Page 1

FANUC Robot ARC Mate 100i MODEL B

FANUC Robot M-6i MODEL B

MAINTENANCE MANUAL

B--81545EN/01

Page 2

B--81545EN/01

A

ARCMate100i

M

MODEL

B

PREFACE

PREFACE

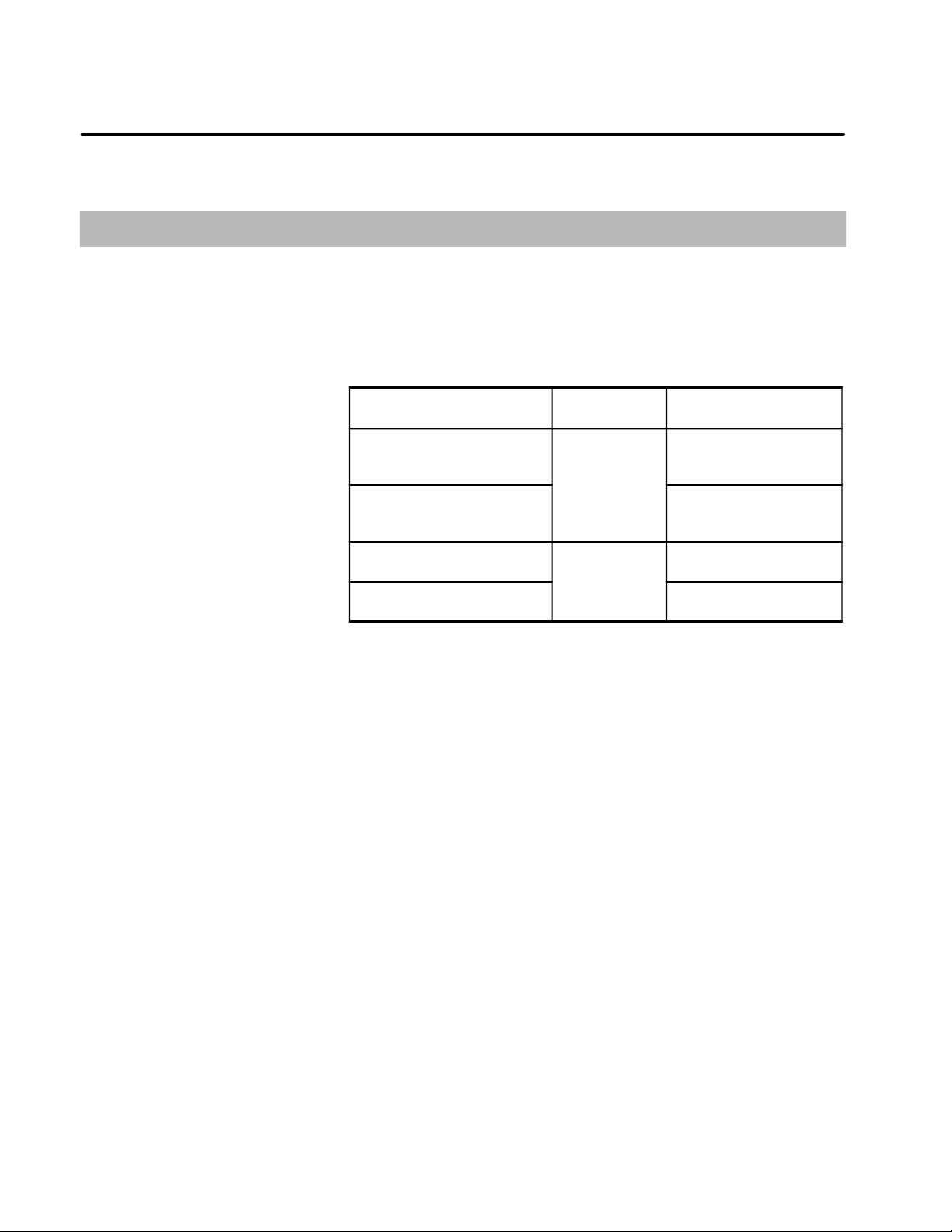

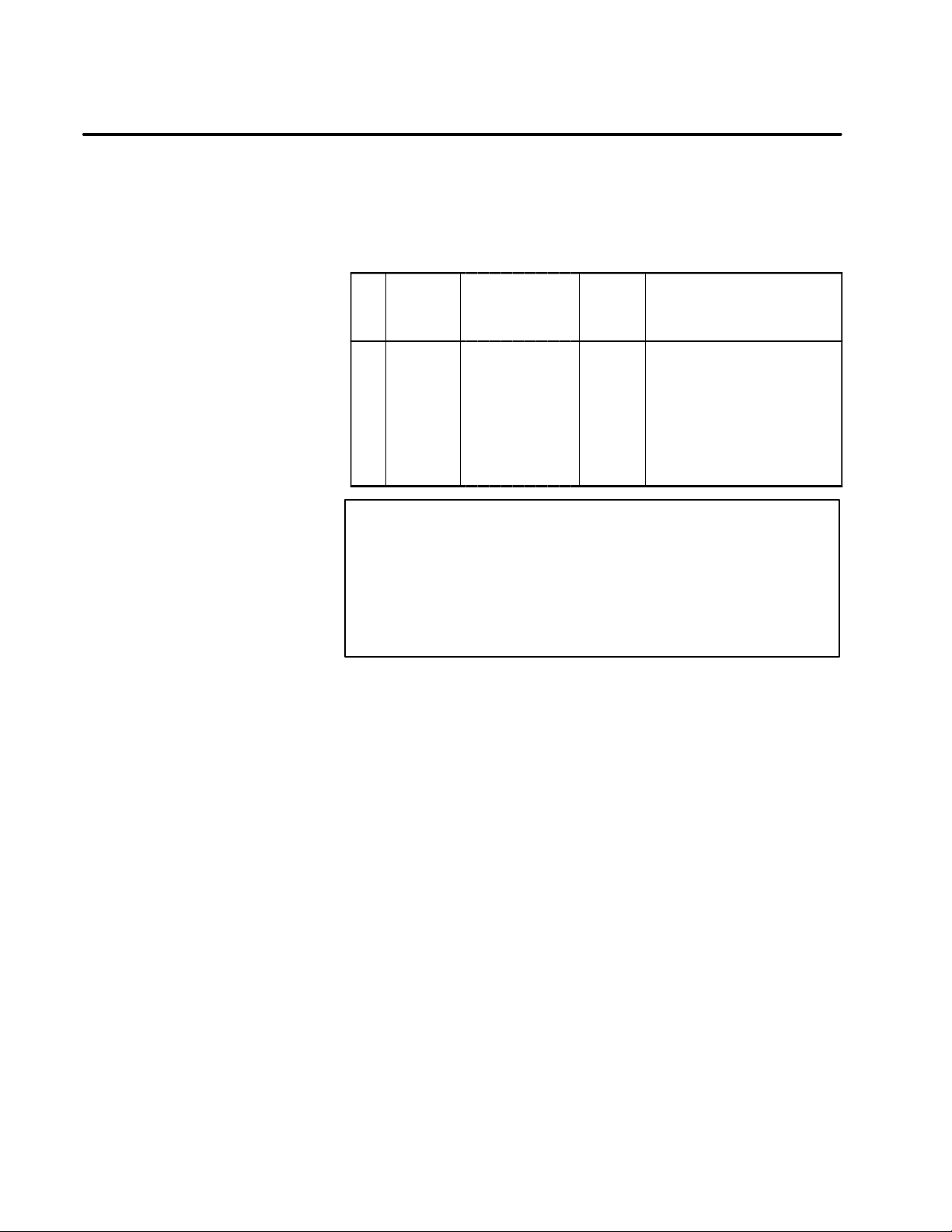

This manual explains the maintenance and connection procedures for the

mechanical units (R--J3i controller) of the following robots. Before

replacing the purts, determine thespecification number ofthe mechanical

unit.:

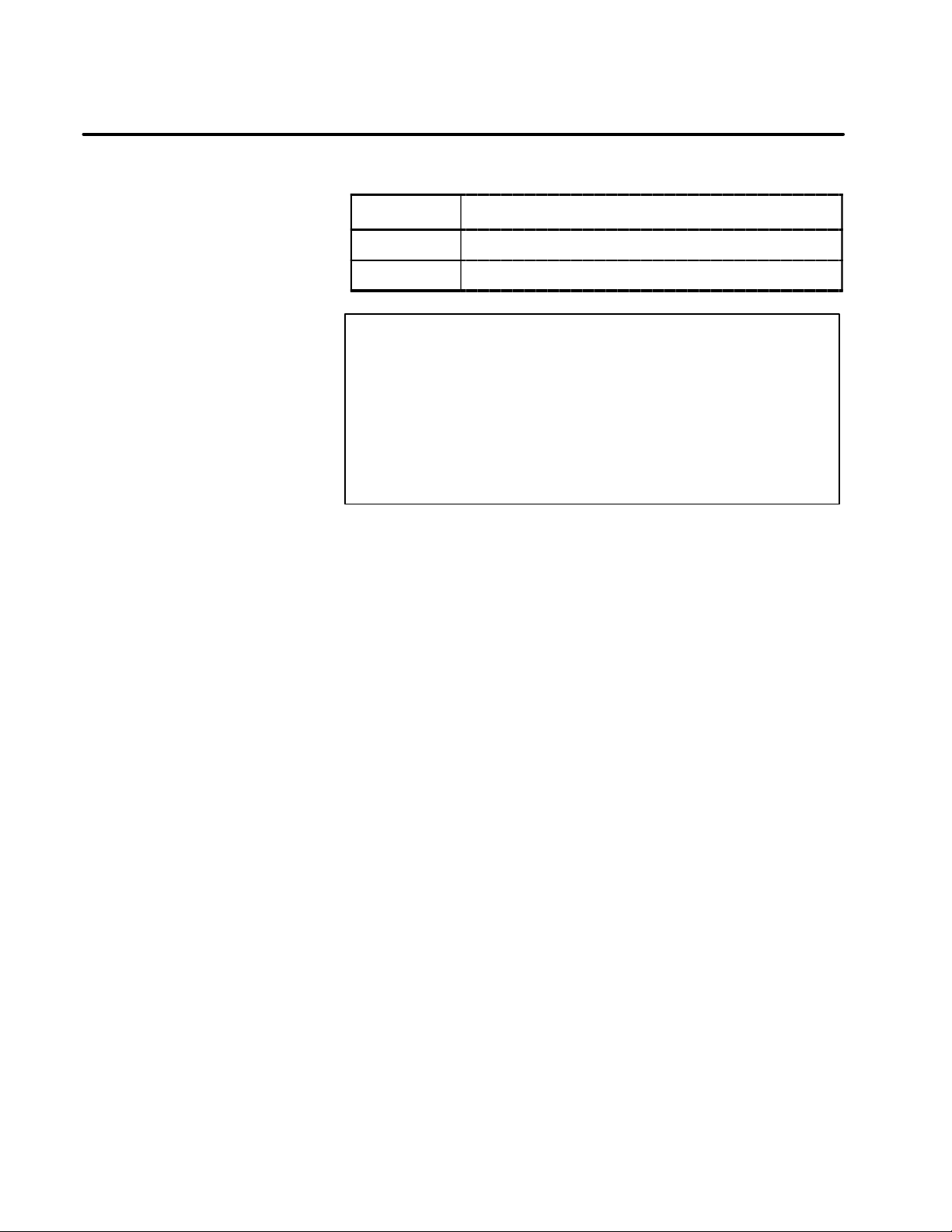

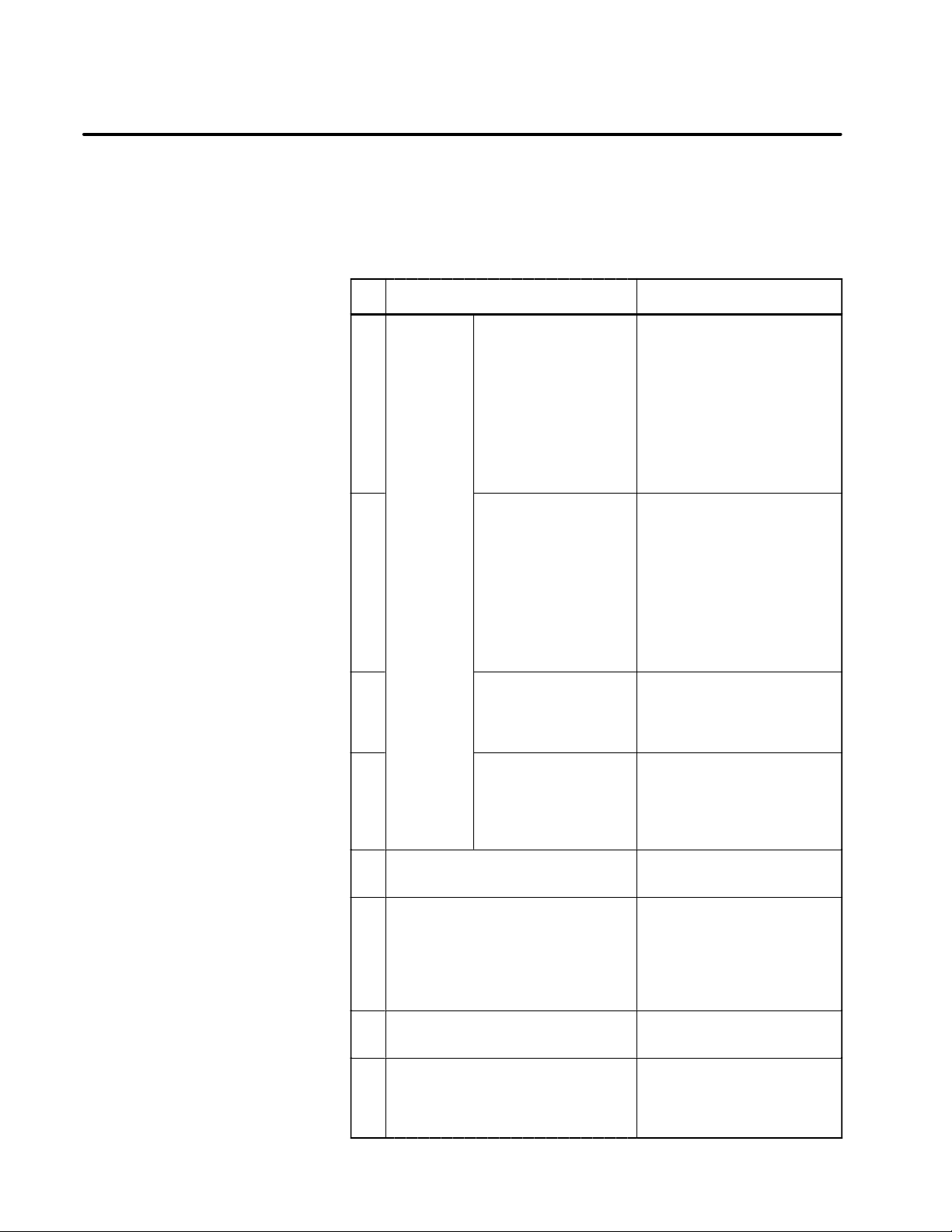

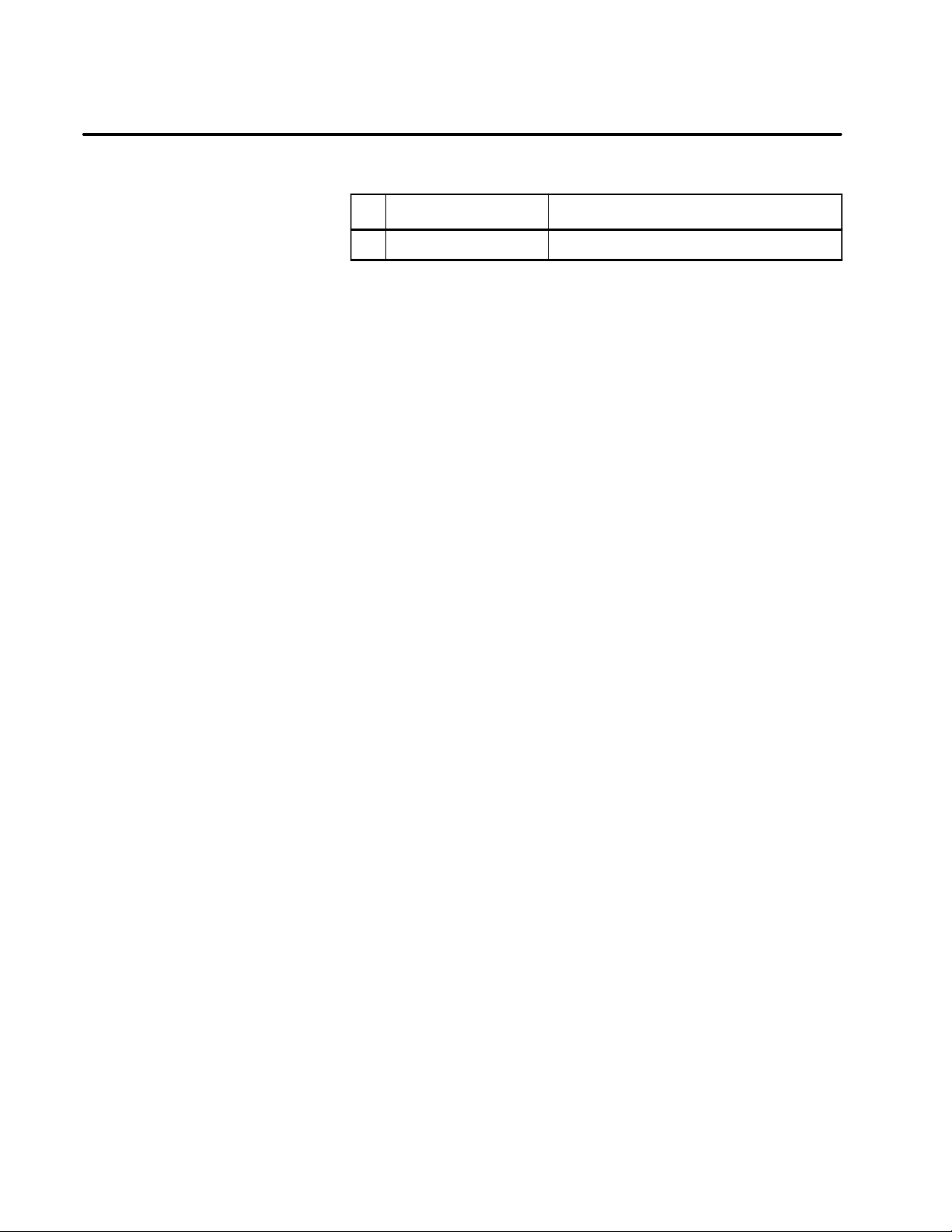

Model name Abbreviation

FANUC Robot ARC Mate 100i

MODEL B

(WithJ2 and J3--axis brake)

FANUC Robot ARC Mate 100i

MODEL B

(Withall axes brake)

FANUC Robot M--6i MODEL B

(WithJ2 and J3--axis brake)

FANUC Robot M--6i MODEL B

(Withall axes brake)

RC Mate 100i

MODEL B

--6i

Mechanical unit

specification No.

