Craftsman 486.248373 Owner's Manual

Operator's Manual

®

42"- 2 STAGE SNOW THROWER TRACTOR ATTACHMENT

STOP

DO NOT RETURN TO STORE For Missing Parts or Assembly Questions Call 1-866-576-8388

Model No. 486.248373

FITS SERIES 917 CRAFTSMAN TRACTORS AND HUSQVARNA TRACTORS.

CAUTION:

Before using this product, read this manual and follow all Safety

Rules and Operating Instructions.

Want more information or assembly tips? Scan for Video Instruction Guide.

•Safety

•Assembly

•Operation

•Maintenance

•Parts

Sears Brands Management Corporation, Hoffman Estates, IL 60179 U.S.A. www.craftsman.com

PRINTED IN U.S.A. |

FORM NO. 42975 (9/12/14) |

TABLE OF CONTENTS

ACCESSORIES............................................................... |

2 |

SAFETY RULES.............................................................. |

3 |

FULL SIZE HARDWARE CHART.................................... |

4 |

CARTON CONTENTS..................................................... |

6 |

ASSEMBLY...................................................................... |

7 |

OPERATION.................................................................. |

26 |

MAINTENANCE............................................................. |

27 |

SERVICE AND ADJUSTMENTS................................... |

28 |

STORAGE...................................................................... |

29 |

TROUBLESHOOTING................................................... |

29 |

REPAIR PARTS ILLUSTRATION........................ |

30,32,34 |

REPAIR PARTS LIST........................................... |

31,33,34 |

SLOPE GUIDE............................................................... |

35 |

PARTS ORDERING/SERVICE.................... |

BACK COVER |

WARRANTY

ONE YEAR FULL WARRANTY

When operated and maintained according to the instructions supplied with it, if this Snow Thrower fails due to a defect in material or workmanship within one year from the date of purchase, call 1-888-331-4569 to arrange for free repair (or replacement if repair proves impossible).

If this product is used for commercial or rental purposes, this warranty applies for only 90 days from the date of purchase.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

Sears, Roebuck and Co., D817WA, Hoffman Estates, IL 60179

ACCESSORIES AND ATTACHMENTS

These and other accessories are recommended for use with your unit. Call 1-888-331-4569 to find out if they are available. If available, they may be purchased at most Craftsman outlets or by calling 1-888-331-4569.

WHEEL WEIGHT |

TIRE CHAINS |

SNOW CAB |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The model number and serial numbers will be found on a |

MODEL NUMBER: |

486.248373 |

|

decal attached to the snow thrower. |

SERIAL NUMBER: |

__________________ |

|

|

|||

You should record both the serial number and the date of |

DATE OF PURCHASE: |

__________________ |

|

purchase and keep in a safe place for future reference. |

|||

|

|

||

|

|

|

2

SAFETY

184045 |

Read and understand the operating instructions before using.

Keep the area of operation clear of all persons, especially small children and pets.

Thoroughly inspect the area to be cleared and remove all door mats, sleds, boards, wires and other foreign objects. Use extreme caution when operating on or crossing gravel surfaces. Never direct discharge at bystanders or allow anyone in front of the snow thrower.

199682 |

Do not place hands near rotating parts. Keep clear of the discharge opening at all times.

•Never allow children to operate the equipment.

•Never allow adults to operate the equipment without proper instruction.

•Disengage all clutches and shift into neutral before starting engine.

•Do not operate equipment without wearing adequate winter outer garments.

•Wear substantial footwear which will protect feet and improve footing on slippery surfaces.

•Check fuel before starting the engine. Do not remove the fuel cap or fill the fuel tank while the engine

is running or hot. Do not fill the fuel tank indoors. Gasoline is an extremely flammable fuel.

•Make sure the snow thrower height is adjusted to clear the type surface it will be used on.

•Do not use the snow thrower without wheel weights attached to the tractor.

•Never make any adjustments while the engine is running.

•Always wear safety glasses or eye shield during operation or while performing adjustment or repair.

