Brother BAS-304A, BAS-311A, BAS-314A, BAS-315A, BAS-326A Service Manual

...

-; ~ ----....-··· |

.. |

' .. ,·.. |

|

|

|

|

|

|

SERVICE MANUAL |

|

|

|

{ELECTRICAL) |

|

|

|

FOR |

|

. ·....._ .. · |

|

BAS-300A SERIES |

|

|

|

BAS-304A•311A•314A•315A ../- ·--- = |

|

|

|

326A•326LA•341A•342A |

|

|

|

|

|

|

|

|

|

,

From the library of: Superior Sewing Machine & Supply LLC

This service manual has been compiled so that it can be made into a book since electrical descriptions for the BAS-300A series are very similar.

Applicable models are BAS-304A, 311A, 314A, 315A, 326A, 326LA, 341A, and 342A.

For some of them, the electrical description is

separated for the air and solenoid specifications.

From the library of: Superior Sewing Machine & Supply LLC

(ELECTRICAL CHECK AND DIP SWITCH)

Warning

Never touch three large-sized capacitors on the power circuit board (see the illustration below). The highvoltage residual charges stay for a minimum of 1-2 minutes after the power is turned off.

Cautions

*During checking or repair work when the power is applied, take care not to short -circuit terminals.

*Check if the cooling fan in the control box works correctly. If it stops. electronic parts and devices may be damaged due to high temperature inside the control box. To prevent the air vents from being choked with dust, clean them at regular intervals.

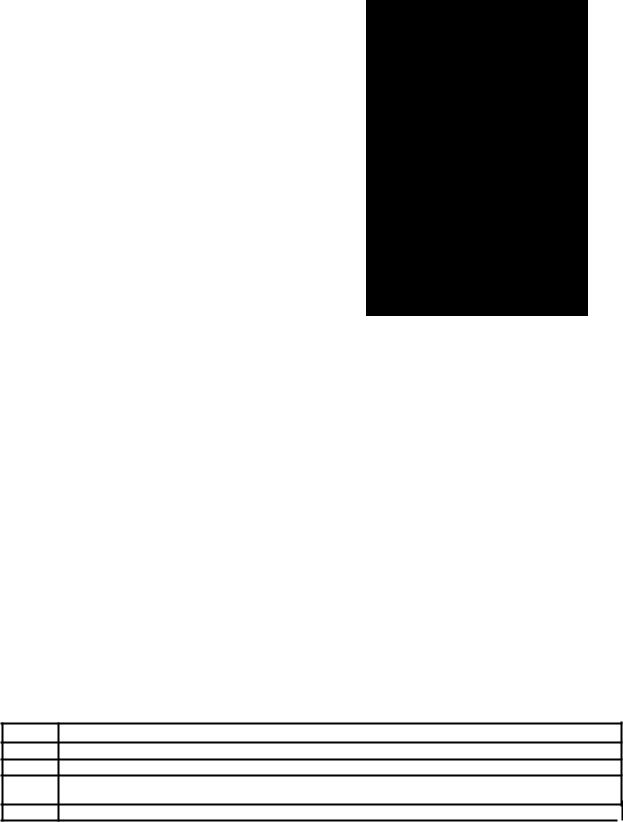

II1 Fuses

Fuse4

Fuse3

Fuse2 -+-Bh

Fuse1

NOTE: When replactng the fuses, be sure to use the specified ones listed below.

No. |

Part name |

Part code |

Manufacturer |

Problem |

|

|

|

|

|

|

|

1 |

|

Fuse2A |

152566-000 |

Fuji Tansi Company |

The work clamp does not |

|

|

(Glass tube fuse, 2A-125V) |

|

FUJI 2A |

operate. |

2 |

|

Fuse SA |

152565-000 |

Fuji Tansi Company |

The power lamp does not come |

|

|

(Glass tube fuse, SA·12SV) |

|

FUJI SA |

on and no operation occurs. |

3 |

|

Fuse 15A |

502887·000 |

Fuji Tansi Company |

The feed plate and presser |

|

|

(Glass tube fuse, 15A-125V) |

|

FUJI 15A |

plate do not operate. |

4 |

|

GfuseSAFB |

508030-000 |

Toyo Fuse Company |

The machine motor does not |

|

|

(Quick melting type, SA-2SOV) |

|

TOYOSA |

tum. |

NOTE: Prior to replacing fuse No.4. be sure to check the TR array assembly.