A05B--1215--B201

A05B--1215--B601

A05B--1215--B202

A05B--1215--B602

Page 3

PREFACE

LETTERS

SERIA

L

PRODUCTIO

N

B--81545EN/01

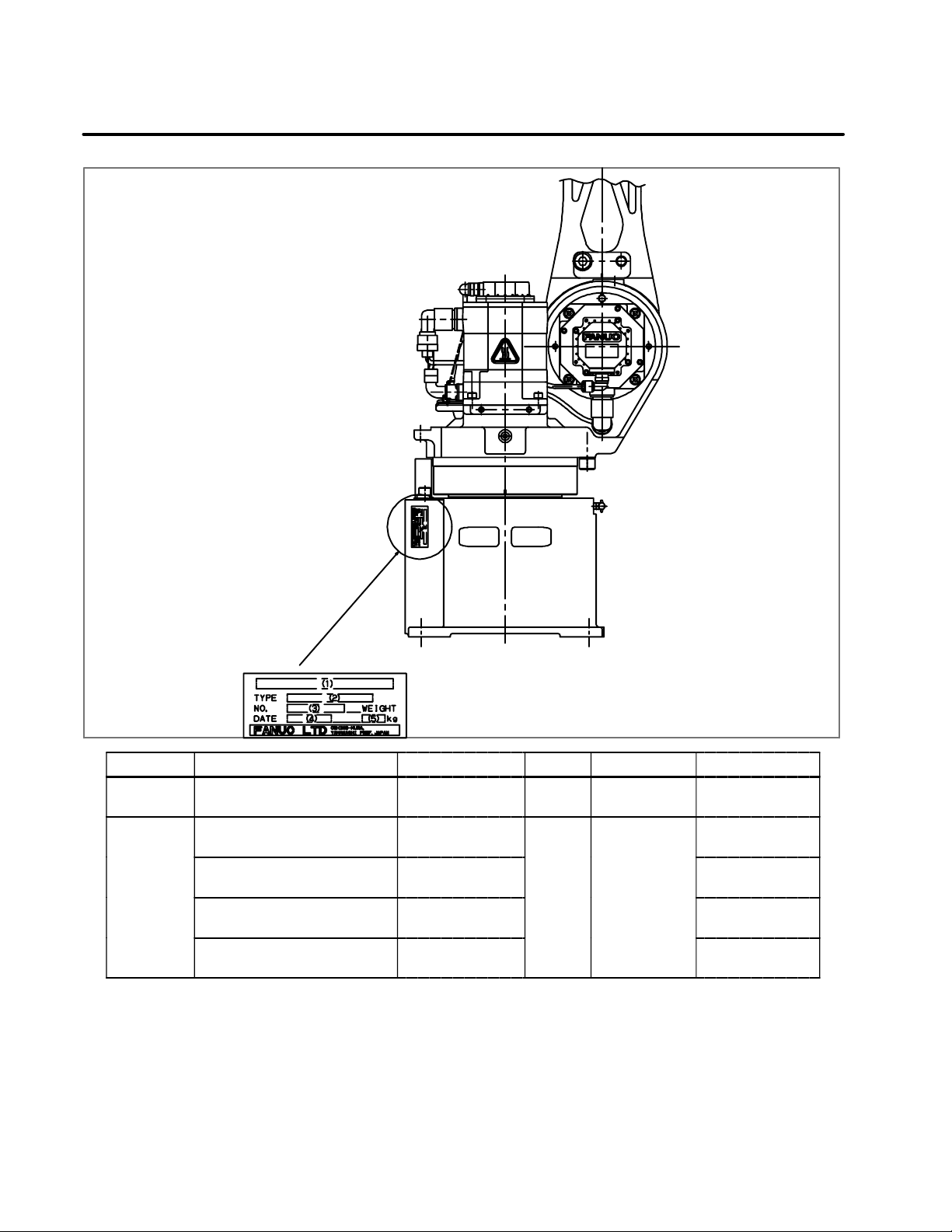

No. (1) (2) (3) (4) (5)

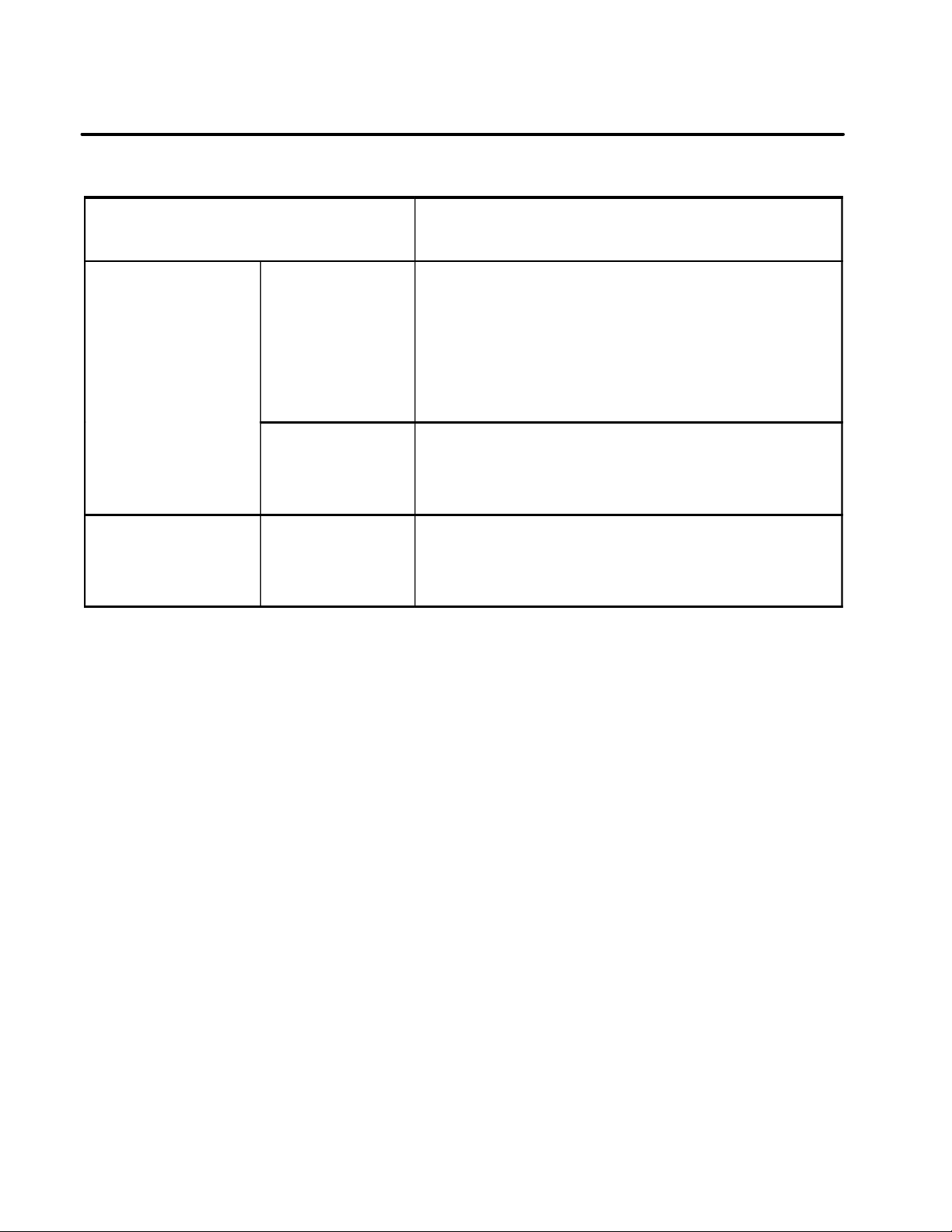

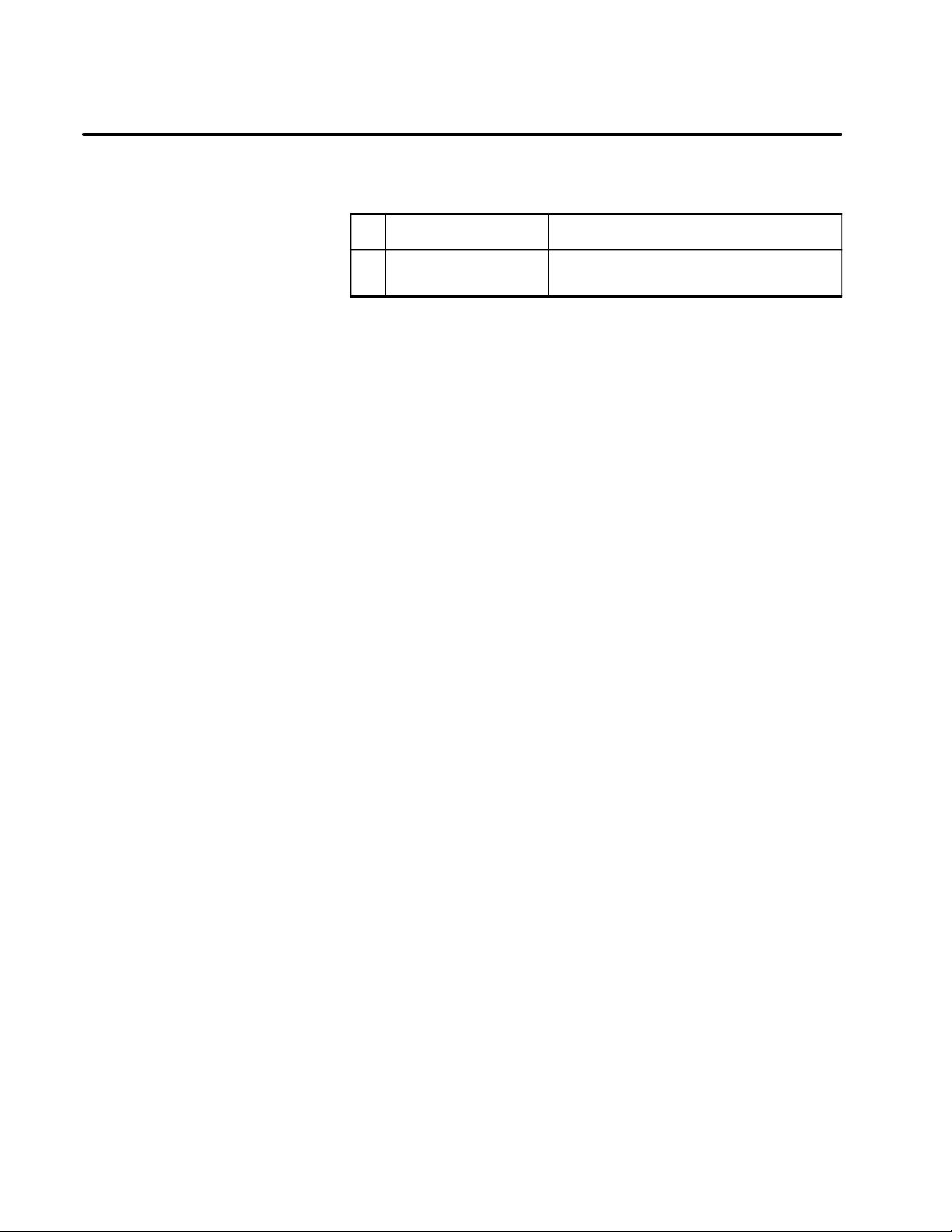

CONTENTS MODEL TYPE No. DATE

FANUC Robot ARC Mate 100i

MODEL B (2-- axis brake)

FANUC Robot ARC Mate 100i

MODEL B (6-- axis brake)

FANUC Robot M--6i MODEL B

(2--axis brake)

FANUC Robot M--6i MODEL B

(6--axis brake)

A05B--1215--B201 184 kg

A05B--1215--B601

A05B--1215--B201

PRINT

NO.

PRINT

PRODUCTION

YEAR AND

MONTH

A05B--1215--B601 138 kg

WEIGHT

(Withoutcontroller)

138 kg

184 kg

Page 4

B--81545EN/01

g

p

PREFACE

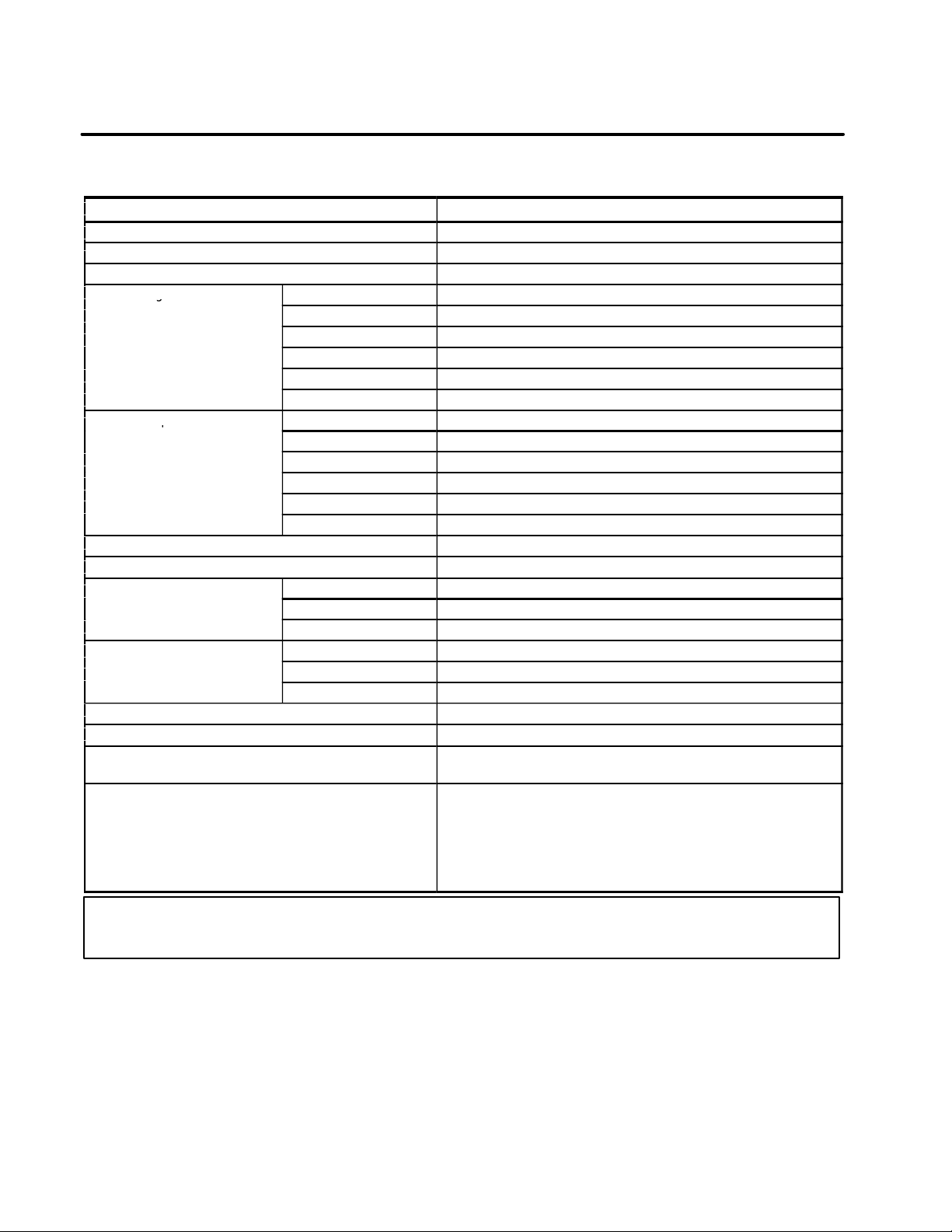

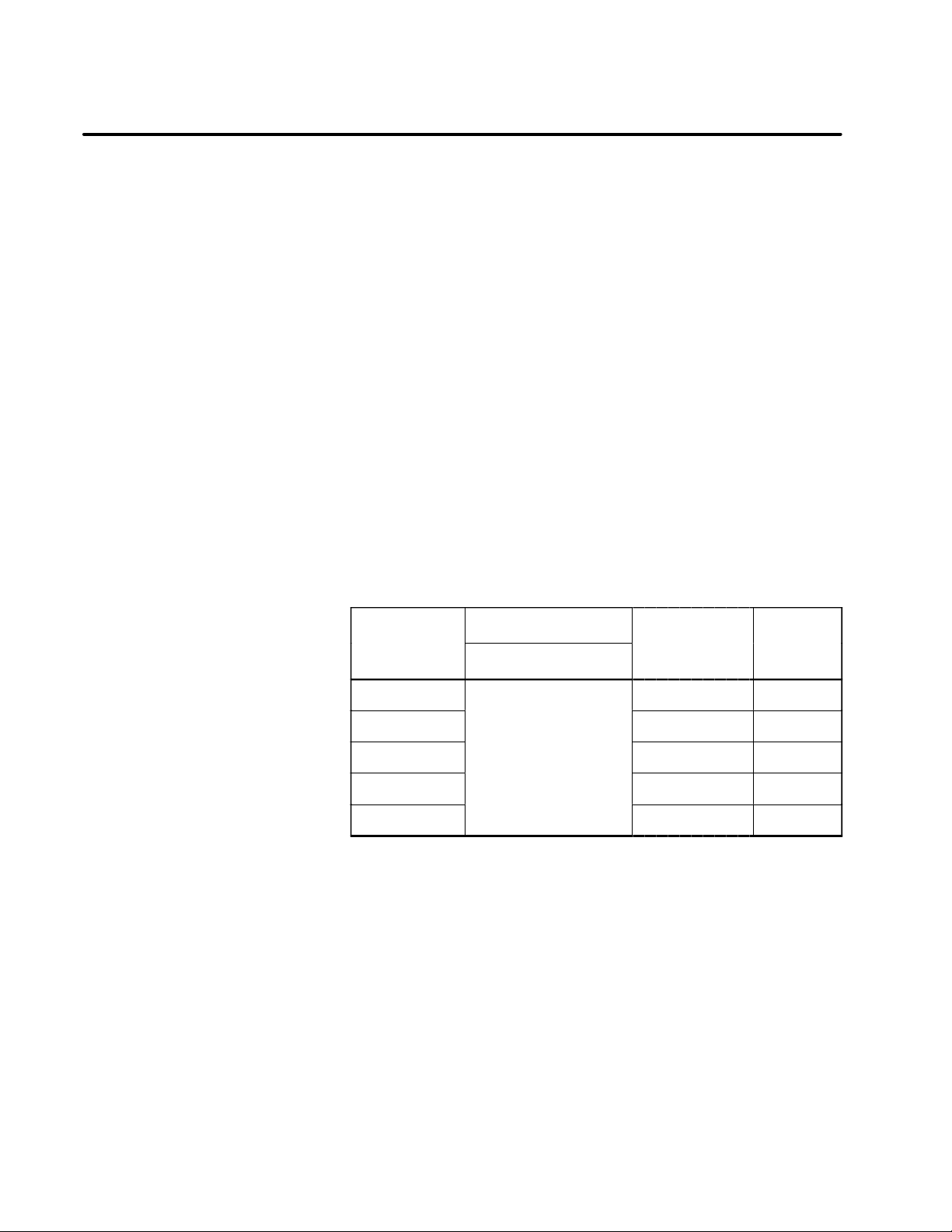

Specification

Item R--2000i/165F

Type Articulated type

Controlledaxes 6 axes (J1, J2, J3, J4, J5, J6)

Installation Floor, Upside--dowm (Wall& Angle mount) (Note 1)

Motion range

(Maximumspeed)

Maximum speed

Max. load capacity at wrist 6kg

Max. load capacity on J3 catting 12kg

Allowableloadmomentatwrist

Allowable load inertiaat wrist

Drive method Electricservo driveby AC servo motor

Repeatability 0.06mm

Weightof mechanicalunit 134kg (2--axis brake type)

Installation environment Ambient temperature : 0 -- 45°C

J1 axis rotation 340° (5.93rad)

J2 axis rotation 250° (4.36rad)

J3 axis rotation 315° (5.60rad)

J4 axis wrist rotation 380° (6.63rad)

J5 axis wrist swing 280° (4.89rad)

J6 axis wrist rotation 720° (12.57rad)

J1 axis 150°/s (2.62rad/s)

J2 axis 160°/s (2.79rad/s)

J3 axis 170°/s (2.97rad/s)

J4 axis 400°/s (6.98rad/s)

J5 axis 400°/s (6.98rad/s)

J6 axis 500°/s (8.73rad/s)

J4 axis 15.7N·m (1.8kgf·m)

J5 axis 9.8N·m (1.0kgf·m)

J6 axis 5.9N·m (0.5kgf·m)

J4 axis 0.63kg·m2(6.4kgf·cm·s2)

J5 axis 0.22kg·m2(2.2kgf·cm·s2)

J6 axis 0.061kg·m2(0.62kgf·cm·s2)

138kg (6--axis brake type)

Ambient humidity : Normally :75%RH or less

: Short time 95%RH or less

(within 1 month)

(No dew or frostallowed)

Vibration : 0.5G (4.9m/s

2

)orless

NOTE

1 Under the installation condition within ( ), the J1 and J2 axis motion range will be limited.

Page 5

PREFACE

B--81545EN/01

Dust--proof/waterproof performance of M--6i B

Normal specification

Wrist+J3 arm IP67

Other part IP54

NOTE

Definition of IP code

Definition of IP 67

6=Dust--tight

7=Protection from water immersion

Definition of IP 54

5=Dust--protected

4=Protection from splashing water

Performance of resistant chemicals and resistant solvents

(1)(1)The robot (including severe dust/liquid protection model) cannot

be used with the following liquids because there is feat that rubber

parts (packing, oil seal, O ring etc.) will corrode.

