Page 1

GE Fanuc Automation

Computer Numerical Control Products

Series 15 / 150 – Model B

Parameter Manual

GFZ-62560E/03 September 1999

Page 2

Warnings, Cautions, and Notes

as Used in this Publication

Warning notices are used in this publication to emphasize that hazardous voltages, currents,

temperatures, or other conditions that could cause personal injury exist in this equipment or

may be associated with its use.

In situations where inattention could cause either personal injury or damage to equipment, a

Warning notice is used.

Caution notices are used where equipment might be damaged if care is not taken.

GFL-001

Warning

Caution

Note

Notes merely call attention to information that is especially significant to understanding and

operating the equipment.

This document is based on information available at the time of its publication. While efforts

have been made to be accurate, the information contained herein does not purport to cover all

details or variations in hardware or software, nor to provide for every possible contingency in

connection with installation, operation, or maintenance. Features may be described herein

which are not present in all hardware and software systems. GE Fanuc Automation assumes

no obligation of notice to holders of this document with respect to changes subsequently made.

GE Fanuc Automation makes no representation or warranty, expressed, implied, or statutory

with respect to, and assumes no responsibility for the accuracy, completeness, sufficiency, or

usefulness of the information contained herein. No warranties of merchantability or fitness for

purpose shall apply.

©Copyright 1999 GE Fanuc Automation North America, Inc.

All Rights Reserved.

Page 3

B–62560E/03 DEFINITION OF WARNING, CAUTION, AND NOTE

DEFINITION OF WARNING, CAUTION, AND NOTE

This manual includes safety precautions for protecting the user and preventing damage to the

machine. Precautions are classified into W arning and Caution according to their bearing on safety .

Also, supplementary information is described as a Note. Read the Warning, Caution, and Note

thoroughly before attempting to use the machine.

WARNING

Applied when there is a danger of the user being injured or when there is a damage of both the user

being injured and the equipment being damaged if the approved procedure is not observed.

CAUTION

Applied when there is a danger of the equipment being damaged, if the approved procedure is not

observed.

NOTE

The Note is used to indicate supplementary information other than Warning and Caution.

` Read this manual carefully, and store it in a safe place.

s–1

Page 4

B–62560E/03 PREFACE

PREFACE

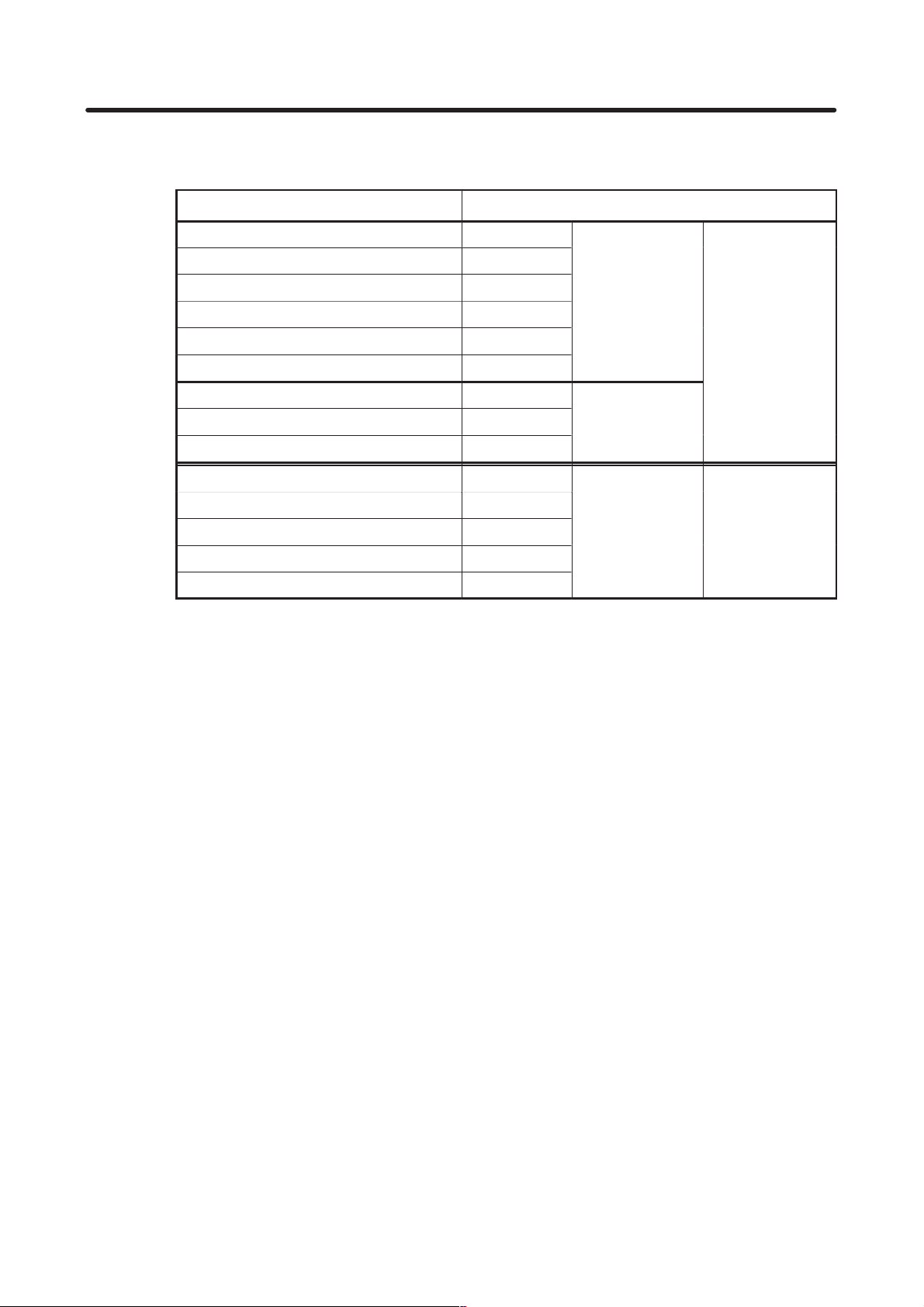

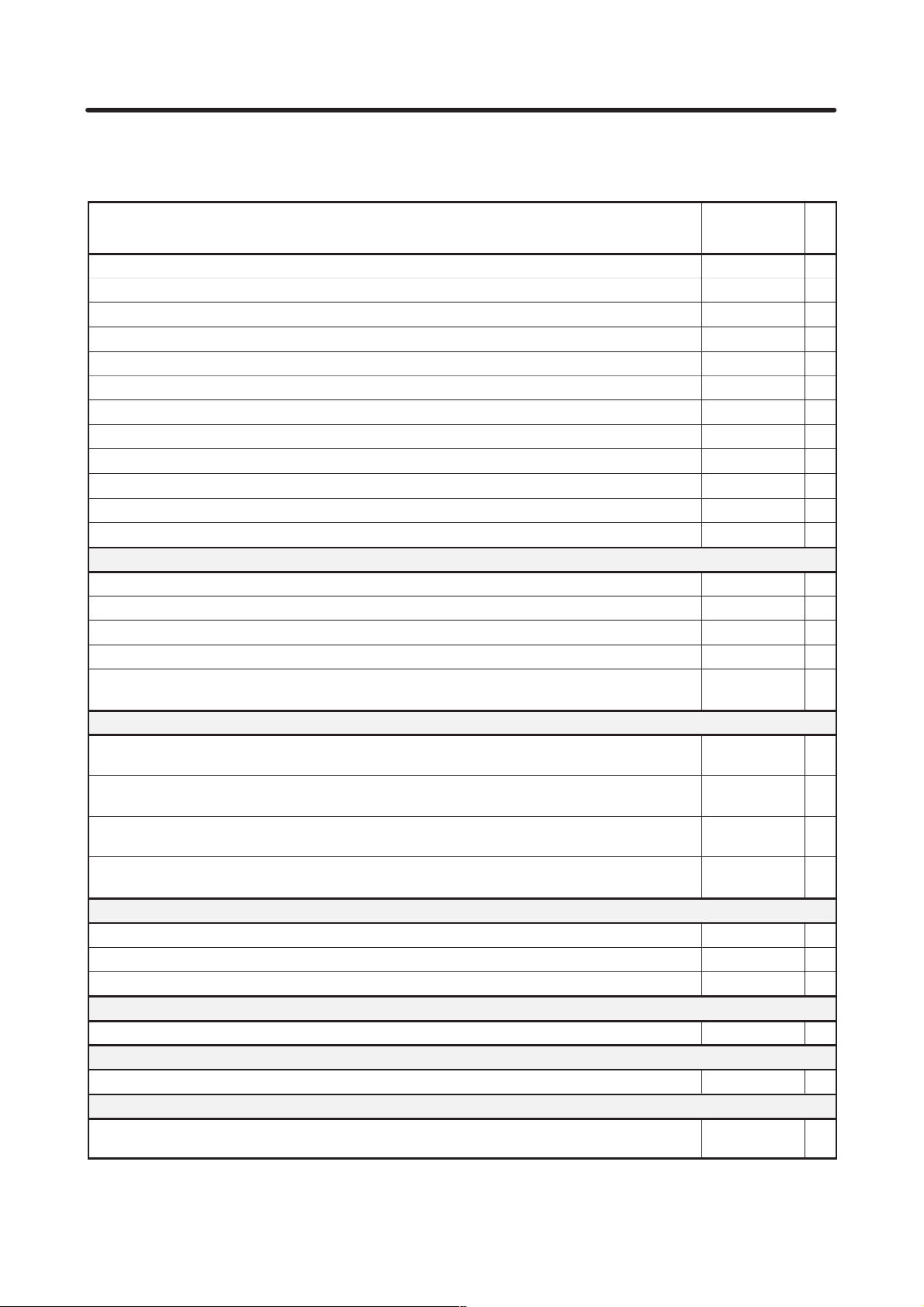

The models covered by this manual, and their abbreviations are :

Product Name

FANUC Series 15–TB 15–TB

FANUC Series 15–TFB 15–TFB

FANUC Series 15TED–MODEL B–4 (*1) 15TED

FANUC Series 15TEE–MODEL B–4 (*1) 15TEE

FANUC Series 15TEF–MODEL B–4 (*1) 15TEF T series

FANUC Series 150–TB 150–TB

FANUC Series 15–TTB 15–TTB

FANUC Series 15–TTFB 15–TTFB 15–TT

FANUC Series 150–TTB 150–TTB

FANUC Series 15–MB 15–MB

FANUC Series 15–MFB 15–MFB

FANUC Series 15MEK–MODEL B–4 (*2) 15MEK 15–M M series

FANUC Series 15MEL–MODEL B–4 (*2) 15MEL

FANUC Series 150–MB 150–MB

(*1) The FANUC Series 15TED/TEE/TEF–MODEL B–4 is a software–fixed CNC capable of 4 contouring axes

switchable out of 8 axes for milling machines and machining centers.

Further the following functions can not be used in the 15TED, 15–TEE or 15TEF.

Abbreviations

15–T

D Increment system D/E (Increment system C is an option function)

D Helical interpolation B

D OSI/ETHERNET function

D High–precision contour control using RISC

D Macro compiler (self compile function)

D MMC–III, MMC–IV

D Connecting for personal computer by high–speed serial–bus

(*2) The FANUC Series 15MEK/MEL–MODEL B–4 is a software–fixed CNC capable of 4 contouring axes

switchable out of 8 axes for milling machines and machining centers.

Further the following functions can not be used in the 15MEK or 15MEL.

D Increment system D/E (Increment system C is an option function)

D Helical interpolation B

D Plane switching

D Designation direction tool length compensation

D 2 axes electric gear box

D Manual interruption of 3–dimensional coordinate system conversion

D 3–dimensional cutter compensation

D Trouble diagnosis guidance

D OSI/ETHERNET function

D High–precision contour control using RISC

D Macro compiler (self compile function)

D MMC–III, MMC–IV

D Smooth interpolation

D Connecting for personal computer by high–speed serial–bus

p–1

Page 5

PREFACE

B–62560E/03

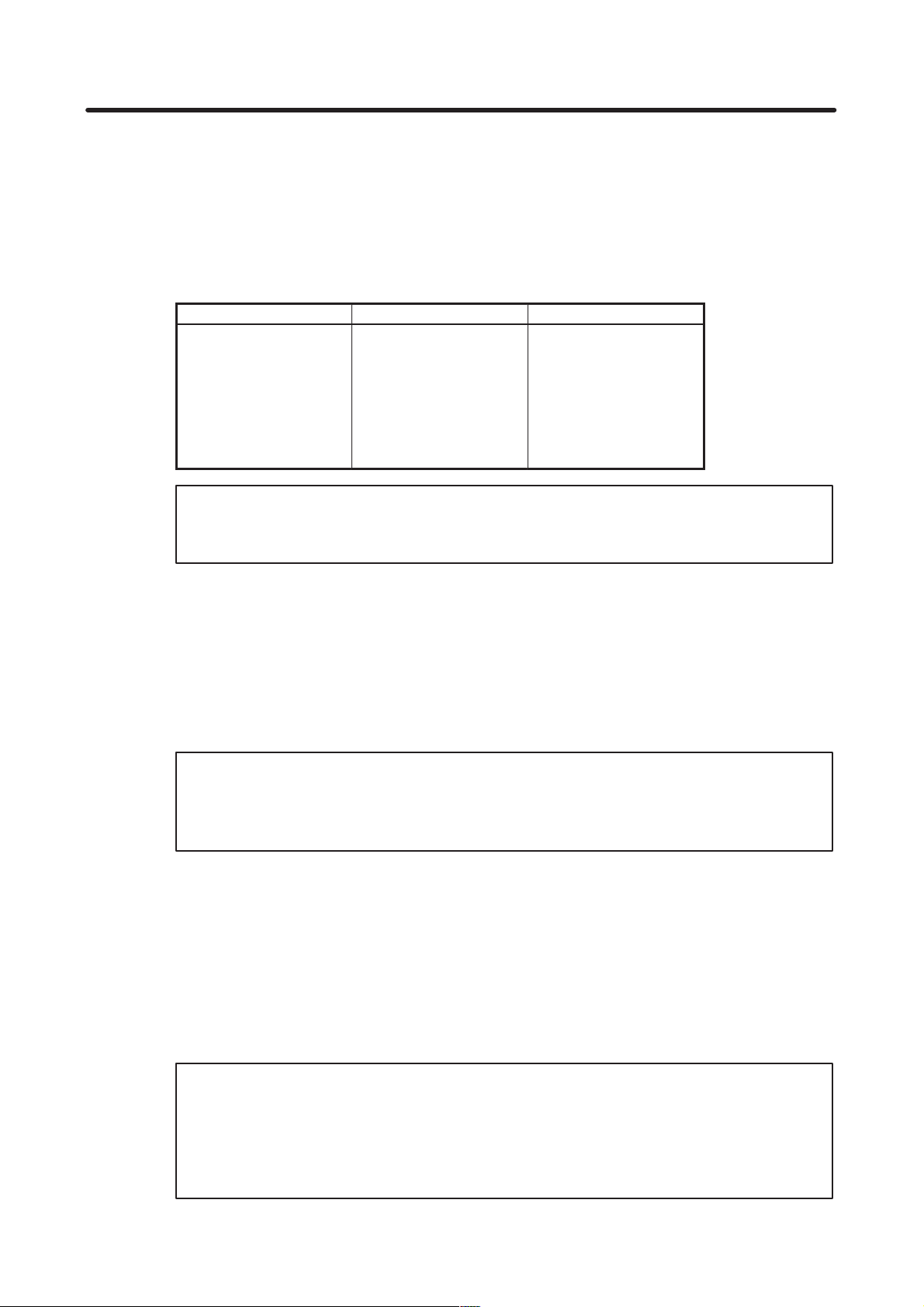

Manuals related to FANUC Series 15/150–MODEL B are as follows.

