Epson 4400, 4450, 4800, 4880 Service Manual

SERVICE MANUAL

Color Large Format Inkjet Printer

EPSON Stylus Pro 4400/4450/4800 4880/4880C

SEIJ04008

Notice:

All rights reserved. No part of this manual may be reproduced, stored in a retrieval system, or transmitted in any form or by any means,

electronic, mechanical, photocopying, recording, or otherwise, without the prior written permission of SEIKO EPSON CORPORATION.

The contents of this manual are subject to change without notice.

All effort have been made to ensure the accuracy of the contents of this manual. However, should any errors be detected, SEIKO EPSON

would greatly appreciate being informed of them.

The above not withstanding SEIKO EPSON CORPORATION can assume no responsibility for any errors in this manual or the consequences

thereof.

EPSON is a registered trademark of SEIKO EPSON CORPORATION.

General Notice: Other product names used herein are for identification purpose only and may be trademarks or registered trademarks of their

respective owners. EPSON disclaims any and all rights in those marks.

Copyright © 2007 SEIKO EPSON CORPORATION.

Imaging Product CS,PL & Environmental Management

PRECAUTIONS

Precautionary notations throughout the text are categorized relative to 1)Personal injury and 2) damage to equipment.

DANGER Signals a precaution which, if ignored, could result in serious or fatal personal injury. Great caution should be exercised in

performing procedures preceded by DANGER Headings.

WARNING Signals a precaution which, if ignored, could result in damage to equipment.

The precautionary measures itemized below should always be observed when performing repair/maintenance procedures.

DANGER

1. ALWAYS DISCONNECT THE PRODUCT FROM THE POWER SOURCE AND PERIPHERAL DEVICES PERFORMING ANY MAINTENANCE

OR REPAIR PROCEDURES.

2. NO WORK SHOULD BE PERFORMED ON THE UNIT BY PERSONS UNFAMILIAR WITH BASIC SAFETY MEASURES AS DICTATED FOR

ALL ELECTRONICS TECHNICIANS IN THEIR LINE OF WORK.

3. WHEN PERFORMING TESTING AS DICTATED WITHIN THIS MANUAL, DO NOT CONNECT THE UNIT TO A POWER SOURCE UNTIL

INSTRUCTED TO DO SO. WHEN THE POWER SUPPLY CABLE MUST BE CONNECTED, USE EXTREME CAUTION IN WORKING ON

POWER SUPPLY AND OTHER ELECTRONIC COMPONENTS.

WARNING

1. REPAIRS ON EPSON PRODUCT SHOULD BE PERFORMED ONLY BY AN EPSON CERTIFIED REPAIR TECHNICIAN.

2. MAKE CERTAIN THAT THE SOURCE VOLTAGES IS THE SAME AS THE RATED VOLTAGE, LISTED ON THE SERIAL NUMBER/RATING

PLATE. IF THE EPSON PRODUCT HAS A PRIMARY AC RATING DIFFERENT FROM AVAILABLE POWER SOURCE, DO NOT CONNECT IT

TO THE POWER SOURCE.

3. ALWAYS VERIFY THAT THE EPSON PRODUCT HAS BEEN DISCONNECTED FROM THE POWER SOURCE BEFORE REMOVING OR

REPLACING PRINTED CIRCUIT BOARDS AND/OR INDIVIDUAL CHIPS.

4. IN ORDER TO PROTECT SENSITIVE MICROPROCESSORS AND CIRCUITRY, USE STATIC DISCHARGE EQUIPMENT, SUCH AS ANTISTATIC WRIST STRAPS, WHEN ACCESSING INTERNAL COMPONENTS.

5. REPLACE MALFUNCTIONING COMPONENTS ONLY WITH THOSE COMPONENTS BY THE MANUFACTURE; INTRODUCTION OF

SECOND-SOURCE ICs OR OTHER NON-APPROVED COMPONENTS MAY DAMAGE THE PRODUCT AND VOID ANY APPLICABLE EPSON

WARRANTY.

6. WHEN AIR DUSTRE IS USED ON THE REPAIR AND THE MAINTENANCE WORK, THE USE OF THE AIR DUSTER PRODUCTS

CONTAINING THE INFLAMMABLE GAS IS PROHIBITED.

About This Manual

This manual describes basic functions, theory of electrical and mechanical operations, maintenance and repair procedures of the printer. The instructions and

procedures included herein are intended for the experienced repair technicians, and attention should be given to the precautions on the preceding page.

Manual Configuration

This manual consists of six chapters and Appendix.

CHAPTER 1.PRODUCT DESCRIPTIONS

Provides a general overview and specifications of the product.

CHAPTER 2.OPERATING PRINCIPLES

Describes the theory of electrical and mechanical operations of

the product.

CHAPTER 3.TROUBLESHOOTING

Describes the step-by-step procedures for the troubleshooting.

CHAPTER 4.DISASSEMBLY / ASSEMBLY

Describes the step-by-step procedures for disassembling and

assembling the product.

CHAPTER 5.ADJUSTMENT

Provides Epson-approved methods for adjustment.

CHAPTER 6.MAINTENANCE

Provides preventive maintenance procedures and the lists of

Epson-approved lubricants and adhesives required for servicing

the product.

APPENDIX Provides the following additional information for reference:

• Connector pin assignments

• Electrical circuit boards schematics

• Exploded diagram & Parts List

Symbols Used in this Manual

Various symbols are used throughout this manual either to provide ad ditional

information on a specific topic or to warn of possible danger present during a

procedure or an action. Be aware of all symbols when they are used, and

always read NOTE, CAUTION, or WARNING messages.

Indicates an operating or maintenance procedure, practice or

condition that is necessary to keep the product’s quality.

Indicates an operating or maintenance procedure, practice, or

condition that, if not strictly observed, could result in damage to,

or destruction of, equipment.

May indicate an operating or maintenance procedure, prac tice or

condition that is necessary to accomplish a task efficiently. It may

also provide additional information that is related to a specific

subject, or comment on the results achieved through a previous

action.

Indicates an operating or maintenance procedure, practice or

condition that, if not strictly observed, could result in injury or loss

of life.

Indicates that a parti cu la r ta sk mu st be ca rr i ed o ut ac co rd ing to a

certain standard after disassembly and before re-assembly,

otherwise the quality of the components in question may be

adversely affected.

Revision Status

Revision Date of Issue Description

A Jun. 2, 2005 First release

B May. 25, 2007 Revised contents:

[Chapter 3]

Recovery (p.163) was changed.

[Chapter 5]

• Procedures were partially changed in 5.1.4 Adjustment Items classified by Part/Unit (p.368).

• 5.8 Installing Firmware for SP 4400 (4-color model) after replacing Main Board with New one (p.445) was added.

C September. 12, 2007 Revised Contents:

[All chapters]

• Information on Stylus 4450/4880/4880C has been added.

EPSON Stylus Pro 4400/4450/4800/4880/4880C Revision C

Contents

Chapter 1 Product Description

1.1 Product Description............................................................................................. 10

1.1.1 Comparison with Stylus Pro 4000.................................... .......................... 10

1.1.2 Features....................................................................................................... 11

1.2 Basic Specifications......................................... .................................................... 13

1.2.1 Print Specifications............................................. ........................................ 13

1.2.2 Character Specification............................................................................... 14

1.2.3 Control Code....................................................... ................................. ....... 14

1.2.4 Paper Feed Specification ............................................................................ 14

1.2.5 Paper Feeder Specification......................................................................... 14

1.2.6 Paper Specification..................................................................................... 15

1.2.7 Mechanism Specifications.......................................................................... 19

1.2.8 Electrical Specification............................................................................... 22

1.2.9 Reliability ................................................................................................... 23

1.2.10 Environmental Conditions........................................................................ 23

1.2.11 Quality Standards for Completed Products .............................................. 25

1.2.12 Overall Dimensions.................................................................................. 25

1.2.13 Accessories............................................................................................... 26

1.3 External View and Parts Names.......................................................................... 28

1.4 Operating Panel ............................................ ....................................................... 30

1.4.1 Buttons and Functions ................................................................................ 30

1.4.2 Panel Display.............................................................................................. 33

1.4.3 Job information........................................................................................... 39

1.4.4 Panel Setting............................. .................................. ................................ 40

1.4.5 Maintenance Mode 1 .................................................................................. 83

1.4.6 Maintenance Mode 2 .................................................................................. 90

1.4.7 MIB Function............................................................................................ 102

1.4.8 Function to Prevent Irregular Printing...................................................... 103

1.4.9 Initialization.............................................................................................. 104

1.4.10 Default Setup Values.............................................................................. 104

1.5 Controller........................................................................................................... 105

1.6 Interface............................................................................................................. 106

1.6.1 USB interface............................................................................................ 106

1.6.2 IEEE1394 Interface ....................................................... ........................... 107

1.6.3 Optional Interface..................................................... ................................ 108

1.6.4 Supplements....................................... .................................. ..................... 110

1.7 Optional Units and Consumables................................................. ..................... 111

1.7.1 Ink Cartridge........................... .................................. ................................ 111

1.7.2 Cleaning cartridge..................................................................................... 112

1.7.3 Maintenance Tank .................................................................................... 112

Chapter 2 Operating Principles

2.1 Overview...................................... .................................................................... . 114

2.2 Printer Mechanism Components....................................................................... 115

2.2.1 Printing Mechanism (Print Head).......................... ................................... 116

2.2.2 Ink Supply Mechanism............................................. ................................ 118

2.2.3 Cleaning Mechanism................................................................................ 120

2.2.4 Carriage (CR) Mechanism........................................................................ 125

2.2.5 Paper Feed Mechanism............................................................................. 131

2.2.6 Paper Eject/Release Mechanism.............................................................. . 140

2.2.7 Multi Sensor ................................................................ ............................. 145

2.2.8 Others...................................... .................................. ................................ 151

2.3 Outline of Control Circuit Board............................................ ........................... 152

2.4 Outline of Power Supply Circuit Board ............................................................ 154

2.5 Colorimetric Calibration (Color ID) Overview....................................... .......... 155

6

EPSON Stylus Pro 4400/4450/4800/4880/4880C Revision C

Chapter 3 Troubleshooting

3.1 Outline............................................................................................................... 157

3.1.1 Check Before Troubleshooting ................................................................. 157

3.1.2 Narrow Down the Trouble........................................................................ 157

3.2 Troubleshooting Based on Panel Messages ...................................................... 158

3.2.1 Message Table.......................................................................................... 158

3.2.2 Corrective Actions for Displayed Warnings............................................. 162

3.2.3 Corrective Actions for Error Display ................................................ ....... 165

3.2.4 Corrective Actions for Service Request Display...................................... 175

3.3 Troubleshooting Based on Your Printout.......................................................... 196

Chapter 4 Disassembly & Assembly

4.1 Introductory Information................................................................................... 201

4.1.1 Cautions.................................................................................................... 201

4.1.2 Tools......................................................................................................... 203

4.1.3 Screws....................................................................................................... 204

4.1.4 Difference Between 8-color And 4-color Models In Disassembly/Assembly

205

4.2 Disassembly Procedures.................................................................................... 206

4.2.1 Basic Operations....................................................................................... 207

4.2.2 Consumable Parts/ASF Cassette Removal............................................... 209

4.2.3 Panel Unit/Housing Removal................................................................... 214

4.2.4 Circuit Board Removal............................................................................. 226

4.2.5 Printer Mechanism Disassembly .............................................................. 241

4.2.6 ASF........................................................................................................... 246

4.2.7 Carriage Mechanism................................................................................. 266

4.2.8 Ink System................................................................................................ 285

4.2.9 Paper Feed Mechanism ............................................................................. 343

4.2.10 Harness Routing...................................................................................... 358

4.2.11 Disassembly/Assembly Unique to 4-color Model (Stylus Pro 4000)..... 36 2

Chapter 5 Adjustment

5.1 Overview...................................... .................................................................... . 367

5.1.1 Cautions...................................................... ................................. ............. 367

5.1.2 Advance of Adjustment............................................................................ 367

5.1.3 The Part/Unit that Requires Adjustment .................................................. 367

5.1.4 Adjustment Items classified by Part/Unit................................................. 368

5.1.5 Adjustment Item .......................................................................... ............. 371

5.1.6 Adjustment Tools ................................. ... .................................. ............... 374

5.1.7 Adjustment Program Basic Operation...................................................... 375

5.2 Mechanical Adjustment........................................................................... .......... 376

5.2.1 CR Timing Belt Tension Adjustment....................................................... 376

5.2.2 PF Timing Belt Tension Adjustment........................................................ 378

5.2.3 Paper Thickness Sensor Adjustment ........................................................ 380

5.2.4 CR Encoder Sensor Position Adjustment................................................. 382

5.2.5 PG Adjustment .............................................................. ........................... 383

5.2.6 Multi Sensor Position Adjustment............................................................ 385

5.3 Basic Adjustment .............................................................................................. 387

5.3.1 RTC&USB ID&IEEE1394 ID ................................................................. 387

5.3.2 Head Rank ID.............................. ............................................................. 388

5.3.3 Multi Sensor Level Adjustment................................................................ 389

5.3.4 T&B&S (Roll Paper)................................................... ............................. 390

5.3.5 T&B&S (Cut Sheet) ................................................................................. 391

5.3.6 Cutter Pressure Adjustment...................................................................... 392

5.3.7 Nozzle Bi-D Adjustment .......................................................................... 393

5.3.8 Print Head Slant Adjustment (PF)........................................................... . 394

5.3.9 Print Head Slant Adjustment (CR)........................................................... 397

5.3.10 Auto Uni-d Adjustment.......................................................................... 401

5.3.11 Multi Sensor Adjustment for Auto Nozzle Check.................................. 402

5.3.12 Skew Check............................................................................................ 404

5.3.13 Platen Position Adjustment .................................................................... 405

5.3.14 1000mm Feed Adjustment...................................................................... 407

5.3.15 Initial Ink charge flag ON/OFF.............................................................. 408

5.3.16 NVRAM Back Up and Write ................................................................. 409

5.3.17 Check Platen Gap ................................................... ................................ 410

5.3.18 Ink Discharge.......................................................................................... 411

5.3.19 Initial Ink Charge.................................................................................... 412

5.3.20 Cleaning.................................................................................................. 412

5.3.21 Rear Sensor Adjustment......................................................................... 413

5.3.22 Colorimetric Calibration (Color ID)....................................................... 414

7

EPSON Stylus Pro 4400/4450/4800/4880/4880C Revision C

5.4 Advanced Adjustment....................................................................................... 430

5.4.1 Auto Bi-d Adjustment............................................................................... 430

5.4.2 Manual Bi-D Adjustment ......................................................................... 431

5.4.3 Destination Setting.................................................................................... 434

5.4.4 PF Micro Feed Adjustment (Bi-D) (TBD) ............................................... 435

5.5 Check Results.................................................................................................... 436

5.5.1 Check Nozzle............................................................................................ 436

5.5.2 Check Alignment...................................................................................... 437

5.5.3 Print Adjustment Check Pattern ............................................................... 438

5.5.4 Image Printing .......................................................................................... 439

5.5.5 Check Cutting........................................................................................... 440

5.6 Reset Counters................................................................................................... 441

5.6.1 Reset Paper Ejection Switching/PG Switching Counter .......................... 441

5.6.2 Reset PF Motor Counter................................................................. .......... 441

5.6.3 Reset ASF Counter................................................................................... 442

5.6.4 Reset When CR Unit Change................................................................... 442

5.6.5 Reset When Cleaning Unit Change.......................................................... 443

5.6.6 Reset When Printhead Change ................................................................. 443

5.7 Installing Firmware ........................................................................................... 444

5.8 Installing Firmware for SP 4400 (4-color model) after replacing Main Board with

New one................................................................................................................... 445

5.9 Device ID Setting.............................................................................................. 446

5.10 Writing MAC Address .................................................................................... 447

Chapter 6 Maintenance

6.1 Overview...................................... .................................................................... . 449

6.1.1 Product Life Information.......................................................................... 450

6.1.2 Important Maintenance Items During Service Operations....................... 450

6.2 Lubrication ................................................. ... .................................. .................. 451

Chapter 7 Appendix

7.1 Connectors................................................................ ......................................... 458

7.2 Exploded Diagrams........................................................................................... 463

7.3 Parts List............................................................................................. ............... 481

8

PRODUCT DESCRIPTION

CHAPTER

1

EPSON Stylus Pro 4400/4450/4800/4880/4880C Revision C

1.1 Product Description

The Stylus Pro 4400/4450/4800/4880/4880C is a large-format printer based on the Stylus Pro 4000.

