Page 1

OPERATOR’S MANUAL

B-75074EN/01

Page 2

Ȧ No part of this manual may be reproduced in any form.

Ȧ All specifications and designs are subject to change without notice.

The export of this product is subject to the authorization of the

government of the country from where the product is exported.

In this manual we have tried as much as possible to describe all the

various matters.

However , we cannot describe all the matters which must not be done,

or which cannot be done, because there are so many possibilities.

Therefore, matters which are not especially described as possible in

this manual should be regarded as ”impossible”.

Page 3

B-75074EN/01 SAFETY PRECAUTIONS

SAFETY PRECAUTIONS

SAFETY PRECAUTIONS describes notes, cautions and warnings to

be observed for safe handling of those machines that have the

FANUC i CELL and FANUC CNC installed. Before using the

functions described in this manual, be sure to read SAFETY

PRECAUTIONS.

When using a function described in this manual, read the relevant

portion of the operator's manual of each CNC to fully understand the

function.

s-1

Page 4

SAFETY PRECAUTIONS B-75074EN/01

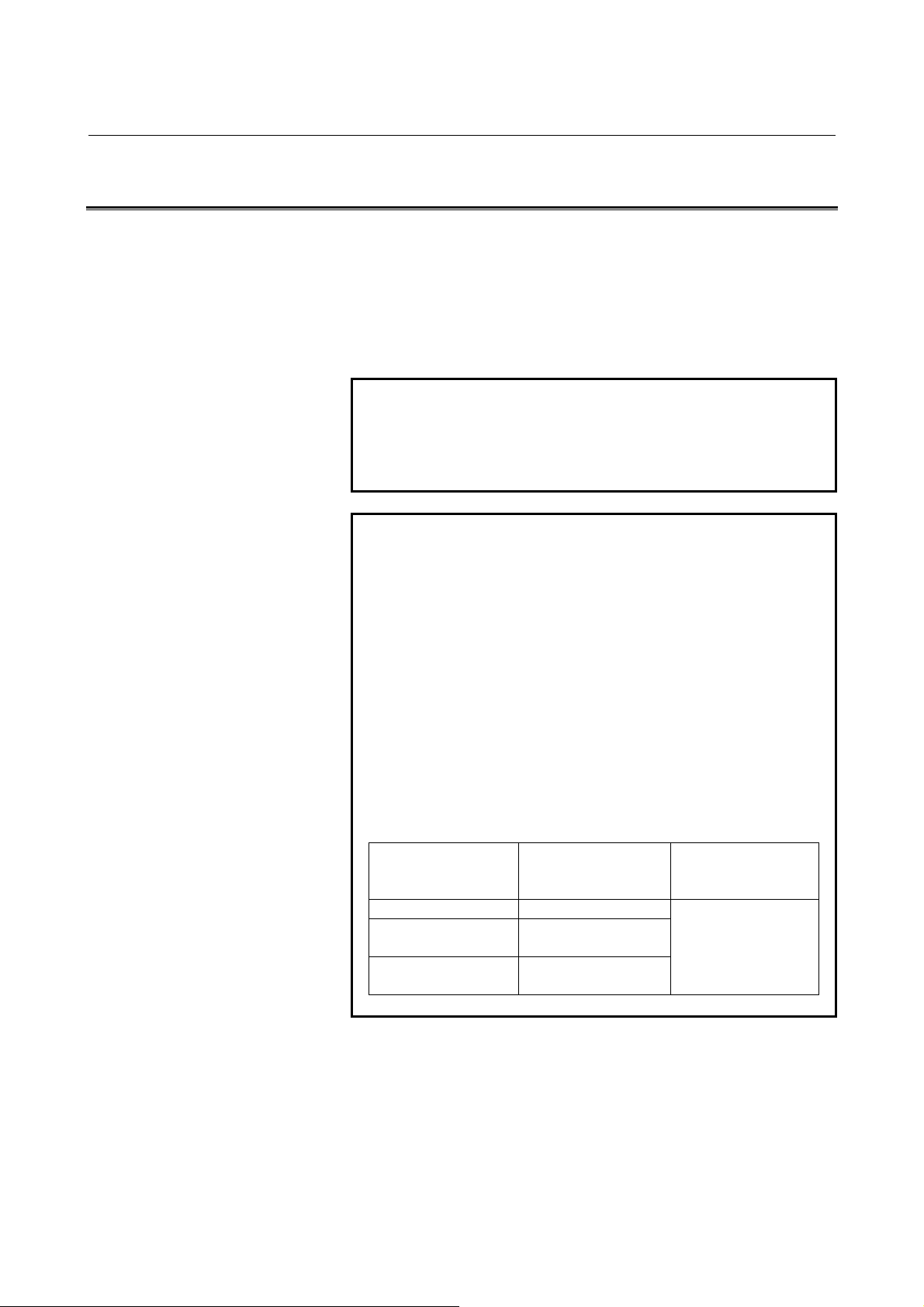

1.1 DEFINITION OF WARNING, CAUTION, AND NOTE

This manual includes safety precautions for protecting the user and

preventing damage to the machine. Precautions are classified into

Warning and Caution according to their bearing on safety. Also,

supplementary information is described as a Note. Read the Warning,

Caution, and Note thoroughly before attempting to use the machine.

WARNING

Applied when there is a danger of the user being

injured or when there is a damage of both the user

being injured and the equipment being damaged if

the approved procedure is not observed.

CAUTION

Applied when there is a danger of the equipment

being damaged, if the approved procedure is not

observed.

NOTE

The Note is used to indicate supplementary

information other than Warning and Caution.

- Read this manual carefully, and store it in a safe place.

s-2

Page 5

B-75074EN/01 SAFETY PRECAUTIONS

1.2 GENERAL WARNINGS AND CAUTIONS

WARNING

1 Before operating the machine, thoroughly check the

entered data. Operating the machine with incorrectly

specified data may result in the machine behaving

unexpectedly, possibly causing damage to the

workpiece and/or machine itself, or injury to the user.

2 Never attempt to machine a workpiece without first

checking the programmed value, compensation value,

current position, and external signal settings. Also,

never attempt to machine a workpiece without first

checking the operation of the machine. Before starting

a production run, ensure that the machine is operating

correctly by performing a trial run using, for example,

the single block, feedrate override, or machine lock

function, or by operating the machine with neither a tool

nor workpiece mounted. Failure to confirm the correct

operation of the machine may result in the machine

behaving unexpectedly, possibly causing damage to

the workpiece and/or machine itself, or injury to the

user.

3 Ensure that the specified feedrate is appropriate for the

intended operation. Generally, for each machine, there

is a maximum allowable feedrate. The appropriate

feedrate varies with the intended operation. Refer to the

manual provided with the machine to determine the

maximum allowable feedrate. If a machine is run at

other than the correct speed, it may behave

unexpectedly, possibly causing damage to the

workpiece and/or machine itself, or injury to the user.

4 When using a tool compensation function, thoroughly

check the direction and amount of compensation.

Operating the machine with incorrectly specified data

may result in the machine behaving unexpectedly,

possibly causing damage to the workpiece and/or

machine itself, or injury to the user.

5 The parameters for the CNC and PMC are factory-set.

Usually, there is no need to change them. When,

however, there is no alternative other than to change a

parameter, ensure that you fully Failure to set a

parameter correctly may result in the machine behaving

unexpectedly, possibly causing damage to the

workpiece and/or machine itself, or injury to the user.

s-3

Page 6

SAFETY PRECAUTIONS B-75074EN/01

CAUTION

1 Immediately after switching on the power, do not touch

any of the keys on the MDI panel until the position

display or alarm screen appears on the CNC unit.

Some of the keys on the MDI panel are dedicated to

maintenance or other special operations. Pressing any

of these keys may place the CNC unit in other than its

normal state. Starting the machine in this state may

cause it to behave unexpectedly.

2 The operator's manual for Ethernet board describes all

the basic functions of the CNC, including the optional

functions. The selected optional functions vary with the

machine. Some functions described in this manual may

not, therefore, be supported by your machine. Check the

machine specifications before using Ethernet board.

3 Some machine operations and screen functions are

implemented by the machine tool builder. For an

explanation of their usage and related notes, refer to the

manual provided by the machine tool builder.

For example:

- On some machines, executing a tool function causes

the tool change unit to operate. When executing a

tool function on such a machine, stand well clear of

the tool change unit. Otherwise, there is a danger of

injury to the operator.

- Many auxiliary functions trigger physical operations,

such as rotation of the spindle. Before attempting to

use an auxiliary function, therefore, ensure that you

are fully aware of the operation to be triggered by that

function.

NOTE

Command programs, parameters, and variables are

stored in nonvolatile memory in the CNC. Generally, the

contents of memory are not lost by a power on/off

operation. However, the contents of memory may be

erased by mistake, or important data in nonvolatile

memory may have to be erased upon recovering from a

failure.

To enable the restoration of data as soon as possible if

such a situation arises, always make a backup of the

data in advance.

s-4

Page 7

B-75074EN/01 SAFETY PRECAUTIONS

1.3 WARNING AND CAUTIONS ON THE FANUC i CELL

Warnings and cautions on the FANUC i CELL are provided

below and in the text of this manual. Read this manual carefully

before using the FANUC i CELL, and observe the warnings,

cautions, and notes.

WARNING

1 When using an NC program on an actual NC

machine, confirm that the operation of the machine

and tool controlled by the NC program is safe,

before operating the machine.

If an incorrect NC program is used or an NC

program is used in a wrong way, the machine and

tool can perform an unexpected operation, thus

damaging the tool, machine, and workpiece, and

exposing humans to a fatal accident.

2 This software does not check whether an NC

program transferred by this software operates

normally on the NC machine. When using an NC

program on an actual NC machine, observe Item 1

above.

