DE12, DE12T &

DE12TI & DE12TIS

DIESEL ENGINE

Shop Manual

65.99892-8030B

Daewoo reserves the righ t to improve our products in a continuing proc ess to provide the best possible

product to the mar ket place. These improvements can be implem ented at any time with no obligation t o

change materials on previously sold products. It is recommended that consumers periodically contact their

distributors for recent documentation on purchased equipment.

This documentation may include attachments and optional equipment that is not available in your

machine’s package. Please call your distributor for additional items that you may require.

Illustrations used throughout this manual are used only as a representation of the actual piece of

equipment, and may vary from the actual item.

65.99892-8030B Shop Manual

FOREWORD

This manual has been prepared to help you use and maintain the DE series diesel engines (DE12,

DE12T, DE12TI and DE12TIS) safely and correctly.

These economical and high-performance diesel engines(6 cylinders, 4 strokes, in-line, direct injection

type) have been designed and manufactured to be used for overland transport or industrial purpose. They meet all the requirements such as low noise, fuel economy, high engine speed and

durability.

Nonetheless, to obtain the best performance and long life of an engine, it is essential to operate it

appropriately and to carry out periodic checks as instructed in this manual. You are requested to

thoroughly read this manual from cover to cover and to acquaint yourself with all the information

contained in this manual.

All information, illustration and specifications continued in this literature are based on the latest

product information available at the time of publication approval. The right is reserved to make

changes at any time without notice.

Please contact Daewoo dealer for the answers to any questions you may have about DE series

engine's features, operation or manuals.

CONTENTS

1. General information

...............................................................................................................

1

1.1. Engine characteristics 1.4. Engine performance curve

1.2. Main data and specifications 1.5. Exterior view of engine

1.3. Engine specification(’98 type)

2. Major maintenance

.............................................................................................................. 22

2.1. Preventive maintenance 2.2. Diagnostics and troubleshooting

for the engine

3. Disassembly and reassembly of major components

....................................................... 37

3.1. Disassembly 3.3. Reassembly

3.2. Inspection 3.4. Breaking-in

4. Maintenance of major components

.................................................................................... 79

4.1. Cooling system 4.3. Fuel system

4.2. Lubricating system 4.4. Turbocharger

5. Scan pole diagnosis for DE12TIS

..................................................................................... 142

5.1. Wire harness connection 5.4. Sensor data

5.2. System & Vehicle selection 5.5. Actuator test

5.3. Self-diagnosis(current) 5.6. Flight record

6. Maintenance specifications

............................................................................................... 154

6.1. Tightening torque 6.2. Maintenance specification table

¥

WORLDWIDE NETWORK

1. General information

1.1. Engine characteristics

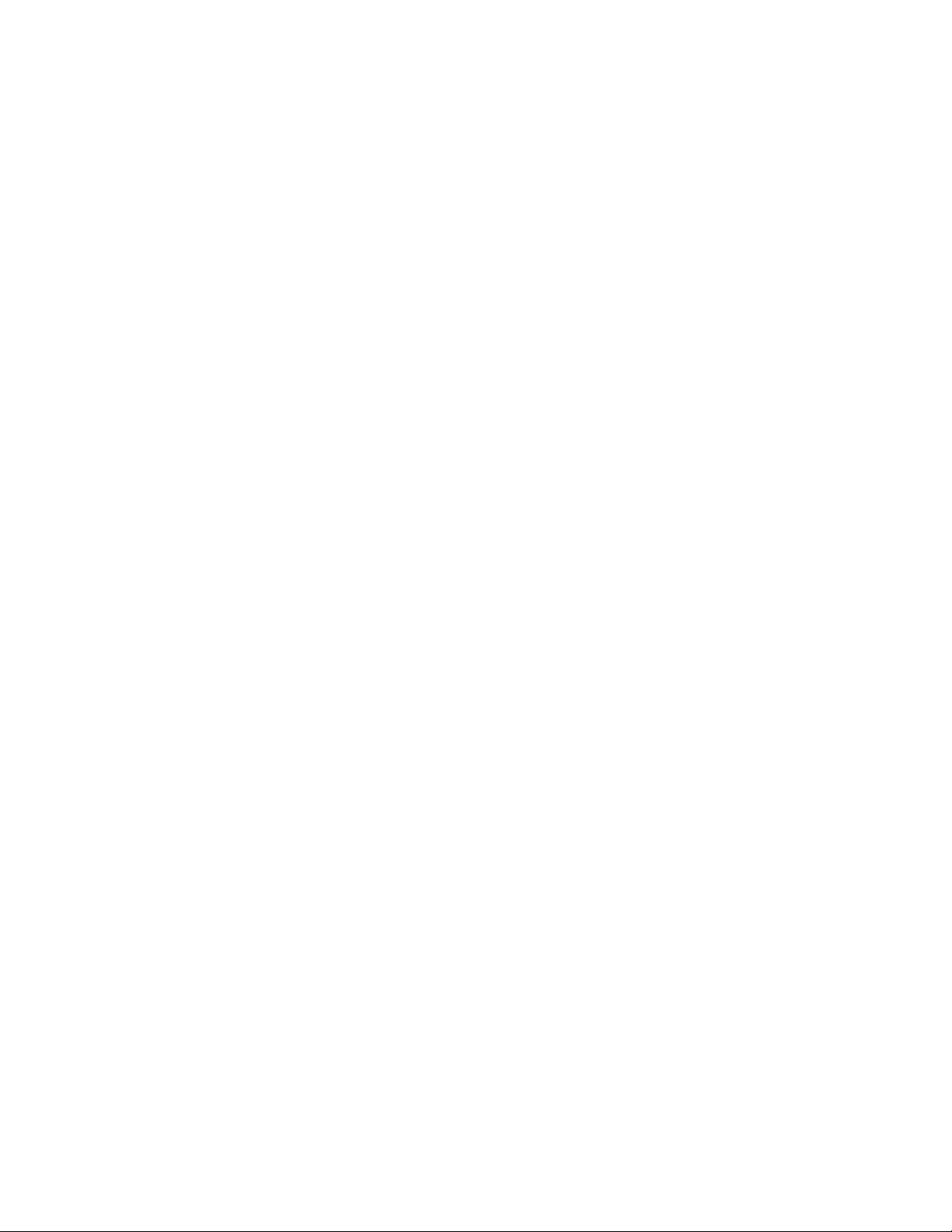

1.1.1. OMEGA combustion bowl

The OMEGA combustion bowl is a unit designed to perform high-efficiency, low- emission

combustion. As the rim around the combustion bowl port of the upper of the piston has been

machined in a smaller size than the interior of the combustion bowl, strong swirl is produced

in the combustion bowl and strong squish flow makes the fuel be mixed more sufficiently with

air.

Due to the application of OMEGA combustion system and optimal ultilization of intake and

exhaust port configuration within the cylinder head, the DE12 series engines discharge a

very low level of hazardous exhaust gases such as smoke, nitrogen oxide, hydrocarbon, or

carbon monoxide and thus ensure high performance and low fuel consumption.

- 1 -

EA2M1001

<Figure. 1-1> OMEGA combustion bowl

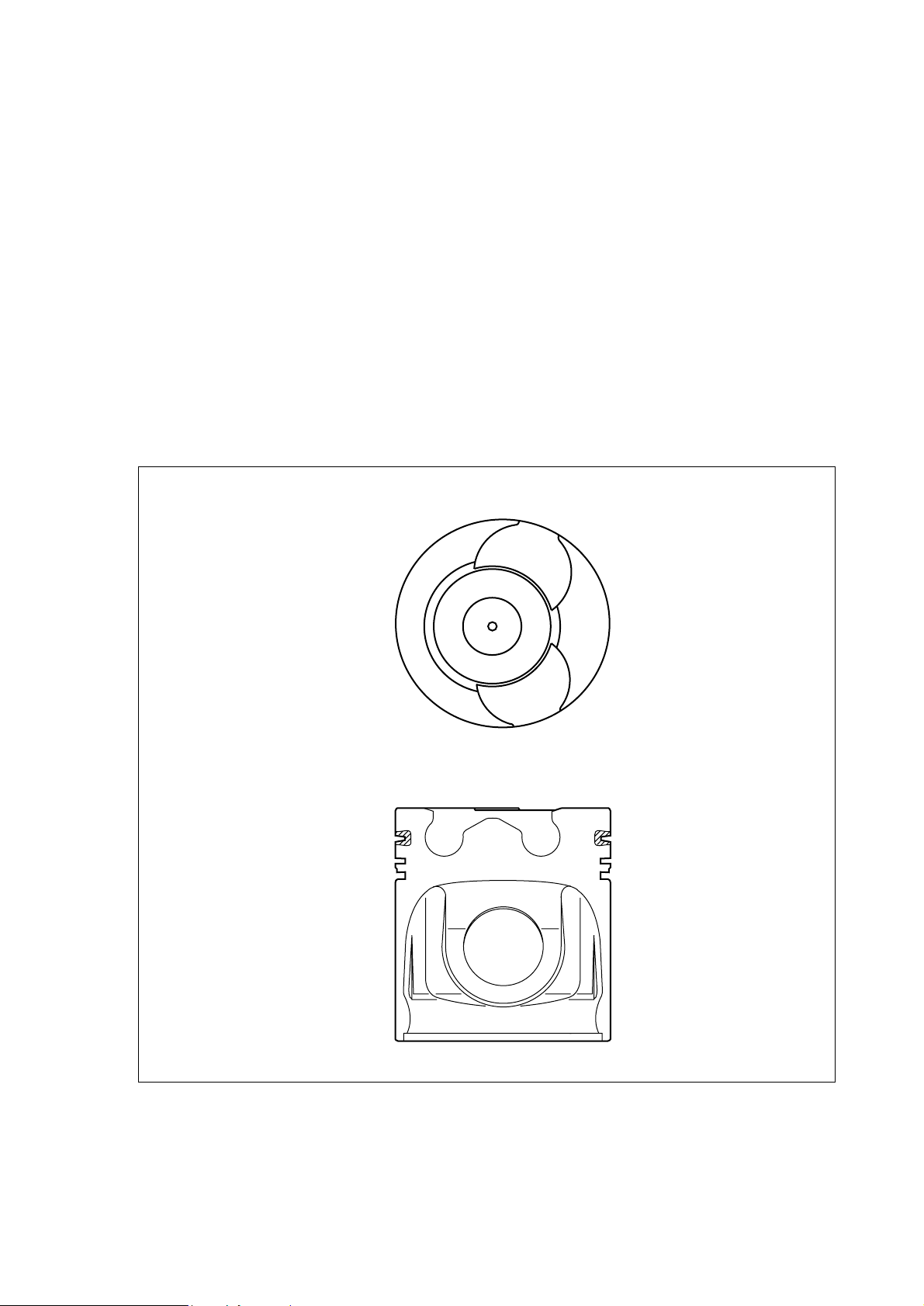

1.1.2. Wastegated turbocharging system

1) What is the wastegated turbocharging system?

Turbocharger is a system designed to pressurize the intake air to increase engine output and

decrease fuel consumption by using the energy of exhaust gas discharged from the engine.

However, the turbocharger has a weak point at low engine speed, its performance may drop,

thus performance at low speed is relatively low.

The WASTEGATED TURBOCHARGING SYSTEM is an up-to-date turbocharging system

remedying such a defect, and the working principle is as follows:

A small-sized high performance turbine is used to improve engine performance at low

speeds. As high charging efficiency can be obtained even If a small amount of exhaust gas

is present at low speed. On the other hand, if higher charging pressure is produced than

what is present at high speed, fuel consumption increases. To correct this, part of exhaust

gas is forced to be discharged into the exhaust manifold through the waste gate, not through

the turbine.

The waste gate is controlled by the ACTUATOR mounted in the turbocharger, and if the

pressure in the turbocharger becomes higher than what is required for the engine, the waste

gate is forced to open.

2) DE12T, DE12TI and DE12TIS engines are featured by the application of turbochager so that

the torque in low speeds can be increased by 30% or more, not only to create high performance, just from the time of starting off the vehicle but also to greatly reduce fuel consumption.

- 2 -

Compressed air outlet por

Intake air

Turbine

Turbine port

Exhaust gas

outlet port

Waste gate

Compressor

Actuator

EQM1003I

<Figure 1-3> Turbochager

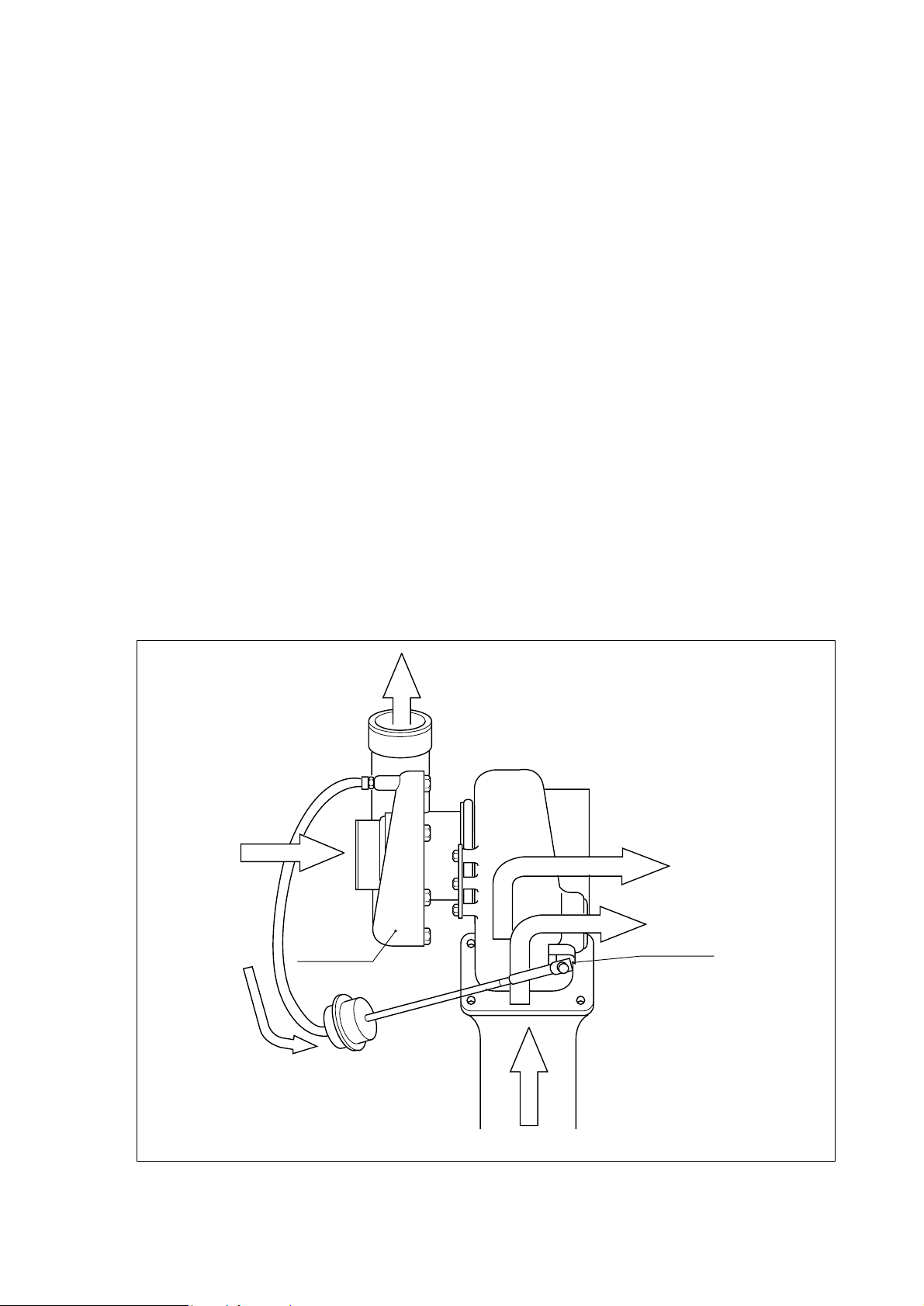

1.2. Main data and specifications

Engine Model DE12 DE12T DE12TI DE12TIS

Type In-line, 4-stroke, vertical type

Combustion chamber type

OMEGA Combustion bowl

Fuel injection Direct injection type

BoreB stroke-No. of cylinders

123mm B 155 - 6

Total displacement 11,051cc

Compression ratio 17.1:1 17.1:1 16.5:1 16.8

Maximum power(PS) 225 ps/2,200 rpm 300 ps/2,200 rpm 340 ps/2,100 rpm

Maximum torque 81.5 kg.m/1,400 rpm 110 kg.m/1,300 rpm 135 kg.m/1,260 rpm

Injection timing 12° BTDC 9° BTDC 12° BTDC 1.0° BTDC

Firing order 1-5-3-6-2-4

Injection pump type S3000 S3000 S3S HD-TICS

Governor type RFD-C/RLD RFD-C RFD-D RLD-J

Timer type SP SP SPG Electronically control

Nozzle type

Multi-hole type(5-N0.29) Multi-hole type(5-N0.31) Multi-hole type(5-N0.33) Multi-hole type(5-N0.29)

Feed pump type K-P K-P K-PS

Valve Timing

Intake valve open at BTDC 18° BTDC 18°

Intake valve close at ABDC 34° ABDC 32°

Exhaust valve open at BBDC 46° BBDC 70°

Exhaust valve close at ATDC 14° ATDC 30°

Oil pump type Gear type

Oil cooler type Water-cooler

Fuel filter type Full flow type

Oil capacity 20M(Oil pan 17M)

Coolant capacity 19M

Thermostat type Wax-pallet

Starter : Voltage-output 24V-6.0Kw

Alternator : Voltage-capacity

24V-45A

- 3 -

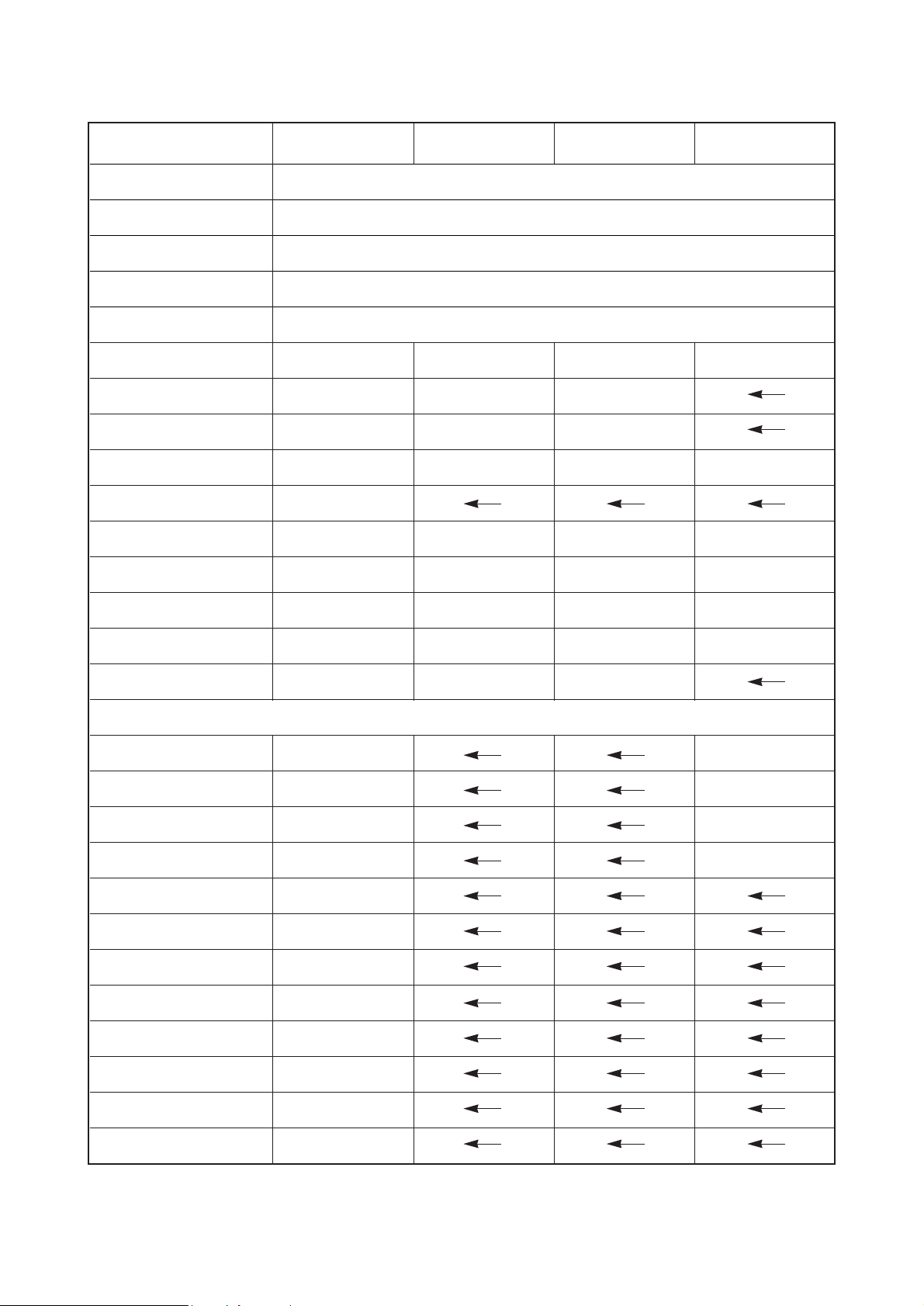

1.3. Engine specification(’98 type)

- 4 -

Item DE12-228 DE12TI-280 DE12TI-310 DE12TIS

Manufacturer DHI

Mounting location Under Seat

Starting type SELF

Engine type Diesel 4 Cycle

Turbocharged & Intercooled

Cylinder(No. arrangement) In-line, vertical

Combustion chamber type Direct injection

Valve position OHV

Diameter x stroke 123x155

Compression ratio 17.1 16.1 16.8

Comp. pressure(kg/cm2-rpm) 28-200

Average efficient comp.(kg/cm2) 9.27 13.08 14.21

Max. horse power(ps/rpm) 228/2,200 280/2,100 310/2,100 340/2,100

Max. torque(kg•m/rpm) 80/1,400 115/1,260 125/1,260 140/1,260

Firing order 1-5-3-6-2-4

Engine dimension(LxWxH) 1,317x747x1,015 1,317x847x1,064

Dry weight(kg) 872 909 910

Cycle 4

Piston Material AL

Comp. ring 2

Oil ring 1

Open BTDC 18° BTDC 18°

Close ABDC 34° ABDC 32°

Open BBDC 46° BBDC 70°

Close ATDC 14° ATDC 30°

Intake 0.3

Exhaust 0.3

Engine speed at no load 550~600

Lubricating Type

Forced pressure type

Oil pump type Gear

Oil filter type Strainer

Oil capacity(M)20

Oil cooler type Water cooled

Intake

Exhaust

No. of piston ring

Valve clearance

(cold engine)

Lubricatring

system

In. & Ex.