The Stylus Pro 4800/4880/4880C is the exclusive model for 8-color inks and the Stylus Pro 4400/4450 is the exclusive model for 4-color inks.

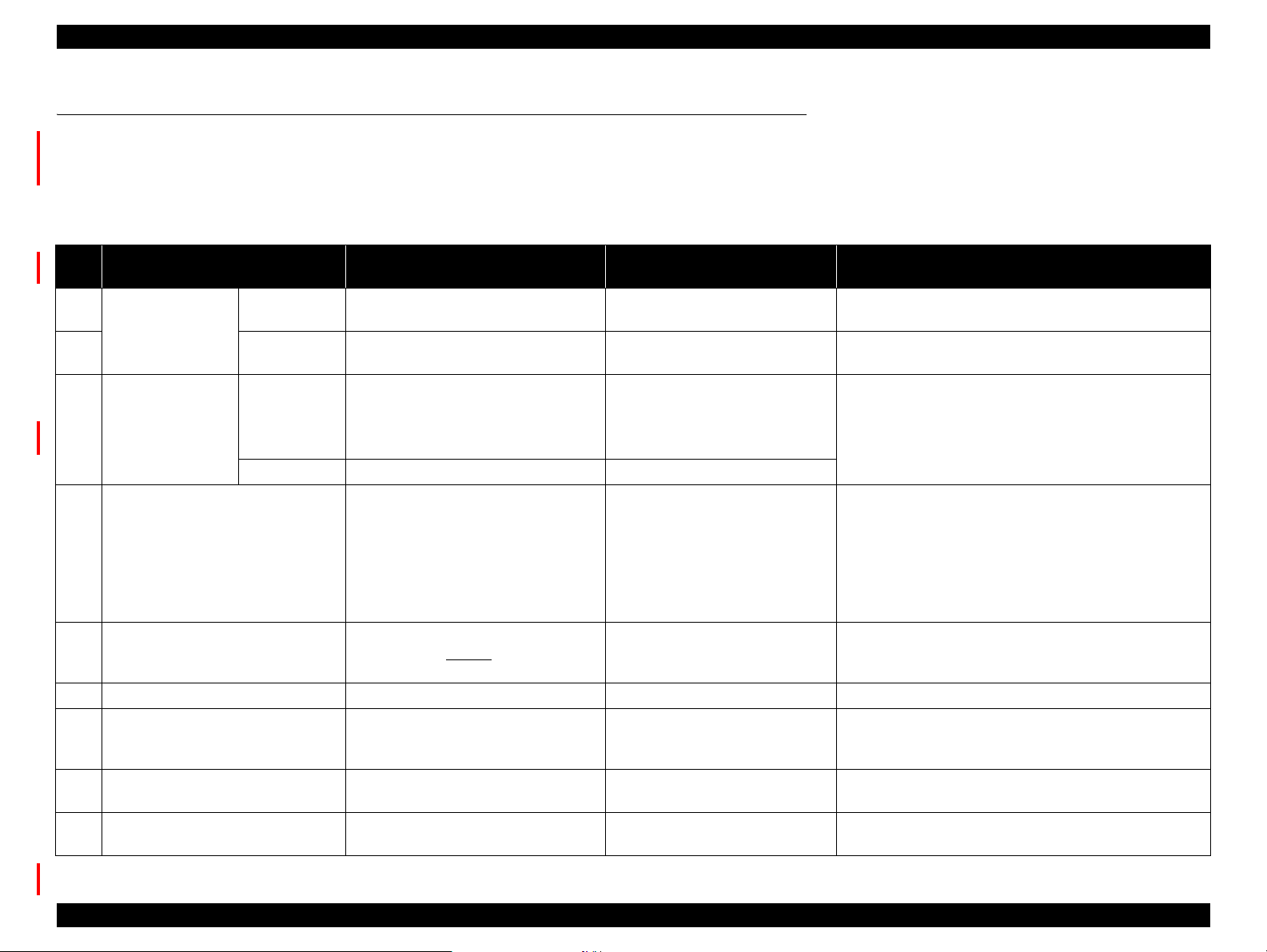

The following table shows the major changes from the Stylus Pro 4000.

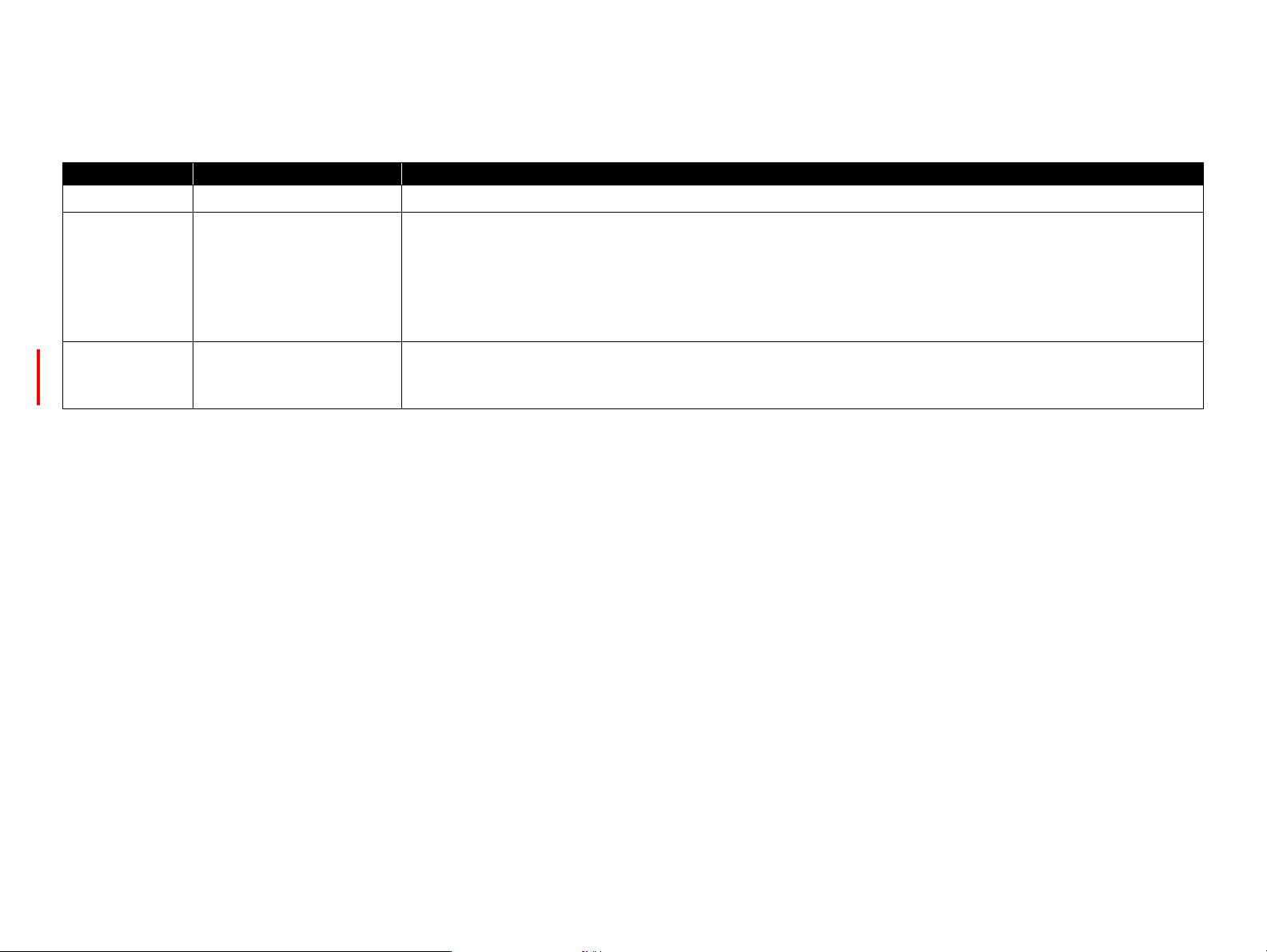

1.1.1 Comparison with Stylus Pro 4000

Table 1-1. Comparative Table

No. Comparative Point

1 Difference between

Hardware The 4-color model is not equipped with

8-color model and

4-color model

2 Printer driver Differs between the 8-color model and

3 Ink set

8-color model

configuration

4-color model MK,C,M,Y

4 Calibration function Colorimetric Calibration:

5 PG setting 5 levels:

6 Harness connection for CR Motor Connected by connectors Connected by soldering Harnesses are made easier to connect/disconnect.

7 Connection between Printhead and

Main Board

8 Material for roll paper guide roller Rubber (elastomer) Plastic (POM) Reduce roller marks traced when roll paper passes

9 Cooling fan Added a cooling fan --- Cools the MAIN Board and the Power Supply Board, and

Note *: PK=Photo Black, MK=Matte Black, LK=Light Black, LLK=Light Light Black, C=Cyan, M=Magenta, LC=Light Cyan, LM=Light Magenta, Y=Yellow, VM=Vivid Magenta,

VLM=Vivid Light Magenta

Stylus Pro 4400/4450/4800

/4880/4880C

an ink holder on the right side.

the 4-color model.

Stylus Pro 4800

K (PK/MK),C,M,Y,LK,LC,LM,LLK

Stylus Pro 4880/4880C

K (PK/MK),C,VM,Y,LK,LC,VLM,LLK

*

*

*

Corrects the amount of dot generation

based on the individual difference

between the following parts:

Printhead

MAIN Board

Power Supply Board

0.7mm/1.2mm/1.5mm

/2.2mm/2.6mm

Added a relay board between

“Printhead, Harness”and the MAIN

Board.

Stylus Pro 4000 Remark

Common ---

Common ---

MK,C,M,Y,PK,LC,LM,LK

MK,C,M,Y

*

Head ID:

Corrects the amount of dot

*

---

Calibration accuracy is improved by taking electrical

variable factor into consideration.

generation based on the individual

difference between the following

part:

Printhead

4 levels:

0.7mm/1.2mm/2.2mm/2.6mm

Added 1.5 mm of PG setting to prevent thin paper from

being damaged. (Lock bush design is changed according

to the added PG setting.)

The Printhead is connected to the

MAIN Board by “Head, Harness”

only.

An additional relay board prevents head drive waveform

being deteriorated when transmitting data form the MAIN

Board to the Printhead.

through the roller.

ventilates the board container.

