Page 1

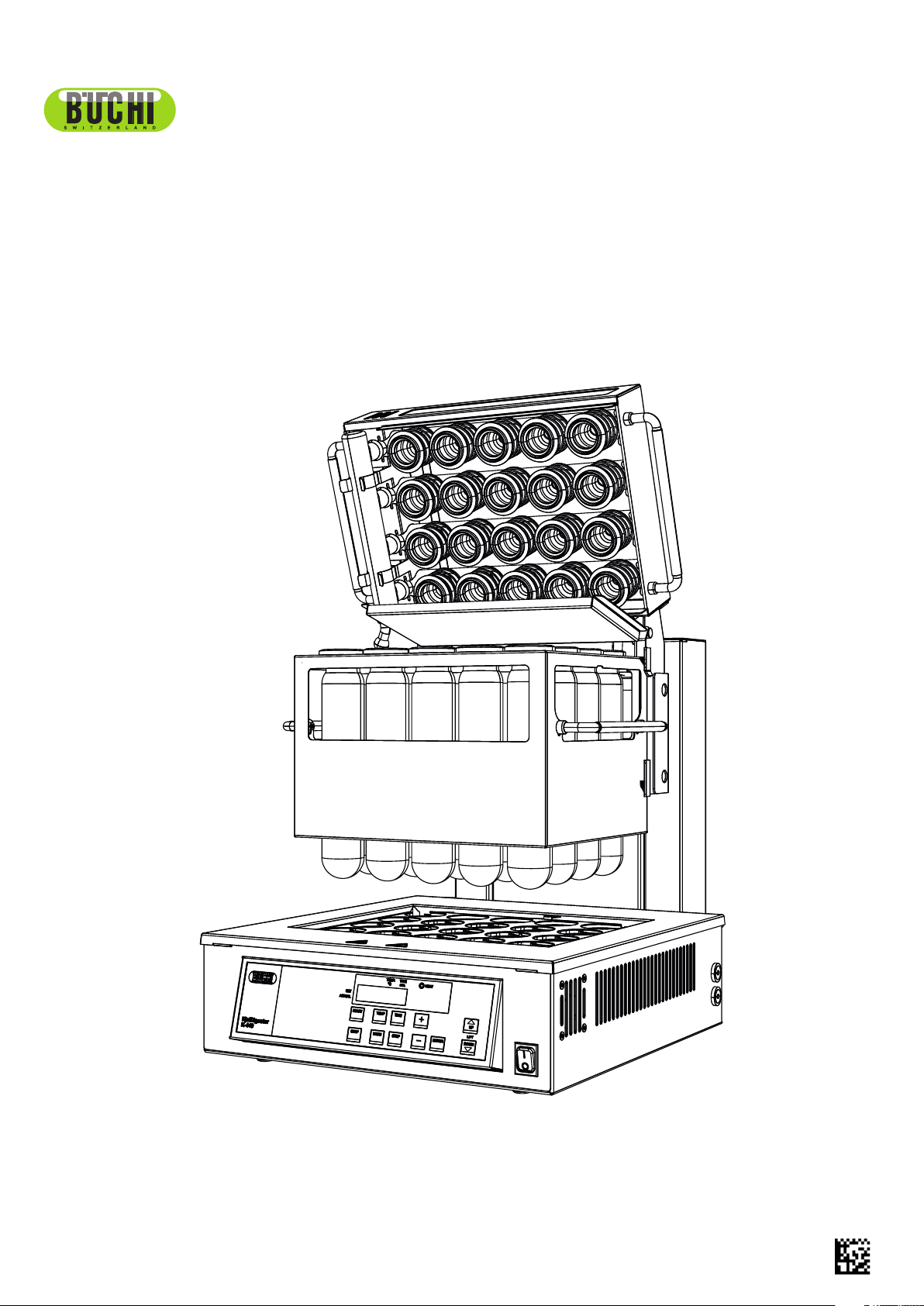

KjelDigester K-446/K-449

Operation Manual

11593546 en

Page 2

Imprint

Product Identification:

Operation Manual, KjelDigester K-446/K-449

115 9354 6 en

Publication date:

09.2013, Version A

BÜCHI Labortechnik AG

Meierseggstrasse 40

Postfach

CH-9230 Flawil 1

E-Mail: quality@buchi.com

BUCHI reserves the right to make changes to the manual as deemed necessary in the light of experience; especially in respect to structure, illustrations and technical detail.

This manual is copyright. Information from it may not be reproduced, distributed, or used for competitive purposes, nor made available to third parties. The manufacture of any component with the aid of this manual without

prior written agreement is also prohibited.

