Page 1

GE Fanuc Automation

Computer Numerical Control Products

I/O Link―II

Connection Manual

GFZ-62714EN/04 February 2001

Page 2

Warnings, Cautions, and Notes

as Used in this Publication

Warning notices are used in this publication to emphasize that hazardous voltages, currents,

temperatures, or other conditions that could cause personal injury exist in this equipment or may

be associated with its use.

In situations where inattention could cause either personal injury or damage to equipment, a

Warning notice is used.

Caution notices are used where equipment might be damaged if care is not taken.

GFL-001

Warning

Caution

Note

Notes merely call attention to information that is especially significant to understanding and

operating the equipment.

This document is based on information available at the time of its publication. While efforts

have been made to be accurate, the information contained herein does not purport to cover all

details or variations in hardware or software, nor to provide for every possible contingency in

connection with installation, operation, or maintenance. Features may be described herein which

are not present in all hardware and software systems. GE Fanuc Automation assumes no

obligation of notice to holders of this document with respect to changes subsequently made.

GE Fanuc Automation makes no representation or warranty, expressed, implied, or statutory

with respect to, and assumes no responsibility for the accuracy, completeness, sufficiency, or

usefulness of the information contained herein. No warranties of merchantability or fitness for

purpose shall apply.

©Copyright 2001 GE Fanuc Automation North America, Inc.

All Rights Reserved.

Page 3

B-62714EN/04 SAFETY PRECAUTIONS

SAFETY PRECAUTIONS

This section describes the safety precautions related to the use of

CNC units, to ensure safe operation of machines fitted with FANUC

CNC units. Read this section carefully before attempting to use any

function described in this manaul.

Users should also read the relevant descriptions in the Operator’s

Manual to become fully familiar with the functions to be used.

CONTENTS

1. DEFINITION OF WARNING, CAUTION, AND NOTE.........s-2

2. GENERAL WARNINGS AND NOTES...................................s-3

s - 1

Page 4

SAFETY PRECAUTIONS B-62714EN/04

1 DEFINITION OF WARNING, CAUTION,

AND NOTE

This manual includes safety precautions for protecting the user and

preventing damage to the machine. Precautions are classified into

Warning and Caution according to their bearing on safety. Also,

supplementary information is described as a Note. Read the Warning,

Caution, and Note thoroughly before attempting to use the machine.

WARNING

Applied when there is a danger of the user being

injured or when there is a damage of both the user

being injured and the equipment being damaged if

the approved procedure is not observed.

CAUTION

Applied when there is a danger of the equipment

being damaged, if the approved procedure is not

observed.

NOTE

The Note is used to indicate supplementary

information other than Warning and Caution.

- Read this manual carefully, and store it in a safe place.

s - 2

Page 5

B-62714EN/04 SAFETY PRECAUTIONS

2 GENERAL WARNINGS AND NOTES

WARNING

1 Before operating the machine, thoroughly check the

entered data.

Operating the machine with incorrect data may

result in the machine behaving unexpectedly,

possibly causing damage to the workpiece and/or

machine itself, or injury to the user.

2 Never attempt to perform a production run, such as

actually machining a workpiece, without first

checking the operation of the machine. Before

starting the machine for a production run, ensure

that the program command values, offsets, current

position, external signals, and other settings are

suitable for the operation to be performed. Also

check that the machine operates correctly by

performing a trial run using, for example, the single

block, feedrate override, or machine lock function or

by operating the machine with neither a tool nor

workpiece mounted.

3 Ensure that the specified feedrate is appropriate for

the intended operation. Generally, for each

machine, there is a maximum allowable feedrate.

The appropriate feedrate varies with the intended

operation. Refer to the manual provided with the

machine to determine the maximum allowable

feedrate.

If a machine is run at other than the correct speed, it

may behave unexpectedly, possibly causing

damage to the workpiece and/or machine itself, or

injury to the user.

4 When using a tool compensation function,

thoroughly check the direction and amount of

compensation.

Operating the machine with incorrectly specified

data may result in the machine behaving

unexpectedly, possibly causing damage to the

workpiece and/or machine itself, or injury to the

user.

s - 3

Page 6

SAFETY PRECAUTIONS B-62714EN/04

WARNING

5 The parameters for the CNC and PMC are factory-

set. Usually, there is not need to change them.

When, however, there is not alternative other than to

change a parameter, ensure that you fully

understand the function of the parameter before

making any change.

Failure to set a parameter correctly may result in the

machine behaving unexpectedly, possibly causing

damage to the workpiece and/or machine itself, or

injury to the user.

6 Immediately after switching on the power, do not

touch any of the keys on the MDI panel until the

position display or alarm screen appears on the

CNC unit.

Some of the keys on the MDI panel are dedicated to

maintenance or other special operations. Pressing

any of these keys may place the CNC unit in other

than its normal state. Starting the machine in this

state may cause it to behave unexpectedly.

7 The operator's manual and programming manual

supplied with a CNC unit provide an overall

description of the machine's functions, including any

optional functions. Note that the optional functions

will vary from one machine model to another.

Therefore, some functions described in the manuals

may not actually be available for a particular model.

Check the specification of the machine if in doubt.

8 Some functions may have been implemented at the

request of the machine-tool builder. When using

such functions, refer to the manual supplied by the

machine-tool builder for details of their use and any

related cautions. Refer to the following two

examples.

<1> Some machines have a tool replacement

device that operates when a tool feature is

executed. When the user is working near the

device, he or she may touch it. Execute tool

features in a place sufficiently away from the

tool replacement device.

<2> Many auxiliary features cause machine

operation such as rotation of the spindle.

Understand the operations of auxiliary features

before using them.

s - 4

Page 7

B-62714EN/04 SAFETY PRECAUTIONS

NOTE

Command programs, parameters, and variables are

stored in nonvolatile memory in the CNC unit.

Usually, they are retained even if the power is turned

off. Such data may be delated inadvertently,

however, or it may prove necessary to delete all data

from nonvolatile memory as part of error recovery.

To guard against the occurrence of the above, and

assure quick restoration of deleted data, backup all

vital data, and keep the backup copy in a safe place.

s - 5

Page 8

B-62714EN/04 Table of Contents

Table of Contents

SAFETY PRECAUTIONS

SAFETY PRECAUTIONS................................

SAFETY PRECAUTIONSSAFETY PRECAUTIONS

I. GENERAL

I. GENERAL

I. GENERALI. GENERAL

1111 GENERAL

GENERAL................................

GENERALGENERAL

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

.......................................................

................................................................

...........................................

................................................................

....................... ssss-1

..............................................

........... 3333

......................

-1

-1-1

1.1

1.2

II. SPECIFICATIONS

II. SPECIFICATIONS

II. SPECIFICATIONSII. SPECIFICATIONS

1111I/O

1.1

1.2

1.3

1.4

1.5

III. OPERATION

III. OPERATION

III. OPERATIONIII. OPERATION

1111 16/18/21-B, 16/18-C

1.1

1.2

1.3

ORGANIZATION .............................................................................................................................. 4

APPLICABLE MODELS................................................................................................................... 5

I/O Link

Link-II I/O FUNCTION

I/O I/O

16/18/21-B, 16/18-C, LCD-MOUNTED TYPE 16

16/18/21-B, 16/18-C16/18/21-B, 16/18-C

-II I/O FUNCTION................................

LinkLink

-II I/O FUNCTION-II I/O FUNCTION

FEATURES...................................................................................................................................... 10

MASTER FUNCTION..................................................................................................................... 11

SLAVE FUNCTION ........................................................................................................................ 12

SPECIFICATIONS.......................................................................................................................... 13

GLOSSARY...................................................................................................................................... 16

, LCD-MOUNTED TYPE 16i/18

, LCD-MOUNTED TYPE 16, LCD-MOUNTED TYPE 16

MASTER FUNCTION..................................................................................................................... 22

SLAVE FUNCTION ........................................................................................................................ 32

DATA CONCURRENCY................................................................................................................. 42

................................................................

................................................................

................................................................

................................................................

/18i/21

/21i-A

-A ................................

/18/18

............................................................

/21/21

-A-A

................................................................

................................................

................................................................

............................ 21

........................................................

................ 9999

................................

21

2121

2222 LCD-MOUNTED TYPE 16

LCD-MOUNTED TYPE 16i/18

LCD-MOUNTED TYPE 16LCD-MOUNTED TYPE 16

2.1

2.2

2.3

3333 Power Mate

3.1

3.2

MASTER FUNCTION..................................................................................................................... 45

SLAVE FUNCTION ........................................................................................................................ 61

DATA CONCURRENCY................................................................................................................. 80

Power Mate-D/F/H

Power MatePower Mate

SLAVE FUNCTION ........................................................................................................................ 83

DATA CONCURRENCY................................................................................................................. 92

-D/F/H ................................

-D/F/H-D/F/H

................................................................

................................................................

/18i/21

/21i-A,

/18/18

/21/21

-A, Power Mate

Power Mate i-D/H

-A, -A,

Power MatePower Mate

................................................................

................................................................

-D/H ................................

..............................................................

-D/H-D/H

................................................................

............................................................

................................................................

c - 1

.............................. 44

............................................................

............................ 82

........................................................

44

4444

82

8282

Page 9

Table of Contents B-62714EN/04

IV. CONNECTION

IV. CONNECTION

IV. CONNECTIONIV. CONNECTION

1111 COMMUNICATION FUNCT

COMMUNICATION FUNCTION CONNECTION

COMMUNICATION FUNCTCOMMUNICATION FUNCT

ION CONNECTION................................

ION CONNECTIONION CONNECTION

................................................................

................................................................

..........................................

................................................................

.......... 97

....................

97

9797

1.1

1.2

1.3

1.4

HARDWARE SPECIFICATIONS .................................................................................................. 98

CABLE CONNECTION .................................................................................................................. 99

SECURING CABLES.................................................................................................................... 101

NOISE PROTECTION.................................................................................................................. 102

1.4.1 Separating Signal Lines ........................................................................................................ 102

1.4.2 Cable Clamps and Shielding ................................................................................................. 102

2222 16/18/21-B, 16/18-C

16/18/21-B, 16/18-C................................

16/18/21-B, 16/18-C16/18/21-B, 16/18-C

2.1

2.2

2.3

3333 LCD-MOUNTED TYPE 16

3.1

3.2

3.3

4444 STAND-ALONE TYPE 16

SPECIFICATIONS........................................................................................................................ 105

INSTALLATION ........................................................................................................................... 106

CABLE CONNECTION ................................................................................................................ 107

LCD-MOUNTED TYPE 16i/18

LCD-MOUNTED TYPE 16LCD-MOUNTED TYPE 16

SPECIFICATIONS........................................................................................................................ 111

INSTALLATION ........................................................................................................................... 112

CABLE CONNECTION ................................................................................................................ 113

STAND-ALONE TYPE 16i/18

STAND-ALONE TYPE 16STAND-ALONE TYPE 16

................................................................

................................................................

/18i/21

/21i-A

/18/18

/21/21

/18i/21

/21i-A

/18/18

/21/21

................................................................

................................................................

-A ................................

................................................................

-A-A

................................................................

-A ................................

................................................................

-A-A

................................................................

............................................................

................................................................

.............................................................

................................................................

.........................................................

................................................................

......................... 104

..................................................

............................ 110

........................................................

............................. 116

..........................................................