Product Description Product Description 10

EPSON Stylus Pro 4400/4450/4800/4880/4880C Revision C

1.1.2 Features

Large Format

Max. paper width: 431.8 mm (17"), A2+ size supported

High-Speed Throughput

Stylus Pro 4400/4800

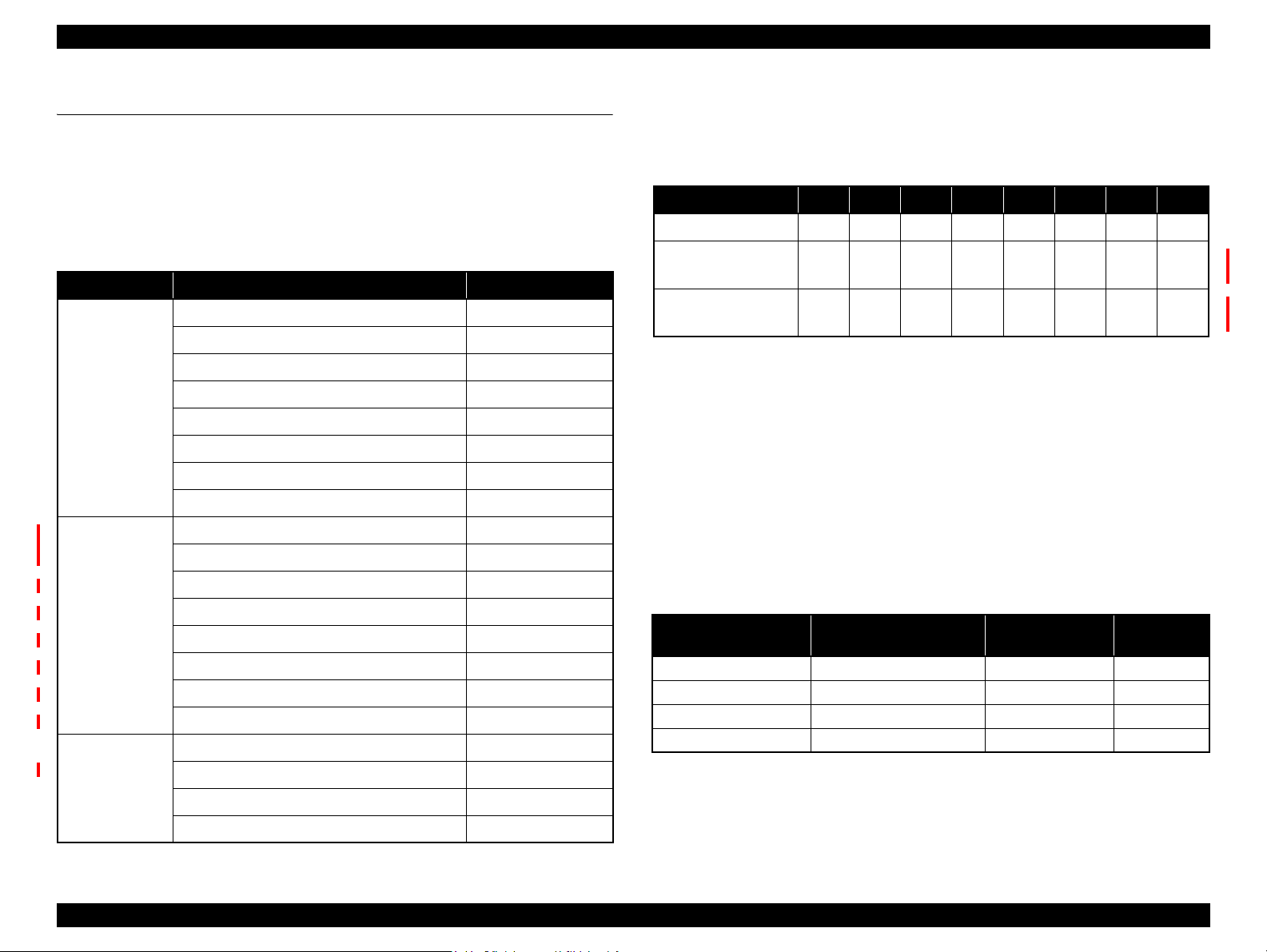

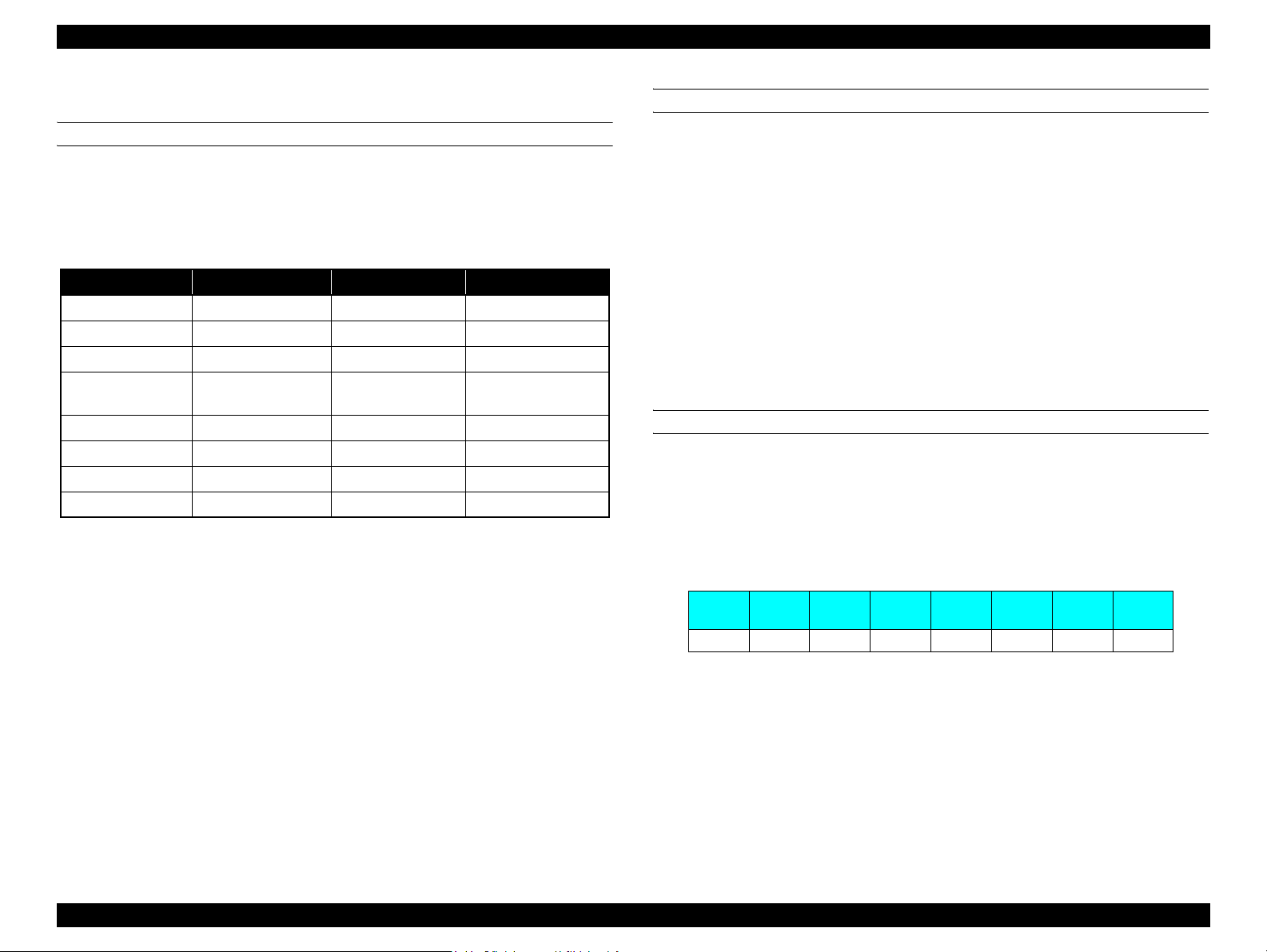

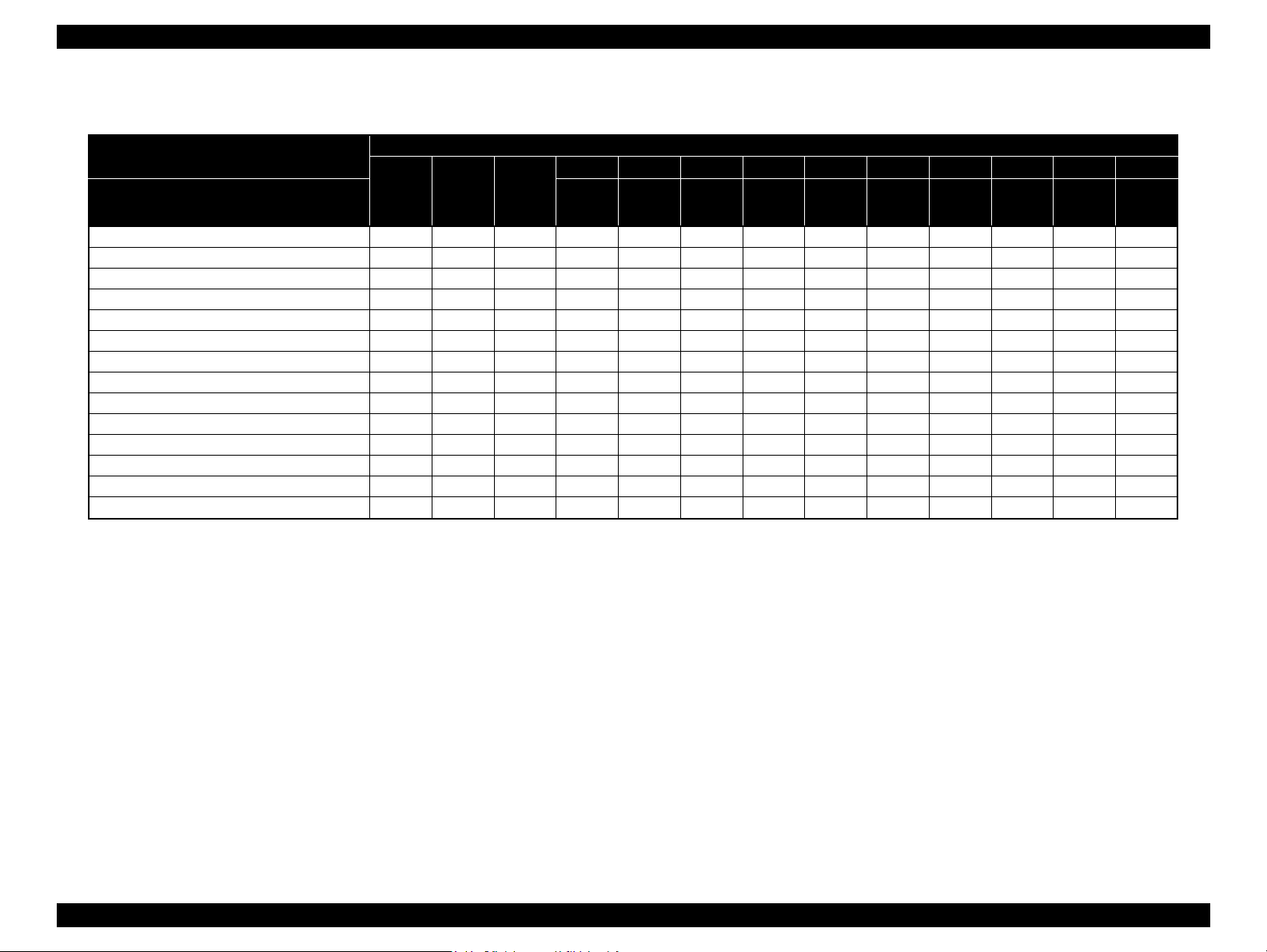

Table 1-2. Throughput (Stylus Pro 4400/4800)

Ink

EPSON

type

8-color Plain

4-color Plain

media

Paper

Matte

Paper

Glossy

Photo

Paper

Paper

Matte

Paper

Glossy

Photo

Paper

Quality Dot size

Economy VSD1 360 x 360 1.3 min.

Speed VSD1 360 x 360 2.3 min.

Quality VSD2 720 x 36 0 2.7 min.

High Quality VSD3 720 x 720 5.5 min.

Speed VSD1 360 x 720 2.3 min.

Quality VSD2 720 x 72 0 5.5 min.

High Quality VSD3 1440 x 720 7.9 min.

High Quality Super

On

Quality VSD2 720 x 72 0 5.5 min.

High Quality 1440 VSD3 1440 x 720 7.9 min.

High Quality 2880 VSD3_HR 2880 x 1440 14.9 min.

Economy VSD1 360 x 360 0.9 min.

Speed VSD1 360 x 360 1.3 min.

Quality VSD2 720 x 36 0 2.3 min.

High Quality VSD3 720 x 720 3.8 min.

Speed VSD1 360 x 720 3.1 min.

Quality VSD2 720 x 72 0 3.8 min.

High Quality VSD3 1440 x 720 5.4 min.

High Quality Super

On

Quality VSD2 720 x 72 0 5.0 min.

High Quality VSD3 720 x 720 7.5 min.

High Quality Super On

VSD3 1440 x 720 14.2 min.

VSD3 1440 x 720 7.3 min.

VSD3 1440 x 720 10.5 min.

Resolution

(dpi)

Throughput

(A2 printing

time *print only)

Stylus Pro 4450/4880/4880C

Table 1-3. Throughput (Stylus Pro 4450/4880/4880C)

Ink

EPSON

type

8-color Plain

4-color Plain

media

Paper

Matte

Paper

Glossy

Photo

Paper

Paper

Matte

Paper

Glossy

Photo

Paper

Quality Dot size

Economy VSD1 360 x 360 1.5 min.

Speed VSD1 360 x 360 2.4 min.

Quality VSD2 720 x 360 2.8 min.

High Quality VSD3 720 x 720 5.2 min.

Speed VSD1 720 x 360 2.4 min.

Quality VSD2 720 x 720 5.2 min.

High Quality 1440 VSD3 1440 x 720 7.5 min.

High Quality 2880 VSD3_HR 2880 x 1440 14.2 min.

Quality VSD2 720 x 720 5.5 min.

High Quality 1440 VSD3 1440 x 720 7.9 min.

High Quality 2880 VSD3_HR 2880 x 1440 14.9 min.

Economy VSD1 360 x 360 1.2 min.

Speed VSD1 360 x 360 1.5 min.

Quality VSD2 720 x 360 2.4 min.

High Quality VSD2 720 x 720 3.7 min.

Speed VSD1 360 x 720 2.5 min.

POP Print VSD2 720 x 720 2.8 min.

Quality VSD2 720 x 720 3.7 min.

High Quality VSD3 1440 x 720 4.3 min.

High Quality Super

On

POP Print VSD2 720 x 720 3.9 min.

Quality VSD2 720 x 720 5.3 min.

High Quality VSD3 1440 x 720 6.4 min.

High Quality Super On

Resolution

(dpi)

VSD3 1440 x 720 5.1 min.

VSD3 1440 x 720 7.7 min.

Throughput

(A2 printing

time *print only)

Product Description Product Description 11

EPSON Stylus Pro 4400/4450/4800/4880/4880C Revision C

Max Quality

High image quality made by various layers of 8-color ink, 2880 x 1440 dpi*,

and minimum of 3.5 pl.

Note *: Stylus Pro 4800/4880/4880C only. 1440 x 720 dpi for Stylus Pro 4400/4450.

Low Running Cost

Independent for each color and 110ml ink cartridge

Optional ink cartridge with larger capacity of 220ml can be used

Paper Handling

Support various media

Automatic roll paper cutter, manual cutter

Automatic cut sheet loading (ASF)

Rear manual feed/ Front manual feed (thick paper only)

Borderless print for 4 sides

ASF support

Compatibility with Other LFPs

Commands are upper compatible with following models.

