Page 1

ENGLISH

GB

Use and maintenance manual

General Index

1. FOREWORD 5

1.1 GENERAL 5

1.2 PURPOSE OF THE MANUAL 5

1.3 WHERE AND HOW TO KEEP THE MANUAL 5

1.4 MANUAL UPGRADES 6

1.5 COLLABORATION WITH USERS 6

1.6 MANUFACTURER 6

1.7 MANUFACTURER’S RESPONSIBILITY AND WARRANTY 6

1.7.1 Terms of warranty 6

1.8 TECHNICAL ASSISTANCE SERVICE 7

1.9 COPYRIGHT 7

2. INSTALLATION 8

3. MACHINE DESCRIPTION 12

3.1 MACHINE FUNCTION 12

3.2 TECHNICAL SPECIFICATIONS 13

3.3 DIMENSIONS 13

3.4 WARNINGS 13

4. WHEEL LIFTING (OPTION) 16

5. WHEEL LOCKING 17

6. USE OF THE WHEEL BALANCING MACHINE 18

6.1 DIMENSION ACQUISITION 18

6.2 CORRECTION MODE SELECTION 19

I 0964 - 12/12 - Rev. 02

Page 2

6.3 UNBALANCE UNIT OF MEASURE SELECTION 20

6.4 UNBALANCE MEASUREMENT (FIRST SET OF BUTTONS) 21

6.4.1 Lock/release wheel in correction position 22

6.5 UNBALANCE MEASUREMENT (SECOND SET OF BUTTONS) 23

6.6 THRESHOLD DISPLAY 24

6.7 UNBALANCE CORRECTION 25

6.7.1 Iron rims 25

6.7.2 Aluminium rims 26

6.7.3 Change weight application distance 27

6.8 UNBALANCE SPLIT 28

6.9 UNBALANCE OPTIMISATION 29

6.10 TYRE SET 30

6.10.1Tyresetvaluecerticate 32

6.10.2 Tyre setcerticatecustomisation 32

6.11 WEIGHT STATISTICS 33

6.12 TRACEABILITY 35

6.13 BALANCING CERTIFICATE PRINTOUT 37

6.13.1 Balancingcerticatecustomisation 38

6.14 SCREENSAVER 43

6.15 WHEEL ANALYSIS 44

6.15.1 Runout 45

6.15.1.1 When and why TO USE MATCHING 45

6.15.1.2 Matching 46

6.15.1.2.1 When to perform matching 47

6.15.1.2.2 How to perform matching 47

6.15.1.3 Peak/peakandrstharmonicgraphs 48

6.15.2 Tread 49

6.15.3 Taper 51

6.16 OUTSIDE RIM RUNOUT 52

7. WHEEL DISMOUNTING 54

8. SETUP 55

8.1 MENU 55

Page 3

8.2 GENERAL SETUP 56

8.2.1 General setup 1/3 56

8.2.1.1 Screensaver customisation 58

8.2.2 General setup 2/3 59

8.2.3 General setup 3/3 60

8.3 RESERVED SETUP 61

8.3.1 LASER calibration 62

8.3.2 CC motor calibration 63

8.3.3 Spindle reset 64

8.3.4 Taper calibration 65

8.3.5 Correction weights 66

8.3.6 Wheel runout 67

8.3.7 Outside rim runout 68

8.3.8 Tread 69

8.3.9 Reserved for technical service 70

8.3.10 Saves the machine calibration 70

8.3.11 Loads the user manual 70

8.3.12 Firmware upgrade 71

8.3.13 Factory setting 72

8.4 MACHINE CALIBRATION 73

8.5 DIMENSIONS 74

8.6 SELF-DIAGNOSTICS 75

8.7 OSK 76

8.8 SOUNDS 78

8.9 TRACEABILITY 79

8.10 INSTRUCTION MANUAL 79

9. DIAGNOSTICS 80

10. MAINTENANCE 84

10.1 GENERAL 84

10.1.1 Introductory notes 84

10.1.2 Safety rules 84

10.1.3 Replacing fuses 84

Page 4

10.1.4 Periodic cleaning 84

11. DISPOSAL 85

11.1 DISPOSING OF THE BALANCER 85

11. 2 DISPOSING OF ELECTRONICS COMPONENTS 85

12. SPARE PARTS 85

12.1 IDENTIFICATION AND ORDERING METHOD 85

13. ATTACHED DOCUMENTATION 85

Page 5

Use and Maintenance Manual Rev. 12-2012

1. Foreword

ENGLISH

1.2 PURPOSE OF THE MANUAL

This manual, and the installation manual, contains the

instructions required to use the machine safely and carry

out routine maintenance work.

ThI s mA NuAl Is AN IN TeGR Al pART of The INsTAllATIoN

WARNING

mAN uAl WhIc h should b e coNsulTe d coNce RNIN G sTARTING

ANd usI NG T he m AchI Ne s Afely.

ReA d cA Refu lly bef oRe coNT INuI NG.

1.1 GENERAL

The machine has been constructed in conformity with the

current EC Directives and the technical standards implementing the requirements, as stated in the declaration

of conformity issued by the manufacturer and attached

to the manual.

This publication, hereinafter simply referred to as ‘man-

ual’, contains all the information required to safely use

and service the machine referred to in the Declaration of

Conformity.

This appliance, hereinafter is generically referred to as

‘machine’.

The manual addresses operators instructed on the precautions to take in relation to the presence of electric current

and moving devices.

This publication is intended for all ‘users’ who as far as

within their competence need to and/or are obliged to

give instructions to others or operate on the machine

themselves.

These persons can be identified as follows:

- operators directly involved in transporting, storing,

installing, using and servicing the machine from when

it is put on the market until when it is scrapped;

- direct private users.

The original Italian text of this publication constitutes the

only reference to resolve any interpretation controversies

related to the translation into the European Community

languages.

This publication forms an integral part of the machine

and must therefore be kept for future reference until final

dismantling and scrapping of the machine.

Any calibrations, adjustments and extraordinary maintenance operations are not considered in this document as

they may only be performed by the service engineer who

must work on the machine according to the technical and

rated characteristics for which it was built.

Though it is fundamental to read this manual, it cannot

replace skilled technical staff who must be adequately

trained beforehand.

The foreseen use and configurations of the machine are

the only ones allowed by the manufacturer; do not attempt

to use the machine in a different way.

Any other use or configuration must be agreed in advance

with the manufacturer in writing and in this case an annex

will be attached to this manual.

For use, the user must also comply with the specific

workplace legislation in force in the country where the

machine is installed.

The manual also refers to laws, directives, etc., that the

user must know and consult in order to accomplish the

goals that the manual sets out to achieve.

1.3 WHERE AND HOW TO KEEP THE

MANUAL

This manual (and relative attachments) must be kept in

a safe and dry place and must always be available for

consultation.

Make a copy and keep it in the archive.

When exchanging information with the manufacturer or

the technical assistance staff authorised by the former,

quote the rating plate information and the serial number

of the machine.

This manual must be kept for the entire lifetime of the

machine, and if necessary (e.g.: damage making all or

some of it illegible, etc.) the user must request another

copy exclusively from the manufacturer, quoting the publication code indicated on the cover.

Introduction

5

Page 6

1.4 MANUAL UPGRADES

Use and Maintenance Manual Rev. 12-2012

This manual is an integral part of the machine and reflects

ENGLISH

the state of the art at the moment it was put on the market.

The publication complies with the directives in force on

that date; the manual cannot be considered inadequate

as a result of regulatory updates or modifications to the

machine.

Any manual upgrades that the manufacturer may see fit to

send to users will become an integral part of the manual

and must be kept together with it.

1.5 COLLABORATION WITH USERS

The manufacturer will be pleased to provide its customers with any further information they may require and will

consider proposals for improving this manual in order to

more fully satisfy the requirements it was written for.

In case of transfer of ownership of the machine,

which must always be accompanied by the use and

maintenance manual, the original user must inform

the manufacturer of the name and address of the

new user in order to allow it to send the new user

any communications and/or updates deemed to be

indispensable.

This publication is the property of the Manufacturer

and may not be fully or partly reproduced without prior

written agreement.

- never exceed the limits of use of the machine;

- always constantly and carefully clean and service the

machine;

- have the machine used by people of proven capacity

and attitude, adequately trained for the purpose.

The manufacturer declines all direct and indirect liability

caused by:

- use of the machine in a different way from that indicated

in this manual

- use of the machine by people who have not read and

fully understood the contents of this manual;

- use in breach of specific regulations in force in the

country of installation;

- modifications made to the machine, software and operating logic, unless authorised by the manufacturer

in writing;

- unauthorised repairs;

- exceptional events.

Transfer of the machine to a third party must also include

this manual; failure to include the manual automatically

invalidates all the rights of the purchaser, including the

terms of warranty, where applicable.

If the machine is transferred to a third party in a country with

a different language from the one written in this manual,

the original user shall provide a faithful translation of this

manual in the language of country in which the machine

will operate.

1.7.1 Terms of warranty

1.6 MANUFACTURER

The machine identification data is indicated on the plate

mounted on the machine.

The plate below is shown for the sake of example.