104

104104

110

110110

116

116116

4.1

4.2

4.3

4.4

5555 Power Mate

5.1

5.2

5.3

5.4

6666 Power Mate

6.1

6.2

6.3

SPECIFICATIONS........................................................................................................................ 117

INSTALLATION ........................................................................................................................... 118

CABLE CONNECTION

(USING CONNECTORS MANUFACTURED BY PHOENIX CONTACT) ............................... 119

CABLE CONNECTION

(USING CONNECTORS MANUFACTURED BY HIROSE ELECTRIC) ................................. 120

Power Mate-D/F/H

Power MatePower Mate

SPECIFICATIONS........................................................................................................................ 123

CONNECTION.............................................................................................................................. 124

COMMUNICATION CABLE CONNECTION............................................................................. 128

CONNECTION WITH BUILT-IN DI/DO .................................................................................... 133

Power Mate i-D/H

Power MatePower Mate

SPECIFICATIONS........................................................................................................................ 145

INSTALLATION ........................................................................................................................... 148

CABLE CONNECTION (I/O Link-II SLAVE BOARD) .............................................................. 149

-D/F/H ................................

-D/F/H-D/F/H

................................................................

................................................................

-D/H ................................

................................................................

-D/H-D/H

................................................................

................................................................

................................................................

................................................................

................................................................

..........................................................

................................................................

...........................................................

................................................................

.......................... 122

....................................................

........................... 144

......................................................

122

122122

144

144144

6.4

CABLE CONNECTION (I/O Link-II SLAVE BOARD B)........................................................... 150

c - 2

Page 10

B-62714EN/04 Table of Contents

V. MAINTENANCE

V. MAINTENANCE

V. MAINTENANCEV. MAINTENANCE

1111 16/18/21-B, 16/18-C

16/18/21-B, 16/18-C................................

16/18/21-B, 16/18-C16/18/21-B, 16/18-C

................................................................

................................................................

................................................................

................................................................

.........................................................

................................................................

......................... 155

..................................................

155

155155

1.1

1.2

1.3

2222 LCD-MOUNT TYPE 16

2.1

2.2

2.3

3333 STAND-ALONE TYPE 16

3.1

COMPONENT LAYOUT .............................................................................................................. 156

LED INDICATIONS AND THEIR MEANINGS......................................................................... 157

SETTING ....................................................................................................................................... 158

LCD-MOUNT TYPE 16i/18

LCD-MOUNT TYPE 16LCD-MOUNT TYPE 16

COMPONENT LAYOUT .............................................................................................................. 160

LED INDICATIONS AND THEIR MEANINGS......................................................................... 161

SETTING ....................................................................................................................................... 162

STAND-ALONE TYPE 16i/18

STAND-ALONE TYPE 16STAND-ALONE TYPE 16

COMPONENT LAYOUT .............................................................................................................. 164

/18i/21

/21i-A

/18/18

/21/21

/18i/21

/18/18

-A ................................

................................................................

-A-A

................................................................

/21i-A

-A ................................

/21/21

................................................................

-A-A

................................................................

................................................................

................................................................

.............................................................

................................................................

.................................... 159

................................................................

............................. 163

..........................................................

3.1.1 Board B1................................................................................................................................. 164

3.1.2 Board B2................................................................................................................................. 165

3.2

3.3

4444 Power Mate

4.1

LED INDICATIONS AND THEIR MEANINGS......................................................................... 166

SETTING ....................................................................................................................................... 167

Power Mate-D/F/H

Power MatePower Mate

COMPONENT LAYOUT .............................................................................................................. 169

-D/F/H ................................

-D/F/H-D/F/H

................................................................

................................................................

................................................................

................................................................

..........................................................

................................................................

.......................... 168

....................................................

159

159159

163

163163

168

168168

4.2

5555 Power Mate

5.1

SETTING ....................................................................................................................................... 170

Power Mate i-D/H

Power MatePower Mate

I/O Link-II SLAVE BOARD.......................................................................................................... 172

-D/H ................................

................................................................

-D/H-D/H

................................................................

................................................................

................................................................

...........................................................

................................................................

........................... 171

......................................................

5.1.1 Component Layout ................................................................................................................ 172

5.1.2 LED Indications and Their Meanings .................................................................................. 173

5.2

I/O Link-II SLAVE BOARD B ...................................................................................................... 174

5.2.1 Component Layout ................................................................................................................ 174

5.2.2 LED Indications and Their Meanings .................................................................................. 175

5.2.3 Setting .................................................................................................................................... 176

171

171171

c - 3

Page 11

I. GENERAL

Page 12

B-62714EN/04 GENERAL 1.GENERAL

1 GENERAL

Describes the organization of this manual, applicable models.

- 3 -

Page 13

1.GENERAL GENERAL B-62714EN/04

1.1 ORGANIZATION

This manual consists of the following parts:

SAFETY PRECAUTIONS

Describes the precautions to be observed in reading this manual.

I. GENERAL

Describes the organization of this manual, applicable models.

II. DESCRIPTION

Describes the general for using the I/O Link-II function.

III. OPERATION

Describes the setting and operation procedures for using the I/O

Link-II function.

IV. CONNECTION

Describes the method of connecting each device and notes on

using the I/O Link-II function.

V. MAINTENANCE

Describes the drawing number of the I/O Link-II board, the

meanings of LED indications, and so forth.

- 4 -

Page 14

B-62714EN/04 GENERAL 1.GENERAL

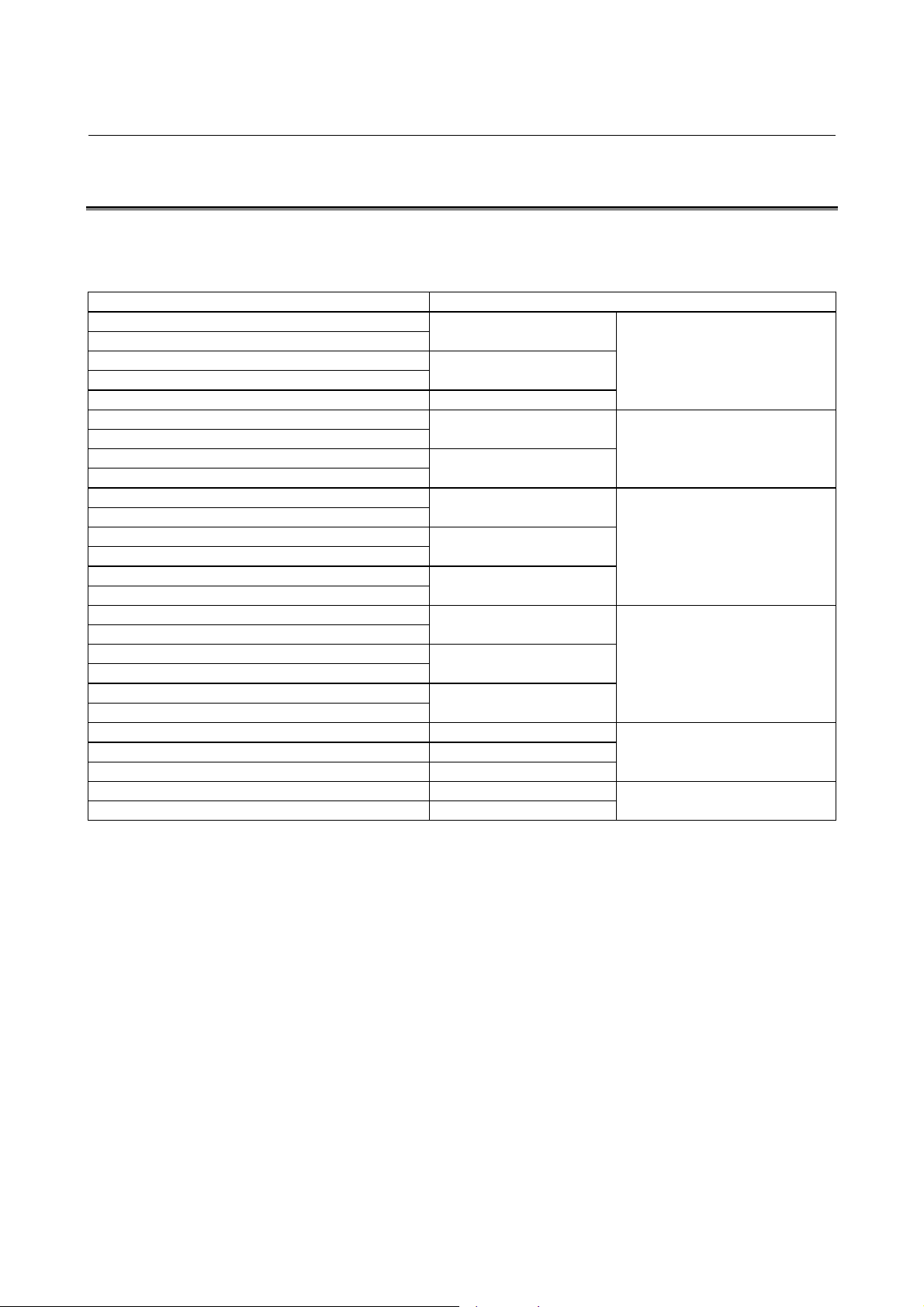

1.2 APPLICABLE MODELS

This manual covers the models listed in the table below. In this

manual, the their abbreviations may be used.

