1= Corner 1 , 2 = Corner 2 , 3 = Corner 3 , 4 = Corner 4.

Slave response:

STX ADD i x yyyyyy BCS2 BCS1 ETX

where x : One digit defining the corner number (0-4). 0 = Sum of the corners.

1= Corner 1 , 2 = Corner 2 , 3 = Corner 3 , 4 = Corner 4.

yyyyyy : 6 digits defining the data (ASCII decimal), of the respective corner.

P. DOWN LOAD PARAMETERS

Used to download scale parameters. Because of the limited buffer size the scale parameters must

be sent in three groups P1, P2, P3.

Master transmission: (PAR 1)

STX ADD P 1 a b c d e f BCS2 BCS1 ETX

a : Conversions per sec : 1=8Hz/ n , 2=20Hz/ n , 3=40Hz/ n , 4=80Hz/ n. n=Nr of Loadcells.

MAXIMUM Conv/sec = 40Hz i.e. the 80Hz with one loadcell is not acceptable.

b : Gain set. 0 = 2 mV/V , 1 = 4 mV/V , for each input (Deadload + Span).

c : Number of loadcells (1, 2, 3, 4)

d : Weight units 0 = kg

e : Digital filter (0, 1, 2) 0 = 1 , 1 = 2 , 2 = 4 samples.

f : No motion samples (1, 2, 3, 4, 5, 6, 7) consecutive conversions within 0.5e.

Slave response :

STX ADD ACK or NAK BCS2 BCS1 ETX

A NAK block will be returned if some parameter is out of range.

Document

FAD - 4 DIGITAL LOADCELL JUNCTION BOX

Date

02.05.00 FAD4_2RM

Code

Rev.

2

Page

10 of 20

FLINTEC

Master transmission: (PAR 2)

STX ADD P 2 aa bb cc BCS2 BCS1 ETX

aa : Weight resolution (01, 02, 05, 10, 20, 50).

bb: The first 2 digits of weighing range (00-99).

cc: DUAL INTERVAL. The first 2 digits of the weighing range for which the lower weight

resolution will be selected automatically. 00 = DUAL INTERVAL NOT ACTIVE.

Slave response:

STX ADD ACK or NAK BCS2 BCS1 ETX

A NAK block will be returned if some parameter is out of range.

Master transmission: (PAR 3)

STX ADD P 3 a b c d e f BCS2 BCS1 ETX

a : Decimal digits (0, 1, 2, 3, 4)

b : Autozero maintenance 0 = NO 1 = YES

c : Autozero on power up 0 = NO 1 = YES

d : Dual digital filter 0 = NO 1 = YES (The filter doubles when not in motion)

e : Leading zero blank 0 = NO 1 = YES

f : Reserved : always 0

Slave response:

STX ADD ACK or NAK BCS2 BCS1 ETX

A NAK block will be returned if some parameter is out of range.

THE VALUE(S) ARE NOT SAVED IN EEPROM UNTIL A STORE COMMAND IS ISSUED.

p. UPLOAD PARAMETERS

Used to upload weight parameters.

The parameter groups a b c d e f are identical with the “P” command.

Master transmission: (PAR 1)

STX ADD p 1 BCS2 BCS1 ETX

Slave response:

STX ADD p 1 a b c d e f BCS2 BCS1 ETX

a : Conversions per sec : 1=8Hz/ n , 2=20Hz/ n , 3=40Hz/ n , 4=80Hz/ n. n=Nr of Loadcells.

MAXIMUM Conv/sec = 40Hz i.e. the 80Hz with one loadcell is not acceptable.

b : Gain set. 0 = 2 mV/V , 1 = m4 mV/V , for each input (Deadload + Span).

c : Number of loadcells (1, 2, 3, 4)

d : Weight units 0 = kg

e : Digital filter (0, 1, 2) 0 = 1 , 1 = 2 , 2 = 4 samples.

f : No motion samples (1, 2, 3, 4, 5, 6) consecutive conversions within 1e.

Master transmission : (PAR 2)

STX ADD p 2 BCS2 BCS1 ETX

Slave response:

STX ADD P 2 aa bb cc BCS2 BCS1 ETX

aa : Weight resolution (01, 02, 05, 10, 20, 50).

bb: The first 2 digits of weighing range (00-99).

cc: DUAL INTERVAL.The first 2 digits of the weighing range for which the lower weight

resolution will be selected automatically. 00 = DUAL INTERVAL NOT ACTIVE.

Document

FAD - 4 DIGITAL LOADCELL JUNCTION BOX

Date

02.05.00 FAD4_2RM

Code

Rev.