1.7 MANUFACTURER’S RESPONSIBILITY

AND WARRANTY

In order to make use of the manufacturer’s warranty, the

user must scrupulously observe the precautions contained

in the manual, in particular he must:

The Manufacturer guarantees the machines it manufacturers against all manufacturing or assembly faults for 12

(twelve) months from the date of collection or delivery.

The Manufacturer undertakes to replace or repair any part

which it deems to be faulty free of charge at its factory,

carriage paid.

If a Manufacturer’s repairman (or a person authorised by

the same) is required to work at the user’s facilities, the

relative travel expenses and board and lodging shall be

charged to the user.

The free supply of parts under warranty is always subject

to the faulty part being inspected by the manufacturer (or

a person authorised by the same).

The warranty is not extended following repairs or other

work done to the machine.

The warranty does not cover damage to the machine

deriving from:

- transport;

- neglect;

- improper use and/or use not in compliance with the

6

Introduction

Page 7

Use and Maintenance Manual Rev. 12-2012

instructions in the operating manual

- incorrect electrical connections.

The warranty is invalidated in case of:

- repairs made by people who were not authorised by

the manufacturer;

- modifications that were not authorised by the manufacturer;

- use of parts and/or equipment that were not supplied

or approved by the manufacturer;

- removal or alteration of the machine identification

plate.

1.8 TECHNICAL ASSISTANCE SERVICE

For any technical service operation, contact the manufacturer

directly or an authorised dealer always quoting the model,

the version and the serial number of the machine.

ENGLISH

1.9 COPYRIGHT

The information contained in this manual may not be

disclosed to third parties. Partial or total duplication, unless authorised by the Manufacturer in writing, through

photocopying, duplication or other systems, including

electronic acquisition, is breach of copyright and can lead

to prosecution.

Introduction

7

Page 8

2. Installation

ENGLISH

Use and Maintenance Manual Rev. 12-2012

1. Unpack the machine and place the front guard on the

ground with the spindle locking/release pedal, the Zero

Weight lift and the side guard (1).

1

3. Do not install the machine in an area directly exposed

to sunlight or where there are reflections from the floor.

The machine might malfunction if there is excess light

(3).

3

4. Avoid positioning objects made of a particularly reflecting

material in the areas indicated in gray, as they might

interfere with laser reading (4).

4

2. Absolutely do not force the side column when unloading

the machine from the pallet and be careful with the

electrical wiring (2).

2

8

Installation

Page 9

Use and Maintenance Manual Rev. 12-2012

5. Hold up the lift using a wooden board (5)

5

6. Screw in the elbow union and fit all the wiring and

pneumatic connectors inside the lift (6)

6

8. Connect the 140 Ø tube (8)

8

ENGLISH

9. Connect the lift pedal cable with a male/female Faston

(9)

9

7. Connect the 8 Ø tube (7)

7

10. Connect the footboard micro limit switch cable with a

male/female Faston (10)

10

Installation

9

Page 10

Use and Maintenance Manual Rev. 12-2012

11. Connect the pneumatic locking pedal microswitch cable

with a male/female Faston (11)

11

8

ENGLISH

12. Position and fasten the front footboard (12)

12

14. Position the lift with the footboard in line with the

spindle (14)

14

13. Position the side guard and fasten it (13)

13

10

Installation

Page 11

Use and Maintenance Manual Rev. 12-2012

15. Drill the holes in the floor using a drill with an 8Ø bit and fit the expandable bolts provided as indicated in the

drawing and tighten them to a torque of 25 Nm. As indicated in the box, in the last phase, fasten the mounting

brackets on the side of the column and tighten to a torque of 25Nm (15) .

15

ENGLISH

25Nm

16. Check that the mains input voltage and frequency

parameters are compatible with the data shown on

the wheel balancing machine plate (±10%) (16).

16

17. Check proper pneumatic connection; the machine and

the lift require at least 8 kg/cm² (~ 0.8 MPa; ~8 BAR;

~115 PSI) (17).

17

17

18. Turn on the machine and carry out

operations:

▪ LASER CALIBRATION

▪ TAPER CALIBRATION

▪ MACHINE CALIBRATION

the following

Installation

11

Page 12

Use and Maintenance Manual Rev. 12-2012

3. Machine description

ENGLISH

3.1 MACHINE FUNCTION

It is a wheel balancing machine for cars, light commercial vehicles and 4-WDs .The wheels must weigh less than 75

kg. It can be operated in a temperature range of 0° to + 45° C.

It can operate only on a flat and non-resilient surface.

Do not mount any wheels other than motorcycle, car or truck wheels on the wheel balancing machine.

Thanks to the new and exclusive VDD (Virtual Direct Drive) system, reliable unbalance measurements can be made in

a short time, almost half the cycle time of other wheel balancing machines in this range.

TFT TOUCH SCREEN

WEIGHT TRAY

LASER POSITIONING

RIM INTERIOR LED LIGHT

PNEUMATIC LOCKING PEDAL

ZERO WEIGHT PEDAL

GUARD

CONE HOLDER

EXTERNAL SCANNING LASER

PNEUMATIC SPINDLE

INTERNAL SCANNING LASER

ZERO WEIGHT CARRIAGE LEVER

ZERO WEIGHT (OPTION)

The main features include:

▪ Automatic dimension measurement

▪ Inside and outside rim eccentricity measurement

▪ Automatic minimisation of static unbalance

▪ wheel taper measurement

▪ Selection of optimal wheel mounting

▪ Customisable certificate printout

▪ Machine setting menu

▪ Unbalance optimisation

▪ Static program, ALUS; SPLIT; BPC; indication of exact position of the correction weights; self-diagnostics; self-

calibration

▪ Statistics of weights used

12

Machine description

Page 13

Use and Maintenance Manual Rev. 12-2012

3.2 TECHNICAL SPECIFICATIONS

The following data refers to the wheel balancing machine

in its standard configuration.

Single phase power supply 115 /230 V 50/60 Hz

Protection class IP 54

Maximum power absorbed 0,15 kW

Balancing speed 100 min

Cycle time per wheel

Measurement uncertainty 0.5 g.

Average noise < 70 dB(A)

Rim width setting range 1.5”-20” or 40 - 510 mm

Settable diameter 10” ÷ 30” or 265 ÷ 765 mm

Min/max. compressed air pressure 8 ÷ 10 Kg/cm2

Machine weight 220 kg.

-1

4.7 seconds (5 3/4"x14") 15 Kg

~ 0.8 ÷ 1 Mpa;

~ 8 to 10 BAR;

~ 115 to 145 PSI.

3.3 DIMENSIONS

The function buttons are selected by pressing on the

TOUCH SCREEN.

cAuTIoN:

pRe ss T he b uTToN s oNly W ITh youR fIN GeRs .

Nev eR us e Th e co uNTe RWeIG hT G RIpp eRs oR oTh eR po INTe d

obj ecTs !

ENGLISH

3.4 WARNINGS

Kee p Th e AR eA I NdIc ATed IN The fIGu Re f Ree of T ools ,

Zona d’azione laser scansione

Scanning laser range

of action

Machine description

cAuTIoN:

AdA pTeR s, e Tc.

Ø250mm

13

Page 14

SE2-MOUNTING

A

C

B

D

E

G

F

SE2 MOUNTING

Page 15

360°

Cone

Quando possibile, centrare le ruote con cono dall'interno (vedi disegno).

Evitare di usare il manicotto RL con cerchi di ferro.

Whenever possible, centre the wheels with the cone from the inside (see the drawing

).

Avoid using the RL sleeve with metal rims.

Lorsque c’est possible, centrer les roues avec le cône de l’intérieur (voir dessin).

Eviter d’utiliser le manchon RL avec les jantes en fer.

Wenn möglich, die Räder mit Konus von Innen heraus zentrieren (siehe Zeichnung).

Bei Eisenfelgen die Verwendung der Muffe RL vermeiden.

Siempre que sea posible, centrar las ruedas con cono desde dentro (véase dibujo).

Evitar usar el manguito RL con llantas de hierro.

Quando possível, centre as rodas com cone pelo lado de dentro (ver

� gura).

Evite utilizar a luva RL com jantes de ferro.

SE2-DISMOUNTING

A

B

C

D

E

IT

GB

FR

DE

ES

PT

SE2 DISMOUNTING

Page 16

4. Wheel lifting (option)

ENGLISH

Use and Maintenance Manual Rev. 12-2012

Zero Weight carriage lever

Pneumatic locking pedal Zero Weight pedal

▪ Position the wheel on the carriage resting it against the ZERO WEIGHT carriage lever. Check that the pneumatic

spindle is enabled for mounting (open); if not, push the pneumatic locking pedal.

▪ Push the Zero Weight pedal.

Nev eR p ush The ZeRo WeI GhT pedA l If The Re I s AN yoNe sTA NdIN G IN The RAN Ge o f Ac TIoN of The lIfT .

bef oRe push ING The pedA l To lIf T A Whee l, A lWAy s ch ecK ThAT The spI Ndle Is opeN

(If NoT , Th e lI fT m IGhT NoT Asc eNd oR A sceN d IN coRR ecTl y).

