A/D Converter

FAD-30

Technical Manual

Flintec GmbH

Bemannsbruch 9

74909 Meckesheim

GERMANY

www.flintec.com

FAD-30 Technical Manual, Rev. 1.06 December 2012 Page 1 of 48

Table of Contents:

1. SAFETY INSTRUCTIONS ........................................................................................................................... 4

2. DECLARATION OF CONFORMITY ........................................................................................................... 5

3. INTRODUCTION ......................................................................................................................................... 6

3.1. Overview ...................................................................................................................................................... 6

3.2. Key features and Specifications .................................................................................................................. 7

3.3. Housing ........................................................................................................................................................ 9

3.4. Accessories .................................................................................................................................................. 9

4. INSTALLATION......................................................................................................................................... 10

4.1. Recommendations ..................................................................................................................................... 10

4.1.1. Control Cabinet Design ................................................................................................................................ 10

4.1.2. Cabling ......................................................................................................................................................... 10

4.1.3. Mechanical Installation ................................................................................................................................. 10

4.2. Electrical Connections ............................................................................................................................... 10

4.2.1. Power Supply and Grounding ...................................................................................................................... 10

4.2.2. Load Cell Connection ................................................................................................................................... 11

4.2.3. Communication Interface ............................................................................................................................. 11

4.3. Commissioning .......................................................................................................................................... 11

5. SETUP ....................................................................................................................................................... 12

5.1. Installation of the xFace Software.............................................................................................................. 12

5.2. Connection to the xFace Software............................................................................................................. 12

5.3. A/D Converter Setup and Calibration ........................................................................................................ 13

5.3.1. Scale Parameters ........................................................................................................................................ 13

5.3.2. Serial Interface Setup .................................................................................................................................. 14

5.3.3. Scale Build and Calibration .......................................................................................................................... 15

5.4. A/D Converter Performance Test .............................................................................................................. 18

5.5. Bus Interface Setup ................................................................................................................................... 18

5.6. Bus Addressing via Setup Switch .............................................................................................................. 18

5.7. Back up Settings and Calibration Data ...................................................................................................... 18

5.8. Continuous Output Data Structure (for FAD-30 + FAD-30MB only) .......................................................... 19

5.9. BSI Data Structure (for FAD-30 + FAD-30MB only) .................................................................................. 20

5.10. Modbus Data Structure (for FAD-30MB + FAD-30EN only) .................................................................. 23

5.11. Profibus and ProfiNet Data Structure (for FAD-30Px only) .................................................................... 25

5.12. CANopen Data Structure (for FAD-30CO only) ..................................................................................... 28

6. FAD-30 / FAD-30MB – WITH RS-485 INTERFACE ................................................................................. 31

6.1. Front View .................................................................................................................................................. 31

6.2. Electrical Connections ............................................................................................................................... 32

6.3. Interfacing .................................................................................................................................................. 32

6.4. Setup and Calibration ................................................................................................................................ 32

6.5. Modbus RTU Setup (for FAD-30MB only) ................................................................................................. 33

7. FAD-30PB – WITH PROFIBUS INTERFACE ........................................................................................... 34

7.1. Front View .................................................................................................................................................. 34

7.2. Electrical Connections ............................................................................................................................... 35

7.3. Interfacing .................................................................................................................................................. 36

7.4. Setup and Calibration ................................................................................................................................ 36

7.5. Profibus Setup ........................................................................................................................................... 36

8. FAD-30PN – WITH PROFINET INTERFACE ........................................................................................... 37

8.1. Front View .................................................................................................................................................. 37

8.2. Electrical Connections ............................................................................................................................... 38

8.3. Interfacing .................................................................................................................................................. 39

8.4. Setup and Calibration ................................................................................................................................ 39

8.5. ProfiNet Setup............................................................................................................................................ 39

9. FAD-30EN – WITH ETHERNET INTERFACE .......................................................................................... 40

9.1. Front View .................................................................................................................................................. 40

9.2. Electrical Connections ............................................................................................................................... 41

9.3. Interfacing .................................................................................................................................................. 42

9.4. Setup and Calibration ................................................................................................................................ 42

9.5. Ethernet Setup ........................................................................................................................................... 42

FAD-30 Technical Manual, Rev. 1.06 December 2012 Page 2 of 48

10. FAD-30CO – WITH CANOPEN INTERFACE ........................................................................................... 43

10.1. Front View .............................................................................................................................................. 43

10.2. Electrical Connections ............................................................................................................................ 44

10.3. Interfacing ............................................................................................................................................... 45

10.4. Setup and Calibration ............................................................................................................................. 45

10.5. CANopen Setup ..................................................................................................................................... 45

11. ERROR TABLE ......................................................................................................................................... 46

12. DIAGNOSTICS .......................................................................................................................................... 47

13. FREQUENTLY ASKED QUESTIONS ...................................................................................................... 48

RIGHTS AND LIABILITIES

All rights reserved.

No part of this publication may be reproduced, stored in a retrieval system, or transmitted in any form or by any

means, mechanical, photocopying, recording, or otherwise, without the prior written permission of Flintec

GmbH

No patent liability is assumed with respect to the use of the information contained herein. While every

precaution has been taken in the preparation of this book, FLINTEC assumes no responsibility for errors or

omissions. Neither is any liability assumed for damages resulting from the use of the information contained

herein.

The information herein is believed to be both accurate and reliable. FLINTEC, however, would be obliged to be

informed if any errors occur. FLINTEC cannot accept any liability for direct or indirect damages resulting from

the use of this manual.

FLINTEC reserves the right to revise this manual and alter its content without notification at any time.

Neither FLINTEC nor its affiliates shall be liable to the purchaser of this product or third parties for damages,

losses, costs, or expenses incurred by purchaser or third parties as a result of: accident, misuse, or abuse of

this product or unauthorized modifications, repairs, or alterations to this product, or failure to strictly comply with

FLINTEC operating and maintenance instructions.

FLINTEC shall not be liable against any damages or problems arising from the use of any options or any

consumable products other than those designated as Original FLINTEC Products.

NOTICE: The contents of this manual are subject to change without notice.

Copyright © 2010-2011 by Flintec GmbH, 74909 Meckesheim, Bemannsbruch 9, Germany

FAD-30 Technical Manual, Rev. 1.06 December 2012 Page 3 of 48

1. SAFETY INSTRUCTIONS

CAUTION READ this manual BEFORE operating or servicing this equipment. FOLLOW

these instructions carefully. SAVE this manual for future reference. DO NOT allow untrained

personnel to operate, clean, inspect, maintain, service, or tamper with this equipment.

ALWAYS DISCONNECT this equipment from the power source before cleaning or performing

maintenance. CALL FLINTEC ENGINEERING for parts, information, and service.

WARNING ONLY PERMIT QUALIFIED PERSONNEL TO SERVICE THIS EQUIPMENT.

EXERCISE CARE WHEN MAKING CHECKS, TESTS AND ADJUSTMENTS THAT MUST BE

MADE WITH POWER ON. FAILING TO OBSERVE THESE PRECAUTIONS CAN RESULT

IN BODILY HARM.

WARNING FOR CONTINUED PROTECTION AGAINST SHOCK HAZARD CONNECT TO

PROPERLY GROUNDED OUTLET ONLY. DO NOT REMOVE THE GROUND PRONG.

WARNING DISCONNECT ALL POWER TO THIS UNIT BEFORE REMOVING THE FUSE

OR SERVICING.

WARNING BEFORE CONNECTING/DISCONNECTING ANY INTERNAL ELECTRONIC

COMPONENTS OR INTERCONNECTING WIRING BETWEEN ELECTRONIC EQUIPMENT

ALWAYS REMOVE POWER AND WAIT AT LEAST THIRTY (30) SECONDS BEFORE ANY

CONNECTIONS OR DISCONNECTIONS ARE MADE. FAILURE TO OBSERVE THESE

PRECAUTIONS COULD RESULT IN DAMAGE TO OR DESTRUCTION OF THE

EQUIPMENT OR BODILY HARM.

CAUTION OBSERVE PRECAUTIONS FOR HANDLING ELECTROSTATIC SENSITIVE

DEVICES.

FAD-30 Technical Manual, Rev. 1.06 December 2012 Page 4 of 48

2. DECLARATION OF CONFORMITY

EG-Konformitätserklärung

EC-Declaration of Conformity

Monat/Jahr: month/year:

05/2010

Hersteller: Manufacturer:

Flintec GmbH

Anschrift: Address:

Bemannsbruch 9

D-74909 Meckesheim

Deutschland / Germany

Produktbezeichnung: Product name:

FAD-30 A/D Converter Series

Das bezeichnete Produkt stimmt mit folgenden Vorschriften der Europäischen Richtlinien überein:

This product confirms with the following regulations of the Directives of the European Community

Richtlinie 2004/108/EG des Europäischen

Parlaments und des Rates vom 15. Dezember 2004

zur Angleichung der Rechtsvorschriften der

Mitgliedstaaten über die elektromagnetische

Verträglichkeit und zur Aufhebung der Richtlinie

89/336/EWG

Directive 2004/108/EC of the European Parliament and of the

Council of 15th December 2004 on the approximation of the

laws of the Member States relating to electromagnetic

compatibility and repealing Directive 89/336/EEC

Richtlinie 2006/95/EG Niederspannungs-Richtlinie

Directive 2006/95/EC Low Voltage Directive

Die Absicherung aller produktspezifischen

Qualitätsmerkmale erfolgt auf Basis eines zertifizierten

Qualitätsmanagement-Systems nach DIN ISO 9001.

All product-related features are assured by a quality

system in accordance with ISO 9001.

Diese Erklärung bescheinigt die Übereinstimmung mit

den genannten Richtlinien, beinhaltet jedoch keine

Zusicherung von Eigenschaften.

This declaration certifies the conformity with the listed

directives, but it is no promise of characteristics.