2

Page

11 of 20

FLINTEC

Master transmission: (PAR 3)

STX ADD p 3 BCS2 BCS1 ETX

Slave response:

STX ADD p 3 a b c d e f BCS2 BCS1 ETX

a = Decimal digits (0, 1, 2, 3, 4) d = Dual digital filter 0=No 1=Yes

b = Autozero maintenance 0=No 1=Yes e = Leading zero blank 0=No 1=Yes

c = Autozero on power up 0=No 1=Yes f = Reserved

Q : DOWNLOAD SETPOINT

Used to download the two digital setpoint values.

Master transmission:

STX ADD Q x yyyyy BCS2 BCS1 ETX

x : One digit (1-2) defining setpoint number.

yyyyy : 5 digits defining setpoint value(ASCII decimal MSD). No decimal point.

Slave response:

STX ADD ACK or NAK BCS2 BCS1 ETX

A NAK is returned if the values are not within Max.

q : UPLOAD SETPOINTS

Used to upload setpoint values in the DJB memory.

Master transmission:

STX ADD q x BCS2 BCS1 ETX

Slave response:

STX ADD q x yyyyy BCS2 BCS1 ETX

x : One digit (1-2) defining setpoint number.

yyyyy : 5 digits defining setpoint value(ASCII decimal MSD).

R : RESET SLAVE

Resets the slave to its power on condition.

Master transmission:

STX ADD R BCS2 BCS1 ETX

Slave response: NONE.

S: DOWN LOAD SETUP

Setup 1 is used to download the tilt switch interface parameters while setup 2 is used to download

serial port 1 (RS485) interface parameters.

Master transmission: (SETUP 1)

STX ADD S 1 X Y RRR BCS2 BCS1 ETX

where X=0 for normally open contact (N.O) or X=1 for normally closed contact (N.C)

Y= 0-9 sec the ON/OFF delay for contact debounce.

RRR= Reserved. If both X=0 and Y=0 the tilt function is disabled.

Slave response:

STX ADD ACK or NAK BCS2 BCS1 ETX

A NAK is returned if the values are out of range.

Document

FAD - 4 DIGITAL LOADCELL JUNCTION BOX

Date

02.05.00 FAD4_2RM

Code

Rev.

2

Page

12 of 20

FLINTEC

Master transmission: (SETUP 2)

STX ADD S 2 a bb cc BCS2 BCS1 ETX

a : Slave address (A - Z)

bb : Baudrate : 24 = 2400 baud 96 = 9600 baud 19 = 19200 baud

38 = 38400baud 57=57600baud 11=115200baud

cc : Data bits / parity : 17 = 7 data bits even parity 08 = 8 data bits, no parity.

Slave response:

STX ADD ACK or NAK BCS2 BCS1 ETX

New settings of baud rate , data bits and parity are not in effect until a write command ‘W’ is issued.

T : TARE

Tares the weight on the scale and switches the FAD-4 to net weight mode.

Master transmission:

STX ADD T BCS2 BCS1 ETX

Slave response: NONE.

Execution of the command should be checked by examining the next status string.

W : WRITE TO EEPROM

Writes setup, parameters, setpoint values, calibration data to EEPROM and resets slave.

Master transmission:

STX ADD W BCS2 BCS1 ETX

Slave response: NONE.

WARNING : The max number of write cycles allowed is 100.000.

Z : ZERO SCALE

Sets the scale to zero if zero conditions are met (stable weight within 2% of scale capacity) .

Master transmission:

STX ADD Z BCS2 BCS1 ETX

Slave response: NONE.

Execution of the command should be checked by examining the next status string.

Document

FAD - 4 DIGITAL LOADCELL JUNCTION BOX

Date

02.05.00 FAD4_2RM

Code

Rev.