(a) Organic solvcnts

(b) Coolant including chlorine / gasoline

(c) Acid, alkali and liquid causing rust

(d) Other liquids or solutions, that will harm NBR

(2) When the robots work in the environment, using water or liquid,

complete draining of J1 base must be done. Incomplete draining of

J1 base will make the robot break down.

Page 6

B--81545EN/01

PREFACE

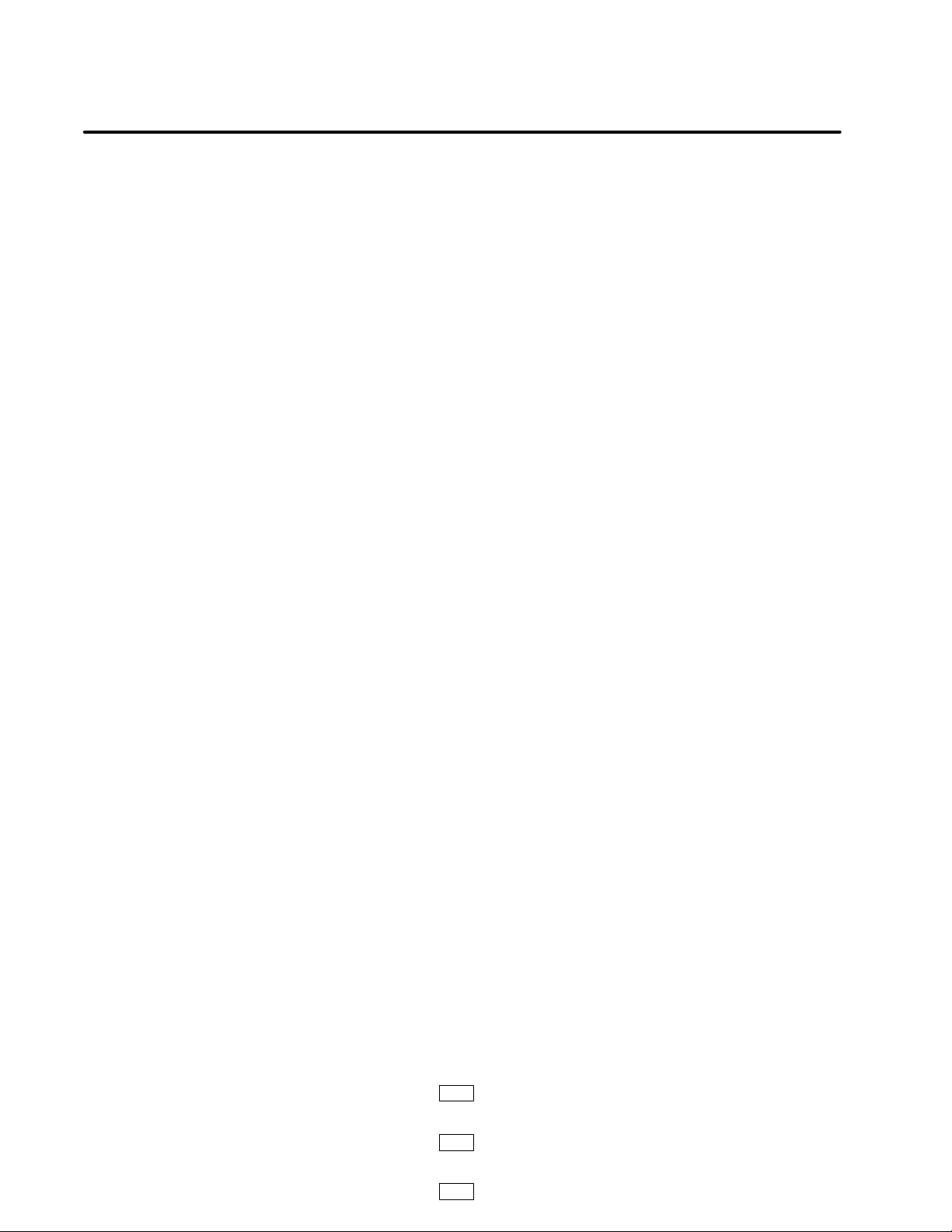

RELATED MANUALS

Safety handbook B--80687EN

All persons who use the FANUC Robot and system de-

signer must read and understand thoroughly this handbook

R--J3i MODEL B controller Setup and Operations

manual

SPOT TOOL

B--81464EN--1

HANDLING TOOL

B--81464EN--2

ARC TOOL

B--81464EN--3

SEALING TOOL

B--81464EN--4

Maintenance manual

B--81465EN

B--81465EN--1

(European

specification)

Mechanical unit Maintenance manual

FANUC Robot ARC Mate

100i B

M--6i B

B--81545EN

For the FANUC Robot series, the following manuals are available:

Intended readers :

All persons who use FANUC Robot, systemdesigner

Topics :

Safety items for robot system design, operation, maintenance

Intended readers :

Operator, programmer, maintenance person, system designer

Topics :

Robot functions, operations, programming, setup, interfaces, alarms

Use :

Robot operation, teaching, system design

Intended readers :

Maintenance person, systemdesigner

Topics :

Installation, connection to peripheral equipment, maintenance

Use :

Installation, start--up, connection, maintenance

Intended readers :

Maintenance person, systemdesigner

Topics :

Installation, connection to the controller, maintenance

Use :

installation, start--up, connection, maintenance

Page 7

B--81545EN/01

Table of Contents

I. MAINTENANCE

1. CONFIGURATION 3............................................................

1.1 J1--AXIS DRIVE MECHANISM 4......................................................

1.2 J2--AXIS DRIVE MECHANISM 5......................................................

1.3 J3--AXIS DRIVE MECHANISM 6......................................................

1.4 J4--AXIS DRIVE MECHANISM 7......................................................

1.5 J5-- AND J6--AXIS DRIVE MECHANISMS 8............................................

1.6 SPECIFICA TIONS OF THE MAJOR MECHANICAL UNIT COMPONENTS 9.................

2. PREVENTIVE MAINTENANCE 11................................................

2.1 DAILY INSPECTION 12.............................................................

2.2 QUARTERLY INSPECTION 14.......................................................

2.3 YEARLY INSPECTION 15...........................................................

2.4 ONE-- AND HALF--YEAR PERIODIC INSPECTION 16...................................

2.5 THREE--YEAR PERIODIC INSPECTION 17............................................

2.6 MAINTENANCE TOOLS 18..........................................................

3. PERIODIC MAINTENANCE 19..................................................

3.1 GREASING 20.....................................................................

3.2 GREASE REPLACEMENT 22........................................................

3.3 BATTERY REPLACEMENT 25.......................................................

4. TROUBLESHOOTING 26......................................................

4.1 OVERVIEW 27.....................................................................

4.2 TROUBLES AND CAUSES 28........................................................

4.3 COMPONENT REPLACEMENT AND ADJUSTMENT ITEMS 31...........................

5. ADJUSTMENTS 32............................................................

5.1 REFERENCE POSITION AND MOVING RANGE 33.....................................

5.2 SIMPLIFIED MASTERING 37........................................................

5.3 MASTERING BY ZERO POSITION MARK ALIGNMENT 39..............................

5.4 JIG--BASED MASTERING 41.........................................................

5.5 CONFIRMING MASTERING 47.......................................................

5.6 J5--AXIS GEAR BACKLASH ADJUSTMENTS 48........................................

5.7 BRAKE RELEASE 50...............................................................

6. COMPONENT REPLACEMENT AND ADJUSTMENTS 52..........................

6.1 REPLACING THE J1--AXIS MOTOR

6.2 REPLACING THE J1--AXIS REDUCER 55..............................................

6.3 REPLACING THE J2--AXIS MOTOR

6.4 REPLACING THE J2--AXIS REDUCER 59..............................................

6.5 REPLACING THE J3--AXIS MOTOR

6.6 REPLACING THE J3--AXIS REDUCER 64..............................................

M1

M2

M3

53...........................................

57...........................................

62...........................................

Page 8

TABLE OF CONTENTS

B--81545EN/01

6.7 REPLACING THE J4--AXIS MOTOR

6.8 REPLACING THE J4--AXIS GEARBOX 67..............................................

6.9 REPLACING THE J5--AXIS MOTOR

6.10 REPLACING THE J5--AXIS GEAR 71..................................................

6.11 REPLACING THE J6--AXIS MOTOR

M4

M5

M6

AND REDUCER 73............................

7. PIPING AND WIRING 77.......................................................

7.1 PIPING DRAWING 78...............................................................

7.2 WIRING DIAGRAMS 79.............................................................

7.3 CABLE MOUNTING DIAGRAM 81...................................................

8. CABLE REPLACEMENT 82....................................................

8.1 CABLE DRESSING 83..............................................................

8.2 REPLACING CABLES 85............................................................

9. COVER OPTION REPLACEMENT 90............................................

9.1 REPLACING THE J2 COVER OPTION (A05B--1210--J401) 91..............................

9.2 REPLACING THE J4 COVER OPTION (A05B--1210--J402) 92..............................

66...........................................

69...........................................

10. M--6i PACKAGES WITH REINFORCED DUST--PROOF AND

DRIP--PROOF CHARACTERISTICS 93.........................................

10.1 DUST--PROOF AND DRIP--PROOF PERFORMANCE OF THE PACKAGES WITH

REINFORCED DUST--PROOF AND DRIP--PROOF CHARACTERISTICS 94..................

10.2 CONFIGURATION OF THE PACKAGES WITH REINFORCED DUST--PROOF AND

DRIP--PROOF CHARACTERISTICS 95.................................................

10.3 CAUTIONS IN SELECTING THE PACKAGES WITH REINFORCED DUST--PROOF

AND DRIP--PROOF CHARACTERISTICS 97............................................

10.4 REPLACING THE COMPONENTS OF THE PACKAGES WITH REINFORCED DUST--PROOF

AND DRIP--PROOF CHARACTERISTICS 98............................................

II. CONNECTION

1. ROBOT OUTLINE DRAWING AND OPERATION AREA DIAGRAM 103.............

1.1 OUTLINE DRAWING AND OPERATION AREA DIAGRAM 104...........................

2. MOUNTING DEVICES ON THE ROBOT 107......................................

2.1 WRIST SECTION END EFFECTOR MOUNTING SURFACE 108...........................

2.2 DEVICE MOUNTING SURFACES 109.................................................

2.3 SETTING THE SYSTEMVARIABLES FOR SHORTEST--TIME CONTROL 111...............

2.4 WRIST LOAD CONDITIONS 114.....................................................

2.5 END EFFECTOR AIR PIPING 115.....................................................

2.6 END EFFECTOR INPUT SIGNALS (RDI/RDO) 116......................................

2.7 CONNECTOR SPECIFICATIONS 117..................................................

Page 9

B--81545EN/01

TABLE OF CONTENTS

3. TRANSPORTATION AND INSTALLATION 118....................................

3.1 TRANSPORTATION 119.............................................................

3.2 STORING THE ROBOT 121..........................................................

3.3 INSTALLATION 122................................................................

3.4 MAINTENANCE CLEARANCE 125...................................................

3.5 ASSEMBLING THE ROBOT FOR INSTALLATION 127...................................

3.6 AIR PIPING 128....................................................................

3.7 INSTALLATION CONDITIONS 130...................................................

APPENDIX

A. SPARE PARTS LISTS 133.....................................................

B. INTRA--MECHANICAL UNIT CONNECTION DIAGRAMS 139......................

C. PERIODIC INSPECTION TABLE 144............................................

D. BOLT MOUNTING TORQUE LIST 145...........................................

Page 10

I. MAINTENANCE

Page 11

B--81545EN/01

1

1. CONFIGURATIONMAINTENANCE

CONFIGURATION

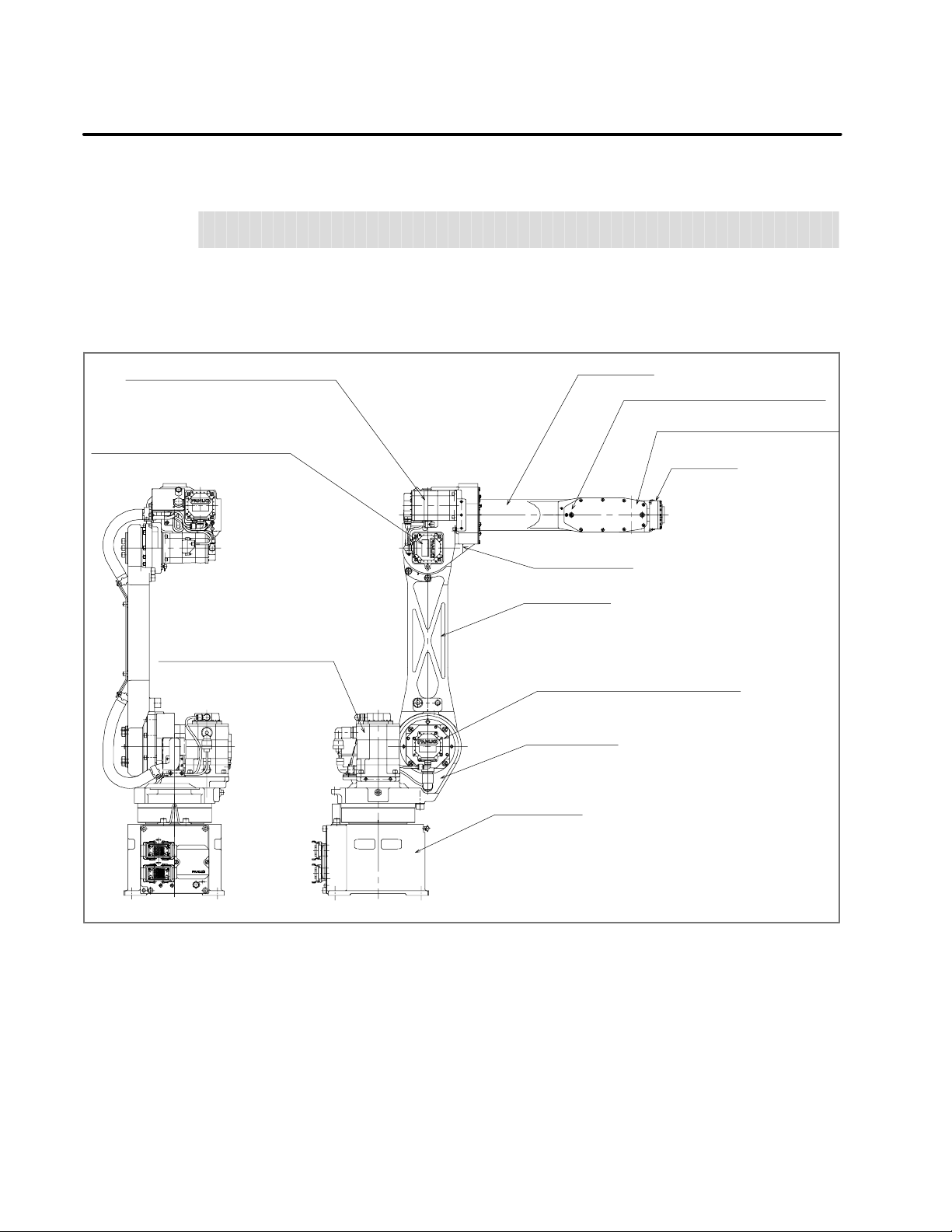

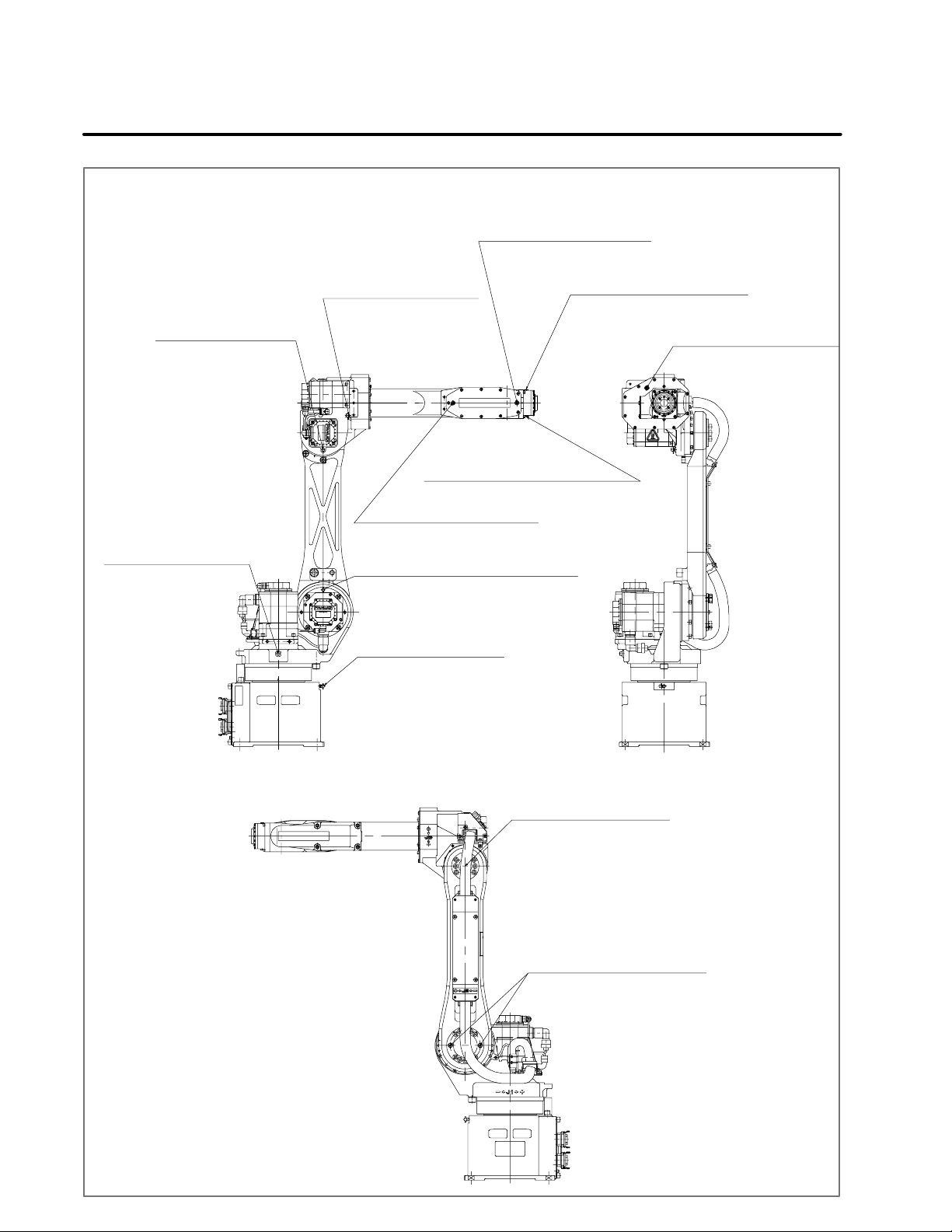

Fig. 1 shows the configuration of the mechanical unit.