Folgende Normen werden zum Nachweis der Übereinstimmung mit den Richtlinien eingehalten:

As a proof of conformity with the directives following standards are fulfilled:

EN 61326-1

Elektrische Mess-, Steuer-, Regel- und Laborgeräte - EMV-Anforderungen - Teil 1: Allgemeine

Anforderungen (IEC 61326-1:2005)

Electrical equipment for measurement, control and laboratory use - EMC requirements - Part 1: General

requirements (IEC 61326-1:2005)

EN 60950-1

Einrichtungen der Informationstechnik - Sicherheit - Teil 1: Allgemeine Anforderungen (IEC 609501:2005, modifiziert);

Information technology equipment - Safety - Part 1: General requirements (IEC 60950-1:2005 modified)

FAD-30 Technical Manual, Rev. 1.06 December 2012 Page 5 of 48

3. INTRODUCTION

FAD-30 A/D Converter

with RS485 interface

FAD-30PB A/D Converter with

Profibus DP interface

FAD-30EN A/D Converter with

Ethernet TCP/IP interface

FAD-30MB A/D Converter with

Modbus RTU interface

FAD-30PN A/D Converter with

ProfiNet interface

FAD-30CO A/D Converter with

CANopen interface

3.1. Overview

The type FAD-30 A/D Converter Series consists of powerful and economic state-of-the-art instruments for static

and dynamic weighing applications plus force and torque measurements.

Each instrument of the series converts the analogue low level signal from a load cell or a strain gauge sensor to

a digital high-resolution and high-accuracy signal and transmits the digital data to an external PLC or PC

system. As a special feature the instruments can switch between unipolar and bipolar input range without

affecting the external resolution.

The type FAD-30 A/D Converter Series comprises various instuments for different industrial bus systems:

Figure 3.1 – FAD-30 A/D Converter series instruments

FAD-30 Technical Manual, Rev. 1.06 December 2012 Page 6 of 48

3.2. Key features and Specifications

Key Features

FAD-30

FAD-30MB

FAD-30PB

FAD-30PN

FAD-30EN

FAD-30CO

Bipolar signal input in Force and Count modes

Yes

Yes

Yes

Yes

Yes

Yes

500 to 100 000 counts external resolution at calibrated data

Yes

Yes

Yes

Yes

Yes

Yes

Unipolar 1 million and bipolar 2 million counts is adjusted and filtered

to external resolution in count mode

Yes

Yes

Yes

Yes

Yes

Yes

High internal resolution up to 8 million counts

Yes

Yes

Yes

Yes

Yes

Yes

Up to 800 conversions per second

Yes

Yes

Yes

Yes

Yes

Yes

Standard Serial interface RS-232C

Yes

Yes

Yes

Yes

Yes

Yes

Standard Serial interface RS-485A

Yes

Yes

No

No

No

No

Modbus RTU interface

No

Yes

No

No

No

No

Profibus DP-V1 interface

No

No

Yes

No

No

No

ProfiNet interface

No

No

No

Yes

No

No

Ethernet (Modbus TCP/IP or BSI) interface

No

No

No

No

Yes

No

CANopen interface

No

No

No

No

No

Yes

Continuous data output

Yes

Yes

No

No

No

No

BSI data interface

Yes

Yes

No

No

No

No

Bus address selection by setup switch (from 0 to 7)

Yes

Yes

Yes

No

No

Yes

Setup by Flintec xFace PC software

Yes

Yes

Yes

Yes

Yes

Yes

Auto-zero tracking and auto-zero at power-up

Yes

Yes

Yes

Yes

Yes

Yes

Motion detection

Yes

Yes

Yes

Yes

Yes

Yes

Zeroing and Taring by bus commands

Yes

Yes

Yes

Yes

Yes

Yes

Adaptive digital filter for fast and stable reading

Yes

Yes

Yes

Yes

Yes

Yes

Up to 6 load cells (350 Ω) or 18 load cells (1100 Ω)

Yes

Yes

Yes

Yes

Yes

Yes

Electronic calibration (eCal) without test weights

Yes

Yes

Yes

Yes

Yes

Yes

Zero and Span calibrations over bus interface

Yes

Yes

Yes

Yes

Yes

Yes

Zero adjustment

Yes

Yes

Yes

Yes

Yes

Yes

Span adjustment with test weights

Yes

Yes

Yes

Yes

Yes

Yes

Span adjustment with temporary zeroing for unloaded tanks

Yes

Yes

Yes

Yes

Yes

Yes

Power-on testing with setup switch

Yes

Yes

Yes

Yes

Yes

Yes

24 V DC power supply (11 to 28 V DC input voltage range)

Yes

Yes

Yes

Yes

Yes

Yes

A/D Converter:

A/D converter type:

24 bit Delta-Sigma radiometric with integral analog and digital filters

Analog input range:

0 mV to +18 mV ( unipolar ) ; - 18 mV to +18 mV ( bipolar )

Linearity:

< 0.0015 % FS

Temperature coefficient:

< 2 ppm/°C

Min. input per vsi

0.1 μV/d (non approved)

Conversion rate:

Up to 800 measurement values per second

Internal resolution:

Up to 8 million counts

External resolution

Up to 100 000 counts (weight value, force, torque) respective

1 million raw counts (unipolar) respective 2 million counts (bipolar)

Calibration and Weighing Functions:

Calibration:

Electronic calibration without test weights (eCal) or calibration by test weights

Digital filter:

10 step programmable adaptive filter

Weighing functions:

Tare, zero, auto zero tracking, motion detection, auto-zero at power-up, save

tare at power-off, increased resolution

Load cells:

Excitation:

5 V DC at 58...1200 Ω, max. 100 mA

Number of load cells:

Up to 6 load cells à 350 Ω or 18 load cells à 1100 Ω in parallel

Connection:

4- or 6-wire technique, cable length 250 m/mm² for 6-wire connection

Specifications

FAD-30 Technical Manual, Rev. 1.06 December 2012 Page 7 of 48

Communication and Setup:

Serial interface RS-232C:

9600 baud (8,N,1)

Other interfaces

Depends on instrument type

Response time

< 4 ms (delay after each read or write command)

Setup and calibration

By PC software via RS232C, backup data stored on PC

Power supply:

DC power supply

10 to 28 VDC, < 200 mA, not galvanically isolated

Environment and Enclosure:

Operation temperature:

Between -10 °C and +40 °C at maximum 85% RH max, non-condensing

Enclosure and protection

Polyamide, for DIN-rail mounting, IP20

Instrument with RS485 interface: Type FAD-30

Communication:

Serial interface RS485

1200 to 57600 baud (8N1, 7E1, 7O1), bus capability up to 31 units

Communication mode

Continuous or requested

Dimensions & weight

99 x 22.5 x 114.5 mm (L x W x H), weighs approx. 110 g

Instrument with Modbus RTU interface: Type FAD-30MB

Communication:

Serial interface RS485

1200 to 57600 baud (8N1, 7E1, 7O1), bus capability up to 31 units

Communication mode

Continuous or requested or Modbus RTU

Address range

1...31

Dimensions & weight

99 x 22.5 x 114.5 mm (L x W x H), weighs approx. 110 g

Instrument with Profibus DP interface: Type FAD-30PB

Communication:

Profibus DP-V0 + DP-V1

9,6 kbit/s to 12 Mbit/s (automatic), galvanically isolated interface

Address range

1...126

Dimensions & weight

99 x 45 x 114.5 mm (L x W x H), weighs approx. 150 g

Instrument with ProfiNet interface: Type FAD-30PN

Communication:

ProfiNet

100 Mbit/s (full duplex), galvanically isolated interface

IP settings

DHCP or manual setup by PC software

Dimensions & weight

99 x 45 x 114.5 mm (L x W x H), weighs approx. 150 g

Instrument with Ethernet TCP/IP interface: Type FAD-30EN

Communication:

Ethernet TCP/IP

10 Mbit/s (half duplex), galvanically isolated interface

IP settings

Manual setup by PC software

Dimensions & weight

99 x 45 x 114.5 mm (L x W x H), weighs approx. 150 g

Other

Web client interface

Instrument with CANopen interface: Type FAD-30CO

Communication:

