Page 1

System description

Electronic monitoring system

EMS 2

Page 2

Page 3

EMS 2

1Foreword

This system description provides an overview of the design and the operation of the electronic monitoring

system (EMS 2).

In addition, the functions which the EMS 2 contains, and the manner in which problems in the engine and in

the EMS 2 can be detected, are explained.

© 0702 Page 55

Page 4

EMS 2

Page 56 © 0702

Page 5

EMS 2

2 Important notes

In the event of critical conditions, the EMS 2 may independently shut the engine off, either

with or without prior warning depending on the configuration, or may merely provide a

warning. The user must be informed of this and must be familiarised with limp-home mode.

! The following states can be recognised with the diagnostic lamp

Display State Indicates

Important notes

Diagnostic lamp

illuminates for 2 s

from ignition on.

Diagnostic lamp

continuously

illuminated.

Diagnostic lamp

flashes rapidly

(approx. 1 Hz).

* Diagnostic lamp

flashes slowly

(approx. 0.5 Hz).

Lamp test System is ready for operation.

Warning

regarding exceeded limit

values and system faults.

Emergency engine

shut-off if shut-off limits

are exceeded or not

achieved.

The limp-home mode

button has been

actuated in order to

bridge the reduction in

power or engine shut-off.

Bridging is stored in the

control unit.

A reduction in power is only possible in combination with

an engine governor, e.g. EMR and MVS.

The reduction in power can be temporarily bridged with

the limp-home mode button. (Depression of the

button is confirmed with slow flashing, see *).

After the engine has been shut-off, fault code enquiry is

possible (see **).

Attention: In a few seconds, the engine will be

automatically shut-off for the purpose of protection.

The reduction in power can be temporarily bridged with

the limp-home mode button. (Depression of the

button is confirmed with slow flashing, see *).

After the engine has been shut-off, fault code enquiry is

possible (see **).

Attention: Following actuation of the limp-home mode

button, the engine continues to run without protection for

a short time, and may become damaged! For this reason,

only actuate the button in the event of an emergency

(e.g. if life is otherwise placed at risk)!

** Fault code

enquiry

! The illumination of the maintenance/service lamp demands that the engine be maintained by the

DEUTZ Service department.

© 0702 Page 57

The diagnostic lamp serves to display a fault

code (a sequence of

short and long flashing

impulses).

In the event of engine standstill, an enquiry regarding the

fault code may be made with the limp-home mode button/

diagnostic button, see Chapter 8.4.

Page 6

Important notes

EMS 2

Page 58 © 0702

Page 7

EMS 2

System description

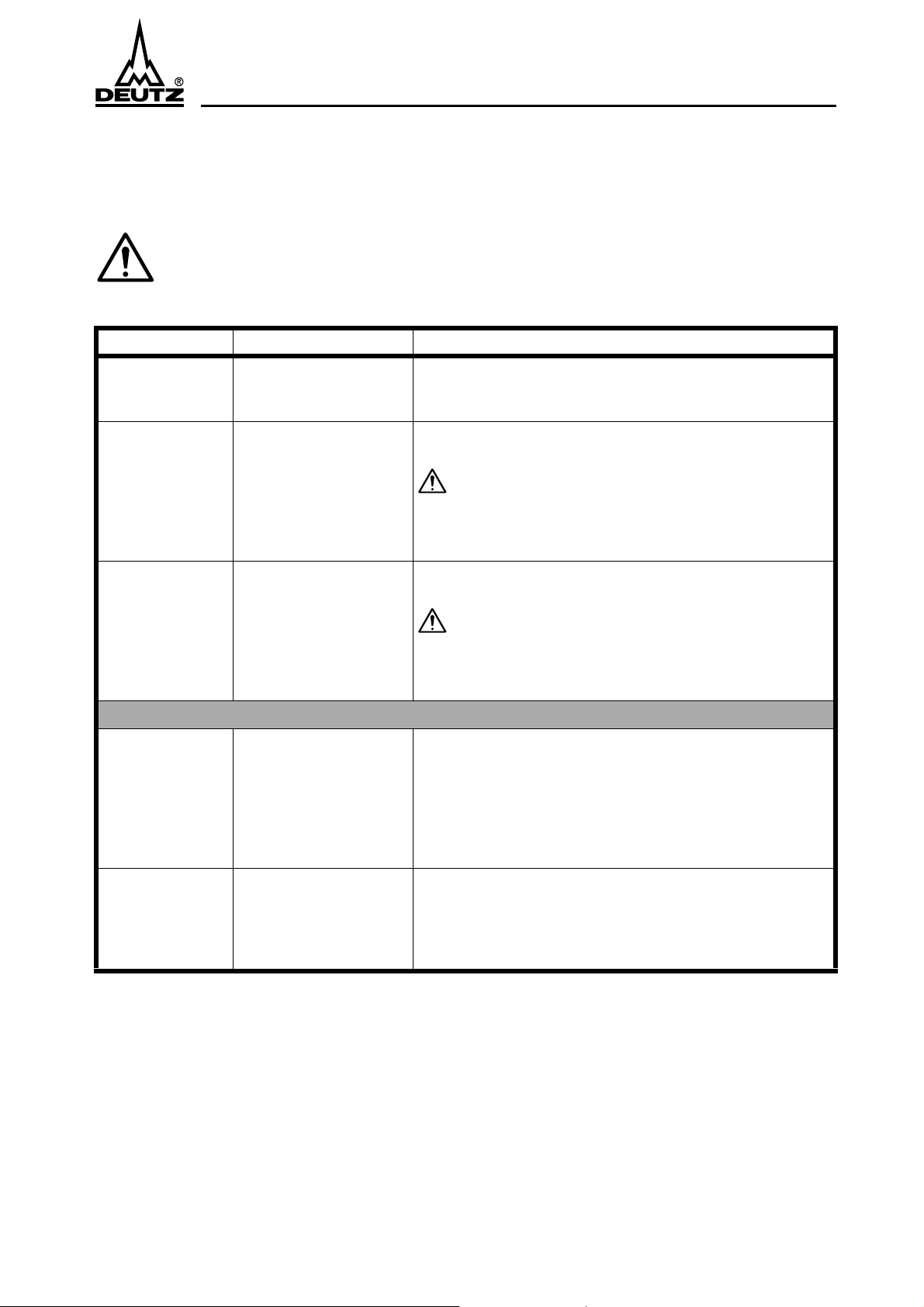

3 System description

3.1 Use of the EMS 2

The EMS 2 is a monitoring system for the 1013, 1015 engine model series. It can be used on its own and

also in combination with the MVS (solenoid valve system) or the EMR (electronic engine governor).

The EMS 2 provides functions for engine protection, for indicating maintenance requirements and for

diagnostic purposes. With the aid of the data recorder function, an overview of the manner of operation,

capacity utilisation and possible causes of engine failure may be obtained. In addition, data exchange with

other electronic control units (e.g. EMR, MVS) is possible via the CAN interface.