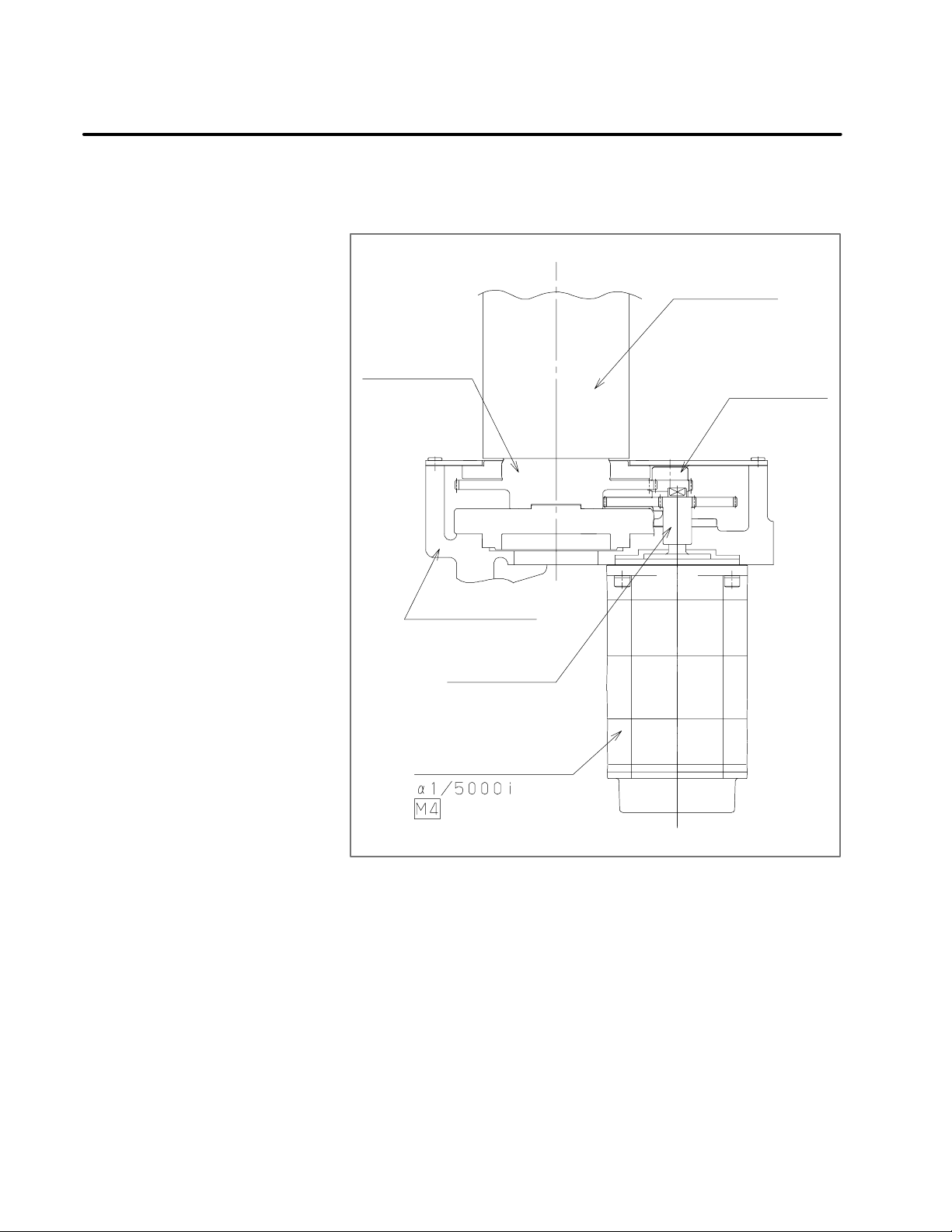

AC servo motor forJ4--axis (M4)

AC servo motor forJ3--axis (M3)

AC servo motor forJ1--axis (M1)

J3--axis arm

AC servo motor forJ5--axis (M5)

AC servo motor forJ6--axis (M6)

Wristunit

J3--axis casing

J2--axis arm

AC servo motor forJ2--axis (M2)

J2--axis base

J1--axis base

Fig 1 Mechanical unit configuration

Page 12

1. CONFIGURATION

MAINTENANCE

B--81545EN/01

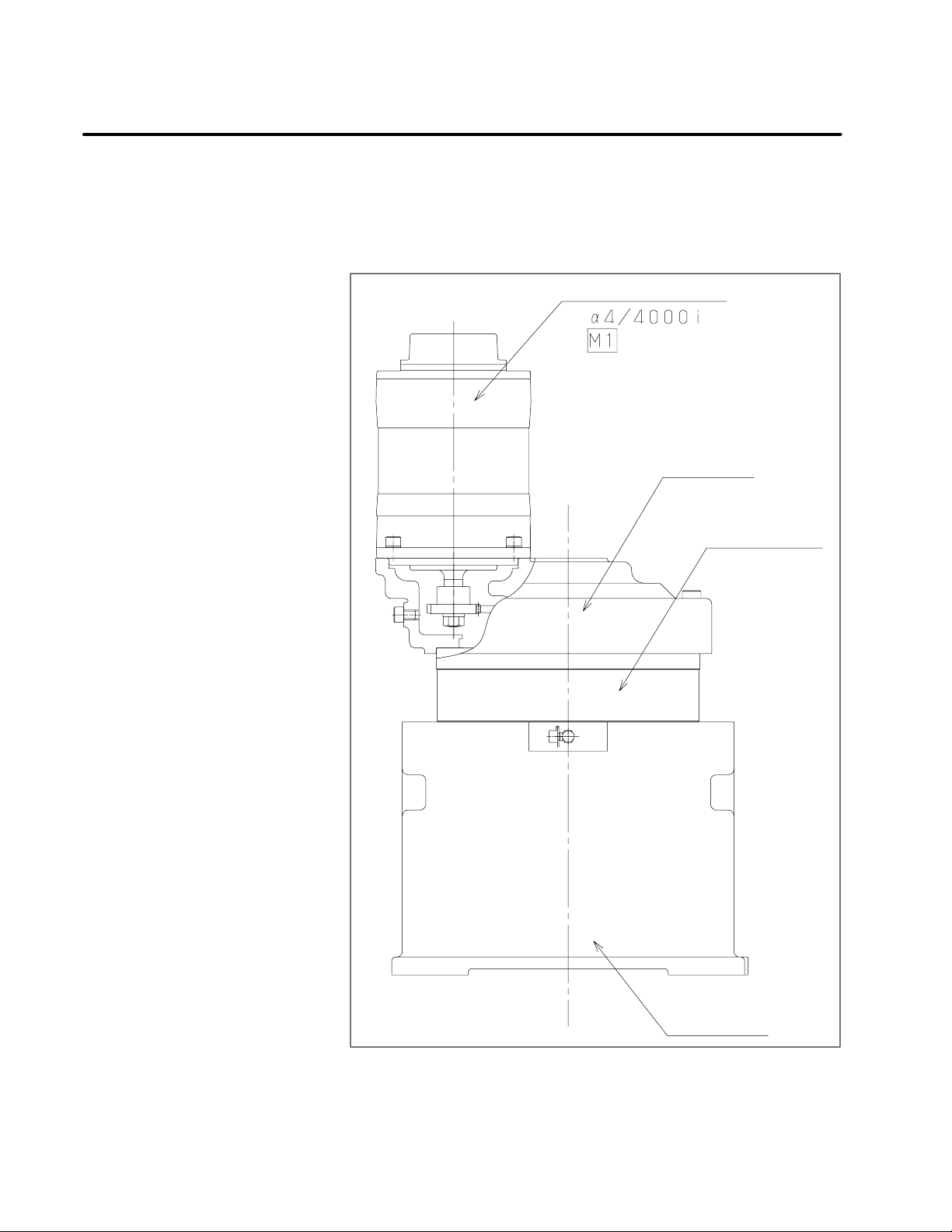

1.1

J1--AXIS DRIVE

MECHANISM

Fig. 1.1 shows the J1--axis drive mechanism.

TheJ1--axis drivemechanismisconfiguredinsuch a waythattheJ2--axis

base is rotated by reducing the rotation speed of an AC servo motor with

a reducer.

The J2--axis base is supported on the J1--axis base through the reducer.

J1--axis AC servo motor

J2--axis base

J1--axis reducer

J1--axis base

Fig 1.1 J1--axis drive mechanism

Page 13

B--81545EN/01

1. CONFIGURATIONMAINTENANCE

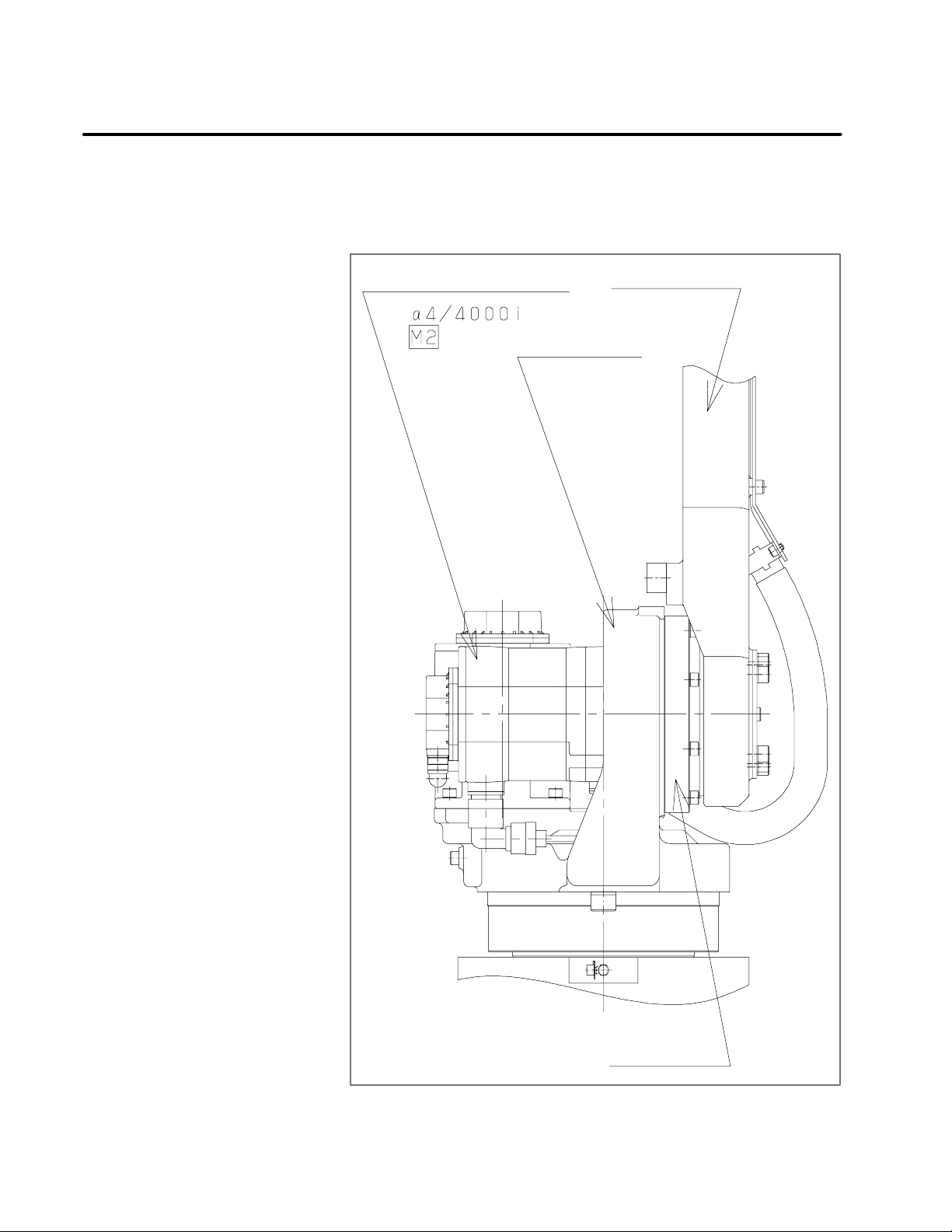

1.2

J2--AXIS DRIVE

MECHANISM

Fig. 1.2 shows the J2--axis drive mechanism. The J2--axis drive

mechanismis configuredin such a waythat the J2--axis armis rotatedby

reducing the rotation speed of an AC servo motor with a reducer.

The J2--axis arm is supported on the J2--axis base through the reducer.

J2--axis AC servo motor

J2--axis base

J2--axis arm

J2--axis reducer

Fig 1.2 J2--axis drive mechanism

Page 14

1. CONFIGURATION

MAINTENANCE

B--81545EN/01

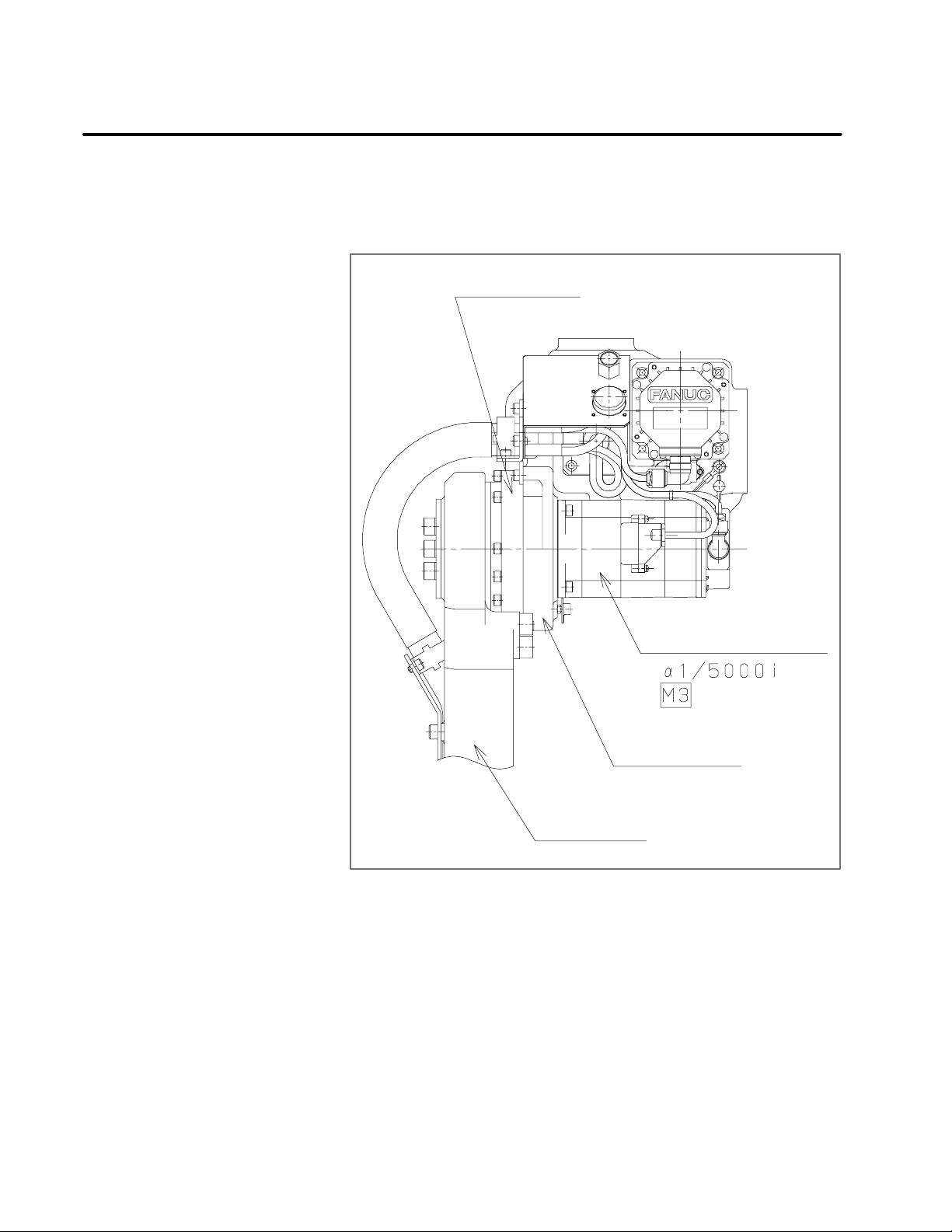

1.3

J3--AXIS DRIVE

MECHANISM

Fig. 1.3 shows the J3--axis drive mechanism. The J3--axis drive

mechanism is configured in such a way that the J3--axis casing is rotated

by reducing the rotation speed of an AC servo motor with a reducer.

The J3--axis casing is supported on the J2--axis arm through the reducer.

J3--axis reducer

J3--axis AC servo motor

J3--axis casing

J2--axis arm

Fig 1.3 J3--axis drive mechanism

Page 15

B--81545EN/01

1. CONFIGURATIONMAINTENANCE

1.4

J4--AXIS DRIVE

MECHANISM

Fig. 1.4 shows the J4--axis drive mechanism. The J4--axis drive

mechanismis configuredin such a waythat the J3--axis armis rotatedby

reducing the rotation speedof an AC servo motor with a two--stage gear.

J3--axis arm

Final gear

Second gear

J3--axis casing

Input gear

J4--axis AC servo motor

Fig 1.4 J4--axis drive mechanism

Page 16

1. CONFIGURATION

MAINTENANCE

B--81545EN/01

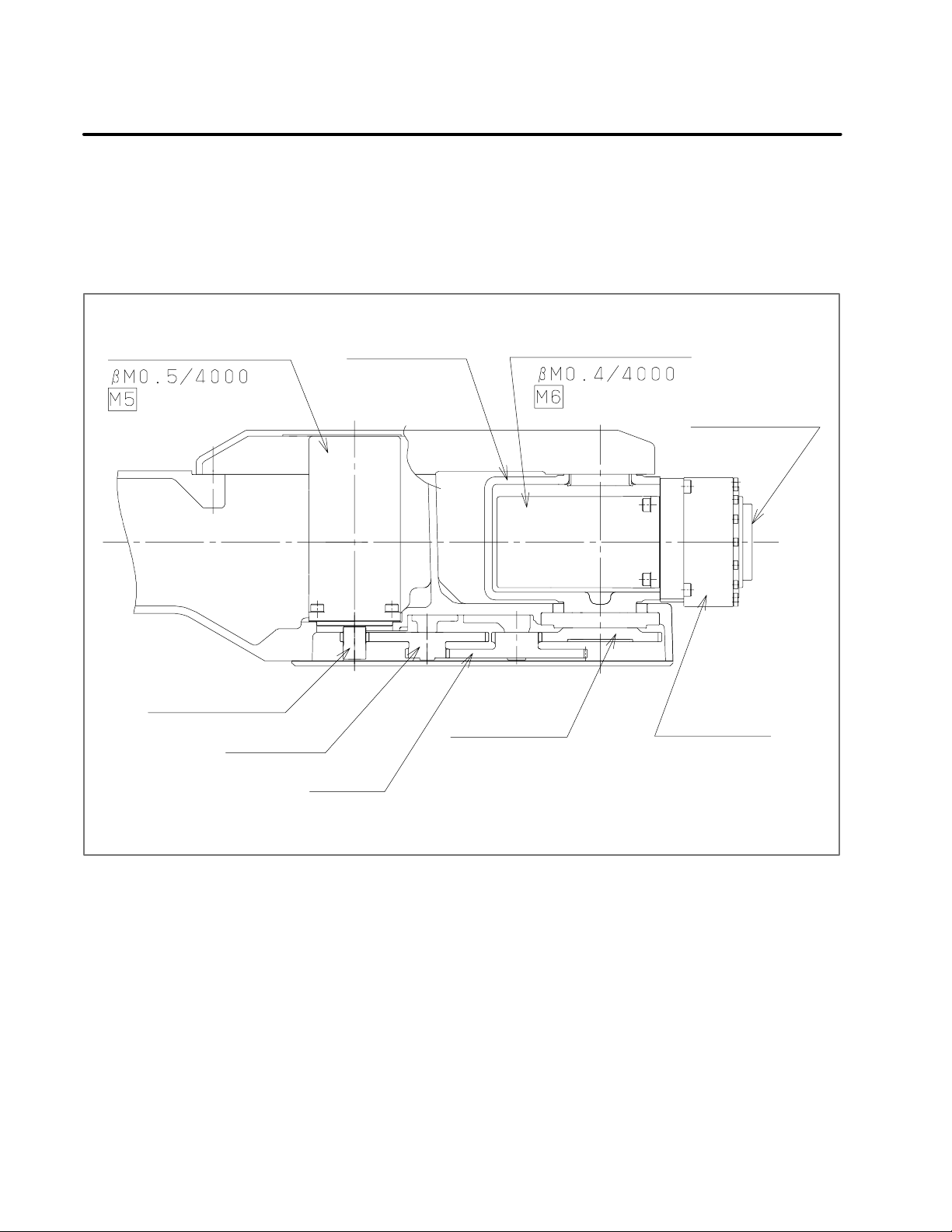

1.5

J5-- AND J6--AXIS

DRIVE MECHANISMS

Fig. 1.5 shows the J5-- and J6--axis drivemechanisms. TheJ5--axis drive

mechanism is configured in such a waythat the J6--axis unit is rotated by

reducingthe rotation speedofan AC servomotor witha three--stage gear.