2

Page

13 of 20

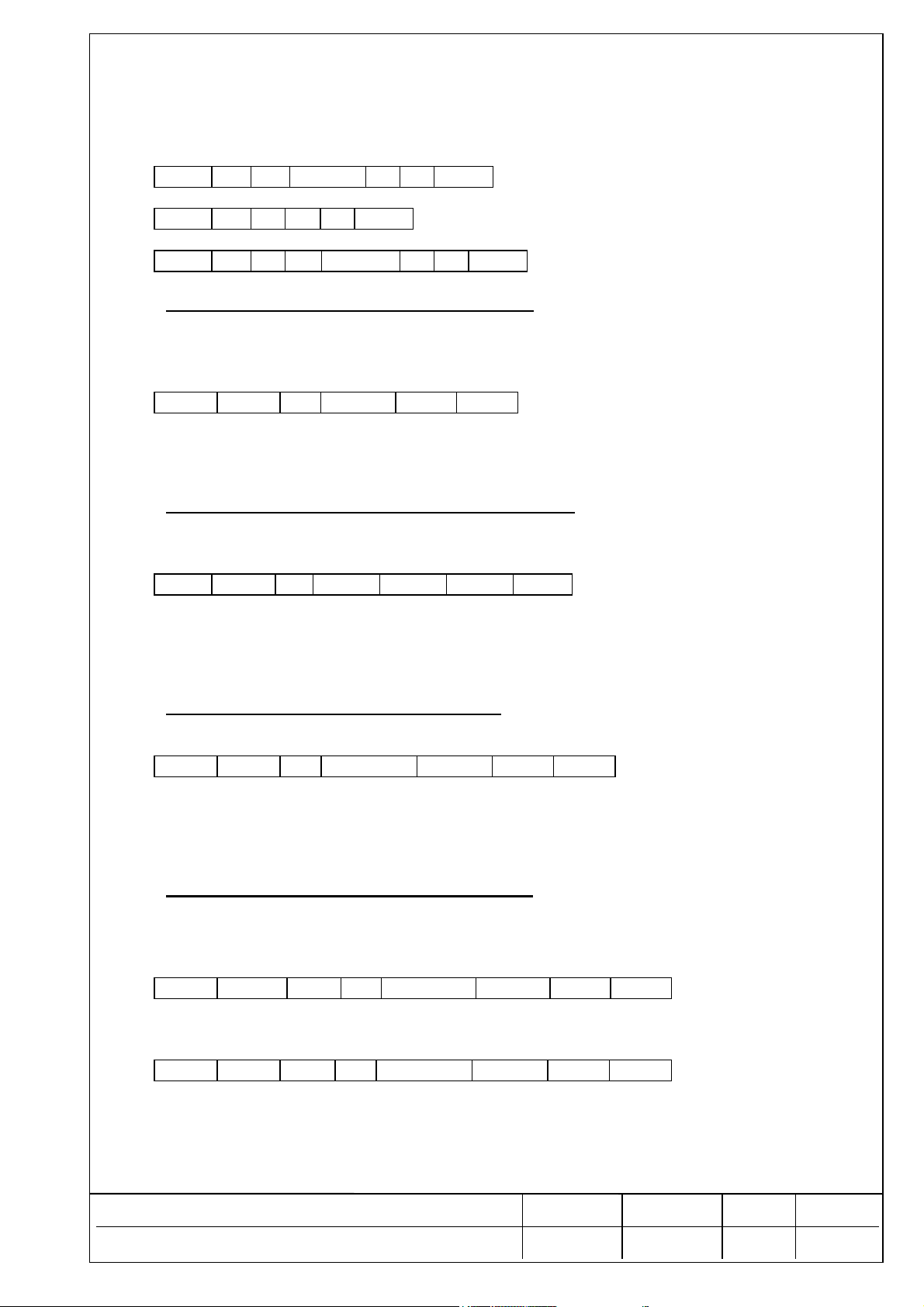

4 SETUP & CALIBRATION SEQUENCE

SEND COMMAND “P1”

SEND COMMAND “P2”

SEND COMMAND “P3”

SEND COMMAND “W”

ELECTRONIC WEIGHTS

SEND COMMAND “C1”

SEND COMMAND “C2”

SEND COMMAND “C3”

SEND COMMAND “C4”

ELECTRONIC WEIGHTS

ELECTRONIC WEIGHTS

SEND COMMAND “B”

POWER ON

CORNER

CALIBRATION

ZERO

CALIBRATION

SPAN

CALIBRATION

FLINTEC

SEND COMMAND “c0”

SEND COMMAND “c1”

SEND COMMAND “c2”

SEND COMMAND “c3”

SEND COMMAND “c4”

SEND COMMAND “a”SEND COMMAND “A”

SEND COMMAND “b”

SEND COMMAND “W”

Document

FAD - 4 DIGITAL LOADCELL JUNCTION BOX

END

Date

02.05.00 FAD4_2RM

Code

Rev.

2

Page

14 of 20

FLINTEC

5 CALIBRATION EXAMPLES

5.1 STANDARD (WEIGHTS)

Assume a scale of 150kg / 50 g with dual interval at 60kg. The scale is constructed with 4x 100kg loadcells

2mV/V at 5 conversion/sec with normal digital filter. The calibration procedure should be as follows :

- Power on the FAD–4 .

