Page 1

Computer Numerical Control Products

AC Spindle Motor Series

(Serial Interface)

Descriptions Manual

(Volume 2 of 4)

GFZ-65042Ef05

January 1994

Page 2

Warnings, Cautions, and Notes

as Used in this Publication

Warning notices are used in this publication to emphasize that hazardous voltages, currents,

temperatures, or other conditions that could cause personal injury exist in this equipment or

may be associated with its use.

In situations where inattention could cause either personal injury or damage to equipment, a

Warning notice is used.

Caution notices are used where equipment might be damaged if care is not taken.

GFL-001

Warning

Caution

Note

Notes merely call attention to information that is especially significant to understanding and

operating the equipment.

This document is based on information available at the time of its publication. While efforts

have been made to be accurate, the information contained herein does not purport to cover all

details or variations in hardware or software, nor to provide for every possible contingency in

connection with installation, operation, or maintenance. Features may be described herein

which are not present in all hardware and software systems. GE Fanuc Automation assumes

no obligation of notice to holders of this document with respect to changes subsequently made.

GE Fanuc Automation makes no representation or warranty, expressed, implied, or statutory

with respect to, and assumes no responsibility for the accuracy, completeness, sufficiency, or

usefulness of the information contained herein. No warranties of merchantability or fitness for

purpose shall apply.

©Copyright 1994 GE Fanuc Automation North America, Inc.

All Rights Reserved.

Page 3

CONSTITUTION OF THIS MANUAL

This manual (B-65042E) is composed of the following 4 volumes.

Vol, 1

I.Ac SPINDLE MOTOR S series

GENERAL/ FEATURES/ SPECIFICATIONS/ OUTPUT AND TORQUE CHARACTERISTICS/

CONFIGURATION AND ORDER DRAWING NUMBER/ CONNECTIONS/

ALLOWABLE RADIAL LOAD/ ASSEMBLING ACCURACY/ EXTERNAL DIMENSIONS

II. AC SPINDLE MOTOR P series

GENERAL/ FEATURES/ SPECIFICATIONS/ OUTPUT AND TORQUE CHARACTERISTICS/

ORDER DRAWING NUMBER/ CONNECTIONS/ ALLOWABLE RADIAL LOAD/

ASSEMBLING ACCURACY/ EXTERNAL DIMENSIONS

III. A C

S P I ND L E MOT 0 R VH s e r i e s (LIQUID-COOLED)

GENERAL/ FEATURES/ SPECIFICATIONS/

OUTPUT AND TORQUE CHARACTERISTICS/ ORDER SPECIFICATIONS/

CAUTIONS IN USE/ ASSEMBLING ACCURACY/ EXTERNAL DIMENSIONS

IV. AC SP I NDLE MOTOR HV .s e r i e s (380/415 VAC INPUT)

GENERAL/ FEATURES/ SPECIFICATIONS/ OUTPUT AND TORQUE CHARACTERISTICS/

CONFIGURATION AND ORDER SPECIFICATIONS/ CONNECTION/ .

ALLOWABLE RADIAL LOAD/ ASSEMBLING ACCURACY/ EXTERNAL DIMENSIONS

V. LIQUID-COOLED AC SPINDLE MOTOR series

NON HOLLOW SHAFT AND WITHOUT SPEED RANGE SWITCHING TYPE/

OUT1 INE/ FEATURES/ SPECIFICATIONS/

CONFIGURATION AND ORDER DRAWING NUMBER/ CONNECTIONS/ CAUTIONS IN USE/

OUTLINE DRAWING OF MOTOR/

HOLLOW SHAFT AND WITH SPEED RANGE SWITCHING TYPE/

OUTLINE/ FEATURES/ SPECIFICATION/

CONFIGURATION AND ORDER SPECIFICATION DRAWING NUMBER/ CONNECTIONS/

CAUTIONS IN USE/ OUTLINE DRAWING OF MOTOR/

Page 4

u.lP65 series

FEATUKES,' SPECIFICAT 1ONSi CHARACTER1 STIC/ EXTERNAL DIMENSIONS/

LOAD METER/ ORDER SPECIFICATION DWG NO.

Vol, 2

W.AC SPINDLE SERVO IJNIT SERIAL

INTERFACE S series

GENERAL/ FEATURES/ CONFIGURATION AND DRAWING NUMBER/

SPECIFICATIONS AND FUNCTIONS/ INSTALLATION/ UNIT CALORIFIC VALUE/

COOLING/ EXTERNAL DIMENSlONS AND MAINTENANCE AREA/ CONNECTION/

INTERFACE SIGNALS

WI.AC SPINDLE SERVO UNIT HV series

GENERAL/ FEATURES/ SPECIFICATIONS/ CONFIGURATION AND ORDER SPECIFICATIONS/

INSTALLATION/ OLING/ EXTERNAL DIMENSIONS AND SERVICE CLEARANCE/

CONNECTION/ CAUTION IN USE

KPOSITION CODER METHOD SPINDLE

ORIENTATION

GENERAL/ FEATURES/ CONFIGURATION AND ORDER DRAWING NUMBER/ SPECIFICATIONS/

CONNECTION/ SIGNAL EXPLANATION/ POSITION CODER

X.MAGNETIC SENSOR METHOD SPINDLE

ORIENTATION

GENERAL/ FEATURES/ CONFIGURATION AND ORDER DRAWING NUMBER/ SPECIFICATIONS/

CONNECTION/ SIGNAL EXPLANATION/ MAGNETIC SENSOR/

TWO-MAGNETIC SENSOR ORIENTATION

Vol, 3

XI. SPINDLE ORIENTATION WITH I--REVOLU'TION

SIGNAL SWITCH

GENERAL/ SYSTEM CONFIGURATION/ SPECIFICATIONS/ CONTROL SEQUENCE/

PMC SIGNAL (DI,DO SIGNAL)/ PARAMETERS/ CABLE CONNECTION/

SPECIFICATIONS OF REFERENCE SWITCH/ SETTING PlNS (SH8 to lo)/

MOUNTING DIAGRAM OF SETTING PINS, CHECK PINS AND VARIABLE RESISTORS/ NOTES

Page 5

XU. l3~JILT-Ih SKNSOR SIGNAL CONVERSION

CIRCUIT

GENEKAL/ FEATURES/ CONFlGUKATIO~/ Sl'ECIFICATIONS/ EXTERNAL DIMENSIONS/

CABLE ROUTING DIAGRAM/ EXAM~PLE OF INSTALLATION/ CONNECTION/ CABLES/

CAUTIONS IN USE

XIKHIGH RESOLUl7ON MAGNETIC PIJLSE CODER

GENERAL/ SYSTEM CONFIGURATION/ SPECIFZCATION METHOD/ SPECIFICATION/

CONNECTIONS/ DIMENSIONS/

CHECKING OUTPUT WAVEFORM AND ADJUSTING THE PREAMPLIFIER

SENSOR AND PREAMPLIFIER FITTING DIAGRAMS/ SENSOR FITTING PROCEDURE

XJKHIGH-RESOLUTION POSITION CODER

GENERAL/ FEATURES/ SYSTEM CONFIGURATION/ SPECIFICATIONS/ CONNECTION/

SHAPE/ INSTALLATION CONDITION AND CAUTIONS

XV.SPEED RANGE SWITHING CONTROL

GENERAL/ CONFIGURATION AND DRAWING NUMBER/ SPECIFICATIONS/ CONNECTIONS/ '

INTERFACE SIGNALS/ SEQUENCE/

ALARMS RELATED TO SPEED RANGE SWITCHING CONTROL/ CAUTIONS IN USE

XKSPINDEL SWITCHING CONTROL

GENERAL/ FUNCTIONS/ RESTRICTIONS/'

CONFIGURATION AND ORDERING DRAWING NUMBERS/

EXTERNAL DIMENSIONS OF SPINDLE SWITCHING CONTROL CIRCUIT/ CONNECTION/

PARAMETERS/ SPINDLE CONTROL SIGNALS/ SEQUENCE/

ALARMS RELATED TO SPINDLE SELECTOR CONTROL/ CAUTIONS IN USE

XVKSWITCHING UNI?