The J6--axis drivemechanism is configured in such a way that theoutput

flangeisrotatedby reducingtherotationspeedofanACservo motorwith

a reducer.

J5--axis AC servo motor J6--axis unit J6--axis AC servo motor

Output flange

Input gear

Second gear

Final gear

Third gear

Fig 1.5 J5-- and J6--axis drive mechanisms

J6--axis reducer

Page 17

B--81545EN/01

1. CONFIGURATIONMAINTENANCE

1.6

SPECIFICATIONS OF

THE MAJOR

MECHANICAL UNIT

COMPONENTS

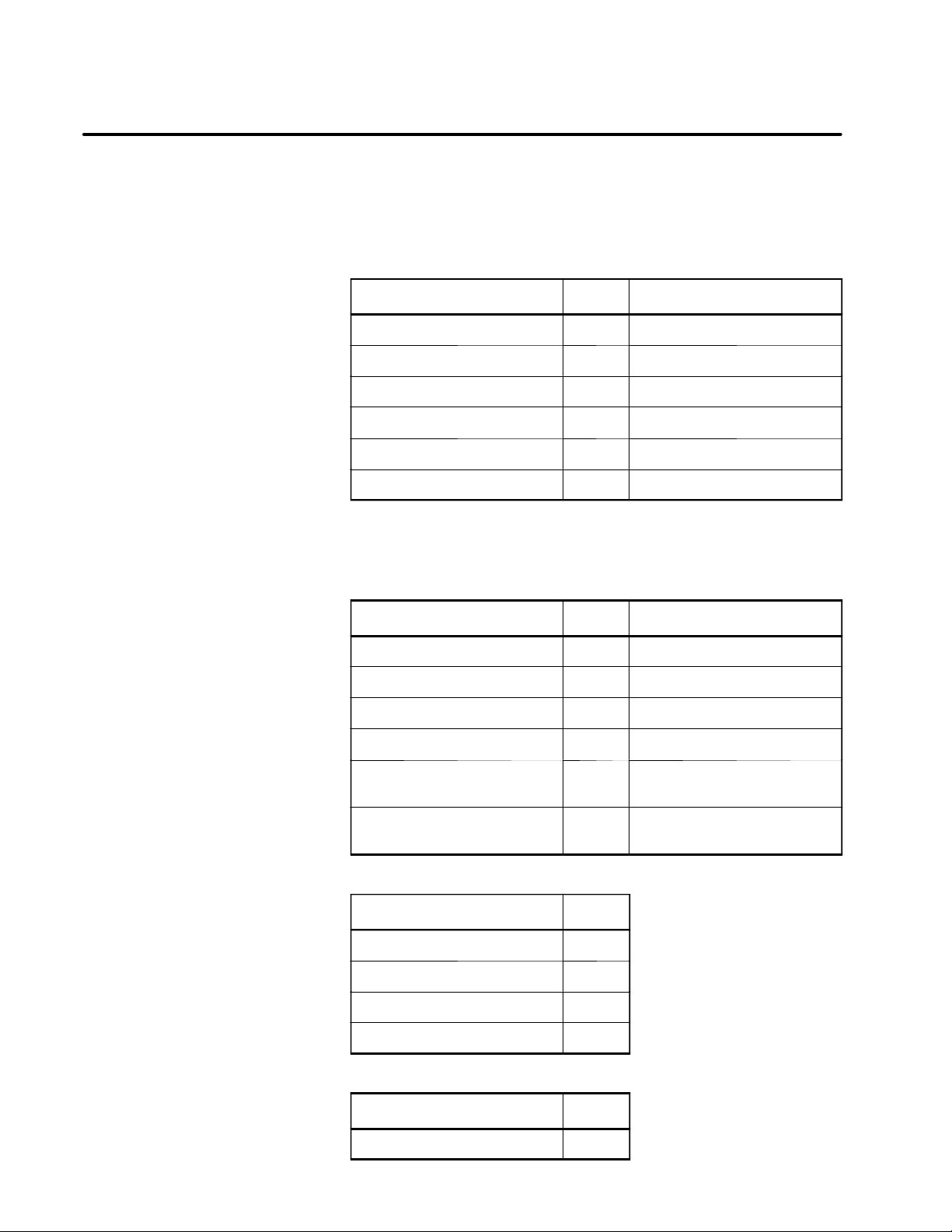

1) Motors

ARC Mate 100i MODEL B

(two--axis, equipped with a brake): A05B--1215--B201

M--6i MODEL B

(two--axis, equipped with a brake): A05B--1215--B202

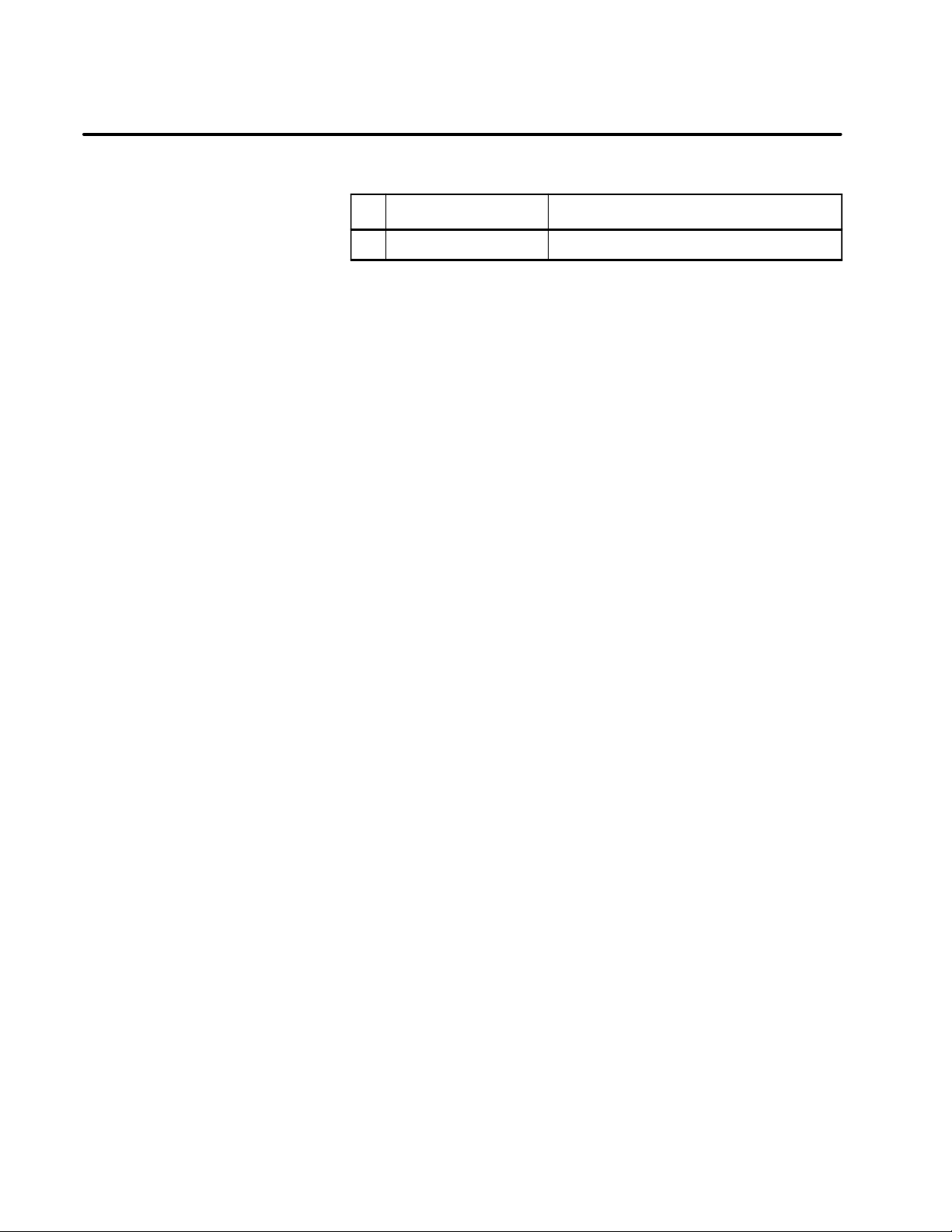

Specification Axis Remark

A06B-0223-B005 J1 α 4/4000i

A06B-0223-B605 J2 α 4/4000i Equipped witha brake

A06B-0202-B605 J3 α 1/5000i Equipped witha brake

A06B-0202-B005 J4 α 1/5000i

A06B-0115-B075#0008 J5 β M0.5/4000

A06B-0114-B075#0008 J6 β M0.4/4000

ARC Mate 100i MODEL B

(six--axis, equipped with a brake): A05B--1215--B601

M--6i MODEL B

(six--axis, equipped with a brake): A05B--1215--B602

Specification Axis Remark

A06B-0223-B605 J1 α 4/4000i Equipped witha brake

A06B-0223-B605 J2 α 4/4000i Equipped witha brake

A06B-0202-B605 J3 α 1/5000i Equipped witha brake

A06B-0202-B605 J4 α 1/5000i Equipped witha brake

A06B-0115-B275#0008 J5 β M0.5/4000

Equipped with a brake

A06B-0114-B275#0008 J6 β M0.4/4000

Equipped with a brake

2) Reducers

Specification Axis

A97L-0218-0288#33 J1

A97L-0218-0289#153 J2

A97L-0218-0295#161 J3

A97L-0218-0224 J6

3) J4--axis gearbox

Specification Axis

A05B-1215-K401 J4

Page 18

1. CONFIGURATION

MAINTENANCE

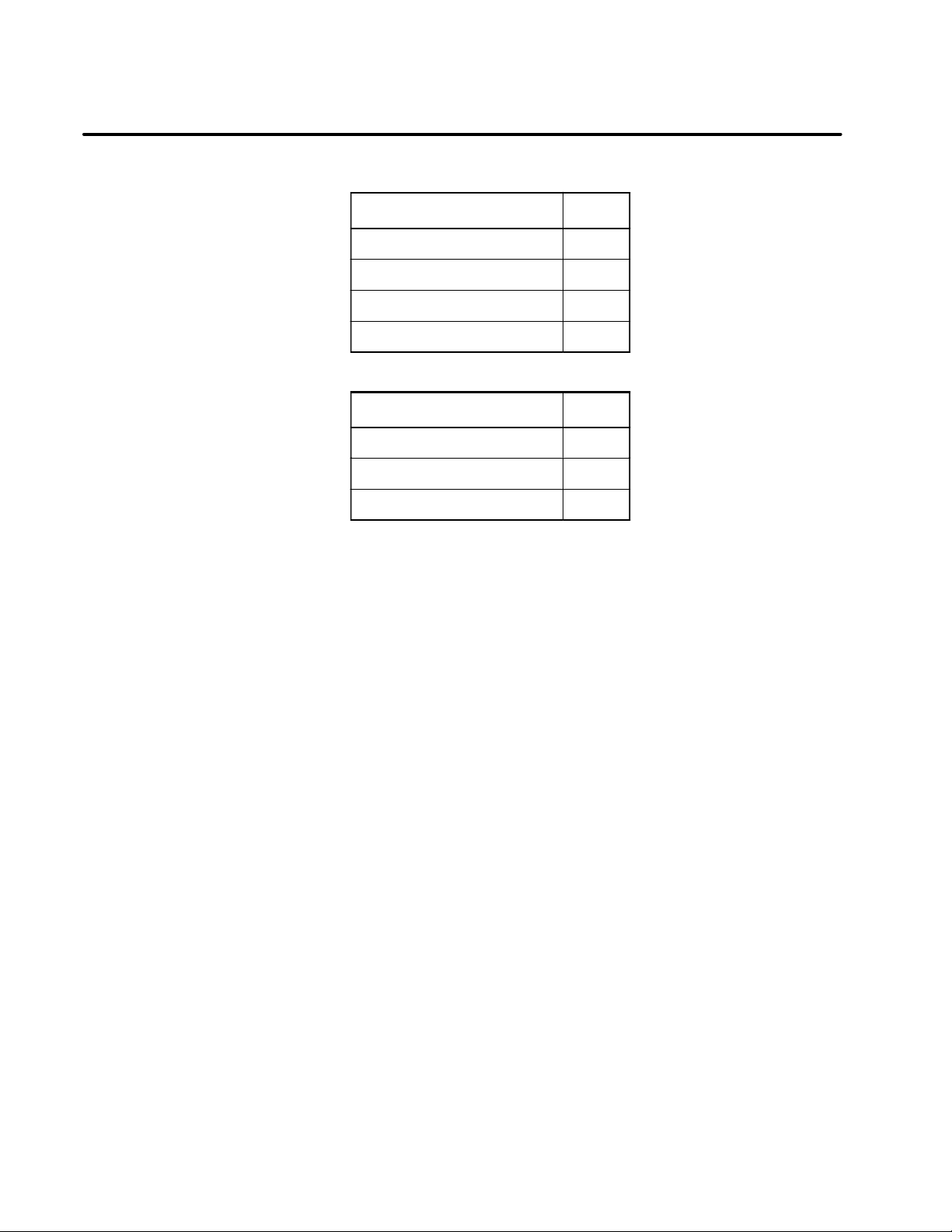

4) Gears

Specification Axis

A290-7215-X511 J5

A290-7215-V501 J5

A290-7215-V502 J5

A290-7215-X514 J5

5) Stoppers

Specification Axis

B--81545EN/01

A290-7215-X241 J1

A290-7215-X323 J2

A290-7215-X324 J3

Note) 330° stopper

Page 19

B--81545EN/01

2

2. PREVENTIVE MAINTENANCEMAINTENANCE

PREVENTIVE MAINTENANCE

Performing daily inspection, periodic inspection, and maintenance can

keep the performance of robots in a stable state for a long period.

Page 20

2. PREVENTIVE MAINTENANCE

MAINTENANCE

B--81545EN/01

2.1

DAILY INSPECTION

Clean and maintain each component of robots during everyday system

operations. At the same time, check the components to see if there is a

crack or break in them. Also check and maintain the following items as

required.

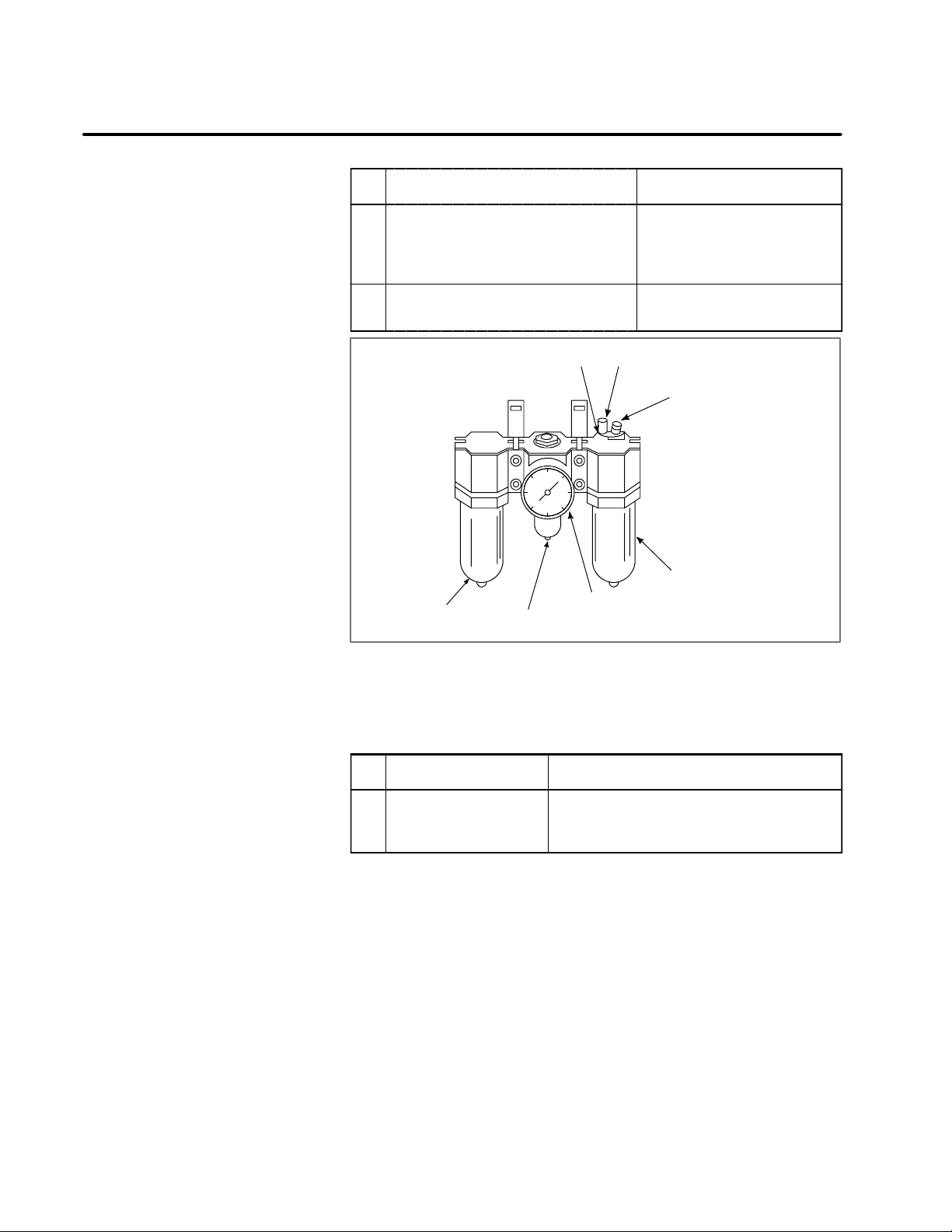

a) Before automatic operation

No. Inspection item Inspection procedure

1 Pneumatic pressure

check

2

For

machines

with a

three--piece

pneumatic

option

Check on the amount of

oil mist

Make a pneumatic pressure

check, using the three--piece

pneumatic option shown in Fig.

2.1.

Ifthemeasuredpneumaticpressure does not fall in the range

between0.5and 0.7MPa(5and

7kg/cm

usingtheregulatorpressuresetting handle.

Putthepneumaticpressuresystem in operation and check the

amount of oil dripping. If the

measuredamountof oildripping

does not meet the rating (one

drop/10 to 20 seconds), make

adjustments, using the oil adjustment knob. The oiler becomes empty after10to 20 days

of normal operation.

2

), make adjustments,

3 Check on the amount of

oil

4 Check for leakage from

the piping

5 Whethercables are abnormal

Mechanical unit

6 Battery voltagecheck Make sure that when thepower

7 Whether there is any abnormal vibra-

tion,noise,or heatgenerationin motors

8 Whetherthereisa change topositioning

precision

Check to see iftheamount of oil

inthethree-- piece option is within the rated level shown in Fig.

2.1.

Check to see if a joint or hose

leaks.

Ifyou finda problem, tighten the

joint or replace any defective

component.

See Chapter8.

isturnedon,theBLAL alarmhas

not been raised. If the BLAL

alarm has been raised, replace

the battery as directed in Section 3.3.

Check thateach axis is running

smoothly.

Check to see if thereis any displacement from the previous

positionand there are variations

in the stop position.

Page 21

B--81545EN/01

2. PREVENTIVE MAINTENANCEMAINTENANCE

No. Inspection procedureInspection item

9 Reliable operation of peripheral equip-

ment

10 Check on the operation of the J2-- and

J3--axis brakes.

Oiler’s oil inlet

Filter

Regulator pressure setting handle

Fig 2.1 Three--piece pneumatic option

Pressure gauge

Check to see if the machine operates exactly according to

directionsfromtherobotandperipheralequipment.

See Section4.2.

