Bosch BORERADWMW243, HEIP056U, BORERADWMW820, BORERADWMW757 Installation manual

Electric and Induction Ranges

Installation Instructions

Slide-In Ranges

HEI8056C, HEI8056U, HEIP056C, HEIP056U, HIIP056C,

HIIP056U, HII8056C, HII8056U, HII8046C, HII8046U,

HEI8046C, HEI8046U

Table of Contents

Safety Definitions . . . . . . . . . . . . . . . 1 Safety . . . . . . . . . . . . . . . . . . . . . . . . . 1

Preparation . . . . . . . . . . . . . . . . . . . . 3

Before You Begin . . . . . . . . . . . . . . . . . . . . . 3

Tools and Parts Needed . . . . . . . . . . . . . . . . 3 Parts Included . . . . . . . . . . . . . . . . . . . . . . . . 3

Additional Parts Needed for Hard-Wired Installations . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Remove Packaging . . . . . . . . . . . . . . . . . . . . 3

Installation Checklist . . . . . . . . . . . . . . . . . . 3 General Information . . . . . . . . . . . . . . . . . . . 4

Overall Dimensions . . . . . . . . . . . . . . . . . . . . 4 Location Level and Plumb . . . . . . . . . . . . . . . 4 Installation Hints . . . . . . . . . . . . . . . . . . . . . . 4

Electrical Requirements . . . . . . . . . . . . . . . . . 4

Cabinet Requirements . . . . . . . . . . . 5

Testing Operation . . . . . . . . . . . . . . . . . . . 17

Service . . . . . . . . . . . . . . . . . . . . . . . 17

Before Calling Service . . . . . . . . . . . . . . . . . 17

Install Ventilation . . . . . . . . . . . . . . . . . . . . . . 5

Required Clearance . . . . . . . . . . . . . . . . . . . . 5

Prepare Walls and Floor . . . . . . . . . . . . . . . . 6

Countertop Requirements . . . . . . . . . . . . . . . 6

Installation Procedure . . . . . . . . . . . 7

Installation of the Anti-Tip Bracket . . . . . . 7

Electrical Connection . . . . . . . . . . . . . . . . . 7

Connect Flexible Conduit . . . . . . . . . . . . . . . 10

Complete the installation . . . . . . . . . . . . . . . 11

Removing the Oven Door . . . . . . . . . . . . . . 13

Replacing the Oven Door . . . . . . . . . . . . . . 14

Removing the Warming Drawer . . . . . . . . . . 15

Replacing the Warming Drawer . . . . . . . . . . 15

This Bosch Appliance is made by

BSH Home Appliances Corporation

1901 Main Street, Suite 600

Irvine, CA 92614

Questions?

1-800-944-2904

www.bosch-home.com/us

Welookforwardtohearingfromyou!

9 IMPORTANT SAFETY INSTRUCTIONS

READ AND SAVE THESE INSTRUCTIONS

Safety Definitions

9WARNING

This indicates that death or serious injuries may occur as a result of non-observance of this warning.

9CAUTION

This indicates that minor or moderate injuries may occur as a result of non-observance of this warning.

NOTICE: This indicates that damage to the appliance or property may occur as a result of non-compliance with this advisory.

Note: This alerts you to important information and/or tips.

Safety

9WARNING

If the information in this manual is not followed exactly, fire or shock may result causing property damage or personal injury.

9WARNING

Do not repair or replace any part of the appliance unless specifically recommended in the manuals. Improper installation, service or maintenance can cause injury or property damage. Refer to this manual for guidance. All other servicing should be done by an authorized servicer.

•Ask your dealer to recommend a qualified technician and an authorized repair service.

•Install only per the installation instructions provided in the literature package accompanying this range.

•Never modify or alter the construction of the range including by removing leveling legs, panels, wire covers, anti-tip brackets or screws, or any other part of the appliance.

PLEASE READ ALL INSTRUCTIONS BEFORE USING THIS APPLIANCE.

9WARNING

TIP OVER HAZARD!

A child or adult can tip the range over and be killed. Verify that the anti-tip bracketissecurelyinstalled. Ensure the anti-tip bracket is engaged whenever the range is moved to a new location.

Do not operate the range without the anti-tip bracket in place. Failure to follow the instructions in this manual can result in death or serious burns to children and adults.

Check for proper installation and use of the anti-tip bracket. Carefully tip the range forward pulling from the back to ensure that the anti-tip bracket engages the range leg and prevents tip-over. Range should not move more than 1” (2.5 cm).

Appliance Handling Safety

9CAUTION

•Unit is heavy and requires at least two persons or proper equipment to move.

•Hidden surfaces may have sharp edges. Use caution when reaching behind or under appliance.

•Do not use the oven or warming drawer (if equipped) for storage.

Do not lift appliance by the oven door handle. Remove the oven door for easier handling and installation. See the section “Removing the Oven Door” in the range Use and Care manual.

Disposing of Packaging Materials

Remove all tape and packaging before using the range. Properly dispose of the carton and plastic bags after unpacking the range. Never allow children to play with packaging materials.

English 1

9 IMPORTANT SAFETY INSTRUCTIONS

READ AND SAVE THESE INSTRUCTIONS

Safety Codes and Standards

This appliance complies with one or more of the following Standards:

•UL 858, Household Electric Ranges

•CAN/CSA-C22.2 No. 61 Household Cooking Ranges

It is the responsibility of the owner and the installer to determine if additional requirements and/or standards apply to specific installations.

Installation Location

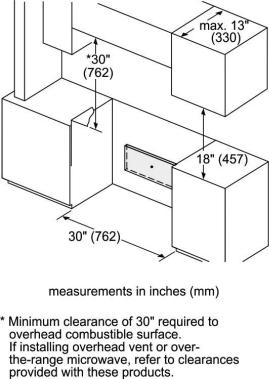

To eliminate the risk of burns or fire by reaching over heated surface units, cabinet storage space located above the surface units should be avoided. If cabinet storage is to be provided, the risk can be reduced by installing a hood that projects horizontally a minimum of 5" (12.7 cm) beyond the bottom of the cabinet.

Verify that cabinets above the range are a maximum of 13" (330 mm) deep.

Child Safety

Do not store items of interest to children in the cabinets above the range or on the backguard of a range. Children climbing on the range to reach items could be seriously injured.

Electric Safety

Before you plug in an electrical cord, be sure all controls are in the OFF position.

Be sure your appliance is properly installed and grounded by a qualified technician in accordance with the National Electrical Code ANSI/NFPA 70 latest edition and local electrical code requirements.

Local codes vary. Installation, electrical connections and grounding must comply with all applicable codes.