- Send scale parameters

STX ADD P 1 2 0 4 0 1 2 BCS2 BCS1 ETX

STX ADD P 2 05 15 06 BCS2 BCS1 ETX

STX ADD P 3 2 0 0 1 1 0 BCS2 BCS1 ETX

STX ADD W BCS2 BCS1 ETX Write to EEPROM

- Wait FAD–4 to power up.

- Empty scale and send command.

STX ADD c 0 BCS2 BCS1 ETX

- Place a test weight (20kg) on CORNER 1 and send command:

STX ADD c 1 BCS2 BCS1 ETX

- Place the same test weight on CORNER 2 and send command:

STX ADD c 2 BCS2 BCS1 ETX

- Place the same test weight on CORNER 3 and send command:

STX ADD c 3 BCS2 BCS1 ETX

- Place the same test weight on CORNER and send command:

STX ADD c 4 BCS2 BCS1 ETX

- Empty scale and send command:

STX ADD a BCS2 BCS1 ETX DEADLOAD CALIBRATION

- Place a calibration weight (100kg) on the center of scale and send command:

STX ADD b 10000 BCS2 BCS1 ETX

Save calibration in EEPROM

STX ADD W BCS2 BCS1 ETX

- End.

Document

FAD - 4 DIGITAL LOADCELL JUNCTION BOX

Date

02.05.00 FAD4_2RM

Code

Rev.

2

Page

15 of 20

FLINTEC

5.2 ELECTRONIC (mV/V).

Assume a scale of Max= 30/60kg , e=0.010/0.020kg , with 4 loadcells of rated capacity 50kg -2mV/V each

and the dead load is 1.940kg.

Conversion rate is 5/sec , the digital filter is normal .

Loadcell data:

L/C1 : 1.9793 mV/V output at 50kg and zero balance : 0.0257 mV/V.

L/C2 : 1.9392 mV/V output at 50kg and zero balance : 0.0276 mV/V.

L/C3 : 1.9577 mV/V output at 50kg and zero balance : 0.0553 mV/V.

L/C4 : 1.9640 mV/V output at 50kg and zero balance : -0.0022 mV/V.

SPAN average = (1.9793 + 1.9392 + 1.9577 +1.9640) / 4=1.9600 mV/V

L/C ZERO BALANCE average = [0.0257 + 0.0276 + 0.0553 + (- 0.0022)] / 4 = 0.0266 mV/V

SCALE DEDLOAD : 1.9600 mV/V . 1.940 kg

OVERALL DEADLOAD = L/C ZERO BALANCE + SCALE DEADLOAD = 0.0456 mV/V

The calibration procedure should be as follows :

- Power on the FAD-4 .

- End.

= 0.0190 mV/V

(4x50kg)

Send CORNER DEFINITION commands:

STX ADD C 1 019793 BCS2 BCS1 ETX CORNER 1

STX ADD C 2 019392 BCS2 BCS1 ETX CORNER 2

STX ADD C 3 019577 BCS2 BCS1 ETX CORNER 3

STX ADD C 4 019640 BCS2 BCS1 ETX CORNER 4

Send DEAD LOAD calibration command :

STX ADD A 000456 BCS2 BCS1 ETX

Send SPAN calibration command :

STX ADD B 50000 BCS2 BCS1 ETX

RATED CAPACITY OF EACH LOADCELL

Send STORE command to save in EEPROM

STX ADD W BCS2 BCS1 ETX

Document

FAD - 4 DIGITAL LOADCELL JUNCTION BOX

Date

02.05.00 FAD4_2RM

Code

Rev.

2

Page

16 of 20

FLINTEC

6 OPERATION

All data from the FAD-4 is available through the serial interface.

When the unit is powered up or when the RESET command is received, the unit goes through an initialisation

procedure during which the CPU, memory and peripherals are checked.

The POST period is approximately 15 seconds. (Depends on the conversion rate).

Then the unit is ready for operation. Immediately after the POST the unit will autozero (if auto zero on

powerup is enabled).

To get the weight scan with file type “?”.

To set the scale to zero send file type “Z” . It will be executed only if the zero conditions are met.

(stable, +

To Tare the scale send file type “T”. It will be executed only if Tare conditions are satisfied (Stable, within

Max). To clear the tare and return to Gross send file type “G”.

To down load the setpoints :

a. send command “Q1” for the first setpoint.

b. send command “Q2” for the second setpoint.

The set point values must be within Max to be accepted.

The set point values downloaded will be lost in power down.

To save them permanently in EEPROM send “W” file type.

To upload the setpoints use the “q” file type.

During the POST period instead of weight the unit will return the following messages in response to “?”

command.

“DJB-4” The software code.

“V2.0” The version number.