As soon as the wheel lifts off the ground, it is ready for mounting on the wheel balancing machine at zero weight.

cAuTIoN:

cAuTIoN:

▪ Position the central hole of the wheel at the height of the spindle and slide the wheel onto the spindle with the aid

of the Zero Weight carriage lever.

16

Wheel lifting

Page 17

Use and Maintenance Manual Rev. 12-2012

5. Wheel locking

To lock/release the wheel on the pneumatic spindle, push the pneumatic locking pedal.

ENGLISH

If T he lIfT Is up A Nd T he p Neum ATIc loc KING ped Al I s pu shed To locK The Whe el o N Th e sp INdl e,

lIf T de sceN T WI ll A uTom ATIc Ally be eNAb led.

Wheel locking

17

Page 18

Use and Maintenance Manual Rev. 12-2012

6. Use of the wheel balancing machine

ENGLISH

6.1 DIMENSION ACQUISITION

Acquires the wheel dimensions

Enables/disables taper and tread

measurement

Return to main screen

Outside rim eccentricity measurement

(use with the rim only)

NEW WHEEL

Press the button to acquire the dimensions.

Close the guard to perform the balancing spin.

ATTeNZIoNe

bef oRe pRe ssIN G T he buTTo N , po sITI oN The Whe el IN such A WAy Th AT A Ny WeIG hTs AlR eAdy oN Th e R Im do NoT fAll WI ThIN

The ReA dING ARe A of The INT eRNA l lA seR, ThAT WAy excl udIN G AN y dI meN sIoN meA suRI NG I NAcc uRAc Ies.

WHEEL THE SAME AS PREVIOUS

Close the guard to perform the balancing spin.

The machine in any case checks the wheel dimensions and if they are different from the previous wheel, automatically

measures them again. With this innovative system you can balance a set of 4-5 wheels measuring the dimensions

only once, thus saving a lot of time.

TAPER AND TREAD MEASUREMENT AT THREE POINTS

Press the button to enable/disable complete taper and tread measurement.

This function uses a special measuring cycle that extends the cycle time by a few seconds.

The setting remains stored even when the wheel balancing machine is turned off.

OUTSIDE RIM ECCENTRICITY MEASUREMENT WITHOUT TYRE

Press the button ( OUTSIDE RIM RUNOUT )

CANCEL DIMENSION SETTING

Press the button .

18

Use of the wheel balancing machine

Page 19

Use and Maintenance Manual Rev. 12-2012

6.2 CORRECTION MODE SELECTION

Press from the unbalance measurement screen.

ENGLISH

Goes back to the unbalance measurement

screen, automatically recalculating the

unbalance values.

Press the weight symbol in the desired correction position.

If doing the unbalance correction in static mode only, press and hold the outside adhesive weight symbol for

once or twice (depending on the current correction mode)..

Use of the wheel balancing machine

19

Page 20

6.3 UNBALANCE UNIT OF MEASURE selection

ENGLISH

Press the button / from the unbalance measurement screen

Use and Maintenance Manual Rev. 12-2012

Selects grams

Selects ounces

Allows selecting whether to view the unbalance values expressed in grams or ounces.

20

Use of the wheel balancing machine

Page 21

Use and Maintenance Manual Rev. 12-2012

6.4 UNBALANCE MEASUREMENT (first set of buttons)

Displays the information screen

Selects unbalance display in g/oz

Traceability management

Enables/disables wheel in correction position

Splits the unbalance

Displays the second set of buttons

ENGLISH

Lift reset with wheel stopped / STOP during spin

To perform an unbalance measurement spin, close the guard.

After performing a balancing spin, the following are displayed:

1. The unbalance values.

▪ White: wheel locked in correction position / Internal scanning laser positioned on the side.

▪ Light blue: position not reached / Internal scanning laser not positioned.

2. The red weights that indicate the unbalance position.

3. The weight shadows that indicate where the correction weight should be applied: at the top at 12 o’clock or at the

point indicated by the internal laser.

If T he “Whe el I N po sITI oN” souN d Is eNA bled , A souN d WI ll b e em ITTe d Wh eN T he c oRRe cTIo N po sITI oN h As b eeN ReAc hed .

If Th e uNbA lANc e Is le ss Th AN The T hRes hold vAlu e seT, oK Is d Ispl Ayed I NsTe Ad of T he uNb AlAN ce vA lue To INdI cATe T hAT Th e

pRe ssIN G Th e bu TToN you cA N IN ANy cAs e vI eW T he R esId uAl uNbA lANc e.

Whe el I s WI ThIN Tol eRAN ce o N Th AT s Ide.

To R esu me W ITh The dIme NsIo Ns o f Th e Wh eel mouN Ted, ope N AN d cl ose The spIN dle.

when on, it indicates that the lasers are moving

when on, it indicates that the lift pedal is pressed

Use of the wheel balancing machine

21

Page 22

Use and Maintenance Manual Rev. 12-2012

when on, it indicates that the wheel locking pedal is pressed

ENGLISH

when on, it indicates that the spindle is closed

when on, it indicates that wheel positioning is enabled.

6.4.1 Lock/release wheel in correction position

The wheel balancer automatically keeps the wheel in the correction position on one of the sides. To release it press

.

If the wheel has been released and you need to move it into the correction position again, press .

22

Use of the wheel balancing machine

Page 23

Use and Maintenance Manual Rev. 12-2012

6.5 UNBALANCE MEASUREMENT (second set of buttons)

Prints the unbalance values

Displays the weight statistics

Menu

Unbalance optimisation

Goes back to the first set of buttons

ENGLISH

Lift reset with wheel stopped / STOP during spin

Use of the wheel balancing machine

23

Page 24

6.6 THRESHOLD DISPLAY

ENGLISH

Use and Maintenance Manual Rev. 12-2012

Displays the information screen

Selects unbalance display in g/oz

Traceability management

Enables/disables wheel in correction position

Splits the unbalance

Displays the second set of buttons

Lift reset with wheel stopped / STOP during spin

Press to view the residual unbalance values with an accuracy of 0.5 g. (0.1oz).

Press to go back to display of the approximate values.

24

Use of the wheel balancing machine

Page 25

Use and Maintenance Manual Rev. 12-2012

6.7 UNBALANCE CORRECTION

After an unbalance measurement spin, the weight shadow indicates the correct application point.

6.7.1 Iron rims

Displays the information screen

Selects unbalance display in g/oz

Traceability management

Enables/disables wheel in correction position

Unbalance split (not selectable for correction with

clip-on weights)

Displays the second set of buttons

ENGLISH

Lift reset with wheel stopped / STOP during spin

WEIGHT APPLICATION POSITION

Correction type Inside Outside

Clip-on weight at 12 o’clock Clip-on weight at 12 o’clock

Clip-on weight at 12 o’clock Adhesive weight at 12 o’clock

Adhesive weight at the point indicated

by the internal laser

Clip-on weight at 12 o’clock

Adhesive weight at the point indicated

Use of the wheel balancing machine

by the internal laser

Adhesive weight at the point indicated by the internal laser

Adhesive weight at 12 o’clock

25

Page 26

6.7.2 Aluminium rims

ENGLISH

Use and Maintenance Manual Rev. 12-2012

Displays the information screen

Selects unbalance display in g/oz

Traceability management

Enables/disables wheel in correction position

Splits the unbalance

Displays the second set of buttons

Lift reset with wheel stopped / STOP during spin

After the spin, the laser indicates the outside correction point; once you have applied the weight, press the “laser

positioning” button ( MACHINE DESCRIPTION) positioned on the weight tray of the wheel balancing machine to

move the laser so that it indicates the inside correction position.

The inside unbalance values indicated by the laser are graphically displayed in white.

WEIGHT APPLICATION POSITION

Correction type Inside Outside

Adhesive weight at the point indicated

by the internal laser

Clip-on weight at 12 o’clock

Adhesive weight at the point indicated by the

internal laser

Adhesive weight at the point indicated by the

internal laser

26

Use of the wheel balancing machine

Page 27

Use and Maintenance Manual Rev. 12-2012

6.7.3 Change weight application distance

ENGLISH

To change the correction positions indicated by the laser and automatically calculated by the machine, operate as

follows:

1. Position on the side to be changed by pressing the laser positioning button.

2. Press

3. Move the wheel by hand to move the laser.

4. When you have reached the desired position, press the button

To cancel this operation, press the button : The laser automatically goes back to indicating the correction

position previously saved.

Use of the wheel balancing machine

27

Page 28

Use and Maintenance Manual Rev. 12-2012

6.8 UNBALANCE SPLIT

ENGLISH

The split function is enabled for the outside of aluminium rims ( ALUMINIUM RIMS) and is used to hide any adhesive

unbalance correction weights behind the rim spokes.

To split the unbalance measured in two different positions, proceed as follows:

1. With the wheel in the outside correction position,

press the button to release it.

2. Select a spoke close to the position indicated by the

laser and press the button

The Wh ITe lINe oN The RIm INdI cATe s Th e uN bAlA Nce

If Th e sym bol A ppeA Rs, I T meAN s ThA T you c ANNo T

coRR ecTIoN pos ITIo N No T sp lIT.

sele cT The fIRs T sp oKe AT T hAT poIN T

(mA xImu m dI sTAN ce 150°).