3.2 System overview

3.2.1 EMS 2 alone

Engine-side facility

Flame system

solenoid valve

Coolant

temperature sensor

Oil pressure

sensor

Oil level switch Alternator Starter

Flame system

temperature sensor

Engine speed

Engine shut-off

lifting magnet

EMS

Control unit

Vehicle-side/

System-side facility

Energy supply

Glow-start switch

Multi-functional display

Configurable outputs

(e.g. indicator lamps)

Maintenance/service

Diagnostic lamp

Diagnostic button/

limp-home button

Diagnostic interfaces

• S, L line (ISO 9141)

• CAN bus (SAE J1939)

• SAE J1708 / J1587

Air filter differential

pressure sensor

Coolant level switch

© 0702

© 0702 Page 59

Page 8

System description

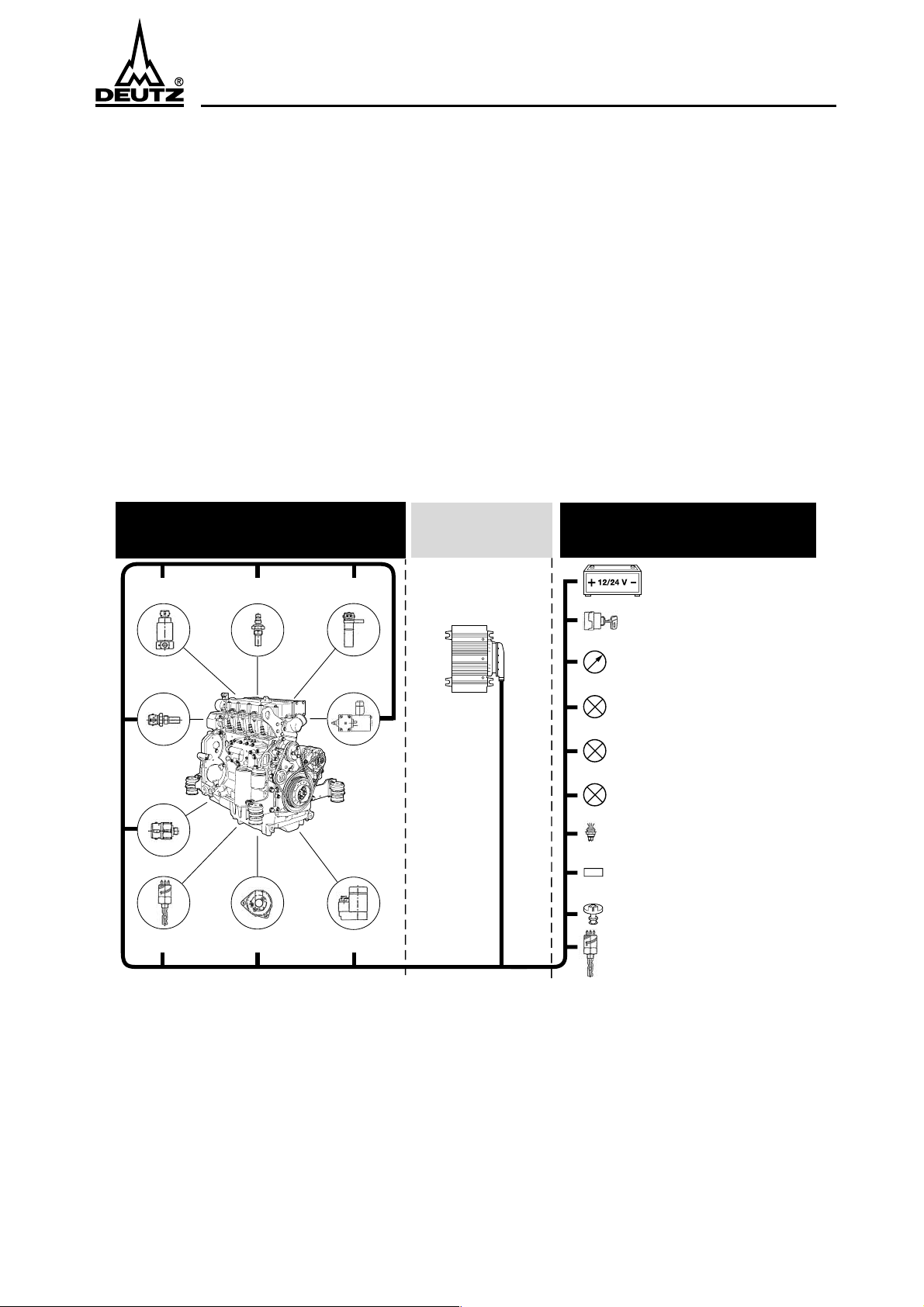

3.2.2 EMS 2 in combination with MVS

EMS 2

DEUTZ scope of delivery

MVS

Engine

© 0702

wiring

harness

Coolant

level sensor

Engine

plug

Vehicle

plug

EMS 2

Central

plug

Vehicle-side installation

Accelerator pedal

Diagnostic lamp (MVS)

Diagnostic button (MVS)

Indicator lamp (EMS)

Maintenance/service (EMS)

Diagnostic lamp (EMS)

Air filter

differential

Interface

SAE J1708/

J1587

X23

CAN

X26

pressure switch

Diagnostic plug

Part No.: 0419 9615

Service

Operating manual

110 / 220 V~

Power supply

or

battery

Interface

Diagnostic button/limp-home button (EMS)

User level

depending on

authorization

Printer

Power supply

or

battery

110 / 220 V~

X25

X22

Software

disc

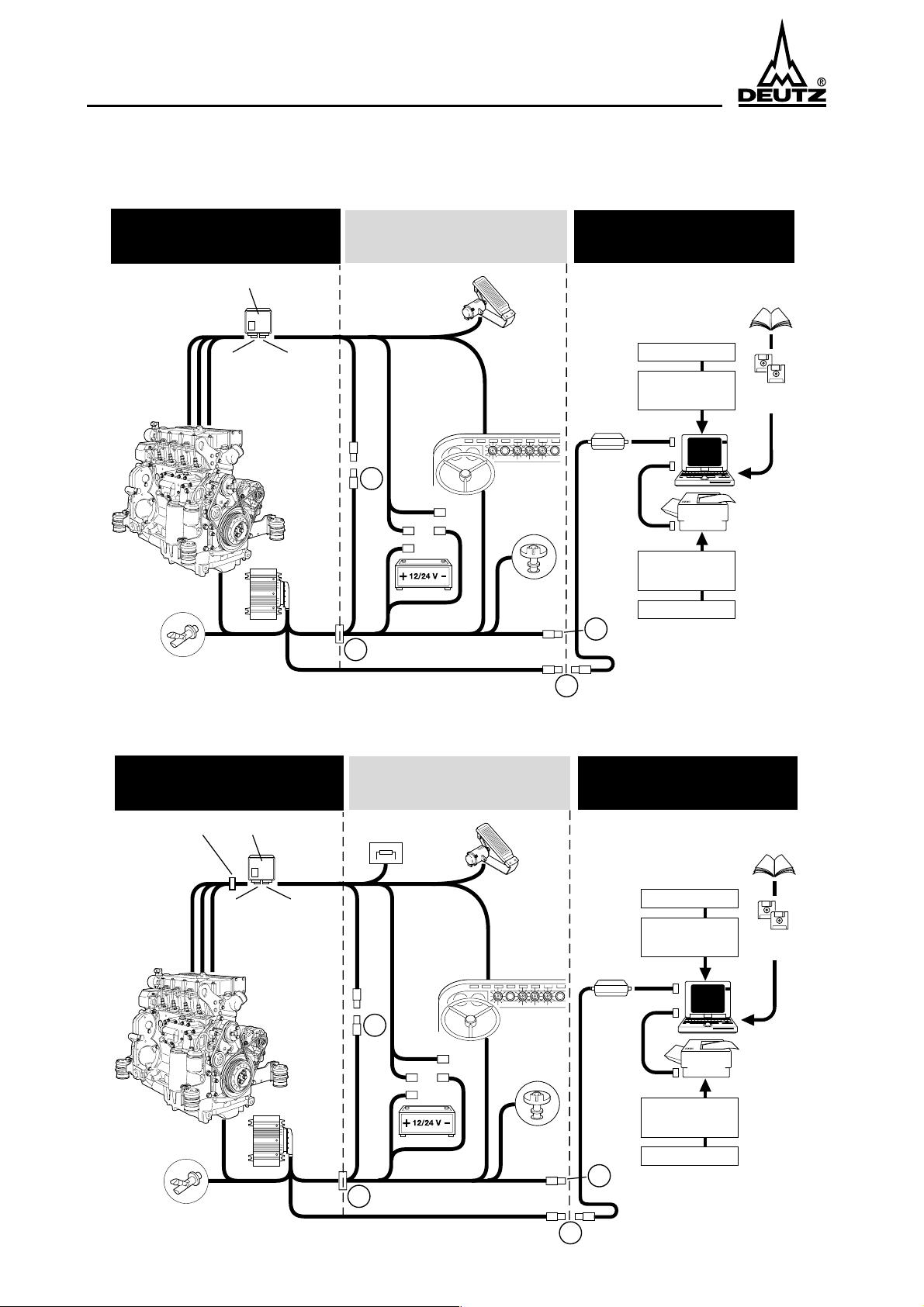

3.2.3 EMS 2 in combination with EMR

DEUTZ scope of delivery

Transfer plug

Engine

wiring

harness

Coolant

level sensor

Engine

plug

EMR

Vehicle

plug

EMS 2

Central

plug

Vehicle-side installation

Terminating

resistor (CAN)