If a Tilt switch is connected the weight output will be inhibited and E tilt will be transmitted when the scale is

tilted. Refer to command S and Annex A for software and hardware details of the tilt switch.

An indicator LED on pcb 703.2 signals the operational status of the FAD by flashing at intervals of 2sec.

One flash signals ok. Two flashes signal error.

2% Max).

Document

FAD - 4 DIGITAL LOADCELL JUNCTION BOX

Date

02.05.00 FAD4_2RM

Code

Rev.

2

Page

17 of 20

FLINTEC

7 ERRORS

This chapter provides information on error messages and troubleshooting instuctions.

Errors may be hardware or software related. They are output in the form Error xx, where xx is the error

code. The Master computer must send ACK block to acknowledge the error.

Following is a list of errors with indication of possible causes and probable remedy.

ERROR

ERR 01

ERR 02 System RAM. Faulty IC 2 Check solder connections or contact manufacturer

ERR 04 Calibration loss or faulty EEPROM IC 1 Recalibrate or contact manufacturer

ERR 05 Mechanical failure or loadcell or A/D converter

ERR 15 System has been initialised due to power failure

ERR 90 Not enough weight for span calibration

ERR 91 Calibration lock jumper is inserted, or software

POSSIBLE CAUSE

System ROM. Faulty IC 2

IC 13

or soft reset

lock is activated.

ACTION TO BE TAKEN

Check solder connections or contact manufacturer

Check scale, loadcell cables, reset DJB, power offwait 5sec-power on, contact manufacturer.

Empty scale and set to Zero .

Recalibrate.

Remove calibration lock jumper, or unlock

calibration.

TROUBLESHOOTING

SYMPTOMS ACTION TO BE TAKEN

* LED D10 does not light. *Check the ac/dc supply. If the power is present but there are no 5VDC check fuse F13.

Replace if necessary with same type fuse only.

*FAD-4 does not *Check communication setup (baud rate, data bits, parity, FAD address).

communicate with HOST. Check communication cable.

Check polarity of RS485 (Refer to drawing ‘FAD-4/703.2/088’).

*Weight output from *Decrease number of DJB (s) to be scanned at HOST.

FAD-4 is too slow. Increase Baud Rate.

Increase number of conversions per second.

*Corner calibration *Check number of load cells connected and setup parameters of FAD.

does not proceed. (e.g for a weigh system with 2 load cells, set number of load cells=2

Place a test weight on each corner in turn and verify (using internal resolution corner

reading) that there is a positive change in resolution.

Use calibration weight equal to 10-30% of each load cell capacity.

Check loadcells and connector screw terminals (if not tight push with a tool from the

opposite side of the screw).

*Weight output from *Check calibration data. Reduce external divisions or lower conversion rate

FAD-4 is not stable. or increase digital filter, check number of load cells. Check power supply

Check load cell connection(s) and cable(s). Check input and output resistance and

resistance between any terminal and shield.

*Weight Output is not the same *Check that the scale is mechanically OK and it is free on all sides.

on each corner. Check load cell connection(s) and cable(s). Check input and output resistance

and resistance between any terminal and shield.

Check calibration data. Recalibrate corners with sufficient stabilization time.

Document

FAD - 4 DIGITAL LOADCELL JUNCTION BOX

Date

02.05.00 FAD4_2RM

Code

Rev.

2

Page

18 of 20

FLINTEC

8 SPECIFICATIONS - MAINTENANCE

8.1 TECHNICAL SPECIFICATIONS

ACCURACY CLASS III

RESOLUTION Selectabe up to 99.000 dd (in accordance with regulations).

MAX TARE EFFECT - Max

AUTO ZERO TRACK Off or 0.5 dd setup selectable.

WEIGHT DIGITS 5

WEIGHT STEPS 1, 2, 5, 10, 20, 50

DIGITAL FILTER Rolling average ( 1, 2, 4 samples).

DIGITAL CALIBRATION Digital corner calibration, Deadload, Span and scale.

Parameters via serial commands. Calibration may be performed by

application of weights or by the mV/V values of each loadcell. No

interaction between deadload and span.

LOADCELL EXCITATION + 5 VDC

NUMBER OF LOADCELLS 1 to 4 selectable.

LOADCELL CONNECTION 4 wire technique. Max 4 loadcells 350 Ohm each.

ANALOG INPUT RANGE -0.25 to 4 mV / V for each loadcell. ( - 1.25 mV to 20 mV ).

MIN INPUT PER VSI 0.4 µV / increment.

INPUT AMPLIFIER Input noise 0.3µVp-p. Analogue filter passive 2pole 10Hz.