CANopen V.2.0

10 kbit/s...1 Mbit/s (automatic), galvanically isolated interface

Address range

1...126

Dimensions & weight

99 x 45 x 114.5 mm (L x W x H), weighs approx. 150 g

FAD-30 Technical Manual, Rev. 1.06 December 2012 Page 8 of 48

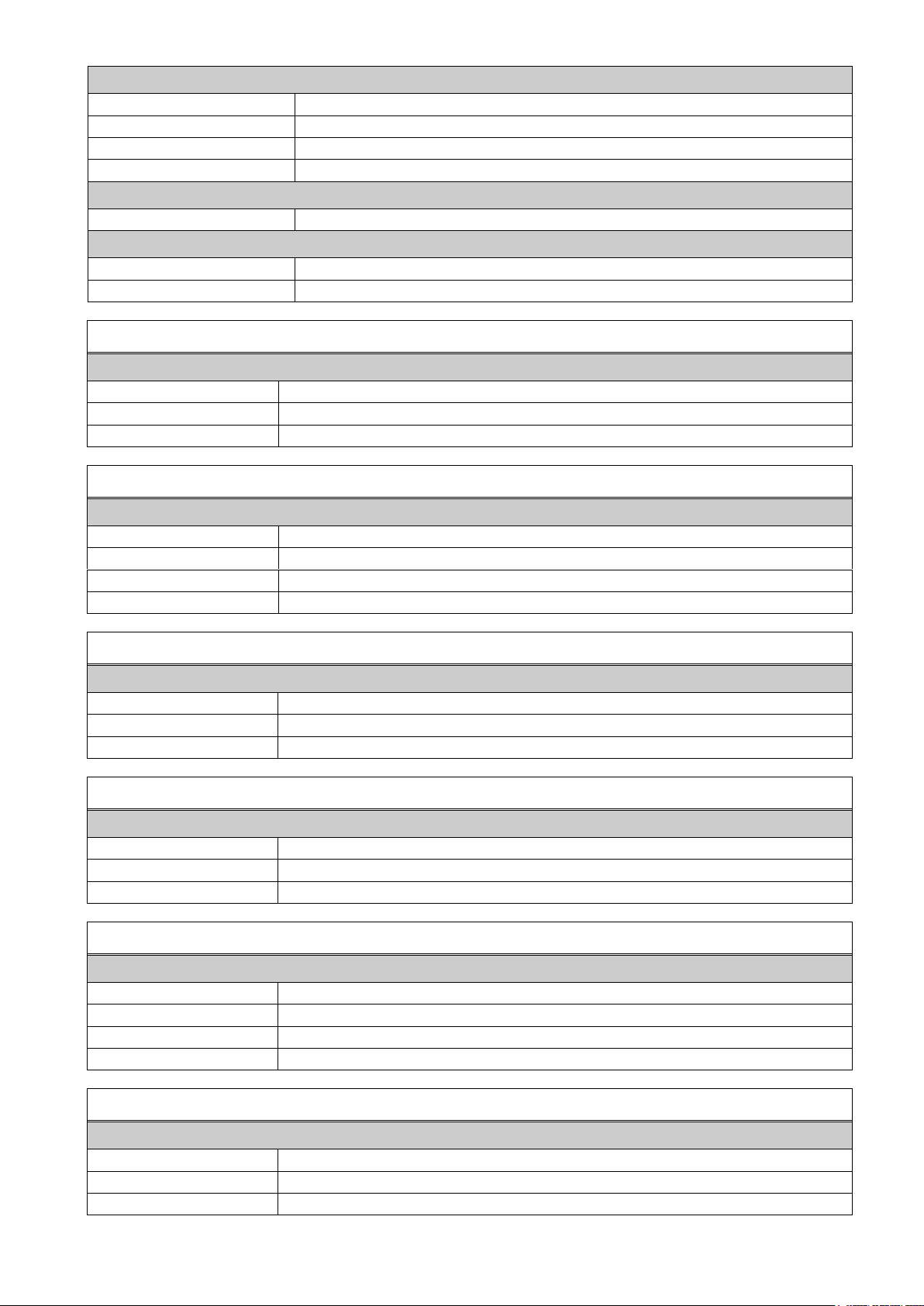

3.3. Housing

22,5 mm 45 mm

99 mm

114,5 mm

View A View B Side view

View A: FAD-30, FAD-30MB

View B: FAD-30PB, FAD-30PN, FAD-30EN, FAD-30CO

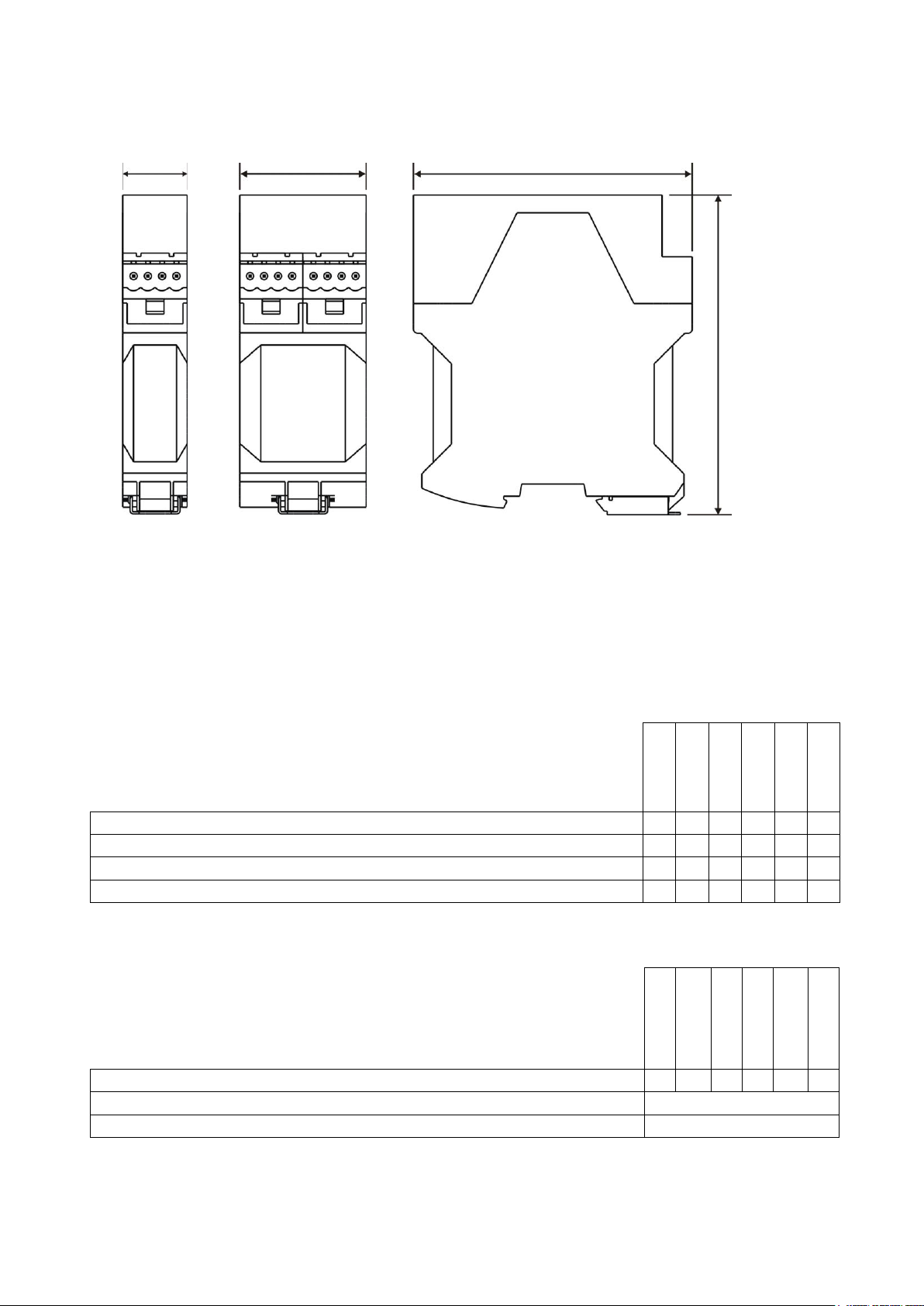

The following accessories are supplied together with the instrument. If any part

is missing, please contact your supplier.

FAD-30

FAD-30MB

FAD-30EN

FAD-30PB

FAD-30PN

FAD-30CO

4-pin and 5 mm pitch plug, light gray

1 1 2 2 2 2 7-pin and 3.81 mm pitch plug for load cell cable, black

1 1 1 1 1

1

6-pin and 3.81 mm pitch plug for RS-232C and RS-485, black

1 1 Installation CD (xFace software, technical documentation)

1 1 1 1 1

1

The following accessories are available from Flintec.

RS-232C cable (3 m long) for connection with PC

√ √ √ √ √ √ Junction box for load cell connection

Refer to Flintec catalog

Open end load cell cable, 6 wire ( 0.22 cm2 each )

Max. 200 meter length

FAD-30 instruments come within a polyamide housing sealed to IP20. They are prepared for mounting on NS

37/7 or NS 35/15 standard DIN rails (see drawings).

Figure 3.2 – Dimensions

3.4. Accessories

Accessories supplied with the instrument

Table 3.1 – Accessories supplied with instrument

Accessories sold separately

FAD-30 Technical Manual, Rev. 1.06 December 2012 Page 9 of 48

Table 3.2 – Accessories supplied separately

4. INSTALLATION

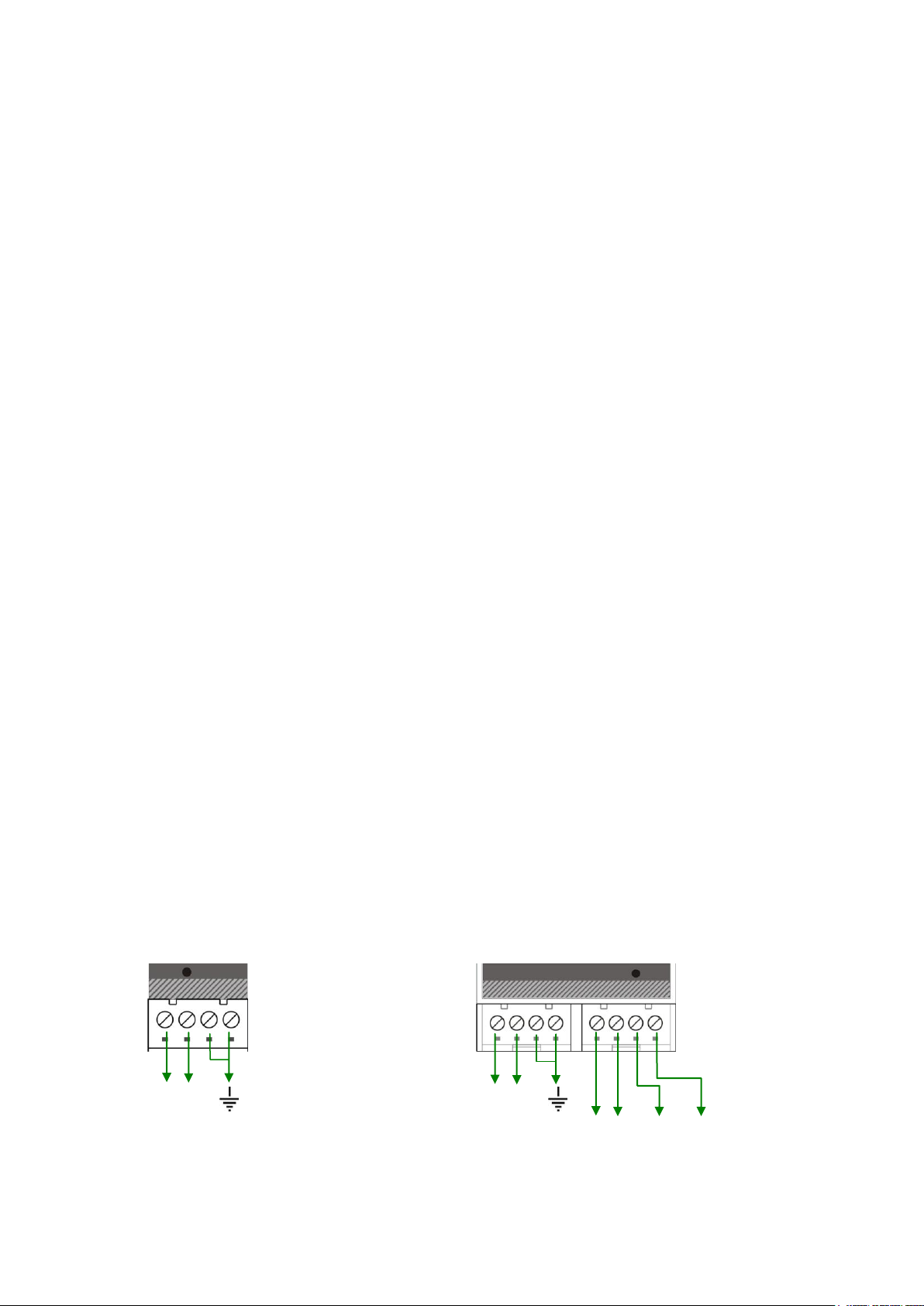

FAD-30 and

FAD-30MB

(front view)

FAD-30EN,

FAD-30PB,

FAD-30PN and

FAD-30CO

(front view)

24V 0V

24V 0V

TX RX GND Shield

Warning: Do not forget to connect the Shield pin to the reference ground.