3 Even when an NC program once used successfully

is reused, the contents of the NC program input to

the NC machine can change for a cause such as

deteriorated NC program storage media and a

change in the communication environment for

transfer based on the communication function.

When using an NC program on an actual NC

machine, observe Item 1 above.

In this manual, a program used to specify an NC

machine operation is referred to as an NC program.

In the manual of an NC machine, an alias such as a

machining program, part program, or program may

be used for an NC program. If the meaning and

purpose of such an alias are the same as for an NC

program used in this manual, be sure to observe the

warnings above.

s-5

Page 8

SAFETY PRECAUTIONS B-75074EN/01

Warning and caution on DNC operation

WARNING

1 When performing DNC operation, check the NC

program. If an incorrect NC program is used, the

machine and tool can perform an unexpected

operation, thus damaging the workpiece and

machine, and causing human injury.

2 When performing DNC operation, do not start

machine immediately. By using functions such as

the single block, feedrate override, and machine

lock functions, check that the machine and tool

controlled by DNC operation operate safely.

If operation is performed using incorrect data, the

machine can perform an unexpected operation,

thus damaging the workpiece and machine, and

causing human injury.

CAUTION

DNC operation may temporarily stop, depending on

the capability of the personal computer, the number

of NCs connected, and the size of the

communication buffer on the NC side. Moreover,

DNC operation may temporarily stop when software

irrelevant to NC program transfer such as software

for personal computer screen operation is

executed. In these cases, reduce the number of

machines on which DNC operation is performed

simultaneously.

Exclusive file control

NOTE

Be careful not to perform multiple operations such

as download, upload, edit, copy, move, and delete

operations simultaneously for the same NC

program.

s-6

Page 9

B-75074EN/01 PREFACE

PREFACE

This manual describes the FANUC i CELL that operates on a

personal computer (called PC for short). The FANUC i CELL is an

application that runs on the CIMPLICITY HMI. Using the Ethernet

communication function available with an NC produced by FANUC,

the FANUC i CELL transfers data such as NC programs between the

NC and personal computer.

Organization of this manual

This manual consists of the following parts:

PREFACE

This part itself

I. GENERAL

This part outlines each function.

II. INSTALLATION

This part describes the method of installation. Be sure to read

this part before starting installation.

III. SETTING

This part describes the setting items required to used each

function.

IV. OPERATION

This part describes the method of screen operation.

APPENDIX

The setting items required for an NC, error codes, and so forth

are described.

Related manuals

CIMPLICITY is a registered trademark of GE Fanuc Automation

North America, Inc..

Microsoft, Windows NT, and Windows 2000 are registered

trademarks of Microsoft Corporation in the U.S.A..

This manual provides related information about NCs produced by

FANUC, the Ethernet communication function, and CIMPLICITY for

using the FANUC i CELL.

However, this manual does not cover all required information. Refer

to the following manuals in addition to this manual:

• FANUC Ethernet Board/DATA SERVER Board Operator's

Manual (B-63354EN)

• Connection manual, maintenance manual, and operator's manual of

an NC to be connected using the FANUC i CELL

• CIMPLICITY HMI Basic System Operator's Manual (B-75064EN)

• CIMPLICITY HMI Option 1 (WebView/Action Calendar/

Statistic Process Management) Operator's Manual (B-75064EN-5)

(This manual describes the method of WebView setting.)

p-1

Page 10

PREFACE B-75074EN/01

Licensing agreement

The terms and conditions set forth by FANUC must be agreed upon

by a customer who purchases the FANUC i CELL.

These terms and conditions represent the licensing agreement

between the customer and FANUC LTD. (referred to as FANUC)

related to the software product (referred to as this software) purchased

by the customer.

Article 1 Licensing of right for use

FANUC grants the customer the following right related to this

software:

<1> This software may be used on one computer.

<2> When this software is used on multiple computers, the

customer shall obtain licenses for this software as many as

the number of computers even if this software is not used at

the same time on those computers.

<3> When this software is read through the network to the

temporary memory of each computer, the customer shall

obtain licenses for this software as many as the number of

computers used.

<4> Only one copy of this software may be produced for

backup.

Article 2 Copyright

FANUC possesses the copyright of this software. Accordingly,

the customer shall not copy this software for any purpose except

for the purpose stipulated in Article 1 "Licensing of right for

use".

Article 3 Restrictions

The customer shall not transfer, lend, sell, distribute, lease, or

rent this software to a third party.

Article 4 Warranty

If the distributed media and manual of this software contains a

physical defect, and the customer so notifies FANUC within

ninety days after the reception of this software, FANUC replaces

this software with a new one at no cost.

Article 5 Exemption

FANUC does not provide any warranty and guarantee related to

this software except the warranty stipulated in Article 4,

"Warranty".

Namely, FANUC is not liable for any direct or indirect damages

arising from the use of this software.

p-2

Page 11

B-75074EN/01 PREFACE

Abbreviations

In this manual, the following abbreviations may be used:

Formal name Abbreviation

FANUC i CELL i CELL

Personal computer PC

Operating system OS

Directory where the i Cell is

installed

%iCELL%

(Used when the path of a particular file name

in the i CELL is described)

p-3

Page 12

Page 13

B-75074EN/01 TABLE OF CONTENTS

TABLE OF CONTENTS

SAFETY PRECAUTIONS.......................................................................... s-1

PREFACE.................................................................................................. p-1

I. GENERAL

1 OVERVIEW ............................................................................................3

2 ABOUT THE FANUC i CELL .................................................................4

2.1 OVERVIEW ...................................................................................................5

3 OPERATING ENVIRONMENT ...............................................................7

3.1 CNC ...............................................................................................................8

3.2 PERSONAL COMPUTER/HARDWARE ......................................................12

3.3 PERSONAL COMPUTER/SOFTWARE ......................................................13

3.4 CONTRACT WITH INTERNET SERVICE PROVIDERS .............................15

4 NC PROGRAM MANAGEMENT ..........................................................16

4.1 NC PROGRAM TRANSFER BY OPERATING

THE NC PROGRAM MANAGEMENT SCREEN .........................................17

4.2 NC PROGRAM FORMAT ............................................................................19

4.3 SUBPROGRAM TRANSFER FUNCTION ...................................................20

4.3.1 Details of the Subprogram Batch Transfer Function............................................. 22

4.3.2 Details of the Subprogram Expanded Transfer Function...................................... 23

4.4 LIST FILE TRANSFER FUNCTION.............................................................24

4.4.1 Details of List File Batch Transfer Function......................................................... 26

4.4.2 Details of List File Expended Transfer Function .................................................. 26

4.4.3 List File Transfer Monitor and Control Function.................................................. 27

5 OPERATION MONITOR.......................................................................29

5.1 OPERATION RESULT SCREEN.................................................................30

5.1.1 Creating Operation Results.................................................................................... 30

5.1.2 Display Information............................................................................................... 31

5.2 WORKPIECE MACHINING RESULTS ........................................................33

5.2.1 Workpiece Machining Result Data ....................................................................... 33

5.2.2 Display Information............................................................................................... 34

5.2.3 Display Format Alteration..................................................................................... 38

5.2.4 Planned Parts Count Input ..................................................................................... 39

5.3 TOOL LIFE MANAGEMENT........................................................................40

c - 1

Page 14

TABLE OF CONTENTS B-75074EN/01

5.3.1 Display Information............................................................................................... 40