For appliances equipped with a cord and plug, do not cut or remove the ground prong. It must be plugged into a matching grounding type receptacle to avoid electrical shock. If there is any doubt as to whether the wall receptacle is properly grounded, the customer should have it checked by a qualified electrician.

If required by the National Electrical Code (or Canadian Electrical Code), this appliance must be installed on a separate branch circuit.

Only a power supply cord kit rated for this appliance and marked “for use with ranges” shall be used.

Installer - show the owner the location of the circuit breaker or fuse. Mark it for easy reference.

English 2

Important - Save these instructions for the local electrical inspector's use.

Before installing, turn power OFF at the service panel. Lock service panel to prevent power from being turned ON accidentally.

Refer to rating label for more information.

See "Rating Label" under "Service" for rating label location.

.

Proposition 65 Warning:

This product may contain a chemical known to the State of California, which can cause cancer or reproductive harm. Therefore, the packaging of your product may bear the following label as required by California:

STATE OF CALIFORNIA PROPOSITION 65 WARNING:

WARNING

&DQFHU DQG 5HSURGXFWLYH +DUP www.P65Warnings.ca.gov

Preparation

Before You Begin

Tools and Parts Needed

•40 or 50 Amp power supply cord kit with strain relief (depending on local code).

Note: Not necessary for Canadian installations, cord is preinstalled at factory.

•Measuring Tape

•Phillips Head Screwdriver

•1¼"Wrench

•Pencil

•T-20 Torx Screwdriver

•Screws (2) and Anchors (2) for Anti-Tip Bracket (Style will vary depending on mounting surface)

•Level

•Drill and Drill Bit (3/16" masonry bit for concrete screws)

•Soapy Water

•Safety Gloves and Goggles

•Cloth or Cardboard (Optional - to Protect Floor)

Parts Included

•Anti-Tip Bracket

•2 wood screws

•2 anchorless concrete screws

•Foam Tape (unless already installed on underside of cooktop sides)

•Terminal lugs (for use with hard-wired installations)

Note: Terminal lugs are not necessary for Canadian installations.

AdditionalPartsNeed edforHard-Wired Installations

•Flexible conduit

•Torque wrench

Note: Power supply cord kit is not necessary for hard-wired installations.

Remove Packaging

1.Cut the straps.

2.Open top of carton and remove top wood frame.

3.Lift the carton up and over the appliance to remove, or carefully cut along the cut line on the back left side of the carton with a blade shorter than 3/4” and remove carton.

4.Carefully remove internal protective packaging taking care to secure any loose accessories and instruction manuals.

5.Remove bracket(s) securing appliance to base pad, if present.

6.The unit should stay on the packaging base until ready to be lifted into cabinet cutout.

7.Install the appliance according to the installation instructions.

Packaging Bracket Removal-Left and

Right Sides

Note: Actual bracket varies in appearance. The bracket remains in the packaging base. The unit should stay on the packaging base until ready to be lifted into cabinet cutout or onto the lower oven.

Preparing Oven

Place oven in front of the cabinet where it is to be installed so that it is in line with the cabinet cutout. Check to be sure all packing materials have been removed from the unit. Also remove the accessories, oven racks, literature pack and any shipping materials from inside the oven cavity.

Installation Checklist

Please refer to the pages following for complete installation instructions. Use this checklist to verify that you have completed each step of the installation process. This can help you avoid mistakes.

___ 1. Before installing the range, be sure to verify the cabinet dimensions are correct for your unit and

that the required electrical connections are present.

___ 2. Refer to the installation manual for content regarding Safety, Cabinet Dimensions, Removing Packaging, Electrical Installation, Testing the Installation and Customer Service.

English 3

___ 3. Removing the oven door and warming drawer prior to installation reduces the unit weight and makes the range easier to move. Additionally, the removal of the oven door provides access to handhold for lifting.

___ 4. Move the range unit into place in front of the installation opening, leaving the bottom packaging on the unit to avoid damaging flooring.

___ 5. Plug the range into a properly configured receptacle.

___ 6. Protect the flooring from damage, then lift the range off of the bottom packaging and slide the range all the way into place, making sure to route the power cord correctly.

___ 7. Reinstall the oven door and warming drawer removed in step 3 above.

___ 8. Consult the complete installation instructions and follow the remainder of the procedures listed, including performing an operation test.

General Information

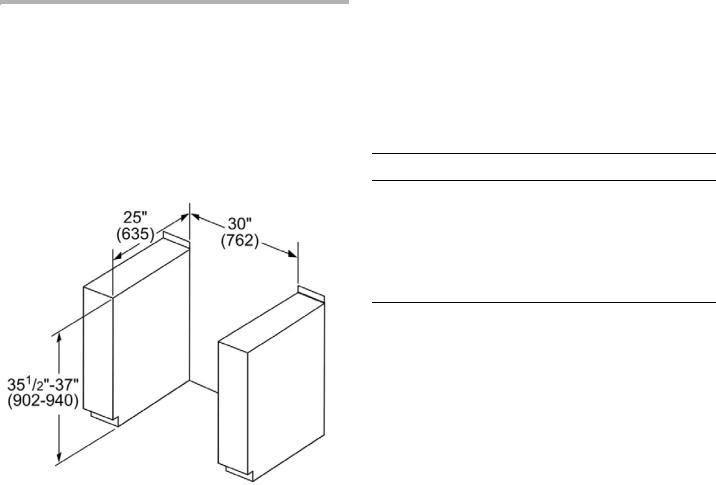

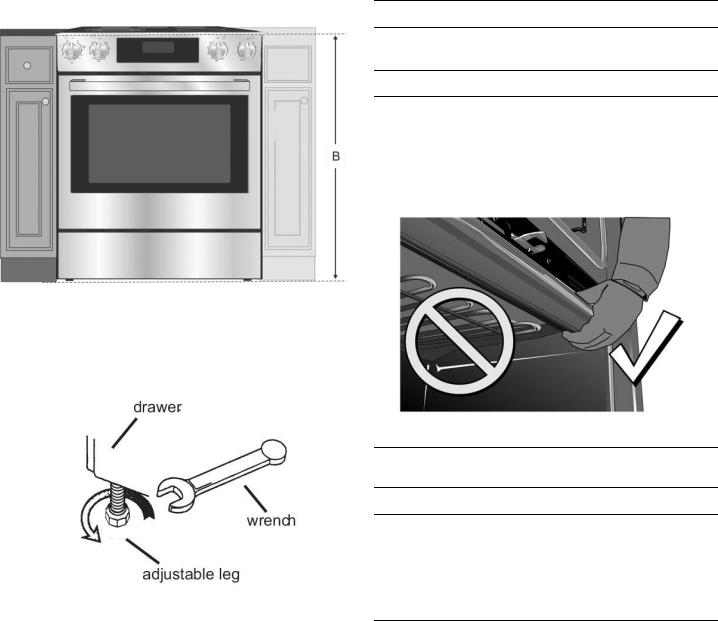

Overall Dimensions

Dimension |

Inches |

Centimeters |

|

|

|

|

|

|

Height |

36½” - 38” |

92.7 cm - 96.6 cm |

|

|

|

Width |

31½” |

80 cm |

|

|

|

Depth |

26¾” |

68.1 cm |

|

|

|

Location Level and Plumb

For best results, cabinets, countertops, walls and floors in the installation location should be as level and plumb as possible. Variance may cause damage to countertops and floors during installation, and may adversely affect cooking and baking performance.