PRECAUTION: Please read this manual carefully before you install the instrument. If you apply all

recommendations in this chapter you will increase the reliability and long term performance of your system.

4.1. Recommendations

4.1.1. Control Cabinet Design

Warning: Please follow the following warnings for designing the control cabinet which will increase the

reliability of your system.

The control cabinet should be designed therefor the A/D converters can operate safely. The panel should be

placed in a clean area, without getting direct sun light if possible, with a temperature between -10 ºC and +40

ºC, humidity not exceeding 85% non-condensing. All external cables should be installed safely to avoid

mechanical damages.

FAD-30 instruments are very low level signal measuring instruments. To avoid electrical noise, the instruments

should be separated from equipment that produces electrical noise. Preferably use a metal cabinet against

radio frequency interference, to protect against electromagnetic disturbance the cabinet shall be connected to

ground. Keep the load cell cable trays separated from others, if possible. If there is noise-generating equipment

such as heavy load switches, motor control equipment, inductive loads etc., please be careful against the EMC

interference in the cabinet. If possible protect FAD-30 instruments by a Faraday cage or install them in a

separate section or install them far a way from this kind of equipment. Install parallel reverse diodes to the DC

inductive loads like relays, solenoids etc. to minimize voltage peaks on the DC power lines.

4.1.2. Cabling

All cables coming to the control cabinet shall be shielded. Please use separate cable trays for these low signal

level cables. Distance from load cell cables, interface cables and DC power supply cables to power line cables

shall be 50 cm at minimum.

4.1.3. Mechanical Installation

After designing the control panel and installing DIN rails according to the recommendation in this chapter, place

the FAD-30 instruments on the DIN rail Be sure that the mechanical installation of the instruments is done

properly.

4.2. Electrical Connections

Warning: Please always remember that FAD-30 instruments are very low voltage measuring instruments. Your

control cabinet design and proper installation increases the reliability and the performance of the instrument.

Please do not forget that the instrument must be powered off before inserting or removing any peripheral

connector. All required electrical connections should be done as described below.

4.2.1. Power Supply and Grounding

The power supply voltage of the instrument shall be between 12 V DC and 28 V DC. The current consumption

of the power supply will be calculated by multiplying 0.2 A and the quantity of instruments. The pin configuration

of the 24 V DC power supply connector located at the bottom front of the instrument is shown below in figure

4.1.

Figure 4.1 – The pin layout of 24 V DC connector

FAD-30 Technical Manual, Rev. 1.06 December 2012 Page 10 of 48

The quality of the instrument‟s ground will determine the accuracy and the safety of your measuring system. A

Load Cell

Connector

4 wire LC connection

6 wire LC connection

Warning: Connect the load cell cable shield to the reference ground or the

shield pin of the load cell connector.

Please refer to the corresponding chapter:

FAD-30 (RS485)

see chapter 6.2

FAD-30MB (Modbus RTU)

see chapter 6.2

FAD-30PB (Profibus)

see chapter 7.2

FAD-30PN (ProfiNet)

see chapter 8.2

FAD-30EN (Ethernet and Modbus TCP)

see chapter 9.2

FAD-30CO (CANopen)

see chapter 10.2

proper ground connection is needed to minimize extraneous electrical noise effects on the measurement. A

poor ground can result in an unsafe and unstable operation. It is important that the instrument should not share

power lines with noise-generating equipment such as heavy load switching, motor control equipments,

inductive loads, etc. If the condition of the power line in the plant is poor, prepare a special power line and

grounding. Before interfering the instrument, turn off the power and wait at least for 30 seconds.

4.2.2. Load Cell Connection

To avoid damages, the load cell wiring should be made carefully before energizing the instrument. Load cell

connection details are shown below in figure 4.2. In 4-wire installations the sense and excitation pins with the

same polarity should be short circuited at the connector side. If you have a junction box in your system, use a 6

wire cable between FAD-30 and the junction box, and short circuit these pins at junction box for better

performance.

Figure 4.2 – Load cell connection

4.2.3. Communication Interface

4.3. Commissioning

PRECAUTION: Please read this manual carefully before energizing the instrument. Perform the commissioning

operation according the procedure given in this chapter. Only trained persons are allowed for cleaning,

commissioning, checking and servicing of the instrument. The interference of untrained person may cause

some unwanted damages or injuries.

Before energizing the instrument, please make the required mechanical and electrical installations. After power

on, you have to setup your FAD-30 instrument before you can start to use the bus interface.

Install the xFace software onto your PC as described in chapter 5 Setup. The xFace software is used for setup,

calibration and testing of FAD-30xx instruments.

After you have successfully checked the performance of the instrument with xFace, you can begin to use the

instrument in your application.

FAD-30 Technical Manual, Rev. 1.06 December 2012 Page 11 of 48

5. SETUP

Typ FAD-30: Select one of the FAD-30

models and press OK button.

Typ FAD-40

Typ MCS-08

Figure 5.1 – xFace type selector window

Protocol: Select the setup port of the instrument. FAD-30 and FAD-30MB

instruments can be setup over RS-232 or RS-485. Other models can be

setup over RS-232C.

Com Port: Select the communication port of the PC

Address: Select the RS-485 address, if RS-485 is selected

Baud rate: Select the RS-485 baud rate, if RS-485 is selected

Setting: Select the RS-485 communication port setting, if RS-485 is selected

Figure 5.2 – xFace Connection Settings

PRECAUTION: Please read this manual carefully before energizing the instrument. Perform the commissioning

according the procedure given in chapter 4.3. Only trained person are allowed for commissioning, checking,

cleaning and servicing of the instrument. The interference of untrained person may cause some unwanted

damages or injures.

FAD-30 series instruments are setup and calibrated by the xFace software supplied with the instrument.

The instruments shall be setup in the sequence described below before you can use the bus interface.

Install the xFace software onto your PC

Connect your PC with the instrument over the serial interface (RS232 respective RS485)

Setup and calibrate the instrument

Check the performance of the instrument

5.1. Installation of the xFace Software

Please follow following steps to install the xFace software:

Close all applications on your PC

Insert the CD that contains the xFace software into the CD-ROM drive

Double click “Setup.exe” to start the installation. The setup Wizard is displayed.

Follow the menus in the setup wizard step by step.

After finishing the installation, the Setup Wizard will inform you about the success of the software

installation. Click the OK button.

After closing the Setup Wizard you can start to use the xFace software.

5.2. Connection to the xFace Software

The connection between FAD-30 and the xFace software is done via the RS-232C service port for all models.

Alternatively Ethernet (for FAD-30EN only) and RS-485 (for FAD-30MB only) can be used for this connection.

You can purchase a suitable PC connection cable as an accessory from Flintec (Refer to chapter 3.4.2).

After running the xFace software select the FAD-30 model you use (see figure 5.1.). Select the PC‟s

communication port within the Connection settings menu in the tools tab (see figure 5.2) and click the connect

icon. After the communication between FAD-30 and your PC has successfully started the traffic light of the

connect icon turns from red to green.

FAD-30 Technical Manual, Rev. 1.06 December 2012 Page 12 of 48

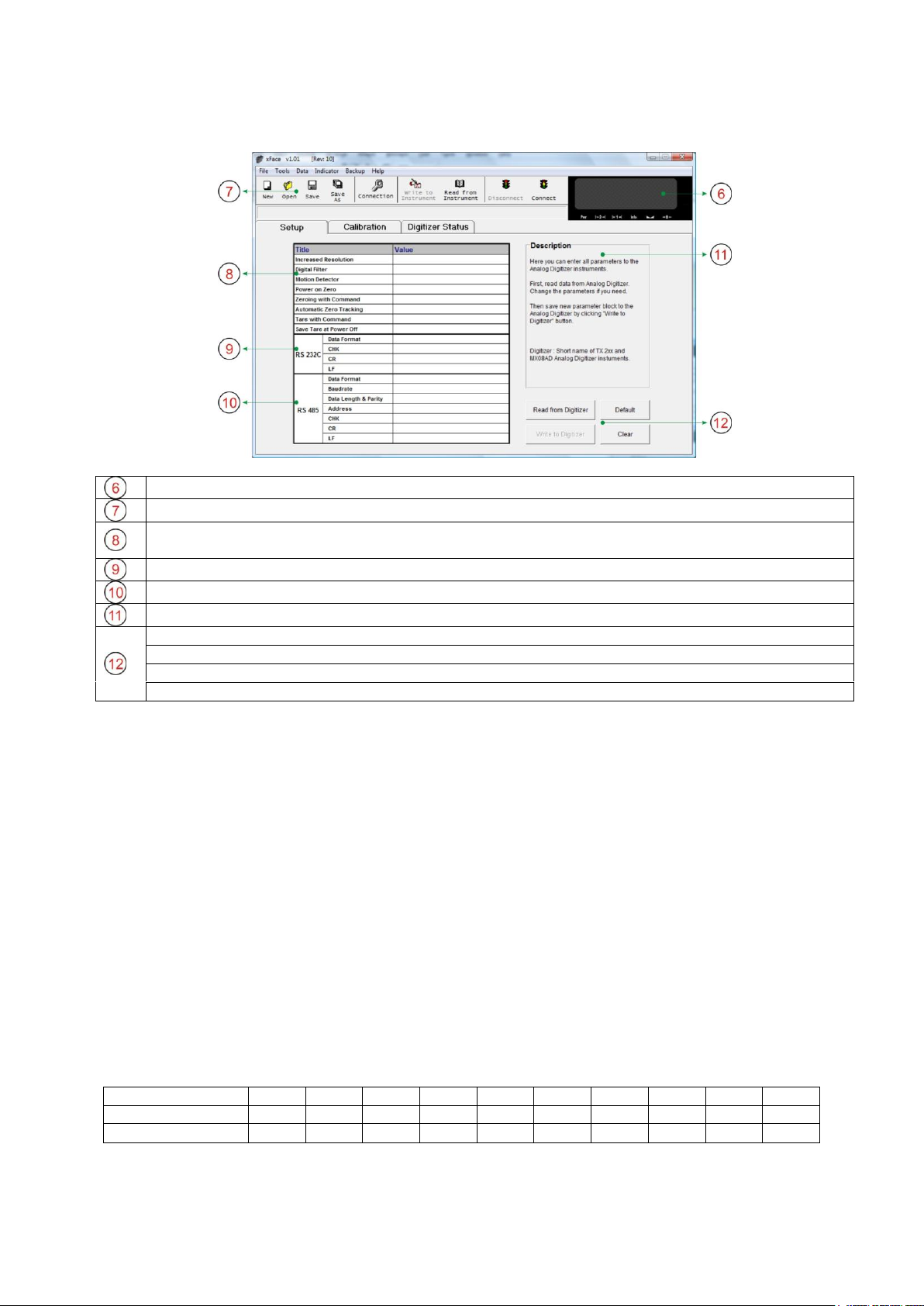

5.3. A/D Converter Setup and Calibration

Visual Weight Display: Displays the weight, count or force value

Toolbox: Contains shortcuts of some special commands

A/D Converter Parameters: This block allows the user to setup the A/D Converter‟s parameter

