CEMB USA N500 User Manual

N500 rev. 3.1 |

|

|

|

|

Contents |

|||||

Chapter 1 - |

General description |

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|||

|

¾ |

Standard accessories |

……………………………… |

1 |

- 1 |

|

||||

|

¾ |

Optional accessories |

……………………………… |

1 |

- 2 |

|

||||

|

¾ |

Connections |

……………………………………… |

1 |

- 2 |

|

||||

|

¾ |

Battery ……………………………………………... |

1 |

- 3 |

|

|||||

|

¾ |

General advice |

……………………………………… |

1 |

- 4 |

|

||||

Chapter 2 - |

|

General layout |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

¾ |

Keys/buttons on the control panel ………...…...……... |

2 |

- 1 |

|

|||||

|

¾ |

General purpose functions |

…………….…..…… |

2 |

- 4 |

|

||||

|

|

|

- Functions associated with measuring phase………. |

2 |

- 4 |

|

||||

|

|

|

- Function "Other functions …" |

………….…... |

2 |

- 5 |

|

|||

|

|

|

- Functions operating on graphs |

………….…... |

2 - 5 |

|

||||

|

|

|

- To save measurements |

……………………... |

2 |

- 9 |

|

|||

|

|

|

- To capture and save displayed images ………….… |

2 |

- 10 |

|||||

Chapter 3 - Home screen (menu) |

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

||

Chapter 4 - Setup mode |

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|||

|

¾ |

Sensor setup |

…………………………………..…. |

4 |

- 1 |

|

||||

|

¾ |

General setup |

………………………………..……. |

4 |

- 3 |

|

||||

Chapter 5 - Vibrometer mode |

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

||||

|

¾ |

Vibrometer setup ……………………………….….…. |

5 |

- 1 |

|

|||||

|

¾ Vibrometer – Measurement screen…………………….. |

5 |

- 3 |

|

||||||

|

¾ |

Monitoring in time |

|

.……………………….……. |

5 |

- 4 |

|

|||

|

¾ |

Monitoring in speed |

……………………….…….. |

5 - 5 |

|

|||||

Chapter 6 - FFT (Fast Fourier Transform) analyzer mode |

|

|

|

|||||||

|

|

|

|

|

|

|

||||

|

¾ |

FFT Setup ……………………………………..………. |

6 |

- 1 |

|

|||||

|

¾ |

Spectrum analysis (FFT) |

……………………..………. |

6 |

- 4 |

|

||||

|

¾ |

Waveform function |

……………………..………. |

6 |

- 6 |

|

||||

|

¾ |

Trigger Setup |

…………………………..…………. |

6 |

- 6 |

|

||||

Contents |

1 |

Chapter 7 - Balancer mode

¾ |

Selection of the balancing program |

………...……. |

7 |

- 2 |

|

¾ |

Calibration sequence ……………………..………. |

7 |

- 6 |

||

¾ |

Execution of measurement…………………….………. |

7 |

- 8 |

||

¾ Unbalance measurement and calculation of the correction |

7 |

- 10 |

|||

¾ |

Splitting of correction weight |

……………………… |

7 |

- 13 |

|

¾ |

Saving of a balancing program |

……………………… |

7 |

- 14 |

|

Chapter 8 - Data manager mode

¾ |

Archive management |

……..…………….………… |

8 - 1 |

¾ |

Copying /shifting archive on USB key….…….….….… |

8 - 2 |

|

¾ |

Sending archive to PC |

……..…………….………… |

8 - 4 |

¾ |

Display of measurements present in the archive ……… |

8 - 5 |

|

Chapter 9 - CEMB PoInTer (optional)

¾ |

System requirements |

………………………...…… |

9 |

- 1 |

||||

¾ |

Installation and registration |

………………..……. |

9 |

- 2 |

||||

¾ |

Measuring points archive ……………………..….…… |

9 |

- 3 |

|||||

|

- Data manager |

……………………..….…… |

9 |

- 3 |

||||

|

- Data protection – Password |

|

………...….… |

9 |

- 5 |

|||

¾ |

List of measurements |

…………………………...… |

9 |

- 5 |

||||

¾ Reading measurements saved on the N500 instrument ... |

9 |

- 6 |

||||||

|

- Loading of new measurements in archive |

…...… |

9 |

- 7 |

||||

|

- Selection and elimination of measurements |

…..… |

9 |

- 8 |

||||

¾ |

List of measurements to represent on a graph |

…....… |

9 |

- 8 |

||||

¾ Display of graphs ………………………..…………..… |

9 |

- 9 |

||||||

|

- Cursor |

………………………..………….… |

9 |

- 10 |

||||

|

- Zoom |

………………………..……….…… |

9 |

- 10 |

||||

|

- Shifting of graphs in window |

….…..………. |

9 |

- 11 |

||||

|

- Separate/Combine graphs |

……………..………. |

9 |

- 11 |

||||

¾ Creation and printing of certificates and reports ….…... |

9 |

- 12 |

||||||

Appendix A - |

Specification |

|

|

|

|

|

|

|

Appendix B - |

Evaluation criteria |

|

|

|

|

|

|

|

Appendix C - A rapid guide to interpreting a spectrum |

|

|

|

|||||

Appendix D - |

Codes that can be used in models for certificates obtained |

|||||||

|

using the CEMB PoInTer program |

|

|

|

|

|||

Attachment: Balancing accuracy for rigid rotors |

|

|

|

|

||||

2 |

Contents |

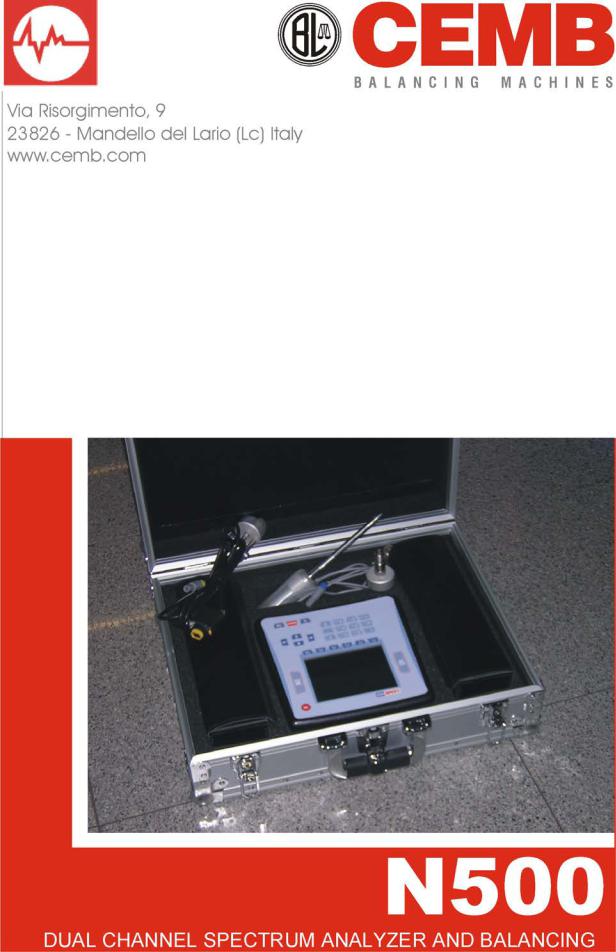

Chapter 1

General description

The N500 instrument is supplied, together with its accessories, in a special case. It is advisable, each time the instrument is used, to place back it in its case in order to avoid risk of damage during transit.

