Bosch BNO055 User Manual

Data sheet

BNO055

Intelligent 9-axis absolute orientation sensor

BNO055: data sheet

Document revision

1.4

Document release date

June 2016

Document number

BST-BNO055-DS000-14

Technical reference code(s)

0 273 141 209

Notes

Data in this document are subject to change without notice. Product

photos and pictures are for illustration purposes only and may differ from

the real product’s appearance.

User Motion

• Quaternion

• Linear Acceleration

• Rotation

• Gravity

• Robust Heading

Bosch Sensortec

BNO055

Data sheet

Page 2

BNO055

INTELLIGENT ABSOLUTE ORIENTATION SENSOR, 9-AXIS SENSOR FUSION

ALL-IN-ONE WINDOWS 8.x COMPLIANT SENSOR HUB

Basic Description

Key features:

Outputs fused sensor data Quaternion, Euler angles, Rotation vector,

Linear acceleration, Gravity, Heading

3 sensors in one device an advanced triaxial 16bit gyroscope, a versatile,

leading edge triaxial 14bit accelerometer and a

full performance geomagnetic sensor

Small package LGA package 28 pins

Footprint 3.8 x 5.2 mm², height 1.13 mm²

Power Management Intelligent Power Management: normal,

low power and suspend mode available

Common voltage supplies V

Digital interface HID-I2C (Windows 8 compatible), I²C, UART

V

Consumer electronics suite MSL1, RoHS compliant, halogen-free

Key features of integrated sensors:

voltage range: 2.4V to 3.6V

DD

voltage range: 1.7V to 3.6V

DDIO

Operating temperature: -40°C ... +85°C

Accelerometer features

Programmable functionality Acceleration ranges ±2g/±4g/±8g/±16g

Low-pass filter bandwidths 1kHz - <8Hz

Operation modes:

- Normal

- Suspend

- Low power

- Standby

- Deep suspend

On-chip interrupt controller Motion-triggered interrupt-signal generation for

- any-motion (slope) detection

- slow or no motion recognition

- high-g detection

BST-BNO055-DS000-14 | Revision 1.4 | June 2016 Bosch Sensortec

© Bosch Sensortec GmbH reserves all rights even in the event of industrial property rights. We reserve all rights of disposal su ch as copying and passing on

to third parties. BOSCH and the symbol are registered trademarks of Robert Bosch GmbH, Germany.

Note: Specifications within this document are subject to change without notice.

BNO055

Data sheet

Page 3

Gyroscope features

Programmable functionality Ranges switchable from ±125°/s to ±2000°/s

Low-pass filter bandwidths 523Hz - 12Hz

Operation modes:

- Normal

- Fast power up

- Deep suspend

- Suspend

- Advanced power save

On-chip interrupt controller Motion-triggered interrupt-signal generation for

- any-motion (slope) detection

- high rate

Magnetometer features

Flexible functionality Magnetic field range typical ±1300µT (x-, y-axis);

±2500µT (z-axis)

Magnetic field resolution of ~0.3µT

Operating modes:

- Low power

- Regular

- Enhanced regular

- High Accuracy

Power modes:

- Normal

- Sleep

- Suspend

- Force

Typical applications

Navigation

Robotics

Fitness and well-being

Augmented reality

Context awareness

Tablets and ultra-books

BST-BNO055-DS000-14 | Revision 1.4 | June 2016 Bosch Sensortec

© Bosch Sensortec GmbH reserves all rights even in the event of industrial property rights. We reserve all rights of disposal su ch as copying and passing on

to third parties. BOSCH and the symbol are registered trademarks of Robert Bosch GmbH, Germany.

Note: Specifications within this document are subject to change without notice.

BNO055

Data sheet

Page 4

General description

The BNO055 is a System in Package (SiP), integrating a triaxial 14-bit accelerometer, a

triaxial 16-bit gyroscope with a range of ±2000 degrees per second, a triaxial geomagnetic

sensor and a 32-bit cortex M0+ microcontroller running Bosch Sensortec sensor fusion

software, in a single package.