GENERAL/ CONFIGURATIQN/ ORDER DKAWING NUMBER/ SPECIFICATIONS/

EXTERNAL DlMENSIONS AND DIMENSIONS FOR MOUNTING/ CONNECTION/

CAUTIONS IN USE

Page 6

XVll.DIFFERENTIAL SPEED CONTROL FUNCTION

DESCRIPTION

OUTLINE/ CHARCTERISTICI CONFIGURATION AND ORDER DRAWING NUMBER/

SPECIFICATION OF POSITION CODER SIGNAL INPUT CIRCUIT/

INPUT AND OUTPUT SIGNAL EXPLANATION/

POSITION CODER SIGNAL INPUT CIRCUIT(OPTION) EXTERNAL DRAWING/

CONNECTION/ CONNECTION DETAIL DRAWING/ JUMPER EXPLANATION

Vol,4

APPENDIX

CABLE SPECIFICATIONS/ TECHNICAL DATA/ SERIAL SPINDLE START-UP PROCEDURE/

METHOD FOR OPERATIING THE SPINDLE MOTOR USING A SERIAL SPINDLE

AMPLIFIER INSTEAD OF THE CNC/

MONITORING INTERNAL DATA OF THE SERIAL SPINDLE/ GROUNDING/ CUSTOMER RECORDS

Page 7

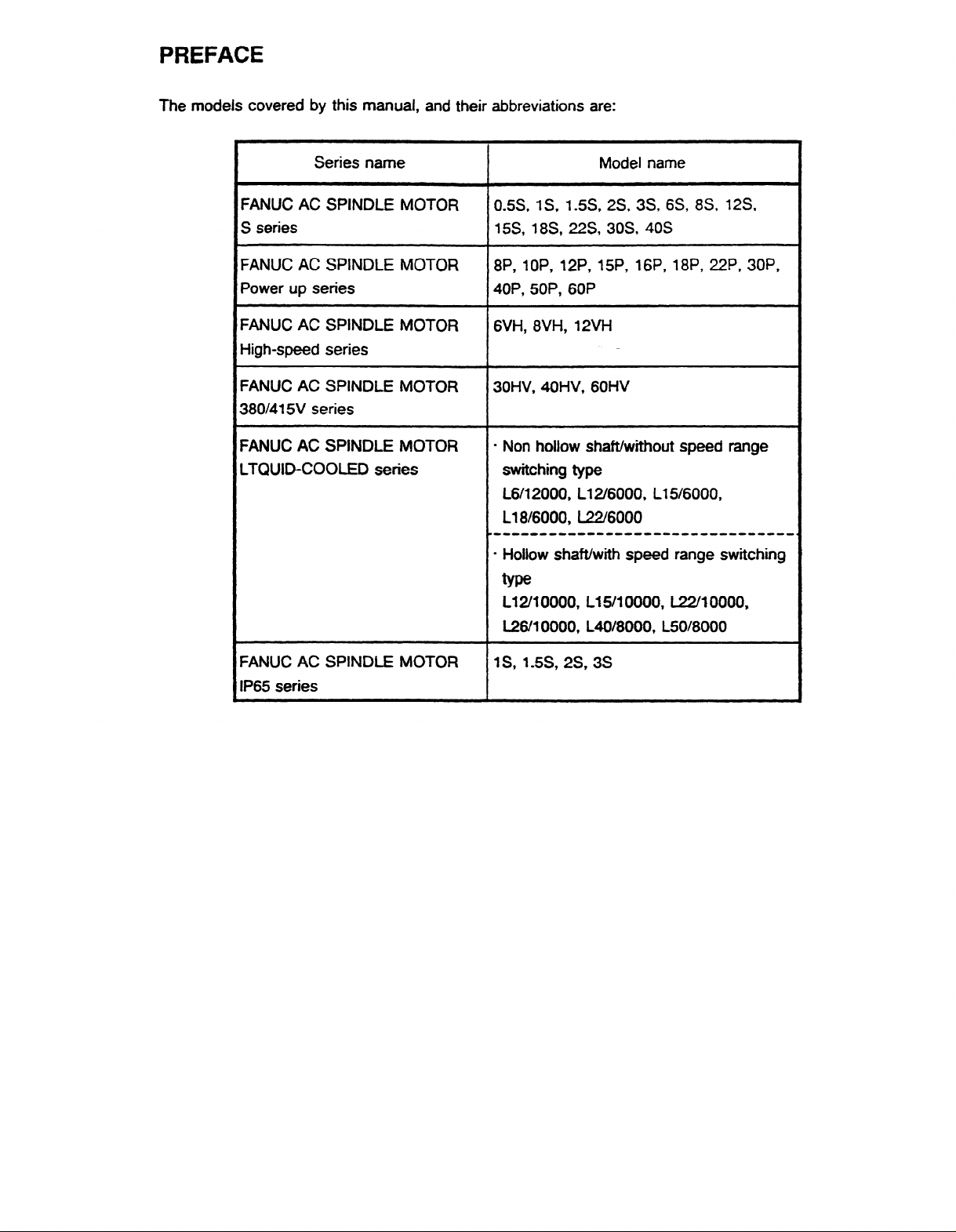

PREFACE

The models covered by this manual, and their abbreviations are:

Series name

FANUC AC SPINDLE MOTOR

S series

L

FANUC AC SPINDLE MOTOR

Power up series

FANUC AC SPINDLE MOTOR

High-speed series

FANUC AC SPINDLE MOTOR

380/415V series

FANUC AC SPINDLE MOTOR

LTQUID-COOLED series

Model name

OSS, IS, 1.5S, 2S, 3S, 6S, 8S, QS,

ISS, 18S, 22s, 30s. 40s

8P, IOP, 12P, 15P, l6P, 78P, 22P, 3OP,

4OP, 5OP, 60P

6VH, BVH, 12VH

_

30HV, 40HV, 60HV

- Non hollow shaft/without speed range

switching type

L6112000, Ll2/6000, L15/6000,

L18/6000, LW6000

.~~~~~~~~~~~~~~~~~-Ir)~~~~~~~~~c~~

l Hollow shaft/with speed range switching

L12(10000, Ll5110000, t22/toooo,

L26/10000, L4018000, L50/8000

FANUC AC SPINDLE MOTOR

IP65 series

Page 8

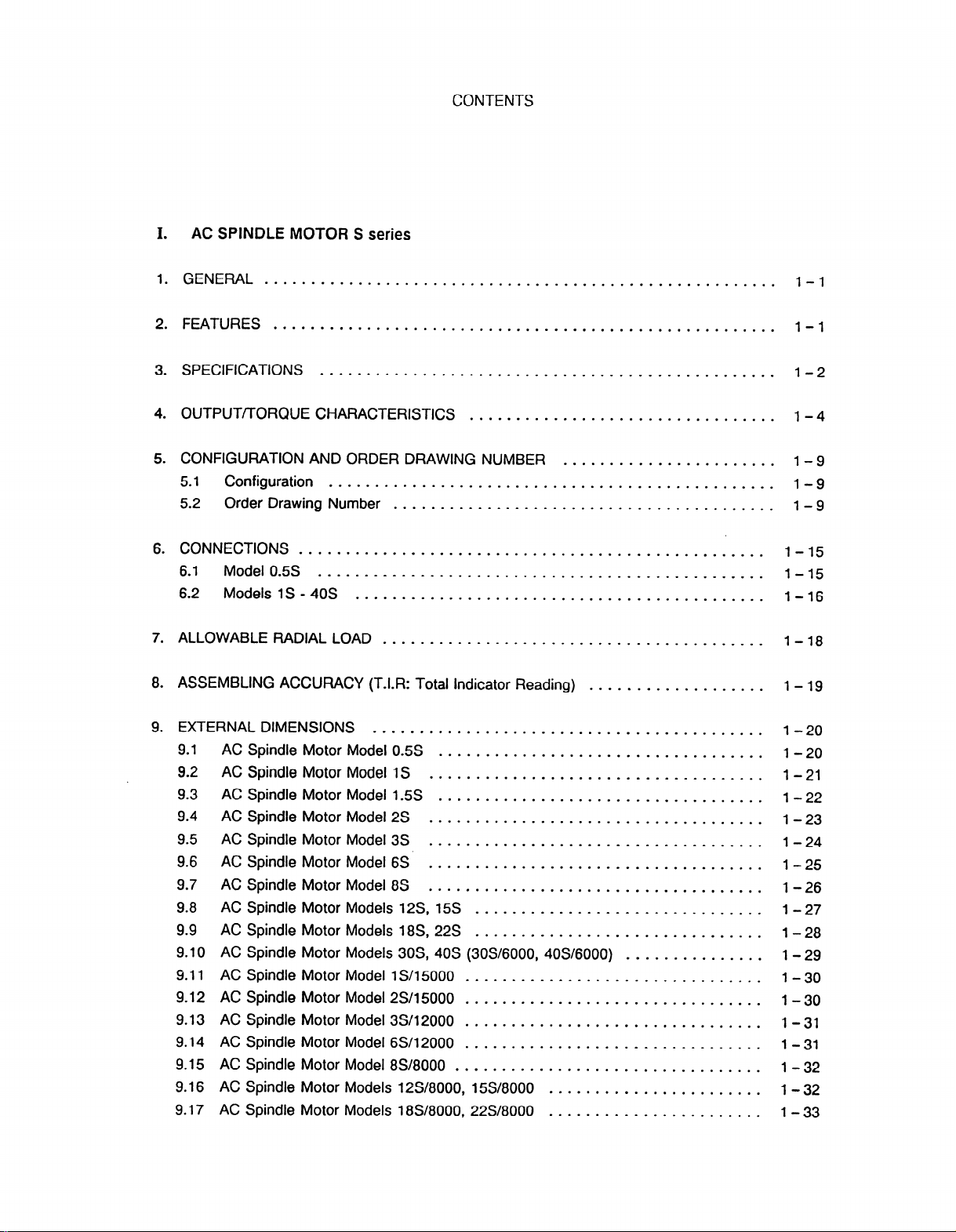

I . AC SPINDLE MOTOR S series

CONTENTS

1. GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. FEATURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3. SPECIFICATIONS

4. OUTPUT/TORQUE CHARACTERISTICS

5. CONFIGURATION AND ORDER DRAWING NUMBER

5.1 Configuration

5.2 Order Drawing Number

6. CONNECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1 Model0.5S

6.2 ModelslS-40s

7. ALLOWABLE RADIAL LOAD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8. ASSEMBLING ACCURACY (T-1-R: Total Indicator Reading) . . . . . . . . . . . . . . . . . . .