CAN

X26

X23

Accelerator

pedal

Fault lamp (EMR)

Indicator lamp (EMS)

Maintenance/service (EMS)

Diagnostic lamp (EMS)

Air filter

differential

pressure switch

Interface

SAE J1708/

J1587

Diagnostic plug

Part No.: 0419 9615

Service

Operating manual

110 / 220 V~

Power supply

or

battery

Interface

Diagnostic button/limp-home button (EMS)

User level

depending on

authorization

Printer

Power supply

or

battery

110 / 220 V~

X25

Software

disc

© 0702

X22

Page 60 © 0702

Page 9

EMS 2

System functions

4 System functions

1

4.1 Introduction

The EMS 2 serves to electronically monitor the engine. Its functions include:

Engine protection functions

●

Warning the operator if limit values are exceeded or not achieved.

●

Reduction in engine power.

●

Emergency engine shut-off if operating data exceed or do not achieve the shut-off limits.

Indication of maintenance requirements

in order to remind the operator and to reduce the consumption of operating media. The maintenance

intervals can be obtained from the DEUTZ engine operating instructions, Chapter 5.1.

●

in the event of excessive air filter differential pressure.

●

if the number of operating hours leads to the achievement of the next maintenance requirements.

●

if the load population reaches a maintenance limit.

●

if calculation of the engine operating statuses (temperatures, speed, etc.) results in the oil change limit's

being exceeded.

Data exchange

with other systems via the CAN interface, e.g. with the solenoid valve system (MVS):

●

Transmission of the output reduction signal if limit values are exceeded.

●

Engine shut-off via the CAN interface sets, e.g. the fuel injection quantity to zero.

●

The integration of measurement data and fault messages via the CAN interface extends the input signals

of the EMS 2 for executing engine protection functions and system diagnosis (see above).

●

Transfer of the EMS 2 measurement data to other systems.

Diagnosis of the entire system

●

System self-diagnosis, i.e. of the control unit, the sensors and the actuators.

●

Display of engine operating data and self-diagnosis data on a PC (ISO9141 / RS232).

●

Forwarding of the engine operating data to the SAE-J1708/1587 interface for diagnostic and display

systems.

●

Actuation of a telltale and output of a flashing code for fault identification.

Data recorder

Determination of the manner of operation, capacity utilisation and causes of engine failure.

●

Recording the most important measurement variable signals.

●

Determination of the load population.

●

Storage of exceeded maintenance intervals.

●

Documentation of hours of engine operation.

Engine operation display

●

Output of a signal (telltale or relay) as soon as the speed exceeds 400 rpm.

1)

Not all functions are available in all applications.

© 0702 Page 61

Page 10

EMS 2

System functions

4.2 Engine protection functions

4.2.1 General

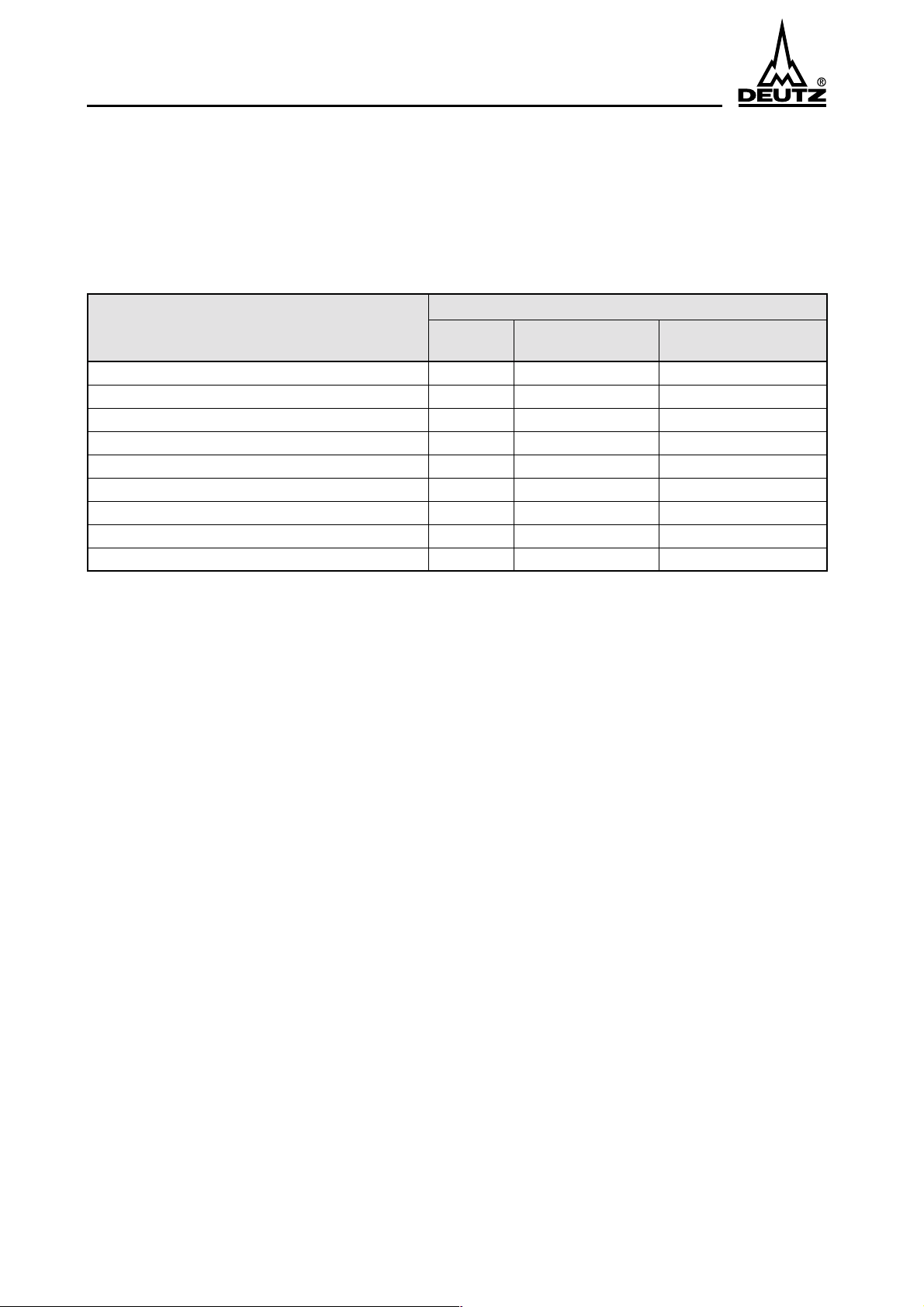

The following table contains an overview of the measurement variables which can be monitored, together

with the relevant, possible engine protection functions.

