Page 1

GE Fanuc Automation

Computer Numerical Control Products

Series 15i Model B

Series 150i Model B

Operator’s Manual

GFZ-63784EN-1/01 June 2002

Page 2

Warnings, Cautions, and Notes

as Used in this Publication

Warning notices are used in this publication to emphasize that hazardous voltages, currents,

temperatures, or other conditions that could cause personal injury exist in this equipment or

may be associated with its use.

In situations where inattention could cause either personal injury or damage to equipment, a

Warning notice is used.

Caution notices are used where equipment might be damaged if care is not taken.

GFL-001

Warning

Caution

Note

Notes merely call attention to information that is especially significant to understanding and

operating the equipment.

This document is based on information available at the time of its publication. While efforts

have been made to be accurate, the information contained herein does not purport to cover all

details or variations in hardware or software, nor to provide for every possible contingency in

connection with installation, operation, or maintenance. Features may be described herein

which are not present in all hardware and software systems. GE Fanuc Automation assumes

no obligation of notice to holders of this document with respect to changes subsequently made.

GE Fanuc Automation makes no representation or warranty, expressed, implied, or statutory

with respect to, and assumes no responsibility for the accuracy, completeness, sufficiency, or

usefulness of the information contained herein. No warranties of merchantability or fitness for

purpose shall apply.

©Copyright 2002 GE Fanuc Automation North America, Inc.

All Rights Reserved.

Page 3

B-63784EN-1/01 SAFETY PRECAUTIONS

SAFETY PRECAUTIONS

This section describes the safety precautions related to the use of CNC units.

It is essential that these precautions be observed by users to ensure the safe operation of machines

equipped with a CNC unit (all descriptions in this section assume this configuration). Note that some

precautions are related only to specific functions, and thus may not be applicable to certain CNC units.

Users must also observe the safety precautions related to the machine, as described in the relevant

manual supplied by the machine tool builder. Before attempting to operate the machine or create a

program to control the operation of the machine, the operator must become fully familiar with the

contents of this manual and relevant manual supplied by the machine tool builder.

CONTENTS

CONTENTS

CONTENTSCONTENTS

1. DEFINITION OF WARNING, CAUTION, AND NOTE.........................s-2

2. GENERAL WARNINGS AND CAUTIONS .............................................s-3

3. WARNINGS AND CAUTIONS RELATED TO PROGRAMMING ........s-5

4. WARNINGS AND CAUTIONS RELATED TO HANDLING .................s-8

5. WARNINGS RELATED TO DAILY MAINTENANCE...........................s-11

s-1

Page 4

SAFETY PRECAUTIONS B-63784EN-1/01

DEFINITION OF WARNING, CAUTION, AND NOTE

This manual includes safety precautions for protecting the user and preventing damage to the machine.

Precautions are classified into Warning and Caution according to their bearing on safety. Also,

supplementary information is described as a Note. Read the Warning, Caution, and Note thoroughly

before attempting to use the machine

WARNING

Applied when there is a danger of the user being injured or when there is a damage of both the user

being injured and the equipment being damaged if the approved procedure is not observed.

CAUTION

Applied when there is a danger of the equipment being damaged, if the approved

procedure is not observed.

NOTE

The Note is used to indicate supplementary information other than Warning and

Caution.

- Read this manual carefully, and store it in a safe place.

s-2

Page 5

B-63784EN-1/01 SAFETY PRECAUTIONS

GENERAL WARNINGS AND CAUTIONS

WARNING

1. Never attempt to machine a workpiece without first checking the operation of the machine. Before

starting a production run, ensure that the machine is operating correctly by performing a trial run

using, for example, the single block, feedrate override, or machine lock function or by operating the

machine with neither a tool nor workpiece mounted. Failure to confirm the correct operation of the

machine may result in the machine behaving unexpectedly, possibly causing damage to the

workpiece and/or machine itself, or injury to the user.

2. Before operating the machine, thoroughly check the entered data.

Operating the machine with incorrectly specified data may result in the machine behaving

unexpectedly, possibly causing damage to the workpiece and/or machine itself, or injury to the user.

3. Ensure that the specified feedrate is appropriate for the intended operation. Generally, for each

machine, there is a maximum allowable feedrate.

The appropriate feedrate varies with the intended operation. Refer to the manual provided with the

machine to determine the maximum allowable feedrate.

If a machine is run at other than the correct speed, it may behave unexpectedly, possibly causing

damage to the workpiece and/or machine itself, or injury to the user.

4. When using a tool compensation function, thoroughly check the direction and amount of

compensation.

Operating the machine with incorrectly specified data may result in the machine behaving

unexpectedly, possibly causing damage to the workpiece and/or machine itself, or injury to the user.

5. The parameters for the CNC and PMC are factory-set. Usually, there is not need to change them.

When, however, there is not alternative other than to change a parameter, ensure that you fully

understand the function of the parameter before making any change.

Failure to set a parameter correctly may result in the machine behaving unexpectedly, possibly

causing damage to the workpiece and/or machine itself, or injury to the user.

6. Immediately after switching on the power, do not touch any of the keys on the MDI panel until the

position display or alarm screen appears on the CNC unit.

Some of the keys on the MDI panel are dedicated to maintenance or other special operations.

Pressing any of these keys may place the CNC unit in other than its normal state. Starting the

machine in this state may cause it to behave unexpectedly.

7. The operator's manual and programming manual supplied with a CNC unit provide an overall

description of the machine's functions, including any optional functions. Note that the optional

functions will vary from one machine model to another. Therefore, some functions described in the

manuals may not actually be available for a particular model. Check the specification of the

machine if in doubt.

s-3

Page 6

SAFETY PRECAUTIONS B-63784EN-1/01

WARNING

8. Some functions may have been implemented at the request of the machine-tool builder. When using

such functions, refer to the manual supplied by the machine-tool builder for details of their use and

any related cautions.

NOTE

Programs, parameters, and macro variables are stored in nonvolatile memory in the CNC unit. Usually,

they are retained even if the power is turned off.

Such data may be deleted inadvertently, however, or it may prove necessary to delete all data from

nonvolatile memory as part of error recovery.

To guard against the occurrence of the above, and assure quick restoration of deleted data, backup all

vital data, and keep the backup copy in a safe place.

s-4

Page 7

B-63784EN-1/01 SAFETY PRECAUTIONS

WARNINGS AND CAUTIONS RELATED TO PROGRAMMING

This section covers the major safety precautions related to programming. Before attempting to perform

programming, read the supplied operator's manual and programming manual carefully such that you are

fully familiar with their contents.

WARNING

1.Coordinate system setting

If a coordinate system is established incorrectly, the machine may behave unexpectedly as a result of the

program issuing an otherwise valid move command.

Such an unexpected operation may damage the tool, the machine itself, the workpiece, or cause injury to

the user.

2.Positioning by nonlinear interpolation

When performing positioning by nonlinear interpolation (positioning by nonlinear movement between

the start and end points), the tool path must be carefully confirmed before performing programming.

Positioning involves rapid traverse. If the tool collides with the workpiece, it may damage the tool, the

machine itself, the workpiece, or cause injury to the user.

3.Function involving a rotation axis

When programming polar coordinate interpolation or normal-direction (perpendicular) control, pay

careful attention to the speed of the rotation axis. Incorrect programming may result in the rotation axis

speed becoming excessively high, such that centrifugal force causes the chuck to lose its grip on the

workpiece if the latter is not mounted securely.

Such mishap is likely to damage the tool, the machine itself, the workpiece, or cause injury to the user.

4.Inch/metric conversion

Switching between inch and metric inputs does not convert the measurement units of data such as the

workpiece origin offset, parameter, and current position.

Before starting the machine, therefore, determine which measurement units are being used. Attempting

to perform an operation with invalid data specified may damage the tool, the machine itself, the

workpiece, or cause injury to the user.

5.Constant surface speed control

When an axis subject to constant surface speed control approaches the origin of the workpiece

coordinate system, the spindle speed may become excessively high. Therefore, it is necessary to specify

a maximum allowable speed. Specifying the maximum allowable speed incorrectly may damage the

tool, the machine itself, the workpiece, or cause injury to the user.

s-5

Page 8

SAFETY PRECAUTIONS B-63784EN-1/01

WARNING

6.Stroke check

After switching on the power, perform a manual reference position return as required. Stroke check is

not possible before manual reference position return is performed. Note that when stroke check is

disabled, an alarm is not issued even if a stroke limit is exceeded, possibly damaging the tool, the

machine itself, the workpiece, or causing injury to the user.

7. Tool post interference check

A tool post interference check is performed based on the tool data specified during automatic operation.

If the tool specification does not match the tool actually being used, the interference check cannot be

made correctly, possibly damaging the tool or the machine itself, or causing injury to the user.

After switching on the power, or after selecting a tool post manually, always start automatic operation

and specify the tool number of the tool to be used.

8. Absolute/incremental mode

If a program created with absolute values is run in incremental mode, or vice versa, the machine may

behave unexpectedly.

