cybelec PCDNC 1200 User Guide

PC / DNC 1200

User Guide (2D + 3D)

CYBELEC SA |

Tel. ++ 41 24 447 02 00 |

RUE DES UTTINS 27 |

Fax ++ 41 24 447 02 01 |

CH - 1400 YVERDON-LES-BAINS |

E-Mail: info@cybelec.ch |

SWITZERLAND |

V-DOC-12PS23D-EN |

|

Information in this document is subject to change without notice, and does not represent a commitment on the part of CYBELEC SA.

The software described in this document is furnished under a license agreement or nondisclosure agreement. The software may be used or copied only in accordance with the terms of the agreement. It is against the law to copy the software on any medium except as specifically allowed in the license or nondisclosure agreement.

Copyright CYBELEC SA. 1991 All rights reserved.

Important:

This notice explains normal and standard programming operations for the numerical control.

In view of the fact that numerical controls can be equipped with configurable functions by the press manufacturer for his own specific purposes, please refer to the manufacturer-supplied complementary instructions regarding the programming of these functions.

Autocad

is a registered trade mark of Autodesk Inc..

is a registered trade mark of Autodesk Inc..

CYBELEC

is a registred trademark of CYBELEC SA.

is a registred trademark of CYBELEC SA.

Ethernet

is a registered trade mark of Xerox Corporation.

is a registered trade mark of Xerox Corporation.

IBM

, PC/AT

, PC/AT

, PC Network

, PC Network

, Token Ring Network

, Token Ring Network

are registered trade marks of the International Business Machines Corporation.

MS-DOS

is a registered trade mark of Microsoft Corporation.

is a registered trade mark of Microsoft Corporation.

MS-Windows

is a registered trade mark of Microsoft Corporation.

is a registered trade mark of Microsoft Corporation.

Novell Netware is a registered trade mark of Novell, Incorporated.

is a registered trade mark of Novell, Incorporated.

Windows NT

is a registered trade mark of Microsoft Corporation.

is a registered trade mark of Microsoft Corporation.

SAFETY AND MAINTENANCE INSTRUCTIONS

The operator must be trained for working with the machine on which the numerical control is installed.

Improper use of the numerical control can cause heavy damage on equipment and/or injuries to people.

Modification of machine parameters can cause important material damage or lead to irregular product quality.

The rear panel may only be removed by a qualified technician (danger of electrocution).

Do not expose the numerical control to excessive humidity so as to avoid any risk of electrocution and any deterioration of the equipment.

Make sure the numerical control is disconnected from the mains power before carrying out any cleaning. Do not use liquids based on alcohol or ammoniac.

In case of malfunction of the numerical control, call a technician.

Do not expose the numerical control to direct sun rays or any other heat source.

Do not place the numerical control in the neighbourhood of magnetic equipment such as transformers, motors or devices which generate interference (welding machines, etc.)

Replace fan filters at regular intervals so as to avoid overheating.

SAFETY AND MAINTENANCE INSTRUCTIONS |

PAGE I |

This page has been left blank intentionally.

PAGE II USER GUIDE PC/DNC 1200 2D&3D

LICENSE AGREEMENT FOR CYBELEC SOFTWARE

GENERAL COPYRIGHT

The CYBELEC software is protected by Copyright, and all the copying rights are reserved.

The CYBELEC software may only be installed and used in authorized equipments (PC or DNC). The user manuals are also covered by copyright, and all rights to use and to copy are reserved.

This document may not, in whole or in part, be copied, photocopied, reproduced, translated or reduced without prior consent, in writing, from CYBELEC.

SPECIAL DISKETTE COPYRIGHT

The legal users of this software product are authorized only to copy the contents of the diskette into the memory of the computer to run the program, and to make one backup copy of the original diskette for safety purposes in case of loss of the original program.

Unauthorized copying, duplicating, selling or otherwise distributing this product is a violation of the law.

SPECIAL EPROM COPYRIGHT

The CYBELEC DNC and CNC units in which the original software made by CYBELEC has been replaced by a copy not made by CYBELEC, and without written authorization of CYBELEC, will immediately lose their warranty.

WARRANTY

CYBELEC does not warrant that its software products will function properly in every computer and programming environment.

The limitations of use of a software product and its technical specifications are decided by CYBELEC only; CYBELEC solely is entitled to decide upon conformity and performance of a given software.

The CYBELEC software does not compensate for incompatibilities in operating system revisions or versions.