9. EXTERNAL DIMENSIONS

9.1 AC Spindle Motor Model 0.5s

9.2 AC Spindle Motor Model 1s

9.3 AC Spindle Motor Model 1.5s

9.4 AC Spindle Motor Model 2s

AC Spindle Motor Model 3s

9.5

AC Spindle Motor Model 6s

9.6

9.7 AC Spindle Motor Model 8s

AC Spindle Motor Models 12S, 1%

9.8

AC Spindle Motor Models l8S, 22s

9.9

9.10 AC Spindle Motor Models 3OS, 40s (3OS/6000, 4OS/SOOO)

9.11

AC Spindle Motor Model lS/15000

9.12 AC Spindle Motor Model 2S/15000

9.13

AC Spindle Motor Model 3S/12000

9.14

AC Spindle Motor Model 6S/12000

9.15

AC Spindle Motor Model 8S/8000

9.16 AC Spindle Motor Models 12S/8000, 155/8000

9.17

AC Spindle Motor Models 18S/8000, 22S/8000

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

....................... l-9

................................................ l-9

......................................... 1-9

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.......................................... I-20

...................................

.................................... l-21

...................................

.................................... l-23

....................................

.................................... l-25

.................................... 1-26

............................... l-27

...............................

............... 1 - 29

................................

................................

................................

................................

.................................

....................... 1 - 32

.......................

l-1

I-1

1-2

l-4

1 - 15

l-15

1-16

1-18

1 - 19

l-20

1-22

l-24

l-28

l-30

l-30

l-31

l-31

l-32

l-33

Page 9

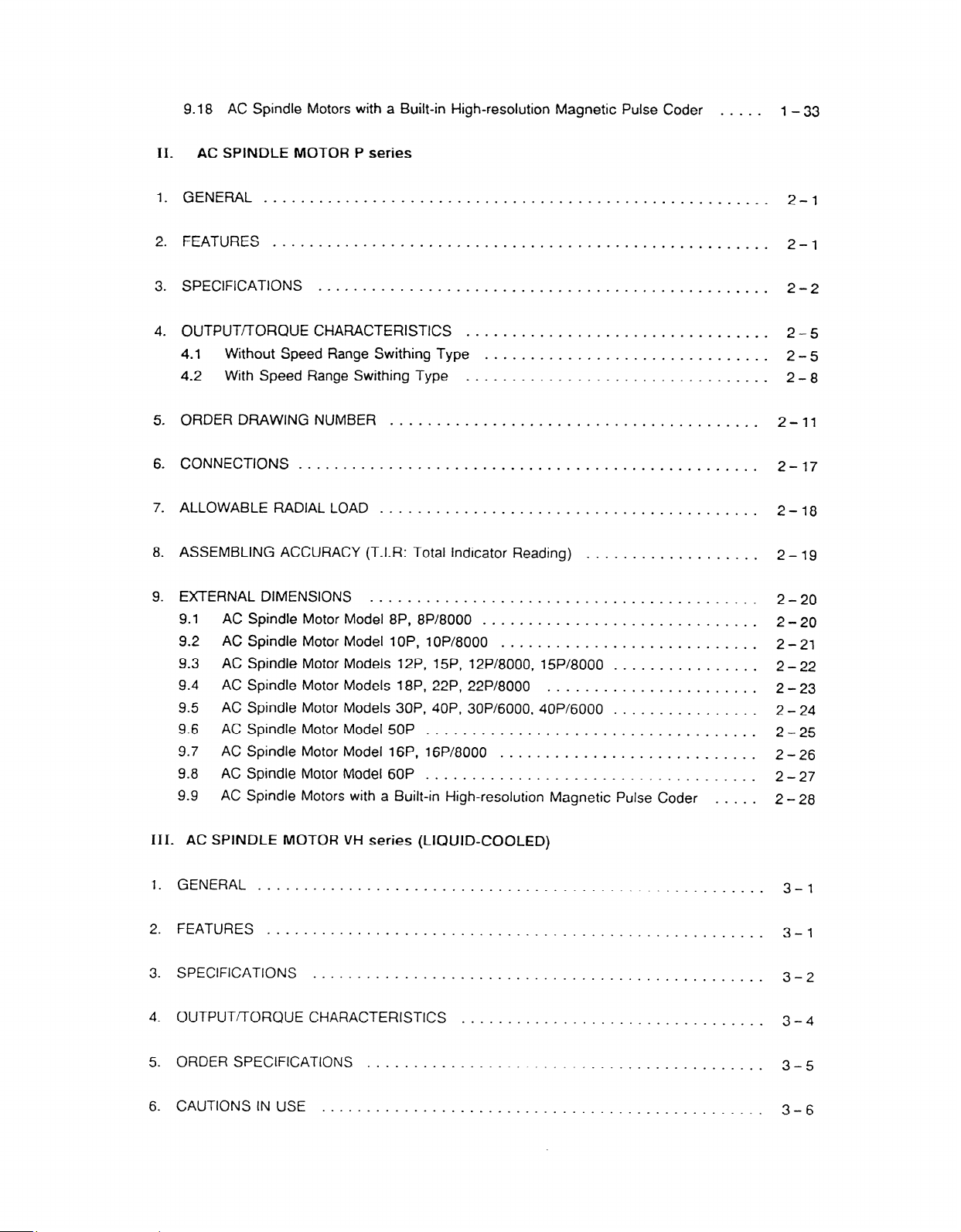

9.18 AC Spindle Motors with a Built-in High-resolution Magnetic Pulse Coder

AC SPINDLE MOTOR P series

II.

..... 1 - 33

I, GENERAL .......................................................

2. FEATURES

3. SPECIFICATIONS

4. OUTPUTTTORQUE CHARACTERISTICS

Without Speed Range Swithing Type

4.1

With Speed Range Swithing Type

4.2

5. ORDERDRAWING NUMBER

6. CONNECTIONS

ALLOWABLE RADIAL LOAD

7.

8. ASSEMBLING ACCURACY (T.i.R: Total indicator Reading)

EXTERNAL DIMENSIONS

9.

AC Spindle Motor Model 8P, 8P/8000

9.1

AC Spindle Motor Model IOP, lOP/8000

9.2

AC Spindle Motor Models 12P, 15P, 12P/8000, 15P/8000

9.3

AC Spindle Motor Models 18P, 22P, 22PI8000

9.4

AC Spindle Motor Models 3OP, 4OP, 3OP/6000, 4OP/6000

9.5

AC Spindle Motor Model 5OP

9.6

AC Spindle Motor Model l6P, 16P/8000

9.7

AC Spindle Motor Model 60P

9.8

AC Spindle Motors with a Built-in High-resolution Magnetic Pulse Coder

9.9

......................................................

.................................................

.................................

...............................

.................................

........................................

..................................................

.........................................

..........................................

..............................

............................

.......................

....................................

............................

.................................... 2-27

...................

................

................

2-l

2-1

2 -2

2 - 5

2 - 5

2 - 8

2-11

2-17

2-18

2 - 19

2-20

2-20

2 - 21

2 - 22

2-23

2 - 24

2-25

2-26

..... 2 - 28

III. AC SPINDLE MOTOR W-i series (LIQUID-COOLED)

1. GENERAL . . . . . . . . . . .._._................_......

2. FEATURES . . . . . .._......................._ _ ._..

SPECIFICATIONS

3.

4. OUTPUT/TORQUE CHARACTERISTICS . . _ _ . . . _ _ . . _ _ _ _ _

ORDER SPECtFiCATiONS . . _ . . _ . . . . . . . _ . . . _ _ . . . . . . .

5.

CAUTIONS 1N USE . . . . . _ . . . . . . _ . . . . . . . . . . . . . . _ _ . .

6.

. . . . . . . . . . . . . _ . . _ . . . . _ . _ _ _ _ _ . _ . _

................

................

................

................

................

................

3-1

3-l

3-2

3-4

3-5

3-6

Page 10

PipingofCoolingOil ...........................................

6.1

6.1.1

6.1.2 Piping block (for reference)

6.1.3 Piping (for reference) .....................................

Motor Cooling Conditions

6.2

Oil-Air lubrication Conditions

6.3

Factory-set piping

.......................................

.......................................

.....................................

................................

3-6

3-6

3-7

3 - 8

3- 9

3- 9

7. ASSEMBLING ACCURACY (T.1.R: Total Indicator Reading)

8. EXTERNAL DIMENSIONS

AC Spindle Motor Model 6VH

8.1

AC Spindle Motor Model 8VH

8.2

AC Spindle Motor Model 12VH

8.3

IV. AC SPINDLE MOTOR HV series (3801415 VAC INPUT)

1. GENERAL . . . . . . . . . . . . . ..r.......................................

2. FEATURES . . . . . . . . . . . . . . . . . ..r..................o.~.............

3. SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4. OUTPUTmORQUE CHARACTERISTICS

5. CONFIGURATION AND ORDER SPECIFICATIONS

Configuration

5.1

Order Specifications

5.2

................................................

..........................................

...................................

...................................

.................................. 3- 12

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.........................

...........................................

. . . . . . - . . - . . . . . . . . .

3-10

3- 11

3-11

3-11

4-1

4-l

4 - 2

4 - 3

4-4

4 - 4

4 - 5

6. CONNECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . _ . . . . . . . . . . . . .

7. ALLOWABLE RADIAL LOAD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8. ASSEMBLING ACCURACY (T-1-R: Total Indicator Reading) . . . . . . . . . . . . . . . . . . . .