Valve

timing

E

n

g

i

n

e

- 5 -

Item DE12-228 DE12TI-280 DE12TI-310 DE12TIS

Turbocharger type -

Exhaust gas driven

Intercooler type - Air cooled

Cooling type

Forced water circulation

Coolant capacity 19(engine only)

Water pump type Centrifugal

Thermostat type Wax pellet

Fuel pump type Plunger

Fuel filter type Full flow

Fuel injection type Mechanical

Electronic control

Type Inline

Timing BTDC 8° BTDC 12° BTDC 1.0°

Plunger Dia. 12

Cam lift(mm) 11 12 14

Nozzle mounting Flange

Nozzle type Multi hole

Orifice

No 5

Dia.(mm) 0.29 0.33 0.29

Inj. pressure(kg/cm2) 220 130/220 163/224

Voltage(V) 24V

Type Electric

Voltage(V) - Amp(A) 22-120

Output(V-A) ---Regulator ---Type Reduction

Output(kW) 24V-6.0kW

Type

Air compression

Cooling

system

Engine

Fuel

system

Electric

system

Inj.

pump

system

Inj.

nozzle

Preheat

-ing

system

Alternator

Starter

Ignition

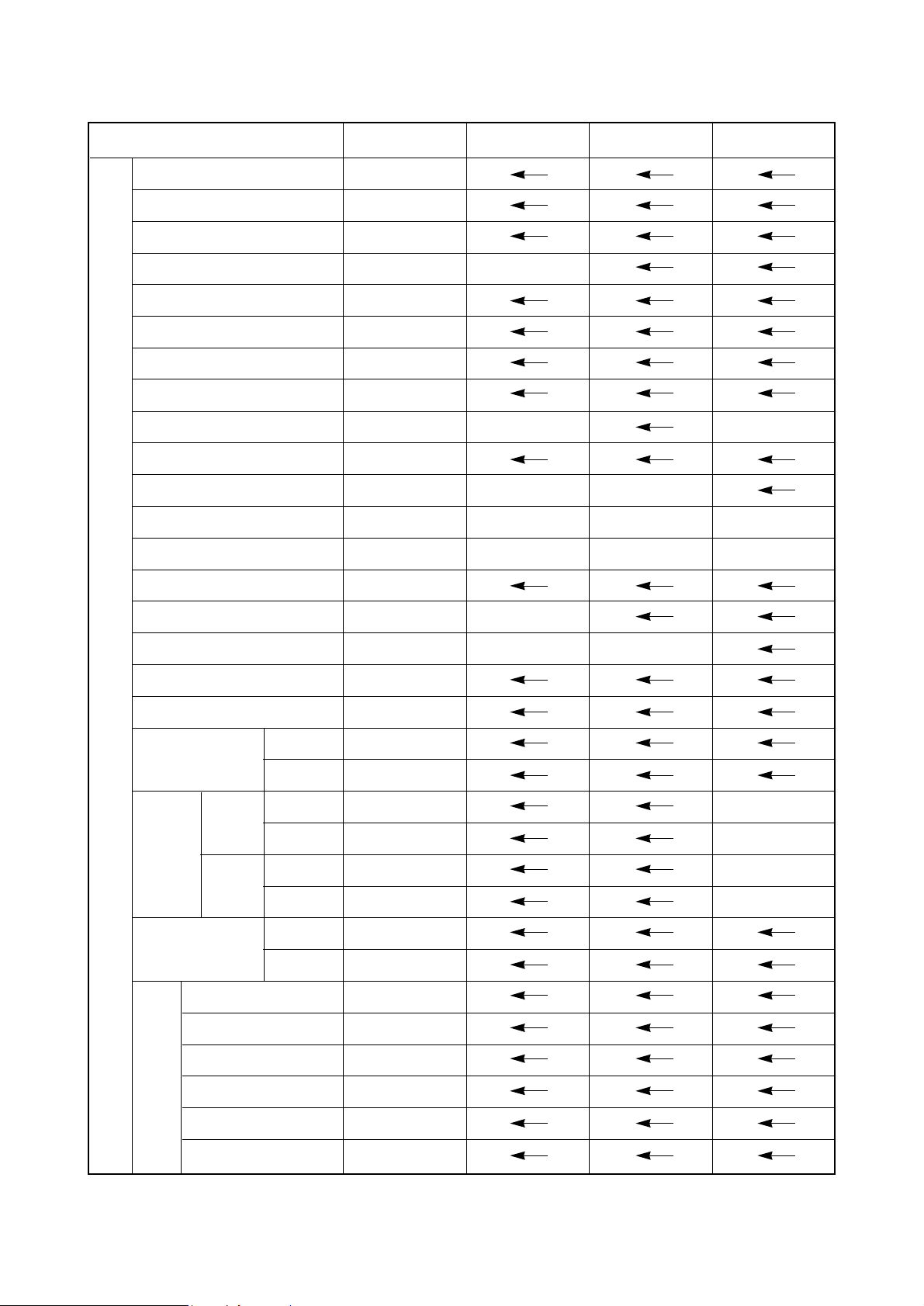

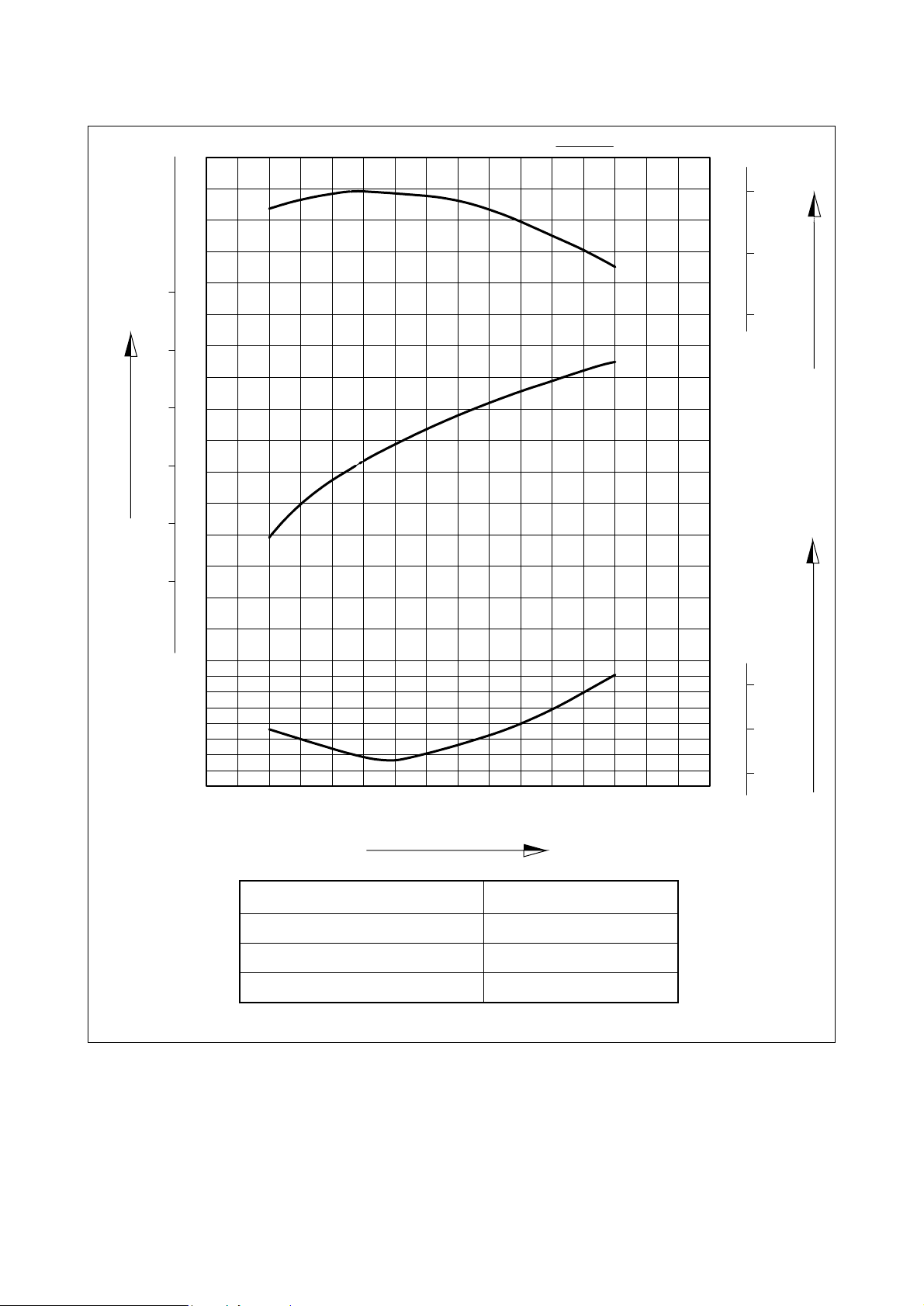

1.4. Engine performance curve

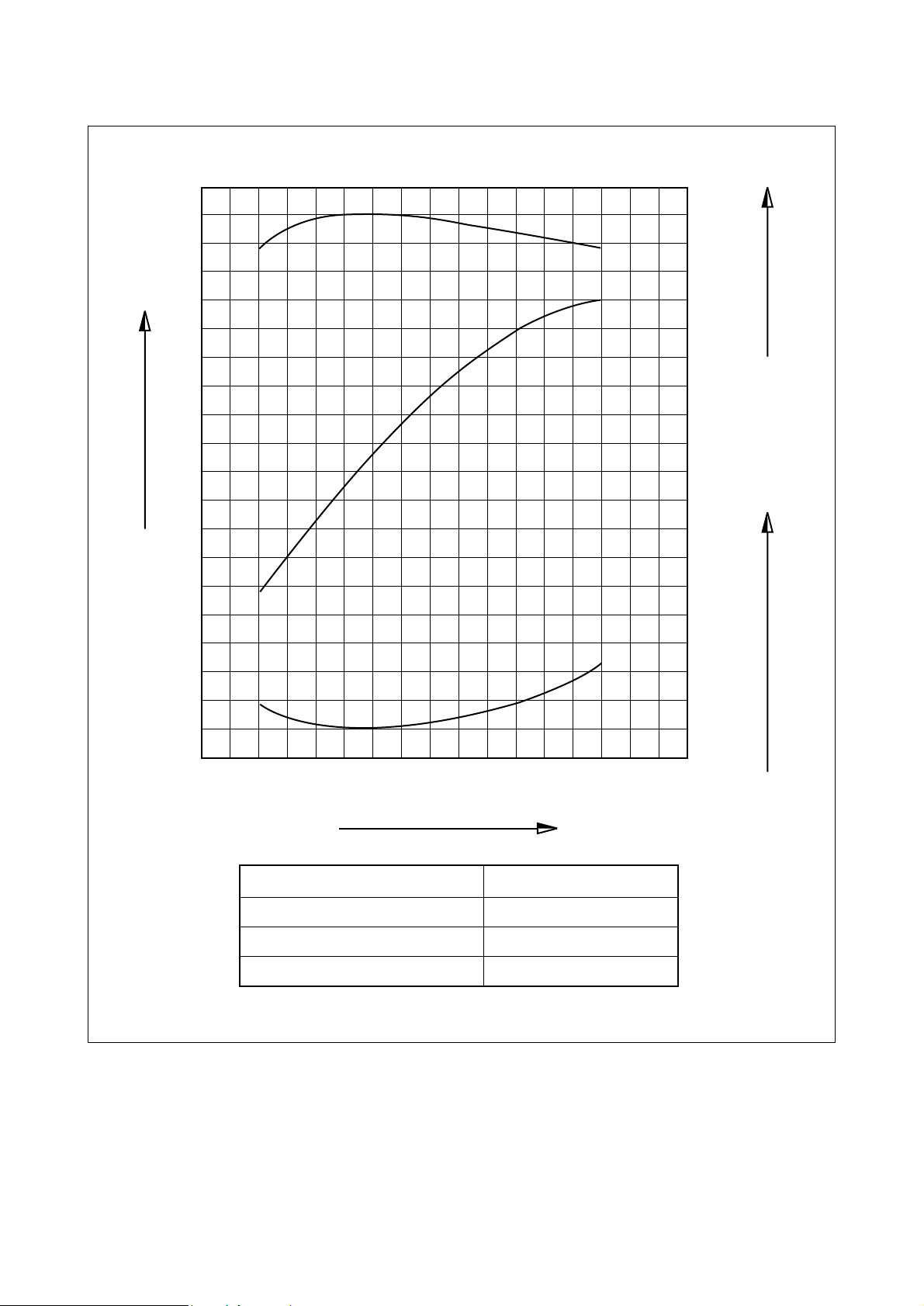

1.4.1. DE12

- 6 -

220

200

180

160

140

120

100

1000 1200 1400 1600 1800 2000 2200 2400

85

80

75

170

160

165

70

Performance criteria ISO 1585(SAE J1349)

Output(Max.) 235 ps/2,200 rpm

Torque(Max.) 81.5 kg.m/1,400 rpm

Fuel consumption ratio(min.) 160 g/ps.h

EQM1004I

Revolution(rpm)

Output(ps)

Torque(kg

.

m)Fuel consumption(g/ps

.

h)

- 7 -

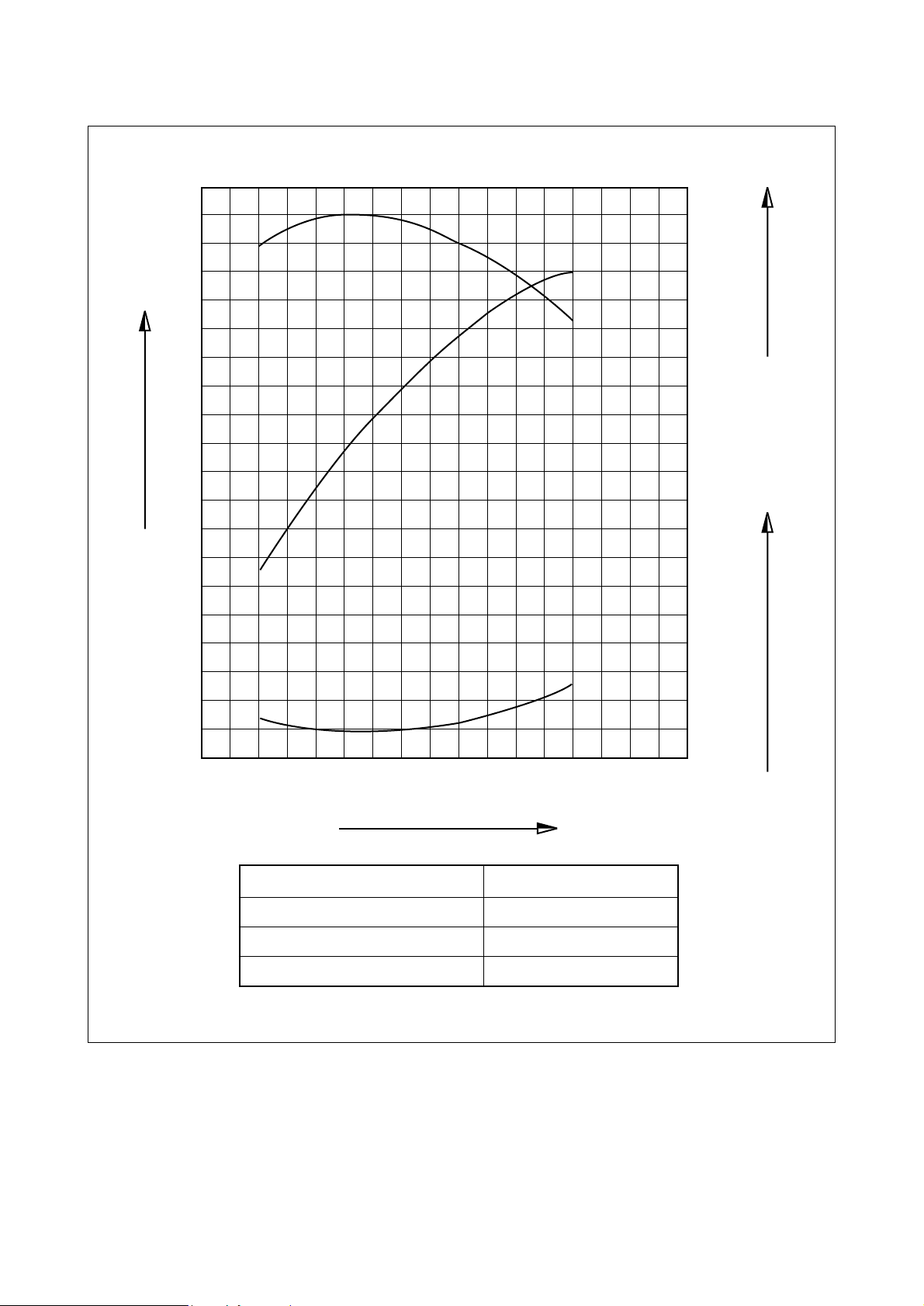

1.4.2. DE12(’98 type)

220

200

180

160

140

120

100

1000 1200 1400 1600 1800 2000 2200 2400

80

75

70

165

160

155

Performance ISO 1585(SAE J1349)

Output(Max.) 228 ps/2,200 rpm

Torque(Max.) 80 kg.m/1,400 rpm

Fuel consumption ratio(min.) 155 g/ps.h

EQM1005I

Revolution(rpm)

Output(ps)

Torque(kg

.

m)Fuel consumption(g/ps

.

h)

