Daewoo RC-400S, RC-4006B Service Manual

S/M No. : RC400SE001

Service Manual

Vacuum Cleaner

Model: RC-400'S

Caution

:In this Manual, some parts can be changed for improving, their performance without notice in the parts list. So, if you need the latest parts information,please refer to PPL(Parts Price List) in Service Information Center (http://svc.dwe.co.kr).

DAEWOO ELECTRONICS CO., LTD.

http : //svc.dwe.co.kr |

May. 2003 |

CONTENTS

|

Page |

1. SPECIFICATIONS -------------------------------------------------- |

2 |

2. EXTERNAL VIEWS ------------------------------------------------ |

3 |

3. DIAGRAM ------------------------------------------------------------ |

4 |

3-1. WIRING DIAGRAM |

|

3-2. CIRCUIT DIAGRAM |

|

4. TROUBLE SHOOTING GUIDE --------------------------------- |

5 |

5. DISASSEMBLING AND TREATMENT ----------------------- |

7 |

5-1. CLEANER ASSEMBLY ------------------------------------------------- |

7 |

5-2. BODY ASSEMBLY ------------------------------------------------------- |

8 |

5-3. MOTOR ASSEMBLY ---------------------------------------------------- |

9 |

5-4. CORDREEL ASSEMBLY ---------------------------------------------- |

10 |

5-5. PCB ASSEMBLY --------------------------------------------------------- |

12 |

5-6. HOSE ASSEMBLY ------------------------------------------------------- |

13 |

5-7. BRUSH ASSEMBLY ----------------------------------------------------- |

14 |

5-8. DUST BOX ASSEMBLY ------------------------------------------------ |

15 |

6. EXPLODED VIEW AND PARTS LIST ------------------------ |

16 |

6-1. CLEANER ASSEMBLY ------------------------------------------------- |

16 |

6-2. BODY ASSEMBLY ------------------------------------------------------- |

20 |

6-3. COVER BODY ASSEMBLY ------------------------------------------- |

22 |