Installation Hints

To make the range lighter and easier to handle during installation, remove the range oven door and warming drawer (see “Removing the Oven Door” on page 13).

If the warming drawer is not removed, then tape must be placed securely on the warming drawer before installation to prevent it from opening while the range is being installed.

Place a piece of cardboard or cloth under the range during installation to protect floors.

Electrical Requirements

Refer to rating label for more information. See the product “Rating Label” in the section on Service in this manual.

We recommend that the range be installed with a power cord set (not supplied with U.S. models). The

electrical rating of the power cord set must be 120/240 volt, 40 amperes minimum. The power cord set must be marked “For Use with Ranges.” Always use a new power cord.

English 4

Verify that wiring to the house is adequate. Contact your local utility company to verify that the present electric service to your home is adequate. In some instances, the size of the wiring to the house and service switch must be increased to handle the electrical load demanded by the range. Some wiring codes require a separate circuit with separate disconnect switch and fuses either in the main entrance panel or in a separate switch and fuse box.

The range requires a minimum of a three-wire 120/240 or 120/208 volt, 40 - 50 amp, 60 Hz AC circuit. Check local codes for proper amperage ratings. A four-wire connection is preferred. Most local building regulations and codes require that electrical wiring be done by licensed electricians. Be sure to install your range according to the electric codes in your region.

Electrical kW Rating

Ranges are dual rated for use on either 120/240 VAC or 120/208 VAC. Check the rating label for the kW rating. Reference the kW rating in the table below to determine amperage requirements.

VOLTS |

HZ |

RATING |

CIRCUIT |

A/C |

|

KW |

BREAKER |

|

|

|

|

120/240 |

60 |

13.0 |

40 or 50 amps* |

|

|

|

|

120/240 |

60 |

13.8 |

40 or 50 amps* |

|

|

|

|

120/208 |

60 |

9.8 |

40 or 50 amps* |

|

|

|

|

120/208 |

60 |

10.4 |

40 or 50 amps* |

|

|

|

|

* Varies by location. Check local codes.

Electric Outlet Location

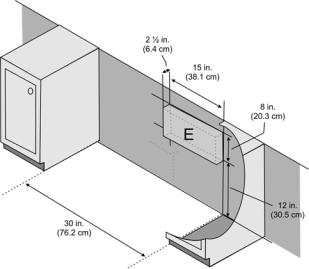

A flush mount 208/240 VAC dedicated circuit outlet is required. Use the diagram below to make sure your installation in properly prepared for the range. Note the available space for the electrical outlet is shown in box (E) in the illustration following.

Cabinet Requirements

This unit is designed for installa tion near adjacent walls and projecting surfaces constructed of combustible materials. Prepare the countertop and cabinets.

Allow a minimum of 30" (76.2 cm) between cabinets where range is to be installed. No side clearance is required. Height is set by adjusting the range legs (see later section, “Complete the installation” on

page 11).

Note: The slide-in range can also replace a freestanding range. In this case, verify that the opening is at least 30" (76.2 cm).

Install Ventilation

Bosch strongly recommends the installation of a ventilation hood above this range. For most kitchens, a certified hood rating of not less than 300 CFM is recommended. The range hood must be installed according to instructions furnished with the hood.

Required Clearance

These instructions were determined using standard American cabinets. Standard base cabinets measure 36" (91.4 cm) high x 25" (63.5 cm) deep. Cabinets over the cooking surface and cabinets adjacent to those over the cooking surface measure 13" (33 cm) deep from backwall. If nonstandard cabinets are used, care should be taken to alter dimensions accordingly.

9WARNING

To eliminate the risk of burns or fire by reaching over heated surface units, cabinet storage space located above the surface units should be avoided. If cabinet storage is to be provided, the risk can be reduced by installing a hood that projects horizontally a minimum of 5" (12.7 cm) beyond the bottom of the cabinet.

From cooktop to materials above:

•There must be a minimum clearance of 30” (762 mm) between the top of the cooking surface and the bottom of an unprotected wood or metal cabinet.

•Bosch recommends the minimum clearances shown in the installation diagrams contained in this manual. Clearances from non-combustible materials are not certified by CSA. Clearances less than shown in the installation diagrams must be approved by local codes and/or by the local authority having jurisdiction.

From the cooking surface to side materials:

No clearance is required from unit walls to adjacent vertical combustible walls on rear, right or left.

English 5

Note: Some cabinet finishes cannot survive the temperatures allowed by safety standards, particularly selfcleaning ovens; the cabinets may discolor or stain. This is most noticeable with laminate cabinets.

Flame retardant materials bear the mark:

UNDERWRITERS LABORATORIES INC. CLASSIFIED MINERAL AND FIBER BOARDS SURFACE BURNING CHARACTERISTICS, followed by the flame spread and smoke ratings. These designations are shown as “FHC (Flame Spread/Smoke Developed)“. Materials with “O” flame spread ratings are flame-retardant. Local codes may allow other flame spread ratings. It is the responsibility of the installer to ensure installation is in accordance with these ratings.

Prepare Walls and Floor

Seal any holes in the walls or floor. Remove any obstructions (extra electrical or gas connections, etc.) so that range will rest against wall properly.

Countertop Requirements

Countertops must be smooth and level.