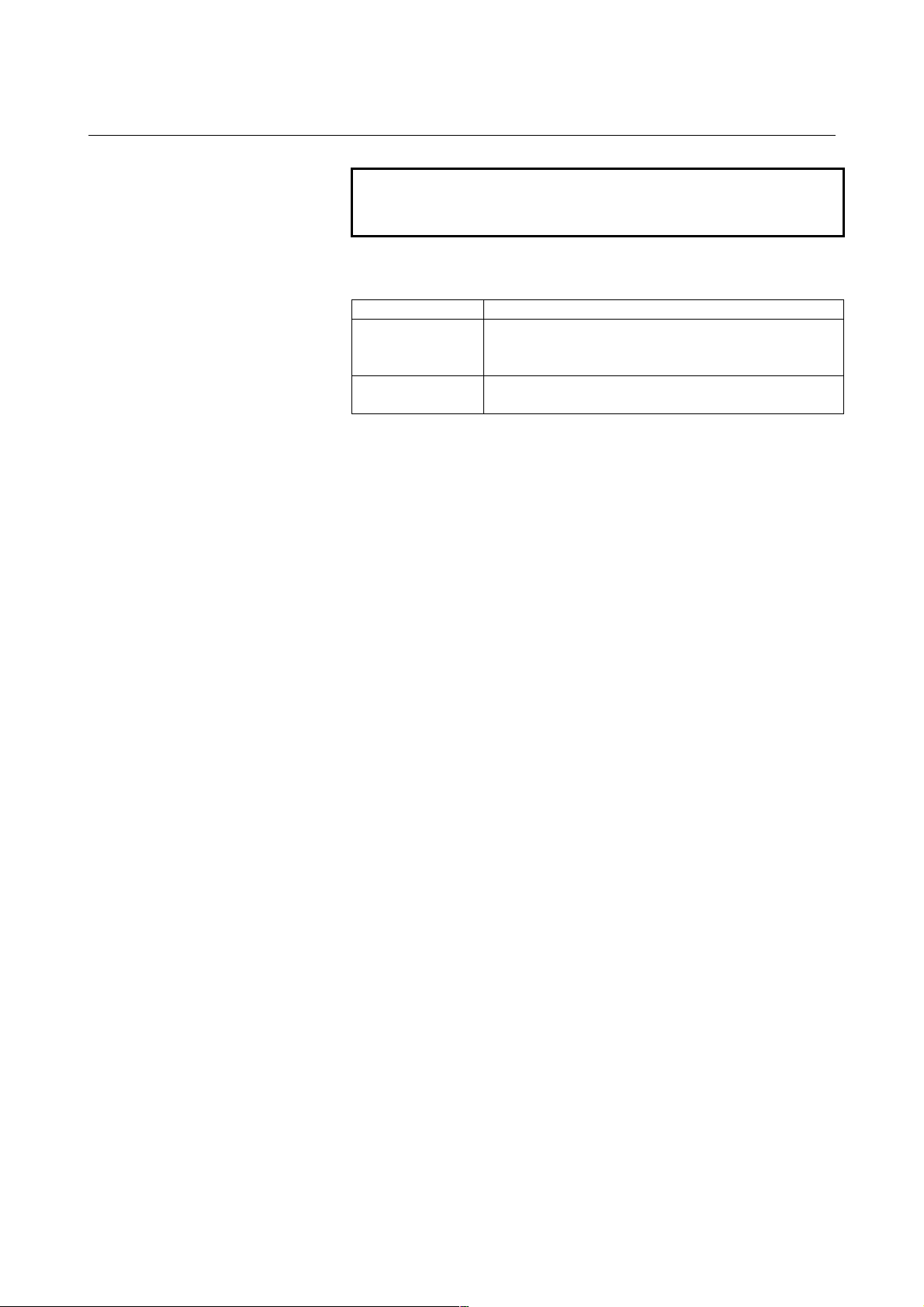

Model Abbreviation

FANUC Series 16-MODEL B

FANUC Series 160-MODEL B

FANUC Series 18-MODEL B

FANUC Series 180-MODEL B

FANUC Series 21-MODEL B 21-B

FANUC Series 16-MODEL C

FANUC Series 160-MODEL C

FANUC Series 18-MODEL C

FANUC Series 180-MODEL C

LCD-mounted type FANUC Series 16i-MODEL A/B

LCD-mounted type FANUC Series 160i-MODEL A/B

LCD-mounted type FANUC Series 18i-MODEL A/B

LCD-mounted type FANUC Series 180i-MODEL A/B

LCD-mounted type FANUC Series 21i-MODEL A/B

LCD-mounted type FANUC Series 210i-MODEL A/B

Stand-alone type FANUC Series 16i-MODEL A

Stand-alone type FANUC Series 160i-MODEL A

Stand-alone type FANUC Series 18i-MODEL A

Stand-alone type FANUC Series 180i-MODEL A

Stand-alone type FANUC Series 21i-MODEL A

Stand-alone type FANUC Series 210i-MODEL A

FANUC Power Mate-MODEL D

FANUC Power Mate-MODEL F

FANUC Power Mate-MODEL H

FANUC Power Mate i-MODEL D PMi-D

FANUC Power Mate i-MODEL H PMi-H

LCD-mounted type 16i-A/B

LCD-mounted type 18i-A/B

LCD-mounted type 21i-A/B

Stand-alone type 16i-A

Stand-alone type 18i-A

Stand-alone type 21i-A

16-B

18-B

16-C

18-C

PM-D

PM-F

PM-H

16/18/21-B

16/18-C

LCD-mounted type 16/18/21i-A/B

Stand-alone type 16/18/21i-A

PM-D/F/H

PMi-D/H

- 5 -

Page 15

II. SPECIFICATIONS

Page 16

B-62714EN/04 SPECIFICATIONS 1.I/O LINK-II I/O FUNCTION

1 I/O LINK-II I/O FUNCTION

The I/O Link-II function is a communication function that conforms

to OPCN-1 (formerly called JPCN-1/JEMA net) defined by the Japan

Electrical Manufacturer's Association.

The I/O Link-II function includes a master function and slave

function.

- 9 -

Page 17

1.I/O LINK-II I/O FUNCTION SPECIFICATIONS B-62714EN/04

1.1 FEATURES

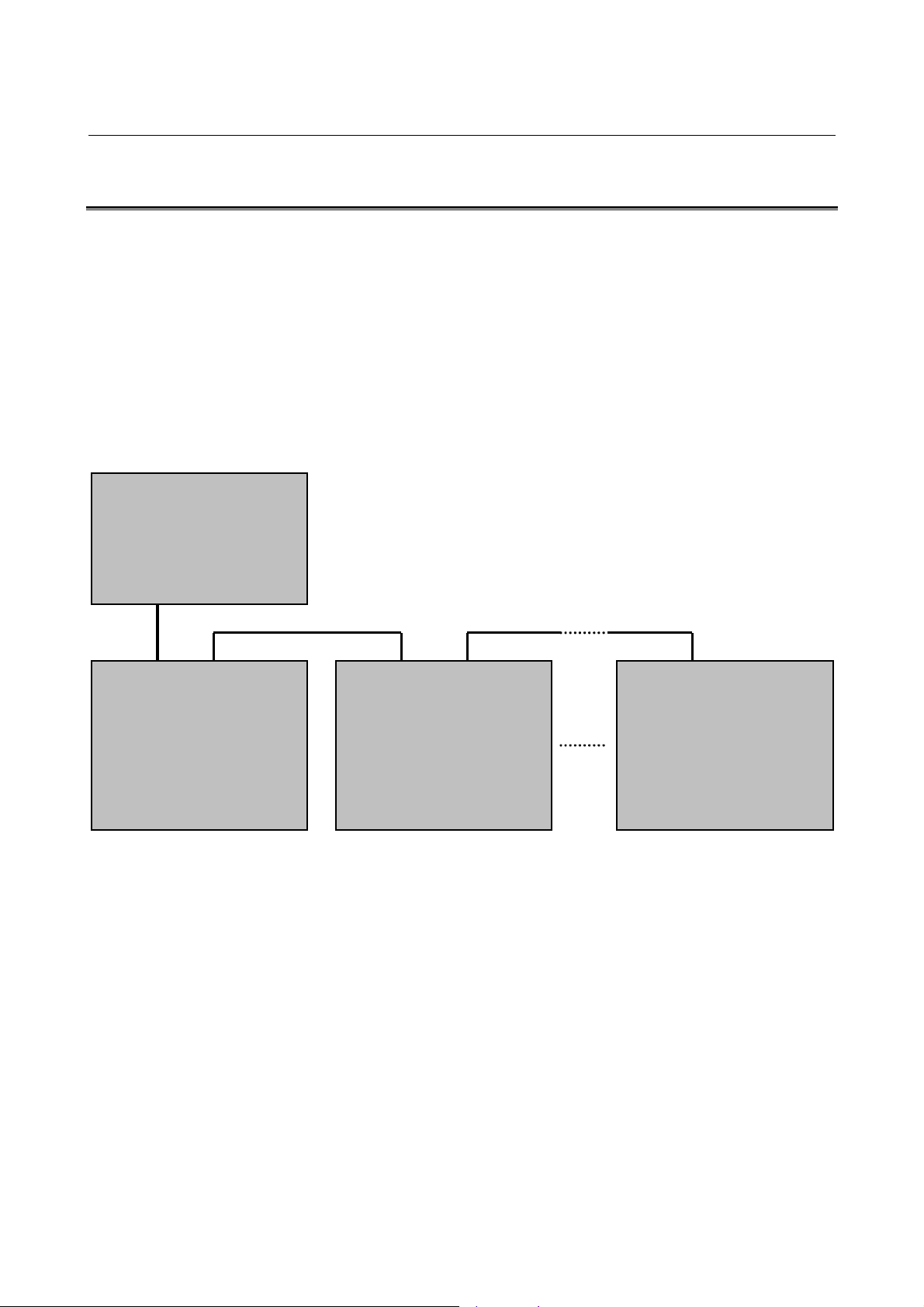

The I/O Link-II function has the features listed below.

(1) A connection can be made with devices (including devices

produced by other manufacturers) that conform to OPCN-1.

(2) The power to a slave station on the network can be turned on and

off at any time without affecting communications performed by

other devices.

(3) Up to thirty-one slave stations can be connected to one master

station.

(4) The slave function includes a global I/O transfer function

(allowing a slave station to receive DO data from other slave

stations).

<Master station>

16/18/21-B

16/18-C

LCD-mounted type 16i/18i/21i-A/B

Stand-alone type 16i/18i/21i-A

(OPCN-1-compliant products of other

manufacturers)

<Slave station> #1

16/18/21-B

16/18-C

LCD-mounted type 16i/18i/21i-A/B

Stand-alone type 16i/18i/21i-A

PM-D/F/H

PMi-D/H

(OPCN-1-compliant products of other

manufacturers)

<Slave station> #2

16/18/21-B

16/18-C

LCD-mounted type 16i/18i/21i-A/B

Stand-alone type 16i/18i/21i-A

PM-D/F/H

PMi-D/H

(OPCN-1-compliant products of other

manufacturers)

<Slave station> #31

16/18/21-B

16/18-C

LCD-mounted type 16i/18i/21i-A/B

Stand-alone type 16i/18i/21i-A

PM-D/F/H

PMi-D/H

(OPCN-1-compliant products of other

manufacturers)

- 10 -

Page 18

B-62714EN/04 SPECIFICATIONS 1.I/O LINK-II I/O FUNCTION

1.2 MASTER FUNCTION

The master function consists of the following function:

(1) DI/DO data transfer function

NOTE

FANUC I/O Link-II (master function) uses the

following services of OPCN-1:

(1) Initialization service

(2) Input/output service

(3) Reset service

- 11 -

Page 19

1.I/O LINK-II I/O FUNCTION SPECIFICATIONS B-62714EN/04

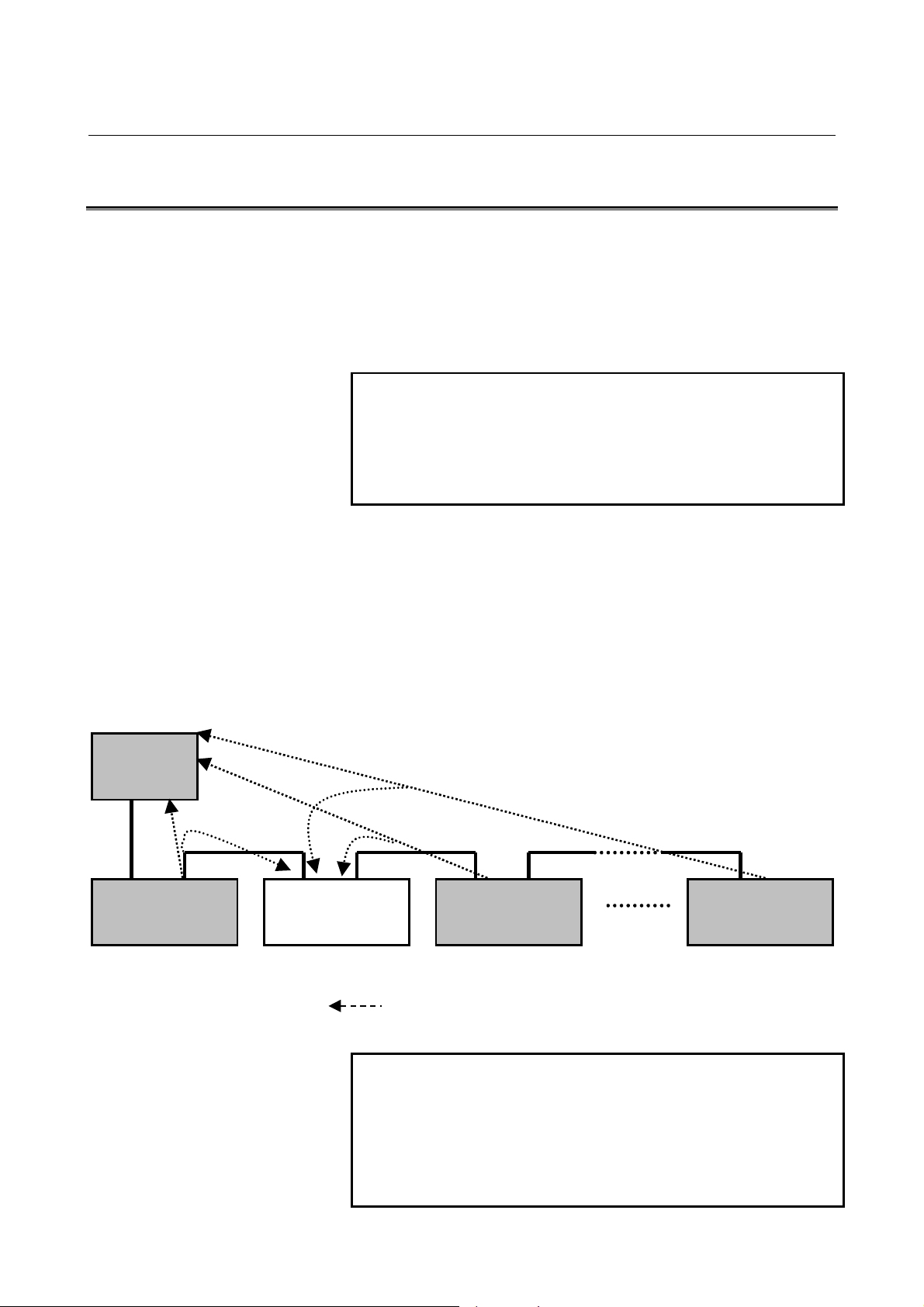

1.3 SLAVE FUNCTION

The slave function consists of the following functions:

(1) DI/DO data transfer function

(2) Global I/O transfer function (FANUC unique function)

(3) Capability of turning on and off the power to a slave station at

any time without affecting communications performed by other

devices

NOTE

FANUC I/O Link-II (slave function) uses the following

services of OPCN-1:

(1) Initialization service

(2) Input/output service

(3) Reset service

About the global I/O transfer function:

The figure below shows DI/DO data transfer performed between a

master station and slave stations #1 to #N. Suppose that a slave

station using the global I/O transfer function is a local slave station,

and the other slave stations are remote slave stations. Then, the local

slave station (#2) can receive DO data sent from the master station

and can also receive DO data sent to the master station from the

remote slave stations. So, the local slave station can make a ladder

reference.

Master

station

Slave station #1

[Remote slave

station]

Slave station #2

[Local slave

station]

NOTE

Slave station #3

[Remote slave

station]

DO data from slave stations #1 to #N (excluding #2)

Slave station #N

[Remote slave

station]

The global I/O transfer function is not a function

defined by OPCN-1 but a FANUC unique function.

This function can be used even when the network

includes products of other manufacturers (even as a

master station). In this case, however, the size of

data that can be transferred is limited.

- 12 -

Page 20

B-62714EN/04 SPECIFICATIONS 1.I/O LINK-II I/O FUNCTION

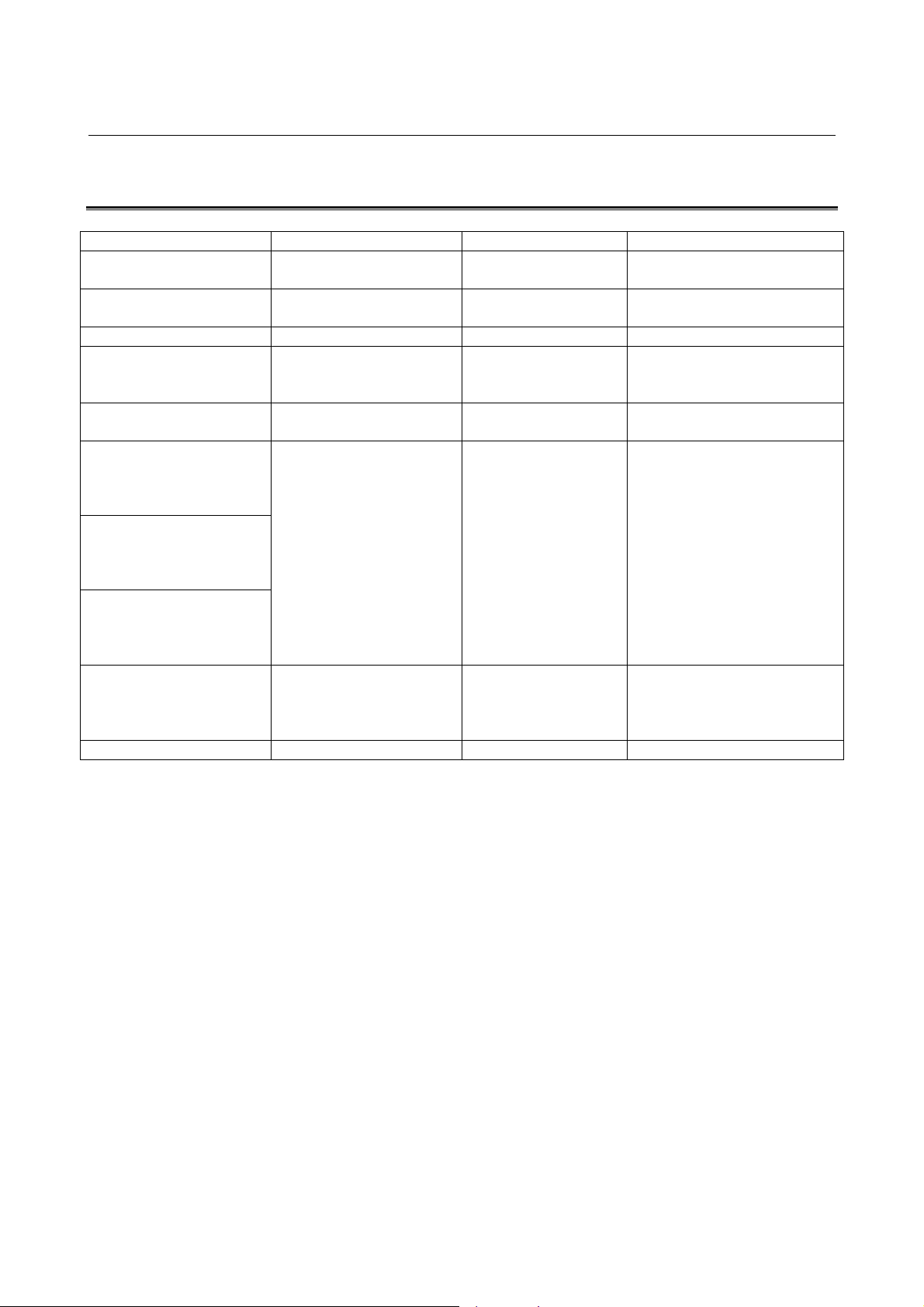

1.4 SPECIFICATIONS

Type Master station Master station Slave station

Applicable CNC 16/18/21-B, 16/18-C

Board (printed circuit board

drawing number)

Control software 6546 series 6546 series 6545 series

Maximum DI/DO size of the

DI/DO data transfer function

Maximum DI/DO size of the

global I/O transfer function

DI/DO allocatable area of

the DI/DO data transfer

function

DI/DO allocatable area of

the global I/O transfer

function

Status information

allocatable area

Reference items of this

manual

JEMA net --- --- ---

I/O Link-II board

A16B-2202-0152

62 bytes/62 bytes (16/18-C)

32 bytes/32 bytes

(16/18/21-B)

--- --- 48 bytes

R0000-R0999 for both DI

and DO

(PMC-SA1/SA3)

R0000-R1499 for both DI

and DO

(PMC-SB3/SC3/SB5)

R0000-R2999 for both DI

and DO

(PMC-SB4/SC4/SB6)

I,II

III-1.1,III-1.3

IV-1,IV-2

V-1

LCD-mounted type

16i/18i/21i-A/B

I/O Link-II board

A20B-8100-0250

128 bytes/128 bytes

R0000-R0999 for both

DI and DO

(PMC-SA1/SA5)

R0000-R1499 for both

DI and DO

(PMC-SB5)

R0000-R2999 for both

DI and DO

(PMC-SB6)

R0000-R7999 for both

DI and DO

(PMC-SB7)

I,II

III-1.1, III-1.3

IV-1,IV-3

V-2

16/18/21-B, 16/18-C

I I/O Link-II board

A16B-2202-0152

62 bytes/62 bytes (16/18-C)

32 bytes/32 bytes (16/18/21-B)

R0000-R0999 for both DI and

DO

(PMC-SA1/SA3)

R0000-R1499 for both DI and

DO

(PMC-SB3/SC3/SB5)

R0000-R2999 for both DI and

DO

(PMC-SB4/SC4/SB6)

I,II

III-1.2, III-1.3

IV-1,IV-2

V-1

- 13 -

Page 21

1.I/O LINK-II I/O FUNCTION SPECIFICATIONS B-62714EN/04

Type Master station Master station Slave station

Applicable CNC

Board (printed circuit board

drawing number)

Control software 6545 series 8816 series 8816 series

Maximum DI/DO size of the

DI/DO data transfer function

Maximum DI/DO size of the

global I/O transfer function

DI/DO allocatable area of

the DI/DO data transfer

function

DI/DO allocatable area of

the global I/O transfer

function

Status information

allocatable area

Reference items of this

manual

JEMA net --- --- ---

LCD-mounted type

16i/18i/21i-A/B

I/O Link-II board

A20B-8100-0250

128 bytes/128 bytes

48 bytes 48 bytes(Caution) 48 bytes(Caution)

R0000-R0999 for both DI

and DO

(PMC-SA1/SA5)

R0000-R1499 for both DI

and DO

(PMC-SB5)

R0000-R2999 for both DI

and DO

(PMC-SB6)

R0000-R7999 for both DI

and DO

(PMC-SB7)

I,II

III-1.2,III-1.3

IV-1,IV-3

V-2

PM-D/F/H

I/O Link-II board

A20B-2100-0041, 0040

32 bytes/32 bytes (PM-F/H)

64 bytes/64 bytes (PM-D)

DI : X1002-X1063

DO : Y1002-Y1063

(PMC-PA1/PA3)

R0000-R0999 for both DI

and DO

(PMC-PA1/PA3)

I,II

III-3.1,III-3.2

IV-1,IV-5

V-4

PMi-D/H

I/O Link-II board

A20B-8100-0310

32 bytes.32 bytes

DI : X1032-X1063

DO : Y1032-Y1063

(PMC-SB5/SB6)

R0000-R0999 for both DI

and DO

(PMC-SB5/SB6)