Running the CYBELEC software under various revisions or versions, or switching between different versions or revisions may result in loss or alteration of data.

LICENSE AGREEMENT |

PAGE III |

SOFTWARE UPDATE SERVICE

Purchase of the CYBELEC software entitles the user, during one year, to delivery of software updates of the "correction" type.

During the use of a revised or corrected version of the software it may occur that data (program, parameters, etc.) is lost, or that the equipment or its connections need to be modified; these effects are not always foreseeable and do not engage CYBELEC's responsibility.

TERMINATION

This agreement shall automatically terminate upon any act of bankruptcy by or against licensee, upon any assignment for the benefit of creditors of the licensee, upon any attachment execution of judgement or process against licensee or its assets that substantially inhibits its ability to do business, or upon dissolution of licensee.

CYBELEC has the right to terminate this agreement immediately, should the licensee violate the aforementioned conditions.

Within 30 days of termination of this agreement for any reason, licensee shall at his option, either: return to CYBELEC or authorized dealer all existent copies of such software and related materials, or

furnish to CYBELEC evidence satisfactory that the original and all copies of the software, in whole and in any form, have been destroyed.

LIMITATION OF LIABILITY

The foregoing warranty is instead of all other warranties, expressed or implied.

Licensee further agrees that CYBELEC shall not be liable for any lost profits, lost savings, loss of use, or other incidental or consequential damages arising from the use or inability to use the software, or for any claim or demand against licensee by any other party.

In no event shall CYBELEC be liable for consequential damages, even if CYBELEC has been advised of the possibility of such damages.

CYBELEC does not warrant that the functions contained in the software will meet the licensee's requirement or that the operation of the software will be totally error free.

Should the software prove defective, the licensee (and not CYBELEC or an authorized dealer or representative) will assume the entire cost of all necessary service, repair or correction.

CYBELEC warrants the diskettes, EPROMS or other magnetic support or cassettes on which the programs are supplied to be free of defects in material and workmanship under normal use for a period of 90 days from the date of shipment to the licensee as evidenced by a copy of the packing slip.

PAGE IV |

LICENSE AGREEMENT |

LIMITATION OF REMEDIES

CYBELEC's entire liability and the licensee's exclusive remedy shall be as follows:

The replacement of any diskettes or EPROMS or magnetic support media or cassettes not meeting CYBELEC's limited warranty and which materials are returned to CYBELEC or an authorized CYBELEC representative with a copy of the packing slip, or

If CYBELEC or its representative is unable to deliver replacement diskettes, magnetic support media, EPROM or cassettes which are free of defects in materials or workmanship, the licensee may terminate this agreement under the terms and conditions herein mentioned, and the purchaser's money will be refunded.

GENERAL

The licensee acknowledges that he has read this agreement, understands it and agrees to be bound by its terms and conditions.

The licensee agrees to hold CYBELEC harmless on all liability associated with licensee's breach of this agreement including, but not limited to, all reasonable attorney's fees and court costs, if any.

This license agreement shall be governed by Swiss law; place of jurisdiction is Lausanne, Switzerland.

MAINTENANCE

CYBELEC will provide one year of software maintenance.The extent of maintenance, and response time for furnishing same, shall be at the sole discretion of CYBELEC.Maintenance shall normally include correction of errors in code, correction of errors in supporting documentation, update versions of the covered software which may be released by CYBELEC during the maintenance period.

In no event shall CYBELEC be obliged to provide technical support in attempting to resolve problems or difficulties resulting from licensee's modification of the licensed software; any such modification by licensee is entirely at licensee's own risk.

LICENSE AGREEMENT |

PAGE V |

This page has been left blank intentionally.

PAGE VI |

LICENSE AGREEMENT |

March 2002 |

V. 2.3 |

CONTENTS |

|

SAFETY AND MAINTENANCE INSTRUCTIONS ........................................................................... |

I |

LICENSE AGREEMENT FOR CYBELEC SOFTWARE.................................................................. |

III |

INTRODUCTION.............................................................................................................................. |

5 |

Safety, Copyright & License agreement.............................................................................. |

5 |

DNC with Windows operating system |

5 |

About this Manual................................................................................................................ |

6 |

Software Installation ............................................................................................................ |

7 |

Typographical Conventions................................................................................................. |

7 |

Definitions............................................................................................................................ |

7 |

QUICK START ................................................................................................................................. |