Oileradjustmentknob

Check oiler’s oil level

Oiler

b) After automatic operation

Once you are finishedwith automatic operation, bring therobot to its

reference position, and turn it off.

No. Inspection item Inspection procedure

1 Componentcleaning

and inspection

Clean and maintain each component. At the

same time, check the components to see if

there is a crack or break in them.

Page 22

2. PREVENTIVE MAINTENANCE

MAINTENANCE

B--81545EN/01

2.2

QUARTERLY

INSPECTION

Inspectthe following items at regularintervalsof threemonths. Increase

the locations and the frequency of i nspection if the conditions under

which the robot is used and the environment in which it runs require so.

No. Inspection item Inspection procedure

1 Loose connector Check that themotor connectors or other con-

nectors are not loose.

2 Loose bolt Check thatthecoverretainingboltsorexternal

bolts are not loose.

3 Debris removal Remove any spatter, debris,anddust from the

mechanical unit.

Page 23

B--81545EN/01

2. PREVENTIVE MAINTENANCEMAINTENANCE

2.3

YEARLY INSPECTION

Inspect the following item at regular intervals of one year.

No. Inspection item Inspection procedure

1 Greasing See Section 3.1.

Page 24

2. PREVENTIVE MAINTENANCE

MAINTENANCE

B--81545EN/01

2.4

ONE-- AND

HALF--YEAR

PERIODIC

INSPECTION

Performthe followinginspection/maintenanceitem at regularintervalsof

one year and half.

No. Inspection item Inspection procedure

1 Battery replacement Replace the battery in the mechanical unit.

(See Section 3.3.)

Page 25

B--81545EN/01

2.5

2. PREVENTIVE MAINTENANCEMAINTENANCE

THREE--YEAR

PERIODIC

INSPECTION

No.

1 Greasereplacement See Section3.2.

Inspection item Inspection procedure

Page 26

2. PREVENTIVE MAINTENANCE

MAINTENANCE

B--81545EN/01

2.6

MAINTENANCE

TOOLS

You should have the following instruments and tools ready for

maintenance.

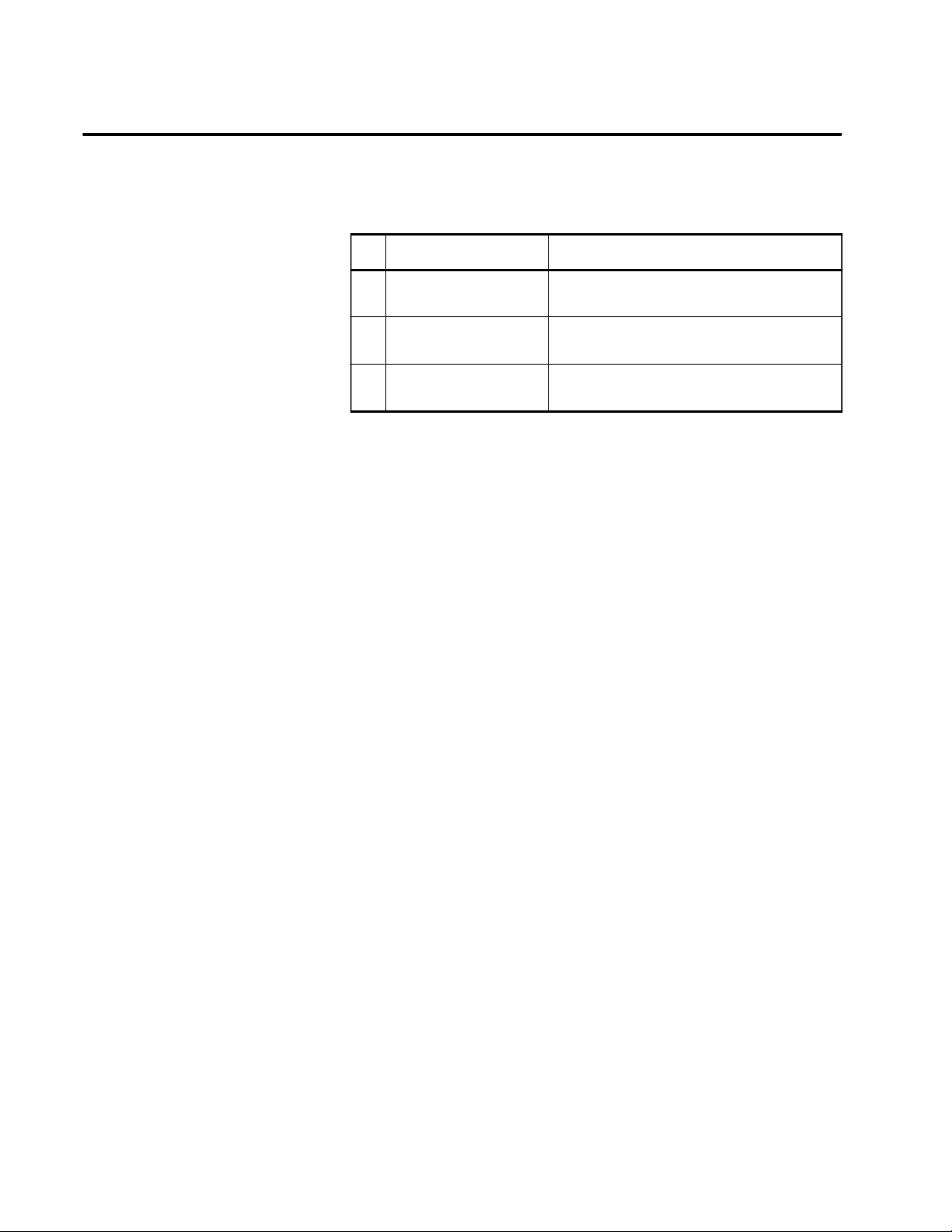

a) Measuring instruments

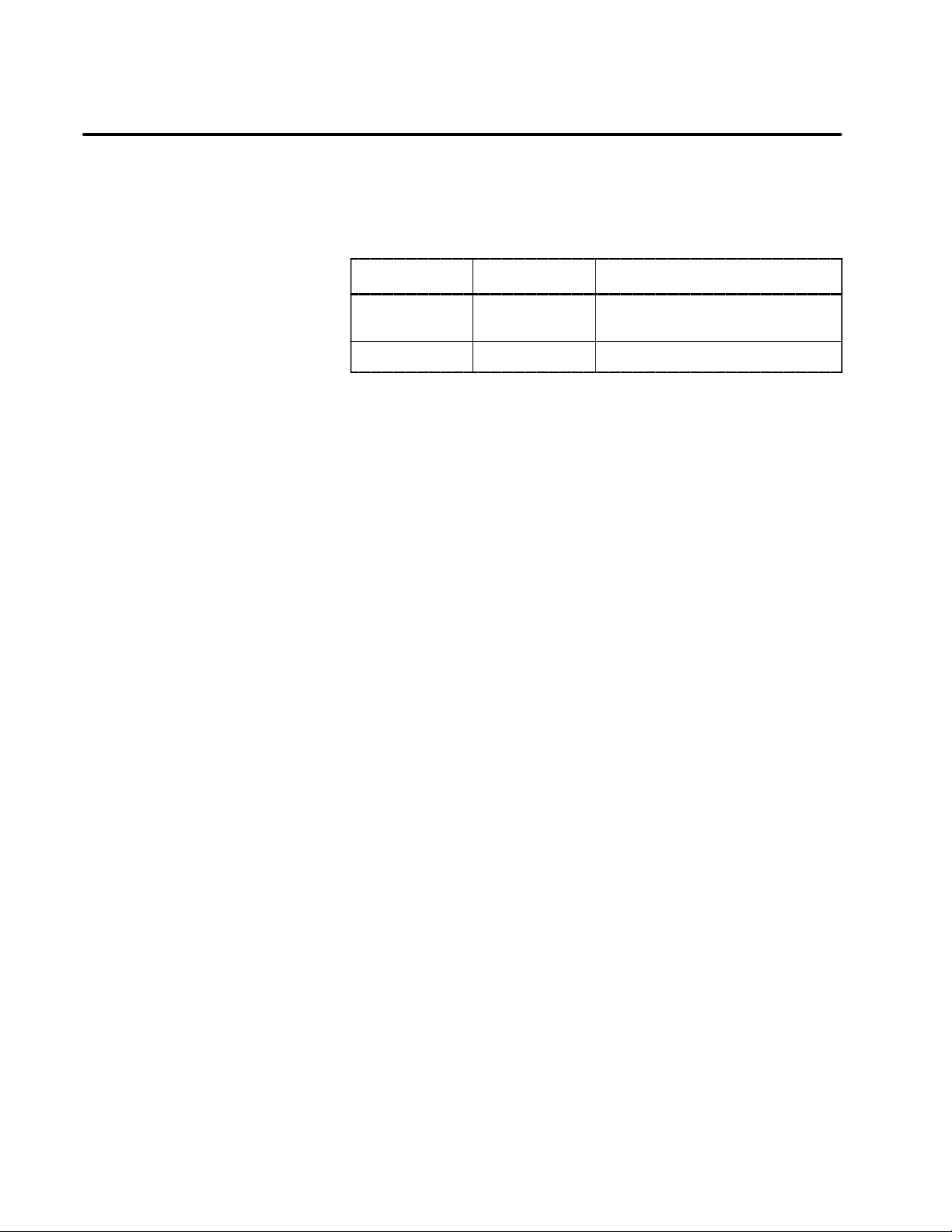

Instrument Condition Use

Dial gauge 1/100mm Forpositioningprecision and backlash

measurement

Calipers 150mm

b) Tools

Phillips screwdrivers (large, medium, and small sizes)

Flat--blade screwdrivers (large, medium, and small sizes)

Box wrenches (M3 to M6)

Allen wrenches (M3 to M16)

Torque wrench

Long T wrenches (M5 and M6)

Adjustable wrenches (medium and small sizes)

Pliers

Long--nose pliers

Cutting pliers

Both--ended wrench

Grease gun

C--ring pliers

Flashlight

Page 27

B--81545EN/01

3

3. PERIODIC MAINTENANCEMAINTENANCE

PERIODIC MAINTENANCE

Page 28

3. PERIODIC MAINTENANCE

MAINTENANCE

B--81545EN/01

3.1

GREASING

When greasing the robot, keep its power turned off.

i) Roughly speaking, replenish the robot with grease once a year.

ii) See Fig. 3.1 and Table 3.1 for greasing points and the method.

Table. 3.1 Greasing points

Greasing

No.

1 J6--axis

point

reducer

Specified

grease

Mori White

RE No.00

(Specification:

A97L-0040-0119)

Amount

of

grease

40cc J6--axis grease inlet and out-

Greasing method

let, and attach the supplied

greasenipple to the greaseinlet. Aftergreasing, remove the

grease nipple, and attach the

flat--head bolts and sealing

washers to the grease inlet

and outlet.

CAUTION

If you grease incorrectly, the pressure in the grease bath

may increase steeply, leading to a broken seal, which will

eventually cause grease leakage or malfunction.

When greasing, be sure to follow the cautions stated in

Section 3.2.

Page 29

B--81545EN/01

Grease nipple at the

grease inlet for the

J3-axis reducer

Seal bolt at the

grease outlet for the

J1-axis reducer

Low head bolt and seal

washer at the grease outlet

for the J5-axis reducer

Grease nipple at the

grease inlet for the

J4-axis reducer

Low head bolt and

seal washer at the grease

outlet for the J6-axis reducer

Low head bolt and seal washer at the

grease inlet for the J5-axis reducer

Grease nipple at the grease inlet

for the J2-axis reducer

3. PERIODIC MAINTENANCEMAINTENANCE

Low head bolt and seal

washer at the grease outlet

for the J6-axis reducer

Low head bolt and seal

washer at the grease outlet for the J4-axis reducer

Grease nipple at the

grease outlet for the

J1-axis reducer

Seal bolt at the

grease outlet for the

J3-axis reducer

Seal bolt at the

grease outlet for the

J2-axis reducer (2 locations)

Fig 3.1 Greasing points

Page 30

3. PERIODIC MAINTENANCE

greasetob

e

turewhe

n

(

S

ificat

i

MAINTENANCE

B--81545EN/01

3.2

GREASE

REPLACEMENT

Follow the procedure stated below to replace the grease in the J1--, J2--,

and J 3--axis reducersand theJ4-- and J5--axis gearboxesonce every three

yearsor after11,520hours of operation. See Fig. 3.1for greasingpoints.

1) Remove the seal bolts from the J1--, J2--, and J3--axis grease outlets

shown in Fig. 3.1. Also remove the flat--bolts and sealing washers

from the J4-- and J5--axis grease outlets.

2) Uncap thegreasenipplesat theJ1--, J2--, J3--, andJ4--axis greaseinlets.

Remove the flat--head bolt fromthe J5--axis grease inlet and attach the

supplied grease nipple to the J5--axis grease inlet.

3) Supply the grease specified in Table 3.2 to the J1--, J2--, and J3--axis

reducers, and J4-- and J5--axis gearboxes through their respective

greasenipples. Keepgreasing untilthe newgrease pushesout theold

grease and comes out from each grease outlet. Ensurethat the amount

of the newly supplied grease equals the amount of the drained grease

so that the grease bath will not become full.

4) Wind sealing t ape around the J1--, J2--, and J3--axis seal bolts you

removed, and attach them to the respective grease outlets.

5) Attach the J4-- and J5--axis flat--head bolts and t he J4-- and J5--axis

sealing washers to the respective grease i nlets and outlets.

Table. 3.2 Grease to be replaced at regular intervals of three years

Specified grease Amount of

Robot pos-

Kyodo Yushi

J1--axis reducer

J2--axis reducer

J3--axis reducer About300 -J4--axis gearbox About 700 -J5--axis gearbox About 400 J4=+90°

Mori White RE No.00

pec

A98L-0040-0119#2.4KG)

on:

applied (cc)

About 1100 --

About 570 --

greased

Page 31

B--81545EN/01

3. PERIODIC MAINTENANCEMAINTENANCE

CAUTION

If you grease incorrectly, the pressurein the grease bath may

increasesteeply,leadingtoabrokenseal,whichwilleventually

cause grease leakage or malfunction.

When greasing, be sure to follow the cautions stated below.

1 Before starting greasing, open the grease outlets (remove

bolts and the like from the grease outlets).

2 Using a manual greasing pump, grease gently and slowly.

3 Avoid using a pneumatic pump driven from a factory

pneumatic line as much as possible.

Ifyou cannotavoid usingit, observea greasingspeedof 15

2

cc/s or lower and a pressure of 75 kgf/cm

or lower.

4 Be sureto use thespecifiedgrease. Otherwise,damage to

reducers or a similar abnormality may occur.

5 Beforecapping thegreaseoutlets, makesure thata grease

flow from the grease outlet has stopped (the remaining

pressure has been released).

6 Wipe offany greasefromthe floor androbot completely, so

no one will slip on it.

Page 32

3. PERIODIC MAINTENANCE

MAINTENANCE

B--81545EN/01

Whenreplacing or supplying grease, keepthe robot in the postureshown

in Fig. 3.2.

Fig 3.2 Robot posture forgreasing

Axis Posture

Free

Page 33

B--81545EN/01

3. PERIODIC MAINTENANCEMAINTENANCE

3.3

BA TTER Y

REPLACEMENT

A backup batteryis used to keep thereference--position data for eachaxis

of the robot.

The battery needs to be replaced at regular intervals of one year and half.

Follow this procedure for battery replacement.

1) Keep the power turned on.

Press the EMERGENCY STOP button of the robot to keep it from

moving.

2) Uncap the battery case.

3) Take out the battery from the battery case.

4) Insert a new batteryinto the batterycasewhile payingattention to the

polarity of the battery.

5) Cap the battery case.

Batterycase

Cap

Battery specifications : A98L--0031-- 0005

(1.5V size--D 4pcs)

Fig 3.3 Battery replacement

Page 34

B--81545EN/01

4

4. TROUBLESHOOTINGMAINTENANCE

TROUBLESHOOTING

Page 35

4. TROUBLESHOOTING

MAINTENANCE

B--81545EN/01

4.1

OVERVIEW

A trouble with a mechanical unit may occur due to a combination of

multiple causes. It is difficult to find out the true cause,and an incorrect

measure may make the trouble worse. When troubleshooting, it is

important to get hold of the situation of any error accurately and take a

correct measure.

Page 36

B--81545EN/01

4. TROUBLESHOOTINGMAINTENANCE

4.2

TROUBLES AND

CAUSES

Symptom

BZAL alarmissued

(battery zero)

Incorrectpositioning

Table 4.2 (a) lists the major troubles in the mechanical unit and their

causes. Ifyoucannot find a causeaccuratelyordonotknowwhatmeasure

to take, please contact FANUC.

Note, however, that the backlash and drop levels listed, respectively, in

Table 4.2 (b) and Table 4.2 (c) and lower are not abnormal.

Table 4.2 (a) Major troubles and causes (1/3)

Cause Measure Remark

The voltage of the memory

backup battery has dropped.

Broken pulse coder signal

cable

Something hit the robot. Correctthe taught point.

The robotis not firmly fixed. Fix it. See Section 3.2 of Part II,

Peripheral equipment has

shifted.

Load too heavy Reducethe load.

Replace the battery,and perform simplified mastering.

Replace the cable, and perform simplified mastering.

Fix it.

Limitthe operatingcondition.

See Section3.3.

See Section5.3.

See Section8.2.

See Section5.3.

“Connection”.

Load on the wrist:

Refer to “Descriptions”.

Peripheralequipment:

See Section 2.2of Part II,

“Connection”.

Incorrectparametersetting Correct it. Referto“Operator’sManual”.

Broken cable Replace the cable. See Section8.2.

Pulse c oder error Replace the motor. See Sections6.1 to 6.11.

Backlash in the mechanical

unit ---- see the next section.

Page 37

4. TROUBLESHOOTING

MAINTENANCE

Table 4.2 (a) Major troubles and causes (2/3)

B--81545EN/01

Vibration

Symptom

Cause Measure Remark

The robotis not firmly fixed. Fix it. See Section 3.2 of Part II,

“Connection”.

The floor is vibrating (especially when the robot is

installed on the second floor

or above).

Load too heavy Reducethe load.

Servo maladjustment Adjust the servo section. Contact FANUC.

Broken cable Replace the cable. See Section8.2.

Robot not grounded Ground the robot. Referto“MaintenanceManu-

Defective motor Replace the motor. See Sections 6.1 to 6.11.

Defective axis printed--circuit

board

Defective reducer Replacethe reducer. See Sections6.2 to 6.11.

Re--examine the location of

installation.

Limitthe operatingcondition

Replace the axis printed--circuit board.

Load on the wrist:

Refer to “Descriptions”.

Peripheralequipment:

See Section 2.2of Part II,

“Connection”.

al for the Controller”.

Referto “MaintenanceManual for the Controller”.

Backlash or wobbling

Abnormal sound

Invalid time constant setting Change the time constant. Referto“Operator’sManual”.

Backlash in the mechanical

unit ---- see the next section.

Loose screw or pin Tighten it (and apply Loctite

to it if specified so)

Defective reducer Replacethe reducer. See Sections6.2 to 6.11.

Gear maladjustment Adjustthe gear. See Section5.7.

Worn gear Adjustor replace the gear. Contact FANUC.

Worn bearing Replacethe bearing. Contact FANUC.

Broken casting or otherpart Replace the broken compo-

nent.

Insufficientgreaseforgear or

reducer

Foreign matter in gear or re-

ducer

Gear maladjustment Adjustthe gear. Contact FANUC.

Worn gear Adjustor replace the gear. Contact FANUC.

Apply grease. See Sections3.1 and 3.2.

Washthegearor reducerand

apply grease.

Contact FANUC.

See Sections 6.2 to 6.11,3.1,

and 3.2.

Worn bearing Replacethe bearing. Contact FANUC.

Servosectionmaladjustment Adjust the servo section. Contact FANUC.

Page 38

B--81545EN/01

4. TROUBLESHOOTINGMAINTENANCE

Table 4.2 (a) Major troubles and causes (3/3)

Symptom

Abnormal heat generation

Arm drop at power turn--off

Grease leakage

Cause Measure Remark

Insufficientgreaseforgear or

reducer

Non--specified grease used Replace the grease. See Sections3.1 and 3.2.