I,II

III-3.1,III-3.2

IV-1,IV-6.1, IV-6.2, IV-6.3

V-5.1

- 14 -

Page 22

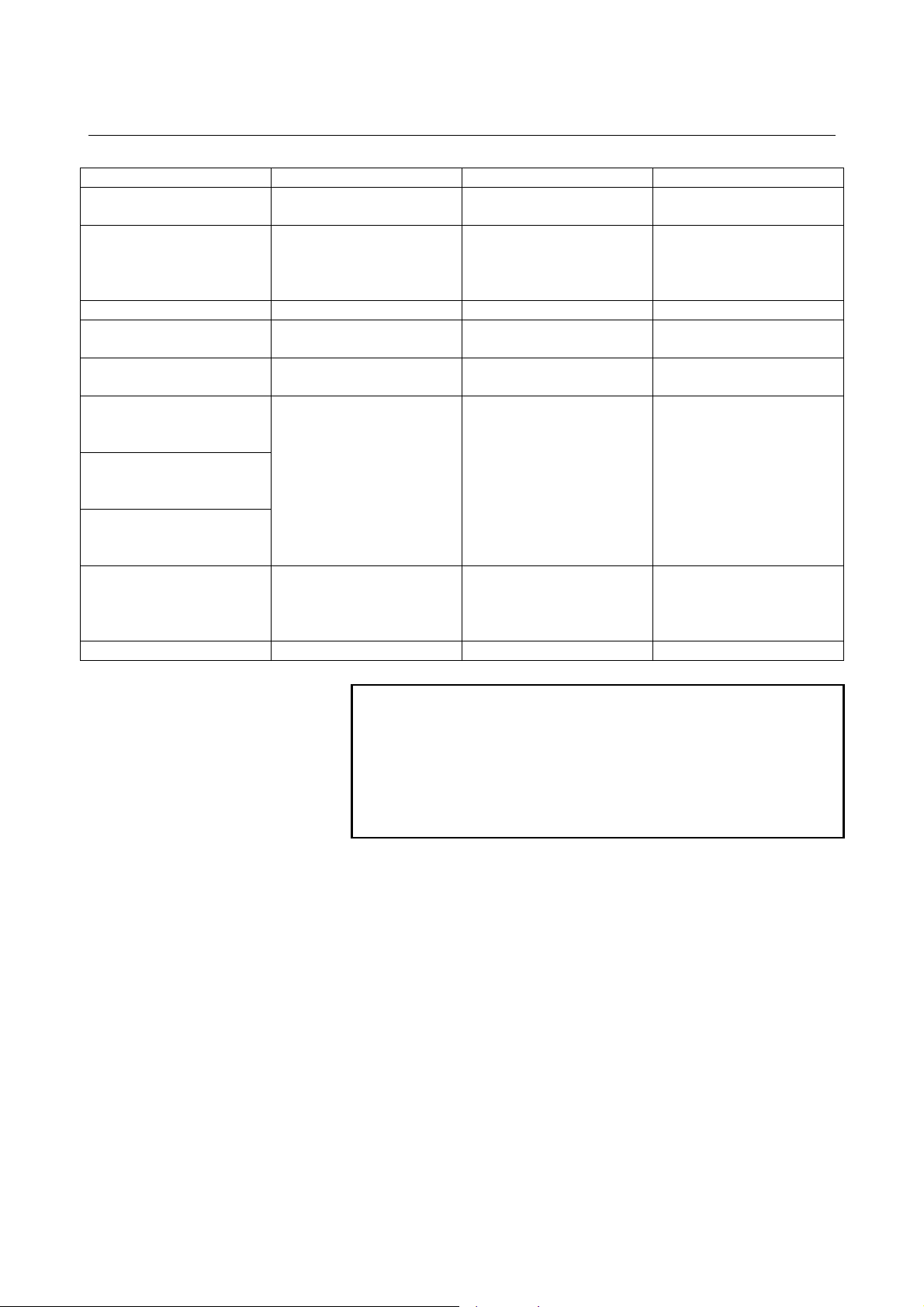

B-62714EN/04 SPECIFICATIONS 1.I/O LINK-II I/O FUNCTION

Type Master station Slave station Slave station

Applicable CNC

Board (printed circuit board

drawing number)

Control software 654B series 654A series 654A series

Maximum DI/DO size of the

DI/DO data transfer function

Maximum DI/DO size of the

global I/O transfer function

DI/DO allocatable area of

the DI/DO data transfer

function

DI/DO allocatable area of

the global I/O transfer

function

Status information

allocatable area

Reference items of this

manual

JEMA net OPCN-1 certified device OPCN-1 certified device OPCN-1 certified device

Stand-alone type

16i/18i/21i-A

I/O Link-II board B1

A20B-8100-0380

I/O Link-II board B2

A20B-8100-0381

128 bytes/128 bytes 128 bytes/128 bytes 128 bytes/128 bytes

--- 48 bytes 48 bytes

R0000-R0999 for both DI

and DO

(PMC-SA1/SA5)

R0000-R1499 for both DI

and DO

(PMC-SB5)

R0000-R2999 for both DI

and DO

(PMC-SB6)

I,II

III-2.1,III-2.3

IV-1,IV-4

V-3

Stand-alone type

16i/18i/21i-A

I/O Link-II board B1

A20B-8100-0380

I/O Link-II board B2

A20B-8100-0381

R0000-R0999 for both DI

and DO

(PMC-SA1/SA5)

R0000-R1499 for both DI

and DO

(PMC-SB5)

R0000-R2999 for both DI

and DO

(PMC-SB6)

I,II

III-2.2,III-2.3

IV-1,IV-4

V-3

PMi-D/H

I/O Link-II board B

A20B-8100-0381

R0000-R1499 for both DI

and DO

(PMC-SB5)

R0000-R2999 for both DI

and DO

(PMC-SB6)

I,II

III-2.2,III-2.3

IV-1, IV-6.1, IV-6.2, IV-6.4

V-5.2

CAUTION

The I/O Link-II board (A20B-2100-041) for PM-D/H

and the I/O Link-II board (A20B-8100-0310) for PMiD/H cannot use the global I/O transfer function

because of a mixture with the other stations (master

station and slave stations) using I/O Link-II boards

B, B1, and B2.

- 15 -

Page 23

1.I/O LINK-II I/O FUNCTION SPECIFICATIONS B-62714EN/04

1.5 GLOSSARY

Key terms used this manual are explained below.

OPCN-1 (formerly called JPCN-1 or JEMA net)

Field network defined by the Japan Electrical Manufacturer's

Association

OPCN-1 certified device

FANUC device that passed the OPCN-1 certification test

Certification number: J990705JPCNM026

Date of certification: July 5, 1999

Master station

Station that establishes and cancels logical communication paths to

multiple slave stations, manages the data transmission service issue

sequence and error recovery sequence, and performs I/O transfer.

One OPCN-1 network can include only one master station.

Slave station

Initialization service

Input/output service

Reset service

Initial state

Station that exercises communication control and performs I/O

transfer to and from the master station according to instructions from

the master station. One OPCN-1 network can include up to 31 slave

stations.

Service defined by OPCN-1 for information exchange and setting to

establish logical communication paths between the master station and

slave stations. When the initialization service is executed successfully,

input/output service can be started.

Service defined by OPCN-1 for DI/DO data transfer between the

master station and slave stations

Service defined by OPCN-1 for the master station to reset slave

stations to the initial state

State where no logical communication path is established

Detachment

Disconnection

State where communication (input/output service being performed)

with the remote station is disabled

State where communication is not performed (such as in the initial

state or detached state)

- 16 -

Page 24

B-62714EN/04 SPECIFICATIONS 1.I/O LINK-II I/O FUNCTION

DI data

Input data when viewed from the local station (master station or slave

station)(Caution)

DO data

Output data when viewed from the local station (master station or

slave station)(Caution)

CAUTION

In the OPCN-1 specifications, data input/output is

defined as data input/output viewed from the master

station. Note that the use of the term in this manual

for slave stations is opposite to the definition in the

OPCN-1 specifications.

For communication with devices of other

manufacturers, check the definition of data

input/output.

DI/DO data transfer function

Function for exchanging DI/DO data between the master station and

slave stations of I/O Link-II. This function is implemented by

input/output service of OPCN-1.

Global I/O transfer function

FANUC unique function. When DI/DO data is exchanged between

the master station and multiple slave stations, a slave station receives

DO data sent from the other slave stations to the master station, thus

achieving I/O transfer between the slave stations.

Successive error detach detection counter

Maximum allowable number of successive communication errors.

When this maximum number is exceeded, a detachment is detected.

One scan

Executing input/output service once for all slave stations connected to

the network

Slave type

Initialization service parameter defined by OPCN-1 for determining

the type of communication between the master station and slave

stations

- 17 -

Page 25

1.I/O LINK-II I/O FUNCTION SPECIFICATIONS B-62714EN/04

stypeM

Slave type set by the master station

stypeM bit 7bit 6bit 5bit 4bit 3bit 2bit 1bit 0

Bits 7 and 6 : Reserved (0 at all times)

Bit 5 : SA (whether information and I/O from the master station to a slave

station are specified)

- When SA = 0, information and I/O from the master station to a

slave station are not specified.

- When SA = 1, information and I/O from the master station to a

slave station are specified

Bit 4 : ST (whether a type of I/O from the master station to a slave station is

specified)

- When ST = 0, no type of I/O from the master station to a slave

station is specified.

- When ST = 0, a type of I/O from the master station to a slave

station is specified.

NOTE

The setting of bits 3 to 1 is valid when ST = 1.

stypeS

Bit 3 : DW (data write)

Set DW = 1 to enable data write service.

Bit 2 : DR (data read)

Set DR = 1 to enable data read service.

Bit 1 : DO (output)

Set DO = 1 to perform input/output service and enable output.

Bit 0 : DI (input)

Set DI = 1 to perform input/output service and enable input.

Slave type set by a slave station

stypeS bit 7bit 6bit 5bit 4bit 3bit 2bit 1bit 0

Bits 7 to 4 : Reserved (0 at all times)

Bit 3 : DW (data write)

Set DW = 1 to enable data write service.

Bit 2 : DR (data read)

Set DR = 1 to enable data read service.

Bit 1 : DO (output from the master station) when viewed from the master

station

Set DO = 1 to perform input/output service and enable output.

Bit 0 : DI (input to the master station) when viewed from the master station

Set DI = 1 to perform input/output service and enable input.

- 18 -

Page 26

III. OPERATION

Page 27

B-62714EN/04 OPERATION 1.16/18/21-B, 16/18-C, LCD-MOUNTED TYPE 16i/18i/21i-A/B

1 16/18/21-B, 16/18-C, LCD-MOUNTED

TYPE 16i/18i/21i-A/B

This chapter describes the setting procedure for operating the master

function and slave function.

NOTE

The parameters related to the I/O Link-II function are

stored in the SRAM on an I/O Link-II board. When

using an I/O Link-II board for the first time, initialize

the SRAM on the board according to Section 1.3,

"SETTING" of Part V, "MAINTENANCE" (for

16/18/21-B and 16/18-C) or Section 2.3 "SETTING"

of the same part (for 16i/18i/21i-A/B).