9 |

Leaving the Software |

10 |

L-ALPHA (2D) PROGRAMMING ..................................................................................................... |

11 |

Step by Step ........................................................................................................................ |

12 |

Clear the Work Zone |

12 |

Punch Adjustment |

13 |

Die Adjustment |

15 |

Choice of Tools |

16 |

General Data |

18 |

Programming Section 1 |

18 |

Programming Section 2 |

19 |

Product Calculation |

21 |

Bending Range (BEND 2D) |

21 |

Position of Axes, other Functions |

23 |

DIRECT PROGRAMMING (BEND NUM) ........................................................................................ |

25 |

Step by Step ........................................................................................................................ |

26 |

Clear the Work Zone |

26 |

General Data |

27 |

Choice of Tools |

28 |

Entering the Data (1) |

28 |

Entering the Data (2) |

30 |

BENDING, TESTS AND CORRECTIONS....................................................................................... |

33 |

12QS23DWIN_EN.DOC |

CONTENTS |

PAGE 1 |

3D PROGRAMMING....................................................................................................................... |

35 |

Creation of the Product....................................................................................................... |

35 |

Step by Step ....................................................................................................................... |

36 |

Clear the Work Zone |

36 |

MEMORIZE OR SEARCH A PRODUCT ........................................................................................ |

43 |

Memorize a Product ........................................................................................................... |

43 |

Search a Product................................................................................................................ |

44 |

Organization of the Memories ............................................................................................ |

48 |

PROTECTION OF THE ACCESS LEVELS .................................................................................... |

49 |

General Information............................................................................................................ |

49 |

The Users ........................................................................................................................... |

50 |

Access by Password .......................................................................................................... |

51 |

Access to Levels superior to 3............................................................................................ |

52 |

Change Password .............................................................................................................. |

53 |

Password forgotten |

54 |

BRIEF OVERVIEW OF THE PAGES.............................................................................................. |

57 |

Menu Page ......................................................................................................................... |

57 |

List of Products Page ......................................................................................................... |

57 |

List of Graphical Products Page......................................................................................... |

58 |

Product / Criteria Search Page........................................................................................... |

58 |

Transfer Page..................................................................................................................... |

58 |

List of Punches Page.......................................................................................................... |

59 |

List of Dies Page................................................................................................................. |

59 |

Punch Programming Page ................................................................................................. |

60 |

Die Programming Page ...................................................................................................... |

60 |

Welcome Page ................................................................................................................... |

61 |

Initialization Page................................................................................................................ |

61 |

Machine Parameters Page ................................................................................................. |

62 |

Product Num Page ............................................................................................................. |

62 |

Tools Position Page............................................................................................................ |

63 |

Comments Page................................................................................................................. |

63 |

Bend Numerical Page......................................................................................................... |

64 |

Bend 2D Page .................................................................................................................... |

64 |

Bend 3D Page .................................................................................................................... |

65 |

Bend Function Page ........................................................................................................... |

65 |

Bend. Tools Page ............................................................................................................... |

66 |

Corrections Page................................................................................................................ |

66 |

INSTALLATION OF THE PC/DNC 1200 SOFTWARE ................................................................... |

67 |

PC Protection key............................................................................................................... |

67 |

Minimum configuration ....................................................................................................... |

69 |

Software support PC 1200 Windows.................................................................................. |

69 |

Software support DNC 1200 Windows............................................................................... |

69 |

Software support DNC 1200 DOS...................................................................................... |

70 |

INSTALLATION OF PC1200 WINDOWS ....................................................................................... |

71 |

INSTALLATION OF PC1200 / PC900 DOS VERSION................................................................... |

73 |

Installation of DNC Windows .............................................................................................. |

74 |

PAGE 2 USER GUIDE PC/DNC 1200 2D&3D

If the keyboard of the DNC doesn't work: |

74 |

Installation of DNC DOS...................................................................................................... |

75 |

If the keyboard of the DNC doesn't work: |

76 |

INDEX .............................................................................................................................................. |

77 |

CONTENTS |

PAGE 3 |

This page has been left blank intentionally.

PAGE 4 USER GUIDE PC/DNC 1200 2D&3D

INTRODUCTION

SAFETY, COPYRIGHT & LICENSE AGREEMENT

Please consult the safety instructions, copyright and license agreement on the first pages of the manual.