Monitorable measurement variable

Possible engine protection function

Warning Power reduction Emergency engine

shut-off

Speed x x

Oil temperature x x x

Coolant temperature x x x

Cylinder temperature 1 x x x

Cylinder temperature 2 x x x

Oil pressure x x x

Coolant leveld x x x

Oil level x x x

Reserve signal T1 x x x

1

The configuration is programmed in the factory.

1

●

If the measurement variable lies within the warning range, the diagnostic lamp is continuously illuminated. As a result of a command via the CAN interface to the EMR or MVS, the power is reduced. If the

measurement variable exceeds/does not achieve the recovery threshold, the lamp is extinguished again.

●

A reduction in power is only possible in combination with EMR and MVS.

●

If the measurement lies within the shut-off range, emergency engine shut-off is carried out following

the expiry of a waiting period. The diagnostic lamp flashes rapidly (frequency approx. 1 Hz). Shut-off is

effected either

-via a shut-off solenoid or

-via the CAN interface on other electronic control units (EMR, MVS)

●

Limit values which are exceeded or not achieved are documented in the fault memory.

●

The fault message is output if the diagnostic button is actuated during engine standstill

- as a flashing code via the diagnostic lamp.

- with a notebook connected via the ISO9141 interface with the SERDIA diagnostic programme.

- via the ISO J1708/1587 interface according to standard.

●

Starting prevention can be recognised via the rapid flashing of the diagnostic lamp (1Hz) in the event of

engine standstill. If the EMS 2 has shut the engine off on the basis of the engine monitoring functions,

restarting is prevented. The same applies if monitoring is carried out during standstill, and engine starting is blocked due e.g. a low coolant level.

●

The engine can be restarted by switching the ignition off/on (terminal 15).

●

Outputs may also be used to initialise lamps or relays if limit values are exceeded or not achieved, see

Chapter entitled Outputs 5.2.

Page 62 © 0702

Page 11

EMS 2

System functions

4.2.2 Override-Funktion

●

In safety-critical cases, emergency engine shut-off or output reduction can be suppressed with the

limp-home button/diagnostic button (override signal). The EMS 2 is programmed in such a manner that

the overwriting of these engine protection functions applies only for a specific period of time (limp-home

time) or until the engine is shut-off.

●

Depression of the button is confirmed via slow slashing (frequency approx. 0.5 Hz). The limp-home

time (override time) begins again each time the button is depressed. Excessively frequent actuation of

the button may damage the engine and lead to the expiry of the warranty (responsibility of the user).

●

Override procedures are stored in the control unit.

●

Following the expiry of the override time, the warning, reduction in power or the shut-off function are

reactivated insofar as the relevant conditions for this are still present.

4.2.3 Speed monitoring

Speed monitoring prevents engine damage as a result of excessive speed, and is defined prior to delivery

depending on the combination (e.g. EMS with MVS) and model series. The speed signal can be supplied to

the EMS 2 control unit in three ways:

●

With a pick-up (magnetic speed sensor).

●

Via the W terminal of the alternator.

●

With data exchange via the CAN interface.

4.2.4 Temperature monitoring

Depending on the engine model series, temperature sensors are available for engine oil, coolant, cylinder

head 1 and 2, and reserve temperatures. Connection to the EMS 2 is carried out in two ways:

●

Either via the inputs (see Chapter 5.1).

●

Or via the CAN interface from other systems (MVS, EMR).

In addition, each time the temperature is exceeded, an output for initialising a lamp or a relay may be allocated, see Chapter entitled Outputs 5.2.

If the temperature falls below the recovery threshold, the diagnostic lamp is shut-off, and the power reduction or emergency shut-off engine protection functions are reset.

4.2.5 Engine oil pressure and reserve pressure monitoring

Oil pressure monitoring is activated following the expiry of a fixed period of time after the engine has been

started.

Depending on the application, the connection to the EMS 2 can be carried out in two ways:

●

Via the inputs (see Chapter 5.1).

●

Or via the CAN interface from other systems (MVS, EMR).

In addition, each time the temperature is exceeded, an output for initialising a lamp or a relay may be allocated, see Chapter entitled Outputs 5.2.

The warning limit is speed-dependent. In order to take pressure fluctuations into consideration, the oil pressure may fall below the warning limit for a speed-dependent period of time before the engine protection

functions respond.

Following the expiry of the waiting period, the diagnostic lamp is continuously illuminated, insofar as the

signal still lies in the warning range.

If the oil pressure exceeds the recovery threshold, the diagnostic lamp is shut-off, and the power reduction

or emergency shut-off engine protection functions are reset.

Other pressures may be monitored depending on the application and the input assignment of the control

unit.

© 0702 Page 63

Page 12

EMS 2

System functions

4.2.6 Filling level monitoring

Depending on the engine model series, sensors are available for engine oil, coolant or reserve fluid filling

levels. Connection to the EMS 2 is carried out in two ways:

●

Via the inputs (see Chapter 5.1).

●

Or via the CAN interface from other systems (MVS, EMR).

If the warning threshold is not achieved, the diagnostic lamp is continuously illuminated. If the level rises

above the recovery threshold due to the fluid's being topped up, the diagnostic lamp is shut-off.

Whilst engine is stationary

Fluid levels are monitored whilst the engine is stationary and the ignition is switched on (terminal 15). If the

level falls below the shut-off limit, starting is prevented following a period of time which is specified in the

factory. During this enquiry time, engine starting is released until starting is prevented.

During engine operation

The engine oil level is not monitored during engine operation. For the other fluid levels, monitoring during

engine operation may also be programmed in the factory.

4.3 Indication of maintenance requirements

Maintenance requirements may be indicated in the following manner:

●

Via the maintenance/service lamp.

●

Via the ISO 9141 interface with SERDIA.

After maintenance has been carried out, the maintenance messages can be reset with SERDIA or by connecting the L lead of the ISO9141 interface to ground for a minimum of 5 to a maximum of 10 seconds. The

functions described in the following may report maintenance requirements, whereby each may initialise the

maintenance lamp. An enquiry regarding the functions which are reporting the maintenance requirements

can be made with the flashing code.

4.3.1 With operating time counter

When the operating time counter reaches the next maintenance interval, the maintenance/service lamp is

switched on, and the operator is reminded that maintenance is due.

4.3.2 With load population

This function is only possible if the EMS 2 receives a load signal, e.g. from another electronic control unit via

the CAN interface.

Maintenance is signalised with the aid of the maintenance/service lamp in accordance with the capacity utilisation of the engine throughout the engine operation period.

4.3.3 With air filter differential pressure sensor

Depending on the engine model series, the engine is equipped with air filter differential pressure sensors. If

the air filter differential pressure exceeds the specified limit during engine operation, i.e. at engine speeds in

excess of 400 rpm, the maintenance/service lamp is switched on. The maintenance message is only reset if

the air filter differential pressure returns to normal.

4.3.4 Oil change interval calculation

This procedure is not applied in the case of all engine model series. The oil change interval depends on the

manner in which the engine is operated. Calculation of the time of the next oil change is carried out with

characteristic engine variables such as temperatures, speed, etc. When the calculation reached the oil

change limit, the maintenance/service lamp is initialised.