•Do not place hands or feet near rotating parts. Keep clear of the discharge opening at all times.

•Do not carry passengers.

•After striking a foreign object, stop the engine, remove the wire from the spark plug and then thoroughly inspect the snow thrower for damage. Repair any damage before restarting and operating the snow thrower.

•If the snow thrower starts to vibrate abnormally, stop the engine immediately and check for the cause.

Vibration is generally a warning of trouble.

•Stop the engine whenever you leave the operating position, before unclogging the snow thrower or making any adjustments or inspections.

199683 |

Do not place feet near rotating parts.

•Take all possible precautions when leaving the unit unattended. Disengage the attachment clutch lever or switch, lower the snow thrower, shift into neutral, set the parking brake, stop the engine and remove the key.

•When cleaning, repairing or inspecting, make certain all moving parts have stopped. Disconnect the spark plug wire and keep it away from the plug to prevent accidental starting.

•Do not run engine indoors except when transporting the snow thrower in or out of the building. Open the outside doors. Exhaust fumes are dangerous.

•Do not clear snow across the face of slopes. Exercise extreme caution when changing direction on slopes.

Do not attempt to clear steep slopes. Refer to the slope guide on page 35 of this manual.

•Never operate the snow thrower without guards, plates or other safety protection devices in place.

•Never operate the snow thrower near glass enclosures, automobiles, window wells, drop offs etc. without proper adjustment of the snow thrower discharge angle.

•Never run the snow thrower into snow at high speeds.

•Do not overload the snow thrower capacity by attempting to clear snow at too fast a rate.

•Never operate the snow thrower at high transport speed on slippery surfaces. Look behind and use care when backing up.

•Watch for traffic and stay alert when crossing or operating near roadways.

•Disengage power to the snow thrower when transporting or when not in use.

•Use only attachments and accessories approved by the manufacturer of the snow thrower (such as wheel weights, counter weights, cabs etc.)

•Never operate the snow thrower without good visibility.

3

HARDWARE PACKAGE CONTENTS

SHOWN ACTUAL SIZE

A |

B |

C |

D |

E |

F |

|

|

|

43182 |

|

|

|

|

43063 |

|

43661 |

48106 |

|

|

|

|

43084

|

|

G |

H |

I |

J |

K |

L |

46938 |

|

49933 |

|

43350 |

|

|

44326 |

|

|

|

|

|

|||

|

|

|

|

|

|

43682 |

|

|

|

42849 |

|

|

|

|

|

|

|

|

|

|

44215 |

|

|

|

|

|

|

|

|

P |

Q |

|

|

|

|

|

|

|

|

|

M |

N |

|

O |

|

|

|

|

|

|

|

|

|

||

|

43080 |

|

|

|

|

|

|

|

|

|

|

47630 |

43088 |

43081 |

|

|

|

47631 |

|

|

|

|

|

|

T |

|

R,S |

U |

V |

|

||

|

|

|

|

|

44695 |

43003 |

47605, 43070 |

|

|

|

|

|

|

|

|

|

|

R19172410 |

|

|

|

W |

X |

Y |

Z |

AA |

43082 |

47810 |

47572 |

46584 |

47598 |

|

4

NOT SHOWN ACTUAL SIZE

|

BB |

CC |

DD |

EE |

46959 |

27809 |

27810 |

|

42848 |

|

FF |

HH |

|

II |

|

GG |

|

|

|

HA3090 |

43343 |

43055 |

|

43038 |

|

|

KK |

|

|

JJ |

|

LL |

|

MM |

|

|

|

||

|

|

|

|

|

23727 |

46963 |

47788 |

|

726-0178 |

IMPORTANT: Not all items supplied in the hardware bag will be needed for your particular tractor. Unneeded items may be discarded after you have completed assembly and checked operation of unit. DO NOT DISCARD the two spare shear bolts (H) and 5/16" nylock nuts (X). Refer to the Service and Adjustments section on page 28.