Standard accessories:

-Two velocity transducers dia. 40

-Two cables for connecting the transducers

-Two magnetic bases

-Two probes

-photocell 18,000 RPM complete with stand and magnetic base

-battery charger

-roll of reflecting paper

-case

-user manual

General description |

1 - 1 |

Optional accessories:

-acceleration transducer type TA-18/S complete with connection cable and magnetic base

-proximity sensor complete with stand, cable and magnetic base

-optical fibre photocell (60,000 RPM) complete with stand and magnetic base

-extension cable, length 10 metres, for transducers

-extension cable, length 10 metres, for photocell

-portable printer for direct printing of certificates on standard thermal or adhesive paper

-software CEMB PoInTer for data filing, management and printing.

N.B.:

After connecting the printer to the RS232 port, wait for about 5 seconds to allow completion of the automatic recognition and initialization procedure. Only at this point will it be possible to make a print-out by pressing relative key

Connections

7 |

6 |

5 |

4 |

3 |

2 |

1 |

1– battery charger

2– VGA output 15-pin (only for CEMB Technical Service)

3– serial port RS232 (connecting of optional portable printer)

4– 2 USB ports type A (master)

5– keyboard input PS2

6– photocell input

7– 2 inputs, measuring channels

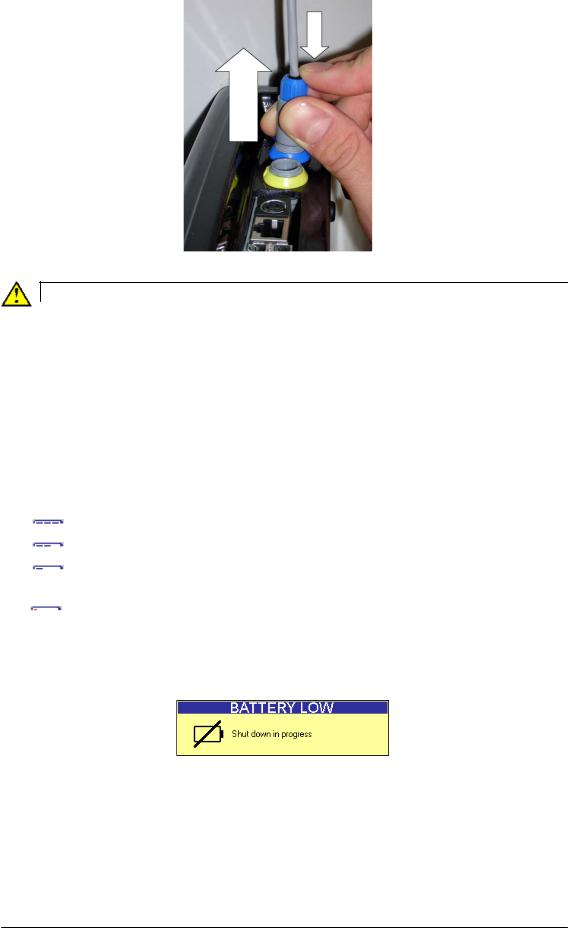

To connect the sensors and photocell, merely plug the connector in the corresponding socket, pushing it until it clicks into place; make sure that the safety connection is correctly aligned as shown in the figure.

1 - 2 |

General description |

Instead, to extract the connector, press its end part (blue or yellow) and at the same time pull the main body (grey), in order to release it.

Caution:

Avoid pulling the connector with force before releasing it as described above, otherwise there would be risk of damaging it.

Battery

The N500 instrument is provided with a built-in rechargeable lithium battery, which allows autonomy of more than eight hours under normal operating conditions of the instrument.

The battery status is indicated by an icon in the upper right hand corner of the screen.

- battery fully charged

battery fully charged

- battery partly charged

battery partly charged

- battery almost flat (battery life remaining when this appears is approx. one hour)

battery almost flat (battery life remaining when this appears is approx. one hour)

– battery flat: recharge within 5 minutes

battery flat: recharge within 5 minutes

If the battery is flat and the instrument is not recharged within 5 minutes, a message will be displayed

and the instrument will then switch off.

This would interrupt any active measurements not yet saved.

General description |

1 - 3 |

Caution:

Caution:

It is strongly recommended to recharge the battery with the instrument switched off: as recharging is completed within less than five hours such precaution prevents the battery charger from being connected for an excessively long period of time (max. 12 hours).

Caution:

Caution:

The lithium battery is able to withstand the recharging-discharging cycles, even on a daily basis, without problems but it could become damaged if allowed to be fully discharged. For this reason it is advisable to recharge the battery at least once every three months, even in the case of extended idle period.

N.B:

N.B:

As the greater consumption is due to the back lighting of the LCD display, the latter is switched off automatically after two minutes if no button is pressed. The pressing of any button (except for and those of the alphanumeric keypad) is sufficient to switch the back lighting on again.

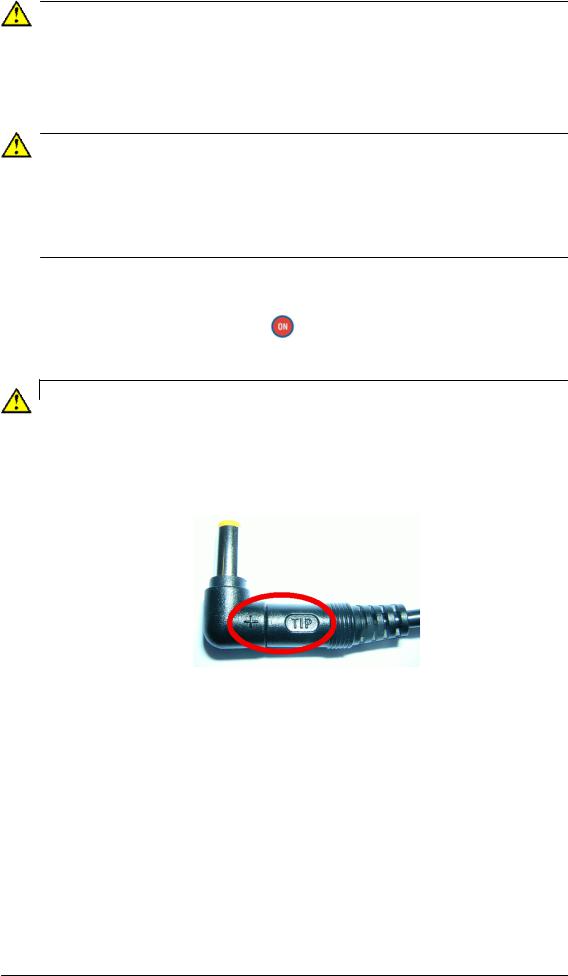

Caution:

If the N500 instrument is provided with battery charger Accord, when plugging the adapter in the socket on the instrument make sure of the correct polarity, by keeping the + symbol on the same side as the wording TIP, as shown in the following image. If not, there is risk of damaging the instrument.

General advice

Keep and use the instrument far from sources of heat and strong electromagnetic fields (inverters and high-power electric motors).

Measurement accuracy could be impaired by the connection cable between the transducer and instrument, therefore it is recommended to:

-not allow such cable to have sections in common with power cables;

-prefer a perpendicular arrangement when overlapping power cables;

-always use the shortest possible length of cable; in fact floating lines would act as active or passive antennae.