related to the operation mode. Refer to chapter 5.3.1

RS-232C: RS-232C serial port communication settings (not for FAD-30 and FAD-30MB)

RS-485: RS-485 port communication settings. (FAD-30 and FAD-30MB only)

Description: This block provides some clear-text explanations

Read from A/D Converter: Click this button to read the parameter settings from the instrument

Write to A/D Converter: Click this button to save the parameter settings to the instrument

Default: Click this button to load the factory default settings

Clear: Empties the parameter settings

Setting

0 1 2 3 4 5 6 7 8

9

Values/s

1600

800

400

200

100

100

100

50

50

50

Settling time [ms]

80

140

250

180

300

420

380

620

720

1800

WARNING: Read this manual carefully before you setup and calibrate the instrument. This will increase the

performance of your weighing system by applying proper setup and calibration.

Figure 5.3 – FAD-30 Setup Parameters

For entering the parameter values enter the setup tab, adjust the parameter settings and then write this data to

the A/D Converter. After changing parameter settings the instrument always requires a re-calibration.

5.3.1. Scale Parameters

In the setup menu the scale parameters of FAD-30 can be viewed, changed or saved to the instrument. These

parameter settings are:

Increased External Resolution

For service purposes this parameter enables the 10 times higher resolution of the weight value than the defined

interval in weighing and force mode. Increased resolution must be disabled for use in normal operation (Not

available in Count Mode). Default setting: „Disable‟.

Digital Filter

Environmental noise like bounding forces, air flow, vibration, motor control instruments etc. may disturb the load

cell signal. The selection of proper filter settings determines how quickly the system will react to the load cell

signal.**Load cell signal digital filtering is done according to this parameter settings. The settings can be

changed from 0 (fastest settling) to 9 (slowest settling). Default setting: „7‟.

FAD-30 Technical Manual, Rev. 1.06 December 2012 Page 13 of 48

Motion Detection

Disable

± 0.3e

± 0.5e (default setting)

± 1e

± 2e

Disable

± 60

± 100 (default setting)

± 200

± 400

Disable (default setting)

± 2%

± 10%

Disable

± 2% (default setting)

± 20%

± 40%

Disable (default setting)

± 0,5e

± 1e

± 3e

Disable:

Port will be disabled. Select “Disable” if this port is not used.

Continuous

The data is transmitted continuously (for FAD-30 and FAD-30MB only).

Refer to chapter 5.8 for details.

BSI

(default setting for FAD30)):

Communicates in BSI data format as a slave.

Refer to chapter 5.9 for details.

Modbus RTU

(default setting for FAD-30MB)):

Modbus RTU communication (for FAD-30MB only).

Refer to chapter 5.11 for details

This parameter defines the motion detection window which determines a stable weighing. If motion detection is

not required, this parameter can be disabled. The available motion detection window values are:

Weighing and Force Mode:

Count Mode:

Power On Zero

This parameter enables automatic zeroing after powering on the instrument. The automatic zeroing is only

done if the total zero drift from the calibrated zero signal is in the defined zeroing window. This zeroing window

will be defined in the percentage of the scale capacity.

To avoid unwanted zeroing at power on this parameter should be disabled or carefully set up in applications

like silo weighing, tank weighing and automatic weighing applications. If the weight is not within the power on

zeroing range, the instrument is powered on without zeroing (Not available in Count Mode).

Zeroing Range

Zeroing of the scale is performed if the difference between load cell signal value and unloaded load cell signal

value at the calibration is in the selected percentage of the scale capacity. Zeroing can be done by zeroing

command when the scale is stable. Zeroing can be done by zeroing command when the scale is stable.

The available zeroing ranges in the percentage of the scale capacity are:

Auto Zero Tracking

AZT automatically re-adjusts the scale to zero for compensating defined small deviations around the center of

zero. AZT only works within the defined zeroing range and stops working if this range is left.To avoid unwanted

zeroing this parameter should be disabled or carefully set up in applications like silo weighing, tank weighing

and automatic weighing applications (Not available in Count Mode). The available AZT window values are;

Tare

If this function is enabled, the weight is tared when the tare command is received. Additional conditions for

taring are positive gross weight and no motion. Multi-taring is possible with FAD-30 series (Not available in

Count Mode). Default setting: „Enable‟.

Save Tare at Power Off

If this function is enabled, the tare value is stored at power off and the instrument starts up in Net mode at

power on (Not available in Count Mode). Default setting: „Enable‟.

5.3.2. Serial Interface Setup

Data Format

This parameter defines the serial communication port data format for RS232 respective RS485. The available

data formats are:

Note: xFace automatically connects to the instrument whatever the data format is. After xFace is disconnected,

the instrument returns to operate with the last saved data format.

Warning: Disable this interface if it is not used to increase the interfacing performance.

FAD-30 Technical Manual, Rev. 1.06 December 2012 Page 14 of 48

Checksum

1200

2400

4800

9600 (default setting)

19200

38400

57600

Mode: Here the user selects the operation mode and the polarity.

Write to A/D Converter: Click this button to save the operation mode and polarity to A/D

Converter.

Calibration block: This block allows the user to calibrate with test weights.

eCal Calibration: This block allows the user to calibrate without test weights.

Calibration Coefficients: This function allows the user to restore a calibration if the calibration

coefficients have been noted before.

The checksum can be enabled or disabled within BSI and Continuous output data format. The checksum

calculation can be found in the related data format description. Default setting: „Enable‟.

Carriage Return

Carriage Return can be enabled or disabled within Continuous output data format. Default setting: „Enable‟.

Line Feed

Line Feed can be enabled or disabled within Continuous output data format. Default setting: „Enable‟.

The RS-485 setup is done by the xFace software as described in this chapter. Select the Setup tab after xFace

has established a connection with your instrument. The Setup tab (see figure 5.3) includes all RS-485 settings.

Baud Rate (for RS485 only)

One of the following baudrate will be selected for the RS-485 communication port.

Data Length and Parity (for RS485 only)

The data length and parity can be selected as 8 None 1 (default), 7 Odd 1 or 7 Even 1.

Address (for RS485 only)

The address range is 01 (default) to 31. If you enter 0, the instrument will operate without address data.

Modbus RTU Setup (for FAD-30MB only)

RS-485 Data Format: „Modbus RTU‟,

RS-485 Data Length & Parity: „8 none 1‟,

RS-485 Address: „01‟ to „31‟

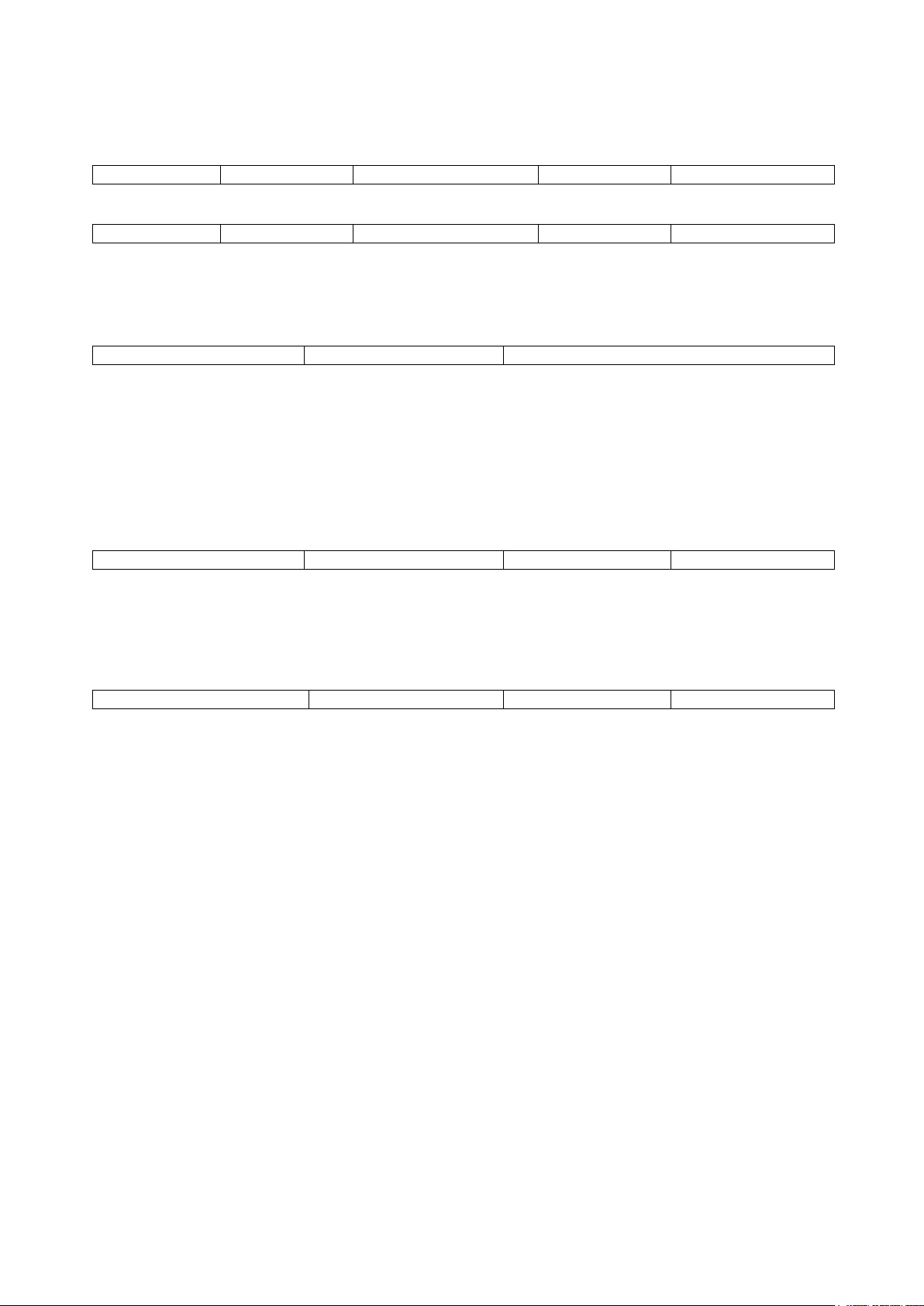

5.3.3. Scale Build and Calibration

Scale build, operation mode selection and scale calibration is performed in the calibration tab of xFace as

shown in figure 5.4. Please follow the procedure in the sequence as described in the following chapters.

