Page 1

Service Manual

Fuller Mid-Range Transmissions

TRSM0130

October 2007

FS-4005A

FS-4005B

FS-4005C

FS-4205A

FS-4205B

FS-4205C

FS-5005A

FS-5005B

FS-5005C

Page 2

For parts or service call us

Pro Gear & Transmission, Inc.

1 (877) 776-4600

(407) 872-1901

parts@eprogear.com

906 W. Gore St.

Orlando, FL 32805

Page 3

A WARNING

Before starting a vehicle always be

in

seated

transmission

the drivers seat, place the

in

neutral, set the park-

ing brakes and disengage the

Before working

transmission

ing brakes and block the wheels.

Before towing the vehicle

transmission

rear wheels off the ground or discon-

on

in

neutral, set the park-

in

neutral, and lift the

a vehicle place the

place the

clutch.

nect the

the transmission during towing.

driveline to avoid damage to

Page 4

TABLE

OF

CONTENTS

FOREWORD

MODEL DESIGNATIONS AND SPECIFICATIONS

LUBRICATION

OPERATION

POWER FLOW

TORQUE RECOMMENDATIONS

PREVENTIVE MAINTENANCE

PRECAUTIONS

DISASSEMBLY

INSPECTION

REASSEMBLY

DISASSEMBLY AND REASSEMBLY - SHIFTING CONTROLS

GEARSHIFT LEVER HOUSING ASSEMBLY

SHIFT BAR HOUSING ASSEMBLY

................................................................

..................................

...............................................................

................................................................

...............................................................

................................................

.................................................

............................................................

..............................................................

.............................................................

.......................................

..............................................

2

3

4

6

7

8

10

12

12

14

15

18

REMOVAL - YOKE AND CLUTCH HOUSING

DISASSEMBLY -TRANSMISSION

REASSEMBLY - TRANSMISSION

INSTALLATION-

INSTALLATION - SHIFTING CONTROLS

OPTIONS

..................................................................

CLUTCH HOUSING

..............................................

..............................................

...........................................

........................................

.....................................

27

29

43

57

58

59

Page 5

FOREWORD

This manual is designed to provide detailed information

necessary to service and repair the

Transmission listed

As outlined

divided into 3 main sections:

a.

Technical information and reference

b.

Removal, disassembly, reassembly, and

installation

c.

Options

The format of the manual is designed to be followed

its entirety if complete disassembly and reassembly of

the transmission is necessary. But if only one component of the transmission needs to be repaired, see the

Table of Contents for the page numbers showing that

component. For example, if you need to work

Shifting Controls, you will find instructions for removal,

on

the cover.

in

the Table of Contents, the manual

Eaton@

Fuller@

in

on

the

is

disassembly, and reassembly

for installation are

Illustrated Parts Lists, Drivers Instructions, and other

forms of product service information for these and other

Eaton Fuller Transmissions are available upon request. A Product Literature Order Form, Service

Bulletins (detailing information

ments), repair procedures, and other service-related

subjects can be obtained by writing to the following

address:

EATON CORPORATION

TRANSMISSION DIVISION

Technical Service Department

P.O. Box 4013

Kalamazoo, Michigan 49003

(616) 342-3344

on

on

page 15. Instructions

page 58. Service Manuals,

on

product improve-

Every effort has been made to ensure the accuracy of

sion Division makes no expressed or implied warranty or representation based on the enclosed information.

Any errors or omissions may be reported to Training and Publications, Eaton Transmission Division, P.O. Box 4013,

Kalamazoo, Ml 49003.

all information

2

in

this brochure. However, Eaton Transmis-

Page 6

MODEL DESIGNATIONS

AND

SPECIFICATIONS

Nomenclature:

Letter Designations

Fuller"'

Synchronized----------""""'

F

I

S-

5005A

IMPORTANT: All Eaton Fuller Transmissions are

identified by the model and serial number. This

information

cation tag and affixed to the case.

DO

NOT REMOVE OR DESTROY THE TRANSMIS-

SION IDENTIFICATION TAG.

I

is

stamped

Number

Designations

Ratio Group

Forward Speeds

Design

Level

x 100 = Nominal Torque

Capacity

on

the transmission identifi-

Specifications:

No:c

Reial

ve

Soeed

PTO

Ne.

Model

FS-5005A

FS-50058

FS-5005C

1.

Lengths measured from clutch housing face to speedo gear rear.

2.

Weights include shift bar housing, clutch housing, less tower assembly, and clutch release parts. For more

Speecs 1 st

7.52

5

5 6.82 2.15

6.82

5

2

nc

2.54

1.99

GearRat'os

3

·a

4th

2.54 1.52

2.15 1.28

1.99 1.17

5

'.1

1.00

1.00

1.00

Rf:'ver:;e

6.27

5.30

5.30

3ear:::

lnpc:

R.P.~A.

Rig

rt

Li:/t

.460 .435

.543 .515

.543 .515

information on available clutch housings, see the transmission's Illustrated Parts List or the Super Parts Book.

All weights are approximate.

3. Oil capacities are approximate, depending

with proper grade and type of

lubricant, to level of filler opening. See LUBRICATION.

on

inclination of engine and transmission. Always fill transmission,

·

_e-g111

ir.

'"1:'1)

21.9

(556.0)

21.9

(556.0)

21.9

(556.0)

~ote

2

l//eo':

Los.

:Kg)

280

(127.0)

280

(127.0}

280

(127.0)

Note

Q,I

Caoaci:y

Pi-ts

1Uersi

10.5

(5.0}

10.5

(5.0)

10.5

(5.0}

S

3

Page 7

LUBRICATION

-

Proper

Lubrication .

..

the Key to long

transmission life

Proper lubrication procedures are the key to a good allaround maintenance program.

job, or if the

procedures

oil level

in

is

ignored, all the maintenance

the world are not going to keep the

transmission running or assure

Eaton Fuller Transmissions are designed so that the

internal parts operate

in

motion of the gears and shafts.

all parts are amply lubricated if these procedures

Thus,

are

closely followed:

1.

Maintain oil level. Inspect regularly.

2. Change oil regularly.

3. Use the correct grade and type of oil.

4.

Buy from a reputable dealer.

Lubrication Change and Inspection

Eaton® Roadranger®

HIGHWAY USE

Firs'

3,000

tc

5,000

{4827

Every t 0,000

(;6090

Every

(402336

Firs~

30

Every

Every

500

Every t .:O·J

First

3.000

I

4827

to

Every

10,000

(t6090

Every

50.000

(80450)

First

3·J

Every

40

Every

500

Every

1,00C

miles

to

8045

Km!

miles

Ker)

250,000

m•les

Krr)

OFF-HIGHWAY USE

hour_;

40

hours

hours

oours

Heavy Duty Engine Lubricant or

Mineral Gear Lubricant

HIGHWAY USE

to

5,COO

riiles

8045

Krr

I

-;iles

~rr•

11

les

OFF-HIGHWAY USE

oours

1purs

rours

hoers

If

the oil is not doing its

long transmission life.

an oil circulating bath by the

CDSO

Transmission Fluid

Factory

1rn:ia

o·ai:-:.

Check

flukl

Check

::::r

iea;.;s.

Craoge

t•ans'.'1•sso1

Factory

initial

d·ain.

lnspec:

fluic

eve!.

Creek

fa•

leaks.

Criange

tra."sriission

71uic

dirt

:::onditions

trans11·ss.0°

off-h

ahway

Fac:oryiill

lubrica'lt

C1eck

tra:isr:i1ss1on

transrr:issio-;

en

new

Chee!\

lubr:cant

di~

condit:ons

off-h:ghway

where

exist.

cse."

imtial.

:or

·eal{s.

lubr•car:.

:.inits.

br

1eaks.

where

exist.

lubricant

t.se.]

severe

lr.soect

lubricaPt

c~.a:ige

transmissior.

sevee

Change

Cra1ge

(Norrra:

l'isoec:

Cha1ge

Cnange

lubricant

1

eve~.

'ransmission

(Norma:

fill

level.

llu·d.

f I

lluid

level.

Recommended Lubricants

Fahrenheit

Type

Eaton@Roadranger(<,

CDSO

Transmission

Fluid

Heavy

Duly

E.0.gine

MIL-L-21048, C or

APl-SF

(Pr9ViOJS

acceotab

M

neral

and

oxi:::a~ion

ft.Pl-GL-'.

Oi

Dor

0'

AP:-CD

API

des1gna~io1s

e1

Gear

OI'

w

'.h

rust

i'":hibitor

Grade

(SAE)

50

50

40

30

90

sew

Ambient

Temperature

All

Above

10' F (-t2'C)

Above

10"F

Below

10'F

Abo'e 1

JF i-'.2'·C)

Below

'O'F i-"2'C)

(Celsius)

(·12"C;

:-12''C)

The use of mild EP gear oil or multi-purpose gear oil

is not recommended, but

be sure to adhere to the

Do

not use mild EP gear oil or multi-purpose gear oil

ifthesegearoilsare

used,

following limitations.

when operating temperatures are above 230° F (110"

C).

Many of these gear oils, particularly 85W140,

break down above 230° F and coat seals, bearings, and

gears with deposits that can cause premature

If

these deposits are observed (especially a coating on

seal areas causing oil leakage), change

Roadranger

gine

oil, or mineral gear oil to assure maximum compo-

nent

life and to maintain your warranty with Eaton.

CD50 transmission fluid, heavy duty en-

failures.

to

Eaton

(Also see "Operating Temperatures".)

