Page 1

Interface I-300

Operation Manual

STOP

11593772D en

Page 2

Imprint

Product Identification:

Operation Manual (Original) Interface I-300

11593772

Publication date: 06.2017

BÜCHI Labortechnik AG

Meierseggstrasse 40

Postfach

CH-9230 Flawil 1

E-Mail: quality@buchi.com

BUCHI reserves the right to make changes to the manual as deemed necessary in the light of experience, especially with respect to structure, illustrations and technical detail.

This manual is copyrighted. Information from it may not be reproduced, distributed, or used for competitive purposes, nor made available to third parties. The manufacture of any component with the aid of this

manual without prior written agreement is also prohibited.

Page 3

BÜCHI Labortechnik AG Contents

Operation Manual Interface I-300 iii

Contents

1 About this document........................................................................................................... 6

1.1 Warning notices in this document........................................................................................................ 6

1.2 Symbols............................................................................................................................................... 6

1.2.1 Warning symbols .....................................................................................................................6

1.2.2 Mandatory directive symbols ...................................................................................................7

1.2.3 Other symbols..........................................................................................................................7

1.3 Available languages............................................................................................................................. 7

1.4 Trademarks.......................................................................................................................................... 7

2 Safety....................................................................................................................................8

2.1 Intended use........................................................................................................................................ 8

2.2 Use other than that intended ............................................................................................................... 8

2.3 Staff qualification ................................................................................................................................. 8

2.4 Residual risks ...................................................................................................................................... 9

2.4.1 Faults during operation ............................................................................................................ 9

2.5 Personal protective equipment ............................................................................................................ 9

2.6 Modifications........................................................................................................................................ 9

3 Product description........................................................................................................... 10

3.1 Description of function ....................................................................................................................... 10

3.2 Configuration ..................................................................................................................................... 10

3.2.1 Front view ..............................................................................................................................10

3.2.2 Rear view ............................................................................................................................... 11

3.2.3 VacuBox (connections).......................................................................................................... 12

3.2.4 LegacyBox (connections)....................................................................................................... 13

3.2.5 Display (touch-screen) ........................................................................................................... 15

3.2.6 Type plate .............................................................................................................................. 16

3.3 Navigating through the menu system ................................................................................................ 17

3.3.1 Main menu ............................................................................................................................. 17

3.3.2 Operating modes ...................................................................................................................18

3.3.3 Configuration..........................................................................................................................20

3.3.4 Libraries ................................................................................................................................. 23

3.4 Specifications supplied ...................................................................................................................... 24

3.4.1 Interface I-300........................................................................................................................24

3.4.2 VacuBox.................................................................................................................................24

3.4.3 LegacyBox ............................................................................................................................. 24

3.5 Technical data ................................................................................................................................... 25

3.5.1 Interface I-300........................................................................................................................25

3.5.2 VacuBox.................................................................................................................................25

3.5.3 LegacyBox ............................................................................................................................. 26

3.5.4 Ambient conditions.................................................................................................................26

3.5.5 Materials ................................................................................................................................26

4 Transport and storage ......................................................................................................27

4.1 Transport ........................................................................................................................................... 27

4.2 Storage .............................................................................................................................................. 27

Page 4

Contents BÜCHI Labortechnik AG

iv Operation Manual Interface I-300

5 Installation.......................................................................................................................... 28

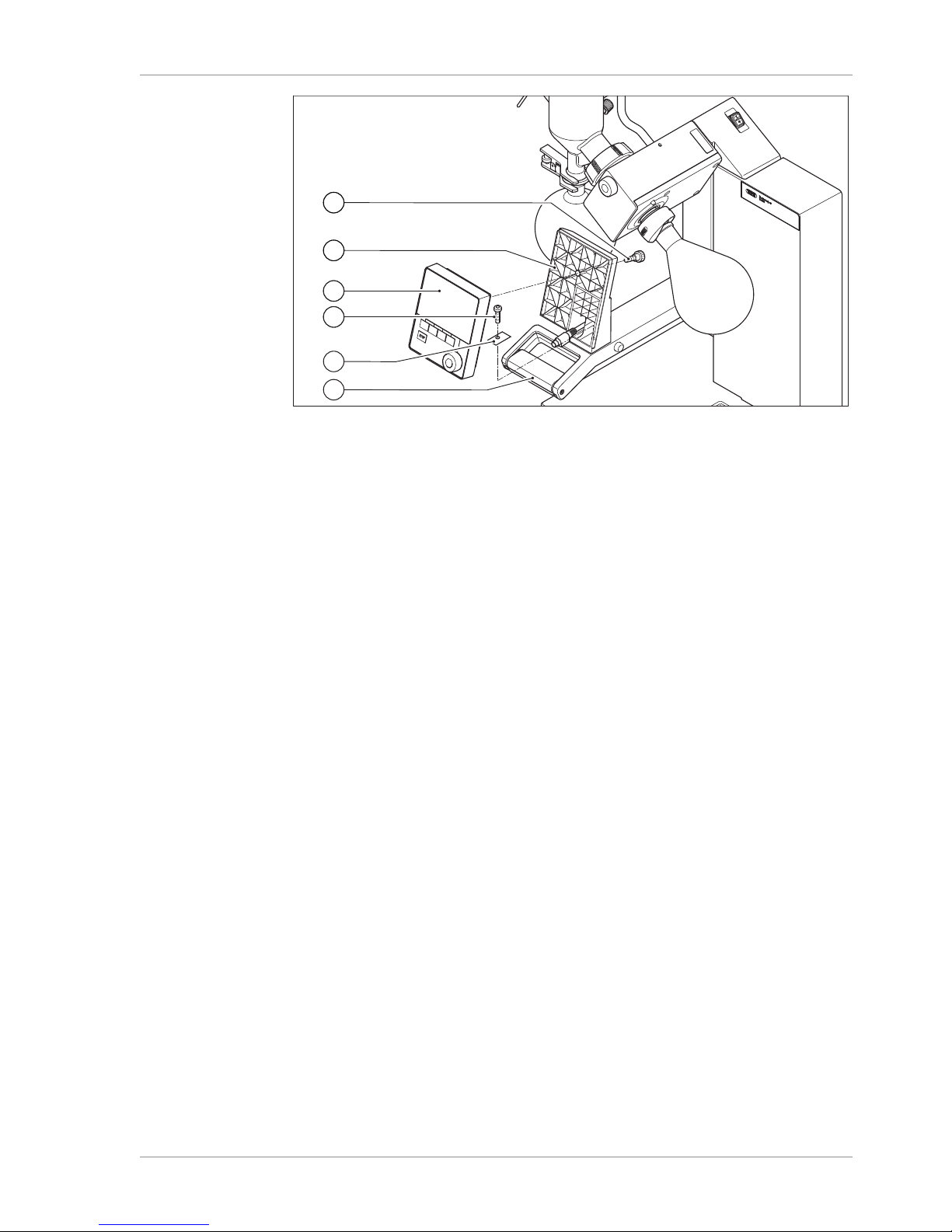

5.1 Fitting the Interface I-300/I-300 Pro................................................................................................... 28

5.1.1 Mounting interface on Rotavapor R-300................................................................................ 28

5.1.2 Fitting interface unit on Vacuum Pump V-300 .......................................................................30

5.1.3 Mounting interface unit on laboratory stand (optional accessory).......................................... 31

5.1.4 Mounting interface unit on a wall bracket (optional accessory) .............................................32

5.2 Assembling the BUCHI distillation system......................................................................................... 33

5.2.1 Connecting communication cables to interface unit............................................................... 33

5.2.2 Overview: setting up communication connections................................................................. 34

5.2.3 Overview: setting up coolant tubing connections...................................................................35

5.2.4 Overview: setting up vacuum tubing connections..................................................................36

5.3 Connecting AutoDest sensor to vapor temperature sensor (optional accessory).............................. 37

5.4 Connecting foam sensor (optional accessory)................................................................................... 39

5.5 Connecting valve unit for external vacuum........................................................................................ 40

5.6 Operating I-300 and I-300 Pro in parallel........................................................................................... 40

6 Operation............................................................................................................................ 41

6.1 Navigating the menu.......................................................................................................................... 41

6.1.1 Selecting menu items............................................................................................................. 41

6.1.2 Entering parameter settings...................................................................................................42

6.1.3 Changing settings .................................................................................................................. 42

6.2 Performing distillation ........................................................................................................................ 44

6.2.1 Overview: typical distillation sequence ..................................................................................45

6.2.2 Basic functions.......................................................................................................................46

6.2.3 Performing manual distillation................................................................................................47

6.2.4 Performing timer-controlled distillation...................................................................................50

6.2.5 Drying the system after distillation ("Continuous pumping") .................................................. 53

6.2.6 Performing automatic distillation............................................................................................ 57

6.2.7 Drying the product..................................................................................................................59

6.3 Using the solvent library .................................................................................................................... 62

6.4 Activating eco mode .......................................................................................................................... 64

6.5 Setting hysteresis .............................................................................................................................. 65

6.6 Creating favorites............................................................................................................................... 66

7 Mobile connection .............................................................................................................67

7.1 Setting up BUCHI Connect Solution.................................................................................................. 67

7.2 Components of the BUCHI Connect Solution.................................................................................... 68

7.3 Requirements for local network settings............................................................................................ 68

7.4 Connecting interface unit to the LAN................................................................................................. 69

7.5 Handling data..................................................................................................................................... 69

7.6 Enabling interface unit for access to BUCHI Cloud ........................................................................... 71

7.7 Assigning IP addresses ..................................................................................................................... 72

7.8 Downloading and installing the BUCHI Rotavapor app ..................................................................... 72

7.9 Viewing the QR code......................................................................................................................... 72

7.10 Generating a password...................................................................................................................... 74

7.11 Connecting to the distillation system with the BUCHI Rotavapor app ............................................... 74

7.12 Scanning the QR code with your smartphone ................................................................................... 75

7.13 Activating push notifications .............................................................................................................. 76

7.14 Remotely retrieving process data ...................................................................................................... 77

7.15 Optional function: setting up a local server........................................................................................ 79