Stylus Pro 4400/4800

Stylus Pro 4000/7000/7500/7600/9000/9500/9600/10000/10000CF/

10000 Dye/10600CF/10600UC

Stylus Pro 4450/4880/4880C

Stylus Pro 4000/4400/4800/7000/7400/7500/7600/7800/9000/9400/

9500/9600/9800/10000/10000CF/10000 Dye/1 0600/

10600CF/10600UC

The latest RIP technology

Stylus Rip Professional 3

Others: Various 3rd Party RIP

Product Description Product Description 12

EPSON Stylus Pro 4400/4450/4800/4880/4880C Revision C

1.2 Basic Specifications

1.2.1 Print Specifications

Printing

On-demand ink-jet

Nozzle configuration

Table 1-4. Nozzle configuration

Model Name Ink Nozzles

Stylus Pro 4800 Black(MK or PK) 180

Light Black 180

Light Light Black 180

Cyan 180

Magenta 180

Light Cyan 180

Light Magenta 180

Yellow 180

Stylus Pro 4880

Stylus Pro 4880C

Stylus Pro 4400

Stylus Pro 4450

Black(MK or PK) 180

Light Black 180

Light Light Black 180

Cyan 180

Vivid Magenta 180

Light Cyan 180

Vivid Light Magenta 180

Yellow 180

Matte Black 360

Cyan 360

Magenta 360

Yellow 360

Nozzle pitch

0.141 mm (1/180 inch) for each color

Ink Set Configuration

Table 1-5. Ink Set Configuration

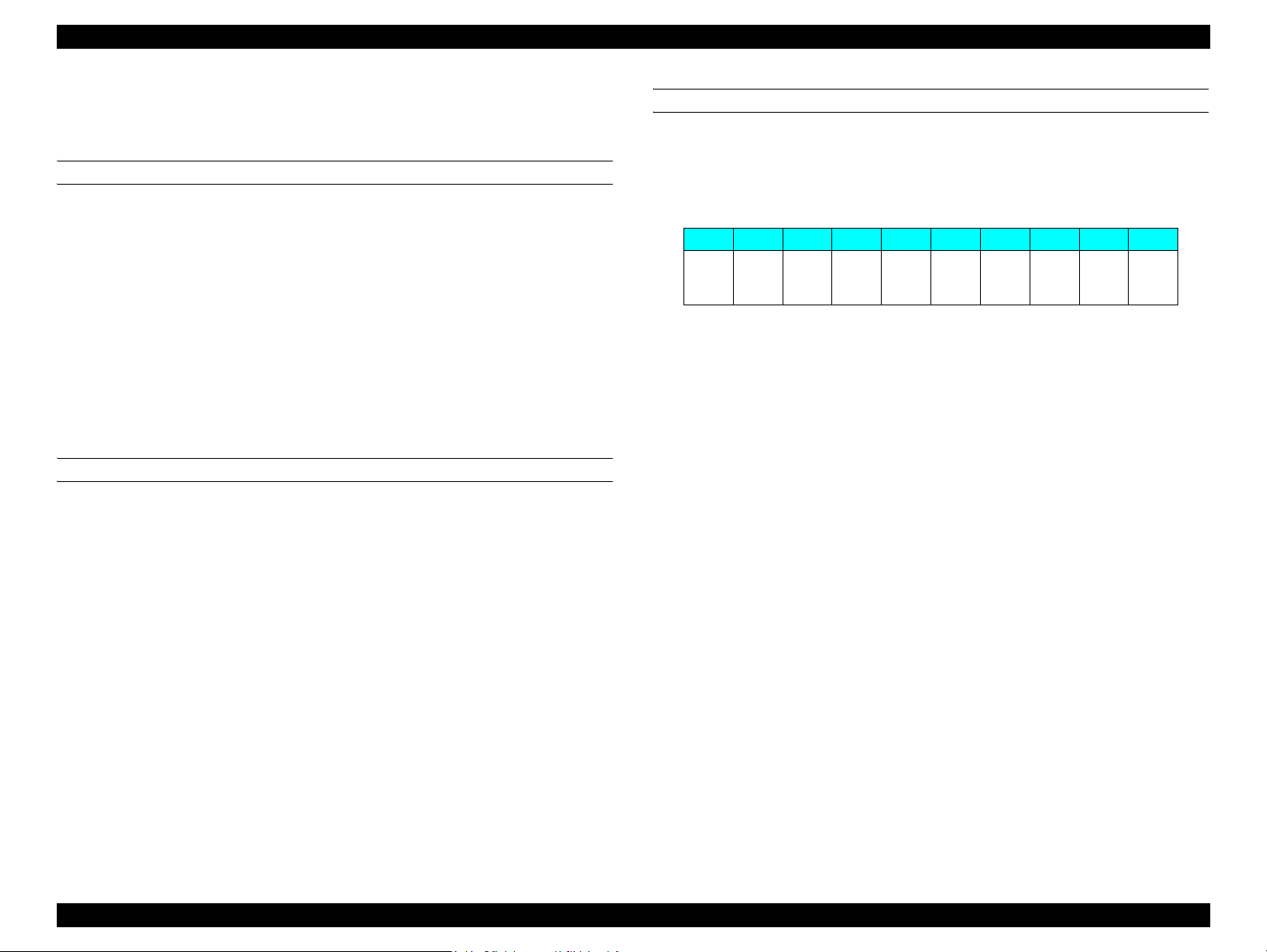

Mode Name 1-row 2-row 3-row 4-row 5-row 6-row 7-row 8-row

*2

Stylus Pro 4800 K

Stylus Pro 4880

Stylus Pro 4880C

Stylus Pro 4400

Stylus Pro 4450

Note *1: Rows below are counted from the front left side of the printer.

*2: Ink change (MK<=>PK) is available to users.

K

MK C M Y - - - -

C M Y LK LC LM LLK

*2

C VM Y LK LC VLM LLK

*1

Printing direction

Bi-direction with logic seeking (high-speed return, high-speed skip only)

Printing speed and printable area

Alphanumeric characters

• Character quality : High quality

• Character pitch : 10 cpi

• Printable area : 167 characters

• Printing speed : 320 cps max.

Graphic Mode

Table 1-6. Graphics Modes

Horizontal resolution

(dpi)

360 439.8 mm (17.31") 6,233 320 cps

720 439.8 mm (17.31") 12,466 240 cps

1440 439.8 mm (17.31") 24,933 240 cps

2880 439.8 mm (17.31") 49,867 240 cps

Note 1: Includes left margin of 5 mm (Maximum), right margin of 3 mm.

2: Standard maximum printable area in normal mode is 425.8 mm (16.7 inch)

Maximum printable area

Maximum number

of printable dots

Printing

speed

Product Description Basic Specifications 13

EPSON Stylus Pro 4400/4450/4800/4880/4880C Revision C

1.2.2 Character Specification

Character tables

PC 437 (Alphanumeric characters extension graphics)

Font

EPSON original font – Alphanumeric character Courier

1.2.3 Control Code

Control code

ESC/P Raster

1.2.4 Paper Feed Specification

Paper fee d i ng

Friction feed

Line spacing

1/6 inch or programmable at 1440 inch

Note: Paper feed resolution is 0.002936758 mm.

Paper pa th

Roll paper

Manual (front/back)

Automatic sheet feeder

Feed speed

6.35 mm paper feed: 215 ± 10 msec

(except front rush, back rush, and hold time)

1.2.5 Paper Feeder Specification

ASF

Feeds paper automatically by Automatic Sheet Feeder.

Rear Manual Feed

Loads automatically from rear manual feed opening.

Front Manual Feed

Loads automatically from front manual feed opening.

Roll Paper Feed

Sets spindle to rear roll-paper holder.

Product Description Basic Specifications 14

EPSON Stylus Pro 4400/4450/4800/4880/4880C Revision C

1.2.6 Paper Specification

1.2.6.1 Roll Paper

CONTAINABLE PAPER

The printer accepts following plain paper and EPSON special paper. It is not

assured feeding and print quality with any other paper except them.

Paper Size

2" core : 203 ~ 432 mm (W) x ~ 45 m (H) (within roll size)

3" core : 203 ~ 432 mm (W) x ~ 202 m (H) (within roll size)

Roll Size

2" core : Under 103 mm ext. diameter for 1 roll setting

3" core : Under 150 mm ext. diameter for 1 roll setting

Thickness : 0.08 mm ~ 0.50 mm

PLAIN PAPER

It is assured feeding only with following specifications.

Paper Size

2" core : 203 ~ 432 mm (W) x ~ 45m (H) (within roll size)

3" core : 203 ~ 432 mm (W) x ~ 202m (H) (within roll size)

Roll Size

2" core : Under 103 mm ext. diameter for 1 roll setting

3" core : Under 150 mm ext. diameter for 1 roll setting

Thickness : 0.08 ~ 0.15 mm

Weight : 64 ~ 130 gf/m

Type : Plain paper, Recycle paper

2

BORDERLESS PRINT WIDTH

Borderless print for right and left is assured with following paper width roll

paper.

Borderless Print Width

Table 1-7. Borderless Print Width

8" 8.25" 8.5" 10" 12" 13" 14" 16" 16.5” 17”

203.2mm210mm

(A4)

(LTR)

216mm

257mm

(A3)

297mm

300mm

(A3+)

329mm

355.6

mm

400mm

(A2)

420mm

431.8

mm

But following types are not recommended for borderless printing.

Single Weight Matte Paper

Enhanced Matte Paper

Textured Fine Art Paper

Ultra Smooth Fine Art Paper

NOTE 1: Paper should have no wrinkles or tears, and the surface should be

smooth.

2: The force to remove the end of the roll paper from the core at the

beginning of rolling paper should be between 300gf and 2000gf.

3: If 3" core is used, a product-exclusive option (roll paper spindle 3")

is necessary.

4: It is used under normal condition (temperature 15°C ~ 25°C,

humidity 40% ~ 60%RH).

5: Roll paper can be printed before paper comes out of the core.

(Reference: Remaining paper length is 300mm approx. when roll

paper come out of the core.)

6: Mechanism clips print data out of over-printable area for

borderless print.

7: For A2 size, spacer is specially needed.

Product Description Basic Specifications 15

EPSON Stylus Pro 4400/4450/4800/4880/4880C Revision C

1.2.6.2 Cut Sheet

CONTAINABLE PAPER

The printer accepts following plain paper and special paper. It is not assure d

feeding and print quality with any other paper except plain paper and special

paper.

Paper Size

Table 1-8. Cut Sheet Size (Containable Paper)

Paper Size Size (H x W) Paper Size Size (H x W)

B3 364 mm x 515 mm US-C Size 17 x 22 inch

B4 257 mm x 364 mm 16 x 20 inch 16 x 20 inch

A2 420 mm x 594 mm 300 mm x 450 mm 300 mm x 450 mm

Super A3/B

(A3 +)

A3 297 mm x 420 mm 11 x 14 inch 11 x 14 inch

A4 210 mm x 297 mm Quarter 10 x 12 inch

Thickness

0.08 ~ 1.50 mm (paper length; 279 mm ~ 610 mm)

NOTE 1: Paper should have no wrinkles, tears, or stains an d

329 mm x 483 mm US-B Size

(Ledger)

Letter 8.5 x 11 inch

8 x 10 inch 8 x 10 inch

11 x 17 inch

the surface should be smooth.

2: Paper should be placed with its fibrous direction same

as the feed direction. (Basically portrait orientation)

3: 0.08 ~ 1.50mm paper thicknesses are supported for

long-edge insertion.

4: A4, letter, or 8 x 10 inch papers should not be placed

in landscape orientation on rear manual feed path.

5: Auto nozzle check is not available for 8 x 10 inch or

smaller paper.

6: Front manual feed is not available for soft paper or

0.2mm or less thickness paper.

PLAIN PAPER

It is assured feeding only with following specifications.

Paper Size : Identical to Table 1-8 "Cut Sheet Size (Containable

Paper)"(p16).

Thickn ess : 0.08 ~ 0.11 mm

Weight : 64 ~ 130 gf/m

2

Type : Plain paper, Recycle paper

NOTE 1: Paper should be placed in portrait orientation.

2: Paper should have no wrinkles, tears, or stains and the surface

should be smooth.

3: It is used under normal condition (temperature 15ºC ~ 25ºC,

humidity 40% ~ 60%RH).

BORDERLESS PRINT WIDTH

Borderless print for right and left is assured with following paper width. But

following types are not recommended for borderless printing.

NOTE: 300 mm, 400 mm are supported for Europe.

Borderless Print Width

Table 1-9. Borderless Print Width

8.25””

210mm

A4 LTR B4 A3 A3+ – 16"

NOTE 1: Mechanism clips print data out of over-printable area for

2: Borderless printing is not available for A2 cut sheet.

8.5"

216mm

10"

257mm

borderless print.

12"

297mm

13"

329mm

14"

355.6mm

16"

400mm

431.8mm

x20" US-C

17"

Product Description Basic Specifications 16

EPSON Stylus Pro 4400/4450/4800/4880/4880C Revision C

1.2.6.3 Special Paper

Cut Sheet

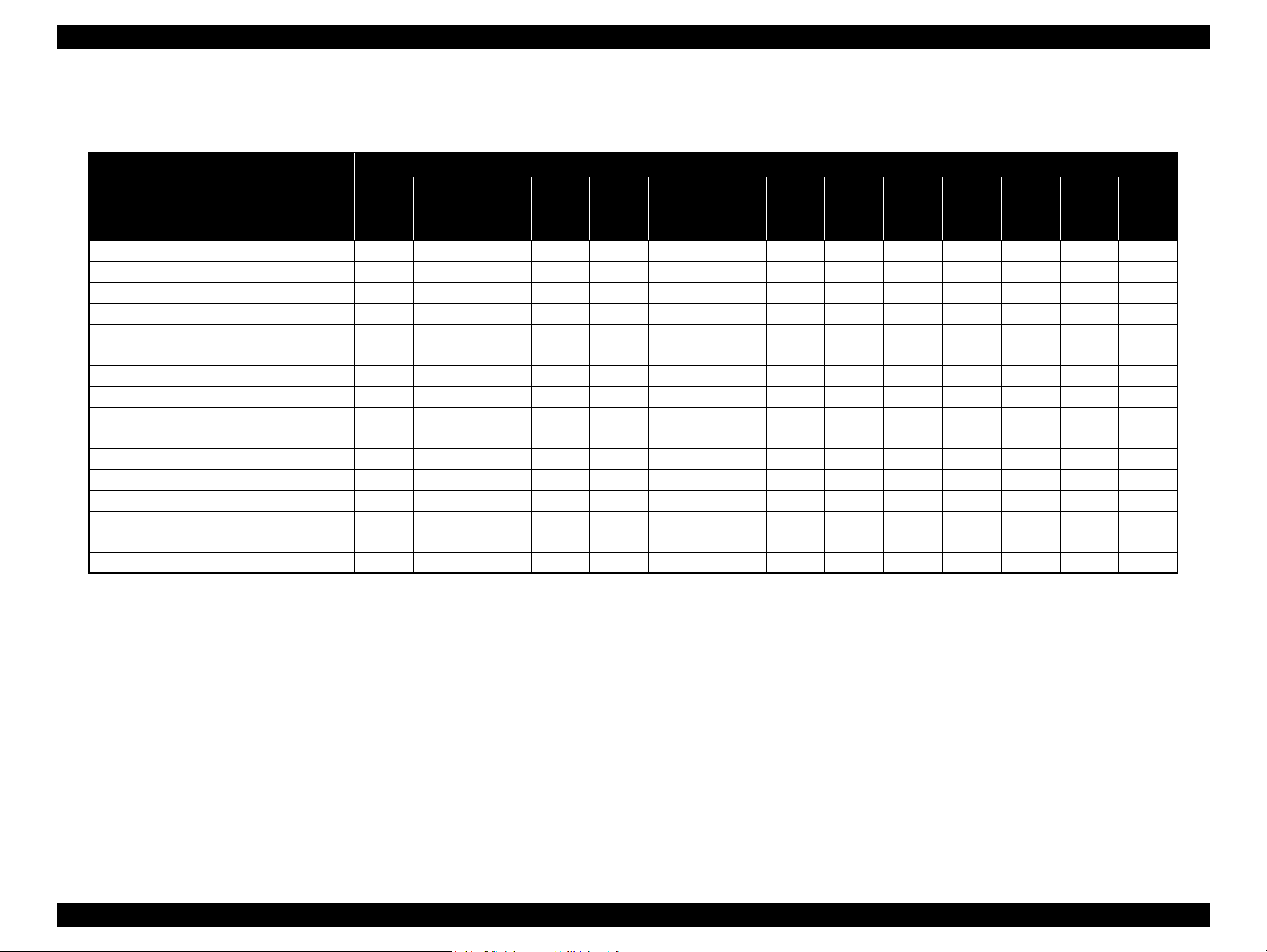

Table 1-10. Availability with Cut Sheet

Media Size

Cut Sheet

PG

Name 203x279 210x297 216x279 229x305 254x364 279x356 297x420 279x432 305x457 329x483 400x600 420x594 432x559