6 NC DISPLAY AND OPERATION .........................................................42

7 NC MAINTENANCE .............................................................................43

8 MAIL FUNCTION .................................................................................45

8.1 IMPLEMENTATION OF THE MAIL FUNCTION BY

DIAL-UP CONNECTION..............................................................................46

9 WEB FUNCTION..................................................................................48

9.1 IMPLEMENTING THE MAIL FUNCTION AND WEB FUNCTION

WITH 24-HOUR CONNECTION..................................................................49

II. INSTALLATION

1 OVERVIEW ..........................................................................................53

2 PREPARATION....................................................................................54

2.1 SETTING UP THE TCP/IP (BASIC FUNCTION) .........................................55

2.2 SETTING UP A DEFAULT GATEWAY (MAIL AND WEB FUNCTIONS) ....56

2.3 SETTING UP THE DNS (MAIL FUNCTION) ...............................................57

2.4 SETTING UP CIMPLICITY (BASIC FUNCTION).........................................58

2.5 SETTING UP ODBC (BASIC FUNCTION) ..................................................59

2.6 REGISTERING THE NEW USER "IUSR_ICELL" (WEB FUNCTION) ........60

2.7 INSTALLING IIS4.0 (WEB FUNCTION) ......................................................61

2.8 INSTALLING IE5.5 (BASIC FUNCTION) .....................................................62

3 INSTALLATION....................................................................................63

3.1 INSTALLATION ...........................................................................................64

3.2 INFORMATION TO BE AUTOMATICALLY SAVED TO THE TCP/IP

SERVICE FILE.............................................................................................69

4 UNINSTALLATION ..............................................................................71

4.1 UNINSTALLATION ......................................................................................72

5 BACKUP AND RESTORATION ...........................................................73

5.1 BACKUP ......................................................................................................74

5.1.1 Opening the IcellBkupRstr Dialog Box................................................................. 74

5.1.2 Selecting Information to Be Backed Up................................................................ 75

5.1.3 Confirming Backup Archive File Paths................................................................. 76

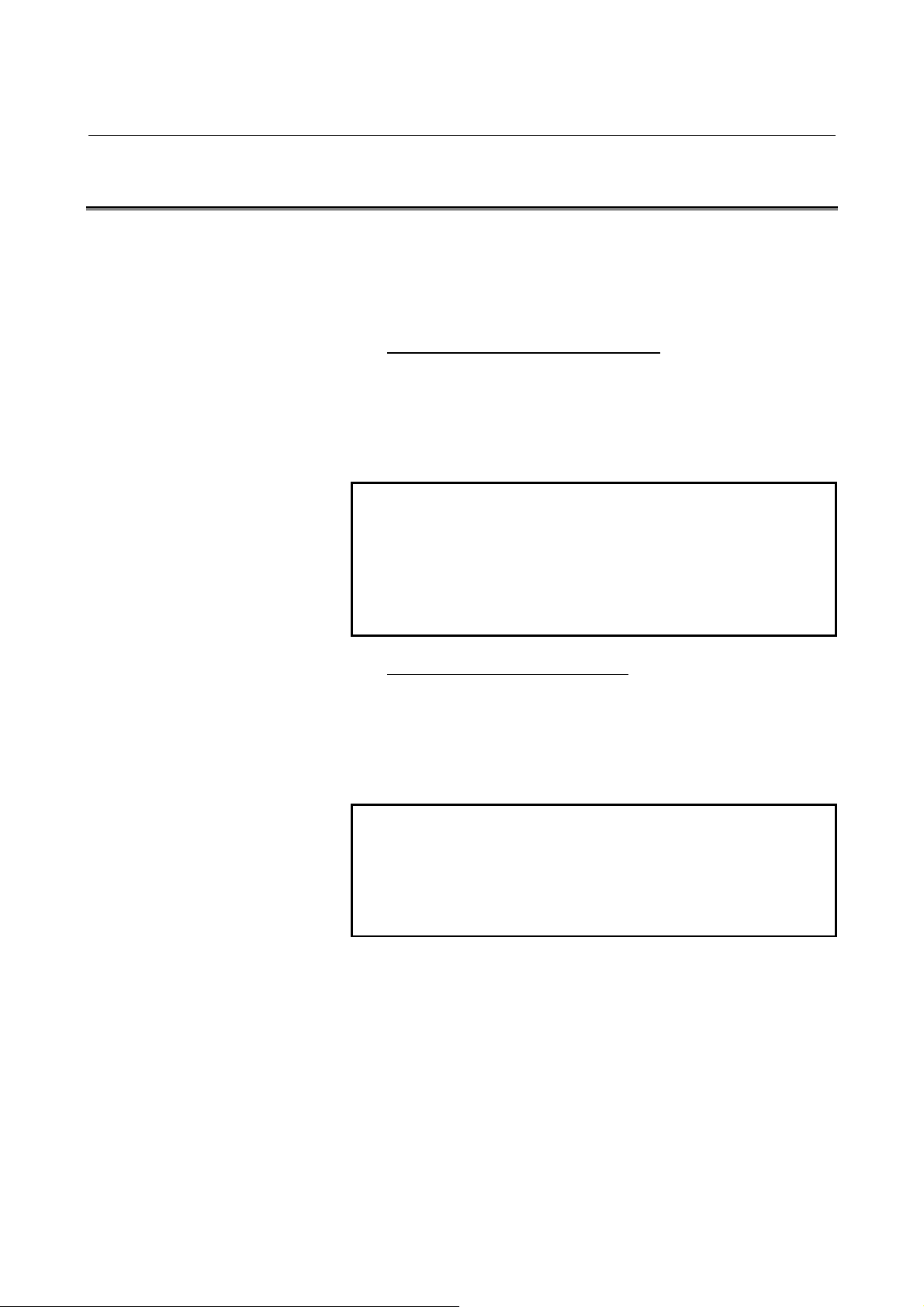

5.1.4 Starting Backup ..................................................................................................... 77

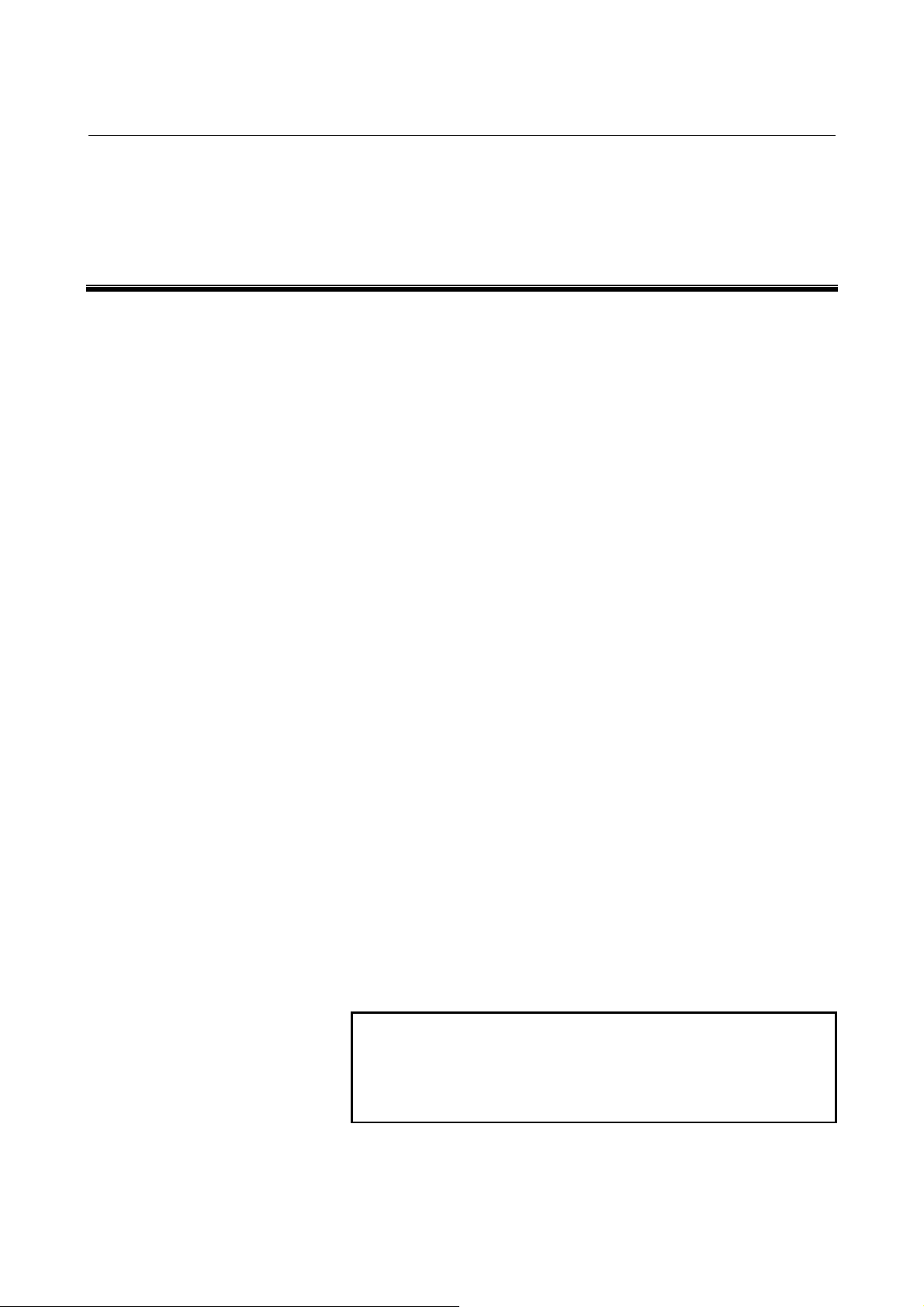

5.1.5 Confirming the Contents of the Backup Archive File........................................... 77

5.1.6 Saving the Backup Archive File............................................................................ 78

c - 2

Page 15

B-75074EN/01 TABLE OF CONTENTS

5.2 RESTORATION...........................................................................................79

5.2.1 Installing i CELL................................................................................................... 79