This manual is marked with an asterisk (*).

List of Manuals Related to Series 15/150–MODEL B

Manual Name

FANUC Series 15–TB/TFB/TTB/TTFB DESCRIPTIONS B–62072E

FANUC Series 15/150–MODEL B For Machining Center DESCRIPTIONS B–62082E

FANUC Series 15/150–MODEL B CONNECTION MANUAL B–62073E

FANUC Series 15/150–MODEL B CONNECTION MANUAL (BMI Interface) B–62073E–1

FANUC Series 15–MODEL B For Lathe OPERAT OR’S MANUAL (Programming) B–62554E

FANUC Series 15–MODEL B For Lathe OPERAT OR’S MANUAL (Operation) B–62554E–1

FANUC Series 15/150–MODEL B For Machining Center OPERAT OR’S MANUAL (Programming) B–62564E

FANUC Series 15/150–MODEL B For Machining Center OPERAT OR’S MANUAL (Operation) B–62564E–1

FANUC Series 15/150–MODEL B PARAMETER MANUAL B–62560E *

FANUC Series 15/150–MODEL B MAINTENANCE MANUAL B–62075E

FANUC Series 15–MODEL B DESCRIPTIONS (Supplement for Remote Buf fer) B–62072E–1

FANUC Series 15–MODEL B PROGRAMMING MANUAL (Macro Compiler / Macro Executer) B–62073E–2

PMC

FANUC PMC–MODEL N/NA PROGRAMMING MANUAL (Ladder Language) B–61013E

FANUC PMC–MODEL NB/NB2 PROGRAMMING MANUAL (Ladder Language) B–61863E

FANUC PMC–MODEL N/NA PROGRAMMING MANUAL (C Language) B–61013E–2

FANUC PMC–MODEL NB PROGRAMMING MANUAL (C Language) B–61863E–1

FANUC PMC–MODEL N/NA

PROGRAMMING MANUAL (C Language – Tool Management Library)

Conversational Automatic Programming Function

CONVERSA TIONAL AUTOMATIC PROGRAMMING FUNCTION FOR MACHINING CENTER

(Series 15–MF/MFB) PROGRAMMING MANUAL

CONVERSA TIONAL AUTOMATIC PROGRAMMING FUNCTION FOR MACHINING CENTER

(Series 15–MF/MFB) OPERA TOR’S MANUAL

CONVERSA TIONAL AUT OMATIC PROGRAMMING FUNCTION FOR LATHE

(Series 15–TF/TTF/TFB/TTFB) OPERA TOR’S MANUAL

CONVERSA TIONAL AUT OMATIC PROGRAMMING FUNCTION II FOR LATHE

(Series 15–TFB/TTFB) OPERA T OR’S MANUAL

Tracing / Digitizing

FANUC Series 15–MB DESCRIPTIONS (Supplement for T racing / Digitizing) B–62472E

FANUC Series 15–MB CONNECTION MANUAL (Supplement for T racing / Digitizing) B–62473E

FANUC Series 15–MB OPERATOR’S MANUAL (Supplement for Tracing / Digitizing) B–62474E

Gas, Laser Plasma Cutting Machine

FANUC Series 15–MB DESCRIPTIONS (FOR GAS, LASER PLASMA CUTTING MACHINE) B–62082EN–1

Multi–Teaching Function

FANUC Series 15–MB CONNECTION MANUAL (Multi–Teaching Function) B–62083E–1

Multiple–axis and Multiple–path Control Function

FANUC Series 15–TTB OPERATOR’S MANUAL

(Supplement Explanations for Multiple–axis and Multiple–path Control Function)

Specification

Number

B–61013E–4

B–61263E

B–61264E

B–61234E

B–61804E–2

B–62074E–1

p–2

Page 6

B–62560E/03

Table of Contents

DEFINITION OF WARNING, CAUTION, AND NOTE s–1. . . . . . . . . . . . . . . . . . . . . . . . . .

PREFACE p–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1. DISPLAYING PARAMETERS 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 DISPLAYING PARAMETERS OTHER THAN PITCH ERROR COMPENSATION DATA 1. . . . .

1.2 DISPLAYING PITCH ERROR COMPENSATION DATA 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. SETTING PARAMETERS 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 PARAMETER TAPE FORMATS 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.1 Parameter tape formats other than tape format for pitch error compensation 2. . . . . . . . . . . . . . . . . . . . .

2.1.2 Format of pitch error compensation tape 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 SETTING PARAMETERS USING PARAMETER TAPE 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 SETTING PARAMETERS FROM THE MDI 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4 PROCEDURE FOR SETTING DIGITAL SERVO PARAMETERS 7. . . . . . . . . . . . . . . . . . . . . . . . .

2.5 COMPATIBILITY OF PARAMETERS WITH THE SERIES

15–MA, –TA, –TTA, –MF, –TF, AND –TTF 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3. PUNCHING PARAMETER TAPE 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 PUNCHING ALL PARAMETERS 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 PUNCHING PARAMETERS OTHER THAN PITCH ERROR COMPENSATION 13. . . . . . . . . . . .

3.3 PUNCHING PITCH ERROR COMPENSATION DATA 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4. DESCRIPTION OF PARAMETERS 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 PARAMETERS RELATED TO SETTINGS 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 PARAMETERS RELATED TO TIMERS 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 PARAMETERS RELATED TO AXIS CONTROL 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4 PARAMETERS RELATED TO CHOPPING 45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5 PARAMETERS RELATED TO COORDINATE SYSTEMS 47. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.6 PARAMETERS RELATED TO FEEDRATE 50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.7 PARAMETERS RELATED TO SCREEN FOR SPECIFYING HIGH–SPEED AND

HIGH–PRECISION MACHINING 65. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.8 PARAMETERS RELATED TO ACCELERATION/DECELERATION CONTROL 66. . . . . . . . . . . .

4.9 PARAMETERS RELATED TO SERVO 76. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.10 TANDEM CONTROL 106. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.10.1 Axis assignment of a system which includes tandem control 107. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.10.2 Preload function 108. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.10.3 Settings (parameters) 108. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.10.4 Connection of axis signals 111. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.11 PARAMETERS RELATED TO DI/DO 112. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.12 PARAMETERS RELATED TO CRT/MDI AND EDITING 124. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.13 PARAMETERS RELATED TO PROGRAM 142. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.14 PARAMETERS RELATED TO SERIAL SPINDLE OUTPUT AND CS CONTOUR

CONTROL FUNCTION 156. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.14.1 Automatic setting method of serial interface spindle parameters

4.14.2 Transfer method of serial interface spindle parameters

(upload from spindle amplifier to CNC) 156. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

(download from CNC to the spindle amplifier) 156. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–1

Page 7

Table of Contents

4.14.3 Other parameters 156. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.14.4 Warning 156. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.14.5 Parameters 157. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B–62560E/03

4.15 PARAMETERS RELATED TO WAVEFORM DIAGNOSIS FUNCTION 189. . . . . . . . . . . . . . . . . . . .

4.16 PARAMETERS RELATED TO GRAPHIC DISPLAY 190. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.17 PARAMETERS RELATED TO READER/PUNCH INTERFACES 194. . . . . . . . . . . . . . . . . . . . . . . . .

4.18 PARAMETERS RELATED TO STROKE LIMIT 205. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.19 PARAMETERS RELATED TO POSITION SWITCHING FUNCTION 214. . . . . . . . . . . . . . . . . . . . .

4.20 PARAMETERS RELATED TO REFERENCE MARKS 217. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.21 PARAMETERS RELATED TO PITCH ERROR COMPENSATION 220. . . . . . . . . . . . . . . . . . . . . . . .

4.22 PARAMETERS RELATED TO GRADIENT COMPENSATION

(VALID ONLY WITH THE SERIES 15–M AND SERIES 15–T) 237. . . . . . . . . . . . . . . . . . . . . . . . . .

4.23 PARAMETERS RELATED TO STRAIGHTNESS COMPENSATION

(VALID ONLY WITH THE SERIES 15–M AND SERIES 15–T) 239. . . . . . . . . . . . . . . . . . . . . . . . . .

4.23.1 Straigtness Compensation 239. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.23.2 Straigtness Compensation at 128 points 240. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.23.3 Interpolation–type straightness compensation 242. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.24 PARAMETERS RELATED TO SPINDLE CONTROL 250. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.25 PARAMETERS RELATED TO RIGID TAPPING WITH THE SERIES 15–TT 282. . . . . . . . . . . . . . .

4.26 PARAMETERS RELATED TO THE ELECTRONIC GEAR BOX (EGB) 290. . . . . . . . . . . . . . . . . . .

4.27 PARAMETERS RELATED TO TOOL OFFSETS 295. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.28 THREE–DIMENSIONAL CUTTER COMPENSATION (SUPPLEMENT) 307. . . . . . . . . . . . . . . . . .

4.29 PARAMETERS RELATED TO CYLINDRICAL INTERPOLATION CUTTING POINT

COMPENSATION 312. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.30 PARAMETERS RELATED TO CANNED CYCLES 314. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.31 PARAMETERS RELATED TO SCALING AND COORDINATE ROTATION 322. . . . . . . . . . . . . . . .

4.32 PARAMETERS RELATED TO AUTOMATIC CORNER OVERRIDE 324. . . . . . . . . . . . . . . . . . . . . .

4.33 PARAMETERS RELATED TO AUTOMATIC FEEDRATE CONTROL USING

INVOLUTE INTERPOLATION 327. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.34 PARAMETERS RELATED TO UNI–DIRECTIONAL POSITIONING 329. . . . . . . . . . . . . . . . . . . . .

4.35 PARAMETERS RELATED TO CUSTOM MACROS 330. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.36 PARAMETERS RELATED TO RESTARTING PROGRAMS 338. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.37 PARAMETERS RELATED TO SKIP FUNCTION 339. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.38 PARAMETERS RELATED TO AUTOMATIC TOOL COMPENSATION

(FOR THE SERIES 15–T ONLY) AND AUTOMATIC TOOL LENGTH MEASUREMENT

(FOR THE SERIES 15–M ONLY) 344. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.39 PARAMETERS RELATED TO TOOL LIFE MANAGEMENT 346. . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.40 PARAMETERS RELATED TO TURRET AXIS CONTROL 349. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.41 PARAMETERS RELATED TO 3–DIMENSIONAL HANDLE FEEL FOR 15–M 352. . . . . . . . . . . . .

4.42 PARAMETERS RELATED TO 15–TT THREE–DIMENSIONAL HANDLE FEED 358. . . . . . . . . . .

4.43 PARAMETERS RELATED TO 15–TT TOOL LENGTH COMPENSATION ALONG

THE TOOL AXIS 366. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.44 PARAMETERS RELATED TO DESIGNATION DIRECTION TOOL LENGTH

COMPENSATION 371. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.45 PARAMETER RELATED TO UPGRADED 5–AXIS CONTROL COMPENSATION 372. . . . . . . . . .

4.45.1 Specifying the coordinates 372. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.45.2 Display 372. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.45.3 Display for three–dimensional coordinate conversion 372. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–2

Page 8

B–62560E/03

4.46 PARAMETERS RELATED TO HIGH–PRECISION CONTOUR CONTROL 373. . . . . . . . . . . . . . . .

4.47 PARAMETERS RELATED TO HIGH–PRECISION CONTOUR CONTROL BASED ON

4.48 OTHER PARAMETERS (PARAMETER NUMBERS 7600 TO 7799) 383. . . . . . . . . . . . . . . . . . . . . .

4.49 PARAMETERS RELATED TO MAINTENANCE 402. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.50 DNC OPERATION WITH THE REMOTE BUFFER 403. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table of Contents

A 64–BIT RISC PROCESSOR 377. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.47.1 Parameters related to axis control 379. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.47.2 Parameters related to automatic feedrate control and acceleration/deceleration before interpolation 379. . .

4.47.3 Parameters related to the positioning/auxiliary function 382. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.50.1 High–speed distribution in DNC operation with the remote buffer 403. . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.50.2 Ultrahigh–speed distribution in DNC operation with the remote buffer 406. . . . . . . . . . . . . . . . . . . . . . . .

c–3

Page 9

B–62560E/03 1. DISPLAYING PARAMETERS

1. DISPLAYING PARAMETERS

1.1 Displaying Parameters Other Than Pitch Error Compensation Data

(1) Press the SERVICE, CHAPTER, and PARAM soft keys in this order. Alternatively, press the SERVICE

hard key several times. The parameter screen is displayed.

(2) Enter the number of the parameter to be displayed, then press the INP–NO. soft key.

Alternatively , instead of entering the parameter number , the cursor or page key can be used to change the

screen.

1.2 Displaying Pitch Error Compensation Data

(1) Press the SERVICE, CHAPTER, and PITCH soft keys in this order. Alternatively , press the SERVICE hard

key several times. The parameter screen is displayed.

(2) Enter the number of the parameter to be displayed, then press the INP–NO. soft key.

Alternatively , instead of entering the parameter number , the cursor or page key can be used to change the

screen.