Premium Ink Jet Plain Paper (Xerox 4024) 1.5 – @ @ @ @ – @ @ @ – – @ @

Premium Ink Jet Plain Paper (Genuine) 1.5 – @ –––––––––––

Bright White Inkjet Paper 1.5 – @ –––––––––––

EPSON Photo Quality Inkjet Paper 1.5 – §§–––§––§–––

EPSON Enhanced (Archival) Matte Paper1.2–§§–––§––§––§

Watercolor Paper-Radiant White 1.2 – ––––––––§–––

EPSON Premium Glossy Photo Paper 0.7 – §§–––§––§–––

EPSON Premium Semigloss Photo Paper0.7–§§–––§––§–––

Premium Semimatte/Luster Photo Paper<250>

Premium Luster Photo Paper 0.7––§––––––§–––

P;atinum Photo Paper 0.7 – §––––§––§–––

EPSON Velvet Fine Art 1.2––§––––––§–––

Single Weight Matte Paper 1.5 – ––––––––§–§§

Ultra Smooth Fine Art Paper 1.5 – ––––––––§––§

Proofing Paper Semimatte 0.7 – ––––––––§–––

Velvet Fine Art Paper – –§––––––§–––

(mm)

8"x10" A4

1.2––––––––––––§

US-A

LTR

Arch.A

9x12"

B4 11"x14" A3 US-B

Arch.B

12x18"

Super

A3/B

400x600 A2 US-C

Note 1: Symbol ~: Assured, @: Assured for plain paper only

2: Assured range for image quality 15°C 40%RH ~ 25°C 60%RH

3: PG setting value of Velvet Fine Art Paper is accordance with the panel setting.

Product Description Basic Specifications 17

EPSON Stylus Pro 4400/4450/4800/4880/4880C Revision C

Roll Paper

Table 1-11. Availability with Roll Sheet

Roll Paper

Core"

Name

Bright White Inkjet Paper 2 1.5 A § – ––––––§–

Single Weight Matte Paper Roll 2 1.2 A – – ––––––§§

Enhanced Matte Paper Roll 3 1.2 A – – –––––––§

Photo Glossy Paper Roll 2 0.7 A – – ––––––§–

Photo Semigloss Paper Roll 2 0.7 A – – ––––––§–

Premium Glossy Photo Paper<250>Roll 3 0.7 A – – –––––§––

Premium Semigloss Photo Paper<250>Roll 3 0.7 A – – –––––§––

Premium Semimatte Photo Paper <250 >Roll 3 0.7 A – – –––––§––

Premium Luster Photo Paper <250 >Roll 3 0.7 A – § §––––§––

Ultra Smooth Fine Art Paper 3 1.5 A – – –––––––§

Textured Fine Art Paper 3 1.2 A – – –––––––§

Proofing Paper Semimatte Roll 2 0.7 A – – ––§––––§

Photo Paper Gloss 250 3 0.7 A – – –––––––§

Tracing Paper 2/3 1.2 A – – ––§–––

SpindlePG(mm)

Cutter

Auto

or

Manual

A4 10" 30cm 12" A3+ 14" 40cm 16" A2 17"

210 254 300 305 329 356 400 406 420 431.6

Media Size

@

–

Note 1: Symbol ~: Assured, @: Assured for plain paper only

2: Assured range for image quality 15°C 40%RH ~ 25°C 60%RH

Product Description Basic Specifications 18

EPSON Stylus Pro 4400/4450/4800/4880/4880C Revision C

1.2.7 Mechanism Specifications

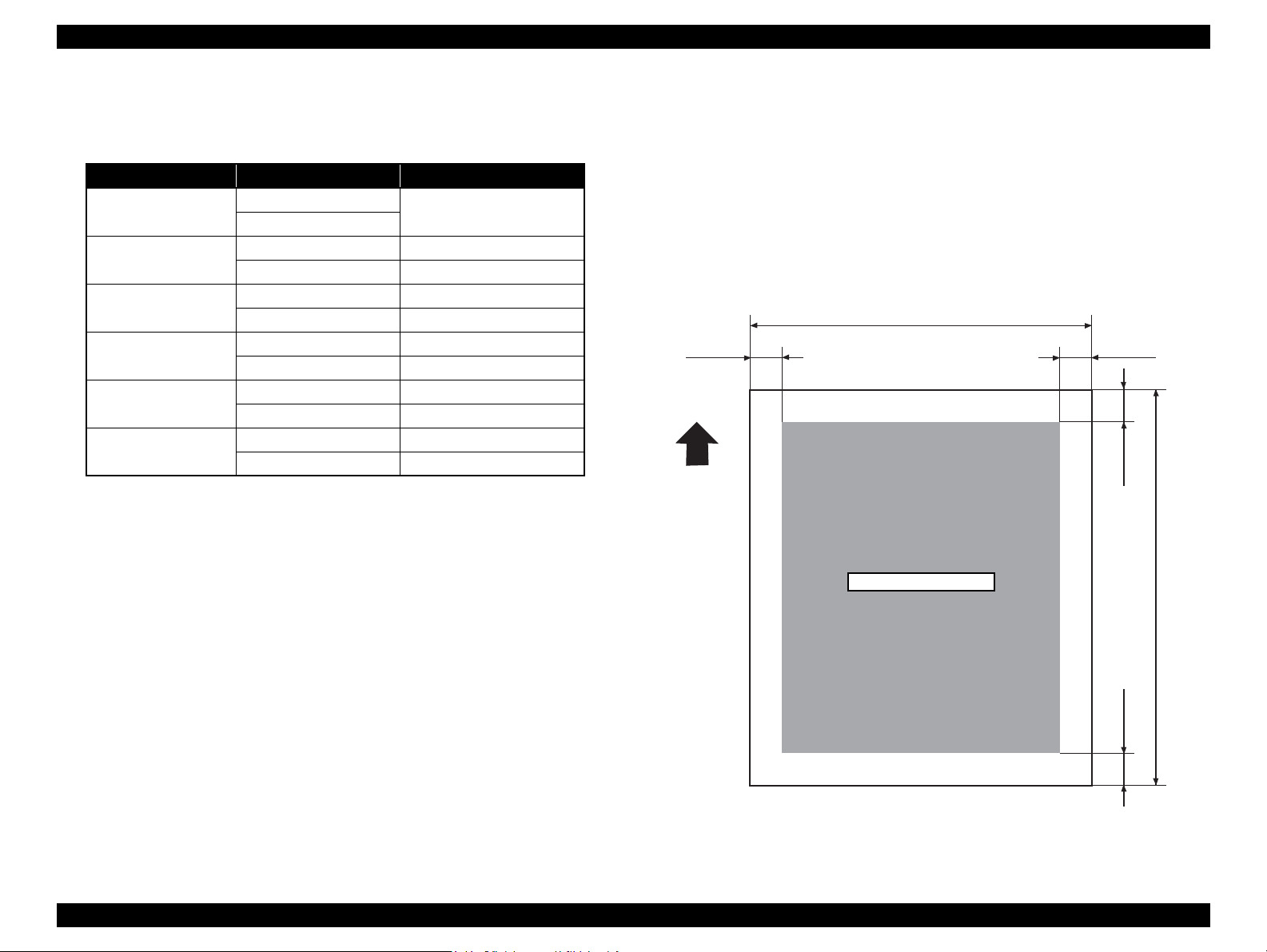

1.2.7.1 Printable Area

Table 1-12. Printable Area

Item Roll paper / Cut Sheet Dimension

PW (Paper width)

PL (Paper length)

TM (Top margin)

BM (Bottom margin)

LM (Left margin)

RM (Right margin)

Note *: Max. value is roll paper 439.8mm(17.31"), and cut sheet 437.8mm (17.24") for

no margin print.

Roll paper

Cut Sheet

Roll paper Max. 202m

Cut Sheet 279mm~594mm

Roll paper 0mm/3mm/15mm/35mm

Cut Sheet 0mm/3mm

Roll paper 0mm/3mm/15mm(/35mm)

Cut Sheet 0mm/3mm/14mm

Roll paper 0mm/3mm/15mm

Cut Sheet 0mm/3mm

Roll paper 0mm/3mm/15mm

Cut Sheet 0mm/3mm

203mm~431.8mm (17")

The printer detects paper width when paper is set (print data is accepted

for ASF). (If set paper width detection is OFF, it doesn't detect paper

width.)

It doesn't print the image beyond printable area specified with paper size

setting or detected paper width. (It may print on the platen if set paper

width detection is OFF.)

Margins of roll paper can be changed with the panel as following;

Top/bottom 15mm, left/right 3mm

Top/bottom 25mm, left/right 3mm

Top/bottom/left/right 3mm

Top/bottom/left/right 15mm

NOTE 1: Under special condition, it is possible to set right and

left margin (LM, RM) to 0.

2: When special internal pattern is printed on roll paper,

right and left side margin are fixed to 3mm. “1.4.4.8

Roll Paper Margin (p.52)” for details.

*

For borderless print, right and left surplus printable area is maximum 3mm

on the home position side and maximum 5mm on the other side distance

from paper edge to platen (sponge width) is less th an 3m m, the m axim u m

surplus print quantity not on platen (0mm~3mm) is printable area.

Conditions for separating into multiple pages for printing cut sheet.

1. For thick paper, print until the bottom edge reaches to 14mm.

Remaining data is invalid and not to be printed.

2. When error occurred such as releasin g paper lever when prin ting, then

print is separated to next page after down margin is printed.

When printing on cut sheet at resolution of 2800 x 1440dpi and setting the

bottom margin to 3mm, the actual bottom margin will be 3.8mm.

PW

LM RM

TM

Printable Area

Paper Feed Direction

Figure 1-1. Printable Area

PL

BM

Product Description Basic Specifications 19

EPSON Stylus Pro 4400/4450/4800/4880/4880C Revision C

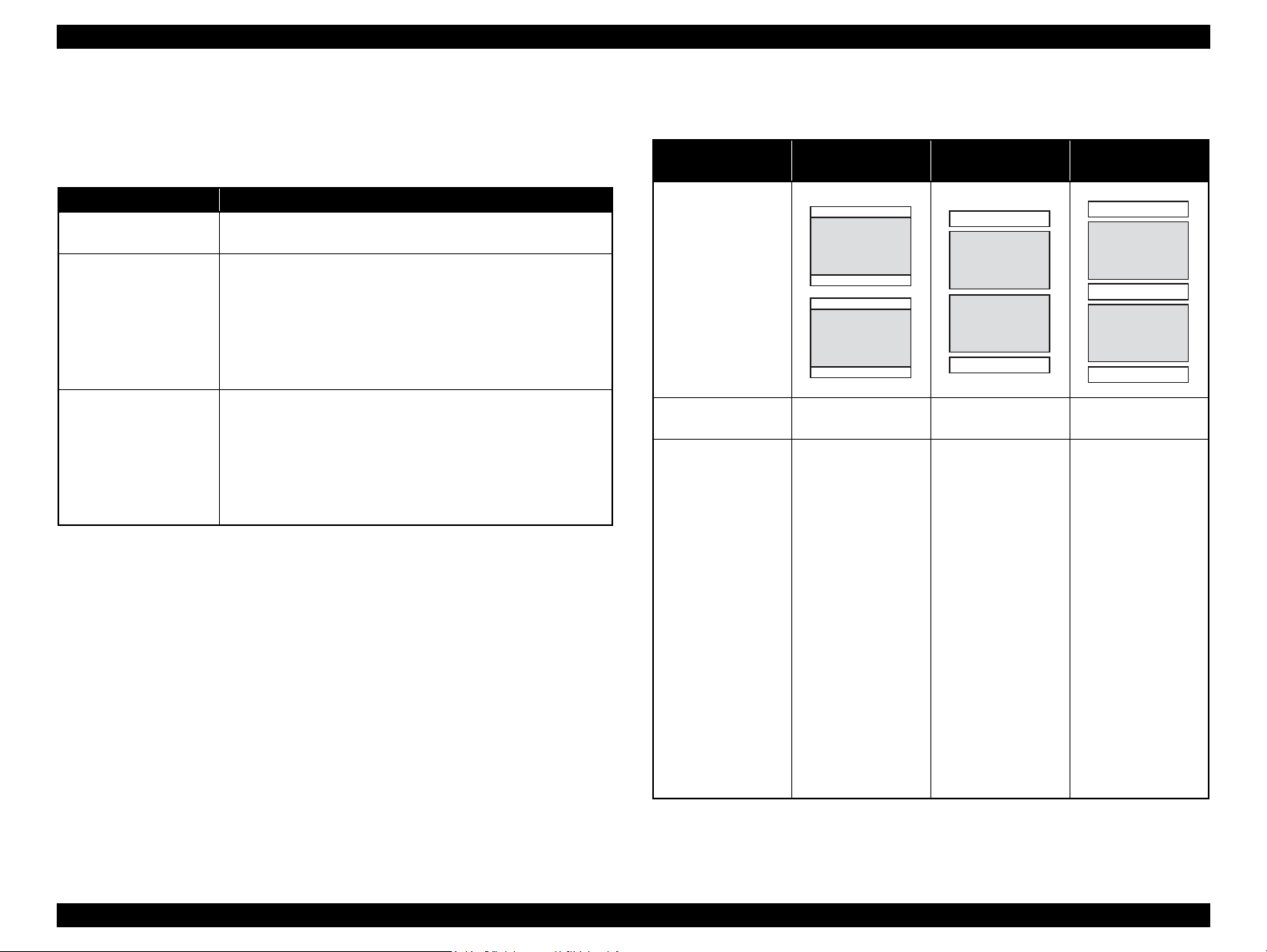

1.2.7.2 Borderless Print Specification

By driver's command transmission, supports the following borderless print

mode. Supports the following 3 modes.