The corresponding chip-sets are integrated into one single 28-pin LGA 3.8mm x 5.2mm x

1.1 mm housing. For optimum system integration the BNO055 is equipped with digital bidirectional I2C and UART interfaces. The I2C interface can be programmed to run with the

HID-I2C protocol turning the BNO055 into a plug-and-play sensor hub solution for devices

running the Windows 8.0 or 8.1 operating system.

BST-BNO055-DS000-14 | Revision 1.4 | June 2016 Bosch Sensortec

© Bosch Sensortec GmbH reserves all rights even in the event of industrial property rights. We reserve all rights of disposal su ch as copying and passing on

to third parties. BOSCH and the symbol are registered trademarks of Robert Bosch GmbH, Germany.

Note: Specifications within this document are subject to change without notice.

BNO055

Data sheet

Page 5

Contents

BASIC DESCRIPTION ........................................................................................................... 2

SPECIFICATION .................................................................................................................. 12

1.1 ELECTRICAL SPECIFICATION .......................................................................................... 12

1.2 ELECTRICAL AND PHYSICAL CHARACTERISTICS, MEASUREMENT PERFORMANCE ................ 13

2. ABSOLUTE MAXIMUM RATINGS .................................................................................. 17

3. FUNCTIONAL DESCRIPTION ......................................................................................... 18

3.1 ARCHITECTURE ............................................................................................................. 18

3.2 POWER MANAGEMENT ................................................................................................... 18

3.2.1 NORMAL MODE ....................................................................................................................... 19

3.2.2 LOW POWER MODE ................................................................................................................. 19

3.2.3 SUSPEND MODE ..................................................................................................................... 20

3.3 OPERATION MODES ...................................................................................................... 20

3.3.1 CONFIG MODE ........................................................................................................................ 22

3.3.2 NON-FUSION MODES .............................................................................................................. 22

3.3.3 FUSION MODES ....................................................................................................................... 22

3.4 AXIS REMAP.................................................................................................................. 24

3.5 SENSOR CONFIGURATION.............................................................................................. 26

3.5.1 DEFAULT SENSOR CONFIGURATION .......................................................................................... 26

3.5.2 ACCELEROMETER CONFIGURATION .......................................................................................... 27

3.5.3 GYROSCOPE CONFIGURATION .................................................................................................. 28

3.5.4 MAGNETOMETER CONFIGURATION............................................................................................ 29

3.6 OUTPUT DATA ............................................................................................................... 30

3.6.1 UNIT SELECTION...................................................................................................................... 30

3.6.2 DATA OUTPUT FORMAT ............................................................................................................ 30

3.6.3 FUSION OUTPUT DATA RATES .................................................................................................. 31

3.6.4 SENSOR CALIBRATION DATA ..................................................................................................... 31

3.6.5 OUTPUT DATA REGISTERS ....................................................................................................... 33

3.7 DATA REGISTER SHADOWING ......................................................................................... 37

3.8 INTERRUPTS ................................................................................................................. 38

3.8.1 INTERRUPT PIN ....................................................................................................................... 38

3.8.2 INTERRUPT SETTINGS ............................................................................................................. 38

3.9 SELF-TEST ................................................................................................................... 46

3.9.1 POWER ON SELF TEST (POST) ............................................................................................... 46

3.9.2 BUILD IN SELF TEST (BIST) ..................................................................................................... 46

3.10 BOOT LOADER ............................................................................................................ 46

3.11 CALIBRATION .............................................................................................................. 47

3.11.1 ACCELEROMETER CALIBRATION ............................................................................................. 47

3.11.2 GYROSCOPE CALIBRATION .................................................................................................... 47

3.11.3 MAGNETOMETER CALIBRATION .............................................................................................. 47

3.11.4 REUSE OF CALIBRATION PROFILE .......................................................................................... 48

BST-BNO055-DS000-14 | Revision 1.4 | June 2016 Bosch Sensortec

© Bosch Sensortec GmbH reserves all rights even in the event of industrial property rights. We reserve all rights of disposal su ch as copying and passing on

to third parties. BOSCH and the symbol are registered trademarks of Robert Bosch GmbH, Germany.

