Page 1

®

HIGH FREQUENCY SECONDARY RECTIFIER

MAJOR PRODUCT CHARACTE RISTICS

STTH3003CW

I

F(AV)

V

RRM

2 x 15 A

300 V

Tj (max) 175 °C

(max) 1 V

V

F

trr (max) 40 ns

FEATURES AND BENE FITS

COMBINES HIGHEST RECOVERY AND

REVERSE VOLTAGE PERFORMANCE

ULTRA-FAST, SOFT AND NOISE-FREE

RECOVERY

DESCRIPTION

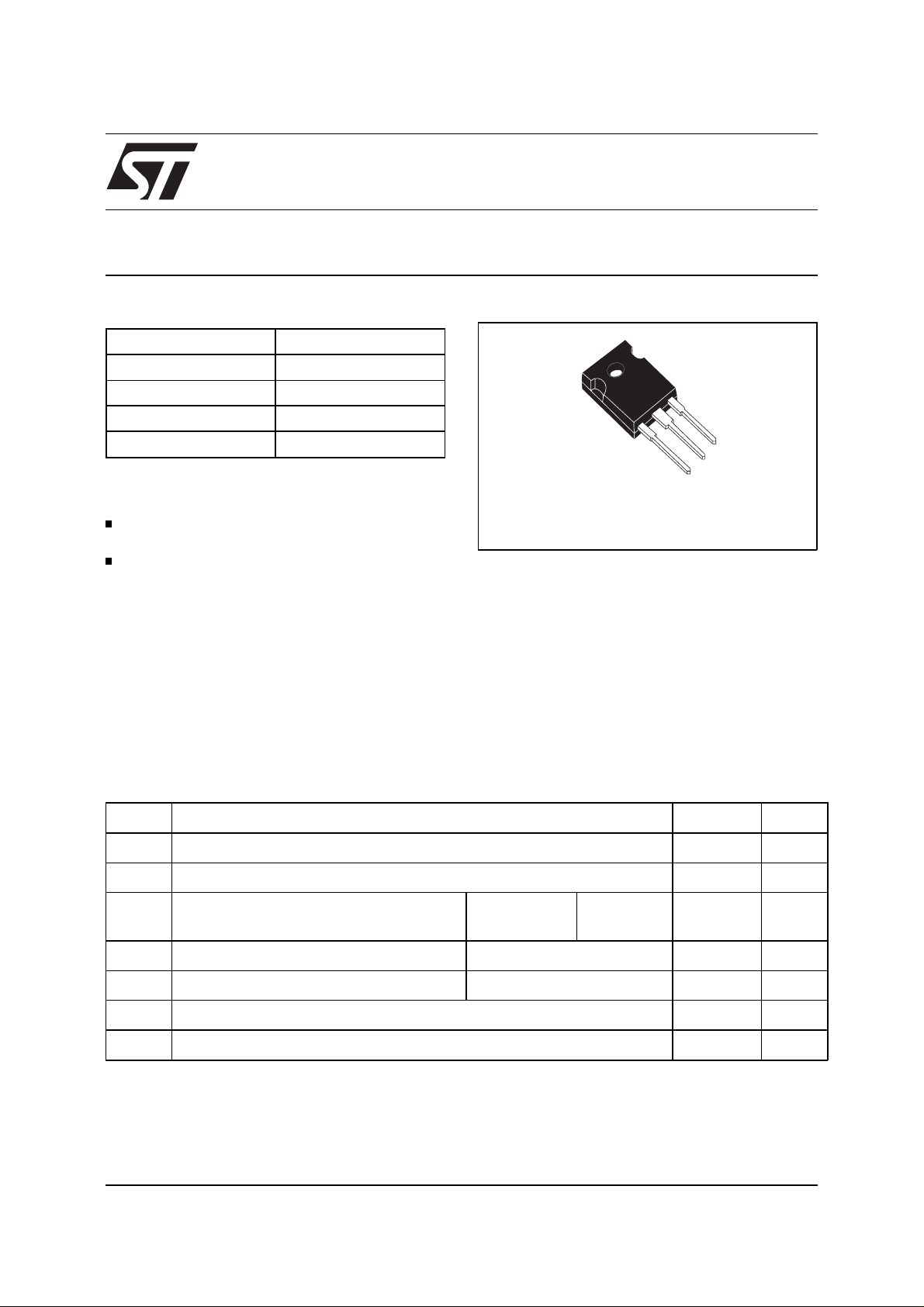

Dual center tap Fast Recovery Epitaxial Diodes

suited for Switch Mode Power Supply and high

frequency DC to DC converters.