REF. |

QTY. |

DESCRIPTION |

REF. |

QTY. |

DESCRIPTION |

A |

1 |

Hex Bolt, 3/8" x 3-1/4" |

U |

2 |

Bowed Washer |

B |

2 |

Hex Bolt, 5/16" x 1-3/4" |

V |

7 |

Lock Washer, 3/8" |

C |

4 |

Hex Bolt, 5/16" x 1" |

W |

2 |

Hex Lock Nut, 3/8" |

D |

4 |

Hex Bolt, 5/16" x 3/4" |

X |

22 |

Nylock Nut, 5/16" (2 spare parts) |

E |

6 |

Hex Bolt, 1/4" x 1" |

Y |

10 |

Flanged Nut, 3/8" |

F |

4 |

Shoulder Bolt, Hex Head |

Z |

1 |

Flanged Nut, 5/16" |

G |

2 |

Shoulder Bolt, Round Head |

AA |

6 |

Flanged Nut, 1/4" |

H |

2 |

Shear Bolt (spare parts) |

BB |

1 |

Spring |

I |

6 |

Carriage Bolt, 3/8" x 1" |

CC |

3 |

Chute Keeper |

J |

2 |

Carriage Bolt, 5/16" x 1-3/4" |

DD |

3 |

Chute Spacer |

K |

2 |

Carriage Bolt , 5/16" x 1-1/4" |

EE |

1 |

Trunnion |

L |

4 |

Carriage Bolt, 5/16" x 1" |

FF |

2 |

Hairpin Cotter, 5/64" |

M |

2 |

Carriage Bolt, 5/16" x 3/4" |

GG |

4 |

Hairpin Cotter, 1/8" |

N |

6 |

Hex Bolt, 3/8" x 1" (Thread Forming) |

HH |

1 |

Hairpin Cotter, 3/32" |

O |

2 |

Hex Bolt, 5/16" x 3/4" (Thread Forming) |

II |

2 |

Lock Pin |

P |

7 |

Washer, 1/4" |

JJ |

1 |

Spacer, 3/8" |

Q |

22 |

Washer, 5/16" (Extra washers included) |

KK |

2 |

Chain, Tensioning |

R |

1 |

Washer, 3/8" (Thin) |

LL |

2 |

Tail Reflector |

S |

3 |

Washer, 3/8" Standard |

MM |

2 |

Nylon Tie |

T |

8 |

Washer, 1/2" x 1-1/2" |

|

|

|

5

CARTON CONTENTS

1. |

Housing Assembly |

13. |

V-Belt, Drive 56" (#48138) |

2. |

Lift Handle and Cable |

14. |

V-Belt, Drive 55" (#46989) |

3. |

Chute Crank Rod Assembly |

15. |

V-Belt, Auger (Attached to Housing Assembly) |

4. |

Support Tube, Crank Rod |

16. |

L.H. Hanger Bracket (Outside Mounting) |

5. |

Engagement Rod (Not used on some models) |

17. |

R.H. Hanger Bracket (Outside Mounting) |

6. |

Cable Bracket |

18. |

L.H. Hanger Bracket (Inside Mounting) |

7. |

Engine Pulley Keeper (Not used on some models) |

19. |

R.H. Hanger Bracket (Inside Mounting) |

8. |

Chute and Control Cable Assembly |

20. |

Left Hand Side Plate |

9. |

Clutch Idler Assembly |

21. |

Right Hand Side Plate |

10. |

Rear Pulley Frame Bracket (2) |

22. |

Pulley |

11. |

Anti-rotation Bracket. |

23. |

Spacer, 3/8" |

12.Front Pulley Frame Bracket (2)

