Doosan G424 Service Manual

SB2215E01

O c t . 2 0 0 1

Service Manual

G424 Gasoline/LP Engine

G424 LP Engine (Low Emission Version)

G20E-3, G25E-3, G30E-3

GC20E-3, GC25E-3, GC30E-3

Important Safety Information

Most accidents involving product operation, maintenance and repair are caused by failure to observe basic safety rules or precautions. An accident can often be avoided by recognizing potentially hazardous situations before an accident occurs. A person must be alert to potential hazards. This person should also have the necessary training, skills and tools to perform these functions properly.

Read and understand all safety precautions and warnings before operating or performing lubrication, maintenance and repair on this product.

Basic safety precautions are listed in the “Safety” section of the Service or Technical Manual. Additional safety precautions are listed in the “Safety” section of the owner/operation/maintenance publication.

Specific safety warnings for all these publications are provided in the description of operations where hazards exist. WARNING labels have also been put on the product to provide instructions and to identify specific hazards. If these hazard warnings are not heeded, bodily injury or death could occur to you or other persons. Warnings in this publication and on the product labels are identified by the following symbol.

WARNING

WARNING

Improper operation, lubrication, maintenance or repair of this product can be dangerous and could result in injury or death.

Do not operate or perform any lubrication, maintenance or repair on this product, until you have read and understood the operation, lubrication, maintenance and repair information.

Operations that may cause product damage are identified by NOTICE labels on the product and in this publication.

DAEWOO cannot anticipate every possible circumstance that might involve a potential hazard. The warnings in this publication and on the product are therefore not all inclusive. If a tool, procedure, work method or operating technique not specifically recommended by DAEWOO is used, you must satisfy yourself that it is safe for you and others. You should also ensure that the product will not be damaged or made unsafe by the operation, lubrication, maintenance or repair procedures you choose.

The information, specifications, and illustrations in this publication are on the basis of information available at the time it was written. The specifications, torques, pressures, measurements, adjustments, illustrations, and other items can change at any time. These changes can affect the service given to the product. Obtain the complete and most current information before starting any job. DAEWOO dealers have the most current information available.