Figure 5.4 – Calibration

FAD-30 Technical Manual, Rev. 1.06 December 2012 Page 15 of 48

Mode selection

Count Mode:

Filtered and normalized ADC count data will be transmitted in this mode. The

calibration is performed at the PLC, if any.

Weighing Mode:

Unipolar weight data in calibrated weighing unit will be transmitted. This mode is

compatible to OIML R76 and EN 45501.

Force Mode:

Bipolar or unipolar force measurement data in calibrated force unit will be transmitted.

Input signal range

Input Signal level

Polarity

External resolution

0 to 5 mV

5 mV

Unipolar

1 million counts

-5 to 5 mV

Bipolar

2 million counts

0 to 10 mV

10 mV

Unipolar

1 million counts

-10 to 10 mV

Bipolar

2 million counts

0 to 15 mV

15 mV

Unipolar

1 million counts

-15 to 15 mV

Bipolar

2 million counts

0 to 18 mV

18 mV

Unipolar

1 million counts

-18 to 18 mV

Bipolar

2 million counts

Capacity:

To select a new value for the scale capacity, click in the text box.

Use the keyboard to enter a new value, or use the drop-down menu.

Increment:

Use the drop-down menu to select the increment.

Unit:

Select the unit

Figure 5.5 – Calibration by test weights

FAD-30 instruments have three operation modes which are:

Select the scale operation mode and the polarity. Then click the “Write to A/D Converter” button to save your

mode selection. The default calibration of FAD-30 instruments is Count Mode and 10 mV unipolar input signal

range. If you select the Count Mode, there is no scale build and instrument calibration. Each FAD-30 instrument

is adjusted for high accuracy during the production. The FAD-30 input signal ranges and their external

resolutions are shown in Table 5.1.

Table 5.1 - Count Mode, Input Signal Ranges and External Resolution

Select the input signal level and polarity for high external resolution. Write your mode selection to the

instrument by clicking “Write to A/D Converter” button. Jump to the chapter 5.4.

Scale Build

The scale capacity, the increment and the unit have to be introduced to the FAD-30 instrument before you can

perform a calibration in Weighing or Force mode.

The scale calibration can be performed by using test weights or by electronic calibration (eCal).

Calibration by Test Weights

This calibration method performs zero and span calibrations using test weights. For accurate calibration the test

weight value should not be less than 1/10 of the scale capacity.

Please note that the scale build values should be entered before you start the calibration.

Select “Full Calibration” for performing a complete scale calibration. Click the “Start” button. Unload the scale

for performing the zero calibration and click the “Yes” button. The virtual display will show the [WAIT] message

during the zero calibration. During the zero calibration the scale must be stable. Approximately 5 seconds later

the span calibration window will be displayed. Load the scale and enter the loaded test weight value, then click

the “OK” button. The scale must be stable during the span calibration. Approximately 5 seconds later the new

calibration settings are saved automatically.

If any error occurs during the calibration an error message warns you. Click the “Yes” button to reload the

previous values or click the “No” button to use the new settings.

You can adjust the zero or the span of your scale without performing a full calibration. Additionally the “span

calibration to the unloaded scale” feature is another tool of FAD-30 instruments for after-sale services.

FAD-30 Technical Manual, Rev. 1.06 December 2012 Page 16 of 48

Zero Adjustment

Figure 5.6 – eCal Calibration

If your scale has a residual zero drift you may perform a zero adjustment only. Select “Zero Adjustment” and

press the “Start” button. Then the zero calibration window will be displayed. Unload the scale and click the “OK”

button. The [WAIT] message appears on the virtual display during the zero adjustment. Approximately 5

seconds later the zero adjustment will be finalized.

Note: Zero adjustment is also performed over the bus interface. Refer to the data structure of the related bus

interface.

Span Adjustment

If your scale has a span drift, you may perform a span adjustment only. After selecting “Span Adjustment” and

pressing the “Start” button, enter the test weight value; place the test weights on the scale and press the “Yes”

button. The [WAIT] message appears on the virtual display approximately for 5 seconds while the span

calibration is being performed. After finalizing the span adjustment, the instrument will save the span

coefficients automatically.

Note: Span adjustment is also performed over the bus interface. Refer to data structure of the related bus

interface.

Span Adjustment under Load

This feature is being used to perform a span adjustment without unloading the scale. This operation is

especially used for the span adjustment for non-empty tanks to make a span adjustment without emptying the

tank. After selecting “Span Adjustment under Load” press the “Start” button. The temporary zeroing message

appears on the monitor. This means the instrument will determine the existing load as the temporary zero. If the

scale is stable press the “Yes” button. The [WAIT] message appears on the virtual display approximately for 5

seconds to determine the temporary zero. Then the span calibration window will be displayed. Load the scale

and enter the loaded test weight value, then click the “OK” button. The scale must be stable in this period.

Approximately 5 seconds later, the new calibration settings are saved automatically.

Please refer to the chapter 5.4 A/D Converter Performance Test).

Electronic Calibration (eCal)

eCal allows to perform a calibration without using test weights. FAD-30 is adjusted during production for

increased eCal accuracy. The calibration will be done based on the scale capacity, the total load cell capacity,

the load cell output and the estimated dead load. If the conditions are convenient for zero calibration, you may

perform automatic zero adjustment instead of entering an estimated dead load.

After selecting eCal calibration enter the following values as:

Total Load Cell Capacity: Enter the total load cell capacity in kg as shown in the example below.

Example: If the weighing system has 4 pcs 1000 kg load cells, then enter 4000 kg.

Average Load Cell Output: Enter the load cell output in mV/V. If the weighing system has more than one load

cell, calculate the mean value of the load cells output as indicated in the certificates of the individual load cells.

Example: If the load cell outputs are LC1: 2.0010, LC2: 1.9998, LC3:1.9986 and LC4:2.0002, the mean value

will be LC output = ( 2.0010 + 1.9998 + 1.9986 + 2.0002 ) ÷ 4 = 1.9999 mV/V.

Estimated Dead Load: Enter the estimated dead load value of the weighing system in kg. You may perform a

zero adjustment in convenient time for an exact dead load compensation.

After pressing “Save eCal Data to Converter” these data will be transferred to the instrument and eCal will be

finalized.

If the scale is empty and you want to make an automatic zero adjustment instead of entering an estimated dead

load, then press the “eCal with Zero Adjustment” button for starting the zero calibration. The display will show

the [WAIT] message during the zero adjustment for approximately 5 seconds. In this period the scale must be

unloaded and stable. The eCal calibration coefficients are saved automatically.

FAD-30 Technical Manual, Rev. 1.06 December 2012 Page 17 of 48

5.4. A/D Converter Performance Test

Gateway Information:

Gives the user info about

the bus interface

Communication setup:

Network parameters

Load Defaults: Loads the

default values

Refresh: Reads the

settings from the instrument

and updates the window

Write to Converter: Saves

and activates the settings to

the instrument

Find on Network: Search

for the instrument on the

network

Figure 5.8 – Bus Interface Setup

Err

Address Number

0 (No address)

Table 5.2 –

Bus Addressing via

Setup Switch

1 2 3 4 5 6 7

Higher than 7

Off On Flash

The scale performance test should be performed before you install the bus connection. The tests are linearity,

repeatability and eccentricity. You can follow the test at the virtual display and/or status tab which show the

measurement data, the instrument data and the software version. For convenience keys for Taring, Zeroing

and Clear are located in this tab.

5.5. Bus Interface Setup

FAD-30 instruments have a bus interface and these parameters have to be setup before the bus will be

connected. Bus communication settings are done in the Gateway tab.

Bus communication parameters and their descriptions can be found in the related instrument chapters.

5.6. Bus Addressing via Setup Switch

The bus addressing of FAD-30 instruments is done by the xFace software (Refer to chapter 5.3.1). The

alternative way for addressing is the setup switch on the front panel for addresses between 0 and 7 for RS-485,

Modbus RTU, Profibus and CANopen interfaces. This feature gives you the practical advantage for addressing

the instrument up to address 7 without requiring a PC connection.

For addressing via the setup switch, press this switch for 5 seconds. Then the status LEDs indicate the bus

address as shown in the table below. If the address is higher then 7 all LEDs are flashing. The address can be

changed by pressing the setup switch sequentially. To save and exit, press the setup switch for 5 seconds. To

return to normal operation without saving, wait 15 seconds without pressing the switch.

5.7. Back up Settings and Calibration Data

The parameter settings and the calibration coefficients can be saved to a backup file after reading these data

from the FAD-30 instrument. This backup file can be re-written to FAD-30 after opening it by xFace.

The backup feature gives a service advantage to FAD-30 instruments. We propose to burn these files to CD /

DVD and save this backup CD / DVD in the control cabinet additionally to a backup file on your PC.

Important note: The previous parameter settings and calibration coefficients in FAD-30 will get lost after

loading a backup to the instrument.