Packaged in TO-247 this device is intended for

secondary rectification.

ABSOLUTE RATINGS (limiting values, per diode)

A2

K

A1

TO-247

Symbol Parameter Value Unit

V

RRM

I

F(RMS)

I

F(AV)

I

FSM

I

RSM

T

stg

Tj

October 1999 - Ed: 5A

Repetitive peak reverse voltage

RMS forward current

Average forward current Tc = 135°C

Surge non repetitive forward current tp = 10 ms sinusoidal

Non repetitive peak reverse current tp = 20 µs square

Storage temperature range

Maximum operating junction temperature

δ = 0.5

Per diode

Per device

300 V

30 A

15

30

140 A

7A

-65 +175 °C

+175 ° C

A

1/5

Page 2

STTH3003CW

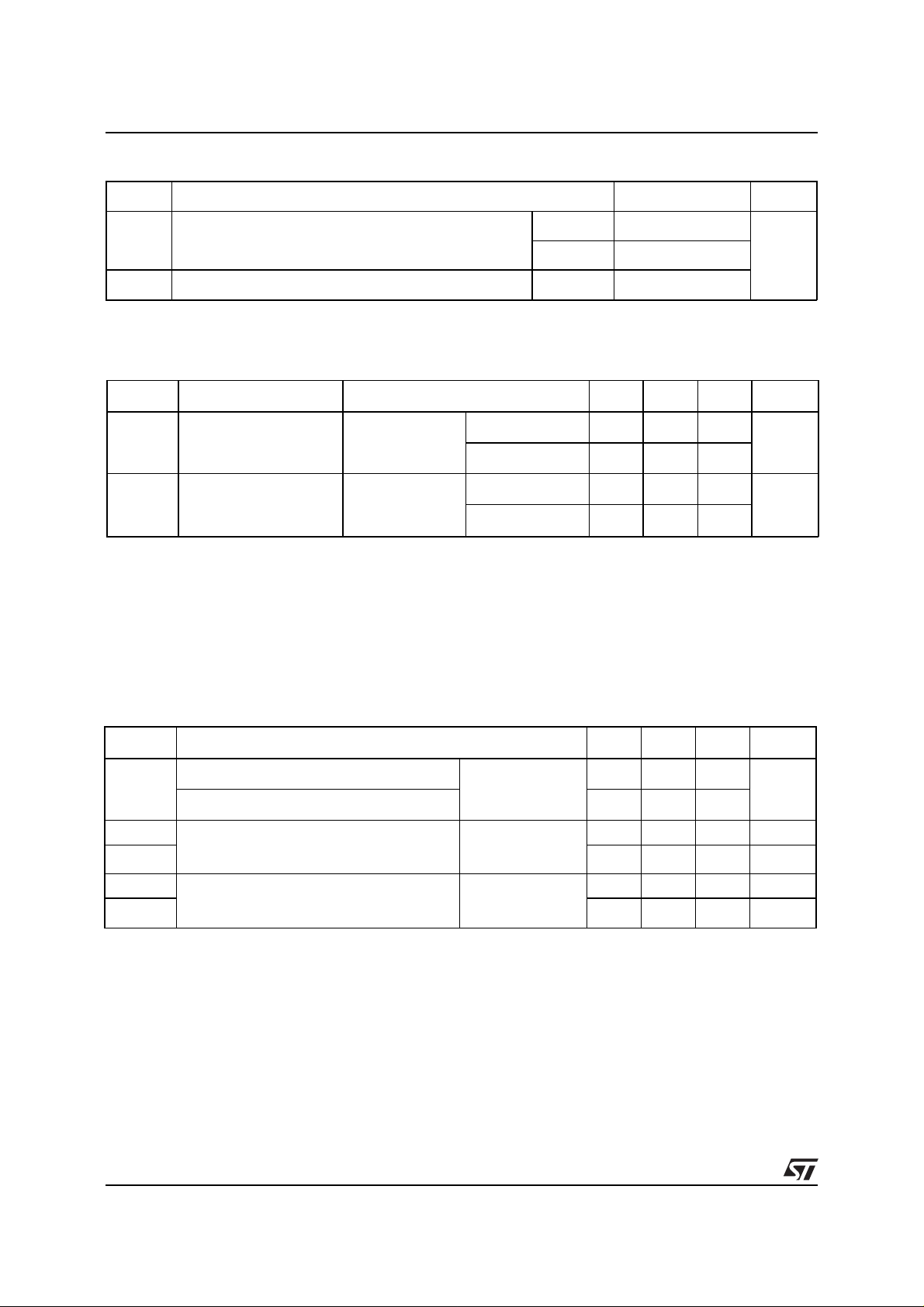

THERMA L RE SISTA NC ES

Symbol Parameter Value Unit

R

th (j-c)

Junction to case Per diode

Total

R

th (c)

Coupling

STATIC ELECTRICAL CHARACTERISTICS (per diode)

Symbol Parameter Tests conditions Min. Typ. Max. Unit

2.0 °C/W

1.05

0.1

*

I

R

V

F

Reverse leakage

current

**

Forward voltage drop I

V

= 300 V Tj = 25°C

R

Tj = 125°C

= 15 A Tj = 25°C

F

Tj = 125°C

40 400

0.85 1

40 µA

1.25 V

Puls e tes t : * tp = 5 m s, δ < 2 %