5.2.2 Copying the Backup Archive File ......................................................................... 79

5.2.3 Selecting Information to Be Restored ................................................................... 79

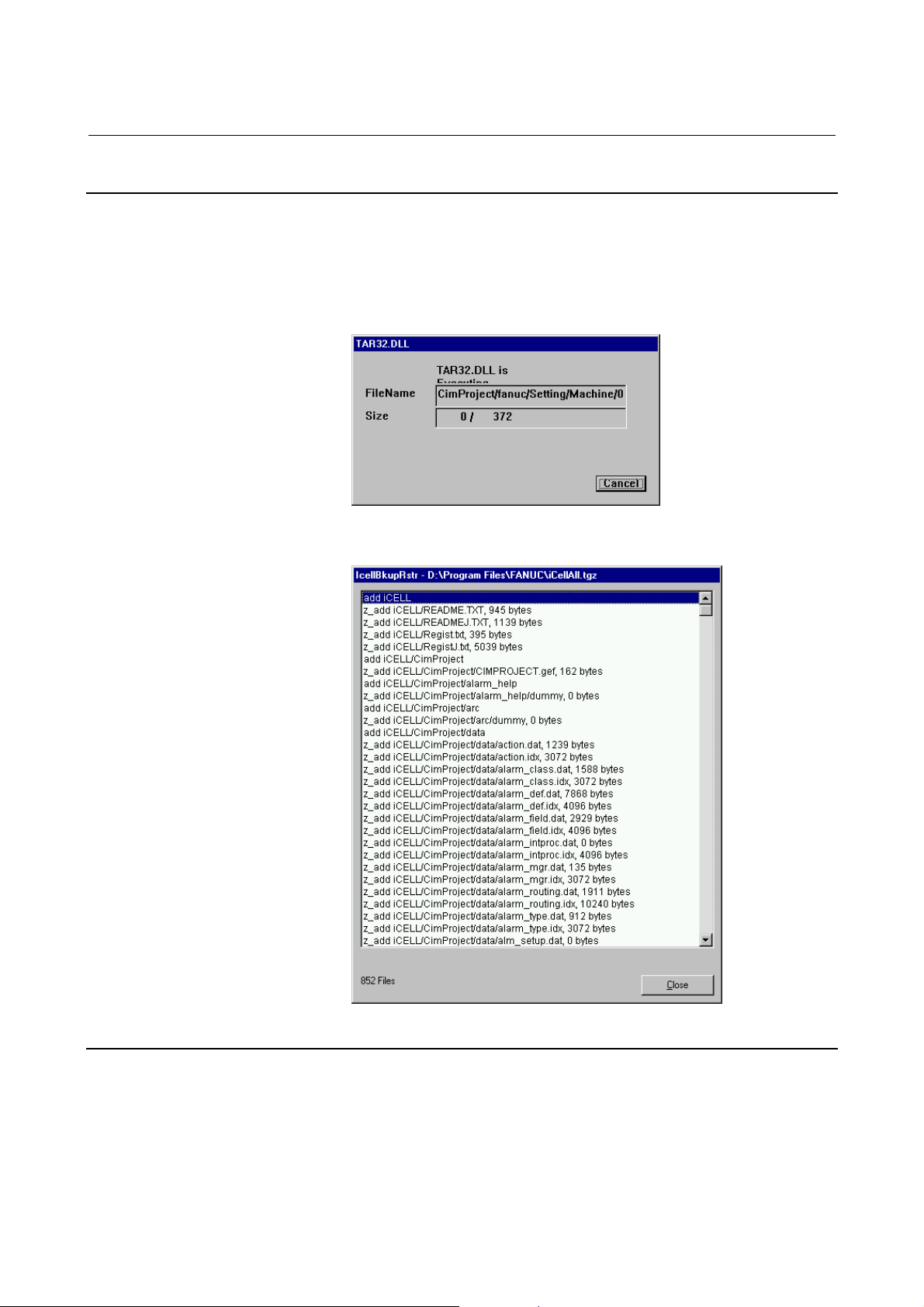

5.2.4 Starting Restoration............................................................................................... 80

5.2.5 Restoring NC Program Management Settings....................................................... 80

III. SETTING

1 OVERVIEW ..........................................................................................83

2 BASIC FUNCTIONS.............................................................................84

2.1 OVERVIEW .................................................................................................85

2.1.1 Setting up the Number of Machines According to Order Password ..................... 85

2.1.2 Setting up the Number of Machines to Be Connected and the Functions to

Be Used.................................................................................................................. 86

2.1.3 Setting up Machine Information............................................................................ 86

2.1.4 Setting up Communication.................................................................................... 86

2.1.5 Setting up NC Program Management.................................................................... 87

2.1.6 Setting up i CELL.................................................................................................. 87

2.2 DIALOG BOX CONFIGURATION................................................................88

2.2.1 Opening the Configuration Dialog Box................................................................. 88

2.2.2 Overview................................................................................................................ 88

2.2.3 Menus .................................................................................................................... 89

2.2.4 How to Change Settings ........................................................................................ 90

2.2.5 Work Flows for Adding and Deleting Machines................................................... 91

2.2.6 Setting Change and CIMPLICITY Project............................................................ 92

2.2.7 Stopping and Updating the i CELL Project........................................................... 93

2.2.8 If an Attempt to Reflect Point Settings to CIMPLICITY Fails............................. 94

2.3 MACHINE COUNT CONFIGURATION........................................................95

2.4 PROJECT PROPERTY ...............................................................................96

2.5 MACHINE INFORMATION ..........................................................................97

2.6 COMMUNICATION......................................................................................99

2.6.1 Setting up Communication.................................................................................... 99

2.6.2 Confirming Communication Setup...................................................................... 102

2.7 NC PROGRAM MANAGEMENT................................................................106

2.7.1 General Tab ......................................................................................................... 107

2.7.2 Download Tab ..................................................................................................... 108

2.7.3 Upload Tab .......................................................................................................... 111

c - 3

Page 16

TABLE OF CONTENTS B-75074EN/01

2.8 i CELL MACHINE ......................................................................................112

2.8.1 Workpiece Process Result ................................................................................... 113

2.9 WORKPIECES PROCESS RESULT SYSTEM CONFIGURATION ..........117

2.10 DATABASE MAINTENANCE.....................................................................119

2.11 NC SETTINGS...........................................................................................122

2.11.1 Machining Result................................................................................................. 122

2.11.2 Workpieces Process Result.................................................................................. 122

2.11.3 Tool Life.............................................................................................................. 125

3 MAIL...................................................................................................126

3.1 OVERVIEW ...............................................................................................127

3.1.1 Trigger Point and Trigger Criteria....................................................................... 127

3.1.2 Mail Destinations................................................................................................. 127

3.1.3 Mail Message and Message Point ....................................................................... 127

3.1.4 Flow of Setting .................................................................................................... 129

3.2 MAILER .....................................................................................................130

3.3 MAIL CONFIGURATION ...........................................................................131

3.4 SEND TEST...............................................................................................135

4 WEB ...................................................................................................136

4.1 OVERVIEW ...............................................................................................137

4.1.1 Web Screen Flow................................................................................................. 137

4.1.2 Logon Screen....................................................................................................... 138

4.1.3 Machine Selection Screen ................................................................................... 138

4.1.4 Machine Detail Screen ........................................................................................ 139

4.1.5 Setting Flow......................................................................................................... 140

4.2 WEB INITIAL CONFIGURATION ..............................................................141

4.3 POINT FOR WEB ......................................................................................142

4.4 ITEM NAME...............................................................................................144

4.5 DISPLAY TABLE .......................................................................................145

IV. OPERATION

1 OVERVIEW ........................................................................................149

2 SCREEN OPERATION.......................................................................150

2.1 ACTIVATING THE i CELL PROJECT .......................................................151

2.2 TERMINATING THE i CELL PROJECT ....................................................153

2.3 SWITCHING AMONG THE SCREENS .....................................................154

2.4 ITEMS COMMON TO THE SCREENS......................................................157

c - 4

Page 17

B-75074EN/01 TABLE OF CONTENTS

2.4.1 Names of Screen Components............................................................................. 157

3 MAIN MENU.......................................................................................159

3.1 OUTLINE ...................................................................................................160

3.2 ACTIVATING THE MAIN MENU................................................................161

3.3 TERMINATING THE MAIN MENU.............................................................162

3.4 OPERATION..............................................................................................163

4 OVERVIEW MENU.............................................................................164

4.1 OUTLINE ...................................................................................................165

4.2 SCREEN OPERATION (1) OVERVIEW SCREEN ....................................166

4.3 SCREEN OPERATION (2) SCREEN LIST

FOR EACH OVERVIEW MACHINE ..........................................................168

4.4 CHANGING THE NUMBER OF CONNECTED MACHINES .....................169

5 NC PROGRAM MANAGEMENT ........................................................171

5.1 OUTLINE ...................................................................................................172

5.2 SCREEN OPERATION..............................................................................173

5.2.1 About The NC PROGRAM MANAGEMENT Window .................................... 173

5.2.2 Work with the File List in the PC........................................................................ 175

5.2.3 Operating the File Directory List on the Personal Computer.............................. 178

5.2.4 Copying, Moving, Deleting and Renaming Files in the PC ................................ 180

5.2.5 Browsing, Editing and Creating New Files in the PC......................................... 182

5.2.6 Transmitting an NC Program............................................................................... 185

5.2.7 Referencing, Editing, and Deleting NC Files...................................................... 189

5.2.8 Setting Options .................................................................................................... 192

5.3 EDIT LIST FILE SCREEN OPERATIONS .................................................195

5.3.1 Structure of Edit List File Screen........................................................................ 195

5.3.2 Editing List Files ................................................................................................. 198

5.4 LIST FILE MONITOR SCREEN OPERATIONS ........................................203

5.4.1 Structure of List File Monitor Screen.................................................................. 203

5.4.2 List File Monitor Operations............................................................................... 205

6 MACHINING RESULTS .....................................................................208

6.1 OUTLINE ...................................................................................................209

6.2 SCREEN OPERATION..............................................................................210

7 WORKPIECE PROCESS RESULTS..................................................214

7.1 OUTLINE ...................................................................................................215

7.2 SCREEN OPERATION..............................................................................216

c - 5

Page 18

TABLE OF CONTENTS B-75074EN/01

8 NC DISPLAY AND OPERATION .......................................................226

8.1 OUTLINE ...................................................................................................227

8.2 SCREEN OPERATION..............................................................................228

8.3 ACTUAL POSITION DISPLAY ..................................................................232

8.4 PROGRAM CHECK...................................................................................234

8.5 PARAMETER SETTING ............................................................................235

8.6 DIAGNOSIS...............................................................................................237

9 NC MAINTENANCE ...........................................................................238

9.1 OUTLINE ...................................................................................................239

9.2 SCREEN OPERATION..............................................................................240

9.3 ALARM HISTORY DISPLAY .....................................................................242

9.3.1 History Data Display ........................................................................................... 243

9.3.2 Outputting History Data ...................................................................................... 243

9.3.3 Clearing History Data.......................................................................................... 243

9.4 OPERATION HISTORY DISPLAY.............................................................244

9.4.1 Operation History Display................................................................................... 245

9.4.2 Outputting History Data ...................................................................................... 246

9.4.3 Clearing History Data.......................................................................................... 246

9.4.4 History Signal Setting.......................................................................................... 247

9.5 VARIOUS DATA BACKUP/RESTORATION..............................................248

9.5.1 Data Backup ........................................................................................................ 249

9.5.2 Data Restoration .................................................................................................. 250

9.5.3 File List Refreshing ............................................................................................. 250