Page 3

Table of contents

1 General 7

1.1 About this manual ...................................................................................... 7

1.1.1 Structure of the manual .................................................................... 7

1.1.2 Additional user information ............................................................... 8

1.1.3 Available languages .......................................................................... 8

1.1.4 Reference documents ...................................................................... 8

1.1.5 Abbreviations ................................................................................... 8

1.2 About the KjelDigester K-446/K-449 .......................................................... 9

1.2.1 General information .......................................................................... 9

1.2.2 Type plate ........................................................................................ 9

1.3 Scope of delivery ...................................................................................... 10

2 Safety 11

2.1 User qualifications .................................................................................... 11

2.2 Proper use ............................................................................................... 11

2.3 Safety warnings ....................................................................................... 11

2.3.1 Warning explanation ....................................................................... 11

2.3.2 Symbols ......................................................................................... 12

2.4 General safety rules .................................................................................. 13

2.4.1 Responsibility of the operator ......................................................... 13

2.4.2 Duty of maintenance and care........................................................ 13

2.4.3 Spare parts to be used .................................................................. 13

2.4.4 Modifications ................................................................................. 13

2.5 Product safety .......................................................................................... 14

2.5.1 General hazards ............................................................................. 14

2.5.2 Specific hazard .............................................................................. 15

2.5.3 Personal protective equipment ....................................................... 16

2.5.4 Built-in safety elements and measures ........................................... 16

3 Technical data 17

3.1 Device dimensions ................................................................................... 17

3.1.1 K-446 ............................................................................................ 17

3.1.2 K-449 ............................................................................................ 17

3.2 General technical data .............................................................................. 17

3.2.1 Electrical system ............................................................................ 18

3.2.2 Environmental conditions ............................................................... 18

4 Description of function 19

4.1 Purpose and design ................................................................................. 19

4.2 KjelDigester overview ............................................................................... 19

4.2.1 Front and side view ........................................................................ 19

4.2.2 Rear view ....................................................................................... 20

4.2.3 Top-side view ................................................................................. 20

3Operation Manual KjelDigester K-446/K-449

Page 4

4.3 Function ................................................................................................... 21

4.3.1 Digestion process .......................................................................... 21

4.4 Control panel ........................................................................................... 22

4.4.1 Control panel display ...................................................................... 22

4.4.2 Control panel buttons..................................................................... 22

4.4.3 Scrubber control (K-449 only) ........................................................ 23

4.5 Rack, cooling and heating position ........................................................... 24

4.6 Functionality comparison K-446/K-449 .................................................... 24

5 Installation 25

5.1 Unpacking ................................................................................................ 25

5.2 Preparation for assembly .......................................................................... 25

5.3 Transport lock, removal ............................................................................ 26

5.4 Device assembly ...................................................................................... 26

5.4.1 Drip tray, installation ....................................................................... 26

5.4.2 Suction module, installation ............................................................ 27

5.4.3 Scrubber/water jet pump, connection ............................................ 27

5.4.4 Device fixation (earthquake) ............................................................ 29

5.4.5 Electrical connection ...................................................................... 29

5.5 Settings .................................................................................................... 29

5.5.1 Accessing the settings menu ......................................................... 29

5.5.2 Adjust the contrast ......................................................................... 30

5.5.3 Adjust the maximum temperature .................................................. 30

5.5.4 Adjust the temperature offset ......................................................... 31

5.5.5 Set the clock (K-449 only) .............................................................. 31

5.5.6 Adjust the Scrubber control (K-449 only) ........................................ 31

5.6 User protection shield, installation ............................................................ 32

5.7 Condensate bottle, installation ................................................................. 33

5.8 Air supply hose, installation ...................................................................... 34

6 Operation 35

6.1 General application information ................................................................ 35

6.2 Start a digestion ....................................................................................... 36

6.3 Set parameters for manual digestion ........................................................ 36

6.3.1 K-446 ............................................................................................ 36

6.3.2 K-449 ............................................................................................ 37

6.4 Editing parameters during a digestion ...................................................... 37

6.5 Abort a digestion ...................................................................................... 38

6.6 Switch off the KjelDigester ........................................................................ 38

6.7 KjelDigester K-446 ................................................................................... 39

6.7.1 Digestion process .......................................................................... 39

6.8 KjelDigester K-449 ................................................................................... 40

6.8.1 Digestion process, manual mode ................................................... 40

4 KjelDigester K-446/K-449 Operation Manual

Page 5

6.8.2 Digestion process, automatic mode ............................................... 41

6.8.3 Digestion process, delayed start .................................................... 42

6.8.4 Set parameters for an automatic digestion ..................................... 43

6.8.5 Edit a method ................................................................................ 44

6.8.6 Select a method ............................................................................. 44

6.8.7 Set up a delayed start time ............................................................ 44

6.8.8 Moving the lift up or down .............................................................. 45

7 Maintenance 47

7.1 Maintenance plan ..................................................................................... 47

7.1.1 Maintenance as required/after use ................................................. 47

7.1.2 Daily maintenance .......................................................................... 47

7.1.3 Maintenance every week ................................................................ 47

7.1.4 Maintenance every year or after every 1000 digestion cycles.......... 48

7.1.5 Maintenance every 3 years ............................................................. 48

7.2 Cleaning ................................................................................................... 48

7.2.1 KjelDigester, cleaning ..................................................................... 48

7.2.2 Scrubber hose, cleaning ................................................................ 49

7.2.3 Suction module sealing and spring, cleaning .................................. 49

7.2.4 Sample tube, cleaning ................................................................... 49

7.3 Suction module sealing and spring ,replacement ...................................... 50

7.4 Fuse power supply, replacement .............................................................. 51

7.5 Rechargeable battery (K-449 only), replacement ...................................... 52

7.6 Suction module, removal .......................................................................... 54

8 Troubleshooting 55

8.1 Customer service ..................................................................................... 55

8.2 Error messages on the display ................................................................. 55

8.3 Faults ....................................................................................................... 56

8.3.1 Broken sample tube during digestion ............................................. 56

8.3.2 Power supply failure [ERR1] during a digestion .............................. 57

8.3.3 Sample tubes jam in the heating block (K-449 only) ....................... 57

8.4 Checks .................................................................................................... 57

8.4.1 Suction module sealing and spring, check ..................................... 57

8.4.2 Glass parts, check ......................................................................... 58

8.4.3 Rechargeable battery (K-449 only), check ...................................... 58

9 Taking out of operation 61

9.1 Transport .................................................................................................. 61

9.2 Taking out of operation ............................................................................. 61

9.3 Materials used .......................................................................................... 62

5Operation Manual KjelDigester K-446/K-449

Page 6

10 Spare parts 63

10.1 General information .................................................................................. 63

10.2 Spare parts KjelDigester K-446/K-449 ..................................................... 64

10.3 Optional accessories ................................................................................ 67

10.3.1 Kjeldahl Tablets .............................................................................. 68

11 Appendix 69

11.1 FCC requirements (for USA and Canada) ................................................. 69

11.2 Declaration of conformity .......................................................................... 70

Index .................................................................................. 71

6 KjelDigester K-446/K-449 Operation Manual

Page 7

1 General

This manual describes the KjelDigester K-446 and K-449 and provides all information required

for its safe operation and to maintain it in good working order.

It is addressed to laboratory personnel in particular.

1.1 About this manual

Read this manual carefully before installing and running the device. Note the safety precautions

in chapter 2 in particular. Store the manual in the immediate vicinity of the device, so that it can

be consulted at any time.

1.1.1 Structure of the manual

The operation manual consists of 11 chapters which cover all information relevant to the operator of the device.

1 General

Chapter Meaning

1 General Gives a general overview about the manual and device. It also

gives a brief information on how to use this manual and other

general information.

2 Safety Describes the safety concept of the device and contains gen-

eral rules of behavior and warnings from hazards concerning

the use of the product.

3 Technical data Introduces the reader to the device specifications. It contains

technical data, requirements and performance data.

4 Description of function Explains the basic principle of the device, shows how it is

structured and gives a functional description of the assemblies.

5 Installation Describes how the device is installed and gives instructions on

initial startup.

6 Operation Gives examples of typical device applications and instructions

on how to operate the device properly and safely.

7 Maintenance Gives instructions on all maintenance work to be performed in

order to keep the device in good working condition.

8 Troubleshooting Helps to resume operation after a minor problem has oc-

curred. It lists possible occurrences, their probable cause and

suggests how to remedy the problem. Explains checks for

troubleshooting and maintenance.

9 Taking out of operation Instructs how to store and dispose the device. It also instructs

users for the reuse after a storage period.

10 Spare parts Lists spare parts, accessories, and options including their

ordering information.

11 Appendix Additional documents regarding requirements.

1 – 7Operation Manual KjelDigester K-446/K-449

Page 8

1 General

1.1.2 Additional user information

Page number

The page number in the footer contains the current chapter (e.g. 1 – 12) and the page number

(e.g. 1 – 12).

Cross-references

Cross-References consist at least the chapter and the page number (1 – 12).

NOTE

Paragraphs starting with NOTE transport helpful information for working with the device/software.

NOTE’s are not related to any kind of hazard or damage.

1.1.3 Available languages

This operation manual is available in the following languages:

Language Order number

English 115 93 54 6

German 115 93 547

French 11593548

Italian 115 93 54 9

Spanish 1159 35 50

Chinese 115 93 5 51

Japanese 115 93 55 2

1.1.4 Reference documents

Scrubber K-415

Language Order number

English 115 93 50 5

German 115 93 50 6

French 1159 35 07

Italian 1159 3 50 8

Spanish 1159 35 09

Chinese 115 93 510

Japanese 115 93 511

1.1.5 Abbreviations

EPDM Ethylene propylene diene monomer

FCC Federal Communications Commission

TKN Total Kjeldahl nitrogen

METH Method

1 – 8

KjelDigester K-446/K-449 Operation Manual

Page 9

MSDS Material safety data sheets

No Number

Pcs Pieces

PTFE Polytetrafluoroethylene

Qty Quantity

1.2 About the KjelDigester K-446/K-449

1.2.1 General information

No technical modifications may be made to the device without the prior written agreement of

BUCHI. Unauthorized modifications may affect the system safety or result in accidents.

1.2.2 Type plate

Type plate is located on the right side of the KjelDigester.

1 General

Fig. 1.1 Key of type plate (example)

a Device name e Maximum power rating

b Serial number f Year of manufacture

c Input voltage range g Country of manufacture

d Frequency of input voltage

1 – 9Operation Manual KjelDigester K-446/K-449

Page 10

1 General

1.3 Scope of delivery

Description Qty Order number

KjelDigester

∙ K-446 with standard suction module

∙ K-446 suction module with condensate trap

∙ K-449 with standard suction module

∙ K-449 suction module with condensate trap

1

–

–

–

–

1154461000

1154462000

1154491000

1154492000

Drip tray holder 1 110 59 8 04

Drip tray 1 110 59 031

Sample tube, 300 mL (4 pcs.) 5 037377

Rack 1 110 59 831

Hose 1.5m, 8mm 1 11056005

Hose connector S19 1 110 57159

Clamp S19 1 110 57149

Power supply cable

∙ Type C H

∙ Type Schuko

∙ Type GB

∙ Type U SA

∙ Type AUS

1

–

–

–

–

–

010010

010016

0178 35

033763

0178 36

–

–

1 – 10

KjelDigester K-446/K-449 Operation Manual

Page 11

2 Safety

The safety of the user and personnel can only be ensured if the safety instructions and the safety

related warnings in the individual chapters are strictly observed and followed. Therefore, the

manual must always be available to all persons performing tasks described herein.

2.1 User qualifications

Before using the KjelDigester the operation manual must be read and understood.

The device may only be used by laboratory personnel and other persons who on account of

training or professional experience have an overview of the dangers which can develop when

operating the device.

2.2 Proper use

The KjelDigester has been designed and built for laboratories. It serves for the heating of concentrated H2SO4 for the oxidation of organic sample components.

2 Safety

2.3 Safety warnings

2.3.1 Warning explanation

DANGER, WARNING, CAUTION and NOTICE are standardized signal words for identifying levels

of hazard seriousness of risks related to personal injury and property damage. All signal words,

which are related to personal injury are accompanied by the general safety sign.

For the safety it is important to read and fully understand the table with the different signal words

and their definitions.

Sign Signal word Definition Risk level

DANGER

WARNING

CAUTION

NOTICE

Indicates a hazardous situation which, if not

avoided, will result in death or serious injury.

Indicates a hazardous situation which, if not

avoided, may result in serious injury or death.

Indicates a hazardous situation which, if not

avoided, may result in minor or moderate injury.

Indicates possible material damage, but no practices related to personal injury.

★★★★

★★★☆

★★☆☆

☆☆☆☆

Supplementary safety information symbols may be placed in a rectangular panel on the left to

the signal word and the supplementary text.

2 – 11Operation Manual KjelDigester K-446/K-449

Page 12

2 Safety

Fig. 2.1 Example of warning

a Safety symbol d Result of danger if not avoided

b Source of danger e Warning title

c Instruction to avoid danger

2.3.2 Symbols

The reference list incorporates safety symbols and their meaning. The symbols can occur in this

operation manual or on the device.