1

Index

GENERAL INFORMATION |

....................................... |

||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

4 |

|||||||||||||||||||

How to Read This Manual |

.................................... |

||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

4 |

|||||||||||||||||||||

Precaution Before Service |

.................................... |

||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

6 |

|||||||||||||||||||||

General |

................................................................. |

||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

8 |

|||

Tightening Torque |

................................................. |

||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

9 |

|||||||||||

Sealant |

................................................................ |

12 |

|||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

SPECIFICATIONS |

................................................... |

13 |

|||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

.......................................... |

|||||||||||||||||||||

General Specification |

13 |

||||||||||||||||||||||||||||

.......................................... |

|||||||||||||||||||||||||||||

Service Specification |

14 |

||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||

MAINTENANCE |

...................................................... |

17 |

|||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

................................ |

||||||||||||

Test Fuel System for Leaks |

17 |

||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|||||||||||||||||||||||

Check Engine Oil Level |

...................................... |

17 |

|||||||||||||||||||||||||||

|

|

|

|

|

|

|

........................... |

||||||||||||||||||||||

Inspect Engine for Fluid Leaks |

17 |

||||||||||||||||||||||||||||

|

|

|

|

||||||||||||||||||||||||||

Change Engine Oil and Filter |

............................. |

17 |

|||||||||||||||||||||||||||

|

|

|

|

|

|||||||||||||||||||||||||

Inspect Accessory Drive Belts ............................ |

|

|

|

|

18 |

||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

.................................... |

||||||||||

Inspect Electrical System |

18 |

||||||||||||||||||||||||||||

|

|

|

|

|

|

......................... |

|||||||||||||||||||||||

Inspect Vacuum lines and fitting |

18 |

||||||||||||||||||||||||||||

|

|

|

|||||||||||||||||||||||||||

Check Coolant Level |

........................................... |

18 |

|||||||||||||||||||||||||||

|

|

|

........................................ |

||||||||||||||||||||||||||

Inspect Coolant Hoses |

18 |

||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||

Inspect Ignition System....................................... |

|

|

|

|

|

|

|

|

|

|

|

18 |

|||||||||||||||||

Replace Spark Plug |

............................................ |

18 |

|||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

............................. |

||||||||||||||||||

Replace LP fuel filter element |

19 |

||||||||||||||||||||||||||||

Test Fuelock (electric) |

......................................... |

19 |

|||||||||||||||||||||||||||

|

|

|

|

|

|

|

............................... |

||||||||||||||||||||||

Replace Gasoline Fuel filter |

20 |

||||||||||||||||||||||||||||

............................... |

|||||||||||||||||||||||||||||

Inspect Gasoline Carburetor |

20 |

||||||||||||||||||||||||||||

|

|

|

|

|

................ |

||||||||||||||||||||||||

Inspect Pressure Regulator/Vaporizer |

20 |

||||||||||||||||||||||||||||

................ |

|||||||||||||||||||||||||||||

Inspect LP Mixer (Standard LP Truck) |

20 |

||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||

Inspect Variable Venturi Air/Fuel Mxer |

|

||||||||||||||||||||||||||||

(Low Emission LP Truck) |

.................................... |

|

|

|

|

|

|

|

|

20 |

|||||||||||||||||||

Inspect Complete Exhaust System for |

|

||||||||||||||||||||||||||||

Leaks,damage |

.................................................... |

20 |

|||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

Engine Control Unit (ECU) and others |

|

||||||||||||||||||||||||||||

(Low Emission LP Truck) |

.................................... |

|

|

|

|

|

|

|

|

20 |

|||||||||||||||||||

Maintenance Schedule |

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

21 |

||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

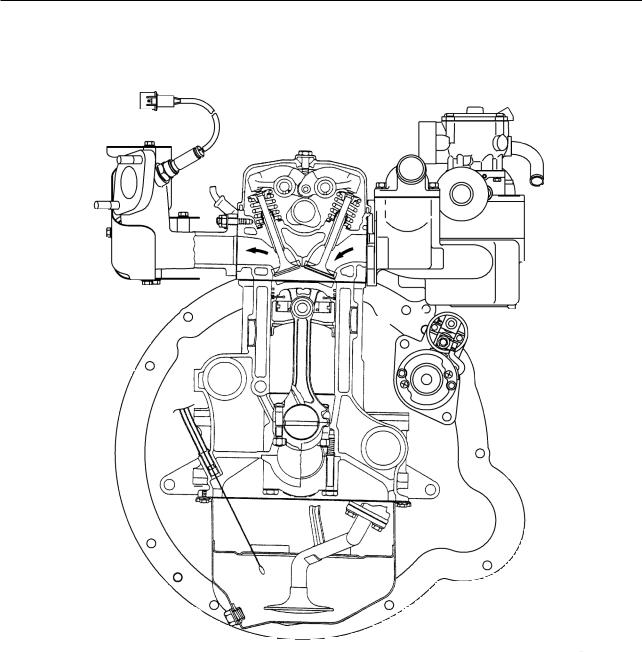

ENGINE SYSTEM |

|

................................................... |

22 |

||||||||||||||||||||||||||

|

|

|

................................................. |

||||||||||||||||||||||||||

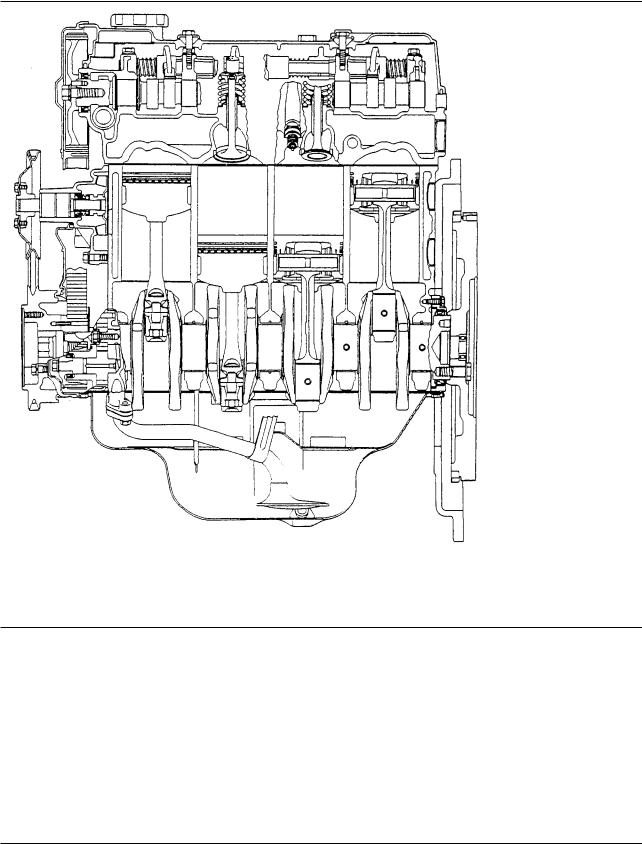

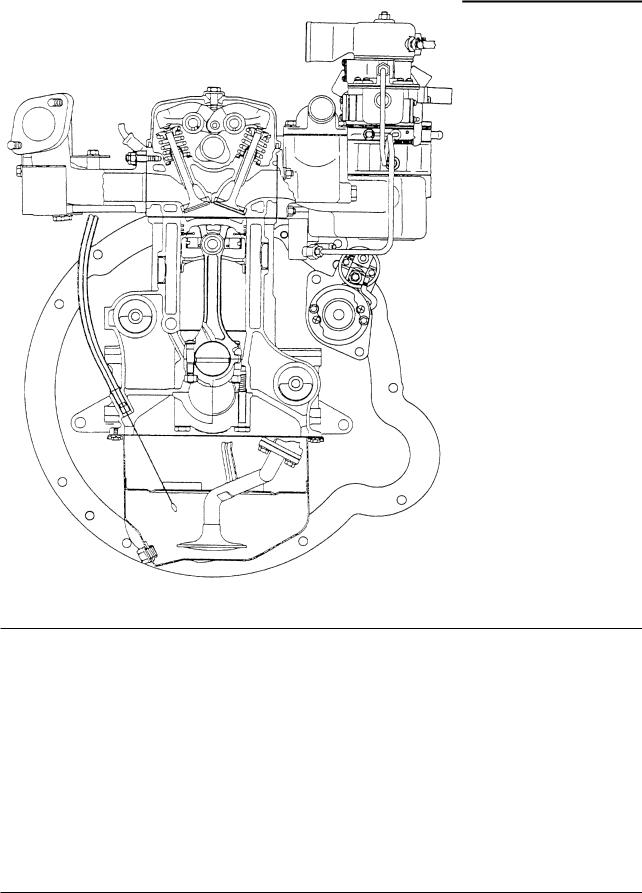

Engine Overview |

22 |

||||||||||||||||||||||||||||

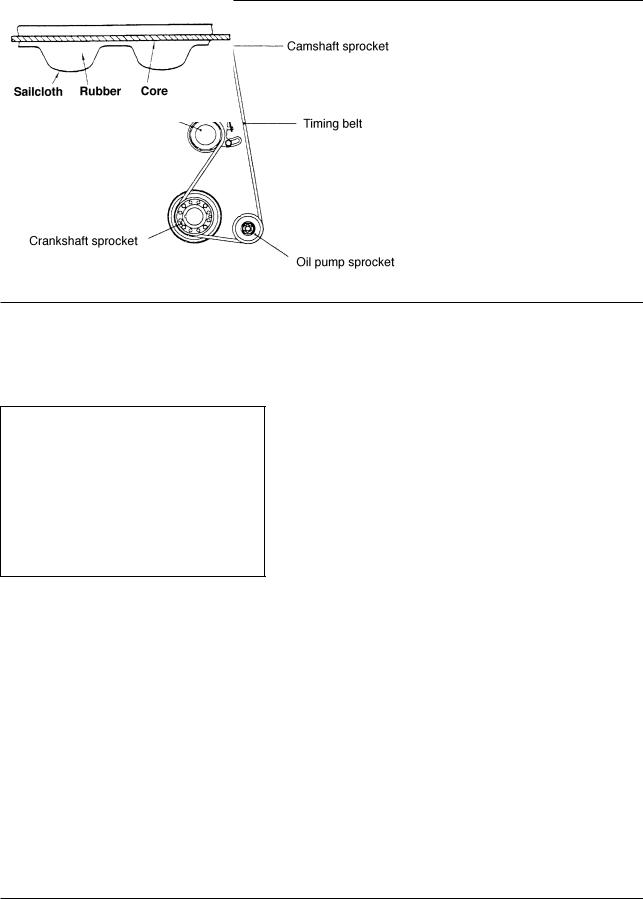

Timing System |

.................................................... |

25 |

|||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

...................................... |

|||||||||||||||||

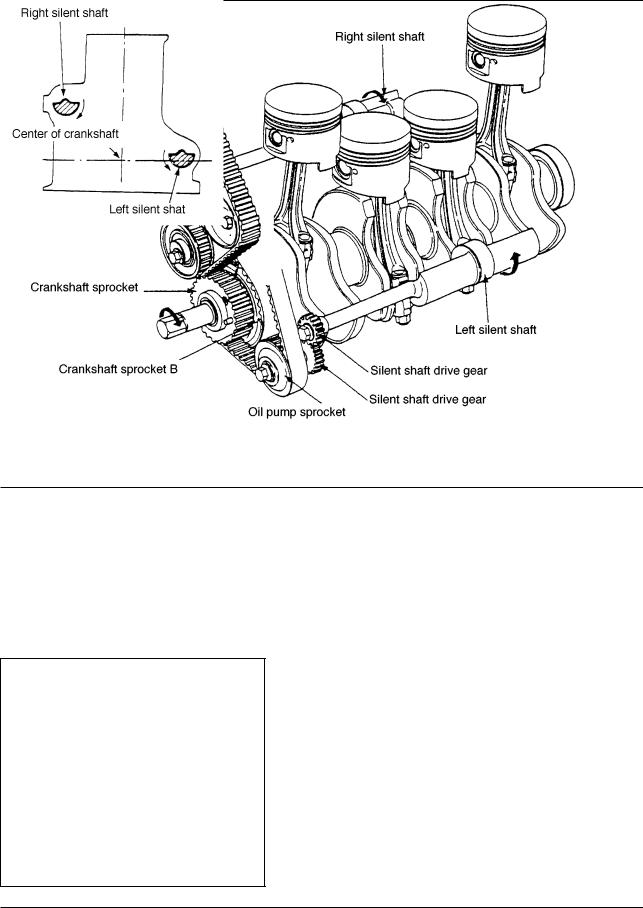

Silent Shaft Mechanism |

26 |

||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||

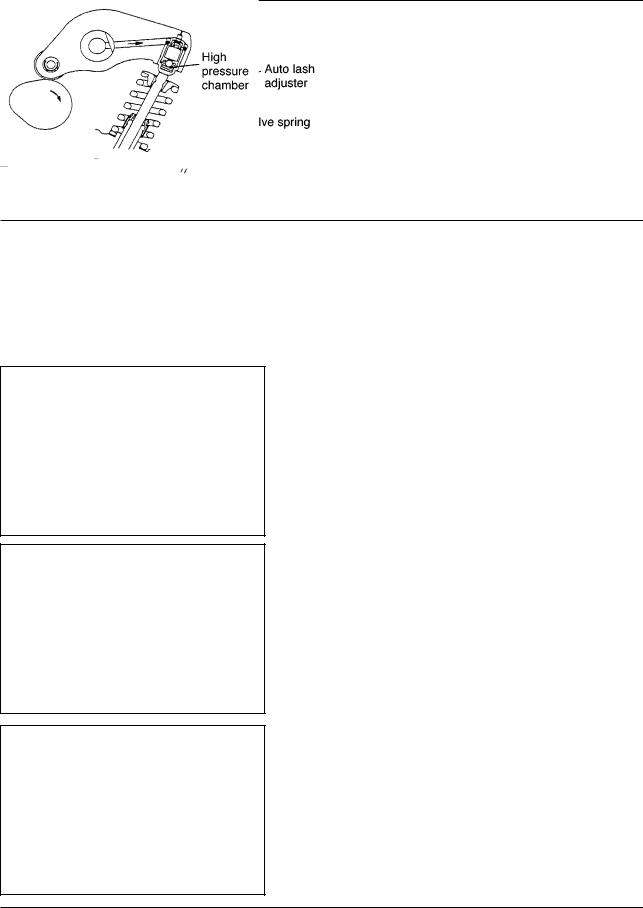

Auto Lash Adjuster |

.............................................. |

27 |

|||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

................................ |

|||||||||||||||||||

Intake and Exhaust System |

28 |

||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|||||||||||||||||||||||

Electrical System |

................................................ |

30 |

|||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||

STARTING SYSTEM |

............................................... |

32 |

|||||||||||||||||||||||||||

|

|

............................................ |

|||||||||||||||||||||||||||

General Description |

32 |

||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||

Start Relay Test |

.................................................. |

35 |

|||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

Start Motor |

.......................................................... |

36 |

|||||||||||||||||||||||||||

|

....................................................... |

||||||||||||||||||||||||||||

Operation |

36 |

||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

............................... |

|||||||||||

Removal and Installation |

39 |

||||||||||||||||||||||||||||

|

|

|

|

...................... |

|||||||||||||||||||||||||

Disassembly and Reassembly |

42 |

||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||

CHARGING SYSTEM |

.............................................. |

47 |

|||||||||||||||||||||||||||

|

............................................ |

||||||||||||||||||||||||||||

General Description |

47 |

||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||

Alternator |

............................................................ |

47 |

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|||

IGNITION SYSTEM ................................................. |

|

|

|

|

|

|

|

|

50 |

||||

Breakerless Ignition System |

|

||||||||||||

|

50 |

||||||||||||

Distributor |

|

|

|

|

|

|

|

|

|

|

|

||

............................................................ |

|

|

|

|

|

|

.................................... |

51 |

|||||

|

|

|

|

|

|

|

|

||||||

Removal and Installation |

54 |

||||||||||||

|

|

|

|

||||||||||

Distributor, disassembly and reassembly ........... |

56 |

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

||

GASOLINE FUEL SYSTEM |

.................................... |

58 |

|||||||||||

|

|

|

|

||||||||||

General Description |

............................................ |

|

|

|

|

|

58 |

||||||

Geasoline Carburetor, Operation |

|||||||||||||

59 |

|||||||||||||

|

|

|

|

|

|

|

|

.................................... |

|||||

Removal and Installation |

64 |

||||||||||||

|

|

|

|

||||||||||

Gasoline Carburetor |

|

|

|

|

|

|

|||||||

Disassembly and Reassembly............................ |

66 |

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

||

LPG FUEL SYSTEM ............................................... |

|

............................................ |

73 |

||||||||||

|

|

|

|

|

|

||||||||

General Description |

73 |

||||||||||||

|

|

|

|

.................................. |

|||||||||

Electric Fuelock Model |

73 |

||||||||||||

Converter |

....................................................... |

74 |

|||||||||||