- 8 -

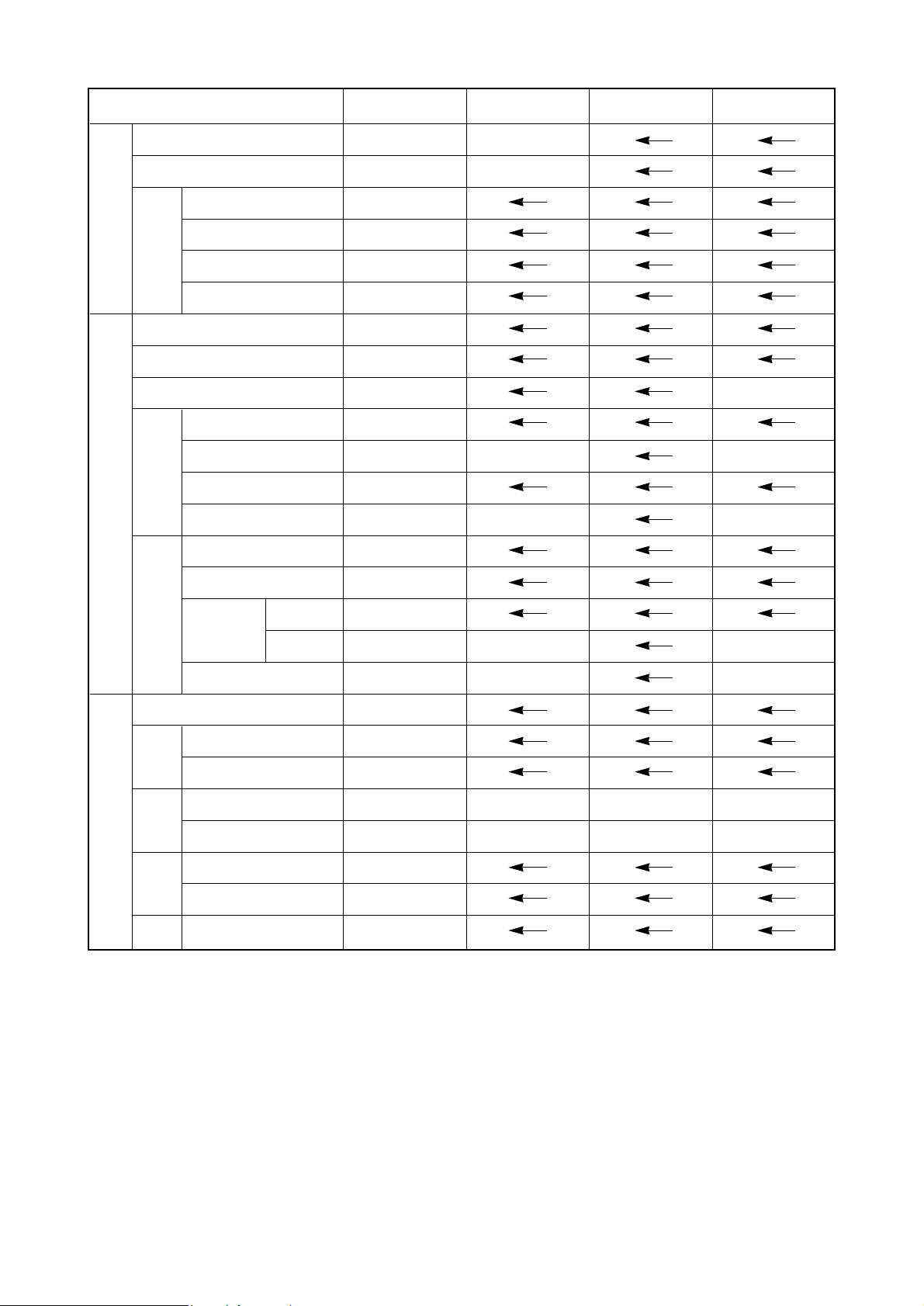

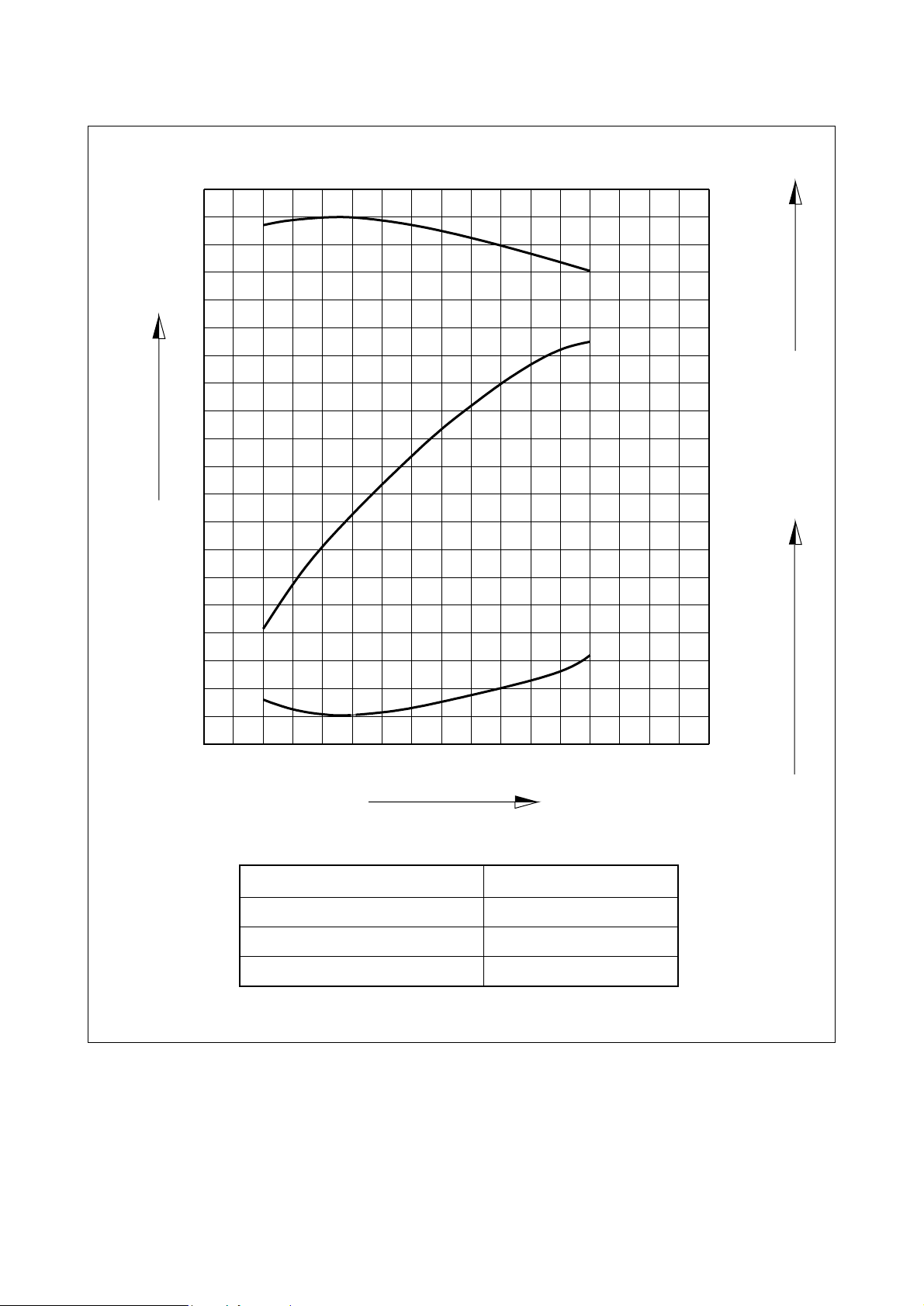

1.4.3. DE12T

155

160

165

170

90

80

100

110

1 000

1200

1400 1600 1800

2000

2200 2400

120

150

180

210

240

270

300

Performance ISO 1585(SAE J1349)

Output(Max.) 300 ps/2,200 rpm

Torque(Max.) 110 kg.m/1,300 rpm

Fuel consumption ratio(min.) 155 g/ps.h

EQM1006I

Revolution(rpm)

Output(ps)

Torque(kg

.

m)

Fuel consumption(g/ps

.

h)

- 9 -

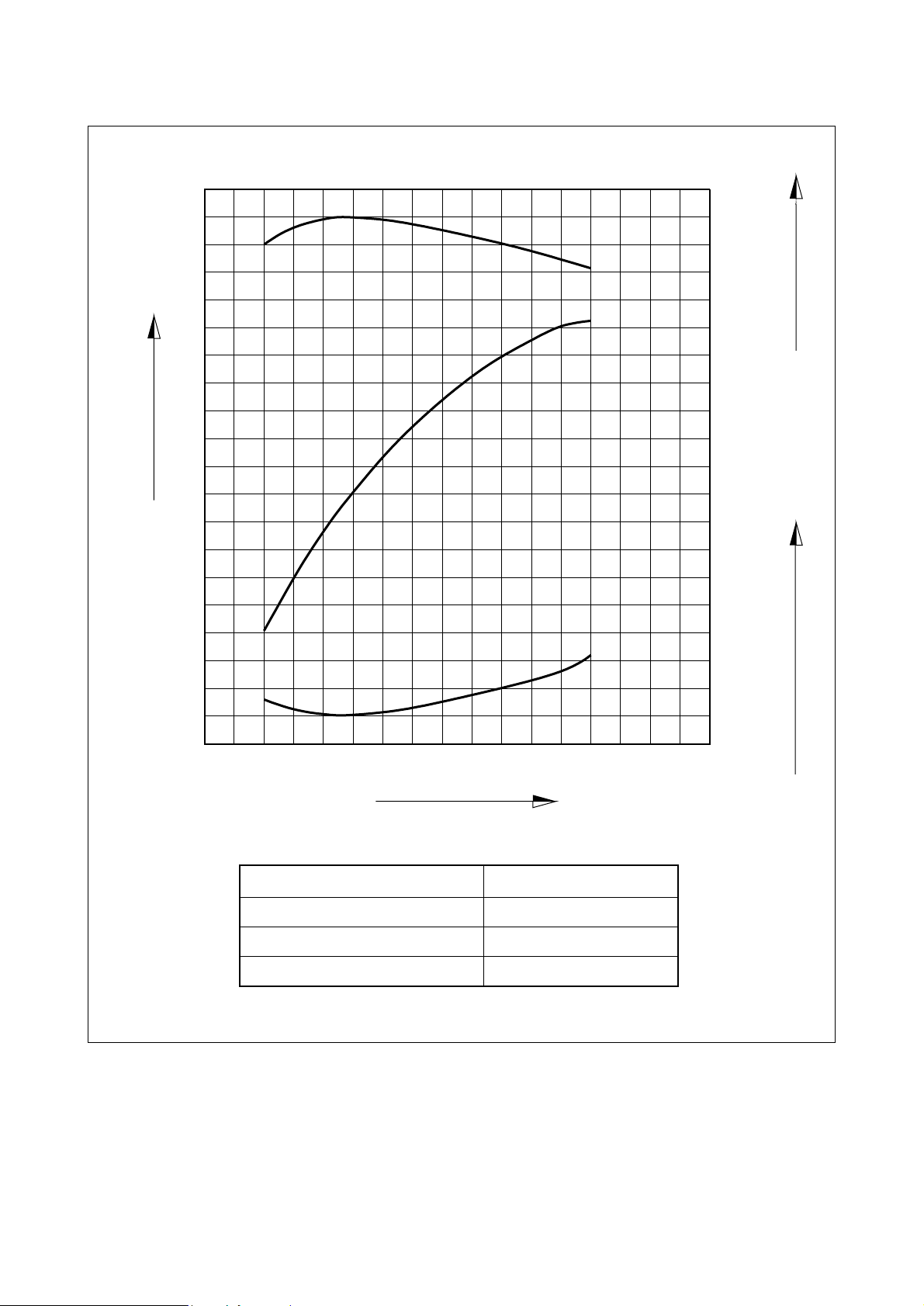

1.4.4. DE12TI

150

155

160

125

120

130

135

1 000

1200

1400 1600 1800

2000

2200 2400

160

190

220

250

280

310

340

Performance ISO 1585(SAE J1349)

Output(Max.) 340 ps/2,100 rpm

Torque(Max.) 135 kg.m/1,260 rpm

Fuel consumption ratio(min.) 147 g/ps.h

EQM1007I

Revolution(rpm)

Output(ps)

Torque(kg

.

m)

Fuel consumption(g/ps

.

h)

- 10 -

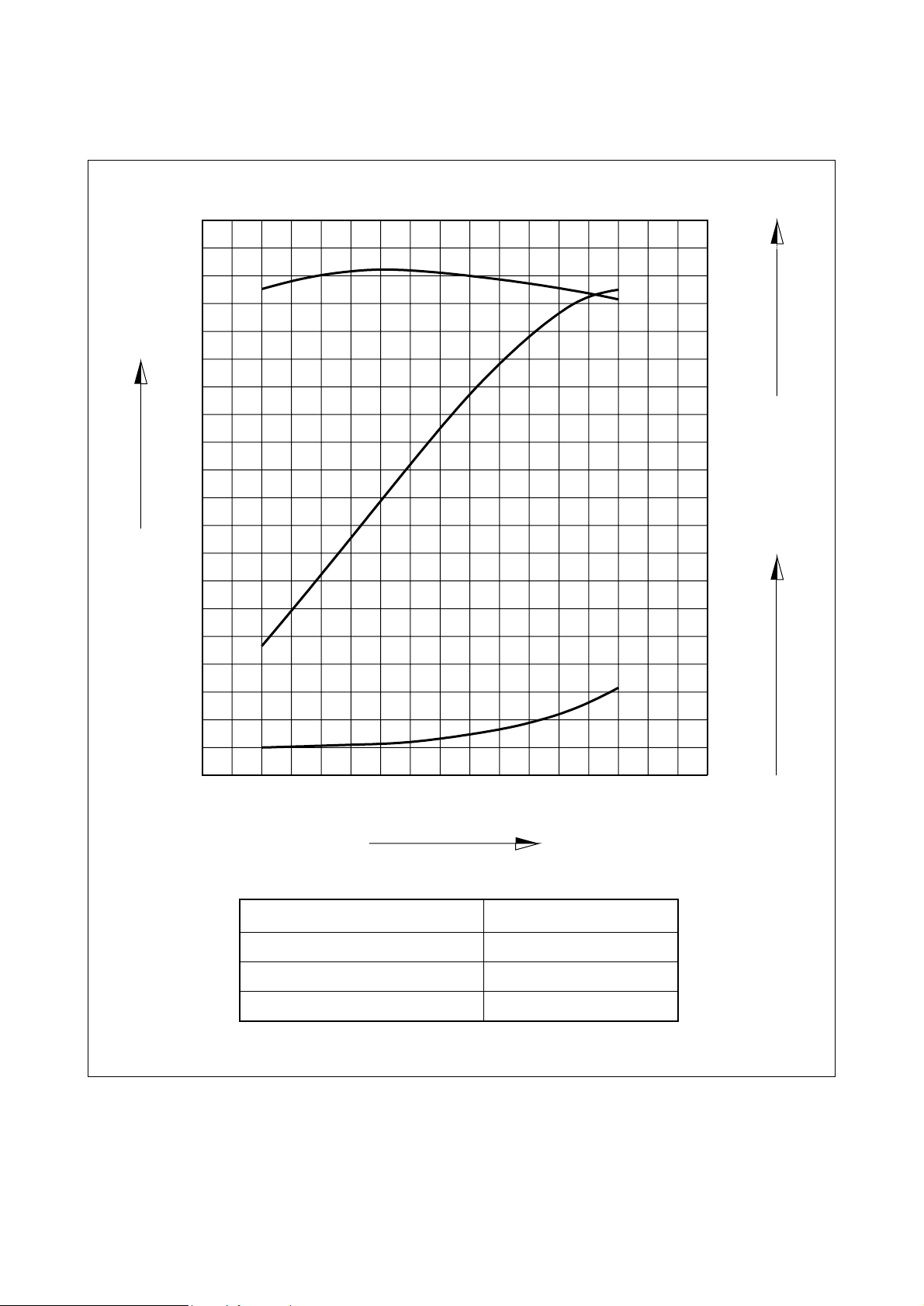

1.4.5. DE12TI(280 ps : ’98 type)

300

220

220

180

1000 1200 1600 1800 2000 2200 2400

145

150

155

115

105

95

1400

140

260

Performance ISO 1585(SAE J1349)

Output(Max.) 280 ps/2,100 rpm

Torque(Max.) 115 kg.m/1,260 rpm

Fuel consumption ratio(min.) 145 g/ps.h

EQM1008I

Revolution(rpm)

Output(ps)

Torque(kg

.

m)

Fuel consumption(g/ps

.

h)

- 11 -

1.4.6. DE12TI(310 ps : ’98 type)

320

125

115

105

155

150

145

280

240

200

160

1000 1200 1400 1600 1800 2000 2200 2400

Performance ISO 1585(SAE J1349)

Output(Max.) 310 ps/2,100 rpm

Torque(Max.) 125 kg.m/1,260 rpm

Fuel consumption ratio(min.) 145 g/ps.h

EQM1009I

Revolution(rpm)

Output(ps)

Torque(kg

.

m)

Fuel consumption(g/ps

.

h)

- 12 -

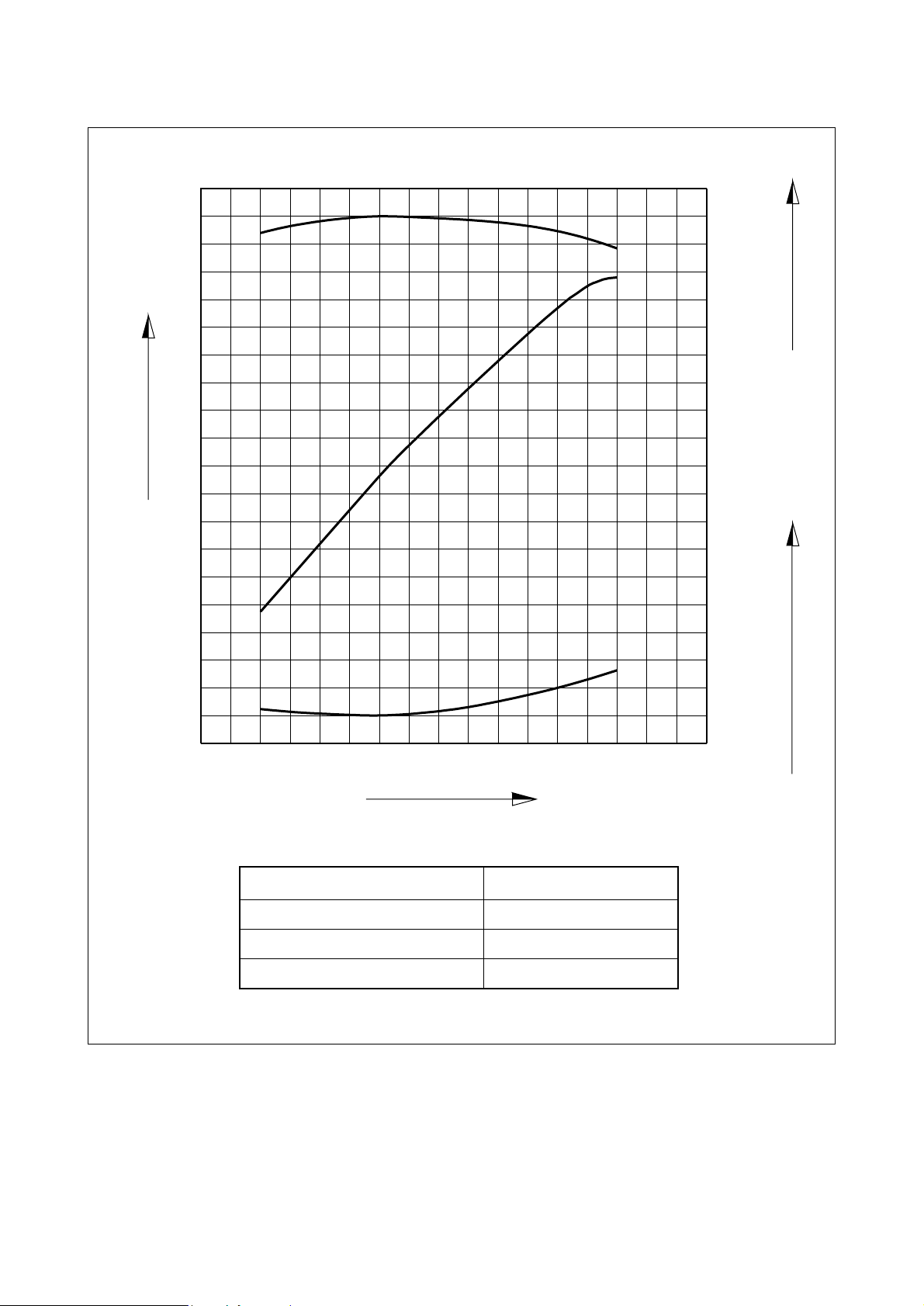

1.4.7. DE12TIS

400

300

100

0

200

ps kW

350

300

250

200

150

1200 120

1400

N.m

g/kW.h g/ps.h

ISO 1585

kg.m

140

1000

200

190

210

160

150

140

220

100

1000

EA2M1002

2000 22001800160014001200

Revolution(rpm)