Warning safety symbols

Symbol Meaning Symbol Meaning

General warning Corrosive hazard

Electrical hazard Flammable

Biohazard Explosive environment

Broken glass Inhalation harmful

Device damage Hot surface

Hand bruising Magnet

2 – 12

KjelDigester K-446/K-449 Operation Manual

Page 13

Mandatory safety symbols

Symbol Meaning Symbol Meaning

Wear protective goggles Wear protective clothes

Wear protective gloves Heavy load, lift with assistance

2.4 General safety rules

2.4 .1 Responsibility of the operator

The head of the laboratory is responsible for training his personnel.

The operator shall inform the manufacturer without delay of any safety-related incidents which

might occur during operation of the device or its accessories.

2 Safety

Issues can be reported to the e-mail address: quality@buchi.com.

Legal regulations, such as local, state and federal laws applying to the device or its accessories

must be strictly followed.

2.4.2 Duty of maintenance and care

The operator is responsible for the proper condition of the device. This includes maintenance,

service and repair jobs that are performed on schedule by authorized personnel only.

2.4.3 Spare parts to be used

Use only genuine BUCHIconsumables and spare parts for maintenance to assure good system

performance, reliability and safety. Any modifications of spare parts or assemblies are only allowed with the prior written permission of BUCHI.

2.4.4 Modifications

Modifications to the device are only permitted after prior consultation and with the written approval of BUCHI. Modifications and upgrades shall only be carried out by an authorized BUCHI

technical engineer. BUCHI will decline any claim resulting from unauthorized modifications.

2 – 13Operation Manual KjelDigester K-446/K-449

Page 14

2 Safety

2.5 Product safety

The device is designed and built in accordance with current state-of-the-art technology. Nevertheless, risks to users, property, and the environment can arise when the device is used carelessly or improperly.

BUCHI has identified the following residual dangers emanating from the device:

∙ The device is operated by insufficiently trained personnel.

∙ The device is not operated according to its proper use.

∙ Appropriate warnings in this manual serve to make the user alert to these residual dangers.

2.5.1 General hazards

The following safety messages show hazards of general kind which may occur when handling

the device. The user shall observe all listed counter measures in order to achieve and maintain

the lowest possible level of hazard.

Additional warning messages can be found whenever actions and situations described in this

manual are related to situational hazards.

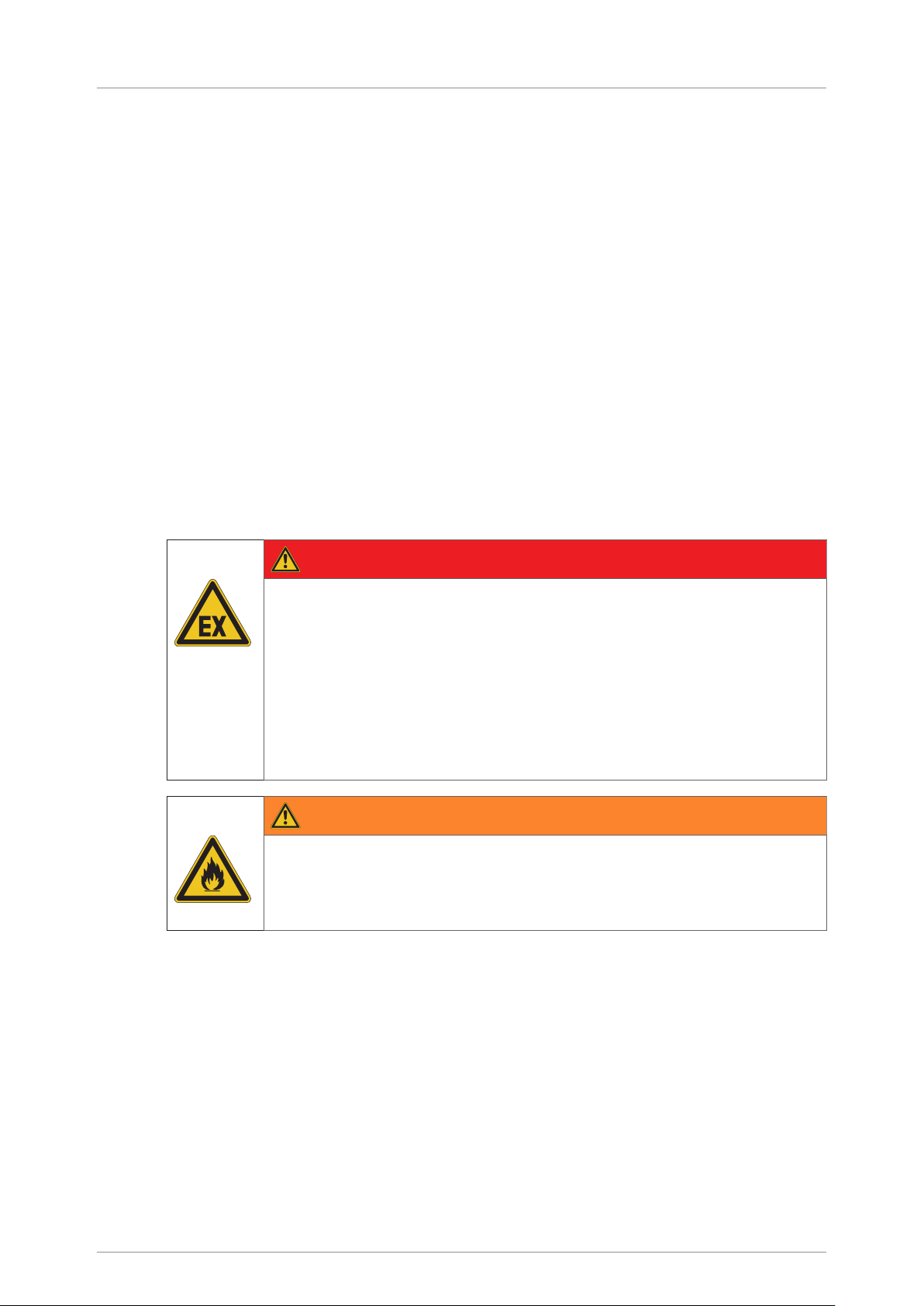

DANGER

Risk of explosion with incorrect use of the device!

Death or serious injuries can result.

1. Do not store or operate the device in explosive environments.

2. Do not store chemicals in the vicinity of the device.

3. Operate the device in a fume hood with sufficient ventilation to directly withdraw fumes.

4. Use the user protection shield when working with H2O2 or larger amounts of

water (>10mL).

5. Follow the safety notes in the application notes.

WARNING

Risk of burns from flammable fumes!

Serious injuries or death can result.

1. Remove all sources of flammable fumes.

2. Do not store flammable chemicals in the vicinity of the device.

2 – 14

KjelDigester K-446/K-449 Operation Manual

Page 15

WARNING

Risk of chemical burns from hot acid or peroxide fumes!

Serious injuries or death can result.

1. Do not operate the system with faulty parts.

2. Check device setup for proper sealing before use.

3. Do not inhale process fumes.

4. Operate the device inside an active fume hood.

5. Use a Scrubber or water jet pump to neutralize exhaust fumes.

6. Do not move the device or parts of it during digestion.

7. Always wear the personnel protective equipment.

CAUTION

Risk of hot machine parts and glassware!

Minor or moderate burns can result.

1. Do not touch hot parts or surfaces.

2. Let the system and inserted glassware cool down safely.

3. Do not move the device or parts of it when hot.

2 Safety

Risk of spilled liquids or mechanical shocks.

Liquids leaking into the housing or mechanical shocks can damage the device.

1. Do not spill liquids over the device or its components

2. Do not move the device when it is loaded with sample liquid

3. Do not drop the device or its components

4. Keep external vibrations away from the device

5. Safely attach the device to the bench in earthquake prone regions

6. For H2O2 or TKN applications, do not operate the device without the user

protection shield installed.

2.5.2 Specific hazard

H2O2 or TKN digestion

Using H2O2 or TKN for the digestion makes it mandatory to perform the following steps to keep

the work place as safe as possible.

NOTICE

2 – 15Operation Manual KjelDigester K-446/K-449

Page 16

2 Safety

WARNING

Risk of explosion and chemical burns!

Serious injuries or death can result.

1. Wear the personal protective equipment.

2. Make sure all components are in proper working condition.

3. Operate the device inside an active fume hood.

4. Follow the safety instructions in the application notes.

1. Use the user protection shield at any time during sample preparation and during

digestion (both H2O2 and TKN).

∙ User protection shield, installation, (5–32).

2. Use a suitable dosing device with tube to safely dose H2O2.

3. Preparation and digestion needs to be done within an active fume hood.

2.5.3 Personal protective equipment

Always wear personal protective equipment such as protective eye goggles, protective clothing

and gloves. The personal protective equipment must meet all requirements of all MSDS for the

chemicals used.

2.5.4 Built-in safety elements and measures

Glassware

All original BUCHI glass parts are made of high temperature, chemical resistant borosilicate glass

and optimal match the heating block.