9.Plane selection

If an incorrect plane is specified for circular interpolation, helical interpolation, or a canned cycle, the

machine may behave unexpectedly. Refer to the descriptions of the respective functions for details.

10.Torque limit skip

Before attempting a torque limit skip, apply the torque limit. If a torque limit skip is specified without

the torque limit actually being applied, a move command will be executed without performing a skip.

11.Programmable mirror image

Note that programmed operations vary considerably when a programmable mirror image is enabled.

12.Compensation function

If a command based on the machine coordinate system or a reference position return command is issued

in compensation function mode, compensation is temporarily canceled, resulting in the unexpected

behavior of the machine.

Before issuing any of the above commands, therefore, always cancel compensation function mode.

s-6

Page 9

B-63784EN-1/01 SAFETY PRECAUTIONS

WARNINGS AND CAUTIONS RELATED TO HANDLING

This section presents safety precautions related to the handling of machine tools. Before attempting to

operate your machine, read the supplied operator's manual and programming manual carefully, such

that you are fully familiar with their contents.

WARNING

1.Manual operation

When operating the machine manually, determine the current position of the tool and workpiece, and

ensure that the movement axis, direction, and feedrate have been specified correctly. Incorrect

operation of the machine may damage the tool, the machine itself, the workpiece, or cause injury to the

operator.

2.Manual reference position return

After switching on the power, perform manual reference position return as required.

If the machine is operated without first performing manual reference position return, it may behave

unexpectedly. Stroke check is not possible before manual reference position return is performed.

An unexpected operation of the machine may damage the tool, the machine itself, the workpiece, or

cause injury to the user.

3.Manual numeric command

When issuing a manual numeric command, determine the current position of the tool and workpiece,

and ensure that the movement axis, direction, and command have been specified correctly, and that the

entered values are valid.

Attempting to operate the machine with an invalid command specified may damage the tool, the

machine itself, the workpiece, or cause injury to the operator.

4.Manual handle feed

In manual handle feed, rotating the handle with a large scale factor, such as 100, applied causes the tool

and table to move rapidly. Careless handling may damage the tool and/or machine, or cause injury to

the user.

5.Disabled override

If override is disabled (according to the specification in a macro variable) during threading, rigid

tapping, or other tapping, the speed cannot be predicted, possibly damaging the tool, the machine itself,

the workpiece, or causing injury to the operator.

s-7

Page 10

SAFETY PRECAUTIONS B-63784EN-1/01

WARNING

6.Origin/preset operation

Basically, never attempt an origin/preset operation when the machine is operating under the control of a

program. Otherwise, the machine may behave unexpectedly, possibly damaging the tool, the machine

itself, the tool, or causing injury to the user.

7.Workpiece coordinate system shift

Manual intervention, machine lock, or mirror imaging may shift the workpiece coordinate system.

Before attempting to operate the machine under the control of a program, confirm the coordinate system

carefully.

If the machine is operated under the control of a program without making allowances for any shift in the

workpiece coordinate system, the machine may behave unexpectedly, possibly damaging the tool, the

machine itself, the workpiece, or causing injury to the operator.

8.Software operator's panel and menu switches

Using the software operator's panel and menu switches, in combination with the MDI panel, it is

possible to specify operations not supported by the machine operator's panel, such as mode change,

override value change, and jog feed commands.

Note, however, that if the MDI panel keys are operated inadvertently, the machine may behave

unexpectedly, possibly damaging the tool, the machine itself, the workpiece, or causing injury to the

user.

9.Manual intervention

If manual intervention is performed during programmed operation of the machine, the tool path may

vary when the machine is restarted. Before restarting the machine after manual intervention, therefore,

confirm the settings of the manual absolute switches, parameters, and absolute/incremental command

mode.

10.Feed hold, override, and single block

The feed hold, feedrate override, and single block functions can be disabled using custom macro system

variable #3004. Be careful when operating the machine in this case.

11.Dry run

Usually, a dry run is used to confirm the operation of the machine. During a dry run, the machine

operates at dry run speed, which differs from the corresponding programmed feedrate. Note that the dry

run speed may sometimes be higher than the programmed feed rate.

s-8

Page 11

B-63784EN-1/01 SAFETY PRECAUTIONS

WARNING

12.Cutter and tool nose radius compensation in MDI mode

Pay careful attention to a tool path specified by a command in MDI mode, because cutter or tool nose

radius compensation is not applied. When a command is entered from the MDI to interrupt in automatic

operation in cutter or tool nose radius compensation mode, pay particular attention to the tool path when

automatic operation is subsequently resumed. Refer to the descriptions of the corresponding functions

for details.

13.Program editing

If the machine is stopped, after which the machining program is edited (modification, insertion, or

deletion), the machine may behave unexpectedly if machining is resumed under the control of that

program. Basically, do not modify, insert, or delete commands from a machining program while it is in

use.

s-9

Page 12

SAFETY PRECAUTIONS B-63784EN-1/01

WARNINGS RELATED TO DAILY MAINTENANCE

WARNING

1.Memory backup battery replacement

When replacing the memory backup batteries, keep the power to the machine (CNC) turned on, and

apply an emergency stop to the machine. Because this work is performed with the power on and the

cabinet open, only those personnel who have received approved safety and maintenance training may

perform this work.

When replacing the batteries, be careful not to touch the high-voltage circuits (marked

with an insulating cover).

Touching the uncovered high-voltage circuits presents an extremely dangerous electric shock hazard.

NOTE

The CNC uses batteries to preserve the contents of its memory, because it must retain data such as

programs, offsets, and parameters even while external power is not applied.

If the battery voltage drops, a low battery voltage alarm is displayed on the machine operator's panel or

screen.

When a low battery voltage alarm is displayed, replace the batteries within a week. Otherwise, the

contents of the CNC's memory will be lost.

Refer to the Maintenance manual for details of the battery replacement procedure.

and fitted

s-10

Page 13

B-63784EN-1/01 SAFETY PRECAUTIONS

WARNING

2.Absolute pulse coder battery replacement

When replacing the memory backup batteries, keep the power to the machine (CNC) turned on, and

apply an emergency stop to the machine. Because this work is performed with the power on and the

cabinet open, only those personnel who have received approved safety and maintenance training may

perform this work.

When replacing the batteries, be careful not to touch the high-voltage circuits (marked

and fitted

with an insulating cover).

Touching the uncovered high-voltage circuits presents an extremely dangerous electric shock hazard.

NOTE

The absolute pulse coder uses batteries to preserve its absolute position.

If the battery voltage drops, a low battery voltage alarm is displayed on the machine operator's panel or

screen.

When a low battery voltage alarm is displayed, replace the batteries within a week. Otherwise, the

absolute position data held by the pulse coder will be lost.

Refer to the Maintenance manual for details of the battery replacement procedure.

s-11

Page 14

SAFETY PRECAUTIONS B-63784EN-1/01

WARNING

3.Fuse replacement

For some units, the chapter covering daily maintenance in the operator's manual or programming

manual describes the fuse replacement procedure.

Before replacing a blown fuse, however, it is necessary to locate and remove the cause of the blown

fuse.

For this reason, only those personnel who have received approved safety and maintenance training may

perform this work.

When replacing a fuse with the cabinet open, be careful not to touch the high-voltage circuits (marked

and fitted with an insulating cover).

Touching an uncovered high-voltage circuit presents an extremely dangerous electric shock hazard.

s-12

Page 15

B-63784EN-1/01 TABLE OF CONTENTS

TABLE OF CONTENTS

SAFETY PRECAUTIONS.......................................................................... s-1

I GENERAL

1 GENERAL ..............................................................................................3

1.1 GENERAL FLOW OF OPERATION OF CNC MACHINE TOOL ...................5

1.2 NOTES ON READING THIS MANUAL..........................................................7

II OPERATION

1 GENERAL ............................................................................................11

1.1 MANUAL OPERATION................................................................................12

1.2 TOOL MOVEMENT BY PROGRAMING – AUTOMATIC OPERATION.......14

1.3 AUTOMATIC OPERATION..........................................................................16

1.4 TESTING A PROGRAM ..............................................................................18

1.4.1 Check by Running the Machine ............................................................................ 19

1.4.2 How to View the Position Display Change without Running the Machine .......... 21

1.5 EDITING A PART PROGRAM.....................................................................22

1.6 DISPLAYING AND SETTING DATA............................................................23

1.7 DISPLAY......................................................................................................27

1.7.1 Program Display.................................................................................................... 27

1.7.2 Current Position Display ....................................................................................... 29

1.7.3 Operator Message Display..................................................................................... 30

1.7.4 Alarm Display........................................................................................................ 30

1.7.5 Parts Count Display, Run Time Display ............................................................... 31

1.7.6 Graphic Display..................................................................................................... 32

1.8 DATA INPUT/OUTPUT................................................................................33

2 OPERATIONAL DEVICES ...................................................................34

2.1 SETTING AND DISPLAY UNITS.................................................................35

2.1.1 9.5"/10.4" LCD Unit.............................................................................................. 36