9. EXTERNAL DIMENSIONS

9.1 AC Spindle Motor Model 30HV/40HV (Flange Mounting)

9.2 AC Spindle Motor Model 3OHV/4OHV (Foot Mounting)

AC Spindle Motor Model 30HVl40HV

9.3

(Footed-Flange/Output Shaft Conforming to DIN Standard)

AC Spindle Motor Model 60HV (Flange Mounting)

9.4

AC Spindle Motor Model 60HV

9.5

AC Spindle Motor Model 60HV (Foot Mounting)

9.6

LIQUID-COOLED AC SPINDLE MOTOR series

v.

1. NON HOLLOW SHAFT/WITHOUT SPEED RANGE SWITCHING TYPE . . . . _ . . . . . . .

...........................................

..................

...................

................

.....................

..................................

.......................

4- 6

4- 7

4 - 8

4-9

4 - 9

4- 9

4 - 10

4- 10

4- 11

4-11

5- 1

Page 11

1.1 Outline ....................................................

1.2 Feature ....................................................

Specifications

1.3

1.3.1

l-3.2

Non hollow shaft’without speed range switching type ..............

Outputs and torque chara(

1.3.2.1 Model L6/‘12000

1.3.2.2 Model Ll2!6000

1.3-2.3 Model Ll5/6000

I .3.2.4 Model Ll8i6000

1.3.2.5 Model L22/‘6000 (without speed range switching type

1.4 Configuration and Order Drawing Number

1.4.1 Configuration

1.4.2

Connections

1.5

1.5.1 Power cable size

1.5.2

Cautions in Use

1.6

1.6.1 Piping of cooling oil

1.6.2 Motor cooling condition

I .6.3 Allowable radial load

1.6.4 Assembly accuracy

1.6.5 Utilization limitation of eye bolt

1.7

Outline Drawing of Motor

1.7.1

1.7.2

1.7.3

Order drawing number

Connection of signal cable

1.6.1.1 State in shipment

1.6.1.2 Example of piping block

l-6.1.3 Piping example

Model L6/12000 (Non hollow shaft)

Model Ll2/6000, Ll5/6000 (Non hollow shaft)

Model Ll8,‘6000, L22/6000 (Non hollow shaft)

................................................

teristics . . . . . . . . . . . . . . . . . . . . . . . . . . .

without speed range switching type

without speed range switching type

without speed range switching type

without speed range switching type

(’

..........................................

....................................

.................................................

........................................

.................................

.............................................

.....................................

................................

................................. 5-13

..................................

....................................

..................................... 5- 15

.......................................

.......

.......

.......

.......

.......

............................

........................... 5- 12

.............................

.......................... 5- 16

..................

.................. 5- 17

5-l

5-I

5 - 2

5 - 2

5 - 3

5-3

5-4

5-5

5-6

5-7

r n

3 - C)

5 - 8

5 - 8

5 - 8

5-8

5- 9

5-11

5-11

5-11

5-14

5-14

5- 15

5-16

5- 16

2. HOLLOW SHAFT,‘WITH SPEED RANGE SWITCHING TYPE

2.1 Outline

2.2 Feature

Specification

2.3

2.3.1

2.3.2 Output and torque character

2.4 Configuration and Order Specification Drawing Number

2.4-l

2.42 Order specification drawing number

2.5

Connections

...................................................

...................................................

............................................... 5-19

List of specification (Hollow shaft/with speed range switching type)

...............................

2.3.2. I Model Ll2/10000 (with speed range switching type

2.3.2.2 Model L15/10000 (with speed range switching type

2.3.2.3 Model L22110000 (with speed range switching type

2.3.2.4 Model L26/10000 (with speed range switching type

2.3.2.5 Model L40;8000 (with speed range switching type)

2.3.2.6

Configuration

Model L50!8000 (with speed range switching type)

......................................... 5 - 27

......................... 5-27

................................................ 5 - 28

.................. 5 - 18

5-18

5- 18

...

5-79

5-21

....... 5-21

.......

.......

5 - 22

5-23

....... 5-24

........

........

5-25

5-26

................. 5 - 27

Page 12

2.5.1

2.5.2

2.53 Magnetic-contactor for switching . _ . . _ . . . . . . . . . . . . . . . . - . . . . . .

2.54 Connection of signal cable . . . . . . . . . . _ . . . . . . . . . . . . . . . . . . . . .

Cautions in Use

2.6

2.6.1 Piping of cooling oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6.2 Motor cooling condition

2.6.3 Connection with machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6.4

2.6.5 Utilization limitation of eye bolt

2.6.6 Connection with through hole . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7

Outline Drawing of Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7.1 Model LWlOOOO, L15/10000 (Hollow shaft) . . . . . . . . . . . . . . . . . . . .

2.7.2

2.7.3 Model l26/10000 (Hollow shaft)

2.7.4 Model L40/8000 (Hollow shaft)

2.7.5 Model L50/8000 (Hollow shaft)

Connection diagram

Power cable size . . . . . . . . . . . _ . . . . . . . . . . . . . . . . . . . . - . . . . . .

. . . . _ . . . . . . . _ . . _ . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . l . . . .

2.6.1.1 State in shipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6.1.2 Example of piping block

2.6.1.3

Piping example

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Assembly accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Model iZ/lOOOO (Hollow shaft)

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

............................

.............................

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 - 28

5-29

5-29

5-30

5-31

5-31

5-31

5-32

5-33

5 - 34

5 - 34

5-36

5 - 36

5-37

5-38

5-38

5-38

5-39

5-39

5-40

Vi. IP65 series

1.

FEATURES

2.

SPECIFICATIONS

2.1 AC Spindle Motor (IP65)

2.2 AC Spindle Servo Unit (Serial Spindle)

3.

CHARACTERISTIC

4.

EXTERNAL DIMENSIONS

4.1

4.2 lP65 1.5S/8000 8100, B190

4.3

4.4 IP65 3S/6000 8100, Bl90

LOADMETER

5.

6.

ORDER SPECIFICATION DWG NO.

VII. AC SPINDLE SERVO UNIT SERIAL INTERFACE S series

IP65 lS/8000 8100,819O

lP652S/8000 8100, 8190

......................................................

.................................................

........................................

..............................

................................................

...........................................

.......................................

......................................

.......................................

.......................................

....................................................

....................................

6-1

6 - 2

6-2

6 - 3

6 - 4

6 - 6

6-6

6-6

6-7

6-7

6-8

6 - 9

.

1.

GENERAL _.._....._...._........_._............................. 7-1

2. FEATURES . . . . . . . . . . . . . . . . .._...................................

7-2

Page 13

3. CONFIGURAJIONANDORDER DRAWING NUMBER

ModeisIS-40s

3.1

3.2 Order Drawing Number

.............................................

.........................................

.......................

7-4

7-4

7 - 5

4. SPECLFICATIONS AND FUNCTIONS

4.1

Specifications

4.2

Major Component Functions and Application

4.2.1

4.2.2

4.2.3

Spindle control unit

Fuse ...............................................

Power transformer (optional)

4.2.4 Unit adapter

4.2.5 Fan unit (This unit is an option for models 30s and 40s.)

5. INSTALLATION

5.1 Environemental Conditions

51.1

5.1.2 Humidity

5.1.3

5.1.4 Atmosphere

5.2

input Power and Grounding

5.3

Protection against Overcurrent

6. UNIT CAtORiFIC VALUE

7.

COOLING

7.1

Cooling the AC Spindle Servo Unit

7.1.1

7.1.2 Models 6s

7.1.3 Small model 15s

7.1.4

7.1.5 Models 30s and 40s

Ambient temperature

Vibration

......................................................

ModelslS-3S,smaJitype6S

Model 26S, small type 30s

................................................

..........................................

..................................................

.............................................

.............................................

..........................................

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

22s

.

....................................

.........................

.....................................

..............................

..........

..................................... 7-23

.................................... 7-23

.....................................

...................................

................................

.............................

.......................................

.......................................

...............................

.................................... 7-33

7- 9

7 - 9

7 - 12

7- 12

7- 19

7-19

7-22

7 - 22

7-23

7-23

7-23

7-23

7-23

7-25

7-26

7-27

7-27

7-27

7-27

7-27

7-28

8.

EXTERNAL DIMENSIONS AND MAINTENANCE AREA . . . . . . . . . . . . . . . . . . . . . .

8.1

External Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1.1

8.12 AC spindle servo unit models 6s - 12S, small type model 15s

8.13

8.1.4 AC spindle servo unit models 1% - 22S, 26S, small type model 30s

8.1.5

8.1.6

8.1.7 AC spindle servo unit model 40s

AC spindle servo unit models 1 S - 3S, small type model 6s

(with an option) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

(with unit adaptor) . . _ . . . . . _ _ . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AC spindle servo unit models 6s - 12S, small type model ISS

(without unit adaptor)

(with unit adaptor) . . . _ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AC spindle servo unit models 15s - 26s. small type model 30s

(without unit adaptor) . . . . . . . . . . . . . . _ . . . . . . . . . . . . . . . . . . . . .