English 6

Installation Procedure

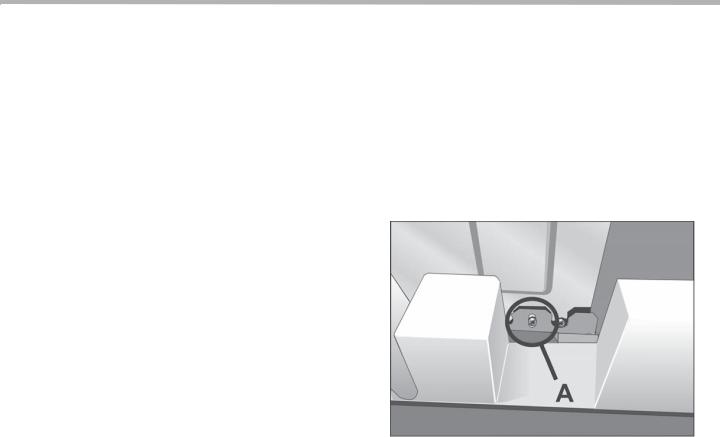

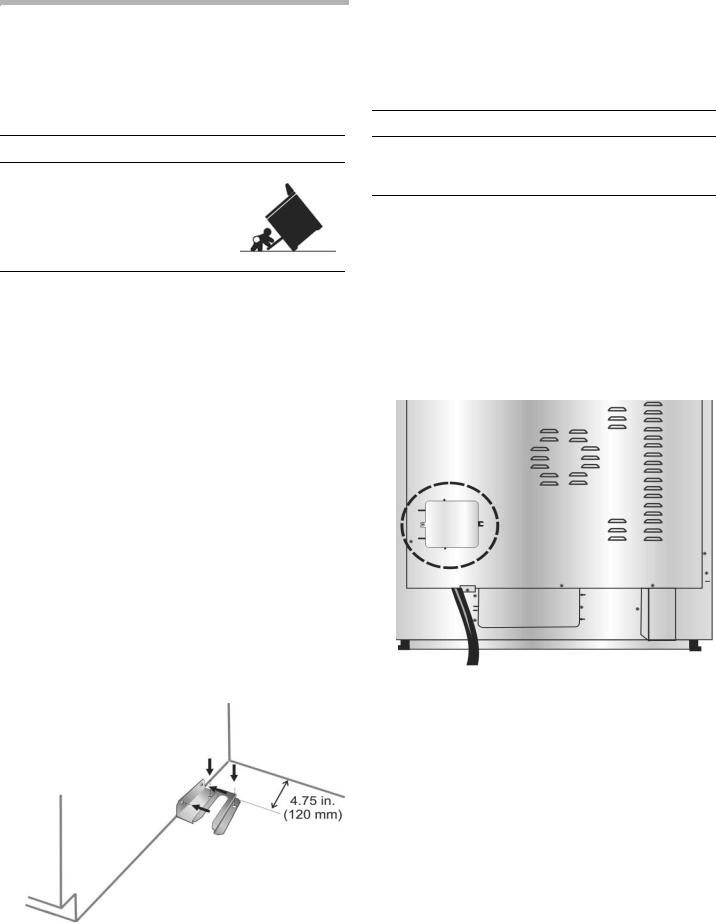

Installation of the Anti-Tip

Bracket

9WARNING

A child or adult can tip the range over and be killed.Verify that the anti-tip bracket is securely installed. Ensure the anti-tip bracket is engaged when the range is moved.

The range can tip forward, potentially causing injury and damage, if the anti-tip bracket is not properly installed. Do not operate the range without the anti-tip bracket in place.

Steps to Install the Anti-Tip Bracket

1.Adjust height of range to match countertop height and level it by rotating the adjustable leg supports on the bottom of the range, using a 1¼" wrench.

2.Position the bracket as shown below in the back left corner of the installation opening, against the back wall and the left cabinet wall. Mount the bracket using two screws into either the floor or the base of the adjacent cabinet. Note: The mounting surface must be secure. When mounting to the cabinet wall make sure the screws engage the frame of the cabinet, not the thin wall of the cabinet only. Do not use a block or spacer to fill a gap between the anti-tip bracket and the cabinet wall.

3.Secure the bracket with two screws to the floor or to the base of the cabinet wall. Depending on the floor or cabinet material, use wood or anchorless concrete screws (included). Concrete screws require the use of a 3/16" masonry bit. Screws should provide firm attachment into solid wood or flooring. Do not attempt to anchor into drywall.

Electrical Connection

The range may be connected using an electric range cord (as specified in the Electrical Requirements section preceeding) or using a flexible conduit electrical

connection.

9WARNING

Do not use an extension cord. If the power supply cord is too short, have a qualified electrician install an outlet near the appliance.

Note: In Canada, the range is shipped from the factory with the range cord already installed. Continue to “Completethe installation” on page 11.

Note: It is recommended that only qualified persons add a power cord or make electrical connections to this appliance.

For installations other than those in Canada, connect the range cord at the terminal block. Access the terminal block by removing the cover in the lower left hand corner of the range back panel.

English 7

Install Strain Relief

Place strain relief in knockout below terminal block.

9WARNING

The strain relief provided with your range cord must be properly installed. Strain reliefs vary. Carefully read and follow the instructions included with your strain relief.

1.In the knockout panel below the terminal block, remove the knockout that fits the strain relief that comes with your range cord.

2.Feed the range cord through the hole and the strain relief up to terminal block. Allow for slack in the cord between the strain relief and terminal block.

3.Once the cord length/slack has been adjusted, attach the strain relief per instructions included with strain relief.

Tip: The knockout panel (below the terminal block) can be removed from the range to install the strain relief. Remove the panel from range, install strain relief in panel and reattach. DO NOT remove entire range back panel.

Preparation for Power Connection

9WARNING

Risk of Electric Shock or Fire. Grounding through the neutral conductor is prohibited for new branchcircuit installations (1996 NEC), mobile homes, and recreational vehicles, or in an area where local codes prohibit grounding through the neutral conductor.

For installations where grounding through the neutral conductor is prohibited: (a) disconnect the link from the neutral, (b) use grounding terminal or lead to ground unit,

(c) connect neutral terminal to lead branch circuit neutral in the usual manner. When the appliance is to be connected by means of a cord kit, use 4-conductor cord for this purpose.

Use only cord kits rated 125/250 volts, 40 amperes (minimum),and labeled “For Us e withRanges”. Strain relief provided with the cord must be installed per instructions included with the cord.