Heating block

The heating block is equipped with a safety overtemperature switch. In case of a temperature

above 500°C the heating block will be switched off and the KjelDigester starts a continuous

beeping sound.

Fume removal

Acid fumes generated during digestion accumulate in the suction module.

The fumes must be safely withdrawn from the suction module via a EPDM hose to a Scrubber

(e.g. Scrubber K-415) or via water jet pump into a sink with sufficient suction flow.

Lift (K-449)

The KjelDigester K-449 is equipped with a rechargeable battery. In case of a power failure the

lift moves up automatically.

2 – 16

Before the lift starts moving down automatically a beeping sound informs the operator.

KjelDigester K-446/K-449 Operation Manual

Page 17

3 Technical data

3.1 Device dimensions

3.1.1 K-446

3 Technical data

3.1.2 K-449

3.2 General technical data

Description K-446 K-449

Weight, total 30kg 37.3kg

Weight, w/o accessory 18.5kg 25.8kg

Approval UL/CSA, CE UL/CSA,CE

Pollution degree 2 2

Overvoltage category II II

Clearance to wall 5cm 5cm

3 – 17Operation Manual KjelDigester K-446/K-449

Page 18

3 Technical data

Description K-446 K-449

Display 2 rowLCD display 2 rowLCD display

Resolution temperature display 1°C 1°C

Temperature range 30 – 450 °C 30 – 450 °C

Average temperature stability ±1°C ±1°C

Absolute temperature accuracy ±7°C at 420°C ±7°C at 420°C

3.2.1 Electrical system

Description K-446 K-449

Input voltage

Frequency 50 – 60 Hz 50 – 60 Hz

Power consumption max. 2300W 2300W

Output current, Scrubber 0.7A 0.7A

Fuse 2× T10A/L250V 2× T10A/L250V

3.2.2 Environmental conditions

Description K-446 K-449

Temperature 5 – 40°C 5 – 40°C

Altitude above sea level max. 2000m 2000m

Humidity Maximum relative humidity 80% for temperatures

Use For indoor use only

220 – 240V ±10 % 220 – 240V ±10%

up to 31°C, decreasing linearly to 50% relative

humidity at 40°C

3 – 18

KjelDigester K-446/K-449 Operation Manual

Page 19

4 Description of function

4.1 Purpose and design

The KjelDigester is suitable for digestion processes with concentrated boiling H2SO4 and a catalyst. The digestion parameters are listed in the BUCHI Application Notes.

4.2 KjelDigester overview

4.2.1 Front and side view

4 Description of function

Fig. 4.1 KjelDigester front and side view

a Fume collection tube g Fuse 10A/250V

b Suction tube h Type plate

c Drip tray i Rack

d Suction hose j Lift (K-449 only)/bracket (K-446)

e Control panel, (4–22) k Suction module

f Cooling fan, electronic

4 – 19Operation Manual KjelDigester K-446/K-449

Page 20

4 Description of function

4.2.2 Rear view

Fig. 4.2 KjelDigester rear view

a Eye bolt c Interface Scrubber

b Power supply KjelDigester

4.2.3 Top-side view

4 – 20

Fig. 4.3 Heating block components

a Magnet e Main switch

b Scrubber hose bracket f Measuring point for external temp. sensor

c Heating block cover g Rack support

d Drip tray holder

KjelDigester K-446/K-449 Operation Manual

Page 21

4.3 Function

The KjelDigester is used to convert organic bound nitrogen (e.g. in proteins) in a sample into

ammonium sulfate. During the digestion process, acid fumes and reaction gases may emerge

and are handled by the Scrubber. The Scrubber is connected to the KjelDigester for neutralizing

acid fumes and adsorbing unpleasant odors.

4.3.1 Digestion process

The aluminum heating blockd generates high temperatures of up to 450°C in order to heat the

samplec up to 370°C (boiling point). The sample is digested in constantly boiling H2SO4. Hot

acid fumes rise into the condensation zoneb, condense and rinse back down to the sample

creating a constant reflux. Residual fumes which escape the condensation zone via the acid

fume outleta are highly corrosive and must be withdrawn and efficiently neutralized (e.g. with

the Scrubber K-415).

The condensation should not take place inside the safety zoneX in order to avoid shortening

the lifetime of the sealings. In case the condensation is too close to the suction module (e.g. due

to very high temperature settings or if too much catalyst was used) losses of nitrogen through

creating N2 are possible and the samples can dry out.

4 Description of function

Fig. 4.4 Function of the KjelDigester

X

Safety zone

c Boiling/digestion sample

a Acid fume outlet d Heating block

b Condensation zone

4 – 21Operation Manual KjelDigester K-446/K-449

Page 22

4 Description of function

4.4 Control panel

4.4.1 Control panel display

Fig. 4.5 K-449 Display

a Display, (4–22) c LED heating block (flashing), (4–22)

b LED heating block (on/off), (4–22)

Display

Shows various informations such as set and actual temperatures, heating and cooling time.

LED heating block (on/off)

On: The heating block is heating.

Off: The heating block is turned off and the temperature is below 60°C.

LED heating block (flashing)

The heating block is not heating but the temperature is above 60°C.

4.4.2 Control panel buttons

Fig. 4.6 KjelDigester K-449 control panel

4 – 22

a Time, (4–23) f Step, (4–23)

b Temperature, (4–23) g Increase/decrease value[+/-]

c Start, (4–23) h Enter

d Stop, (4–23) i Lift up/down, (4–23)

e Method, (4–23)

KjelDigester K-446/K-449 Operation Manual

Page 23

4 Description of function

Time

Range 0 – 999minutes

Activates the heating time value for an adjustment.

Temperature

Range 30 – 450°C

Activates the heating temperature of the heating block for an adjustment.

Start

Starts a digestion process.

Stop

∙ Stops a digestion process.

∙ Enables access to the settings menu.

∙ Stops the Scrubber.

Method (K-449 only)

Range 0 – 9 methods

Up to 9 methods can be programmed. Each method contains 4 adjustable steps. In each step,

the temperature and time can be set. Also the cool down time can be adjusted.

NOTE

The first step is also used as the preheat function.

Method number0 is reserved for the manual mode on the K-449. No steps can be programed.

Step (K-449 only)

Allows to navigate forward within a method during editing.

Lift up/down (K-449 only)

Allows to move the rack up and down at any time.

4.4.3 Scrubber control (K-449 only)

5.5.6 Adjust the Scrubber control (K-449 only), (5–31).

Range 0 – 255 minutes

The Scrubber can be controlled via the KjelDigester. E.g. can the Scrubber be controlled intermitted for 1minute on, for 1minute off.

NOTE

An altered value will also be active during the cooling time in the automatic mode.

BUCHI recommends to leave this setting by default (on 0min:, off 0min.) unless a adjustment

becomes necessary due to a special application.

4 – 23Operation Manual KjelDigester K-446/K-449

Page 24

4 Description of function

4.5 Rack, cooling and heating position

Fig. 4.7 Cooling and heating position of the samples

a Rack in cooling position b Rack in heating position

In the cooling position the rack hangs over the heating block, the samples are not heated. In the

heating position the sample are lowered into the heating block for digestion.

For the KjelDigester K-446, the rack is moved between the two positions by hand, for the K-449

via the automatic lift.

4.6 Functionality comparison K-446/K-449

Function K-446 K-449

Scrubber control (on/off) • •

Temperature adjustment during digestion (method 0) • •

Overtemperature switch • •

Lift for rack (up/down) – •

Programmable methods – •

Backup battery for cooling and lift (power loss) – •

Delayed start time – •

4 – 24

KjelDigester K-446/K-449 Operation Manual

Page 25

5 Installation

5.1 Unpacking

5 Installation

DANGER

Risk pacemaker malfunction!

Death or serious injuries can result.

1. Keep a distance of at least 15cm between a pacemaker and the magnets of

the rack support.

CAUTION

Risk of injuries due to weight of the device!

Minor or moderate injuries can result.

1. Call a second person to lift the device.

2. Do not lift the device alone.

1. Unpack the device.

CAUTION

Risk of cuts from damaged glass parts!

Minor or moderate cuts can result.

1. Handle glass parts with care.

2. Check all glass parts for damage before installation.

3. Do not use any damaged parts.

4. Do not touch cracks or bits of broken glass with bare hands.

2. Check the device for any damage caused during the transportation.

3. Report damage to the responsible transportation company.

4. Keep the original packaging for future transportation.

5. Check all glass parts for damage.

∙ 8.4.2 Glass parts, check, (8–58).

5.2 Preparation for assembly

1. Place the device in a fume hood.

∙ It is recommended that the fume hood complies with the norm DINEN14175-2.

∙ Keep around the device a free space of at least 5cm.

2. If using a Scrubber, place it on the left side of the KjelDigester.

NOTE

Keep the Scrubber suction hose as short and straight as possible. It prevents cooling air of

the Scrubber blowing towards the heating block of the KjelDigester.