Note: Specifications within this document are subject to change without notice.

BNO055

Data sheet

Page 6

4. REGISTER DESCRIPTION .............................................................................................. 49

4.1 GENERAL REMARKS ...................................................................................................... 49

4.2 REGISTER MAP ............................................................................................................. 50

4.2.1 REGISTER MAP PAGE 0 ........................................................................................................... 50

4.2.2 REGISTER MAP PAGE 1 ........................................................................................................... 53

4.3 REGISTER DESCRIPTION (PAGE 0).................................................................................. 54

4.3.1 CHIP_ID 0X00 ....................................................................................................................... 54

4.3.2 ACC_ID 0X01 ........................................................................................................................ 54

4.3.3 MAG_ID 0X02 ....................................................................................................................... 54

4.3.4 GYR_ID 0X03 ........................................................................................................................ 54

4.3.5 SW_REV_ID_LSB 0X04 ....................................................................................................... 55

4.3.6 SW_REV_ID_MSB 0X05 ...................................................................................................... 55

4.3.7 BL_REV_ID 0X06 .................................................................................................................. 55

4.3.8 PAGE ID 0X07 ....................................................................................................................... 55

4.3.9 ACC_DATA_X_LSB 0X08 ..................................................................................................... 56

4.3.10 ACC_DATA_X_MSB 0X09 .................................................................................................. 56

4.3.11 ACC_DATA_Y_LSB 0X0A .................................................................................................. 56

4.3.12 ACC_DATA_Y_MSB 0X0B ................................................................................................. 56

4.3.13 ACC_DATA_Z_LSB 0X0C .................................................................................................. 57

4.3.14 ACC_DATA_Z_MSB 0X0D ................................................................................................. 57

4.3.15 MAG_DATA_X_LSB 0X0E .................................................................................................. 57

4.3.16 MAG_DATA_X_MSB 0X0F ................................................................................................. 57

4.3.17 MAG_DATA_Y_LSB 0X10 .................................................................................................. 58

4.3.18 MAG_DATA_Y_MSB 0X11 ................................................................................................. 58

4.3.19 MAG_DATA_Z_LSB 0X12 .................................................................................................. 58

4.3.20 MAG_DATA_Z_MSB 0X13 ................................................................................................. 58

4.3.21 GYR_DATA_X_LSB 0X14 .................................................................................................. 59

4.3.22 GYR_DATA_X_MSB 0X15 ................................................................................................. 59

4.3.23 GYR_DATA_Y_LSB 0X16 .................................................................................................. 59

4.3.24 GYR_DATA_Y_MSB 0X17 ................................................................................................. 59

4.3.25 GYR_DATA_Z_LSB 0X18 ................................................................................................... 60

4.3.26 GYR_DATA_Z_MSB 0X19 .................................................................................................. 60

4.3.27 EUL_DATA_X_LSB 0X1A ................................................................................................... 60

4.3.28 EUL_DATA_X_MSB 0X1B .................................................................................................. 60

4.3.29 EUL_DATA_Y_LSB 0X1C ................................................................................................... 61

4.3.30 EUL_DATA_Y_MSB 0X1D .................................................................................................. 61

4.3.31 EUL_DATA_Z_LSB 0X1E ................................................................................................... 61

4.3.32 EUL_DATA_Z_MSB 0X1F .................................................................................................. 61

4.3.33 QUA_DATA_W_LSB 0X20 ................................................................................................. 62

4.3.34 QUA_DATA_W_MSB 0X21 ................................................................................................ 62

4.3.35 QUA_DATA_X_LSB 0X22 .................................................................................................. 62

4.3.36 QUA_DATA_X_MSB 0X23 ................................................................................................. 62