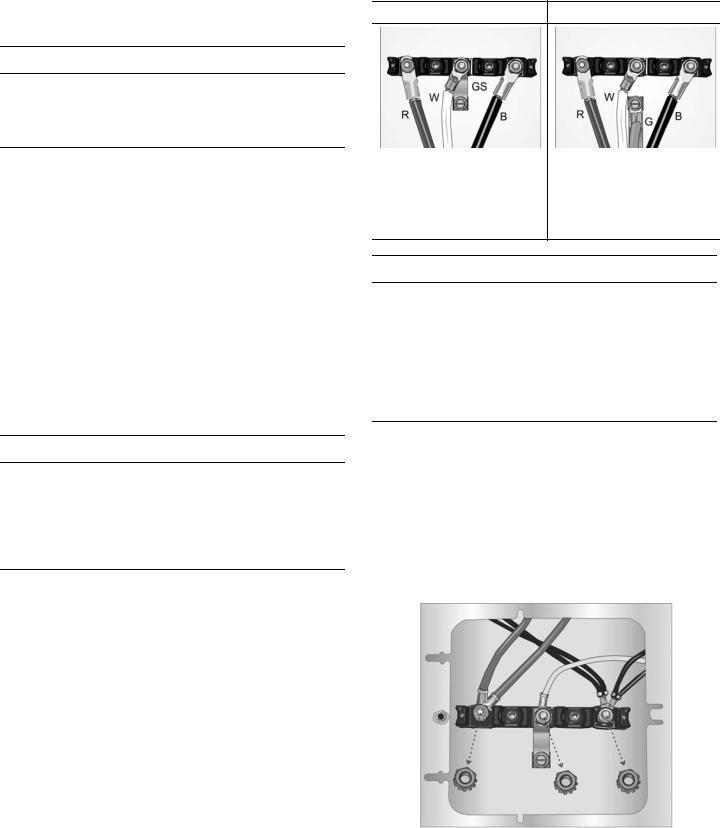

3-Wire Hookup |

4-Wire Hookup |

R= Red |

R= Red |

W = White |

W = White |

GS = Grounding Strip |

G = Green |

B = Black |

B = Black |

9WARNING

To prevent electrical shock, the grounding prong on the range cord should not be cut or removed under any circumstances. It must be plugged into a matching grounding type receptacle and connected to a correctly polarized 240-Volt circuit. If there is any doubt as to whether the wall receptacle is properly grounded, have it checked by a qualified electrician.

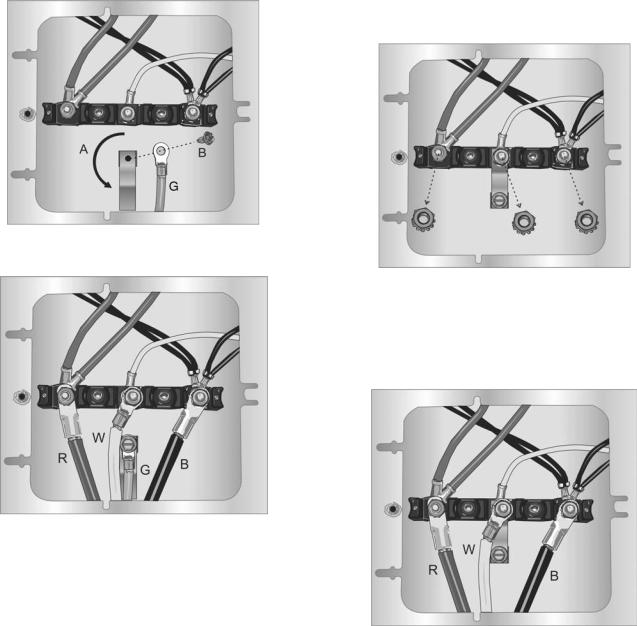

Four-wire Range Cord Connection

(Recommended Method)

1.Disconnect electrical power at breaker box. Remove the terminal block cover to expose the terminal block.

2.Remove the top nut (has an attached locking washer) from each post.

Note: DO NOT removethesecondnut/washeroneach post; these must stay in place to anchor the internal wiring attached to the terminal block.

3.Remove screw from the bottom end of the ground strap.

English 8

4.Remove the green grounding screw from the lower end of the grounding strap. Remove the upper end of the grounding strap from the center post of the junction bar. Rotate the grounding strip (A) so that the wide end is up and align the hole with the grounding hole below the terminal block. Use the green grounding screw (B) to attach the green wire (G) on top of grounding strap. Tighten the grounding screw firmly, but do not overtighten.

5.Attach the red wire to the left junction block terminal using one of the nut/washers removed in step 2.

6.Attach the white wire to the center junction block terminal using one of the nut/washer parts.

7.Attach the black wire to the right junction block terminal using one of the nut/washer parts.

8.Tighten all connections securely and replace terminal block cover.

9.Properly secure strain relief (see previous section). Note: DO NOT plug in the range at this time.

Three-wire Range Cord Connection (Alternate Method)

The four-wire connection (above) is preferred, but where local codes and ordinances permit grounding through the neutral and where conversion to four-wire is impractical,

the unit may be connected to the power supply via a threewire connection.

1.Disconnect electrical power at breaker box.

2.Remove the terminal block cover to expose the terminal block.

3.Remove the top nut (has an attached locking washer) from each terminal post.

Note: DO NOT removethesecond nut/washeroneach post. These must stay in place to anchor the internal wiring attached to the terminal block.

4.Attach the white wire to the center junction block terminal using one of the nut/washer parts.

5.Attach the red wire to the left junction block terminal using one of the nut/washer parts removed in step 2.

6.Attach the black wire to the right junction block terminal using one of the nut/washer parts.

7.Tighten all connections securely and replace terminal block cover.

8.Properly secure strain relief (see previous section).

Note: DO NOT plug in range at this time.

English 9

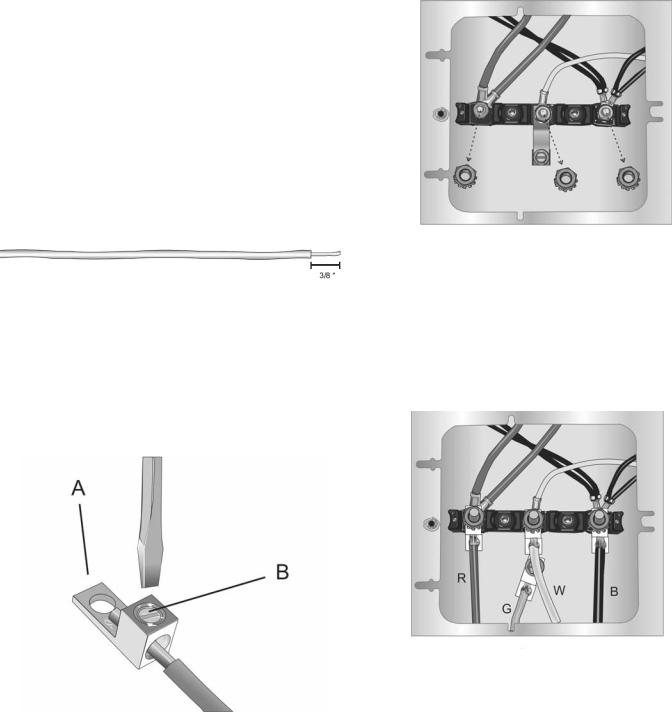

Connect Flexible Conduit

The range can also be connected via flexible conduit. If using this method, always use the lugs supplied.