- 21 -

Page 28

1.16/18/21-B, 16/18-C, LCD-MOUNTED TYPE 16i/18i/21i-A/B OPERATION B-62714EN/04

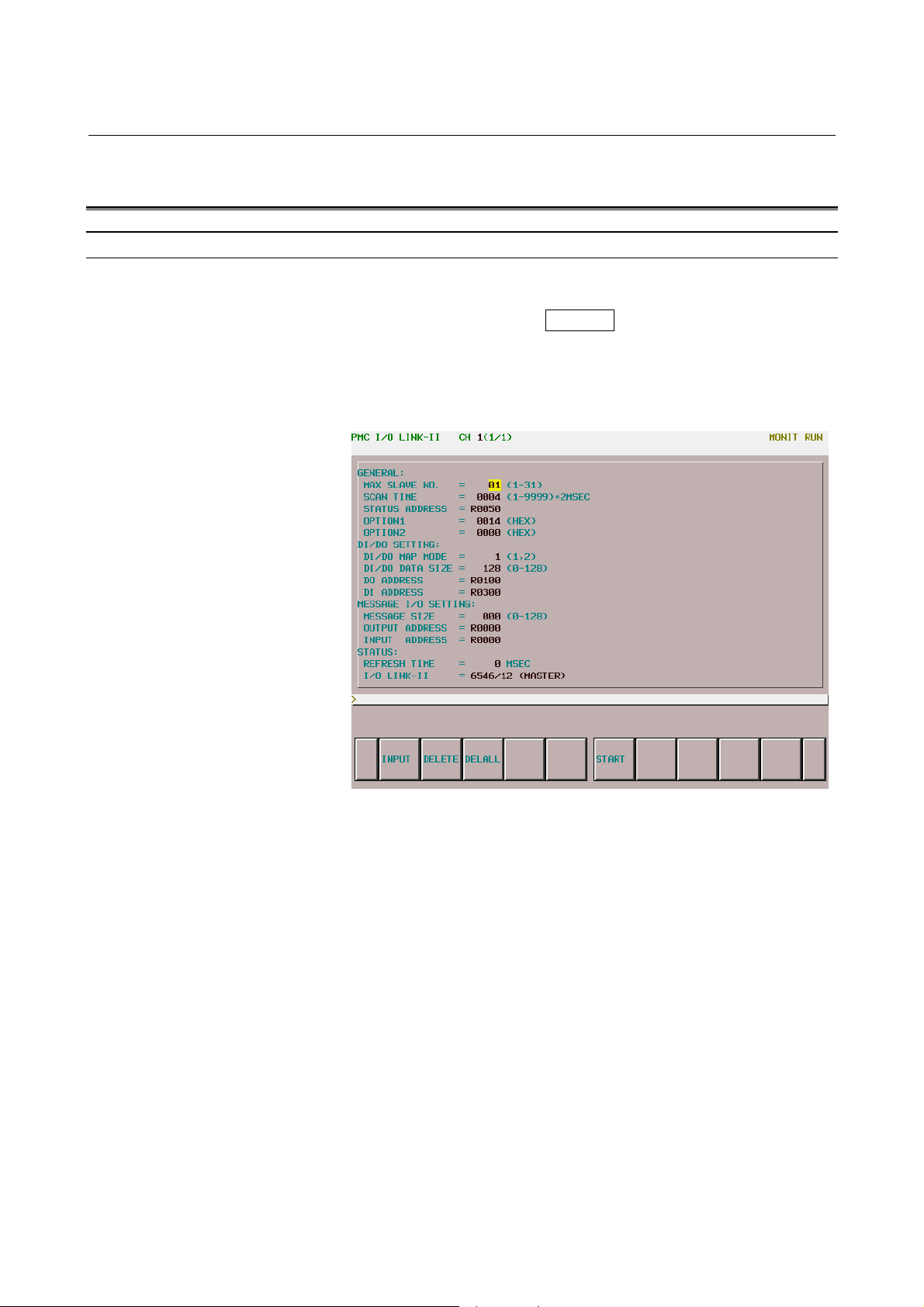

1.1 MASTER FUNCTION

Display of the setting screen

Procedure

(1) Press the function key SYSTEM, then select the soft key [PMC]

to switch to the PMC screen.

(2) Select the soft keys [PMCDGN], [I/OCHK], and [IOLNK2] in

this order. Screen 1-1 appears.

- 22 -

Screen 1-1

Page 29

B-62714EN/04 OPERATION 1.16/18/21-B, 16/18-C, LCD-MOUNTED TYPE 16i/18i/21i-A/B

Setting items and display items

Setting items

Table III-1-1

Item Description

Maximum slave station number used for

MAX SLAVE NO.

SCAN TIME

STATUS ADDRESS

OPTION1

OPTION2

DI/DO MAP MODE

DI/DO DATA SIZE

DO ADDRESS

DI ADDRESS

MESSAGE SIZE Not used

OUTPUT ADDRESS Not used

INPUT ADDRESS Not used

communication with the master station.

Setting range: 1 to 31

Interval for performing one scan of input/output

service.

Set a value greater than the value of REFRESH

TIME.

Guideline for setting:

SCAN TIME = MAX SLAVE NO. × 2 + 2

Setting unit: 2 msec

Setting range: 1 to 9999

Example of setting:

When 4 is set in SCAN TIME, the setting of 8 msec

is assumed.

Start address of an area for storing communication

status.

Setting range: R area of the PMC

Slave station communication monitoring time

Recommended setting: 14 [hexadecimal] → 40 msec

Setting unit: msec

Setting range: 03 to D0 (hexadecimal)

Successive error detach detection counter.

Recommended setting: 3 [hexadecimal]

Setting range: 00 to FF (hexadecimal)

When the default value 0 is used, the setting of 3 is

assumed for operation.

Determines the method of allocating a DI/DO data

area.

Setting: 1, 2

1: A DI data area and DO data area are allocated for

the number of stations set in MAX SLAVE NO..

2: A DI data area is allocated for the number of

stations set in MAX SLAVE NO., and a DO data

area is allocated for one station.

DI/DO data area size.

Setting range: 0 to 62 (16/18/21-B, 16/18-C)

Setting range: 0 to 128 (LCD-mounted type

16i/18i/21i-A)

(Unit: Bytes)

DO data area start address.

Setting range: R area of the PMC

DI data area start address.

Setting range: R area of the PMC

- 23 -

Page 30

1.16/18/21-B, 16/18-C, LCD-MOUNTED TYPE 16i/18i/21i-A/B OPERATION B-62714EN/04

NOTE

The baud rate cannot be changed, but is fixed at 1

Mbps.

Display items

Table III-1-1

Item Description

Interval at which DI data from all slave stations set in

REFRESH TIME.

I/O LINK-II

MAX SLAVE NO. is reflected in the R area of the PMC.

Unit: 1 msec

The series and edition of the EPROM installed on the

I/O Link-II board are displayed.

- 24 -

Page 31

B-62714EN/04 OPERATION 1.16/18/21-B, 16/18-C, LCD-MOUNTED TYPE 16i/18i/21i-A/B

Operations of the setting screen

Setting parameters

(1) Place the CNC in the MDI mode.

(2) Press the function key SYSTEM

, then select the soft key [PMC]

to switch to the PMC screen.

(3) Select the soft keys [PMCDGN], [I/OCHK], and [IOLNK2] in

this order. Screen 1-1 appears.

(4) With the cursor keys, move the cursor to an item for which data

is to be entered.

(5) Enter data with the MDI keys.

(6) Select the soft key [INPUT] or press the function key INPUT

to

execute the input of data.

Example: Setting 2 in MAX SLAVE NO.

(a) Move the cursor to MAX SLAVE NO..

(b) Enter 2 with the MDI key.

(c) Select the soft key [INPUT] or press the function key

INPUT

to execute the input of data.

Thus, the set data is stored in the nonvolatile memory on the I/O LinkII board.

- 25 -

Page 32

1.16/18/21-B, 16/18-C, LCD-MOUNTED TYPE 16i/18i/21i-A/B OPERATION B-62714EN/04

Deleting parameters

(1) Place the CNC in the MDI mode.

(2) Press the function key SYSTEM

(3) Select the soft keys [PMCDGN], [I/OCHK], and [IOLNK2] in

(4) With the cursor keys, move the cursor to an item whose setting

(5) Select the soft key [DELETE] or press the function key

Thus, the data is deleted from the nonvolatile memory on the I/O

Link-II board.

Deleting parameters in a batch

(1) Place the CNC in the MDI mode.

(2) Press the function key SYSTEM

(3) Select the soft keys [PMCDGN], [I/OCHK], and [IOLNK2] in

to switch to the PMC screen.

this order. Screen 1-1 appears.

to be deleted.

DELETE

to switch to the PMC screen.

this order. Screen 1-1 appears.

to delete the data.

, then select the soft key [PMC]

, then select the soft key [PMC]

Restart

(4) Select the soft key [DELALL] to delete all data in a batch.

Thus, all data is deleted in a batch from the nonvolatile memory on

the I/O Link-II board.

(1) Place the CNC in the MDI mode.

(2) Press the function key SYSTEM

to switch to the PMC screen.

(3) Select the soft keys [PMCDGN], [I/OCHK], and [IOLNK2] in

this order. Screen 1-1 appears.

(4) Select the soft key [START]. The master function is restarted

with the current settings displayed on Screen 1-1.

, then select the soft key [PMC]

- 26 -

Page 33

B-62714EN/04 OPERATION 1.16/18/21-B, 16/18-C, LCD-MOUNTED TYPE 16i/18i/21i-A/B

(5) If the settings are correct, LINK STARTED is displayed, and

initialization service is performed.

(6) If a setting item is incorrect, START ERROR is displayed, and

the system waits for the incorrect setting item to be corrected.

CAUTION

When the soft key [START] is selected, the set

parameters are updated, and reset service is also

performed for slave stations #1 to #[MAX SLAVE

NO].

So, the same processing as performed when the

power is turned on again after resetting the network

to the initial state (initialization service for the slave

stations → input/output service) is performed.

- 27 -

Page 34

1.16/18/21-B, 16/18-C, LCD-MOUNTED TYPE 16i/18i/21i-A/B OPERATION B-62714EN/04

DI/DO data allocation of the master function

DO data allocation (when DI/DO MAP MODE = 1)

A DO area is allocated for each slave.

[DO ADDRESS]

+[DI/DO DATA SIZE] ×1

+[DI/DO DATA SIZE] ×2

+[DI/DO DATA SIZE] ×3

+[DI/DO DATA SIZE]×

([MAX SLAVE NO]-1)

DO data from the master station to

slave station #1

DO data from the master station to

slave station #2

DO data from the master station to

slave station #3

DO data from the master station to

slave station #4

::

::

::

DO data from the master station to

slave station #[MAX SLAVE NO]

Example:

When [MAX SLAVE NO] = 2, [DI/DO MAP MODE] = 1, [DO

ADDRESS] = R0100, and [DI/DO ADDRESS SIZE] = 10, DO

data is allocated as follows:

R0100

R0110

DO data from the master station to

slave station #1

DO data from the master station to

slave station #2

↑

[DI/DO DATA SIZE]

↓

DO data allocation (when DI/DO MAP MODE = 2)

Common DO data is allocated for all slaves.

[DO ADDRESS] DO data from the master station to

slave stations #1 to slave station

#[MAX SLAVE NO]

- 28 -

↑

[DI/DO DATA SIZE]

↓

Page 35

B-62714EN/04 OPERATION 1.16/18/21-B, 16/18-C, LCD-MOUNTED TYPE 16i/18i/21i-A/B

DI data allocation (when DI/DO MAP MODE = 1 or 2)

[DI ADDRESS]

+[DI/DO DATA SIZE]×1

+[DI/DO DATA SIZE]×2

+[DI/DO DATA SIZE]×3

+[DI/DO DATA SIZE]×

([MAX SLAVE NO]-1)

DI data from slave station #1 to the

master station

DI data from slave station #2 to the

master station

DI data from slave station #3 to the

master station

DI data from slave station #4 to the

master station

::

::

::

DI data from slave station #[MAX

SLAVE NO] to the master station

Example:

When [MAX SLAVE NO] = 3, [DI ADDRESS] = R0300, and

[DI/DO ADDRESS SIZE] = 10, DI data is allocated as follows:

R0300

R0310

R0320

DI data from slave station #1 to the

master station

DI data from slave station #2 to the

master station

DI data from slave station #3 to the

master station

↑

[DI/DO DATA SIZE]

↓

- 29 -

Page 36

1.16/18/21-B, 16/18-C, LCD-MOUNTED TYPE 16i/18i/21i-A/B OPERATION B-62714EN/04

Communication status for ladder detection of the master function

Communication status allocation

[STATUS ADDRESS]

ERROR STATUS

ERROR STATUS

+1

+2

+3

+[MAX SLAVE NO]

Status of communication with

slave station #1

Status of communication with

slave station #2

Status of communication with

slave station #3

::

::

::

Status of communication with

slave station #[MAX SLAVE NO]

ERROR STATUS (1 byte):

Communication line errors detected by the master station are

indicated.

bit 7bit 6bit 5bit 4bit 3bit 2bit 1bit 0

Bit 7 : Reserved (0 at all time)

Bit 6 : Short frame error

Bit 5 : Abort detection

Bit 4 : Detection of data consisting of an incorrect number of bits

Bit 3 : Overrun error detection

Bit 2 : FCS error detection

Bits 1, 0 : Reserved (0 at all times)

NOTE

Many errors are caused by hardware failures (on

communication boards or communication cables)

and noise. Recheck the method of communication

cable connection, terminating resistor, and noise

protection.