1 - 4 |

General description |

Chapter 2

General layout

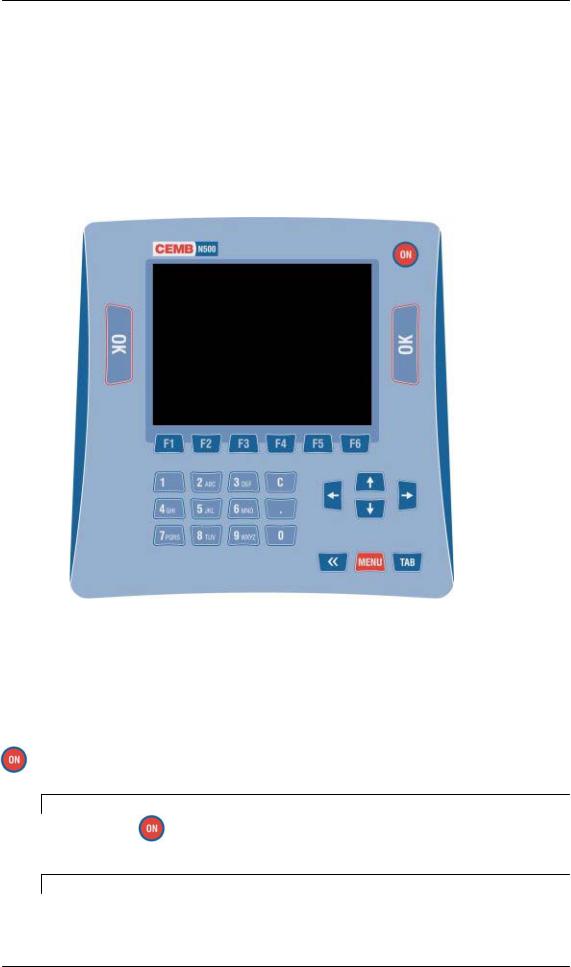

Keys/buttons on the control panel

The control panel of the CEMB N500 instrument incorporates a keypad where the various keys or buttons can be subdivided by function:

- on / off button

Press this button to switch the instrument on;

hold it down for at least 3 seconds to switch it off , then release the button.

N.B. |

|

After pressing |

, the instrument is ready for use only at the end of the switching |

on procedure, signalled by the appearance of the home screen (see Chap. 3).

Note:

After the insrument has been switched off, about 30 seconds must pass before it can be switched back on again.

General layout |

2 - 1 |

- buttons for navigating between the pages

When this button is pressed in the setup screen, it confirms the settings selected and allows going onto the next screen.

Instead, in the Measurement screen, it has the function of starting/stopping the actual measurement (see 2-4 Start / Stop the acquisition).

N.B.

To facilitate use of the instrument also with the left hand, the button is located on both sides of the display.

When this button is pressed, it causes quitting of the current screen with return to the previous one, without taking into account any changes (or saves) in the settings.

Used for returning to the Main page, from any other page.

Used for returning to the Main page, from any other page.

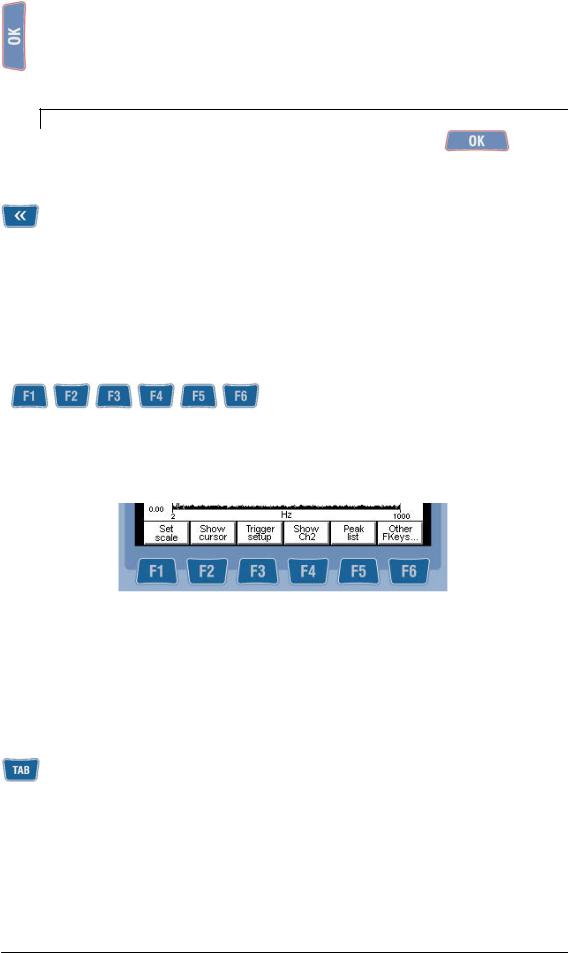

- function keys

Each function key is linked to different functions in the various screens. Such functions are indicated in each individual case by the buttons shown at the bottom of the display: each function is activated by pressing the function key under it.

In the setup screens they are used for setting the various parameters, each one being indicated by a number corresponding to that of the function key to be pressed to modify it.

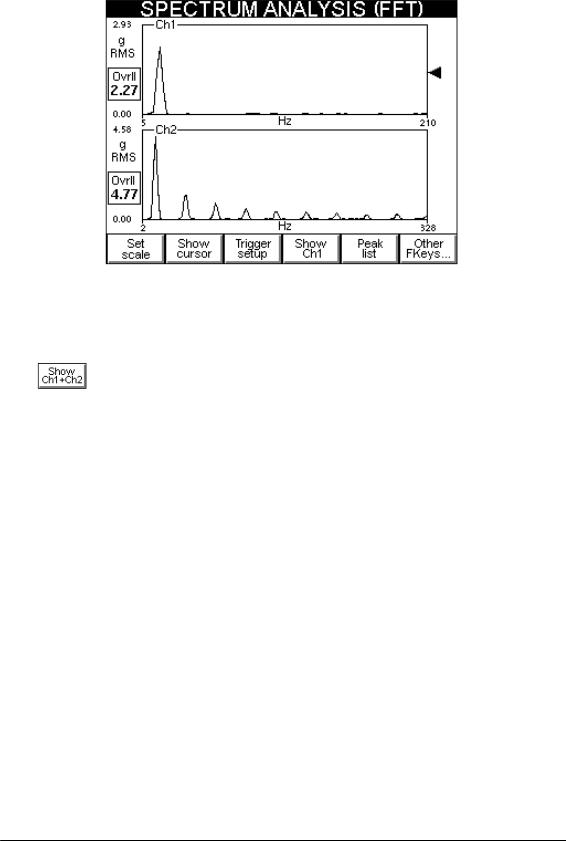

- tab key

This key can only be used when two graphs are plotted on the same page; when pressed, it changes the active graph to which the selected functions will be applied. The active graph can be identified by the  symbol located on the right side.

symbol located on the right side.

2 - 2 |

General layout |

- arrow keys

When a graph is displayed, these keys increase or decrease respectively |

the |

||||

minimum or max. value of the x axis ( |

, |

) or the y axis ( |

, |

). |

|

Instead, when inputting a value for a parameter, they either shift the cursor to the left or right ( ,

, and increase or decrease the value in question (

and increase or decrease the value in question ( ,

,  ).

).

