Danfoss VLT 6000 HVAC Application guide

VLT® 6000 HVAC

■Introduction

Variable speed drives have been used in industrial applications for years because of their ability to provide precise process control. They have also become the standard method of control for heating ventilation and air-conditioning (HVAC) systems due to their precise control and significant energy savings.

The operational concerns for HVAC systems are quite different from those for industrial applications. In most HVAC installations there is a large installed base of sensitive electronic equipment such as computers, outstations and radios. Airports, hospitals and research facilities will for example make much heavier demands on the variable speed drives than the industrial plants.

This feature note will deal with one aspect of electrical noise generation in variable speed drives: Radio Frequency Interference (RFI) on the AC power line. We describe the causes and effects of such noise as well as the considerations that are to be made in connection with the selection and installation of a variable speed drive.

■ Causes of Radio Frequency Interference

(RFI)

ee

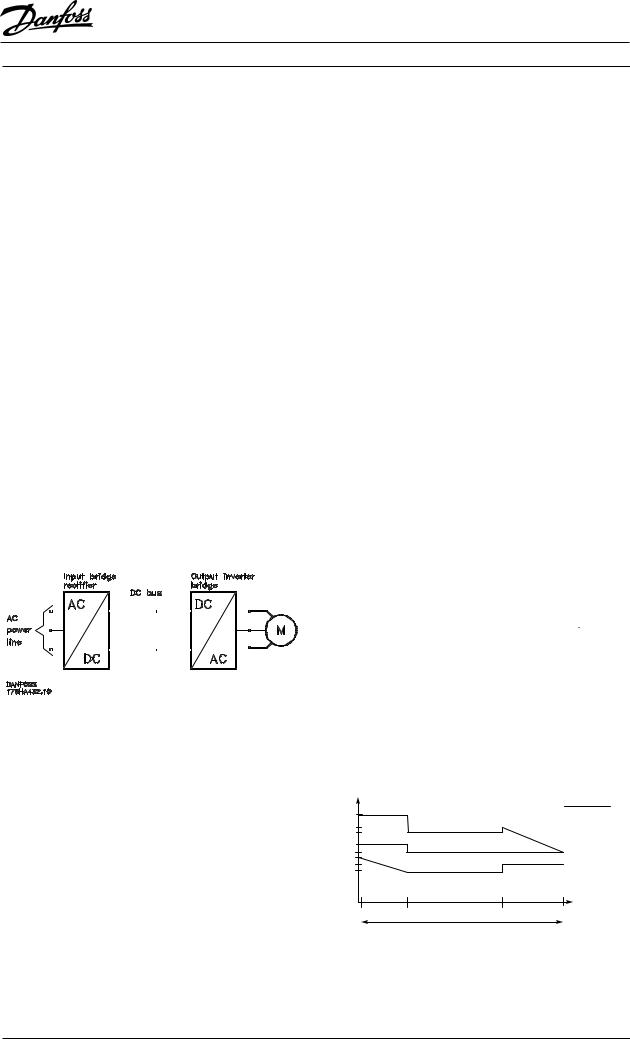

Figure 1: Schematic of Basic Drive design

Most variable speed drives operate by using a bridge rectifier to convert the incoming AC voltage into a DC bus voltage. The inverter bridge of the drive then converts the DC bus voltage into the controlled voltage and frequency that the motor requires.

For the most common types of drives in use today, IGBTs are used to convert the DC voltage into an AC voltage with controlled amplitude and frequency. To perform this control most drives incorporate sophisticated control circuitry with micro-processors of high clock frequencies.

Both the inverter and the control circuitry generate electrical noise at frequencies higher than 150 kHz.

If the drive is not designed carefully, this noise will be conducted to the surroundings, causing malfunction of other electronic equipment, especially if it is not designed with a high level of immunity to such high frequency noise.

■ Measuring Radio Frequency Interference

The levels of RFI from a drive is dependent on many different factors. The design of the drive is most important, since this determines how low the distortion can get.

The measuring results for different drives may vary a lot, so to get a real picture it is important to know exactly how the measuring was made. Some of the most important factors are:

Impedance between drive chassis and ground Type of motor cable used or transfer impedance of cable screen

Length of motor cable

Radiated emission is almost impossible to reproduce. The reason is that even a slight change in the measuring set-up will influence the results a lot. Measuring made on site will always be unreliable, since it is impossible to create a clean environment.

■Radio frequency interference limits

The most important international standard defining RFI limits for drives is:

EN 55011/CISPR 11

EN55011 sets three different limits:

Emission,

screened motor cable

dB/uV |

|

|

Average levels |

90 |

|

|

EN 55011 2A |

80 |

|

|

|

76 |

|

|

|

66 |

|

|

|

60 |

|

|

EN 55011 1A |

56 |

|

|

EN 55011 1B |

50 |

|

|

|

|

|

|

|

46 |

|

|

|

150 kHz |

500 kHz |

5 MHz |

30 MHz |

Figure 2: Average conducted emission levels

MN.60.G1.02 - VLT is a registered Danfoss trademark |

1 |

Loading...

Loading...