Page 5

BÜCHI Labortechnik AG Contents

Operation Manual Interface I-300 v

8 Cleaning and servicing .....................................................................................................80

8.1 Cleaning the casing/display............................................................................................................... 80

8.2 Performing a leak test........................................................................................................................ 80

8.3 Fitting GL14 cap nut with tube seal ................................................................................................... 81

8.4 Checking seals .................................................................................................................................. 82

8.5 Calibrating AutoDest sensor.............................................................................................................. 83

8.6 Calibrating the pressure sensor......................................................................................................... 83

8.6.1 Offset calibration.................................................................................................................... 84

8.6.2 Simple calibration................................................................................................................... 84

8.6.3 Loading factory calibration..................................................................................................... 85

9 Help with faults ..................................................................................................................86

9.1 Faults, possible causes and remedies............................................................................................... 86

9.2 Error messages ................................................................................................................................. 87

9.3 Customer service............................................................................................................................... 87

10 Taking out of service and disposal.................................................................................. 88

10.1 Taking out of service.......................................................................................................................... 88

10.2 Disposal ............................................................................................................................................ 88

11 Appendix ............................................................................................................................89

11.1 Solvent table...................................................................................................................................... 89

11.2 Spare parts and accessories ............................................................................................................. 91

11.2.1 Accessories............................................................................................................................91

11.2.2 Wear parts .............................................................................................................................92

11.2.3 Spare parts ............................................................................................................................93

11.3 Health and safety approval................................................................................................................ 94

11.4 Health and safety............................................................................................................................... 95

Page 6

1 | About this document BÜCHI Labortechnik AG

6/96 Operation Manual Interface I-300

1 About this document

These operating instructions describe the Interface I-300 at the time supplied. They

are an integral part of the product and contain important information that is necessary

for safe operation and maintenance.

These operating instructions apply to all variants of the Interface I-300 and are

intended primarily for laboratory staff.

u To ensure safe and trouble-free operation, read these operating instructions

before starting up the device and follow the guidance they contain.

u Keep the operating instructions somewhere near to the device.

u Pass on the operating instructions to any subsequent owner or user.

BÜCHI Labortechnik AG accepts no liability whatsoever for any faults or damage that

result from the failure to follow these operating instructions.

u If you still have any questions after reading these operating instructions, please

contact BÜCHI Labortechnik AG Customer Service. Contact details for your local

agents can be found on the Internet at http://www.buchi.com.

1.1 Warning notices in this document

Warning notices warn you of dangers that can occur when handling the device. There

are four danger levels, each identifiable by the signal word used.

Signal word Meaning

DANGER Indicates a danger with a high level of risk which could result in

death or serious injury if not prevented.

WARNING Indicates a danger with a medium level of risk which could result in

death or serious injury if not prevented.

CAUTION Indicates a danger with a low level of risk which could result in

minor or medium-severity injury if not prevented.

IMPORTANT Indicates a danger that could result in damage to property.

1.2 Symbols

The following symbols may be displayed in this instruction manual or on the device:

1.2.1 Warning symbols

Symbol Meaning Symbol Meaning

General warning Corrosive substance

Dangerous electrical voltage Flammable substance

Biological hazard Potentially explosive atmos-

phere

Breakable items Dangerous gases

Page 7

BÜCHI Labortechnik AG About this document | 1

Operation Manual Interface I-300 7/96

Symbol Meaning Symbol Meaning

Hot surface Health-harming or irritant

substances

Risk of hand injury Strong magnetism

1.2.2 Mandatory directive symbols

Symbol Meaning Symbol Meaning

Wear safety goggles Wear protective clothing

Wear protective gloves Heavy load, do not lift with-

out assistance

1.2.3 Other symbols

NOTE

This symbol draws attention to useful and important information.

R This character draws attention to a requirement that must be met before the

instructions below are carried out.

u This character indicates an instruction that must be carried out by the user.

5 This character indicates the result of a correctly carried out instruction.

1.3 Available languages

These operating instructions were originally produced in German and have been

translated into several other languages. The translations are available on the

enclosed CD or can be obtained as a PDF file via http://www.buchi.com.

1.4 Trademarks

Product names and registered or unregistered trademarks that are used in this

instruction manual are used only for identification and remain the property of the

owner in each case.

For example, Rotavapor® is a registered trademark of BÜCHI Labortechnik AG.

Page 8

2 | Safety BÜCHI Labortechnik AG

8/96 Operation Manual Interface I-300

2 Safety

2.1 Intended use

The Interface I-300 is intended for indicating vacuum within an operating range of

0mbar to ambient atmospheric pressure. The measurement and regulation of the

vacuum is performed by means of a VacuBox. The Interface I-300 has been designed

and built as an item of laboratory equipment and can be used in conjunction with the

following devices:

Distillation apparatus, especially rotary evaporators

Vacuum-drying cabinets

Vacuum pumps

Recirculating chiller

2.2 Use other than that intended

Use of any kind other than that described in the section Chapter2.1 "Intended use",

page8 and any application that does not comply with the technical specifications

(see Chapter3.5 "Technical data", page25) constitutes use other than that intended.

In particular, the following applications are not permissible:

Use of the device in areas that require apparatus that is safe to use in potentially

explosive atmospheres.

Use as a calibration device for other equipment.

Operation at pressures above atmospheric

Damage or hazards attributable to use of the product other than as intended are

entirely at the risk of the user alone.

2.3 Staff qualification

Unqualified persons are unable to identify risks and are therefore exposed to greater

dangers.

The device may only be operated by suitably qualified laboratory staff.

These operating instructions are aimed at the following target groups:

Users

Users are persons that meet the following criteria:

They have been instructed in the use of the device.

They are familiar with the contents of these operating instructions and the

applicable safety regulations and apply them.

They are able on the basis of their training or professional experience to assess

the risks associated with the use of the device.

Page 9

BÜCHI Labortechnik AG Safety | 2

Operation Manual Interface I-300 9/96

Operator

The operator (generally the laboratory manager) is responsible for the following

aspects:

The device must be correctly installed, commissioned, operated and serviced.

Only suitably qualified staff may be assigned the task of performing the operations

described in these operating instructions.

The staff must comply with the locally applicable requirements and regulations for

safe and hazard-conscious working practices.

Safety-related incidents that occur while using the device should be reported to the

manufacturer (quality@buchi.com).

BUCHI service technicians

Service technicians authorized by BUCHI have attended special training courses and

are authorized by BÜCHI Labortechnik AG to carry out special servicing and repair

measures.

2.4 Residual risks

The device has been developed and manufactured using the latest technological

advances. Nevertheless, risks to persons, property or the environment can arise if the

device is used incorrectly.

Appropriate warnings in this manual serve to alert the user to these residual dangers.

2.4.1 Faults during operation

If a device is damaged, sharp edges, moving parts or exposed electrical wires can

cause injuries.

u Regularly check device for visible damage.

u If faults occur, switch off the device immediately, unplug the power cord and

inform the operator.

u Do not continue to use devices that are damaged.

2.5 Personal protective equipment

Depending on the application, hazards due to heat and/or corrosive chemicals may

arise.

u Always wear appropriate personal protective equipment such as safety goggles,

protective clothing and gloves.

u Make sure that the personal protective equipment meets the requirements of the

safety data sheets for all chemicals used.

2.6 Modifications

Unauthorized modifications may impair safety and lead to accidents.

u Use only genuine BUCHI accessories, spare parts and consumables.

u Technical modifications to the device or accessories should only be carried out

with the prior written approval of BÜCHI Labortechnik AG and only by authorized

BUCHI technicians.

BUCHI accepts no liability whatsoever for damage arising as a result of unauthorized

modifications.

Page 10

3 | Product description BÜCHI Labortechnik AG

10/96 Operation Manual Interface I-300

3 Product description

3.1 Description of function

The Interface I-300 is designed for indicating, adjusting and controlling the complete

distillation system. The Interface I-300 settings enable precise specification of the

individual process parameters.For example:

Rotation speed of the evaporating flask

Specified temperature of the heating bath

Specified temperature of the coolant

Specified vacuum pressure

Duration of the distillation process

The pressure is measured and regulated by the associated VacuBox. Measurement

is independent of the solvent used.