2.1.2 MDI Unit ............................................................................................................... 37

2.1.3 MDI Unit (Full-keyboard) ..................................................................................... 38

2.1.4 MDI Unit (Main Panel A/B) for Machine Operator's Panel.................................. 39

2.2 EXPLANATION OF THE KEYBOARD.........................................................40

2.3 OPERATION SCREEN DISPLAY................................................................42

2.4 OPERATIONS SUPPORTED BY EACH OPERATION SCREEN ...............43

c-1

Page 16

TABLE OF CONTENTS B-63784EN-1/01

2.5 FUNCTION KEYS AND SOFT KEYS ..........................................................44

2.5.1 General Screen Operations .................................................................................... 44

2.5.2 Function Keys........................................................................................................ 45

2.5.3 Soft Keys ............................................................................................................... 46

2.5.4 Function Selection Keys........................................................................................ 46

2.5.5 Chapter selection keys........................................................................................... 47

2.5.5.1 Position ..............................................................................................................47

2.5.5.2 Program.............................................................................................................. 48

2.5.5.3 Offset/Setting .....................................................................................................49

2.5.5.4 System................................................................................................................ 50

2.5.5.5 Messages ............................................................................................................ 51

2.5.5.6 Drawing..............................................................................................................51

2.5.6 Key Input and Input Buffer.................................................................................... 52

2.5.6.1 Inserting characters ............................................................................................52

2.5.6.2 Deleting characters............................................................................................. 53

2.5.7 Warning Messages................................................................................................. 54

2.6 LANGUAGE SELECTION............................................................................55

2.7 EXTERNAL I/O DEVICES ...........................................................................56

2.7.1 FANUC Handy File............................................................................................... 58

2.7.2 FANUC Floppy Cassette ....................................................................................... 58

2.7.3 FANUC FA Card................................................................................................... 59

2.8 POWER ON/OFF.........................................................................................60

2.8.1 Turning on the Power ............................................................................................ 60

2.8.2 Power Disconnection............................................................................................. 61

3 MANUAL OPERATION ........................................................................62

3.1 MANUAL REFERENCE POSITION RETURN.............................................63

3.2 JOG FEED...................................................................................................65

3.3 INCREMENTAL FEED.................................................................................67

3.4 MANUAL HANDLE FEED............................................................................68

3.5 MANUAL FEED IN A SPECIFIED DIRECTION...........................................70

3.6 MANUAL NUMERIC COMMAND ................................................................72

3.7 MANUAL ABSOLUTE ON AND OFF...........................................................79

3.8 EFFECT OF MANUAL INTERVENTION .....................................................86

3.9 THREE-DIMENSIONAL HANDLE FEED.....................................................87

3.9.1 Handle Feed Interruption in the Longitudinal Direction of the Tool.................... 88

3.9.2 Handle Feed in the Transverse Direction of the Tool ........................................... 92

3.9.3 Rotational Handle Feed and Interruption Around the Center of the Tool Tip...... 96

3.9.4 Control Point Compensation in Three-dimensional Handle Feed......................... 99

c-2

Page 17

B-63784EN-1/01 TABLE OF CONTENTS

3.10 CHANGING TOOL LENGTH COMPENSATION

IN THE LONGITUDINAL DIRECTION OF THE TOOL ..............................101

3.11 TOOL HOLDER OFFSET ..........................................................................102

3.12 ROTARY AXIS ORIGIN COMPENSATION

AND ROTARY AXIS OFFSET ...................................................................103

3.13 PRECAUTIONS DURING 3-DIMENSIONAL HANDLE FEED ...................104

3.14 DISPLAYING THE COORDINATES OF THE TOOL TIP ..........................108

3.15 DISPLAYING PULSE VALUES AND AMOUNT OF MOVEMENT

BY MANUAL INTERRUPT.........................................................................110

3.16 MANUAL INTERRUPTION FUNCTION

FOR THREE-DIMENSIONAL COORDINATE CONVERSION ..................112

4 AUTOMATIC OPERATION ................................................................114

4.1 DNC OPERATION .....................................................................................115

4.2 MEMORY OPERATION.............................................................................116

4.3 MDI OPERATION ......................................................................................117

4.4 SELECTION OF EXECUTION PROGRAMS.............................................120

4.4.1 Program Number Search...................................................................................... 120

4.4.2 Search by Sequence Number............................................................................... 121

4.4.3 Rewind................................................................................................................. 122

4.5 EXECUTING AUTOMATIC OPERATION..................................................123

4.6 STOP/TERMINATION OF AUTOMATIC OPERATION .............................124

4.7 PROGRAM RESTART...............................................................................127

4.8 OUTPUT OF PROGRAM RESTART M, S, T AND B CODES...................138

4.9 BLOCK RESTART .....................................................................................141

4.10 TOOL WITHDRAWAL AND RETURN .......................................................149

4.11 RETRACE..................................................................................................162

4.12 ACTIVE BLOCK CANCEL .........................................................................172

4.13 MANUAL HANDLE INTERRUPT ...............................................................174

4.14 MANUAL INTERVENTION AMOUNT RETURN

DURING AUTOMATIC OPERATION.........................................................177

4.15 SIMULTANEOUS AUTOMATIC AND MANUAL OPERATION ..................178

5 TEST OPERATION ............................................................................181

5.1 MACHINE LOCK AND AUXILIARY FUNCTION LOCK .............................182

5.2 DRY RUN...................................................................................................184

5.3 SINGLE BLOCK.........................................................................................186

c-3

Page 18

TABLE OF CONTENTS B-63784EN-1/01

6 SAFETY FUNCTIONS........................................................................188

6.1 EMERGENCY STOP .................................................................................189

6.2 OVERTRAVEL...........................................................................................190

6.3 STROKE CHECK.......................................................................................192

6.4 STROKE LIMIT CHECK PRIOR TO PERFORMING MOVEMENT ...........197

7 ALARMS AND SELF DIAGNOSTC FUNCTIONS ..............................200

7.1 CHECKING WITH THE DIAGNOSIS SCREEN.........................................201

7.1.1 DI/DO Monitor Function..................................................................................... 203

7.1.2 Waveform Diagnosis Function............................................................................ 203

7.2 INTERNAL POSITION COMPENSATION DATA DISPLAY FUNCTION...204

7.3 COORDINATE SYSTEM RELATED DATA DISPLAY ...............................214

7.4 PERIODIC MAINTENANCE SCREEN.......................................................215

7.5 MAINTENANCE INFORMATION SCREEN...............................................226

8 EDITING PROGRAMS .......................................................................227

8.1 INPUTTING AND OUTPUTTING PROGRAMS.........................................228

8.1.1 Inputting Programs .............................................................................................. 228

8.1.2 Outputting Programs............................................................................................ 236

8.1.3 Collating Programs.............................................................................................. 245

8.1.4 Keys and Program Encryption............................................................................. 248

8.1.5 Stored Program Lengths and Number of Registerable Programs........................ 253

8.2 CURSOR ...................................................................................................254

8.2.1 Cursor/Editing Units/Words................................................................................ 254

8.2.2 Positioning the Cursor ......................................................................................... 255

8.3 PROGRAM NUMBER SEARCH................................................................256

8.4 WORD SEARCH/ADDRESS SEARCH .....................................................258

8.4.1 Word Search ........................................................................................................ 258

8.4.2 Address Search .................................................................................................... 260

8.4.3 Search Repeat Function....................................................................................... 261

8.5 INSERTING WORDS AND BLOCKS ........................................................262

8.6 CHANGING WORDS AND BLOCKS.........................................................263

8.6.1 Overwriting Words.............................................................................................. 263

8.6.2 Replacing Words and Character Strings.............................................................. 264

8.6.3 Replacing Addresses............................................................................................ 268