Note: In Canada, the range is shipped from the factory with the range cord already installed. Continue to “ Completethe installation”. For installations other than those in Canada, connect the flexible conduit at the terminal block.

Terminal Lug/Wire Connection

In each instance where a wire is to be attached to a terminal lug, perform the following steps:

1.Strip 3/8” (9.5 mm) of insulation from the end of the wire.

2.Insert the stripped end of the wire into the terminal lug (see A in the figure below) and then tighten each clamping screw (see B in the figure below) with the appropriate torque (see table).

Wire Gauge |

Torque (in/lbs) |

Torque (Nm) |

|

|

|

6 |

35 |

3.95 |

|

|

|

8 |

25 |

2.82 |

|

|

|

Four-wire Flexible Conduit Connection

1.Disconnect electrical power at the breaker box.

2.Remove the terminal block cover to expose the terminal block.

3.Remove the top nut (has an attached locking washer) from each terminal post.

Note: DO NOT remove the second nut/washer on each post. These must stay in place to anchor the internal wiring attached to the terminal block.

4.Remove the green grounding screw from the lower end of the grounding strap.

5.Remove the grounding strap from the center post on the terminal block. The strap will not be needed with the flexible conduit electric installation. Remove it from the unit.

6.Attach the insulated grounding wire (G) to a terminal lug (packaged with this manual) and secure the terminal lug to the grounding hole with the green grounding screw. Tighten the screw firmly, but do not overtighten.

7.Attach the red wire (R) to a terminal lug and place the terminal lug onto the left post. Replace the nut/washer on the post and tighten to 20 in/lbs. (50.8 cm) of torque.

8.Attach the black wire (B) to a terminal lug and place the terminal lug onto the right post.Replace the nut/washer on the post and tighten to 20 in/lbs. (50.8 cm) of torque.

English 10

9.Properly secure the flexible conduit at knockout on angle and at supply side junction box. The wiring is now complete.

Note: DO NOT connect electrical power to the range at this time.

Three-wire Flexible Conduit Connection

The four-wire connection is preferred, but where local codes and ordinances permit grounding through neutral and/or conversion to four-wire is impractical, the unit may be connected to the power supply via a three-wire connection.

1.Disconnect electrical power at the breaker box.

2.Remove the terminal block cover to expose the terminal block.

3.Remove the top nut, star washer, and round washer from each post.

7.Properly secure flexible conduit at knockout panel on range and at supply side junction box. The wiring is now complete.

Note: DO NOT connect electrical power to the range at this time.

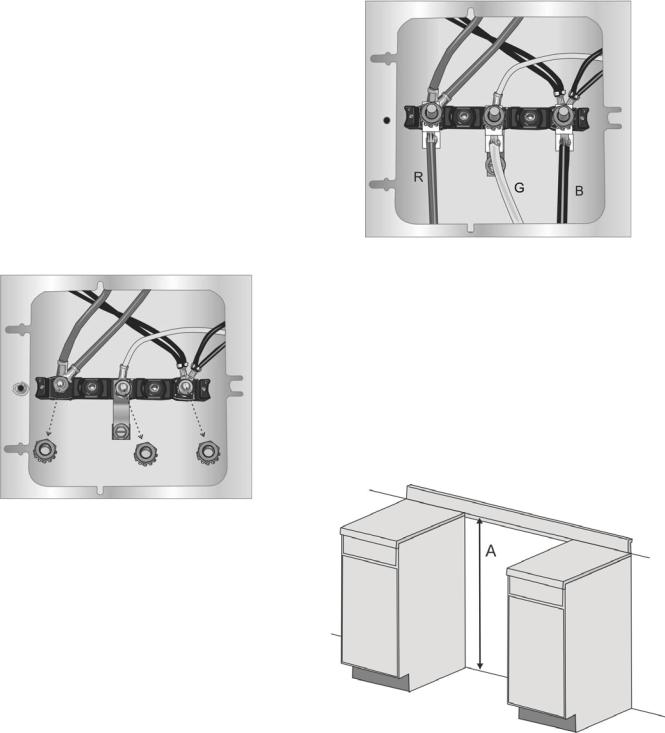

Complete the installation

Adjust Leveling Legs

1. Make sure that the circuit breaker is off and then plug range cord into the electrical outlet.

2. Line up range in front of opening.

3. Measure (A) back left corner of opening from floor to the top of the countertop.

Note: DO NOT remove last round washer, last nut or internal wire leads.

4.Attach the red wire (R) to a terminal lug (packaged with this manual) and place the terminal lug onto the left post. Replace the nut/washer on the post and tighten to 20 in/lbs. (50.8 cm) of torque.

5.Attach the black wire (B) to a terminal lug and place the terminallugontotherightpost.Replacethenut/washer on the post and tighten to 20 in/lbs. (50.8 cm) of torque.

6.Attach the green wire (G) to a terminal lug and place the terminal lug onto the center post. Replace the nut/ washer on the post and tighten to 20 in/lbs. (50.8 cm) of torque.

English 11

4.Measure the back left corner of the range to the bottom of cooktop (B). Adjust leveling legs until this height is the same as the corner dimension.

5.Repeat in the back right corner.

6.Use a 1¼ “ wrench to adjust front leveling legs so that the height from the bottom of the cooktop to the floor matches the height of the corresponding countertop surface.

English 12

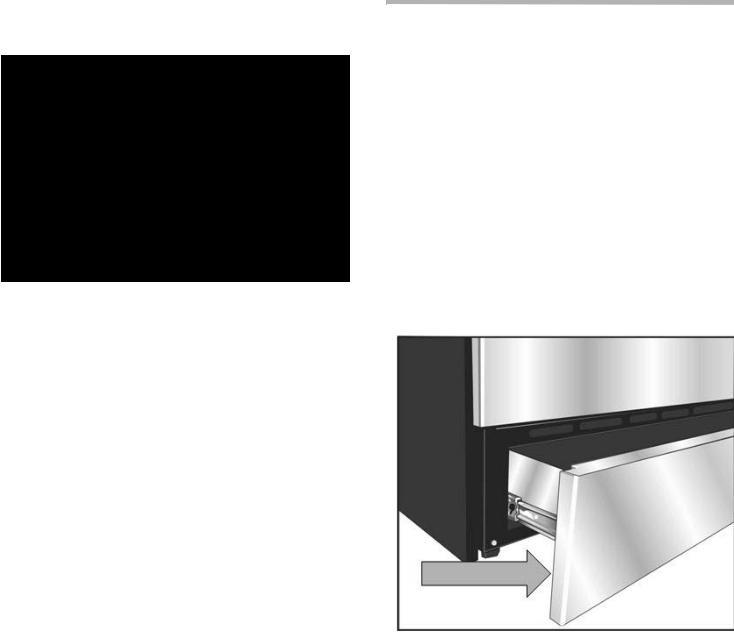

Slide Range into Opening

9CAUTION

Unit is heavy and requires at least two persons or proper equipment to move.