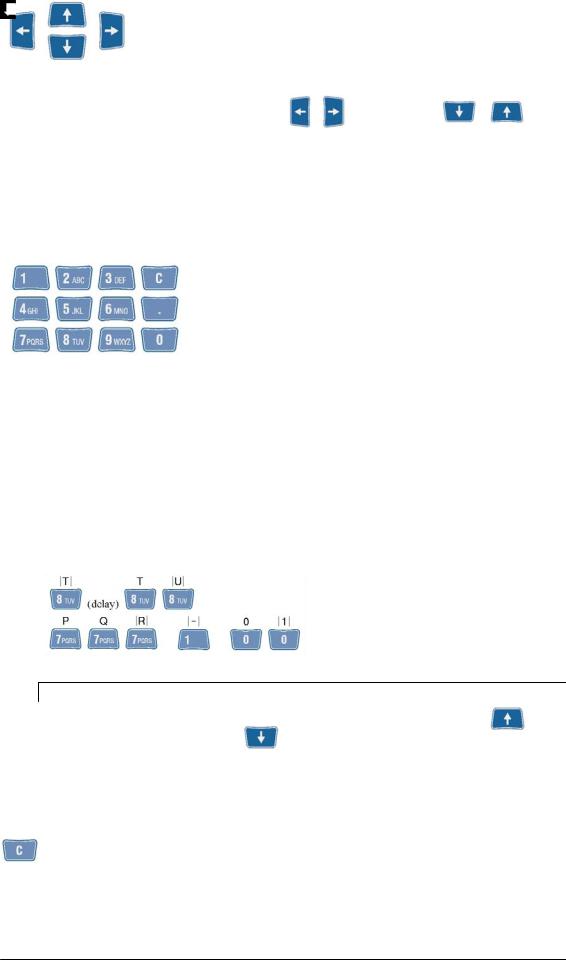

- alphanumeric keypad

This keypad serves for entering alphanumeric characters in the fields which do not allow just default selections. Where it is possible to enter just numbers, it acts like a normal numeric keypad.

To enter a character, press a key repeatedly to scroll the characters assigned to it (e.g. M N O 6) until the required one is displayed.

The cursor passes on automatically to the next position after a pause of one second, or else after pressing another key.

With  it is possible to delete the character to the left of the cursor.

it is possible to delete the character to the left of the cursor.

For example, suppose we wish to enter the word “TUR-1” press:

N.B. |

|

|

|

An icon indicates whether the UPPER CASE style (selectable with |

) or |

||

lower case |

(selectable with |

) is enabled for the letters. |

|

- image capture key

Pressing of this key has the function of capturing the image present on the display and opening a screen which allows it to be saved (see 2-10 capture and saving of displayed images).

General layout |

2 - 3 |

General purpose functions

In addition to many functions, specific for each different purpose and described in relative sections, there are certain general purpose functions which are described below.

- Functions associated with the measuring phase

Start / Stop acquisition: |

|

|

In all the Measurement screens, acquisition is started by pressing |

, and is |

|

subsequently stopped by again pressing |

. |

|

The active acquisition status is easily to recognize (except in the balancing function) by the presence of a bar indicating level of the input signal to each of the activated channels.

Instead, in the Balancing functions, this status is signalled by an indication of the quality of the measurement in progress (see 7-8 Execution of measurement).

To modify amplification of the channels:

When the measurement is activated (apart from the Balancing functions where this would be counter-productive), the analog amplification can be enabled or disabled separately for each of the channels activated: this is possible by selecting either  or

or  . The activated amplification condition is signalled

. The activated amplification condition is signalled

by symbol  placed immediately above the corresponding signal level bar.

placed immediately above the corresponding signal level bar.

N.B.

In order to obtain a good measurement, always start with the amplification disabled. Start the acquisition and observe the level bar for each activated channel: enable amplification if the signal is small. Again check the level of the signal: if far from full scale (saturation zone), maintain the amplification, otherwise disable it again and perform the measurement with the non amplified channel.

2 - 4 |

General layout |

Caution:

Caution:

After changing the amplification, wait for a few seconds until the measurement becomes steady.

- Function “Other functions...”

When there are more than six functions accessible from a certain screen, there are not enough function keys to correspond to them; in such cases the key is associated with

Pressing of this key causes substitution of the functions corresponding to ... with another five. The original correspondence can be reset by again pressing

- Functions operating on the graphs

Scale setting:

allows selecting the function for modification of the minimum and maximum values of the axes in a graph; in this way it is possible to display just the zone of greater interest. When activated, the following sub-functions are made available:

allows selecting the function for modification of the minimum and maximum values of the axes in a graph; in this way it is possible to display just the zone of greater interest. When activated, the following sub-functions are made available:

: quit the Scale Setting function

: quit the Scale Setting function

: preset minimum value of the x axis

: preset minimum value of the x axis

: preset maximum value of the x axis

: preset maximum value of the x axis

: preset minimum value of the y axis

: preset minimum value of the y axis

: preset maximum value of the y axis

: preset maximum value of the y axis

: sets the axis limits to be coherent with the graph data

: sets the axis limits to be coherent with the graph data

The value of the limit selected (xmin, xmax, Ymin or else Ymax, displayed by white wording on black background), can be increased or decreased by pressing

or

or  for x axis and

for x axis and  or

or  for the y axis.

for the y axis.

N.B.

Measurement can be started with also while Set scale is activated but it would automatically cause exit from this function.

N.B.

When two graphs are shown both at the same time on the same screen, the scale functions operate on the active graph (identified by symbol ). To change the active graph, proceed to press the key

General layout |

2 - 5 |

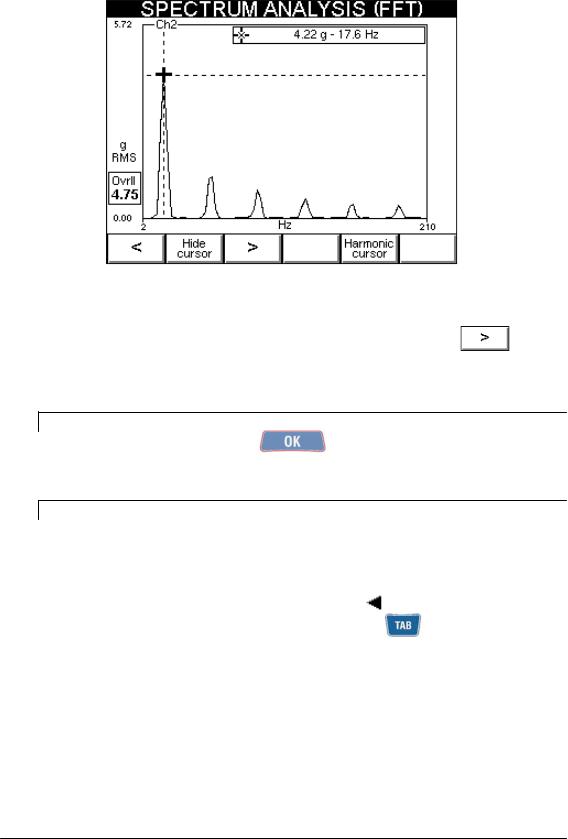

Use of the cursor

For easier reading and interpretation of the displayed data, it is possible to introduce a cursor in any graph, provided the visible region is not blank:

this can be done with  . A window at the top right corner of the graph contains the co-ordinates of the point where the cursor lies.

. A window at the top right corner of the graph contains the co-ordinates of the point where the cursor lies.

The cursor can be shifted by one step to the right or to the left by using the following keys  or

or  respectively .

respectively .

For quick reaching of points from the current position, hold down or  . With

. With  the cursor is removed.

the cursor is removed.

N.B.

Measurement can started with also while the cursor is visible; at the end of the measurement, the cursor remains visible.

N.B.