A/D CONVERTER Sigma delta 550.000 internal counts max.

Conversion speed 8, 20, 40 , 80 conversions / sec (selectable) divided by

the number of loadcells used (Max 40).

LINEARITY Within 0,002% of full scale.

SPAN TEMP - COEFF <

ZERO TEMP - COEFF <

LONG TERM STABILITY 0.005 % of full scale per year.

DIGITAL PART CPU 89C55 with reset and watchdog ,EEPROM calibration memory.

COMMUNICATIONS - RS485A serial port half duplex. (Default it is 9600, E, 7, 1. )

- Baudrate 2400 to 115000 baud set up selectable.

- 1 start bit, 7 or 8 data bits, even or no parity, 1 stop bit.

POWER SUPPLY 7-10 VAC or 7.5 – 12 VDC external / 150mA.

POWER CONSUMPTION 1.8 W max with 4 x 350 Ohm loadcells.

DIGITAL INPUT (x1) 24Vdc +

On/Off delay 2msec. Optoisolated to 2.5 kV.

DIGITAL OUTPUT (x2) 24Vdc +

ANALOG OUTPUT Optoisolated, current out . Hardware selectable 0-20 mA or 4-20 mA.

POWER SUPPLY External 15-24 VDC / 35 mA max.

RESOLUTION 16 bit (1/65535) Full scale.

RELATIVE ACCURACY + 0.012% MAX.

OFFSET AT 25oC + 0.05% MAX.

OFFSET DRIFT 50ppm/

TOTAL OUTPUT ERROR +0.15% (20mA) AT 25

TOTAL OUTPUT DRIFT 50ppm /

EMC COMPATIBILITY Compliant with EN 45501 standards.

2 ppm / oC

2 ppm / oC

TTL serial port for either Display and Keyboard or analogue interface Digital

tilt interface. TTL multiprocessor interface.

20% negative common. Input impedance 3.3 KΩ.

10% transistor (sink) negative common.

Max Current 10mA. Max off state voltage 30VDC. Leakage current

50µA. On/off delay 2msec. Optoisolated to 2.5 kV.

o

C.

o

C MAX.

o

C.

Document

FAD - 4 DIGITAL LOADCELL JUNCTION BOX

Date

02.05.00 FAD4_2RM

Code

Rev.

2

Page

19 of 20

FLINTEC

8.2 ENVIRONMENTAL CONSIDERATIONS

AMBIENT : Storage -10 to +70 0C.

TEMPERATURE Operating -10 to +40

HUMIDITY : 40 to 90% RH (non condensing)

VIBRATION : Severe vibration can affect the accuracy of weighing and damage

electric / electronic components.

AIR : The surrounding air should be dust free and not contain any corrosive

gasses or materials which could adversely affect the equipment.

PROTECTION : IP65.

ELECTROMAGNETIC: Heavy electrical equipment should not be installed close to the weighing

FIELDS equipment.

INCOMING AND : Relays and contactors connected to the equipment must have reliable and

OUTGOING SIGNALS effective interference suppression. This also applies to other equipment

located within a distance of 3m from out equipment. Cabling must be

performed according to normal practice.

NOTES : - WELDING on or in the vicinity of the equipment is strictly

prohibited.

- STATIC loads, caused by thunderstorms, have to be prevented from

developing by use of reliable lightning conductors.

- ENSURE that the cooling of the equipment is not obstructed.

0

C.

8.3 MAINTENANCE

The unit does not require any routine maintenance. It may be necessary to perform periodic check of the

calibration of the scale due to mechanical reasons. The frequency of the calibration checks depends on the

application condition and on the required measuring accuracy.

It may happen that, in exceptional conditions, the unit locks on a wrong memory location and it is no

possible to restart because the keyboard is not operative.

To restart it is necessary to switch the power OFF the ON again.

8.4 SERVICE

- There are no serviceable parts. The unit may be repaired by trained personal only. The user may

check loadcell connection and power supply.

- LOADCELLS

Loadcells are reliable and very rarely present errors. Check input and output resistance, and

resistance between any terminal and shield. Check loadcell connection and cable.

- POWER SUPPLY

Check the ac/dc supply. If the power is present but there are no 5 VDC on the board check the

200 mA auto-reset fuse. Replace if necessary with same type fuse only.

Document

FAD - 4 DIGITAL LOADCELL JUNCTION BOX

Date

02.05.00 FAD4_2RM

Code

Rev.