9.5.4 File Deletion ........................................................................................................ 251

9.6 FROM/SRAM DATA BACKUP/RESTORATION........................................252

9.6.1 FROM Data Backup ............................................................................................ 253

9.6.2 FROM Data Restoration...................................................................................... 254

9.6.3 SRAM Data Backup ............................................................................................ 255

9.6.4 File List Refreshing ............................................................................................. 255

9.6.5 FROM Data Deletion........................................................................................... 256

10 TOOL LIFE MANAGEMENT ..............................................................257

10.1 OUTLINE ...................................................................................................258

10.2 SCREEN OPERATION..............................................................................259

11 ALARM AND WARNING....................................................................262

11.1 OUTLINE ...................................................................................................263

11.2 SCREEN OPERATION (1) ALARM MESSAGE SCREEN.........................264

c - 6

Page 19

B-75074EN/01 TABLE OF CONTENTS

11.3 SCREEN OPERATION (2) ALARM LOG DISPLAY SCREEN...................266

APPENDIX

A HOW TO INSTALL AND REGISTER CIMPLICITY ............................269

A.1 HOT TO INSTALL CIMPLICITY.................................................................270

A.1.1 Installing CIMPLICITY ...................................................................................... 270

A.1.2 How to Start Installation...................................................................................... 271

A.1.3 Newly Installing CIMPLICITY HMI.................................................................. 272

A.1.4 Installing New Options with CIMPLICITY HMI ............................................... 277

A.2 REGISTERING USE OF CIMPLICITY.......................................................278

A.2.1 Registering Use of CIMPLICITY HMI Software ............................................... 278

A.2.2 Newly Registering for CIMPLICITY HMI ......................................................... 279

A.2.3 Registering for CIMPLICITY HMI Options and Upgrading .............................. 281

A.2.4 Using CIMPLICITY HMI without License......................................................... 283

B FOCAS1/ETHERNET FUNCTIONS ...................................................284

B.1 SETTING THE FOCAS1/Ethernet OF THE OPTION BOARD

FOR Series 16i/18i/21i-A/B AND Power Mate i.........................................285

B.1.1 Precautions to Be Observed when using the FOCAS1/Ethernet Functions

for the First Time................................................................................................. 285

B.1.2 FOCAS1/Ethernet Parameter Screen................................................................... 286

B.1.3 Configuring a Small-scale Network .................................................................... 289

B.1.4 Configuring a Large-scale Network .................................................................... 289

B.2 SETTING THE FOCAS1/ETHERNET WITH THE EMBEDDED

Ethernet FUNCTION FOR 16i/18i/21i-B....................................................290

B.2.1 Precautions to Be Observed when using the FOCAS1/Ethernet Functions

for the First Time................................................................................................. 290

B.2.2 FOCAS1/Ethernet Parameter Screen................................................................... 291

B.2.3 Configuring a Small-scale Network .................................................................... 294

B.2.4 Configuring a Large-scale Network .................................................................... 294

C ERROR CODES.................................................................................295

C.1 NC PROGRAM MANAGEMENT ERROR CODES ....................................296

D DETAILS OF CIMPLICITY POINTS ...................................................301

D.1 OVERVIEW ...............................................................................................302

D.1.1 CIMPLICITY Points and i CELL........................................................................ 302

D.1.2 Point Naming Rules............................................................................................. 303

D.2 LIST OF POINTS.......................................................................................304

c - 7

Page 20

TABLE OF CONTENTS B-75074EN/01

D.2.1 Machine-Specific Points...................................................................................... 304

D.2.2 i CELL -Common Points ..................................................................................... 307

E SETTING UP IIS.................................................................................308

E.1 ADDING THE ACCESS PERMISSION FOR DIRECTORIES....................309

E.2 CONSTRUCTING WEB SITES .................................................................310

F EXAMPLE CONTRACT FOR DIALUP CONNECTION.......................316

c - 8

Page 21

I. GENERAL

Page 22

Page 23

B-75074EN/01 GENERAL 1.OVERVIEW

1 OVERVIEW

Organization of this part

This part (GENERAL) outlines the FANUC i CELL.

- 3 -

Page 24

2.ABOUT THE FANUC i CELL GENERAL B-75074EN/01

2 ABOUT THE FANUC i CELL

- 4 -

Page 25

B-75074EN/01 GENERAL 2.ABOUT THE FANUC i CELL

2.1 OVERVIEW

The FANUC i CELL is a software package for centrally manage

multiple CNC machine tools connected to a network. The FANUC i

CELL supports normal operations such as part machining and

machining result collection to improve productivity, and also supports

prompt recovery in case of a failure. With the enhanced network

function, the system can be remotely monitored from a personal

computer or i-mode cellular phone.

The FANUC i CELL has an operation support function and a remote

support and service function for supporting failure recovery. The

major operation support capabilities are:

• NC program management:

Input/output of machining programs between the personal

computer and each NC

• CNC display and operation:

CNC state display and operation handling from the personal

computer

• Operation monitoring:

Monitoring of machine operation and collection of machining

results

• Maintenance:

Saving and restoring of a variety of NC data items

Another feature is the remote support and service function. When a

CNC alarm is issued, this function enables the user to contact the

FANUC service center through the Internet or telephone line to

identify the possible cause. The possible cause of trouble can be

identified by responding to a simple menu-based query related to the

trouble. This function interacts with the CS24i service of FANUC.

(For details of the remote support and service function, refer to the

relevant manual.)

FANUC i CELL

NC Program

Management

Windows NT 4.0

FOCAS1 / Ethernet

CIMPLICITY HMI

CNC

Display &

Operation

Operation

Monitoring

CNC machine tool

Maintenance

- 5 -

Software

prepared

by MTB

iMode Server

Remote

Network

Support &

Service

Remote Site

Monitoring

by Web View

FANUC

Service

CS24i

Monitoring

by iMode

Page 26

2.ABOUT THE FANUC i CELL GENERAL B-75074EN/01

The FANUC i CELL is developed using CIMPLICITY( HMI, which

has found applications in SCADA (monitoring control and data

collection) software. The user can utilize a wide variety of functions

available with this tool. Moreover, the tool can be modified to meet

the operation of the user, and user-specific screens and functions can

be added.

In addition, by using the enhanced network function of CIMPLICITY

HMI, a distributed system where multiple personal computers are

installed at necessary locations can be built easily. Multiple

CIMPLICITY viewer personal computers can reference a personal

computer (server) that is performing central management with the

FANUC i CELL. With the Web view function, operating status

monitored with the FANUC i CELL can be monitored from a remote

personal computer via the Internet by using a browser such as Internet

Explorer. (The Web view is an option of CIMPLICITY.)

An i-mode cellular phone can externally monitor some of operating

statuses being monitored with the FANUC i CELL. A specified event

such as the completion of machining and the occurrence of an error

can be posted by mail to another personal computer or cellular phone.

For the former monitoring, connection with the Internet must be

maintained at all times.

By introducing the FANUC i CELL, the utilization of production

equipment can be improved, and quick recovery can be performed if a

failure occurs. As the network, FOCAS1/Ethernet supporting the

Ethernet, which is practically standard in the FA field, is used. Today,

network utilization is an area to be challenged in the machine tool

industry. FANUC hopes that the FANUC i CELL will be fully

utilized as a package for building a system and providing a base for

operation.

- 6 -

Page 27

B-75074EN/01 GENERAL 3.OPERATING ENVIRONMENT

3 OPERATING ENVIRONMENT

This chapter describes the operating environment for using the

FANUC i CELL.

- 7 -

Page 28

3.OPERATING ENVIRONMENT GENERAL B-75074EN/01

3.1 CNC

Usable CNCs

An Ethernet is required for the following CNCs:

Series 16i-MODEL A/B, Series 160i-MODEL A/B

Series 18i-MODEL A/B, Series 180i-MODEL A/B

Series 21i-MODEL A/B, Series 210 i-MODEL A/B

Power Mate i-MODEL D/H

NOTE

1 The FANUC i CELL can be used with up to two-

path control CNC with one CPU.

2 The FANUC i CELL cannot be used with three-path

control CNC with two CPUs.

NOTE

The i CELL uses the FOCAS1/Ethernet function for

communication with NCs.

When the i CELL is operated, three

FOCAS1/Ethernet clients are used.

With the embedded Ethernet function, no more

than five FOCAS1/Ethernet clients can be used.

Accordingly, when the embedded Ethernet function

is used, one NC can communicate with only one i

CELL product. An option board is required for one

NC to communicate with multiple i CELL products.

The table below indicates the number of

FOCAS1/Ethernet clients usable with various

Ethernet boards, and the number of i CELL

products connectable with one NC.