When two graphs are represented on the same screen simultaneously, it is possible to display the cursor on both in order to have easier comparisons and assessments. However, pressing of the function keys will only have effect on that of the

currently activated graph (identified by the symbol |

). |

To change the activated graph, proceed to press the |

key . |

2 - 6 |

General layout |

Change of display channel:

If both measuring channels are enabled, various types of display are possible, namely:

-just graph of channel Ch1

-just graph of channel Ch2

-graphs of channels Ch1 and Ch2 simultaneously

The passing in sequence between the various possibilities is obtained by repeatedly pressing  . This corresponds in each case to these options

. This corresponds in each case to these options

or  .

.

General layout |

2 - 7 |

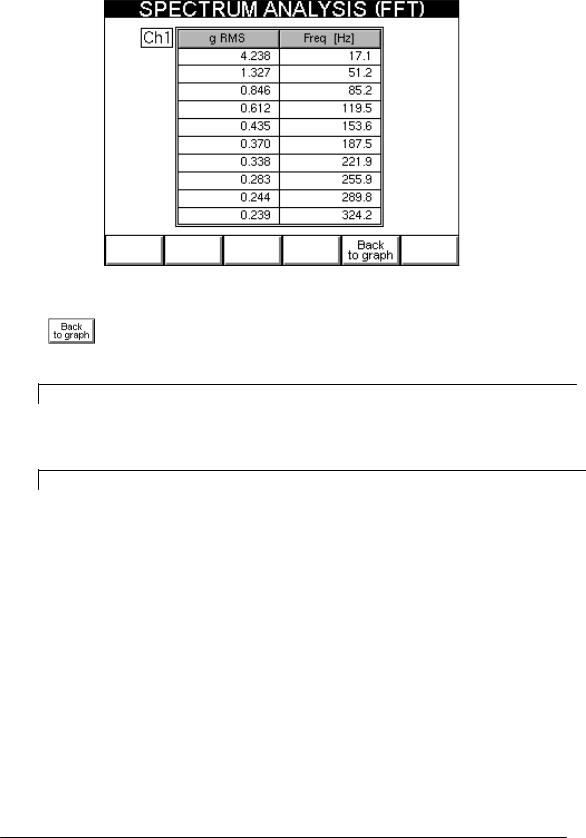

List of peaks

When this function is selected, a table appears with the 10 peaks of highest value present in the zone of the spectrum displayed, and associated with the corresponding frequencies. Their value is calculated by applying an interpolation algorithm to the FFT graph; this also allows identifying peaks not situated in correspondence to one of the lines of the spectrum.

When |

is pressed, the system quits this function and again displays the graph (or |

graphs). |

|

N.B.

The 10 highest peaks are determined in relation to the highest value present in the spectrum; hence in certain cases the list could contain less than 10 peaks.

N.B.

If graphs of both channels are displayed, the list of peaks should be calculated for the active one (identifiable by the symbol  ).

).

2 - 8 |

General layout |

- to save measurements

The N500 instrument allows easy saving of the acquired data; for such purpose, four different archives are available for the four different types of acquisition possible:

-waveform

-spectra (FFT)

-monitoring in time

-monitoring in speed

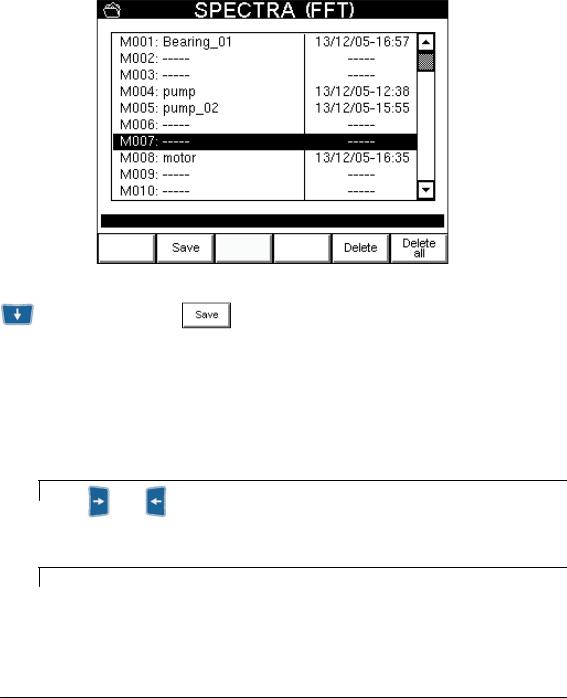

Pressing of  allows displaying the archive corresponding to the measurement made. All 50 overall positions (marked respectively with M001 … M050) are listed; the blank ones can be recognized by the symbol -----, the other positions give the name, date and time of saving their contents.

allows displaying the archive corresponding to the measurement made. All 50 overall positions (marked respectively with M001 … M050) are listed; the blank ones can be recognized by the symbol -----, the other positions give the name, date and time of saving their contents.

To select the position where to save the measurement made, use the arrow keys  and

and

, then merely press to display a pop-up in which to enter the required name, as explained in 2-3 – Alphanumeric keyboard.

If a two-channel acquisition has been performed, data save is performed automatically for both channels in the same file.

To delete a measurement and to clear the corresponding position in the archive, press  button. Instead with

button. Instead with  it is possible to fully clear the measurements archive.

it is possible to fully clear the measurements archive.

N.B.

Keys and , which either increase or decrease by 10 respectively the position selected, can be used for quick scrolling of the archive.

N.B.

As the spectrum is the type of measurement of greater interest, the N500 instrument allows memorization of up to 500 FFTs.

General layout |

2 - 9 |

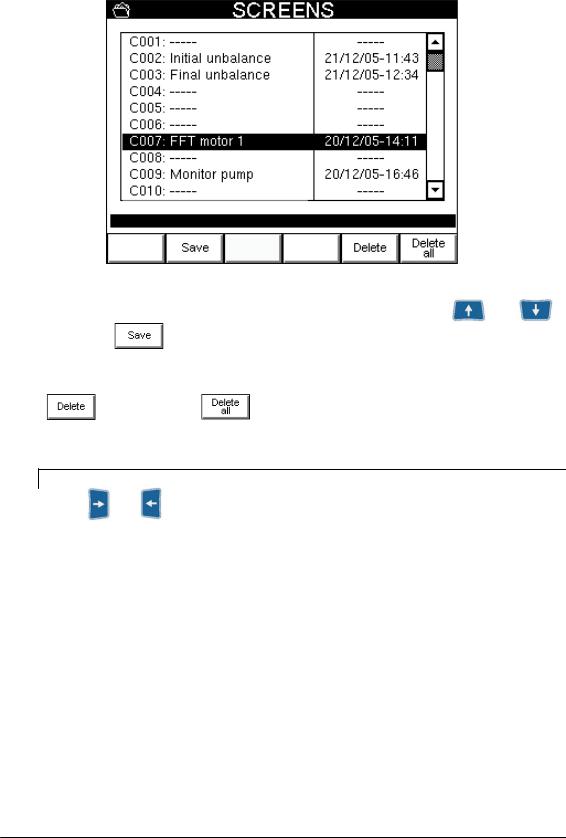

- to capture and save displayed images

In all screens of the N500 instrument, the image visible on the display can be captured with  then saved in png format in an appropriate archive. This image can be used subsequently if required to accompany documentation produced by the operator.

then saved in png format in an appropriate archive. This image can be used subsequently if required to accompany documentation produced by the operator.

Selection of the position where to save can be done with the arrow keys |

and |

|||

then merely press |

to display a pop-up where to enter the required name, as |

|||

explained in 2-3 – Alphanumeric keypad. |

|

|||

To delete an image, and clear the corresponding position in the archive, |

merely press the |

|||

button |

. Instead with |

it is possible to fully clear the image file. |

||

N.B.

