Danfoss WVTS 40, WVTS 50, WVTS 100 Installation guide [da]

Installation guide

Thermostatic water valves

WVTS

| <![if ! IE]> <![endif]>016R9557 |

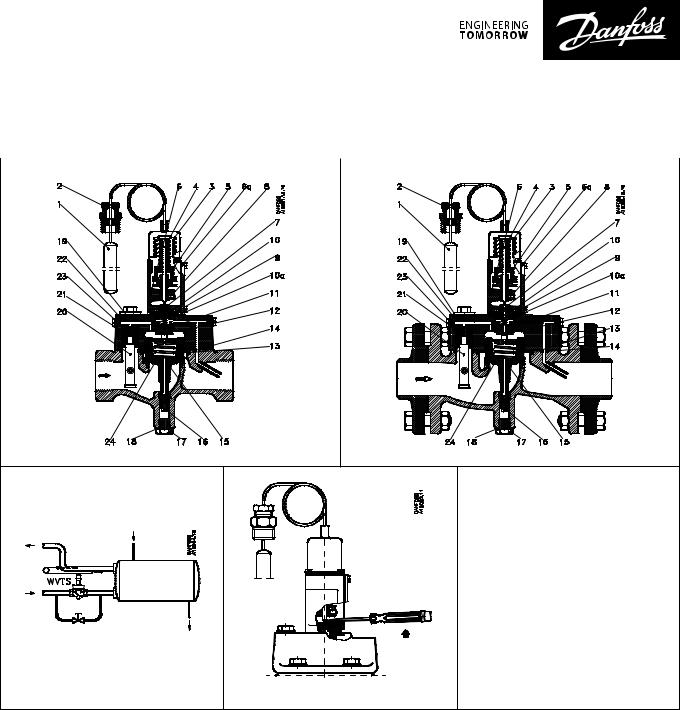

WVTS 40 |

WVTS 50 - WVTS 100 |

|

Fig. 1 |

Fig. 2 |

Type |

Spring / Fjeder / Feder / Ressort |

|

1 – 10 bar (100 – 1000 kPa) |

||

|

||

WVTS 32 |

016D1327 |

|

WVTS 40 |

016D0575 |

|

WVTS 50 |

016D0576 |

|

WVTS 65 |

016D0577 |

|

WVTS 80 |

016D0578 |

|

WVTS 100 |

016D0579 |

Fig. 3 |

Fig. 4 |

Fig. 5 |

<![endif]>016R9557

|

|

|

16. |

Servo piston button screw |

|

Max. 4 atm. (4 bar = 400 kPa) |

|

ENGLISH |

|

|

|||

|

|

17. |

Drain plug |

|

WVTS 50 - WVTS 100: |

|

|

|

|

|

|||

Thermostatic Water Valves |

|

18. |

Drain plug gasket |

|

Min. 0.3 atm. (0.3 bar = 30 kPa) |

|

|

19. |

Strainer assembly, complete |

* |

Max. 4 atm. (4 bar = 400 kPa) |

||

Technical data (Fig. 1–3) |

|

|||||

|

20. Self-cleaning strainer |

|

|

|||

1. |

Bulb |

|

|

If WVTS is required with a differential |

||

|

21. |

Pilot nozzle |

|

|||

2. |

Stuffing box |

|

|

|||

|

22. |

Gasket |

|

pressure of 1 – 10 atm. (1 – 10 bar; |

||

3. |

Bellows element |

|

|

|||

|

23. |

O-ring |

|

100 – 1000 kPa), the servo spring (24) is to |

||

4. |

Push rod |

|

|

|||

|

24. |

Servo spring |

** |

be replaced. See ordering table, Fig. 5. |

||

5. |

Regulating nut |

|

||||

|

* |

Please state valve size. |

|

|

||

6. |

Top part |

|

|

Permissible temperature of medium |

||

|

** |

See table Fig. 5. |

|

|||

6a. |

Cover |

|

|

|||

|

|

|

|

For water: Max. 90 °C |

||

7. |

Pilot insert |

|

Assembly |

|

||

|

|

For brine: Min. -25 °C |

||||

8. |

Pilot cone |

|

Screws connecting pilot unit with valve |

|||

|

|

|||||

9. |

Teflon sleeves |

|

body to be tighten with 8.5 Nm. |

|

Max. bulb temperature |

|

10. |

Insulating disc |

|

|

|

|

|

|

Max. test pressure |

|

57 °C for the range of 0 – 30 °C |

|||

10a. |

Pilot insert seal |

|

|

|||

|

|

90 °C for the range of 25 – 65 °C |

||||

11. |

Pilot insert O-ring |

|

16 atm.g (pe = 16 bar = 1600 kPa) |

|

||

|

|

125 °C for the range of 50 – 90 °C |

||||

12. |

Cover |

|

|

|

|

|

|

Opening differential pressure |

|

|

|||

13. |

O-ring for cover |

* |

|

Fitting |

||

14. |

O-ring for pilot channel |

|

WVTS 32 - WVTS 40: |

|

||

|

|

WVTS is to be fitted in the cooling water |

||||

15. |

Servo piston |

* |

|

Min. 0.5 atm. (0.5 bar = 50 kPa) |

||

|

|

|||||

|

|

|

|

|

|

|

© Danfoss | DCS (jmn) | 2016.02 |

|

|

|

|

DKRCC.PI.DB0.A1.52 | 520H10725 | 1 |

|

inlet with flow in the direction of the arrow and with the bellows element facing upwards.

It is recommended that a strainer should be inserted before the valve.

The bulb is to be fitted where it is required to maintain or control the water temperature.