NOTICE

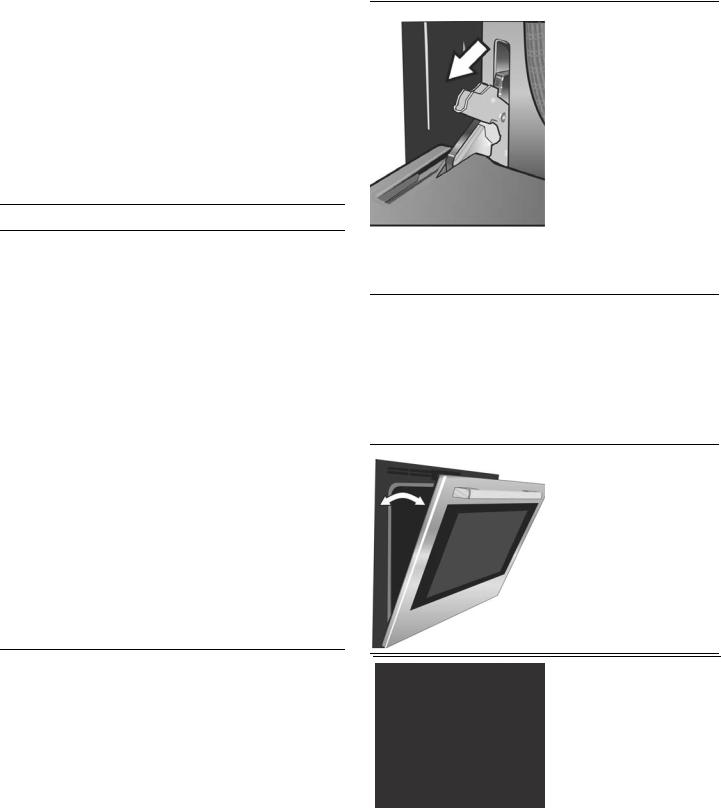

To avoid risk of damage to the range oven door, do not lift, push, or pull the range by holding the door handle. After the door has been removed, reach inside the top of the oven cavity to locate a ridged area near the front of the oven. Take care not to touch the oven heating element also located at the top of the oven cavity, just behind the ridged area.

9CAUTION

It is recommended to wear gloves and long sleeves to protect hands and forearms from abrasion and potential scratches during the lifting process. It is also recommended to take off watches and jewelry and to wear work shoes during installation for foot protection.

1.Remove oven door using the procedure “Removing the Oven Door” on page 13 and lift the range off of the packaging base.

2.Plug in the power cord.

3.Dampen countertop and floor at bottom of opening with soapy water.

Note: Clean up any remaining soapy water immediately after sliding the range in place.

4.Slide the range into the opening, being careful not to damage countertops, floors, or the range door or warming drawer front. Do not apply pressure to cooktop when sliding into position. Be careful not to crimp the flexible electrical connector.

5.Install the oven door using the procedure “Replacing the Oven Door” on page 14.

Check Back of Range for Proper Installation

1.The cooktop should rest lightly on the countertop.

2.There should not be any gap between the countertop and the cooktop; however, the weight of the range must not rest on the countertop. Look under the range to verify that both back legs are resting solidly on the floor. Also verify that the left range leg is retained by the anti-tip bracket.

Removing the Oven Door

9WARNING

When removing the door:

•Make sure oven is cool and power to the oven has been turned off before removing the door. Failure to do so could result in electrical shock or burns.

•The oven door is heavy and parts of it are fragile. Use both hands to remove the oven door. The door front is glass. Handle carefully to avoid breakage.

•Grasp only the sides of the oven door. Do not grasp the handle as it may swing in your hand and cause damage or injury.

•Failure to grasp the oven door firmly and properly could result in personal injury or product damage.

•To avoid injury from hinge bracket snapping closed, be sure that both levers are securely in place before removing the door. Also, do not force door open or closed—the hinge could be damaged and injury could result.

•Do not lay removed door on sharp or pointed objects as this could break the glass. Lay on a flat, smooth surface, positioned so that the door cannot fall over.

To help avoid injury or damage be sure to read the above WARNING before attempting to remove the oven door.

1.Open the oven door to its fully open, horizontal position.

2.Flip levers on hinges toward you.

Note: It may be necessary to use a tool, such as a screwdriver, to gently pry the upper part of the lever away from the housing. Take care to avoid scratching the housing.

3.Bring both door hinge levers to their fullest down position as shown in the illustration. The left and right door hinge levers may differ slightly but operate in the same manner.

4.Close the oven door until it catches on the hinge stop levers, locking the hinges at the proper angle for door removal. The door will be open about 7 inches at the top. This takes the spring tension off the hingessothedoorcan be easily lifted out.

5.The door is heavy. Use both hands to firmly grip it by the

sides. Do not grip the door by the handle. Maintaining the door angle, lift the door straight up approximately ¾" to unhook the hinges fromtheslotsandthen pull it out towards you until the hinges are clear of the oven housing.

6.Place the door in a convenient and stable location for cleaning.

English 13

Replacing the Oven Door

1. Holdingthedoorfirmly in both hands, grip it on either side, not by the handle.

2. Tilt the door back

slightly towards you

until it opens about 7"

at the top.

3. Slide the hinges into the slots as far as they will go and then lower the door straight down. The angle of the door may need to be adjusted slightly to allow the hinges to engage properly and the door to lower into place. The door should lower about ¾" and stop. If not, the hinges have not engaged properly and the door could fall if it is released.

4. Once both hinges are fully engaged as described in Step 3, gently open the door until it is fully open.

5. Push the levers on both the hinges up and forward until they are locked into the slot, flush with the front of the oven body.

6. Close and open door slowly to be sure it is correctly and securely in place.

English 14

Removing the Warming Drawer

9CAUTION

To prevent burns, do not remove drawer while hot. Be sure the drawer is empty before removing.