3. Turn the wheel in the direction indicated on the screen

and select the second spoke by pressing the button

If Th e sym bol A ppeA Rs, I T meAN s ThA T you c ANNo T

sele cT The seco Nd s poKe AT ThAT poI NT

(mI NImu m dI sTAN ce 18°, mAxI mum dIsT ANce 120°).

4. At this stage, two indications appear on the screen for

positioning of the unbalance correction weights.

To cancel the split, press the button :

Any error in this procedure is clearly shown on screen.

28

Use of the wheel balancing machine

Page 29

Use and Maintenance Manual Rev. 12-2012

6.9 UNBALANCE OPTIMISATION

ENGLISH

Confirm

Return to main screen

Press the button from the second set of buttons on the unbalance measurement screen after performing a

balancing spin.

ThI s fu NcTI oN c ANNo T be Acc esse d If you hAv e No T fI RsT peRf oRme d A bAlA NcIN G sp IN.

The program allows total wheel unbalance to be reduced by compensating, when possible, tyre and rim unbalance

values. It requires two spins, rotating the tyre on the rim on the second spin.

At the end of the procedure, mark the rim and tyre positions indicated by the machine with a piece of chalk and remount both so that they coincide.

Use of the wheel balancing machine

29

Page 30

6.10 TYRE SET

ENGLISH

Use and Maintenance Manual Rev. 12-2012

Selects any one-way direction of the wheel

Prints the tyre set values

Return to main screen

Manual wheel position setting

This function allows balancing the four wheels of a vehicle, plus the spare wheel if necessary, and obtaining information

on how to mount them in order to reduce to a minimum the vibrations due to the residual eccentricity of each wheel.

The TYRE SET function can be enabled or disabled from the MENU; to best use this function, proceed as follows:

1. Prepare adhesive symbols to identify the wheels.

2. Mount the first wheel, measure the dimensions, balance it and identify it with the number 1.

3. Dismount the wheel and mount the next one, close the guard and balance the wheel without acquiring the

dimensions again.

4. Repeat step 3 for the remaining 3 wheels, plus any spare wheel, each time identifying the wheel with a progressive

number from 2 to 5.

5. Each time the spindle is opened, the wheel balancing machine indicates the best way to mount the wheels balanced

up to that point. On the left-hand side of the screen, a stylized vehicle is displayed with the four tyres plus the

spare wheel; at each spin, the number of the wheel to be mounted in each position is indicated on each of them

(right/left front/rear axle).

6. The procedure can be reset by measuring the dimensions like for a new wheel. If the spindle is incorrectly opened,

the balancing sequence is interrupted and consequently the end result will be incorrect.

7. To view a summary table with the wheel values, press the button :

Static residual unbalance

Radial runout

Tread measured as one value

30

Tread measurement

Wheel taper

Use of the wheel balancing machine

Page 31

Use and Maintenance Manual Rev. 12-2012

In the case of directional wheels, i.e. which can be mounted only on the right or only on the left, press the button

to set the direction:

▪ Left

▪ Right

▪ Left/right

The machine changes and immediately displays the new mounting order.

The wheel mounting order is established based on the residual radial eccentricity value of each wheel.

ENGLISH

To manually set the order of the wheels press + :

drag one wheel at a time to the desired position on the vehicle drawing and drop it when

the edges turn green

Resets the manual setting

Confirms manual setting

Cancels manual setting

AT e Ach uNb AlAN ce R ecAl culATI oN, The TyRe seT seT TING Goe s bA cK T o be ING bAse d oN The Whe el R uNou T.

Use of the wheel balancing machine

31

Page 32

6.10.1 Tyre set value certificate

ENGLISH

Press the button from the tyre set value summary screen.

LOGO

Use and Maintenance Manual Rev. 12-2012

Printout data setting

Saves the certificate to USB key

Loads the certificate from USB key

Prints the unbalance values

Return to main screen

6.10.2 Tyre set certificate customisation

Follow the instructions for customising the balancing certificate ( BALANCING CERTIFICATE CUSTOMISATION).

The .htm file to be customised is TyreSet.htm.

32

Use of the wheel balancing machine

Page 33

Use and Maintenance Manual Rev. 12-2012

6.11 WEIGHT STATISTICS

Clip-on weight graph

No. of daily spins:Indicates the number of spins performed by the machine per day

Total no. of spins: Indicates the number of spins performed by the machine starting from the reset date.

The two tables list all the weights (clip-on and adhesive) used starting from the reset date.

Adhesive weight graph

Resets the statistics

Print statistics

Displays the statistics of the weights used in grams

and ounces

Return to main screen

ENGLISH

When the RESET STATISTICS button is pressed, a pop-up menu appears that allows selecting which parameters

to reset.

Selects the counter to reset

Deselects the counter to reset

Resets the counters selected

Goes back to the measurement screen

Appears if the relative counter is selected to be reset.

Use of the wheel balancing machine

33

Page 34

ENGLISH

Use and Maintenance Manual Rev. 12-2012

Pressing on the buttons in the table header, graphic

display of the statistics of the weights used is enabled, which allows more intuitively understanding

the most common types of weight adopted.

34

Use of the wheel balancing machine

Page 35

Use and Maintenance Manual Rev. 12-2012

6.12 TRACEABILITY

Allows setting a series of information indicated on the balancing certificates.

ENGLISH

Allows alphanumerical setting of the field

Allows scrolling a list of possible selections

Confirms all the settings

Resets all the settings

(completely clearing the form)

Pressing the button to set a field, a virtual keyboard appears::

The virtual keyboard works exactly like a physical keyboard.

In particular:

Cancels any settings made

Resets the entire field

Deletes only the last character typed

Switches between small and capital letters (and vice versa)

Use of the wheel balancing machine

35

Page 36

Selects the QWERTY keyboard

Use and Maintenance Manual Rev. 12-2012

ENGLISH

Switches between various pages of special characters

Cancels the setting

Confirms the setting

36

Use of the wheel balancing machine

Page 37

Use and Maintenance Manual Rev. 12-2012

6.13 BALANCING CERTIFICATE PRINTOUT

Press the button from the second set of buttons on the unbalance measurement screen.

LOGO

Printout data setting

Saves the certificate to USB key

Loads the certificate from USB key

Prints the unbalance values

ENGLISH

Return to main screen

Use of the wheel balancing machine

37

Page 38

6.13.1 Balancing certificate customisation

ENGLISH

Insert a USB key in the port at the rear of the machine.

Use and Maintenance Manual Rev. 12-2012

USB PORT

Press to save the certificate management files to the USB key.

Afoldercalled“Certif”iscreatedonthekeycontainingallthelestobeeditedtocustomisethebalancing

certicate:

38

Use of the wheel balancing machine

Page 39

Use and Maintenance Manual Rev. 12-2012

File to be customised using an HTML editor (FinalCertificate.htm):

LOGO

Balancing certificate logo: 1241 × 278 pixel. It can be replaced with a personalised logo.

LOGO

ENGLISH

Use the following codes to insert the possible printable values in the balancing certificate.

Numeric code Field

Generic

#1# Date

#2# Time

Actual unbalances values

#10# Internal unbalance valueP2

#11# External unbalance value

#12# Static unbalance value

Run-out

#20# Radial run-out value

#21# Rim run-out value

#22# Tyre run-out value

Tread

#23# Tyre tread depht (standard)

#24# Tyre tread depht left (3 zones)

#25# Tyre tread depht center (3 zones)

#26# Tyre tread depht right (3 zones)

#27# Conicity value

Use of the wheel balancing machine

Conicity

39

Page 40

ENGLISH

Use and Maintenance Manual Rev. 12-2012

Units

#30# Unbalance unit measure (g/oz)

#31# Run-out unit measure (mm/”)