8.7 DELETING WORDS AND BLOCKS ..........................................................270

8.8 CUTTING AND PASTING..........................................................................271

8.8.1 Basic Operations.................................................................................................. 271

c-4

Page 19

B-63784EN-1/01 TABLE OF CONTENTS

8.8.2 Copying, Moving, and Deleting Words and Blocks ............................................ 275

8.9 CANCELING THE EFFECTS OF EDITING WORDS AND BLOCKS ........276

8.10 COPYING PROGRAMS ............................................................................278

8.11 MERGING PROGRAMS............................................................................279

8.12 DELETING PROGRAMS ...........................................................................280

8.13 RESTORING A DELETED PROGRAM .....................................................282

8.14 BACKGROUND EDITING..........................................................................283

8.15 EDITING TWO PROGRAMS SIMULTANEOUSLY ...................................285

8.16 EDITING PROGRAMS IN OPERATION....................................................287

8.17 CONDENSING THE PROGRAM MEMORY..............................................288

8.18 CREATING PROGRAMS USING THE MDI PANEL..................................290

8.19 PLAYBACK................................................................................................291

8.20 AUTOMATICALLY INSERTING SEQUENCE NUMBERS.........................295

8.21 STAMPING THE MACHINING TIME.........................................................296

9 SETTING AND DISPLAYING DATA ..................................................299

9.1 DISPLAYING AND SETTING TOOL OFFSET VALUES ...........................300

9.2 DISPLAYING AND SETTING WORKPIECE ORIGIN OFFSETS ..............307

9.3 DISPLAY AND SETTING OF SETTING PARAMETERS ..........................311

9.4 DISPLAYING AND SETTING CUSTOM MACRO VARIABLE VALUES....317

9.5 INPUT/OUTPUT OPERATION OF CUSTOM MACRO

COMMON VARIABLES .............................................................................321

9.6 DISPLAYING AND SETTING PARAMETERS...........................................325

9.7 DISPLAYING AND SETTING PITCH ERROR COMPENSATION DATA ..332

9.8 MANUAL TOOL LENGTH MEASUREMENT.............................................333

9.9 MANUAL WORKPIECE ORIGIN SETTING...............................................337

9.10 TOOL LENGTH/WORKPIECE ORIGIN MEASUREMENT ........................343

9.11 MENU SWITCHES ....................................................................................362

9.12 DISPLAYING AND SETTING TOOL LIFE MANAGEMENT DATA............364

9.13 DISPLAYING AND SETTING THE SOFTWARE OPERATOR'S PANEL..374

9.14 DISPLAYING AND SETTING TOOL OFFSET DATA BASED

ON TOOL NUMBERS................................................................................377

9.15 FLOATING REFERENCE POSITION SETTING .......................................387

9.16 SERVO SPINDLE SCREEN ......................................................................389

9.17 COMMUNICATION SETTING SCREEN ...................................................390

9.18 HIGH-SPEED HIGH-PRECISION MACHINING SETTING SCREEN........393

9.19 CALCULATION KEY..................................................................................400

9.20 POWER MATE CNC MANAGER FUNCTION...........................................403

c-5

Page 20

TABLE OF CONTENTS B-63784EN-1/01

9.21 MODEM CARD SETTING SCREEN..........................................................410

9.22 CHANGING ACTIVE OFFSET VALUE WITH MANUAL MOVE ................413

9.23 DO SIGNAL OUTPUT BY SOFT KEY .......................................................418

9.24 AUTOMATIC FEEDRATE CONTROL BY AREA.......................................419

9.25 DIAMETER ENTRY FOR TOOL COMPENSATION VALUE .....................422

10 DISPLAY ............................................................................................423

10.1 PROGRAM DISPLAY ................................................................................424

10.2 PROGRAM AND SEQUENCE NUMBER DISPLAY, STATUS DISPLAY,

AND DATA SETTING AND INPUT/OUTPUT OPERATION WARNING

DISPLAY....................................................................................................431

10.3 PROGRAM AND SEQUENCE NUMBER DISPLAY ..................................432

10.4 STATUS DISPLAY AND DATA SETTING AND INPUT/OUTPUT

OPERATION WARNING DISPLAY ...........................................................433

10.5 CURRENT POSITION DISPLAY ...............................................................437

10.5.1 Presetting the Current Position............................................................................ 442

10.5.2 Presetting a Workpiece Coordinate System ........................................................ 444

10.6 OPERATOR MESSAGE DISPLAY............................................................446

10.7 ALARM MESSAGE DISPLAY....................................................................448

10.8 TOOL PATH DRAWING ............................................................................450

10.9 OPERATING MONITOR SCREEN............................................................463

10.10 DISPLAY AND SETTING OF THE PARTS COUNTS,

OPERATING TIME, AND CLOCK .............................................................465

10.11 BACKGROUND DRAWING.......................................................................468

10.12 FLOPPY DIRECTORY SCREEN...............................................................487

10.13 MEMORY CARD SCREEN........................................................................493

10.14 SUB SCREENS .........................................................................................499

10.15 HELP FUNCTION......................................................................................510

10.15.1 Help Menu ........................................................................................................... 511

10.15.2 Alarm Help .......................................................................................................... 512

10.15.3 G Code Help ........................................................................................................ 515

10.15.4 Moving the Cursor between the Ordinary Operation Screen and the Help

Screen .................................................................................................................. 517

10.15.5 Notes 518

10.16 DIRECTORY DISPLAY / PUNCH FOR EACH GROUP ............................519

10.17 PROGRAM NAME 48 CHARACTERS ......................................................523

10.18 FINE TORQUE SENSING .........................................................................526

10.19 2-LCD-UNIT CONNECTION FUNCTION ..................................................538

c-6

Page 21

B-63784EN-1/01 TABLE OF CONTENTS

10.20 αi SERVO AND SPINDLE INFORMATION SCREENS.............................540

11 CLEARING THE SCREEN .................................................................541

11.1 CLEARING THE SCREEN ........................................................................542

11.1.1 Erase Screen Display........................................................................................... 542

11.1.2 Automatic Erase Screen Display......................................................................... 543

12 INPUTTING/OUTPUTTING DATA......................................................544

12.1 FILES.........................................................................................................545

12.2 SPECIFYING PARAMETERS REQUIRED FOR INPUT/OUTPUT............547

12.2.1 Setting Parameter Screen..................................................................................... 547

12.2.2 Communication Setting Screen ........................................................................... 548

12.3 INPUTTING AND OUTPUTTING PROGRAMS.........................................551

12.3.1 Outputting Programs............................................................................................ 551

12.3.2 Program Inputting................................................................................................ 557

12.4 INPUTTING AND OUTPUTTING SYSTEM PARAMETERS .....................561

12.4.1 Outputting System Parameters ............................................................................ 561

12.4.2 Inputting System Parameters ............................................................................... 563

12.5 INPUTTING AND OUTPUTTING TOOL OFFSET DATA ..........................564

12.5.1 Outputting Tool Offset Data................................................................................ 564

12.5.2 Inputting Tool Offset Data .................................................................................. 566

12.6 INPUTTING AND OUTPUTTING WORKPIECE ZERO POINT

OFFSET DATA ..........................................................................................567

12.6.1 Outputting Workpiece zero point offset data ...................................................... 567

12.6.2 Inputting System Parameters ............................................................................... 569

12.7 INPUTTING AND OUTPUTTING CUSTOM MACRO VARIABLE .............570

12.7.1 Outputting Custom Macro Variable.................................................................... 570

12.7.2 Inputting Custom Macro Variable....................................................................... 572

12.8 INPUTTING AND OUTPUTTING THREE-DIMENSIONAL ERROR

COMPENSATION DATA ...........................................................................573

12.8.1 Outputting Three-dimensional Error Compensation Data................................... 573

12.8.2 Inputting Three-dimensional Error Compensation Data ..................................... 575

12.9 INPUTTING AND OUTPUTTING TOOL OFFSET DATA

BY TOOL NUMBER...................................................................................576

12.9.1 Outputting Tool Offset Data by Tool Number.................................................... 576

12.9.2 Inputting Tool Offset Data by Tool Number ....................................................... 578

12.10 INPUTTING AND OUTPUTTING FIXTURE OFFSET DATA.....................579

12.10.1 Outputting Fixture Offset Data............................................................................ 579

c-7

Page 22

TABLE OF CONTENTS B-63784EN-1/01

12.10.2 Inputting Fixture Offset Data .............................................................................. 581

12.11 INPUTTING AND OUTPUTTING ROTARY HEAD DYNAMIC TOOL

OFFSET DATA ..........................................................................................582

12.11.1 Outputting Rotary Head Dynamic Tool Offset Data........................................... 582

12.11.2 Inputting Rotary Head Dynamic Tool Offset Data.............................................. 584

12.12 OUTPUTTING SYSTEM CONFIGURATION DATA ..................................585

12.12.1 Outputting System Configuration Data ............................................................... 585

12.13 INPUTTING AND OUTPUTTING DATA

USING THE FLOPPY DIRECTORY SCREEN ..........................................587

12.14 INPUTTING AND OUTPUTTING DATA

USING THE MEMORY CARD SCREEN ...................................................588

12.15 EXTERNAL I/O EQUIPMENT CONTROL .................................................589

12.16 SCREEN HARD COPY FUNCTION ..........................................................590

13 AXIS CONTROL.................................................................................592

13.1 AXIS CONTROL BY THE PMC .................................................................593

13.2 MIRROR IMAGE........................................................................................594

14 ABSOLUTE-POSITION DETECTION ................................................597

III MAINTENANCE

1 INVESTIGATION OF TROUBLE GENERATION SITUATION ...........603

1.1 DISPLAY OF SYSTEM CONFIGURATION SCREEN ...............................604

1.2 SYSTEM LOG SCREEN............................................................................606

1.2.1 Displaying the Contents of Memory ................................................................... 608

APPENDIX

A STATUS WHEN TURNING POWER ON, WHEN RESET ..................611

c-8

Page 23

I GENERAL

Page 24

Page 25

B-63784EN-1/01 GENERAL 1.GENERAL

1 GENERAL

Operator’s Manuals consist of the PROGRAMMING Manual and

OPERATION Manual.