– 1 –

Page 10

2. SETTING PARAMETERS

2. SETTING PARAMETERS

2.1 Parameter Tape Formats

2.1.1 Parameter tape formats other than tape format for pitch error compensation

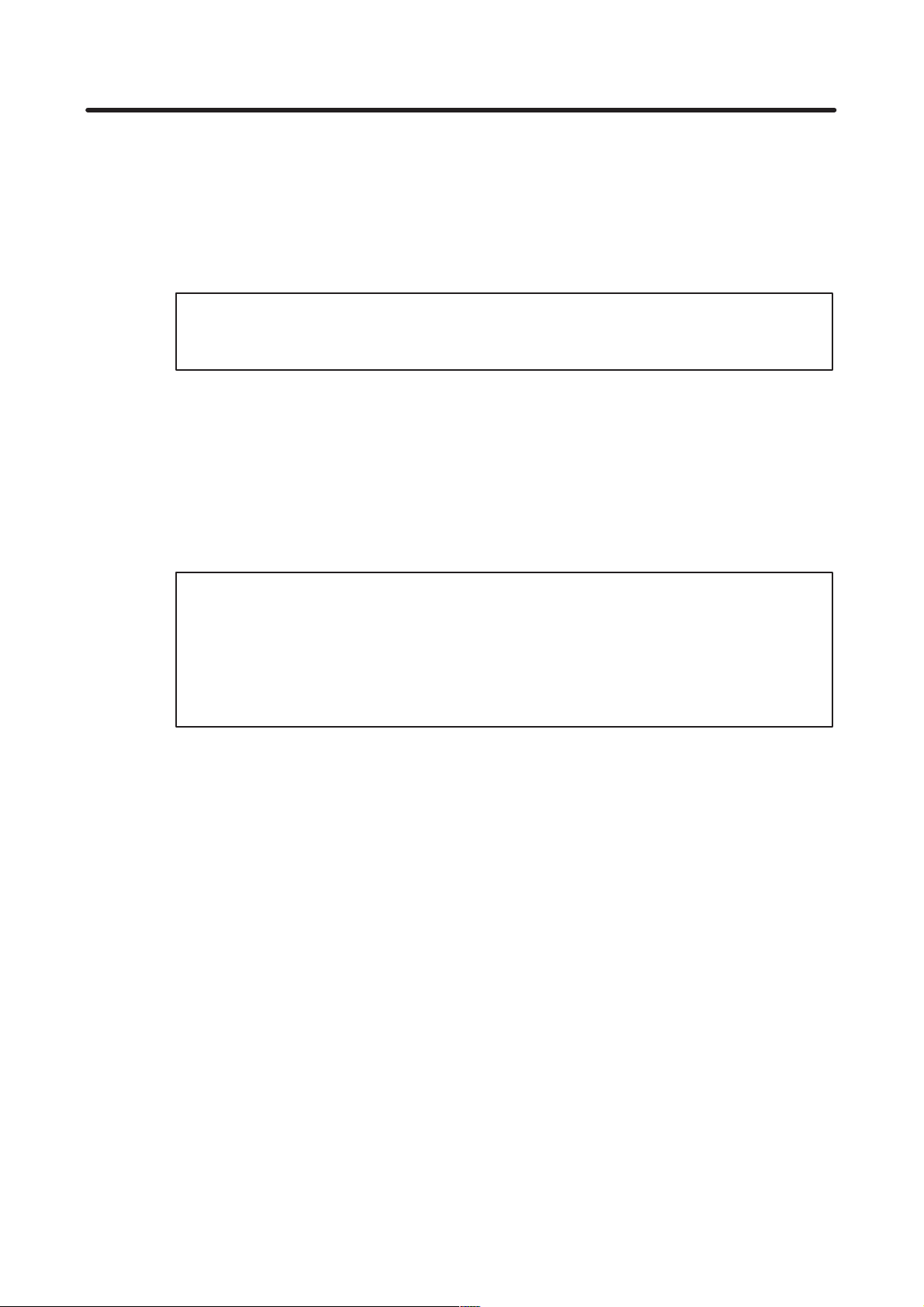

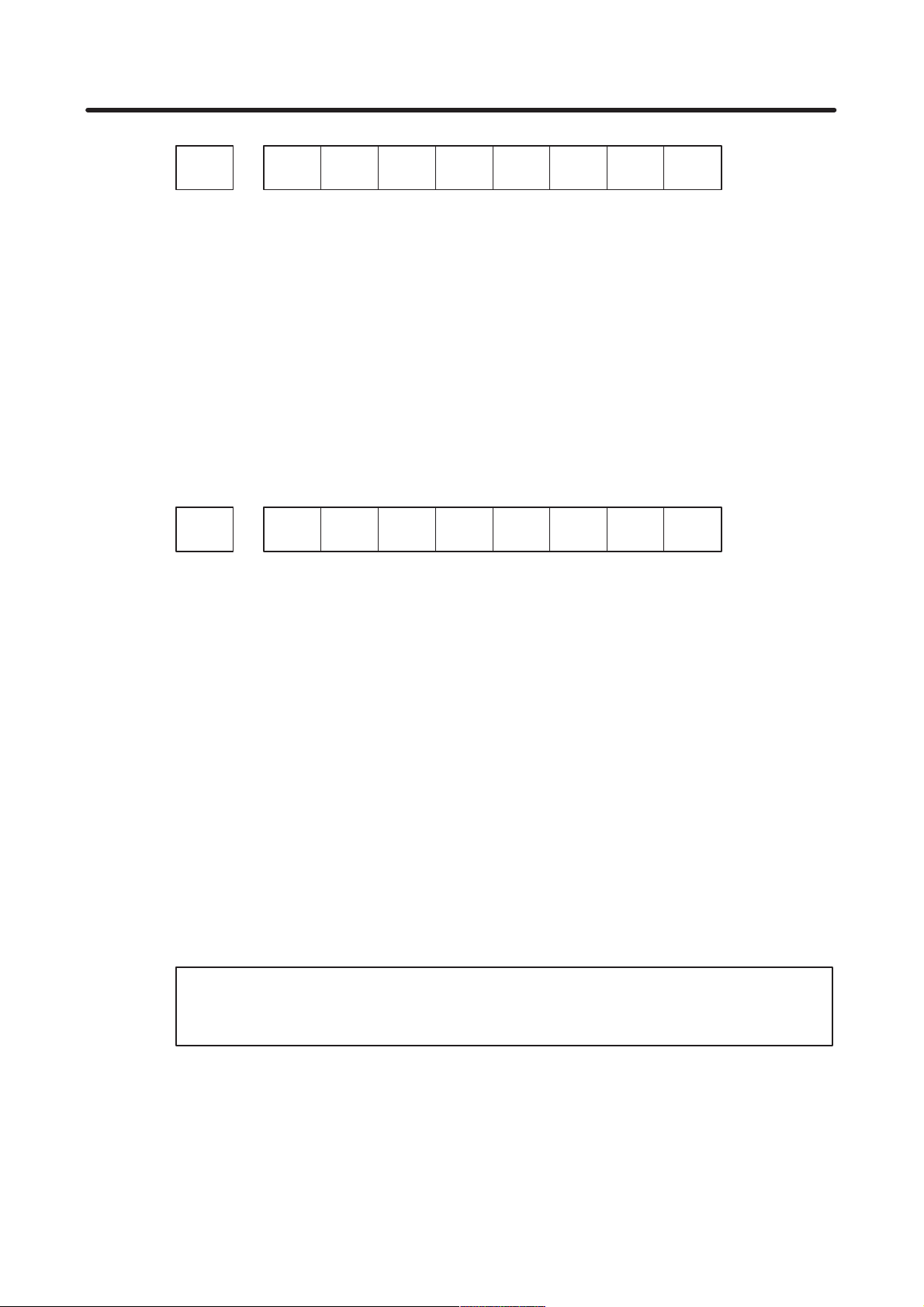

Parameters are classified according to data formats, as follows:

B–62560E/03

Data format

Bit type 0 or 1

Bit axis type 0 or 1

Byte type 0 to ±127

Byte axis type 0 to ±127

Word type 0 to ±32767

Word axis type 0 to ±32767

2–word type 0 to ±99999999

2–word axis type 0 to ±99999999

NOTE 1 “Axis” means that independent data can be set for each control axis.

NOTE 2 A valid data range is a general range. The valid range depends on parameters. For details,

see the explanation of each parameter.

(1) Format of bit parameter tape

N ___ P____ ;

N ___ : A 4–digit numeric value following address N specifies a parameter number.

(Positive integer)

P ____ : An 8–digit numeric value following address P specifies parameter value 0 or 1. Each data

number contains eight bit–type parameters. Parameter value 0 or 1 of bit 0 is set in the first

digit. Parameter value 0 or 1 of bit 7 is set in the eighth digit. (Positive integer)

; : End of block (LF for ISO code and CR for EIA code)

Data range Remarks

NOTE 1 Addresses N and P must be specified in that order.

NOTE 2 Leading zeros cannot be omitted.

Example

N0000 P00010001 ;

(2) Format of bit axis parameter tape

N ___ A __ P ____;

N ___ : A 4–digit numeric value following address N specifies a parameter number.

(Positive integer)

A __ : Axis number (1 to 6). (Positive integer)

P ____ : An 8–digit numeric value following address P specifies parameter value 0 or 1. Each data

number contains eight bit–type parameters. Parameter value 0 or 1 of bit 0 is set in the first

digit. Parameter value 0 or 1 of bit 7 is set in the eighth digit. (Positive integer)

; : End of block (LF for ISO code and CR for EIA code)

NOTE 1 Addresses N, A, and P must be specified in that order.

NOTE 2 Leading zeros cannot be omitted.

Example

N0012 A1 P00000011 ;

N0012 A2 P00000010 ;

N0012 A3 P00000010 ;

– 2 –

Page 11

B–62560E/03 2. SETTING PARAMETERS

(3) Format of byte parameter tape

N ___ P ____ ;

N ___ : A 4–digit numeric value following address N specifies a parameter number.

(Positive integer)

P ____ : A numeric value following address P specifies a parameter value. (Integer)

The valid data range that can be set depends on parameters.

; : End of block (LF for ISO code and CR for EIA code)

NOTE Addresses N and P must be specified in that order.

Example

N2010 P100 ;

(4) Format of byte axis parameter tape

N ___ A __ P ____ ;

N ___ : A 4–digit numeric value following address N specifies a parameter number.

(Positive integer)

A __ : Axis number (1 to 6). (Positive integer)

P ____ : A numeric value following address P specifies a parameter value. (Integer)

The valid data range that can be set depends on parameters.

; : End of block (LF for ISO code and CR for EIA code)

NOTE Addresses N, A, and P must be specified in that order.

Example

N1020 A1 P88 ;

N1020 A2 P89 ;

N1020 A3 P90 ;

The parameters of each axis can be specified in one block as follows:

M1020 A1 P88 A2 P89 A3 P90;

(5) Format of word parameter tape

Same as the format of the byte parameter tape

(6) Format of word axis parameter tape

Same as the format of the byte axis parameter tape

(7) Format of two words parameter tape

Same as the format of the byte parameter tape

(8) Format of two words axis parameter tape

Same as the format of the byte axis parameter tape

Example of NC tape where parameters other than pitch error compensation data are punched

% ;

N0 P1 ;

N3 P0 ;

N10P10 ;

N1 1P0 ;

:

:

:

%

– 3 –

Page 12

2. SETTING PARAMETERS

2.1.2 Format of pitch error compensation tape

N ___ P ____ ;

N ___ : A 5–digit numeric value following address N specifies a number which is equal to (10000 + number

of pitch error compensation point). (Positive integer)

P ____ : A numeric value following address P specifies the value of pitch error compensation data. (Integer)

–7 to 7 can be set (valid range).

; : End of block (LF for ISO code and CR for EIA code)

NOTE Addresses N and P must be specified in that order.

Example of punching NC tape with pitch error compensation data (ISO code)

% ;

N10000 P1 ;

N10001 P4 ;

N10002 P–7 ;

N10003 P3 ;

N10004 P2 ;

:

:

:

%

B–62560E/03

– 4 –

Page 13

B–62560E/03 2. SETTING PARAMETERS

2.2 Setting Parameters Using Parameter Tape

1 Set the emergency stop status.

2 Press the SETTING soft or hard key to select the setting screen.

3 Enter 8000.

4 Press the INP–NO. soft key to display parameter No. 8000.

5 Enter 1 and press the INPUT soft key. PWE, a bit of parameter No. 8000 is set to 1, thereby enabling subse-

quent parameter setting. The NC enters the alarm status.

6 Press the function menu key to restore the soft keys to the function selection status.

7 Press the SERVICE soft key, then press the PARAM soft key, or press the SERVICE hard key several

times. The parameter screen is displayed.

8 Set the parameter tape in the tape reader.

9 Press the READ soft key, then press the ALL soft key. The parameter tape is read and the parameters

are set.

10 Temporarily turn off NC power.

– 5 –

Page 14

2. SETTING PARAMETERS

2.3 Setting Parameters from the MDI

1 Set the MDI mode or emergency stop status.

2 Press the SETTING soft or hard key to select the setting screen.

3 Enter 8000.

4 Press the INP–NO. soft key to display parameter No. 8000.

5 Enter 1 and press the INPUT soft key. PWE, a bit of parameter is set to 1, thereby enabling subsequent

parameter setting. The NC enters the alarm status.

6 Press the function menu key to restore the soft keys to the function selection status.

7 Press the SERVICE soft key, then press the PARAM soft key (for pitch error compensation data, press

PITCH), or press the SERVICE hard key several times. The parameter screen is displayed.

8 Enter the number of the parameter to be set and press the INP–NO. soft key. The screen containing the

parameter to be set is displayed.

9 Enter the data to be set and press the INPUT soft key. The entered data is set.

To continuously enter data items from the selected parameter, delimit them with a comma (;).

Example

When 10;20;30;40 is entered and the INPUT soft key is pressed, 10, 20, 30, and 40 are sequentially

set, starting at the parameter indicated by the cursor.

10 Repeat steps (7), (8), and (9).

1 1 When parameter setting is completed, set PWE a bit of parameter No. 8000 to 0 to inhibit subsequent pa-

rameter setting.

12 Reset the NC and release the alarm “Parameters can be set.” If the alarm “The parameter requesting that

NC power be turned off once has been set” is issued, turn off the NC power.

B–62560E/03

NOTE 1 The blank bits in the parameter list (4. “Description of Parameters”) and the parameter

numbers that are displayed on the CRT but not listed in the list are reserved for future

expansion. Be sure to set these bits to 0.

NOTE 2 Be sure to set digital servo parameters in the emergency stop status. Data set in statuses other

than the emergency stop status is invalid. The following digital servo numbers can be set:

1700 to 1738, 1806 to 1890, 1852 to 1879, 1891, and 1895, 1951 to 1999

– 6 –

Page 15

B–62560E/03 2. SETTING PARAMETERS

2.4 Procedure for Setting Digital Servo Parameters

After connecting the NC and the motor, use the following procedure to set the digital servo parameters.