Page 64 © 0702

Page 13

EMS 2

System functions

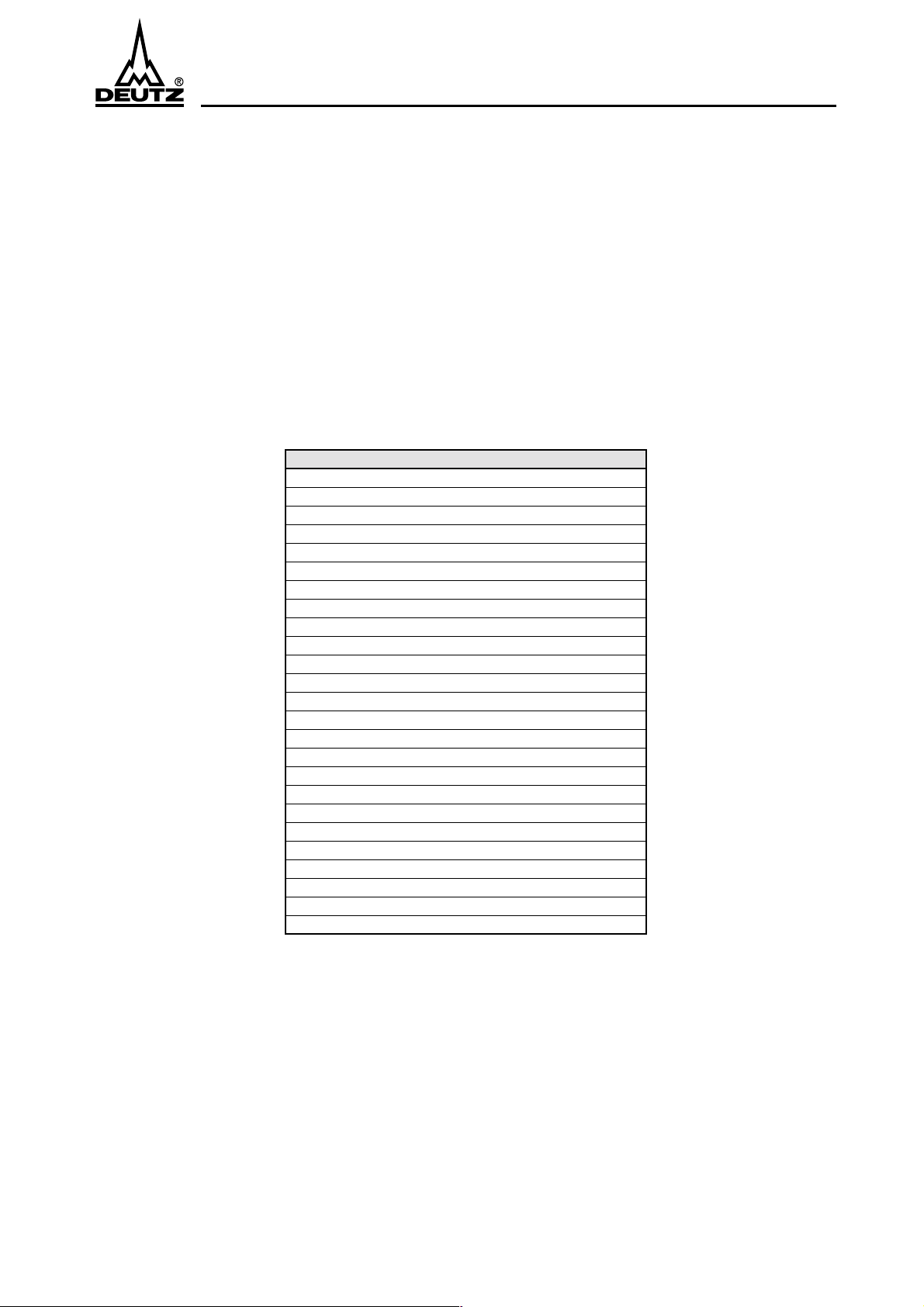

4.4 Data recording

4.4.1 Data channels

The EMS 2 contains a maximum of 32 memory domains, in which a maximum of 32 measurement and calculation values (speed, temperatures, pressures, fluid levels, output signals, etc.) can be recorded. Some of

these signals, e.g. charge air pressure and charge air temperature, can also be read in from engine governor

systems via the CAN interface. In the relevant memory domains, identical measurement signals with different sampling rates can be recorded (most rapid sampling rate 5 Hz).

Depending on the spacing of the measurement points, measurement value recording of up to several thousand is possible. Either the current, maximum, minimum or the mean measurement values are recorded.

Depending on the engine model series and system expansion, values from the following table may be

recorded:

Possible measurement signals

Charge air pressure

Charge air temperature

Operating time counter

Speed

Oil temperature

Coolant temperature

Cylinder head temperature 1

Cylinder head temperature 2

Reserve temperature 1

Reserve temperature 2

Engine oil pressure

Reserve oil pressure 1

Reserve oil pressure 2

Coolant level

Engine oil leve

Fluid level 1

Fluid level 2

Fluid level 3

Load signal

Fuel injection quantity (via CAN)

Output switching statuses

Power reduction signal

Override signal

Shut-off limit exceeded

Test operation mode

The EMS 2 is programmed with a sensible data recording configuration in the factory. Changes must be

coordinated with head office, and are only possible with SERDIA.

Data recording is only carried out whilst the engine is running.

The data are read out with SERDIA, and are available in a standard format for commercially available gra-

phics and evaluation programmes, e.g. Excel.

© 0702 Page 65

Page 14

EMS 2

System functions

4.4.2 Load population determination

If a load signal is transmitted from an electronic control unit via the CAN interface, the EMS 2 is able to

determine the capacity utilisation of the engine. In order to achieve this, the hours of engine operation are

allocated to the relevant load and speed ranges. Optimally-designed engines may therefore be made

available to the customer for special usages.

Load population:

S1 to S9 are operating time counters for the relevant range.

For maintenance information, the range counters are weighted with factors.

Load %

S7 S8 S9

L

2

S4 S5 S6

L

1

S1 S2 S3

Engine speed n

© 0702

The load population can be displayed and printed out with SERDIA.

4.4.3 Override memory

If limit values are exceeded, the operator can, as in the case of the engine protection functions, see 4.2,

prevent the reduction in power or emergency engine shut-off via a button for a brief period of time or until

the engine is next stationary (depending on the EMS 2 programme).

The interruption of the protective functions is stored in the control unit of the EMS 2, and cannot be deleted.

4.4.4 Maintenance overdue memory

The EMS 2 stores the point in time at which maintenance was required and the reset time, i.e. when maintenance was acknowledged.

These values may also be read with SERDIA.

n

1

n

2

4.5 Engine operation display

The EMS 2 may also be used for the purpose of engine operation display. As soon as the engine speed

exceeds a speed threshold of 400 rpm, a lamp is initialised. This function is not in use in all engine model

series.

Page 66 © 0702

Page 15

EMS 2

Inputs/Outputs

5 Inputs/Outputs

5.1 Inputs

The following table provides an overview of the possible outputs at the EMS 2.

No. Pin GND Designation can be connected measured Especially suitable for

1

1A 1

1B 10, 27 Pick-up

2 25 29 Limp-home and

3 8 PWM input PWM signal switch Pulse-duty fac-

415 13Pressure mea-

5 14 31 NTC input NTC (temperature-

6 32 30 PT100-1 PT100 (temperature7 17 PT100-2

Speed input

diagnosis

surement input

W terminal Frequency For speed measurement only.

Sensor to ground Voltages 0 and 5

V (digital)

tor (digital)

Voltage sensor Voltages 0 to 5 V

(analogue)

Resistors (ana-

dependent resistor)

dependent resistor)

logue)

Resistors (ana-

logue)

For error code enquiry and limphome only.

Integration of a physical variable

from another control unit (e.g. oil

pressure).

Oil pressure measurement

Coolant temperature

Oil temperature

Cylinder head temperature

8 16 Analogue 1 Voltage sensor Voltages 0 to

U

9 34 Analogue 2

10 33 12 Analogue 3 Voltage sensor Voltages 0 to 5 V

1

Speed input available as an option only.