2

Page

20 of 20

Flintec GmbH

Bemannsbruch 9

D 74909 Meckesheim

0

FLINTEC

Konformitätserklärung

Declaration of conformity

Déclaration de conformité

Die nichtselbsttätige Waage

The non-automatic weighing instrument

L’instrument de pesage à fonctionnement non automatique

Hersteller:

Manufacturer.

Fabricant:

Typ/ Modell:

Type l Model:

Type / modèle:

Nr. der EG-Bauartzulassung (gegebenenfalls):

No of the EC type-approval certificate (where applicable):

N° du certificat d'approbation CE de type (le cas échéant):

entspricht dem in der Bescheinigung über die Bauartzulassung beschriebenen Baumuster sowie

den Anforderungen der EG-Richtlinie 90/384/EWG in der jeweils geltenden Fassung und den

Anforderungen folgender Richtlinien:

corresponds to the production model described in the EC type-approval certificate and to the requirements

of the Council Directive 901384lEEC as amended and to the requirements of the following EC directives:

correspond au modèle décrit dans le certificat d'approbation CE de type, aux exigences de la directive

90/384/CEE modifiée et aux exigences des directives CE suivantes:

89/336/EWG 891336lEE 89/336/CEE

73/23/EWG 73123lEEC 73/23/CEE

entsprechend den folgenden Normen:

in conformity with the following standards:

conforme aux normes suivantes:

EN 45501

EN 50081-1

EN 50082-1

EN 60950

Diese Erklärung gilt nur in Verbind ung m it einer Konf o rmitätsbescheinigung einer benannten Stelle.

This declaration is only valid with a certificate of conformity by a notified body.

Cette déclaration est valide seulement avec une attestation de conformité d'un organisme notifié.

III

Flintec GmbH

FT-01, FT-02, FT-03, FT-04

FAD-1, FAD-4, FDT-A/B

DK 0199.37/1

Unterschrift Datum 8. Februar 2002

Signature Date February 8, 2002

Signature Date 8ième février 2002

Directeur

Gerhard K. Adam

Geschäftsführer

General Manager

ADDITION No. DK 0199.37/1

to

CERTIFICATE

of

EU TYPE-APPROVAL

No. DK 0199.37

of

FT-01 / FT-02 / FT-03 / FT-04 / FAD-1 / FAD-4 / FDT-A/B

NON-AUTOMATIC WEIGHING INSTRUMENT

Issued by DELTA Danish Electronics, Light & Acoustics

EU - Notified Body No. 0199

In accordance with the requirements of the non-automatic weighing instruments regulation

No. 560 of 23 June 1992 which implements, in Denmark, Council Directive 90/384/EEC.

Issued to Flintec GmbH

Bemannsbruch 9

74909 Meckesheim

Germany

In respect of Non-automatic weighing instrument designated

FT-01 / FT-02 / FT-03 / FT-04 / FAD-1 / FAD-4 / FDT-A/B

with variants of modules.

Accuracy class III

Maximum capacity, Max: From 1 kg up to 99,000 kg

Verification scale interval: e = Max / n

Maximum number of verification scale intervals: n = 10000

(however dependent on environment and the composition

of the modules).

Variants of modules and conditions for the composition

of the modules are set out in the ANNEX.

The conformity with the essential requirements in annex 1 of the Directive is met.

Note: This addition is a revised edition, which replaces the certificate

No. DK 0199.37.

The principal characteristics and approval conditions are set out in the descriptive

ANNEX to this certificate.

DELTA

Danish Electronics,

Light & Acoustics

Venlighedsvej 4

2970 Hørsholm

Denmark

Tel. (+45) 72 19 40 00

Fax (+45) 72 19 40 01

www.delta.dk

VAT DK 12275110

The ANNEX comprises 30 pages.