For details on digital servo parameters, refer to HAC Servo Unit Maintenance Manual (B–65005).I

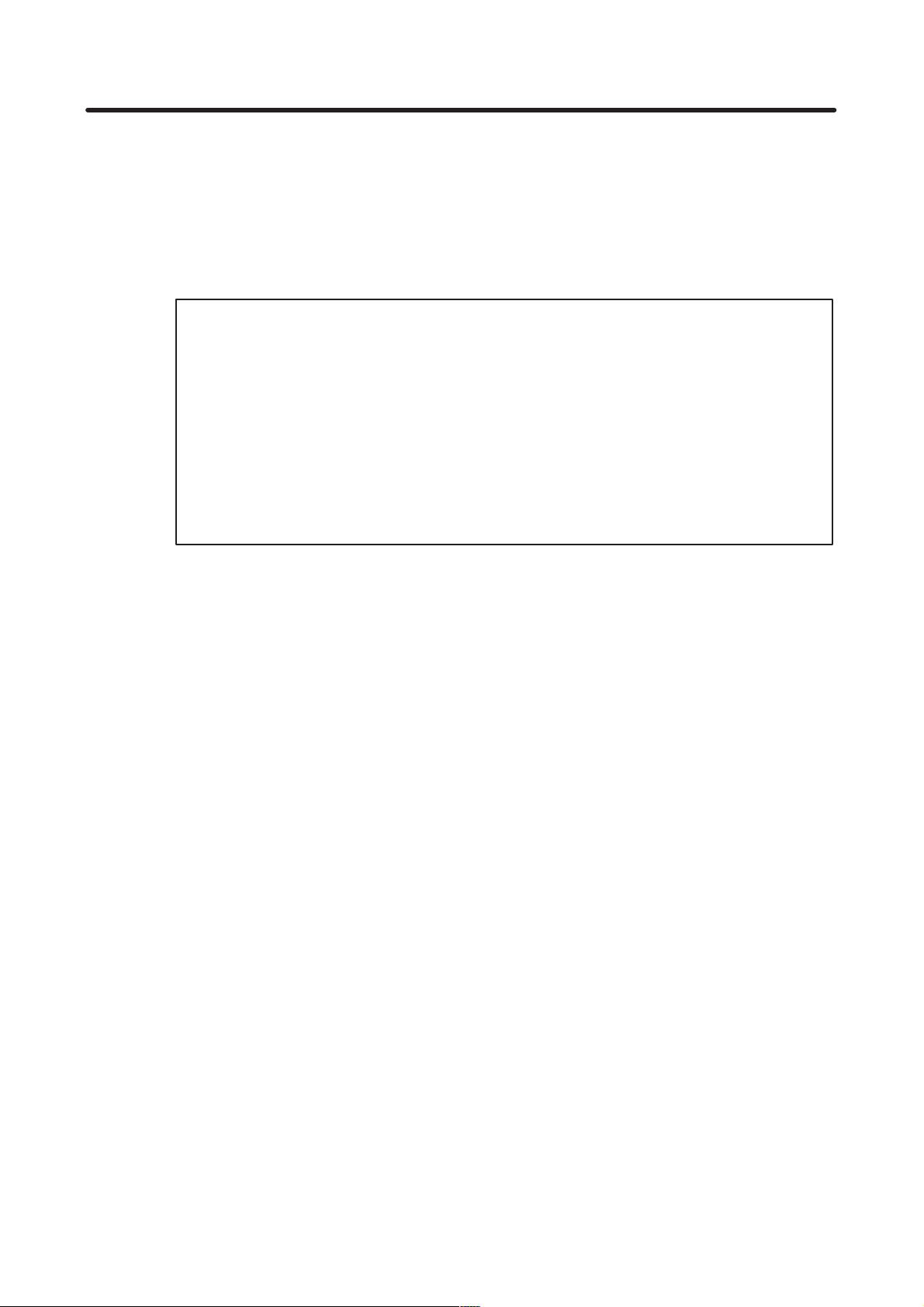

(1) First, press the NC soft key SERVICE several times. Then, the screen (servo setting screen) shown below

appears on the CRT.

SERVO SETTING 01000 N0000

X axis Z axis

Initialization bit 00000000 00000000

Motornumber 0 0

AMR 00000000 00000000

CMR 0 0

Feed gear 0 0

Feed gear 0 0

Move direction 0 0

Number of speed pulses 0 0

Number of position pulses 0 0

Reference counter 0 0

Number=

N

M

Initialization bit No. 1804

Motor number No. 1874

AMR No. 1806

CMR No. 1820

Feed gear N No. 1977

(N/M) M No. 1978

Move direction No. 1879

Number of speed pulses No. 1876

Number of position pulses No. 1891

Reference counter No. 1896

(2) Complete servo parameter initialization by setting each parameter on this screen according to the flow-

charts described below.

– 7 –

Page 16

2. SETTING PARAMETERS

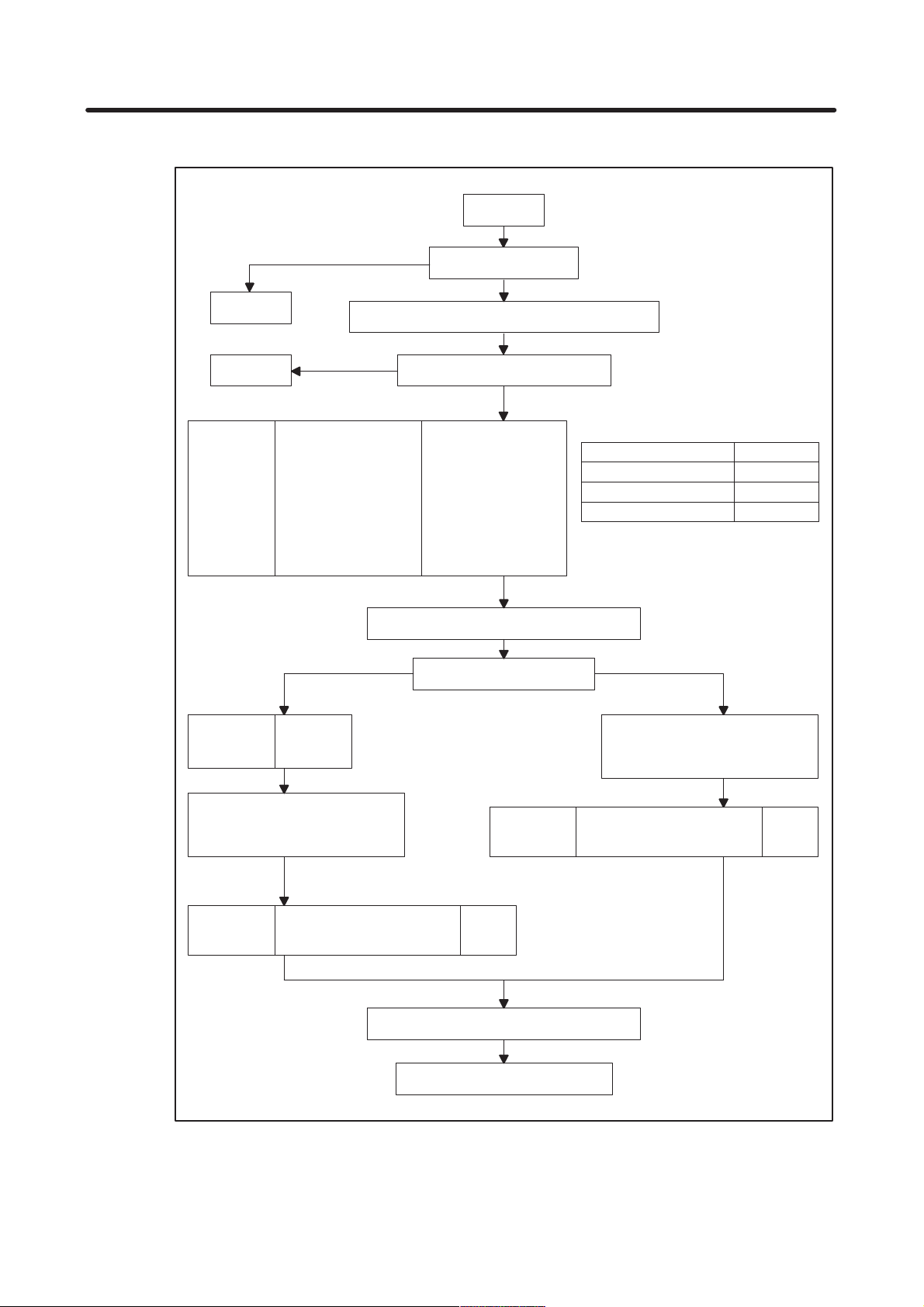

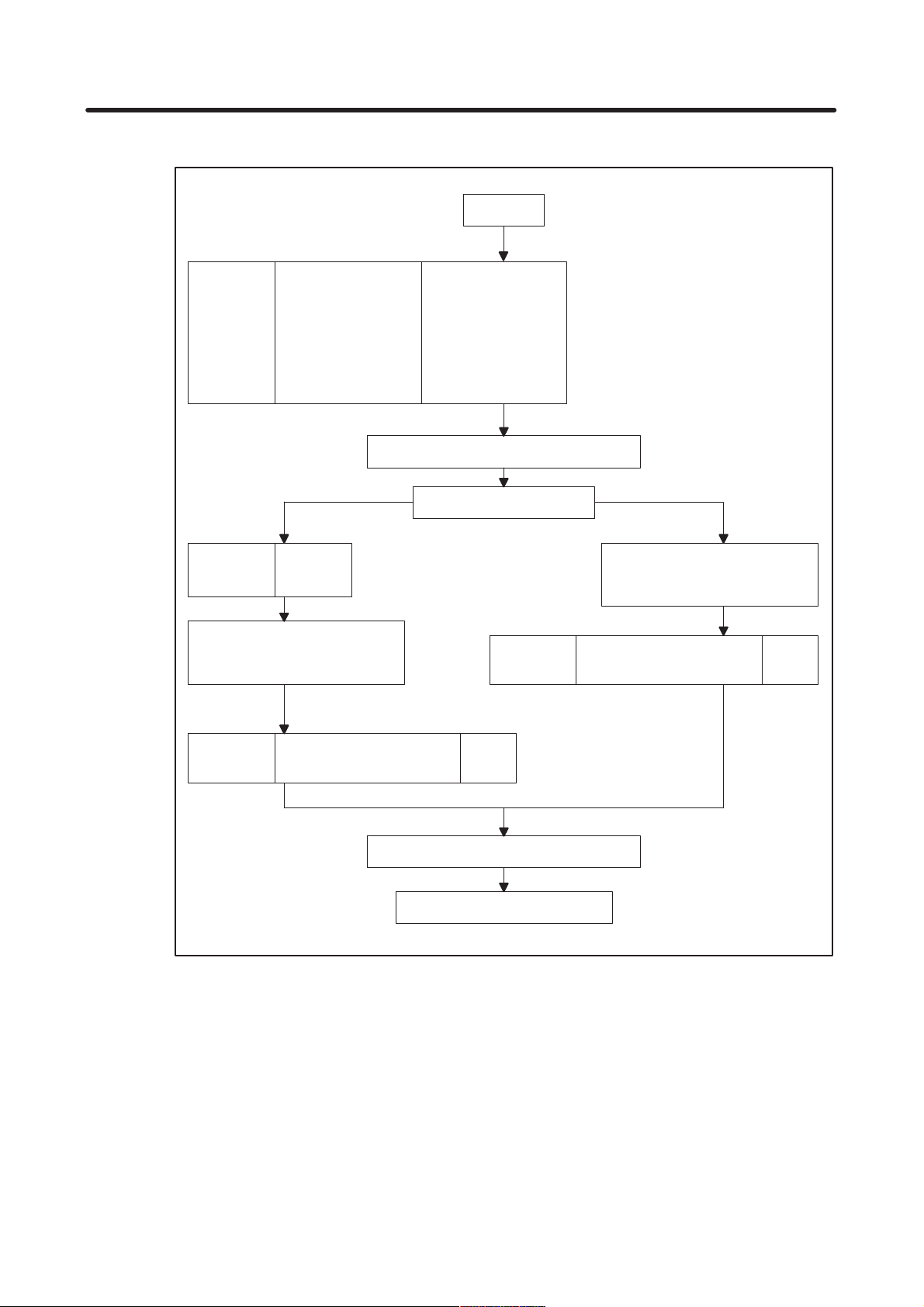

[Flowchart for servo parameter initialization]

Serial pulse coder C

Setting 3

Setting2 Least input increment 0.1 m ?

1874

1806

1820

1879

1896

Setting 1

Type of pulse coder ?

Turn on power to NC in emergency stop state

YES

NO

Initialization bit

Motor number No. 39 and later

AMR

CMR

Move direction

Reference counter

bit1=0,bit0=0No. 1804

See the table shown

at the right.

111 (CCW)

-111 (CW)

Serial pulse coder A or B

Motor

AC5-0

AC3-0S, 4-0S

Other than the above

B–62560E/03

AMR setting

AMR

10000010

00000011

00000000

Turn off the power, then turn it on again

Close loop

No. 1807

1815

Set fiexible feed gear :

1977 (N) Numerator of DMR

1978 (M) Denominator of DMR

1891

bit3=1

bit1=1

Number of speed pulses

Number of position pulses Ns

Turn off the power, then turn it on again

Type of machine system ?