3.2 Configuration

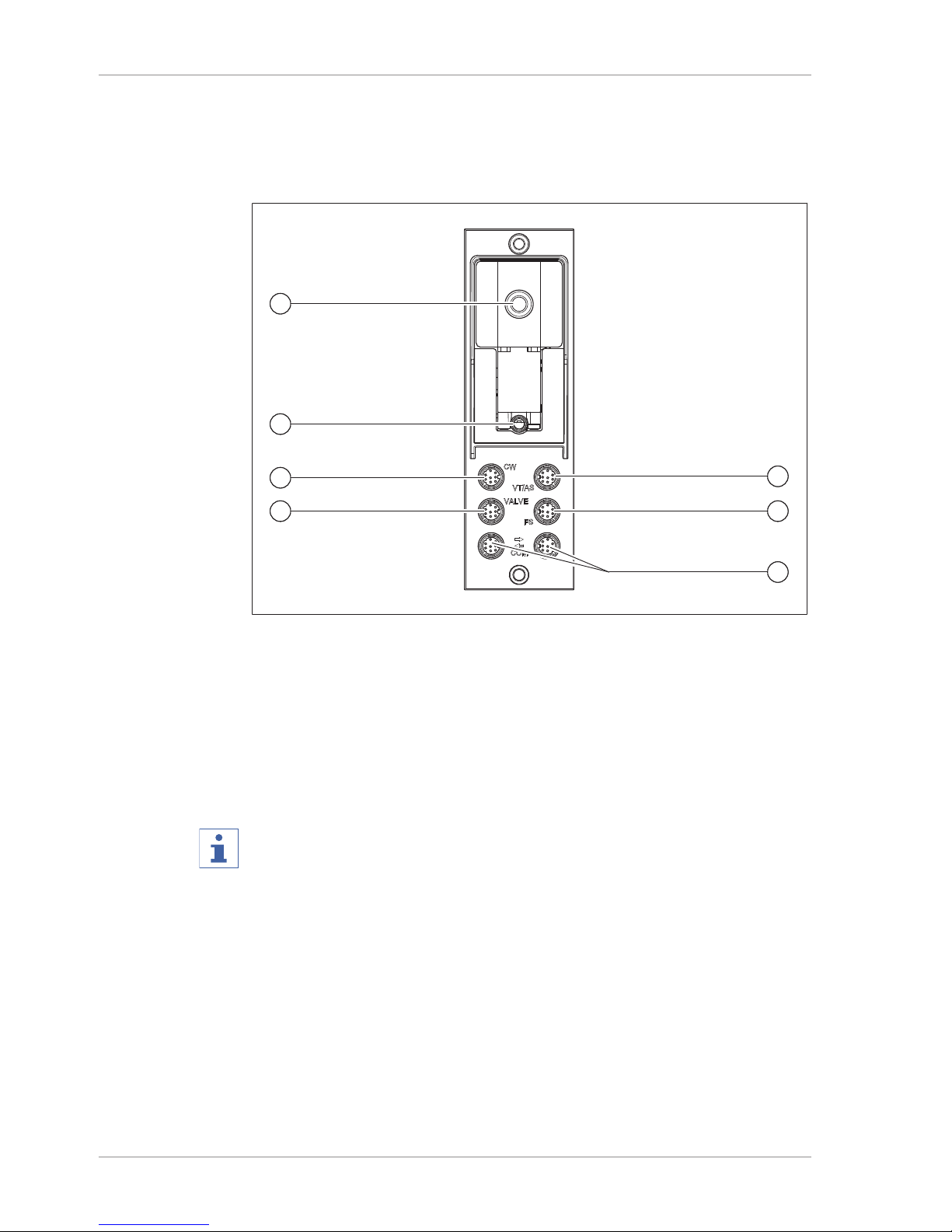

3.2.1 Front view

STOP

1

3

2

4

Fig.1: Front view of Interface I-300

1 Display 3 Navigation control

2 STOP button (emergency stop) 4 Function buttons

Page 11

BÜCHI Labortechnik AG Product description | 3

Operation Manual Interface I-300 11/96

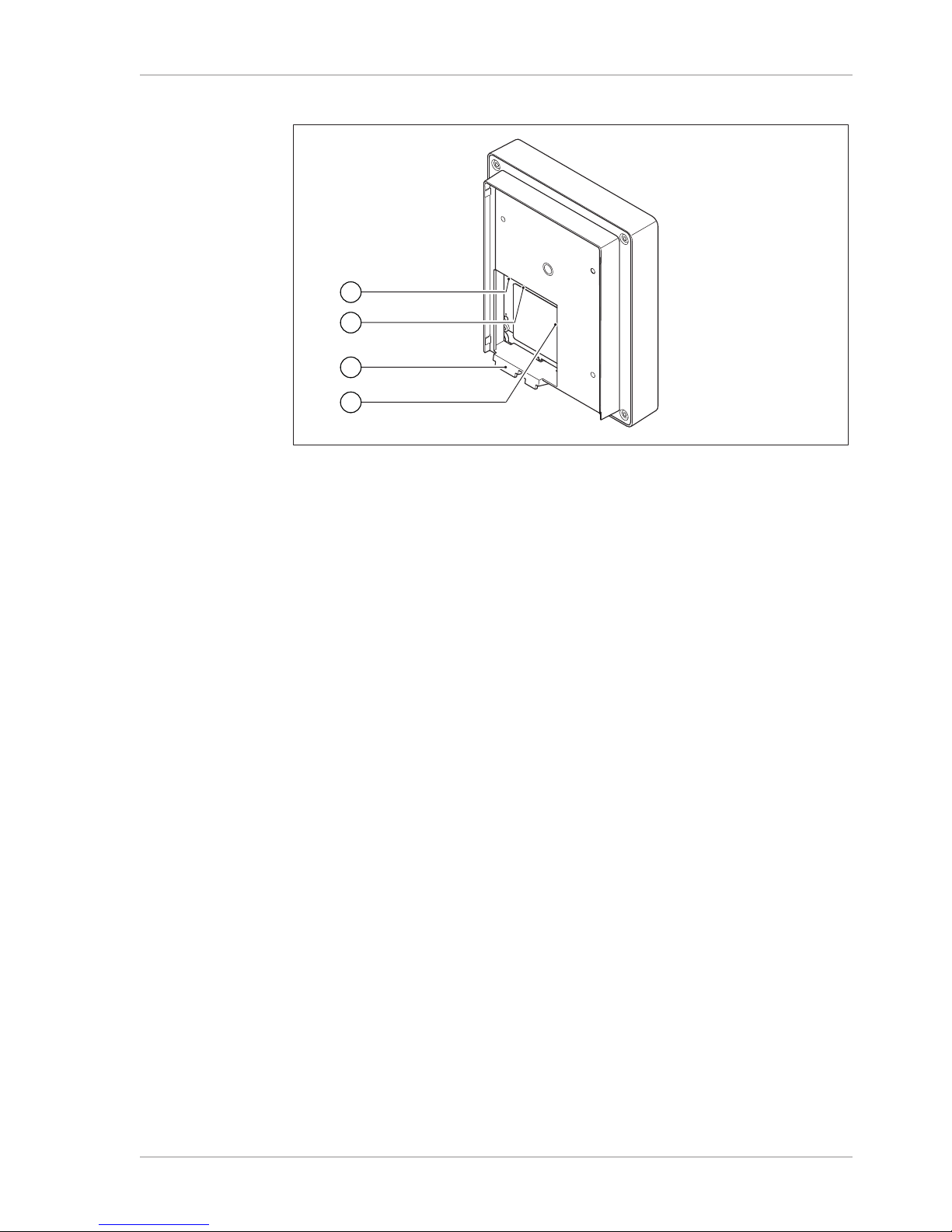

3.2.2 Rear view

3

4

1

2

Fig.2: Rear view of Interface I-300

1 LAN port 3 Locating lug for bracket

2 Standard BUCHI communication port

(COM)

4 MicroSD card (not used)

Page 12

3 | Product description BÜCHI Labortechnik AG

12/96 Operation Manual Interface I-300

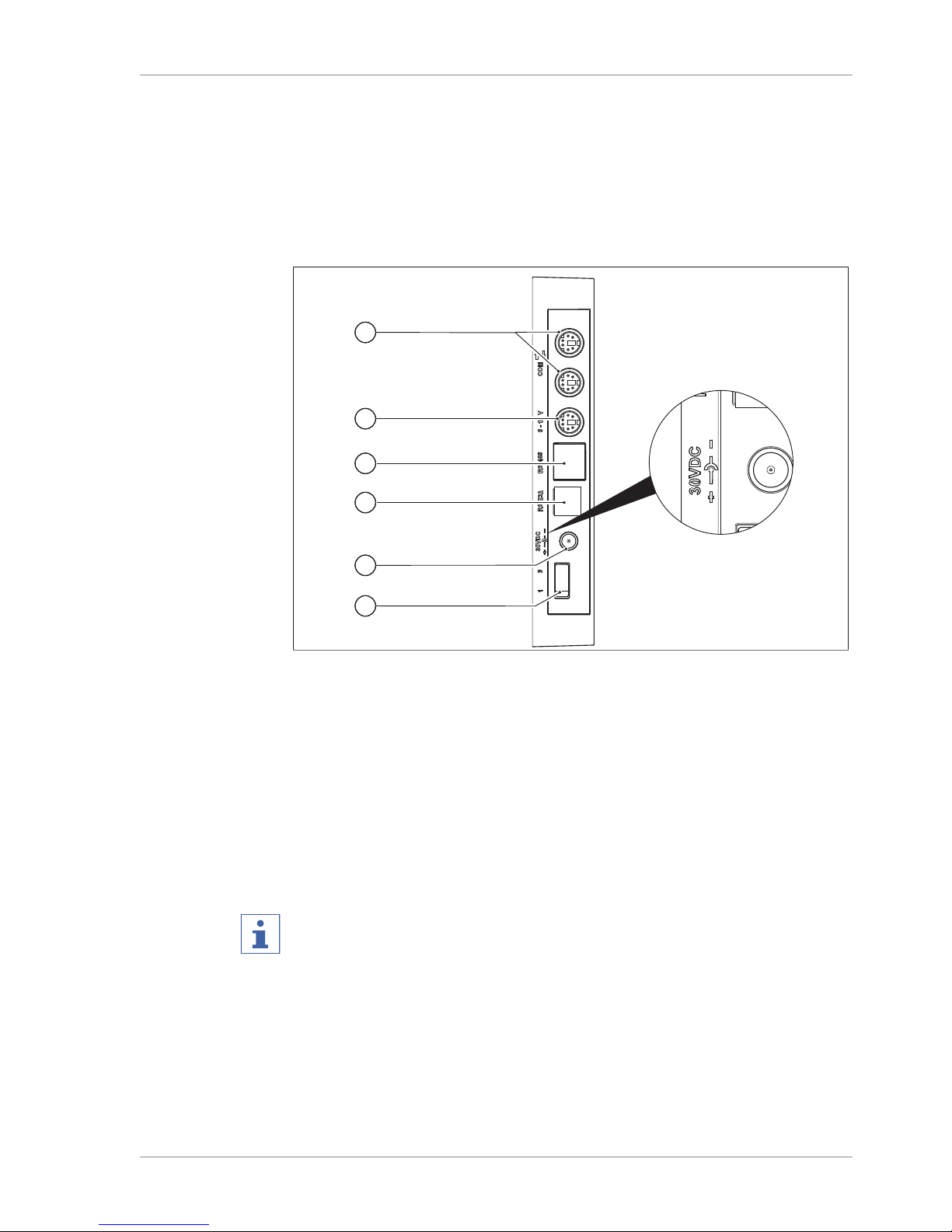

3.2.3 VacuBox (connections)

Other BUCHI laboratory equipment is connected to the Interface I-300 in series

together with the VacuBox. The individual devices are connected to one another via

the standard BUCHI communication port (7). See Chapter5.2.2 "Overview: setting up

communication connections", page34.