An example of pin assignment (engine 1015, EMS and MVS) is shown in Chapter 11.8.

The EMS 2 control unit can be configured in the factory in such a manner that further input signals can be

read via the CAN bus.

Batt

(analogue)

(analogue)

Suitable for many signals, e.g.

air filter differential pressure,

fluid levels, etc.

Suitable for many signals, e.g.

pressures, temperatures, fluid

levels, etc.

© 0702 Page 67

Page 16

EMS 2

Inputs/Outputs

5.2 Outputs

5.2.1 General

On configuration of outputs 1 to 6 as digital outputs, these function as switches to ground.

+U

Batt

21

15

+U

Batt

3

15

Pull Up

1k

Ω

Digital output PWM output

© 0702

Via configuration, a digital value (e.g. "Speed in the shut-off range") may be allocated as a parameter to

each digital output (with the exception of the diagnostic lamp output).

Parameters can be used to set whether the output is switched on or off on the occurrence of the condition.

If outputs 3 and 4 are configured as PWM outputs (PWM = pulse-width modulation), analogue measure-

ment values, which enter the control unit via CAN or the inputs, and internal EMS 2 variables, can be output.

A measurement value (e.g. "Speed") may be allocated to each PWM output via configuration.

The output frequency of the PWM signal can be parameterised in the range from 85 Hz to 500 Hz, whilst the

pulse-width, i.e. the high or low time, changes in the same manner as the variable which is adjusted via a

characteristic curve.

In the event of a fault, a cable break or a short-circuit can be diagnosed for all outputs.

The following Table provides an overview of the possible outputs at the EMS 2.

Nr. Pin Designation Can e.g. be used for

1 21 Digital 3 Oil pressure telltale

2 22 Digital 4 Shut-off solenoid relay initialisation

3 3 Digital / PWM1 Coolant temperature telltale

4 4 Digital / PWM2 Air filter differential pressure telltale

5 5 Maintenance/service lamp Maintenance/service lamp

6 23 Diagnostic lamp Diagnostic lamp only

Page 68 © 0702

Page 17

EMS 2

Inputs/Outputs

5.2.2 Diagnostic lamp output

This output actuates a diagnostic lamp for displaying fault codes, e.g. continuous illumination, slow flashing

or rapid flashing to ground.

When the ignition is switched on, the lamp illuminates for approx. 2 s for a lamp test.

Continuous illumination indicates a warning, i.e. either a measurement variable is in the warning range or

a system component reports faulty behaviour such as, e.g. sensor cable break or short-circuit (see Fault

messages).

Rapid flashing indicates imminent or current engine protection shut-off.

If the operator interrupts one of the engine protection functions, such as a reduction in power or imminent

engine shut-off, by pressing the limp-home button whilst the engine is running, this is acknowledged with

slow flashing.

If the limp-home button/diagnostic button is actuated whilst the engine is stationary, flashing codes are

output for the fault messages.

© 0702 Page 69

Page 18

Inputs/Outputs

EMS 2

Page 70 © 0702

Page 19

EMS 2

Data interfaces

6 Data interfaces

6.1 ISO interface

The ISO interface is a serial data interface which is standardised according to ISO 9141, and which enables

the exchange of data with the control unit. The ISO interface has the following functions:

●

Diagnosis with SERDIA.

●

Exchange of diagnostic data.

●

Control unit end-of-tape programming (reading and programming of parameters).

●

Execution of engine test functions.

●

Reading of measured and calculated variables.

●

Reading the data recorder out.

6.2 CAN interface

The CAN interface is a rapid serial data bus which is standardised according to SAE J1939, and which enables the exchange of data between several control units (e.g. EMR, MVS, transmission electronics, traction

control). The CAN interface has the following functions:

●

Exchange of diagnostic data (error messages, deletion of error memory).

●

Reading of measured and calculated variables.

●

Suppression of fuel injection.

●

Reduction of output.

6.3 SAE-J1708/1587 interface

●

Output of all data received via the inputs or via the CAN interfaces.

●

Output of the fault memory.

●

Deletion of all fault messages.

Note:

☞

In the event of communication via the ISO9141 interface, the SAE-J1587 interface is shut-off!

© 0702 Page 71

Page 20

Data interfaces

EMS 2

Page 72 © 0702

Page 21

EMS 2

Diagnosis

7 Diagnosis

7.1 Self-diagnosis

Self-diagnosis becomes active when a minimum supply voltage (> 9 V) is exceeded.

In this case, both internal control unit faults are determined and the inputs and outputs and the sensors and

output loads are checked for cable break and short-circuit. The fault must be present for a minimum period

of time before it is stored. Continuous diagnostic lamp illumination indicates that a fault is currently present.

A maximum of 15 faults are stored simultaneously. The individual faults which this involves can be seen

from the fault message Table.

The fault messages are displayed as flashing codes as described in Section 7.2, and via the interfaces to

PCs and diagnostic units as described in Chapter 8.2.

7.2 Diagnosis with flashing codes

The diagnostic lamp informs the operator of the presence of a fault or exceeded limit values, as described

in the case of the engine protection functions in Chapter 4.2, with continuous illumination.

When the engine is stationary, each depression of the diagnostic/override button leads to the output of a

flashing code which indicates which fault or signal has exceeded the limit value.

Each time the button is pressed, the next fault is displayed. Following the last fault, the first fault message is

output again.

The flashing code is comprised of long and short flashing pulses which the operator counts.

The appropriate fault can be seen in the fault message Table (Chapter 8.4).

7.3 Diagnosis with SERDIA software

Together with the interface and notebook (or PC), SERDIA (Service Diagnosis software) forms a combined

special service tool. With the aid of the SERDIA diagnostic software, information regarding the following

can be displayed:

- Fault memory

- Configuration (authorisation is determined via the interface level)

- Measurement values

- Maintenance data

- Load population.

Fault messages for passive or eradicated faults can be deleted with SERDIA.

SERDIA (Service Diagnosis) is a software programme which the operator can use, via the PC, to monitor

measurement values and detect faulty operating behaviour whilst the diesel engine is running.

In order to achieve this, the PC is connected to the diagnostic interface via an interface. Communication

with the control unit is carried out via a special EMS 2 protocol.

With regard to handling SERDIA, see separate manual. The acquisition of SERDIA is explained via a DEUTZ

service memorandum.

© 0702 Page 73

Page 22

Diagnosis

EMS 2

Page 74 © 0702

Page 23

EMS 2

Fault messages

8 Fault messages

8.1 Integration of the fault messages via CAN

The EMS 2 is able to communicate with other electronic engine regulation systems via the CAN interface.

Such an application includes the MVS (solenoid valve system). This transmits the fault messages to the

EMS 2, and the diagnostic lamp is continuously illuminated. The messages can then be output via only one

lamp as a flashing code. The nature of the flashing code indicates the system in which a fault is present (see

code Table, Chapter 8.4). The operator is only required to heed one lamp, wiring expenditure is reduced.

The faults and measurement values from other control units (e.g. MVS), which are read by EMS 2 via the

CAN bus, are also output via the ISO9141 interface to a notebook with the SERDIA diagnostic programme.

8.2 Output of messages on a notebook or diagnostic systems

The EMS 2 stores the fault messages and transits these as a fault code via the ISO9141 interface. The

codes are listed in the fault message Table (Chapter 8.4).

The fault messages can be read with the SERDIA diagnostic software and a notebook. In addition, measurement values which existed at the point in time at which the fault occurred are displayed on the screen for

each fault.

Instead of using the ISO9141 interface for fault messages, the user may also use the SAE-J1708/1587

interface of the EMS 2 for outputting the faults on diagnostic systems.