1891

Ns: Number of feedback

8192No. 1876

pulses per motor

revolution sent from

the scale

Semi-closed loop

Set fiexible feed gear :

1977 (N) Numerator of DMR

1978 (M) Denominator of DMR

Number of speed pulses

Number of position pulses

8192No. 1876

12500

Completion of parameter setting

– 8 –

Page 17

B–62560E/03 2. SETTING PARAMETERS

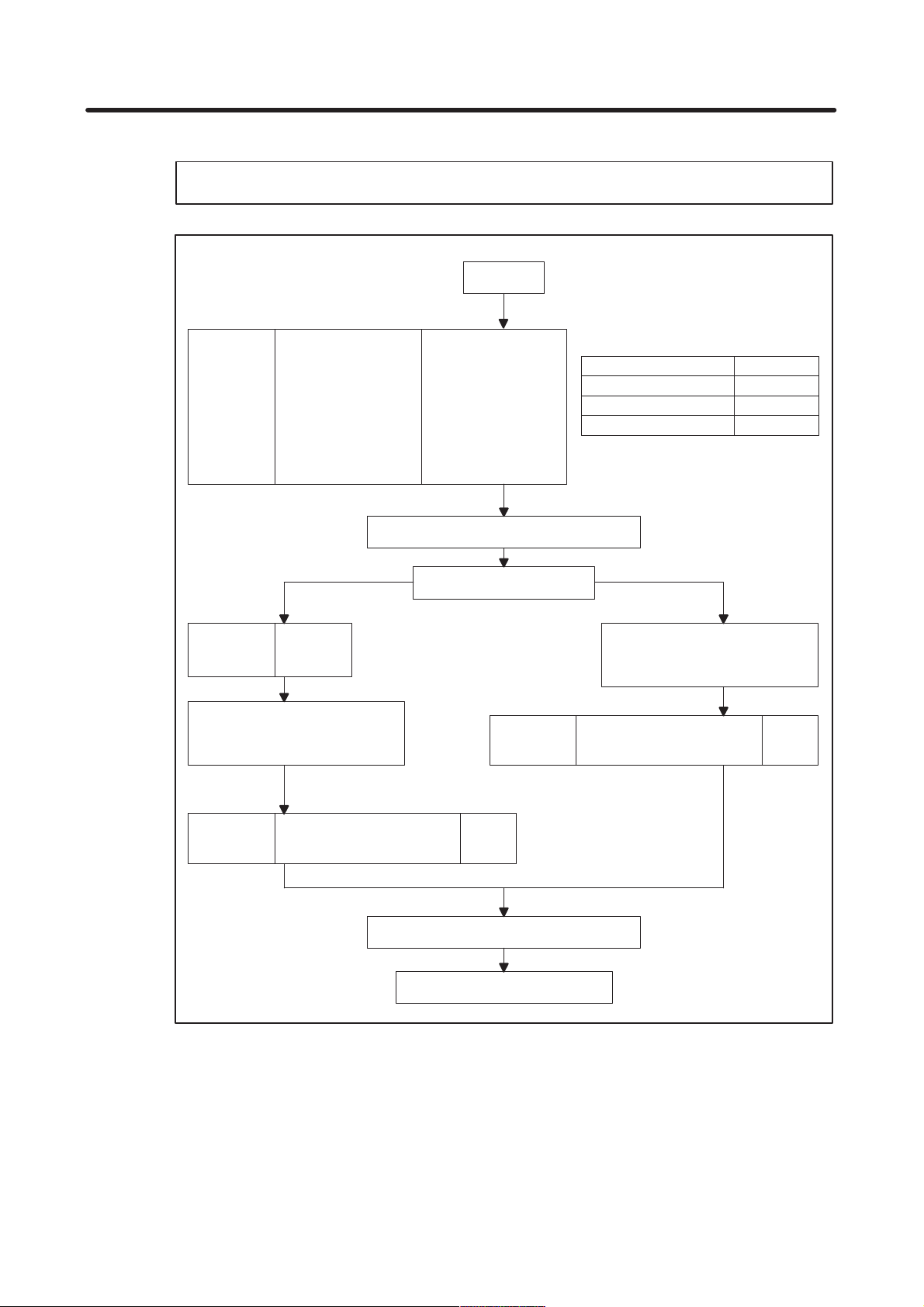

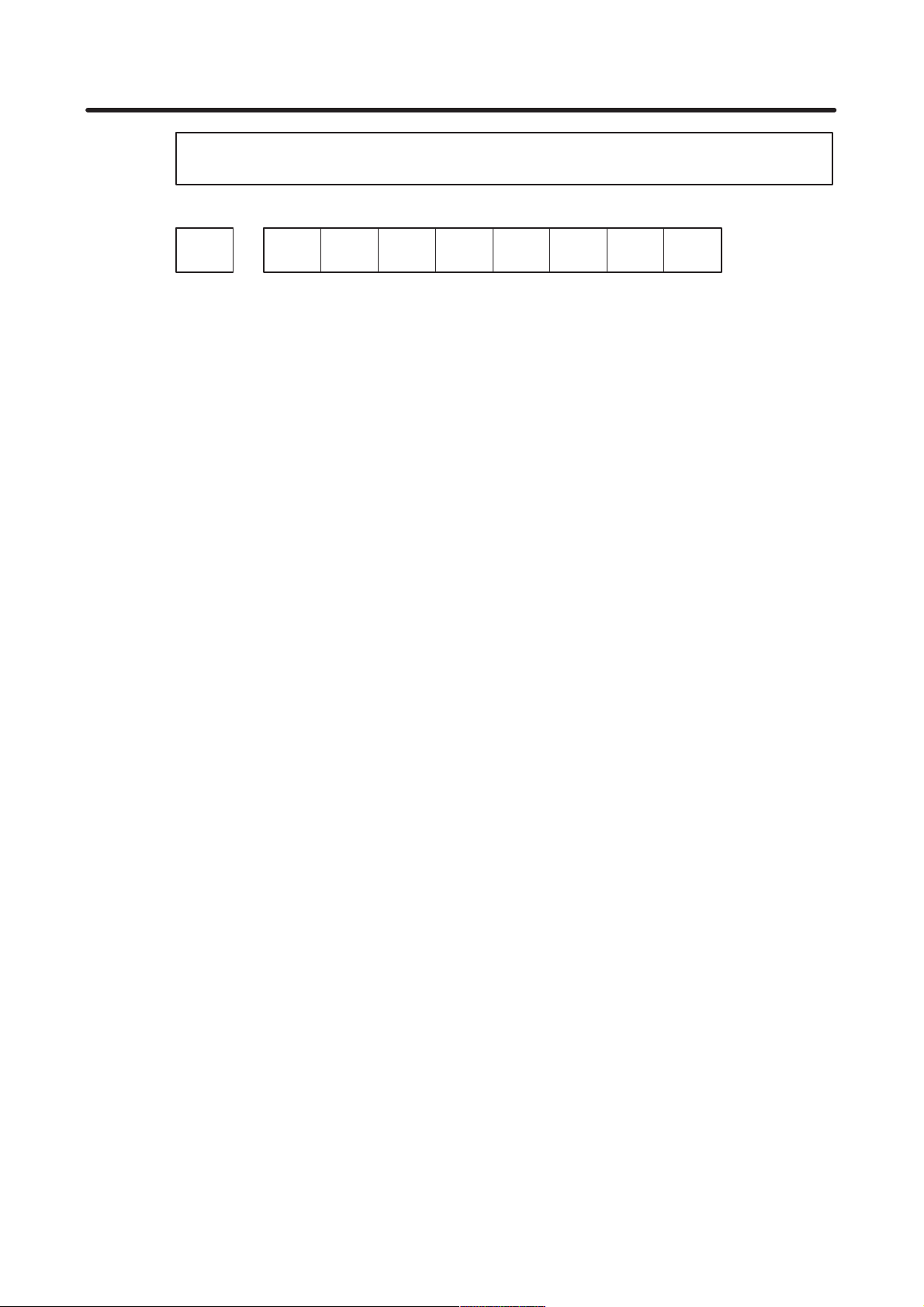

[Flowchart for setting when serial pulse coder A or B is used with a least input increment of 0.1µm]

NOTE An optional parameter for 0.1µm control is required.

Setting 2

Initialization bit

1874

1806

1820

1879

1896

No. 1807

1815

Set fiexible feed gear :

1977 (N) Numerator of DMR

1978 (M) Denominator of DMR

Motor number No. 39 and later

AMR

CMR

Move direction

Reference counter

Turn off the power, then turn it on again

Close loop

bit3=1

bit1=1

bit1=0,bit0=0No. 1804

See the table shown

at the right.

111 (CCW)

-111 (CW)

Type of machine system ?

1891

AMR setting

Motor

AC5-0

AC3-0S, 4-0S

Other than the above

Semi-closed loop

Set fiexible feed gear :

1977 (N) Numerator of DMR

1978 (M) Denominator of DMR

Number of speed pulses

Number of position pulses

AMR

10000010

00000011

00000000

819No. 1876

1250

1891

Number of speed pulses

Number of position pulses Ns/10

Turn off the power, then turn it on again

Completion of parameter setting

8192No. 1876

– 9 –

Ns: Number of feedback

pulses per motor

revolution sent from

the scale

Page 18

2. SETTING PARAMETERS

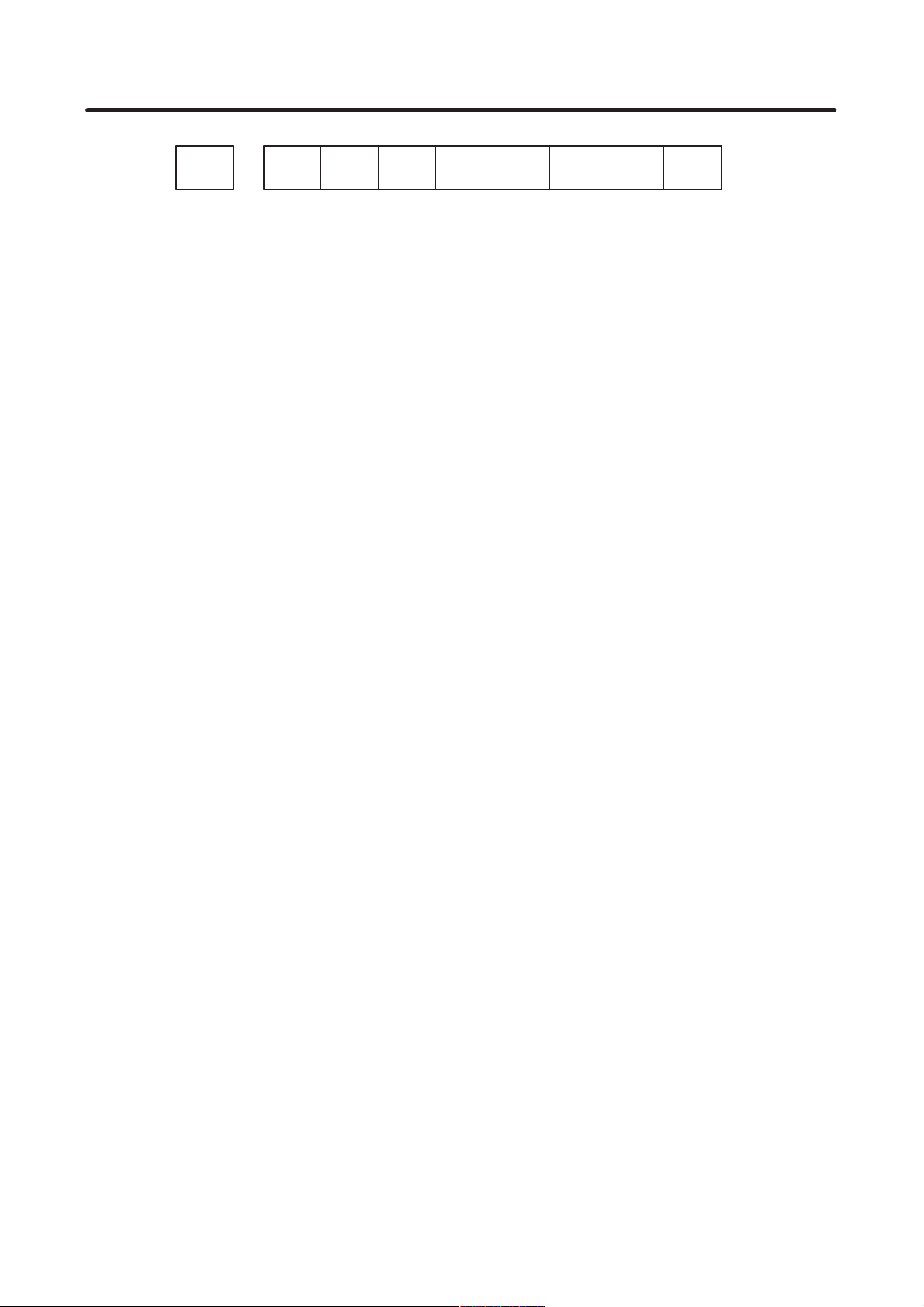

[Flowchart for setting when serial pulse coder C is used with a least input increment of 0.1µm]

B–62560E/03

Setting 3

Initialization bit

1874

1806

1820

1879

1896

No. 1807

1815

Set fiexible feed gear :

1977 (N) Numerator of DMR

1978 (M) Denominator of DMR

Motor number No. 39 and later

AMR

CMR

Move direction

Reference counter

Turn off the power, then turn it on again

Close loop

bit3=1

bit1=1

bit1=0,bit0=0No. 1804

00000000

111 (CCW)

-111 (CW)

Type of machine system ?

1891

Semi-closed loop

Set fiexible feed gear :

1977 (N) Numerator of DMR

1978 (M) Denominator of DMR

Number of speed pulses

Number of position pulses

4000No. 1876

4000

1891

Number of speed pulses

Number of position pulses Ns/10

Turn off the power, then turn it on again

Completion of parameter setting

4000No. 1876

Ns: Number of feedback

pulses per motor

revolution sent from

the scale

– 10 –

Page 19

B–62560E/03 2. SETTING PARAMETERS

[Setting the flexible feed gear]

When using a motor with a serial pulse coder, be sure to use the flexible feed gear for DMR setting.

An alarm is issued when the flexible feed gear is not used.

(Serial pulse coder A or B)

Numerator of DMR (No. 1977) Number of position feedback pulses per motor revolution

Denominator of DMR (No. 1978) 1,000,000

NOTE 1 The maximum specifiable number is 32767 for both the numerator and denominator. So,

reduce the above fraction to its lowest terms.

NOTE 2 When the T Series motor (serial pulse coder B) is used, the numerator of DMR (No. 1977) must

not be greater than 250,000, and the denominator of DMR (No. 1978) must be 1,000,000.

NOTE 3 Make sure the numerator <denominator.

Whenthenumeraor > denominator, an alarm is issued.

(Serial pulse coder C)

Numerator of DMR (No. 1977) Number of position feedback pulses per motor revolution

Denominator of DMR (No. 1978) 40,000

NOTE The maximum specifiable number is 32767 for both the numerator and denominator. So,

reduce the above fraction to its lowest terms.

=

=

(Closed loop)

Numerator of DMR (No. 1977) Number of position feedback pulses per motor revolution

Denominator of DMR (No. 1978) Number of pulse per encoder revolution

NOTE The maximum specifiable number is 32767 for both the numerator and denominator. So,

reduce the above fraction to its lowest terms.

=

– 11 –

Page 20

2. SETTING PARAMETERS

2.5 Compatibility of Parameters with the Series

15–MA, –TA, –TTA, –MF, –TF, and –TTF

1) For the above models, there were parameters for which the increment system used increased by a factor

of ten when the high–resolution detector interface was used (when PLC01, a bit of parameter No. 1804

is set to 1). However, for the Series 15–MB, –TB, –TTB, –MFB, –TFB, and –TTFB, the units remain the

same.

The following parameters for the models that used the high–resolution detection interface are no longer

compatible. For the Series 15–MB, –TB, –TTB, –MFB, –TFB, and –TTFB, be sure to specify the settings

for the following parameters with values ten–times larger than the original settings.

–– Parameters

1410, 1411, 1421, 1423, 1424, 1425, 1426, 1427, 1428

1451, 1452, 1453, 1454, 1455, 1456, 1457, 1458, 1459, 1460, 1461

1621, 1623, 1625, 1627, 1629

1827, 1828, 1829, 1830, 1832, 1837, 1850, 1896

7211, 7212, 7213, 7214, 7311, 7312, 7313

2) For the above models, there where parameters for which the increment system used increased by a factor

of ten when a maximum feedrate of 12 to 24 m per minute was used (when F24, a bit of parameter No.