Additives and friction modifiers are not recommended

in

for use

Eaton Fuller Transmissions.

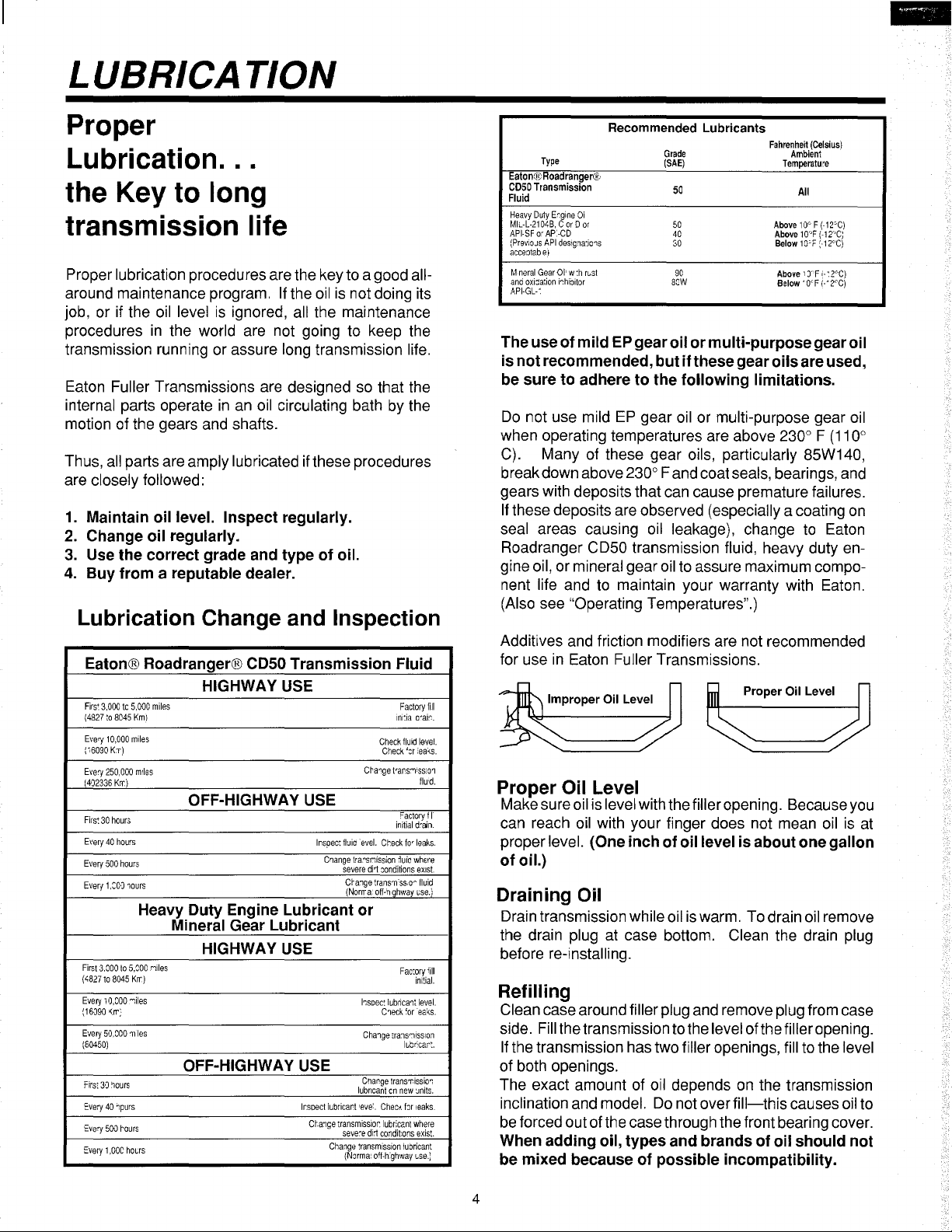

Proper Oil Level

Proper Oil Level

Make sure oil is level with the filler opening. Because you

can reach

proper

of

oil.)

oil with your finger does not mean oil is at

level. (One inch of oil level is about one gallon

Draining Oil

Drain transmission while oil is warm. To drain oil remove

the drain

plug at case bottom. Clean the drain plug

before re-installing.

Refilling

Clean case around filler plug and remove plug from case

side.

Fill the transmission to the level of the filler opening.

If

the transmission has two filler openings, fill to the level

of both openings.

The exact amount of

inclination and model. Do not over

be forced out of the case through the front bearing cover.

When adding

oil, types and brands of oil should not

be mixed because of

oil depends on the transmission

fill-this

causes oil to

possible incompatibility.

4

Page 8

LUBRICATION

Operating Temperatures

-With

Eaton Roadranger

CDSO

Transmission Fluid

Heavy Duty Engine Oil

and Mineral Oil

The transmission should not be operated consistently

at temperatures above

intermittent operating temperatures to

do not harm the transmission. Operating temperatures

above

and shorten its effective

ating temperature

can require more frequent

cooling.

The following conditions

operating temperatures of over

consistently at

tures,

exhaust system too close to transmission,

horsepower, overdrive operation.

External oil coolers are available to reduce operating

temperatures when the above conditions are encountered.

Transmission

250° F increase the lubricant's oxidation rate

slow speeds,

(3)

restricted air flow around transmission,

Oil

250° F (120° C}. However,

300° F (149°

life. When the average oper-

is

above 250°

in

any combination can cause

Coolers

F,

the transmission

oil changes or external

250°

F:

(2)

high ambient tempera-

are:

(1

)operating

(5)

C}

(4)

high

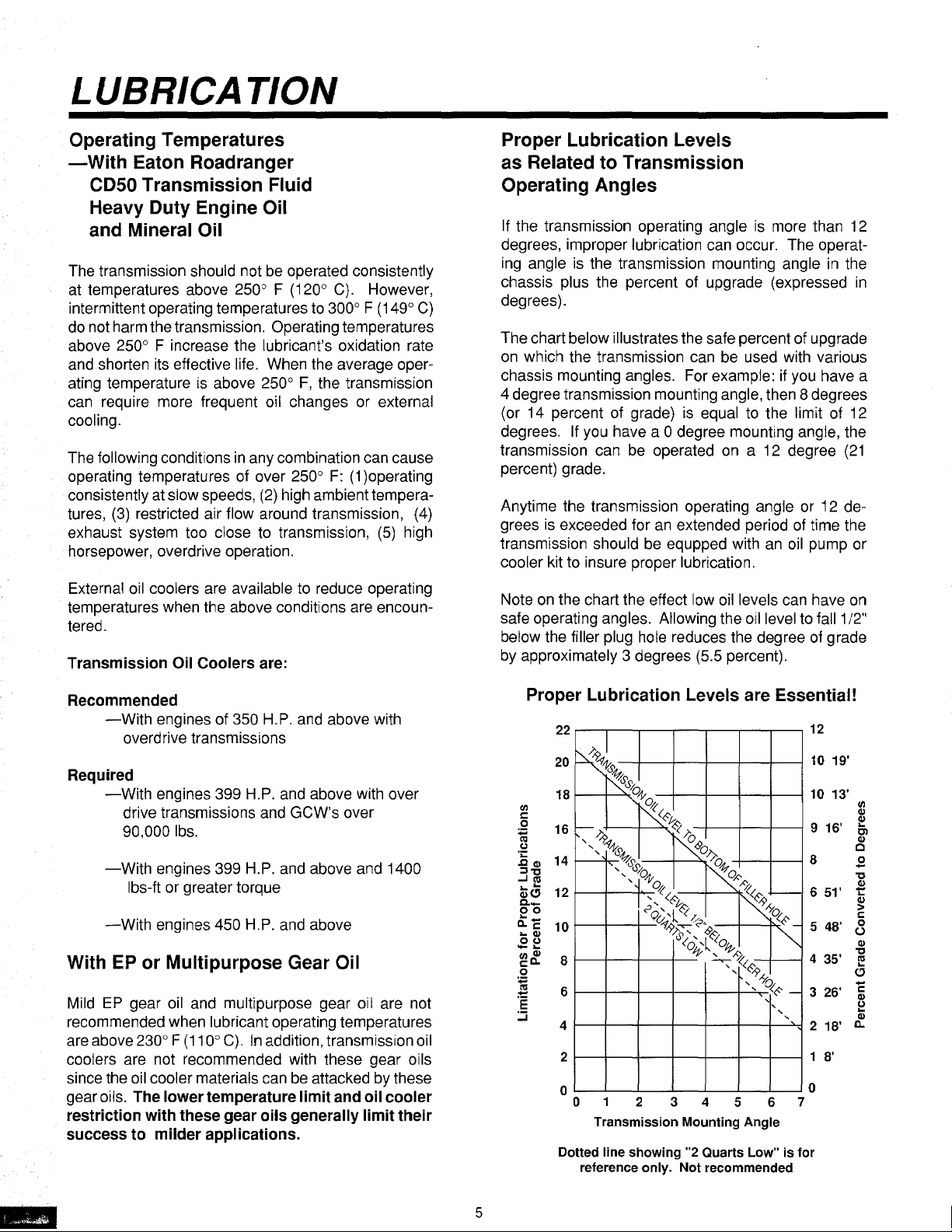

Proper Lubrication Levels

as Related

Operating

If the transmission operating angle

degrees, improper

ing angle

chassis

degrees).

The chart below

on

which the transmission can be used with various

chassis mounting

4 degree transmission mounting angle, then 8 degrees

(or 14 percent of grade)

degrees.

transmission can be operated on a 12 degree

percent} grade.

