cybelec DNC 600S Data Sheet

Numerical Control |

DNC 600S |

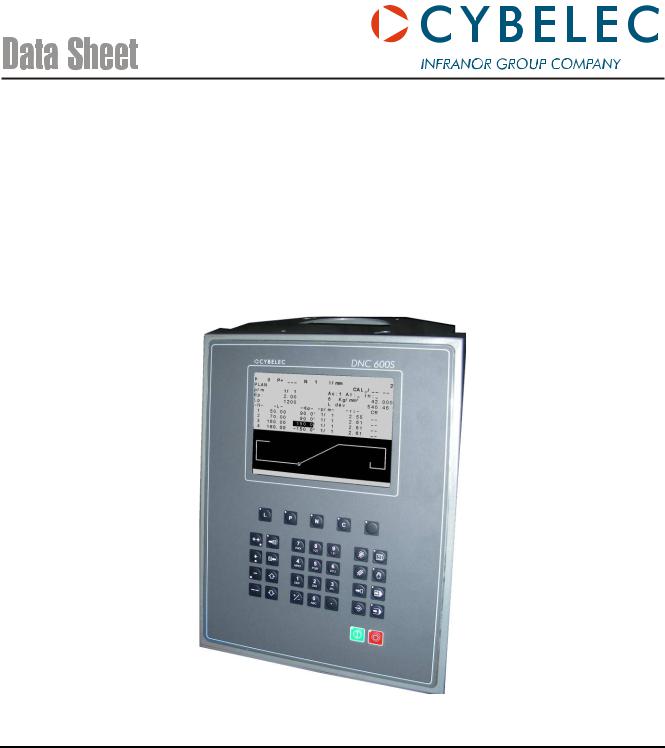

The DNC 600S numerical control with 2D graphic display is specifically designed for sheet metal working. Depending on the software installed, it can be used for synchronized or non-synchronized press-brakes, of up-stroking or down-stroking type (see list of versions below).

The standard version of the DNC 600S numerical control can control up to 4 axes, of which two are synchronized hydraulic axes, specifically designed for press-brakes. The large monochrome screen and a simplified keyboard with large keys make the DNC easy to program.

The software allows the machine manufacturer to configure axes, inputs/outputs, and auxiliary functions according to their needs.

Versions

DNC 600S |

PS, PSS |

Numerical control for synchronized press-brakes. Configurable from version PS, the version |

||

|

|

PSS is designed for single-cylinder presses. |

|

|

|

|

Max. configuration: Y1-Y2, X, R, or other combinations (max. 2 motor axes). |

|

|

|

|

Pressure and crowning control as standard |

|

|

DNC 600S |

PC |

Like the DNC 600 PS, but for press-brakes with mechanical (or hydraulic) stops and beam |

|

|

|

|

control by means of a linear encoder. Max. 3 motor axes. |

|

|

|

|

Max. configuration: Y0-Y, X, R, or other combinations (max. 3 motor axes). |

|

|

|

|

Pressure and crowning control as standard |

|

|

DNC 600S |

P |

Like the DNC 600 PC, but without linear encoder beam control |

|

|

|

|

Max. configuration: Y, X, R, or other combinations (max. 3 motor axes). |

|

|

|

|

Pressure and crowning control as standard |

|

|

600S_E.DOC |

C-PUB-CDS600S-EN |

V1.1 |

10.11.2008 |

|

Order information

DNC 600S Panel S-DNC 604S-PS/P

DNC 600S Box S-DNC 604S-PS/B (including handle)

Axes and auxiliary functions for press-brakes

All features listed here are supported and can be configured in the standard software supplied with all numerical controls.

The number of features that can be installed on a machine depends on the number of axes and inputs/outputs available in its hardware.

Y1 – Y2 |

Synchronized axes for the beam (servo-valves, proportional valves). |

|

Should current output be needed, this would require the MSV 400 accessory, an external amplifier |

|

to be mounted inside the electrical cabinet (see data sheet of MSV 400). |

Yo – Y |

Press with mechanical stop: Yo = beam position measurement. |

|

Y = management of the depth stop. |

X, X1, X2 |

Main backgauge axes. |

X1 ABS, X2 REL |

Secondary gauge axes in absolute or relative mode. |

R, R2 |

Backgauge height adjustment axes. |

Pressure |

Voltage output (0-10VDC) for pressure valve control. |

Crowning |

Voltage output (0-10VDC) for adjustment of hydraulic crowning. |

|

Should current output be needed, CYBELEC recommends the MVP 100 accessory, an external |

|

amplifier to be mounted inside the electrical cabinet. |

F1 to F5 |

Configurable auxiliary functions (possibly, the number of AFs may be limited, depending on the |

|

type of function and management). Voltage output (0-10VDC) or 24VDC digital outputs, with or |

|

without position control by means of a potentiometrical position transducer. |

|

Special controls for gauge fingers, bending aids, die movement. |

Languages |

Choice of 3 languages for the operator |

|

The machine manufacturer may install a combination of up to 3 languages picked from the list |

|

below: |

|

French, German, English, Chinese, Italian, Danish, Swedish, Finnish, Norwegian, |

|

Portuguese, Dutch, Spanish, Czech, Polish, Russian, Slovenian, Serbian, Turkish |

600S_E.DOC |

V1.1 |

Modification rights reserved |

Loading...

Loading...