AC spindle servo unit model 30s

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . _ . . . . . . . . . . . . . . . _ . . _ . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

7 - 34

7-34

7-34

7-35

7 - 36

7-37

7- 38

7-39

7-39

Page 14

8-1.8 Unit adapter models 6s - 12s

(Order Spec. DWG No.: A06B-6059-K031

8.1.9 Unit adapter small type model 15s

(Order Spec. DWG No.: A06B-6059.K033

8.1 .lO Unit adapter models 15s - 22s

(Order Spec. DWG No.: AO6B-60590K032)

8.1 .l 1 Unit adapter model 26S, small type model 305

(Order Spec. DWG No.: A06B-6059-K038)

8.1.12 Power transformer for models 1 S - 3s

(Order Spec. DWG No.: A06B-60520JOOl)

8.1 .I3 Power transformer for models 6S, 8S, small type model 6s

(Order Spec. DWG No.: AOSB-60440JOOS)

8.1 ,I 4 Power transformer for models 12s. 15S, small type model 15s

(Order Spec. DWG No.: A06B-60440J007)

8.1 .I 5 Power transformer for models l8S, 22s. 26s

(Order Spec. DWG No.: A06B-6044-JOlO)

8.1 .I 6 Power transformer for small type model 3OS, models 3OS, 40s

(Order Spec. DWG No.: A06B-60440JOE)

8.1.17 Fan unit for models 30s. 40s

(Order Spec. DWG No.: AO6B-6044-K040)

Maintenance Area

8.2

8.2.1

8.2.2 AC spindle servo unit models 6s - 125, small type model 1%

8.2.3

8.2.4 AC spindle servo unit models 15s - 22s. 26S, small type model 30s

8.2.5

8.2.6 AC spindle servo unit models 3OS, 40s

Panel Hole Machining Diagram and Mounting

8.3

8.3.1 AC spindle servo unit models 1s - 3S, small type model 6s

8.3.2

8.3.3

8.3.4

8.3.5

Cautions for Mounting

8.4

8.4.1 Cautions for mounting a unit for models 30s and 40s .............

Sealing ...................................................

8.5

8.5.1

8.5.2 AC spindle servo unit models SS - 26S, small type models ISS, 30s . .

8.5.3 AC spindle servo unit models 305, 40s

Consideration to Inlet and Outlet Ports

0.6

8.6-l AC spindle servo unit models 1s - 3S, small type model 6s ........

AC spindle servo unit models 1S - 3S, small type model 6s

(with an optional PCB)

(with unit adapter)

AC spindle servo unit models 6s - 12S, small type model 1%

(without unit adapter)

(with unit adapter)

AC spindle servo unit models 15s - 26S, small type model 30s

(without unit adapter)

AC spindle servo unit models 6s - 12S, small type model 15s

AC spindle servo unit models 15s - 26S, small type model 30s

AC spindle servo unit model 30s (with fan unit)

AC spindle servo unit model 40s (with fan unit)

AC spindle servo unit models 1 S - 3S, small type model 6s

............................................

...................................

......................................

....................................

......................................

....................................

.........................................

.............................

....................

....................

......................

.....................

.....................

.....................

.....................

....................

.......................

........................

.................

.................

.......................

........

......

........

.....

7-40

7-41

7-42

7-43

7-44

7-45

7-46

7-47

7-48

7-49

7-50

7-50

7-51

7-52

7-53

7-54

7-55

7-56

7-56

7-57

7-58

7-59

7-60

7-61

7-61

7-61

7-61

7-61

7-61

7 - 63

7-63

Page 15

9. CONNECTlON

Connection Diagram

9.1

9.1.1

9.1.2 Motor models IS . 3S, small type model 6s ...................

9.1.3

9.1.4 Motor models 3OS, 40s

9.1.5 Connection between the CNC and AC spindfe servo unit ..........

Cable Routing

9.2

9.2.1 Cable routing diagram of models 1s

9.2.2

9.2.3

9.2.4 Cable routing diagram of models 3OS, 40s ....................

Detailed Connection Diagram ....................................

9.3

9.3.1

9.3.2

9.3.3

9.3.4 Connection diagram of AC spindle servo unit and fan unit

9.3.5

Cable ....................................................

9.4

9.4.1

9.4.2 Cable length

...................................................

..........................................

Motor model 0.5s (Amplifier model IS)

Motor models 6s - 26S, small type model 15S, small type model 30s . 7 - 65

.......................

..................................

..............................................

7- 64

7 - 64

7-64

7-64

7-65

7 - 66

7-67

. 3S, small type model 6s ...... 7 - 67

Cable routing diagram of models 6s . 12S, small type model 1 SS .... 7 - 68

Cable routing diagram of models 1% . 26S, small type model 305 ... 7 - 69

7 - 70

7-71

Connection of power source

Connection of AC spindle servo unit and magnetics cabinet ........ 7 - 73

Connecting AC spindle servo unit with unit adapter

...............................

7- 71

(models 6S . 26S, small type model I%, small type model 30s) ..... 7 - 74

(Models 3OS, 40s)

Connection of AC spindle servo unit and AC spindle motor .........

Details of cable K4

.....................................

..................................... 7-79

..........................................

7-75

7-76

7-79

7-81

10. INTERFACE SIGNALS

10.1 Emergency Stop Signals (ESP1 ,ESP2) -Contact Input Signal-

10.2 Signals for Checking the Contact of the Magnetic Contactor

in the Spindle Amplifier (VIN, PC24V, and PCOV) for models 1s to 26s

10.3 Spindle Control Signals

10.3.1 First spindle control DI signal (PMC to CNC)

10.3.2 Second spindle 01 signal (PMC to CNC)

1 O-3.3 First spindle control DO signals (CNC to PMC)

10.3.4 Second spindle control DO signals (CNC to PMC)

10.4 Detailed Explanation of Spindle Control Signal

10.4.1 Torque restriction command signal (TLMLA, TLMHA) .............

10.4.2 Forward rotation command signal (SFRA)

10.4-3 Reverse rotation command signal (SRVA) .....................

10.4.4

10.4.5 Alarm reset signal (ARSTA)

10.4.6 Emergency stop signal (‘ESPA)

10.4.7 Spindle alarm signal (ALMA)

10.4.8 Zero-speed detecting signal (SSTA)

10.4.9

10.4.10 Speed arrival signal (SARA)

10.4-l 1 Load detection siqnal (LDTlA, LDT2A)

10.4.12 Soft start stop cancel signal (SOCAN) .......................

Machine ready signal (MRDYA)

Speed detecting signal (SDTA)

.............................................

........................................

......................

........................ 7-94

.....................

............................

............................... 7-97

............................

...............................

.........................

............................

..............................

.......................

...........

......

...................

.................

............... 7 - 91

7-82

7-82

7-83

7-84

7-85

7-86

7 - 90

7-94

7-95

7-95

7-96

7-98

7- 98

7-99

7 - 100

7-101

7-103

7-104

Page 16

10.4.13 Signal for controlling velocity integration (INTGA)

10.4.14 Spindle override command (function) with analog input voltage (OVRA)

10.4.15Motor power off signal (MPOF)

Speed Indication Voltage Signal (SM, OM)

10.5

Load indication Voltage (LM, OM)

10.6

VXII. AC SPINDLE SERVO UNIT HV series

............................

......................... 7- 108

...............................

............... 7 - 105

7 - 105

7-107

7- 109

1. GENERAL .......................................................

2. FEATURES ......................................................

3. SPECIFICATIONS

4. CONFIGURATION AND ORDER SPECIFICATIONS

4.1 Configuration

Order Specifications

4.2

5. INSTALLATION

Ambient Temperature

5.1

Humidity ...................................................

5.2

Vibration

5.3

Atmosphere

5.4

6. COOLING .......................................................

7. EXTERNAL DIMENSIONS AND SERVICE CLEARANCE

External Dimensions

7.1

7.1.1

7.1.2 AC spindle servo unit model 60HV

Fan Unit

7.2

7.2.1 For model 30HW40HV (specification number: A06B-6044-K040)

7.2.2 For model 60HV (specification number: A06B-6065-K301

Maintenance Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3

Panel Holes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.4

.................................................

................................................

...........................................

...................................................

..........................................

...................................................

.................................................

...........................................

AC spindle servo unit model 30HW40HV

...........................

..................................................

.........................

......................

.......................

8-1

8-l

8-2

8-3

8 - 3

8 - 4

8-5

8 - 5

8-5

8 - 5

8-5

8-6

8 - 9

8 - 9

8-9

8 - 9

8-10

..... 8 - 10

......... 8-11

.......... 8-12

..........

8-13

8. CONNECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connection Diagram (without High-Resolution Magnetic Sensor Pulse Coder)

8.1

8.1.1

8.1.2 AC spindle servo unit model 60HV . . . _ . . . . . . . . . . . . . . . . . . . . . .

Detailed Connection Diagram . . . . . . . . . . . . . . . . _ . . . . . . . . . . . . . . . . . . .

8.2

Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3

9. CAUTION IN USE

Unit Structure

9.1

Installing the Unit

9.2

AC spindle servo unit model 3OHW4OHV . . . . . . . . . . . . _ . . . . . . . _ . 8- 14

................................................

...............................................

............................................

. . . - . . . . .

8-14

. 8-14

8-14

8- 15

8-17

8-18

8-18

8- 18

Page 17

Sealing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .._.................

9-3

IX. POSITION CODER METHOD SPINDLE ORIENTATION

8-18

1. GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..-................

2. FEATURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3. CONFIGURATION AND ORDER DRAWING NUMBER

3.1

3.2

3.3

4. SPECIFICATIONS

5. CONNECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6. SIGNAL EXPLANATION

6.1

6.2

6.3

6.4 When Stop Position External Setting Type

6.5

Orientation Using Position Coder

Orientation Using Built-in Sensor

Order Drawing Number

3.3.1

3.3.2

Position coder

Spindle orientation function software (optional CNC software)

.........................................