Measure the resistance between the EB and e terminals.

- If 20 - 30 n: Replace fuse 1. The TR array assembly works correctly. (by 1oon range)

- If 0 Q or co: Replace the TR array assembly and the pulse motor drive (PMD) PCB, instead of fuse 1.

-1-

From the library of: Superior Sewing Machine & Supply LLC

rzl Voltage measurement

1.Checkng the control voltage

ru·m on power while connecting the connector P8 to the control PCB, then measure the voltages between pins 1 and 2, 3 and 4, and between 5 and 6 of connector P1.

Check points of P8 |

Acceptable value |

|

on the control PCB |

||

|

||

Between pins 1 and 2 |

Approx. 65 Vdc |

|

Between pins 3 and 4 |

Approx. 11 Vdc |

|

Between pins 5and 6 |

Approx. 25 Vdc |

2.Checkng the + SV source

Turn on power while connecting the connector P7 to the control PCB, then measure the voltage between pins 1 and 2 of connector P7.

3. Checkng solenoids'voltages

P1

1

Check points of P7 |

Acceptable value |

|

on the control PCB |

||

|

||

Between pins 1 and 2 |

Approx. 65 Vdc |

... _.,.,.

(1)Turn off the power.

Remove P1 from J1, and measure each solenoid's resistance.

Resistance values are different according to the sewing machine model.

Check points |

Solenoid |

Value |

304A |

326A |

|

341A |

|||

311A |

326LA |

|

342A |

||||||

Between |

Intermittent |

Resistance |

50 |

12n |

|

~ |

|||

pins1 and2 |

presser foot |

Voltage |

12V |

20V |

|

_/" |

|||

|

Proslerfoot(Oftly |

Resistance |

50 |

. /'~ |

|||||

|

|

forsolennl |

|

|

|||||

Between |

tpedfb11oct) |

Voltage |

10V |

. /'~ |

|||||

pins3and4 |

|

Tension |

Resistance |

:;?' |

50 |

|

_/" |

||

|

|

|

|||||||

|

|

release |

Voltage |

~ |

20V |

~ |

|||

|

|

|

|

|

|||||

Between |

|

Thread |

Resistance |

50 |

sn |

100 |

|||

pins5and6 |

|

trimmer |

Voftege |

30V |

20V · |

60V |

|||

|

|

|

|

|

|||||

Between |

|

Thread |

Resistance |

60 |

110 |

|

60 |

||

pins7and8 |

|

wiper |

|

Voltage |

30V |

20V |

30V |

||

|

|

|

|

|

|||||

)&( Resistance and voltage values are approximate.

(2) lnsertP1 intoJ1,andturnonthe power.

Insert the test probe from the lead wire side, and measure the voltage.

•As for the presser foot and intermittent presser foot solenoids, measure the voltage while raising and lowering them.

·As for tension release, thread trimmer, and thread wiper solenoids, start sewing, then measure the voltage upon finishing ofsewing.

Since, in this case, the indicator only oscillates very briefly, the value is used as a rough measure.

Each voltage value is as in the above table.

·2-

From the library of: Superior Sewing Machine & Supply LLC

4. Checkng air valve'svoltage

NOTE: When the machine is for solenoid specification of the BAS-304A or 311A, there is no need to

connect the air valves.

1) Turn the power switch OFF. Disconnect connector

P8 from J8, then measure the resistance of each valve.

Resistance of each valve (from (t) to$, e to~) should be approx. 3000.

2) Connect connector P8 to J8, then turn the power switch ON.

Insert the test probes into connector P8 from the lead wire side, then measure the voltages.