- 30 -

Page 37

B-62714EN/04 OPERATION 1.16/18/21-B, 16/18-C, LCD-MOUNTED TYPE 16i/18i/21i-A/B

Status of communication with remote slave stations

Status of communication with remote slave stations #1 to #[MAX

SLAVE NO]:

The status of communication with each slave station is indicated (1

byte for each).

bit 7bit 6bit 5bit 4bit 3bit 2bit 1bit 0

Bit 7: LINK STATUS (status of the link with a slave station)

- When LINK STATUS = 0, the link is disconnected.

- When LINK STATUS = 1, communication is performed

normally.

Bits 6 to 1: Reserved (0 at all times)

Bit 0: Communication error flag

- When communication error flag = 0, the successive error detach

detection counter is not exceeded.

- When communication error flag = 1, the successive error detach

detection counter is exceeded.

- 31 -

Page 38

1.16/18/21-B, 16/18-C, LCD-MOUNTED TYPE 16i/18i/21i-A/B OPERATION B-62714EN/04

1.2 SLAVE FUNCTION

Display of the setting screen

Procedure

(1) Press the function key SYSTEM, then select the soft key [PMC]

to switch to the PMC screen.

(2) Select the soft keys [PMCDGN], [I/OCHK], and [IOLNK2] in

this order. Screen 1-2 appears.

- 32 -

Screen 1-2

Page 39

B-62714EN/04 OPERATION 1.16/18/21-B, 16/18-C, LCD-MOUNTED TYPE 16i/18i/21i-A/B

Setting items and display items

Setting items

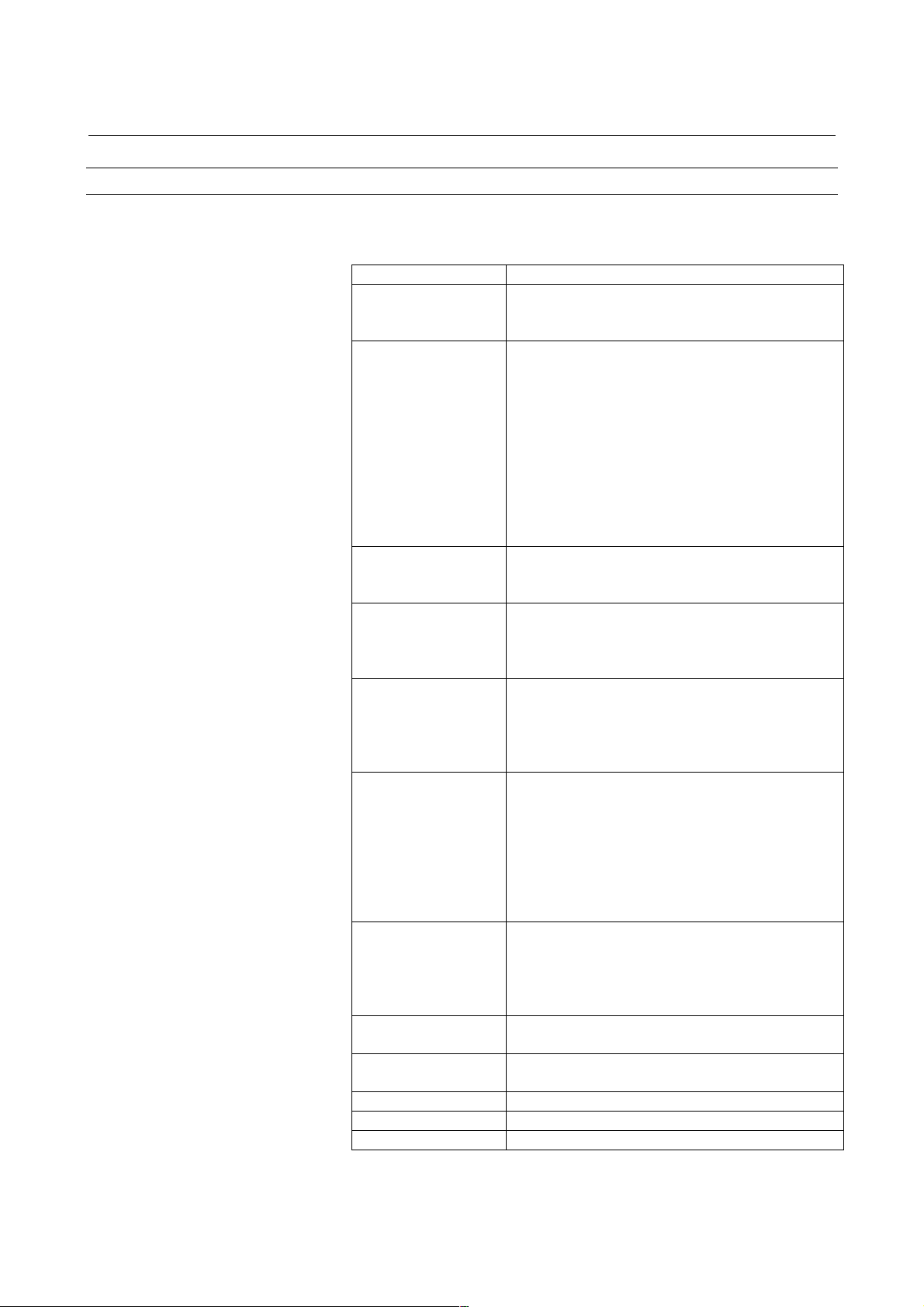

Table III-1-3

Item Description

Maximum slave station number used for

MAX SLAVE NO.

SCAN TIME

STATUS ADDRESS

OPTION1

OPTION2 Not used

DI/DO MAP MODE

DI/DO DATA SIZE

DO ADDRESS

DI ADDRESS

MESSAGE SIZE Not used

OUTPUT ADDRESS Not used

INPUT ADDRESS Not used

communication with the master station.

Setting range: 1 to 31(Note)

Station number of the slave station.

Setting range: 1 to 31(Note)

Start address of an area for storing communication

status.

Setting range: R area of the PMC

Slave station communication monitoring time

Guideline for setting:

OPTION1 = MAX SLAVE NO. × 5

Setting unit: 100 msec

Setting range: 0000 to 1000 [hexadecimal]

When the default value 0 is used, a value

determined by the guideline for setting is assumed

for operation.

Determines the method of allocating a DI/DO data

area.

Setting: 0, 2

0: DI/DO data transfer function

A DI data area and DO data area are allocated for

one station.

2: Global I/O transfer function(Caution)

A DI data area is allocated for the number of

stations set in MAX SLAVE NO. plus 1, and a DO

data area is allocated for one station.

DI/DO data area size.

For the DI/DO data transfer function

Setting range: 0 to 32 (16/18/21-B)

Setting range: 0 to 62 (16/18-C)

Setting range: 0 to 128 (LCD-mounted type

16i/18i/21i-A)

For the global I/O transfer function

Setting range: 0 to 48

(Unit: Bytes)

DO data area start address

Setting range: R area of the PMC

DI data area start address

Setting range: R area of the PMC

CAUTION (*1)

When using the global I/O transfer function, ensure

that the DI data size and DO data size of each slave

station on the network do not exceed 48 bytes.

- 33 -

Page 40

1.16/18/21-B, 16/18-C, LCD-MOUNTED TYPE 16i/18i/21i-A/B OPERATION B-62714EN/04

NOTE

- The baud rate cannot be changed but is fixed at 1

Mbps.

- When using the global I/O transfer function, set

slave station numbers sequentially to allocate an

area efficiently.

Display items

Table III-1-4

Item Description

I/O LINK-II

The series and edition of the EPROM installed on

the I/O Link-II board are displayed.

- 34 -

Page 41

B-62714EN/04 OPERATION 1.16/18/21-B, 16/18-C, LCD-MOUNTED TYPE 16i/18i/21i-A/B

Operations of the setting screen

Setting parameters

(1) Place the CNC in the MDI mode.

(2) Press the function key SYSTEM

, then select the soft key [PMC]

to switch to the PMC screen.

(3) Select the soft keys [PMCDGN], [I/OCHK], and [IOLNK2] in

this order. Screen 1-2 appears.

(4) With the cursor keys, move the cursor to an item for which data

is to be entered.

(5) Enter data with the MDI keys.

(6) Select the soft key [INPUT] or press the function key INPUT

to

execute the input of data.

Example: Setting 2 in MAX SLAVE NO.

(a) Move the cursor to MAX SLAVE NO..

(b) Enter 2 with the MDI key.

(c) Select the soft key [INPUT] or press the function key

INPUT

to execute the input of data.

Thus, the set data is stored in the nonvolatile memory on the I/O LinkII board.

- 35 -

Page 42

1.16/18/21-B, 16/18-C, LCD-MOUNTED TYPE 16i/18i/21i-A/B OPERATION B-62714EN/04

Deleting parameters

(1) Place the CNC in the MDI mode.

(2) Press the function key SYSTEM

(3) Select the soft keys [PMCDGN], [I/OCHK], and [IOLNK2] in

(4) With the cursor keys, move the cursor to an item whose setting

(5) Select the soft key [DELETE] or press the function key

Thus, the data is deleted from the nonvolatile memory on the I/O

Link-II board.

Deleting parameters in a batch

(1) Place the CNC in the MDI mode.

(2) Press the function key SYSTEM

(3) Select the soft keys [PMCDGN], [I/OCHK], and [IOLNK2] in

to switch to the PMC screen.

this order. Screen 1-2 appears.

to be deleted.

DELETE

to switch to the PMC screen.

this order. Screen 1-2 appears.

to delete the data.

, then select the soft key [PMC]

, then select the soft key [PMC]

(4) Select the soft key [DELALL] to delete all data in a batch.

Thus, all data is deleted in a batch from the nonvolatile memory on

the I/O Link-II board.

- 36 -

Page 43

B-62714EN/04 OPERATION 1.16/18/21-B, 16/18-C, LCD-MOUNTED TYPE 16i/18i/21i-A/B

Restart

(1) Place the CNC in the MDI mode.

(2) Press the function key SYSTEM

to switch to the PMC screen.

(3) Select the soft keys [PMCDGN], [I/OCHK], and [IOLNK2] in

this order. Screen 1-2 appears.

(4) Select the soft key [START]. The slave function is restarted

with the current settings displayed on Screen 1-2.

(5) If the settings are correct, LINK STARTED is displayed, and

initialization service is awaited.

(6) If a setting item is incorrect, START ERROR is displayed, and

the system waits for the incorrect setting item to be corrected.

, then select the soft key [PMC]

NOTE

The soft key [START] provides an auxiliary way to

validate settings modified on this screen.

If the soft key [START] is selected after modifying

settings, communication may be suspended

halfway, and may not be performed normally,

depending on the state of the master station. In

such a case, restart the master station and slave

station.

- 37 -

Page 44

1.16/18/21-B, 16/18-C, LCD-MOUNTED TYPE 16i/18i/21i-A/B OPERATION B-62714EN/04

DI/DO data allocation of the slave function

DO data allocation

↑

[DI/DO DATA SIZE]

↓

[DO ADDRESS]

DO data from the local slave station to

the master station

DI data allocation when DI/DO data transfer is set (when DI/DO MAP MODE = 0)

↑

[DI/DO DATA SIZE]

↓

[DO ADDRESS]

DI data from the master station to the

local slave station

DI data allocation when global I/O transfer is set (when DI/DO MAP MODE = 2)

↑

[DI/DO DATA SIZE]

↓

[DO ADDRESS]

+[DI/DO DATA SIZE]×1

+[DI/DO DATA SIZE]×2

+[DI/DO DATA SIZE]×3

+[DI/DO DATA SIZE]×

[STATION NO]

+[DI/DO DATA SIZE]×

[MAX SLAVE NO]

DI data from the master station to the

local slave station

DO data from slave station #1 to the

master station

DO data from slave station #2 to the

master station

DO data from slave station #3 to the

master station

::

Not used.(The area for the local slave

station is not used. The area can be

used for other purposes such as a DO

data output area for the local station.)