Keys and , which either increase or decrease by 10 respectively the position selected, can be used for quick scrolling of the archive.

2 - 10 |

General layout |

Chapter 3

Home screen (menu)

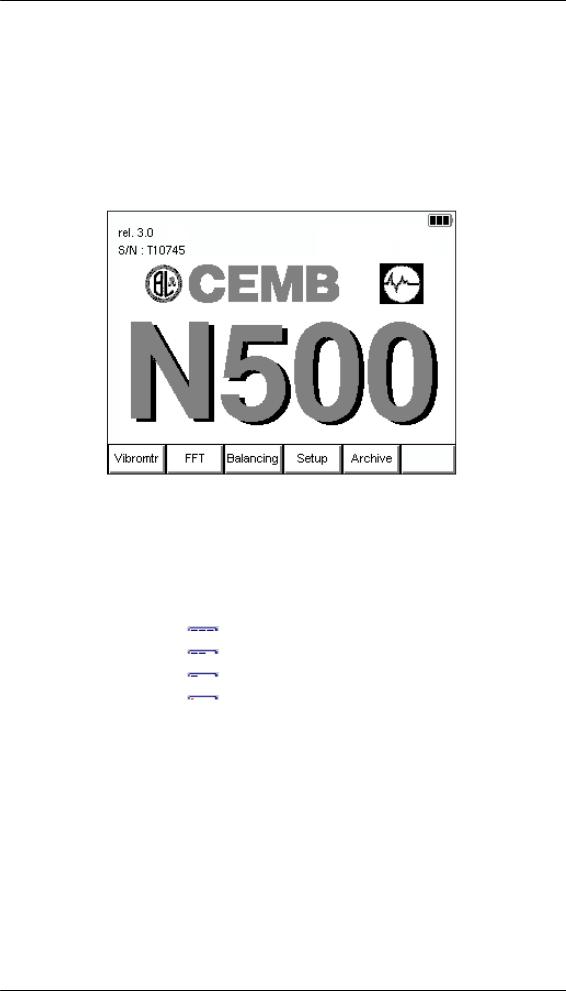

After fully switching on the N500 instrument, it shows its Home screen

which, besides showing a set of information:

–Manufacturer logo and name of the instrument

–Serial number (S/N) of the instrument

–Current program version

–Battery state:

- fully charged  - partly charged

- partly charged  - almost flat

- almost flat  - flat

- flat

– instrument being charged (connection to socket via the battery charger  supplied) as a normal menu, it also proposes and allows selection of the available modes, namely:

supplied) as a normal menu, it also proposes and allows selection of the available modes, namely:

1.Vibrometer mode

-Measurement of the total value and synchronous measurement of vibration

-Measurement and memorization of the trend in vibration against variation in time or rotor speed

Home screen |

3 - 1 |

2.FFT analyzer mode

-Splitting of the vibration into its component frequencies

-Display of waveform of the vibration

3.Balancer mode

-Balancing of rotors

4.Setup mode

-Setting of the characteristics of sensors connected to the instrument

-Setting of the general operating parameters of the instrument

5.Data manager mode

-Data management (change of the name or delete the data saved on instrument N500)

-Copying or shifting data to USB key.

N.B.

It is possible to return to this screen from any other by pressing

3 - 2 |

Home screen |

Chapter 4

Setup mode

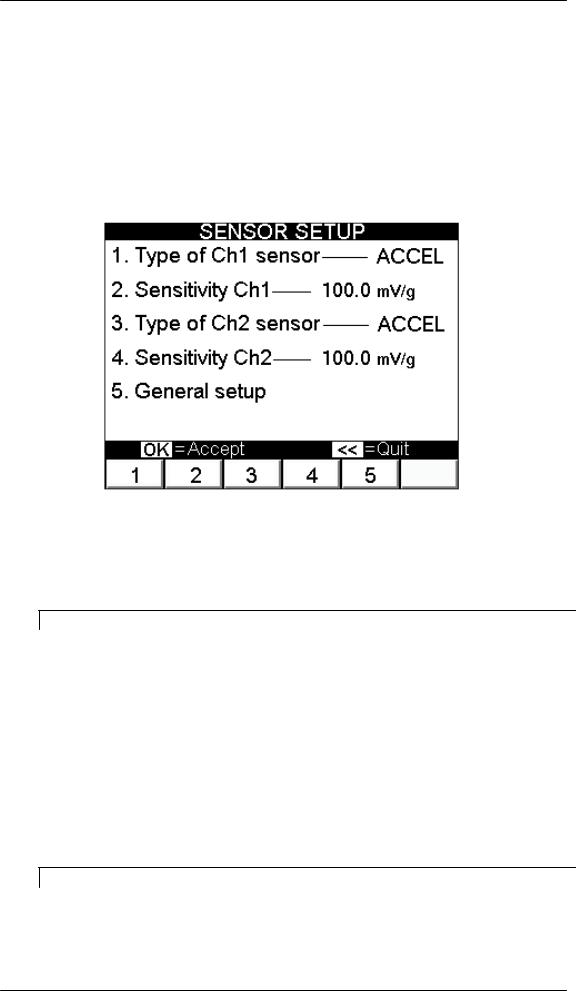

Sensor setup

The N500 instrument can be used with different types and models of sensors. Therefore in order to ensure correct measurement, it is necessary to preset exactly the type of sensitivity of the sensors actually connected.

N.B.

Although the instrument can operate correctly with any combination of sensors, it is advisable to connect sensors of the same type and model to the two channels.

1. Type of sensor:

Any one of the following possibilities can be selected:

–OFF : sensor not present (or else channel to be kept switched off)

–ACCEL : accelerometer

–VELOC : velocity sensor

–DISPLC : proximity sensor (non-contact)

N.B.

It is not possible to set both channels to OFF; at least one of the two channels should be activated.

Setup mode |

4 - 1 |

N.B.

Although the required unit of measurement can differ from the natural one of the sensor, these are the only combinations are possible.

TYPE OF SENSOR |

REQUIRED MEASUREMENT |

|

|

ACCEL |

acceleration, speed, displacement |

|

|

VELOC |

speed, displacement |

|

|

DISPLC |

displacement |

|

|

N.B.

The N500 instrument is able to determine automatically whether there is no sensor connected to an enabled channel (i.e. not set to OFF Sensors Setup) and it signals

this by showing the symbol |

in the vicinity of the signal bar of the |

corresponding channel (only during measurement).

To avoid displaying this symbol, it is advisable to disable the channel when not used, by setting to OFF.

Caution:

The appearance of this symbol for a channel where a sensor is really connected, could indicate a possible malfunction of the sensor or else a problem in connection (e.g. the cable could have been sheared).

In such case it is advisable to carry out a few tests by connecting a sensor (which is known to be operating properly) to the channel in question; if the indication persists, contact CEMB Technical Service.

2. Sensitivity of the sensor

This is the number of volts per unit produced by the sensor: it is expressed for the various types in:

TYPE OF SENSOR |

SENSITIVITY |

TYPICAL VALUE |

|

|

|

ACCEL |

mV/g |

100 |

|

|

|

VELOC |

mV/(mm/s) |

21.2 |

|

|

|

DISPLC |

mV/µm |

0,25 |

|

|

|

Caution:

Caution:

Different models can have sensitivity differing from the typical values; pay attention when taking the correct value from the sensor documentation and preset it .