1

1

3

4

5

6

7

1

2

Fig.3: Connections on the VacuBox

1 Vacuum connection 5 Connection for vapor temperature/

AutoDest sensor (VT/AS)

2 Venting valve/inert gas connection

(optional)

6 Foam sensor connection (FS)

3 Water coolant valve connection (CW) 7 Standard BUCHI communication port

(COM)

4 Connection for valve unit or straight-

way valve (VALVE)

NOTE

Connecting VacuBox with R-220 Pro:

If the Interface I-300 Pro and the VacuBox are operated in the Rotavapor R-220 Pro

system, the following points should be noted: The external valves must always be

connected to the Rotavapor R-220 Pro even if there is an alternative connection on

the VacuBox.

Page 13

BÜCHI Labortechnik AG Product description | 3

Operation Manual Interface I-300 13/96

3.2.4 LegacyBox (connections)

Connection of a LegacyBox is required whenever legacy BUCHI laboratory equipment is to be controlled via the Interface I-300. The LegacyBox is connected to the

distillation system using a standard BUCHI communication cable and has other

connection options such as an RS-485 communication port. There is also the option

of incorporating pumps of other makes in the Rotavapor system and controlling them

via the interface. In that case, the pump requires a 0 – 10 V input.

The LegacyBox is fixed to a Rotavapor R-300 or a laboratory stand clamp.

2

4

3

1

6

5

Fig.4: Connections on the LegacyBox

1 Standard BUCHI communication port

(COM)

4 RS-232 (not used)

2 0 – 10 V communication port – for

connecting pumps of other makes

5 External power supply – for genuine

BUCHI mains adaptor, 30 V, 30 W

(see Chapter11.2.1 "Accessories",

page91)

3 RS-485 communication port – for

connecting legacy BUCHI laboratory

equipment (Vacuum Pumps V-700 /

V-710, Rotavapors: R-210 / R-215,

Recirculating Chiller F-1xx)

6 On/Off switch

NOTE

The external power supply is only necessary if the LegacyBox is not connected to a

Rotavapor or a vacuum pump and is used for other vacuum control applications

instead. Otherwise the vacuum pump or the Rotavapor supplies the LegacyBox with

power.

0 – 10 V communication port

This connection comprises a 0 – 10 V output for connecting pumps of other makes

and electrically isolated relay contacts. There is also a valve control contact.

Page 14

3 | Product description BÜCHI Labortechnik AG

14/96 Operation Manual Interface I-300

Fig.5: 8-pin MiniDin pin assignment, view of socket

Pin

8-pin notation

Symbol Description

1 Ground Ground connection for valve and 10 V

output

2 Valve Vacuum valve connection

3 Spare

4 10 V output 0 – 10 V (max. 20 mA, min. 500 Ohm)

5 Relay In Max. 30 V 2 A, electrically isolated

6 Spare

7 Spare

8 Relay Out Max. 30 V 2 A, electrically isolated

S Shield Shield, connected to ground

Page 15

BÜCHI Labortechnik AG Product description | 3

Operation Manual Interface I-300 15/96

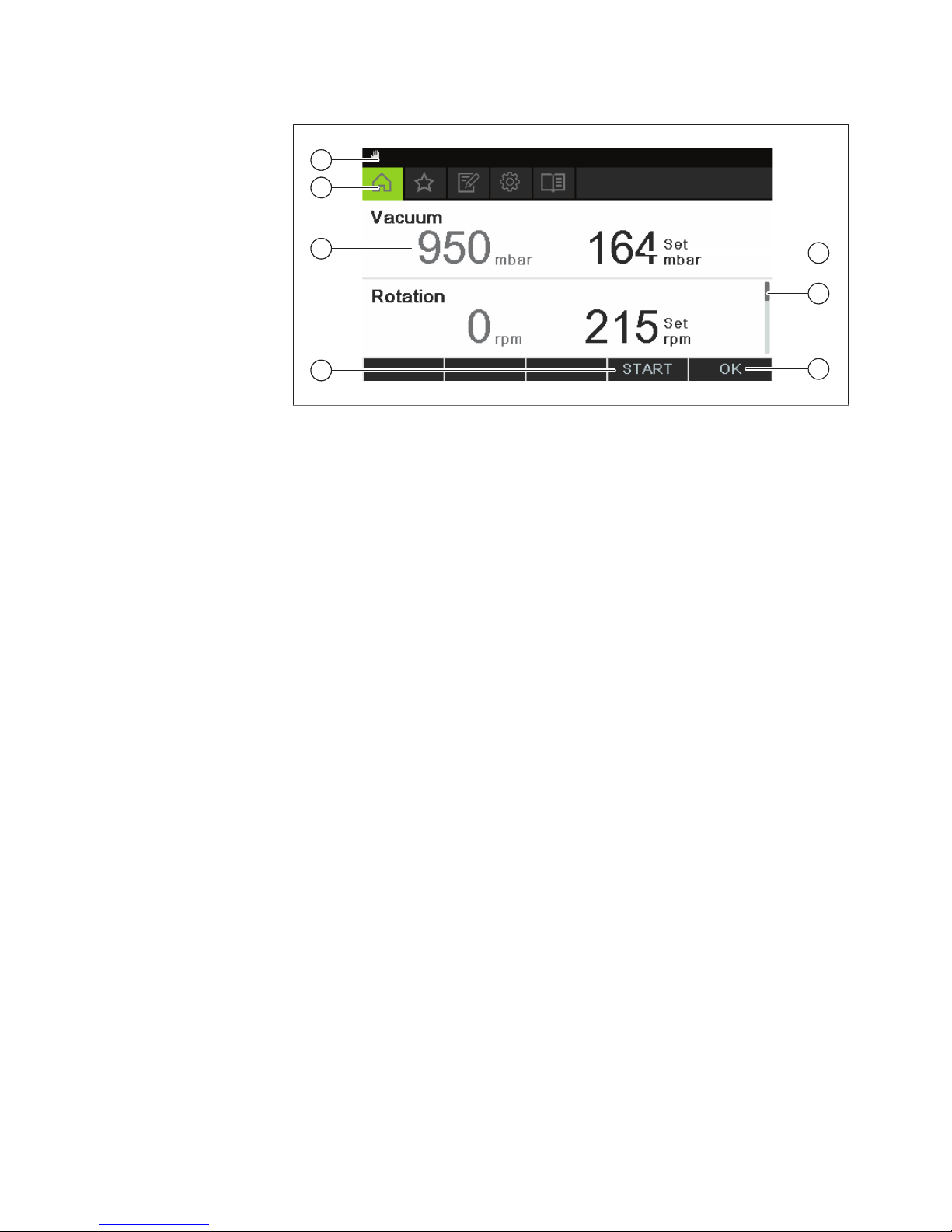

3.2.5 Display (touch-screen)

1

2

3

4

1

5

6

7

1

1

Fig.6: Display layout

1 Status bar 5 Current setting (e.g. vacuum)

2 Menu bar 6 Scroll bar

3 Current reading (e.g. vacuum) 7 Function activated if navigation

control is pressed

4 Functions of the function buttons

below (context-dependent)

Page 16

3 | Product description BÜCHI Labortechnik AG

16/96 Operation Manual Interface I-300

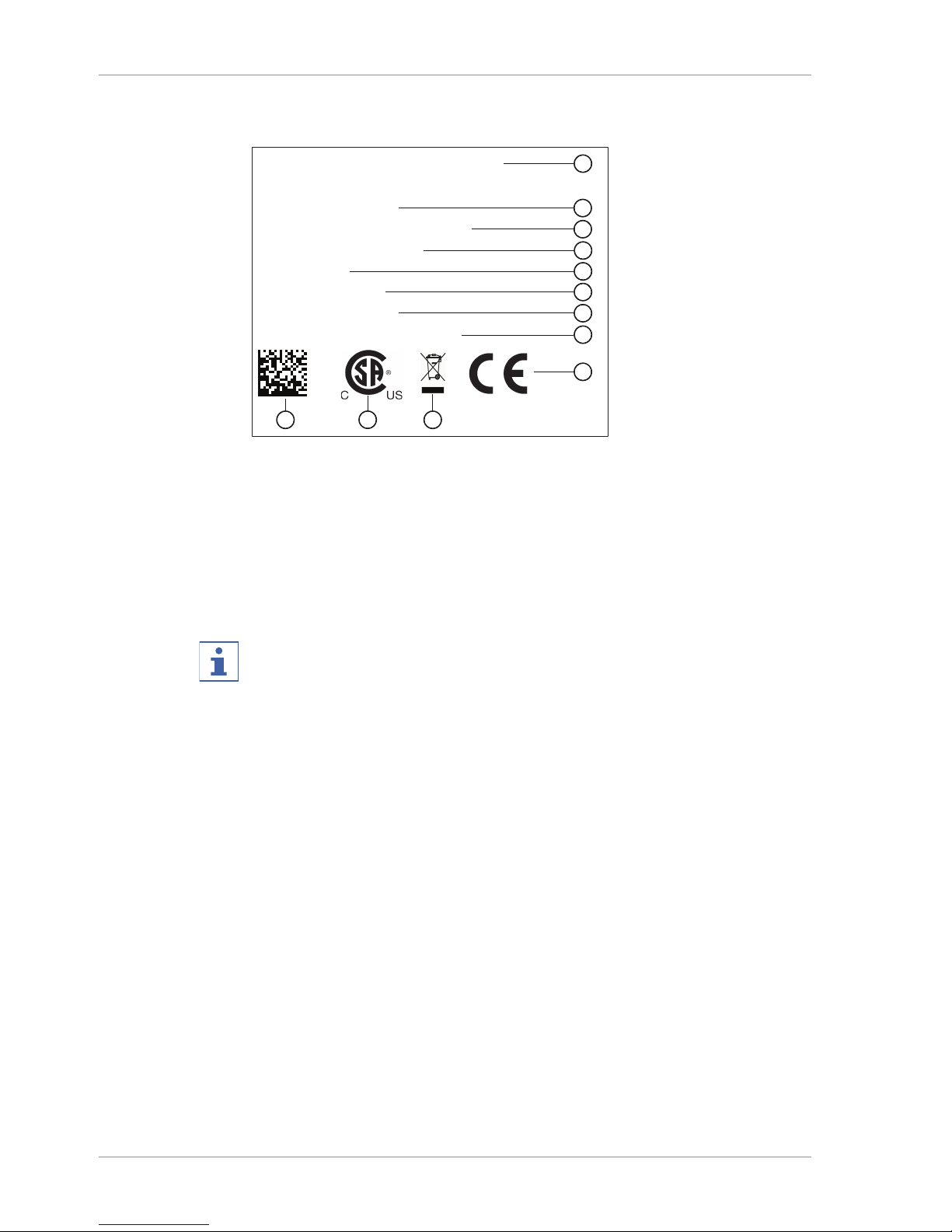

3.2.6 Type plate

The type plate is on the rear of the Interface I-300.