About this Operator’s Manual

OPERATOR’S MANUAL (PROGRAMMING) (B-63784EN)

I. GENERAL

Describes chapter organization, applicable models, related

manuals, and notes for reading this manual.

II. PROGRAMMING

Describes each function: Format used to program functions in the

NC language, characteristics, and restrictions..

APPENDIX

Lists tape codes, valid data ranges, and alarms.

OPERATOR’S MANUAL (OPERATION) (B-63784EN-1)

I. GENERAL

Describes chapter organization, applicable models, related

manuals, and notes for reading this manual.

II. OPERATION

Describes the manual operation and automatic operation of a

machine, procedures for inputting and outputting data, and

procedures for editing a program.

III. MAINTENANCE

Describes investigation of trouble generation situation.

APPENDIX

Status when turning power on, when reset

Some functions described in this manual may not be applied to some

products. For detail, refer to the DESCRIPTIONS manual (B63782EN).

Applicable product name

This manual does not describe parameters in detail. For details on

parameters mentioned in this manual, refer to the manual for

parameters (B-63790EN).

This manual describes all optional functions. Look up the options

incorporated into your system in the manual written by the machine

tool builder.

The models covered by this manual, and their abbreviations are:

Product name Abbreviations

FANUC Series 15i-MB 15i-MB Series 15i

FANUC Series 150i-MB 150i-MB Series 150i

- 3 -

Page 26

1.GENERAL GENERAL B-63784EN-1/01

Special symbols

This manual uses the following symbols:

P_ : Indicates a combination of axes such as X_ Y_ Z (used in

PROGRAMMING.).

; : Indicates the end of a block. It actually corresponds to the ISO

code LF or EIA code CR.

Related manuals

The table below lists manuals related to MODEL B of Series 15i, and

Series 150i. In the table, this manual is marked with an asterisk (*).

Table 1 (a) Related Manuals

Manual name

DESCRIPTIONS B-63782EN

CONNECTION MANUAL (HARDWARE) B-63783EN

CONNECTION MANUAL (FUNCTION) B-63783EN-1

OPERATOR'S MANUAL (PROGRAMMING) B-63784EN

OPERATOR'S MANUAL (OPERATION) B-63784EN-1 *

MAINTENANCE MANUAL B-63785EN

PARAMETER MANUAL B-63790EN

Specification

number

- 4 -

Page 27

B-63784EN-1/01 GENERAL 1.GENERAL

1.1 GENERAL FLOW OF OPERATION OF CNC MACHINE

TOOL

When machining the part using the CNC machine tool, first prepare the

program, then operate the CNC machine by using the program.

(1) First, prepare the program from a part drawing to operate the CNC

machine tool. How to prepare the program is described in the

OPERATOR’S MANUAL (PROGRAMMING).

(2) The program is to be read into the CNC system. Then, mount the

workpieces and tools on the machine, and operate the tools

according to the programming. Finally, execute the machining

actually. How to operate the CNC system is described in the

OPERATOR’S MANUAL (OPERATION).

Part

drawing

PROGRAMMING

Part

programming

CNC MACHINE TOOL

OPERATION

Before the actual programming, make the machining plan for how to

machine the part.

Machining plan-

1. Determination of workpieces machining range

2. Method of mounting workpieces on the machine tool

3. Machining sequence in every machining process

4. Machining tools and machining

Decide the machining method in every machining process.

Machining process

Machining procedure

1. Machining method :

Rough

Semi

Finish

2. Machining tools

3. Machining conditions :

Feedrate

Cutting depth

4. Tool path

123

Feed

cutting

Side

cutting

Hole

machining

- 5 -

Page 28

1.GENERAL GENERAL B-63784EN-1/01

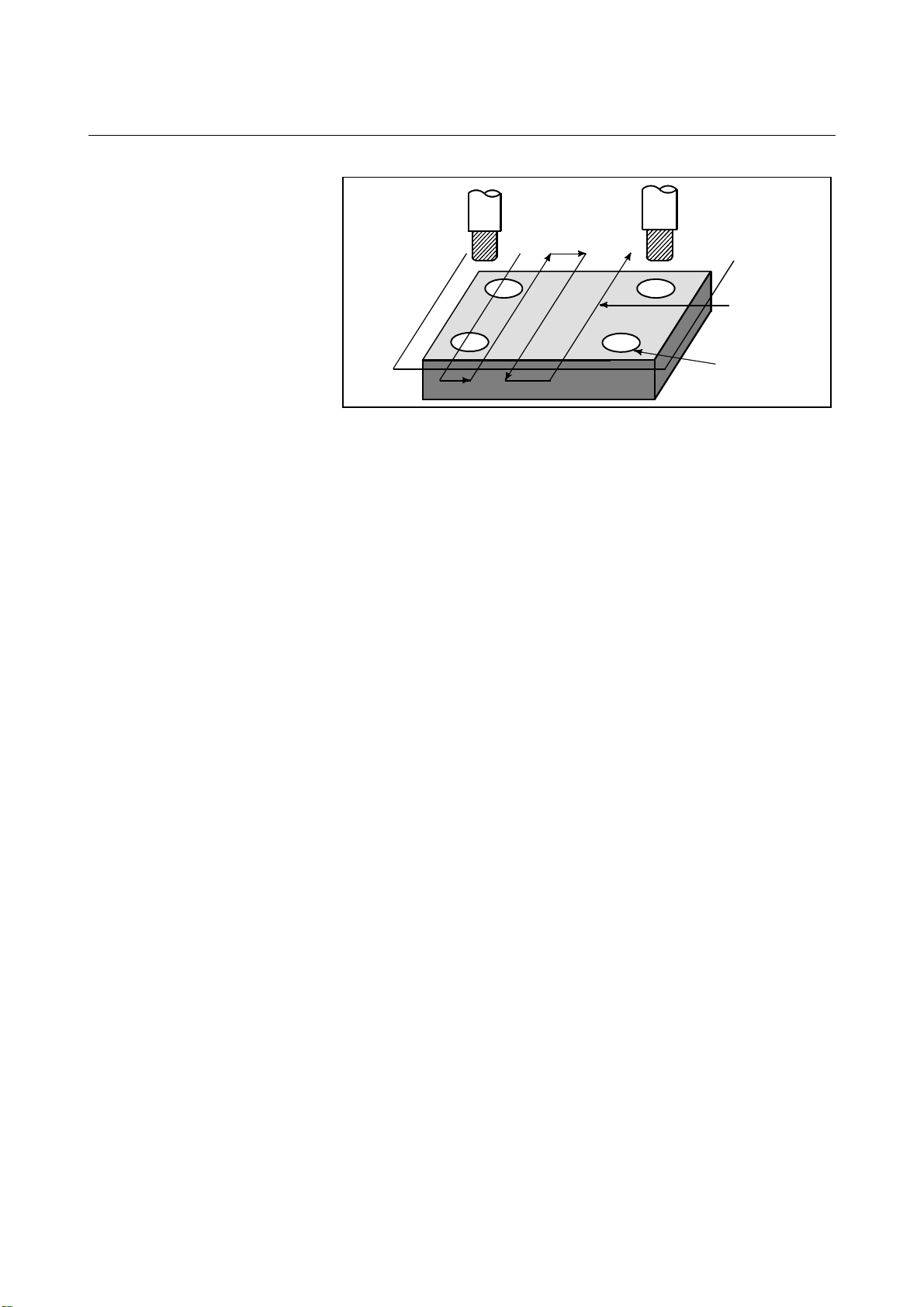

Tool

Side cutting

Face cutting

Hole machining

Prepare the program of the tool path and machining condition

according to the workpiece figure, for each machining.

- 6 -

Page 29

B-63784EN-1/01 GENERAL 1.GENERAL

1.2 NOTES ON READING THIS MANUAL

NOTE

1 The function of an CNC machine tool system

depends not only on the CNC, but on the

combination of the machine tool, its magnetic

cabinet, the servo system, the CNC, the operator's

panels, etc. It is too difficult to describe the function,

programming, and operation relating to all

combinations.

This manual generally describes these from the

stand-point of the CNC. So, for details on a particular

CNC machine tool, refer to the manual issued by the

machine tool builder, which should take precedence

over this manual.

2 Headings are placed in the left margin so that the

reader can easily access necessary information.

When locating the necessary information, the reader

can save time by searching though these headings.

3 Machining programs, parameters, variables, etc. are

stored in the CNC unit internal non-volatile memory.

In general, these contents are not lost by the

switching ON/OFF of the power. However, it is

possible that a state can occur where precious data

stored in the non-volatile memory has to be deleted,

because of deletions from a maloperation, or by a

failure restoration.

In order to restore rapidly when this kind of mishap

occurs, it is recommended that you create a copy of

the various kinds of data beforehand.

4 This manual describes as many reasonable

variations in equipment usage as possible. It cannot

address every combination of features, options and

commands that should not be attempted.

If a particular combination of operations is not

described, it should not be attempted.