Anytime the transmission operating angle or 12 degrees

is

transmission should

cooler kit to insure proper lubrication.

Note

on

safe operating angles.

below the filler plug hole reduces the degree of grade

by approximately 3 degrees (5.5 percent}.

to

Transmission

Angles

is

more than 12

lubrication can occur. The operat-

is

the transmission mounting angle

plus the percent of upgrade (expressed

illustrates the safe percent of upgrade

angles. For example: if you have a

is

equal to the limit of 12

If you have a 0 degree mounting angle, the

exceeded for

the chart the effect

an

extended period of time the

be

equpped with

low

Allowing the oil level to fall 1 /2"

an

oil

levels can have on

oil

pump or

in

the

in

(21

Recommended

-With

Required

-With

-With

-With

With

Mild

EP

recommended when lubricant operating temperatures

are above

coolers are not recommended with these gear oils

since the oil cooler materials can

gear

oils. The

restriction

success

engines of 350 H.P. and above with

overdrive transmissions

engines 399 H.P. and above with over

drive transmissions and GCW's over

90,000 lbs.

engines 399 H.P. and above and 1400

lbs-ft

or greater torque

engines 450 H.P. and above

EP

or

Multipurpose Gear Oil

gear oil and multipurpose gear oil are not

230° F (110°

lower

with

to

milder

C).

temperature

these

gear

applications.

In

addition, transmission oil

be

attacked by these

limit

and

oil

cooler

oils

generally

limit

their

Proper Lubrication Levels are Essential!

2

t---+--l--+--+--l---1---1

0 0

0 2 3 4 5

Transmission Mounting Angle

Dotted line showing "2 Quarts Low"

reference

only. Not recommended

67

is

1 8'

for

5

Page 9

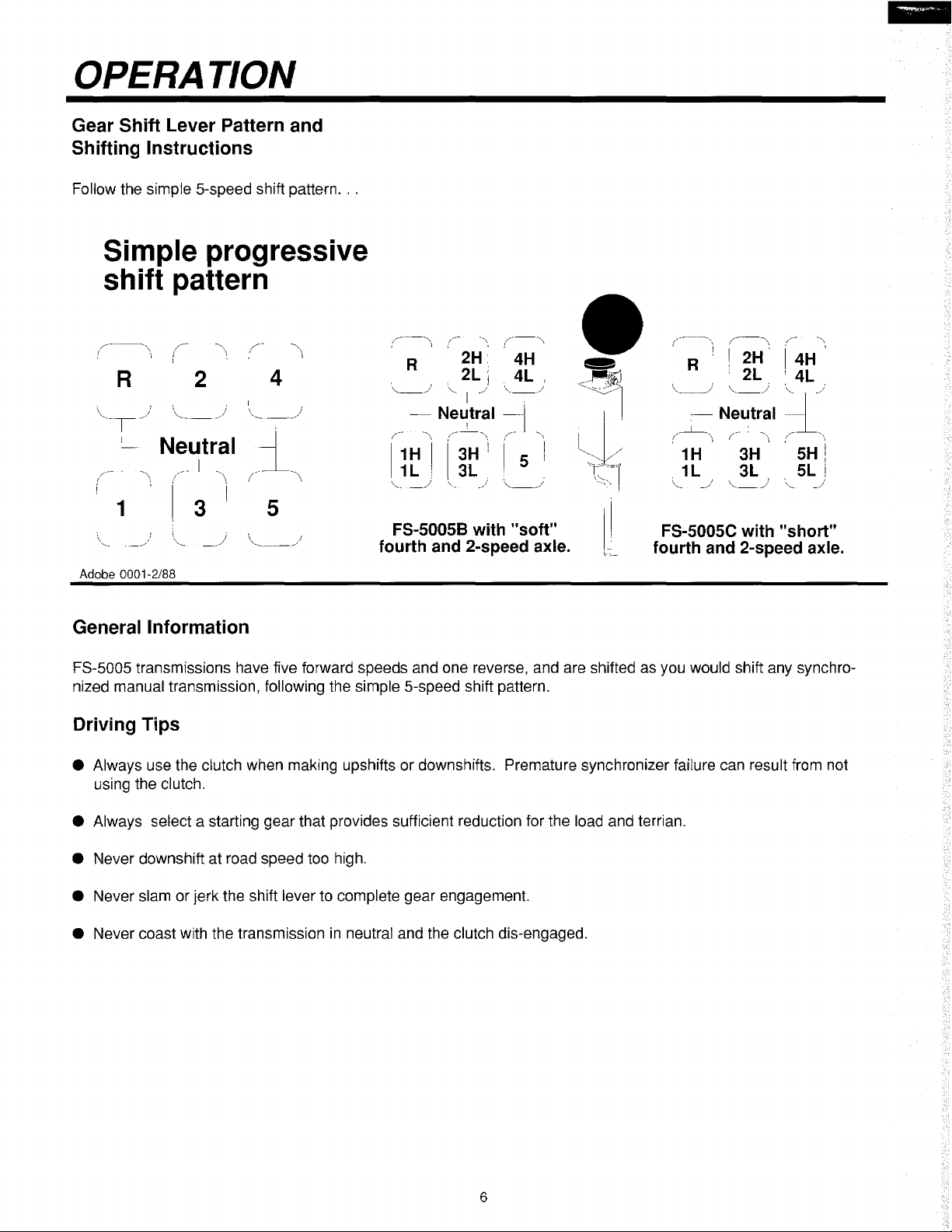

OPERATION

Gear Shift Lever Pattern and

Shifting

Instructions

Follow the simple 5-speed shift pattern.

Simple progressive

shift pattern

-,

(--

R 2

I

/

"-·-1

I

-,

-,\

\,

__

..

__

)

Neutral

I

.,

I

\

,

(

4

____

_/

]

___

i

j

'

\

I

1

··--"

Adobe 0001-2/88

3

J

/

General Information

5

j

\

..

____

J

./

..

R

<__;

-

1

1 H

-

1L , 3L ·

1

\ ____ ) "·-

FS-SOOSB

2H• 4H

2L

i 4L ,

\...

I

./

Ne~tral

.,,

1(-

3H

-,i

: < _

with "soft"

fourth and 2-speed axle.

--j

,--

s

(--\

I

R

.

,;

-,I

_;

\, _ _ )

/-~\

, 1 H , 3H , ,

\,_

I 2L : 4L

\.._.)

~-

Neutral

(--

1L 3L

__/

\

___

I

2H. I 4H'

""-

-1

: -..\

(,,.-

SH

SL

_

.)

,__

-

.\

_)

·-,,

j

!

FS-5005C with "short"

fourth and 2-speed axle.

FS-5005 transmissions have five forward speeds and one reverse, and are shifted as you would shift any synchronized manual transmission, following the simple 5-speed shift pattern.

Driving Tips

• Always use the clutch when making upshifts or downshifts. Premature synchronizer failure can result from not

using the clutch.

• Always select a starting gear that provides sufficient reduction for the load and terrian.

• Never downshift at road speed too high.

• Never slam or jerk the shift lever to complete gear engagement.

• Never coast with the transmission

in

neutral and the clutch dis-engaged.

6

Page 10

POWER FLOW

The transmission must efficiently transfer the engine's power, in terms of torque, to the vehicle's rear wheels. Knowledge of whattakes

1.

Power (torque) from the engine is transferred to the input shaft and drive gear.

2.

Torque is transferred to the countershaft drive gear.

3.

Torque is delivered along the countershaft to all countershaft gears.

4.

Torque

5.

Engaged mainshaft gear internal clutching teeth transfers torque to mainshaft through synchronizer assembly.

6. Mainshaft transfers torque directly to driveshaft through rear yoke.

1.

place

in

the transmission during torque transfer is essential when troubleshooting and making repairs.

is

transferred to "engaged" mains haft gear. The cross section illustrates 1st speed gear position.

5.

3.

4.

7

Page 11

TORQUE RECOMMENDATIONS

Correct torque application is important to assure long transmission life. Over or under tightening of fasteners can

in

a loose installation and,

in

many instances, can eventually cause damage to the transmission. Use a torque wrench

obtain recommended torque ratings. Do not torque capscrews dry.

SHIFT RAIL RETAINER

9

CAPSCREWS

20-25 LBS.-FT.

3/8-16 THREAD

17

SHIFT

CAPSCREWS

20-25 LBS.-FT.

3/8-16 THREAD

BAR

HOUSING

4 FRONT BEARING

COVER CAPSCREWS

15-20 LBS.-FT.

5/16-18 THREAD

SHIFT LEVER HOUSING

4

CAPSCREWS

20-25 LBS.-FT.

3/8-16 THREAD

resul1

to

2 HAND

COVER CAPSCREWS

5 LBS.-FT.

1/4-12 THREAD

HOLE

@

4 CLUTCH HOUSING

CAPSCREWS

145-155 LBS.-FT.

5/8-16 THREAD

OUTPUT SHAFT NUT

300-350

11/4-18 THREAD

NYLON LOCKING INSERT

(OILED

INSTALLATION)

LBS.-FT.

AT

VEHICLE

WITH

Adobe 0002-2/88

8

Page 12

TORQUE

4 MAINSHAFT REAR BEARING

COVER NUTS

LBS.-FT.

60-70

1 /2-32 THREAD

USE LOCKWASHERS

RECOMMENDATIONS

14

CAPSCREWS

10-15 LBS.-FT.

3/8-16 THREADS

Adobe

0003-2/88

PTO

COVER

4 COUTNERSHAFT REAR BEARING

COVER

20-30 LBS.-FT.