Tire set

#40# Radial run-out value for wheel nr.1

#41# Tyre tread depht. for wheel nr.1

#42# Internal unbalance value for wheel nr.1

#43# External unbalance value for wheel nr.1

#44# Static unbalance value for wheel nr.1

#45# Radial run-out value for wheel nr.2

#46# Tyre tread depht. for wheel nr.2

#47# Internal unbalance value for wheel nr.2

#48# External unbalance value for wheel nr.2

#49# Static unbalance value for wheel nr.2

#50# Radial run-out value for wheel nr.3

#51# Tyre tread depht. for wheel nr.3

#52# Internal unbalance value for wheel nr.3

#53# External unbalance value for wheel nr.3

#54# Static unbalance value for wheel nr.3

#55# Radial run-out value for wheel nr.4

#56# Tyre tread depht. for wheel nr.4

#57# Internal unbalance value for wheel nr.4

#58# External unbalance value for wheel nr.4

#59# Static unbalance value for wheel nr.4

#60# Radial run-out value for wheel nr.5

#61# Tyre tread depht. for wheel nr.5

#62# Internal unbalance value for wheel nr.5

#63# External unbalance value for wheel nr.5

#64# Static unbalance value for wheel nr.5

#65# Right front tyre number

#66# Left front tyre number

#67# Right rear tyre number

#68# Left rear tyre number

#69# Spare tyre number

#70# Tyre tread depht. 3 zones for wheel nr.1

#71# Tyre tread depht. 3 zones for wheel nr.1

#72# Tyre tread depht. 3 zones for wheel nr.1

#73# Tyre tread depht. 3 zones for wheel nr.2

#74# Tyre tread depht. 3 zones for wheel nr.2

#75# Tyre tread depht. 3 zones for wheel nr.2

#76# Tyre tread depht. 3 zones for wheel nr.3

#77# Tyre tread depht. 3 zones for wheel nr.3

#78# Tyre tread depht. 3 zones for wheel nr.3

#79# Tyre tread depht. 3 zones for wheel nr.4

#80# Tyre tread depht. 3 zones for wheel nr.4

#81# Tyre tread depht. 3 zones for wheel nr.4

#82# Tyre tread depht. 3 zones for wheel nr.5

#83# Tyre tread depht. 3 zones for wheel nr.5

#84# Tyre tread depht. 3 zones for wheel nr.5

#85# Conicity value for wheel nr.1

#86# Conicity value for wheel nr.2

40

Use of the wheel balancing machine

Page 41

Use and Maintenance Manual Rev. 12-2012

#87# Conicity value for wheel nr.3

#88# Conicity value for wheel nr.4

#89# Conicity value for wheel nr.5

Runout

#90# PP wheel runout

#91# I harmonic wheel runout

#92# II harmonic wheel runout

#93# III harmonic wheel runout

#94# IV harmonic wheel runout

#95# PP rim runout

#96# I harmonic rim runout

#97# II harmonic rim runout

#98# III harmonic rim runout

#99# IV harmonic rim runout

Rim Runout

#100# PP internal rim runout

#101# I harmonic internal rim runout

#102# II harmonic internal rim runout

#103# III harmonic internal rim runout

#104# IV harmonic internal rim runout

#105# PP external rim runout

#106# I harmonic external rim runout

#107# II harmonic external rim runout

#108# III harmonic external rim runout

#109# IV harmonic external rim runout

ENGLISH

Tolerance

#120# Runout tolerance

#121# Tread tolerance

#122# Conicity tolerance

Printout

#130# Unbalance

#131# Internal

#132# External

#133# Static

#134# Radial runout

#135# Rim runout

#136# Tire runout

#137# Tread depth

#138# Conicity

#139# Signature

Traceability

#150# Workshop laber

#151# Workshop

#152# Customer label

#153# Customer

Use of the wheel balancing machine

41

Page 42

ENGLISH

Use and Maintenance Manual Rev. 12-2012

#154# Car model label

#155# Car model

#156# Label Km

#157# Km

#158# Label registration

#159# Registration

#160# Label wheel position

#161# Wheel position

#162# Label tyre

#163# Tyre

#164# Label rim

#165# Rim

#166# Label pressure

#167# Pressure

#168# Label notes

#169# Notes

#170# Label 01

#171# Custom field 01

#172# Label 02

#173# Custom field 02

#174# Label 03

#175# Custom field 03

Edit the Finalcertificate.htm file based on your needs and save it to the USB key.

Insert the key in the machine and press to reload the customised balancing certificate.

42

Use of the wheel balancing machine

Page 43

Use and Maintenance Manual Rev. 12-2012

6.14 SCREENSAVER

ENGLISH

CUSTOMISED SCREENSAVER

If the machine is not used and remains on the initial screen for longer than the time settable from the menu, the

screensaver is automatically activated. Pressing on the screen at any point or moving the wheel, the main screen will

automatically be activated. Automatic start-up operated by the protection system is not available from the screensaver for safety reasons.

Use of the wheel balancing machine

43

Page 44

6.15 WHEEL ANALYSIS

ENGLISH

Press the button from the first set of buttons on the measurement screen.

Goes to the peak/peak and first harmonic graph screen

Goes to the tread analysis screen

Prints the information screen

Use and Maintenance Manual Rev. 12-2012

Return to main screen

This screen shows all the data read in the various unbalance measurement and wheel analysis phases.

For more information, refer to the paragraphs RUNOUT, TREAD, TAPER .

The button is displayed with a red I when:

▪ The first harmonic of the wheel runout exceeds the limit set in the setup parameters.

▪ The first harmonic value of the rim runout exceeds the limit set in the setup parameters.

▪ The tread value is less than the limit set in the setup parameters.

▪ The wheel taper value is considered unacceptable (indicator on red level).

44

Use of the wheel balancing machine

Page 45

Use and Maintenance Manual Rev. 12-2012

wheel

wheel

wheel

6.15.1 Runout

6.15.1.1 When and why TO USE MATCHING

The software associated with the eccentricity measurement is a powerful tool to determine the need to perform

the relative rotation between the wheel and the rim in

order to reduce the eccentricity to within acceptable limits. The criterion used is based on the fact that a rim with

acceptable tolerance, mounted with acceptable tyre, can

statistically generate an unacceptable total eccentricity

that can be improved by matching.

ER 100 is capable of automatically measuring the eccentricity of both the tyre and the rim from the inside.

The latter measurement generally corresponds to the rim

eccentricity in the tyre fitting area.

The RIm cAN be meA suRe d mo Re AccuRA Tely usI NG The sp ecIf Ic

pRo GRAm WIT houT The TyR e.

Example 1

ENGLISH

virtual wheel

rim

tyre

rotation axis

Tyre - 0.6 mm

Wheel + 0,3 mm

The eccentricity of the single elements is compensated.

The wheel is acceptable.

Example 3

virtual wheel

rim

tyre

rotation axis

Rim + 0.8 mm

Tyre + 0.6 mm

Wheel + 1.3 mm

The wheel eccentricityis excessive because an acceptable

rim or tyre has randomly been positioned in an “unfor-

tunate” position”.

virtual wheel

rim

tyre

rotation axis

Rim - 0 mm

Tyre + 1,2 mm

Wheel + 1.2 mm

The wheel eccentricity cannot be compensated by the rota-

tion because the rim is perfect!

SOLUTION: turn the tyre on the rim by 180°

RESULT: wheel eccentricity 0.3 – 0.4 mm (in tolerance)

Rim + 0.8 mm

Use of the wheel balancing machine

SOLUTION: turn the tyre on the rim by 180°

RESULT: No improvement.

45

Page 46

6.15.1.2 Matching

ENGLISH

Use and Maintenance Manual Rev. 12-2012

Goes to the peak/peak and first harmonic graph

screen.

Goes to the tread analysis screen

Prints the information screen

Enables/disables wheel in position

Return to main screen

The rim and wheel runout measurements are automatically made during the unbalance measurement cycle and no

extra time is required.

The purpose of these measurements is to check whether it is possible to reduce the total wheel runout by turning

only the tyre on the rim.

The information shown on the screen is:

Grey rim: outer tyre surface

Yellow rim: rim surface

: Tyre runout position (moved by turning the wheel)

: Rim runout position (moved by turning the wheel)

When highlighted:

indicates that the tyre needs to be marked with a piece of chalk at the top at 12 o’clock.

When highlighted:

indicates that the rim needs to marked with a piece of chalk at the top at 12 o’clock.

Wheel runout (rim plus tyre):

46

Tyre runout

Rim runout

The wheel and rim runout values are shown in white if they are within tolerance and in red if they are out of

tolerance.

Use of the wheel balancing machine

Page 47

Use and Maintenance Manual Rev. 12-2012

displayed when Wheel Runout or Rim Runout is out of tolerance.

displayed when both Wheel Runout and Rim Runout are within tolerance.

Percentage wheel runout reduction

Estimated residual wheel runout after matching

The rotation symbol and the residual wheel runout value are shown in red if the estimated value after matching is out

of tolerance with respect to the value set in the runout setup parameters.

6.15.1.2.1 When to perform matching

It is advisable to perform matching if the wheel runout value is displayed on a red background and the residual wheel

runout value is displayed in the Match box on a green background.

ENGLISH

6.15.1.2.2 How to perform matching

▪ Turn the wheel and mark the tyre and the rim with a piece of chalk at the two points indicated in the graph.

▪ Turn the tyre on the rim until the two marks coincide.

Use of the wheel balancing machine

47

Page 48

6.15.1.3 Peak/peak and first harmonic graphs

ENGLISH

Use and Maintenance Manual Rev. 12-2012

Goes back to the runout/matching analysis

screen

Displays the peak/peak, 1st, 2nd, 3rd, 4th harmonic graphs and values of the tyre and the rim.

Pressing on the graphs you can enlarge them to better highlight any wheel and rim defects.

you cAN dIs Able The Whe el o R RI m ec ceNT RIcI Ty m eAsu Reme NT f Rom GeNe RAl seTu p.

48

Use of the wheel balancing machine

Page 49

Use and Maintenance Manual Rev. 12-2012

6.15.2 Tread

ENGLISH

Goes to the peak/peak and first harmonic graph

screen.

Goes to the tread analysis screen

Prints the information screen

Enables/disables wheel in position

Return to main screen

Tread analysis can be performed

1. During the balancing cycle to obtain an average value measured over the whole tyre width.

No extra time is required.

2. Enable a special measuring cycle using the button to obtain the tread value for the three different areas:

inside edge, centre and outside edge of the tyre.

The cycle time is slightly longer.

The tread values that are out of tolerance are shown in red.

displayed when at least one tread value is out of tolerance.

displayed when all the tread values are within tolerance

By law (to be verified for each country) the minimum tread thickness must be 1.6mm at each point.