- 7 -

Page 30

Page 31

II OPERATION

Page 32

Page 33

B-63784EN-1/01 OPERATION 1.GENERAL

1 GENERAL

- 11 -

Page 34

1.GENERAL OPERATION B-63784EN-1/01

1.1 MANUAL OPERATION

Explanations

- Manual reference position return

The CNC machine tool has a position used to determine the machine

position.

This position is called the reference position, where the tool is replaced

or the coordinate are set. Ordinarily, after the power is turned on, the

tool is moved to the reference position.

Manual reference position return is to move the tool to the reference

position using switches and pushbuttons located on the operator's

panel.(See II-3.1)

Reference Position

Tool

Machine operator’s panel

Fig.1.1 (a) Manual reference position return

The tool can be moved to the reference position also with program

commands.

This operation is called automatic reference position return (See

Programming Manual II-6).

- 12 -

Page 35

B-63784EN-1/01 OPERATION 1.GENERAL

- The tool movement by manual operation

Using machine operator's panel switches, pushbuttons, or the manual

handle, the tool can be moved along each axis.

Machine operator's panel

Manual

pulse

generator

Tool

Workpiece

Fig.1.1 (b) The tool movement by manual operation

The tool can be moved in the following ways:

(i) Jog feed (See Section II-3.2)

The tool moves continuously while a pushbutton remains pressed.

(ii) Incremental feed (See Section II-3.3)

The tool moves by the predetermined distance each time a button

is pressed.

(iii) Manual handle feed (See Section II-3.4)

By rotating the manual handle, the tool moves by the distance

corresponding

to the degree of handle rotation.

(iv) Manual feed at an arbitrary angle (See Section II-3.5)

The tool moves in an arbitrary direction on a plane.

(v) Manual numeric command (See Section II-3.6)

By entering numeric data from the MDI keyboard, the tool moves

through the distance corresponding to the entered data.

- 13 -

Page 36

1.GENERAL OPERATION B-63784EN-1/01

1.2

TOOL MOVEMENT BY PROGRAMING – AUTOMATIC

OPERATION

Explanations

- Memory operation

Automatic operation is to operate the machine according to the created

program.

It includes memory, MDI and DNC operations. (See Section II-4).

Program

O1000 ;

M_ S_ T_ ;

G92 X_ ;

G00 ;

G01 ;

:

:

Fig. 1.2 (a) Tool Movement by Programming

Tool

After the program is once registered in memory of CNC, the machine

can be run according to the program instructions. This operation is

called memory operation.

CNC

Memory

Machine

Fig. 1.2 (b) Memory Operation

- 14 -

Page 37

B-63784EN-1/01 OPERATION 1.GENERAL

- MDI operation

After the program is entered, as an command group, from the MDI

keyboard, the machine can be run according to the program. This

operation is called MDI operation.

- DNC operation

CNC MDI keyboard

Program entry by

manual

Fig.1.2 (c) MDI operation

Machine

In this mode of operation, the program is not registered in the CNC

memory. It is read from the external input/output devices instead. This

is called DNC operation. This mode is useful when the program is too

large to fit the CNC memory.

- 15 -

Page 38

1.GENERAL OERATION B-63784EN-1/01

A

A

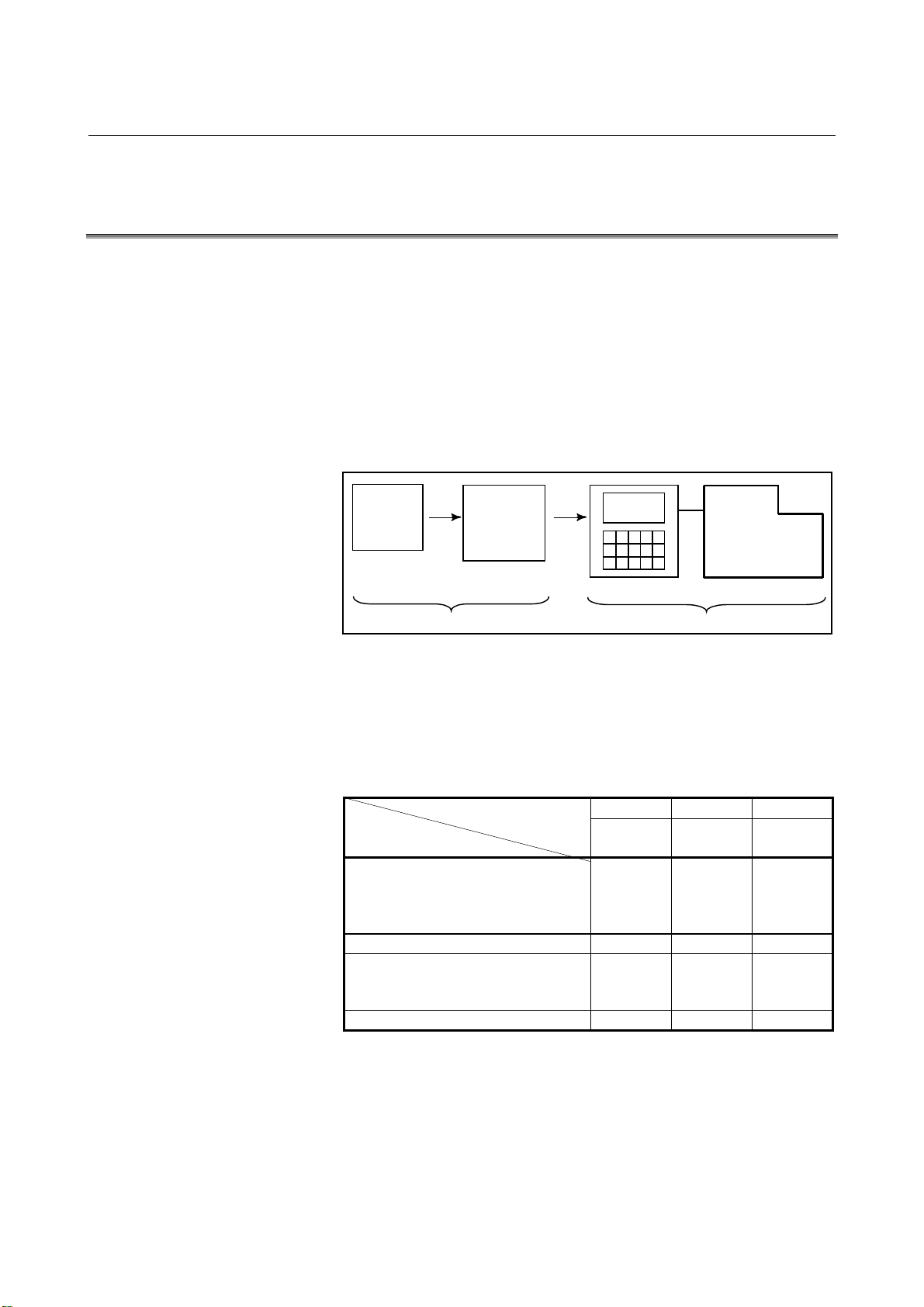

1.3 AUTOMATIC OPERATION

Explanations

- Program selection

Select the program used for the workpiece. Ordinarily, one program is

prepared for one workpiece. If two or more programs are in memory,

select the program to be used, by searching the program number

(Section II-4.4.1).

In memory or on a tape

O1001

G92

M30

O1002

G92

Program number

Work-1

program

Program number

Work-2

program

Program number

search

utomatic

operation

- Start and stop

M30

O1003

G92

M30

Fig.1.3 (a) Program Selection for Automatic Operation

Program number

Work-3 program

Pressing the cycle start pushbutton causes automatic operation to start.

By pressing the feed hold or reset pushbutton, automatic operation

pauses or stops. By specifying the program stop or program termination

command in the program, the running will stop during automatic

operation. When one process machining is completed, automatic

operation stops. (See Section II-4)

Cycle start

Feed hold Reset

Stop

Start

utomatic operation

Program stop

Program end

Fig.1.3 (b) Start and Stop for Automatic Operation

Stop caused

by program

- 16 -

Page 39

B-63784EN-1/01 OERATION 1.GENERAL

X

p

- Restart

You can continue machining of paused workpieces. If, for example, the

tool breaks during machining, you can replace the tool, and then restart

machining. (Refer to II-4.7.)

- Handle interruption

Tool

Workpiec e Workpiec e

When machining of a paused workpiece is rest arted. When a t ool breaks

Fig.1.3 (c) Restart on automatic operation

Paused

drilling

Tool

Tool breakage

While automatic operation is being executed, tool movement can

overlap automatic operation by rotating the manual handle. (See

Section II-4.13)

Tool position during

automatic operation

tion

Programmed

depth of cut

Z

Tool position after

handle interru

Depth of

cut by

Fig.1.3 (d) Handle Interruption for Automatic Operation

- 17 -

Page 40

1.GENERAL OERATION B-63784EN-1/01

1.4 TESTING A PROGRAM

Before machining is started, the automatic running check can be

executed. It checks whether the created program can operate the

machine as desired. This check can be accomplished by running the

machine actually or viewing the position display change (without

running the machine) (See Section II-5).