::

DO data from slave station #[MAX

SLAVE NO] to the master station

Example:

When [STATION NO] = 2, [MAX SLAVE NO] = 3, [DI

ADDRESS] = R0300, and [DI/DO DATA SIZE] = 10, DI data is

allocated as follows:

R0300

R0310

R0320 Not used

R0330

DI data from the master station to

slave station #2

DO data from slave station #1 to the

master station

DO data from slave station #3 to the

master station

NOTE

For global I/O transfer, note the following when

allocating DI data:

- [DI/DO DATA SIZE] must match the maximum

size of other slaves.

- The total DI data area size required is [DI/DO

DATA SIZE] × [MAX SLAVE NO].

- 38 -

Page 45

B-62714EN/04 OPERATION 1.16/18/21-B, 16/18-C, LCD-MOUNTED TYPE 16i/18i/21i-A/B

Restrictions on the global I/O transfer function

Conditions for taking in DO data from a remote slave station to the master

station

When the two conditions below are satisfied, DO data from a remote

slave station to the master station is taken in.

Condition 1 : 48 bytes ≥ x bytes ≥ y bytes

where

x: Size of DI data from the master station to the local slave

station

y: Size of DO data from a remote slave station to the master

station

Condition 2 : Station m ≥ Station n

where

m: [MAX SLAVE NO] set at the local slave station

n: Station number of a remote slave station

Example:

When the station number of the local slave station is 2, there are

five remote slave stations, and each slave station is set as

follows:

- Setting of slave station #1: DO data size = 16 bytes

- Setting of slave station #2: [MAX SLAVE NO] = 4,

[STATION NO] = 2, [DI/DO MAP MODE] =2, [DI/DO

DATA SIZE] = 32

- Setting of slave station #3: DO data size = 32 bytes

- Setting of slave station #4: DO data size = 48 bytes

- Setting of slave station #5: DO data size = 8 bytes

According to the restrictions on global I/O transfer:

- Slave station #4 does not satisfy condition 1.

- Slave station #5 does not satisfy condition 2.

So, slave station #2 takes in only DO data from slave station #1

to the master station and DO data from slave station #3 to the

master station.

DI data allocation at slave station #2

DO data from slave station #1

(16 bytes) 32 bytes

Not used

(16 bytes)

Not used

(Area for the local station number)

DO data from slave station #3 32 bytes

Not used

(For slave station #4)

- 39 -

32 bytes

32 bytes

Page 46

1.16/18/21-B, 16/18-C, LCD-MOUNTED TYPE 16i/18i/21i-A/B OPERATION B-62714EN/04

Communication status for ladder detection of the slave function

Communication status allocation (when DI/DO MAP MODE = 0 [DI/DO data

transfer])

[STATUS ADDRESS] Status of communication with the

master station

Communication status allocation (when DI/DO MAP MODE = 2 [global I/O

transfer])

[STATUS ADDRESS] Status of communication with the

master station

+1 Status of communication with

slave station #1

+2 Status of communication with

slave station #2

+3 Status of communication with

slave station #3

::

(This area corresponds to the

+[STATION NO]

+[MAX SLAVE NO] Status of communication with

local slave station, and is not

used. This area cannot be used

for other purposes.)

::

slave station #[MAX SLAVE NO]

Status of communication with the master station

Status of communication with the master station (1 byte):

The status of communication with the master station is indicated.

bit 7bit 6bit 5bit 4bit 3bit 2bit 1bit 0

Bit 7 : LINK STATUS (status of the link with the master station)

- When LINK STATUS = 0, the link is disconnected.

- When LINK STATUS = 1, communication is performed

normally.

Bit 6 : Short frame error

Bit 5 : Abort detection

Bit 4 : Detection of data consisting of an incorrect number of bits

Bit 3 : Overrun error detection

Bit 2 : FCS error detection

Bits 1, 0 : Reserved (0 at all times)

NOTE

Many errors are caused by hardware failures (on

communication boards or communication cables)

and noise. Recheck the method of communication

cable connection, terminating resistor, and noise

protection.

- 40 -

Page 47

B-62714EN/04 OPERATION 1.16/18/21-B, 16/18-C, LCD-MOUNTED TYPE 16i/18i/21i-A/B

Status of communication with remote slave stations

Status of communication with remote slave stations #1 to #[MAX

SLAVE NO]:

The status of reception of DO data from remote slave stations to

the master station is indicated (1 byte for each).

bit 7bit 6bit 5bit 4bit 3bit 2bit 1bit 0

Bit 7 : LINK STATUS (status of the link with the master station)

- When LINK STATUS = 0, the link is disconnected.

- When LINK STATUS = 1, communication is performed

normally.

Bits 6 to 0 : Reserved (0 at all times)

- 41 -

Page 48

1.16/18/21-B, 16/18-C, LCD-MOUNTED TYPE 16i/18i/21i-A/B OPERATION B-62714EN/04

1.3 DATA CONCURRENCY

When DI data is handled by a ladder program, the I/O Link-II function

guarantees the concurrency of data on a byte-by-byte basis, but does

not guarantee the concurrency of multiple bytes of data.

The I/O Link-II function does not exchanges data in synchronism with

a ladder program, so that the function does not guarantees the

concurrency of DI data consisting of 2 bytes or more. This means that

when a ladder program reads 2-byte DI data, for example, the higher

byte and lower byte of the data may be updated at different timings.

Example where concurrency is not guaranteed

When the 2-byte data 1234 (hex) is entered from the I/O Link-II board

to the area R0300 set to the value 0000 (hex), the ladder program may

read the value 0034 (hex).

DI data R area of the PMC

R0300 00 00

34

R0300 00 34

12 If the ladder program reads R0300

during this period, 0034 (hex) is read.

R0300 12 34

Example of countermeasure: Control using synchronization flags

Concurrency can be guaranteed by providing a synchronization flag

before and after multi-byte data and synchronizing the data with the

flags. An example of guaranteeing the concurrency of 6-byte data is

given below.

(1) Data structure

A synchronization flag is prepared at the byte position preceding

the 6-byte data and at the byte position following the 6-byte data,

thus allocating an 8-byte area in total.

R0099 Synchronization flag 1

R0100

: Data section

R0105

R0106 Synchronization flag 2

(2) Processing on the data write side

The data is updated using the procedure below.

1 Synchronization flag 1 is incremented.

2 The data section is updated.

3 The same value as set in synchronization flag 1 is set in

synchronization flag 2.

- 42 -

Page 49

B-62714EN/04 OPERATION 1.16/18/21-B, 16/18-C, LCD-MOUNTED TYPE 16i/18i/21i-A/B

(3) Processing on the data read side

The data is processed using the procedure below.

1 At the start of the second level, the 8 bytes are copied from

R0099 to the synchronization area R0199.

2 A check is made to see if R0199 = R0206.

3 If R0199 = R0206, R0200 is handled as 6-byte data.

CAUTION

If the size of the data section to be synchronized is

increased by combining multiple bytes of data,

synchronization may become difficult.

In such a case, divide the data section on a

variable-by-variable basis before setting

synchronization flags.

- 43 -

Page 50

2.LCD-MOUNTED TYPE 16i/18i/21i-A, Power Mate i-D/H OPERATION B-62714EN/04

2 LCD-MOUNTED TYPE 16i/18i/21i-A,

Power Mate i-D/H

This chapter describes the setting procedure for operating the master

function and slave function.

NOTE

Notes on PMi-D/H

-With PMi-D/H, only the slave function can be

used.

-With PMi-D/H, the I/O Link-II board (A20B-8100-

0310) and I/O Link-II board B (A20B-8100-0381)

can be used.

This chapter provides descriptions based on the

use of I/O Link-II B. When using the I/O Link-II

board, the same specifications as for Power

Mate-D/F/H described in Chapter 3 are

applicable. So, see Chapter 3.

- 44 -

Page 51

B-62714EN/04 OPERATION 2.LCD-MOUNTED TYPE 16i/18i/21i-A, Power Mate i-D/H

2.1 MASTER FUNCTION

Display of the setting screen

Procedure

(1) Press the function key SYSTEM, then select the soft key [PMC]

to switch to the PMC screen.

(2) Select the soft keys [PMCDGN], [I/OCHK], and [IOLNK2] in

this order. Screen 2-1 appears.

Screen 2-1

(3) Select the soft key [MASTER]. Screen 2-2 appears.

Screen 2-2

- 45 -

Page 52

2.LCD-MOUNTED TYPE 16i/18i/21i-A, Power Mate i-D/H OPERATION B-62714EN/04

(4) Select the soft key [ADDR] on Screen 2-2. Screen 2-3 appears.

When setting 15 stations or more, switch the screen with the

page keys ↑

and ↓ .

Screen 2-3

- 46 -

Page 53

B-62714EN/04 OPERATION 2.LCD-MOUNTED TYPE 16i/18i/21i-A, Power Mate i-D/H

Setting items and display items

Setting items

Table III-2-1

Item Description

Maximum slave station number used for

MAX SLAVE NO.

SCAN TIME

BAUD-RATE

STATUS ADDRESS

OPTION1 Not used

OPTION2

DO ADDR

DO SIZ

DI ADDR

DI SIZ

communication with the master station.

Setting range: 1 to 31

Interval for performing one scan of input/output

service. A maximum speed is set automatically

according to [MAX SLAVE NO], so that this parameter

need not be set.

Communication speed.

Setting range: 0 to 3

0: 1.0 Mbps

1: 500 kbps

2: 250 kbps

3: 125 kbps

Two methods of setting are available:

- Input using numeric keys

- Input by soft key selection

(Displayed when the cursor is placed on this

parameter)

Start address of an area for storing communication

status.

Setting range: R area of the PMC

The storing of communication status can be disabled

by selecting the soft key [DISABLE] displayed when

the cursor is placed on this parameter.

When the storing of communication status is

disabled, "----" is displayed.

Successive error detach detection counter.

Recommended setting: 3 [hexadecimal]

Setting range: 00 to FF (hexadecimal)

When the default value 0 is used, the setting of 3 is

assumed for operation.

DO data area start address.

Setting range: R area of the PMC

DO data area size.

Setting range: 0 to 128

(Unit: Bytes)

When DO is not used, set 0.

DI data area start address.

Setting range: R area of the PMC

DI data area size.

Setting range: 0 to 128

(Unit: Bytes)

When DI is not used, set 0.

- 47 -

Page 54

2.LCD-MOUNTED TYPE 16i/18i/21i-A, Power Mate i-D/H OPERATION B-62714EN/04

Table III-2-1

Item Description

Parameter stypeM for initializing slave stations.

Setting range: 31 to 33 (hexadecimal)

Set one of the following values according to the type

TYPE

MAXT

REFRESH TIME

of communication:

- When enabling both DO and DI: 33 (hexadecimal)

- When enabling both DI only: 31 (hexadecimal)

- When enabling both DO only: 32 (hexadecimal)

Parameter max_int (slave station communication

monitoring time) for initializing slave stations.

Setting range: 0 to 65535

(Unit: 10 msec)

When no slave station needs to monitor the

communication of the master station, set 0 (for waiting

infinitely).

Interval at which DI data from all slave stations set in

MAX SLAVE NO. is reflected in the R area of the

PMC.

Unit: 1 msec

Operations of the setting screen

Setting parameters

(1) Place the CNC in the MDI mode.

(2) Press the function key SYSTEM

(3) Select the soft keys [PMCDGN], [I/OCHK], [IOLNK2], and

(4) With the cursor keys, move the cursor to an item for which data

(5) Enter data with the MDI keys.