DNC WITH WINDOWS OPERATING SYSTEM

The CYBELEC DNCs equipped with Windows have been installed in the factory with a configuration especially realised for the numerical control (see technical information).

This configuration ensures that a minimum of files are present on the DNC, offering in this way a maximum speed to execute the programs. This configuration also ensures that the drivers are correct and that the whole guarantees an optimal functioning of the numerical control.

As Windows is a very open system, it is advised to not modify the Windows installation nor to install other programs. You risk to disturb the functioning of the the numerical control.

If you wish to install a network or a printer, please call a specialist.

Remember that the DNC is equipped with a CD-ROM reader and that it is very easy or even tempting to install external softwares, utilities or games coming from specialized magazines.

CYBELEC accepts no responsibility in case of misfunctioning of the numerical control if other programs have been installed or if the original configuration has been modified.

We also remind you that the Windows environment is infested with virus and utmost caution is to be taken when using data or softwares coming from outside. A regular back-up enables you to get your data in safety.

We certify that our numerical controls are delivered virus free.

INTRODUCTION |

PAGE 5 |

ABOUT THIS MANUAL

This User Guide treats some simple examples, in order to rapidly acquire the programming concept.

The Reference manual furnishes supplementary information to this document.

Remark: In this manual, it is assumed that the DNC has an operational configuration (i.e. machine parameters and tools are programmed).

This manual describes the software version U3 or higher. Some represented figures can possibly not correspond with previous versions.

This manual can evolve, it is you, the operators, who can contribute to help you more. If you have any remarks concerning this manual, please write to us at:

CYBELEC S.A.

Dpt Communication

Rue des Uttins 27

CH-1401 Yverdon-les-Bains

Fax ++ 41 24 447 02 01

E-Mail: info@cybelec.ch

PAGE 6 USER GUIDE PC/DNC 1200 2D&3D

SOFTWARE INSTALLATION

See at the end of this manual, page 67.

TYPOGRAPHICAL CONVENTIONS

Arial bold |

Quotations of text as seen on the screen. |

|||||||||||

Arial bold italic |

Used to indicate the name of a DNC input or |

|||||||||||

|

|

|

|

|

|

output. |

|

|

|

|

||

Italic |

Reference to a written element, a paragraph or a |

|||||||||||

|

|

|

|

|

|

manual. |

|

|

|

|

||

|

|

|

|

|

|

For example: See Typographical Conventions. |

||||||

|

|

|

|

|

|

Indicates a double click on the |

|

|

|

|

|

key. |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|||||

DEFINITIONS

In this manual the following terms are used:

Select |

This term designates a choice operation. |

||||||||||||||||||||||||||||||

|

According to the situation the choice can be |

||||||||||||||||||||||||||||||

|

done in different ways. |

||||||||||||||||||||||||||||||

|

To validate a field, just leave the field or press |

||||||||||||||||||||||||||||||

|

the |

|

|

|

|

(Enter) key. |

|||||||||||||||||||||||||

|

|

|

|

|

|||||||||||||||||||||||||||

|

|

|

|

|

|||||||||||||||||||||||||||

|

|

|

|

||||||||||||||||||||||||||||

|

The word "select" will also be used to reach a |

||||||||||||||||||||||||||||||

|

specific page. |

||||||||||||||||||||||||||||||

Point out |

Position the cursor on the described point. |

||||||||||||||||||||||||||||||

|

Use therefore the cursor keys |

||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

or the tracksensor. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

Mouse/Tracksensor |

Means a mouse for a PC, |

||||||||||||||||||||||||||||||

|

a tracksensor for a DNC. |

||||||||||||||||||||||||||||||

Click |

Press the left tracksensor button. |

||||||||||||||||||||||||||||||

Click right |

Press the right tracksensor button. |

||||||||||||||||||||||||||||||

Click left/right |

Press simultaneously the left and right |

||||||||||||||||||||||||||||||

|

tracksensor buttons. |

||||||||||||||||||||||||||||||

Round robin lists |

or multiple choice fields: |

||||||||||||||||||||||||||||||

|

They are violet coloured and signify that several |

||||||||||||||||||||||||||||||

|

options are available. |

||||||||||||||||||||||||||||||

|

The choice of the content is made by pressing |

||||||||||||||||||||||||||||||

|

|

|

|

key or click right. |

|||||||||||||||||||||||||||

|

the |

|

|

|

|

||||||||||||||||||||||||||

|

|

|

|

|

|||||||||||||||||||||||||||

|

|

|

|

|

|||||||||||||||||||||||||||

|

|

|

|

|

|||||||||||||||||||||||||||

|

|

|

|

|

|||||||||||||||||||||||||||

|

|

|

|

|

|||||||||||||||||||||||||||

|

|

|

|

|

|||||||||||||||||||||||||||

INTRODUCTION |

PAGE 7 |

A window appears with the list of the available choices for this field.