- 18 -

Page 41

B-63784EN-1/01 OERATION 1.GENERAL

1.4.1 Check by Running the Machine

Explanations

- Dry run

Remove the workpiece, check only movement of the tool. Select the

tool movement rate using the dial on the operator's panel. (See Section

II-5.2)

Tool

- Feedrate override

Table

Fig.1.4 (a) Dry run

Check the program by changing the feedrate specified in the program.

(See Programming II-5.2)

Feed rate specified by program : 100 mm/min.

Tool

Feed rate after feed rate override (20%) :

20 mm/min.

Workpiece

- 19 -

Fig 1.4 (b) Feedrate Override

Page 42

1.GENERAL OERATION B-63784EN-1/01

- Single block

Each time the cycle start button is pressed, one block of a program is

executed, then the tool stops.

A program is checked by executing it on a block-by-block basis. (See

Section II-5.3.)

Cycle start

Cycle start Cycle start

Tool

Cycle start

Workpiece

StopStop

Stop

Fig.1.4 (c) Single Block

- 20 -

Page 43

B-63784EN-1/01 OERATION 1.GENERAL

X

1.4.2

How to View the Position Display Change without Running the Machine

Explanations

- Machine lock

- Auxiliary function lock

The machine tool does not move, and only the position coordinates are

updated.

MDI

Tool

Workpiece

The tool remains stopped, and only the

positional displays of the axes change.

Fig 1.4 (d) Machine Lock

Y

Z

When automatic running is placed into the auxiliary function lock

mode during the machine lock mode (See Sections II-5.1), all auxiliary

functions (spindle rotation, tool replacement, coolant on/off, etc.) are

disabled. (See Section II-5.1)

- 21 -

Page 44

1.GENERAL OERATION B-63784EN-1/01

1.5 EDITING A PART PROGRAM

After a created program is once registered in memory, it can be

corrected or modified from the MDI panel (See Section II-8).

This operation can be executed using the part program storage/edit

function.

Program registration

CNC

Program correction or modification

Tape reader

CNC tape

(program)

Fig.1.5 (a) Part Program Editing

MDI

CNC

- 22 -

Page 45

B-63784EN-1/01 OERATION 1.GENERAL

1.6 DISPLAYING AND SETTING DATA

The operator can display or change a value stored in CNC internal

memory by key operation on the MDI screen (See II-9).

Data setting

Data display

Screen Keys

MDI

CNC memory

Fig.1.6 (a) Displaying and Setting Data

Explanations

- Offset value

Screen

MDI

Fig.1.6 (b) Displaying and Setting Offset Values

Setting

Display

Geometry

compensation

Tool compensation

number1 12.3 25.0

Tool compensation 20.0 40.0

number2

Tool compensation . . . . . .

number3

. . . . . . . . . . . . . . .

. . . . . . . . . . . . . . .

CNC memory

Wear

compensation

The tool has the tool dimension (length, diameter). When a workpiece

is machined, the tool movement value depends on the tool dimensions.

By setting tool dimension data in CNC memory beforehand,

automatically generates tool routes that permit any tool to cut the

workpiece specified by the program. Tool dimension data is called the

offset value (See Section II-9.1).

- 23 -

Page 46

1.GENERAL OERATION B-63784EN-1/01

g

A

1st tool path

Ma ch in ed

shape

2nd tool path

Offset value of the 1s t tool

Offset value of the 2nd tool

Fig.1.6 (c) Offset Value

- Displaying and setting

operator's setting data

Apart from parameters, there is data that is set by the operator in

operation. This data causes machine characteristics to change.

For example, the following data can be set:

- Inch/Metric switching

- Selection of I/O devices

- Mirror image cutting on/off

The above data is called setting data (See Section II-9.3).

Setting data

·

Inch/Metric switching

·

Selection of I/O device

·

Mirror image ON/OFF setting

:

:

:

CNC Memory

Operational

characteristics

utomatic

operation

Movement of

the machine

Screen Keys

MDI panel

Settin

Displaying

Program

Fig.1.6 (d) Displaying and Setting Operator's setting data

- 24 -

Page 47

B-63784EN-1/01 OERATION 1.GENERAL

A

- Displaying and setting

parameters

The CNC functions have versatility in order to take action in

characteristics of various machines.

For example, CNC can specify the following:

- Rapid traverse rate of each axis

- Whether increment system is based on metric system or inch

system.

- How to set command multiply/detect multiply (CMR/DMR)

Data to make the above specification is called parameters (See Section

II-9.3).

Parameters differ depending on machine tool.

Parameter

Rapid traverse rate

Position control

Reference position return

Backlash compensation data

Pitch error compensation

data

:

:

:

Screen Keys

MDI

Setting

Display

CNC memory

Operational

characteristics

Program

Fig.1.6 (e) Displaying and setting parameters

utomatic

operation

Movement

of the

machine

- 25 -

Page 48

1.GENERAL OERATION B-63784EN-1/01

- Data protection key

A key called the data protection key can be defined. It is used to

prevent part programs, offset values, parameters, and setting data from

being registered, modified, or deleted erroneously. Refer to the relevant

manual published by the machine tool builder for details.

Data Setting

Screen

MDI

Keys

Protection Key

Registration / modification inhibition

Program

Offset value

Parameters

Setting data

CNC memory

Fig.1.6 (f) Data Protection Key

Signal

Machine operator's

panel

Data protection

key

- 26 -

Page 49

B-63784EN-1/01 OERATION 1.GENERAL

1.7 DISPLAY

1.7.1 Program Display

The contents of the currently active program are displayed. In addition,

the programs scheduled next and the program list are displayed.(See

Section II-10.1)

Active sequence number

Active program number

Program

CONTEN

The cursor indicates the currently

executed location

Fig.1.7 (a) Currently executed program

- 27 -

Page 50

1.GENERAL OERATION B-63784EN-1/01

Fig.1.7 (b) Program list

- 28 -

Page 51

B-63784EN-1/01 OERATION 1.GENERAL

X

X

1.7.2 Current Position Display

The current position of the tool is displayed with the coordinate values.

The distance from the current position to the target position can also be

displayed. (See Section II-10.5)

Y

Y

Workpiece coordinate system

- 29 -

Page 52

1.GENERAL OERATION B-63784EN-1/01

1.7.3 Operator Message Display

Messages stored to memory are displayed when the operator must be

instructed during machining. (Refer to II-10.6)

1.7.4 Alarm Display

"Load t he workpi ece."

CRT di spl ay

Me m o r y

Message 1

Message displ ay

number

Message 2

Message 3

When a trouble occurs during operation, error code and alarm message

are displayed on the screen. (See Section II-10.7)

See PROGRAMMING Appendix F for the list of error codes and their

meanings.