4.3.37 QUA_DATA_Y_LSB 0X24 .................................................................................................. 63

4.3.38 QUA_DATA_Y_MSB 0X25 ................................................................................................. 63

4.3.39 QUA_DATA_Z_LSB 0X26 ................................................................................................... 63

4.3.40 QUA_DATA_Z_MSB 0X27 .................................................................................................. 63

4.3.41 LIA_DATA_X_LSB 0X28 ..................................................................................................... 64

4.3.42 LIA_DATA_X_MSB 0X29 .................................................................................................... 64

4.3.43 LIA_DATA_Y_LSB 0X2A .................................................................................................... 64

4.3.44 LIA_DATA_Y_MSB 0X2B ................................................................................................... 64

4.3.45 LIA_DATA_Z_LSB 0X2C .................................................................................................... 65

4.3.46 LIA_DATA_Z_MSB 0X2D ................................................................................................... 65

4.3.47 GRV_DATA_X_LSB 0X2E .................................................................................................. 65

4.3.48 GRV_DATA_X_MSB 0X2F ................................................................................................. 65

4.3.49 GRV_DATA_Y_LSB 0X30 .................................................................................................. 66

4.3.50 GRV_DATA_Y_MSB 0X31 ................................................................................................. 66

BST-BNO055-DS000-14 | Revision 1.4 | June 2016 Bosch Sensortec

© Bosch Sensortec GmbH reserves all rights even in the event of industrial property rights. We reserve all rights of disposal su ch as copying and passing on

to third parties. BOSCH and the symbol are registered trademarks of Robert Bosch GmbH, Germany.

Note: Specifications within this document are subject to change without notice.

BNO055

Data sheet

Page 7

4.3.51 GRV_DATA_Z_LSB 0X32 ................................................................................................... 66

4.3.52 GRV_DATA_Z_MSB 0X33 .................................................................................................. 66

4.3.53 TEMP 0X34 ......................................................................................................................... 67

4.3.54 CALIB_STAT 0X35.............................................................................................................. 67

4.3.55 ST_RESULT 0X36 .............................................................................................................. 67

4.3.56 INT_STA 0X37 .................................................................................................................... 68

4.3.57 SYS_CLK_STATUS 0X38 ................................................................................................... 68

4.3.58 SYS_STATUS 0X39 ............................................................................................................ 68

4.3.59 SYS_ERR 0X3A .................................................................................................................. 69

4.3.60 UNIT_SEL 0X3B.................................................................................................................. 69

4.3.61 OPR_MODE 0X3D .............................................................................................................. 70

4.3.62 PWR_MODE 0X3E.............................................................................................................. 70

4.3.63 SYS_TRIGGER 0X3F ......................................................................................................... 70

4.3.64 TEMP_SOURCE 0X40 ........................................................................................................ 70

4.3.65 AXIS_MAP_CONFIG 0X41 ................................................................................................. 71

4.3.66 AXIS_MAP_SIGN 0X42 ...................................................................................................... 71

4.3.67 ACC_OFFSET_X_LSB 0X55 .............................................................................................. 71

4.3.68 ACC_OFFSET_X_MSB 0X56 ............................................................................................. 72

4.3.69 ACC_OFFSET_Y_LSB 0X57 .............................................................................................. 72

4.3.70 ACC_OFFSET_Y_MSB 0X58 ............................................................................................. 72

4.3.71 ACC_OFFSET_Z_LSB 0X59 .............................................................................................. 72

4.3.72 ACC_OFFSET_Z_MSB 0X5A ............................................................................................. 73

4.3.73 MAG_OFFSET_X_LSB 0X5B ............................................................................................. 73

4.3.74 MAG_OFFSET_X_MSB 0X56C .......................................................................................... 73

4.3.75 MAG_OFFSET_Y_LSB 0X5D ............................................................................................. 73

4.3.76 MAG_OFFSET_Y_MSB 0X5E ............................................................................................ 74