6-4. COVER DUST ASSEMBLY -------------------------------------------- |

23 |

6-5. DUST BOX ASSEMBLY ------------------------------------------------ |

24 |

6-6. MOTOR ASSEMBLY ---------------------------------------------------- |

25 |

6-7. CORDREEL ASSEMBLY ---------------------------------------------- |

26 |

6-8. CASE MOTOR UPPER ASSEMBLY -------------------------------- |

28 |

6-9. HOSE ASSEMBLY ------------------------------------------------------- |

30 |

6-10. PIPE ASSEMBLY ------------------------------------------------------- |

32 |

6-11. BRUSH ASSEMBLY --------------------------------------------------- |

33 |

1. SPECIFICATIONS

MODEL |

RC-4005B'S |

RC-4006B'S |

|

|

|

Rated Voltage/Frequency |

AC 230V, 50/60Hz |

¢¸ |

|

|

|

Input Watt |

1500W |

1600W |

|

|

|

Suction Power |

350W |

370W |

|

|

|

Noise Level |

75dB(A) |

73dB(A) |

|

|

|

Weight (Body) |

4.7Kg |

¢¸ |

|

|

|

Electrical Components |

Thermostat (T80:80¡É OFF ) |

¢¸ |

|

|

|

Dimension (WXHXD) |

437 X 229 X 294 mm |

¢¸ |

|

|

|

Cord Length |

5.0m |

¢¸ |

|

|

|

Filter |

General |

HEPA |

|

|

|

Pipe |

2 Steel |

Telescopic |

|

|

|

Nozzle |

Pedal |

¢¸ |

|

|

|

|

Crevice Nozzle |

¢¸ |

|

|

|

2

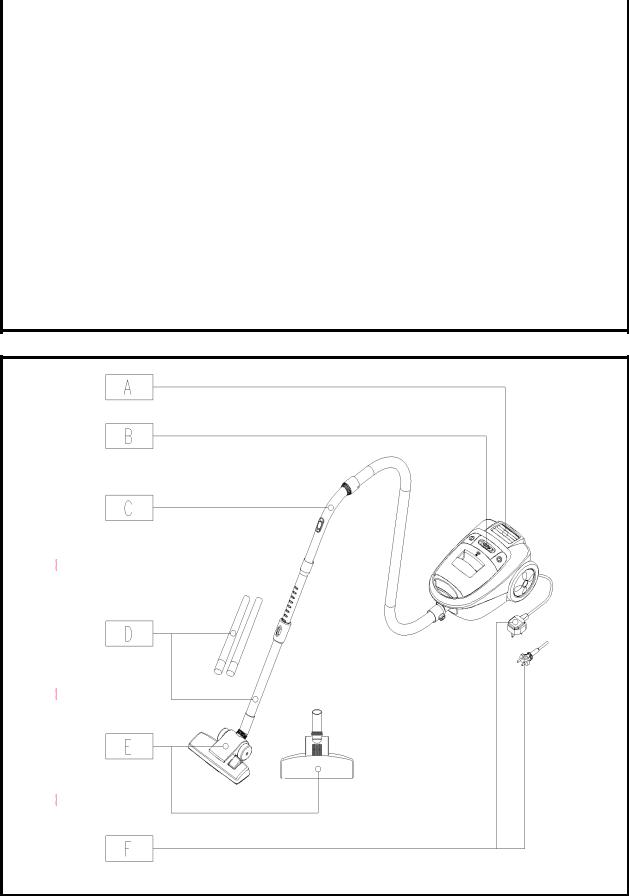

2. EXTERNAL VIEWS

|

|

|

|

|

|

|

|

|

PART NAME |

RC-4005B'S |

RC-4006B'S |

|

|

|

|

A |

FILTER |

General |

HEPA |

|

|

|

|

B |

BODY VARIABLE |

O |

O |

|

|

|

|

C |

HOSE HANDLE |

FLAT Type |

FLAT Type |

|

|

|

|

D |

PIPE |

2 STEEL |

TELESCOPIC |

|

|

|

|

E |

NOZZLE |

PEDAL |

PEDAL |

|

|

|

|

F |

POWER CORD |

O |

O |

|

|

|

|

¡ß FILTER : GENERAL(3621909500, SPONGE 20T), HEPA(3621908510)

¡ß PIPE : 2 STEEL(3624409000), TELESCOPIC(3624411470)

¡ß NOZZLE : CLEAN(3629311200), PEDAL(3629306610)