3/8-16 THREAD

USE PLAIN

CAPSCREWS

FLAT

WASHERS

OIL FILL PLUG

20-25 LBS.-FT.

3/4

PIPE THREAD

2

COUNTERSHAFT REAR

NOTE:

BEARING

5-10 LBS.-FT.

1/4 THREAD

OIL DRAIN PLUG

20-25 LBS.-FT.

PIPE THREAD

3/4

APPLY

ALL

LOCTITE #262 TO THREADS OF

CAPSCREWS BEFORE INSTALLING.

CAP

SET SCREWS

9

Page 13

PREVENTIVE MAINTENANCE

10

Page 14

PREVENTIVE MAINTENANCE

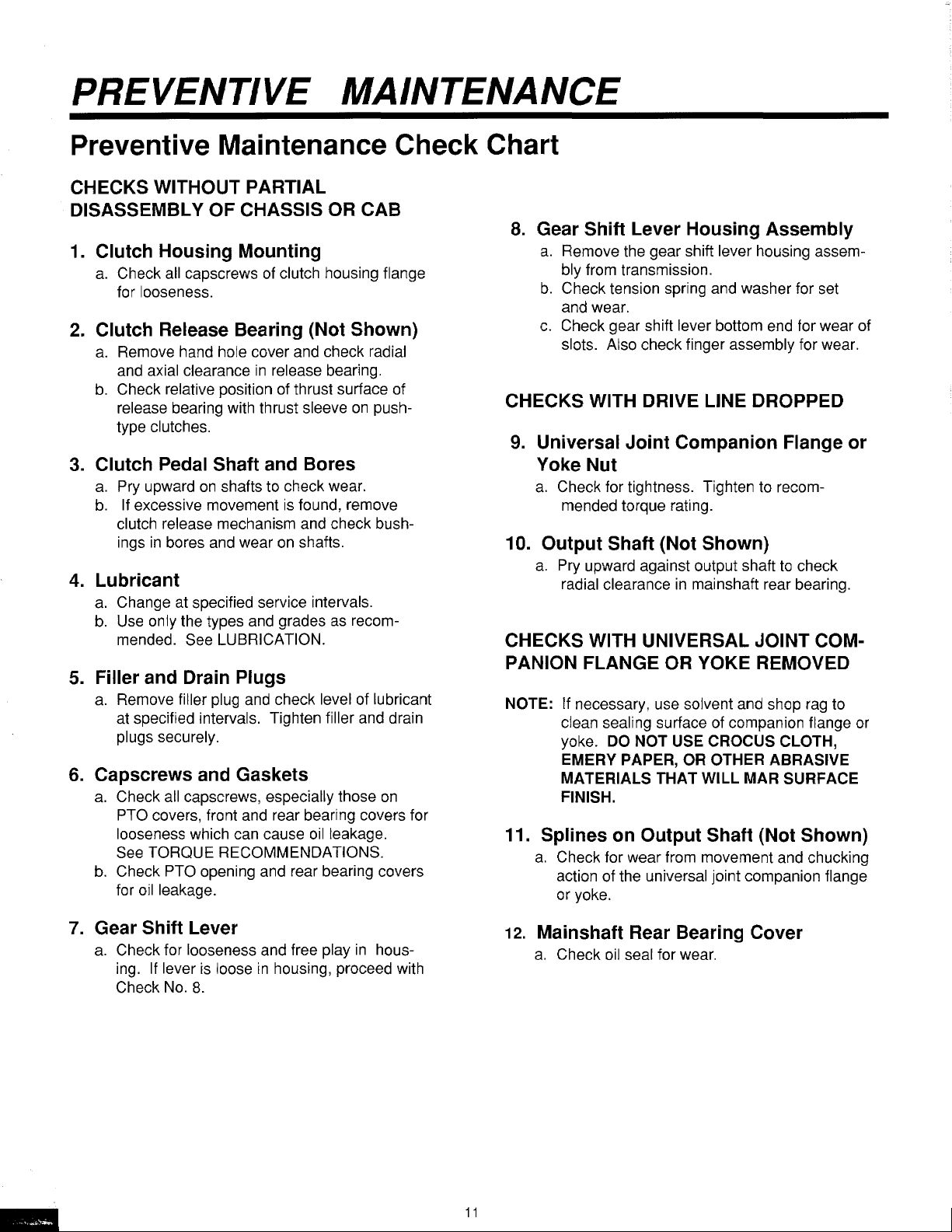

Preventive Maintenance Check Chart

CHECKS WITHOUT PARTIAL

DISASSEMBLY

1.

Clutch Housing Mounting

a.

Check all capscrews of clutch housing flange

for looseness.

2.

Clutch Release Bearing (Not Shown)

a.

Remove hand hole cover and check radial

and axial clearance

b.

Check relative position of thrust surface of

release bearing with thrust sleeve

type clutches.

3.

Clutch Pedal Shaft and Bores

a.

Pry upward

b.

If excessive movement

clutch release mechanism and check bush-

ings

in

4.

Lubricant

a.

Change at specified service intervals.

b.

Use only the types and grades as recommended. See LUBRICATION.

5.

Filler and Drain Plugs

a.

Remove filler plug and check level of lubricant

at specified intervals. Tighten filler and drain

plugs securely.

6.

Capscrews and Gaskets

a.

Check all capscrews, especially those

PTO covers, front and rear bearing covers for

looseness which can cause

See TORQUE RECOMMENDATIONS.

b.

Check PTO opening and rear bearing covers

for oil leakage.

OF CHASSIS OR CAB

in

release bearing.

on

shafts to check wear.

is

found, remove

bores and wear

on

shafts.

oil

leakage.

on

push-

on

8.

Gear Shift Lever Housing Assembly

a.

Remove the gear shift lever housing assembly from transmission.

b.

Check tension spring and washer for set

and wear.

c.

Check gear shift lever bottom end for wear of

slots. Also check finger assembly for wear.

CHECKS WITH DRIVE LINE DROPPED

9.

Universal Joint Companion Flange or

Yoke Nut

a.

Check for tightness. Tighten to recom-

mended torque rating.

10. Output Shaft (Not Shown)

a.

Pry upward against output shaft

radial clearance

CHECKS WITH UNIVERSAL JOINT COMPANION

NOTE: If necessary, use solvent and shop rag to

FLANGE

clean sealing surface of companion flange or

yoke. DO NOT USE CROCUS CLOTH,

EMERY PAPER,

MATERIALS

FINISH.

11. Splines on Output Shaft (Not Shown)

a.

Check for wear from movement and chucking

action of the universal joint companion flange

or yoke.

to

check

in

mainshaft rear bearing.

OR

YOKE REMOVED

OR OTHER ABRASIVE

THAT WILL MAR SURFACE

7.

Gear Shift Lever

a.

Check for looseness and free play

ing.

If

lever is loose

Check No.

8.

in

hous-

in

housing, proceed with

12. Mainshaft Rear Bearing Cover

a.

Check

11

oil

seal for wear.

Page 15

PRECAUTIONS

Disassembly

It

is

assumed

necessary

lever housing assembly

however, this assembly must be detached from shift bar housing before transmission can

in

the detailed assembly instructions that the lubricant has been drained from the transmission, the

linkage disconnected and the transmission has been removed from vehicle chassis. Removal of the gear shift

is

included in the detailed instructions (Disassembly and Reassembly-Shifting Controls);

be

removed.

-

FOLLOW CLOSELY EACH PROCEDURE

ILLUSTRATIONS, AND PHOTOGRAPHS PROVIDED.

1.

BEARINGS-Carefully

reuseable bearings as removed and protectively

wrapped

planned to be reused with pullers designed for

this purpose.

2.

ASSEMBLIES-When

assemblies, such as the mainshaft, countershafts, and shift bar housing,

clean bench

procedure simplifies reassembly and reduces the

possibility of

3.

SNAP

designed for this purpose. Snap rings removed

in

this manner can

sprung or

until ready for use. Remove bearings

in

the same order as removed. This

losing parts.

RINGS-Remove

loose.

wash and relubricate

disassembling the various

lay all parts

snap rings with pliers

be

reused,

if

they are not

IN

THE DETAILED INSTRUCTIONS, MAKING USE OF THE TEXT,

all

on

a

Inspection

Before

determine reuse or replacement. When

to assure continued performance and extended

Since the cost of a new part

questionable part which

reuse or

application, etc.

Recommended inspection procedures are provided

reassembling the transmission, check each part carefully for abnormal or excessive wear and damage to

replacement

replacement

is

generally a small fraction of the total cost of downtime and labor, avoid reusing a

could lead to additional repairs and expense soon after reassembly. To aid

of

any transmission part, consideration should also be given to the unit's history, mileage,

is

lite from your unit.

in

the following checklist.

4.

CLEANLINESS-Provide

It

is

important that no dirt or foreign material

enters the unit during repairs. Dirt

and can damage bearings.

practice to

starting the

5.

WHEN USING TOOLS TO MOVE

Always apply force to shafts, housings, etc, with

restraint. Movement of some parts

Never

stops

mauls for

necessary, use only genuine Eaton Fuller Transmission parts

clean the outside of the unit before

planned disassembly.

apply force to the part being driven after it

solidly. The use of soft hammers, bar, and

all disassembly work

a clean place to work.

is

an

abrasive

It

is

always good

PARTS-

is

restricted.

is

recommended.

in

determining the

A.

BEARINGS

1. Wash all bearings

rollers,

and

pitted,

disassembly.

2.