To validate the choice:

- enter the number indicated next to the choice or

- place the cursor on the choice and press the

key.

key.

It is possible, without displaying the choice window, to make appear one after the other the

|

choices by pressing the |

|

|

|

|

|

|

|

|

key. |

|

|

|

|

|

|

|

|

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||

|

To validate, leave the field. |

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||

Menu |

Designates the main menu page which can be |

|||||||||||||||||||||||||||||||

|

reached by pressing the |

|

|

|

|

key. |

|

|

|

|

|

|

|

|

||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||

|

A choice window "Menu |

Menuname" is also |

||||||||||||||||||||||||||||||

|

called when pressing one of the |

|

|

|

|

to |

|

|

|

|

|

|

||||||||||||||||||||

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||

|

|

|

|

|

||||||||||||||||||||||||||||

|

keys. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

Function key |

Each time you are asked to press a function key |

|||||||||||||||||||||||||||||||

|

|

|

|

to |

|

|

|

|

|

|

|

, the corresponding menu |

||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||

|

|

|

|

|

|

|||||||||||||||||||||||||||

|

|

appears. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

Generally the name of the function key is used.

For example: press PIECE designates the

key

.

.

Rapid validation |

To facilitate the operator's work, the DNC |

|

|

|||||||||

|

memorizes the last choice made in a menu. |

|

|

|||||||||

|

To validate a menu option quickly, simply |

|

|

|||||||||

|

double click on a function key (e.g.: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

), |

||

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|||||

|

to validate directly the last page selected. |

|

|

|

||||||||

For more information, see the same paragraph in the Reference Manual.

PAGE 8 USER GUIDE PC/DNC 1200 2D&3D

QUICK START

This chapter describes, by means of some simple examples, diverse ways of using your DNC.

|

L-alpha Programming. |

|

This method is the fastest and the most currently used in the workshop |

|

when the operator has to create himself a product from a paper |

|

drawing. |

|

Direct Programming. |

|

This type of programming is often used for simple products or by |

|

operators having worked on conventional pressbrakes without |

|

numerical controls. |

|

This page is very close to what an operator has to do, since he has on |

|

one single screen all the information and fields necessary for the |

|

programming of his product. |

|

3D Programming. |

|

This type of programming enables the user to visualize the |

|

construction of its product in 3D. This mode also enables more |

|

elaborated constructions and modifications than in 2D mode. |

|

We assume in this part that all the necessary tools have already been |

|

programmed as well as the machine parameters. |

Access levels |

We presume that the operator knows how to reach level 1, or that the key of |

|

the front panel (option) is on position 1. Should this not be the case, see |

|

chapter Protection of the Access Levels further in this manual. |

|

The screens of this manual have been captured with the PC 1200 Windows |

|

software. The screens however are identical in the DNC 1200 2D. |

|

Reminder: |

|

You will find the correspondence between the keys of the DNC and those of |

|

a PC keyboard in the 2D Reference Manual under External keyboard. |

|

These procedures indicate to the operator a programming method |

|

recommended by CYBELEC, enabling to assimilate by the example the |

|

functioning of the software. |

|

For additional information, please consult the 2D Reference Manual and/or |

|

the 3D Reference Manual, which each contains a table of contents and a |

|

detailed index facilitating the search for information. |

QUICK START |

PAGE 9 |

LEAVING THE SOFTWARE

It is possible at any time to quit the task after having memorized the current state. However it is important to leave the software in the correct way by

calling up the MENU page

and pressing the QUIT key.

and pressing the QUIT key.

The same procedure can be used on the PC software, or press the

+

+

keys on any page.

keys on any page.

PAGE 10 USER GUIDE PC/DNC 1200 2D&3D

L-ALPHA (2D) PROGRAMMING

This chapter describes, by means of a concrete example, how to create a product by using the "L-alpha" method (length-angle).

This method is fast and easy and allows to display the product in 2D, which usually is sufficient when products are being programmed in the workshop.