Table 1-13. Borderless Print Specification mode

Mode Operation

Right and left

borderless (default)

4 sides borderless/1 cut You can set 4 sides margins to zero. Use the following

4 sides borderless/2 cut You can set 4 sides margins to zero. Use the following

Note 1: For 4 sides borderless, after cutting, up and down size of the printing will be

smaller by approximately 2mm than the actual printing size.

2: When the roll paper cutter is OFF and page line printing is ON, print the page

line at each cutting position including front edge page.

3: In following media, if 1 cut is selected at borderless printing, it is cut as 2 cut to

prevent scraping top of paper.

• Premium Glossy Photo Paper

• Premium Semigloss Photo Paper

Note *: Recommended a borderless length for glossy paper is 60mm, for other paper

is 100mm.

You can set only the right and left margins to zero. At this time,

up and down margins are set by roll paper margin setting.

method for cutting.

Starting of JOB, take minimum cut length for margin and

cut while printing.

While JOB, new page has no margin, cut at image border

position in continuing print.

End of JOB, cut at the bottom of the image.

method for cutting.

At the front edge page, take refresh margin length for

margin, cut while printing.

At the end of the page, cut at the bottom of the image.

To discard the remaining part of printing after cut, cut the

paper after advancing the paper to minimum cut length.

*

Borderless setting method

Table 1-14. Borderless setting

Borderless mode

Right and left

borderless

Printer operation

Driver setting Borderless print Borderless print

Note Default setting

4 sides borderless

(1 cut)

Single cut

The upper edge

cut is performed

by interrupting

print operation;

there is chance of

color shading

according to data.

By adjusting

cutter position,

there is chance of

data from

continuous page

remaining in top

or bottom edge of

the page.

4 sides borderless

(2 cut)

Borderless print

Double cut

The upper edge

cut is performed

by interrupting

print operation;

there is chance of

color shading

according to data.

To avoid

remaining of

margin, cut off the

top and bottom

part of the paper

by going inside of

image.

Therefore the

actual size will be

about 2mm

smaller than the

specified print

area.

Product Description Basic Specifications 20

EPSON Stylus Pro 4400/4450/4800/4880/4880C Revision C

Borderless Print Assurance Conditions

Borderless print is assured under the following conditions.

Temperature condition: 15 to 25 degrees C, 40 to 60%

Media Type: Photo media

POP/Poster media

Note 1: Refer to “1.2.6 Paper Specification (p.1 5)” for details on assured media for

borderless print.

2: Borderless printing is not assured if the surface of few rolls is extended due to

moisture absorbent.

3: Medea types and sizes other than above assure borderless margins equal to or

more than PX-10000 / PX-9000. However, margins may appear on the right and

left edges, if paper wrinkled due to conditions such as temperature is used.

*1,*2

Right and Left Surplus Printable Area

For right and left surplus printable area

available:

Left (opposite side of home position) = 1.5mm/ right (home position side) =

1.5mm

Left (opposite side of home position) = 3.0mm/ right (home position side) =

3.0mm

Left (opposite side of home position) = 5.0mm/ right (home position side) =

3.0mm

Note *1: Right and left surplus printable area can be selected on the driver.

*2

*2: When the media is wrinkled, a selection of "Left (oppo site side of home

position) = 5.0mm/ right (home position side) = 3.0mm" is recommended to

prevent margins from appearing on the right and left edges.

*1

, the following settings are

1.2.7.3 Paper Set Lever

Table 1-15. Paper Set Lever

Lever Position Description

Backward Position for paper setting

(Paper holding is released, and paper can be set.)

Forward Ready-to-print position

(Paper is fixed, and it becomes ready to be printed.)

1.2.7.4 Cut Specification

There are two types, auto cut and manual cut for roll paper cutting.

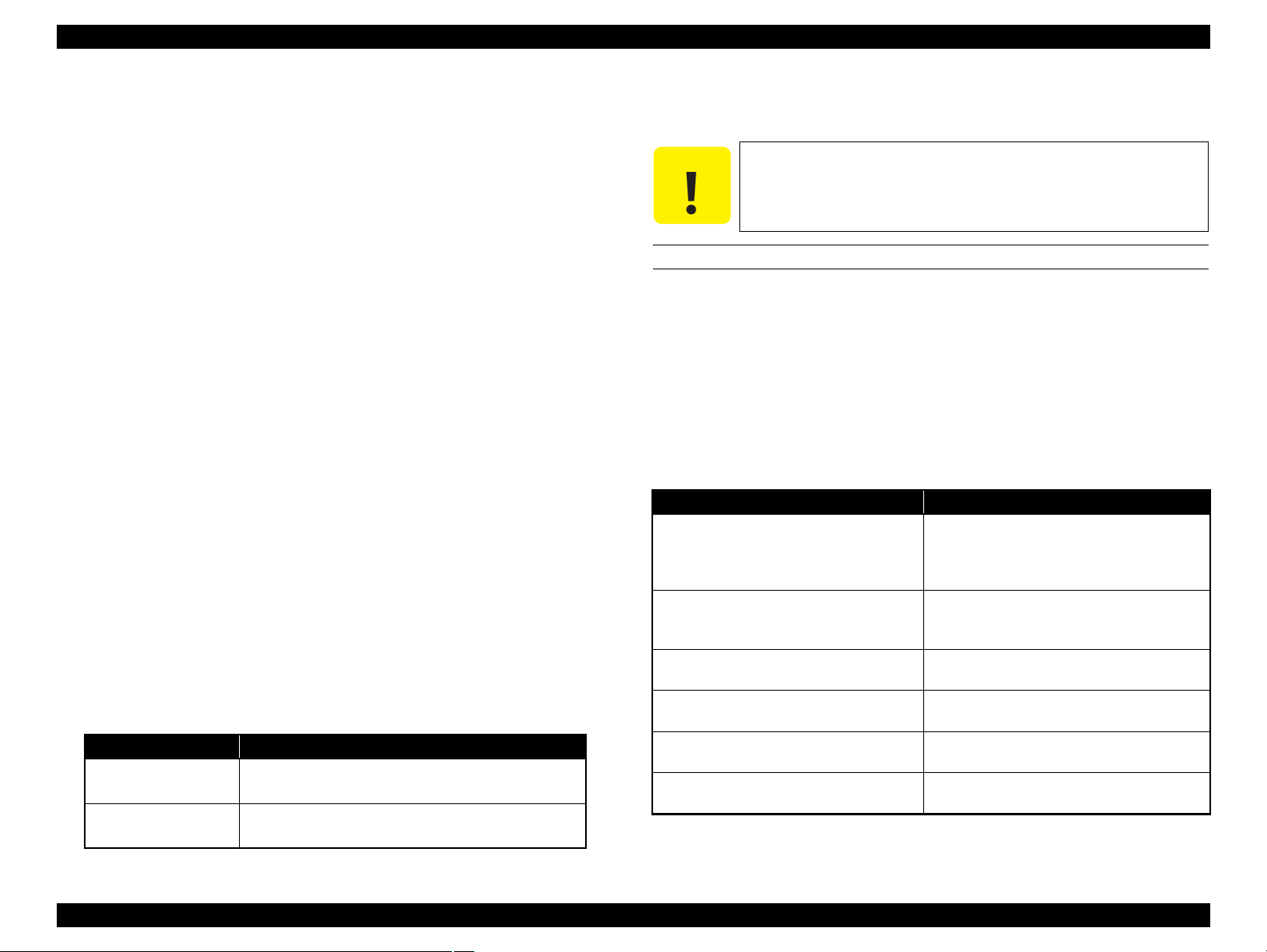

C A U T I O N

AUTOMATIC CUT FOR ROLL PAPER

For paper that automatic cut is admitted, cut the paper using the following

method by setting panel setting to "roll paper automatic cut".

Mechanic condition

Distance between the cutting position and paper setting position

Distance between the cutting position and cutter mark

Minimum cut length

Initial cut

(Pressing the lever down when there is

paper and pushing the [Paper Source/

Paper Cut (<)] key for 3 sec.)

Cut when driver ends print. Cutting method (include Star Wheel

Initial cut when printing Cut while printing is prohibited in this

Initial cut in an original standby situation Deliver size of L1 paper and cut by 2-step

After printing in automatic cut OFF mode,

start initial cut in automatic cut ON mode.

Cut when paper width detection is OFF. Same as paper width detection is ON.

Note *: User need to remove the strip of paper that remains between eject roller and

Making cutting action to paper wh ich au to ma ti c cu tt in g is

prohibited will cause damage to the printhead.

L0=205.43mm

L1=27.6 mm

L2=130 mm (default value)

Table 1-16. Cutting Conditions and Cutting Methods

Cut condition Cutting method

Deliver size of L1 paper and cut by 2-step with

roll paper holding Star Wheel. (100cps)

holding), cutting pressure, minimum cut

length follows to the media table.

model. (Product specification)

with roll paper holding Star Wheel. (100cps)

Cut by 2-step with roll paper holding Star

Wheel reserving size of L2. (100cps)

(Paper jam is not occurred for 2-step cut.)

nip roller when executing this operation without L2 reservation.

*

Product Description Basic Specifications 21

EPSON Stylus Pro 4400/4450/4800/4880/4880C Revision C

MANUAL CUT FOR ROLL PAPER

When using paper for which automatic cutting is prohibited, use manual cut

with the steps below.

1. Use [Paper Source / Paper Cut] button to select Roll Paper Auto Cut OFF

(" ").

2. Press and hold the [Paper Source / Paper Cut] button for 3 seconds.

3. The paper will be automatically fed to the manual cut position and the

printer will go offline, indicating “Pause”on the panel.

4. Cut off paper using own scissors.

5. Then press the [Pause] button and the paper will be fed back, and the

printer will be online.

NOTE 1: Auto cutter supports all genuine roll paper.

2: Paper of 3rd party media and generally auto cutter is prohibited.

• Fiber-form paper such as cloth.

• Rigidity is extremely high paper such as Vinyl (Outdoor type) or

Fine Art type.

1.2.8 Electrical Specification

Rated voltage: AC 100 ~ 240V

Input voltage range: AC 90 ~ 264V

Rated frequency range: 50 ~ 60Hz

Input frequency range: 49 ~ 61Hz

Rated current: 100-240V ac, 50-60Hz, and 1.0-0.5A

Power consumption

operation status

• Stylus Pro 4400/4800: Less than 59 W

• Stylus Pro 4450/4880/4880C: Less than 55 W

Less than 5 W for low power status (Shifting time: 15 minutes)

Less than 1 W for Power OFF

Insulation resistance: More than 10M ohms

(Between AC line and chassis is DC 500V)

Dielectric strength: AC 1.0kV rms 1min. or AC1.2kV rms 1 sec.

(Between AC line and chassis)

Leakage: Less than 0.25mA

[Adapts Japan National Electronics Development

Incorporated Association "Personal Computer

Industry Standard" (PC-11-1988)]

Adapted standard regulation

Adapts International Star Program

(Adapts category: measure for harmonic

component suppression guideline)

Adapts VCCI class B

Product Description Basic Specifications 22

EPSON Stylus Pro 4400/4450/4800/4880/4880C Revision C

1.2.9 Reliability

PRINTER LIFE

Approx. 20,000 pages (A2, plain paper, quality, 720 x 360 FOL, Bi-D)

AVERAGE CUTTER LIFE

Coated paper: Approx. 2,000 cut

Film: Approx. 1,000 cut

REPLACEMENT PARTS LIFE

Maintenance Unit: Approx. 20,000 sheets

(A2, plain paper, speed mode, continuous printing)

The maintenance unit reaches its end of life when

the number of the pump rotation exceeds 160,000

times.

1.2.10 Environmental Conditions

1.2.10.1 Temperature/Humidity

Table 1-17. Temperature/Humidity

Condition Temperature

During operation 10 ~ 35°C 20 ~ 80%

During storage -20

During transport -20

Note *1: Within one month for 40ºC, within 120 hours for 60ºC

*2: No condensation. These values are applicable only within the range as shown

below. Print quality is assured only within a temperature of 15 to 25 degrees C

and a humidity of 40 to 60%.

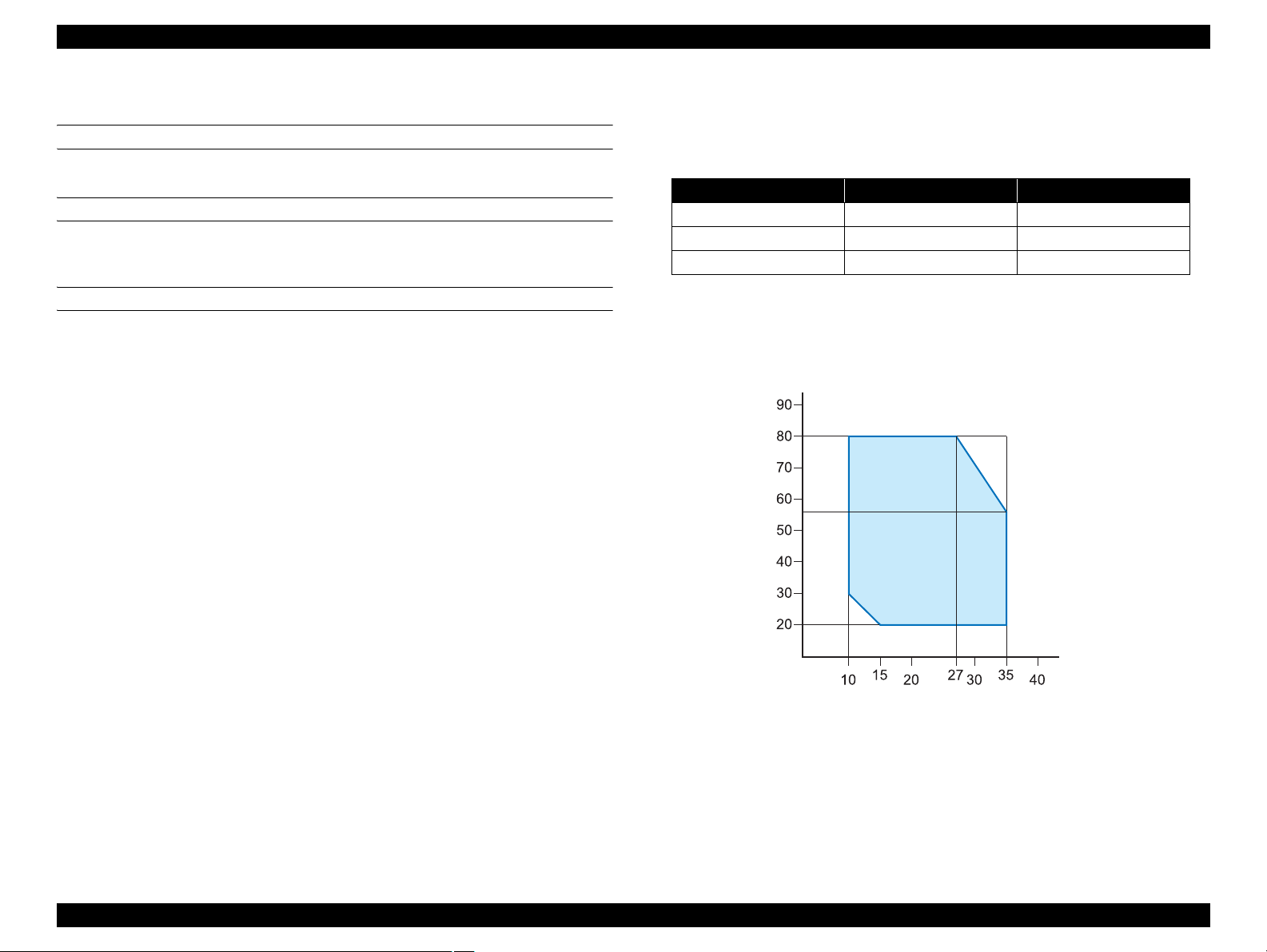

Humidity (%)

~ 40°C 20 ~ 85%

~ 60°C 5 ~ 85%

*1

Humidity

*2

Temperature (°C)

Figure 1-2. Environmental Conditions: Temperature/Humidity

Product Description Basic Specifications 23

EPSON Stylus Pro 4400/4450/4800/4880/4880C Revision C

1.2.10.2 Vibration

During op e ratio n: 0.15G, 10-55Hz X, Y, Z direc tio ns

During storage: 0.50G, 10-55Hz X, Y, Z directions

1.2.10.3 Shock

During op e ratio n: 1G, 1ms max. X, Y, Z directions

During storage: 2G, 2ms max. X, Y, Z directions

NOTE 1: Check that the printhead is capped during storage.