....................................................... |

|||||||||||||

Fuel Tank |

75 |

||||||||||||

|

|

|

.............................................. |

||||||||||

LP Relief Valve |

75 |

||||||||||||

|

|

|

|

|

|

|

|||||||

Carburetor |

..................................................... |

76 |

|||||||||||

|

|

|

|

........................................... |

|||||||||

Tests or Adjustments |

77 |

||||||||||||

|

|

|

.................................. |

||||||||||

Carburetor Adjustment |

77 |

||||||||||||

|

.............................. |

||||||||||||

Fuel System Leak Check |

79 |

||||||||||||

|

|||||||||||||

Recommendation for LP Fuel System .......... |

80 |

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

||

LP Converter - Check, Clean ........................ |

81 |

||||||||||||

Disassembly and Assembly ................................ |

|

82 |

|||||||||||

LPG Carburetor |

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

82 |

|||||||

LP Gas Fuelock |

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

84 |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

||

LP Gas Converter.......................................... |

|

|

|

|

85 |

||||||||

LPG FUEL SYSTEM (LOW EMISSION VERSION)..87 |

|||||||||||||

General Description |

............................................ |

87 |

|||||||||||

|

|

|

|

|

|

||||||||

LP Carburetor |

................................................ |

89 |

|||||||||||

|

|

|

|

|

................................... |

||||||||

Vacuum switch (MAP) |

90 |

||||||||||||

|

|

|

|||||||||||

Vacuum switch |

.............................................. |

|

|

|

|

|

|

90 |

|||||

LP Converter |

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

91 |

|||||

Fuel Control Valve |

|

|

|

|

|||||||||

|

|

|

|

92 |

|||||||||

Fuelock Valve |

................................................ |

|

|

|

|

|

|

|

92 |

||||

Engine Control Unit (ECU) |

|||||||||||||

93 |

|||||||||||||

Oxygen Sensor |

|

|

|

|

|

|

|

||||||

.............................................. |

|

|

|

|

|

|

94 |

||||||

Catalytic Muffler |

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

95 |

|||||||

Tests or Adjustments |

|

|

|

|

|

||||||||

|

|

|

|

|

96 |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

||

LP Carburetor - Check, Clean....................... |

97 |

||||||||||||

LP Converter-Check,Clean ........................... |

97 |

||||||||||||

Inspection of Fuelock Valve |

|||||||||||||

97 |

|||||||||||||

Inspection of Fuel Control Valve |

|||||||||||||

97 |

|||||||||||||

Inspection of Vacuum switch |

|||||||||||||

97 |

|||||||||||||

Inspection of Vacuum switch (MAP) |

|||||||||||||

97 |

|||||||||||||

Inspection of Oxygen sensor......................... |

98 |

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

||

Disassembly and Assembly |

................................99 |

|

LPG Carburetor |

||

99 |

||

|

||

LP Gas Converter........................................ |

101 |

|

|

G424 Service Manual |

2 |

Index |

DUAL FUEL SYSTEM |

........................................... |

102 |

||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

GOVERNING SYSTEM |

......................................... |

103 |

||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||

General Description |

.......................................... |

103 |

||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

.......... |

||||||||||

Governor,Disassembly and Reassembly |

104 |

|||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||

LUBRICATION SYSTEM |

....................................... |

106 |

||||||||||||||||||||||||||

General Description |

.......................................... |

106 |

||||||||||||||||||||||||||

|

|

........................................ |

||||||||||||||||||||||||||

Testing and Adjusting |

107 |

|||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||

Engine Oil |

............................................... |

107 |

||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

.................. |

||||||||||

Lubrication System Problem |

107 |

|||||||||||||||||||||||||||

|

|

|

|

|||||||||||||||||||||||||

Oil Pressure Check |

................................ |

109 |

||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||

COOLING SYSTEM |

............................................... |

|||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

110 |

||||||

General Description |

.......................................... |

|||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

110 |

|||||||||

Testing and Adjusting |

........................................ |

|||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

111 |

|||||||||||

Cooling System Visual Inspection |

............... |

|||||||||||||||||||||||||||

|

|

|

111 |

|||||||||||||||||||||||||

Cooling System Tests |

.................................. |

|||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

111 |

|||||||||||||||

Thermostat |

................................................... |

|||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

113 |

|||

Cooling system Heat Problem |

..................... |

|||||||||||||||||||||||||||

|

|

|

|

|

114 |

|||||||||||||||||||||||

Cooling System Recommendation .............. |

|

|

114 |

|||||||||||||||||||||||||

Belt Adjustment |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

............................................ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

116 |

|||||||

V-belt Diagnosis |

........................................... |

|||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

116 |

||||||||

Serivce Procedure |

............................................ |

|||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

117 |

|||||||

Draining and Filling Cooling System |

........... |

|||||||||||||||||||||||||||

|

|

117 |

||||||||||||||||||||||||||

Flushing the Cooling System |

....................... |

|||||||||||||||||||||||||||

|

|

|

|

|

|

118 |

||||||||||||||||||||||

Radiator Service |

.......................................... |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

118 |

||||||||

Removal & Install Water Temperature Sender..119 |

||||||||||||||||||||||||||||

BASE ENGINE SERVICE PROCEDURE ............. |

|

|

120 |

|||||||||||||||||||||||||

|

........................................................ |

|||||||||||||||||||||||||||

Timing Belt |

120 |

|||||||||||||||||||||||||||

|

|

................................................. |

||||||||||||||||||||||||||

Intake Manifold |

129 |

|||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

.................. |

||||||||

Exhaust Manifold and Water Pump |

130 |

|||||||||||||||||||||||||||

|

|

|

|

|||||||||||||||||||||||||

Rocker Arms and Camshaft |

.............................. |

133 |

||||||||||||||||||||||||||

Cylinder Head and Valves |

................................ |

139 |

||||||||||||||||||||||||||

Front Case and Oil Pan |

.................................... |

145 |

||||||||||||||||||||||||||

|

|

|

|

.............................. |

||||||||||||||||||||||||

Piston and Connecting Rod |

154 |

|||||||||||||||||||||||||||

|

|

|

......................... |

|||||||||||||||||||||||||

Crankshaft and Cylinder Block |

162 |

|||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|||||||||||||||||||||

ADJUSTMENT AND TROUBLESHOOTING ........169 |

||||||||||||||||||||||||||||

Adjustment |

........................................................ |

169 |

||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

......................... |

||||||||||

Valve Clearnce Adjustment |

169 |

|||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|||||||||||||||||||||

Ignition Timing Adjustment |

.......................... |

169 |

||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

||||||||||||||||||||

Idle Speed Adjustment |

................................ |

171 |

||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||

Air Governor Adjustment |

............................. |

|

|

|

|

|

|

|

|

|

171 |

|||||||||||||||||

Anti-Hunting Adjustment |

.............................. |

171 |

||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||

Troubleshooting |

................................................ |

172 |

||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

Engine Performance |

.................................... |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