|

1 |

|

|

3 |

|

4 |

5 |

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

46948 |

|

|

|

|

2 |

|

6 |

7 |

|

|

|

|

|

|

||

|

|

10 |

|

11 |

|

24558 |

47043 |

|

|

|

|

|

|

||

|

9 |

|

|

|

|

14 |

|

|

|

|

|

27509 |

|

|

|

8 |

|

|

|

|

13 |

|

46989 |

|

|

|

|

|

|

||

|

|

25728 |

12 |

|

|

15 |

|

|

|

|

|

|

|

48138 |

|

|

|

|

|

|

|

|

|

|

|

|

27016 |

|

42992 |

||

|

|

|

|

|

|

||

|

16 |

17 |

18 |

|

19 |

|

|

65367 |

65450 |

64451 |

64452 |

|

|

|

|

|

|

20 |

|

|

21 |

22 |

23 |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

25679 |

|

25678 |

|

|

48883 |

25780 |

|

6

ASSEMBLY

TOOLS REQUIRED FOR ASSEMBLY

(2) 7/16" Wrenches

(2) 1/2" Wrenches

(2) 9/16" Wrenches

(2) 3/4" Wrenches

(1) Screw Driver

(1) Knife

ADDITIONAL ITEMS REQUIRED

General Purpose Grease

REMOVAL OF PARTS FROM CARTON

•Remove all loose parts, parts bags and hardware bags from the carton. Lay out and identify parts and hardware using the illustrations on pages 4, 5 and 6.

IMPORTANT: Not all items supplied in the hardware bag will be needed for your particular tractor. Unneeded items may be discarded after you have completed assembly and checked operation of unit. DO NOT DISCARD the two spare shear bolts and 5/16" nylock nuts. Refer to the Service and Adjustments section on page 28.

CAUTION: Before starting to assemblethe snowthrower,removethesparkplugwire(s), set the parking brake and remove the key from the tractor ignition.

TRACTOR PREPARATION

Before performing these instructions, refer to the Service and Adjustments section of your tractor owner's manual for specific safety instructions.

•Allow engine, muffler and exhaust deflector to cool before beginning.

•Remove any front or rear attachment which is mounted to your tractor.

•Remove the mower deck. Refer to your tractor owner's manual for removal instructions. Mark all loose parts and save for reassembly.

•Remove the tractor hood. Refer to your tractor owner's manual for removal instructions.

IMPORTANT: Right hand (R.H.) and left hand (L.H.) side of the tractor are determined from the operators position while seated on the tractor.

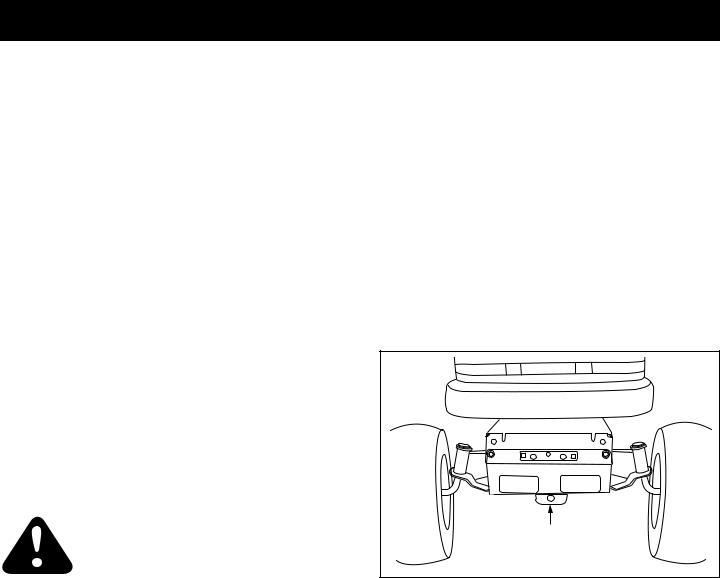

IDENTIFYYOUR TRACTOR

STEP 1: (SEE FIGURE 1)

•Locate the front mower deck suspension bracket(s).

A. If there is a single mower deck suspension bracket located underneath the middle of the front axle, continue on to step 2 on the next page.

OR

B. If your tractor does not have a mower deck suspension bracket underneath the middle of the front axle, skip to step 21 on page 14 for instructions for tractors with dual side mounted mower deck suspension brackets.