4.3.77 MAG_OFFSET_Z_LSB 0X5F ............................................................................................. 74

4.3.78 MAG_OFFSET_Z_MSB 0X60 ............................................................................................. 74

4.3.79 GYR_OFFSET_X_LSB 0X61 .............................................................................................. 74

4.3.80 GYR_OFFSET_X_MSB 0X62 ............................................................................................. 75

4.3.81 GYR_OFFSET_Y_LSB 0X63 .............................................................................................. 75

4.3.82 GYR_OFFSET_Y_MSB 0X64 ............................................................................................. 75

4.3.83 GYR_OFFSET_Z_LSB 0X65 .............................................................................................. 75

4.3.84 GYR_OFFSET_Z_MSB 0X66 ............................................................................................. 76

4.3.85 ACC_RADIUS_LSB 0X67 ................................................................................................... 76

4.3.86 ACC_RADIUS_MSB 0X68 .................................................................................................. 76

4.3.87 MAG_RADIUS_LSB 0X69 .................................................................................................. 76

4.3.88 MAG_RADIUS_MSB 0X6A ................................................................................................. 76

4.4 REGISTER DESCRIPTION (PAGE 1).................................................................................. 77

4.4.1 PAGE ID 0X07 ........................................................................................................................ 77

4.4.2 ACC_CONFIG 0X08 ................................................................................................................ 77

4.4.3 MAG_CONFIG 0X09 ............................................................................................................... 77

4.4.4 GYR_CONFIG_0 0X0A ........................................................................................................... 78

4.4.5 GYR_CONFIG_1 0X0B ........................................................................................................... 78

4.4.6 ACC_SLEEP_CONFIG 0X0C ................................................................................................... 79

4.4.7 GYR_SLEEP_CONFIG 0X0D ................................................................................................... 80

4.4.8 INT_MSK 0X0F ..................................................................................................................... 81

4.4.9 INT_EN 0X10 ........................................................................................................................ 82

4.4.10 ACC_AM_THRES 0X11 ...................................................................................................... 82

4.4.11 ACC_INT_SETTINGS 0X12 ................................................................................................... 83

4.4.12 ACC_HG_DURATION 0X13 ............................................................................................... 83

4.4.13 ACC_HG_THRES 0X14 ...................................................................................................... 83

4.4.14 ACC_NM_THRES 0X15 ...................................................................................................... 84

4.4.15 ACC_NM_SET 0X16 ........................................................................................................... 84

4.4.16 GYR_INT_SETTING 0X17 .................................................................................................. 85

4.4.17 GYR_HR_X_SET 0X18 ....................................................................................................... 85

4.4.18 GYR_DUR_X 0X19 ............................................................................................................. 86

BST-BNO055-DS000-14 | Revision 1.4 | June 2016 Bosch Sensortec

© Bosch Sensortec GmbH reserves all rights even in the event of industrial property rights. We reserve all rights of disposal su ch as copying and passing on

to third parties. BOSCH and the symbol are registered trademarks of Robert Bosch GmbH, Germany.

Note: Specifications within this document are subject to change without notice.

BNO055

Data sheet

Page 8

4.4.19 GYR_HR_Y_SET 0X1A ...................................................................................................... 86

4.4.20 GYR_DUR_Y 0X1B ............................................................................................................. 86

4.4.21 GYR_HR_Z_SET 0X1C ...................................................................................................... 87

4.4.22 GYR_DUR_Z 0X1D ............................................................................................................. 87

4.4.23 GYR_AM_THRES 0X1E ..................................................................................................... 87

4.4.24 GYR_AM_SET 0X1F ........................................................................................................... 88

4.5 DIGITAL INTERFACE ....................................................................................................... 89

4.6 I2C PROTOCOL ............................................................................................................. 90

4.7 UART PROTOCOL ......................................................................................................... 93

4.8 HID OVER I2C .............................................................................................................. 94

5. PIN-OUT AND CONNECTION DIAGRAM ....................................................................... 95

5.1 PIN-OUT ....................................................................................................................... 95