** tp = 380 µs, δ < 2%

To evaluate the maximum conduction losses use the following equation :

P = 0.75 x I

F(AV)

+ 0.017 I

F2(RMS)

RECOVERY CH ARACTE RIST ICS

Symbol Tests conditions Min. Typ. Max. Unit

trr

= 0.5 A Irr = 0.25 A IR = 1A Tj = 25°C

I

F

IF = 1 A dIF/dt = - 50 A/µ s VR = 30V

tfr

V

FP

I

= 15 A dIF/dt = 100 A/µs

F

V

= 1.1 x VF max.

FR

Tj = 25°C

30 ns

40

300 ns

3.5 V

2/5

S

factor

I

RM

Vcc = 200 V IF = 15 A

dI

/dt = 200A/µs

F

Tj = 125°C

0.3 -

8.5 A

Page 3

STTH3003CW

Fig. 1: Conduction losses versus average current

(per diode).

P1(W)

20

18

16

14

δ = 0.05

δ = 0.1

δ = 0.2

δ = 0.5

δ = 1

12

10

8

6

T

4

2

0

02468101214161820

IF(av) (A)

δ

=tp/T

tp

Fig. 3: Relative variation of thermal impedance

junction to case versus pulse duration.

Zth(j-c)/Rth(j-c)

1.0

0.8

δ = 0.5

0.6

δ = 0.2

0.4

δ = 0.1

0.2

Single pulse

tp(s)

0.0

1E-3 1E-2 1E-1 1E+0

δ

=tp/T

T

tp

Fig. 2: Forward voltage drop versus forward

current (maximum values, per diode).

IFM(A)

200

100

Tj=125°C

10

Tj=25°C

Tj=75°C

VFM(V)

1

0.50 0.75 1.00 1.25 1.50 1.75 2.00 2.25 2.50

Fig. 4: Peak reverse recovery current versus

dI

/dt (90% confidence, per diode).