.........................................

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I . . . . . .

.............................................

Spindle Control Signals

6.1.1

6.1.2 DO signals (CNC to PMC)

Details of Signals

6.2.1 Orientation (fixed position stop) command (ORCMA)

6.2.2 Orientation (fixed position stop) completion signal (ORARA)

6.2.3 Gear/clutch signal (CTHl A, CTH2A)

6.2.4 Command for changing the stop position in spindle orientation (INDXA)

6.2.5 Direction command for the shorter route when the stop position

6.2.6 Command specifying the direction of rotation when the stop position

6.2.7 Spindle orientation command in which the stop position is specified

Sequences

6.3.1

6.3.2 Orientation command during high-speed rotation

Spindle Orientation Function is Used

Using the Spindle Orientation Function

with the incremental Command Set Externally (Spindle Speed Control)

6.5.1

6.52 System configurations

6.5.3 Control sequence

6.5.4

6.5.5 Parameters

DI signals (PMC to CNC)

changes in spindle orientation (NRROA)

changes in spindle orientation (ROTAA)

externally (SflAl 1 to SHAOO)

................................................

Orientation command while stopping

General .............................................

PMC signals (Dl,iDO signals)

.........................................

.............................................

......................................

...........................................

..................................

..................................

..................................

.................................

...............................

..............................

...................................

..............................

.......................

........ 9 - 3

.............. 9 - 6

......... 9 - 7

..........................

.......................

.......................

.........................

................ 9 - I 0

......

9-1

9-1

9-2

g-2

9 - 2

S-3

9 - 3

9 -4

9-5

9 - 6

9 - 6

9-6

9-6

9 - 6

9 - 8

. 9 - 8

9 - 9

9- 9

9 - 9

9-10

9 - I 0

9- 71

9- 12

9-12

9- 13

9- 14

9-16

9- 10

Page 18

Page 19

6.3.1

6.3.2 Orientation command during high-speed rotation

Parameter Setting for the MS Signal Gain through Magnetizing Element

6.4

6.5

Parameter Setting for the MS Signal Constant

Orientation command while stopping

........................

......................

...............

....

IO-10

IO-10

10-11

IO-12

7. MAGNETIC SENSOR

Electrical Specifications

7.1

External View

7.2

Magnetic Sensor Mounting Method

7.3

Cautions on Installation

7.4

8. TWO-MAGNETIC SENSOR ORIENTATION

Configuration ..............................................

8.1

Change-over Circuit

8.2

8.2.1 Selection signal of magnetic sensor (SB signal) ...............

8.2.2 Signal change-over relay

Fine Adjustment of Stop Position

8.3

XI. SPINDLE ORIENTATION WITH I-REVOLUTION SIGNAL SWITCH

I. GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. SYSTEM CONFIGURATION

3. SPECIFICATIONS

.............................................

.......................................

..............................................

..............................

.......................................

.............................

.........................................

................................

................................

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IO-13

IO-13

IO-14

IO-20

lo-23

lo-27

IO-27

lo-28

IO-28

IO-28

IO-30

11-l

11-2

11-3

4. CONTROL SEQUENCE

5. PMC SIGNAL (DVDO SIGNAL)

6. PARAMETERS

7. CABLE CONNECTION

Connection Diagram

7.1

Pin Assignment of Each Cable

7.2

Details of TB 1 (For External Reference Switch)

7.3

8. SPECIFICATIONS OF REFERENCE SWITCH . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9. SETTING PINS (St-i8 TO 10)

SH8 (Selection of Reference Signal)

9.1

SH9, 10 (Selection of Reference Signal Edge)

9.2

10. MOUNTING DIAGRAM OF SETTING PINS, CHECK PINS AND

VARIABLE RESISTORS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 - 19

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

............................................

.........................................

..................................

......................

.......................................

.............................

......................

11-5

11 -6

11 -8

ll- 10

II- 10

11-11

11- 12

11-13

11-14

ll- 14

11-14

Page 20

11. NOTES

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . ..-.....

XII. BUILT-IN SENSOR SIGNAL CC?NVERSlON CIRCUIT

. . .

II-20

1. GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..o...............

2. FEATURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3. CONFIGURATION

3.1 Example of Configuration

3.1.1 Separate signal conversion circuit

3.1.2 Signal conversion circuit mounted in the unit

3.2 Order Drawing Numbers

3.2.1 Signal conversion circuits

3.2.2 Amplifiers for which the built-in signal conversion circuit can be used . .

4. SPECIFICATIONS

4.1

Compatibility with Conventional Specifications

(Compatibility Provided by Setting Pins SH6 and SH7) . . . . . . . . . . . . . . . . . .

4.2

Position Coder Output Signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.1

4.2.2 Output signal specifications of position coder

4.2.3

4.3 Input Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4

Maximum Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ambient Temperature

4.5

................................................

.......................................

...........................

...................

.......................................

.................................

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Number of detector pulses and number of

position coder signal output pulses

(connector CN2 signal) - at constant speed of 1500 min - 1

Output circuit configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . 12 - 7

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12-l

12-2

12-3

12-3

12 - 3

12 - 3

12 - 4

12-4

12 - 5

12 - 6

12 - 6

12-6

12-6

12-7

12-7

12-8

12-8

5. EXTERNAL DIMENSIONS

5.1 Separate Type

5.2 Unit Mounting Type

6. CABLE ROUTING DIAGRAM

6.1

SeparateType

6.2

Unit Mounting Type

7. EXAMPLE OF INSTALLATION

7.1 Separate Type

7.2 Unit Mounting Type

8. CONNECTION

8.1 Block Diagram

8.1.1

8.1.2

Details of Connections between Units

8.2

..................................................

Separate type

Unit mounting type

..............................................

.............................................

.............................................

.............................................

..........................................

..........................................

.......................................

.........................................

......................................

.........................................

........................................

....................................

.............................

12-9

12-9

12-9

12-10

12- 10

12- 10

12- 11

12-11

12-11

12- 12

12- 12

12- 12

12- 13

12- 14

Page 21

8.2.1 Built-in sensor and connector (motor) (cable symbol: KlO) . . . . . . . .

8.22 Motor and built-in sensor signal conversion circuit

(cable symbol: Kll) . . . . . . . . . . . _ . . ‘I . . . . . . . . . . . . . . . . . . . . .

8.2.3 Motor model 0.5s and built-in sensor signal conversion circuit

(cable symbol: K4) _ . . . . _ . . . . _ . . . . . . . . . _ . . . . . . . . . . . . . . .

8.24 BuiJt-in sensor signal conversion circuit and serial interface series

spindle servo unit . . . . . . . . . . . . . . . . . . . _ . . . . . . . . . . . . . . . . .

120 14

12- 15

120 19

12-21

9. CABLES

9.1

9.2

lo.CAUTlONStNUSE

XIII. HIGH RESOLUTION MAGNETIC PULSE CODER

1. GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. SYSTEM CONFIGURATION

2.1

2.2 Built-in Spindle Motor

3. SPECIFICATION METHOD

3.1

3.2

4. SPECIFICATION

5.

CONNECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . _ . . . . . . . . . . . . . . . . . . . . . . . .

5.1

5.2

5.3

5.4

......................................................

Details of the Cable (KlO)

Cable (Kll) Length

. . . . . . . . . . . . . . . . . . . . . . . _ . . . . . . . . . . . . . . . . . . . . . .

.....................................

..........................................

.........................................

Motor and Spindle Linked Belt or Similar Device

......................

.........................................

..........................................

Sensor

Detection Circuit

Connection Diagram

Connection Diagram of the AC Spindle Servo Unit and AC Spindle Motor

Cable Details

Cable Routing Diagrams

...................................................

.............................................

. .._.................... . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . _ . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . _ . . . . _ . . . . . . . . . . . . . . . . . . . .

. . . .

12-24

12-25

12-26

12-28

13-l

13-2

13-2

13-2

13-3

13-3

13-3

13-4

13-5

13-5

13 - 7

13-8

13- 10

6. DIMENSIONS

6.1 External Sensor Dimensions

6.1.1

6.1.2 Dimensions of sensors A860-0382-Tl23, Tl43

6.1.3 Dimensions of sensors A860-0382-Ti 24, T144

6.1.4

6.2 Sensor Circuit Dimensions

7. CHECKING OUTPUT WAVEFORM AND ADJUSTING THE PREAMPLIFIER

7.1

Spindle Sensor Preamplitier Adjustment Method

7.2 Spindle Motor Built-in Sensor

. . . . . . . . . . . . . . . . . . . . . . . . . _ _ . . . . _ . . . . . . . . . . . . . . . . . .

. _ . . . . . . . . . . . . . . _ . . . . . . . . . . . . . . . . . .

Dimensions of sensors A860-0382-T12 1, TI 4 1

External preamplifier dimensions . . . . . . _ . _ _ _ . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

. . . . . . . . . . _ _ . . . . . . . . . . . . . . . . . . . . . . . .

.....................

...................................

......

13- 14

13- 14

13- 14

130 15

13- 17

13- 19

13-20

13 - 21

13-22

13-26

Page 22

8. SENSOR AND PREAMPLlFiER Fl7TlNG DIAGRAMS

. . . . . . . . . . . . . . . . . . . . . .