BÜCHI Labortechnik AG

CH-9230 Flawil/Switzerland

Type: I-300

SN: 1000000000

Volt: 30 VDC

Frequ.:

Power: 3 W

Built: 2014

Made in Switzerland

3

7

2

1

5

4

6

8

9

1011

9

Fig.7: Type plate (example)

1 Company name and address 7 Year of manufacture

2 Device name 8 Country of manufacture

3 Serial number 9 Approvals

4 Input voltage 10 Symbol for "Do not dispose of as

household waste"

5 Frequency 11 Product code

6 Maximum power rating

NOTE

The VacuBox and the LegacyBox each have their own type plate on the rear.

Page 17

BÜCHI Labortechnik AG Product description | 3

Operation Manual Interface I-300 17/96

3.3 Navigating through the menu system

3.3.1 Main menu

Highest menu level

Symbol Meaning Sub-items

Home page Process control

parameters

Favorites Bookmarks for fre-

quently used individual

starting points

Operating modes Manual

Timer

Continuous pumping

AutoDest

Drying

Configuration Servicing

Settings

Service

System information

Libraries Solvent library

Consumables

Page 18

3 | Product description BÜCHI Labortechnik AG

18/96 Operation Manual Interface I-300

3.3.2 Operating modes

Fig.8: "Operating modes" selected on main menu of Interface I-300

The Interface I-300 distinguishes between the following operating modes for a

distillation system:

Operating mode Purpose Consists of

Manual Carrying out distil-

lation with manually

set parameters

User-definable configuration of specified

settings for the individual process

parameters:

Vacuum

Evaporating flask rotation

Heating bath temperature

Coolant temperature

The actual values for the above

parameters are displayed, plus:

Vapor temperature

Timer Carrying out a dis-

tillation process

with manually set

parameters which

is to be stopped after a set time has

elapsed

User-definable configuration of specified

settings for the timer and individual

process parameters:

See "Manual"

Timer

Continuous

pumping

Drying the system

after distillation

Continuous operation of pump without

option of setting pressure.

AutoDest Carrying out auto-

matic single or

multi-stage distillation with specified

settings for the vacuum continuously

adjusted by the

system

Precondition: AutoDest sensor

connected to the system and supplying

readings:

Coolant inlet temperature

Coolant outlet temperature

Vapor temperature

The algorithm continuously adjusts the

specified settings for the pressure.

Process stops automatically as soon as

distillation is completed.

Page 19

BÜCHI Labortechnik AG Product description | 3

Operation Manual Interface I-300 19/96

Operating mode Purpose Consists of

Drying Post-drying of con-

tents of evaporating

flask.

Drying of evaporating flask contents.

Evaporating flask rotates in alternating

directions for a defined period of time.

User-definable configuration of specified

settings for the individual process

parameters:

See "Manual"

Timer

Rotation interval

Page 20

3 | Product description BÜCHI Labortechnik AG

20/96 Operation Manual Interface I-300

3.3.3 Configuration

Fig.9: "Configuration" selected on main menu of Interface I-300

The menu item "Configuration" on the main menu of the Interface I-300 offers the following options:

Servicing

"Servicing" provides access to information on seal servicing and the option of carrying

out a leak test on the distillation system.

Action Option Explanation

Leak test START For carrying out a leak test on the distil-

lation system.

Seal servicing Information Hours of rotation since last service.

Facility for resetting rotation hours

counter.

Settings

The "Settings" submenu provides the facility for changing basic settings on the

distillation system.

Action Option Explanation

Mobile connection

QR code

Display Interface shows QR code for the

connected distillation system, see

Chapter7.9 "Viewing the QR code",

page72.

Mobile connection

password

Display For viewing password and entering on

mobile device (alternative to QR code)

On finish: vent

system

On/Off System is vented after automatic or

manual termination of distillation.

On start: start rotation

On/Off Evaporating flask starts rotating when

distillation is started.

On finish: stop rotation

On/Off Evaporating flask stops rotating after

automatic or manual termination of

distillation.

On start: immerse

flask

On/Off Evaporating flask is automatically

immersed in the heating bath when d

istillation is started.

On finish: lift out

flask

On/Off Evaporating flask is automatically lifted

out of the heating bath after automatic or

manual termination of distillation.

On finish: stop

heating

On/Off Heating of heating bath stops after

automatic or manual termination of d

istillation.

Page 21

BÜCHI Labortechnik AG Product description | 3

Operation Manual Interface I-300 21/96

Action Option Explanation

On finish: stop

cooling

On/Off The Recirculating Chiller F-3xx automati-

cally switches off (after a run-on period 5

minutes) after automatic or manual

termination of distillation.

On finish: play

sound

On/Off An audible signal is sounded after

automatic or manual termination of d

istillation.

Pressure hysteresis

Entry of pressure Entry of figure for the maximum

allowable difference between the actual

vacuum and the specified figure before

the vacuum pump switches on again?

Language Choice of language

used for Interface

display

English, Deutsch, Francais, Italiano,

Espanol, Russian, Portugues, Japanese,

Chinese, Indonesian, Korean

Button tone On/Off A beep sounds when a function button or

the navigation control is pressed.

Seal servicing information

On/Off The interface shows information about

regular servicing of the system seals.

The message appears periodically after

every 500 hours of rotation.

Temperature unit Choice of unit for

indication of temperatures

°C(Celsius), °F(Fahrenheit) or

K(Kelvin)

Pressure unit Choice of unit for

indication of (negative) pressure

hPa (hectopascals), mbar (millibars),

torr (=mmHg), mmHg (millimeters of

mercury)

Height above sea

level

Entry of figure Altitude of location above mean sea

level: max.4000m.

For determination of max. allowable

pressure when working with the solvent

library.

Max. permissible

pressure

Entry of figure Max. pressure level present in the

system: max. 1400 mbar.

Max. pump delivery

Entry of figure Max. pump speed in %: 10–100%.

Display brightness

Entry of figure Display illumination level in %:

0–100%.

eco mode On/Off and entry of

figures

Settings for eco mode in respect of

"Delay" (minutes), "Bath reduction" (temperature), "Coolant increase"

(temperature)

Network Entry of details System name

DHCP: Yes/No

Network addresses for "Device IP

address", "Gateway", "Subnet mask",

"Server IP address"

BUCHI Cloud: Yes/No

Delete APP connection

Confirmation question

All connections settings entered for the

device are reset.

Page 22

3 | Product description BÜCHI Labortechnik AG

22/96 Operation Manual Interface I-300

Service

The "Service" submenu provides options for adjusting/calibrating the connected

measuring instruments.

Action Option Consists of

Calibrate AutoDest sensor

Perform calibration Calibration sequence between the two

condenser sensors. Precondition: the

two condenser sensors are at the same

temperature. See Chapter8.5

"Calibrating AutoDest sensor", page83.

Pressure offset Entry of reference

figure for measuring system pressure

The pressure inside the distillation

system is measured by a reference

sensor. That reading is entered as the

reference figure for the system's internal

pressure sensor. See Chapter8.6.1

"Offset calibration", page84.

Pressure calibration

Calibration of pressure sensor and

entry of reference

pressure

The pressure sensor is calibrated in five

stages for the set pressures of approx.

950 mbar (ambient pressure), 800 mbar,

600 mbar, 400 mbar, 200 mbar and 10

mbar. See Chapter8.6.2 "Simple

calibration", page84.

Loading factory

calibration

Calibration reset The current pressure sensor calibration

data is overwritten by the factory

calibration settings. See Chapter8.6.3

"Loading factory calibration", page85.

System information

The submenu "System information" provides details of the laboratory equipment

connected and on network connection diagnosis.

Page 23

BÜCHI Labortechnik AG Product description | 3

Operation Manual Interface I-300 23/96

3.3.4 Libraries

Fig.10: "Libraries" selected on main menu

The menu item "Libraries" on the main menu of the Interface I-300 offers access

to two libraries:

Solvent library

Wearing parts

Solvent library

The Interface I-300 has an internal solvent library. That library lists the most common

solvents (e.g. ethanol) in alphabetical order. For each solvent, the library contains an

algorithm that calculates the optimum vacuum setting from the actual figures for

heating bath temperature and coolant temperature. The specified vacuum setting is a

dynamic figure that alters automatically according to the current temperatures of

coolant and heating bath until they too have reached their specified settings.

Fig.11: Entries in the solvent library

NOTE

The individual solvents can be saved as favorites. A distillation process can be

started directly from the solvent library.

NOTE

When the heating bath and the recirculating chiller are connected, the actual figures

are automatically applied. If equipment of a different make is connected, the set

temperatures on the devices concerned have to be entered as specified settings on

the interface.

Wearing parts

The Interface I-300 offers a list containing a selection of the wearing parts for the

BUCHI Rotavapor system. The list is divided into two columns. The left-hand column

itemizes the wearing parts in alphabetical order. The right-hand column shows the

order numbers for the wearing parts.