5.2 CONNECTION DIAGRAM I2C ............................................................................................ 97

5.3 CONNECTION DIAGRAM UART ....................................................................................... 98

5.4 CONNECTION DIAGRAM HID-I2C .................................................................................... 99

5.5 XOUT32 & XIN32 CONNECTIONS................................................................................ 100

5.5.1 EXTERNAL 32KHZ CRYSTAL OSCILLATOR ............................................................................... 100

5.5.2 INTERNAL CLOCK MODE ......................................................................................................... 100

6. PACKAGE ..................................................................................................................... 101

6.1 OUTLINE DIMENSIONS.................................................................................................. 101

6.2 MARKING .................................................................................................................... 102

6.3 SOLDERING GUIDELINES ............................................................................................. 102

6.4 HANDLING INSTRUCTIONS ............................................................................................ 102

6.5 TAPE AND REEL SPECIFICATION.................................................................................... 103

6.6 ENVIRONMENTAL SAFETY ............................................................................................ 103

6.6.1 HALOGEN CONTENT............................................................................................................... 103

6.6.2 INTERNAL PACKAGE STRUCTURE ............................................................................................ 103

7. LEGAL DISCLAIMER .................................................................................................... 104

7.1 ENGINEERING SAMPLES............................................................................................... 104

7.2 PRODUCT USE ............................................................................................................ 104

7.3 APPLICATION EXAMPLES AND HINTS ............................................................................. 104

8. DOCUMENT HISTORY AND MODIFICATIONS ............................................................ 105

BST-BNO055-DS000-14 | Revision 1.4 | June 2016 Bosch Sensortec

© Bosch Sensortec GmbH reserves all rights even in the event of industrial property rights. We reserve all rights of disposal su ch as copying and passing on

to third parties. BOSCH and the symbol are registered trademarks of Robert Bosch GmbH, Germany.

Note: Specifications within this document are subject to change without notice.

BNO055

Data sheet

Page 9

Table of Figures

Figure 1: system architecture ...............................................................................................18

Figure 2: Principle of any-motion detection ...........................................................................40

Figure 3: High rate interrupt ..................................................................................................42

Figure 4: Principle of any-motion detection ...........................................................................44

Figure 5: I²C timing diagram .................................................................................................91

Figure 6: I²C write .................................................................................................................92

Figure 7: I²C multiple read ....................................................................................................92

Figure 8: Pin-out bottom view ...............................................................................................95

Figure 9: I2C connection diagram .........................................................................................97

Figure 10: UART connection diagram ...................................................................................98

Figure 11 : HID via IC connection diagram ...........................................................................99

Figure 12 : External 32kHz Crystal Oscillator with Load Capacitor ..................................... 100

Figure 13: Outline dimensions ............................................................................................ 101

BST-BNO055-DS000-14 | Revision 1.4 | June 2016 Bosch Sensortec

© Bosch Sensortec GmbH reserves all rights even in the event of industrial property rights. We reserve all rights of disposal su ch as copying and passing on

to third parties. BOSCH and the symbol are registered trademarks of Robert Bosch GmbH, Germany.

Note: Specifications within this document are subject to change without notice.

BNO055

Data sheet

Page 10

List of Tables

Table 0-1: Electrical parameter specification ........................................................................12

Table 0-2: Electrical characteristics BNO055 ........................................................................13

Table 2-1: Absolute maximum ratings (preliminary target values) .........................................17

Table 3-1: power modes selection ........................................................................................19

Table 3-2: Low power modes - Interrupts .............................................................................19

Table 3-3: Operating modes overview ..................................................................................20

Table 3-4: Default sensor settings ........................................................................................21

Table 3-5: operating modes selection ...................................................................................21

Table 3-6: Operating mode switching time ............................................................................21

Table 3-7: Default sensor configuration at power-on ............................................................26

Table 3-8: Accelerometer configurations ..............................................................................27