Power output(ps)

Fuel consumption(g/ps

.

h)

Torque(kg

.

m)

Performance ISO 1585(SAE J1349)

Output(Max.) 340 ps/2,100 rpm

Torque(Max.) 140 kg.m/1,260 rpm

Fuel consumption ratio(min.) 143 g/ps.h

1.5. Exterior view of engine

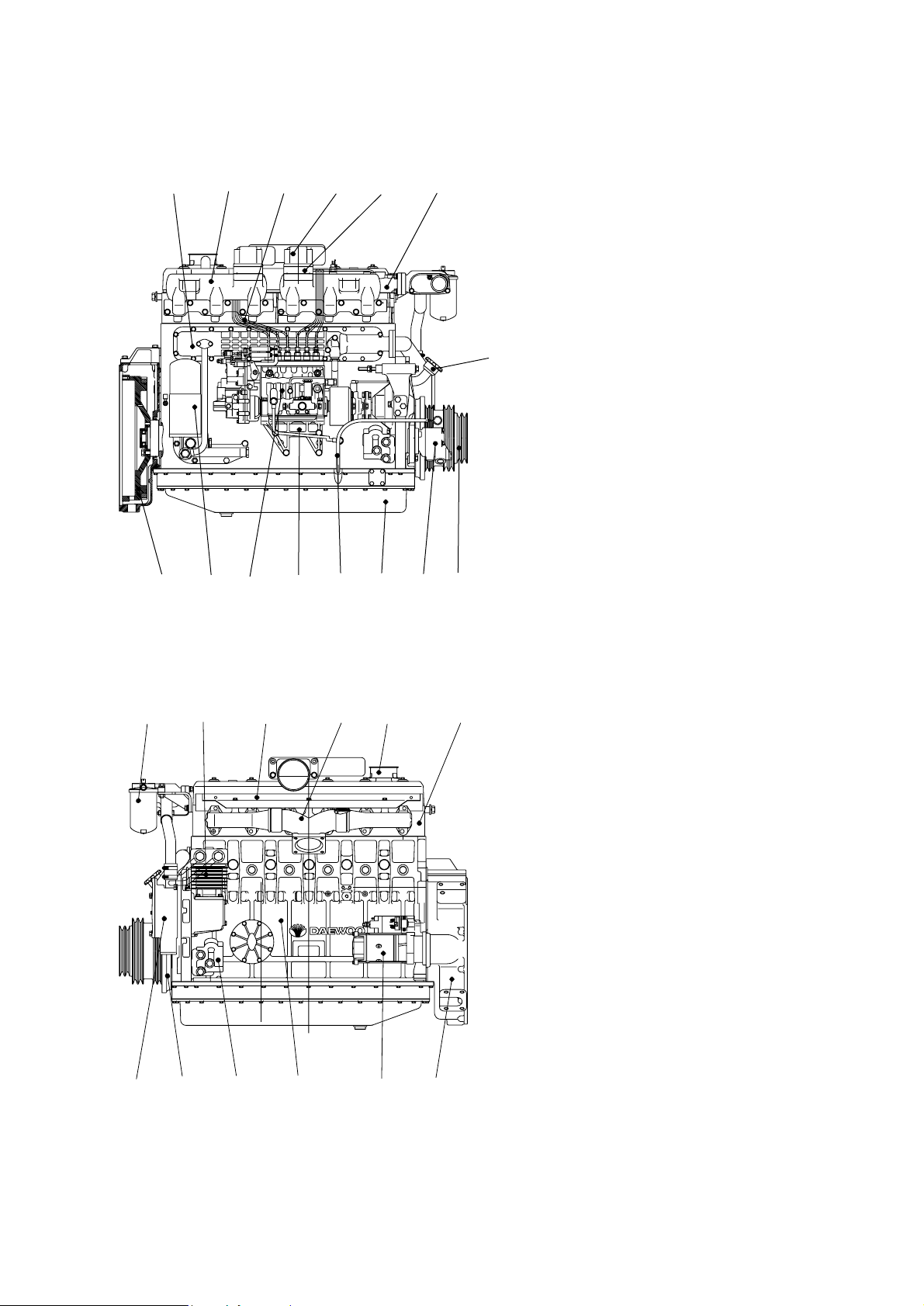

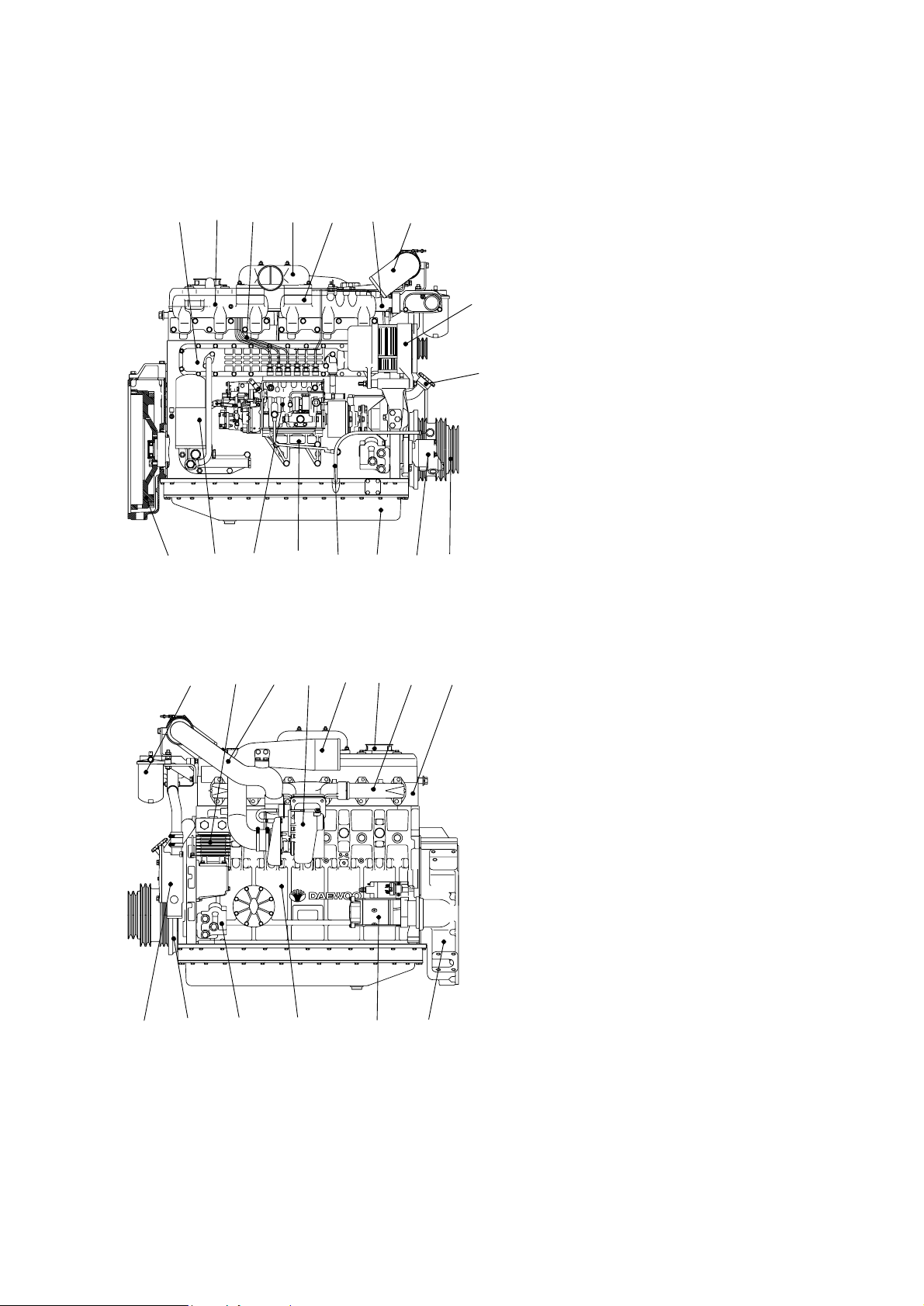

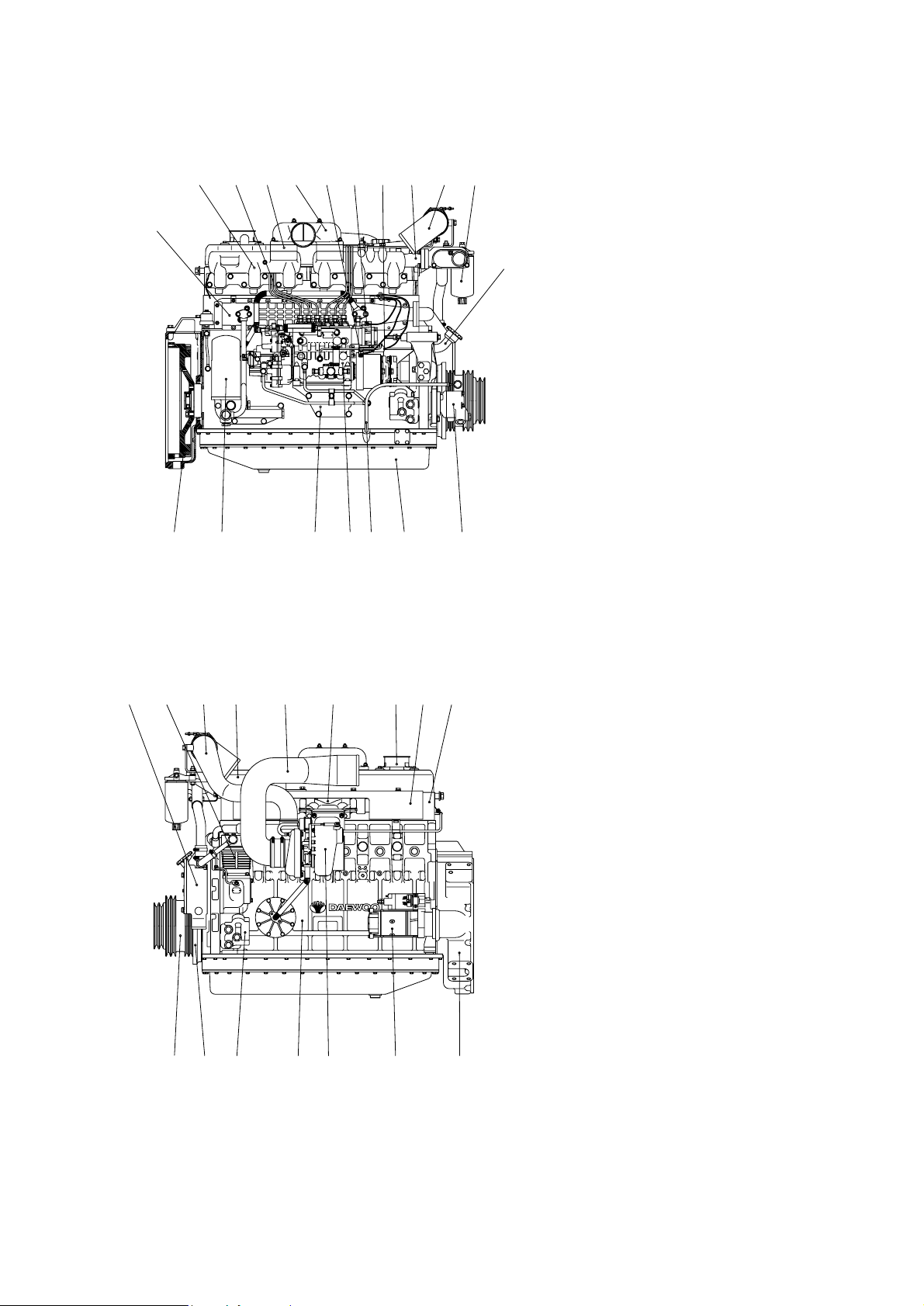

1.5.1. DE12- for Bus

- 13 -

17 19 18 13

4

67920

22

14 5 1 226 23

25 16 15 3 8

21 12 11 27

2410

1. Cylinder block

2. Flywheel housing

3. Breather

4. Oil filler pipe

5. Vibration damper

6. Flywheel

7. V-pulley

8. Cylinder head

9. Oil filter

10. Oil cooler

11. Oil pan

12. Oil dipstick

13. Cooling water pipe

14. Water pump

15. Exhaust manifold

16. Heat shield

17. Intake manifold

18. Intake stake

19. Injection pipe

20. Injection pump

21. Injection pump bracket

22. Fuel filter

23. Starter

24. Air heater

25. Air compressor

26. Mounting bracket

27. Power steering pump

EQM1010I

- 14 -

1.5.2. DE12- for Truck

18

24

7

610

15

2251285

EA2M1003

30 17938

22 294121321

16

272319 142620

11

1. Cylinder block

2. Flywheel housing

3. Breather

4. Oil filler pipe

5. Vibration damper

6. Flywheel

7. Idle pulley

8. Cylinder head

9. Cylinder head cover

10. Oil filter

11. Oil cooler

12. Oil pan

13. Oil dipstick

14. Cooling water pipe

15. Water pump

16. Cooling fan

17. Exhaust manifold

18. Intake manifold

19. Intake stake

20. Injection pipe

21. Injection pump

22. Injection pump bracket

23. Fuel filter

24. Alternator

25. Starter

26. Air heater

27. Air-conditioning compressor

28. Engine mounting bracket

29. Power steering pump

30. Air compressor

- 15 -

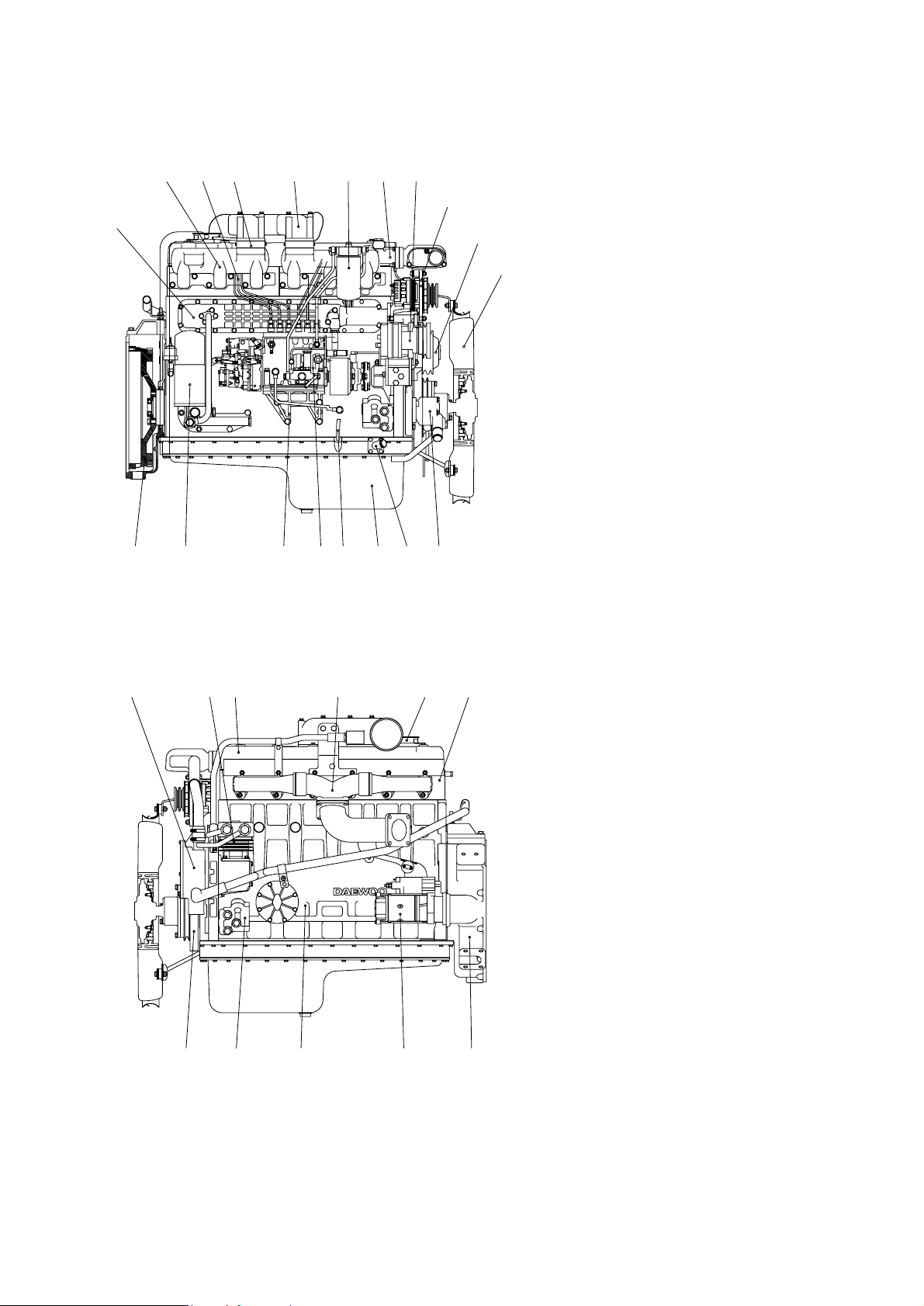

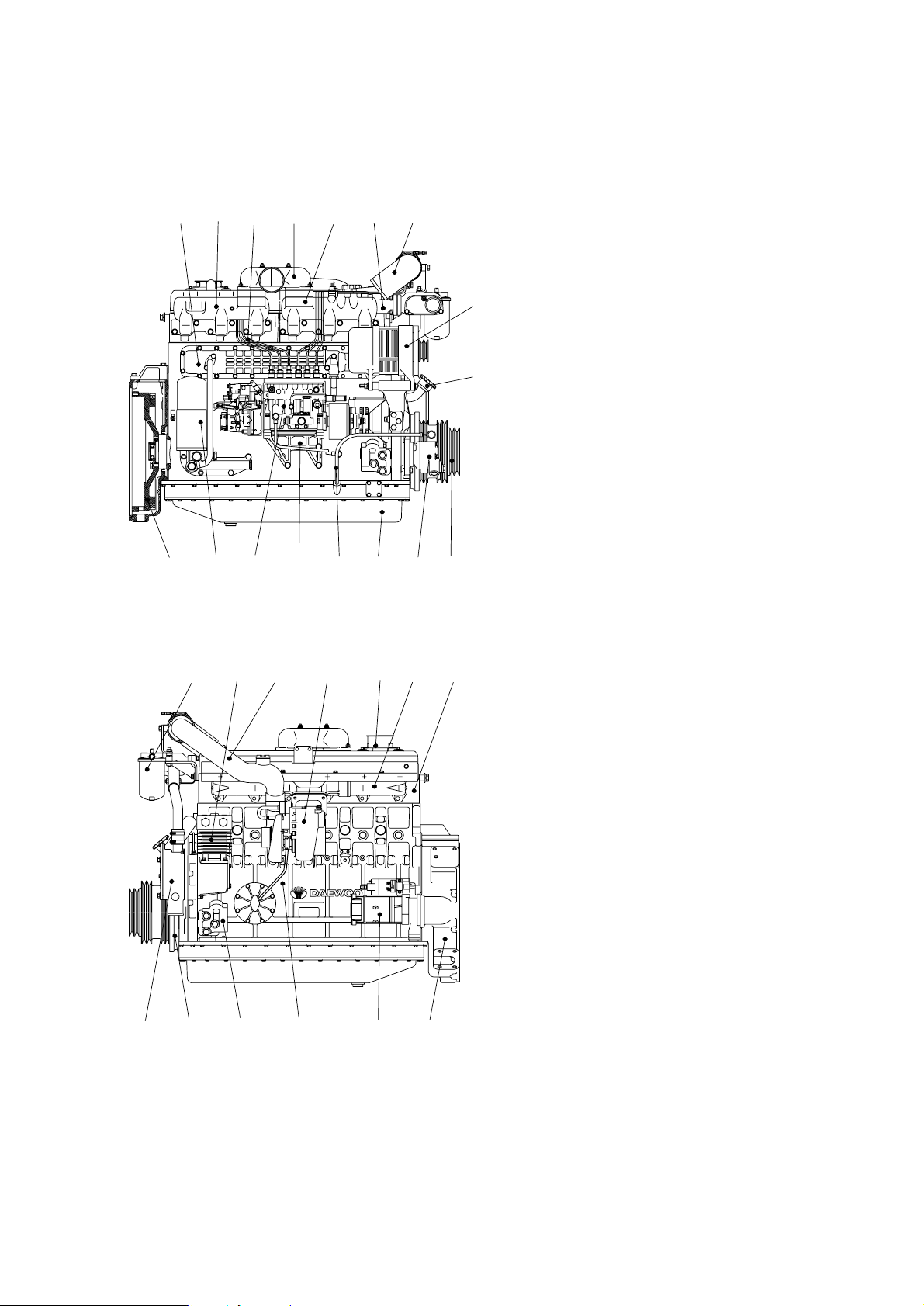

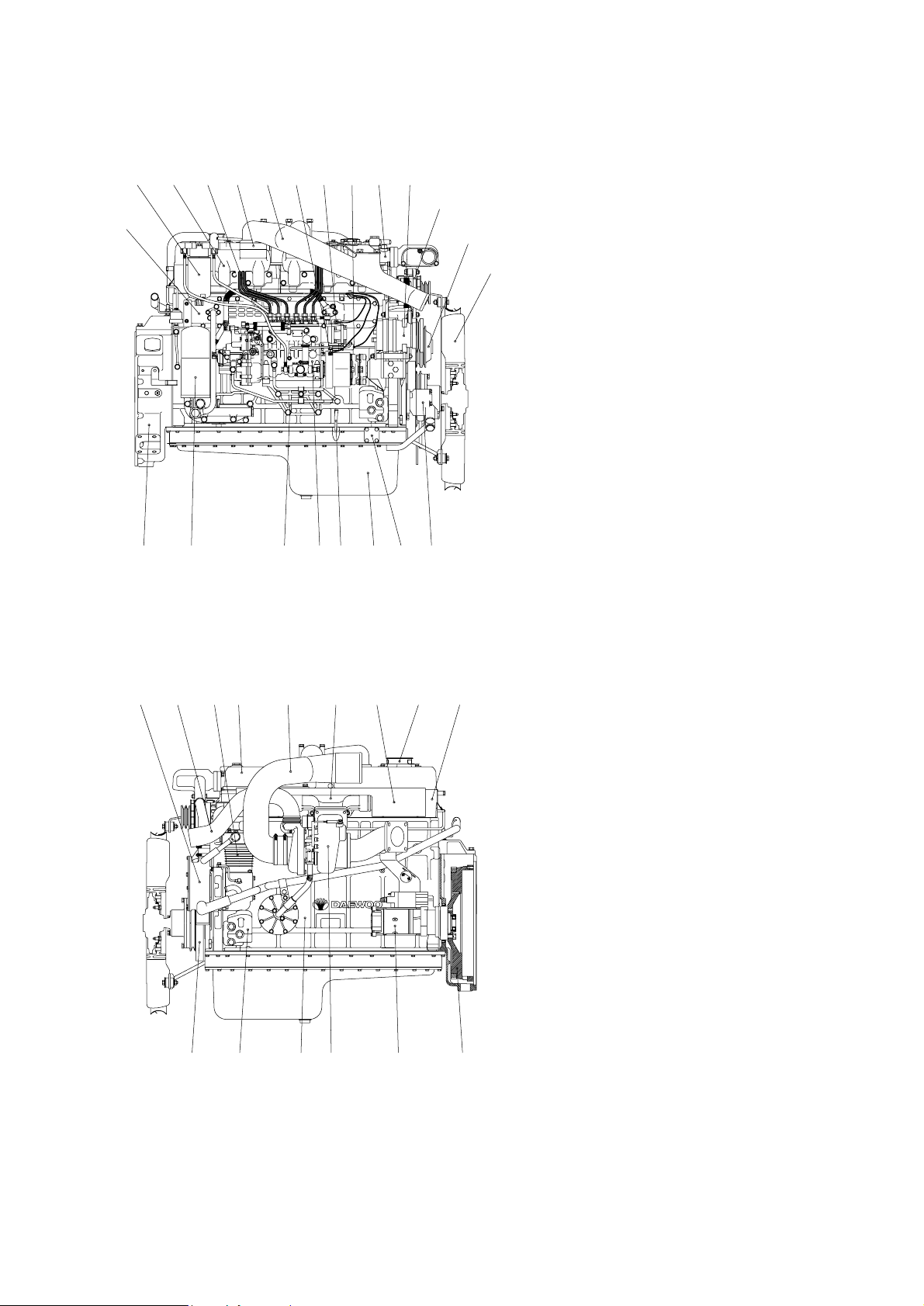

1.5.3. DE12T- for Bus

10 2016 18 13

4

621

23

111222 2897

25

26

17

19

3

15

8

14

5

27

1

24

2

1. Cylinder block

2. Flywheel housing

3. Breather

4. Oil filler pipe

5. Vibration damper

6. Flywheel

7. V-pulley

8. Cylinder head

9. Oil filter

10. Oil cooler

11. Oil pan

12. Oil dipstick

13. Cooling water pipe

14. Water pump

15. Exhaust manifold

16. Intake manifold

17. Heat shield

18. Intake stake

19. Turbocharger

20. Injection pipe

21. Injection pump

22. Injection pump bracket

23. Fuel filter

24. Starter

25. Air heater

26. Air compressor

27. Mounting bracket

28. Power steering pump

EQM1011I

- 16 -

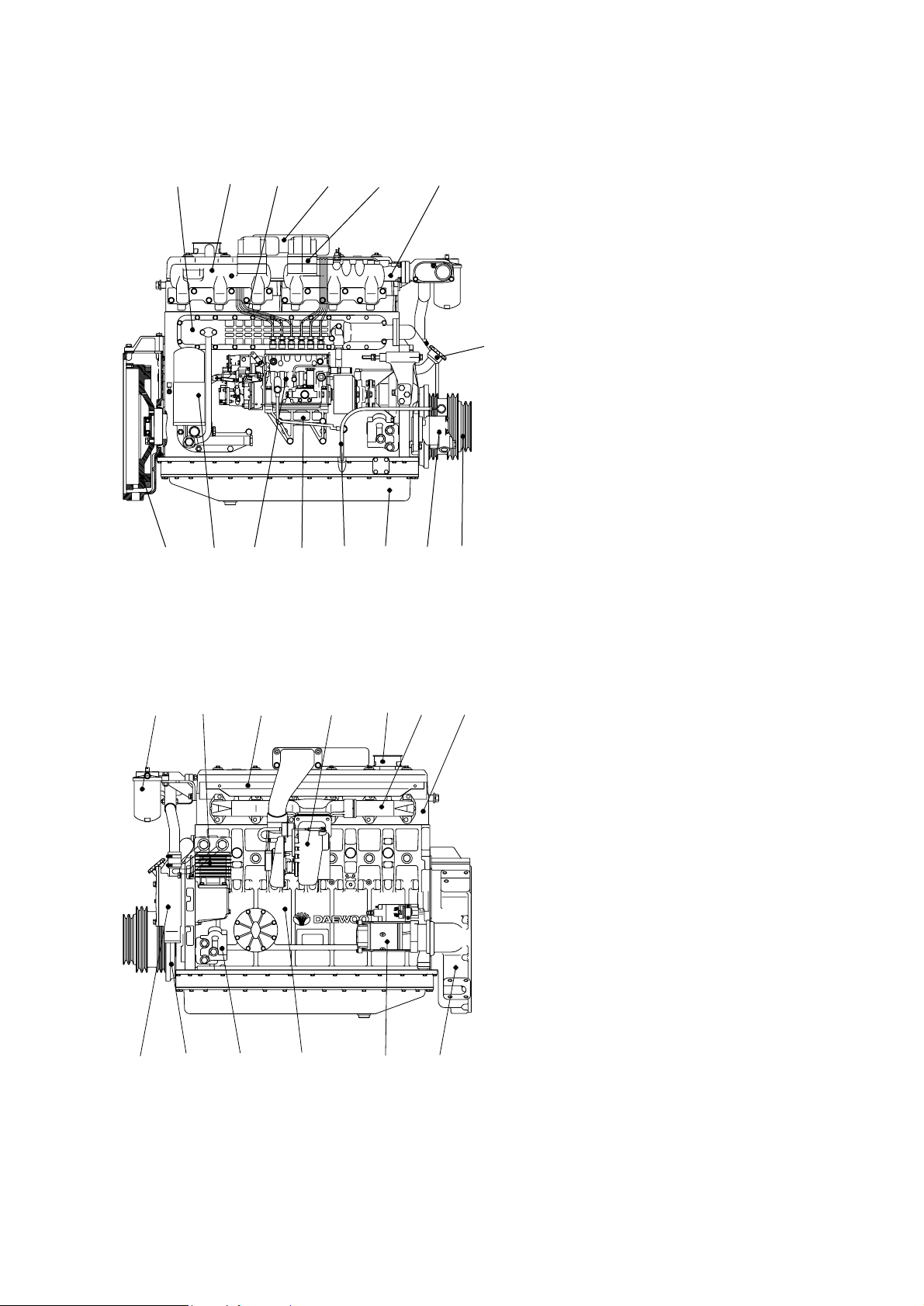

1.5.4. DE12TI(340 ps)- for Bus

10 16 22 17 27 21

29

4

67923

25 28 20 18

14 30 2651 2

19 1538

24 12 3111

13

1. Cylinder block

2. Flywheel housing

3. Breather

4. Oil filler pipe

5. Vibration damper

6. Flywheel

7. V-pulley

8. Cylinder head

9. Oil filter

10. Oil cooler

11. Oil pan

12. Oil dipstick

13. Cooling water pipe

14. Water pump

15. Exhaust manifold

16. Intake manifold

17. Intake stake

18. Turbocharger

19. Air pipe, T/C-A/P

20. Air pipe, A/P-I/C

21. Air pipe, A/P-I/C

22. Injection pipe

23. Injection pump

24. Injection pump bracket

25. Fuel filter

26. Starter

27. Air heater

28. Air compressor

29. Alternator

30. Mounting bracket

28. Power steering pump

EQM1012I

- 17 -

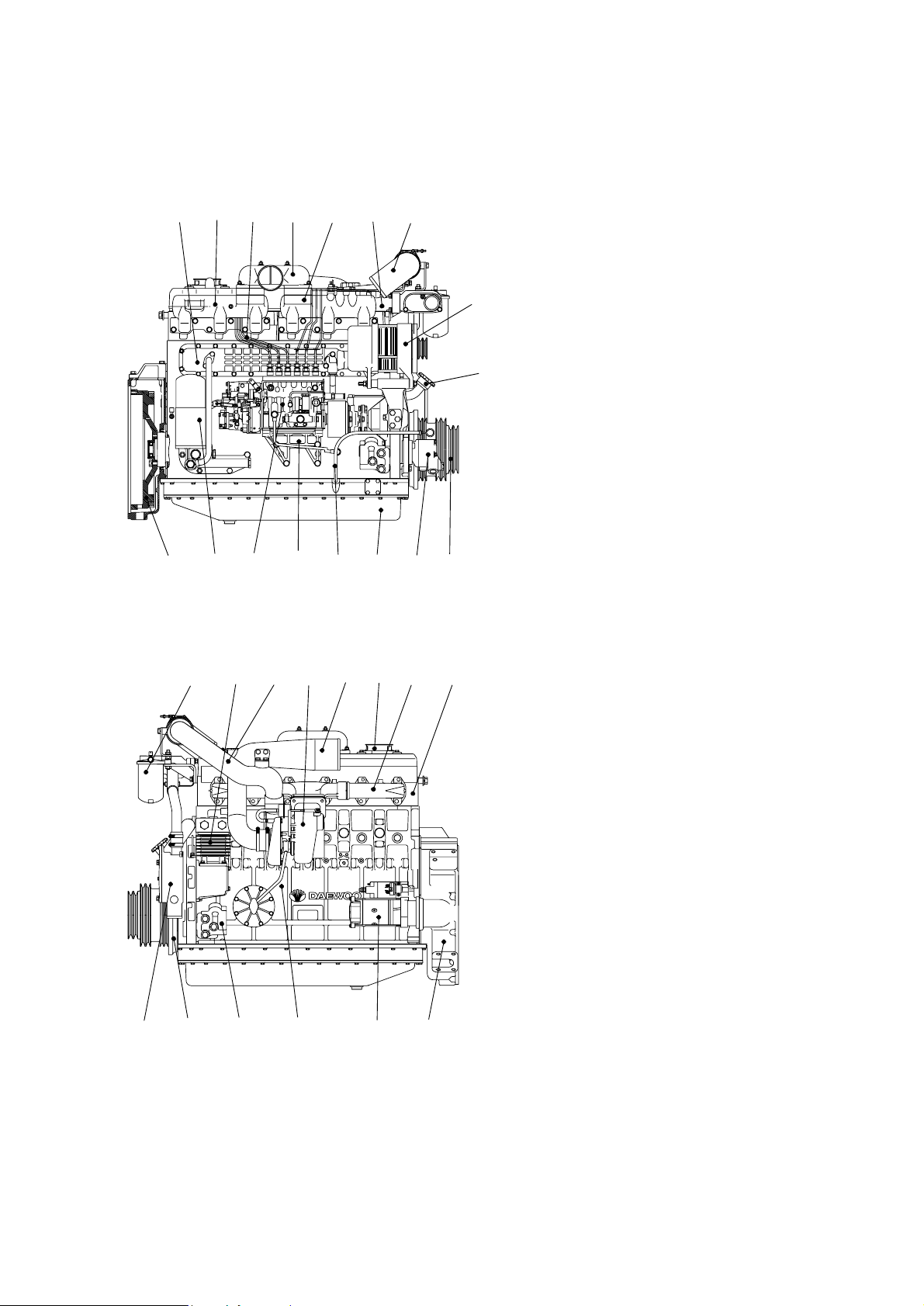

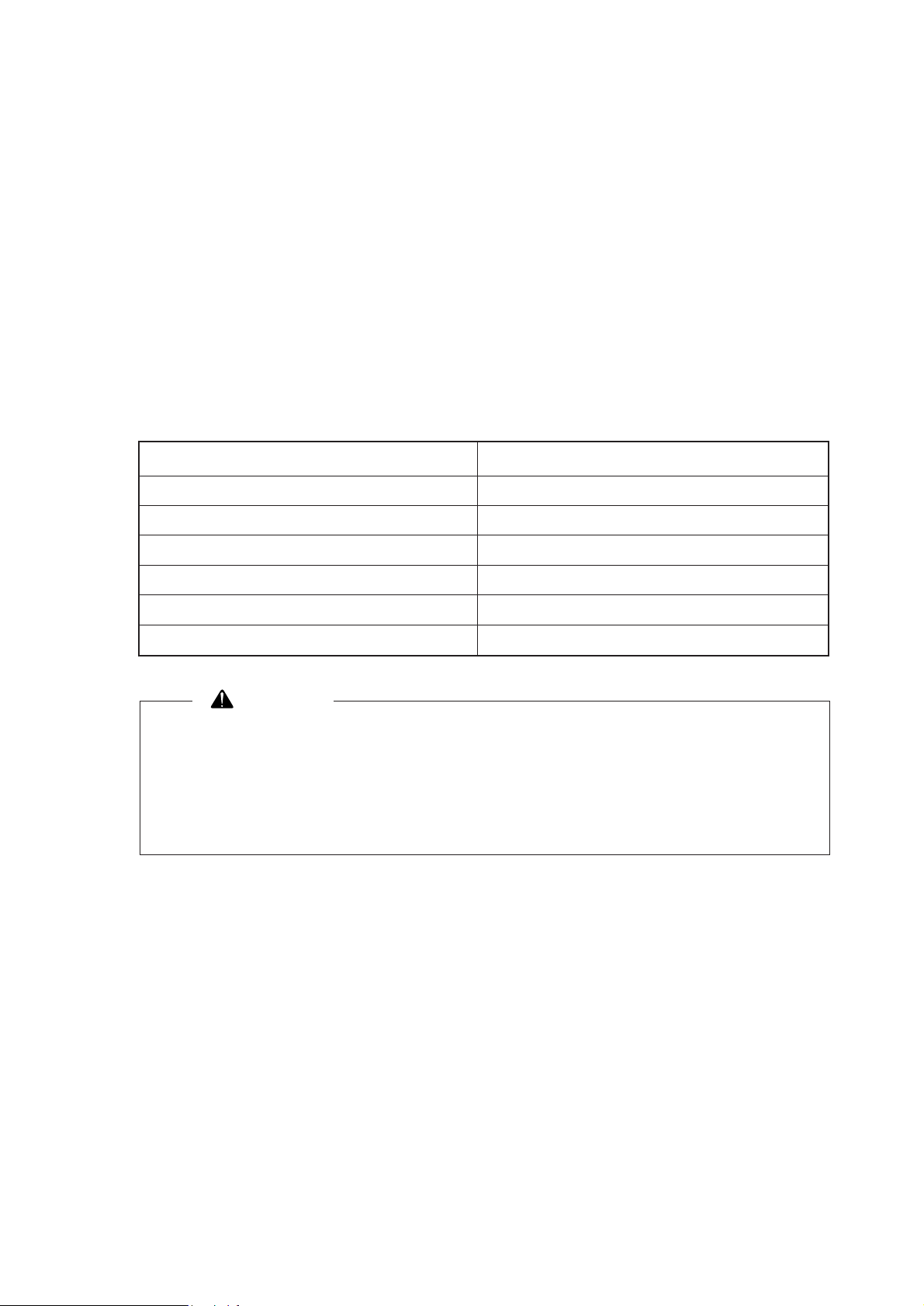

1.5.5. DE12TI(280 ps : ’98 type)- for Bus

10

28

4

9722

24 27 19 18

14 29 2551 2

1538

12 11 30236

17 1321 26 2016

1. Cylinder block

2. Flywheel housing

3. Breather

4. Oil filler pipe

5. Vibration damper

6. Flywheel

7. V-pulley

8. Cylinder head

9. Oil filter

10. Oil cooler

11. Oil pan

12. Oil dipstick

13. Cooling water pipe

14. Water pump

15. Exhaust manifold

16. Intake manifold

17. Intake stake

18. Turbocharger

19. Air pipe, T/C-A/P

20. Air pipe, A/P-I/C

21. Injection pipe

22. Injection pump

23. Injection pump bracket

24. Fuel filter

25. Starter

26. Air heater

27. Air compressor

28. Alternator

29. Mounting bracket

30. Power steering pump

EQM1013I

- 18 -

1.5.6. DE12TI(310 ps : ’98 type)- for Bus

10 16 22 17 27 21

29

4

67923

25 28 20 18

14 30 2651 2

19 1538

24 12 3111

13

1. Cylinder block

2. Flywheel housing

3. Breather

4. Oil filler pipe

5. Vibration damper

6. Flywheel

7. V-pulley

8. Cylinder head

9. Oil filter

10. Oil cooler

11. Oil pan

12. Oil dipstick

13. Cooling water pipe

14. Water pump

15. Exhaust manifold

16. Intake manifold

17. Intake stake

18. Turbocharger

19. Air pipe, T/C-A/P

20. Air pipe, A/P-I/C

21. Air pipe, A/P-I/C

22. Injection pipe

23. Injection pump

24. Injection pump bracket

25. Fuel filter