MOWER DECK

SUSPENSION

BRACKET

FIGURE 1

7

INSTRUCTIONS FOR TRACTORS WITH A SINGLE FRONT DECK SUSPENSION BRACKET

STEP 2: (SEE FIGURE 2)

•Remove the browning shield from the front of the tractor as shown. Hold onto the shield as you remove the second screw to prevent it from falling.

•Be sure to reinstall the browning shield when so instructed in step 3.

|

REMOVE |

|

FRONT SCREWS |

|

REMOVE |

|

BROWNING SHIELD |

FIGURE 2 |

RIGHT SIDE VIEW |

INSTALL SIDE PLATES

STEP 3: (SEE FIGURE 3)

•Fasten the R.H. Side Plate (bend facing out) to the front three holes in the tractor frame using three 3/8" x 1" carriage bolts, three 1/2" x 1-1/2" washers (see note) and three 3/8" flange nuts. For the rear hole, use a 5/16" x 1" carriage bolt, a 1/2" x 1-1/2" washer and a 5/16" nylock nut Place the washers between the tractor frame and the side plate. Repeat for L.H. side plate.

•Reinstall the browning shield onto the tractor frame using the original screws.

NOTE: If there is an engine mounting plate (shown with dotted lines) leave the washer off the bolt that goes through the plate.

5/16" x 1" |

ENGINE MOUNTING |

|

CARRIAGE BOLT |

||

PLATE |

||

|

||

|

SEE NOTE |

|

5/16" |

|

|

NYLOCK |

|

|

NUT |

|

|

|

(3) 3/8" x 1" |

|

|

CARRIAGE |

|

|

BOLTS |

|

|

(4) 1/2" x 1-1/2" WASHERS |

|

|

(3) 3/8" FLANGE NUTS |

|

FIGURE 3 |

RIGHT SIDE VIEW |

STEP 4: (SEE FIGURE 4)

•Assemble a shoulder bolt and a 3/8" washer to the outside of R.H. side plate, securing it with a 3/8" flanged nut. Repeat for L.H. side plate.

SHOULDER |

|

|

BOLT |

|

|

|

3/8" WASHER |

3/8" FLANGED |

|

|

|

|

|

NUT |

FIGURE 4 |

|

RIGHT SIDE VIEW |

8

INSTALL HANGER BRACKETS AND SHOULDER BOLTS TO OUTSIDE OF FRAME

STEP 5: (SEE FIGURE 5)

•Remove the bolt, if present, in the hole directly behind the brake rod on the left side of the tractor frame.

•Attach the L.H. Hanger Bracket (tube facing out) to the hole using a 5/16" x 3/4" self threading bolt.

•Install a round head shoulder bolt into the hole that is 9-1/2" to the rear of the bolt you just installed. Secure it with a 3/8" flange nut on the inside of the frame.

|

BRAKE ROD |

|

|

|

5/16" x 3/4" SELF |

|

|

THREADING BOLT |

|

L.H. HANGER |

SHOULDER |

|

BRACKET |

|

|

BOLT |

|

|

|

|

|

|

3/8" FLANGED |

|

|

NUT |

FIGURE 5 |

|

LEFT SIDE VIEW |

STEP 6: (SEE FIGURE 6)

•Remove the bracket, if present, from the hole directly behind the end of the brake rod on the right side of the tractor frame. Store the bracket and bolt.

•Attach the R.H. Hanger Bracket to the hole using a 5/16" x 3/4" self threading bolt.

•Install a round head shoulder bolt into the hole that is 9-1/2" to the rear of the bolt you just installed. Secure it with a 3/8" flange nut on the inside of the frame.

|

5/16" x 3/4" SELF |

|

|

THREADING BOLT |

RIGHT END OF |

|

|

|

|

R.H. HANGER |

BRAKE ROD |

|

|

|

|

BRACKET |

|

SHOULDER |

|

|

BOLT |

|

|

|

3/8" FLANGED |

|

|

NUT |

|

FIGURE 6 |

RIGHT SIDE VIEW |

|

9

THIS SECTION IS FOR TRACTORS WITH A MANUAL ATTACHMENT CLUTCH

If your tractor has an electric attachment clutch go to step 14 on page 12.