172 |

||||||||||||

Engine Starting Problems |

|

|

|

|

|

|

|

|

|

|||||||||||||||||||

|

|

........................ |

172 |

|||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

Charging System Problems |

173 |

|||||||||||||||||||||||||||

|

|

|

|

|

|

|

||||||||||||||||||||||

Instrument Problems |

................................... |

173 |

||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||

Engine Noise |

............................................... |

174 |

||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

............................. |

||||||||||||||||

Oil Pressure Diagnostics |

176 |

|||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||

Oil Pressure Problems |

................................ |

177 |

||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||

Water in Engine |

........................................... |

178 |

||||||||||||||||||||||||||

|

|

|

|

....................................... |

||||||||||||||||||||||||

Engine Overheting |

179 |

|||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

LP Fuel System |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

(Standard and/or Low Emission Version).... |

180 |

|||||||||||||||||||||||||||

Troubleshooting Flow Chart |

........................ |

187 |

||||||||||||||||||||||||||

|

|

|

|

|

|

|

||||||||||||||||||||||

General |

.................................................. |

187 |

|||

|

|

||||

Engine |

.................................................... |

189 |

|||

Carburetor .............................................. |

|

190 |

|||

|

|

|

........................... |

||

Electrical Components |

192 |

||||

|

|||||

SPECIAL TOOLS |

.................................................. |

195 |

|||

|

|

||||

G424 Service Manual |

3 |

Index |

GENERAL INFORMATION

How To Read This Manual

Scope of Explanation

This book describes the service procedures for the engine removed from the vehicle.

For procedures concerning removal of the engine from the vehicle and on-vehicle inspection and servicing, refer to the appropriate service manuals separately prepared for the individual models.

Maintenance and Servicing Procedures

(1) A diagram of the component parts is provided |

• Removal steps: |

near the front each section in order to give the |

The part designation number corresponds to the |

reader a better understanding of the installed |

number in the illustration to indicate removal steps. |

condition of component parts. |

|

|

• Installation steps: |

(2) The numbers provided within the diagram |

Specified in case installation impossible in reverse |

indicate the sequence for maintenance and |

order of removal steps. Omitted if installation is |

servicing procedures; the symbol N indicates a |

possible in reverse order of removal steps. |

non-reusable part; the tightening torque is |

|

provided where applicable. |

• Disassembly steps: |

|

The part designation number corresponds to the number |

|

in the illustration to indicates disassembly steps. |

|

• Reassembly steps. |

|

Specified in case reassembly is impossible in |

|

reverse order of disassembly steps. Omitted if |

|

reassembly is possible in reverse order of |

|

disassembly steps. |

Classification of Major Maintenance/Service points

When there are major points relative to maintenance and servicing procedures (such as essential maintenance and service points, maintenance and service standard values, information regarding the use of special tools, etc.), these are arranged together as major maintenance and service points and explained in detail.

A : Indicates that there are essential points for removal or disassembly. B : Indicates that there are essential points for installation or reassembly.

Symbols for Lubrication, Sealants and |

following the component parts page, and |

|

Adhesives |

explained. |

|

Information concerning the locations for |

|

|

lubrication and for application of sealants and |

.... Sealant or adhesive |

|

|

||

adhesives if provided, by using symbols, in the |

|

|

diagram of component parts, or on the page |

.... Engine oil or gear oil |

|

|

|

|

Inspection

Only the inspections to be performed by using special tools or measuring instruments are covered. General service procedures not covered in this manual, such as visual inspections and cleaning of parts, however, should always be performed during actual service operations.