Check points |

Acceptable value |

Between pins 1 (-}and 10 C+) |

0.1V-24V |

Between pins 2 (-)and 10 C+) |

0.1V-24V |

Between pins 3 (-}and 10 (+) |

0.1V-24V |

(J) Presser foot (R) valve e Presser foot (L) valve

GIntermittent presser valve (only for BAS-341A and 342A)

® Inner clamp valve $ Option valve 1

8 Option valve 2

(/) Option valve 3

8 Needle cooler valve

~ +24V

®+24V

NOTE: @to 8 are options.

When the work clamp pedal is treadled, each reading should be max. 24V I min. 0.1V.

3) When the optional valve Is used:

Measure the resistance between each valve and ®. (Refer to step 1.)

Measure the resistance between each valve (-) and ® ( +) when each valve operates. (Refer to step2.)

-3-

From the library of: Superior Sewing Machine & Supply LLC

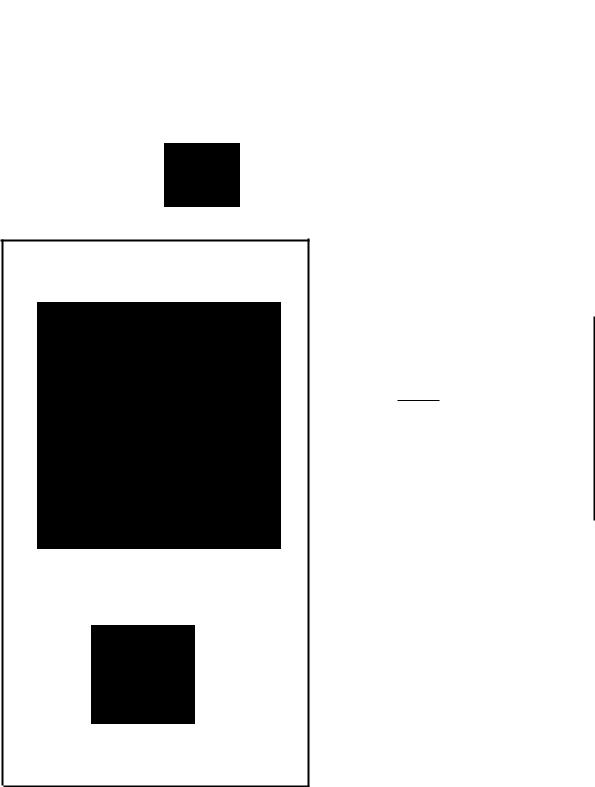

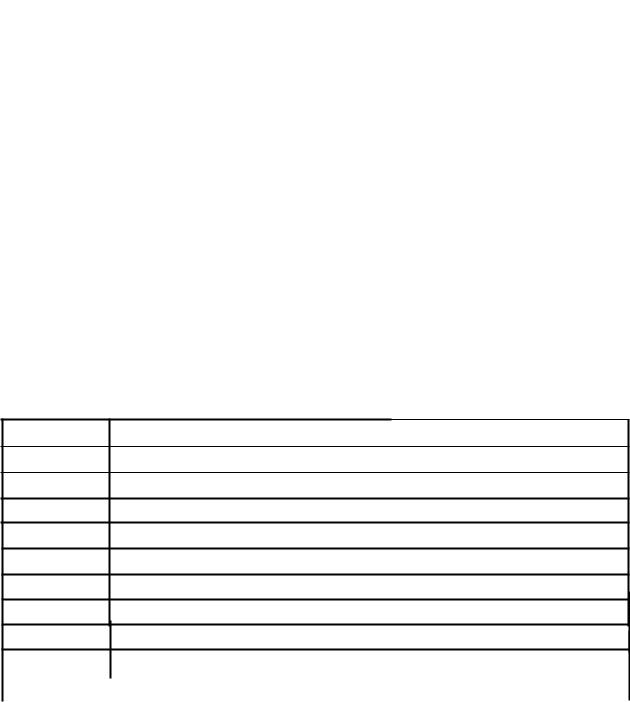

Ill Control box

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

J2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

~0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

JS |

J4 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

~~ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

r---., |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

lra:QJI |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

: |

1s1o |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

~Kmlr |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

'"---.J |

0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

J1 |

|

J8 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

J6 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

fi~---~, |

|

|

|

|

J9 |

|

|

|

|

|

|

|

|

|

"---- |

•. |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

lool |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

J1 |

Solenoid connector |

J2 |

Synchronizer connector |

J3 |

Connector for emergency stop, zero-point |

|

sygnal and thread breakage detection |

J4 |

X-drive pulse motor connector |

JS |

Y-drive pulse motor connector |

J& |

Foot switch connector |

J7 |

Programming device connector |

J8 |

Air valve connector |

J9 |

Machine light connector (6V AC. 2A) |

J10 : |

Marker light connector (SV AC, 3A) |

From the library of: Superior Sewing Machine & Supply LLC

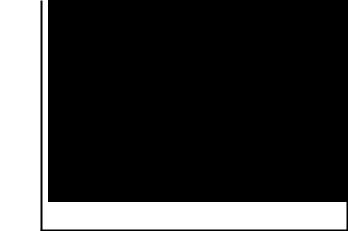

Ill Explanation of connectors