3. Remove the transport lock, (5–26).

5 – 25Operation Manual KjelDigester K-446/K-449

Page 26

5 Installation

5.3 Transport lock, removal

1. Remove the 2screwsa and spacersb from the heating block.

2. Keep the removed parts for future transportation.

5.4 Device assembly

5.4.1 Drip tray, installation

1. Install the drip tray holdera at the two holes on the left side of the device.

5 – 26

KjelDigester K-446/K-449 Operation Manual

Page 27

2. Place the drip traya in the drip tray holderb.

5.4.2 Suction module, installation

1. Hold the suction module on both handlesa and place it on the rack supportc.

∙ Make sure both hinge boltsb are located in the notches of the rack support.

NOTE

The magnetsd on the rack support will hold the suction module in the open position.

5 Installation

5.4.3 Scrubber/water jet pump, connection

aPreliminary tasks

1. Place the Scrubber next to the KjelDigester on the left side.

5 – 27Operation Manual KjelDigester K-446/K-449

Page 28

5 Installation

bTas k s

WARNING

Risk of acid or toxic fume inhalation.

Serious injuries or death can result.

1. Always run the Scrubber or water jet pump during the digestion process.

2. Operate the Scrubber and KjelDigester only in a fume hood.

3. Close the fume hood door as far as possible.

NOTICE

Risk of wrong power input on the Scrubber.

Wrong input voltage of the Scrubber can damage electronic components.

1. Do only connect a Scrubber with 230V input to the KjelDigester. Output voltage of the KjelDigester is 240V only.

1. Connect the Scrubber connection cable on the rear of the KjelDigester.

2. Connect the hosec with the ball joint hose connector to the fume collection tubea.

3. Secure the connection with the catchpot clipb.

4. Shorten the other end of the hosec to keep the hose as short and straight as possible.

5. Connect the hosec to a Scrubber or water jet pump.

5 – 28

cFollow-on tasks

1. Depending on the configuration continue with following step:

∙ Install the condensate bottle (5–33).

KjelDigester K-446/K-449 Operation Manual

Page 29

5.4.4 Device fixation (earthquake)

NOTICE

Risk of device damage from earthquakes.

An unsecured device can be damaged in earthquake prone regions.

1. Use the eye bolts on the rear of the device for fixation.

1. Tie down the device on the 2eye boltsa on the rear of the device.

∙ Eye bolt M4×10

5 Installation

5.4.5 Electrical connection

NOTICE

Risk of electrical damage.

The device can be damaged by the wrong power supply and input voltage.

1. The external power supply must meet the voltage given on the type plate.

1. Connect the external power supply cable to the device on the rear side.

∙ Make sure the device complies with the local voltage range before connecting.

∙ The external power supply must be equipped with a ground connection.

∙ Use a plug-in location which allows to disconnect the device at any time.

NOTE

The allowed voltage range for the device can be checked on the type plate.

5.5 Settings

5.5.1 Accessing the settings menu

1. Pressa [STOP] for 3seconds.

∙ The settings menu appears.

2. Pressa [STOP] to switch through the settings menu.

∙ Contrast, (5–30).

∙ Maximum temperature, (5–30).

∙ Temperature calibration, (5 –31).

∙ Clock, (5 –31).

∙ Scrubber control, (5–31).

5 – 29Operation Manual KjelDigester K-446/K-449

Page 30

5 Installation

5.5.2 Adjust the contrast

aPreliminary tasks

1. 5.5.1 Accessing the settings menu, (5–29).

bTas k s

1. Pressa [STOP].

∙ The contrast menu appears.

2. Set the contrast to the desired value by pressing b [+/-].

3. Press c[ENTER] to confirm the new value.

5.5.3 Adjust the maximum temperature

aPreliminary tasks

1. 5.5.1 Accessing the settings menu, (5–29).

bTas k s

1. Pressa [STOP] until the maximum temperature menu appears.

NOTE

Temperatures above 420°C can cause a loss of nitrogen or dried out samples.

2. Set the maximum temperature to the desired value by pressing b [+/-].

∙ Range 30 – 450°C.

3. Press c[ENTER] to confirm the new value.

5 – 30

KjelDigester K-446/K-449 Operation Manual

Page 31

5.5.4 Adjust the temperature offset

aPreliminary tasks

1. 5.5.1 Accessing the settings menu, (5–29).

bTas k s

1. Pressa [STOP] until the offset menu appears.

2. Set the temperature offset to the desired value by pressing b [+/-].

∙ The offset value can be measured with a additional temperature sensor.

3. Press c[ENTER] to confirm the new value.

5 Installation

5.5.5 Set the clock (K-449 only)

aPreliminary tasks

1. 5.5.1 Accessing the settings menu, (5–29).

bTas k s

1. Pressa [STOP] until the clock menu appears.

2. Adjust the hours by pressing b [+/-].

3. Press c[ENTER] to confirm the new value.

4. Adjust the minutes by pressing b [+/-].

5. Press c[ENTER] to confirm the new value.

CLOCK 13:04

1

5.5.6 Adjust the Scrubber control (K-449 only)

2

3

aPreliminary tasks

1. 5.5.1 Accessing the settings menu, (5–29).

5 – 31Operation Manual KjelDigester K-446/K-449

Page 32

5 Installation

bTas k s

WARNING

Risk of acid or toxic fume inhalation with a wrong setting of the Scrubber control.

Serious injuries or death can result.

1. Make sure the Scrubber is removing fumes during the complete digestion

process.

1. Pressa [STOP] until the Scrubber control menu appears.

2. Adjust the interval time for switching on the Scrubber by pressing b [+/-].

∙ Range 0 – 255 minutes.

3. Press c[ENTER] to confirm the new value.

4. Adjust the interval time for switching off the Scrubber by pressing b [+/-].

∙ Range 0 – 255 minutes.

5. Pressa [STOP].

∙ The default menu appears.

SCRUBBER

ON

OFF

0

0

1

5.6 User protection shield, installation

NOTE

Install the user protection shield when working with H2O2 or larger amounts of water (>10mL).

1. Install the user protection shielda on the rack handlesb.

∙ 11057889 User protection shield

2

3

5 – 32

KjelDigester K-446/K-449 Operation Manual

Page 33

5.7 Condensate bottle, installation

CAUTION

Risk of acid or peroxide fume inhalation!

Minor or moderate chemical burns of the airways.

1. Keep the suction hoses between the KjelDigester and Scrubber as straight

as possible to prevent liquid blocking the hoses.

2. Make sure the condensate bottle is placed lower than the suction module.

3. Operate and maintain the Scrubber according to its operation manual.

4. Make sure the hoses are not damaged.

1. Connect the hosec with the hose connector to the fume collection tubea.

2. Secure the connection with the catchpot clipb.

5 Installation

3. Connect the hosec coming from the KjelDigesterB to the condensate bottleb.

∙ 025100 Condensate bottle

4. Connect the hosea from the ScrubberA to the condensate bottle.

5. Close the 2 remaining connections of the condensate bottle with 2plugs.

5 – 33Operation Manual KjelDigester K-446/K-449

Page 34

5 Installation

5.8 Air supply hose, installation

1. Remove the 2TORX-screwsb.

2. Position the air supply hosea on the housing of KjelDigester and tighten the

2TORX-screws.

∙ 040079 Air supply hose

3. Guide the hose inlet to the outside of the fume hood to provide fresh air to the elec-

tronic components.

5 – 34

KjelDigester K-446/K-449 Operation Manual

Page 35

6 Operation

6 Operation

WARNING

Risk of poisoning from contact with or ingestion of harmful substances

and fumes at use!

Serious injuries or death can result.

1. Before operation, check the device for correct assembling.

2. Before operation inspect sealing, springs glass parts and hoses for good

condition and tightness.

3. Exchange worn out or defective parts.

4. Withdraw released fumes and gaseous substances by a Scrubber or water

jet pump.

5. Dispose condensate in tubings and glassware safely after use.

6. Do not inhale digestion fumes.

CAUTION

Risk of cuts from broken glass and sharp metal parts!

Minor or moderate cuts can result.

1. Handle glass parts with care.

2. Visually inspect every glass part before mounting.

3. Wear protective gloves when touching cracks or bits of broken glass.

6.1 General application information

Typically 15 – 20 mL of H2SO4 is used for a sample amount of approx. 1g of organic material.

For weighed portions over and above this, approx. 3 – 5 mL of H2SO4 (5 – 10 mL for greases and

mineral oils) must be used additionally for each additional gram of organic material.

WARNING

Risk of burns from corrosives!

Serious injuries or death can result.

1. Observe all MSDS of the used chemicals.

2. Handle corrosives in well ventilated environments only.

3. Always wear protective goggles.

4. Always wear protective gloves.

5. Always wear protective clothes.

6. Do not use damaged glassware.

6 – 35Operation Manual KjelDigester K-446/K-449

Page 36

6 Operation

NOTICE

Risk of material damage due to wrong handling.

Improper handling of device components can cause a device damage.