8.3 Deletion of fault messages

Insofar as the faults no longer occur, the fault messages are automatically deleted after the ignition key has

been actuated a number of times. If the fault messages are to be deleted directly following a repair operation, the ignition is actuated a corresponding number of times in succession, whereby waiting must be carried out each time during the lamp test time (approx. 3 seconds).

The fault messages can also be deleted with the SERDIA diagnostic programme and a notebook via the

ISO9141 interface or also with also diagnostic systems according to the SAE-J1708/1587 standard.

© 0702 Page 75

Page 24

EMS 2

Fault messages

8.4 Fault messages and fault codes

The following table contains an overview of the possible fault messages and codes.

Notes in the event of diagnosis with telltale:

Depending on the flashing code, the telltale provides a sequence of short and long flashing impulses.

Example: Flashing code S1 L1 S2: one short flash, one long, two short

Note in the event of diagnosis with SERDIA:

The programme displays the location of the fault, the type of fault and the frequency of the fault on the

screen.

Example:

●

Location of the fault: Oil pressure input

●

Type of fault: Cable break or short-circuit to U

Batt

Location of the fault Type of fault Flashing code

S-short

L-long

Zero fault information S1 dispen-

SAE

J1587

FMI

PID/SID

SAE-J1587

xxx

sed

with

Speed pick-up input Cable break S1 L1 S1 5 xxx

Oil pressure input Short-circuit to GND

Cable break or short-circuit to U

NTC input Short-circuit to GND

Cable break or short-circuit to U

PT100-1 input Short-circuit to GND

Cable break or short-circuit to U

PT100-2 input Short-circuit to GND

Cable break or short-circuit to U

Analogue input 1 Short-circuit to GND

Cable break or short-circuit to U

Analogue input 2 Short-circuit to GND

Cable break or short-circuit to U

S1 L1 S2 4

Batt

S1 L1 S3 4

Batt

S1 L1 S4 4

Batt

S1 L1 S5 4

Batt

S1 L1 S6 4

Batt

S1 L1 S7 4

Batt

xxx

3

xxx

3

xxx

3

xxx

3

xxx

3

xxx

3

1

Analogue input 3 Short-circuit to GND

Cable break or short-circuit to U

S1 L1 S8 4

Batt

3

xxx

CAN connection S1 L2 S1 12 SID 231

Override/diagnostic button fault S1 L2 S2 - Digital output 3 Cable break or short-circuit to GND

Short-circuit to U

Batt

S1 L2 S3 4

SID 26

3

Digital output 4 Cable break or short-circuit to GND

Short-circuit to U

Batt

S1 L2 S4 4

SID 40

3

Digital / PWM output 1 Cable break or short-circuit to GND

Short-circuit to U

Batt

S1 L2 S5 4

SID 57

3

Page 76 © 0702

Page 25

EMS 2

Fault messages

Location of the fault Ty pe of f au lt Flashing code

S-short

L-long

Digital / PWM output 2 Cable break or short-circuit to GND

Short-circuit to U

Maintenance lamp output Cable break or short-circuit to GND

Short-circuit to U

Diagnostic lamp output Cable break or short-circuit to GND

Short-circuit to U

Speed exceeded in warning range

in shut-off range

reduction in power

Engine oil temperature exceeded in warning range

in shut-off range

reduction in power

Coolant temperature exceeded in warning range

in shut-off range

reduction in power

Cylinder head temperature 1 in warning range

in shut-off range

reduction in power

Cylinder head temperature 2 in warning range

in shut-off range

reduction in power

Reserve temperature 1 in warning range

in shut-off range

reduction in power

Reserve temperature 2 in warning range

in shut-off range

reduction in power

Engine oil pressure in warning range

in shut-off range

reduction in power

Reserve pressure 1 in warning range

in shut-off range

reduction in power

Reserve pressure 2 in warning range

in shut-off range

reduction in power

Coolant level in warning range

in shut-off range

reduction in power

Engine oil level in warning range

in shut-off range

reduction in power

Fluid level 1 in warning range

in shut-off range

reduction in power

Fluid level 2 in warning range

in shut-off range

reduction in power

Fluid level 3 in warning range

in shut-off range

reduction in power

© 0702 Page 77

Batt

Batt

Batt

S1 L2 S6 4

S1 L2 S7 4

no flashing

code

S1 L3 S1 0 PID 190

S1 L3 S2 0 PID 175

S1 L3 S3 0 PID 110

S1 L3 S4 0 Parameter

S1 L3 S5 0 Parameter

S1 L3 S6 0 Parameter

S1 L3 S7 0 Parameter

S1 L3 S8 1 PID 100

S1 L4 S1 1 Parameter

S1 L4 S2 1 Parameter

S1 L4 S3 1 PID 111

S1 L4 S4 1 PID 98

S1 L4 S5 1 Parameter

S1 L4 S6 1 Parameter

S1 L4 S7 1 Parameter

SAE

J1587

FMI

3

3

4

3

PID/SID

SAE-J1587

SID 58

SID 51

SID 238

Page 26

Fault messages

EMS 2

Location of the fault Type of fault Flashing code

S-short

L-long

Engine protection shut-off

executed

Start prevention executed S1 L5 S2 - Reduction in power override

executed

Engine shut-off override

executed

Control unit EEPROM

memory fault

Control unit RAM or

RAM buffering defective

Bosch control unit CAN fault

codes

Maintenance interval reached

(operating hours)

Maintenance interval reached

(Load population)

Oil change limit reached S1 L6 S3 dispen-

S1 L5 S1 - -

S1 L5 S3 - -

S1 L5 S4 - -

S1 L5 S5 12 SID 253

S1 L5 S6 - -

Bosch

flashing code

S1 L6 S1 dispen-

S1 L6 S2 dispen-

SAE

J1587

FMI

--

sed

with

sed

with

sed

with

PID/SID

SAE-J1587

-

-

-

Maintenance signal 1 exceeds

limit value

Maintenance signal 2 exceeds

limit value

Air filter differential pressure

exceeded

1

xxx = PID of the signal read via this input.

S1 L6 S4 dispen-

sed

with

S1 L6 S5 dispen-

sed

with

S1L6S6 dispen-

sed

with

-

-

-

Page 78 © 0702

Page 27

EMS 2

Repair

9 Repair

All components can only be replaced (repair is not possible) and are available individually. As the control

unit has to be programmed with an engine-specific data record, the following specifications are necessary:

●

Engine number.

●

Complete part number.

Please contact your DEUTZ service partner.

Attention:

In order to avoid damaging the control units, the plug connections on the control unit must be disconnected

prior to electric welding operations!

© 0702 Page 79

Page 28

Repair

EMS 2

Page 80 © 0702

Page 29

EMS 2

Installation

10 Installation

●

Depending on the design of the configuration, the wiring to be carried out by the customer can be seen

in the engine-specific wiring diagram, which is delivered together with the engine.

●

With regard to the mechanical installation of the control unit, reference is made to the installation guidelines regarding the installation of electronic systems in DEUTZ diesel engines, order No. 0399 1990/1.

Further information can be obtained from

DEUTZ AG

Installation Consultancy Department

Tel.: (0221) 822 3140

Fax.: (0221) 822 3198

Sensors and actuators must not, either for checking or test purposes, be individually connected to or between external voltage sources, but only in combination with the EMS 2, as the risk of destruction otherwise

exists!

Despite polarity reversal protection in the control units, polarity reversal must be avoided. Polarity reversal

may lead to damage to the control units!

The control unit plug connections are only dust and water-tight when the counter-plugs are connected!

Until the counter-plugs are connected, the control units must be protected against spray water and electrical discharge at the contacts due to touching!

Attention:

Sensors and actuators must not, either for checking or test purposes, be individually connected to or between external voltage sources, but only in combination with the EMS 2, as the risk of destruction otherwise

exists!