G424 Service Manual |

4 |

General Information |

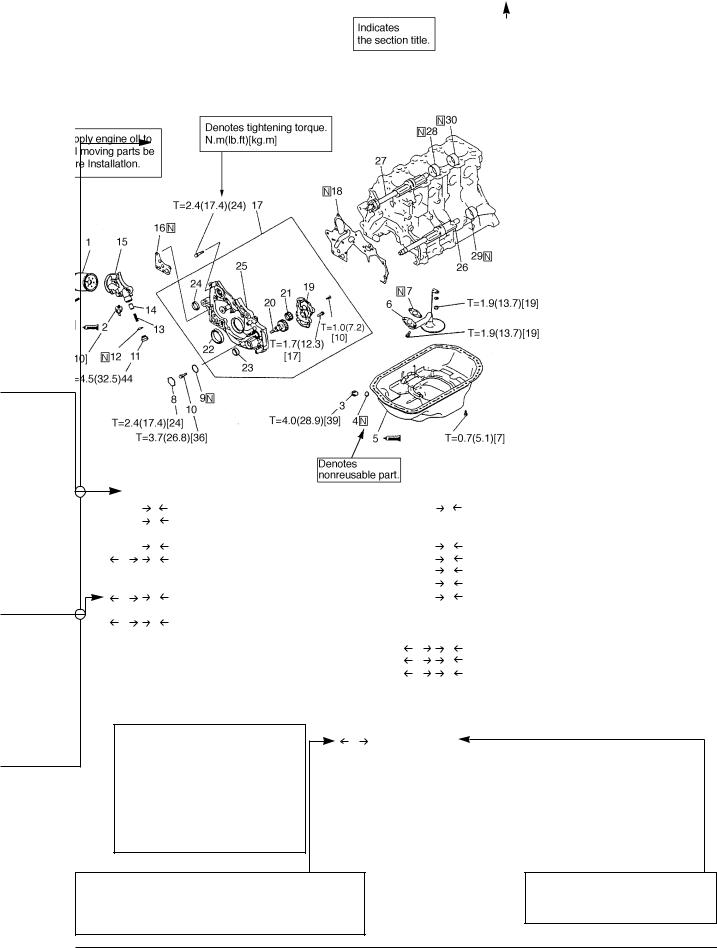

FRONT CASE AND OIL PAN

REMOVAL AND INSTALLATION

|

|

|

|

|

|

|

|

|

6EN1898 |

|

|

|

N |

1. |

Oil filter |

|

H |

17. |

Oil pump case assembly |

|

|

|

|

||||||

|

|

|

|

||||||

|

|

|

M |

2. |

Oil pressure switch |

|

|

18. |

Front case gasket |

|

|

|

|

3. |

Drain plug |

|

G |

19. |

Oil pump cover |

|

|

|

L |

4. |

Drain plug gasket |

|

G |

20. |

Oil pump drive gear |

|

|

A |

K |

5. |

Oil pan |

|

G |

21. |

Oil pump driven gear |

|

|

|

|

6. |

Oil screen |

|

F |

22. |

Crankshaft front oil seal |

|

|

|

|

7. |

Oil screen gasket |

|

E |

23. |

Oil pump oil seal |

|

|

B |

J |

8. |

Plug |

|

D |

24. |

Counterbalance shaft oil seal |

|

|

|

|

9. |

O-ring |

|

|

25. |

Front case |

|

|

|

|

|

|

||||

|

|

C |

I |

10. |

Flang bolt |

|

|

26. |

Counterbalance shaft, left |

|

|

|

|

||||||

|

|

|

|

11. Relief plug |

|

|

27. |

Counterbalance shaft, right |

|

|

|

|

|

12. |

Gasket |

D |

C |

28. |

Counterbalance shaft, front bearing |

|

|

|

|

13. |

Relief spring |

E |

B |

29. |

Counterbalance shaft, rear bearing, left |

|

|

|

|

14. |

Relief plunger |

E |

A |

30. |

Counterbalance shaft, rear bearing, right |

15.Oil filter bracket

16.Oil filter bracket gasket

|

REMOVAL SERVICE POINTS |

MD998727 |

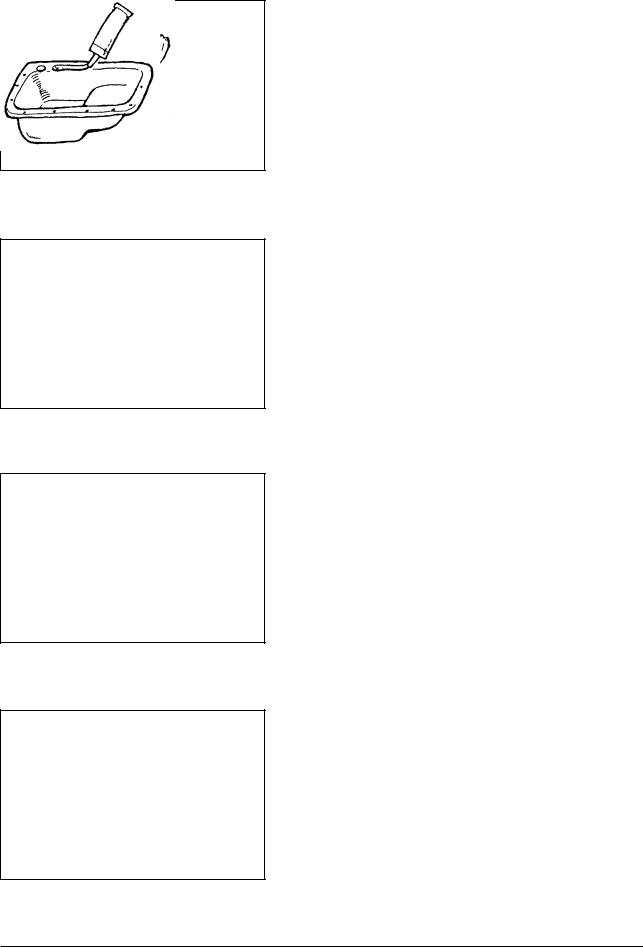

A Oil pan removal |

|

(1)Remove the all oil pan bolts.

(2)Drive in the special tool between the cylinder block and oil pan.

(3)Side the tool by striking the edge of the special tool to separate the oil pan from the cylinder block.

6EN0698

This alphabetical letter corresponds to the one assigned to a part in the removal, installation, disassembly or reassembly steps that are indicated in the drawing on the first page of each section.

Operating procedures, cautions, etc. on removal, installation, disassembly and reassembly are described

G424 Service Manual |

5 |

General Information |

SEALANT

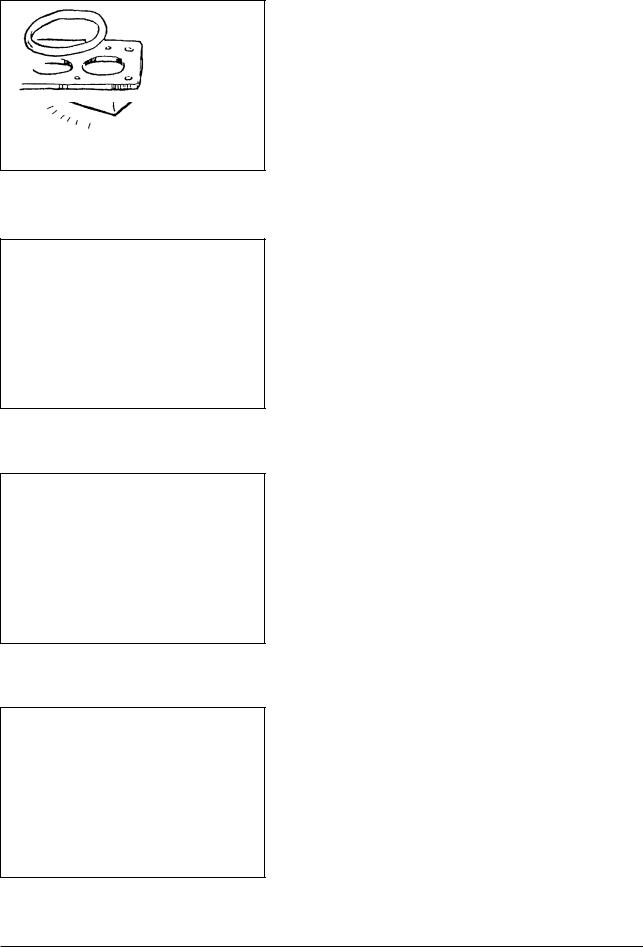

Precautions Before Servce

Removal and Disassembly

For prevention of wrong installation or reassembly and for ease of operation, put mating marks to the parts where no function is adversely affected.

1EN0018

Special Tool

Be sure to use Special Tools when their use is specified for the operation.

Use of substitute tools will result in malfunction of the part or damage it.

1EN0019

Tightening Torque

Tighten the part properly to specified torque.

1EN0020

Sealant

Use specified brand of sealant.

Use of sealant other than specified sealant may cause water or oil leaks.

1EN0021

G424 Service Manual |

6 |

General Information |

Replacement Part

When oil seal, O-ring, packing and gasket have been removed, be sure to replace them with new parts. However, rocker cover gasket may be reused if it is not damaged.

1EN0022

Rubber Parts

Do not stain timing belt and V-belt with oil or water. Therefore, do not clean the pulley and sprocket with detergent.

1EN0023

Oil and Grease

Before reassembly, apply specified oil to the rotating and sliding parts.

1EN0024

Genuine Part

When the part is to be replaced, be sure to use genuine part.

For selection of appropriate parts, refer to the Parts Catalog.

1EN0025

G424 Service Manual |

7 |

General Information |

General

Engine models and numbers

Engine model |

Fuel type |

|

|

G424 |

Gasoline, LPG, LPG (Low Emission Version) |

|

|

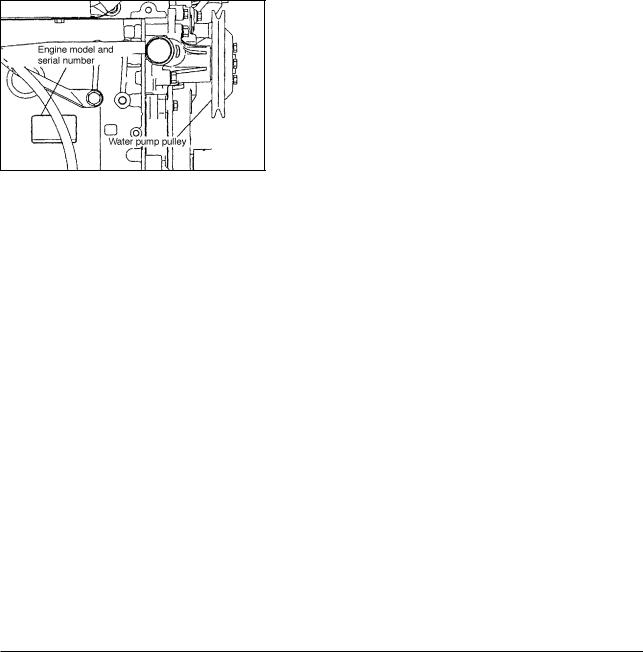

Indication of engine model and number

The engine model and serial number are stamped on the right side of cylinder block surface.