1804, is set to 1). However, for the Series 15–MB, –TB, –TTB, –MFB, –TFB, and –TTFB, the units remain

the same.

The following parameters for the models that used the high–resolution detector interface are no longer

compatible. For the Series 15–MB, –TB, –TTB, –MFB, –TFB, and –TTFB, be sure to specify the settings

for the following parameters with values ten–times larger than the original settings.

–– parameters

1420, 1422

B–62560E/03

– 12 –

Page 21

B–62560E/03 3. PUNCHING PARAMETER TAPE

3. PUNCHING PARAMETER TAPE

3.1 Punching All Parameters

1 Connect a punch unit to the input/output interface.

2 Set the EDIT mode.

3 Press the SERVICE soft key, then press the PARAM soft key, or press the SERVICE hard key several

times. The parameter screen is displayed.

4 Press the PUNCH soft key, then press the ALL soft key. All the parameters are punched.

3.2 Punching Parameters Other Than Pitch Error Compensation

1 Connect a punch unit to the input/output interface.

2 Set the EDIT mode.

3 Press the SERVICE soft key, then press the PARAM soft key, or press the SERVICE hard key several

times. The parameter screen is displayed.

4 Press the PUNCH soft key, then press the P ARAM soft key. Parameters other than pitch error compensa-

tion are punched.

3.3 Punching Pitch Error Compensation Data

1 Connect a punch unit to the input/output interface.

2 Set the EDIT mode.

3 Press the SERVICE soft key , then press the PITCH soft key , or press the SERVICE hard key several times.

The pitch error compensation data screen is displayed.

4 Press the PUNCH soft key, then press the PITCH soft key. Pitch error compensation data is punched.

– 13 –

Page 22

4. DESCRIPTION OF PARAMETERS

4. DESCRIPTION OF PARAMETERS

Parameters are classified according to functions.

4.1 Parameters Related to Settings (Parameter Nos. 0000–0032) 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 Parameters Related to Timers (Parameter Nos. 0100–0119) 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 Parameters Related to Axis Control (Parameter Nos. 1000–1059) 27. . . . . . . . . . . . . . . . . . . . . . . . . .

4.4 Parameters Related to Chopping (Parameter Nos. 1191–1197) 45. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5 Parameters Related to Coordinate Systems (Parameter Nos. 1200–1260) 47. . . . . . . . . . . . . . . . . . .

4.6 Parameters Related to Feedrate (Parameter Nos. 1400–1494) 50. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.7 Parameters Related to Screen for Specifying High–Speed and High–Precision Machining

(Parameter Nos. 1517–1518) 65. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.8 Parameters Related to Acceleration/Deceleration Control (Parameter Nos. 1600–1653) 66. . . . . . . .

4.9 Parameters Related to Servo (Parameter Nos. 1800–1999) 76. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.10 Tandem Control 106. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 1 Parameters Related to DI/DO (Parameter Nos. 2000–2052) 112. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.12 Parameters Related to CRT/MDI and Editing (Parameter Nos. 2200–2388) 124. . . . . . . . . . . . . . . . . .

4.13 Parameters Related to Program (Parameter Nos. 2400–2900) 142. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.14 Parameters Related to Serial Spindle Output and Cs Contour Control Function

(Parameter Nos. 3000–3303) 156. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.15 Parameters Related to Waveform Diagnosis Function (Parameter Nos. 4640–4646) 189. . . . . . . . . . .

4.16 Parameters Related to Graphic Display (Parameter Nos. 4821–4883) 190. . . . . . . . . . . . . . . . . . . . . . .

4.17 Parameters Related to Reader/Punch Interfaces (Parameter Nos. 5000–5162) 194. . . . . . . . . . . . . . .

4.18 Parameters Related to Stroke Limit (Parameter Nos. 5200–5248) 205. . . . . . . . . . . . . . . . . . . . . . . . . . .

4.19 Parameters Related to Position Switching Function (Parameter Nos. 5200–5299) 214. . . . . . . . . . . . .

4.20 Parameters Related to Reference Marks (Parameter Nos. 1008, 5226–5227) 217. . . . . . . . . . . . . . . .

4.21 Parameters Related to Pitch Error Compensation (Parameter Nos. 5420–5433) 220. . . . . . . . . . . . . .

4.22 Parameters Related to Gradient Compensation

(Valid only with the Series 15–M and Series 15–T)(Parameter Nos. 5461–5474) 237. . . . . . . . . . . . . .

4.23 Parameters Related to Straightness Compensation

(Valid only with the Series 15–M and Series 15–T)(Parameter Nos. 5481–5574) 239. . . . . . . . . . . . . .

4.24 Parameters Related to Spindle Control (Parameter Nos. 5600–5820) 250. . . . . . . . . . . . . . . . . . . . . . .

4.25 Parameters Related to Rigid Tapping with the Series 15–TT

(Parameter Nos. 3000–3213, 5610–5955) 282. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.26 Parameters Related to the Electronic Gear Box (EGB) (Parameter Nos. 5990–5998) 290. . . . . . . . . .

4.27 Parameters Related to T ool Of fsets (Parameter Nos. 6000–6121) 295. . . . . . . . . . . . . . . . . . . . . . . . . . .

4.28 Three–Dimensional Cutter Compensation (Supplement)(Parameter Nos. 6080–6115) 307. . . . . . . . .

4.29 Parameters Related to Cylindrical Interpolation Cutting Point Compensation

(Parameter Nos. 6004–6113) 312. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.30 Parameters Related to Canned Cycles (Parameter Nos. 6200–6240) 314. . . . . . . . . . . . . . . . . . . . . . .

4.31 Parameters Related to Scaling and Coordinate Rotation (Parameters Nos. 6400–6421) 322. . . . . . . .

4.32 Parameters Related to Automatic Corner Override (Parameter Nos. 6610–6614) 324. . . . . . . . . . . . . .

4.33 Parameters Related to Automatic Feedrate Control Using Involute Interpolation

(Parameter Nos. 6620–6634) 327. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.34 Parameters Related to Uni–Directional Positioning (Parameter No. 6820) 329. . . . . . . . . . . . . . . . . . .

4.35 Parameters Related to Custom Macros (Parameter Nos. 7000–7089) 330. . . . . . . . . . . . . . . . . . . . . . .

4.36 Parameters Related to Restarting Programs and Blocks and T ool Retraction and Recovery

(Parameter No. 71 10) 338. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.37 Parameters Related to Skip Function (Parameter Nos. 7200–7220) 339. . . . . . . . . . . . . . . . . . . . . . . . .

4.38 Parameters Related to Automatic Tool Compensation (for the Series 15–T only) and

Automatic Tool Length Measurement (for the Series 15–M only)(Parameter Nos. 7300–7333) 344. .

B–62560E/03

– 14 –

Page 23

B–62560E/03 4. DESCRIPTION OF PARAMETERS

4.39 Parameters Related to Tool Life Management (Parameter Nos. 7400–7442) 346. . . . . . . . . . . . . . . . .

4.40 Parameters Related to Turret Axis Control (Parameter Nos. 7500–7536) 349. . . . . . . . . . . . . . . . . . . . .

4.41 Parameters Related to 3–Dimensional Handle Feel for 15–M (Parameter Nos. 7537–7558) 352. . . .

4.42 Parameters Related to 15–TT Three–Dimensional Handle Feed

(Parameter Nos. 7546–7759, 1000) 358. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.43 Parameters Related to 15–TT T ool Length Compensation Along the Tool Axis

(Parameter Nos. 6001–7752) 366. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.44 Parameters Related to Designation Direction T ool Length Compensation

(Parameter No. 771 1) 371. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.45 Parameter Related to Upgraded 5–Axis Control Compensation (Parameter Nos. 7559–7614) 372. . .

4.46 Parameters Related to High–Precision Contour Control 373. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.47 Parameters Related to High–Precision Contour Control Based on a 64–Bit RISC Processor

(Parameter Nos. 1009–8481) 377. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.48 Other Parameters (Parameter Nos. 7600–7799) 383. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.49 Parameters Related to Maintenance (Parameter Nos. 8000–8010) 402. . . . . . . . . . . . . . . . . . . . . . . . . .

4.50 DNC Operation with the Remote Buffer 403. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

– 15 –

Page 24

4. DESCRIPTION OF PARAMETERS

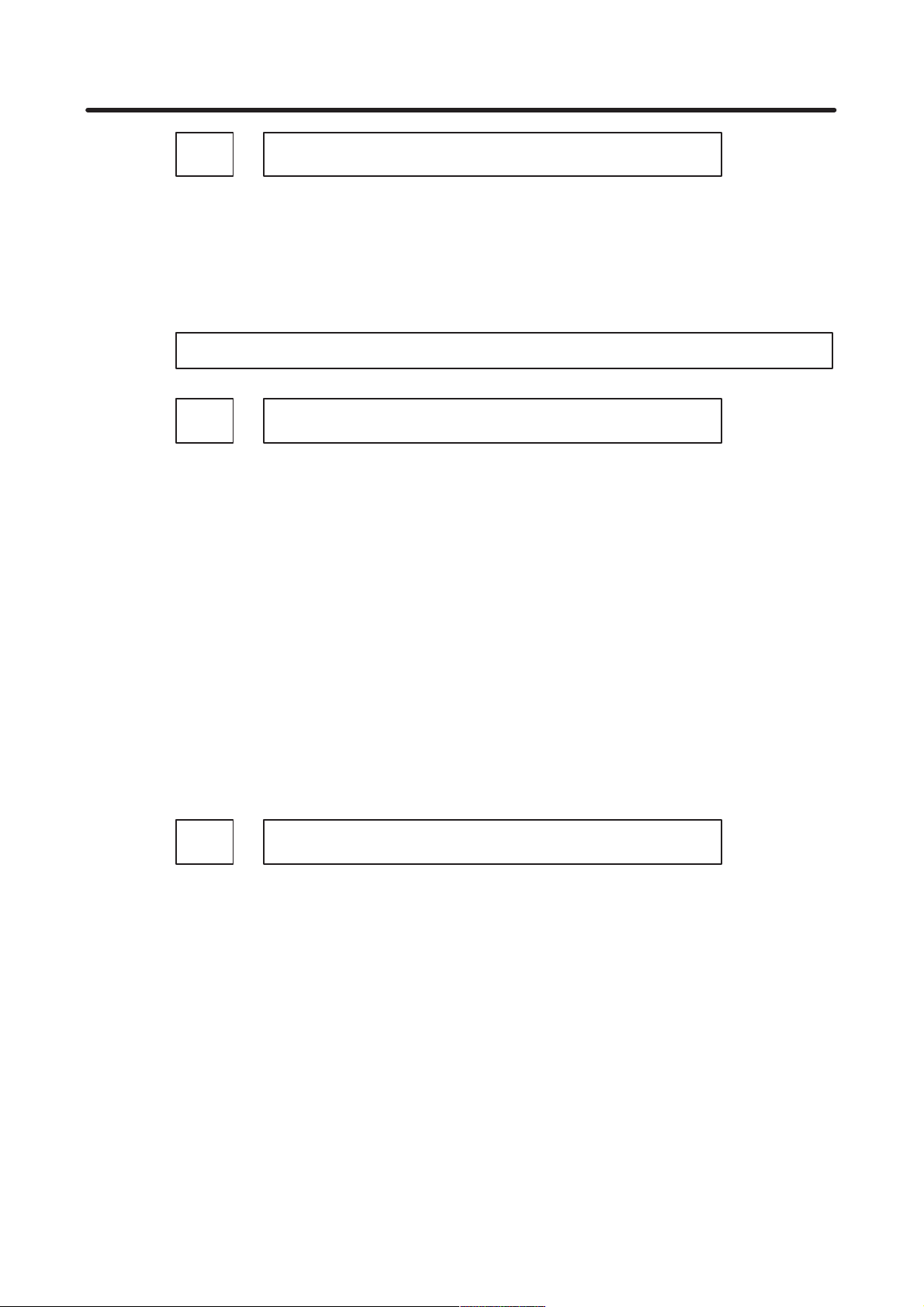

4.1 Parameters Related to Settings

#7 #6 #5 #4 #3 #2 #1 #0

0000 RMTDG DNC EIA NCR ISP CTV TVC

Setting input

Data type : Bit

TVC Specifies whether TV check is performed.

0 : Do not perform.

1 : Perform.

CTV Specifies whether characters are counted for TV check during control out.

0 : Count.

1 : Do not count.

ISP Specifies whether ISO codes contain a parity bit.

0 : Contain parity bit.

1 : Do not contain parity bit.

(A parity bit is located at channel 8 in a punched tape in the ISO code.)

NCR Specifies how to punch an EOB (end–of–block) code when using ISO codes.

0 : Punch LF CR CR.

1 : Punch LF.

EIA Specifies the code system to use for punch codes.

0 : ISO code

1 : EIA code

DNC Specifies conditions for DNC operation with the remote buffer.

0 : Enable high–speed distribution if high–speed distribution conditions are satisfied.

1 : Perform normal distribution.

RMTDGSpecifies whether to perform remote diagnosis.

0 : Not performed.

1 : Performed.

B–62560E/03

#7 #6 #5 #4 #3 #2 #1 #0

0003 XTST KGRG NKGRH

Setting input

Data type : Bit

NKGRHSpecifies whether to stop drawing graphic A when the screen is switched to another one during

drawing.

0 : Stop.

1 : Do not stop.

KGRG In the graphic guidance function.

0 : Graphics are drawn for guidance.

1 : Graphics are not drawn for guidance.

NOTE This function is not available in Series 15–MB(MA2).

XTST Specifies how data is obtained for the internal investigation function used when diagnostic guidance

is activated.

0 : Read specified data automatically.

1 : Use data input by the operator as the function value.

– 16 –

Page 25

B–62560E/03 4. DESCRIPTION OF PARAMETERS

NOTE When this bit is set to 1, the user can set the internal investigation function to any value. This

allows the user to check and debug the knowledge base.

#7 #6 #5 #4 #3 #2 #1 #0

0010 SB0 SBC SBM SB8 SB7 GRPBG SQN INI

Setting input

Data type : Bit

INI Specifies whether the increment system is metric or in inches.

0 : Metric input

1 : Inch input

SQN Specifies whether sequence numbers are automatically inserted.

0 : Do not insert.

1 : Insert.

GRPBGSpecifies whether to display an graphic display or background graphic display.

0 : Graphic Display

1 : Background Graphic Display

SB7 Specifies whether to stop after each block of custom macro statements in programs 07000 to 07999.