26. Starter

27. Air heater

28. Air compressor

29. Alternator

30. Mounting bracket

31. Power steering pump

EQM1014I

- 19 -

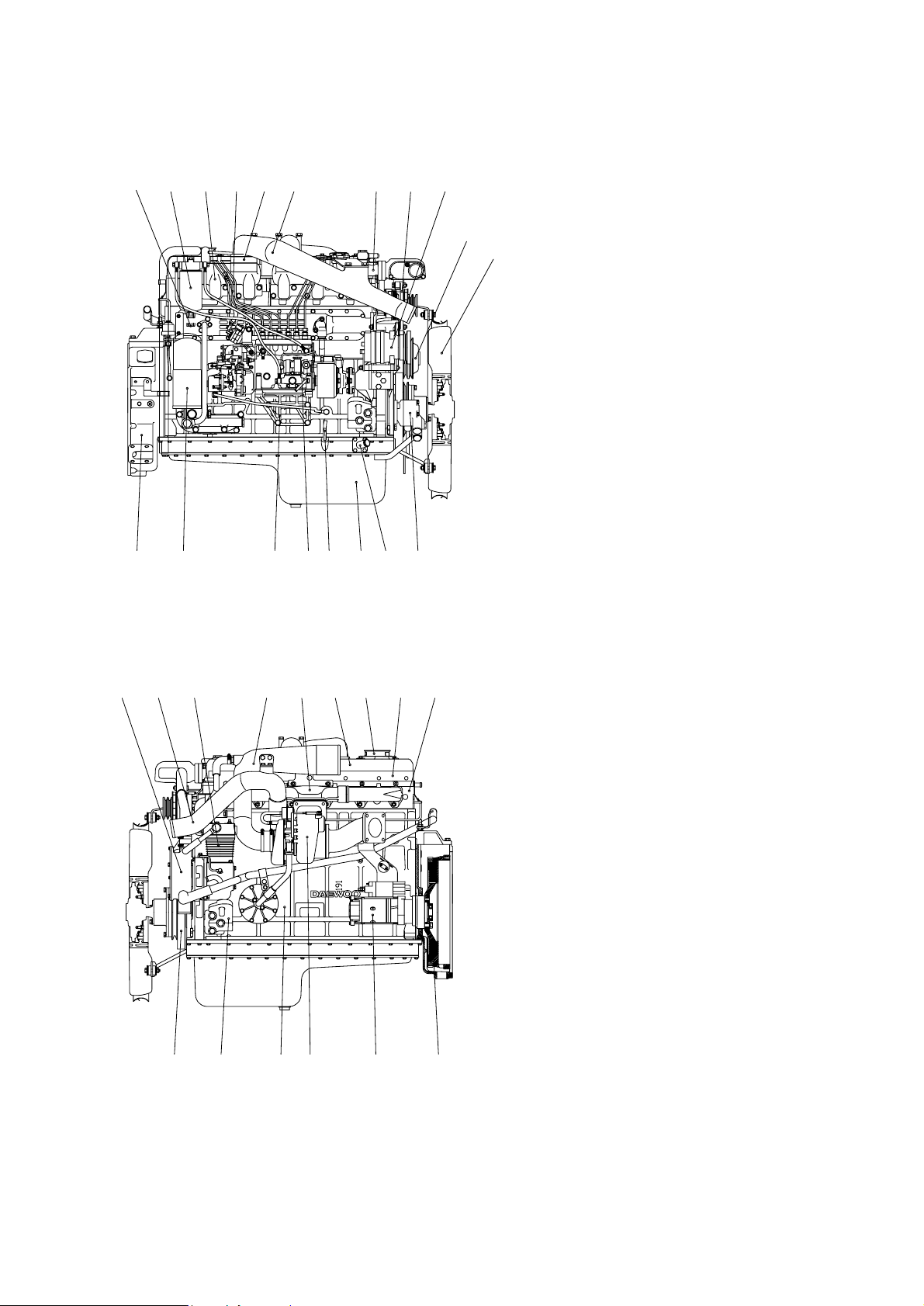

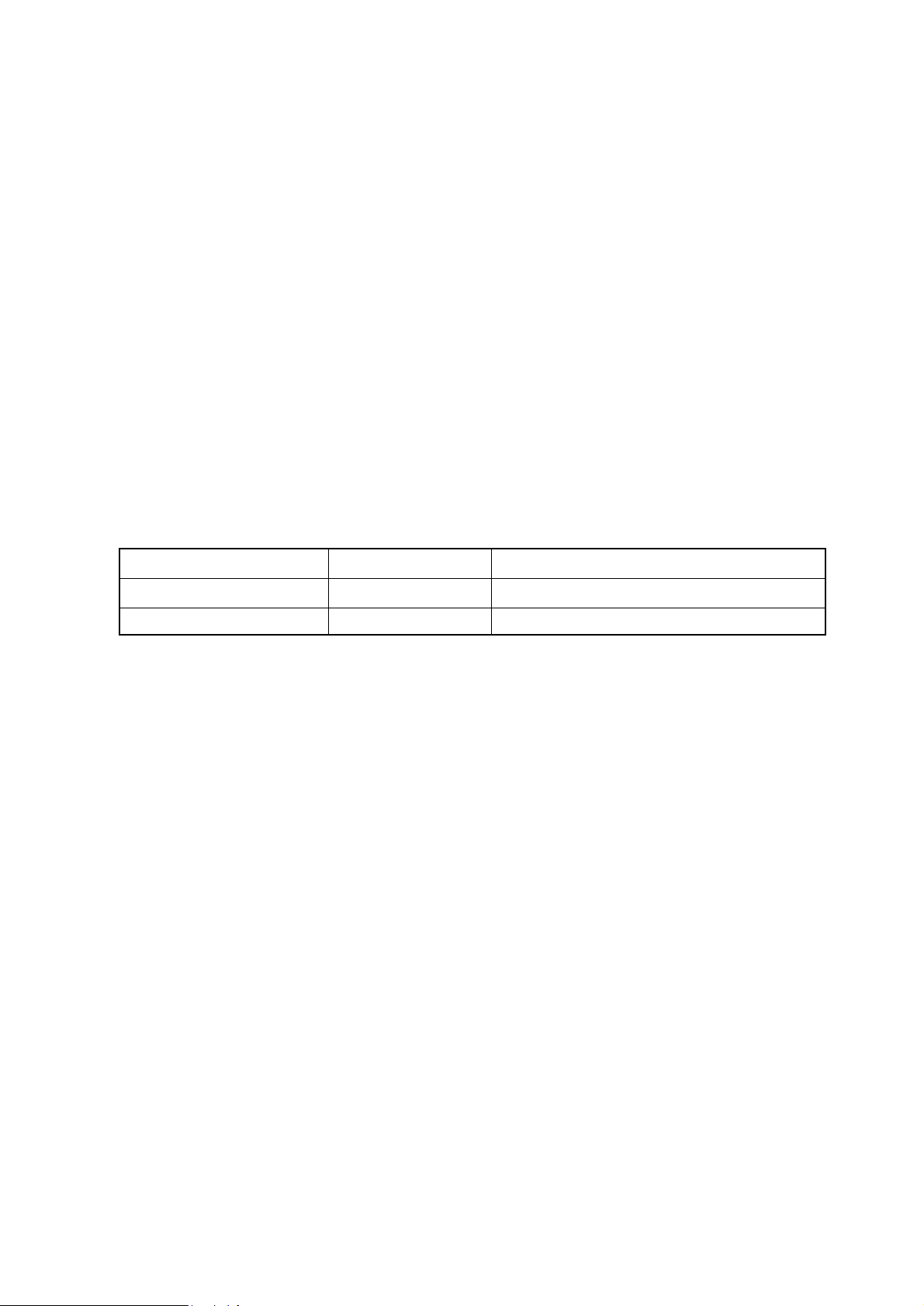

1.5.7. DE12TI - for Truck

EA2M1004

11 14 28 3119 24 30 20

7

16

15 23 34 22 17 1893 8

27

2134

5 32 1 29 621

3312252610

1. Cylinder block

2. Flywheel housing

3. Breather

4. Oil filler pipe

5. Vibration damper

6. Flywheel

7. Idle pulley

8. Cylinder head

9. Cylinder head cover

10. Oil filter

11. Oil cooler

12. Oil pan

13. Oil dipstick

14. Cooling water pipe

15. Water pump

16. Cooling fan

17. Exhaust manifold

18. Heat screen

19. Intake manifold

20. Intake stake

21. Turbocharger

22. Air pipe, A/C-T/C

23. Air pipe, T/C-I/C

24. Injection pipe

25. Injection pump

26. Injection pump bracket

27. Fuel filter

28. Alternator

29. Starter

30. Air heater

31. Air-conditioning compressor

32. Engine mounting bracket

33. Power steering pump

34. Air compressor

- 20 -

1.5.8. DE12TIS - for Bus

EA2M1005

18

11

4

6

15

71 233 31205

1735 22 21 16938

10 2912 12 341325

24 32 19 1426 23 3027 28

1. Cylinder block

2. Flywheel housing

3. Breather

4. Oil filler pipe

5. Vibration damper

6. Flywheel

7. Crank shaft pulley

8. Cylinder head

9. Cylinder head cover

10. Oil filter

11. Oil cooler

12. Oil pan

13. Oil dipstick

14. Cooling water pipe

15. Water pump

16. Exhaust manifold

17. Heat screen

18. Intake manifold

19. Intake stake

20. Turbocharger

21. Air pipe, A/C-T/C

22. Air pipe, T/C-A/P

23. Air pipe, A/P-I/C

24. Injection pipe

25. Injection pump

26. Pick-up sensor

27. Prestroke actuator sensor

28. Rack sensor

29. Injection pump bracket

30. Fuel filter

31. Starter

32. Air heater

33. Engine mounting bracket

34. Power steering pump

35. Air compressor

- 21 -

1.5.9. DE12TIS - for Truck

30

11

31

16

7

20 26 27 28 34332419 14

2410

15

56135 3221

923 37 22 17 18 3 8

29 25 13 12 36

EA2M1006

1. Cylinder block

2. Flywheel housing

3. Breather

4. Oil filler pipe

5. Vibration damper

6. Flywheel

7. Idle pulley

8. Cylinder head

9. Cylinder head cover

10. Oil filter

11. Oil cooler

12. Oil pan

13. Oil dipstick

14. Cooling water pipe

15. Water pump

16. Cooling fan

17. Exhaust manifold

18. Heat screen

19. Intake manifold

20. Intake stake

21. Turbocharger

22. Air pipe, A/C-T/C

23. Air pipe, T/C-I/C

24. Injection pipe

25. Injection pump

26. Pick-up sensor

27. Prestroke actuator sensor

28. Rack sensor

29. Injection pump bracket

30. Fuel filter

31. Alternator

32. Starter

33. Air heater

34. Air-conditioning compressor

35. Engine mounting bracket

36. Power steering pump

37. Air compressor

2. Major maintenance

2.1. Preventive maintenance

2.1.1. Cooling water

1) Check the coolant level of the radiator by removing the radiator filler cap, and add coolant if

necessary.

2) Check the pressure valve opening pressure using a radiator cap tester. Replace the radiator

filler cap assembly if the measured value does not reach the specified limit.

3) When injecting antifreeze solution, first drain out the old coolant from the cylinder block and

radiator, and then clean them with cleaning solution.

4) Be sure to mix soft water with antifreeze solution .

5) A proportion of antifreeze is represented as the ratio of antifreeze in volume, and antifreeze

must be added according to each ambient temperature as described below:

6) When the ratio of antifreeze in the mixture decreases new coolant should be added to make

up for the loss in old coolant resulting from engine operation, check the mix ratio with every

replenishment of coolant, and top up as necessary.

7) To prevent corrosion or air bubbles in the coolant path, be sure to add a specific additive, i.e.

corrosion inhibitor, to the coolant.

• Type : DAC65L

• Mix ratio : 1.5M of inhibitor to 50M of coolant

(Namely, add corrosion inhibitor amounting to 3% of water capacity.)

8) Add antifreeze of at least 5% in volume to prevent possible engine corrosion in hot weather.

If you add antifreeze in excess of 50% in volume, the engine may be overheated.

Avoid this.

As the individual freezing points corresponding to the above proportions of antifreeze

are subject to change slightly according to the kind of antifreeze, you must follow the

specifications provided by the antifreeze manufacturer.

Antifreeze solution(%) Freezing point(C)

20 -10

27 -15

33 -20

40 -25

44 -30

50 -40

- 22 -

CAUTION

2.1.2. Fan belt

1) Use a fan belt of specified dimensions, and replace if damaged, frayed, or deteriorated.