It is quite normal for tyres to wear irregularly and that the pivot pins wear more on one side.

By means of tread analysis at several points, you can measure the tyre tread depth with adequate accuracy on the

edges and in the centre.

Use of the wheel balancing machine

49

Page 50

For detailed tread analysis, press the button :

ENGLISH

Use and Maintenance Manual Rev. 12-2012

Increases the scale

Decreases the scale

Increases the scale

Decreases the scale

Enables cursor display for

tread measurement

Goes back to the information screen

When pressing the button two cursors are displayed (one red and one yellow) and a black window that shows

the difference in millimetres measured between the two cursors.

Dragging the cursors with your finger,

you can move them to another point

of the tread.

Goes back to the information screen

Indicates the distance between the

two cursors.

50

Use of the wheel balancing machine

Page 51

Use and Maintenance Manual Rev. 12-2012

6.15.3 Taper

ENGLISH

Goes to the peak/peak and first harmonic graph

screen.

Goes to the tread analysis screen

Prints the information screen

Return to main screen

Examination of the wheel taper requires a special measuring cycle to be enabled using the button and

requires a slightly longer cycle time.

After the measurement, you obtain:

GREEN indicator: wheel NOT TAPERED and in good conditions

YELLOW indicator: wheel SLIGHTLY TAPERED

to the right

or to the left

as indicated in the graph:

it is advisable to check the wheel soon.

RED indicator: TAPERED wheel

to the right

or to the left

as indicated in the graph.

Check the taper of the wheel to be mounted on the same axle, assess if there is any

toe-inor replace the wheel.

displayed when the wheel is not tapered.

displayed when the wheel taper value is deemed unacceptable (indicator on red level)

The wheel taper measurement is important to solve any vehicle drift problems. Wheels tapered in the same

direction and mounted on the same axle might lead to the vehicle having problems in maintaining the trajectory on a straight line.

Use of the wheel balancing machine

51

Page 52

6.16 OUTSIDE RIM RUNOUT

ENGLISH

Press the button after closing the spindle.

Use and Maintenance Manual Rev. 12-2012

mouN T o Nly The RIm WIT houT The TyR e.

Close the guard and press the button

Confirm

Goes back to the measurement screen

Return to main screen

52

Use of the wheel balancing machine

Page 53

Use and Maintenance Manual Rev. 12-2012

The machine automatically reads the rim dimensions and performs a spin.

During rotation the outside eccentricity measurement is executed on the inner and outer edges of the rim in the positions laid down by the international standards.

When complete, a screen with the graphs of the values just measured is displayed.

Repeats the outside rim eccentricity measurement

Goes back to the measurement screen

Return to main screen

ENGLISH

Identifies the rim outside

Identifies the rim inside

Outside rim runout within tolerance

Outside rim runout out of tolerance

Theoutsiderimrunoutmeasuredontheedgesoftherimisdeemedwithintoleranceifboththerstharmonic

and the peak/peak values measured are less than the limits set in OUTSIDE RIM RUNOUT setup

Use of the wheel balancing machine

53

Page 54

Use and Maintenance Manual Rev. 12-2012

7. Wheel dismounting

ENGLISH

▪ Push the Zero Weight pedal. The carriage moves up to the wheel retrieval position.

▪ Push the tyre locking pedal to open the spindle.

▪ Push the Zero Weight pedal or push on the Zero Weight carriage lever to lower the carriage and dismount the

wheel.

If T he Whee l hA s be eN m ouNT ed W ITho uT u sING The ZeR o We IGhT lIf T, p ushI NG T he ZeRo WeIG hT p edAl AN eRRo R me ssAG e

WIll be dIs plAyed: dIs mouN T Th e Wh eel WIT houT The AId of The lIfT IN The sAme WAy IT WAs m ouNT ed.

The Whe el m ouNT ING/dIsm ouNT ING opeR ATING loGI c Im plIe s Th AT The Whe el b e mo uNTe d AN d dI smo uNTe d

usI NG T he l IfT ANd NoT by h ANd.

54

Use of the wheel balancing machine

Page 55

Use and Maintenance Manual Rev. 12-2012

8. Setup

8.1 MENU

Press the button from the measurement screen (second set of buttons)

ENGLISH

Setup

55

Page 56

8.2 GENERAL SETUP

ENGLISH

Use and Maintenance Manual Rev. 12-2012

Gives the user the possibility of setting the machine according to need. All the settings remain

when the machine is turned off.

8.2.1 General setup 1/3

Decreases the value

Increases the value

Confirms the default parameters

Goes back to the main menu screen

Goes to the setup screen 2/3

Return to main screen

unaltered even

Language:

Screensaver (min.):

Screensaver type: allows customising the screensaver with any kind of image in .jpg format. ( SCREEN-

Linear unit of measure: selects the unit of measure (mm/inch)

Correction method: allows selecting from 3 correction methods: STANDARD, EXTERNAL PLANES, BPC

STANDARD The wheel balancing machine considers the unbalance within tolerance when the value of

EXTERNAL PLANES The unbalance is considered within tolerance when the weight recalculated on the external

allows selecting the language to be used to display the descriptive and diagnostic messages

relating to machine operation.

allows selecting when the screensaver will be activated after the machine has not been

used for a certain time.

SAVER CUSTOMISATION)

each single plane is lower than the tolerance set.

planes (clip-on weight) is lower than the tolerance set.

56

Setup

Page 57

Use and Maintenance Manual Rev. 12-2012

BPC (Best Possible Correction) Provides the best possible solution for reduction of vibrations noticeable in the

vehicle.

Many elements affect the vibration perceived in the vehicle due to wheel unbalances:

▪ Residual static unbalance

▪ Residual dynamic (or torque) unbalance

▪ Wheel weight (the heavier the wheel, the less the unbalance will make it vibrate)

▪ Wheel diameter (on which the application radiuses of the counterweights depend)

Comparison between conventional balancing and the BPC method

CONVENTIONAL BALANCING:

▪ Given a set tolerance of 5g, a wheel is considered balanced also with a residual unbalance of 4.9g per plane in

approximately the same angular position. This means that a static unbalance of 9.8 grams is tolerated, even

though the static unbalance is deemed the main cause of vibrations noticeable by the driver.

▪ The balancing tolerance for all wheel types, not taking any unbalance of 10g into account, produces different

vibrations on a 13” or a 22" wheel. The residual vibrations are inversely proportional to the wheel weight.

▪ The angular position of the residual unbalances is not taken into account.

BALANCING USING THE BPC METHOD:

▪ With this method, the balancing tolerance value is reprocessed based on the wheel dimensions and the permissible

residual static and torque unbalances, which are numerically different (greater torque unbalance than static

unbalance is permitted).

▪ The tolerance no longer refers to the correction planes but is UNIQUE and indicates the residual vibration limit

value permissible on the wheel.

▪ An indicator on the screen provides information on the residual vibration obtained after balancing with respect

to the maximum tolerable vibration.

▪ Bymeans of complex mathematical calculations, it indicates how many and where correction weights should be

added for the best possible reduction of the vibrations noticeable by the driver. This means that the customer

receives the best possible service.

ENGLISH

No alternative method can be more accurate, using moderate weights with steps of 5g.

The machine also measures by HOW MUCH the “noticeable vibration” in the vehicle has been reduced with respect to the

conventional method, indicating the percentage reduction, i.e. by how much it has improved with respect to conventional

machines.

Less vibration, more satised customers!

Display pitch: This represents the unbalance display pitch and varies based on the unit of measure

selected.

such as to set the static unbalance value to 0 (theoretical).

It is advisable to set this function for normal use of the machine, as it improves the

ancing quality. The computer makes a complex calculation

residualstaticunbalancebyvaryingthevalueandthepositionofthecounterweightsxed

in steps of 5 grams (1/4 oz).

Tolerance:

Default parameter setting: Resets the default machine settings.

This is the unbalance threshold below which OK appears on the screen instead of the

unbalance value at the end

Selecting 5g (1/4 oz) enables display of the correction values

which allows cancelling the

of the spin.

on the two sides

bal-

Setup

57

Page 58

Use and Maintenance Manual Rev. 12-2012

8.2.1.1 Screensaver customisation

ENGLISH

From the General Setup screen, select CUSTOMISED SCREENSAVER and press the button

CUSTOMISED

SCREENSAVER

Saves the current screensaver to the USB key. The directory ER100_Screensave is created on the key

containing the file screensave.jpg; replace this file with the desired image, keeping the same name and

the same format (.jpg)

Loads the customised screensaver to the machine.

58

Goes directly to the screensaver screen.

Goes back to the general setup screen

Setup

Page 59

Use and Maintenance Manual Rev. 12-2012

8.2.2 General setup 2/3

ENGLISH

Decreases the value

Increases the value

Confirms the default parameters

Goes back to the setup screen 1/3

Goes to the setup screen 3/3

Return to main screen

Static unbalace always present: Enables/disables temporary display of the unbalance on the correction planes

selected and the STATIC unbalance

Wheel locking: Enables/disables wheel locking in the correction position

Wheel runout: Enables/disables wheel eccentricity measurement

Rim runout: Enables/disables rim eccentricity measurement

Runout diagnosis: Enables/disables display of the runout values on the unbalance measurement

screen

Lift: Enables/disables the lift

Selecting ON+HELP, online help is enabled on the measurement screen, cre-

ated with the aim of helping the user to properly use the lift.