If the machine has been disassembled or adjusted during repair work, most of the machine troubles are due to connector problems including improper connection or weak contact. It is, therefore, necessary to check each connector number and pin contact for correct connection prior to proceeding to the troubleshooting procedures.

The table below lists the connector numbers and symptoms resulting from wrong connections. For detailed connector and harness arrangement, refer to •coNTROL CIRCUIT BLOCK DIAGRAM•.

|

Connector No. and location |

Drive signals and source |

Symptoms resulting from wrong connection |

|

||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Control power source |

• |

Abnormal motion |

|

|

|

|

|

|

|

|

|

|

Main PCB |

|

|

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

I |

|

|

P8 |

|

|

I |

|

|

|

|

|

|

|

• |

Nomotion |

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

• Only Pan motor operates |

|

|

|

|

|

|

|

|

|

|

|

I |

|

|

P3 |

|

|

I |

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

PMDPCB |

|

|

|

|

|

|

|

|

|

|

|||||||||

|

II |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

I |

Solenoid drive power source |

• |

Faulty operation of the presser plate, |

|

|||||

|

|

|

|

|

|

.MainPCB |

|

|

|

|

|

|||||||||||||||||

|

|

|

|

|

P6 |

|

I |

|

|

I |

|

PS |

|

|

|

I |

|

|

presser foot, thread wiper components, |

|

||||||||

|

|

|

m [5[5 |

|

|

main presser, thread trimming , thread |

|

|||||||||||||||||||||

|

|

|

|

|

release components |

|

||||||||||||||||||||||

|

|

|

ElBgI J11 I |

|

|

|

|

|||||||||||||||||||||

|

|

|

|

|

|

|

||||||||||||||||||||||

|

|

|

Solenoid |

|

|

Air valve |

|

|

|

|

||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

~In~ |

Pulse motor drive power |

• |

Step out in X and Yaxes |

|

||||||||||||||||||||

|

|

|

|

source |

• Unusual noises of X-drive andY-drive pulse |

|

||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

~~ |

|

|

|

|

|

motors |

|

|||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

PS |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Y nlsve. |

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

pu |

a |

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

motor |

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Start/stop control currents for |