STEP 7: (SEE FIGURE 7)

•Attach the cable bracket to the double hole in the clutch/idler assembly as shown, using a 5/16" x 3/4" carriage bolt and a 5/16" nylock nut. Place the bolt in the front hole of the bracket and in the end of the hole closest to the pulley. Do not tighten yet.

5/16" x 3/4" |

CARRIAGE BOLT |

CABLE |

BRACKET |

5/16" NYLOCK |

NUT |

FIGURE 7

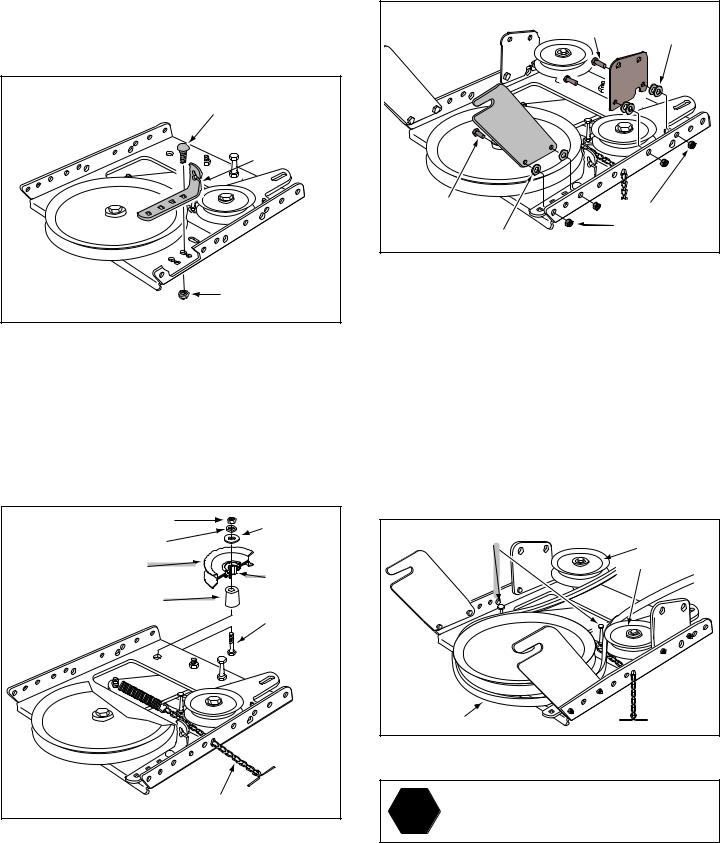

STEP 8: (SEE FIGURE 8)

•Attach the pulley (long end of hub facing down) and the 3/8" spacer to the clutch/idler assembly. Use

a 3/8" x 3-1/4" hex bolt, a 3/8" washer, a 3/8" lock washer and a 3/8" hex lock nut.

•Insert a tensioning chain through the hole shown and attach the end link to the spring on the lower idler arm.

3/8" HEX LOCK NUT |

3/8" |

3/8" LOCKWASHER |

WASHER |

|

|

PULLEY |

LONG END |

|

|

3/8" SPACER |

OF HUB |

|

|

|

3/8" x 3-1/4" |

|

HEX BOLT |

TENSIONING CHAIN |

|

FIGURE 8

STEP 9: (SEE FIGURE 9)

•Attach each rear pulley frame bracket to the inside of the clutch/idler assembly using two 5/16" x 3/4" hex bolts, 5/16" washers and 5/16" nylock nuts.

•Attach each front pulley frame bracket to the inside of the clutch/idler assembly using two 5/16" x 1" hex bolts, four 5/16" washers and two 5/16" nylock nuts.