Printer: Enables/disables the printer

Tyre set: Enables/disables the tyre set function

Default parameter setting: Resets the default machine settings

Setup

59

Page 60

8.2.3 General setup 3/3

ENGLISH

Use and Maintenance Manual Rev. 12-2012

Decreases the value

Increases the value

Confirms the default parameters

Goes back to the setup screen 2/3

Return to main screen

Rim interior light: Enables/disables a light to come on when the wheel is in the correction

position

Anticipated laser movement: Enables/disables anticipated laser movement as soon as you start closing

the guard.

If disabled, the lasers start measuring the wheel dimensions only after

having completely closed the guard.

Vibration reduction display: Enables/disables display of the vibration reduction percentage of the BPC

method with respect to the conventional method.

Functions only if the BPC method is enabled.

Default parameter setting: Resets the default machine settings

Status icon: enables/disables display of status icons on the main screen

Positioning: enables/disables wheel positioning.

60

Setup

Page 61

Use and Maintenance Manual Rev. 12-2012

8.3 RESERVED SETUP

Access to this screen is password protected [1 - 3 - 5 - 7 ].

ENGLISH

Press to access to reserved setup second screen.

INc oRRe cTly cA RRyIN G ou T Th e Re seRv ed s eTup pRo cedu Res mIGh T cA use seRI ous pRo blem s WI Th W heel bAl ANcI NG A Nd d IAGN osIs .

Reserved Setup

61

Page 62

8.3.1 LASER calibration

ENGLISH

Use and Maintenance Manual Rev. 12-2012

Saves the laser calibration values

Confirm

Goes back to the measurement screen

Return to main screen

1. Open the spindle and fit the specific calibration tool as shown in the figure.

The Tool cAN NoT be f ITTe d IN A p osIT IoN dIff eReN T fR om T hAT I NdIc ATed I N Th e fI GuRe .

do N oT peRf oRm A bA lANc ING spIN WIT h Th e cA lIbR ATIoN Tool fIT Ted.

AlWAys fI T Th e cA p o N Th e co llAR .

1. Close the spindle and the guard and press the button.

2. Remove the calibration tool and press

3. Press to save the calibration

4. Press to exit from the screen.

62

Reserved Setup

Page 63

Use and Maintenance Manual Rev. 12-2012

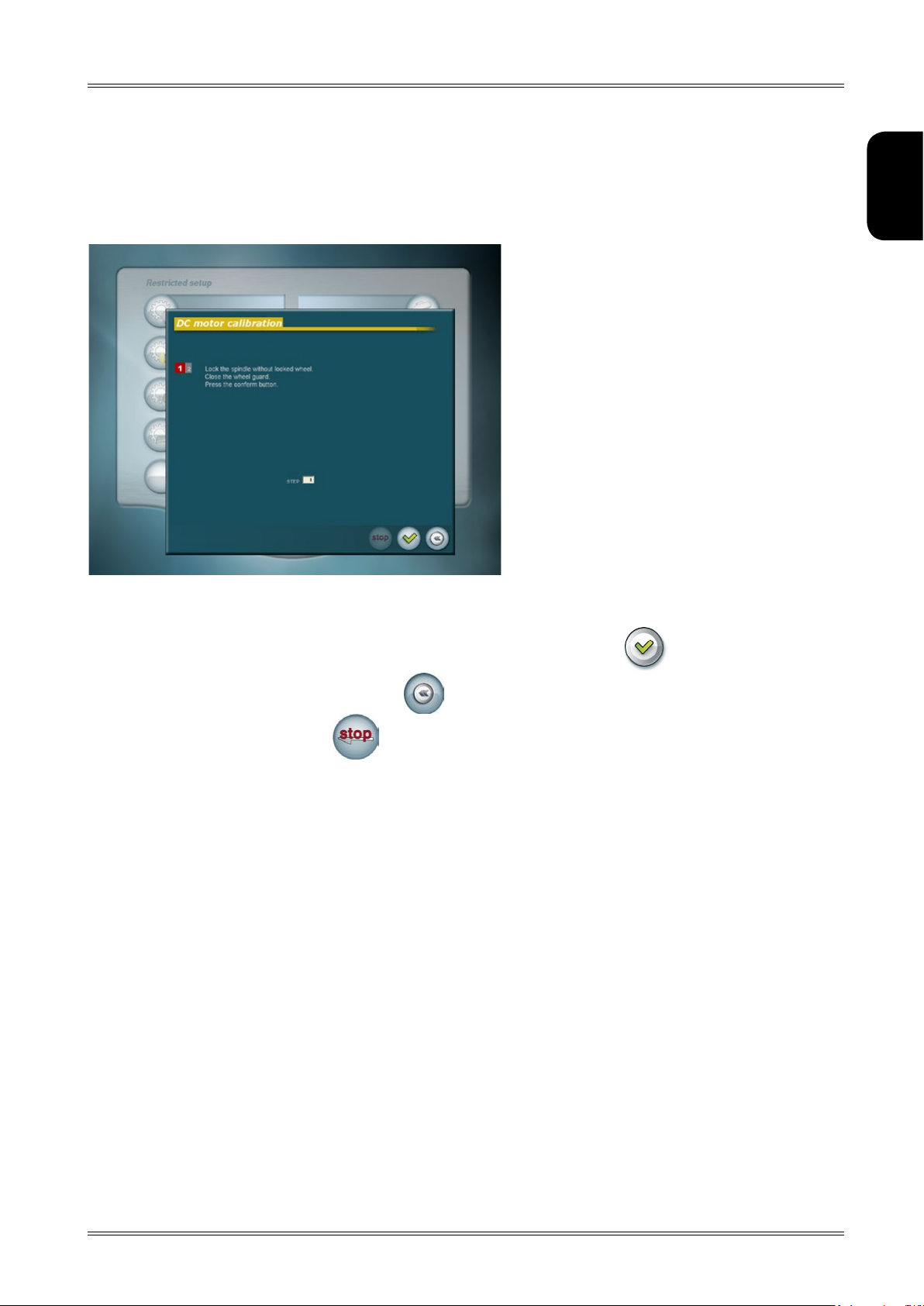

8.3.2 CC motor calibration

ENGLISH

1. Lock the spindle without a wheel or tools mounted. Close the guard and press

2. Wait for the procedure to complete.

3. If erroneously accessing the function, press

4. To interrupt the procedure, press .

Reserved Setup

63

Page 64

8.3.3 Spindle reset

ENGLISH

Use and Maintenance Manual Rev. 12-2012

Resets the spindle reset values.

Displays the spindle reset values saved

Saves the spindle reset values.

Confirm

Goes back to the measurement screen

Return to main screen

1. Lock the spindle without a wheel or tools. Close the guard and press the button

2. View the spindle reset values just read (if necessary for particular tests requested by Technical Service).

3. Press to save the spindle reset values

4. Press to exit from the screen.

64

Reserved Setup

Page 65

Use and Maintenance Manual Rev. 12-2012

8.3.4 Taper calibration

ENGLISH

Saves the calibration

Confirm

Goes back to the reserved setup screen

Return to main screen

1. Open the spindle and fit the calibration tool fastening it to the adapter with the screw and nut provided.

2. Position the tool in such a way that the laser crosses its central part during normal reading movement.

3. Close the guard and press the button

4. When prompted on the screen, remove the tool and then fit it on the other side.

do N oT opeN The spI Ndle .

5. When reading is complete, remove the calibration tool.

dAN GeR! do NoT peRf oRm A sp IN W ITh The Tool fITT ed!

6. Save the calibration.

7. Press to go back to the main screen.

Reserved Setup

65

Page 66

8.3.5 Correction weights

ENGLISH

Use and Maintenance Manual Rev. 12-2012

Decreases the value

Increases the value

Displays a calculator to

enter values directly

Confirms the default parameters

Goes back to the reserved setup screen

Return to main screen

Correctly set the length of the correction weights in order to improve the balancing quality.

Default parameter setting: Resets the default machine settings.

The zinc weights used for balancing generally become very long as the weight increases; in this condition the

weight can no longer be considered concentrated at the barycentre and the effect, for example, is a weight of

only 47 instead of 50 grams.

Correctly setting the length of the correction weights allows the wheel balancing machine to automatically compensate for the fact that all the weight cannot be applied at one point.

66

To o bTAIN The bes T Re sulTs, AlWAys u se W eIGh Ts o f Th e sA me m ANufA cTuR eR.

Reserved Setup

Page 67

Use and Maintenance Manual Rev. 12-2012

8.3.6 Wheel runout

ENGLISH

Decreases the value

Increases the value

Confirms the default parameters

Goes back to the reserved setup screen

Return to main screen

Wheel first harmonic limit: Represents the first harmonic limit beyond which it is considered appropriate

to turn the tyre on the rim by 180°. Recommended limit = 1.2 mm.

Rim first harmonic limit: Represents the first harmonic limit of the rim below which it is not considered

appropriate to turn the tyre on the rim.