FAD-30 Technical Manual, Rev. 1.06 December 2012 Page 18 of 48

5.8. Continuous Output Data Structure (for FAD-30 + FAD-30MB

Status

Indicated

Tare

STX

STA

STB

STC

D5

D4

D3

D2

D1

D0

D5

D4

D3

D2

D1

D0

CR

LF

CHK

Status

Count Data

Not used

STX

STB

D7

D6

D5

D4

D3

D2

D1

D0

D5

D4

D3

D2

D1

D0

CR

LF

CHK

Definition Table for Status A (STA)

Bits 0, 1 and 2

Bits 3 and 4

Bit 5

Bit 6

Bit 7

0 1 2

Decimal point

3 4 Increment size

Always 1

Always 1

X

0 0 0

XXXXOO

1 0 X 1 1 0 0 XXXXXO

0 1 X 2 0 1 0 XXXXXX

1 1 X 5 1 1 0 XXXXX.X

0 0 1 XXXX.XX

1 0 1 XXX.XXX

0 1 1 XX.XXXX

1 1 1 X.XXXXX

Definition Table for Status B (STB)

Bit 0

Gross = 0

Net = 1

Bit 1

Weight positive = 0

Weight negative = 1

Bit 2

No Error = 0

Error = 1

Bit 3

Stable = 0

Unstable = 1

Bit 4

Always = 1

Bit 5

Always = 1

Bit 6

Not power on zeroed

Zeroed with power on zero = 1

Bit 7

x

Definition Table for Status C (STC)

Bit 0

Always 0

Bit 1

Always 0

Bit 2

Always 0

Bit 3

Always 0

Bit 4

Always 1

Bit 5

Always 1

Bit 6

Always 0

Bit 7

x

only)

The continuous data output of the instrument will be transmitted in the following data structure at the speed

which is determined by the baud rate and the data length. The definition of the continuous data format is

described below.

In weighing mode and force mode:

In count mode:

The definition of the status bytes STA, STB and STC is described below.

CHK (Checksum) = 0 – (STX STATUS A ..... LF)

Error Messages: UNDER, OVER, A.OUT, L-VOLT, H-VOLT are annunciated in the Indicated or Count Data

fields.

Note: Weight data is represented with right alignment, error messages with left alignment.

FAD-30 Technical Manual, Rev. 1.06 December 2012 Page 19 of 48

5.9. BSI Data Structure (for FAD-30 + FAD-30MB only)

1.

Commands are only in CAPITAL letters

2.

CHK (2 ASCII char) can be enabled or disabled from both command and response.

3.

Weight data is 8-byte with dot and non-significant zeros on the left.

4.

Address (2 ASCII char) will be located in the structure if not 00.

A

Read all weight data immediately

B

Read Gross weight value immediately

C

Clear the tare memory

D

Read Count value immediately

I

Read current (indicated) weight value immediately

P

Print: Read the current stable weight value

S

Read Status

T

Tare

X

Read current weight value in increased resolution immediately

Z

Zero

A

Acknowledged, the command is operated successfully

D

Unstable weight

E

Errors except of H, L, O, +, −

H

High voltage detected

I

The weight is in range

L

Low voltage detected

N

Not acknowledged, the command couldn‟t be operated

O

ADC out

S

Stable weight

X

Syntax error (received command not recognized)

+

Overload

−

Underload

Depending on their functionality all new generation Flintec instruments launched on the market support the

standardized command set with BSI data structure. This easy data format gives a reliable and fast interface for

communicating with PLC or PC for process control or transactional applications. You can expand your system

with additional scales from Flintec without having to change your application program base.

General Rules:

Command format:

A general description of the command is the following:

[ADR][COMMAND][CHK][CR][LF]

Response format with weight / force or count data

A general description of the response is the following:

[ADR][COMMAND][STATUS][SIGN][WEIGHT/FORCE/COUNT][CHK][CR][LF]

Response format without weight / force or count data

[ADR][COMMAND][STATUS][CHK][CR][LF]

Command Table:

Status Table:

Note: CHK, CR and LF will not be shown in the below data format descriptions in this chapter.

FAD-30 Technical Manual, Rev. 1.06 December 2012 Page 20 of 48

Commands and Responses

A

Read all weight data

B

Read Gross weight

C

Clear the tare memory

D

Read Count value immediately

I

Read indicated weight

P

Print :Read the stable weight

Command: [ADR][A]

Response: [ADR][A][STATUS][SIGN][NET W][SIGN][TARE W][SIGN][GROSS W]

Example:

Command : 01A

Response : 01AS+000123.4+000111.1+000234.5

01AD+000123.4+000111.1+000234.5

01AO ( ADC out error )

Comments: The response is net, tare and gross weight values or error status. All weight data will be

transmitted immediately after receiving the command.

Command: [ADR][B]

Response: [ADR][B][STATUS][SIGN][WEIGHT VALUE]

Example:

Command: 01B

Response: 01BS+000123.4 (gross weight is stable and 123.4)

01BD+000123.4 (gross weight is unstable and 123.4)

01B− (under load)

Comments: The response is the gross weight value (stable or unstable) or error status. Gross weight data

will be transmitted immediately after receiving command.

Command: [ADR][C]

Response: [ADR][C][A] (Cleared and the scale is in gross mode)

[ADR][C][X] (Clear command is unavailable in count mode)

Comments: The response status is always Ack in weighing or force mode and always X in count mode.

Command: [ADR][D]

Response: [ADR][D][STATUS][SIGN][COUNT VALUE]

Example:

Command: 01D

Response: 01DD+00123400

01DO (ADC out error)

01DX (Not in count mode)

Comments: Count value will be sent immediately.

Command: [ADR][I]

Response: [ADR][I][STATUS][SIGN][WEIGHT VALUE]

Example:

Command: 01I

Response: 01IS+000123.4 ( weight is stable and 123.4 )

01ID+000123.4 ( weight is unstable and 123.4 )

01I+ ( overload )

Comments: The response is the indicated weight value (stable or unstable). It will be transmitted

immediately after receiving the command. The weight value may be in gross or net.

Command: [ADR][P]

Response: [ADR][P][STATUS][SIGN][WEIGHT VALUE]

Example:

Command: 01P

Response: 01PS+000123.4 (weight is stable and 123.4) or

01PN (could not print)

Comments: Checks status and it must be stable. Else Nack status will be sent. There is no time period for

stability checking. Status can be Stable or Nack.

FAD-30 Technical Manual, Rev. 1.06 December 2012 Page 21 of 48

S

Read Status

Command: [ADR][S]

T

Tare

X

Read weight value in increased resolution

Z

Zero

Response: [ADR][S][STATUS-1][STATUS-2][STATUS-3]

Example:

Command: 01S

Response: 01SSGI (Stable, Gross, In Range)

01SDGL (Unstable, Gross, Low voltage error)

Comments: The response includes 3 status information.

STATUS-1 can be Stable or Unstable.

STATUS-2 can be Gross or Net.

STATUS-3 can be „in range‟, „out of range‟, „low voltage‟ or „high voltage‟.

Command: [ADR][T]

Response: [ADR][T][A] (Taring is done successfully and scale is in net)

[ADR][T][N] (Taring could not be executed)

[ADR][T][X] (Taring is disabled or instrument is in count mode)

Comments: The tare value will be overwritten by the new tare weight value. The status must be stable

within 2 seconds delay time. If so, Ack will be sent. Otherwise Nack will be sent.

Command: [ADR][X]

Response: [ADR][X][STATUS][SIGN][WEIGHT VALUE]

Example:

Command: 01X

Response: 01XS+00123.41 (weight is stable and 123.41) or

01XD+00123.41 (weight is unstable and 123.41) or

01XE (Error)

Comments: The response includes the weight data with the increment divided by 10.

Command: [ADR][Z]

Response: [ADR][Z][A] (Zeroed)

[ADR][Z][N] (Zeroing could not be operated)

[ADR][Z][X] (Zeroing is disabled)

Comments: The Zero command does not work in net weighing mode. The Weight or Count must be within

the zeroing range for all operating modes. The status must be stable within 2 seconds delay

time. If so, Ack will be sent. Otherwise Nack will be sent.

CHK will be transmitted as two ASCII characters calculated with the checksum formula:

Checksum = 0 – (SUM of all response data before CHK)

Example: Read stable current weight data

BSI Examples: (CHK is enabled and instrument address is 01)

Command: 01P[CHK][CR][LF]

Checksum = 0 − (0x30 + 0x31 + 0x50) = 0 − 0XB1 = 0x4F

CHK = Char „4‟ and „F‟

Response: 01PS+000123.4[CHK][CR][LF]

Checksum = 0 − (0x30 + 0x31 + 0x50 + 0x53 + 0x2B + 0x30 + 0x30 + 0x30 + 0x31+ 0x32 + 0x33 + 0x2E +

0x34) = 0 − 0x02B7 = 0x49:

CHK = Char „4‟ and Char „9‟

FAD-30 Technical Manual, Rev. 1.06 December 2012 Page 22 of 48

5.10. Modbus Data Structure (for FAD-30MB + FAD-30EN only)

Address

R/W

Word

Command

Definition

40001

R 2 Weight / Force / Count Data

40003

R 1 Status

D0

0 – System Ready

1 – System Busy

D1

0 – Error

1 – Data ok

D2

0 – Weight Stable

1 – Weight unstable

D3

0 – Gross Mode

1 – Net mode

D4

Not Used

D5

0 – Weight / Force

1 – Count Mode

D6-D11

Not Used

D12

0 – Out of zero range

1 – Weight is in zero range

D13

D14

D15

Error Code

0

No Errors

1

ADC out of range

2

ADC over range

3

ADC under range

4

System error

5

In setup mode

6

Low/High voltage det.

40004

R 2 Tare weight

40006

R 2 Gross weight

40008

R 1 Status

Motion, Net mode, Data ok, (image of register 40003)

40009

R/W

1

Control

0

None

1

Zero

2

Tare

3

Clear

40010

R/W

1

Calibration

0

None

188

Adjust Zero Calibration

220

Adjust Span Calibration (First load calibration weight

on scale and load 40011 with span test weight value)

40011

R/W

2

Span Calibration Value

40013

R

1

Calibration

Status

D0 .. D7

Calibration

Process

Status

1

Ready for calibration

3

Zero calibration in process

4

Span calibration in process

9

Error (Refer to D8 ... D15 )

D8 .. D15

Calibration

Errors

1

Calibration Timeout

- Restart calibration

2

ADC Error

- Re-energize the instrument

- If seen again, change the board.