2) Check the fan belt for belt tension. If belt tension is lower than the specified limit, adjust the

tension by relocating the alternator and air conditioner. (Specified deflection: 10~15mm when

pressed down with thumb)

2.1.3. Engine oil

1) Check oil level using the oil dipstick and replenish if necessary.

2) Check the oil level with the vehicle stationary on a level ground, engine cooled. The oil level

must be between MAX and MIN lines on the stick.

3) Engine oil should be changed at the specified intervals. Oil in the oil filter also should be

changed simultaneously.

(First oil change : 1,000km running)

• Suggested engines oils

2.1.4. Oil filter

1) Check for oil pressure and oil leaks, and repair or replace the oil filter if necessary.

2) Change the oil filter element simultaneously at every replacement of engine oil.

2.1.5. Fuel filter

1) Drain water in cartridge with losen the cock under filter from time to time.

2) The fuel filter should be replaced at every 20,000km

2.1.6. Air cleaner

1) Replace any deformed or broken element or cracked air cleaner.

2) Clean or replace the element at regular intervals

Engine Model SAE NO. API NO

DE12, DE12T,DE12TI 15W40 CD grade or above

DE12TIS 15W40 CG grade

- 23 -

2.1.7. Valve clearance

1) Turn the crank shaft so that the piston in No. 1 cylinder reaches the TDC on compression

stroke, then adjust the valve clearance.

2) After releasing the lock nut for the rocker arm adjusting screw, insert a feeler gauge of specified thickness into the clearance between the rocker arm and valve stem, and adjust the

clearance with the adjusting screw. Fully tighten the lock nut when a correct adjustment is

obtained.

3) Carry out the same adjusting operation according to the firing order(1-5-3-6-2-4)

(Valve clearance(with engine cooled): 0.30mm for both intake and exhaust)

2.1.8. Cylinder compression pressure

1) Stop the engine after warming up, then remove the nozzle holder assembly.

2) Install a special tool(gauge adapter) in nozzle holder hole and mount the compression gauge

in position of the nozzle holder.

3) Cut off fuel circulation, rotate the starter, then measure compression pressure in each cylinder.

6 Testing conditions: Coolant temperature 20C, Engine speed, 200 rpm (10 turns)

2.1.9. Injection nozzle

1) Assemble a nozzle to a nozzle tester.

2) Check injection pressure, and adjust the nozzle using the adjusting shim if the pressure does

not meet the specified limit.

3) Check nozzle spray patterns and replace if damaged.

Standard 28 kg/cm2over

Limit 24 kg/cm2or less

Difference between each cylinder L10% or less

- 24 -

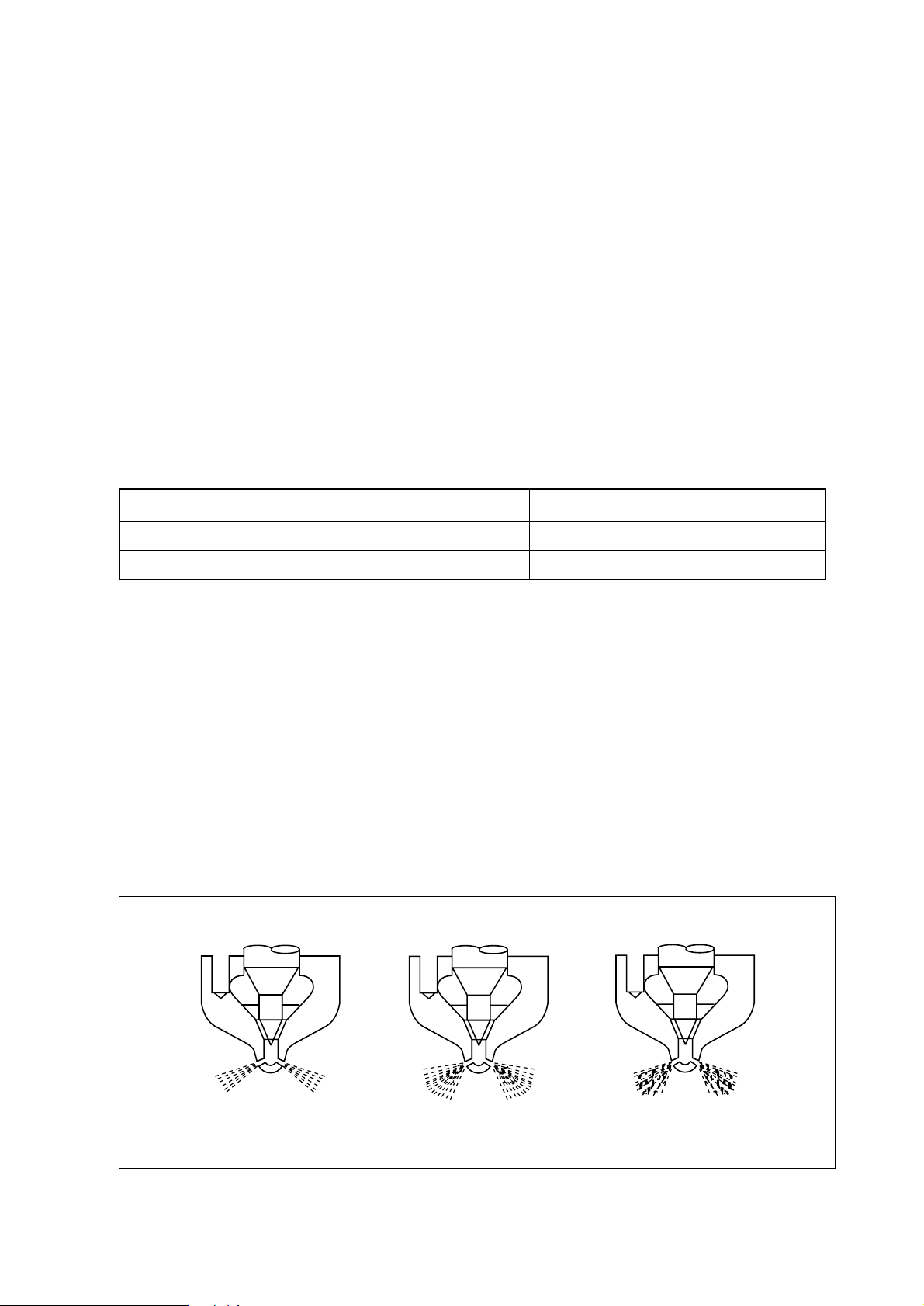

Normal Abnormal Abnormal

<Figure 2-1> Nozzle spray patterns

EFM1006I

2.1.10. Fuel injection pump

1) Check the fuel injection pump housing for cracks or breaks, and replace if damaged.

2) Check and see if the lead seal for idling control and speed control levers have not been

removed.

2.1.11. Battery

1) Check the battery for damage or leaking of battery fluid(electrolyte) from cracks on the battery. Replace the battery if damaged.

2) Check battery fluid level and add distilled water if necessary.

3) Measure the specific gravity of the electrolyte in the battery. Recharge the battery if the

hydrometer readings are lower than the specified limit(1.12~1.28)

- 25 -

2.2. Diagnostics and trouble shooting for the engine

2.2.1. Diagnostics

- 26 -

1. Engine won’t start

Starter does not turn Starter turns but engine does not start

Check battery fluid and specific gravity Engine Fuel

Too low Check air cleaner Check fuel level

Replenish or recharge

Check cable connections

Check starter s/w

Check starter relay

Check magnetic s/w

Disassemble and check starter motor

Disassemble and check injection pump

Normal

Fouled

Replace or clean element

Check compression pressure

Check other parts

Check cylinder head gasket

Overhaul the engine

(valve assembly, cylinder

liner, piston, etc.)

Check fuel feed pump for function

Check feed pump valve and strainer Air in the fuel

Retighten the joint and/or replace gasket

Air bleeding

Continuous entry of air in fuel system

Disassemble and check feed pump

Dirty element and/or overflow valve faulty

Check fuel filter

Replace

Normal

Too low

Retighten or replace

Check valve clearance

Normal

No fuel

Replenish

Check fuel injection

Normal

AdjustNormal

Repair or replaceNormal

No fuel injection

Air bleeding and re-start

Check injection timing

Check injection nozzle(injection

pressure, injection condition, etc.)