Lubricate bearings that are not pitted, discolored, or spalled and check for axial and radial

clearances.

Replace

3.

Check bearing fit. Bearing inner races should

be tight to shaft; outer races slightly tight to

slightly loose

freely

and raceways for pitting, discoloration,

spalled areas. Replace bearings that are

discolored, spalled, or damaged during

bearings with excessive clearances.

in

bore, case should

in

clean solvent. Check balls,

in

case bore. If bearing spins

be

replaced.

12

B.

GEARS

1. Check gear teeth for frosting and pitting. Frost-

ing of gear teeth faces present no threat of

transmission failure.

tion of the unit, frosted gears

progress to the pitting stage.

gears with

considerable gear

reused, but gears with advanced stage pitting

should be replaced.

2.

Check for gears with clutching teeth abnormally

worn, tapered, or reduced

ing

in

these conditions.

light to moderate pitted teeth have

shifting. Replace gears found

Often

in

continued opera-

"heal" and do not

In

most cases,

life remaining and can be

in

length from clash-

in

any of

Page 16

PRECAUTIONS

Inspection

3.

Check axial clearance of gears. Where excessive clearance is found, check gear snap ring,

split washer, clutch hub, and gear hub for excessive wear.

C. SPLINES

1.

Check splines

If sliding clutch gears, companion flange, or

clutch hub have worn into the sides of the

splines, replace the specific shaft affected.

D.

WASHERS

1. Check surfaces of all washers. Washers

scored or reduced

replaced.

E.

REVERSE IDLER GEAR ASSEMBLIES

1.

Check for excessive wear from action of roller

bearings.

F.

GRAY IRON PARTS

1.

Check all gray iron parts tor cracks and breaks.

Replace or repair parts found to be damaged.

Heavy castings may be welded or brazed provided the cracks do not extend into the bearing

bores or bolting surfaces. When welding, never

place the ground so current passes through the

transmission.

(cont.)

on

all shafts for abnormal wear.

in

thickness should be

I.

GEAR SHIFT LEVER HOUSING ASSEMBLY

1.

Check spring tension

tension spring if lever moves too freely.

2.

If

housing is disassembled, check gear shift

lever bottom end and shift finger assembly for

wear. Replace both gears

J.

BEARING COVERS

1. Check covers for wear from thrust of adjacent

bearing. Replace covers damaged from thrust

of bearing outer race.

on

shift lever. Replace

if

excessively worn.

2. Check cover bores for wear. Replace those

worn oversized.

K.

OIL SEALS

1.

Check oil seal

cover.

stroyed, replace seal.

L.

SYNCHRON~ERASSEMBLY

1. Check synchronizer for burrs, uneven and

excessive wear at contact surface, and

particles.

It

in

input shaft and rear bearing

sealing action of lip has been de-

metal

2. Check blocker pins for excessive wear or loose-

ness.

G.

CLUTCH RELEASE PARTS

1. Check clutch release parts. Replace yokes

worn at cam surfaces and bearing carrier worn

at contact pads.

2. Check pedal shafts. Replace those worn at

bushing surfaces.

H.

SHIFT BAR HOUSING ASSEMBLY

1.

Check tor wear on shift yokes and finger as

sembly at pads and lever slot. Replace excessively worn parts.

2. Check yokes for correct

sprung yokes.

3.

Check lockscrews

plates. Tighten those loose.

alignment. Replace

in

yoke assembly retainer

13

3.

Check synchronizer contact surfaces on the

synchronizer cups for wear.

Page 17

PRECAUTIONS

Reassembly

-

Make sure that case interiors and housings are clean.

of the transmission during reassembly. Dirt is

Use certain precautions, as listed below, during reassembly.

1.

GASKETS-Use

transmission as it is being rebuilt. Make sure all

gaskets are installed.

can result

bearing covers.

2.

CAPSCREWS-To

loosening, use Loctite #262 thread sealant

capscrews. For recommended torque ratings,

see TORQUE RECOMMENDATIONS.

3. SHIMS-Apply a light coat of Loctite

sides

leakage.

4.

ASSEMBLY-See

detailed disassembly instructions as a guide to

reassembly.

in

of

shims before final installation to prevent

new gaskets throughout the

An

omission of any gasket

oil

leakage or misalignment of

prevent oil leakage and

the illustrations provided

an

abrasive and can damage polished surfaces of bearings and washers.

on

51

O to both

in

all

the

It

is

important that dirt and other foreign materials are kept out

5.

INITIAL LUBRICATION-Coat all thrust washers,

synchronizers, and bearings with transmission

lubricant during reassembly to prevent damage

during initial start up.

6.

AXIAL CLEARANCES-Maintain original axial

clearances for mainshaft gears.

7.

BEARINGS-Using a sleeve type driver that

contacts the bearing inner race prevents damage

to the rollers and cage.

8.

UNIVERSAL JOINT COMPANION FLANGE OR

YOKE-Pull

place with the output shaft nut, using 300-350

lbs.-ft. (407-475 Nm) of torque. Make sure the

speed ometer drive gear or a replacement spacer

has been installed. Failure to properly torque the

nut can result

bearing.

the companion flange or yoke into

in

damage to the mainshaft rear

IMPORTANT: SEE THE APPROPRIATE ILLUSTRATED PARTS LIST (SPECIFIED

ENSURE

THAT PROPER PARTS ARE USED DURING REASSEMBLY OF THE TRANSMISSION.

BY

MODEL SERIES) TO

14

Page 18

DISASSEMBLY

AND

REASSEMBLY

SHIFTING CONTROLS

Gearshift Lever Housing Assembly

LCV(RGAl=P,---

·

9---

HOUSING

~

,,...,,,,

PIN

WAS"ER~

):t-

~PRING

GAS!<H~

y

ousrcovrR

~CAPSCREVi

_PIN

"SHJFT

LEVE.A

A.

Removal and Disassembly

1. T

wn

ou1

tCMJr

bly

and

gasket from

capsctews

the

arld

shllt bar

remove

hous.ing

the

tower a5Sem-

of

Gearshift Lever Housing

2.

Remove

sorure

a

large

forongthe

a1 a lime

the shifl levergripand

assmbly

scrc·

.

wdriver

Spl'ing

In

a vise

from

to

twisi

under

with

between

the

tne

llovsing

boo1

housing

spnrig

from

bottom

lugs-

...

the

shift

lever,

up.

and

houSJng

. Dooneooi

Use

,

15

Page 19

I a

DISASSEMBLY

AND

REASSEMBLY

SHIFTING CONTROLS

Gearshift Lever Housing Assembly (cont.)

(

3. Rem

-

ovo

tho

ten&1on

spring trom

the

haualng

5.

Remov

e the

spadO

pins lrom housi

ng

bo1e

.

4,

Remove

houM'lg

tne

Remove

wasf'le(

the

and gearshtl\

boot

from

..

ver

trom

die gear 1htfl IGVlf

ttle

16

Page 20

DISASSEMBLY

AND

REASSEMBLY

SHIFTING

CONTROLS

B. Reassembly

1.

Secure

spade

1he

gearshift lever housing In a

pins in housing

bore.

of

Gearshift Lever Housing Assembly

3.

Use

vise,

Install the

under

a spMg

the

housing

driving

lugs,

tool

to

seating

Install

one

ooll

tho

at a

tension

ume

sp<ing

-

2.

POSihon

in

1ho

levor ball slot and

over

tho

ball

gearshlh lever In housing with the

ins1all

the lension spnng washer

. dlslled

side

up

spade

pins

17

4.

Remove

boot

l

nsl.all

ovEK

1he

ass9'mbty

the

gearshlJt

shrf1

lev9I

lrom

gn.p

lhe

klver

.

vise

-and

and

tnstaJI

against

lhe

tt1<I

rubbe<

housing

,

Page 21

DISASSEMBLY

SHIFTING CONTROLS

AND

REASSEMBLY

hift

Bar Housing Assembly

..

Page 22

DISASSEMBLY

AND

REASSEMBLY

SHIFTING

CONTROLS

C. Removal and Disassembly

. -

' ' I

t '

1.

Sh

11100

capscrewa.

11'\c

oate

(1rigtHI.

transmission into

and I It

the

neutral

shift bar

po81hon,

housing

and

remove

OdSklll

the

honl

of

Shift Bar Housing

3.

Rcmo11e

ors.

tile

r8$1

of

1he

capsorewS:

and

tne

two

retain

2.

Uy

MO

capecr9W$

into

.&th

h

""111>11'

speed

~onlhe,......

a.s

showo

position

and

W'trl

shh

4th·~

a

$C~Nvr

_

)'Ok.o

-·

1:111

n:itf

19

Page 23

DISASSEMBLY

AND

REASSEMBLY

SHIFTING CONTROLS

Shift

5. Remove

(Inset).

Bar

Housing Disassembly (cont.)

2nd

-3rd yoke

assembly

and lnteflock pin

7.

If

neoossary

shdt

baf'

remove

tho

front

spacer from

1st-1evetse

6.

Rernove

remove the front spaoer from 1st-reverse shift bar (ln$el).

1SJ

•toverso bar assembly II neoessary

20

8.

RQ1~\ove

shift

yoke

(1nsel).

lhe

1st·reverse

tISsembly

lock

Remove

p10

from

the

1st0reverso

Iha

1st-reverse

shift

yoke

Page 24

DISASSEMBLY

AND

REASSEMBLY

SHIFTING

CONTROLS

Shift Bar Housing Disassembly (cont.)

,

'

r

9.