3

Instrument cannot be calibrated

- Check load cell cable

- Re-energize the instrument

34

Instrument cannot be calibrated

- Load cell signal is very low or too high

35

Calibration Error

- Calibration test weight is not enough

- Increase calibration weight value (40011)

- Check load cell connections

37

Scale unstable

- Wait until scale become stable

- Check grounding wiring

40014

R/W

1

Operation Mode

Selector

0

Count Mode Unipolar

1

Count Mode Bipolar

2

Force Mode Unipolar

3

Force Mode Bipolar

4

Weight Mode Unipolar

FAD-30 Technical Manual, Rev. 1.06 December 2012 Page 23 of 48

Address

R/W

Word

Command

Definition

40015

R/W

1

mV operation

in Count Mode

0

5 mV

1

10 mV

2

15 mV

3

18 mV

40016

R/W

1

Digital filters

0

Fast

1 2 3 4

5

Medium

6 7

Default

8 9

Slow

EXPLANATION

Attention: For hardware connection details, please refer to the related hardware descriptions in this manual.

In the two word registers the data is stored to the registers in big-endian format. The least significant word is

stored to the highest register address; and the most significant word is stored to the lowest register address.

Please find Modbus information in the web site of http://www.modbus.org

Exception codes:

1: Function code is not supported.

2: Out of address range

3: Invalid value or wrong byte number

4: Operation error

Examples:

Performing Read and Write operations according to hex system with the instrument set to address “0x01”.

Request weight data: 01,03,00,00,00,02,C4,0B

Answer of requested weight: 01,03,04,00,01,86,A0,38,4A

Weight is 100000

Request status data : 01,03,00,02,00,01,25,CA

Taring: 01,10,00,08,00,01,02,00,02,26,D9

Request tare data: 01,03,00,03,00,02,34,0B

Answer of requested tare: 01,03,04,00,00,27,10,E0,0F

Tare is 10000

Weight Mode Selection: 01,10,00,0D,00,01,02,00,04,A6,8E

Count in Unipolar Mode Selection: 01,10,00,0D,00,01,02,00,00,A7,4D

5 mV Input signal range selection: 01,10,00,0E,00,01,02,00,00,A7,7E

Load Medium (5) to Digital filter: 01,10,00,0F,00,01,02,00,05,66,AC

Request Calibration Status: 01,03,00,0C,00,01,44,09

Answer of requested Calibration Status: 01,03,02,00,01,79,84

Instrument is ready for calibration

Zero Calibration Command: 01,10,00,08,00,01,02,00,01,66,D8

Span Calibration with Span Value 50000: 01,10,00,09,00,03,06,00,DC,00,00,C3,50,B7,B0

FAD-30 Technical Manual, Rev. 1.06 December 2012 Page 24 of 48

5.11. Profibus and ProfiNet Data Structure (for FAD-30Px only)

Dword

D31

D30

D29

D28

D27

D26

D25

D24

D23

D22

D21

D20

D19

D18

D17

D16

D15

D14

D13

D12

D11

D10

D9

D8

D7

D6

D5

D4

D3

D2

D1

D0

1st

Dword

Reserved

2nd

Dword

W31

MSB

W30

W29

W28

W27

W26

W25

W24

W23

W22

W21

W20

W19

W18

W17

W16

W15

W14

W13

W12

W11

W10

W9

W8

W7

W6

W5

W4

W3

W2

W1

W0

LSB

3rd

Dword

Not in use

Error codes of converter

Not in use

Op.

mode

Zero

range

Gross

Net

MD

Read command response

Cmd

Flag

Bit no.

3rd Dword Description

D31…D16

Not in use

D15…D12

Error codes of

converter

0000

No error found

0001

ADC out

0010

ADC over

0011

ADC under

0100

System error

0101

In setup mode

0110

Low/High voltage error

0111

Instrument not found

D11…D10

Not in use

D9

Operation mode

0

Weight & Force Mode

1

Count Mode

D8

Zero range

0

Weight is out of zero range

1

Weight is in zero range

D7

Indication

0

Gross

1

Net

D6

MD –

Motion detection

0

Stable

1

Unstable

D5

D4

D3

D2

D1

Read command

response

00000

Indicated weight

00001

Gross weight

00010

Tare weight

00011

Indicated weight (floating point type)

00100

Gross weight (floating point type)

00101

Tare weight (floating point type)

10000

Calibration Status (Refer to table 8.2)

D0

CMD flag

A change of Flag indicates: The command is applied successfully

Hardware Configuration Hint

To install the FAD-30PB or FAD-30PN into the PLC Hardware Configuration use the GSD file memory parts to

create exactly the following memory structure:

Input 2 Words

Output 2 Words

Input 2 Words

Input 2 Words

Output 2 Words

Output 2 Words

FAD-30Px Output to PLC Input

FAD-30Px Output to PLC Input 2nd Dword

The 2nd Dword contains the weight value respective the calibration information according to the “read command

response” (Refer to PLC Output to FAD-30Px Input 3rd Dword).

FAD-30Px Output to PLC Input 3rd Dword

FAD-30 Technical Manual, Rev. 1.06 December 2012 Page 25 of 48

Calibration Status

Bit no.

2nd Dword descriptions when read command is ‘Calibration Status’.

Refer to PLC Output to FAD-30Px Input 3rd Dword

D31…D16

Not in use

D15…D8

Calibration

error

0000 0001

Calibration timeout: - Restart calibration

0000 0010

ADC error: - Re-energize the instrument

0000 0011

Instrument cannot be calibrated

- Check load cell cable; - Re-energize the instrument

0010 0010

Instrument cannot be calibrated

- Load cell signal is very low or too high

0010 0011

Calibration Error

- Calibration test weight is too small; Increase calibration weight

value (Write test weight value from PLC Output to FAD-30Px Input

2nd Dword then restart the calibration)

- Check load cell connections

0010 0101

Scale unstable: - Wait until scale becomes stable

- Check ground wiring

D7...D0

Calibration

process

status

0000 0001

System ready for calibration

0000 0011

Zero calibration in process

0000 0100

Span calibration in process

0000 1001

Error (Calibration error)

FAD-30 Technical Manual, Rev. 1.06 December 2012 Page 26 of 48

PLC Output to FAD-30Px Input

Dword

D31

D30

D29

D28

D27

D26

D25

D24

D23

D22

D21

D20

D19

D18

D17

D16

D15

D14

D13

D12

D11

D10

D9

D8

D7

D6

D5

D4

D3

D2

D1

D0

1st Dword

Not in use

2nd

Dword

W31

MSB

W30

W29

W28

W27

W26

W25

W24

W23

W22

W21

W20

W19

W18

W17

W16

W15

W14

W13

W12

W11

W10

W9

W8

W7

W6

W5

W4

W3

W2

W1

W0

LSB

3rd Dword

Not in use

Not in use

Command List

Data Selection

New

CMD

Bit no.

3rd Dword descriptions

D31…D11

Not in use

D10…D6

Command

list

00000

No command is activated

00001

Zero

00010

Tare

00011

Clear

00101

Adjust zero calibration

00110

Adjust span calibration (First load calibration weight on scale then load

2nd Dword with span test weight value*, then apply this command with

New CMD)

01000

Operation mode selection (First

load 2nd Dword with selected

value, then apply this command

with New CMD)

Load 2nd Dword with one of these:

0: Count mode unipolar

1: Count mode bipolar

2: Force mode unipolar

3: Force mode bipolar

4: Weight mode unipolar

01001

mV operation in Count Mode

(First load 2nd Dword with

selected value, then apply this

command with New CMD)

Load 2nd Dword with one of these:

0: 5 mV

1: 10 mV

2: 15 mV

3: 18 mV

01010

Digital filter

(First load 2nd Dword with

selected value, then apply this

command with New CMD)

Load 2nd Dword with one of these:

0: Fast

…

5: Medium

…

…

7: Default

…

9: Slow

D5...D1

Read

selected

data

00000

Indicated weight

00001

Gross weight

00010

Tare weight

00011

Indicated weight (Floating point)

00100

Gross weight (Floating point)

00101

Tare weight (Floating weight)

10000

Calibration status

D0

New CMD

Apply commands which are listed in “Command list” (Responds on bit changes)

PLC Output to FAD-30Px Input 2nd Dword

The 2nd Dword contains the setting / parameter value (Refer to “Command List”, see PLC Output to FAD-30Px

Input 3rd Dword).

PLC Output to FAD-30Px Input 3rd Dword

*Span test weight value has to be entered ignoring the decimal point;

e.g. “300.00” has to be entered as “30000”

FAD-30 Technical Manual, Rev. 1.06 December 2012 Page 27 of 48

5.12. CANopen Data Structure (for FAD-30CO only)

Dword

D31

D30

D29

D28

D27

D26

D25

D24

D23

D22

D21

D20

D19

D18

D17

D16

D15

D14

D13

D12

D11

D10

D9

D8

D7

D6

D5

D4

D3

D2

D1

D0

TxPDO 1

(T_DW1)

reserved

TxPDO 2

(T_DW2)

W31

MSB

W30

W29

W28

W27

W26

W25

W24

W23

W22

W21

W20

W19

W18

W17

W16

W15

W14

W13

W12

W11

W10

W9

W8

W7

W6

W5

W4

W3

W2

W1

W0

LSB

TxPDO 3

(T_DW3)

Not in use

Error codes of converter

Not in use

Op.

mode

Zero

range

Gross

Net

MD

Read command response

Cmd

Flag

Bit no.

T_DW3 Description

D31…D16

Not in use

D15…D12

Error codes of

converter

0000

No error found

0001

ADC out

0010

ADC over

0011

ADC under

0100

System error

0101

In setup mode

0110

Low/High voltage error

0111

Instrument not found

D11…D10

Not in use

D9

Operation mode

0

Weight & Force Mode

1

Count Mode

D8

Zero range

0

Weight is out of zero range

1

Weight is in zero range

D7

Indication

0

Gross

1

Net

D6

MD –

Motion detection

0

Stable

1

Unstable

D5

D4

D3

D2

D1

Read command