13-27

9. SENSOR FITTING PROCEDURE

XIV. HIGH-RESOLUTION POSITION CODER

1. GENERAL . . . . . . . . . . . .._....._._........-.......................

2. FEATURES ..-.........r.....rr...........o.....................

3. SYSTEM CONFIGURATION .........................................

Configuration

3.1

Order Drawing Number ........................................

3.2

3.2.1 High-resolution position coder

3.2.2 Detection circuit for the high-resolution position coder

4. SPECIFICATIONS

Electrical Specifications of High-resolution Position Coder System

4.1

Mechanical Specifications of High-resolution Position Coder

4.2

Environmental Conditions

4.3

5. CONNECTION ...................................................

Connection Diagram

5.1

Details of Cable K9

5.2

Cable Routing Diagram

5.3

...............................................

................................................

...........................................

.................................

. _ _ _ . . . . . _ . . . . . . . . . . . . . . . . . . . . _ . . . . . 13-28

..............................

...................................... 14-5

........................................

............

..........

..............

1 .........

14- 1

14-l

14-2

14-2

14-3

14-3

14-3

14-4

14-4

14-5

14-6

14-6

14-7

14-8

6. SHAPE ........................................................

6.1 External Dimensions of High-resolution Position Coder ..................

External Dimensions of Detection Circuit

6.2

7. INSTALLATION CONDITION AND CAUTIONS

7.1 High-resolution Position Coder

7.1.1 How to connect the position coder

7.1.2 Impact

7.1.3 Atmosphere

7.2 Detection Circuit

7.3 Checking and Adjusting the Waveform of the High-resolution Magnetic

Pulse Coder Which is Built in the AC Spindle Motor

XV. SPEED RANGE SWITCHING CONTROL

1. GENERAL . . . . . . .._..............._................~............

2. CONFIGURATION AND ORDER DRAWING NUMBER

Configuration

2.1

2.2 Order Specifications

.............................................

.........................................

............................................

...............................................

..........................................

.................................. 14-11

........................... 140 10

........................... 14-11

.........................

...................

......................

14-9

14-g

14-11

14- 12

14- 12

14- 12

14- 12

15- 1

15-2

15-2

15-2

Page 23

3. SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15-3

4. CONNECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1

Type A

4.2

Type B

4.3

Details of Connection between PMC and Switching Unit

5. INTERFACE SIGNALS

5.1

Spindle Control Signals

5.1.1

5.1.2

5.1.3

5.1.4

5.1.5 Additional information about the Gear/Clutch signal (CTHI , 2) ....... 15 - 8

5.2

Output Signal (DO signal) CNC --) PMC ...........................

5.2.1

52.2 Change completion signal (RCFNA, RCFNB) .................. 15 - 14

5.23 Speed detecting signal (SDTA, SDTB) ...................... 15-14

................................................... 15-4

...................................................

.................

.............................................

........................................

input signals (Di signals) PMC to CNC .......................

Change request signal (RSIA, RSLB)

Power-line status check signal (RCHA, RCHB)

........................

.................

High-speed characteristic side electromagnetic contactor status signal

(RCHHGA, RCHHGB)

Power-line change signal (RCHPA, RCHPB)

.

...................................

..................

6. SEQUENCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1

When the Status of both Electromagnetic Contactors for a Low-speed

Characteristic (RCHA) and for a High-speed Characteristic (RCHHGA) is

Confirmed and the Speed Range Switching Control Works . . . . . . . . c . . . . .

6.1.1 Change-operation of a low-speed characteristic --) a high-speed

characteristic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.12 Change-operation of a high-speed characteristic + a low-speed

characteristic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2

When the Speed Range Switching Control Works by Confirming

Only the Power-line Status Check Signal (RCHA) . . . . . . . . . . . . . . . . . - . . 15-17

6.2.1

6.22

Change-operation of a low-speed characteristic + a high-speed

characteristic . . . . . _ . . . . . . . _ . . . . . . . . . . . . . . . . . . . . . . . . . .

Change operation of a high speed characteristic + a low-speed

characteristic . . - . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15-4

15-4

15 - 5

15-6

15 - 6

15-6

15 - 6

15 - 7

15- 8

15- 13

15 - 13

15-15

15 - 15

l5- 15

150 16

15-17

15 18

7. ALARMS RELATED TO SPEED RANGE SWITCHING CONTROL

7.1

Speed Range Switching Control Sequence Alarm ....................

7.2

Power-line Status Abnormal Alarm ...............................

8. CAU-I-lONS IN USE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-21

XVI. SPINDLE SWITCHING CONTROL

1. GENERAL .~.~...~..._..........._..___.........................

2. FUNCTIONS .~..............._..................................

.............

15- 19

15- 19

15-19

16-l

16-2

Page 24

3. RESTRICTIONS . . . . . . . . . . . . . . . _ . . - . . _ . . . . . a . . . . . . . . . . . . . . . . . . . . .

16-3

4. CONFIGURATION AND ORDERING DRAWING NUMBERS

Configuration

4.1

Motor Assembly, Unit

4.2

Order Drawing Number

4.3

EXTERNAL DIMENSIONS OF SPINDLE SWITCHING CONTROL CIRCUIT

5.

Models 6S-22s .............................................

5.1

External Figure of Spindle Switching Control Circuit

5.2

CONNECTION

6.

Connecting Diagram

6.1

6.1.2 Velocity feedback signal and position coder signal

6.1.3 Switching for velocity feedback signal and magnetic sensor signal

Details of Connections for the PMC and Switching Unit ................

6.2

Connector ................................................

6.3

7. PARAMETERS .................................................

Automatic Setting Method of 1 Spindle Parameter

7.1

Parameters Related to the Spindle Switching Control Function

7.2

Changing Parameters

7.3

...............................................

.........................................

........................................

....................

...................................................

..........................................

....................

........................................

..................

..............

........ 16 - 7

...

...........

76-5

16-5

16-5

16 - 6

16-7

16 - 7

16-8

I 6 - 8

16-10

160 12

16-14

16-16

16-17

16-17

160 18

160 19

SPINDLE CONTROL SIGNALS

8.

input Signals (DI Signals) PMC to CNC

8.1

8.1 .l Change request signal (SPSiA, SPSLB)

8.1.2 Power-line status check signal (MCFNA, MCFNB)

8.1.3 Main spindle side electromagnetic contactor status signal

(MFNHGA, MFNHGB)

Output Signal (DO signal) CNC + PMC

8.2

8.2.1

8.2.2 Change completion signal (CFINA, CFINB)

8.2.3 Speed zero signal (SSTA, SSTB)

9. SEQUENCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

When the Status of Both Electromagnetic Contactors for the Sub Spindle

9.1

(MCFNA) and for the Main Spindle (MFNHGA) is Confirmed on the Spindle

Side and the Spindle Selector Control Works . . . . . . . . . . . . . . . . . . . . . . .

When the Spindle Selector Control Works by Confirming Only the Power-line

9.2

Status Check Signal (MCFNA) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

lo. ALARM RELATED TO SPINDLE SELECTOR CONTROL

10.1 Spindle Selector Control Sequence Alarm

10.2 Power-line Status Abnormal Alarm

Power-line change signal (CHPA, CHPB)

......................................

...........................

.....................

..............

.................................

..........................

.....................

...................

..........................

....................

..........................

...............................

16-22

16-22

16 -22

16-23

16 - 23

16-24

16-24

16-25

16-25

16-26

16-26

16-27

16-28

16-28

16-28

11. CAUTIONS IN USE

. . . . . . . _. . . . . . . . . . . . . . -. . . . . . . . . . . . . . . _. . . . _. .

16-30

Page 25

Page 26

5. INPUT/OUTPUT SIGNAL EXPLANATION

Signal Dl (PMC -+ CNC)

5.1

The Remarks Concerning Differential Speed Control Function

5.2

Serial Spindle Parameter Related to Differential Speed Control Function

5.3

Example of Sequence of Differential Speed Rigid Tap

5.4

6. POSITION CODER SIGNAL INPUT CIRCUIT (OPTION) EXTERNAL DRAWING . . . . 18 - 8

.......................................

................................

18-4

18-4

.............

18-4

..... I 8 - 5

.................. 18 - 7

7. CONNECTION

Cable Withdrawing Figure

7.1

Connection Chart

7.2

8. CONNECTION DETAIL DRAWING

Cable Sign Kl4

8.1

...................................................

......................................

...........................................

. . . . . . . . . . _ . . . . . . . . . . . . . . . . . . . . . . . .

: Spindle 1 Position Coder to Position Coder Signal Input Circuit

: Spindle 2 Position Coder to AC Spindle Servo Unit

Cable Sign K15 : Output of Position Coder Signal input Circuit

8.2

g. JUMPEREXPLANATION

Jumper Position

9.1

9.1.1 P.C.B edition No.OlA

9.1.2 P.C.B edition No.02A and later

Setting

9.2

APPENDIX

APPENDIX 1 CABLE SPECIFICATIONS . . . . . . . . . . _ . . . . . _ _ . . . . . . . . . . . . . . . . .

...................................................

..........................................

............................................

...................................

............................

. . . . . . . . . . . . _ . . . . .

. . . . . . . . . . .