Remove lhe

tst-~verae

actua1or

11. Remove

from

1he

shift bar housing

1he

revetse

plu:noer

reta.in

tng plug and

ga.Ske:t

1

O.

Remove

100

ltlrce back

trom

the

tile f

up

shltc bar

our

interlockballs.

liQht

swnch

hou-.sing

.

1ha

lhf'eedeten1 balls.

bafls, and the 1.hree springs

12.

Remove

the

reverse plunger spring.

Page 25

DISASSEMBLY

AND

REASSEMBLY

SHIFTING CONTROLS

Shift Bar Housing Disassembly (cont.)

13.

Remove

1he

reverse

p1u~er

s1op

15. II the

trom

sh1t1

bottom

yokej)OO~

yOke

01

yOke

nre tObe repl;ieed, remove worn pnd

1n.s1:ill

now

•

p.'dandbend

tabG.

over

top

and

164 I'

removed

hammer as shown

22

necess.ary

bydr1vi1"1Q

itllft

bll)Cll.S

IOCkp.n

from

and

sh

shift

yokes

f1

bar

with a punch aod

ca..,

be

Page 26

DISASSEMBLY

AND

REASSEMBLY

SHIFTING

CONTROLS

D. Reassembly

1. Pillot

1ns11.1U 1ho

tho

shift bar

rovo1so

housing

plunger.

of

on

Sh

ift Bar Housing

1tr

side

as

shOwn

ond

3.

I

nstaD

r

everse

!he 1

plunge

ev~so

ptungor

r plug 101

gaske1

1101ecommended

ancf

plug

Tighteo

tCKq1,1e

lhO

2.

-

1ns1o1

.,.

""""""

,...,...

-

~"II"'

-

r.-i

ll>d

,,,.

4. If shdt block$

yoke or

klck P'"

NOTE: II

teverse

23

b6ock

p11MOU

sh1h

or

with

1>a1

before

st

1fl

yok•

01.gnment

sly

IQl'l'IOVOd

•nstotllng

were removed ahgn sh

holo 1n the

install

both

shrl't

bar end

two

spacers on

shift

blocks

11

inaer1

1$l·

(inse-11.

Page 27

DISASSEMBLY

AND

REASSEMBLY

SHIFTING CONTROLS

Shift

s. Install

following

swrleh

oore

?OStbOn

Bar

Housing

intoOOck

bails,

deten1

seQUence; position

and instaJl

(2 ) balls

1s1-reversedetentspnngand

In

adjacent

Assembly

balls

and

~

3)

balls

in

the

cross

bore

and

(cont.)

springs in the

reverse

instal

bght

bal

l.

l 2nd·

3rd detent

cross

bore

OT

E: Salls

N

spring

and

insta

and

and

ball Position (2> balls

ll

4th~51h

SJ)llngs

can

deten1

be

used

ui

adjacent

spnr.g

and

ball

lnterohangeabl)'

.

6.

Seal

over

the

1he

actuator

1st

rQVQrse

pll/01

actuatOf

ptn, as

In

the sh1h bar

shown

housing

,

7.

POStbon

housing

assembly

tst·reverse yoke assembly in dle shift

(inset) Install

.

the

1st-reverse

lock pin

in

the

bar

yoke

Page 28

DISASSEMBLY

AND

REASSEMBLY

SHIFTING

Shift

8.

sembty

NOTE:

Bar Housing Assembly (cont.)

Position

151-tev~rse

as

shown.

Position

bat

spacQrs

CONTROLS

assambfy

as

shOwn

in

mo

hous.ng

as·

-

--

1 O.

Position

assembly

-

as

1he

4th· 5th

shown

yoke

assembly

.

in

lhe

hovslng

9.

ln!lalt

POSlbon

bly

as

shown

the

the

2nd·3rct

2nd-3rd

yoke

yoke

assembly

assembly

interlock

ln

the

housing

pin

(1ose1~

ass.em·

.

'

11.

Place

retaine

e.apsaews

as&&mbfy

rs

atld

lhe still!

lhe tout

10100

into 4tll

yokes

an

oou11at

capscrews

recommenced

speed

pos111on

and

Install

as

sllO•llfl

tOtQUB. Shih

.

the

Tigh1on

4th· Sth

1

wo

the

yoke

Page 29

DISASSEMBLY

AND

REASSEMBLY

SHIFTING CONTROLS

Shift Bar Housing Assembly (cont. )

12.

lns1au lhe

capsc1&w1

remaln1ng

10 1

ooommcnded 1orque

rwo

capscrews

nnd

tight

en

Page 30

REMOVAL - YOKE

AND

CLUTCH HOUSING

Yoke and Clutch Housing

....

,,.;_

~

kA~fl

!Of:

0

COVE-A

A.

Removal

1.

Lock

1he

as

Shown

rc1a!n

ng

nul

of

11ansrn.r.s1on

(111&00

.

from

by

Use

a latge

lhe output

Yoke

oogaglng

b<oakCf

shaft

••

~

lwo

mi\lnMnl1geat&

bar

10

tutn

1.0C

~A

1he

w

:z.

Removo

!he

yoko

from

1he

output

shalt.

v

Page 31

REMOVAL - YOKE

AND

CLUTCH HOUSING

B. Removal

1.

Remove

lhe

four

retaining

of

the

bOlts

as

Clutch

sh<>wn.

Housing

2 • .kir

clutch

houslng

transmission

case.

\\/Ith a rubber

mal'6l

and

pul1

lrom

the

28

Page 32

DISASSEMBLY - TRANSMISSION

Input Shatt Assembly

INPUT

SHArT

ANO

DRJVE

BeAfl:lNGCUP

GEAR

A. Removal & Disassembly

1. Remove ltle four capscrews trom lhe front bearing

oover

a.nd

remove

oovershlms

necessary

can

come

remove

1he

cover and

oft

the

oi1

\Vlth

seal

shims

1he

from

The

tront beanng

front bean.ng cover. If

the

cover (inset) .

of

Input Shaft Assembly

2.

Remove

..

..,

I.he

input shaft assembly

from

the

transmls·

29

Page 33

DISASSEMBLY - TRANSMISSION

Input Shaft Disassembly (cont.)

3. It

nectSSatY.

beaung

rtltntion

remDVe

ring

me

ratan!Joo

snap

r.ng

Mel

the

5. use a

Ins.tall

beanng

...,.,.

shalt.

c:hisef

puster

lO

remove

anct

the

remoye

beamg

the

bearing

cage

and rollers

race

lrom N

4,

It

ma.n

neoeuary

drive gear

temove

bearing

the

1.a

poc:f(et

roller

bearings

tron1

tna

30

Page 34

DISASSEMBLY - TRANSMISSION

Malnshaft Assembly

c

tH

!>I

H

ASS£t.•Bl..V

S:YNCl~llfl1

'IMAIA:l

'""""""'"'"'

"""

•ARI~~

'>..

'-...

~ru-

OfAA

...

o

,

~

I

......

"\

ASHER

c..

COii<

"'"""'

....

B. Removal and Disassembly

1. Rffmovt the toor rcta1ntng nuts and

remove

Oii

i;.1181

the

lrom

'9at

covet

beardlQ

("5e!J

rove.-

It

kx:kw~hers

R808INI')'.

t8"T10Y91he

and

of

31

Ma

2.

Remove

tron1

ol

abou! 1

a>d

locoong

inshaft

speedon'lelerdrNe gear

Ille

main

Iha~

10

4"

UM

pry bwa

"""'mg

,,_.

U'8

to

t8"nCri9 lh&

(inset).

ma.nsha~

rear

Tap on

,..._d

beanng

1ne

a.,

Page 35

DISASSEMBLY - TRANSMISSION

Mainshaft Disassembly {cont.)

3.

Wrap

a

S'l1ng

Use a hotst

to

transmtSslon

or

remove

case

rope

around

the

mainsllaft

the

2nd-3

assembly

rd

S)'OChronlzer

from

the

S.

Remove

the

throst

bearing

and

bearing

race.

4. Install

soh

)aws or

51h

speed

the

malnshaft assembly in a vise equipped mlh

wood

,

shah

lronl

synchronizer

and

facing up.

wps.

Remove

!ht!

4th-

32

6.

RemO\l'e 41h-51h

speed

clutch

hub

.

Page 36

DISASSEMBLY - TRANSMISSION

Mainsha

tt Disassembly (cont.)

-

7.

Remove the

4th

spaoo

geaf

9. Rem

ove

3rd speed gear

reta

ini

ng

snap ring.

a. Rem

ove

4ltl

geru

beari

ng

10. A

en1ove

locating ball.

31d speed

gea

1 1hrusl wasllor.

Remo

ve the

Page 37

DISASSEMBLY - TRANSMISSION

Mainshaft Disassembly (cont.)

1

1.

Remove

1he

lid

speQd

g.ear

1

3.

!lizer

Remove

assembly

lhe

,

3rd

gear synchronizer cup and

synehrO

·

12. Remove

the

3rd

gear

beanng

.

14. Reposition

ma.inshalt

In Lhevlse

so

reat beating is

up

Page 38

DISASSEMBLY - TRANSMISSION

Malnshafl Disassembly (cont.)

15

U8'llg • g90r

bW"ll•"-'

ouller.

remove

lhl"'""""""

,..,

17.

RemoYethelll-ip14washer

18

.

Remov&

beanng

rOllors

thO

1

S.I

..-lho

gea1

,.,

Use cavtjon

gear(.,...).

so

n01

10

IDM

Page 39

DISASSEMBLY - TRANSMISSION

Malnshaft Disassembly (cont.)

19.