0 : Do not stop after each block.

1 : Stop after each block. (Used to debug custom macros.)

SB8 Specifies whether to stop after each block of custom macro statements in programs 08000 to 08999.

0 : Do not stop after each block.

1 : Stop after each block. (Used to debug custom macros.)

SBM Specifies whether to stop after each block of custom macro statements in any program.

0 : Do not stop after each block. (However, when stopping is specified in SB7 or SB8, stopping will

occur in programs affected by these parameters.)

1 : Stop after each block. (Used to debug custom macros.)

SBC Specifies whether to stop after each block in hole–machining canned cycles (Not used in the Series

15–TT).

0 : Do not stop after each block.

1 : Stop after each block. (Used when trouble occurs with canned cycles.)

SBO Specifies whether to stop after each block automatically generated in the NC for cutter or tool tip

radius compensation.

0 : Do not stop after each block.

1 : Stop after each block. (Used when trouble occurs with cutter or tool tip radius compensation.)

– 17 –

Page 26

4. DESCRIPTION OF PARAMETERS

#7 #6 #5 #4 #3 #2 #1 #0

0011 G50 HSO NOT TIM HSDLD ND8 NE8

Setting input

Data type : Bit

NE8 Specifies whether to permit editing of 08000 to 08999 programs.

0 : Permit editing.

1 : Do not permit editing.

ND8 Specifies whether to display the program being executed on the CRT for programs 08000 to 08999.

0 : Display program being executed.

1 : Do not display program being executed.

HSDLD Specifies whether the high–speed part program registration function is used.

0 : Not used.

1 : Used.

Normally, set this bit to 0.

When there is no need to display custom macros or other programs being executed, set this parameter to 1.

This function speeds up the registration of part programs in the foreground mode (EDIT mode). In the back-

ground mode, part programs are registered at normal speed.

If the power is disconnected during registration of part programs, the system operates as follows when the pow-

er is restored:

(1) Displays “CLEAR PROGRAM FILE (HSPD DLOAD)” on the CRT screen.

(2) Clears all part programs (including high–speed machining programs).

(3) Halts when the IPL monitor screen is displayed.

To restart the system, select “6 END IPL” by entering 6, or turn the power off then on again.

When part programs are being registered, they are not displayed.

When part programs are being registered, screens cannot be updated in some cases.

TIM Specifies the information displayed on the screen for the program No. and name directory.

0 : Display program No., name, and memory used.

1 : Display program No., name, and processing time.

NOT Specifies whether to use tool Nos. to specify output of tool pot Nos. and tool offsets.

0 : Use tool Nos. (H/D codes cannot be used to specify tool length compensation and cutter com-

pensation).

1 : Do not use tool Nos. (H/D codes can be used to specify tool length compensation and cutter com-

pensation Neither entering H or D codes in the tool life management function nor specifying H99

codes or D99 codes can be performed.).

HSO Specifies operation performed when the G10.3 L1/L2 command is used.

0 : Skip the program up to G11.3 and execute high–speed machining using previously registered

data (call operation mode).

1 : Convert commands up to G11.3 into high–speed machining data, then register the data and use

it to perform high–speed machining (register operation mode).

G50 Specifies whether to allow use of code G50 (G92 in G code system B and C; for specifying the coordi-

nate system) when using the Series 15–T.

0 : Allow G50 (G92 in G code system B and C) to be used in a program command

1 : Do not allow G50 (G92 in G code system B and C) to be used in a program command. If G50 is

used, a P/S alarm will be generated.

Set this parameter to 1 when the coordinate system is set using a tool geometry offset (instead of G50).

In this case, an alarm will be generated if G50 is used inadvertently .

B–62560E/03

– 18 –

Page 27

B–62560E/03 4. DESCRIPTION OF PARAMETERS

#7 #6 #5 #4 #3 #2 #1 #0

0012 RMVx SCLx MIRx

Setting input

Data type : Bit axis

MIRx For each axis, specifies whether to use its mirror image.

0 : Do not use mirror image (normal).

1 : Use mirror image (mirror).

SCLx For each axis, specifies whether scaling is used (only for the Series 15–M)

0 : Use scaling.

1 : Do not use scaling.

RMVxFor each axis, specifies whether to detach the shaft corresponding to the control axis.

0 : Do not detach.

1 : Detach.

Effective when RMBx, a bit of parameter No. 1005, is set to 1.

#7 #6 #5 #4 #3 #2 #1 #0

0013 DSYS HDIO HKEY NDSP PCMN

Setting input

Data type : Bit

PCMN Specifies whether to display the PMC user screen (PCMDI) directly with the PMC/CNC key.

0 : Do not display the screen.

1 : Display the screen.

NDSP Specifies whether to display multiple subscreens on the PMC screen.

0 : Display multiple subscreens.

1 : Do not display multiple subscreens.

HKEY Specifies whether to store the history of key operations with the operation history function key.

0 : Do not store the history.

1 : Store the history.

HDIO Specifies whether to store the history of DI/DO with the operation history function key.

0 : Do not store the history.

1 : Store the history.

DSYS Specifies whether to display the system history screen.

0 : Do not display the screen.

1 : Display the screen.

– 19 –

Page 28

4. DESCRIPTION OF PARAMETERS

#7 #6 #5 #4 #3 #2 #1 #0

0014 HD2 BDSP FMST

Setting input

Data type : Bit

FMST Specifies whether to output alarm OH001, ”FAN MOTOR STOP.”

0 : Output the alarm.

1 : Do not display the alarm.

BDSP Specifies the units used for the file sizes in the disk directory display.

0 : Meters (metric input) or feet (inch input)

1 : Bytes

HD2 Specifies whether the size of one file can exceed 2000 m when using a floppy cassette, the PRO

GRAM FILE Mate, HANDY FILE, or FA card.

0 : Within 2000 m

1 : Can exceed 2000 m

#7 #6 #5 #4 #3 #2 #1 #0

0015 KYON HION HPOF SPOF SVOF

B–62560E/03

Parameter input

Data type : Bit

SVOF Specifies whether to display the servo screen.

0 : Display the servo screen.

1 : Do not display the servo screen.

SPOF Specifies whether to display the spindle screen.

0 : Display the spindle screen.

1 : Do not display the spindle screen.

HPOF Specifies whether to display the screen for high–precision contour control.

0 : Display the screen.

1 : Do not display the screen.

HION

0 :The operation history is not displayed. (Note that the alarm history is still displayed. )

1 : The operation history is displayed.

KYON

0 : [ERASE] key on the operation history screen is disabled.

1 : [ERASE] key on the operation history screen is enabled.

NOTE On the operation history screen, using the erase key can erase:

– Operation history data

– Alarm history data

– 20 –

Page 29

B–62560E/03 4. DESCRIPTION OF PARAMETERS

0016 Screen saver start time

Setting entry

Data type : Byte

Data unit : Minute

Data range : 0 to 127

When the operator does not operate the keyboard for the period specified in this parameter, the saver screen

is displayed. When 0 is specified, the screen saver function is disabled.

NOTE This function is not available in Series 15–MB(MA2).

0020 Interface No. of input device for foreground

Setting input

Data type : Byte

Assignment of input device numbers for foreground

0 : Reader connected to JD5A of main CPU board

1 : Reader connected to JD5A of main CPU board (Settings 0 and 1 are identical.)

2 : Reader connected to JD5B of main CPU board

3 : Reader connected to JD5J of the subboard

4 : DNC1

9 : PMC

10: Remote buffer

13: Reader connected to JD6D of the subboard

14: Data Server

15: MMC DNC operation interface

16: MMC upload/download interface

Perform system reset after setting this parameter.

0021 Interface No. of output device for foreground

Setting input

Data type : Byte

Assignment of output device numbers for foreground

1 : Punch connected to JD5A of main CPU board

2 : Punch connected to JD5B of main CPU board

3 : Punch connected to JD5J of the subboard

4 : DNC1

9 : PMC

10: Remote buffer

13: Punch connected to JD6D of the subboard

14: Data Server

15: MMC DNC operation interface

16: MMC upload/download interface

Perform system reset after setting this parameter.

– 21 –

Page 30

4. DESCRIPTION OF PARAMETERS

0022 Interface No. of input device for background

Setting input

Data type : Byte

Assignment of input device numbers for background

0 : Reader connected to JD5A of main CPU board

1 : Reader connected to JD5A of main CPU board (Settings 0 and 1 are identical.)

2 : Reader connected to JD5B of main CPU board

3 : Reader connected to JD5J of the subboard

4 : DNC1

9 : PMC

10: Remote buffer

13: Reader connected to JD6D of the subboard

14: Data Server

15: MMC DNC operation interface

16: MMC upload/download interface

Perform system reset after setting this parameter.

B–62560E/03

0023 Interface No. of output device for background

Setting input

Data type : Byte

Assignment of output device numbers for background

1 : Punch connected to JD5A of main CPU board

2 : Punch connected to JD5B of main CPU board

3 : Punch connected to JD5J of the subboard

4 : DNC1

9 : PMC

10: Remote buffer

13: Punch connected to JD6D of the subboard

14: Data Server

15: MMC DNC operation interface

16: MMC upload/download interface

Perform system reset after setting this parameter.

0031 Initial value used for automatic setting of sequence Nos.

Setting input

Data type : Two words

Valid range : 0 to 99999

0032 Increment used for automatic setting of sequence Nos.

Setting input

Data type : Two words

Valid range : 0 to 99999

– 22 –

Page 31

B–62560E/03 4. DESCRIPTION OF PARAMETERS

4.2 Parameters Related to Timers

0100 Timer 1 (time accumulated since power–on)

Parameter input

Data type : Two words

Unit : Minutes

Valid range : 0 to 99999999

Timer 1 : Sets and displays the time accumulated since power–on.

0101 Timer 2 (time accumulated during automatic operation)

Setting input (For the Series 15–TT, this parameter is for the first tool post.)

Data type : Two words

Unit : Milliseconds

Valid range : 0 to 60000

Timer 2 : Sets and displays the time accumulated during automatic operation.

0102 Timer 3 (time accumulated during automatic operation)

Setting input (For the Series 15–TT, this parameter is for the first tool post.)

Data type : Two words

Unit : Minutes

Valid range : 0 to 99999999

Timer 3 : Sets and displays the time accumulated during automatic operation.

0103 Timer 4 (time accumulated during cutting)

Setting input (For the Series 15–TT, this parameter is for the first tool post.)

Data type : Two words

Unit : Milliseconds

Valid range : 0 to 60000

Timer 4 : Sets and displays the time accumulated during cutting.

0104 Timer 5 (time accumulated during cutting)

Setting input (For the Series 15–TT, this parameter is for the first tool post.)

Data type : Two words

Unit : Minutes

Valid range : 0 to 99999999

Timer 5 : Sets and displays the time accumulated during cutting.

– 23 –

Page 32

4. DESCRIPTION OF PARAMETERS

B–62560E/03

0105

Setting input

Data type : Two words

Unit : Milliseconds

Valid range : 0 to 60000

Timer 6 : Sets and displays the time accumulated while the TMRON signal is on.

0106

Setting input

Data type : Two words

Unit : Minutes

Valid range : 0 to 99999999

Timer 7 : Sets and displays the time accumulated while the TMRON signal is on.

Timer 6 (time accumulated while general–purpose integrating

meter activating signal TMRON is on)

There is an integrating meter in the control unit that is activated by an input signal from the machine. This integrating meter can be preset by this parameter.

Timer 7 (time accumulated while general–purpose integrating

meter activating signal TMRON is on)

There is an integrating meter in the controller that is activated by an input signal from the machine side. This integrating meter can be preset by this parameter.

0107 Total number of parts machined

Setting input

Data type : Two words

Unit : Number of parts

Valid range : 0 to 99999

Sets and displays the total number of parts machined.

For the Series 15–TT, this parameter applies to the first spindle.

0108 Total number of parts

Setting input

Data type : Two words

Unit : Number of parts

Valid range : 0 to 99999999

For the Series 15–TT, this parameter indicates the total number of parts for the first spindle.

0109 Number of parts required

Setting input

Data type : Two words

Unit : Number of parts

Valid range : 0 to 99999999

When the total number of machined parts (parameter No. 0107) exceeds the number of parts

required, a signal is output to the machine.

For the Series 15–TT , this parameter indicates the total number of parts machined by the first

spindle.

– 24 –

Page 33

B–62560E/03 4. DESCRIPTION OF PARAMETERS

0111

Setting input (only for the Series 15–TT)

Data type : Two words

Unit : Milliseconds

Valid range : 0 to 60000

Timer 8 : Sets and displays the time accumulated during automatic operation of the second tool post.

0112

Setting input (only for the Series 15–TT)

Data type : Two words

Unit : Minutes

Valid range : 0 to 99999999

Timer 9 : Sets and displays the time accumulated during automatic operation of the second tool post.

0113 T imer 10 (time accumulating during cutting with the 2nd tool post)

Setting input (only for the Series 15–TT)

Data type : Two words

Unit : Milliseconds

Valid range : 0 to 60000

Timer 10 : Sets and displays the time accumulated during cutting with the second tool post.

Timer 8 (time accumulated during automatic operation of the

2nd tool post)

Timer 9 (time accumulated during automatic operation of the

2nd tool post)

0114 T imer 11 (time accumulating during cutting with the 2nd tool post)

Setting input (only for the Series 15–TT)

Data type : Two words

Unit : Minutes

Valid range : 0 to 99999999

Timer 11 : Sets and displays the time accumulated during cutting with the second tool post.

0117 Total number of parts machined (with the 2nd spindle)

Setting input (only for the Series 15–TT)

Data type : Two words

Unit : Number of parts

Valid range : 0 to 99999999

This parameter indicates the total number of parts machined by the second spindle.

– 25 –

Page 34

4. DESCRIPTION OF PARAMETERS

0118 Total number of parts machined (with the 2nd spindle)

Setting input (only for the Series 15–TT)

Data type : Two words

Unit : Number of parts

Valid range : 0 to 99999999

This parameter indicates the total number of parts machined by the second spindle.

0119 Number of parts required to be machined (with the 2nd spindle)

Setting input (only for the Series 15–TT)

Data type : Two words

Unit : Number of parts

Valid range : 0 to 99999999

This parameter indicates the total number required to be machined by the second spindle.