Recommended limit = 0.3 mm.

Minimum correction limit: Represents the minimum correction limit obtainable below which it is not

considered appropriate to turn the tyre on the rim. Recommended limit =

0.8 mm.

Default parameter setting: Resets the default machine settings.

Reserved Setup

67

Page 68

8.3.7 Outside rim runout

ENGLISH

Use and Maintenance Manual Rev. 12-2012

Decreases the value

Increases the value

Confirms the default parameters

Goes back to the reserved setup screen

Return to main screen

Outside rimrunout: Enables/disables the outside rim runout measurement function

Inside first harmonic limit: Represents the threshold beyond which the first harmonic value read for

the rim inside is not considered acceptable.

Outside first harmonic limit: Represents the threshold beyond which the first harmonic value read for

the rim outside is not considered acceptable.

Inside peak/peak limit: Represents the threshold beyond which the peak/peak value read for the

rim inside is not considered acceptable.

Outside peak/peak limit: Represents the threshold beyond which the peak/peak value read for the

rim outside is not considered acceptable.

Default parameter setting: Resets the default machine settings.

68

Reserved Setup

Page 69

Use and Maintenance Manual Rev. 12-2012

8.3.8 Tread

ENGLISH

Decreases the value

Increases the value

Confirm

Goes back to the reserved setup screen

Return to main screen

Tread limit: Represents the threshold beyond which the tread is no longer acceptable.

Default parameter setting: Resets the default machine settings.

Reserved Setup

69

Page 70

8.3.9 Reserved for technical service

ENGLISH

Password-protected area reserved for technical service only.

Use and Maintenance Manual Rev. 12-2012

Acc ess To ThIs ARe A WIT houT The N eces sARy K NoWl edGe mIG hT le Ad To INcoRRecT fuN cTIo NING ANd e veN m ATeRI Al dA mAGe To Th e

Whe el b AlAN cING mAc hINe .

8.3.10 Saves the machine calibration

Saves the machine calibration values to key.

8.3.11 Loads the user manual

Allows loading manuals in languages different from that loaded in the machine.

70

Reserved Setup

Page 71

Use and Maintenance Manual Rev. 12-2012

8.3.12 Firmware upgrade

Allows updating the board firmware.

ENGLISH

Confirms access to the function

Goes back to the reserved setup screen

1. Press the Confirm button

2. Press the Browse Folders button to select the new firmware.

3. Select the file .BL5 and press the button

Browse folders

Goes back to the reserved setup screen

Starts the firmware upgrade

4. When the operation is complete, press to exit the function.

Reserved Setup

71

Page 72

8.3.13 Factory setting

ENGLISH

Use and Maintenance Manual Rev. 12-2012

Confirms loading of the factory settings

Goes back to the reserved setup screen

Restore all the default settings of the machine, including the instruction manual in English.

exe cuTe ThI s fu NcTI oN o Nly Whe N Re ques Ted by spec IAlI sed peRs oNs.

72

Reserved Setup

Page 73

Use and Maintenance Manual Rev. 12-2012

8.4 MACHINE CALIBRATION

ENGLISH

Reserved for Technical Service

Saves the calibration values

Confirm

Goes back to the setup screen

Goes back to the main screen

1. Select a commercial wheel or sample wheel based on the type of wheel you intend to use for calibration and press

the button.

2. Mount the wheel selected, close the guard and press the button.

3. Set the value of the sample weight used for the calibration.

4. Open the guard, apply the sample weight on the outside of the wheel, close the guard and press the button.

5. Open the guard, apply the sample weight on the inside of the wheel in the same position as it was applied on the

outside, close the guard and press the button.

6. Move the sample weight to 12 o’clock and press the button.

7. Press the calibration save button .

8. Press the button to go back to the measurement screen.

Reserved Setup

73

Page 74

8.5 DIMENSIONS

ENGLISH

Allows accessing the manual wheel dimension setting screen.

TEST scR eeN Res eRve d fo R ex peRT s.

use oNl y IN spe cIfI c cA ses.

Use and Maintenance Manual Rev. 12-2012

74

Reserved Setup

Page 75

Use and Maintenance Manual Rev. 12-2012

8.6 SELF-DIAGNOSTICS

ENGLISH

Automatic measuring cycle

Laser reset

Diagnosis parameter printout useful for Technical Service.

Goes back to the main menu screen

Return to main screen

Displays a screen containing numerous test parameters useful for the maintenance technician.

Enables an automatic unbalance and runout cycle useful to check any machine oscillation problems.

Execute this function only on specific request of Technical Service.

Enables a laser reset cycle, to be executed only on specific request of Technical Service.

Reserved Setup

75

Page 76

8.7 OSK

ENGLISH

Use and Maintenance Manual Rev. 12-2012

Increases the value

Decreases the value

Confirm

Goes back to the main menu screen

Time: enables/disables the display clock on the measurement screen

Hour screensaver: enables/disables the display clock on the screensaver screen

Time format: select the format to display the time

Allows correctly setting the date and time.

Increases the value

Decreases the value

Confirm

Goes back to the main menu screen

76

Reserved Setup

Page 77

Use and Maintenance Manual Rev. 12-2012

Press the button to go to date setting.

Increases the value

Decreases the value

Confirms and goes back to the main

menu screen

Goes back to the main menu screen

ENGLISH

Reserved Setup

77

Page 78

8.8 SOUNDS

ENGLISH

Use and Maintenance Manual Rev. 12-2012

Decreases the value

Increases the value

Confirms the default parameters

Goes back to the main menu screen

Return to main screen

Introduction: Enables/disables an introduction sound during machine power on.

Touch buttons: Enables and selects/disables the sound emitted when pressing any button

sev eRAl Typ es o f so uNd ARe AvAI lAbl e; s elec T Th e oN e yo u lI Ke T he m osT.

Wheel in position:

Default parameter setting: resets the default machine settings.

Enables/disables the sound emitted when the wheel is in the correction position

78

Reserved Setup

Page 79

Use and Maintenance Manual Rev. 12-2012

8.9 TRACEABILITY

ENGLISH

Traceability:

OFF: disabled

PRINTOUT: enables access to a screen for setting a series of parameters indicated on the balancing

certificates.

Default parameter setting: restores the default machine settings.

8.10 INSTRUCTION MANUAL

Displays the machine instruction manual .

Reserved Setup

79

Page 80

9. Diagnostics

ENGLISH

Use and Maintenance Manual Rev. 12-2012

The I NfoR mATI oN IN The possIble Remedy colu mN Re quIR es Wo RK To be peR foRm ed by spec IAlI sT Te chNI cIAN s oR oT heR A uTho R-

WARNING

Ise d peo ple Who musT AlW Ays W oRK usIN G Th e pe RsoN Al pRoTe cTIv e equ Ipme NT I NdIc ATed IN The INsTAllATIoN mAN uAl. IN s ome

SOFTWARE

ERRORS

Black The wheel balancing machine does not

Err. 1 STOP button pressed with the motor

Err. 2 Speed too low during measurement.

Err. 3 Unbalance too high. 1. Check the wheel dimensions setting.

Err. 5 Guard open.

Err. 6 Spindle open

Err. 8 Errorintransferoftheoutsideprole

Err. 9 Errorintransferoftheinsideprole

Err. 10 The inside adhesive weight distance is

Err. 11 Speed too high error.

Err.15 Error dimensions stored invalid (only for

Err. 16 Internal laser position error during the

CAUSE POSSIBLE REMEDY

switch on.

running.

During the unbalance measurement

spins, the wheel speed dropped to

below 42 rpm.

Guard opening during the measuring

cycle

Spinenabledwithoutrsthavingclosed

the spindle.

measurement data from the acquisition

board to the PC.

measurement data from the the acquisition board to the PC.

greater than the outside adhesive weight

distance.

During unbalance measurement rotation, wheel speed is more than 270 rpm.

releases prior to M3390).

machine calibration function.

cAs es, ThIs WoR K cA N be peR foRm ed b y A NoRm Al o peRA ToR.

1. Check the machine is properly connected to the mains power supply.

2. Check the fuses on the power board and replace if necessary.

3. Check display functioning.

4. Replace the PC.

1. Repeat the measuring cycle avoiding to press the STOP button

unless for an emergency.

1. Make sure that a vehicle wheel is mounted on the wheel balancing machine.

2. Use the self-diagnostics function to check the encoder.

3. Disconnect the measuring head connector from the board and perform

a spin (if there is no error, replace the measuring heads)

4. Replace the acquisition board.

2. Check the detection unit connections.

3. Run the machine calibration function.

4. Mountawheelwithamoreorlessknownunbalance(denitely less

than 100 grams) and check the response of the machine.

5. Replace the acquisition board.

1. Check functioning of the protection microswitch

2. Repeat the measurement keeping the guard closed until the end

of the spin.

1. Check functioning of the spindle closing microswitch

2. Close the spindle

3. Lower the guard

1. Repeattheoutsideprolemeasurement.

2. Replace the acquisition board.

1.Repeattheinsideprolemeasurement.

2. Replace the acquisition board.

1. Repeat the wheel dimension measurement.

2. Repeat the laser calibration function.

3. Replace the acquisition board.