Remove

1.he

beanng rollers and spacers.

21

. Remove the 1si-1everse sliding cl

u1ch

20. Remove 1s1-

reverse

sluf1

hvbsnap

ring

. 22. R

36

emove

dte

shih hub.

Page 40

DISASSEMBLY - TRANSMISSION

Mainshaft Disassembly (cont.)

23. Remove

the

reverse

gear

25. Remove

2nd gear split washer retainer ring

24

. Rem

ove

the r

BWrSe

gear beanng

37

26. R

jmse1)

emove

lh&

2nd

gear

spl I washer

and

locaung

bail

Page 41

DISASSEMBLY - TRANSMISSION

Mainshaft Disassembly (cont.)

27.

-.

2l'ld

speed

gear

311

Page 42

DISASSEMBLY - TRANSMISSION

ountershaft Assembly

. -

Reverse

CUI

ISJn t111

Idler Assembly

o..EACE.AR

C.

Removal and Disassembly

Idler

1.

Romovt the lour

i.aring

oover

and

gaskel

cac:iwews

and

Lhe

coun

lerthah

rear

of

Countershaft and Reverse

2.

Remove

beanng

NOTE

beanng

:

the 1wo

reta

nor oul

Countllrsl\llft

bolt

t-r

may

RO

I

race.

screws

and

shims

i.hde

to

(1fls&1}.

the

rear

Remove

aoo

ou1

oi

1he

mo

Page 43

DISASSEMBLY - TRANSMISSION

5.

3.

Movo

from

the

the

transmission

coun1ershatt

case

asse

.

mbly to

the

rear

~nd

1111 ti

Using a wedge bar,

remove

the

roverse idler

shaft

.

4.

Remove

retainer

1ho

<averse

l~r

r

etain

ing

capscrew

and

the

6.

Remove

thrust washers.

•o

the tevers&

Idiot

bearings.

spacer.

and

Page 44

DISASSEMBLY - TRANSMISSION

7. It

dnve

and

the

countofShah

ltl&

bofe

dr1ve

1he

plug

race

tront

through

to

the

reartoWard

bearing

the

#ron1

raoe

is

to

of

the

the

case's insrde.

be

replaced

transmlsslson

9.

ring

U$9

a screwdriver

out

ot

snap

and

snap ring pilers to move the snap

rlng

groove and against Iha beanng back.

•

8.

Position gear

shah

bearing

pulAer

and

and

remove

c1a1opb&h1nd

the

beanng.

tho

<ear

coun1er

10.

Use

the

·

then

f)fess

countershaft.

countershaft

the drive

gear,

dove

gear

snap ring

rear

and

face

as a base

bearing

from

,

1he

Page 45

DISASSEMBLY - TRANSMISSION

Countershaft and Reverse

Idler

Disassembly (cont.)

13. Remove 4th

gear

key

ltom

lhe

c:ouotlfl'Shah

12. Remove

eoun1l'!rshatt

.ttli gear

Page 46

REASSEMBLY - TRANSMISSION

A. Reassembly and Installation

Idler

of

Countershaft and Reverse

1.

Install

4th

and

knyways

way toshal1 key

hub

(1ns&t1

to

stlaJt lront

611l

.

Align

Pr~

spoed

gear

key$

in

1he

41h

speed oountorshalt gear key·

4th gear on lhe

ex>OOl9f!>h_.n

countOfshafl

long

3. l

groov

nsta

e.

JI

11nap

ring 111

the

oountersha-ft

1ron1

snap

nng

.

2.

Prvs.s

...

,

S1h

speed

coomor8'latt gear on,

long

hub to stiaft

4.

H&11t

And

CAUTION,

It

PM

l>l""

1nstal11he

Do

not

heat1ne

use a

heat~

front

coun1orshafi

bu>tong

aa

the

above

source

beanno

275 F 1136

~)

Page 47

REASSEMBLY - TRANSMISSION

Reassembly Countershaft and Reverse I

dler

(cont.)

• •

•

5.

Heat

and

CAUTION

If

posstble.

lnstol11he

Do

noll1oat1he

use

a

heal

rear oountersllatt

lamp

bearing

as

the

above

sou1ce

beanng.

275"F ( 136 C).

,

7.

Use

hold

ers

ttle

grease

In

place

In

housing

rea

r

on

. Insta

groove

the

two

ll

reverse

.

w.th

reverse

the

ldJer

idlergearwtfh

small

reverse

thrust

tangs

washers

of wasti·

idler

gear

to

to

6.

UpreVtOusly

front

bearing race {

plug Coat

#510

befo

re

removed,

from

1he

outer diame1er

install

ing,

1nstall

inside of

the

snapnng, oountershaft

case)

and lronl

of

bore plug with loctita

casa

bore

8.

tnsen

1he

gQarneectie

capscrew

lines

1he

(Inset). Make

t1p

wrlh the

tacommended

revtuse

bearings

capsc1ew

1orqua

Idler

lnsi.all

su1e

shaft

through

the

reverse

Ille Idiot shall locking groove

hole.

1he

Tlgtiten

case

and

tdlerretrunOf

100

capsctew

.

Idler

and

to

Page 48

REASSEMBLY - TRANSMISSION

Reassembly Countershaft and Reverse Idler (cont.)

I.

Caretuly lower the counierihafl into the

....

11:31'1$.mission

11.

klstal h

~case

count~'!

asshcM't'I

rear beanng race .n10 the

10.

Pos1t100

PMtllon ttle

.....

100

1raM.m1sa1on

coun1eralio

case

oo

lt

assembly ln10 the

end

front

•

RI

l:M!ating

shown.

t 2.

Teimporanly

(inset)

recomn1ended

lns1at11he

inS:tall

new Shim

reta11"101

lol'QU(j

and I

M'ltO

the beanng

oghtenthe

rat.1

no1

set sorewtto the

Page 49

REASSEMBLY - TRANSMISSION

Reassembly Countershaft

13.

Rota1e

Position

with

be

set

end

NOTE: Once

apply a light coat ot LoctilB #510

and

Coat

recommended

1hecounte1shatt

the

dial

1t1dicator

a

screwdfrl/ertomeasuro

aJ

.00

2-.0

08

(0.05·0.20

play

and

1emove

end play Is cotrecl

the

tataln9f lace

setscrewt~eads

torque

to

as

stllms lor loss

w

1th

Loc11

.

seat

tho

bearings

sOOwn

. lilt

tho.end

mm)

ptny

Add

end

remove

to

each side

1e #262and tighten

and

Reverse Idler (cont.)

and

1aces

the

countershaft

End

play

must

shims

play

the

tor

more

retainet and

of

tho

shims

to

the

1

4.

Install Ille

Coatcapscrewthreads wtlh Loeltle #262 and bghten

recommended

oountersha.ft

torque

.

1earbaa11ng

covoc

and

gas1<e1

co

tho

Page 50

REASSEMBLY - TRANSMISSION

8.

Reassembly and Installation

of

Mainshaft

1

1ns1all

1ht

t:wat1>1W'l

- 2nd

main!ihattreatfacing~

maJO&ha'I

&pOed

9""r bOanng

in a v«Se

eq1J•ppeid

w

1h

wooa

Lubnc:a11tandlnstal

Of

3.

1he

tnsian

loc:allflg ball (lnsu

spin

nngs

JO"

..

Ille

t1and2nc:f

1ocallng

bal

gear

splr1

washer

50

4.

'f'lS.lall

2nd gear aplll

was.hQr

riilaine< nng

Page 51

REASSEMBLY - TRANSMISSION

Reassembly

of

Mainshaft (cont.)

$.

Install

m;:unshalt

nwef'Se

gear

bearing.

7.

Instal

l mwnshaft

1st-reverse

speed clutch

hub.

6.

lnsiau

malnshaft

reverse

gear

••

8. lnstatl

1s1.;eve

rse gear

slidlng

Clutch

Page 52

REASSEMBLY - TRANSMISSION

10. Coatlhiem.,1nlh.l"'

grease

Shah

cM

around

spacOf

beat'll'IQS

44

tNI

1>ear1nos

the

ring

lay

a

ttM

l"lfledle

bean

lay a sec:ond

ma1os.haf'I

ovtK

~

11'\e

11

tt11tall

beat!nQt

calCh

d'l8

111@9ar~tlOnWlUlaf\lghqualrty

l"llKKIB

ns

on

l

baannos

Place a spacer

row ol

top

o1

tNi

op

ol

the

second

around

nng

44

noecfle

spacer

row

over

ring

die

ma1n-

the

beanngs

l

nstatr

of

needle

1op

a

12. ln•t<u O loc0"'1g ball

spoed

10Cf"11

ge;11

ng bad

tnainlhafl 1

wlli

<';ICl"'CJ

~roller beantlQ$

llJl•I

&1

gaar-

-

0<1

washef. so

ovet

!tie mainshofl. Install I

1he

-..

the

SQI•

two

rows

Be

ca'llflJI

nngs Jon

ol

nee<le

"°'

at

10

st

lhe

49

Page 53

REASSEMBLY - TRANSMISSION

Reassembly

of

Mainshaft (cont.)

1

3.

tns1an

lhespli1

washer retainer

1lng

Dvef

lhe

spl

1

rings.

15.

Reposition

malnshaft 3rd

mainshal1

speed

gear

in vise so

synch.tonizer

rronl Is up. Install !he

assel'nbly

.