Load too heavy Reduce the load.

Gear maladjustment Adjustthe gear. Contact FANUC.

Invalid time constant setting Change the time constant

Too large a brake gap Replace the motor. See Sections 6.1 to 6.11.

Brake drive relay contactde-

position

Deteriorated or broken

O--ring, oil seal, or gasket

Broken casting or otherpart Replace the broken compo-

Apply grease. See Sections3.1 and 3.2.

Load on the wrist:

Limitthe operatingcondition.

setting.

Replace the relay Referto“MaintenanceManu-

Replace the O--ring, oil seal,

or gasket.

nent.

Refer to “Descriptions”.

Peripheralequipment:

See Section 2.2of Part II,

“Connection.”

Referto“Operator’sManual”.

al for the Controller”.

Contact FANUC.

Contact FANUC.

Loose screw Tightenit.

Table 4.2 (b) Allowable backlash level for each axis

J1 J2 J3 J4 J5 J6

Backlashintermof

angle (min)

Backlashintermof

displacement(mm)

2.5 2.5 2.5 3.0 4.5 3.0

0.95

(1300)

NOTE

The backlash in term of displacement (mm) is measured in

the direction of rotation at a distance represented with a

value enclosed in parentheses.

Table 4.2 (C) Allowable arm drop

At power turn--off time

At emergency stop time 5mm

0.44

(600)

5mm

0.44

(600)

0.17

(200)

0.2

(200)

0.17

(200)

Page 39

4. TROUBLESHOOTING

MAINTENANCE

B--81545EN/01

4.3

COMPONENT

REPLACEMENT AND

ADJUSTMENT ITEMS

Adjustments are needed after a component is replaced.

The following table lists componentsand the adjustment items that must

be made after their replacement. After replacing a component, make

necessary adjustments according to this table.

Component replacement or

function change

Cable replacement (a) Cable dressing

(b) Simplified mastering

Change to J1--axis stroke (a) Change to stopper position

(b) Change to parameter

Battery replacement

(The battery should be replaced once

a year.)

Replace the battery with the power

kept on.

No adjustmentis needed.

Adjustment item

Page 40

B--81545EN/01

5

5. ADJUSTMENTSMAINTENANCE

ADJUSTMENTS

Each part of the mechanical units of a robot is set to the best condition

beforethe robot is shipped to the customer. The customerdoes not need

to make adjustments on the robot when it is delivered.

If a mechanical unit of the robot has a large backlash because of a

long--term use or component replacement, make adjustments according

to this section.

Page 41

5. ADJUSTMENTS

MAINTENANCE

B--81545EN/01

5.1

REFERENCE

POSITION AND

MOVING RANGE

1) Reference position and operation limit

Each controlled axis is provided with a reference position and

operation limit.

A state in which a controlled axis has reached its operation limit is

known as overtravel (OT). For each axis, an overtravel condition can

be detected at the both ends of it. As long as the robot does not

encountera servo section error or system errorthat causes a reference

position to be lost, the robot is controlled insuch a way that it will not

go out of its operation area.

Fig. 5.1 (a) to Fig. 5.1 (g) show the reference position and operation

area (stroke) of each axis and their mechanical stopper positions.

Fig. 5.1 (h) shows the operation directions (+/-- directions) of each

axis.

Stroke

Mechanical stopper Mechanical stopper

Fig 5.1 (a) J1--axis swiveling (typically 340°)

Note)Motion limit is restricted by the

position of the J3--axis

Mechanical

stopper

Stroke end

Fig 5.1 (b) J2--axis rotation

Stroke endStroke end

Stroke

Stroke end

Mechanical stopper

Page 42

B--81545EN/01

Note)Motion limit is restricted by the

position of the J2--axis

Stroke end

Mechanical

stopper

Mechanical

stopper

Stroke end

Fig 5.1 (c) J3--axis rotation

5. ADJUSTMENTSMAINTENANCE

Stroke

Stroke endStroke end

Note) The mechanical s topper are not provided forJ4--axis

Fig 5.1 (d) J4--axis rotation

Stroke end

Mechanical stopper

Mechanical stopper

Stroke end

Fig 5.1 (e) J5--axis wrist rotation

Stroke

Page 43

5. ADJUSTMENTS

MAINTENANCE

Fig 5.1 (f) J6--axis wristrotation

B--81545EN/01

Stroke endStroke end

Stroke

Mechanical stopper

Stroke end

J3--axis arm

Interference

angle 170°

J2--axis arm

Fig 5.1 (g) J2/J3 limit interference angle

Interference angle 10°

Stroke end

Mechanical stopper

Page 44

B--81545EN/01

5. ADJUSTMENTSMAINTENANCE

Fig 5.1 (h) Operation directions of each axis

Page 45

5. ADJUSTMENTS

MAINTENANCE

B--81545EN/01

5.2

SIMPLIFIED

MASTERING

The term simplified mastering refers to a procedure for resuming the

previous position completely after a pulse coder battery backup is

disconnected because of cable replacement.

Simplifiedmasteringcannotbe usedifthe pulse coderphasehas changed

mechanically because of a motor or reducer having been replaced. To

calibrate the robot position accurately, perform the jig--based mastering

describedinSection5.4.

1) Procedure

Described below is the simplified mastering to be performed with a

posture of zero degrees for all axes after cable replacement.

1 Before replacing the cable, be sure to take note of the system

variable $DMR_GROUP.$MASTER_COUN[1] to [6] (previous

mastering data).

2 Replace the cable according to the cable replacement procedure

describedinSection8.2.

3 If you want to release brake control, set the system variable

$PARAM_GROUP.$SV_OFF_ENB to FALSE for all axes, turn

off the power, and then perform a cold start.

4 After the power is turned on, the alarm message BZAL alarm is

displayed. Select “TRUE” for the system variable

$MCR.SPC_RESET, turn off the power, and then perform a cold

start.

5 After the power is turned on again, the message Pulse not

established is displayed. Rotate each axis through 20° or so in

either (+ or --) direction, using an individual--axis feed command,

and then press the alarm reset key to reset this message.

6 By performing an individual--axis feed command foreach axis, set

the zero--degree mark within +/--1 mm from the scribed line. (See

Fig. 5.2.) If no reference position has been set up at zero degrees

for all axes, using simplified mastering, go to 7. Otherwise, go to

8.

7 Assign the mastering data in $DMR_GROUP.$MASTER_

COUN[1] to [6] that was taken note of at 1 to the system variable

$DMR_GROUP.$REF_CONUT[1] to [6] (simplified mastering

data). Loadthesystemvariable$DMR_GROUP. $REF_POS[1]to

[6] (simplified mastering reference positions) with “0”. Select

“TRUE” for the $DMR_GROUP.$REF_DONE (simplified

mastering completion flag). Now the simplified mastering

reference position has been set up at zero degrees for all axes.

8 Press the screen selection key to select “0” NEXT, and select

SYSTEM from the menu.

9 Press the F1 key TYPE, select the system variable, and set

$MASTER_ENB value inthelist to1. Press theF1 key TYPEand

select MASTER / CAL.

10 Select The system calibration menu from the system positioning

menu, andpress theFAkey YES to performsimplified mastering.

Now the mastering data obtained from the pulse coder counter

valueisset inthesystem variable$DMR_GRP .MASTER_COUN,

and the system variable $DMR_GRP.MASTER_DONE

(mastering completion flag) is set to “TRUE”.

Page 46

B--81545EN/01

5. ADJUSTMENTSMAINTENANCE

11 Select CALIBRATE from the system positioning menu, and press

the F4 key YES Now positioning is carried out, and teaching and

replaying are enabled.

12 After you are finished with mastering, reset the system variable

$MASTER_ENB to 0.

13 If you released brake control before, re--set the system variable

$P ARAM_GROUP.$SV_OFF_ENB for each axis to the previous

value, turn off the power, and then perform a cold start.

Oncemasteringis completed,updatethedatasheetsupplied togetherwith

the robot with the new mastering data ($DMR_GROUP.$MASTER_

COUN[1] to [6]).

J3--axis

J4--axis

J2--axis

J5--axis

J6--axis

J1--axis

Fig 5.2 Marking of the zero--degree position for each axis

Page 47

5. ADJUSTMENTS

MAINTENANCE

B--81545EN/01

5.3

MASTERING BY

ZERO POSITION

MARK ALIGNMENT

Each robot axis is provided with the scribed lines shown in Fig. 5.2 for

positioning. When these markings are aligned to each other, each axis is

at the zero--degree position. If the markings get misaligned because of

motor or reducer replacement, the following procedure can be used for

rough positional calibration. This is a simplified method. To perform

accurate positional calibration, use the jig--based mastering described in

Section 5.4.

1) Procedure (zero--position mastering)

1 If you want to release brake control, set the system variable

$PARAM_GROUP.$SV_OFF_ENBto “FALSE”forall axes, turn

off the power, and then perform a cold start.

2 After the power is turned on, if the alarm message BZAL alarm is

displayed, select “TRUE” for the system variable $MCR.SPC_

RESET, turn off the power, and then perform a cold start.

3 After the power is turned on again, if the message Pulse not

established isdisplayed, rotate each axisthrough 20° orso in either

(+ or --) direction, using an individual--axis feed command, and

then press the alarm reset key to reset this message.

4 By performing an individual--axis feed command foreach axis, set

each axis to the zero--degree mark. (See Fig. 5.2.)

5 Press the screen selection key to select “0” NEXT, and select

SYSTEM from the menu.

6 Press the F1 key TYPE, select the system variable, and set

$MASTER_ENB value inthelist to1. Press theF1 key TYPEand

select MASTER/CAL.

7 Select ZERO POSITION MASTER from the system positioning

menu, and press the F4 key YES to perform zero--position

mastering. Now the system variable $DMR_GRP.MASTER_

COUNis set withthemasteringdata obtained fromthepulse coder

counter value, and the system variable $DMR_GRP.MASTER_

DONE (mastering completion flag) is set to “TRUE”.

8 Select MASTER/CAL from the system positioning menu, and

press the F4keyYES. Now positioningis carriedout, andteaching

and replaying are enabled.

9 After you are finished with mastering, reset the system variable

$MASTER_ENB to 0.

10 If you released brake control before, re--set the system variable

$PARAM_GROUP.$SV_OFF_ENB to the previous value for all

axes, turn off the power, and then perform a cold start.

Oncemasteringis completed,updatethedatasheetsupplied togetherwith

the robot with the new mastering data ($DMR_GROUP.$MASTER_

COUN[1] to [6]).

If you want to perform mastering for a specific axis, use the following

single--axis masteringprocedure. Newposition informationfor thataxis

is stored, and position information for the other axes is preserved.

As for the J2-- and J3--axes, each of which is accompanied by the other,

perform mastering for them simultaneously.

Page 48

B--81545EN/01

5. ADJUSTMENTSMAINTENANCE

2) Procedure (single--axis mastering)

1 If you want to release brake control, set the system variable

$PARAM_GROUP.$SV_OFF_ENBto “FALSE”forall axes, turn

off the power, and then perform a cold start.

2 After the power is turned on, if the alarm message BZAL alarm is

displayed, select “TRUE” for the system variable $MCR.SPC_

RESET, turn off the power, and then perform a cold start.

3 After the power is turned on again, if the message Pulse not

established isdisplayed, rotate each axisthrough 20° orso in either

(+ or --) direction, using an individual--axis feed command, and

then press the alarm reset key to reset this message.

4 Byperformingan individual-- axis feedcommandfora desiredaxis,

set the axis to the zero--degree mark. (See Fig. 5.2.)

5 Press the screen selection key, select “0” NEXT, and select

SYSTEM from the menu.

6 Press the F1 key TYPE, select the system variable, and set

$MASTER_ENBvalueinthelist to 1. PresstheF1key TYPE, and

select MASTER/CAL.

7 Select SINGLE AXIS MASTER from the system positioning

menu. Asettingmenu foreach axisappears. Enter“1” in the(SEL)

column for the axis for which you want to perform mastering.

Enter “0” for the other axes. Enter “0” (zero degrees) i n the

MASTERING POSITION column, and press the F5 key EXEC to

perform zero--degree position mastering for the selected axis.

8 Select MASTER/CAL from the system positioning menu, and

press the F4keyYES. Now positioningis carriedout, andteaching

and replaying are enabled.

9 After you are finished with mastering, reset the system variable

$MASTER_ENB to 0.

10 If you released brake control before, re--set the system variable

$PARAM_GROUP.$SV_OFF_ENB to the previous value for all

axes, turn off the power, and then perform a cold start.

Oncemasteringis completed,updatethedatasheetsupplied togetherwith

the robot with the new mastering data ($DMR_GROUP.$MASTER_

COUN[1] to [6]).

Page 49

5. ADJUSTMENTS

MAINTENANCE

B--81545EN/01

5.4

JIG--BASED

MASTERING

If the current--position value stored through the pulse coder becomes

differentfrom the actualposition ofeach axis becausea majorcomponent

of the mechanical unit of the robot is replaced, masteringis performed by

specifying the geometric position of the robot. (Mastering is performed

at a position of J1 = 0(.) For all robots, mastering is performed at the

factory.

When calibrating the robot, have it satisfy the following conditions.

D Level out the installation base for the robot (1 mm/base).

D Remove the hand and all other components from the wrist.

D Keep the robot from any external force.

NOTE

When the robotisbeing subjected to mastering, itdoesnot

make a stroke check. Pay sufficient attention to the

operation of the robot axes.

1) Mastering procedure

a) Assembling mastering jigs

i) Assembling the jig base

As shown in Fig. 5. 4 (a),attachmasteringjig Bto mastering jig

C.

Mastering jig C

Bolt:M5×16 (3pcs)

Washer: M5 (3pcs)

Fig 5.4 (a) Assembling the jib base

Mastering jig B

Page 50

B--81545EN/01

5. ADJUSTMENTSMAINTENANCE

ii) Attaching to the robot main body

As shown in Fig. 5.4 (b), mount dial gauges to the jig base.

Using a calibration block, set the pointer of each dial gauge to

3.0mm,andfixthedialgaugeswith M5 bolts. (Becarefulwhen

tightening the bolts. Tightening them too firmly can break the

dial gauges.)

Calibration block

Dial gauge

(Push all the dial gauges against the calibration

block, and make adjustments so that they read

3 mm.)

Fig 5.4 (b) Attaching the dial gauge

(6pcs)

Page 51

5. ADJUSTMENTS

MAINTENANCE

B--81545EN/01

iii)Attaching to the robot main body

As shown in Fig. 5.4 (c), attach the jig baseto the J1 base with

bolts and pins.

Pin A

A290-7215-X955

Pin B

A290-7215-X956

Bolt:M12×25 (2pcs)

Washer: M12 (2pcs)

J1 base

Fig 5.4 (c) Attaching to the robot main body

Page 52

B--81545EN/01

5. ADJUSTMENTSMAINTENANCE

iv)Attaching the jig to the wrist

Manuallymove thewrist axis to a position of J4 = J5 = J6 = 0°.

Attach mastering jig A to the J6--axis in the orientation shown

in Fig. 5.4 (d).

Mastering jig A

Bolt:M6×12 (2pcs)

Washer: M6 (2pcs)

Pin

Fig 5.4 (d) Attaching the jig to the wrist

b) Performing mastering

1 First perform the mastering by zero--degree positioning

describedinSection5.3.

This procedure will set an approximate, temporary coordinate

origin in the robot.

2 To disable brake control, set the system variable

$PARAM_GROUP_SV_OFF_ENB to FALSE for all axes,

turn the power off, and perform a cold start.

3 Press the screen selection key ,select “0” NEXT ,and thenselect

SYSTEM from the menu. Press the F1 key TYPE, and select

the system variable. For $DMR_GROUP.$MASTER_DONE

(simplifiedmasteringcompletionflag),select“FALSE”so that

each axis can move out of the stroke range. When operating the

robot, keep its taught override speed low.

4 Using a single--axis feed command, place the robot in the

mastering posture shown in Fig. 5.4 (e).

Page 53

5. ADJUSTMENTS

MAINTENANCE

B--81545EN/01

Masteringposture

Fig 5.4 (e) Mastering posture

5 Press the screen selection key , select “0” NEXT, and select

SYSTEM from the menu. Press the F1 key TYPE, and select

thesystemvariable. In thelist, set$MASTER_ENB to 1. Then

press the F1 key TYPE, and select MASTER/CAL.

6 Select FIXTURE POSITION MASTER from the system

positioning menu, and press the F4 function key YES.

Mastering is performed. Now, the system variable $DMR_

GRP.MASTER_COUN is set with themastering dataobtained

from the pulse coder counter value, and the system variable

$DMR_GRP.MASTER_DONE (mastering completion flag)is

set to “TRUE”.

7 Select MASTER/VOL from the system positioning menu, and

press the F4 key YES. Positioning is performed, and teaching

and replaying become enabled.

8 Onceyou arefinishedwith mastering,resetthe system variable

$MASTER_ENB value to 0.

9 To enablebrake control, re--set the $PARARM_GROUP.$SV_

OFF_ENB to theprevious value forall axes, turnoffthe power,

and perform a cold start.

Page 54

B--81545EN/01

5. ADJUSTMENTSMAINTENANCE

Oncemasteringis completed,updatethedatasheetsupplied togetherwith

the robot with the new mastering data ($DMR_GROUP.$MASTER_

COUN[1] to [6]).

Ifyou want to performmasteringforaspecific axis, takenoteof thevalue

of the mastering data (system variable $DMR_GROUP.$MASTER_

COUN), and then perform mastering for all axes. Once you are finished

with mastering, re--enter the mastering data of the axes other than that

specific axis. New position information for that axis is stored, and

position information for the other axes is preserved.

Page 55

5. ADJUSTMENTS

MAINTENANCE

B--81545EN/01

5.5

CONFIRMING

MASTERING

1) Confirming that mastering was performed normally

Usually, positioning is performed automatically when the power is

turned on. To confirmthat mastering was performednormally, check

that the current--position display matches the actual position of the

robot, using this procedure.

a) Replay the taught operation of the robot to set each axis to zero

degrees, and visually check that the zero--degree position marks

shown in Fig. 5.2 are aligned.

b) Replay a specific portion of the program,and check that the robot

has moved to the taught position.

2) Possible alarms in positioning

The following paragraphs describe alarms that may occur in

positioning and explain how to handle them.

a) BZAL alarm

This alarm is raisedif thevoltageof the pulsecoderbackupbattery

becomes 0V when the controller power is off. Mastering must be

performed again because the counter has already lost data.

b) BLAL alarm

This alarm indicates that the voltage of the pulse coder backup

battery is too low to run the pulse coder. If this alarm is issued,

replace the backup battery soon while keeping the power on, and

checkwhether the current--position datais correct,using amethod

described in item (1).

c) CKAL,RCAL,PHAL,CSAL, DTERR,CRCERR, STBERR, and

SPHAL alarms

If any of these alarms is issued, contact your FANUC service

representative. A motor may have to be replaced.

Page 56

B--81545EN/01

5. ADJUSTMENTSMAINTENANCE

5.6

J5--AXIS GEAR

BACKLASH

ADJUSTMENTS

Gear 2 assembly

Seal bolt with washer :

M5×12 (4pcs)

Plane washer (4pcs)

Low head bolt : M5×10 (9pcs)

If the backlash in the J5--axis is harder than the allowable value (output

axis angle of 4.5 minutes) listed in Table 4.2 (b), make backlash

adjustments, using this procedure. (See Fig. 5.6.)

1 Place the robot in a posture of J4 = +90° andJ5=J6=0°.

2 Remove the nine M5×10 flat--head bolts, and dismount the J5--axis

gearbox cover (A290--7215--X524) from the J3 arm (A290--7215-X402).

J3 arm

Gear J5--4

Bolt with washer :

M5×25 (6pcs)

Loctite

Gear 3 assembly

Seal bolt with washer :M5×12 (6pcs)

Cover J 5--1

Reference bolt

(Do not remove the bolt. Just loosen it.

Be sure to replace it with a new one after

adjustmentsare completed.)