1. Do not use cold water to cool down hot sample tubes after digestion.

2. Make sure that the rack containing the sample tubes is placed in and removed from the digestion block with reasonable care.

3. Make sure that the rack is properly adjusted at the lift of the K-449, to make

the tubes smoothly slight into the openings of the digestion block.

4. Use digestion rods instead of use glass beads.

To vaporize larger amounts of water (10 – 200mL), use digestion rods as this will prevent boiling

delays for optimal user protection from possible splashes due to boiling delays. Always use the

user protection shield installed at the rack.

The digestion time and profile depends on the substance to be digested. Information on this

can be found in the BUCHI Application Notes. If no BUCHI application is available, the digestion

method must be ascertained by means of experiments. If the solution has become clear, continue

to boil the solution for about 30 minutes. Once the samples have cooled off, the sample tube

can be connected directly to a BUCHI distillation unit or the KjelSampler for distillation.

Due to different heat transfer and air flows between the sample tubes and the heating block, not

all 20samples boil simultaneously. However, as long as it is ensured that the digestion time and

digestion temperatures are sufficient, the different boiling times have no influence on the results.

If the digested samples are allowed to cool down for a long period of time, the samples might

solidify occasionally.

In this case, the sample must be liquefied again before it can be distilled:

∙ by adding very carefully a small quantity of distilled water

∙ by slightly warming it up in the KjelDigester

6.2 Start a digestion

1. For the K-446:

∙ 6.7.1 Digestion process, (6–39).

2. For the K-449:

∙ 6.8.1 Digestion process, manual mode, (6–40).

∙ 6.8.2 Digestion process, automatic mode, (6–41).

6.3 Set parameters for manual digestion

6.3.1 K-446

1. Pressa [TEMP] and adjust the temperature by pressingc [+/-].

1. Pressd [ENTER] to confirm the new value.

2. Pressb [TIME] and adjust the time by pressingc [+/-].

3. Pressd [ENTER] to confirm the new value.

6 – 36

KjelDigester K-446/K-449 Operation Manual

Page 37

6.3.2 K-449

1. Press Method [METH] and select method number 0 by pressing c[+/-], pressd

[ENTER] to confirm.

2. Method number 0 is used for a manual digestion or to heat the device without lift

movement.

3. Pressa [TEMP] and adjust the temperature by pressingc [+/-].

4. Pressd [ENTER] to confirm the new value.

5. Pressb [TIME] and adjust the time by pressingc [+/-].

6. Pressd [ENTER] to confirm the new value.

6 Operation

6.4 Editing parameters during a digestion

NOTE

Parameters on the K-449 cannot be changed during a digestion in the automatic mode

(METH1 – 9).

1. Pressa [TEMP] and adjust the temperature by pressingc [+/-].

2. Pressd [ENTER] to confirm the new value.

3. Pressb [TIME] and adjust the time by pressingc [+/-].

4. Pressd [ENTER] to confirm the new value.

6 – 37Operation Manual KjelDigester K-446/K-449

Page 38

6 Operation

6.5 Abort a digestion

1. Press stop[STOP] at any time during the digestion to abort a process.

NOTE

The Scrubber continues to run until the stop[STOP] button is pressed again.

CAUTION

Risk of burns from hot rack handles!

Minor or moderate burns can result.

1. Wear protective gloves when lifting the rack. Rack handles can exceed temperatures of 70°C.

2. On the K-446:

∙ Lift the rack and suction module out of the heating block into the cooling position.

3. On the K-449:

∙ The rack moves automatically out of the heating block into the cooling position.

6.6 Switch off the KjelDigester

NOTICE

Insufficient cooling of the device.

Switching off the device without cooling down can damage electrical components.

1. Do not switch off the device when the heating block is warmer than 60°C.

1. Tilt up the suction module.

2. Insert the drip tray.

3. Remove the rack.

4. Let the KjelDigester cool down.

∙ The heating block is cooled down if the LED [HEAT] goes off.

5. Switch off the main switcha.

6 – 38

KjelDigester K-446/K-449 Operation Manual

Page 39

6.7 KjelDigester K-446

6 . 7.1 Digestion process

aPreliminary tasks

1. Turn on the main switch.

2. Set the desired temperature and time.

∙ 6.3 Set parameters for manual digestion, (6–36)

3. Press the start [START] button.

∙ The preheating of the heating block starts.

∙ When the set temperature is reached ready [READY] appears on the display.

6 Operation

bTas k s

1. Place the sample tubes into the rack.

2. Pour the samples and reagents into the sample tubes.

3. Use glass caps for any unoccupied positions to close the suction circuit.

4. Fit the sample rack into the cooling position.

5. Remove the drip tray.

6. Tilt down the suction module onto the sample tubes.

7. Check if all the sealings of the suction module are fitting the sample tubes.

8. Place the rack and suction module into the heating position.

WARNING

Risk of acid or toxic fume inhalation.

Serious injuries or death can result.

1. Always run the Scrubber or water jet pump during the digestion process.

2. Operate the Scrubber and KjelDigester only in a fume hood.

3. Close the fume hood door as far as possible.

9. Press the start [START] button on the control panel.

∙ The Scrubber starts (if connected).

10. Start the Scrubber (if not connected) or the water jet pump.

6 – 39Operation Manual KjelDigester K-446/K-449

Page 40

6 Operation

Risk of burns from hot rack handles!

Minor or moderate burns can result.

1. Wear protective gloves when lifting the rack. Rack handles can exceed temperatures of 70°C.

11. Place the rack in the cooling position when the digestion is finished.

∙ A beep sound is audible for 10 seconds to inform the user about the finished digestion.

∙ The message [FINISH] appears on the display.

12. Wait until the samples are cooled down.

∙ The LED[HEAT] flashes until the temperature of the heating block is below 60°C.

13. Tilt up the suction module when no more fumes are escaping from the sample tubes.

14. Place the drip tray between the suction module and the samples.

15. Switch off the Scrubber (if connected) by pressing the stop [STOP] button.

6.8 KjelDigester K-449

CAUTION

6.8.1 Digestion process, manual mode

aPreliminary tasks

1. Turn on the main switch.

2. Select the method number0.

3. Set the desired temperature and time.

∙ 6.3 Set parameters for manual digestion, (6–36)

4. Press the start [START] button.

∙ The preheating of the heating block starts.

∙ When the set temperature is reached ready [READY] appears on the display.

bTas k s

1. Place the sample tubes into the rack.

2. Pour the samples and reagents into the sample tubes.

3. Use glass caps for any unoccupied positions to close the suction circuit.

4. Fit the sample rack into the cooling position.

5. Remove the drip tray.

6. Tilt down the suction module onto the sample tubes.

7. Check if all the sealings of the suction module are fitting the sample tubes.

6 – 40

KjelDigester K-446/K-449 Operation Manual

Page 41

6 Operation

WARNING

Risk of acid or toxic fume inhalation.

Serious injuries or death can result.

1. Always run the Scrubber or water jet pump during the digestion process.

2. Operate the Scrubber and KjelDigester only in a fume hood.

3. Close the fume hood door as far as possible.

8. Press the start button.

∙ The rack lowers automatically into the heating block.

∙ The Scrubber starts (if connected).

9. Start the Scrubber (if not connected) or the water jet pump.

10. After the digestion process the rack will move automatically into cooling position.

∙ The message [FINISH] appears on the display.

∙ A beep sound is audible for 10 seconds to inform the user about the finished digestion.

11. Wait until the samples are cooled down.

∙ The LED[HEAT] flashes until the temperature of the heating block is below 60°C.

12. Tilt up the suction module when no more fumes are escaping from the sample tubes.

13. Place the drip tray between the suction module and the samples.

14. Switch off the Scrubber by pressing the stop [STOP] button.

6.8.2 Digestion process, automatic mode

aPreliminary tasks

1. Turn on the main switch.

2. Select or setup a method (Method 1 – 9).

∙ 6.8.6 Select a method, (6–44).

∙ 6.8.4 Set parameters for an automatic digestion, (6–43).

3. Press the start [START] button.

∙ The start time setting appears.

4. Press the start [START] button.

∙ The block is heated to the set temperature of step1.

∙ The rack will lower automatically into the heating block when the temperature of step1

is reached.

∙ The Scrubber starts (if connected).

bTas k s

1. Place the sample tubes into the rack.

2. Pour the samples and reagents into the sample tubes.

3. Use glass caps for any unoccupied positions to close the suction circuit.

4. Fit the sample rack into the cooling position.

5. Remove the drip tray.

6. Tilt down the suction module onto the sample tubes.

7. Check if all the sealings of the suction module are fitting the sample tubes.

6 – 41Operation Manual KjelDigester K-446/K-449

Page 42

6 Operation

cFollow-on tasks

WARNING

Risk of acid or toxic fume inhalation.

Serious injuries or death can result.