Table 3-9: Gyroscope configurations ....................................................................................28

Table 3-10: Magnetometer configurations ...........................................................................29

Table 3-11: unit selection .....................................................................................................30

Table 3-12: Fusion data output format ..................................................................................30

Table 3-13: Rotation angle conventions ...............................................................................30

Table 3-14: Fusion output data rates ....................................................................................31

Table 3-15: Accelerometer Default-Reg settings ..................................................................31

Table 3-16: Accelerometer G-range settings ........................................................................31

Table 3-17: Accelerometer Unit settings ...............................................................................31

Table 3-18: Magnetometer Default-Reg settings ..................................................................32

Table 3-19: Magnetometer Unit settings ...............................................................................32

Table 3-20: Gyroscope Default Reg-settings ........................................................................32

Table 3-21: Gyroscope range settings ..................................................................................33

Table 3-22: Gyroscope unit settings .....................................................................................33

Table 3-23: Radius Default-Reg settings ..............................................................................33

Table 3-24: Radius range settings ........................................................................................33

Table 3-25: Acceleration data ...............................................................................................34

Table 3-26: Magnetic field strength data ...............................................................................34

Table 3-27: Yaw rate data ....................................................................................................34

Table 3-28: Compensated orientation data in Euler angles format........................................35

Table 3-29: Euler angle data representation .........................................................................35

Table 3-30: Compensated orientation data in quaternion format ..........................................35

Table 3-31: Quaternion data representation .........................................................................35

Table 3-32: Linear Acceleration Data ...................................................................................36

Table 3-33: Linear Acceleration data representation ............................................................36

Table 3-34: Gravity Vector Data ...........................................................................................36

Table 3-35: Gravity Vector data representation ....................................................................36

Table 3-36: Temperature Data .............................................................................................37

Table 3-37: Temperature data representation ......................................................................37

Table 3-38: Temperature Source Selection ..........................................................................37

Table 3-39: No-motion time-out periods................................................................................39

Table 3-40: Timing of No-motion interrupt ............................................................................39

Table 3-41: Any-motion Interrupt parameters and Axis selection ..........................................41

Table 3-42: High-G Interrupt parameters and Axis selection.................................................41

Table 3-43: High Rate Interrupt parameters and Axis selection ............................................43

Table 3-44: Axis selection and any motion interrupt .............................................................45

Table 3-45: Power on Self Test ............................................................................................46

Table 3-46: Power on Self Test ............................................................................................46

Table 4-1: Register Access Coding ......................................................................................50

Table 4-2: Register Map Page 0 ...........................................................................................50

BST-BNO055-DS000-14 | Revision 1.4 | June 2016 Bosch Sensortec

© Bosch Sensortec GmbH reserves all rights even in the event of industrial property rights. We reserve all rights of disposal su ch as copying and passing on

to third parties. BOSCH and the symbol are registered trademarks of Robert Bosch GmbH, Germany.

Note: Specifications within this document are subject to change without notice.

BNO055

Data sheet

Page 11

Table4-3: Register Map Page 1 ............................................................................................53

Table 4-4: protocol select pin mapping .................................................................................89

Table 4-5: Mapping of digital interface pins ..........................................................................89

Table 4-6: Electrical specification of the interface pins ..........................................................89

Table 4-7: I2C address selection ..........................................................................................90

Table 4-8: I²C timings ...........................................................................................................90

Table 5-1: Pin description .....................................................................................................96

Table 5-2: Crystal Oscillator Source Connections ............................................................... 100

Table 6-1: Marking of mass production parts ...................................................................... 102

BST-BNO055-DS000-14 | Revision 1.4 | June 2016 Bosch Sensortec

© Bosch Sensortec GmbH reserves all rights even in the event of industrial property rights. We reserve all rights of disposal su ch as copying and passing on

to third parties. BOSCH and the symbol are registered trademarks of Robert Bosch GmbH, Germany.

Note: Specifications within this document are subject to change without notice.