Engine model |

Engine number |

|

|

4G64 |

AA0001 to YY9999 |

|

|

6EN1916

G424 Service Manual |

8 |

General Information |

Tightening Torque

Major Bolts and Nuts

|

Item |

|

|

Torque |

|

|

Remarks |

||

|

|

|

|

|

|

|

|||

|

kg•m |

|

lb•ft |

|

N•m |

||||

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

Water pump pulley bolt |

0.9 |

|

6.5 |

|

9 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Crankshaft pulley bolt |

2.5 |

|

18.1 |

|

25 |

|

|

|

|

|

|

|

|

|

|

|

|

|

Ignition system |

Spark plug |

2.5 |

|

18.1 |

|

25 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Distributor nut |

1.2 |

|

8.7 |

|

12 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Timing belt cover bolt |

1.1 |

|

8.0 |

|

11 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0.9 |

|

6.5 |

|

9 |

|

|

|

|

|

|

|

|

|

|

|

|

|

Tensioner spring spacer |

4.9 |

|

35.4 |

|

48 |

|

|

|

|

|

|

|

|

|

|

|

|

|

Tensioner belt |

Tensioner bolt |

4.9 |

|

35.4 |

|

48 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Oil pump sprocket nut |

5.5 |

|

39.8 |

|

54 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Crankshaft bolt |

12.0 |

|

86.8 |

|

118 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Tensioner B bolt |

1.9 |

|

13.7 |

|

19 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Counterbalance shaft |

4.6 |

|

33.3 |

|

45 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Engine support bracket bolt |

3.6 |

|

26.0 |

|

35 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Camshaft sprocket bolt |

9.0 |

|

65.1 |

|

88 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Timing belt rear bolt |

1.4 |

|

10.1 |

|

14 |

|

|

|

|

|

|

|

|

|

|

|

|

|

Fuel system |

Carburetor nut |

1.2 |

|

8.7 |

|

12 |

|

|

|

|

|

|

|

|

|

|

|

|

|

carburetor |

Air horn nut |

1.2 |

|

8.7 |

|

12 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Stud |

1.2 |

|

8.7 |

|

12 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Fuel pump |

1.1 |

|

8.0 |

|

11 |

|

|

|

|

|

|

|

|

|

|

|

|

|

Fuel system |

LPG carburetor nut |

1.2 |

|

8.7 |

|

12 |

|

|

|

|

|

|

|

|

|

|

|

|

|

LPG carburetor |

Fuel pump cover |

1.1 |

|

8.0 |

|

11 |

|

|

|

|

|

|

|

|

|

|

|

|

|

Intake manifold |

Water outlet bolt |

1.4 |

|

10.1 |

|

14 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Intake manifold bolt/nut |

1.8 |

|

13.0 |

|

18 |

|

|

|

|

|

|

|

|

|

|

|

|

|

Exhaust |

Oil level gauge guide bolt |

1.4 |

|

10.1 |

|

14 |

|

|

|

|

|

|

|

|

|

|

|

|

|

manifold |

Heat protector bolt |

0.9 |

|

6.5 |

|

9 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Exhaust manifold nut |

3.5 |

|

25.3 |

|

34 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Water inlet pipe bolt |

1.4 |

|

10.1 |

|

14 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Water pump bolt |

1.4 |

|

10.1 |

|

14 |

|

|

|

|

|

|

|

|

|

|

|

|

|

Rocker arm |

Rocker cover bolt |

0.6 |

|

4.3 |

|

6 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

M8 B 25 |

2.4 |

|

17.4 |

|

24 |

|

|

|

and camshaft |

Bearing cap bolt |

|

|

|

|

||||

|

|

|

|

|

|

|

|

||

M6 B 65 |

2.0 |

|

14.5 |

|

20 |

|

|

||

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

Cylinder head, |

|

|

8.0 kgf•m(57.9 lb•ft)[78 N•m]+ 0 + |

|

|||||

|

|

|

|

||||||

valve |

Cylinder head bolt |

2.0 kgf•m(14.5 lb•ft)[20 N•m]+ |

|

||||||

|

|

|

|

1/4 turn + 1/4 turn |

|

|

|

||

|

|

|

|

|

|

|

|

|

|

G424 Service Manual |

9 |

General Information |

|

Item |

|

Torque |

|

|

Remarks |

|

|

|

|

|

|

|||

|

kg•m |

lb•ft |

N•m |

||||

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

Drain plug |

4.0 |

28.9 |

39 |

|

|

|

|

|

|

|

|

|

|

|

|

Oil pan bolt |

0.7 |

5.1 |

7 |

|

|

|

|

|

|

|

|

|

|

|

|

Oil screen bolt/nut |

1.9 |

13.7 |

19 |

|

|

|

|

|

|

|

|

|

|

|

|

Oil pressure switch |

1.0 |

7.2 |

10 |

|

|

|

|

|

|

|

|

|

|

|

Front case, |

Plug |

2.4 |

17.4 |

24 |

|

|

|

|

|

|

|

|

|

|

|

doil pan |

Flange bolt |

3.7 |

26.8 |

36 |

|

|

|

|

|

|

|

|

|

|

|

|

Relief plug |

45 |

32.5 |

44 |

|

|

|

|

|

|

|

|

|

|

|

|

Oil filter bracket |

1.9 |

13.7 |

19 |

|

|

|

|

|

|

|

|

|

|

|

|

Oil pump cover bolt |

1.7 |

12.3 |

17 |

|

|

|

|

|

|

|

|

|

|

|

|

Oil pump cover screw |

1.0 |

7.2 |

10 |

|

|

|

|

|

|

|

|

|

|

|

|

Front case bolt |

2.4 |

17.4 |

24 |

|

|

|

|

|

|

|

|

|

|

|

Piston, |

Connecting rod bearing nut |

2.0 kg•m(14.5 lb•ft) [20 N•m]+ 1/4 turn |

|

||||

connecting rod. |

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Flywheel bolt |

13.5 |

97.6 |

132 |

|

|

|

|

|

|

|

|

|

|

|

|

Rear plate bolt |

|

0.9 |

6.5 |

9 |

|

|

Crankshaft, |

|

|

|

|

|

|

|

|

6.0 |

43.4 |

59 |

|

|

||

|

|

|

|

||||

|

|

|

|

|

|

|

|

cylinder block |

Rear plate cover |

1.1 |

8.0 |

11 |

|

|

|

|

|

|

|

|

|

|

|

|

Oil seal case bolt |

1.1 |

8.0 |

11 |

|

|

|

|

|

|

|

|

|

||

|

Bearing cap bolt |

2.0 kg•m(14.5 lb•ft) [20 N•m]+ 1/4 turn |

|

||||

|

|

|

|

|

|

|

|

Starter motor |

Starter motor bolt |

2.7 |

19.5 |

26 |

|

|

|

G424 Service Manual |

10 |

General Information |

General Bolts and Nuts Tightening Torque

Standard Bolts and Nuts

|

|

|

Torque, kg•m (lb•ft) [N•m] |

|

|||

Nominal |

|

|

|

|

|

|

|

Pitch |

Bolt, stud, nut (with spring washer) |

Flange bolt, flange nut |

|||||

diameter |

|||||||

|

|

|

|

|

|

||

|

Head mark 4 |

Head mark 7 |

Head mark 10 |

Head mark 4 |

Head mark 7 |

||

|

|

||||||

|

|

|

|

|

|

|

|

M5 |

M5 |

- |

0.5 (0.5) [3.6] |

- |

- |

0.6 (4.3) [5.9] |

|

|

|

|

|

|

|

|

|

M6 |

M6 |

- |

0.9 (6.5) [8.8] |

1.2 (8.7) [12] |

- |

1.0 (7.2) [9.8] |

|

|

|

|

|

|

|

|

|

M7 |

M7 |

1.2 (8.7) [12] |

2.2 (15.9) [22] |

3.0 (21.7) [29] |

1.3 (9.4) [13] |

2.4 (17.4) [24] |

|

|

|

|

|

|

|

|

|

M8 |

M8 |

2.5 (18.1) [25] |

4.5 (32.5) [44] |

6.0 (43.4) [59] |

2.6 (18.8) [25] |

5.0 (36.2) [49] |

|

|

|

|

|

|

|

|

|

M9 |

M9 |

4.2 (30.4) [41] |

8.6 (60.0) [81] |

10.7 (77.4) [105] |

4.7 (34.0) [46] |

9.5 (68.7) [93] |

|

|

|

|

|

|

|

|

|

M10 |

M10 |

7.3 (52.8) [72] |

14.0 (101.3) [137] |

14.5 (104.9) [142] |

- |

- |

|

|

|

|

|

|

|

|

|

Tapered Threads

|

Torque, kg•m (lb•ft) [N•m] |

||

|

|

|

|

Size |

Material of internal threads: |

Material of internal threads: |

|

|

Aluminum alloy |

Cast iron or steel |

|

|

|

|

|

NPTF 1/16 |

0.5 to 0.8 (3.6 to 5.8) |

[5 to 8] |

0.8 to 1.2 (5.8 to 8.7) [8 to 11] |

|

|

|

|

PT 1/8 |

0.8 to 1.2 (5.8 to 8.7) [8 to 11] |

1.5 to 2.2 (10.8 to 15.9) [15 to 21] |

|

|

|

|

|

PT 1/4 |

2.0 to 3.0 (14.5 to 21.7) |

[20 to 29] |

3.5 to 4.5 (25.3 to 32.5) [34 to 44] |

|

|

|

|

NPTF 1/4 |

2.0 to 3.0 (14.5 to 21.7) |

[20 to 29] |

3.5 to 4.5 (25.3 to 32.5) [34 to 44] |

|

|

|

|

PT 3/8 |

4.0 to 5.5 (28.9 to 39.8) |

[39 to 59] |

5.5 to 7.5 (39.8 to 54.2) [54 to 73] |

|

|

|

|

PT 1/2 |

7.0 to 10.0 (50.6 to 72.3) [69 to 98] |

12.0 to 16.0 (86.8 to 115.7) [118 to 156] |

|

|

|

|

|

New Tightening Method-By Use of Bolts to be Tightened in Plastic Area

A new type of bolts, to be tightened in plastic area, is currently used in some parts of the engine. The tightening method for the bolts is different from the conventional one. Be sure to observe the method described in the text when tightening the bolts.