B–62560E/03

– 26 –

Page 35

B–62560E/03 4. DESCRIPTION OF PARAMETERS

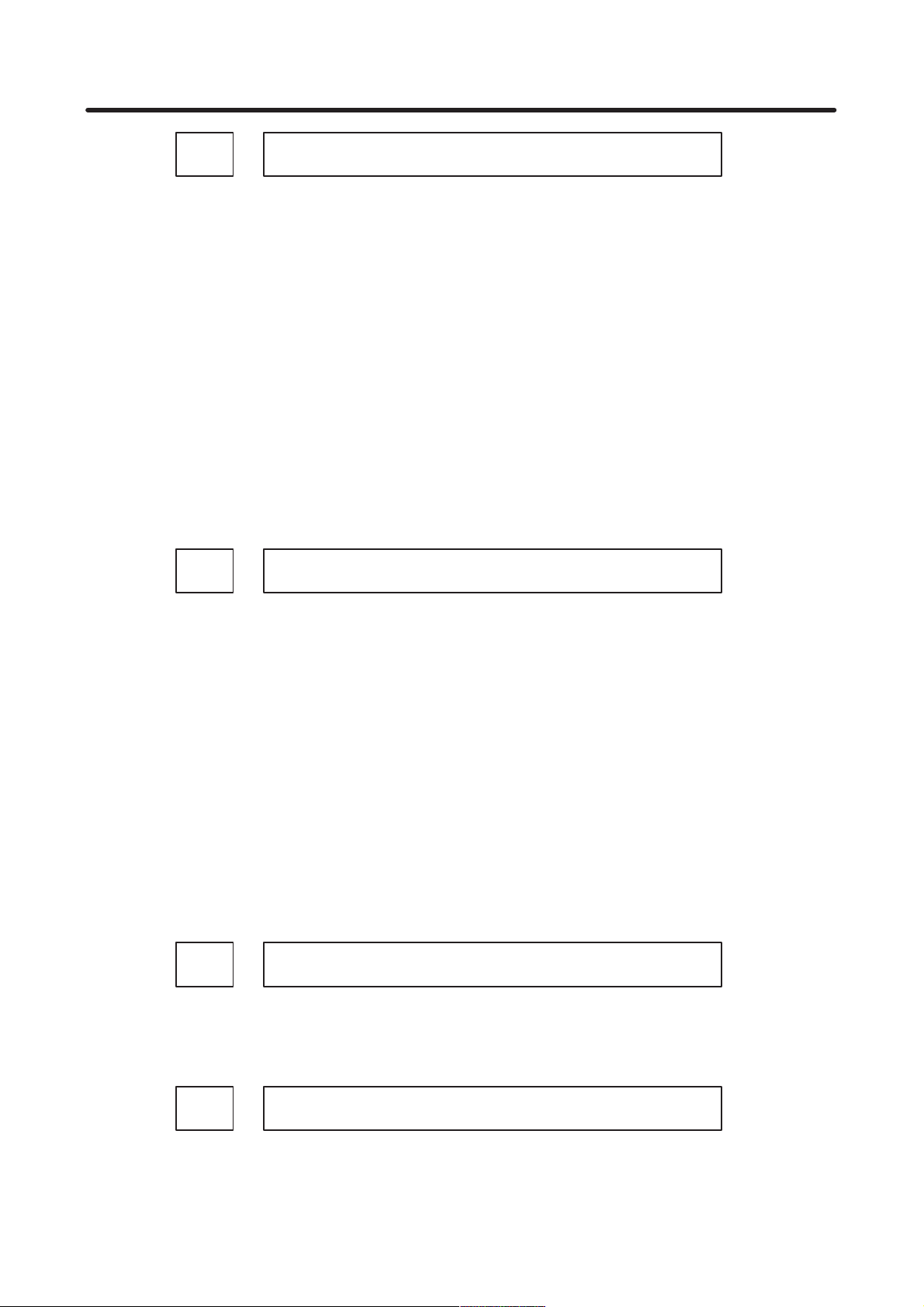

4.3 Parameters Related to Axis Control

#7 #6 #5 #4 #3 #2 #1 #0

1000 HLB EMI EHM FPI XIK CSZ CIP

Parameter input

Data type : Bit

CIP Specifies whether to perform an in–position check after deceleration.

0 : Do not perform in–position check (during deceleration, wait until the feedrate reaches zero before

executing next block).

1 : Perform in–position check (during deceleration, wait until the feedrate reaches zero and then also

confirm the machine reaches the specified position before executing next block).

CSZ Specifies whether to enable the in–position check signal (*CSMZ)

0 : Disable

1 : Enable

XIK When axis interlock is applied during non–linear interpolation positioning (when LRP , a bit of parame-

ter No. 1400 is se to 0), specifies whether to stop only the axis to which interlock was applied or all axes.

0 : Stop axis to which interlock was applied. (Other axes continue operation.)

1 : Stop all axes.

FPI Specifies whether to perform an in–position check at the temporary stop–point in G60 mode.

0 : Do not perform in–position check.

1 : Perform in–position check.

EHM Specifies conditions when handle interruption is valid.

0 : When in G01, G02, or G03 mode, handle interruption is valid during automatic operation startup,

stopping, and resting.

1 : Handle interruption is only valid for G01, G02, and G03 blocks during automatic operation startup.

EMI Specifies validity of manual interrupts and manual setup operations during simultaneous

manual–automatic operation.

0 : Manual interrupts are invalid and manual setup operations are valid.

1 : Manual interrupts and manual setup operations are valid.

HLB Specifies the rotation axes during 3–dimensional handle feed when the axis of the tool is on the Z–axis

0 : Axes A and C.

1 : Axes B and C.

NOTE Set TLAX and SLAB, bits of parameter No. 7550 to 0. If either of these bits is set to 1, HLB will

be ignored.

– 27 –

Page 36

4. DESCRIPTION OF PARAMETERS

#7 #6 #5 #4 #3 #2 #1 #0

1001 CHPX PED PGDM IMCW NCOD RPC

Parameter input (only for the Series 15–M)

Data type : Bit

RPC Specifies whether the axes are switched when a reference position return (G29) is performed.

0 : Axes are switched.

1 : Axes are switched.

NCOD Specifies the conditions for calculating a spline when 0 x t x T.

0 : T = 1 for the first segment of the spline and T is the ratio of the chord of each consecutive segment

to the chord of the first segment.

Assuming that the specified point array is P

the following equations are satisfied:

T=P P/PP=1

T=P P/PP

……………

=Pn– Pn / P P

T

n–

1 : T = 1 for all segments.

IMCW Specifies the forward direction of one rotation axis of the two axes for which hypothetical axis control

is possible.

0 : Forward direction is counterclockwise.

1 : Forward direction is clockwise.

B–62560E/03

, P2, ..., Pn and T of each segment is T1, T2, ..., T

1

n–1

,

NOTE This function is not available in Series 15–MB(MA2).

PGDM Specifies whether the G code (G10.9) for selecting diameter or radius programming is valid for axis

commands in the program.

0 : Invalid.

1 : Valid.

PED Specifies whether to enable the external deceleration function in axis control by PMC.

0 : Disables the external deceleration function.

1 : Enables the external deceleration function.

CHPX Specifies whether the settings that specify the chopping axis and chopping rate can be set.

0 : Can be set.

1 : Cannot be set.

#7 #6 #5 #4 #3 #2 #1 #0

1002 DC2 DC4 ROPS INM

Parameter input

Data type : Bit

INM Specifies whether the detection unit for the linear axis of the machine is metric or in inches.

0 : Metric

1 : Inches

ROPSSpecifies which parameter enables or disables the roll–over function for a rotation axis.

0 : RDAx bit of parameter 1008

1 : RDA2x bit of parameter 1009

DC4 Specifies how to establish a reference position for a linear scale having reference marks.

0 : An absolute position is established by detecting three reference marks.

1 : An absolute position is established by detecting four reference marks.

– 28 –

Page 37

B–62560E/03 4. DESCRIPTION OF PARAMETERS

DC2 When the reference position establishment by the distance coded linear scale,

0 : Conforms to DC4.

1 : The axis moves until two reference marks are detected.

NOTE 1 When this parameter is set to 1, set the direction of scale zero in the parameter

(No.191 1#SCLPx) correctly.

NOTE 2 Even if DC2 is ”1”, the rotary axis (parameter No.1006#ROTx=1) follows DC4.

#7 #6 #5 #4 #3 #2 #1 #0

1004 PDSx DSPx ISDx IPRx ISFx ISRx

Parameter input

Data type : Bit

ISRx, ISFx, ISDx, ISEx (parameter No. 1009) Specify an increment system for each axis

ISEx Specifies an increment system for each axis in parameter No. 1009.

ISDx ISFx ISRx Least input increment, least command increment Abbr.

ISEx

0 0 0 0 0.001 mm, 0.001 deg, or 0.0001 inch IS–B

0 0 0 1 0.01 mm, 0.01 deg, or 0.001 inch IS–A

0 0 1 0 0.0001 mm, 0.0001 deg, or 0.00001 inch IS–C

0 1 0 0 0.00001 mm, 0.00001 deg, or 0.000001 inch IS–D

1 0 0 0 0.000001 mm, 0.000001 deg, or 0.0000001 inch IS–E

Always set the increment system of the spindle positioning (indexing) axis to 0.001 deg (IS–B).

NOTE When using the Series 15–TT, select the same increment system for those axes that have the

same axis name assigned with head 1/head 2.

IPRx Specifies whether to set the least input increment of each axis to ten times the least command incre-

ment.

0 : Do not set to ten times the least command increment.

1 : Set to ten times the least command increment.

When the above parameter is set to 1, the least input increments become as follows:

IS–A

IS–B 0.01 mm, 0.01 deg, or 0.001 inch

IS–C 0.001 mm, 0.001 deg, or 0.0001 inch

IS–D 0.0001 mm, 0.0001 deg, or 0.00001 inch

IS–E 0.00001 mm, 0.00001 deg, or 0.000001 inch

NOTE When IS–A is used as the increment system, the least input increment cannot be set to ten

times the least command increment.

DSPx Specifies whether to display axis positions on the position screen and other screens.

0 : Display axis positions.

1 : Do not display axis positions.

0.01 mm, 0.01 deg, or 0.001 inch

NOTE When using the electronic gear box function (EGB), specify 1 for the dummy axis of the EGB

to disable position display .

– 29 –

Page 38

4. DESCRIPTION OF PARAMETERS

This parameter is used to select whether the following screens are displayed:

Position, program check, operating monitor, tool of fset, and graphics screens

This parameter does not affect the axis display on the following screens:

Workpiece offset, parameter, diagnosis, and servo check screens

PDSx Specifies whether to display axis positions on the playback screen.

0 : Do not display axis positions.

1 : Display axis positions.

NOTE 1 This parameter is valid when the total number of controllable axis is six or more. Set

parameters to 1 which correspond to five axes of which the positions are displayed. However,

note that this parameter is ineffective when the NXT –AX and PRV –AX soft keys are displayed

on the playback screen.

NOTE 2 When increment system IS–D is selected, the maximum travel (largest value that can be

specified at once) for linear and circular interpolation is as follows:

No. of simultaneous

moving axis.

2 7500.00000 mm 750.000000 inch

3 6000.00000 mm 600.000000 inch

4 5300.00000 mm 500.000000 inch

5 4800.00000 mm 480.000000 inch

6 4300.00000 mm 430.000000 inch

B–62560E/03

Maximum travel

NOTE 3 Values specified when IS–D is selected

The unit of values for the following addresses are 0.00001 mm, 0.00001 deg, and 0.000001

inch. For example, if X1000 is specified (in the case of decimal point input), the resulting values

are X0.01 mm, X0.01 deg, and X0.001 inch.

T able 3 Basic address and command value range

Function

Dimension ward

Feedrate per

minute

Feedrate per

revolution thread

leading

NOTE 1 When inch input is used on a millimeter machine or metric input is used on an inch machine,

the command value range differs partially.

NOTE 2 When an arc radius is specified using R, it can be specified as "999999999 (nine digits).

Address Metric input Inch input

X, Y, Z, A, B, C,

U, V , W, I, J, K, R

F

F

±9999.99999

mm or deg

0.0001 to

10000 mm/min

0.0000001 to

5.0000000 mm/rev

±999.999999

inch or deg

0.00001 to

1000 inch/min

0.00000001 to

0.50000000

inch/rev

– 30 –

Page 39

B–62560E/03 4. DESCRIPTION OF PARAMETERS

#7 #6 #5 #4 #3 #2 #1 #0

1005 RMBx ZNGx EDMx EDPx PLZx ALZx ZRNx

Parameter input

Data type : Bit axis

ZRNx Specifies whether the reference position return function is provided for each axis.

0 : Provided

1 : Not provided

ALZx Specifies the method to use for automatic reference position return (G28).

0 : Return to reference position using positioning control (rapid traverse). If reference position return

has not been performed since power–on, it is performed using the same operation sequence as

for manual reference position return.

1 : Use the same operation sequence as for manual reference position return.

Usually , set this bit to 0.

PLZx Specifies the condition for presetting the work coordinate system when manual reference position

return is performed.

0 : Preset only when in reset state (e.g. OP signal is off).

1 : Always preset.

See ZNP in parameter No. 2402, which is common to all axes.

EDPx For each axis, specifies whether the external deceleration signal for the positive direction is valid

during cutting feed.

0 : Invalid

1 : Valid

EDMx For each axis, specifies whether the external deceleration signal for the negative direction is valid

during cutting feed.

0 : Invalid

1 : Valid

ZNGxSpecifies whether machine lock is valid for each axis.

0 : Invalid

1 : Valid

RMBx For each axis, specifies whether the control axis detach signal and setting input RMVx (parameter

No.0012) is valid.

0 : Invalid

1 : Valid

– 31 –

Page 40

4. DESCRIPTION OF PARAMETERS

#7 #6 #5 #4 #3 #2 #1 #0

1006 RTRx NDCx ZMIx DIAx ROPx ROSx ROTx

Parameter input

Data type : Bit axis

ROTx Specifies whether the axis requires inch/metric conversion.

0 : Axis requires inch/metric conversion (linear axis).

1 : Axis does not require inch/metric conversion (rotation axis).

ROSxSpecifies whether the machine coordinate system used for stroke check and automatic reference

position return is linear or rotational.

0 : Linear (linear axis)

1 : Rotation (rotation axis)

For a rotation axis, the machine coordinate system is normalized to 0 to 360 degrees. In this case,

automatic reference position return (G28, G30) is performed in the same direction as manual reference position return and the degree of rotation does not exceed 360 degrees. Also see the item on

parameter No. 1260.

ROPxSpecifies whether the machine coordinate system used to perform the retained pitch error compensa-

tion is linear or rotational.

0 : Linear (linear axis)

1 : Rotation (rotation axis)

When the coordinate system used is rotational, up to the angle which corresponds to one cycle of re-

tained pitch error compensation data can be specified. This allows pitch compensation to be performed for pitch compensation cycles of other than 360 degrees. Also see the item on parameter No.

5425.

DIAx Specifies whether movement along each axis is specified by diameter or radius.

0 : Specified by radius.

1 : Specified by diameter.

ZMIx Specifies the direction of manual reference position return.