4 - 2 |

Setup mode |

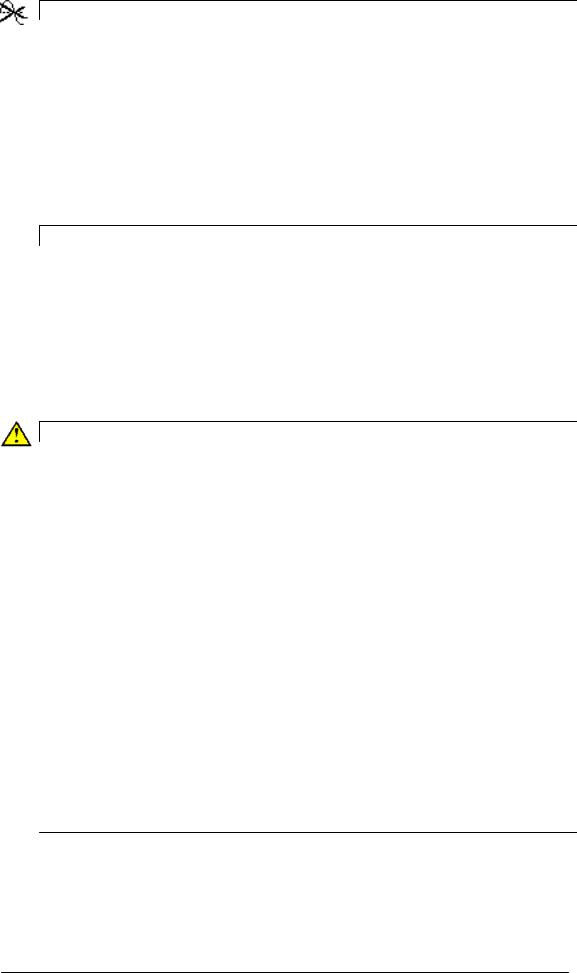

General Setup

N.B. |

|

When the |

key is pressed, the SYSTEM INFO pop-up appears, containing |

full information concerning the system. Strike any key to close this window.

The parameters for general use of the instrument should be preset in this page.

1. Date

Use the alphanumeric keypad to enter the date in the format DD/MM/YYYY.

2. Time

Use the alphanumeric keypad to enter the date in the format HH:MM:SS.

3. Language

Select one of the possible languages:

-ITALIANO

-ENGLISH

-DEUTSCH

-FRANÇAIS

-ESPAÑOL

4.Measurement system

The units of measure for the acceleration, speed and displacement values can be the following respectively:

-g; mm/s; µm : metric units

-g; inc/s; mils : imperial units

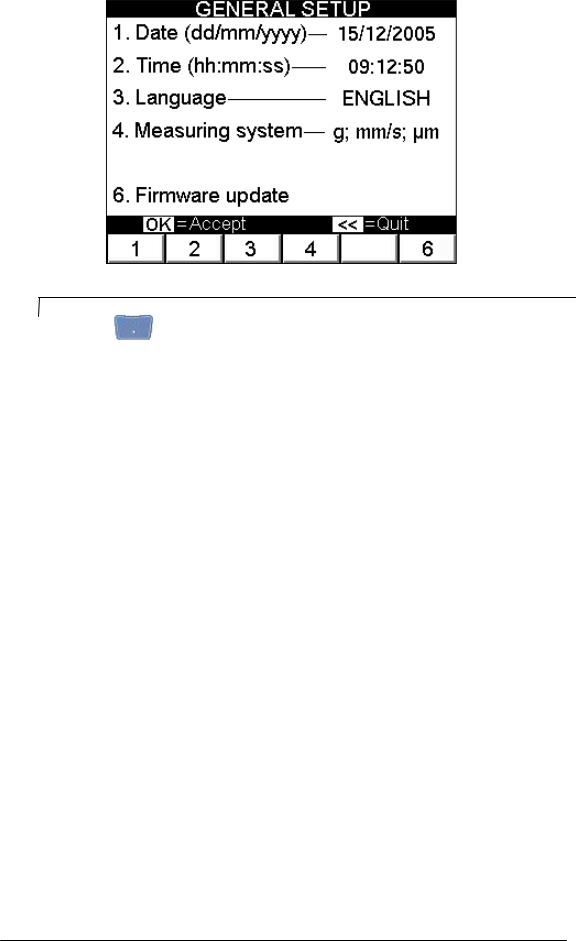

6.Updating of firmware

Pressing of key  does not set any parameter, but it does allow updating the program (firmware) inside the instrument, if this proves necessary. Each new firmware version consists of a file with the extension fmw, which should be copied in the main directory on the USB key supplied. Merely insert the pendrive in one of the USB ports of

does not set any parameter, but it does allow updating the program (firmware) inside the instrument, if this proves necessary. Each new firmware version consists of a file with the extension fmw, which should be copied in the main directory on the USB key supplied. Merely insert the pendrive in one of the USB ports of

Setup mode |

4 - 3 |

the instrument, then press |

to start the automatic updating procedure, at the |

end of which the pop-up |

|

signals successful transfer of the file and requests switching the instrument off, then on again to complete the operation.

Caution:

Updating of the firmware is a delicate operation, which could last a few minutes. It should be carried out by paying careful attention to the instructions supplied in order not to cause malfunctions or data loss; for this reason, a confirmation is requested before activating this procedure.

Only the firmware obtained directly from CEMB Technical Service should be used. It is advisable to remove the USB key before rebooting the instrument.

Caution:

If the automatic updating operation is not performed successfully, contact CEMB Technical Service, citing the type of error signalled.

4 - 4 |

Setup mode |

Chapter 5

Vibrometer mode

One of the simplest, but at the same time most significant information in vibration analysis, is the overall value of the actual vibration. In fact, this is very often the first parameter to be considered when evaluating the operating conditions of a motor, fan, pump, machine tool...

Appropriate tables allow discrimination between an optimum state and a good state, or from an allowable, tolerable, non-permissible or even a dangerous one. (see Appendix B

– Evaluation criteria).

In certain situations instead, it could be interesting to know the values of modulus and phase of the synchronous vibration (1xRPM), i.e. corresponding to the speed of rotation of the rotor.

The vibrometer mode is designed to make this type of measure and also makes available two monitoring functions, for observing the trend of vibration plotted against time or against variation in rotor speed.