- 30 -

Page 53

B-63784EN-1/01 OERATION 1.GENERAL

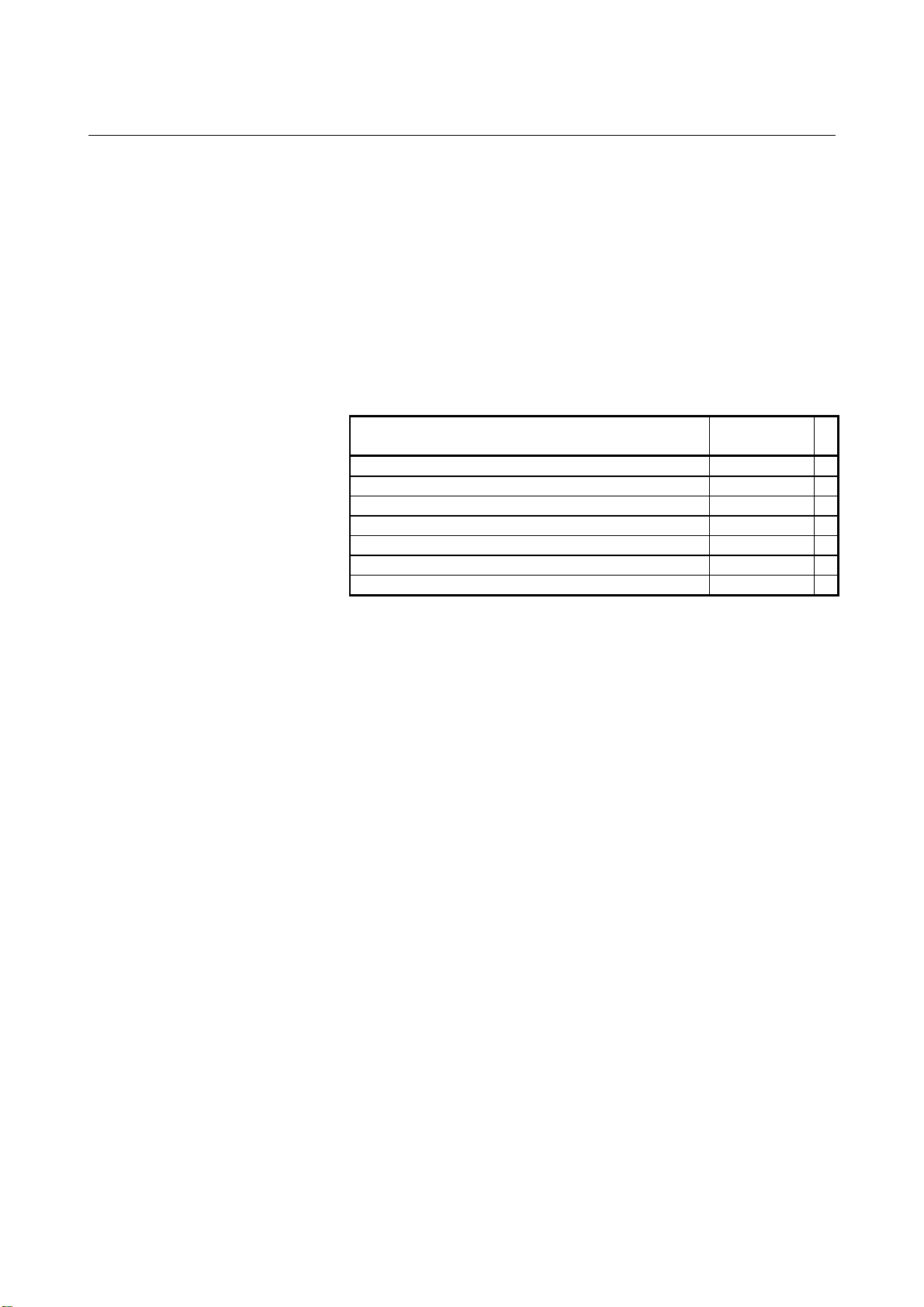

1.7.5 Parts Count Display, Run Time Display

When this option is selected, five types of run time and number of parts

are displayed on the screen. (See Section II-10.10)

- 31 -

Page 54

1.GENERAL OERATION B-63784EN-1/01

X

X

1.7.6 Graphic Display

Programmed tool movement can be displayed on the following planes:

(See Section II-10.8)

1) XY plane

2) YZ plane

3) XZ plane

4) Three dimensional display

(1)

Y

Display on the XY plane

Z

Display on the XZ plane

Fig. 1.7 (c) Graphic display

(2)

Z

Display on the YZ plane

(4)(3)

X

Three dimensional display (isometric)

Z

Y

Y

- 32 -

Page 55

B-63784EN-1/01 OERATION 1.GENERAL

A

1.8 DATA INPUT/OUTPUT

Programs, offset values, parameters, etc. input in CNC memory can be

output to paper tape, cassette, or a floppy disk for saving. After once

output to a medium, the data can be input into CNC memory. (See II-

12.)

FANUC Floppy

FANUC Floppy

cassette

Cassette

Memory

Program

Offset

Parameters

:

:

:

CNC

Reader/puncher

interface

Fig.1.8 (a) Data Output

SYSTEM P

utomatic programming

system

Memory card adapter

(incorporated CNC)

Floppy disk

Memory card

- 33 -

Page 56

2.OPERATIONAL DEVICES OPERATION B-63784EN-1/01

2 OPERATIONAL DEVICES

The available operational devices include the setting and display unit

attached to the CNC, the machine operator's panel, and external

input/output devices such as a PPR, Handy File, Floppy Cassette, and

FA Card.

- 34 -

Page 57

B-63784EN-1/01 OPERATION 2.OPERATIONAL DEVICES

2.1 SETTING AND DISPLAY UNITS

The setting and display units are shown in Subsections II-2.1.1 to II-

2.1.3.

9.5"/10.4" LCD unit ................................................................II-2.1.1

MDI unit..................................................................................II-2.1.2

MDI unit (full-keyboard) ........................................................II-2.1.3

- 35 -

Page 58

2.OPERATIONAL DEVICES OPERATION B-63784EN-1/01

2.1.1 9.5"/10.4" LCD Unit

LCD units are following three kinds.

- 9.5-inch monochrome (with graphic display)

- 9.5-inch monochrome (without graphic display)

- 10.4-inch monochrome (with graphic display)

NOTE

The LCD brightness of the 9.5-inch monochrome

LCD unit with or without graphic display is lowered at

low ambient temperatures. (Particularly, the LCD

screen is dark immediately after power-up.) This is a

characteristic of the LCD, and not a failure. As the

ambient temperature rises, the LCD screen becomes

brighter.

- 36 -

Page 59

B-63784EN-1/01 OPERATION 2.OPERATIONAL DEVICES

/

A

AK@

2.1.2 MDI Unit

Help key

Shift key

ResetT key

O(N)GEP

RESET

XUYVZWQ

I,J

HELP

M#S=T*L

F[D]H&B

SHIFT

PAG E

PAG E

Page change keys

ddress/numeric keys

8 9

7

C

?

R

SP

5 64

21

-

0

EOB

POS PROG

SYSTEM MESSAGE GRAPH

Function key

Cursor keys

3

.

CAN

OFFSET

SETTING

ALTER

INSERT

DELETE

INPUT

CUSTOM

Edit key

Cancel (CAN) key

Input key

- 37 -

Page 60

2.OPERATIONAL DEVICES OPERATION B-63784EN-1/01

A

A

/

K

¥

,

2.1.3 MDI Unit (Full-keyboard)

Rest kry

C

ddress/numeric

keys

Shift key

Help key

RESET

I J

R S

7

-

+

!B"

,

8 9

5 64

21

0

=

:L;

T U

3

.

D#E$F%G

MSPN O?P

V[W]X(Y

-

ALTER

SHIFT

CALC

INSERT

HELP

CAN

DELETE

EOB

INPUT

POS PROG

SYSTEM MESSAGE GRAPH

PAG E

PAG E

OFFSET

SETTING

H

&

*

Q

<

>

Z

)

@

CUSTOM

Function keys

Page change keys

Cursor kys

Edit keys

Input keyCancel (CAN) key

- 38 -

Page 61

B-63784EN-1/01 OPERATION 2.OPERATIONAL DEVICES

2.1.4 MDI Unit (Main Panel A/B) for Machine Operator's Panel

The following MDI unit for machine operator's panel can be used.

Reset key

Address/numeric keys

Shift key

Function keys

Page change key

Help key

Edit keys

- 39 -

Input key

Cancel key

Cursor keys

Page 62

2.OPERATIONAL DEVICES OPERATION B-63784EN-1/01

RESET

2.2 EXPLANATION OF THE KEYBOARD

Table2.2 (a) Explanation of the MDI keyboard

Number Name Explanation

1 RESET key Press this key to reset the CNC, to cancel an alarm, etc.

2 HELP key Press this button to use the help function when uncertain about the operation of an MDI

key (help function).

3

Soft keys

4 Address and numeric

keys

N

,

)

4

The soft keys have various functions, according to the Applications.

The soft key functions are displayed at the bottom of the screen.

Press the inside of the rectangle area of the soft key button on the screen, when the

CNC with the touch panel function is used.

The button of the soft key becomes dented and indicated.

And, the same operation treatment as the present soft key is done.

Press these keys to input alphabetic, numeric, and other characters.

5 SHIFT key Some keys have two characters on their keytop. Pressing the <SHIFT> key switches

the characters. Special character # is displayed on the screen when a character

SHIFT

indicated at the bottom right corner on the keytop can be entered.

6 INPUT key When an address or a numerical key is pressed, the data is input to the buffer, and it is

displayed on the screen. To copy the data in the key input buffer to the offset register,

INPUT

etc., press the key. This key is equivalent to the [INPUT] key of the soft keys, and

either can be pressed to produce the same result.

7 Cancel key

CAN

Press this key to delete the last character or symbol input to the key input buffer.

When the key input buffer displays

>N001X100Z_

and the cancel <CAN> key is pressed, Z is canceled and

>N001X100_

is displayed.

8 Program edit keys Press these keys when editing the program.

ALTER

: Alteration

ALTER INSERT

9 Function keys

DELETE

INSERT

: Insertion

DELETE

: Deletion

Press theses keys to switch display screens for each function.

See lll - 2.5 for details of the function keys.

POS PROG

- - -

- 40 -

Page 63

B-63784EN-1/01 OPERATION 2.OPERATIONAL DEVICES

Table2.2 (a) Explanation of the MDI keyboard

Number Name Explanation

10 Cursor move keys There are four different cursor move keys.

: This key is used to move the cursor to the right or in the forward

direction. The cursor is moved in short units in the forward direction.

: This key is used to move the cursor to the left or in the reverse direction.

The cursor is moved in short units in the reverse direction.

: This key is used to move the cursor in a downward or forward direction.

The cursor is moved in large units in the forward direction.

: This key is used to move the cursor in an upward or reverse direction.

The cursor is moved in large units in the reverse direction.

11 Page change keys Two kinds of page change keys are described below.

PAGE

PAGE

PAGE

PAGE

: This key is used to changeover the page on the screen in the

forward direction.

: This key is used to changeover the page on the screen in the

reverse direction.

- 41 -

Page 64

2.OPERATIONAL DEVICES OPERATION B-63784EN-1/01

2.3 OPERATION SCREEN DISPLAY