Type of Ethernet

board

Embedded 5

Ethernet board

Data server

Fast Ethernet board

Fast data server

Number of

FOCAS1/Ethernet

clients

10

20

Number of clients

used by the i CELL

3

- 8 -

Page 29

B-75074EN/01 GENERAL 3.OPERATING ENVIRONMENT

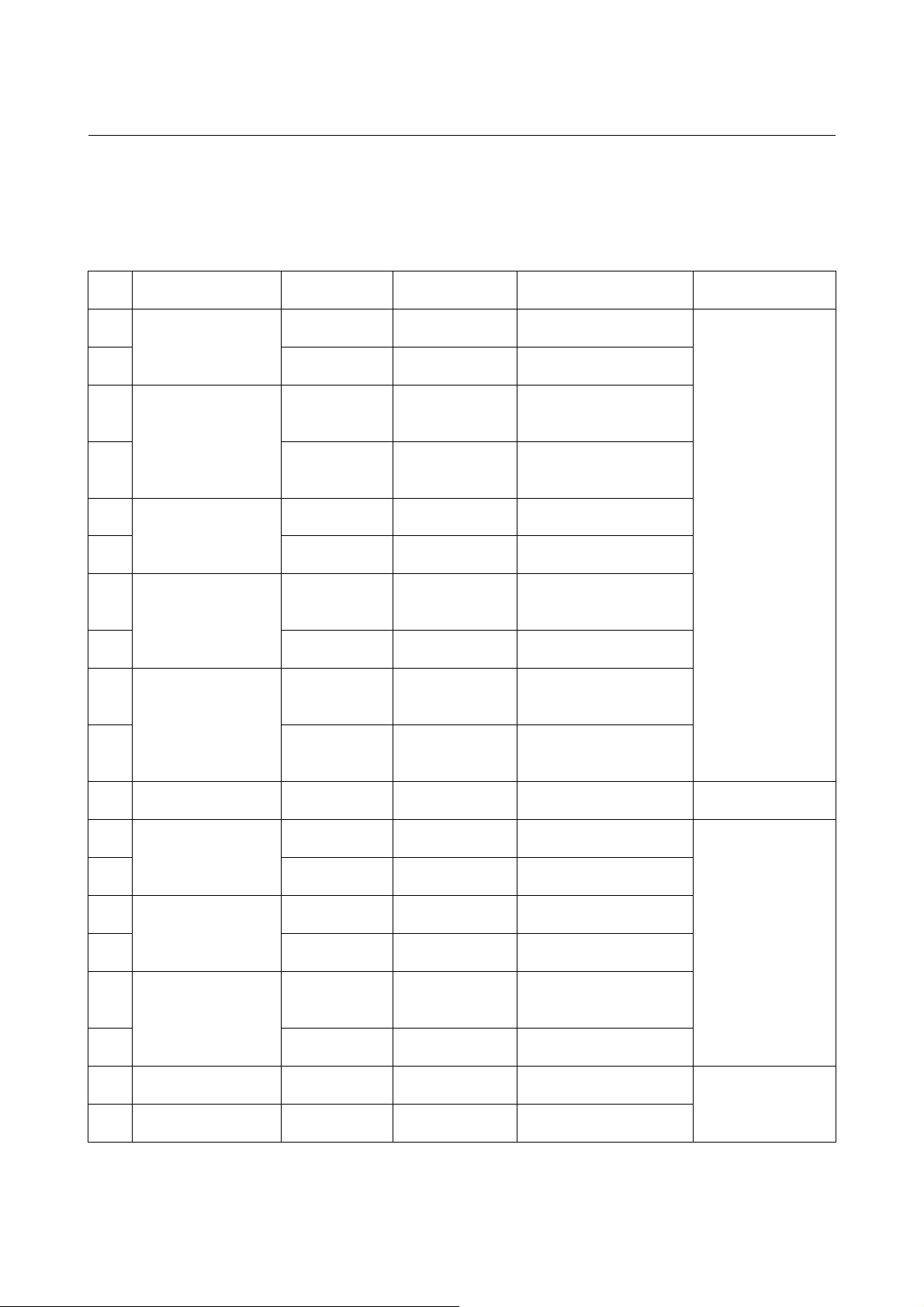

Ethernet boards and CNC options

The table below indicates the Ethernet boards usable with the i CELL,

and required CNC options.

Ethernet boards and required options

No Name

1

Ethernet board for

LCD-mounted type

2

3

ATA server for LCD-

4

5

6

7

ATA server for stand-

8

9

10

11 Ethernet board

12

Fast Ethernet board

13

14

Fast Ethernet board

for stand-alone type

15

16

17

18 Embedded Ethernet

Embedded Ethernet

19

CNC

mounted type CNC

Ethernet board for

stand-alone type

CNC

alone type CNC

RISC+ATA data

server for stand-

alone type CNC

for LCD-mounted

type CNC

CNC

Fast data server for

LCD-mounted type

CNC

(*8)

Applicable

model

FS 16i /18i /21i

-TA/MA

FS 16i /18i /21i

-TB/MB

FS 16i /18i /21i

-TA/MA

FS 16i /18i /21i

-TB/MB

FS 16i /18i /21i

-TA/MA

FS 16i /18i /21i

-TB/MB

FS 16i /18i /21i

-TA/MA

FS 16i /18i /21i

-TB/MB

FS 16i /18i

-TA/MA

FS 16i /18i

-TB/MB

Power Mate i

-D/H

FS 16i /18i /21i

-TA/MA

FS 16i /18i /21i

-TB/MB

FS 16i /18i /21i

-TA/MA

FS 16i /18i /21i

-TB/MB

FS 16i /18i /21i

-TA/MA

FS 16i /18i /21i

-TB/MB

FS 16i /18i

-TB/MB

FS 21i

-TB/MB

Drawing

number

A02B-0236-J292

A02B-0281-J292

A02B-0236-J145

A02B-0281-J145

A02B-0265-J291

A02B-0281-J298

A02B-0265-J145

A02B-0281-J148

A02B-0265-J154

A02B-0281-J158

A02B-0281-J160

(*4)

A02B-0259-J230

A02B-0236-J293

A02B-0281-J293 A02B-XXXX-S707 (*1)

A02B-0265-J293

A02B-0281-J299 A02B-XXXX-S707 (*1)

A02B-0236-J140

A02B-0281-J146

- Not required (*7)

- Not required (*8)

CNC option Control software

A02B-XXXX-S707 (*1)

A02B-0207-J800 (*2)

A02B-XXXX-S707 (*1)

A02B-0207-J800 (*2)

A02B-XXXX-S707 (*1)

A02B-0207-J800 (*2)

A02B-XXXX-S737 (*3)

A02B-XXXX-S707 (*1)

A02B-0207-J800 (*2)

A02B-XXXX-S737 (*3)

A02B-XXXX-S707 (*1)

A02B-0207-J800 (*2)

A02B-XXXX-S707 (*1)

A02B-0207-J800 (*2)

A02B-XXXX-S707 (*1)

A02B-0207-J800 (*2)

A02B-XXXX-S737 (*3)

A02B-XXXX-S707 (*1)

A02B-XXXX-S737 (*3)

A02B-XXXX-S707 (*1)

A02B-0207-J800 (*2)

A02B-XXXX-S737 (*3)

A02B-XXXX-S707 (*1)

A02B-XXXX-S737 (*3)

A02B-0259-J862 (*5)

A02B-0259-J847 (*6)

A02B-XXXX-S707 (*1)

A02B-0207-J800 (*2)

A02B-XXXX-S707 (*1)

A02B-0207-J800 (*2)

A02B-XXXX-S707 (*1)

A02B-0207-J800 (*2)

A02B-XXXX-S737 (*3)

A02B-XXXX-S707 (*1)

A02B-XXXX-S737 (*3)

A02B-0236-J561

#6561

A02B-0259-J561

#6561

A02B-0281-J561

#6567

A02B-0281-J571

#656A

- 9 -

Page 30

3.OPERATING ENVIRONMENT GENERAL B-75074EN/01

(*1) A02B-XXXX-S707: Ethernet function for FS 16i/18i/21i

This option is required when an external board for Model A or

Model B is used.

Specify one of the following drawing numbers in XXXX

according to the NC type:

0236 (16i -TA) 0238 (18i -TA) 0247 (21i -TA)

0237 (16i -MA) 0239 (18i -MA) 0248 (21i -MA

0281 (16i -TB) 0283 (18i -TB) 0285 (21i -TB)

0282 (16i -MB) 0284 (18i -MB) 0286 (21i -MB)

(*2) A02B-0207-J800: Extended driver library for FS 16i/18i/21i

This option is required when Model A is used.

This option is not required for Model B, regardless of whether

the embedded function or external board is used.

(*3) A02B-XXXX-S737: Data server function

Specify a drawing number in XXXX according to the NC type.

See (*1). This option is not required if a connection is made only

with the i CELL, and the data server function is not used.

(*4) A02B-0281-J160 is the high-speed version of A02B-0281-J158.

(*5) A02B-0259-J862: Ethernet function for Power Mate i-D/H

(*6) A02B-0259-J847: Extended driver library for Power Mate i-D/H

(*7) When the embedded Ethernet function is used with FS 16i/18i-

TB/MB, no option is required on the NC side.

(*8) When the embedded Ethernet function is used with FS 21i-

TB/MB, the main CPU board with the embedded Ethernet

function needs to be specified. No option is required on the NC

side.

- 10 -

Page 31

B-75074EN/01 GENERAL 3.OPERATING ENVIRONMENT

CNC options for functions other than the Ethernet function

The table indicates an option required for each function used.

Corresponding

No. Option name

Parts count and

1

operating time

display

2 Custom macro B

Custom macro B

and custom

3

macro variable

addition

External

message

function or

4

external data

input function

Pitch error

5

compensation

function

Workpiece

6

coordinate

system

Tool life

7

management

function in the

part for operation

6. Operation results

7. Workpiece

machining

results

9.5 Various data

backup/restorat

ion

7. Workpiece

machining

results

9.3 Alarm history

display

9.5 Various data

backup/restorat

ion

9.5 Various data

backup/restorat

ion

10. Tool line

management

Remarks

When the operation result

collection function is used

When the workpiece

machining result collection

function is used

When custom macro

variable data is

input/output

When the workpiece

machining result collection

function is used, and the

custom macro common

area has no free space

When the external

operator message history

data is used

When the pitch error

compensation data is

input/output

When a workpiece origin

offset is input/output

When the tool life

management function is

used

NC program modification

NOTE

The following Ethernet-related options are not

required:

Basic operation package 1 A02B-0207-J810

CNC screen display function A02B-0207-J850

In workpiece machining result collection, a subprogram for writing

information such as a workpiece ID and machining state to custom

macro variables in the NC program needs to be called. For a sample

subprogram, see Subsection 2.11.2, "Workpiece Machining Results",

in Part III, "SETTING".