3

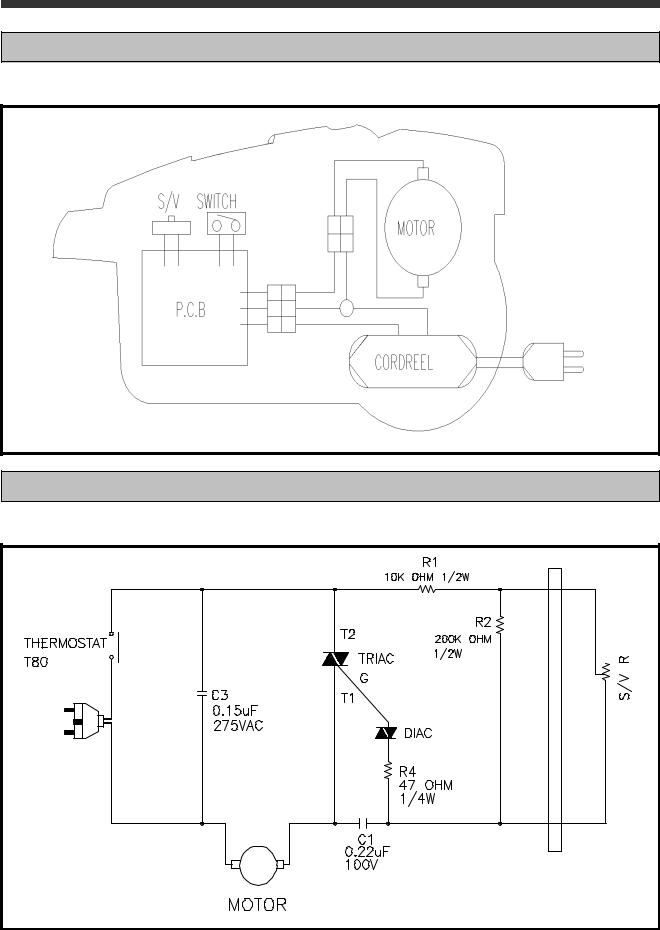

3. DIAGRAM

3-1. WIRING DIAGRAM

1) MODEL RC-4005B'S, 4006B'S

3-2. CIRCUIT DIAGRAM |

1) MODEL RC-4005B'S. RC-4006B'S |

4 |

4. TROUBLE SHOOTING GUIDE

TROUBLE |

|

CAUSE |

|

|

|

SUCTION POWER IS WEAK

VACUUM CLEANER DOES NOT WORK

MOTOR DOES NOT STOP EVEN IF SWITCH

FILTER BAG(PAPER)/DUST BOX IS FULL WITH DUST

FILTER PRE IS CLOGGY WITH DUST

CLOGGING OR TEAR IN HOSE

DEFECTIVE MOTOR

THE OPENING IN BRUSH IS CLOGGY WITH DUST

BREAKING IN POWER CORD

(AT BLADE TIP OR ROOT OF PLUG)

BREAKING OF CONNECTIONS IN HOSE ASSEMBLY

DEFECTIVE SLIDE VOLUME LOCATED IN CASE MOTOR UPPER

DEFECTIVE PCB ASSEMBLY

BREAKING OF CONNECTIONS OR POOR CONTACTS IN CORD REEL ASSEMBLY

DEFECTIVE MOTOR

BREAKING OF CONNECTIONS IN BODY ASSEMBLY

BREAKING IN A FUSE

DEFECTIVE PCB ASSEMBLY

COUNTERMEASURE

CHANGE IT WITH NEW ONE (See 5-1,8) REMOVE THE DUST IN DUST BOX

REMOVE THE DUST (See 5-2)

REMOVE OBSTACLE

OR REPLACE THE HOSE (See 5-6)

REPLACE THE MOTOR (See 5-3)

REMOVE THE DUST (See 5-7)

REPLACE THE POWER CORD (See5-4)

REPLACE IT (See 5-3)

REPLACE IT (See 5-5)

REPAIR (See 5-4)

REPLACE IT (See 5-3)

REPAIR (See 5-2)

REPLACE IT (See 5-5)

5

|

|

|

|

|

|

|

|

|

|

TROUBLE |

|

CAUSE |

|

COUNTERMEASURE |

|

|

|

|

|

POWER CORD IS NOT WOUND UP

CAUTION

POWER CORD DOES NOT STOP AT AN ARBITRARY POSITION

BROKEN REEL SPRING OF CORD REEL

POWER CORD BROKE AWAY FROM THE BOBBIN

REPLACE IT (See 5-4)

REPAIR (See 5-4)

BE CAREFUL WHEN BREAKING UP THE CORD REEL, THE REELSPRING MAY SPRING OUT OF THE SPRING COVER.

ABRASION OF THE ROLLER BRAKE OF CORD REEL

LEVER SPRING BROKE AWAY FROM THE CORD REEL BRACKET

REPLACE THE ROLLER

BRAKE (See 5-4)

REPAIR (See 5-4)

6

5. DISASSEMBLING AND TREATMENT

5-1. CLEANER ASSEMBLY

1)LIFT THE DUST COVER(8), GRILLE(10), FILTER(9) AND UNSCREW THE 6 SCREWS(6) AND THEN LIFT THE COVER ASSEMBLY(5) UP FROM THE BODY ASSEMBLY(1).

2)CHECK THE DUST BOX.

3)CHECK THE HEPA(OR GENERAL) FILTER (9).

7

5-2. BODY ASSEMBLY

1)CHECK THE SAFETY VALVE ASSEMBLY (14).

2)CHECK THE GASKET (11).

3)CHECK THE HOLDER FILTER (9).

4)CHECK THE FILTER PRE (12).

8

5-3. MOTOR ASSEMBLY

1)TAKE THE MOTOR ASSEMBLY OUT OF THE CASE MOTOR ASSEMBLY.