The bulb can be fitted warmer or colder than the valve body, with no effect on the regulating capacity.

The bulb must be fitted horizontally or with the blank end of the bulb at the lowest level.

The capitals UP and the red line on the bulb must face upwards at horizontal or inclined fitting.

On condensers (Fig. 3) the bulb can either be fixed to the discharge pipe by means of a clip, be inserted in a pocket or placed in direct contact with the cooling water.

When the plant is started, the bulb must be affected at once by the temperature variations of the cooling water flow. A bypass with a shut-off valve can, therefore, be necessary in order to ensure a cooling water flow during start-up.

If the bulb is fitted in direct contact with the cooling water, it must be fixed so that pulsations cannot affect the bulb and thus destroy the capillary tube. If a bulb pocket is used, good heat transmission is obtained by filling the pocket with heat-conductive compound.

On air compressors and similar equipment the bulb is fitted in the water-filled cooling jacket. No bypass is required. The heating of the water at the start of the compressor always ensures a suitable impulse to the bulb.

Setting

Place a thermometer at the point where the bulb is fitted.

Remove the cover (6a). Turn the regulating nut (5) to adjust the medium flow until the thermometer shows the required

temperature on the discharge side. A lower temperature can be obtained by turning the regulating nut (5) anti-clockwise (to slacken the regulating spring) – and vice versa.

When the refrigeration system stops, the temperature drops at the bulb, and so WVTS closes.

Service

The water valve must close tightly when the refrigeration system is stopped. If not, it may be due to the fact that large impurities have settled on the valve seat of the servo piston of pilot cone. The strainer (20) or the pilot nozzle (21) may be clogged up.

Impurities can be removed as shown in Fig. 4. Insert a screwdriver between the pilot cone spindle (8) and the push rod

(4). Tilting the screwdriver forces the pilot cone down, and the valve opens to full cooling water flow.

If still the water valve does not close

tightly, shut off the cooling water supply to the water valve. Unscrew the strainer assembly (19) and clean both the strainer and the pilot nozzle.

If the strainer or pilot nozzle is not clogged up, dismount the top part (6) and the valve cover (12), which can be done without relieving the system of its pressure. Remove the strainer assembly from the valve cover, clean it, and apply a coat of water-resistant, acid-free grease to it. Fill the same kind of grease into the

space over the Teflon sleeves (9). It may be necessary to grind the pilot cone in its seat. Clean the servo piston and valve seat and apply a coat of water-resistant, acid-free grease to the servo cylinder and the servo piston guide.

The pilot channels in the valve cover can be cleaned after the screws have been unscrewed from the sides of the valve cover.