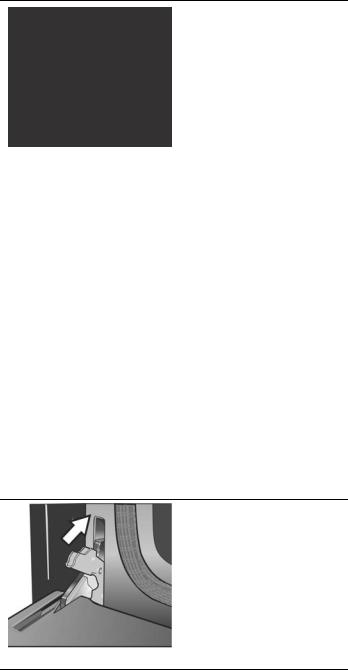

Removing Drawer from Housing

NOTICE: The following is the manufacturer’s recommendations for removing and installing the drawer to minimize the risk of damage to the PTO mechanism.

1.Remove the drawer from the drawer housing.

Pull drawer to fully open position.

Press down right drawer release lever.

Lift up left drawer release lever.

Firmly pull the drawer straight out.

Retract cabinet rails while drawer is removed.

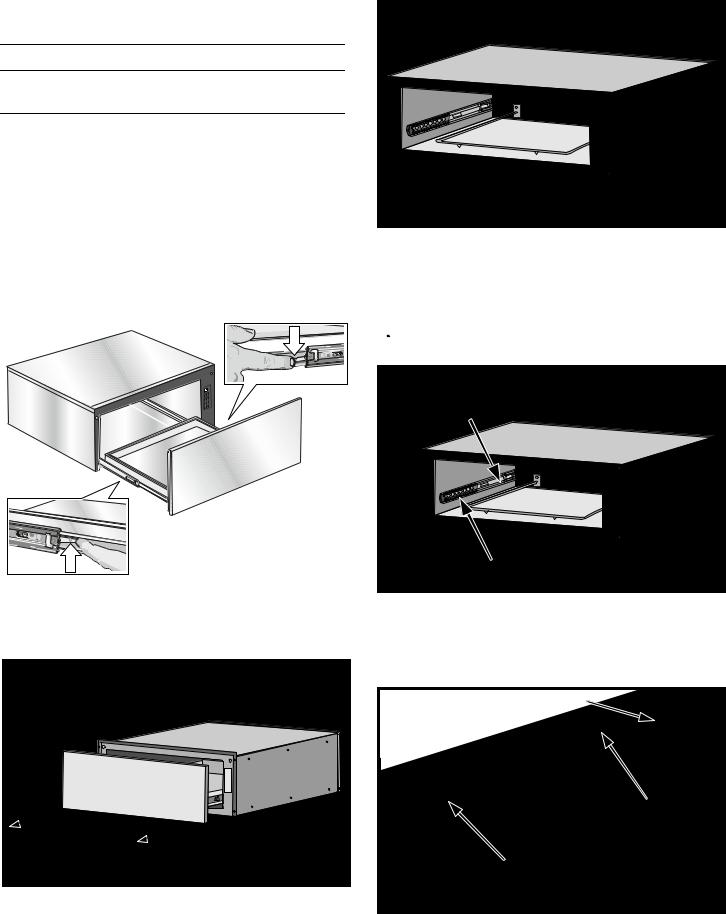

Installing Drawer to Housing

The slides mounted to each side of the housing wall have two moving components, an inner rail and a ball bearing carrier which need to be in the proper orientation for accurate installation and alignment.

There is also a visible locking mechanism located at the rear of each slide.

6OLGH ,QQHU 5DLO

2.Grasp both sides of the drawer and pulling straight and level, carefully remove the drawer housing. This step may require light to moderate force to completely remove drawer.

3. Install or service (clean) housing with drawer removed.

Note: The housing of your warming drawer should match the image below identically before starting your installation. The ball bearing carrier should be locked in to the inner rail’s black plastic rail tip at the front of the inner rail.

/RFNLQJ 0HFKDQLVP

6OLGH ,QQHU 5DLO

%DOO %HDULQJ &DUULHU

English 15

1.With the drawer removed, set the slide inner rail to the drawer locked position by pushing the slide inner rail toward the rear of the housing until it locks in place.

-PDLJOH .FDIBOJTN

4MJEF *OOFS 3BJM

Notes

A slight side-to-side wiggle motion may be required to properly get the ball bearings to accurately align.

Remember: You are attempting to align two sets of ball bearings at this point. If more than a moderate force is required to insert the drawer at this time, remove the drawer and repeat the installation procedure to this point.

3.Continue to insert the drawer keeping the drawer level and square to the housing until a slight increase in resistance is felt at the approximate position shown below.

Note: A moderate force pushing on the black plastic ball carrier locking mechanism is required to set the slide to the drawer locked position. The drawer is locked when it remains in place and does not spring back to the open position.

4MJEF *OOFS 3BJM JT JO MPDLFE QPTJUJPO

2.Position the drawer assembly in front of the housing assembly and align the rail (plastic rail tip) to the slide ball carrier assembly. Keeping the drawer assembly level and square to the housing, gently insert the drawer to the housing assembly.

NOTICES

At this position, a slight increase in closure force is required with several small increments of force applied to the drawer to accurately align and set the drawer for proper operation.

An audible “click” should be heard when the drawer is properly closed causing the drawer to lock in the closed position.

English 16

4.Test the operation of the PTO drawer by pushing on the center lower portion of the drawer front (optimum location for function).

Note: It should be noted the recommended and optimum location for opening the drawer is the lower center front. The drawer will operate with an opening force applied to any location on the drawer front, however a slight increase in opening force may be required.

Testing Operation

Test the Oven

1.Turn on power at the breaker.

2.Test the oven mode.

Select the BAKE mode. See the Use and Care Manual for detailed operation instructions.

3.Verify that the oven light comes on and the oven begins to preheat.

4.Test the door lock.

Set the SELF CLEAN mode. Confirm that the door locks when the lock icon appears in the display.

5.If any of the tests do not result as explained above, contact Bosch service for assistance. Otherwise, continue with testing the rangetop burners.

If any of the tests do not result as explained above, contact Bosch Service for assistance. Otherwise, the installation is complete at this time.

Service

Before Calling Service

See Use and Care Manual for troubleshooting information. Refer to the Statement of Limited Warranty in the Use and Care Manual.

To reach a service representative, see the contact information at the front of the manual. Please be prepared with the information printed on your product rating label when calling.

Rating Label

The rating label shows the model and serial number. Refer to the rating label on the appliance when requesting service. The rating label is located on the back side of the drawer front. Open the drawer to see it.

English 17

Loading...

Loading...