Despite polarity reversal protection in the control units, polarity reversal must be avoided. Polarity reversal

may lead to damage to the control units!

The control unit plug connections are only dust and water-tight when the counter-plugs are connected!

Until the counter-plugs are connected, the control units must be protected against spray water and electrical discharge at the contacts due to touching!

© 0702 Page 81

Page 30

Installation

EMS 2

Page 82 © 0702

Page 31

EMS 2

11 Technical data

11.1 Inputs/Outputs

The following tables contain an overview of the technical data of the EMS 2.

11.1.1 Input table

No. Pin GND Designation Range

1A 1 Speed input 0/U

1B 10, 27

2 25 29 Limp-home and diagnosis Button only (0/U

38 PWM input 0 to U

4 15 13 Pressure measurement input 0 to 5 V (analog)

5 14 31 NTC input 0° C to 130° C

6 32 30 PT100-1 0° C to 300° C

7 17 PT100-2 0° C to 300° C

816 Analogue 1 0 to U

934 Analogue 2 0 to U

10 33 12 Analogue 3 0 to 5 V (analogue)

Batt

Batt

Batt

Batt

Technical data

Batt

(digital)

(analogue)

(analogue)

)

11.1.2 Outputs table

1

No. Pin Designation max. current load

1 21 Digital 3 3 A

2 22 Digital 4 3 A

33 Digital / PWM1 0.5 A

44 Digital / PWM2 0.5 A

55 Maintenance/Service

0.5 A

lamp

6 23 Diagnostic lamp 0.5 A

11.2 Electrical specifications

Nominal voltages: 12 V and 24 V,

each unit functions with both nominal voltages

Operating voltage range: U

Polarity reversal protection: The unit is protected against battery voltage polarity reversal.

Overvoltage protection: The unit is equipped with load-dump protection against 65 V for

Short-circuit strength: All of the unit's connections are short-circuit-proof in the case of

Off-ground nature: The housing is off-ground.

Stray power emission: Via air convection.

Terminal 30 load: < 10 mA with terminal 15 shut-off

1)

Open collector

© 0702 Page 83

from 9 V to 32 V

Batt

300 ms.

conducting connections with +U

against each other.

Batt

, -U

and the connections

Batt

Page 32

EMS 2

Technical data

11.3 EMV/ESD protection

according to guidelines: EU 95/54 EG

EN 61000-4-4

EN 61000-4-2

ISO 7637-2

ISO 7637-3

ISO 11452-2 100 kHz - 1 GHz 100 V/m

57 MHz - 61 MHz 50 V/m Class B, else Class A

ISO TR 10605

11.4 Climatic conditions

Operating temperature: -40 °C to 80 °C

Storage temperature: -55 °C to 80 °C not temporally restricted

Temperature change: IEC 68-2-14

Humidity:

relative humidity: up to 95%

maximum temperature: +55 °C

Salt spray resistance: The system is resistant to salt spray in accordance with

IEC 68-2-52.

Salt content (NaCl): max. (5±1) % percentage per mass

Low air pressure: The unit is resistant to vacuum.

Transportation and storage: max. 150 mbar ±1%

Operation: max. 533 mbar ±5%

Industrial climate: according to DIN 50018, 6 cycles

11.5 Contamination

The unit is resistant to being coated with the following media:

●

Engine oils and additives.

●

Transmission fluids.

●

Lubricating oils.

●

Paints.

●

Hydraulic fluids.

●

Coolants.

●

Greases.

●

Fuels.

●

Cold cleaners.

Page 84 © 0702

Page 33

EMS 2

Technical data

11.6 Mechanical conditions

Free fall: The unit must survive a free fall from a height of 1 m onto concrete or

steel in each of the three main axes without damage. Falling onto the

plug side is not taken into consideration

Vibration:

For any of the main axes, the following maximum values apply:

Amplitude: 0,35 mm

Frequency: 10 Hz to 60 Hz.

Acceleration amplitude: 50 m/s

Frequency: 60 Hz to 500 Hz.

Shock resistance: According to IEC-68-2-27

Peak acceleration: 294 m/s

11.7 Protection class

2

2

, semi-sinoidal form in each main axis

Protection class: IP66K according to DIN 40050.

© 0702 Page 85

Page 34

EMS 2

Technical data

11.8 Pin assignment

Pin Designation Application example in engine, e.g. 1015

1 W terminal (input 1A) Free

19 Ground for outputs to the insulated ground node (GND)

2 Ground for outputs to the insulated ground node

20 Ground for outputs Oil level switch ground (if available)

3 PWM1 (output 3) 0,5 A Coolant temperature lamp

21 Digital 3 (output 1) 3 A Oil pressure lamp

4 PWM2 (output 4) 0,5 A Air filter differential pressure lamp

22 Digital 4 (output 2) 3 A Engine shutt-off lifting magnet

5 Maintenance lamp (output 5) 0,5 A Maintenance lamp

23 Diagnostic lamp (output 6) 0,5 A Diagnostic lamp

6 5V sensor supply Oil pressure sensor supply voltage

24 SAE-J1939 CAN high SAE-J1939 CAN high

7 SAE-J1939 CAN low SAE-J1939 CAN low

25 Diagnostic request sampling element

(input 2)

8 PWM input (input 3) U

26 ISO 9141 S lead ISO 9141 S lead

9 ISO 9141 L lead ISO 9141 L lead

27 Inductive speed sensor - (input 1B) Pickup - input

10 Inductive speed sensor + (input 1B) Pickup + input

28 SAE J1708 + SAE J1708 +

11 SAE J1708 - SAE J1708 -

29 Measurement ground Diagnosis and limp-home button ground

12 Measurement ground Charge air pressure sensor ground (if available)

30 Measurement ground Charge air temperature sensor ground (if available)

13 Measurement ground Oil pressure ground

31 Measurement ground Coolant temperature ground

14 NTC input (input 5) Coolant temperature input

32 PT100-1 (input 6) Charge air temperature input

15 Oil pressure (input 4) 5 V Oil pressure sensor input

33 Analogue 3 (input 10) 5 V/switch Charge air pressure (if available)

16 Analogue 1 (input 8) U

34 Analogue 2 (input 9) U

17 PT100-2 (input 7) switch Oil level switch input (if available)

35 Terminal 30, battery positive Terminal 30

18 Terminal 15, ignition lock Terminal 15

Free

Batt

/switch Coolant level input (if available)

Batt

/switch Air filter differential pressure switch input

Batt

Diagnostic and limp-home button

Coolant level ground and air filter differential pressure switch ground to ground node.

© 0702

Page 86 © 0702

Page 35

12 Appendix

12.1 Drawings (examples)

●

Connection diagram, EMS 2 alone (example)

●

Communication lead EMS with EMR (example)

●

Communication lead EMS with MVS (example)

EMS 2

Appendix

© 0702 Page 87

Page 36

Appendix

EMS 2

Page 88 © 0702

Page 37

EMS 2

12.2 Connection diagram, EMS 2 alone (example)

Note: Only the engine-specific wiring plan is valid!

Appendix

© 0702

© 0702 Page 89

Page 38

Appendix

EMS 2

Page 90 © 0702

Page 39

EMS 2

12.3 Communication lead EMS with EMR (example)

Note: Only the engine-specific wiring plan is valid!

Appendix

© 0702

© 0702 Page 91

Page 40

Appendix

EMS 2

Page 92 © 0702

Page 41

EMS 2

12.4 Communication lead EMS with MVS (example)

Note: Only the engine-specific wiring plan is valid!

Appendix

© 0702

© 0702 Page 93

Page 42

Appendix

EMS 2

Page 94 © 0702

Loading...

Loading...