F

IRM(A)

16

VR=200V

14

Tj=125°C

12

IF=IF(av)

10

8

6

4

2

0

0 50 100 150 200 250 300 350 400 450 500

dIF/dt(A/µs)

IF=2*IF(av)

IF=0.5*IF(av)

Fig. 5: Reverse recovery time ver sus dI

F

confidence, per diode).

trr(ns)

100

80

60

IF=2*IF(av)

40

20

IF=0.5*IF(av)

dIF/dt(A/µs)

0

0 50 100 150 200 250 300 350 400 450 500

VR=200V

Tj=125°C

IF=IF(av)

/dt (90%

Fig. 6: Softness factor versus dI

/dt (typical

F

values, per diode).

S factor

0.60

0.50

0.40

0.30

0.20

0.10

0.00

0 50 100 150 200 250 300 350 400 450 500

dIF/dt(A/µs)

VR=200V

Tj=125°C

3/5

Page 4

STTH3003CW

Fig. 7: Re lative variati on of dynamic par ameters

versus junction temperature (reference: Tj = 125°C).

2.6

2.4

2.2

2.0

1.8

1.6

1.4

1.2

1.0

0.8

0.6

0.4

0.2

0.0

25 50 75 100 125

Fig. 9: Forward recovery time versus dI

IRM

S factor

Tj(°C)

/dt (90%

F

confidence, per diode).

tfr(ns)

500

450

400

350

300

250

200

150

100

50

0

0 50 100 150 200 250 300 350 400 450 500

dIF/dt(A/µs)

VFR=1.1*VF max.

IF=IF(av)

Tj=125°C

Fig. 8: Transient peak forward voltage versus

dI

/dt (90% confidence, per diode).

F

VFP(V)

8

IF=IF(av)

7

Tj=125°C

6

5

4

3

2

1

0

0 50 100 150 200 250 300 350 400 450 500

dIF/dt(A/µs)

4/5

Page 5

PACKAGE MECHANICAL DAT A

TO-247

V

V

H

L5

L

F2

F4

L1

F3

L3

F1

V2

F(x3)

G

= =

Dia.

L4L2

D

ME

A

STTH3003CW

DIMENSIONS

REF.

A 4.85 5.15 0.191 0.203

D 2.20 2.60 0.086 0.102

E 0.40 0.80 0.015 0.031

F 1.00 1.40 0.039 0.055

F1 3.00 0.118

F2 2.00 0.078

F3 2.00 2.40 0.078 0.094

F4 3.00 3.40 0.118 0.133

G 10.90 0.429

H 15.45 15.75 0.608 0.620

L 19.85 20.15 0.781 0.793

L1 3.70 4.30 0.145 0.169

L2 18.50 0.728

L3 14.20 14.80 0.559 0.582

L4 34.60 1.362

L5 5.50 0.216

M 2.00 3.00 0.078 0.118

V5° 5°

V2 60° 60°

Dia. 3.55 3.65 0.139 0.143

Millimeters Inches

Min. Typ. Max. Min. Typ. Max.

Ordering code Marking Package Weight Base qty Delivery mode

STTH3003CW STTH3003CW TO-247 4.36g 30 Tube

Cooling method: by conduction (C)

Recommended torque value: 0.8 N.m.

Maximum torque value: 1.0 N.m.

Epoxy meets UL 94,V0

Information furnished is believed to be accurate and reliable. However, STMicroelectronics assumes no responsibility for the consequences of

use of such information nor for any infringement of patents or other rights of third parties which may result from its use. No license is granted by

implication or otherwi se un der any pat ent or patent rights of STMic roelec tronics. S pecifications ment ioned in t his publ ication are subject to

change without notice. This publication supersedes and replaces all information previously supplied.

STMicroelectronics products are not author i zed f or use as critical comp onents i n l i fe s upport devices or systems without express written approval of STMicroelectronics.

The ST logo is a registered trademark of STMicroe lectronics

© 1999 STMicroelectronics - Printed in Italy - All rights reser ved.

STMicroelectronics GROUP OF COMPANIES

Australia - Brazil - China - Finland - France - Germany - Hong Kong - India - Italy - Japan - Malaysia

Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - U.S.A.

http://www.st.com

5/5

Loading...

Loading...