2)CHECK THE MOTOR(2) (WHETHER THE MOTOR IS BURNT OUT OR NOT).

3)CHECK THE CONNECTION BETWEEN MOTOR TERMINAL AND THE LEADS.

4)CHECK THE SLIDE VOLUME(5) AND SWITCH(6).

9

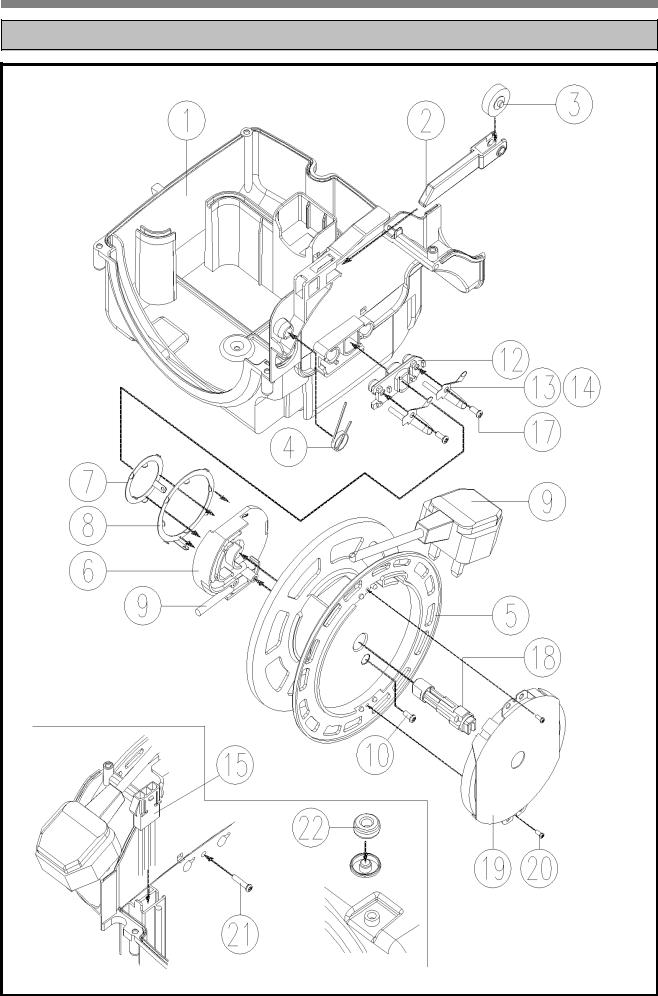

5-4. CORDREEL ASSEMBLY

10

1)TAKE THE CORD REEL ASSEMBLY OUT OF THE BODY ASSEMBLY.

2)UNSCREW THE SCREW(21).

3)SEPARATE THE BOBBIN(5) FROM THE CASE MOTOR BOTTOM(1) AND CHECK THE CONTACTS BETWEEN THE Y TYPE TERMINALS(13,14) AND

THE RING TYPE TERMINALS(7,8).

4)CHECK THE LEVER SPRING(4).

5)IF THE ROLLER BRAKE(3) IS WORN OUT AND SEPARATE THE LEVER(2) FROM THE CASE MOTOR BOTTOM(1), THEN REPLACE THE ROLLER BRAKE(3).

AT THIS TIME, THE BOBBIN(5) IS ROTATED COUNTERCLOCKWISE DUE TO THE PRESERVED WINDING.

6)IF THE REEL SPRING(19) IS BROKEN, UNSCREW THE 2 SCREWS(20) AND REPLACE IT.

|

|

|

CAUTION |

WHEN DISASSEMBLING, THE REEL SPRING MAY |

|

SPRING OUT OF THE COVER. |

||

|

||

|

|

|

|

|

7)UNSCREW THE SCREW (10) AND SEPARATE THE HOLDER TERMINAL(6) FROM THE BOBBIN(5).

8)CHECK THE CONNECTIONS BETWEEN THE POWER CORD(9) AND THE RING TERMINALS(7,8).

9)WHEN ASSEMBLING, MAKE THE RESERVED WINDING 5 REVOLUTIONS OF THE BOBBIN CLOCKWISE.

11

Loading...

Loading...