• |

Abnormal rotation speed of the pulley |

|

|

I-[ |

Motor |

|

|

|

ll |

Main PCB I |

|

||||||||||||||||||||

|

|

|

|

the machine |

• |

Stop operation failure |

|

|||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

L·I |

|

|

P13 |

|

|

|

LJ |

|

|

||||||||

|

;. |

|

|

|

|

|

|

|

I: |

:I |

|

|

|

|

|

I: |

|

• |

The pulley does not rotate |

|

||||||||

|

1: |

|

|

|

|

|

:~M+r: :1 |

|

|

|

|

|||||||||||||||||

|

I |

|

|

|

|

|

|

|

|

|

|

I |

I |

|

|

|

|

|

|

|

I |

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

|

|

|

|

|

|||

|

I |

|

|

|

|

|

|

|

|

|

|

PMD |

|

|

|

|

|

I |

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

+SV |

• |

The machine sews at abnormally high |

|

|

|

|

|

I |

|

|

Main PCB |

|

|

I |

Needle stop position control, |

|

speed, then stops. (The EMERGENCY stop |

|

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

I |

|

|

P14 |

|

|

I |

|

|

|

lamp lights.) |

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

synchronization control, and |

|

|

|||||||||||||||

|

|

|

|

|

~ |

|

|

|

|

|||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

rotation control signals |

• |

The machine does not stop with the needle |

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

at the upper position. |

|

||||||||||

|

|

|

|

|

|

|

|

|

I |

|

|

|

P2 |

|

|

I |

|

|

|

|

|

|

|

• |

The pulley rotates, but the feed mechanism |

|

||

|

|

|

|

|

r. |

Synchronizer |

l |

|

|

|||||||||||||||||||

|

|

|

|

|

|

|

does not work. |

|

||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

..s-

From the library of: Superior Sewing Machine & Supply LLC

Connector No. and location |

Drive signals and source |

|

Symptoms resulting from wrong connection |

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

+SV |

• The POWER lamp does not come on. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

Main PCB |

|

|

|

|

|

Speed control signal |

• |

Although the speed <ontrol dial is turned, |

||

|

|

|

|

|

|

[PO |

|

|

|

|

|

|

|

|

the machine does riot change the rotation |

|

|

f |

|

I P1 |

l |

|

J |

|

|

speed and keeps it at 2000 spm. |

|||||||

|

|

|

|

|

|

|||||||||||

|

1control panel PCBJ |

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Key and switch signals |

• |

Malfunction of programming device |

|

|

|

|

|

|

Main PCB |

|

|

|

|

|

Indicator control sig~ls |

|

|

||

|

|

|

|

|

|

em] |

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

·I Programmer |

~ |

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Read and write signals |

• |

The floppy disk data cannot be read. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

from/to floppy disks |

|

(Error No.4) |

|

|

I |

|

MainPCB |

.J |

|

||||||||||

|

|

|

|

|

|

|||||||||||

|

|

|

IIP31 |

|

P7 |

II |

|

|

|

|||||||

86 |

|

|

|

|

|

|

||||||||||

|

|

|

I |

|

Floppy disk |

|

I |

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

X andY home position |

• |

The machine cannot detect home position. |

|

|

|

|

|

|

Main PCB |

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

signals |

|

|

|||

|

|

|

|

|

|

Qifl |

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

EM switch signal |

• |

The emergency stop function cannot be |

|||

|

|

|

|

|

~ |

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

activated. |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

~ |

|

|

|

|

|

LED signal |

• |

The EMERGENCY stop lamp lights and its |

|||

|

|

|

|

|

|

|

|

|

|

|

|

function cannot be canceled. |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

r ,,2 |

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

T |

T |

|

|

|

|

|

|

|

|

|

|

|

|

I . . |

Y |

h |

|

|

I .. |

|

|

|

|||||

Xhome position |

ome positiOn |

|

|

|

||||||||||||

|

|

|

I |

PCB |

|

PCB |

|

|

i |

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Drive signal |

• |

The machine neither starts operation nor |

|

|

|

|

|

|

Main PCB |

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

Presser plate lifting signal |

|

lifts the presser plate If the corresponding |

|||

|

|

|

|

|

|

QCJ |

|

|

|

|

|

|

foot switch is depressed. |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

From the library of: Superior Sewing Machine & Supply LLC

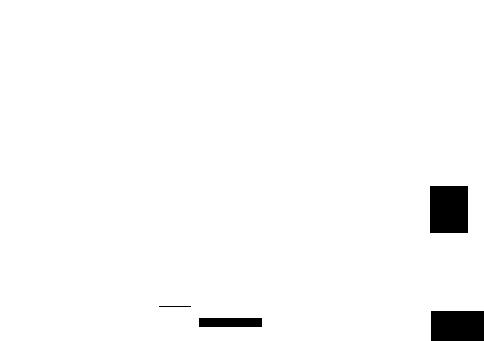

liJ Dip switch settings

NOTE: Be sure to turn offthe power before changing the DIP switch settings.

ct::::J.