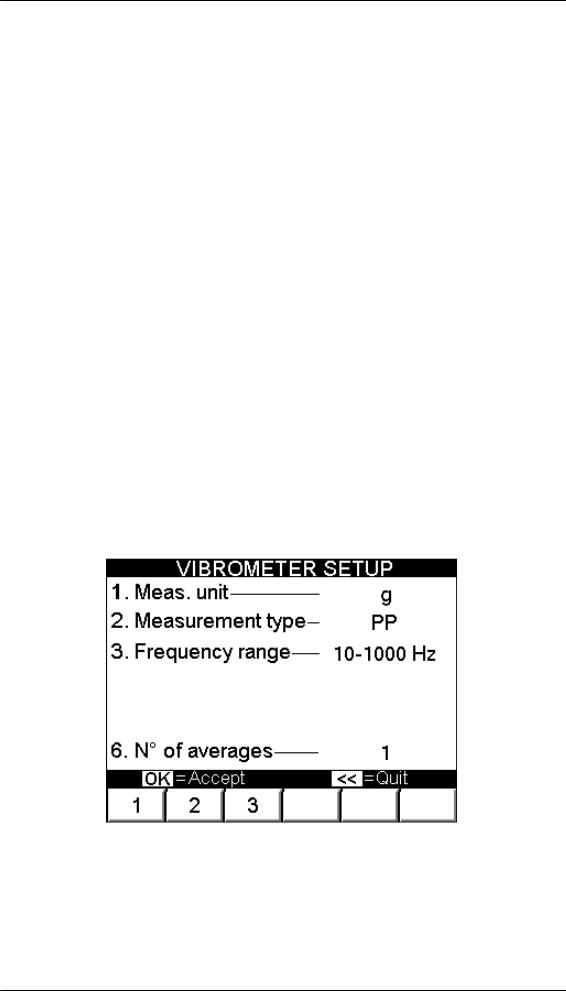

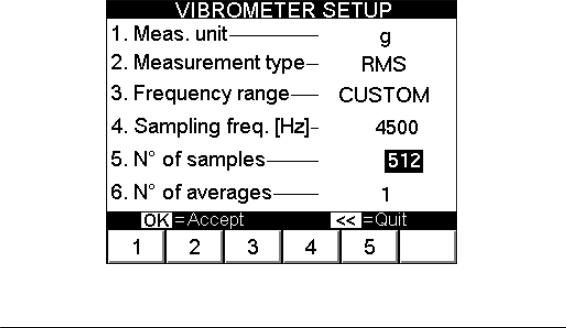

Vibrometer setup

Settings required for correct measurement of the overall value are selected in the

VIBROMETER SETUP page.

1. Unit of measurement

Select the unit of measurement in which to supply the vibration; possibilities are as follows:

–acceleration (g)

–speed (mm/s or inch/s)

–displacement (µm or mils)

Vibrometer mode |

5 - 1 |

2. Type of measurement

As with all physical quantities, vibration has a value which can vary from instant to instant: mathematically it may be described as a function of time. Hence its overall value can be calculated according to three different types:

–RMS (Root Mean Square):

This is the average value of the vibration previously squared;

This is the typically used value, above all, for acceleration or speed measurements.

–PK (Peak):

This is the maximum value reached by the vibration in a certain interval of time.

–PP (Peak-to-Peak):

This is the difference between maximum value and minimum value reached by the vibration in a certain period of time;

It is normally used for measuring displacement.

3.Frequency range

The overall value of vibration normally originates from the sum of various contributory factors, caused by several phenomena, and therefore they occur associated with different frequencies. Depending on the case, it could be of interest to take into account, in the overall value, only those corresponding to a certain frequency band, namely:

–3-300 Hz if the range of interest is limited to phenomena with low frequencies

–10-1000 Hz to meet conditions of ISO 10816-1 standard (typical)

–10-10000 Hz to take into account a wide band

A CUSTOM frequency range is available for expert users (and for very particular conditions). This range allows setting as required both the sampling frequency fs and the number of samples Ns. In fact the overall value is calculated with digital techniques starting from the signal spectrum; therefore, the sampling parameters determine the band limits according to the following relationships:

fmin = 2 |

fs |

fmax = |

fs |

|

Ns |

2.56 |

|||

|

|

5 - 2 |

Vibrometer mode |

N.B.

Use of the CUSTOM frequency band is only recommended for expert users who have sound knowledge of the basic concepts in digital signal processing. In fact, an incorrect choice of sampling parameters could lead to unsatisfactory results. For example, with too low a fmax, there is risk of losing important high frequency information; on the other hand, with too high a frequency, the resolution could be insufficient to distinguish the two peaks.

4. Average N°

This is the number of value which should be calculated and averaged between each other to increase stability of the measurement. Four averages are more than sufficient for normal vibration measurements on rotating machines.

After making the required settings, |

press to access the VIBROMETER |

Measurement screen. |

|

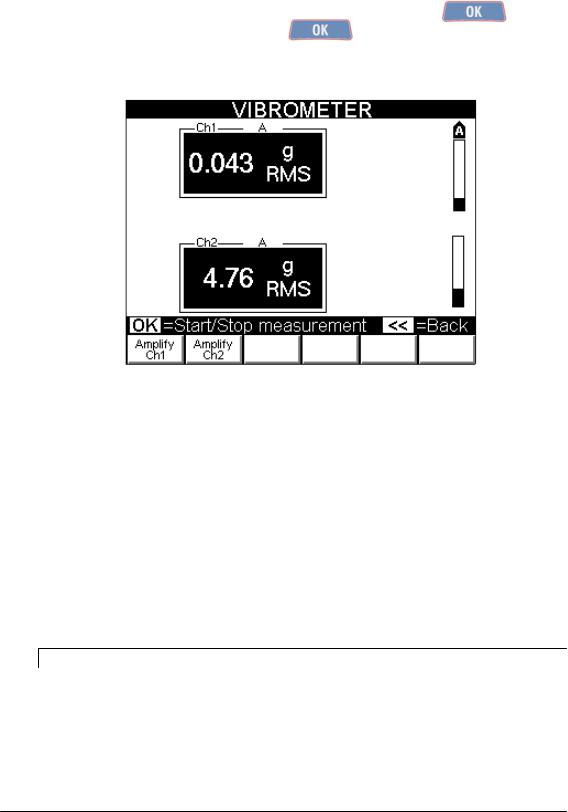

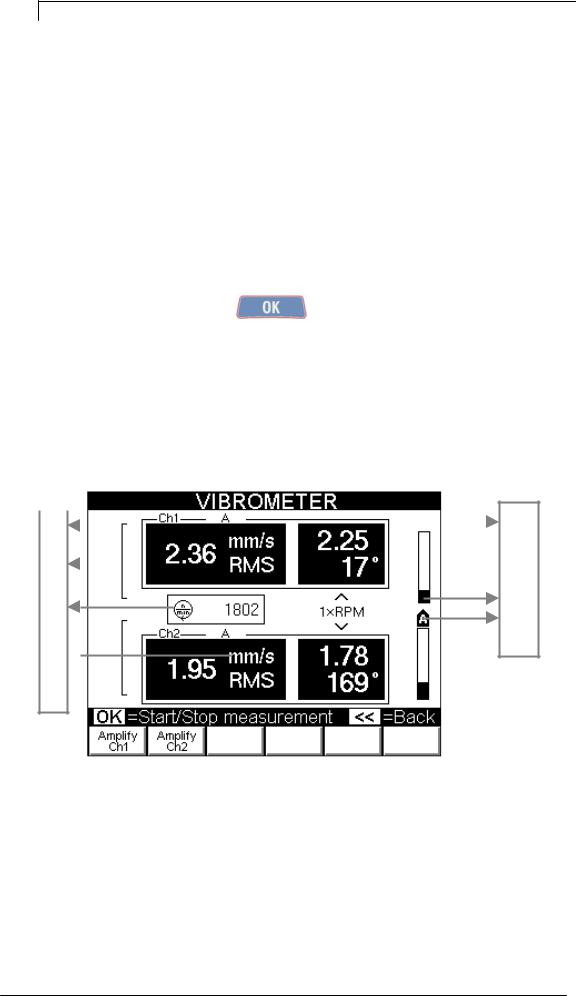

Vibrometer – Measurement screen

The Measurement page supplies a series of information, organized as shown in the figure:

|

|

|

2 |

|||

1 |

||||||

|

|

|

|

|

||

|

|

|

|

|

||

6 3

6 3

7

7

8

9

10

4

5

1.channel measured

2.measurement information: indicates unit of the sensor (A, V or D) and any conversion made to supply the overall value (e.g. AÆV means that the measurement is made with an accelerometer, but the vibration is supplied in speed)

3.overall value of the vibration

4.unit of measurement

5.type of measurement

6.value of the synchronous vibration

7.phase of the synchronous vibration

8.speed rotation of rotor

9.signal level bar

Vibrometer mode |

5 - 3 |

Loading...

Loading...