The product being used as an example is composed of 2 sections (profiles), but the procedure is identical for one or several sections.

|

0 |

|

. |

|

0 |

0 |

|

2 |

|

40.0

30.0

45.0

150.0

2 0 . 0

The side flaps with the oblong holes, which are included in section 1, will be made first, so that a punch of identical length as that for section 2 can be used.

To make this product, we will use 2 mm thick ST37 type steel.

L-ALPHA PROGRAMMING |

PAGE 11 |

STEP BY STEP

CLEAR THE WORK ZONE

The user has to clear the work memory before creating a new product.

Call the PRODUCT NUMERICAL page, which enables the data introduction in L-Alpha mode.

Press the PRODUCT

function key.

function key.

Select PRODUCT NUMERICAL. For that, enter the number

indicated next to the choice  key

key

or place the cursor on the choice and press

or click on the choice.

or click on the choice.

The figure below shows the PRODUCT NUMERICAL page containing a previous product.

Clear the work zone to create a new product

PAGE 12 USER GUIDE PC/DNC 1200 2D&3D

Press the ACTION

key.

key.

Select ERASE PRODUCT. For that, enter the number indicated next

to the choice  key

key

or place the cursor on the choice and press

or click on the choice, and then CONFIRM ( |

|

|

|

|

|

). |

|

|

This operation erases only the data of the work memory. That means that the product which is possibly located in the work memory is not lost if it has been saved beforehand.

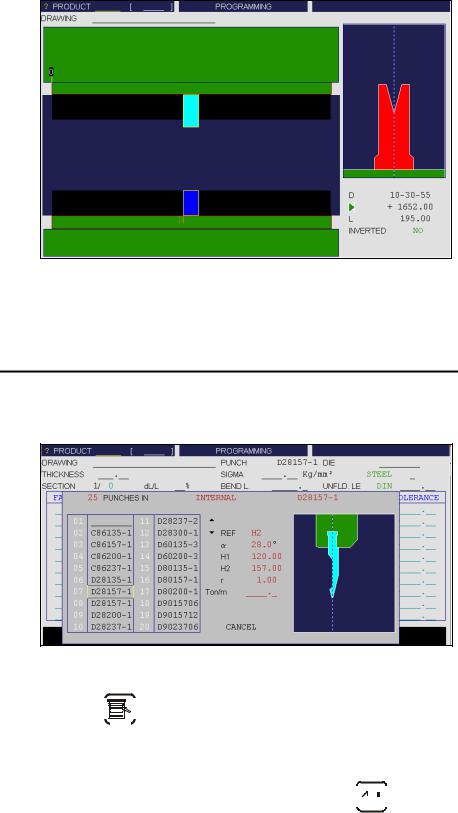

PUNCH ADJUSTMENT

Punch adjustment

Window without any tools selection

This chapter as well as the following Die Adjustment are optional when programming in 2D mode.

It is interesting to look them over, for the TOOLS POSITION page enables to define several places of work and hence to the operator to visualize the tools assembly.

If the tools assembly is not important, skip these two chapters.

The tools definition will be made directly in the PRODUCT NUMERICAL page (page in which you still are at this stage of the procedure).

Call the TOOLS POSITION page by pressing the PRODUCT function key and select TOOLS POSITION.

Selection field : P or D

Field L (total available length)

L-ALPHA PROGRAMMING |

PAGE 13 |

Check that a punch or / and the letter P are displayed in the right-hand window (selection field).

If there is a die or the letter D, change it using the

key.

key.

Place the cursor on the P field and press the |

|

|

|

|

|

key to open the |

|

|

|||||

punch LIST OF CHOICES menu. |

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Select the required punch by entering the number indicated next to the choice with a two-digit number. Example: 01 for 1, 02 for 2, etc… or

Place the cursor on the choice and validate with the

key or

key or

Click on the requested choice.

Modify the  field by introducing a value equal to the half of field L minus the half of the tool length, which corresponds to the central point of the machine on which the punch is fixed. (In our example: 3500/2 – 195/2 = 1652.5 mm).

field by introducing a value equal to the half of field L minus the half of the tool length, which corresponds to the central point of the machine on which the punch is fixed. (In our example: 3500/2 – 195/2 = 1652.5 mm).

Modifiy the L field by introducing the value of 195 mm which corresponds to the required tool length. In the front view the selected tool appears in dark blue.