Disassemble and check

injection pump

Normal

AdjustNormal

ReplaceNormal

Clean or replaceNormal

Normal

Replenish or recharge

Normal

Replenish or recharge

Normal

ReplaceNormal

Replenish or recharge

Normal

Overhaul the engine

- 27 -

2. Engine overheating

Cooling system Fuel system

Check coolant level Check fuel quality

Operating conditions

1. Overload

2. Clogged radiator core

3. Continued overrunning

Too lowNormal Bad

Repair or replaceNormal

ReplaceNormal

ReplaceNormal

Damaged

Repair or replace

Normal

Check fan belt for tension, wear, or breaks Clean or replace with the specified fuel

Check radiator cap Replenish

Check thermostat

Check radiator

Repair or replaceNormal

Check water pump

Check water pump

InternalExternal

Overhaul engineRetighten or repair

Clean coolant path

Abnormal

Repair or replace

Normal

Check injection nozzles

Excessive fuel rate

Adjust or repair injection pump

- 28 -

3. Lack of power

Engine Chassis

Check for clutch slip

Adjust or replace clutch

Fuel system Others

Check fuel line for air Check air cleaner

Check engine control rod, link and

cable

Check fuel feed pump

Check fuel filter element and overflow valve

Check injection piping

Check injection nozzle(injection pres-

sure, nozzle spray patterns, etc.)

Normal Clean or replace

Normal Clean or replace

Normal

Check valve clearance

Check cylinder head gasket for break

Overhaul engine(valve assembly)

Adjust

Normal Adjust

Normal Replace

Normal Replace

Normal Repair or replace

Normal Adjust or replace

Normal Adjust

Check injection timing

Overhaul engine or injection pump

- 29 -

4. Low oil pressure

Normal

Normal Too high

Normal

Normal Adjust or replace

Check if oil pressure gauge

indicates exactly

Check cooling water temperature

Too low

Refill with recommanded oil

Check oil quality Refer to ‘Engine overheating’

Check oil pressure relief valve Water, fuel, etc. mixed in oil

Overhaul engine or injection pump

Inadequate

Replace with suggested lub. oil

Overhaul the engine

Check oil level

- 30 -

5. High fuel consumption

Normal

Normal Adjust or replace

Normal

Normal

Normal

Normal

Check injection timing

Check compression pressure

Disassemble injection pump

Check head gasket

Overhaul engine

(valve assembly, piston,

cylinder liner, etc.)

Check injection nozzle (injection

pressure, spray patterns, etc.)

Causes according to operating conditions

1. Overload

2. Frequent use of low gear position at high speed

3. Frequent use of high gear position at low speed

4. Clutch slip

5. Too low tire inflation pressure

Oil leakage

Retighten or replace

Check fuel leakage

Adjust

Check valve clearance

Repair or replace

Cylinder liner

Piston ring

Piston

Adjust

Replace

Clean or replace

Oil leak

External Internal

Normal

Disassemble cylinder

head(valve stem seal)

Check compression pressureRetighten or replace

Overhaul engine

(piston, cyl. liner)

- 31 -

6. Excessive oil consumption

Normal

Check oil quality

Replace with suggested lub. oil

Causes according to operating conditions

1. Too high lub. oil level

2. Continuous driving at low speed or

with excessive cold engine

Check oil leakage Check air cleaner

- 32 -

7. Engine knocks(excessive)

Identified

Overhaul engineCheck compression pressure

Check injection timing

Check fuel quality

Use suggested fuel

Normal Too low

Check valve clearance, cyl.

head gasket for damage

Normal Adjust

Normal Replace or adjust

Overhaul engine

Check fuel and oil burning(Check

carbon deposit from exhaust gas)

Not identified

- 33 -

8. Dead or weak battery

Alternator

Check fan belt for

deflection, damage, etc.

Check battery fluid level

Harness, switch

Check wiring connections

for short, etc

Repair or replace

Battery

Normal

Replenish Replace Recharge

Check battery fluid specs.

Damaged battery case

Normal

Check charging condition

Discharged

Disassemble alternator

and regulator

Abnormal

Adjust or replace

Battery discharged Battery overcharged

Check alternator and

voltage regulator

Complaint Cause Correction

- 34 -

1) Difficulty in engine

starting

(1) Trouble in starter

(2) Trouble in fuel system

(3) Lack of compression

pressure

2) Rough engine idling

3) Lack of engine power

(1) Engine continues to

lack power

(2) Engine lacks power on

acceleration

4) Engine overheating

(See <2.2.1>)

(See <Section 4.3 Fuel system>)

Valves holding open, skewed valve stem

Valve springs damaged

Leaky cylinder head gasket

Worn pistons, piston ring, or liner

Wrong injection timing

Air in injection pump

Valve clearance incorrect

Valve poorly seated

Leaky cylinder head gasket

Piston rings worn, sticking, or

damaged

Injection timing incorrect

Volume of fuel delivery insufficient

Nozzle injection pressure incorrect

or nozzles seized

Feed pump faulty

Restrictions in fuel pipes

Volume of intake air insufficient

Compression pressure insufficient

Injection timing incorrect

Volume of fuel delivery insufficient

Injection pump timer faulty

Nozzle injection pressure or spray

angle incorrect

Feed pump faulty

Volume of intake air insufficient

Lack of engine oil or poor oil

Lack of coolant

Fan belts slipping, worn or damaged

Water pump faulty

Thermostat inoperative

Valve clearance incorrect

Back pressure in exhaust line

7

6

5

4

3

2

1

7

6

5

4

3

2

1

10

9

8

7

6

5

4

3

212

1

4

3

2

1

Check valve and valve seat,

then repair or replace

Replace valve springs

Replace gasket

Replace

Adjust

Air bleeding

Adjust

Repair

Replace gasket

Replace piston rings

Adjust

Adjust injection pump

Adjust or replace nozzles

Repair or replace

Repair

Clean or replace air cleaner

Overhaul engine

Adjust

Adjust injection pump

Repair or replace

Repair or replace

Repair or replace

Clean or replace air cleaner

Replenish or replace

Replenish or replace

Adjust or replace

Repair or replace

Replace

Adjust

Clean or replace

2.2.2. Trouble shooting

- 35 -

Complaint Cause Correction

5) Engine noises

(1) Crankshaft

(2) Conn. rod and conn.

rod bearings

(3) Pistons, piston pins,

and piston rings

(4) Others

6) Excessive fuel

consumption

It is important to correctly locate the

causes of noise since generally noises may originate from various engine

components such as rotating parts,

sliding parts, etc.

Oil clearance excessive due to

worn bearings or crankshaft

Crankshaft worn out-of-round

Restrictions in oil ports and resultant lack of oil supply

Bearings seized up

Conn. rod bearings worn out-ofround

Crank pin worn out-of-round

Conn. rod skewed

Bearings seized up

Restrictions in oil ports and resultant lack of oil supply

Piston clearance excessive due to

worn piston and piston rings

Piston or piston pin worn

Piston seized up

Piston poorly seated

Piston rings damaged

Crankshaft and/or thrust bearing

worn

Camshaft end play excessive

Idle gear end play excessive

Timing gear backlash excessive

Valve clearance excessive

Tappets and cams worn

Injection timing incorrect

Volume of fuel injection excessive

Tire under-inflated

Gear selection inadequate(frequent

use of low gears)

4

3

2

1

6

5

4

3

2

1

5

4

3

2

1

5

4

3

2

1

4

3

2

1

Replace bearings and grind

crankshaft

Grind or replace crankshaft

Clean oil path

Replace bearings and grind

crankshaft

Replace bearings

Grind crankshaft

Repair or replace

Replace bearings and grind

crankshaft

Clean oil path

Replace pistons and piston

rings

Replace pistons and piston

rings

Replace pistons

Replace pistons

Replace piston rings

Replace thrust bearings

Replace thrust plate

Replace thrust washers

Adjust or replace

Adjust valve clearance

Replace tappets and camshaft

Adjust

Adjust injection pump

Adjust

Select gears correctly according to load

- 36 -

Complaint Cause Correction

7) High oil consumption

(1) Oil leaking into

combustion chamber

(2) Oil leaking past cylinder

head

(3) Oil leaks

Clearance between cylinder liner

and piston excessive

Piston rings and ring grooves

worn excessively

Piston rings broken, worn, or sticking

Piston rings gaps set incorrectly

Piston skirt portion broken, worn

excessively

Oil return holes in oil control ring

restricted

Oil ring seated incorrectly

Breather piping restricted

Valve stems and valve guide

loose excessively

Valve stem seals worn

Leaky cylinder head gasket

Applicable parts loosened

Applicable packings worn

Oil seals worn

3

2

1

3

2

1

8

7

6

5

4

3

2

1

Replace

Replace pistons and piston

rings

Replace piston rings

Correct

Replace pistons

Replace piston rings

Replace piston rings

Clean or replace

Replace as complete set

Replace seals

Replace gasket

Replace or repair gasket

Replace packings

Replace oil seals

3. Disassembly and reassembly of major components

3.1. Disassembly

3.1.1. General precautions

1) Maintenance operation should be carried out in a bright and clean place.

2) Before disassembly, provide parts racks for storage of various tools and disassembled parts.

3) Arrange the disassembled parts in the disassembly sequence and take care to prevent any

damage to them.

3.1.2. Engine oil

1) Take out the oil dipstick.

2) Remove the drain plug from the oil pan

and drain out the engine oil into a container.

3) Reassemble the drain plug with the oil

pan after draining out the engine oil.

- 37 -

EQM3001I

3.1.3. Cooling water

1) Remove the drain plug from the cylinder

block and drain out the cooling water into

a container.

EQM3002I

3.1.4. Fan belt

1) Remove the fan guide and bracket.

2) Loosen the tension adjusting nuts

installed on the alternator and air-conditioning compressor, and take off the fan

belt.

EQM3003I

3.1.5. Cooling fan

1) Remove the flange fixing bolts, then take

off the flange and cooling fan.

- 38 -

EQM3004I

3.1.6. Oil level gauge guide tube

1) Loosen the flange nut installed on the

ladder frame to remove the guide tube.

EQM3005I

3.1.7. Alternator

1) Loosen the alternator fixing bolts to disassemble the alternator, then remove

the tension adjusting bolt and bracket.

EQM3006I

3.1.8. Air-conditioning compressor

1) Remove the compressor fixing bolts and

disassemble the A/C compressor.

2) Disassemble the A/C compressor tension adjusting bolt and alternator fixing

bracket.

3) Disassemble the A/C compressor fixing

bracket.

EQM3007I

3.1.9. Fuel filter

1) Remove fuel hoses connected to the fuel

injection pump, take off the bracket fixing

bolts, then disassemble the fuel filter.

3.1.10. Breather

1) Loosen the clamp screw to remove the

rubber hose.

- 39 -

EQM3008I

3.1.11. Injection pipe

1) Unscrew the hollow screws to disassemble the fuel return pipe.

2) Remove the nuts installed on the fuel

injection pump and nozzles, then disassemble the injection pipe.

EQM3009I

3.1.12. Air heater

1) Remove the electrical wiring for the air

heater.

2) Disassemble the intake pipes by loosening the nuts installed thereon.

3) Disassemble the air heater and gasket.

EQM3010I

3.1.13. Intake manifold

1) Remove the air hose connected to the

fuel injection pump.

2) Loosen the intake manifold fixing bolts,

then disassemble the intake manifold.

EQM3011I

3.1.14. Turbocharger (for DE12T / DE12TI /

DE12TIS only)

1) Release the clamp screw of the rubber

hose connected to the intake manifold,

and take off the intake pipes both simultaneously.

2) Unscrew the exhaust pipe bracket fixing bolts, release the nuts installed on

the turbocharger, then disassemble the

exhaust pipe.

3) Remove the turbocharger after removing the oil supply pipe and return pipe

and releasing the fixing nuts.

3.1.15. Exhaust manifold

1) Release the exhaust manifold fixing

bolts, disassemble the exhaust manifold, then remove the heat shield and

gasket.

Note : Make sure to release the nuts one

after another because the exhaust

manifold will be removed if you

unscrew the two nuts simultaneously.

3.1.16. Starter

1) Unscrew the starter fixing bolts, then

disassemble the starter.

- 40 -

EQM3012S

EQM3013S

EQM3014I

EQM3015I

3.1.17. Thermostat

1) Remove the by-pass pipe connected to

the water pump, unscrew the thermostat fixing bolts, then dissemble the

thermostat assembly.

2) Disassemble the thermostat housing

and remove the thermostat.

3) Disassemble the water pipe by

unscrewing the bolts and nuts installed

on the cylinder head.

3.1.18. Fuel injection pump

1) Remove the oil supply pipe and return

pipe connected to the fuel injection

pump.

2) Unscrew the bolts connecting the coupling and drive shaft, loosen the injection pump attaching bolts, then disassemble the injection pump.

Note : Place the No.1 cylinder in the

exact 'OT' position to disassemble the injection pump.

3) Release the pump fixing bracket bolts

to disassemble the bracket from the

cylinder block.

Note : Do not interchange the shims as

they must be installed in their

original positions at reassembly.

3.1.19. Oil filter

1) Using a filter remover, remove the filter

element.

2) Remove the pipe connected to the oil

cooler.

3) Loosen the oil filter fixing bolts and disassemble the oil filter head from the

cylinder block.

3.1.20. Idle pulley

1) Remove the bolts and disassemble the

idle pulley.

- 41 -

EQM3017I

EQM3016I

EQM3018S

EQM3019S

3.1.21. Power steering pump

1) Remove the oil hoses.

2) Unscrew the hex bolts and remove the

steering pump.

- 42 -

EQM3020S

3.1.22. Water pump

1) Remove the water pipe connected to

the expansion tank

2) Remove the water pipe and hoses connected to the water pump.

3) Unscrew the water pump fixing bolts

and remove the water pump.

EQM3021S

3.1.23. Air compressor

1) Remove the oil hose, water pipe, air

pipe connected to the air compressor,

remove the air cooler fixing bolts, then

disassemble the air compressor from

the timing gear case.

EQM3022S

3.1.24. Vibration damper

1) Unscrew the pulley fixing bolts and disassemble the pulley-vibration damper

assembly.

2) Unscrew the vibration damper fixing

bolts and disassemble the damper from

the pulley.

EQM3023S

3.1.25. Timing gear case cover

1) Disassemble the oil seal using an oil

seal removing jig.

2) Remove the cover fixing bolts and disassemble the cover from the timing

gear case.

- 43 -

EQM3024I

3.1.26. Idle gear

1) Unscrew the idle gear fixing bolts and

disassemble the thrust washer and idle

gear.

2) Disassemble the idle gear pin using a

rubber hammer to prevent damage to

them.

EQM3025S

3.1.27. Fuel injection pump drive assembly

1) Remove the dowel pin for the steering

pump.

2) Unscrew the injection pump drive shaft

bearing housing fixing bolts and remove

the injection pump drive assembly in

which the shaft, gear, bearings, and

housing are put together.

EQM3026I

3.1.28. Cylinder head cover

1) Unscrew the cover fixing bolts and disassemble the cover.

2) Keep the bolts in an assembly state so

that the packings and washers may not

be lost, and keep the cover packing as

assembled with the cover.

EQM3027I

3.1.29. Rocker arm assembly

1) Unscrew the rocker arm bracket bolts

and remove the rocker arm assembly.

2) Take off the snap rings to remove the

washers and rocker arm, then unscrew

the bracket fixing bolts to take off the

bracket and springs.

3) Take out the push rods.

- 44 -

EQM3028I

3.1.30. Injection nozzle

1) Remove the nozzle fixing nuts and

extract the nozzles.

2) Remove the nozzle tube using nozzle

tube removing jig.

Do not perform disassembly operation unless coolant, gas, etc. leak

out.

EQM3029I

3.1.31. Cylinder head

1) Unscrew the cylinder head fixing bolts

and take off the cylinder head.

2) Remove the cylinder head gasket.

EQM3030I

3.1.32. Valve and valve stem seal

1) Compress the valve spring retainer using

a jig and take off the valve cotter pin.

2) Disassemble the valve springs and

retainer.

3) Take off the valve.

4) Remove and discard the valve stem

seal using a general tool as it should

not be re-used.

EJM3027S

Compress the spring

3.1.33. Oil cooler

1) Remove the water pipe connected to

the water pump.

2) Unscrew the oil cooler cover fixing bolts

and disassemble the oil cooler assembly from the cylinder block.

3) Unscrew the oil cooler fixing bolts and

remove the oil cooler from the oil cooler

cover.

3.1.34. Oil pan

1) Stand the engine with the flywheel

housing facing toward the bottom.

2) Release the oil pan fixing bolts, remove

the stiffeners, then disassemble the oil

pan.

- 45 -

EQM3031I

EQM3032I

3.1.35. Oil pump and oil pipe

1) Unscrew the oil inlet pipe bracket bolts,

releasing the pipe fixing bolts, then disassemble the oil suction pipe assembly.

2) Disassemble the oil pipe feeding oil

from the oil pump to the cylinder block.

3) Unscrew the oil pump fixing bolts and

disassemble the oil pump.

EQM3033I

3.1.36. Ladder frame

1) Disassemble the ladder frame.

EQM3034I

3.1.37. Piston and connection rod

1) Disassemble the pistons by two hands

while turning the crankshaft.

2) Unscrew the conn. rod fixing bolts and

take off the pistons and conn. rods in

the direction of piston.

- 46 -

EQM3035I

3) Remove the piston pin snap rings, take

off the piston pin, then disconnect the

conn. rod from the piston.

EQM3036S

4) Disassemble the piston rings using ring

pliers.

5) Take care not to interchange the disassembled parts and keep them in the

sequence of cylinder No.

EQM3037S

3.1.38. Cylinder liner

1) Take off the cylinder liner.

EQM3038I

Piston ring jig

3.1.39. Flywheel

1) Position the engine so that the head

installing surface of the cylinder block

faces down.

2) Unscrew the flywheel fixing bolts and fit

a dowel pin.

3) Install flywheel disassembling bolts in

the bolt holes machined on the flywheel,

and disassemble the flywheel.

3.1.40. Oil seal

1) Take off the rear oil seal using an oil

seal disassembling jig.

2) If only the inside guide ring is removed,

use a general tool to take off the outside

seal.

- 47 -

EQM3039I

EQM3040I

3.1.41. Flywheel housing

1) Loosen the housing fixing bolts and disassemble the flywheel housing.

EQM3041I

3.1.42. Cam shaft and tappet

1) Remove the cam shaft gear.

2) Take off the cam shaft gear thrust

washer.

3) Take out the cam shaft carefully not to

damage the cam shaft.

4) Slide out the tappets by hand.

EQM3042I

3.1.43. Crankshaft gear and oil pump idle

gear

1) Loosen the socket head bolts and take

out the oil pump idle gear.

2) Use a puller to remove the crankshaft

gear.

- 48 -

EQM3043S

3.1.44. Timing gear case

1) Unscrew the case fixing bolts and disassemble the timing gear case.

EQM3044I

3.1.45. Crankshaft

1) Unscrew the main bearing cap fixing

bolts and remove the bearing cap.

2) Take off the crankshaft.

3) Take off the main bearing.

EQM3045S

3.1.46. Oil spray nozzle

1) Remove the oil spray nozzles.

EQM3046S

Puller

3.2. Inspection

3.2.1. Cylinder block

1) Clean the cylinder block thoroughly and make a visual inspection for cracks or damage.

2) Replace if cracked or severely damaged, and correct if slightly damaged.

3) Check oil and water flow lines for restriction or corrosion.

4) Make a hydraulic test to check for any cracks or air leaks.

(Hydraulic test) :

Stop up each outlet port of water/oil passages in the cylinder block, apply air pressure of

about 4kg/cm

2

against the inlet ports, then immerse the cylinder block in water for about 1

minute to check any leaks. (Water temperature: 70

C)

3.2.2. Cylinder head

1) Check the cylinder head for cracks or damage.

(1) Carefully remove carbon from the lower face of the cylinder head using nonmetallic mate-

rial to prevent scratching of the valve seat faces.

(2) Check the entire cylinder head for very fine cracks or damage invisible to ordinary sight

using a hydraulic tester or a magnetic flaw detector.

2) Check the lower face of the cylinder

head for distortion.

(1) Measure the amount of distortion

using a straight edge and a feeler

gauge at six positions as shown in

the figure right.