Fig 5.6 J5--axis gear backlash adjustments

1) Gear 3 assembly and gear J5--4 backlash adjustments

1 Remove the four M5×12 seal bolts with a washer, and retract the

gear2 assembly (A290--7215--V501) tosuch a pointthat it will not

be engaged with the gear 3 assembly (A290--7215--V502).

Page 57

5. ADJUSTMENTS

MAINTENANCE

B--81545EN/01

2 Remove the five M5×12 seal bolts with a washer. These bolts

work not only for mounting but also sealing the gear unit grease

bath. Once you have removed them, replace them with new ones.

In reference to the bolt (Do not remove this bolt; just loosen it.

However, looseningitimpairsits ability toseal. Once adjustments

are completed, after the other seal bolts are tightened, replace this

bolt with a new one. Otherwise, grease may leak.) shown in Fig.

5.6, push the gear 3 assembly against the output gear

(A290--7215--X514), and fix the gear 3 assembly temporarily.

Afteryou havefixed the gear3 assemblytemporarily, rotate theJ6

housing (output gear)in bothpositive andnegative directions, and

check whether their rotation is abnormally heavy and any portion

has a serious backlash. Repeat the above procedure until any

backlash becomes lower than the maximum allowable value and

the engagement and rotation torque becomes moderate.

3 Onceyou have completed adjustments,fixthe J3 armwith new six

M5×12 seal bolts.

2) Gear 2 assembly and gear 3 assembly backlash adjustments

1 Shift the gear 2 assembly in a direction vertical to the gear 3

assembly and input gear (A290--7215--X511) so that the backlash

is reduced, and fix t he gear 2 assembly to the J3 arm with four

M5×12 seal bolts with a washer.

2 Rotate t he gear 2 assembly, and check the operation of the J5--axis

by operating i t within its stroke (--140° to +140°). Repeat step 1

forreducing thebacklashuntilthe gearswill notinterfere with each

other.

Fix the gear 2 assembly temporarily in the same manner as stated

in(1). Once you havecompletedadjustments,mount theassembly

with new M5×12 seal bolts with a washer.

3 Make sure that the total backlash in the J5--axis unit is lower than

the maximum allowable value (output axis angle of 4.5 minutes)

listed in Table 4.2 (b). If the requirement is not satisfied, go back

to 1 of procedure (1).

4 Fix the J5--axis gearbox cover to the J3 arm with nine M5×10

flat--head bolts.

5 Apply the specifiedgreaseto theJ5--axis gearbox by followingthe

grease replacement procedure stated in Section 3.2.

6 Perform mastering as stated in Sections 5.3 and 5.4.

Page 58

B--81545EN/01

5. ADJUSTMENTSMAINTENANCE

5.7

BRAKE RELEASE

Whenthe robotpower is off, the brakesof the robot can bereleasedusing

the brake release unit (option). In this case, the robot can be put in a

different posture. Observe Notes 1 to 4 given below.

NOTE

1 When releasing the brakes of the J2-- axis or J3--axis motor

(M2orM3), suspendtherobot witha craneas showninFig.

5.7.

2 When releasing the brakes of the J4--axis to J6--axis motor

(M4 to M6), suspend the end effector with a crane so that

it will not fall.

3 When releasing the brakes of motors, use slings having a

sufficient tensile strength.

4 Do not release the brakes of more than one motor

simultaneously.

Page 59

5. ADJUSTMENTS

MAINTENANCE

B--81545EN/01

Fig 5.7 Releasing the brakes of the J2--axismotor

Page 60

B--81545EN/01

6

MAINTENANCE

6. COMPONENT REPLACEMENT AND

ADJUSTMENTS

COMPONENT REPLACEMENT AND ADJUSTMENTS

Adjustments are needed after a component is replaced.

The following table lists componentsand the adjustment items that must

bemade after thecomponents arereplaced. Afterreplacing acomponent,

make necessary adjustments according to this table.

Replacement component Adjustment item

Motor (a) Mastering

J1--, J2--, and J3--axis reducers (a) Mastering

J4--axis gearbox (a) Mastering

J5--axis gearbox (a) Mastering

J6--axis reducer (a) Mastering

NOTE

Be verycarefulwhen dismounting andmounting the heavy

components that are listed below.

Component Weight

J3--axis arm (See Fig. 6.8.) 10.4kg

All components from J3--axis reducer to wrist unit (See

Fig. 6.6.)

All components from J2--axisarm to wrist unit(See Fig.

6.4. (a).)

All components from J2--axis base to wrist unit (See

Fig. 6.2 (a) and (b).)

31kg

38.7kg

69.4kg

Page 61

6 COMPONENT REPLACEMENT

AND ADJUSTMENTS

6.1

REPLACING THE

J1--AXIS MOTOR M1

MAINTENANCE

1 Turn off the controller power.

2 Remove the J1--axis motor connector.

3 Removethe four M8×20 motormountingbolts. Dismountthemotor

fromthe J1--axis unit. When dismounting the motor,be careful ofthe

grease that may drop from the motor if the robot is suspended from a

ceiling or mounted on a wall.

4 Remove the M10 hexagonal nutfrom themotor shaft, andpull outthe

gear (A290--7215--X211).

5 Attach the gear to a new motor (with two axes equipped with a brake

(A06B--0223-- B005) or six axes equippedwith a brake(A06B--0223-B605)).

6 Attach an M10 spring washer, apply Loctite 242 to the M10 threaded

portion of the motor, and tighten the M10 nut with a specifiedtorque

of [16.7 Nm].

7 Make sure that the O--ring (G105) is correctly attached to the J2 base

(A290--7215--X301) portion where the J1--axis motor is to be

mounted, and fasten them with four M8×20 bolts.

8 Attach the cable connector to the J1--axis motor.

9 According to Section 3.2, supply the J1--axis grease bath with the

specified grease.

10 While referencing Chapter 5, perform mastering.

B--81545EN/01

NOTE

If there is a danger that the J1-- axis section may swivel, for

example, because the robot is installed on a tilted surface,

fix the J1-- axis section during replacement work, for

example, by pushing the J1--axis mechanical stopper

against to the J1--axis section.

Page 62

B--81545EN/01

M10 Screw washer

M10 hex agonal nut

Loctite

MAINTENANCE

6. COMPONENT REPLACEMENT AND

ADJUSTMENTS

Bolt:M8×20 (4pcs)

Washer: M8 (4pcs)

J1--axis motor

Gear

O--ring

J2 base

Fig 6.1 Replacing the J1--axis motor

Page 63

6 COMPONENT REPLACEMENT

AND ADJUSTMENTS

6.2

REPLACING THE

J1--AXIS REDUCER

MAINTENANCE

1 Put the robot in such a posture that the J2 base andthe portions above

it can be suspended with a crane or the like (hereafter abbreviated as

a crane), and then turn off the controller power.

2 While referencing Section 8.2, pull out the cables below the J2 base

(A290--7215--X301) from the J1--axis hollow pipe section toward the

upper portion of the J2 base.

3 While referencing Section 6.1, remove the J1--axis motor from the J2

base.

4 As shown in Fig. 6.2 (a), remove the eight M10×50 bolts that fasten

the J2 base to the J1--axis reducer .

5 While referencing Section 3.1 of Part II, “Connection,” hoist the J2

base and portions above it slowly.

6 As shown in Fig. 6.2 (a), remove the O--ring (A290--7207--X342),

bearing, and center gear (A290--7215--X212).

7 Remove the six M12×80 bolts that fasten the J1--axis reducer to the

J1 base (A290--7215--X201), and dismount the reducer.

8 Asshown in Fig. 6.2 (b),removethefour M4×10 boltsthatfastenthe

pipe (A290--7215--X213) to the reducer, and dismount the pipe.

9 Make sure that the pipe is fitted with the O--ring (G60) correctly, and

attach the pipe to a new reducer (A97L--0218--0288#33) with four

M4×10 bolts.

10 Attach the O--rings (SO100 and SO150) to the reducer, and fasten the

reducerto a newJ1 basewith six M12×80 bolts(by applying Loctite

262 and tightening with a torque of [129 Nm]).

11 Mount the center gear, bearing (with Loctite 675 applied to its outer

ring), and O--ring (A290--7207--X342) to the reducer.

12 Fasten the J2 base to the reducer with eight M10×50 bolts (by

applying Loctite 262 and tightening with a torque of [73.5 Nm]). Be

careful not to let the pipe damage the oil seal.

13 According to Section 6.1, mount the J1--axis m otor on the J2 base.

14 According to Section 3.2, supply the J1--axis grease bath with the

specified grease.

15 While referencing Chapter 5, perform mastering.

B--81545EN/01

Page 64

B--81545EN/01

(4pcs)

MAINTENANCE

6. COMPONENT REPLACEMENT AND

ADJUSTMENTS

O--ring

Bearing

Bolt:M12×80 (6pcs)

Loctite

Washer : M12 (6pcs)

J1--axisreducer

J1--axis motor

Bolt: M10X50 (8pcs)

Loctite

Washer : M10 (8pcs)

O--ring

Center gear

O--ring

O--ring

Fig 6.2 (a) Replacing the J1--axis reducer

J1 reducer

O--ring

Pipe

Bolt

(4pcs)

Washer

Fig 6.2 (b) Replacing the J1--axis reducer

Page 65

6 COMPONENT REPLACEMENT

AND ADJUSTMENTS

6.3

REPLACING THE

J2--AXIS MOTOR M2

MAINTENANCE

1 Push the J2--axis section against the mechanical stopper, or fix it in

such a way that it will not swivel when the motor is dismounted, for

example, by placing it in the direction of gravity.

NOTE

If the J2--axis section is not pushed against the stopper

correctly, or it is not placed in the direction of gravity, there

is a danger that the J2--axis section will swivel when the

J2--axis motor is removed.

2 Turn off the controller power.

3 Remove the J2--axis motor connector.

4 Remove the four M8×20 motor mounting bolts, and dismount the

motor from the J2 base.

5 Remove the M6 hexagonal nut that fastens the input spline, and

dismount theinput spline. Also remove the draw bolt from the motor

shaft.

6 Apply Loctite 242 to the threaded portion of a new motor

(A06B--0223--B605), and tighten the drawbolt with a torque of [16.7

Nm].

7 Put the input gear over the draw bolt, attach an M6 spring washer,

apply Loctite 242 to the M6 threaded portion of the draw bolt, and

tighten the M6 nut with a torque of [5.5 Nm].

8 Make sure that the O--ring (G115) is correctly attached to the J2 base

(A290--7215--X301) portion where the motor is to be mounted, and

fasten the motor to the J2 base with four M8×20 bolts. Do not force

in the motor. Otherwise,the input spline may not settle in the correct

place, possibly causing vibration (ifthe splineis engagedcorrectly,the

motor will be mounted smoothly).

9 Attach the cable connector to the J2--axis motor.

10 According to Section 3.2, supply the J2--axis grease bath with the

specified grease.

11 While referencing Chapter 5, perform mastering.

B--81545EN/01

Page 66

B--81545EN/01

MAINTENANCE

Draw bolt

Loctite

6. COMPONENT REPLACEMENT AND

ADJUSTMENTS

Input spline

M6 Springwasher

J2--axis motor

O--ring

Bolt:M8×20 (4pcs)

Washer: M8 (4pcs)

J2 base

M6 nut

Loctite

Fig 6.3 Replacing the J2--axis motor

Page 67

6 COMPONENT REPLACEMENT

AND ADJUSTMENTS

6.4

REPLACING THE

J2--AXIS REDUCER

MAINTENANCE

1 Put the robot insuch aposture that the J2arm (A290--7215--X302)and

the componentson it can be suspended with a crane,and then turn off

the controller power.

2 Suspend the J2 arm andthe componentson it with a crane so that they

will not drop when the J2 arm is dismounted.

3 Asshown in Fig. 6.4 (a),removetheten M10×50 boltsthatfastenthe

J2 arm, dismount the J2 arm and plate (A290--7215--X321) from the

J2--axisreducer,andthendismountadapter1(A290--7210--X321). B e

careful not to allow an excessive load to be put on the cables (because

the cables are left attached when the reducer is dismounted).

4 Remove the eight M8×35 bolts that fasten the J2--axis reducer to the

J2 base, and dismount the J2--axis reducer from the J2 base.

5 Attach the O--ring (AS258) to a new reducer (A97L--0218--0289#153),

insert it into the J2 base, and fasten them with eight M8×35 bolts (by

applying Loctite 262 and tightening with a torque of [37.2 Nm]).

6 Degrease both the J2 arm and the J2--axis reducer surfaces that are to

meet each other, and as shown in Fig. 6.4 (b), apply sealant (Loctite

No. 518) to the J2 arm surface on which the J2 reducer is to be

mounted.

7 After attachingadapter 1 (A290--7210--X321) to the J2--axis reducer,

mount the J2 arm on the J2 reducer, insert the plate

(A290--7215--X321), and fasten the J2 arm with ten M10×50 bolts

(by applying Loctite 262 and tightening with a torque of [73.5 Nm]).

8 According to the grease replacement procedure described in Section

3.2, supply the J2--axis grease bath with the specified grease.

9 While referencing Chapter 5, perform mastering.

B--81545EN/01

Page 68

B--81545EN/01

MAINTENANCE

Adapter

6. COMPONENT REPLACEMENT AND

ADJUSTMENTS

Bolt:M8×35 (8pcs)

Loctite

Washer : M8 (8pcs)

Plate

J2- -axis reducer

O--ring

Bolt:M10×50 (10pcs)

Loctite

Washer : M10 (10pcs)

Fig 6.4 (a) Replacing the J2--axis reducer

Fig 6.4 (b) Applying sealant to the J2--axis reducer

Page 69

6 COMPONENT REPLACEMENT

AND ADJUSTMENTS

MAINTENANCE

B--81545EN/01

NOTE

Observe the following cautions when applying sealant

(Loctite No. 518).

1 Greasing the surface where sealant is to be applied

1) Remove dust from the surface and the inside of the tap,

for example, by blowing it off.

2) Degrease thesurfacecompletelywith acloth dampened

with solvent. Do not spray solvent directly onto the

surface.

3) Wipe off any solvent from the surface with a dry cloth.

Makesurethat nosolventisleftin thetap oron anyother

portion.

4) Always use a new surface of a cloth so that the grease

oncewipedupwiththe clothwillnotgeton thedegreased

surface.

2 Allowing time during which the sealant can cure

To let the applied sealantcure, avoid runningthe robot and

applying grease for at least four hours after the sealant is

applied.

3 Wiping off excessive sealant

After attaching the cover, wipe off any excessive sealant

that comes out from the sealed section with a cloth or

spatula. Do not use solvent.

Page 70

B--81545EN/01

6.5

REPLACING THE

J3--AXIS MOTOR M3

MAINTENANCE

1 Push the J3--axis section to the mechanical stopper, or fix it in such a

waythat it willnot swivel when themotor isdismounted,forexample,

by placing it in the direction of gravity.

NOTE

If the J3--axis section is not pushed against the stopper

correctly, or it is not placed in the direction of gravity, there

isadangerthat J3--axissectionwillswivelwhen theJ3--axis

motor is removed.

2 Turn off the controller power.

3 Remove the connector of a cable leading to the J3--axis motor.

4 Remove the fourM6×14 boltsthat fastenthe J3--axis motor to theJ3

casing (A290--7215--X401), and dismount the motor and gasket.

5 Remove the M5 nut from the motor shaft, and dismount the input

spline and draw bolt.

6 Apply Loctite 242 to the threaded portion of a new motor

(A06B--0202--B605), and tighten the draw bolt with a torque of [3.2

Nm].

7 Put the input gear over the draw bolt, attach an M5 spring washer,

apply Loctite 242 to the M5 threaded portion of the draw bolt, and

tighten the M5 nut with a torque of [3.2 Nm].

8 Attachanewgasket(A98L--0040--0042#03),andinsertthe motor into

the reducer. Keep the J3--axis degrease outlet on the J2 arm side open

(seeFig.3.1),andlook into the outlettomakesurethatthe input spline

hassettledin thecorrectplace. Evenone teethof ashift inengagement

cancausevibration. (Iftheinput splineis engagedcorrectly, themotor

can get in the reducer smoothly.)

9 Fasten the motor to the J3--axis reducer with four M6×14 bolts. Be

sure to use a new gasket so as to prevent grease leakage.

10 Attach the cable connector to the J3--axis motor.

11 According t o Section 3.2, supply the J3--axis grease bath with the

specified grease.

12 While referencing Chapter 5, perform mastering.

6. COMPONENT REPLACEMENT AND

ADJUSTMENTS

Page 71

6 COMPONENT REPLACEMENT

AND ADJUSTMENTS

Packing

MAINTENANCE

M5 Springwasher

B--81545EN/01

J3--axis motor

M5 nut

Loctite

Input gear

J3--axis casing

Fig 6.5 Replacing the J3--axis motor

Draw bolt

Loctite

Bolt:M6×14 (4pcs)

Washer: M6 (4pcs)

Page 72

B--81545EN/01

6.6

REPLACING THE

J3--AXIS REDUCER

MAINTENANCE

1 Put the robot in such a posture that the J3--axis section and the

components on it can be suspended with a crane, and then turn off the

controller power.

2 While referencing Section 8.2, remove the cable from the J2 arm

section.

Suspend theJ3--axis section and the components on it with a crane so

thattheywillnotdropwhenthereducerisdismountedfromtheJ2 arm.

Be careful not to allow an excessive load to be put on the cable

(because the cables areleft attached when the reducer is dismounted).

3 As shown in Fig. 6.6, remove the six M10×45 bolts that fasten the

J3--axis reducer to the J2 arm, and dismount the J3 arm unit from the

J2 arm.

4 While referencing Section 6.5, dismount the J3--axis motor from the

J3 arm unit.

5 Remove ten M6×30 bolts that fasten the J3--axis reducer to the J3

casing(A290--7215--X401), dismount theJ3--axis reducerfrom theJ3

casing, and remove the O--ring from the J3--axis reducer.

6 AttachanO--ring (SO120)toa new reducer(A97L--0218--0295#161),

mount thereducer on the J3casing, andfasten themwith tenM6×30

bolts (by applying Loctite 262 and tightening with a torque of [15.7

Nm]).

7 WhilereferencingSection6.5, mountthe J3--axismotor onthe J3 arm

unit.

8 Remove the O--ring from the J2 arm, degrease both the J2 arm andthe

J3--axis reducer surfaces that are to meet each other, and as shown in

Fig. 6.6 (b), apply sealant (Loctite No. 518) to the J2 arm surface on

which the J3 reducer is to be mounted.

9 Attach adapter 2 (A290--7210--X322) and the O--ring (SO100) to the

J2 arm surface on which the J3--axis reducer is to be mounted.

10 Suspend the J3--axissectionandthe components on it with a crane,and

fasten the J2 arm and J3--axis reducer with six M10×45 bolts (by

applying Loctite 262 and tightening with a torque of [73.5 Nm]).

11 While referencing Section8.2, dress thecable into the previousform.

12 According to Section 3.2, supply the J3--axis grease bath with the

specified grease.

13 While referencing Chapter 5, perform mastering.

6. COMPONENT REPLACEMENT AND

ADJUSTMENTS

Page 73

6 COMPONENT REPLACEMENT

AND ADJUSTMENTS

Bolt:M10×45 (6pcs)

Loctite

MAINTENANCE

B--81545EN/01

Washer : M10 (6pcs)

Plate

Adapter

O--ring

Bolt:M6×30 (10pcs)

Loctite

Washer : M6 (10pcs)

J3 casing

Packing

O--ring

J3- -axis reducer

J3--axis motor

Fig 6.6 (a) Replacing the J3--axis reducer

Fig 6.6 (b) Applying sealant to the J3--axis reducer

Page 74

B--81545EN/01

6.7

REPLACING THE

J4--AXIS MOTOR M4

MAINTENANCE

6. COMPONENT REPLACEMENT AND

ADJUSTMENTS

1 Placetherobot in aposture ofJ4 =--90°. Keepthiscondition until step

<10> (mastering). Note that if the operation for setting the

zero--degree position is performed incorrectly, the cable may be

twisted more than allowed, leading to a broken cable. If the robot is