Check whether the O-rings need replacement.

After fitting or overhaul the water valve must be flushed vigorously for some minutes in order to remove any impurities from pipelines, etc. See Fig. 4.

If there is any risk of the valve bursting due to frost during standstill periods, it should be drained of water. It can be done by unscrewing the drain plug (17) and the bottom screw (16).

DANSK

Termostatiske vandventiler

Tekniske data (Fig. 1–3)

1.Føler

2.Pakdåse

3.Bælgelement

4.Trykstang

5.Reguleringsmøtrik

6.Indstillingshus

6a. Dæksel

7.Pilotindsats

8.Pilotkegle

9.Teflonmanchetter

10.Isolationsskive

10a. Pakning for pilotindsats

11.O-ring for pilotindsats

12.Dæksel

13. O-ring for dæksel |

* |

14.O-ring for pilotkanal

15. Servostempel |

* |

16.Bundskrue for servostempel

17.Bundprop

18.Pakning for bundprop

19. |

Komplet filterindsats |

* |

20. |

Selvrensende filter |

|

21. |

Pilotdyse |

|

22. |

Pakning |

|

23. |

O-ring |

|

24. |

Servofjeder |

** |

*Angiv ventilstørrelsen.

**Se tabellen fig. 5.

Samling

Skruer, der forbinder pilotenhed med Ventilhus der skal spændes med 8,5 Nm.

Maks. prøvningstryk

16 ato (Pe = 16 bar = 1600 kPa)

Åbningsdifferenstryk

WVTS 32 - WVTS 40:

Min. 0.5 at (0.5 bar = 50 kPa) Maks. 4 at (4 bar = 400 kPa)

WVTS 50 - WVTS 100:

Min. 0.3 at (0.3 bar = 30 kPa) Maks. 4 at (4 bar = 400 kPa)

Hvis WVTS ønskes med et differenstryk på 1 – 10 at (1 – 10 bar, 100 – 1000 kPa), udskiftes servofjederen (24). Se bestillingstabellen, fig. 5.

Tilladelig medietemperatur

For vand: Maks. 90 °C

For brine: Min. -25 °C

Maks. følertemperatur

57 °C for området 0 – 30 °C

90 °C for området 25 – 65 °C

125 °C for området 50 – 90 °C

Montering

WVTS monteres i kølevandstilgangen med gen-nemstrømning i pilens retning og med bælg-elementet opad. Det anbefales at montere et smudsfilter foran ventilen. Føleren anbringes, hvor den ønskede vand-temperatur skal overholdes.

Føleren kan uden indvirkning på regule-ringsevnen anbringes varmere eller koldere end ventilhuset.

De øvrige områder skal føleren monteres vandret eller med følerens frie ende lavest. Bogstaverne UP og den røde streg på føleren skal vende opad ved vandret eller skrå montering.

På kondensatorer (fig. 3) kan føleren enten fastgøres til afgangsrøret med spændebånd, monteres i en følerlomme i afgangsrøret eller anbringes i direkte kontakt med kølevandet.

Ved anlæggets start skal føleren straks kunne påvirkes af det strømmende kølevands temperaturvariationer. Derfor kan et omløb med en afspærringsventil være nødvendigt for at sikre en kølevandsstrøm under opstart. Monteres føleren i direkte kontakt med kølevandet, fastgøres den, så pulsationer ikke kan påvirke føleren og derved ødelægge kapillarrøret.

Anvendes følerlomme, opnås en god varme-overgang, når lommen fyldes med kobberpasta.

På luftkompressorer og lignende monteres føleren i den vandfyldte kølekappe. Et omløb er ikke nødvendigt her. Opvarmningen af vandet ved kompressorens start giver altid tilstrækkelig impuls til føleren.

Indstilling

Anbring et termometer på det sted, hvor føleren er placeret.

Fjern dækslet (6a). Med reguleringsmøtrikken (5) reguleres mediets gennemstrømning, indtil termometeret viser den ønskede temperatur på afgangssiden.

© Danfoss | DCS (jmn) | 2016.02 |

DKRCC.PI.DB0.A1.52 | 520H10725 | 2 |

Loading...

Loading...