(2) If the measured value exceeds the

standard value(0.2mm), reface the

head with grinding paper of fine grain

size to correct such defect.

(3) If the measured value exceeds the

maximum allowable limit(0.3mm),

replace the cylinder head.

3) Measure flatness of the intake/exhaust

manifolds fitting surfaces on the cylinder

head using a straight edge and a feeler

gauge.

4) Hydraulic test method for the cylinder

head is the same as that for cylinder

block.

- 49 -

EF

A

B

C D

EQM3047I

<Figure 3-1> Measuring cylinder head

distortion

3.2.3. Valve and valve guide

1) Inspecting the valve

Clean the valves with clean diesel oil,

then inspect them as follows:

(1) Measure the valve stem outer diam-

eter at 3 positions(top, middle, and

bottom). If the amount of wear is

beyond the limit(0.18mm), replace

the valve.

(2) Check the valve seat contacting

faces for scratches or wear, and correct the faces with grinding paper as

necessary. Replace if severely damaged.

(3) Measure the valve head thickness,

and replace the valve if the measured value is 1mm or less(a).

Dimensions

Standard Limit

Descriptions

Intake valve

N10.950~10.970 10.87

stem (mm)

Exhaust valve

N10.935~10.955 10.84

stem (mm)

2) Inspection and measurement of valve guide

(1) Install the valve into the valve guide and measure the clearance between them by valve

movement. If the clearance is excessive, measure the valve and replace either the valve or

the valve guide, whichever worn more.

(2) Install the valve into the cylinder head valve guide, then check and see if it is centered with

the valve seat using a special tool.

- 50 -

END OF STEM

EFM2036I

<Figure 3-2> Measuring valve stem

EQM3048I

<Fig. 3-3> Measuring thickness of valve head

a

3) Inspection and correction of valve seat

(1) Measure the contacting face

between the intake valve seat and

exhaust valve seat for valve seat

wear, and replace if the measured

value exceeds the specified limit.

(2) Install the valve into the valve seat on

the cylinder head, and check the

amount of depression of the valve

from the lower portion of the cylinder

head using a dial gauge.

If the amount of depression is beyond the specified limit, replace the valve seat.

(3) For removal of the valve seat, apply arc welding work to two points of valve seat insert,

and pull out valve seat insert with inner extractor.

(4) Undercool a new valve seat with dry ice for about 2 hours and press the valve seat insert

into position in the cylinder head using a special tool(bench press).

(5) Apply valve lapping compound to the valve head seating face on the valve seat and lap

the valve seat by turning it until it is seated in position, then wipe out the lapping compound.

- 51 -

EQM3049I

4) Inspection and correction of valve spring

(1) Visually check the exterior of the

valve springs for damage, and

replace if necessary.

(2) Measure free length and spring ten-

sion with a valve spring tester.

(3) Measure the spring inclination with a

square.

(4) Compare the measured value with

the standard value to determine

whether to replace or repair.

1mm or less

Free length

Square

EFM2039I

<Figure 3-4> Measuring spring tension and

inclination

-0.3~0

3.2.4. Rocker arm shaft assembly

1) Measurement of rocker arm shaft

(1) Place the rocker arm shaft on two V-

blocks and inspect the shaft for bend

using a dial gauge.

If the amount of this run-out is small,

press the shaft with a bench press to

correct the run-out. Replace the

shaft if the measured value exceeds

the limit.

(2) With an outside micrometer, measure the rocker arm shaft diameter at the point where

the rocker arms have been installed. Replace the rocker arm if the amount of wear is

beyond the specified limit.

2) Inspection of rocker arm

(1) Visually check the face of the rocker arm in contact with the valve stem end for scores

and step wear. If the wear is small, correct it with an oil stone or grinding paper of fine

grain size. Rocker arm with a considerable amount of step wear should be replaced.

(2) Measure the inside diameter of the rocker arm bushing with an inside micrometer or

vernier calipers, and compare the measured values with the rocker arm shaft diameter. If

the clearance exceeds the limit, replace either bushing or shaft, whichever worn more.

- 52 -

EDM2037I

<Figure 3-5> Measuring run-out of rocker arm

shaft

3) Inspection of tappet and push rod

(1) Measure the outer diameter of the

tappets with an outside micrometer.

If the amount of wear is beyond the

specified limit, replace tappets.

(2) Visually check the face of the tappets

in contact with the cam for pitting,

scores or cracks, and replace if

severely damaged. If the amount of

cracks or pitting is small, correct with

an oil stone or grinding paper.

(1) Pitting (2) Crack (3) Normal

(4) Abnormal

EFM2041I

<Figure 3-6> Inspecting tappet face

(3) Support the push rod on two V-

blocks and check for bend using a

feeler gauge.

EDM2037I

<Figure 3-7> Measuring push rod run-out

3.2.5. Cam shaft

1) Inspection of cam

(1) Measure the cam height with a

micrometer and replace the camshaft

if the measured value is beyond the

specified limit.

(2) Inspect the cam face for scratch or

damage.

Slight step wear or damage on the

cam face may be corrected with oil

stone or oiled grinding paper. But,

replace if severely damaged.

- 53 -

EDM2045I

<Figure 3-8> Measuring cam height

2) Inspection of cam shaft

(1) With an outside micrometer, mea-

sure the camshaft journal diameter.

(2) Measure the inside diameter of the

camshaft bushing on the cylinder

block using a cylinder bore indicator,

and compare the measured value

with the camshaft outside diameter to

determine the clearance.

(3) Replace the bushing if the measured

value is beyond the specified limit.

(4) Support the cam shaft on two V-

blocks and check for run-out using a

dial indicator. Correct or replace the

cam shaft if the amount of run-out is

beyond the value indicating need for

servicing.

EAOM4063

<Figure 3-9> Measuring inside diameter of

cam shaft bushing on cylinder block

EFM2046I

<Figure 3-10> Measuring cam shaft run-out

3) Cam shaft end play

(1) Push the thrust plate toward the cam

gear.

(2) With a feeler gauge, measure the

clearance between the thrust plate

and cam shaft journal.

(3) If the end play is excessive, replace

the thrust plate.

EAOM4067

<Figure 3-11> Measuring cam shaft axial play

Cam bushing

3.2.6. Crank shaft

1) Inspection for scores or cracks

(1) Visually check the crank shaft journal and crank pins for scores or cracks.

(2) Using a magnetic power and color check, inspect the crank shaft for cracks, and replace

the crank shaft which has cracks.

2) Checking crank shaft for wear

(1) With an outside micrometer, measure the diameter of the crank shaft journals and pins in

the directions as shown, and compare the measured values to determine the amount of

wear.

(2) If the amount of wear is beyond the limit, have the crank shaft ground and install under-

size bearings. However, if the amount of wear is within the limit, you can correct the wear

using an oil stone or oiled grinding paper of fine grain size.

(Be sure to use grinding paper which has been immersed in oil.)

•Undersize bearings available

(1) Standard

(2) 0.25 (Inside diameter is 0.25mm

lesser than the standard size.)

(3) 0.50 (Inside diameter is 0.50mm

lesser than the standard size.)

(4) 0.75 (Inside diameter is 0.75mm

lesser than the standard size.)

(5) 1.00 (Inside diameter is 1.00mm

lesser than the standard size.)

Undersize bearings are available in

4 different sizes as indicated above,

and the crankshaft can be reground

to the above sizes.

- 54 -

B B

B

A

A

B

EFM2047I

<Figure 3-12> Measuring crank shaft outer

diameter

Note : When regrinding the crank

shaft as described above, the

fillet section 'R' should be finished correctly.

Avoid sharp corners or insufficient fillet.

Standard values of 'R'

Crankshaft pin 'R' : 4.5

Crankshaft journal 'R' : 4

" R "

" R "

" R "

Right Wrong Wrong

" R " " R "

EFM2048I

<Figure 3-13> The shape of crankshaft 'R'

1

2

“R”

3) Measurement of crankshaft run-out

(1) Support the crankshaft on V-blocks.

(2) Turn the crankshaft with a dial indi-

cator placed on the surface plate and

take the amount of crank shaft runout.

- 55 -

EDM2040S

<Figure 3-14> Measuring crank shaft run-out

EDM2041S

<Figure 3-15> Measuring crank shaft outer

diameter

3.2.7. Crank shaft bearing and connecting

rod bearing

1) Visually check the crank shaft bearing

and connecting rod bearing for scores,

uneven wear or damage.

2) Check oil clearance between crankshaft

and bearing.

(1) Install the main bearing in the cylin-

der block, tighten the bearing cap to

specified torque, then measure the

inside diameter.

(2) Install the connecting rod bearing in

the conn. rod bearing cap, tighten the

connecting rod cap bolts to specified

torque, then measure the inside

diameter.

EDM2042S

EQM3050S

<Figure 3-16> Measuring main bearing inside

diameter

(3) Compare the two values obtained

through measurement of bearing

inside diameter with the outside

diameters of crankshaft journals and

pins to determine the oil clearance.

(4) If the clearance deviates from the

specified range, have the crankshaft

journals and pins ground and install

undersize bearings.

- 56 -

EDM2044I

<Figure 3-17> Measuring conn. rod bearing

inside diameter

3) Inspection of bearing spread and crush

(1) Check to see that the bearing

requires a considerable amount of

finger pressure at reassembly operation.

(2) With a bearing crush aligner, mea-

sure bearing crush.

•Standard bearing crush

Crank shaft bearing crush(mm)

0.15~0.25

Conn. rod bearing crush(mm)

0.3~0.5

EDM2046S

<Figure 3-18> Checking bearing tension

<Figure 3-19> Bearing and cylinder block

O A

Spread = O A - O B

O B

EDM2047I

EDM2048I

<Figure 3-20> Measuring main bearing crush

(3) Conn. rod bearing crush can be

checked as follows:

Install the bearing and cap in the

conn. rod big end, retighten the bolts

to specified torque, unscrew out one

bolt completely, then measure the

clearance between the bearing cap

and conn. rod big end using a feeler

gauge.

- 57 -

EDM2049I

<Figure 3-21> Conn. rod bearing crush

4) Measurement of crank shaft end play

(1) Assemble the crankshaft to the cylin-

der block.

(2) With a dial gauge, measure crank

shaft end play.

EPM2018S

<Figure 3-22> Measuring crankshaft end play

3.2.8. Piston

1) Visually check the pistons for cracks,

scuff or wear, paying particular attention

to the ring groove.

2) Measurement of the clearance between

the piston and cylinder liner.

(1) With an outside micrometer, mea-

sure the piston outside diameter at a

point 18mm away from the lower end

of piston skirt in a direction at a right

angle to the piston pin hole.

EQM3051S

<Figure 3-23> Measuring piston outside

diameter

<Figure 3-24> Measuring cylinder liner inside

diameter

(2) Using a cylinder bore gauge, mea-

sure cylinder liner inside diameter at

3 points (cylinder top ring contacting

face, middle, and oil ring contacting

face on BDC) in a direction at an

angle of 45°. Take the mean value

with the largest and smallest values

excepted.

2

EQM3052I

Position of measuring

outside diameter

(3) The clearance is computed by sub-

tracting the piston outside diameter

from the cylinder liner inside diameter. Replace either piston or cylinder

liner, whichever damaged more, if

the clearance is beyond the specified

limit.

3.2.9. Piston rings

1) Replace the piston rings with new ones if

detected worn or broken when the

engine is overhauled.

2) Measure piston ring gap.

(1) Insert the piston ring into the upper

portion of the cylinder liner bore so

that it is held at a right angle to the

cylinder liner wall.

(2) Measure the piston ring gap with a

feeler gauge.

(3) Replace piston rings with new ones if

the gap is beyond the limit.

3) Measure piston ring side clearance.

(1) Fit the compression ring and oil ring

in the piston ring groove.

(2) With a feeler gauge, measure side

clearance of each ring, and replace

either the ring or piston if the measured value is beyond the specified

limit.

Dimensions

Standard(mm) Limit(mm)

Descriptions

Top ring 0.40~0.65 1.5

2nd ring 0.40~0.65 1.5

Oil ring 0.30~0.60 1.5

Liner Standard Limit

Cylinder line

inside diameter l123

+0.005

123.225

(mm)

-0.015

- 58 -

EFM2053I

<Figure 3-25> Measuring piston ring gap

4) With a tension tester, measure piston

ring tension. Replace the piston ring if

the measured value is beyond the limit.

3.2.10. Piston pin

1) Measure the amount of wear on the piston pin

(1) Measure the amount of wear on the

piston pin at the points as shown.

The measured values are beyond

the limit(0.005mm or greater),

replace the pin.

(2) Measure the clearance between the

piston pin and conn. rod bushing,

and replace either of them, which

ever damaged more, if the measured value is beyond the

limit(0.011mm).

2) Check the engaged condition of the piston and piston pin. If it is possible to

force the pin into the piston heated with

piston heater, the piston is normal.

When replacing the piston, be sure to

replace the piston pin together.

Dimensions

Standard(mm) Limit(mm)

Descriptions

Top ring 2nd ring 0.07~0.102 0.15

Oil ring 0.05~0.085 0.15

- 59 -

B

A (A) (B) (C)

EDM2058I

<Figure 3-26> Measuring piston pin

3.2.11. Connecting rod

1) Check the connecting rod for distortion.

As shown in the figure right, install the

conn. rod to the conn. rod tester, and

check for distortion using a feeler

gauge. If the conn. rod is found distorted, never re-use it and replace it with a

new one.

2) Measure the alignment of the conn. rod

piston ring bushing holes with conn. rod

big end holes. At this time also, use

both conn. rod tester and feeler gauge.

3) Inspection of the amount of wear on the

conn. rod big end and small end

(1) Assemble the conn. rod to the crank

shaft and measure conn. rod big

end side clearance using a feeler

gauge.

(2) Assemble the conn. rod to the piston

and measure conn. rod small end

side clearance.

(3) If the measured values are beyond

the limit(0.5mm), replace the connecting rod.

- 60 -

EJM2087I

<Figure 3-27> Measuring alignment of

conn. rod

3.2.12. Tappet

1) Check the tappets for cracks, scores, or

damage.

2) With an outside micrometer, measure

the tappet outside diameter. If the measured value is beyond the limit, replace

tappets.

EDM2061I

<Figure 3-28> Measuring tappet outside

diameter

3.3.3. Oil spray nozzle

1) Tighten and assemble the oil spray nozzle flange with fixing bolts.

- 61 -

EQM3053I

3.3.4. Tappet and cam shaft

1) Undercool a new bush with dry ice for

about 2 hours and press it into position in

the cylinder block using a bench press.

After the pressing operation, measure

the inside diameter of the cam bush to

check if it is not deformed.

2) Apply engine oil to the entire face of the

tappets and slide them into the tappet

holes on the cylinder block.

EDM2059S

3.3. Reassembly

3.3.1. General precautions

1) Wash clean all the disassembled parts, particularly oil and water ports, using compressed air,

then check that they are free from restrictions.

2) Arrange the general and special tools for engine assembly operation.

3) To wet each sliding part, prepare clean engine oil.

4) Prepare service materials such as sealant, etc.

5) Discard used gaskets, seal rings, and consumable parts, and replace with new ones.

6) Apply only the specified torque for bolts in the specified tightening order and avoid over-tightening.

7) Be sure to check that all the engine parts operate smoothly after being reassembled.

8) Check the bolts for looseness after preliminary reassembly.

9) After completing the engine reassembly operation, check if there is missing parts or shortage

of parts.

10) Keep your hands clean during the working

3.3.2. Cylinder block

1) Cover the floor of the workshop with wood plate or thick paper to prevent damage to the

cylinder head, and place the cylinder block with the head fitting surface facing downward.

3) Wet the cam bush inside diameter and

cam shaft with oil, and carefully assemble them while turning the cam shaft.

4) Check to see that the cam shaft rotates

smoothly.

- 62 -

EDM2060I

3.3.5. Crank shaft

1) Install the main bearing machined with

two holes in the cylinder block so that the

key is aligned with the key groove, then

apply oil to the bearing surface.

2) Apply sealant in the inside wall of the

crank shaft gear evenly before placing

over the shaft

3) Semi-tighten a bolt at both sides of the

crank shaft, apply engine oil to journals

and pins, then assemble the crank shaft

with the cylinder block by tightening the

fixing bolts.

4) Install the oiled thrust washers with the

oil groove facing outward.

EQM3054S

EQM3055S

EQM3056S

Oil port and passage

Key groove

5) Install the bearing and thrust washers to

the bearing cap and apply oil to the bearing and thrust washers.

- 63 -

EQM3057I

6) Install the bearing cap by matching the

cylinder block No. with the bearing cap

No.

7) Apply oil to the entire part of the bearing

cap bolts, then tighten in tightening

sequence to specified torque(30kg

•

m).

8) After semi-tightening both bolts evenly,

tighten them diagonally to about 15kg

•

m

for the first stage and 25kg

•

m for the

second stage respectively, then tighten

them completely to the specified torque

using a torque wrench.

9) Tighten the bearing cap in the sequence

of 4-3-5-2-6-1-7.

10) Check to see that the assembled crank

shaft turns smoothly.

3

4

5

6

7

2

1

EQM3058I

EQM3059I

3.3.6. Flywheel housing

1) Temporarily install the guide bar on the

cylinder block.

2) Apply gasket to the cylinder block.

3) Using the dowel pin and guide bar,

install the flywheel housing and tighten

the fixing bolts in a diagonal sequence to

specified torque(12kg°m)

EQM3060I

3.3.7. Rear oil seal

1) Apply lubricating oil to the outside of the

oil seal and flywheel inside diameter and

fit them over the crank shaft, then

assemble the oil seal using an oil seal fitting jig.

- 64 -

EQM3061I

3.3.8. Flywheel

1) Install a guide bar into a bolt hole on the

crank shaft, and lift the flywheel to align

the dowel pin with the pin hole on the flywheel for temporary assembly operation.

2) Install bolts in the remaining holes with

no guide bar installed, take out the guide

bar, then install a bolt in the hole where

the guide bar had been inserted.

3) Tighten the fixing bolts using a torque

wrench in a diagonal sequence to specified torque(18kg•m).

EQM3062I

2

6

4 8

1

5

7

3

EQM3063I

3.3.9. Timing gear case

1) Mount gasket using dowel pin.

2) Install the timing gear case by aligning

the dowel pin with the dowel pin hole on

the timing gear case.

EQM3064I

<Tightening sequence for flywheel fixing bolts>

3.3.10. Fuel injection pump drive gear

assembly

1) Mount gasket by aligning the bolt holes

with the pin holes on the bearing housing.

2) Tighten up the fixing bolts in the direction

of fuel injection pump.

- 65 -

EQM3065I

3.3.11. Timing gear

1) Install the oil pump idle gear onto the

No. 7 bearing cap.

2) Install a thrust washer over the cam

shaft and assemble the cam gear by

aligning it with cam shaft key groove.

3) With the oil port on the idle gear pin facing the cylinder head, install the idle

gear pin.

4) Install the idle gear by coinciding the

marks impressioned on the crank gear,

cam gear, fuel injection pump drive

gear, and idle gear.

5) Install a thrust washer on the idle gear

and tighten to specified torque (6.2kg

•

m).

6) Check and adjust the amount of backlash between gears using a feeler

gauge. (backlash : 0.1~0.2)

EQM3066I

Fuel injection

pump drive

gear

Idle gear

Cam gear

Crank

gear

EDM2075I

3.3.12. Timing gear case cover

1) Install dowel pin on the timing gear case.

2) Mount a gasket by aligning the fixing

bolt holes with those on the gasket.

3) Align the dowel pin with the cover pin

hole, then install the cover with a light tap.

4) Tighten the fixing bolts beginning with

the oil pan fitting face.

EQM3067S

<Timing gear marks>

3.3.13. Front oil seal

1) Apply lubricating oil to the outside of the

oil seal and timing gear case inside

diameter and fit them over the crank

shaft, then assemble the oil seal using

an oil seal fitting jig.

- 66 -

EQM3068I

3.3.14. Cylinder liner

1) Stand the cylinder block so that the flywheel faces downward.

2) Thoroughly clean the liner flange fitting

surface and bore inside with compressed air to prevent the entry of foreign substances.

3) After the cleaning operation, make the

cylinder liner dried up and push it into

the cylinder block by hand.

4) Wet the liner inside diameter with

engine oil.

EQM3069I

3.3.15. Piston and connecting rod