5/16" x 1" |

(2) 5/16" |

|

HEX BOLT |

||

WASHERS |

||

|

5/16" x 3/4" |

5/16" |

|

HEX BOLT |

||

NYLOCK |

||

|

5/16" WASHER NUT

FIGURE 9

STEP 10: (SEE FIGURE 10)

•Two different length drive belts are included with your snow thrower. Tractors with manual attachment

clutches and single front deck suspension brackets use the 56" drive belt with #48138 printed on the outside of the belt. DO NOT USE the other drive belts.

•Slightly loosen the hex bolt next to the flat idler pulley. Install the drive belt down between the hex bolt and the flat idler pulley with the flat side of the belt against the pulley. Retighten the hex bolt.

•Loop the belt around the large v-pulley, placing it between the v-pulley and the hex bolt next to the pulley. Place the belt to the inside of the other flat idler pulley.

HEX BOLTS |

FLAT IDLER |

|

|

|

PULLEYS |

(#48138) |

|

DRIVE BELT |

|

FIGURE 10

Did you select the correct drive belt for your STOP tractor? Using the wrong length belt may

cause premature bearing or belt failure.

10

STEP 11: (SEE FIGURE 11)

•Find the cable clip that is attached to the left side of the tractor frame underneath the footrest. Open the clip and remove the mower clutch cable. Do not remove the clip from the tractor frame.The cable reattaches to the clip when using the mower deck.

•Move the attachment clutch lever on the dash panel to the disengaged position.

•Place the clutch/idler assembly on the floor on the left side of the tractor.

•Attach the tractor's mower clutch cable to the cable bracket on the clutch/idler assembly. Secure the cable housing guide (groove down) to the cable bracket using the original collar and a 5/64" hair cotter pin.

•Place a 1/4" spacer on the welded pin on the idler arm. Hook the end of the clutch cable spring over the pin and secure it with a 1/4" washer and a 5/64" hair cotter pin.

•Align cable bracket with welded pin and tighten the nut assembled in step 9.

5/64" HAIR |

COTTER PIN |

1/4" WASHER |

1/4" SPACER |

5/64" HAIR |

COTTER PIN |

TRACTOR'S |

CLUTCH CABLE |

CABLE |

BRACKET |

FIGURE 11

ATTACH CLUTCH IDLER ASSEMBLY TO TRACTOR

STEP 12: (SEE FIGURE 12)

•Attach the clutch/idler assembly to the tractor frame. Hook the notched rear pulley frame brackets onto the two shoulder bolts assembled to the outside of the tractor frame. Lift the front of the assembly and attach it to the R.H. and L.H. hanger brackets using two pivot lock pins and 1/8" hairpin cotters.

•Loosely attach the mower clutch cable to the left side of the tractor frame with a nylon tie. Do not pull the nylon tie completely tight.The cable may need to be removed from the nylon tie when using the mower deck.

PIVOT LOCK PIN |

1/8" HAIRPIN |

NYLON TIE |

|

(use this hole) |

COTTER |

|

|

L.H. HANGER |

SHOULDER |

||

BRACKET |

|

BOLT |

|

|

MOWER |

|

|

|

CLUTCH |

|

|

|

CABLE |

|

|

FIGURE 12 |

VIEWED FROM LEFT SIDE |

||

STEP 13: (SEE FIGURE 13)

•Assemble the drive belt onto the engine pulley first and then onto the large pulley on top of the clutch/ idler assembly.The belt must be placed inside the engine pulley belt keeper(s) and between the large pulley and the keeper bolt next to it.

IMPORTANT: Do Not assemble the "V" belt outside of the engine pulley keepers or outside of the keeper bolt next to the large pulley.

•Go to step 48 on page 22.

ENGINE |

ENGINE |

PULLEY |

PULLEY |

KEEPER |

KEEPER |

|

Left Side |

|

of Tractor |

IDLER |

|

PULLEY |

KEEPER BOLT |

|

|

FIGURE 13 |

VIEWED FROM UNDERNEATH |

11

Loading...

Loading...