Page 24

3 | Product description BÜCHI Labortechnik AG

24/96 Operation Manual Interface I-300

3.4 Specifications supplied

3.4.1 Interface I-300

Component Quantity sup-

plied

Interface I-300 1

Device bracket assembly:

Screw, M6x16 1

Torx key, Tx20 1

Torx key, Tx30 1

Holder 1

Metal plate 1

Knurled-head screw 1

3.4.2 VacuBox

Component Quantity sup-

plied

VacuBox 1

VacuBox accessory set:

Screw, M4x20 2

Torx key, Tx20 1

MiniDIN lead, 0.3 m 1

NOTE

The VacuBox is an essential requirement for use of the Interface I-300/I-300 Pro.

3.4.3 LegacyBox

Component Quantity sup-

plied

LegacyBox 1

LegacyBox accessory set:

Screw, M4x30 2

Screw, M4x50 2

Torx key, Tx20 1

MiniDIN lead, 0.3 m 1

Page 25

BÜCHI Labortechnik AG Product description | 3

Operation Manual Interface I-300 25/96

3.5 Technical data

3.5.1 Interface I-300

Dimensions (W x H x D) 121 x 141 x 50 mm

Weight 400 g

Power supply voltage 30 VDC ±5 %

Power consumption 3 W

Enclosure rating IP21

Approval CE/CSA

3.5.2 VacuBox

Dimensions (W x H x D) 50 x 167 x 57 mm

Weight 400 g

Power supply voltage 30 VDC ±5 %

Power consumption 8 W

Solenoid valve power supply 24 V

Measurement range 1400 – 0 mbar

Regulating range Ambient pressure – 0 mbar

Measurement accuracy ± 2 mbar (after calibration at constant

temperature)

Temperature compensation 0.07 mbar/K

Hysteresis Automatic or 1 – 200 mbar

Vacuum connection GL14

Enclosure rating IP21

Approval CE/CSA

Page 26

3 | Product description BÜCHI Labortechnik AG

26/96 Operation Manual Interface I-300

3.5.3 LegacyBox

Dimensions (W x H x D) 50 x 167 x 28 mm

Weight 200 g

Power supply voltage 30 VDC ±5 %

Power consumption 8 W

Enclosure rating IP21

Approval CE/CSA

3.5.4 Ambient conditions

Max. altitude above sea level 2000 m

Ambient temperature 5 - 40 °C

Maximum relative humidity 80 % for temperatures up to 31 °C

decreasing linearly to 50 % at 40 °C

The laboratory equipment described in this document may only be used in indoor

areas.

3.5.5 Materials

Component Material

Pressure foil Polyester

Casing PBT

Vent tube connection PPS

Pressure sensor Al₂O₃ 96%

Page 27

BÜCHI Labortechnik AG Transport and storage | 4

Operation Manual Interface I-300 27/96

4 Transport and storage

4.1 Transport

IMPORTANT

Risk of breakage due to incorrect transportation

u Make sure that all parts of the device are safely packed in such a way as to

prevent breakage, ideally in the original box.

u Avoid sharp movements during transit.

u After transportation, check the device for damage.

u Damage that has occurred in transit should be reported to the carrier.

u Keep packing for future transportation.

4.2 Storage

u Make sure that the ambient conditions are complied with (see Chapter3.5

"Technical data", page25).

u Wherever possible, store the device in its original packaging.

u After storage, check the device for damage and replace if necessary.

Page 28

5 | Installation BÜCHI Labortechnik AG

28/96 Operation Manual Interface I-300

5 Installation

5.1 Fitting the Interface I-300/I-300 Pro

The Interface I-300/I-300 Pro can be mounted on one of the following BUCHI

laboratory devices:

Rotavapor R-300

Vacuum Pump V-300

Rotavapor R-220 Pro

Alternatively, the Interface I-300/I-300 Pro can be mounted separately on a laboratory

stand, see Chapter5.1.3 "Mounting interface unit on laboratory stand (optional

accessory)", page31.

5.1.1 Mounting interface on Rotavapor R-300

The Interface I-300 can be mounted and connected up on the vertically adjustable

arm of the Rotavapor R-300.

Tools required: Torx keys Tx20 and Tx30

1

3

2

Fig.12: Handle of Rotavapor R-300

1 Cover 3 Fixing screw for cover

2 Communication cables

u Remove the screw on the underside of the vertically adjustable arm (3) using a

Torx key and remove the cover (1) from the top of the arm.

u Remove the pre-fitted communication cable (2) from the cover.

Page 29

BÜCHI Labortechnik AG Installation | 5

Operation Manual Interface I-300 29/96

2

3

4

6

5

1

Fig.13: Fitting the holder and interface unit on the handle

1 Knurled-head screw 4 Fixing screw for holder

2 Holder for interface unit 5 Metal plate

3 Interface unit 6 Rotavapor arm and handle

u Position the holder (2) for the interface unit on the Rotavapor arm (6). At the same

time, feed the communication cable through the bottom hole in the holder.

u Fix the holder to the Rotavapor arm with a screw (4). When doing so, pass the

screw through the hole in the metal plate (5).

u Connect the communication cable to the COM port on the rear of the interface

unit.

u Position the interface unit (3) on the holder and fix it in place using the knurled-

head screw (1) supplied. When doing so, make sure that the communication cable

is not trapped.

Page 30

5 | Installation BÜCHI Labortechnik AG

30/96 Operation Manual Interface I-300

5.1.2 Fitting interface unit on Vacuum Pump V-300

1

4

5

6

7

2

3

Fig.14: Fitting interface unit on Vacuum Pump V-300

1 Interface unit 5 Casing front

2 Fixing screw for holder 6 Knurled-head screw

3 Metal plate 7 Holder

4 Rubber plug and threaded hole

Tools required:

Torx key Tx30

The Interface I-300 can be mounted on the top of the Vacuum Pump V-300 using a

holder.

u Remove the rubber plug (4) from the top panel of the vacuum pump. Use a

screwdriver if necessary.

Underneath the rubber plug is a threaded hole for a screw.

u Position the holder (7) over the threaded hole (4) and fix it in place using the screw

(2) supplied. When doing so, pass the screw through the hole in the metal plate

(3).

u Feed the communication cable through the holder from the rear and connect it to

the COM port on the back of the interface unit.

u Position the interface unit (1) on the holder and fix it in place using a knurled-head

screw (6) inserted from the back.

Page 31

BÜCHI Labortechnik AG Installation | 5

Operation Manual Interface I-300 31/96

5.1.3 Mounting interface unit on laboratory stand (optional accessory)

2

1

4

3

5

Fig.15: Mounting interface unit on laboratory stand

1 Holder for interface unit 4 Knurled-head screw

2 Interface unit 5 T-screw

3 Laboratory stand

The Interface I-300 can also be mounted on a laboratory stand using a holder.

u Position the holder (1) on the laboratory stand (3) and fix it in place using the

T-screw (5).

u Position the interface unit (2) on the flat face (1) of the holder and fix it in place

using a knurled-head screw (4).

Page 32

5 | Installation BÜCHI Labortechnik AG

32/96 Operation Manual Interface I-300

5.1.4 Mounting interface unit on a wall bracket (optional accessory)

STOP

2

1

4

5

6

3

Fig.16: Two-piece wall bracket for interface unit

1 Front plate of wall bracket 4 Rear plate of wall bracket

2 Interface unit 5 Slot in rear plate

3 Fixing screws for interface unit 6 Lug on front plate

The Interface I-300 can also be mounted directly onto a plastered or tiled wall or a

laboratory fume hood with the aid of a wall bracket.

u Position the rear plate (4) of the two-part wall bracket on the wall. Note: the word

"UP" stamped in the rear plate must be at the top.

u Option 1: peel protective foil off the back of the plate and press the plate firmly

against the wall/glass panel in the desired position so it is held in place by the

self-adhesive pad.

u Option 2: mark the positions of the four holes in the rear plate, drill four holes in

the wall in those positions and fix the plate to the wall using screws.

u Position the interface unit (2) on the outer face of the front plate (1) and fix it in

place using three screws (3).

u Fit the front plate together with interface unit onto the rear plate. As you do so,

locate the lugs (6) on the front plate in the slots (5) on the rear plate and then

press the front plate down.

Page 33

BÜCHI Labortechnik AG Installation | 5

Operation Manual Interface I-300 33/96

5.2 Assembling the BUCHI distillation system

In order to use the Interface I-300/I-300 Pro to best effect, we recommend that it is

used together with the following devices:

3

4

5

1

3

4

5

Fig.17: Typical application (example)

1 Recirculating Chiller F-3xx 4 Vacuum Pump V-300

2 Rotavapor R-300 with heating bath

B-305 or B-301

5 Interface I-300

3 VacuBox

The F-3xx is a recirculating chiller with a sealed circulation system. It is available in

various capacity ratings.

The Interface I-300/I-300 Pro together with the VacuBox can be used to control and

monitor the vacuum. It can control the Rotavapor, the Vacuum Pump V-300 and the

Recirculating Chiller F-3xx.

The Vacuum Pump V-300 is a diaphragm pump designed for evacuating laboratory

apparatus. It can be operated either as a standalone device or combined with optional

accessories such as an interface unit and a secondary condenser to form a complete

vacuum system. The laboratory equipment to be evacuated is connected to the

vacuum pump and the VacuBox by means of vacuum tubing. See Chapter5.2.4

"Overview: setting up vacuum tubing connections", page36.

Data communication between the laboratory equipment takes place via the

communication ports. See Chapter5.2.2 "Overview: setting up communication

connections", page34.

The coolant circulates around the distillation system through a separate circulation

system. See Overview: setting up coolant tubing connections.

5.2.1 Connecting communication cables to interface unit

The communication connections between the Interface I-300, the VacuBox and the

other BUCHI laboratory equipment are established using the standard BUCHI

communication cable (with green connector). The corresponding connection sockets

Page 34

5 | Installation BÜCHI Labortechnik AG

34/96 Operation Manual Interface I-300

are on the rear panels of the devices and are marked "COM" for identification. Details

of the precise positions of the connection sockets are provided in the operating

instructions for the devices.

For connection options on the Interface I-300 see Chapter3.2.2 "Rear view",

page11.