0

®

No. |

When ON |

|

|

|

|

|

|

1 |

Work clamp does not rise when sewing complated |

|

|

2 |

Rfght..,.lefttwo-stepwork clamp (When No.4 fs ON) |

Fer the BAS-304A or 311A |

|

3 |

Left~righttwo-step work clamp (When No. 41s ON) |

||

with solenoid spedfication, |

|||

|

|

||

4 |

When the switches 2, 3 and 4 are on. left and right work clamps will descend |

set® No.2~3# and 4 to OFF. |

|

at one timer and presser foot will descend With two positions. |

|

||

|

|

||

5 |

Work clamp does not rise during split mode operation. |

|

|

6 |

Presser crank of Innerclamping device turns to the other side |

|

|

(Inner damping device Isoptional.) |

|

||

|

|

||

7 |

Single pedal operation possible using the st.rting pedal |

|

|

8 |

Activates thread breakage detector (Thread breakage detector Isoptional.) |

|

|

|

|||

|

|

|

|

No. |

When ON |

|

|

|

|

|

|

1 |

Single split mode possible |

|

|

2 |

8000-stitch sewing mode possible |

|

|

3 |

Thread trimming does not function when emergency stopswitd1 is pressed. |

|

|

4 |

Needle coolercan be used. (Needle cooler device Is optional.) |

|

|

5 |

Thread breakage detection stitch margin setting can besetto either 8 or 14stitches. |

||

6 |

Ad:ivates fiber thread breakagedetector (optional part) |

|

|

7 |

Triplet pedal operation possible {Triplet pedal is optional.} |

|

|

8 |

High feed speed |

|

|

©

No,.

2

3

4

When ON

The first two stitches are sewn at low speed (approx. 260 spm).

Thelalttwo stitches are sewn at lowspeed (approx. 260 spm).

The upparshaftturns In the reverse direction afterttvead breakage, and the machine stops with the needle at its highest position.

Does not output error No.2 even Ifsynchronizer Is notconnocted

-7-

From the library of: Superior Sewing Machine & Supply LLC

@ The setting ofthe DIP switch@ in the control box determinesthe machine model. |

||||||||||||||

|

*Ifthe setting is not correct for the machine head, It may cause damage to a printed circuit board. |

|||||||||||||

|

|

|

|

D-2 |

|

D-3 |

|

D-4 |

|

|||||

|

|

0-1 |

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

304A |

OFF |

OFF |

|

OFF |

|

OFF |

|

|

|||||

|

311A |

ON |

OFF |

|

OFF |

|

OFF |

|

|

|||||

|

326A |

OFF |

ON |

|

OFF |

|

OFF |

|

|

|||||

|

326LA |

ON |

ON |

|

OFF |

|

OFF |

|

|

|||||

|

341A |

OFF |

OFF |

|

ON |

|

OFF |

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

342A |

ON |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

No.2 0N |

No.1,20N |

No.1, 3,4 OFF |

No.3,40FF |

|

|

( ERROR NO. LIST)

No. |

Cause |

1Emergency stop switch pressed

2Trouble with the motor or synchronizerI Motor stopped when voltage dropped

3Over-area

4Floppy disk not inserted, or cable not properly connected

5Floppy disk is locked (write protected)

6No program registered

7Error occurred in program mode

8Thread breakage detected

9 |

Protection network activated because of abnormal voltage |

|

A |

No usable pattem data on di'k· |

|

|

|

|

From the library of: Superior Sewing Machine & Supply LLC

Loading...

Loading...