1. Always run the Scrubber or water jet pump during the digestion process.

2. Operate the Scrubber and KjelDigester only in a fume hood.

3. Close the fume hood door as far as possible.

8. Start the Scrubber (if not connected) or the water jet pump.

∙ The device beeps 3times before the lift starts moving down into heating position.

1. After the digestion process the rack will move automatically into the cooling position.

∙ The LED[HEAT] flashes until the temperature of the heating block is below 60°C.

∙ The Scrubber keeps running until the cooling time is completed as defined in the

method.

2. Tilt up the suction module.

3. Place the drip tray between the suction module and the samples.

4. Press the start [START] button to repeat the same method or press stop [STOP] to

select another method.

6.8.3 Digestion process, delayed start

aPreliminary tasks

1. Connect the Scrubber to the K-449.

2. 5.5.5 Set the clock (K-449 only), (5–31).

3. 6.8.6 Select a method, (6–44).

4. 6.8.7 Set up a delayed start time, (6–44).

bTas k s

1. Press the start [START] button.

∙ 6.8.7 Set up a delayed start time, (6–44).

2. Place the sample tubes into the rack.

3. Pour the samples and reagents into the sample tubes.

4. Use glass caps for any unoccupied positions to close the suction circuit.

5. Fit the sample rack into the cooling position.

6. Remove the drip tray.

7. Tilt down the suction module onto the sample tubes.

8. Check if all the sealings of the suction module are fitting the sample tubes.

WARNING

Risk of acid or toxic fume inhalation.

Serious injuries or death can result.

6 – 42

1. Always run the Scrubber during the digestion process.

2. Operate the Scrubber and KjelDigester only in a fume hood.

3. Close the fume hood door as far as possible.

9. Make sure the Scrubber main switch is on and the cooling water is working.

KjelDigester K-446/K-449 Operation Manual

Page 43

6.8.4 Set parameters for an automatic digestion

1. Press Method [METH].

2. Select a method number between 1 and 9.

∙ 6.8.6 Select a method, (6–44).

3. Pressc [STEP].

∙ The text [STARTTIME] on the display appears.

4. Set a delayed start time if required or pressc [STEP] to continue.

∙ 6.8.7 Set up a delayed start time, (6–44).

5. Pressa [TEMP] and adjust the temperature by pressingd [+/-].

6. Presse [ENTER] to confirm the new value.

7. Pressb [TIME] and adjust the time by pressingd [+/-].

8. Presse [ENTER] to confirm the new value.

9. Pressc [STEP].

10. Repeat the steps 5 – 9.

NOTE

If not all of the 4 steps are required, set the time to zero on the remaining steps.

6 Operation

11. Pressa [TIME] and adjust the cooling time to keep the Scrubber running after the

digestion is finished by pressingc [+/-].

NOTE

Set up a time amount big enough that no more fumes are evading from the sample tubes

when the Scrubber stops. BUCHI recommends a starting value of 30minutes.

12. Pressd [ENTER] to confirm the new value.

13. Pressb [STEP].

6 – 43Operation Manual KjelDigester K-446/K-449

Page 44

6 Operation

6.8.5 Edit a method

1. Edit a method according to the next step:

∙ 6.8.4 Set parameters for an automatic digestion, (6–43).

6.8.6 Select a method

1. Press a [METH].

∙ The method number flashes.

2. Select the desired method number by pressingb [+/-].

3. Pressc [ENTER] to confirm the method.

NOTE

Method number 0 is reserved for the manual mode.

6.8.7 Set up a delayed start time

1. Select the desired method.

2. Pressb [STEP].

∙ The text [STARTTIME] on the display appears.

3. Pressa [TIME] and adjust the hour by pressingc [+/-].

4. Pressd [ENTER] to confirm the new value.

5. Adjust the minutes by pressingc [+/-].

6. Pressd [ENTER] to confirm the new value.

NOTE

Make sure that the internal clock is set properly for an accurate work of the delayed start

time.

6 – 44

KjelDigester K-446/K-449 Operation Manual

Page 45

6.8.8 Moving the lift up or down

WARNING

Risk of hand bruising and burns due to the moving lift!

Serious injuries or death can result.

1. Do not reach between the heating block and rack during the lift movement.

2. Do not touch the device during the lift operation.

1. Move the lift up or down by pressinga or b [UP/DOWN].

∙ The lift moves automatically in the automatic mode.

NOTE

The lift can be moved manually at any time.

6 Operation

6 – 45Operation Manual KjelDigester K-446/K-449

Page 46

6 Operation

6 – 46

KjelDigester K-446/K-449 Operation Manual

Page 47

7 Maintenance

All maintenance and repair work described in this manual can be carried out by the operator.

All other tasks must be carried out by trained service personnel. Therefore contact the BUCHI

customer service or the sales representative.

Use only genuine BUCHIconsumables and spare parts for maintenance to assure good device

performance, reliability and safety. Any modifications of spare parts or assemblies are only allowed with the prior written permission of BUCHI.

7.1 Maintenance plan

7.1.1 Maintenance as required/after use

No Ta sk

1. Clean the suction module (7–49)

2. Check the sealings and springs (8–57)

3. Check the glass parts:

∙ Suction tubes and fume collection tube

∙ Check the sample tubes

∙ Hose connector on the fume collection tube

4. Clean the sample tubes (7–49)

5. Clean the drip tray

6. Clean the heating block holes with a wire brush

7 Maintenance

(8–58)

7.1.2 Daily maintenance

No Ta sk

1. Clean the suction module (7–49)

2. Clean the KjelDigester (7–48)

3. Check the glass parts:

∙ Suction tubes and fume collection tube

∙ Check the sample tubes

∙ Hose connector on the fume collection tube

7.1 . 3 Maintenance every week

No Ta sk

1. Clean the rack

2. Clean the magnets of the rack support with a damp cloth

3. Clean the catchpot clip.

4. Clean the Scrubber hose (7–49)

(8–58)

7 – 47Operation Manual KjelDigester K-446/K-449

Page 48

7 Maintenance

7.1 . 4 Maintenance every year or after every 1000 digestion cycles

No Ta sk

1. Check the rechargeable battery (8–58)

2. Replace the sealings and springs of the suction module (7–50)

7.1 . 5 Maintenance every 3 years

No Ta sk

1. Replace the rechargeable battery (7–52)

7.2 Cleaning

7.2.1 KjelDigester, cleaning

NOTICE

Risk of liquids leaking into the housing or electrical components!

Device damage by liquids and detergents and corrosion through chemicals.

1. Let the device cool down before cleaning.

2. Do not spill liquids over the device, wipe off any liquids instantly.

3. Use a pipette to remove remaining liquid.

4. Use ethanol or soapy water as detergent only.

aPreliminary tasks

1. Let the heating block cool down (<60°C).

2. Switch off the main switch.

WARNING

Risk of electric shock or burns from electric current during cleaning!

Serious injuries or death can result.

1. Switch off the device.

2. Disconnect the power supply cable from the device.

3. Wait until the device is completely dry before reusing.

3. Disconnect the power supply cable of the device.

bTas k s

7 – 48

1. Clean the drip tray with water and store it in the drip tray holder.

2. Clean the device surfaces and covers with a damp cloth to remove acid splashes.

∙ Remove the heating block cover for cleaning.

3. Clean the heating block cover.

4. Clean all spaces, e.g. between heating block and housing.

∙ In case of a strong contaminant of the heating block use the wire brush and drilling

machine.

5. Put back the cover onto the heating block.

KjelDigester K-446/K-449 Operation Manual

Page 49

7.2.2 Scrubber hose, cleaning

1. Disconnect the Scrubber hose on the both ends (Scrubber and KjelDigester).

2. Carry the hose with both openings showing upwards to prevent liquid to leak out.

3. Flush hose with hot water.

∙ Use ethanol as a detergent for major contaminants.

4. Reconnect the hose on the Scrubber and KjelDigester.

7.2.3 Suction module sealing and spring, cleaning

aPreliminary tasks

1. Remove the suction module (7– 54).

bTas k s

1. Put the suction module upside down in to a washing bath.

2. Clean the sealings and springs with water and a brush.

∙ Use ethanol or soapy water as detergent for major contaminants.

3. Clean the suction tubes and the fume collection tube with detergent and a brush.

4. Flush the suction tubes and the fume collection tube with water.

5. Dry the sealings with a soft cloth.

NOTE

The complete suction module can also be cleaned in a laboratory dishwasher.

7 Maintenance

6. In case of a strong contaminant disassemble the suction module and clean the parts

in a ultrasonic bath.

cFollow-on tasks

1. Check the glass parts (8–58).

7.2.4 Sample tube, cleaning

NOTICE

Risk of sample tube damage.

Sample tubes can break due to mechanical or temperature shocks.

1. Do not cool down sample tubes with cold water.

2. Do not place hot sample tubes and the rack on a cold surface.

Single tube

1. Place the sample tubes into the dish washer.

2. Make sure the sample tubes are properly mounted in the dishwasher to prevent any

damage.

NOTE

Sample tubes with scratches or chips can break during a digestion.