Service limits are provided for the bolts. Make sure that the service limits described in the text are strictly observed.

•Area where the bolts are in use:

(1)Cylinder head bolts

(2)Main bearing cap bolts

(3)Connecting rod cap bolts

•Tightening method

After tightening the bolts to the specified torque, tighten them another 90° or 180° (twice 90°). The tightening method varies on different areas. Observe the tightening method described in the text.

G424 Service Manual |

11 |

General Information |

Sealant

Part to be Applied |

Brand |

|

|

Semi circular packing |

3MTM AAD Part No.8672 or equivalent |

|

|

Rocker cover |

3MTM AAD Part No.8672 or equivalent |

Oil pressure switch |

3MTM AAD Part No.8672 or equivalent |

|

|

Oil pan |

Silicone RTV sealant or eguivalent |

|

|

Rear oil seal case |

Silicone RTV sealant or eguivalent |

|

|

Rear plate bolt |

3MTM AAD Part No.8672 or equivalent |

|

|

Oil seal case bolt |

3MTM AAD Part No.8672 or equivalent |

|

|

From in Place Gasket (FIPG)

The engine has several areas where the from-in-place gasket(FIPG) is in use. To ensure that gasket fully serves its purpose, it is necessary to observe some precautions when applying the gasket. Bead size, continuity and location are of paramount importance. Too thin a bead could cause leaks. Too thick a bead, on the other hand, could be squeezed out of location, causing blocking or narrowing of the fluid feed line. To eliminate the possibility of leaks from a joint, therefore, it is absolutely necessary to apply the gasket evenly without a break, while observing the correct bead size.

Since the FIPG used in the engine hardens as it reacts with the moisture in the atmospheric air, it is normally used in the metallic flange areas.

Disassembly

The parts assembled with the FIPG can be easily disassembled without use of a special method. In some cases, however, the sealant between the joined surfaces may have broken by lightly striking with a mallet or similar tool. A flat and thin gasket scraper may be lightly hammered in between the joined surfaces. In this case, however, care must be taken to prevent damage to the joined surfaces. For removal of the oil pan, the special tool “Oil Pan Remover” (MD998727) is available. Be sure to use the special tool to remove the oil pan.

Surface preparation

Thoroughly remove all substances deposited on the gasket application surfaces, using a gasket scraper or wire brush.

Check to ensure that the surfaces to which the FIPG is to be applied is flat. Make sure that there are no oils, greases and foreign substances deposited on the application surfaces. Do not forget to remove the old FIPG remaining in the bolt holes.

From-in-place gasket Application

Applied FIPG bead should be of the specified size and without breaks. Also be sure to encircle the bolt hole circumference with a completely continuous bead. The FIPG can be wiped away unless it is hardened. While the FIPG is still moist (in less than 15 minutes), mount the parts in position. When the parts are mounted, make sure that the gasket is applied to the required area only.

The FIPG application procedure may vary on different areas. Observe the procedure described in the text when applying the FIPG.

G424 Service Manual |

12 |

General Information |

SPECIFICATIONS

General Specifications

Item |

Engine model |

G424 |

||

|

|

|

||

|

|

|

|

|

|

|

|

|

|

Type |

|

|

|

Water-cooled, 4-cycle, gasoline-powered and L.P.G.-powered |

|

|

|

|

|

No. of cylinders and arrangement |

|

4, in-line |

||

|

|

|

|

|

Combustion chamber type |

|

Semi-spherical |

||

|

|

|

|

|

Valve mechanism |

|

|

|

OHC |

|

|

|

|

|

Total displacement, cm3(cc) [cu in.] |

|

2350 (2350) [143] |

||

Bore x stroke, mm (in.) |

|

86.5 B 100 (3.41 B 3.94) |

||

|

|

|

|

|

Dry weight, kg (lb) |

|

|

|

146 (322) |

|

|

|

|

|

Compression ratio |

|

|

|

8.6 |

|

|

|

|

|

Compression pressure, kPa (kgf/cm2) [psi] |

1128 (11.5) [163.5] |

|||

|

Intake |

|

Open |

12° BTDC |

|

|

|

|

|

Valve timing |

valve |

|

Close |

40° ABDC |

|

|

|

|

|

Exhaust |

|

Open |

54° BBDC |

|

|

|

|||

|

|

|

|

|

|

valve |

|

Close |

6° ATDC |

|

|

|

|

|

Firing order |

|

|

|

1 - 3 - 4 - 2 |

|

|

|

|

|

Ignition timing, BTDC/rpm |

|

4°/740 (gasoline), 9°/740 (L.P.G.), 4˚/740(dual fuel) |

||

|

|

|

|

|

Fuel pump |

|

|

Gasoline |

Mechanical (diaphragm type) |

|

|

|

|

|

Carburetor |

|

|

|

Down-draft type |

|

|

|

|

|

Governor |

|

|

|

Air flow type |

|

|

|

|

|

Lubrication system |

|

|

|

Pressure feed, full-flow filtration type |

|

|

|

|

|

Oil pump |

|

|

|

Gear, driven by timing belt |

|

|

|

|

|

Oil filter |

|

|

|

Filter paper, cartridge type |

|

|

|

|

|

Cooling system |

|

|

|

Water-cooled, forced circulation |

|

|

|

|

|

Water pump |

|

|

|

Centrifugal, driven by V-belt |

|

|

|

|

|

Thermostat |

|

|

|

Wax type |

|

|

|

|

|

Electrical system |

|

|

|

12V DC, negative ground |

|

|

|

|

|

Alternator, (12V-61A) |

|

|

|

Alternator current, built-in fan and regulator |

|

|

|

|

|

Starter motor, (12V-1.2kW) |

|

Reduction drive |

||

|

|

|

|

|

Distributor |

|

|

|

Equipped with automatic timing controller, breaker less type |

|

|

|

|

|

Spark plug (NGK) |

|

|

Gasoline |

BPR4ES |

|

|

|

|

|

|

|

|

L. P. G. |

BPR5ES |

|

|

|

|

|

Quantity of lubricating oil, cm3 (liter) [U.S.gal] |

4000(4.0) [1.06 ]( including 300 cm3(0.3 liter)[0.08 U.S.gal ]in oil filter |

|||

Quantity of coolant, cm3 (liter) [U.S.gal] |

3100 (3.1) [0.82] (in engine proper) |

|||

IDLE RPM |

LOW (RPM) |

|

700 L 25 |

|

|

|

|

|

|

|

HIGH (RPM) |

|

2700 L 50 |

|

|

|

|

|

|

G424 Service Manual |

13 |

Specifications |

Service Specifications

|

|

|

|

|

|

|

|

Unit : mm(in.) |

|

|

|

|

|

|

|

|

|

|

|

|

Item |

|

Standard value |

Limit |

Remarks |

|

|

|

|

|

|

|

|

|

|

|

Flatness of gasket surface |

|

0.03 |

(0.0012) |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Total resurfacing |