2: Check that the printhead is capped, then remove ink cartridges

from the body, and make sure ink cartridge cover is closed during

transport.

3: If the printer head uncapped, and the ink cartridge is attached,

switch the power ON. Switch the power OFF when capping is

completed.

4: Left out in condition of temperature under -15°C; the ink in the

printhead and ink cartridge freezes. It takes about 3 hours for the

frozen ink to be usable under the condition of 25°C.

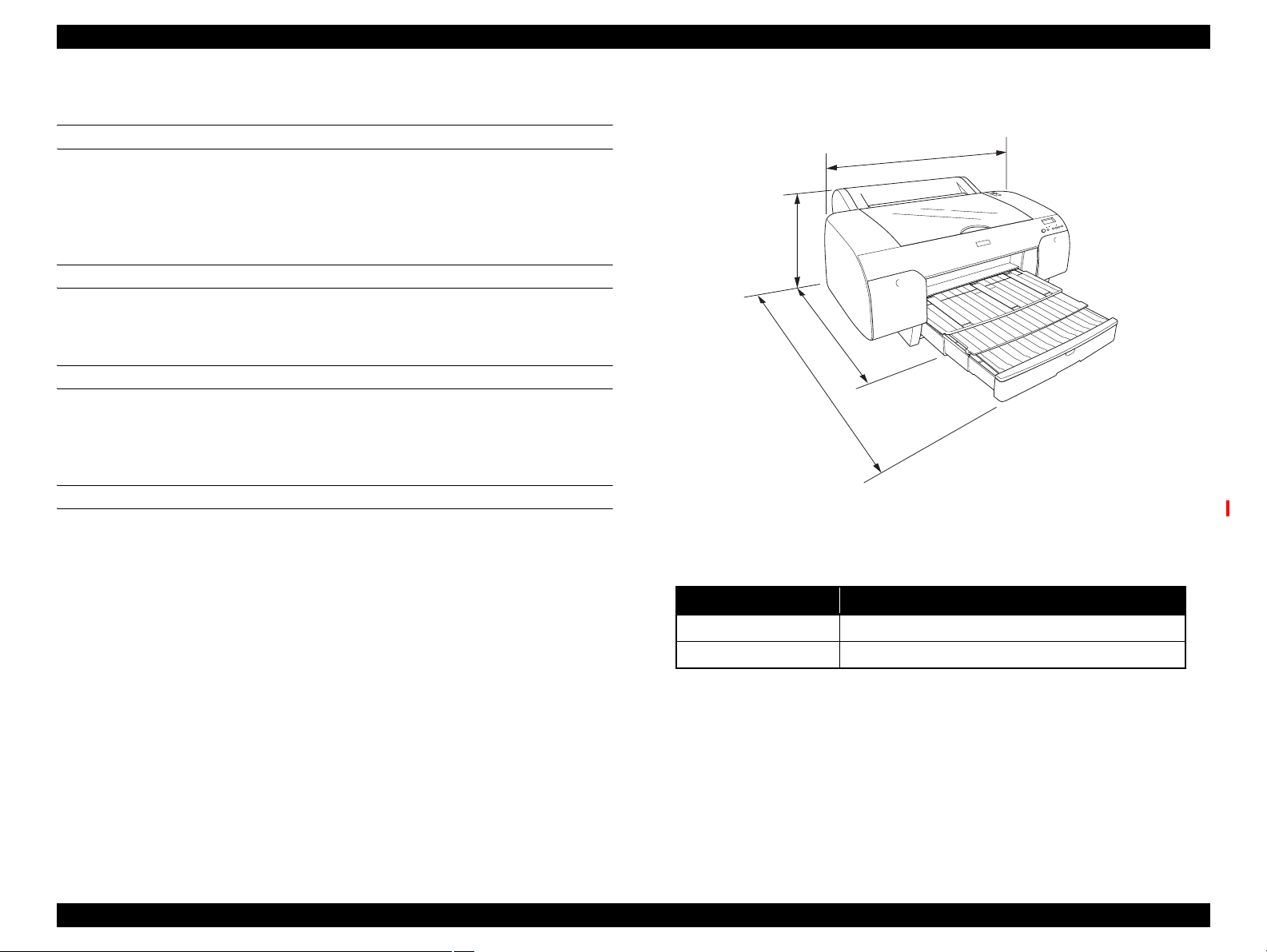

1.2.10.4 Surrounding Space

Provide the printer with an enough surrounding space to ensu re proper

installation of accessories and replacement of consumables and easy wo rk for

daily maintenance.

From the front of the printer: 35cm or more

(When the paper tray is extended.)

From the rear of the printer: 40cm or more

(When cut sheets are set by hand

insertion from the front.)

From the both sides of the printer: 15cm or more

40cm or

more

15cm or

more

35cm or more

15cm or

more

Figure 1-3. Surrounding Space

Product Description Basic Specifications 24

EPSON Stylus Pro 4400/4450/4800/4880/4880C Revision C

1.2.11 Quality Standards for Completed Products

NOISE

Sound pr essure level: Less than 50 dB

(4 direction average, compliant with ISO9296)

*Should be no impact, abnormal or harsh noise.

INITIALIZING TIME AT POWER ON

Within 1 minu te (* exclud in g waiting time such as Timer CL)

TIME FOR INITIAL INK CHARGE

Less than 8 minutes

(* until initial ink charge is finished after the ink lever is lowered)

MTBF (MEAN TIME BETWEEN FAILURES)

20,000 hours with power on (except when electronic parts and fans have

any malfunction)

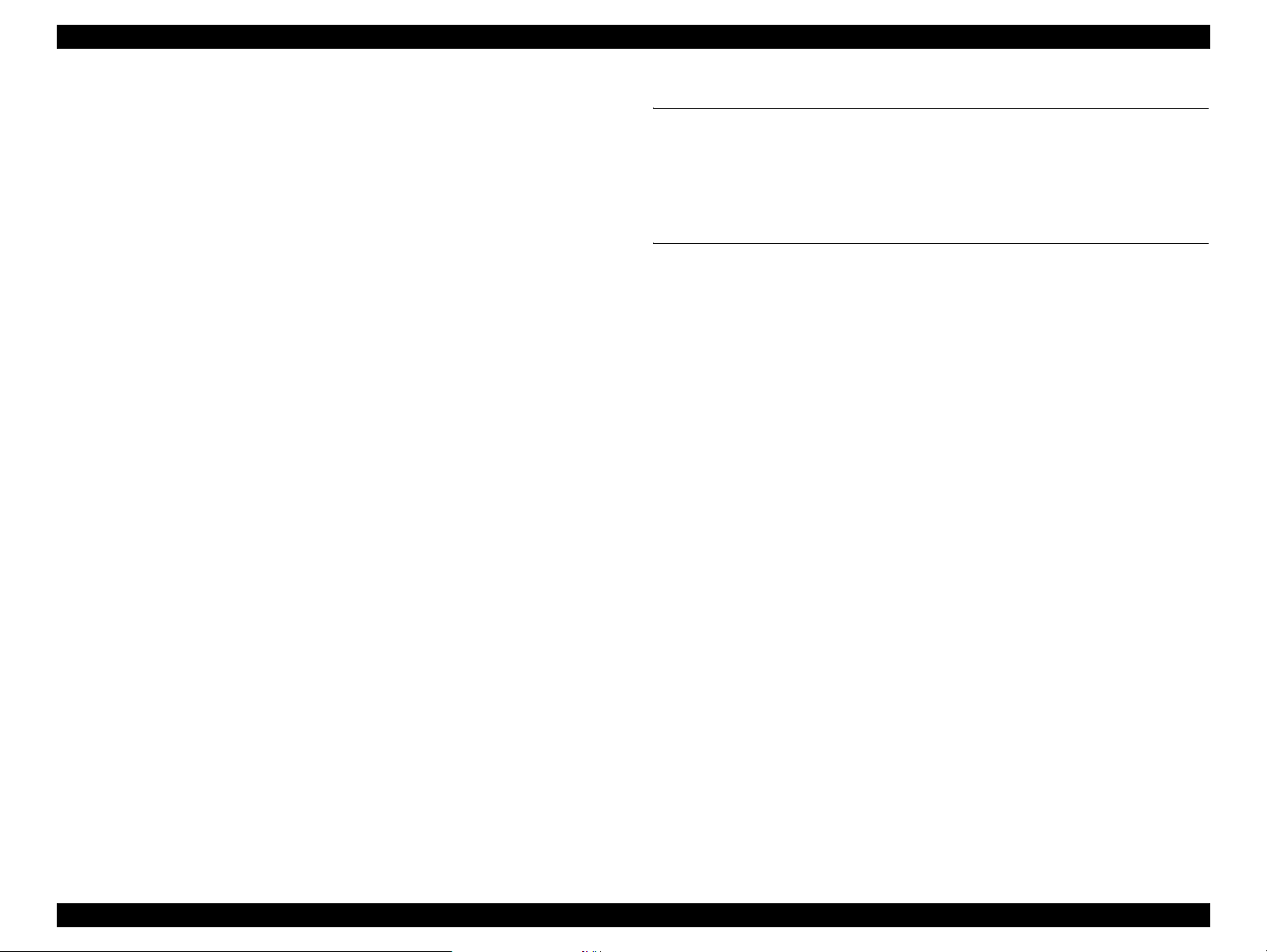

1.2.12 Overall Dimensions

848

354

764

1099

Figure 1-4. Overall Dimensions of Stylus Pro 4400/4450/4800/4880/4880C

Dimensions of Unit

Condition Width (W) x Depth (D) x Height (H) (mm)

When tray is stored 848 x 764 x 354

When tray is extended 848 x 1099 x 354

Weight

8-color model: Approx. 40.2kg (ink cartridge and paper is not included)

4-color model: Approx. 39.0kg (ink cartridge and paper is not included)

Product Description Basic Specifications 25

EPSON Stylus Pro 4400/4450/4800/4880/4880C Revision C

1.2.13 Accessories

Stylus Stylus Pro 4400/4450/4800/4880/4880C accessories and options are

shown below.

Standard Accessories

Manual set

Software CD-ROM

• Printer Driver

• EPSON LFP Remote Panel

AC Cable

Spacer for borderless printing 8”/A2 roll paper

17 (2"/3") inch normal tension spindle (With 2 adapters for exclusive

paper core use)

Ink cartridges 110ml 1 each

8-color model

• Stylus Pro 4800: PK,C,M,Y,LC,LM,LK,LLK

• Stylus Pro 4880/4880C: PK,C,VM,Y,LC,VLM,LK,LLK

4-color model

• Stylus Pro 4400/4450: MK,C,M,Y

Maintenance Tank

Guarantee Card

Card holder

Individual Packaging

Special Options

Maintenance Tank (C12C890191)

Special Consumables

Ink cartridge (8-color)

• Stylus Pro 4800

Table 1-18. Ink Cartridge (Stylus Pro 4800)

Model Number

Ink cartridge

110 ml 220 ml

Photo Black C13T564100 C13T565100

Matte Black C13T543800 C13T544800

Cyan C13T564200 C13T565200

Magenta C13T564300 C13T565300

Yellow C13T564400 C13T565400

Light Cyan C13T564500 C13T565500

Light Magenta C13T564600 C13T565600

Light Black C13T564700 C13T565700

Light Light Black C13T564900 C13T565900

• Stylus Pro 4880/4880C

Table 1-19. Ink Cartridge (Stylus Pro 4880/4880C)

Model Number

Ink cartridge

110 ml 220 ml

Photo Black C13T605100 C13T606100

Matte Black C13T613800 C13T614800

Cyan C13T605200 C13T606200

Vivid Magenta C13T605300 C13T606300

Yellow C13T605400 C13T606400

Light Cyan C13T605500 C13T606500

Vivid Light Magenta C13T605600 C13T606600

Light Black C13T605700 C13T606700

Light Light Black C13T605900 C13T606900

Product Description Basic Specifications 26

EPSON Stylus Pro 4400/4450/4800/4880/4880C Revision C

Ink cartridge (4-color model)

• Stylus Pro 4400

Table 1-20. Ink Cartridge (Stylus Pro 4400)

Model Number

Ink cartridge

110 ml 220 ml

Matte Black C13T543800 C13T544800

Cyan C13T543200 C13T544200

Magenta C13T543300 C13T544300

Yellow C13T543400 C13T544400

• Stylus Pro 4450

Table 1-21. Ink Cartridge (Stylus Pro 4450)

Model Number

Ink cartridge

110 ml 220 ml

Matte Black C13T613800 C13T614800

Cyan C13T613200 C13T614200

Magenta C13T613300 C13T614300

Yellow C13T613400 C13T614400

Options Common to Other Printers

2/3 inch Dual Roll Feed Spindle (C12C811171)

2/3 inch Dual Roll Feed Spindle (High Tension) (C12C811191)

Roll Paper Belt (C12C890121)

EpsonNet 10/100 BASE RX High Speed Int. Print Server

(C12C824052*) (Stylus Pro 4400/4800 only)

Borderless Print Spacer for 420 mm and 8 inch Roll Paper

(C12C811201)

Auto Cutter Spare Blade (C12C815291)

Note *: The asterisk (*) is a substitute for the last digit of the product code, which

varies by location.