7 – 49Operation Manual KjelDigester K-446/K-449

Page 50

7 Maintenance

Tubes and rack

1. Place the sample tubes and rackb on the rack standc.

2. Install the retaining plate a and lock it with the 2 latchesd to secure the sample

3. Turn the rack upside down and place it in the dishwasher.

NOTE

To clean the tubes and rack together in the dishwasher additional accessories are required.

tubes.

aFollow-on tasks

1. Check the glass parts (8–58).

7. 3 Suction module sealing and spring ,replacement

aPreliminary tasks

1. Remove the suction module (7– 54).

7 – 50

KjelDigester K-446/K-449 Operation Manual

Page 51

bTas k s

NOTICE

Risk of sealing damage by sharp objects.

The sealings can be damaged by the use of sharp objects.

1. Do not bring sealings in contact with sharp objects.

2. Use ethanol or soapy water as detergent only.

3. Do not lubricate sealings.

1. Hold back the suction tubea and pull down the sealingc by hand.

NOTE

Replacing the sealing under running, warm water will ease the removal.

2. Remove the springb.

7 Maintenance

3. Install the spring and sealing in reverse order.

7. 4 Fuse power supply, replacement

WARNING

Risk of electric shock with connected power supply cable!

Serious injuries or death can result.

1. Switch off the device

2. Disconnect the power supply cable from the device.

1. Switch off the main switch.

2. Disconnect the power supply cable from the device.

3. Unscrew the fuse carrierb.

∙ Make sure the O-ring on the fuse carrier is not damaged.

4. Replace the defective fusea.

5. Screw in the fuse carrier.

6. Connect the power supply cable.

7 – 51Operation Manual KjelDigester K-446/K-449

Page 52

7 Maintenance

7. If the fuse brakes repeatedly contact the customer support.

∙ 8.1 Customer service, (8–55).

7. 5 Rechargeable battery (K-449 only), replacement

aRequired tools:

• TORX screw driver T10

bPreliminary tasks

1. Remove the drip tray and store it on the drip tray holder on the left side of the device.

2. Remove the suction module (7–54).

cTas k s

1. Make sure the lift is in the cooling position.

WARNING

Risk of electric shock with connected power supply cable!

Serious injuries or death can result.

1. Switch off the device.

2. Disconnect the power supply cable from the device.

2. Switch off the device.

3. Disconnect the power supply cable from the device.

4. Remove the 4TORX screwsa of the lift cover.

Required tools

TORX screw driver T10

7 – 52

5. Slide out the lift coverb.

KjelDigester K-446/K-449 Operation Manual

Page 53

6. Move the batterya upwards out of the bracketb.

7. Disconnect the electrical plugc of the battery cable.

7 Maintenance

8. Install the new battery.

9. Assemble in reverse order.

dFollow-on tasks

1. Check the rechargeable battery (8–58).

7 – 53Operation Manual KjelDigester K-446/K-449

Page 54

7 Maintenance

7.6 Suction module, removal

1. Disconnect the Scrubber hosec from the fume collection tube and store it the

bracket left of the device.

2. Hold the suction modulea on both handlesb and lift it up and to the rear.

NOTE

The magnets on rack support will hold the suction module back until the force of the magnetic field is overcome by lifting up.

CAUTION

Risk of chemical burns from acid!

Minor or moderate cuts can result.

1. Wear the personal protective equipment.

3. Store and carry the suction module upside down to prevent acid drops pour out of

the suction module.

7 – 54

KjelDigester K-446/K-449 Operation Manual

Page 55

8 Troubleshooting

8.1 Customer service

Only authorized service personnel are allowed to perform repair work on the device which is

not described in this manual. Authorization requires a comprehensive technical training and

knowledge of possible dangers which might arise when working at the device. Such training

and knowledge can only be provided by BUCHI.

The customer service and support offers the following support:

∙ Spare part delivery

∙ Repairs

∙ Technical advice

Addresses of official BUCHI customer service offices can be found on the BUCHI website.

www.buchi.com

8 Troubleshooting

8.2 Error messages on the display

The troubleshooting table lists possible malfunctions and errors of the device. The operator is

enabled to correct some of those problems or errors. For this, appropriate corrective measures

are listed in the column “Corrective measure”.

Malfunction Possible cause Corrective measure

ERR 1 POWER Power supply interrupted.

The heat is turned off automatically.

ERR 2 TEMP The current heating block

temperature exceeds 500°C

(constant beeping sound).

ERR 3 SHUT OFF MAINS Due to a blocked or defective

fan the internal temperature of

the device exceeds 60°C.

PT 1000 ERROR Temperature sensor short or

circuit interrupted.

Restart. Delete the error

message from the display by

pressing [STOP].

Switch off the main switch.

Restart. Delete the error

message from the display by

pressing [STOP].

Switch off the device and

contact the BUCHI customer

service.

Switch off the device and

contact the BUCHI customer

service.

8 – 55Operation Manual KjelDigester K-446/K-449

Page 56

8 Troubleshooting

8.3 Faults

8.3.1 Broken sample tube during digestion

WARNING

Risk of burns from corrosives!

Serious injuries or death can result.

1. Observe all MSDS of the used chemicals.

2. Handle corrosives in well ventilated environments only.

3. Wear the personnel protective equipment.

WARNING

Risk of acid or toxic fume inhalation!

Serious injuries or death can result.

1. Run a Scrubber or water jet pump during a digestion and cool down time.

2. Close the fume hood as far as possible.

1. Abort the digestion by pressing the stop [STOP] button on the control panel.

2. Close the fume hood completely.

3. Wait until the heating block is cooled down.

4. Switch off the Scrubber.

5. Tilt up the suction module and place the drip tray underneath.

6. Remove the rack.

7. Remove residual bits of glass with a long forceps.

8. Remove the heating block cover and wash it.

9. Remove liquid from the heating block with a pipet.

NOTE

If liquid is flown into the insulation frame jack up the device (2cm) on one side and collect the

liquid on the other side.

10. Clean the heating block with the use of a long forceps and paper towel.

NOTE

Use distilled water to remove residues.

11. Clean the surface below and around the KjelDigester.

NOTICE

Risk of sample tube damage.

The sample tubes can brake due to residues in the heating block holes.

8 – 56

1. Remove all residues (e.g. liquid, glass or crystals) from the heating block

holes before reusing the device.

12. Make sure that no residues (e.g. liquid, glass or crystals) are left in the heating block

holes.

13. Reinstall the heating block cover.

KjelDigester K-446/K-449 Operation Manual

Page 57

aFollow-on tasks

1. Clean the KjelDigester (7–48).

2. Check the glassware (8–58).

8.3.2 Power supply failure [ERR1] during a digestion

CAUTION

Risk of acid or toxic fume inhalation!

Minor or moderate chemical burns of the airways.

1. Close the door of the fume hood as far as possible.

2. Leave the room.

1. Close the door of the fume hood as far as possible.

2. Leave the room and secure it until no fumes are left.

3. Try to reestablish the power supply so that the fume will be aspirated.

4. Restart the digestion.

8.3.3 Sample tubes jam in the heating block (K-449 only)

1. Perform a glass part check (8–58).

2. Contact the BUCHI customer service to align the rack support and heating block.

8 Troubleshooting

8.4 Checks

8.4.1 Suction module sealing and spring, check

1. Check all sealingsb and springsa on the suction module.

∙ No damaged spotsc on the sealings.

∙ No broken springs.

8 – 57Operation Manual KjelDigester K-446/K-449

Page 58

8 Troubleshooting

aResults

Sealings and springs show no damage:

∙ The sealings and springs are O.K.

Sealings and springs are damaged or show wear:

∙ Replace the sealings and springs (7– 50).

8.4.2 Glass parts, check

1. Check all glass parts for scratchesa or chipsb:

∙ Sample tubes

∙ Suction tubes

∙ Fume collection tube

∙ Hose connector

NOTE

Sample tubes with scratches or chips can break during a digestion.

aResults

Glass parts show no damage:

∙ The glass parts are O.K.

Glass parts have scratches or chips:

∙ Replace faulty glass parts.

8.4.3 Rechargeable battery (K-449 only), check

NOTE

This check can be done before a regular digestion.

1. Prepare the sample tubes and the rack for a digestion.

2. Place the filled rack into cooling position.

3. Turn on the main switch.

4. Move the lift to the heating position by pressing the down button on the control

panel.

5. Disconnect the power supply cable from the device.

8 – 58

KjelDigester K-446/K-449 Operation Manual

Page 59

8 Troubleshooting

aResults

The lift moves completely up to the cooling position:

∙ The battery is O.K.

The lift does not completely move up to the cooling position:

∙ Replace the rechargeable battery (7–52).

bFollow-on tasks

1. After restarting the device press [STOP] to clear the error message [ERR1].

8 – 59Operation Manual KjelDigester K-446/K-449

Page 60

8 Troubleshooting

8 – 60

KjelDigester K-446/K-449 Operation Manual

Page 61