|

Grinding limit |

|

|

|

|

0.2 (0.008) |

depth of both |

|

|

|

|

|

|

cylinder head and |

|||

|

|

|

|

|

|

|

|

cylinder block |

head |

|

|

|

|

|

|

|

|

Overall height |

|

|

89.9 to 90.1 |

(3.539 to 3.547) |

|

|

||

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

Cylinder |

Oversize rework |

0.05 (0.0020) |

13.05 to 13.07 |

(0.5138 to 0.5146) |

|

|

||

dimensions of valve |

0.25 (0.0098) |

13.25 to 13.27 |

(0.5217 to 0.5224) |

|

|

|||

|

|

|

||||||

|

guide hole |

|

|

|

|

|

|

|

|

|

0.50 (0.0197) |

13.50 to 13.57 |

(0.5315 to 0.5343) |

|

|

||

|

|

|

|

|

|

|

|

|

|

Oversize |

|

Intake |

0.30 (0.0118) |

47.30 to 47.33 |

(1.8622 to 1.8634) |

|

|

|

rework |

|

|

|

|

|

|

|

|

|

0.60 (0.0236) |

47.60 to 47.63 |

(1.8740 to 1.8752) |

|

|

||

|

dimensions of |

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

Exhaust |

0.30 (0.0118) |

40.30 to 40.33 |

(1.5866 to 1.5878) |

|

|

|

|

valve seat |

|

|

|

||||

|

ring hole |

|

|

0.60 (0.0236) |

40.60 to 40.63 |

(1.5984 to 1.5996) |

|

|

|

|

|

|

|

|

|

|

|

Camshaft |

Cam height |

|

Intake |

41.62 (1.6386) |

41.12 (1.6189) |

|

||

|

|

|

|

|

|

|||

|

|

Exhaust |

41.62 (1.6386) |

41.12 (1.6189) |

|

|||

|

|

|

|

|

||||

|

|

|

|

|

|

|

||

|

Journal diameter |

|

33.935 to 33.950 (1.33602 to 1.33661) |

|

|

|||

|

|

|

|

|

|

|

|

|

|

Oil clearance |

|

|

0.05 to 0.09 (0.0020 to 0.0035) |

|

|

||

|

|

|

|

|

|

|

|

|

|

Overall length |

|

Intake |

106.6 (4.197) |

106.1 (4.126) |

|

||

|

|

|

|

|

|

|

||

|

|

Exhaust |

105.2 (4.142) |

104.7 (4.122) |

|

|||

|

|

|

|

|

||||

|

|

|

|

|

|

|

||

|

Valve stem projection |

|

42.05 (1.6555) |

42.55 (1.6752) |

|

|||

|

|

|

|

|

|

|

|

|

|

Stem diameter |

|

Intake |

7.960 to 7.975 (0.31339 to 0.31398) |

|

|

||

|

|

|

|

|

|

|

|

|

Valve |

|

|

|

Exhaust |

7.930 to 7.950 (0.31220 to 0.31299) |

|

|

|

|

|

|

|

|

|

|

||

Face angle |

|

|

45° to 45.5° |

|

|

|||

|

|

|

|

|

|

|

|

|

|

Thickness of valve |

Intake |

1.2 |

(0.047) |

|

|

||

|

|

|

|

|

|

|

|

|

|

head (margin) |

|

Exhaust |

2.0 |

(0.079) |

|

|

|

|

|

|

|

|

|

|

|

|

|

Stem-to-guide |

|

Intake |

0.025 to 0.058 (0.00098 to 0.00228) |

|

|

||

|

|

|

|

|

|

|

|

|

|

clearance |

|

Exhaust |

0.050 to 0.088 (0.00197 to 0.00346) |

|

|

||

|

|

|

|

|

|

|

|

|

spring |

Free height |

|

|

48.0 (1.89) |

47.0 (1.85) |

|

||

|

|

|

|

|||||

|

|

|

|

|

|

|

||

Valve |

Load/installed height |

|

176.5N (18kg) [39.7lbf]/40.4 (1.591) |

|

|

|||

|

|

|

|

|

|

|||

Out-of-squareness |

|

2° or less |

4° |

|

||||

|

|

|

|

|

|

|

|

|

guide |

Overall length |

|

Intake |

47 (1.85) |

|

|

||

|

|

|

|

|

|

|||

|

Exhaust |

52 (2.05) |

|

|

||||

Valve |

|

|

|

|

|

|||

|

|

|

|

|

|

|

||

Inner diameter |

|

|

8.000 to 8.018 (0.31496 to 0.31567) |

|

|

|||

|

|

|

|

|

|

|

||

seat |

Valve contact width |

|

0.9 to 1.3 (0.035 to 0.051) |

|

|

|||

Valve |

|

|

|

|

|

|

|

|

Sinkage |

|

|

|

|

0.2 (0.008) |

|

||

|

|

|

|

|

|

|

|

|

Piston |

Outside diameter |

|

86.47 to 86.50 |

(3.4043 to 3.4055) |

|

|

||

|

|

|

|

|

|

|||

Piston clearance |

|

0.02 to 0.04 (0.0008 to 0.0016) |

|

|

||||

G424 Service Manual |

14 |

Specifications |

|

|

|

|

|

|

|

Unit : mm(in.) |

|

|

|

|

|

|

|

|

|

Item |

|

Standard value |

Limit |

Remarks |

||

|

|

|

|

|

|

|

|

ring |

End gap |

|

No. 1 ring |

0.25 to 0.40 (0.0098 to 0.0157) |

0.8 (0.031) |

|

|

|

|

|

|

|

|

|

|

|

|

|

No. 2 ring |

0.45 to 0.60 (0.0177 to 0.0236) |

0.8 (0.031) |

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

Piston |

|

|

|

Oil ring |

0.20 to 0.60 (0.0079 to 0.0236) |

1.0 (0.039) |

|

|

|

|

|

|

|

|

|

Ring-to-ring groove |

|

No. 1 |

0.03 to 0.07 (0.0012 to 0.0028) |

|

|

||

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

clearance |

|

No. 2 |

0.03 to 0.07 (0.0012 to 0.0028) |

|

|

|

|

|

|

|

|

|

|

|

pin |

Outside diameter |

|

22.002 to 22.005 (0.86622 to 0.86634) |

|

|

||

|

|

|

|

|

|

|

|

Press-in load |

|

7350 to 17160 |

|

|

|||

Piston |

|

|

|

||||

(at room temperature), |

|

(750 to 1750) |

|

|

|||

|

|

|

|

||||

|

N (kg) [lbf] |

|

[1650 to 3860] |

|

|

||

|

|

|

|

|

|

||

rod |

Big end center-to small end center |

149.9 to 150.0 (5.902 to 5.906) |

|

|

|||

length |

|

|

|

|

|||

Connecting |

|

|

|

|

|||

|

|

|

|

|

|

||

Big end thrust clearance |

|

0.10 to 0.25 (0.0039 to 0.0098) |

|

|

|||

|

Bend |

|

0.05 (0.0020) |

|

|

||

|

Twist |

|

0.10 (0.0039) |

|

|

||

|

|

|

|

|

|

|

|

|

End play |

|

0.05 to 0.18 (0.0020 to 0.0071) |

|

|

||

|

|

|

|

|

|

|

|

|

Journal outside diameter |

|

56.982 to 57.000 (2.24338 to 2.24409) |

|

|

||

|

|

|

|

|

|

|

|

Crankshaft |

Pin Outside diameter |

|

44.985 to 45.000 (1.77106 to 1.77165) |

|

|

||

|

|

|

|

|

|

|

|

Out-of-roundness and taper of |

0.005 (0.00020) |

|

|

||||

|

|

|

|||||

|

journal and pin |

|

|

|

|||

|

|

|

|

|

|||

|

|

|

|

|

|

||

|

Concentricity journal and pin |

0.03 (0.0012) |

|

|

|||

|

Oil clearance of journal |

|

0.02 to 0.04 (0.0008 to 0.0016) |

|

|

||

|

Oil clearance of pin |

|

0.02 to 0.05 (0.0008 to 0.0020) |

|

|

||

block |

Cylinder inner diameter |

|

86.50 to 86.53 (3.4055 to 3.4067) |

|

|

||

Flatness of gasket surface |

|

0.05 (0.0020) |

|

|

|||

|

|

|

|

||||

Cylinder |

|

|

|

|

|

|

Total resurfacing |

Grinding limit |

|

|

0.2 (0.008) |

depth of both |

|||

|

|

|

|||||

|

|

|

cylinder head and |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

cylinder block |

|

Overall height |

|

289.9 to 290.1 (11.413 to 11.421) |

|

|

||

Oil pump |

Side clearance |

|

|

Drive gear |

0.08 to 0.14 (0.031 to 0.0055) |

|

|

|

|

Drive gear |

0.06 to 0.12 (0.0024 to 0.0047) |

|

|

||

|

|

|

|

|

|||

Drive belt |

Deflection |

|

|

New belt |

7.0 to 10.0 (0.28 to 0.39) |

|

|

|

|

Used belt |

10 (0.39) |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Throttle bore diameter |

|

32 (1.26) |

|

|

||

|

Outer venturi diameter |

|

24 (0.94) |

|

|

||

Carburetor |

Inner venturi diameter |

|

9 to 12 (0.35 to 0.47) |

|

|