- 11 -

Page 32

3.OPERATING ENVIRONMENT GENERAL B-75074EN/01

3.2 PERSONAL COMPUTER/HARDWARE

The hardware used to operate the FANUC i CELL is described below.

Computer

Select <1> or <2> below.

<1> Computer compatible with IBM PC/AT

• CPU: Pentium with 166 MHz or more is recommended.

• Memory: 128MB or more

• HDD: 300MB or more

• A keyboard, mouse, and CD-ROM are required.

• An Ethernet board is required.

NOTE

Software required varies according to the function

used.

Check the computer manufacturer to confirm that

the software products listed in Section 3.3,

"PERSONAL COMPUTER/SOFTWARE", can run

on the personal computer used.

Display

Internet communication unit

<2> CNC display unit with PC function

• Personal computer suitable for use in the FA floor

• Touch panel available (option)

• Display unit: 12.4-inch, 15-inch

• A CD-ROM is required.

• An Ethernet board is required.

NOTE

When the CNC display unit with PC function is

used, the Web function cannot be used.

To use the Web function, Windows NT 4.0 Server

is required as the OS. However, the CNC display

unit with PC function does not support this OS.

• Resolution: 1024 × 768 dots or more

• Color: 16 colors or more

When the mail function or Web function is used, the ISDN line and

dial-up router for ISDN are required. When the mail function and

Web function are not used, the ISDN line and dial-up router for ISDN

are not required.

Dial-up router for ISDN

Example: NTT-ME MN128-SOHO SLOTIN

- 12 -

Page 33

B-75074EN/01 GENERAL 3.OPERATING ENVIRONMENT

3.3 PERSONAL COMPUTER/SOFTWARE

Operating system and related software

(A) When the Web function is used

All of <1> through <3> below are required.

<1> Microsoft Windows NT

<2> Microsoft Internet Information Server 4.0

(Included in Microsoft Windows NT

this product from Microsoft.)

<3> Microsoft Internet Explorer 5.5 and later

(B) Cases other than (A) above

<1> or <2>, and <3> below are required.

<1> Microsoft Windows NT

(Microsoft Internet Information Server 4.0 required for the Web

function is not required.)

<2> Microsoft Windows NT

later

<3> Microsoft Internet Explorer 5.5 and later

Server 4.0 ServicePack 6a and later

4.0 Option Pack. Obtain

Server 4.0 ServicePack 6a and later

WorkStation 4.0 ServicePack 6a and

Virtual memory

NOTE

The following Ethernet-related software products

are not required:

- FOCAS1/Ethernet library (A02B-0207-K732)

- Basic operation package 1 (A02B-0207-K752)

- CNC screen display function disk

(A02B-0207-K772)

Set 200MB or more.

Select Control Panel from Settings on the Start menu, then activate

System. Next, set 200MB or more in Virtual Memory of the

Performance tab.

- 13 -

Page 34

3.OPERATING ENVIRONMENT GENERAL B-75074EN/01

CIMPLICITY

system

The i CELL is shipped as two CDs.

The first CD is used to install the i CELL.

The second one is the CD holding CIMPLICITY HMI Version 4

described in <1> below.

The software of <2> below is included on the i CELL installation CD.

Purchase the license of the main CIMPLICITY body and necessary

options.

<1> CIMPLICITY

(To be shipped with the i CELL.)

<2> CIMPLICITY

(included in the i CELL installation CD)

HMI Version 4

HMI Version 4 ServicePack 10

NOTE

Even if the user is already using CIMPLICITY, a

new personal computer and CIMPLICITY need to

be purchased when the user is using CIMPLICITY

not based on the unlimited point count

specification.

CIMPLICITY has such a restriction that multiple

projects cannot be executed simultaneously if the

unlimited point count specification is not employed.

So, in this case, the user's project and i CELL

project cannot be executed simultaneously. The

user is to prepare a personal computer for the i

CELL, and CIMPLICITY additionally.

If the user's project and i CELL project are

integrated with each other, the projects are no

longer multiple projects and can be used

simultaneously.

- 14 -

Page 35

B-75074EN/01 GENERAL 3.OPERATING ENVIRONMENT

3.4 CONTRACT WITH INTERNET SERVICE PROVIDERS

When the user does not use the mail and Web functions, no contract

with an Internet service provider is required.

(A) When the mail function only is used with dial-up connection

ISDN dial-up connection

Example: NTT Communications OCN dial access

(B) When the mail function is used with 24-hour connection, and when the Web

function is used

ISDN 24-hour connection

Example: NTT Communications OCN economy

- 15 -

Page 36

4.NC PROGRAM MANAGEMENT GENERAL B-75074EN/01

4 NC PROGRAM MANAGEMENT

NC program management connects a personal computer as a NC

program file server to multiple NCs.

By operating the NC program management screen on the personal

computer, the processing below can be performed.

NC program transfer

By operating the personal computer, an NC program on the personal

computer can be downloaded to the NC memory.

At this time, those subprograms that are used in the main program can

be automatically found and downloaded.

Moreover, multiple main programs can be registered in a list file, and

can be downloaded sequentially.

By operating the personal computer, NC programs can be uploaded

from the NC memory to the personal computer.

Displaying a list of NC programs held in the NC memory

A list of NC programs held in the NC memory can be displayed on

the NC program management screen on the personal computer.

Editing and referencing NC programs held in the NC memory

An NC program held in the NC memory can be edited and referenced.

A specified NC program can be automatically uploaded to the

personal computer for editing or referencing on the personal computer.

If an NC program on the personal computer has been edited,

download the NC program to the NC after confirmation.

Deleting NC programs held in the NC memory

An NC program held in the NC memory can be deleted by operating

the personal computer.

Management of NC programs for two paths

Programs for path 1 and path 2 can be managed under separate

directories or under the same directory.

NOTE

When the eight-digit O number option is used, NC

programs cannot be uploaded and downloaded at

present. (Support for uploading and downloading

NC programs in such a case is scheduled.)

- 16 -

Page 37

B-75074EN/01 GENERAL 4.NC PROGRAM MANAGEMENT

4.1 NC PROGRAM TRANSFER BY OPERATING THE NC

PROGRAM MANAGEMENT SCREEN

NC programs can be transferred by operating the NC program

management screen on the personal computer.

NC programs downloaded to the NC are placed under a directory

specified for each machine. Such a directory is referred to as a default

directory.

NC programs uploaded from the NC are stored in a default directory.

File system of the personal computer

Set as the default

directory of machine 2

Directory B

Directory D

= File (NC program)

= Directory, drive

Drive A

Directory C

File transfer between directory D and machine 2

Set as the default

directory of machine 1

File transfer

between directory

C and machine 1

Machine 1

Machine 2

- 17 -

Page 38

4.NC PROGRAM MANAGEMENT GENERAL B-75074EN/01

r

y

g

The NC program management screen displays a default directory and

a list of NC programs held in the NC memory. The operator transfers

NC programs by operating this screen.

List of files in the default directory

of a machinet

List of NC programs in the NC

memor

of a machine

NC programs can be downloaded and

uploaded by drag and drop operation.

NC programs can also be transferred

usin

the screen menu.

For the method of default directory setting, see Subsection 2.7.1,

"General Setting", in Part III, "SETTING". For the method of NC

program management screen operation, see Chapter 5, "NC

PROGRAM MANAGEMENT", in Part IV, "OPERATION".

- 18 -

Page 39

B-75074EN/01 GENERAL 4.NC PROGRAM MANAGEMENT

4.2 NC PROGRAM FORMAT

NC programs used with the system are managed under the formats

indicated below. The program field must contain a main program

including an NC program number, or must contain a subprogram.

Example 1: Main program ending with M30

% ; OXXXX; . . . Part program . . . ;M30; %

Example 2: Main program ending with M02

% ; OXXXX; . . . Part program . . . ;M02; %

Example 3: Subprogram ending with M99

% ; OXXXX; . . . Part program . . . ;M99; %

";" is used to mark an "end of block". Actually, ";" is the EOB code

determined for the NC as with an LF code.

"XXXX" represents an NC program number.

Use ASCII as the character code for NC programs. Some editors may

be set to create a file using Unicode. An error occurs if an attempt is

made to transfer an NC program created using Unicode.

Whether an NC program is created using Unicode can be checked

according to the procedure below.

1. Open the NC program in Notepad, then select [File]→[Save As].

2. If the check box for "Save in Unicode" in the Save As dialog box

is checked, the NC program is saved using Unicode.

If the NC program is saved using Unicode, uncheck the check box for

"Save in Unicode", then save the NC program again.

- 19 -

Page 40

4.NC PROGRAM MANAGEMENT GENERAL B-75074EN/01

4.3 SUBPROGRAM TRANSFER FUNCTION

Subprogram transfer function

When an NC program is downloaded, and a subprogram call is

included in the NC program, the subprogram transfer function

downloads the subprogram as well.

Subprogram transfer is divided into two types: batch transfer and

expanded transfer.

(1) Batch transfer

A main program is analyzed. If a subprogram call is specified,

the subprogram is transferred after the main program.

(2) Expanded transfer

A main program is analyzed. If a subprogram call is specified,

the main program is transferred with the subprogram expanded

in the main program.

On the NC program management setting screen, the user can choose

from three subprogram transfer options for each machine: "no transfer,

batch transfer, and expanded transfer".