Issued on 2002-03-08

Valid until 2011-07-11 Signatory: P. Bengtsen

DK 0199.37A1e.doc

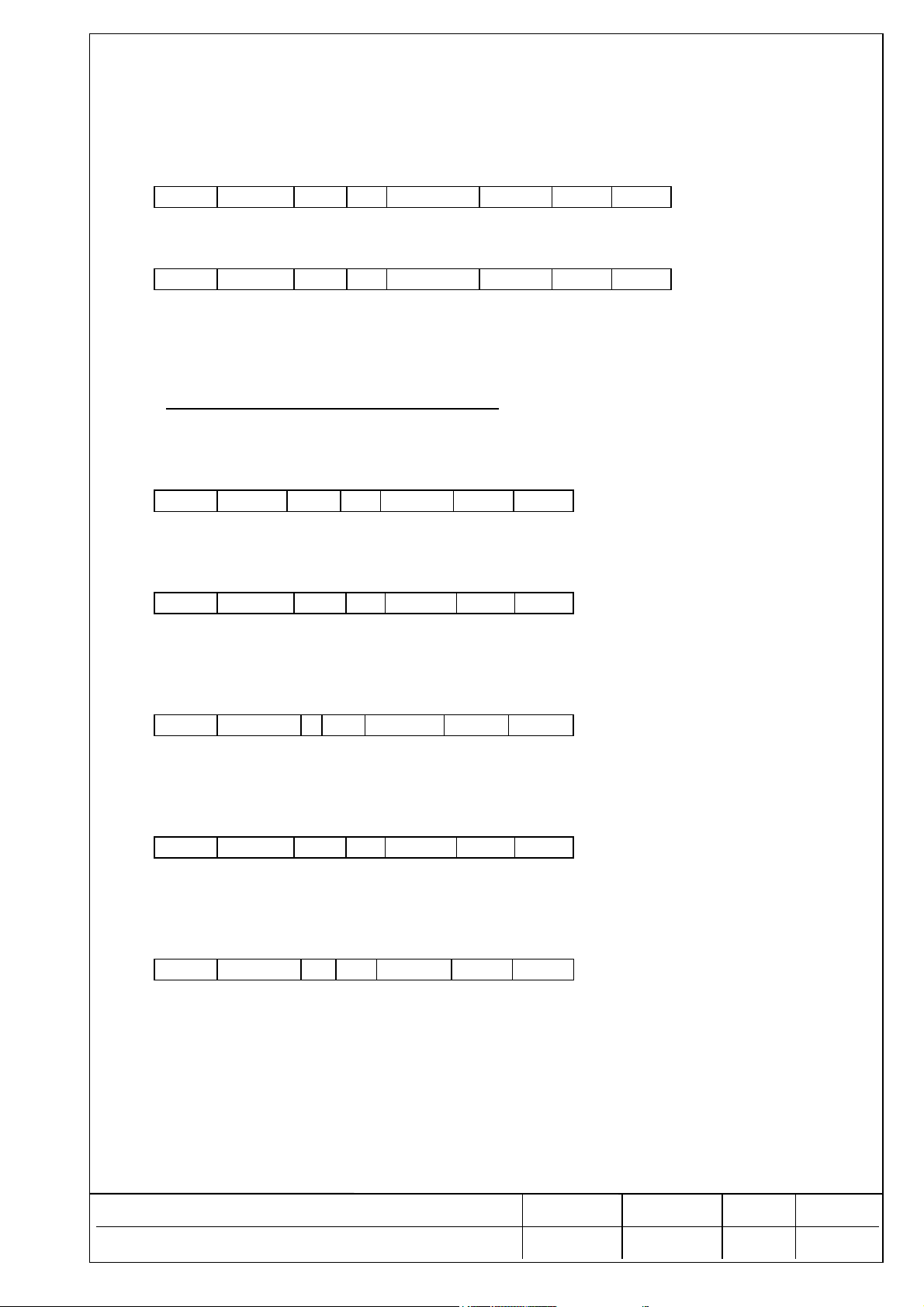

ST 5

ST 3

Power supply

24 VDC

1

F

23

common (-)

1

Input (Zero)

2

Setpoint 2

3

Setpoint 1

4

4 1

2

Tilt sensor

312 4

ST2

4

(0 - 20 mA / 4 - 20 mA)

3

2

(15 - 24 VDC / 35 mA)

1

ST1

JP1

JP2

4-20 mA

JP1

JP2

0-20 mA

Output selection

FAD-4

FAD-4

FAD-4

MASTER (PC, PLC)

+ V

470R

e

c

n

A

a

t

s

i

s

e

R

l

a

n

i

m

r

e

T

B

470R

RT

150R

SLAVE 1

A B

SLAVE 2

A

B

2 x 0,34 qmm (twisted pair) , shielded

Max. length 1000 m

SLAVE 26

A B

Terminal -

RT

Resistance

Cabling RS 485 Network

1

2

load cells

3

4

- SIG

+ SIG

SHLD

- EXC

+ EXC

- SIG

+ SIG

SHLD

- EXC

+ EXC

- SIG

+ SIG

SHLD

- EXC

+ EXC

- SIG

+ SIG

SHLD

- EXC

+ EXC

St6

St7

St8

St9

FLINTEC

FAD - 4

JP1

CAL - lock

ST1

ST2

RS485 Termination

Resistor

ST3

ST4

ST5

JP2

Power supply

7-10 VAC / 7,5-12 VDC

A

RS485

B

Tilt sensor

Output 1

Output 2

Input

common

Loading...

Loading...