For connection options on the VacuBox see Chapter3.2.3 "VacuBox

(connections)", page12.

5.2.2 Overview: setting up communication connections

The laboratory apparatus can be connected in any order. Important: as well as the

Interface I-300/I-300 Pro, a VacuBox also has to be connected.

Below is an example of the connections between the laboratory apparatus.

Vacu

Box

Recirculating

Chiller F-3XX

Interface I-300/

I-300 Pro

Rotavapor

R-300

Vacuum Pump

V-300 / V-600

Fig.18: Schematic diagram of communication connections between the BUCHI laboratory

equipment (example)

u Connect the Recirculating Chiller F-3xx to the Rotavapor R-300.

u Connect the Rotavapor R-300 to the VacuBox.

u Connect the VacuBox to the Vacuum Pump V-300/V-600.

u Connect Rotavapor to the Interface I-300/I-300 Pro.

NOTE

Connections on R-220 Pro:

Information on the connection of communication cables, coolant and vacuum tubing

with the Rotavapor R-220 Pro can be found in the operating instructions for the Rotavapor R-220 Pro.

Page 35

BÜCHI Labortechnik AG Installation | 5

Operation Manual Interface I-300 35/96

5.2.3 Overview: setting up coolant tubing connections

The tubing connections between the various items of BUCHI laboratory equipment

form a sealed circulation system. The starting and finishing point is always the

recirculating chiller (F-3xx).

Below is an example of the tubing connections between the laboratory apparatus.

Recirculating

Chiller F-3XX

Rotavapor

R-300

Vacuum Pump

V-300 / V-600

2

3

6

4

1

5

Fig.19: Coolant tubing connections in a BUCHI distillation system (example)

1 Inlet on Recirculating Chiller F-3xx 4 Condenser outlet on Rotavapor

R-300

2 Outlet on Recirculating Chiller F-3xx 5 Secondary condenser inlet on

Vacuum Pump V-300

3 Condenser inlet on Rotavapor R-300 6 Secondary condenser outlet on

Vacuum Pump V-300

u Connect a tube between the outlet of the recirculating chiller (2) and the inlet of

the condenser on the Rotavapor R-300 (3).

u Connect a tube between the outlet of the condenser on the Rotavapor R-300 (4)

and the inlet of the secondary condenser on the Vacuum Pump V-300 (5).

u Connect a tube between the outlet of the secondary condenser on the Vacuum

Pump V-300 (6) and the inlet of the recirculating chiller (1).

NOTE

Connections on R-220 Pro:

Information on the connection of communication cables, coolant and vacuum tubing

with the Rotavapor R-220 Pro can be found in the operating instructions for the Rotavapor R-220 Pro.

Page 36

5 | Installation BÜCHI Labortechnik AG

36/96 Operation Manual Interface I-300

5.2.4 Overview: setting up vacuum tubing connections

The vacuum tubing connections in a typical BUCHI distillation system lead from the

Rotavapor R-300 via a Woulff bottle to the Vacuum Pump V-300/V-600. The vacuum

is measured by means of the VacuBox, which is also connected to the Woulff bottle.

Vacu

Box

Rotavapor

R-300

Vacuum Pump

V-300 / V-600

Extraction

device

5

6

3

2

1

4

Fig.20: Coolant tubing connections in a BUCHI distillation system

1 Secondary condenser outlet 4 Woulff bottle outlet (PUMP)

2 Vacuum Pump V-300/V-600 outlet 5 Woulff bottle inlet (CONTR)

3 Vacuum Pump V-300/V-600 inlet 6 VacuBox vacuum connection

u Connect a tube between the Rotavapor R-300 and the top inlet of the Woulff

bottle.

u Connect a tube between the outlet of the Woulff bottle marked PUMP (4) and the

pump inlet (3).

u Connect the secondary condenser to the pump outlet (2).

u For measuring and controlling the vacuum, connect a tube between the inlet of the

Woulff bottle marked CONTR (5) and the VacuBox (6).

The pressure is measured in the VacuBox. The current working pressure can be

indicated and controlled by means of the Interface I-300/I-300 Pro.

NOTE

The VacuBox and Woulff bottle can be mounted either on the Rotavapor R-300 or

the Vacuum Pump V-300/V-600. What is important is that the VacuBox and Woulff

bottle are as close as possible to each other (on the same device) as otherwise there

is a vacuum control lag.

NOTE

Connections on R-220 Pro:

Information on the connection of communication cables, coolant and vacuum tubing

with the Rotavapor R-220 Pro can be found in the operating instructions for the Rotavapor R-220 Pro.

Page 37

BÜCHI Labortechnik AG Installation | 5

Operation Manual Interface I-300 37/96

5.3 Connecting AutoDest sensor to vapor temperature sensor

(optional accessory)

The Interface I-300 offers a program for carrying out an automatic distillation process

(see Chapter6.2.6 "Performing automatic distillation", page57). Automatic distillation requires connection of an AutoDest sensor to the Rotavapor R-300. The AutoDest sensor is connected to the inlet and outlet of the cooling condenser and continuously measures the following temperatures:

Temperature of the incoming coolant

Temperature of the outgoing coolant

Temperature of the vapor exiting the evaporating flask

1

3

6

4

2

5

Fig.21: AutoDest sensor, vapor temperature sensor and cooling condenser with evaporating

flask and receiving flask of a Rotavapor R-300

1 Vapor temperature sensor 4 Cooling condenser

2 AutoDest sensor 5 Coolant inlet on condenser

3 Communication connection between

AutoDest sensor and VacuBox

6 Coolant outlet on condenser

NOTE

There are two arrows stamped on the AutoDest sensor indicating the direction of flow

for the coolant. The coolant tubing should be connected accordingly.

Page 38

5 | Installation BÜCHI Labortechnik AG

38/96 Operation Manual Interface I-300

u Connect two tubes between the AutoDest sensor (2) and the cooling condenser

(4). When doing so pay attention to the direction of flow of the coolant. The arrows

on the AutoDest sensor indicate the direction of flow.

NOTE

The distance between the AutoDest sensor and the cooling condenser should not be

more than

10 to 20 cm so as not to falsify the readings for the incoming and outgoing coolant

temperatures in the distillation system.

u Connect a tube between the coolant inlet (5) on the AutoDest sensor and the

outlet of the recirculating chiller.

u Connect a tube between the coolant outlet (6) on the AutoDest sensor and either

the inlet of the recirculating chiller or another cooling condenser.

u Insert a vapor temperature sensor (1) in the cooling condenser and fix it in place.

u Connect the outgoing cable (3) from the AutoDest sensor to the VacuBox. Use the

connection marked "VT/AS" for this lead.

NOTE

The coolant must not contain any air bubbles as otherwise proper functioning of the

AutoDest sensor is not guaranteed.

NOTE

Installing automatic mode sensor on R-220 Pro:

The installation of the automatic mode sensor on the Rotavapor R-220 Pro is described in the operating instructions of the Rotavapor R-220 Pro.

Page 39

BÜCHI Labortechnik AG Installation | 5

Operation Manual Interface I-300 39/96

5.4 Connecting foam sensor (optional accessory)

The foam sensor uses infra-red to measure the level of foam formation inside the

evaporating flask and initiates one or more short venting bursts to combat the foam.

When de-foaming is active, it is indicated by the symbol on the status bar of the

Interface I-300/I-300 Pro.

The foam sensor passes through the cooling condenser of the R-300 into the

evaporating flask. The communication cable from the foam sensor is connected to the

VacuBox, see Chapter3.2.3 "VacuBox (connections)", page12.

IMPORTANT

Risk of heat damage to electronic components

u Only use the foam sensor at vapor temperatures up to 85 °C.

1

2

3

4

5

Fig.22: Foam sensor in the evaporation unit of a Rotavapor R-300

1 Foam sensor 3 Cooling condenser

2 Evaporating flask 4 Holder for foam sensor

5 Clamp nut

u Fit the tapered holder (4) over the upper end of the foam sensor (1).

u Feed the foam sensor together with holder through the cooling condenser and the

vapor duct into the evaporating flask of the Rotavapor R-300 and fix in place with

the clamp nut. When inserting the foam sensor, make sure that the sensor rod

Page 40

5 | Installation BÜCHI Labortechnik AG

40/96 Operation Manual Interface I-300

passes centrally through the components.

The tip of the foam sensor should be positioned approx. 4 to 5 cm below the

ground neck of the evaporating flask.

u Connect the communication cable from the foam sensor to the VacuBox. Plug the

connector into the socket marked "FS". For details, see Chapter3.2.3 "VacuBox

(connections)", page12.

NOTE

If the immersion angle of the Rotavapor is to be more than 30°, the small washer

supplied must be fitted on the foam sensor in order to prevent the condensate

running back into the evaporating flask. The washer is slid over the glass tube of the

foam sensor so that it comes to rest in the area below the drip catcher of the cooling

condenser. The tip of the washer should point downwards.

5.5 Connecting valve unit for external vacuum

The Interface I-300 can be used together with the VacuBox to control an external

vacuum. That requires the use of a vacuum valve and a mains power supply adaptor.

For precise control of the vacuum, the use of a Woulff bottle is also recommended.

The interface unit and the VacuBox can be mounted on a laboratory stand, see

Chapter5.1.3 "Mounting interface unit on laboratory stand (optional accessory)",

page31.

u Connect the vacuum valve to the VacuBox using the connection marked VALVE.

u Connect vacuum tubing between the laboratory apparatus to be evacuated, the

VacuBox and the external vacuum unit.

u If a Rotavapor is not connected, connect the VacuBox to the external power

supply by means of the mains adaptor.

NOTE

To adjust the regulation accuracy, the hysteresis can be altered on the interface unit,

see Chapter6.5 "Setting hysteresis", page65.

5.6 Operating I-300 and I-300 Pro in parallel

If the Rotavapor is to be controlled from outside a fume hood, there is the option of

connecting two separate interface units in parallel. In that case, distillation can be

controlled from either interface unit. The readings displayed are continuously

synchronized. The servicing functions (e.g. leak test) are controlled by the interface

unit that is currently being used.