Special paper (Refer to "1.2.6 Paper Specification (p.15)" for paper

type and size)

Black ink conversion kit (ICCVK36)

Product Description Basic Specifications 27

EPSON Stylus Pro 4400/4450/4800/4880/4880C Revision C

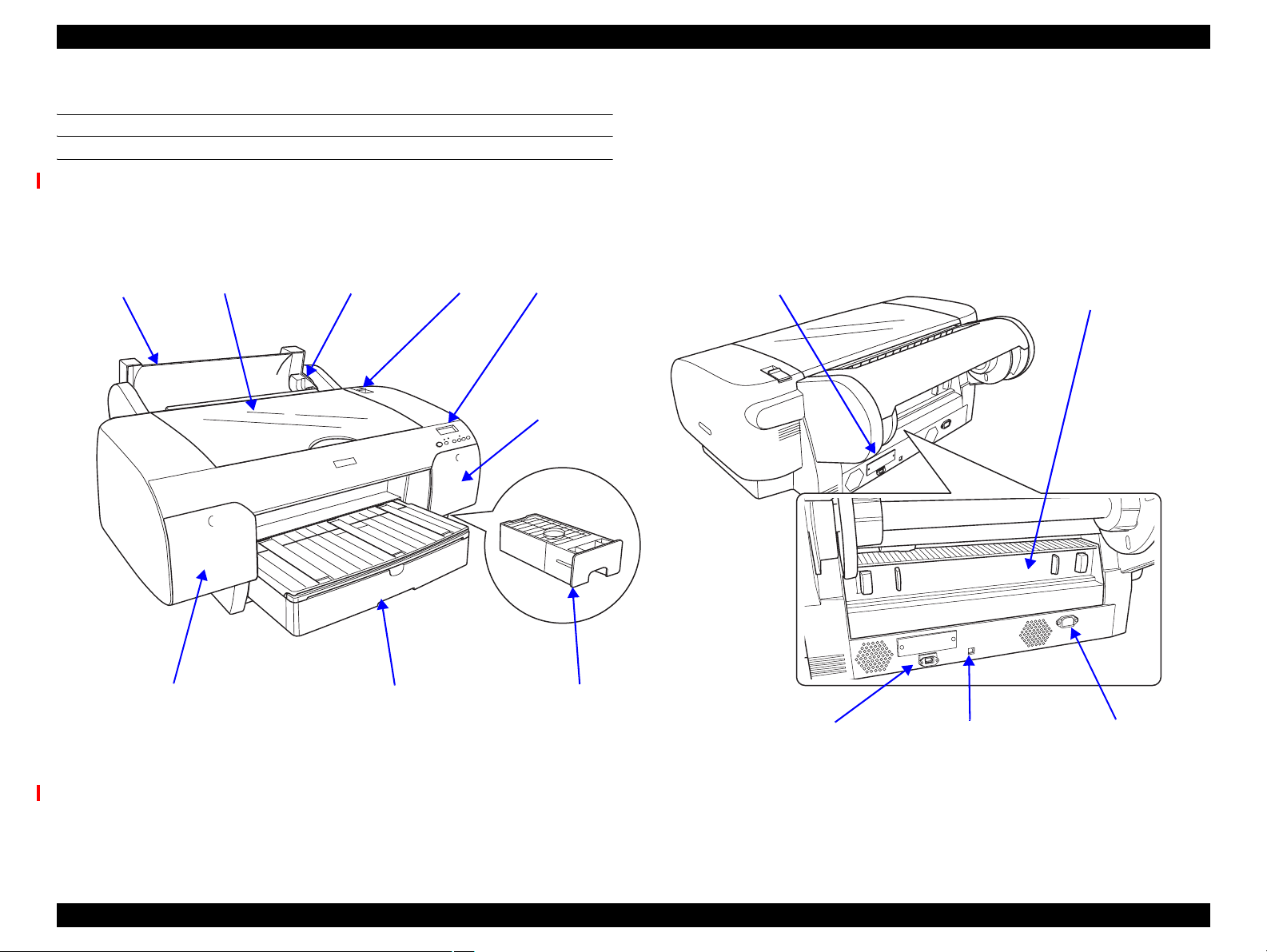

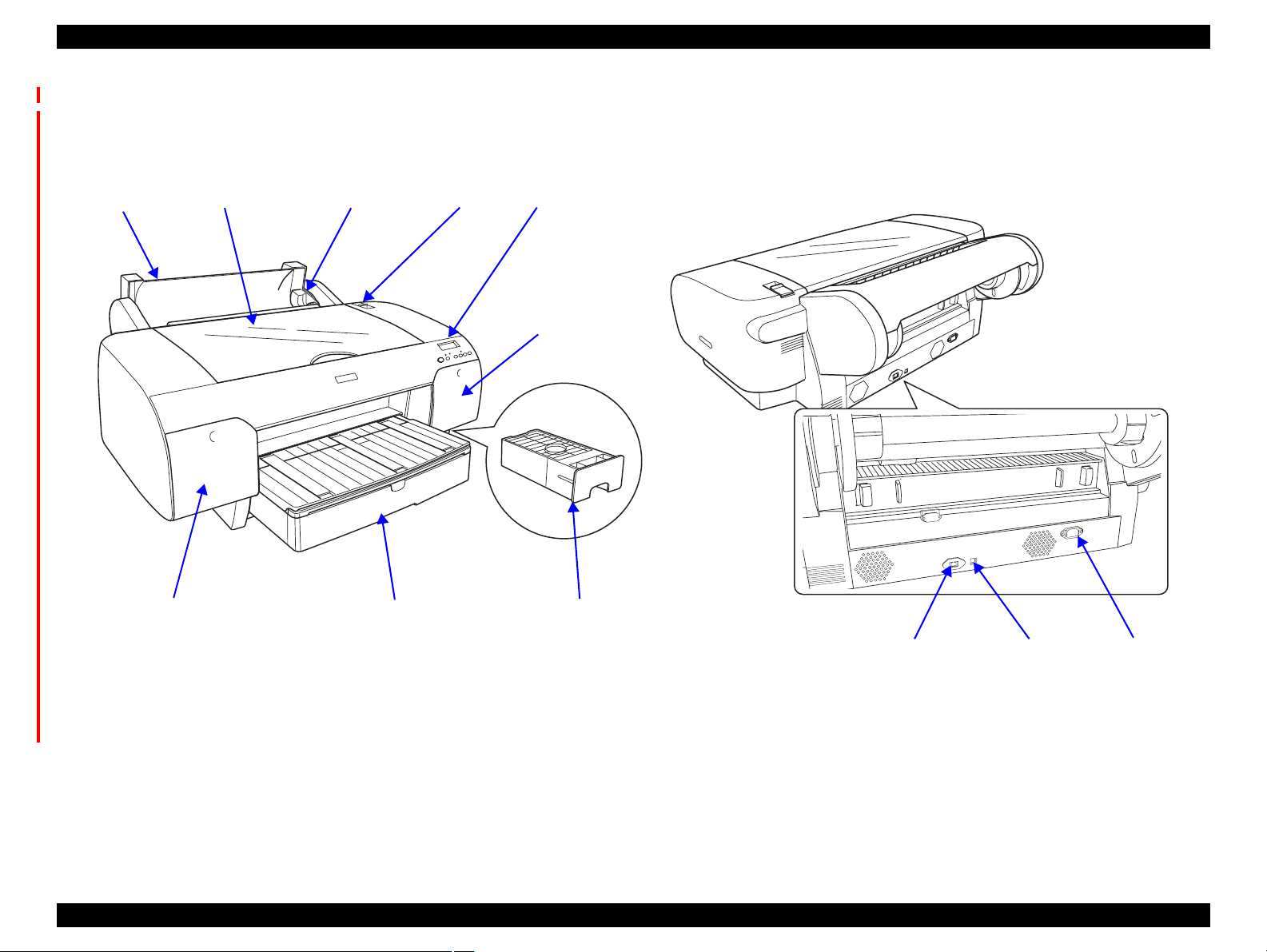

1.3 External View and Parts Names

EXTERNAL VIEW

Stylus Pro 4400/4800

Paper Cover

(Left side)

Printer Cover Spindle Paper Set Lever Control Panel

Ink Cartridge Box

(Right side)

ASF Cassette Maintenance TankInk Cartridge Box

Type-B Interface

IEEE1394 Interface AC InletUSB Interface

Paper Guide Center Unit

(Rear cover)

Figure 1-5. External View and Parts Names (Stylus Pro 4400/4800)

NOTE: 4-color model is equipped with a cover instead of the ink cartridge box (right).

Product Description External View and Parts Names 28

EPSON Stylus Pro 4400/4450/4800/4880/4880C Revision C

Stylus Pro 4450/4880/4880C

Paper Cover

(Left side)

Printer Cover Spindle Paper Set Lever Control Panel

Ink Cartridge Box

(Right side)

ASF Cassette Maintenance TankInk Cartridge Box

Network Interface AC InletUSB Interface

Figure 1-6. External View and Parts Names (Stylus Pro 4450/4880/4880C)

4-color model is equipped with a cover instead of the ink cartridge box (right).

Product Description External View and Parts Names 29

EPSON Stylus Pro 4400/4450/4800/4880/4880C Revision C

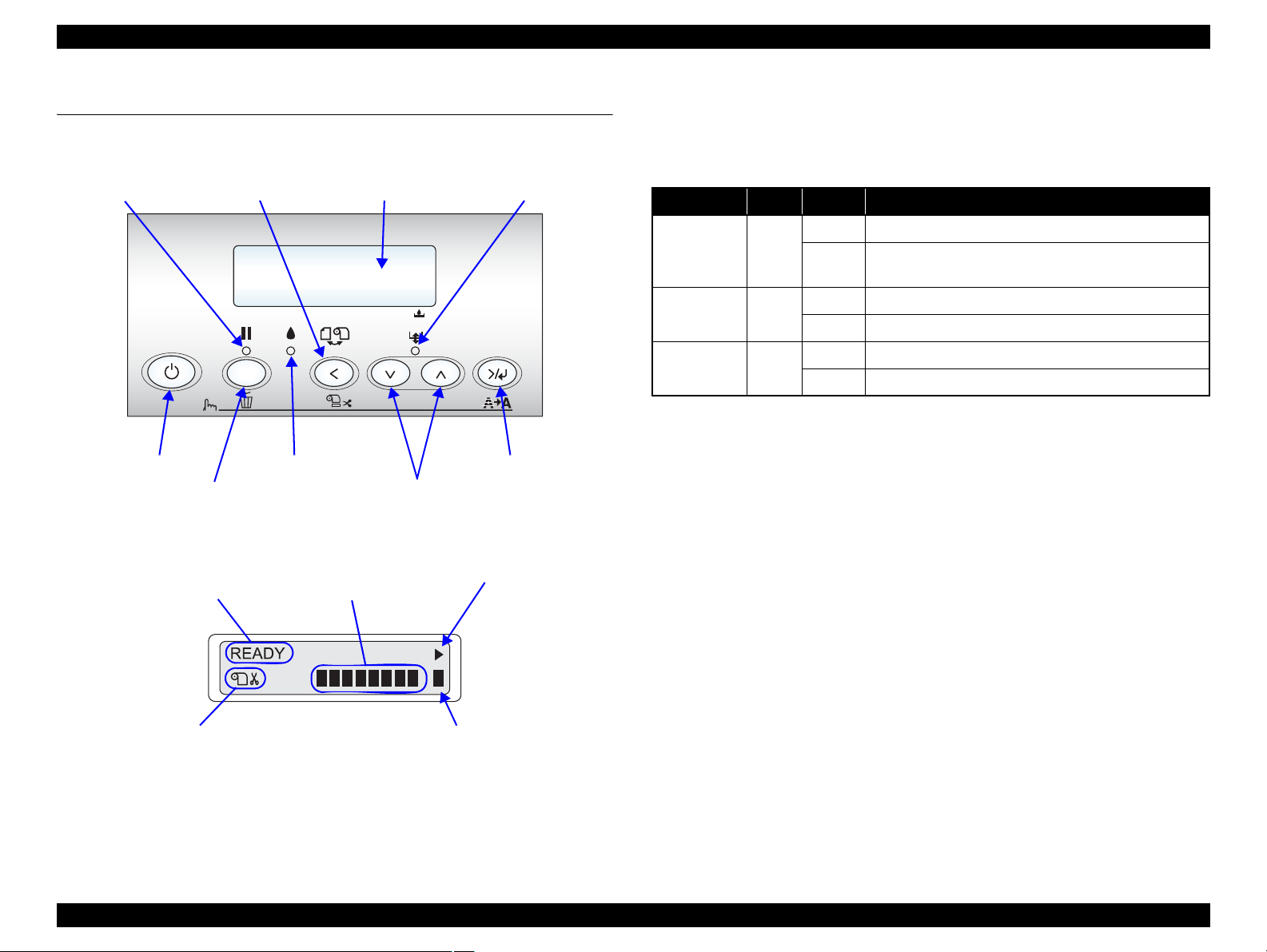

1.4 Operating Panel

1.4.1 Buttons and Functions

Pause LED

Panel Display

(Refer to "1.4.2 Panel

Display (p33)".)

Paper Source / Paper Cut

3sec.

Power

Pause

1 2 3 4 5 6 7 8

Ink check LED

Paper Feed / Eject Paper

Figure 1-7. Panel Design

Remaining Ink Cartridge

(Refer to "1.4.2.4 Ink Remaining

Indicator Display (p38)".)

LCD Paper check LED

Menu

Menu / Cleaning

Shifts to Setting

Item Selection Menu

1.4.1.1 LED

Panel LED types are the following 3 types. The LEDs indicate printer status as

follows.

Table 1-22. LED

LED Color Display Printer Status

On Indicates that the paper is not printable.

Paper check Red

Blink

On Indicates printer pauses operation.

Pause Green

Blink Indicates printer is in operation.

On Indicates error regarding ink occurred.

Ink check Red

Blink Indicates warning status regarding ink.

Indicates error that occurred when feeding / ejecting

paper.

Cut availability for Paper

Type/Roll Paper selection

Available rate of Maintenance Tank

(Refer to "1.4.2.4 Ink Remaining Indicator

Display (p38)".)

Figure 1-8. LCD Panel (8-color model)

Product Description Operating Panel 30

Loading...

Loading...