18-9

18 - 9

18-10

18-11

18-11

18 - 11

18-12

180 12

18-12

180 12

18-12

Al - I

APPENDIX 2 TECHNICAL DATA

2.1 How to Obtain Load Inertia Reflected to Motor Shaft

2.2 LoadTorque

2.3 Spindle Speed Change Gear Stages

2.4 Determining the Acceleration Time

2.5 Cutting Amount of Machine

2.6 Constant Surface Speed Control

2.7 Tapping

2.8

How to Find Allowable Duty Cycle

2.9 The Calculating Method of the Orientation Time

APPENDIX 3 SERIAL SPINDLE START- UP PROCEDURE

START - UP PROCEDURE FOR NORMAL OPERATION

1.

Start - up Procedure for Normal Operation (Flowchart)

I .I

Parameters for Normal Star-t of the Serial Spindle

1.2

1.2.1 Parameters for the serial spindle system

1.2.2 Parameters for automatic parameter settq

................................................

...................................................

........................................

...............................

.................................

......................................

.................................

................................ A2 - 23

A& I

....................

A2 - I

A.24

142 - 4

A2 - 5

M-7

A242

A247

...................... A2 - 25

.....................

A3 - I

................. A3 - 1

...............

...................

....................

..................

A3-1

A3-2

A3-2

A3-2

Page 27

I-2.3 Parameters related to the spindle speed command . . . . . . . . . . . . .

1.2.4 Parameters related to the detector

1.25 Outline of serial spindle speed command processing

Cs CONTOUR CONTROL FUNCTION START- UP PROCEDURE

2.

. . . . . . . . . . . . . . . . . . . . . . . .

2.1 Start - up Procedure of the Cs Contour Control Function (Flowchart)

01 and DO Signals for Cs Contour Control

2.2

2.2.1 DI signal (PMC+CNC)

2.2.2 DO signal (CNC+PMC)

2.3 Sample Sequence in the Cs Contour Control Mode

2.4 Cs Contour Control Parameters

2.5 Diagnosis

2.6 Adjustment Procedure in the Cs Contour Control Mode

2.6.1 Adjustment in reference position return operation.

2.6.2 Direction of spindle rotation in the Cs contour control mode

..............................................

(parameter No.6500#1)

................................

...............................

..............................

...............................

.......................

................

2.6.3 Setting the position gain in the Cs contour control mode

2.6.4 Rapid traverse time constant for the Cs contour control axis

(No.0524)

2.6.5 Gear ratio of the spindle and motor (No.6556 to 6559)

2.6.6 Improving the rigidity during cutting operation

in the Cs contour control mode

2.6.7 Excessive error in Cs contour control mode switching

2.7 Additional Description of Series OC in the Cs Contour Control Mode

2.7.1 Axis arrangement in the Cs contour control mode

2.7.2 Gear selection signals (CTHl A, CTH2A)

2.7.3 Position gain in the Cs contour control mode

2.7.4 Return to the reference position in the Cs contour control mode

2.7.5 Others

2.7.6 Alarm

Additional Description of Series 15

2.8

2.8.1 Axis arrangement in the Cs contour control mode

2.8.2 Gear seiection signals and position gain

in the Cs contour control mode

2.8.3 Automatic position gain setting when switching between

the spindle rotation control mode and Cs contour control mode

2.8.4 Return to the reference position in the Cs contour control mode

2.8.5 Others

2.9 Method of Calculating a Cutting Load Variation in Cs Contour Control

2.9.1 Outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . _.

2.9.2 E3lock diagram indicating the method of calculating

a cutting variation

2.9.3 Example of calculating a load torque

2.9.4 Example of calculating a cutting variation

2.10 Velocity Loop Control Gain

2.10.lOutiine

2.10.2 Control block diagram

.........................................

..........................

...................

................

...........................................

............................................

............................

..........................

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

...................................

......................

...................

.................................

...........................................

................................

A3 - 3

A3 - 4

........... A3 - 5

......... A3 - I I

.... A3 - I I

A3- 12

A3-12

A3- 12

A3 - 13

A3 - 14

A3-15

............. A3 - 16

............. A3 - 16

A3 - 16

........ A3 - 16

A3- 17

......... A3 - 17

A3- 17

.......... A3 - I 8

.... A3 - I 8

............. A3 - I 8

A3 - I 8

A3 - I 9

. . A3 - 20

A3-22

A3-22

A3-23

............. A3 - 23

A3-23

. . .

A3-25

. . A3 - 25

A3-27

. . . A3 - 28

A3-28

A3-29

A3 - 30

A3 - 31

A3-33

A3-33

A3-33

Page 28

2.10.3Notes ............................................

START- UP PROCEDURE FOR SPINDLE SYNCHRONIZATION CONTROL

3.

Start - up Procedure for Spindle Synchronization Control ............

3.1

3.2 DL'DO Signals Used for Spindle Synchronization Control .............

3.2.1 Explanation of spindle synchronization control ...............

3.2.2 Dl signals (PMC to CNC)

3.2.3 DO signals (CNC to PMC)

3.24 Sample sequence in spindle synchronization control ...........

Parameters Used for Spindle Synchronization Control

3.3

(Upper Row: First Spindle, Lower Row: Second Spindle) ...........

Diagnosis

3.4

..............................................

..............................

.............................

3.5 Additional Explanations of the Parameters Used

for Spindle Synchronization Control

...........................

3.5.1 Error pulse in spindle synchronization control ................

3.5.2 Automatic detection of the signal indicating a rotation

when spindle synchronization control mode is changed l . . . - . . . - A3-47

3.5.3 Determining the shift (parameter) in synchronous

control of spindle phase . . . . . . . . . _ . . . . . . . . . . . . . . . . . . . . . A3-48

3.5.4 Function for detecting an abnormal position coder signal

and for issuing alarm AL-47

Additional Explanations of the Function of Spindle Synchronization

3.6

Control, Series OTC

3.6.1 Alarm

............................................

......................................

........................... A3-48

3.7 Additional Explanations of the Function of Spindle Synchronization

Control, Series OTTC

3.7.1 Alarm

Additional Explanations of the Function of

3.8

Spindle Synchronization Control, Series I 5TT

3.8.1 Sequence state in spindle synchronization control

4. SPINDLE ORIENTATION FUNCTION IN SPINDLE SYNCHRONIZATION

CONTROL

4.1

4.2

4.3

4.4 PMC Signals (DVDO Signals)

4.5

5. SERIAL SPINDLE RIGID TAPPING TECHNICAL MANUAL

5.1 Outlines ...............................................

5.2 System Configuration

5.3

..................................................

Outline ................................................

Example of System Configuration

Example of Control Sequence

Setting Parameters

5.2.1 Classification by the detector

52.2 Classification by the CNC Series

Rigid Tapping Sequence (PMC Ladder Program)

5.3.1 Outline

5.3.2 Sequence

5.3.3 DVDO signals relating to rigid tapplnq

53.4 Gear signal of Series OClI6f18

............................................

...........................................

.....................................

....................

............ A3 - 54

.............................

...............................

................................

.......................................

................ A3- 66

.....................................

...........................

.........................

..................

.........................................

.....................

..........................

A3-35

. A3 - 36

A3 - 36

A3 - 37

A3 - 37

A3-38

A3-39

A3 - 42

A3 - 45

A3-46

A3 - 47

A3 - 47

A3 -49

A3-50

A3-51

A3-52

A3 - 53

A3-55

A3-55

A3-56

A3-56

A3-61

A3-63

A3-66

A3-66

A3-66

A3-67

A3 - 69

A3-69

A3-69

A3-70

A3-72

Page 29

5.3.5 Rigid tapping by the second spindle of Turning system of

Series OC/16/18. (The multi -

5.4 Parameter Setting

Parameter setting procedure

5.4.1

5.42 Set the parameter r Position coder signal is used 1 (= I) ...... A3 - 74

5.4.3 Set the parameter

r Rotation direction of the motor and the spindle J

........................................ A3-73

5.4.4 Set the parameter I Attached direction of the position coder 1 ...

5.45 Parameter setting relating to the system

in which the position coder is used.

54.6 Parameter setting relating to the system in which the motor

with the built - in sensor (including the built - in motor) is used. ...

54.7 Parameter setting of

r Gear ratio between the spindle and the motor 1

5.4.8 Parameter setting of r Position gain 1

5.4.9 Parameter setting of r Acceferation/Deceleration time constant 1

and r Spindle maximum speed at rigid tapping 1

5.4.10 Parameter setting relating to the motor voltage.

5.4.11 % Spindle backlashj

5.5 Rigid Tapping Parameter Table

Operation Check

5.6

5.6.1 Check of the position error value of the spindle at rigid tapping. ...

56.2 Check the spindle motor velocity error during the rigid tapping. ... A3 - 97

Diagnosis

5.7

5.8 Alarm ................................................

5.8.1 Program error (P/S alarm)

5.8.2 Servo alarm

6. SERIAL SPINDLE RIGID TAPPING TECHNICAL MANUAL (N0.2)

The Outline of the Rigid Tapping

6.1

Rigid Tapping Adjusting Method of the Spindle Side.

6.2

7. ITEMS CONCERNING SPINDLE ORIENTATION WITH A POSITION CODER . A3 - log

7.1 DlandDOSignals ......................................

7.1.1 01 signals (PMC --) CNC)

7.1.2 DO signals (CNC + PMC)

7.2 Spindle Orientation Parameters (Number following #: Bit number) .....

7.3 Adjusting the Serial Spindle Orientation

7.4 Adjusting the Parameter Which Indicates the Amount of Shift of

Orientation Stop Position

.........................................

..............................................

......................................

..................................

spindle control option is needed.) ... A3 - 72

............................

...........

.......................

............

....................

............. A3 - 86

..............

................................

..............................