Punch adjustment

Punch placed in the middle of the machine

PAGE 14 USER GUIDE PC/DNC 1200 2D&3D

DIE ADJUSTMENT

Die adjustment

Window with punch selection but without die

Same remark as for Punch Adjustment.

Selection field : D |

Stay on TOOLS POSITION page.

Select the die using the

key.

key.

Place the cursor on the D field and press the |

|

|

|

|

|

key to open the |

|

|

|

|

|

||

|

|

|

|

|||

|

|

|

|

|

||

|

|

|

|

|

||

|

|

|

|

|

||

die choice menu. |

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Select the required die by entering the number indicated next to the choice with a two-digit number. Example: 01 for 1, 02 for 2, etc… or

Place the cursor on the choice and validate with the

key or

key or

Click on the requested choice.

Modify the  field by introducing a value equal to the half of field L minus the half of the tool length, which corresponds to the central point of the machine on which the die is fixed. (In our example: 3500/2 – 195/2 = 1652.5 mm).

field by introducing a value equal to the half of field L minus the half of the tool length, which corresponds to the central point of the machine on which the die is fixed. (In our example: 3500/2 – 195/2 = 1652.5 mm).

Modify the L field by introducing the value of 195 mm which corresponds to the required tool length.

L-ALPHA PROGRAMMING |

PAGE 15 |

Die adjustment

Final mounting of the tools

Window with selection of the punch and the die

Return to the PRODUCT NUMERICAL page via the PRODUCT menu.

CHOICE OF TOOLS

As mentioned above, if the tools position is not indispensable, you can define the tools directly in the PRODUCT NUMERICAL page.

Choice of tools

Cursor on PUNCH field (upper part of the screen)*.

Key |

|

|

|

|

|

or right click to display the LIST OF CHOICES. |

|

|

Select the desired tool by by entering the number indicated next to the choice with a two-digit number. Example: 01 for 1, 02 for 2, etc… or

Place the cursor on the choice and validate with the

key or

key or

Click on the desired choice.

PAGE 16 USER GUIDE PC/DNC 1200 2D&3D

Remark: Each window contains 20 tools. It is possible to reach the

next or previous 20 tools by using respectively the

or

or

keys.

keys.

Each database (punchs and dies) is limited to 200 tools.

You can also call the end of the list by introducing the value 999 or recall the begin of the list by introducing 001.

Proceed in the same way for the DIE.

Remark: It is possible to make the same choice, and in the same way, in the TOOLS BEND page (via the BEND menu). This enables to see the tools profile, along with their main characteristics.

* The PUNCH and DIE fields in the upper part of the screen designate the general tool for the calculation of the product. If a product is being programmed via the PRODUCT NUMERICAL page, it is mandatory to enter these two items.

The PUNCH and DIE columns in the table allow to specify a different tool for a given bend.

In the BEND NUMERICAL page, there are also a PUNCH and a DIE field. If the product has been programmed via the PRODUCT NUMERICAL page, these fields will be empty or partially filled if tools have been entered in the corresponding columns of the table of the PRODUCT NUMERICAL page. This is so because these fields correspond to the ones in the table. (Also see the section Direct Programming (BEND NUM) further in this manual).

L-ALPHA PROGRAMMING |

PAGE 17 |

GENERAL DATA

Enter:

-the punch

-the die

-the sigma/material

-the type of material

-the bending length

Place the cursor on the THICKNESS field and enter the thickness of the material being used.

Place the cursor on the SIGMA field and introduce the force/mm² of the material used. (E.g.: Steel = 37 Kg/mm²)

Leave the round-robin list on STEEL.

Place the cursor on the BEND L. field and introduce the bending length for the product (section 1 = 150.0 mm).

PROGRAMMING SECTION 1

The dimensions of the faces are given in external cotation according to DIN.

See 2D Reference Manual, section Unfolded length.

|

45.0 |

|

45.0 |

45.0 |

90.0° |

200.0 |

90.0° |

|

|||

|

|

200.0 |

|

When introducing the data in L-Alpha mode, just "begin" the profile by one of the extremities and furnish one after the other the values of each face and angle. At the last face there is no angle corresponding to.

45.0 |

|

45.0 |

90.0° |

200.0 |

90.0° |

Remark: As shown in the following figure, the profile of section 1 is automatically drawn as a function of the introduced data (length and angle), thus the value of the internal radius is automatically calculated.

PAGE 18 USER GUIDE PC/DNC 1200 2D&3D

Loading...

Loading...