If a mobile connection (see Chapter7 "Mobile connection", page67) is desired when

the I-300 and I-300 Pro are operating in parallel, the LAN cable must only be

connected to one of the interface units, preferably the I-300 Pro.

u Connect the remote interface unit to the interface unit on the Rotavapor using the

standard BUCHI communication port (COM). Use a standard BUCHI

communication cable to do so.

Page 41

BÜCHI Labortechnik AG Operation | 6

Operation Manual Interface I-300 41/96

6 Operation

6.1 Navigating the menu

The I-300 Pro offers the fundamental option of navigating the menu either by using

the function buttons and the navigation control or by means of the touch-screen functionality of the display.

The touch-screen functions can be operated using laboratory gloves. Liquids on the

screen do not pose a problem either and do not impair functionality in any way.

6.1.1 Selecting menu items

The main menu icons are shown in the top menu bar on the display. The home

screen is the starting point. Rotating the navigation control selects each symbol in

turn. The currently selected menu icon is highlighted in green.

u To open the main menu, press the MENU function button.

Fig.23: Opening the menu on the Interface I-300

u To select a menu item from the main menu, turn the navigation control until the

desired icon is highlighted in green.

u Press the navigation control to choose OK and confirm the selection.

5 The display shows the desired submenu.

Fig.24: Submenu

u To select a menu item from the submenu, turn the navigation control until the

desired item is highlighted in green.

u Press the navigation control to choose OK and confirm the selection.

5 The display shows the desired submenu on the next menu level down.

u To return to the previous menu level, press the function button .

u To return to the main menu, press the MENU function button.

Page 42

6 | Operation BÜCHI Labortechnik AG

42/96 Operation Manual Interface I-300

6.1.2 Entering parameter settings

The Interface I-300 offers the facility for manually setting various parameters. The

parameters are shown on the home screen of the interface unit. Rotating the

navigation control selects each parameter in turn. The currently selected parameter is

highlighted in green.

Fig.25: Entering the settings

u Use the navigation control to select the desired parameter.

u Press the navigation control to choose EDIT and confirm the selection.

The selected figure is shown in inverse type and the word "Set" flashes.

Fig.26: Edited parameter shown in inverse type

u To increase or decrease the figure, turn the navigation control clockwise or

counter-clockwise.

u Press the navigation control to choose SAVE and save the setting.

The new parameter setting is shown highlighted in green again.

6.1.3 Changing settings

The Interface I-300 offers the facility for manually entering various settings.

u Use the navigation control to select the desired setting, see Chapter6.1.1

"Selecting menu items", page41.

Fig.27: Example of a setting

u Press the navigation control to choose EDIT and confirm the selection.

The options for the setting are shown.

u To select an option, turn the navigation control. A green bar appears next to the

selected option.

Page 43

BÜCHI Labortechnik AG Operation | 6

Operation Manual Interface I-300 43/96

Fig.28: Options for the setting

u Press the navigation control to choose SAVE and save the selected option.

Page 44

6 | Operation BÜCHI Labortechnik AG

44/96 Operation Manual Interface I-300

6.2 Performing distillation

The Interface I-300 offers the following options for performing distillation:

Manuall

For performing manual distillation,

see Chapter6.2.3 "Performing manual distillation", page47.

Timer

For performing timer-controlled distillation,

see Chapter6.2.4 "Performing timer-controlled distillation", page50.

Drying

For drying the product,

see Chapter6.2.7 "Drying the product", page59

AutoDest

For performing automatic distillation,

see Chapter6.2.6 "Performing automatic distillation", page57

Continuous pumping

For drying the system after distillation,

see Chapter6.2.5 "Drying the system after distillation ("Continuous pumping")",

page53.

Page 45

BÜCHI Labortechnik AG Operation | 6

Operation Manual Interface I-300 45/96

6.2.1 Overview: typical distillation sequence

Proper performance of a distillation process typically requires the following steps in

the order indicated.

NOTE

The steps listed below in "Starting distillation" and "Stopping distillation" can also be

pre-programmed via the interface unit, see Chapter3.3.3 "Configuration", page20.

Starting distillation

Step Component Action

1 Heating bath Set the required temperature

and start the heating bath.

2 Recirculating chiller Set the required temperature

and start the recirculating chiller.

3 Rotavapor Start rotation at a slow speed.

4 Vacuum pump Set the required pressure and

start the vacuum pump.

5 Rotavapor Immerse the evaporating flask in

the heating bath.

6 Rotavapor Increase rotation to the desired

speed.

Stopping distillation

Step Component Action

1 Vacuum pump/Valve unit Stop pressure regulation.

2 Interface unit

Rotavapor

Vent the system (AERATE).

Vent the system (open glass

stopcock, open cooling condenser).

3 Rotavapor Reduce rotation speed.

4 Rotavapor Lift evaporating flask out of

heating bath.

5 Rotavapor Stop rotation.

6 Heating bath Stop heating.

7 Interface unit

Recirculating chiller

Stop cooling ( ).

Stop cooling.

Page 46

6 | Operation BÜCHI Labortechnik AG

46/96 Operation Manual Interface I-300

6.2.2 Basic functions

Venting during distillation

There is the possibility to briefly venting the system while distillation is in progress.

u To briefly vent the system while distillation is in progress, press and hold the

AERATE function button until the desired pressure is reached.

While venting is active, the status bar is shown in yellow on the display.

Fig.29: Home screen during venting

u To evacuate the system to the specified vacuum again after venting, press the

function button HOLD OFF.

Venting after completion of distillation

If venting has not been pre-programmed on the interface unit, the system can be fully

vented manually after completion of the distillation process.

Fig.30: Home screen after completion of distillation

u After completion of distillation, press the AERATE function button.

5 The system is vented until it reaches ambient pressure.

Manually stopping the cooling process

The cooling function continues after completion of a distillation process. If the system

has been pre-programmed accordingly, the cooling process stops after 5 minutes.

While cooling is active, the status bar shows the symbol . The cooling process can

be stopped manually at any time regardless of how the system has been

pre-programmed.

Precondition:

R After completion of distillation, the system has been fully vented by pressing the

AERATE function button.

u To manually stop the cooling process, press the function button .

5 The cooling process is stopped and the cooling symbol disappears from the status

bar.

Stopping everything

There is the possibility to immediately stopping all apparatus connected to the system

while distillation is in progress.

Page 47

BÜCHI Labortechnik AG Operation | 6

Operation Manual Interface I-300 47/96

u To stop all apparatus immediately, press the red STOP button (emergency stop).

6.2.3 Performing manual distillation

In "Manual" operating mode (manual distillation), the distillation process can be

controlled by manually setting the individual process parameters.

CAUTION

Risk of personal injury and property damage from unexpected

equipment behavior

u Always carefully check the pre-programmed settings before every distillation

process. In particular, check the setting for immersion of the evaporating flask at

the start of the distillation process.

Navigation path

➔ Operating modes ➔ Manual

Fig.31: Selecting "Manual distillation" on the "Operating modes" screen

u Navigate to the "Operating modes" screen and select the menu item "Manual", see

Chapter6.1 "Navigating the menu", page41.

The display shows the home screen with the symbol for manual distillation in the

status bar.

Fig.32: Home screen showing "Manual" symbol

u Enter the required settings for the process parameters.

In this operating mode, the following parameters and readings are available:

Parameters and readings Equipment possibly required

Specified setting for vacuum

Actual reading for current pressure in

distillation system

VacuBox (e.g. with Vacuum Pump

V-300/V-600)

Actual reading and specified setting

for rotation speed (evaporating flask)

Rotavapor R-300

Page 48

6 | Operation BÜCHI Labortechnik AG

48/96 Operation Manual Interface I-300

Parameters and readings Equipment possibly required

Actual reading and specified setting

for heating bath temperature

Heating Bath B-301/B-305

Actual reading and specified setting

for cooling temperature

Recirculating Chiller F-3xx

Actual reading for vapor temperature AutoDest sensor or vapor temperature

sensor

Actual reading for lift

Parameters and readings Equipment possibly required

Specified setting for vacuum

Actual reading for current pressure in

distillation system

VacuBox (e.g. with Vacuum Pump

V-300/V-600)

Actual reading and specified setting

for rotation speed (evaporating flask)

Rotavapor R-300

Actual reading and specified setting

for heating bath temperature

Heating Bath B-301/B-305

Actual reading and specified setting

for cooling temperature

Recirculating Chiller F-3xx

Actual reading for vapor temperature AutoDest sensor or vapor temperature

sensor

Starting manual distillation

Precondition:

R Process parameters have been set.

u Press the function button START.

The display shows the home screen in inverse type.

The status bar shows the symbol for distillation in progress.

Fig.33: Distillation process started

The actual readings are shown more brightly in the left-hand column of the

display. The right-hand column shows the specified settings.

u To abort the cooling process prematurely, press the function button STOP.

Page 49

BÜCHI Labortechnik AG Operation | 6

Operation Manual Interface I-300 49/96

Editing parameters during manual distillation

There is the facility for changing individual parameter settings while distillation is in

progress.

Precondition:

R Distillation process has been started.

u Select the parameter that is to be adjusted while distillation is in progress, see

Chapter6.1 "Navigating the menu", page41.

The display shows the selected parameter setting highlighted in inverse type.

Fig.34: Editing parameters while distillation is in progress

u Raise or lower the selected parameter setting.

While the parameters are being edited, the distillation process continues running

in the background (identifiable by the symbol on the status bar).

5 After the parameter setting has been altered, the display shows the home screen

in inverse type with the current readings displayed more brightly.

Stopping manual distillation

u To stop the distillation process, press the function button STOP.

5 The display shows the home screen with the current readings and specified

settings. The status bar shows the cooling symbol, if applicable, together with a

timer that is counting down.

Page 50

6 | Operation BÜCHI Labortechnik AG

50/96 Operation Manual Interface I-300

6.2.4 Performing timer-controlled distillation

In "Timer" mode, a distillation process with a predefined duration is started.

CAUTION

Risk of personal injury and property damage from unexpected

equipment behavior