14.

as

r>hcr.vn

Using

a bearing

.

dmrer.

inslaU

mainshaf1

rear beari

ng

50

16. Install

assho·Nn

Ul&mrunshaft

3rd

speed

gear

syndl

ron12er cup

Page 54

REASSEMBLY - TRANSMISSION

Reassembly

of

Malnshalt (cont.)

t

7.

lnstaD

mrunshott

3rd

gpeed

gear

boar.no

.

1

9.

lns1oll

locating ball and 3ttl epeed gear

ttuus1

wo:.110!'

1

r

l'.

~

,'

..

,

'll!!ll

...,.,

-

<IC;.

..

• . -

.

18. lnsiall maJnshaft

OOvm

31d

$pOOd

gear

ciutcl'wng

100th

tac:lng

SI

20.

tn$1')11mainshah3rd

tt\13

'IMP

ring

groove.

, ,

speed

oear

reuun1ng

Stl8'1nng1n

Page 55

REASSEMBLY - TRANSMISSION

Reassembly

of

Malnshaft (

cont

.)

22. Install malnthaf'I

up

41'1

~&edgoar.

clutching teetn f

acing

24

. Install

shilti

lhru.&t

.c1h-51t1

clu1ch

bearing and

hub

boar1ng

race

on

the

main·

Page 56

REASSEMBLY - TRANSMISSION

Reassembly

of

Mainshaft (cont.)

25.

lns1al'

ma1111shett

4th-5th

4th-5th ciJtCh

speed

syncllfonlzer

hub

end

cups over

1ne

27. II previousty

main drivegeai

mg

and

retenlOl

•

l>gh

quality-

removlil'd

beanng

nng

,

ln&:talt

poc:kal

(

tntot

1'1

lnslall ttie

f,

11.bncaJe

rollerbeafing!.

retenUOtl

sne

beanngs w

in

11'11

lf"l8')

tr'I

26.

Remove

or

rope

the

n1runshnft

!he

around

mainshati

2nd-3ld

synchron1zor.

assembly

from

lh8

in

tranam11slon

w::e

Use

aod

a

hOtSI

case

V'l'ra?

to iflsta•

a

sfi1ig

28..

Hl:!at

tf'le

mput

sriafl beanng

lh•

W1put

stiatL

CAUTION: Oonol nombconngobove 275 F(136

ponlble use a heat

53

lomp

o.s

1he

ancf

inSlal

source-

the

beanrig on

C)

II

Page 57

REASSEMBLY - TRANSMISSION

Installation of Mainshaft (cont.)

31.

Insta

ll

29.

Install

dnve gear

c

up.

the

Input shatl by

with

tee

aligning

th

Jn mainshaft 5th speed synchronl2et

clutching

teeth

on

sctows.

beat the

and lighten 10

NO

TE:

Input shafl

The

f

ront bearing

top

.

Apply

rooom

Bearing

LoctiteD262.tothreads

cover~

bearing

mended torque.

oover

cover lubricat

marked

lor

gaske1, and

ion

oil

groove must

ol

capscsrews

ptopec insta

<:ap·

lla1fo

n

••

ll

30. Coal lhe outer diameter of the input

covar oil seal v.·

fro

nt

be.anng

the input

proper beruing dflver.

ith

coveJ

bearing

Loc1ite

wilh a

race

in

#S10

. I

bearing

the

front

nstall

the

driver as

bearing cover with

shati

oil

seal

shown

be.anng

on the

. l

ns1ell

the

32. Inst.alt the

oulpul shaft

spoo®mete< d

rlvo

gear

or

rotor on

the

54

Page 58

REASSEMBLY - TRANSMISSION

Installa

3

3.

rns1an

Olltpul shaft

tion

1he

main

bearlng

of

Malnshaft (cont.)

shal1

1ear

outer

llEWtng

bore.

'

·~

taco

1n

1119

35. Coal both sides

with

Loctite

bearing

lutxlcatton

N

OTE:

#510, and

cover Install

on

groove

Roar

bflaring cover tS marked

uon

of

a

posffion

the

w!lh

nevi

rear beanng

rear

bearing

case

hole

1he

gasket

oover. position

.

IOI

oover

~ske

on

the

rear

the

proper inslalla·

l

34.

II

a new

driver. Coat the oil

od

seal

1n

iS

required,

seal

ouLor

dt.ameter

Install

with Lociite

using e

llanged

#51

O.

36.

ol

totque. Using

oons,

the

urementsa11d

1

hickn&ss

$hims

above

in$1all

lour

me.nded

55

Tigh1.en

transmlSSiOn

ca1ainmg

the

record

the gap

10

start the end

to

equal

p1ocedure

lhe

shim

lo(que.

lroo1

add

ltlO 101

pack.

ca,pscraws.

beating

1wo

reeler

bB!wQeo

case.

Average

0.016. This

pt.ay

a1

shim

.

Remov&

Reptace

cover

capsctews

gages

at

the

the

fron1

the

two

totatg~vos

measurement Combine

pack

rneasuremen1

the ffonl beating cover

1he

lfon1

tig

ltten

capscrS\.,,S

to

capsaew

bearing

recorded

you a shim

beanng

30

cover

from

cover

10

If! ·

lbs

toca·

and

moos·

pack

1ho

the

and

and

recom·

Page 59

REASSEMBLY· TRANSMISSION

Installation

37. Pl

torqut. Rotato !ht

seal

Install

aoo

1ra

nsmission In a vertlcal

yoke

and nut. Tighten the

the

bonrings

of

Mainshaft (cont.)

posiUon

yoke

nut 10

lnpU1

and

shattstxt1

rsce.s.

mes

ineadl d r0t.1lon

.

o.s

shown

te<:ommendect

to

38.

-•cNllndcalO'as.,_.,onlhe

Pry

on

1119

C>Jtput

.,...

mainst\olrt end

012

(0 20·0.30mm) Addsllims1olhefrontboarlngoaver

more

lor

1he

and

al

oove1

OO\+&r

beanno

Ind

00t1ec1 ond

tlhlms. Coo.I bo

LOCl<le

#610. lnstotl

on

1he

cap1e11W1

oove1

llange

p&ay

play or

remove

p&ay

is

set rem

lh

s.dos

transmission

with

LOCllt

. 8"d

tighten

and

read

End

play

shims

ove

of the &lilms w

tOe

shims

case Coal

& .-262, Install

to

Ole

reoomtnllnded

1l1e

muse

for

lhe

and 1ho

c>aJ

be

less

fro

the

_

_,.,,

bet'ktlen

end

nt

boanng

l11l

hont

fron

1n

_,

to

get

ooe

play, After

cover

a hghl

ooa

boar1

ng

t bearing

1ho tronl

totque

l

Page 60

INSTALLATION - CLUTCH HOUSING

A. Installation

of

Clutch Housing

1.

Position

housing

bol1s

and tighten

the

on

u'e

1ransmission

11ansmlS&On

10

the

as

case I nstatl

1eoommended

shown. Place

1he

rour

1orqoe.

I.he

dutch

retaining

57

Page 61

INSTALLATION - SHIFTING CONTROLS

A.

Installation

of

Shift Bar Housing and Gear

Shift

Lever

1. Pince

Place

make

chrOfllt•rs

2.

capeo..,.,

ngn1en

1he

l1a

.nsm1SStOn

1ho 1h!l1 bot

sure

1hG

and

Atll>'Yloc:<!0l2!;21t>-ol_.,..

Into Ill n

10

1M

housing

shift

shchog

recomm&f'lded

lnflootral and

yak.Gs

allg.n

dutch..

bat

hous>ng

in

nO\ltral

and

wilh

correspoodlng

•'°9""*'' ...,...

~e

•nstnll

ln11au

the gaskol

on

case.

&yn-

lnolallwO

and

3. Install lhe rem[I nlng ca,pscrews and lighten to 1

recommended

4.

Coat

there"'""""capecrewsthreads...,

andWlSla.

IO<que

torqvo

TIQIMnlhocapeo-IO

~e•262

hi~

tie

Page 62

OPTIONS

REMOTE SHIFT ARM

SHIFT FINGER

Cut 727-8/87

REMOTE CONTROL HOUSING ASSEMBLY

CAPSCREW

)

BREATHER

~

Cut 728-6/87

59

Page 63

Page 64

Page 65

Copyright Eaton Corporation, 2012.

Eaton hereby grant their customers,

vendors, or distributors permission

to freely copy, reproduce and/or

distribute this document in printed

format. It may be copied only in

its entirety without any changes or

modifications. THIS INFORMATION

IS NOT INTENDED FOR SALE OR

RESALE, AND THIS NOTICE MUST

REMAIN ON ALL COPIES.

Note: Features and specifications

listed in this document are subject to

change without notice and represent

the maximum capabilities of the

software and products with all options

installed. Although every attempt has

been made to ensure the accuracy of

information contained within, Eaton

makes no representation about the

completeness, correctness or accuracy

and assumes no responsibility for

any errors or omissions. Features and

functionality may vary depending on

selected options.

For spec’ing or service assistance,

call 1-800-826-HELP (4357) or visit

www.eaton.com/roadranger.

In Mexico, call 001-800-826-4357.

Roadranger: Eaton and trusted partners

providing the best products and services in the

industry, ensuring more time on the road.

Eaton Corporation

Vehicle Group

P.O. Box 4013

Kalamazoo, MI 49003 USA

800-826-HELP (4357)

www.eaton.com/roadranger

Printed in USA

Page 66

For parts or service call us

Pro Gear & Transmission, Inc.

1 (877) 776-4600

(407) 872-1901

parts@eprogear.com

906 W. Gore St.

Orlando, FL 32805

Loading...

Loading...