Main program

%

O0001

(MAIN START)

M98P5001

(MAIN END)

M30

%

+

Subprogram file name

%

O0001

(MAIN START)

M98P5001

(MAIN END)

M30

O5001

(SUB START)

(SUB END)

M99

%

%

O0001

(MAIN START)

(SUB START)

(SUB END)

(MAIN END)

M30

%

Subprogram

%

O5001

(SUB START)

(SUB END)

M99

%

Subprogram batch

transfer

A subprogram file name must be described in the format "O"+4-digitnumber+"."+3-character-extension. For example, a subprogram file

name may be O0001.DAT. A 3-character extension must be registered

in [Subprogram extension] of the [General] panel on the NC program

management setting screen.

- 20 -

Page 41

B-75074EN/01 GENERAL 4.NC PROGRAM MANAGEMENT

Subprogram file format

In a subprogram file, one O number and one M99 code must be

described. See Example 3 in Section 4.2, "NC PROGRAM

FORMAT". A subprogram containing multiple O numbers and/or

multiple M99 codes cannot be transferred. An error occurs if an

attempt is made to call a subprogram that contains M02 or M30

instead of M99.

Subprogram file storage directory

Up to three subprogram file storage directories can be specified in

[Subprogram search directory 1-3] of the [Download] panel on the

NC program management setting screen. Each of three directories has

a subprogram search priority set. When each of the first directory and

the second directory holds a subprogram of the same name, for

example, the subprogram of the first directory is transferred.

NOTE

Only the directories set in [Subprogram search

directory 1-3] are searched for a subprogram.

When storing a subprogram in the default directory,

specify the same directory as the default direction

in any of [Subprogram search directory 1-3].

Disabling subprogram call

Even when the main program calls a subprogram, the transfer of the

subprogram can be disabled. For example, a setting can be made so

that the transfer of subprograms in the eight thousands and nine

thousands is disabled because those subprograms are held in the NC

memory. The transfer of subprograms can be disabled by specifying

subprogram numbers in steps of one thousand in [Subprograms not

transferred] of the [Download] panel on the NC program management

setting screen.

Subprogram call code setting

A call code for transferring a subprogram can be set. This capability

supports three types of calls: M98, G65, and G66. In accordance with

a set call type only, subprograms are called.

A subprogram call code can be set in [Call type] of the [Download]

panel on the NC program management setting screen.

- 21 -

Page 42

4.NC PROGRAM MANAGEMENT GENERAL B-75074EN/01

4.3.1 Details of the Subprogram Batch Transfer Function

Subprogram call format

A main program can use four subprogram call formats:

(1) M98PxxxxLyy

(2) M98Pyyxxxx

(3) G65PxxxxLyy

(4) G66PxxxxLyy

In these formats, xxxx represents a program number, and yy

represents the number of call repeats. The number of repeats can be

omitted. When format (2) is used, a 4-digit program number must be

specified.

In a batch transfer, however, the number of repeats is ignored because

a subprogram called several times by the main program is transferred

only once.

The calling depth of subprograms must not exceed 8 levels.

If a subprogram called by the main program is found to be nonexistent,

an error occurs when an attempt is made to transfer the nonexistent

subprogram after the transfer of the main program.

NOTE

1 The program number xxxx must be directly

specifiable. A program number specified with a

macro variable cannot be transferred.

2 M99Pnnnn (function for returning to a sequence

number) cannot be used. When a subprogram is

read up to M99, the end of the subprogram is

assumed. Control returns to the main program, and

Pnnnn is ignored.

3 Instructions such as branch instructions (GOTO, IF,

WHILE) are not processed, but are transferred to

the NC without modification.

- 22 -

Page 43

B-75074EN/01 GENERAL 4.NC PROGRAM MANAGEMENT

4.3.2 Details of the Subprogram Expanded Transfer Function

Subprogram call format

A main program can use four subprogram call formats:

(1) M98PxxxxLyy

(2) M98Pyyxxxx

(3) G65PxxxxLyy

(4) G66PxxxxLyy

In these formats, xxxx represents a program number, and yy

represents the number of call repeats. The number of repeats can be

omitted. When format (2) is used, a 4-digit program number must be

specified.

In an expanded transfer, a subprogram called several times by the

main program is transferred the specified number of times, with the

subprogram expanded each time in the main program.

The calling depth of subprograms must not exceed 8 levels.

When a subprogram called by the main program is found to be

nonexistent in the set directory, an error occurs. This means that the

transfer of the main program stops halfway, and the subprogram is not

transferred.

NOTE

1 The program number xxxx must be directly

specifiable. A program number specified with a

macro variable cannot be transferred.

2 M99Pnnnn (function for returning to a sequence

number) cannot be used. When a subprogram is

read up to M99, the end of the subprogram is

assumed. Control returns to the main program, and

Pnnnn is ignored.

3 Instructions such as branch instructions (GOTO, IF,

WHILE) are not processed, but are transferred to

the CNC without modification.

4 In an expanded transfer, the transfer of a

subprogram alone is impossible. If a subprogram

alone is transferred, an error indicating that the

main program contains M99 occurs.

5 In a block that calls a subprogram, no other

address can be specified.

Example:When the block M98P9000G00X00Y00 is

sent in an expanded transfer, the

subprogram O9000.DAT can be

transferred, but the portion of G00X00Y00

cannot be transferred.

- 23 -

Page 44

4.NC PROGRAM MANAGEMENT GENERAL B-75074EN/01

4.4 LIST FILE TRANSFER FUNCTION

List file transfer function

The list file transfer function transfers multiple NC programs

described in "List file" to the NC.

A list file is created on the list file editing screen.

In a list file, up to 9999 NC programs can be registered.

The list file transfer function is divided into two types: batch transfer

and expanded transfer.

• List batch transfer

This function sequentially transfers the NC programs registered

in a list file. This function assumes that multiple main programs

are registered in the NC memory.

• List expanded transfer

This function deletes O numbers and M30 from the NC

programs registered in a list file, and transfers the NC programs

as a single NC program. This function assumes that multiple

main programs are linked into a single program for DNC

operation.

O0001.DAT

%

O0001

(O0001 DATA)

M30

%

O0002.DAT

%

O0002

(O0002 DATA)

M30

%

O0003.DAT

%

O0003

(O0003 DATA)

M30

%

On the NC program management setting screen, the user can choose

between two list file transfer options for each machine: "batch

transfer and expanded transfer".

List file creation

screen

List file

O0001.LST

O0001.DAT

O0002.DAT

+

O0003.DAT

List batch transfer

List expanded

transfer

%

O0001

(O0001 DATA)

M30

O0002

(O0002 DATA)

M30

O0003

(O0003 DATA)

M30

%

O0001

(O0001 DATA)

(O0002 DATA)

(O0003 DATA)

M30

%

- 24 -

Page 45

B-75074EN/01 GENERAL 4.NC PROGRAM MANAGEMENT

List file name

A 3-character extension for a list file must be registered in [List file

extension] of the [General] panel on the NC program management

setting screen.

A list file can be created and edited only on the list file editing screen.

When a list file is saved, the list file extension is automatically set. So,

the user need not consider a file name when creating a list file.

When [List file extension] is registered on the NC program

management setting screen, a different extension only can be set in

each of [Default extension] and [Subprogram extension]. So, for

example, the main program O0001.DAT and the list file O0001.LST

can be created.

The list file transfer function is enabled when the NC makes a request

for transfer of a file with a list file extension.

List file format

A list file can be created and edited only on the list file editing screen,

so that the user need not consider the list file format when creating a

list file with an editor.

List file storage directory

Store a list file in the directory specified in [Default directory] on the

NC program management setting screen. Before a list file can be

specified by file number or file name from the NC after a list of files

on the personal computer is displayed, the list file must be stored in

[Default directory].

Combinations of the list file transfer and subprogram transfer functions

The following combinations are possible:

Subprogram transfer type

Batch Expanded

List file transfer

type

Batch

Expanded

OO

XO

- 25 -

Page 46

4.NC PROGRAM MANAGEMENT GENERAL B-75074EN/01

4.4.1 Details of List File Batch Transfer Function

The NC programs registered in a list file are transferred in the order

of registration.

The contents of registered NC program files are transferred without

deleting O numbers, and M02, M30, and M99 codes.

When a request is made for batch transfer of a list file specifying both

a main program and subprogram, both of the main program and

subprogram are transferred.

NOTE

1 Batch transfer of NC programs that have no O

number is disabled. If such an attempt is made, an

error occurs.

2 Batch transfer of NC programs that have the same

O number is disabled. If such an attempt is made,

an error occurs.

4.4.2 Details of List File Expended Transfer Function

The multiple main NC programs registered in a list file are transferred

after being linked into a single NC program.

The O numbers, and M30 and M02 codes in the registered NC

programs are not transferred.

As the O number transferred at the start of an expanded transfer, the

user can specify one of the following on the list file editing screen:

(1) O number of the first NC program registered in the list file

(2) O number specified in [Specify O number for expanded transfer]

on the list file editing screen.

Expanded transfer allows the user to transfer an NC program that has

no O number. In this case, an O number must be specified according

to (2) above.

At the end of an expanded transfer, an M30 code is transferred.

NOTE

1 Expanded transfer of a list file specifying a main

program and subprogram is disabled. If such an

attempt is made, the M02/M03 code in the main

program is deleted, but the M99 code in the

subprogram is transferred without being deleted.

2 Expanded transfer of NC programs that have the

same O number is disabled. If such an attempt is

made, an error occurs.

- 26 -

Page 47

B-75074EN/01 GENERAL 4.NC PROGRAM MANAGEMENT

4.4.3 List File Transfer Monitor and Control Function

The list file monitor screen enables transfer monitor display and

exercises control functions such as temporary stop, transfer skip,

transfer sequence alteration, and so forth for those NC programs not

transferred yet in a list file.

Monitor display of list file transfer

During list file transfer, up to which NC program have been

transferred can be displayed.

When DNC operation is performed based on the expanded transfer of