BNO055

Data sheet

Page 12

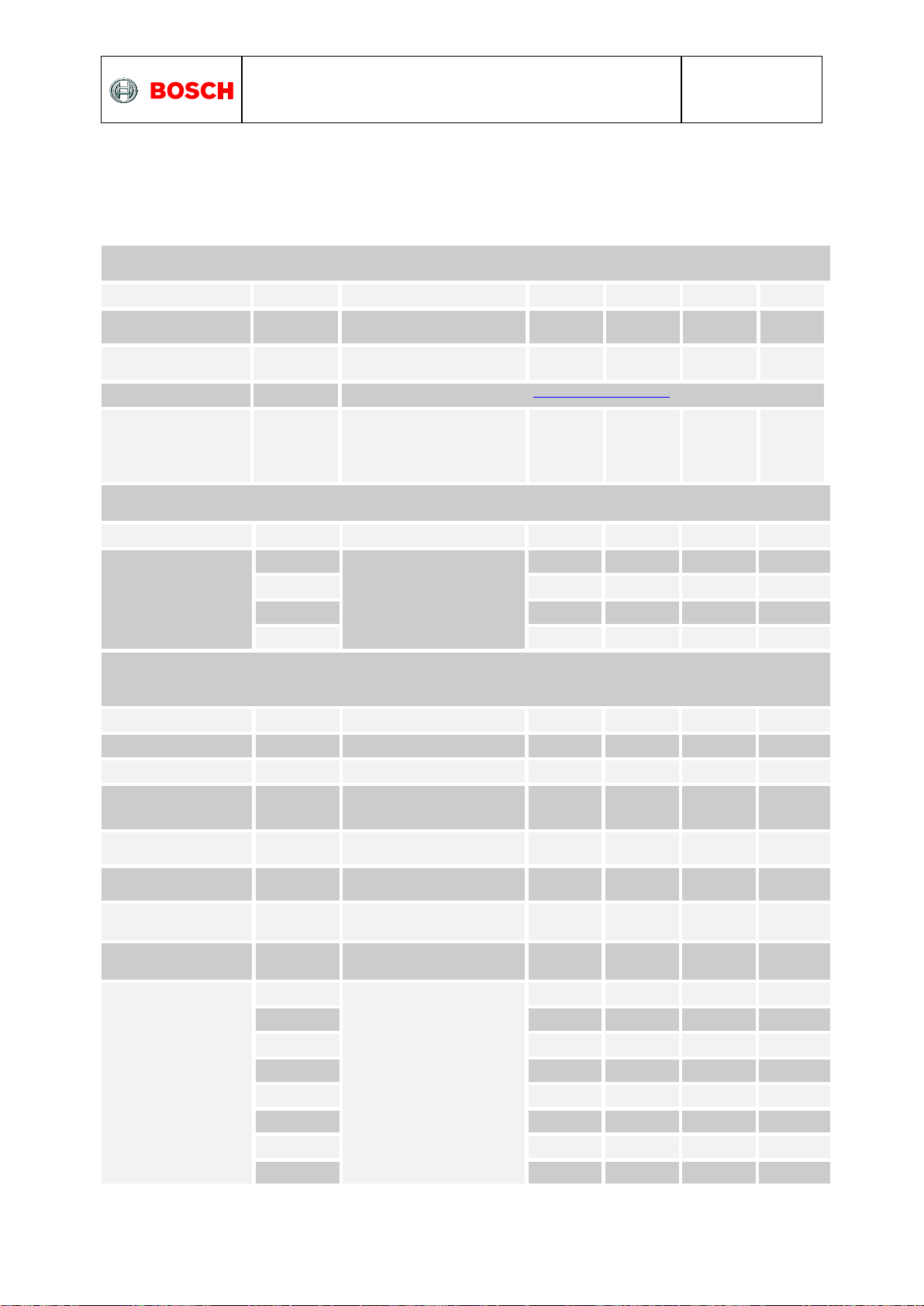

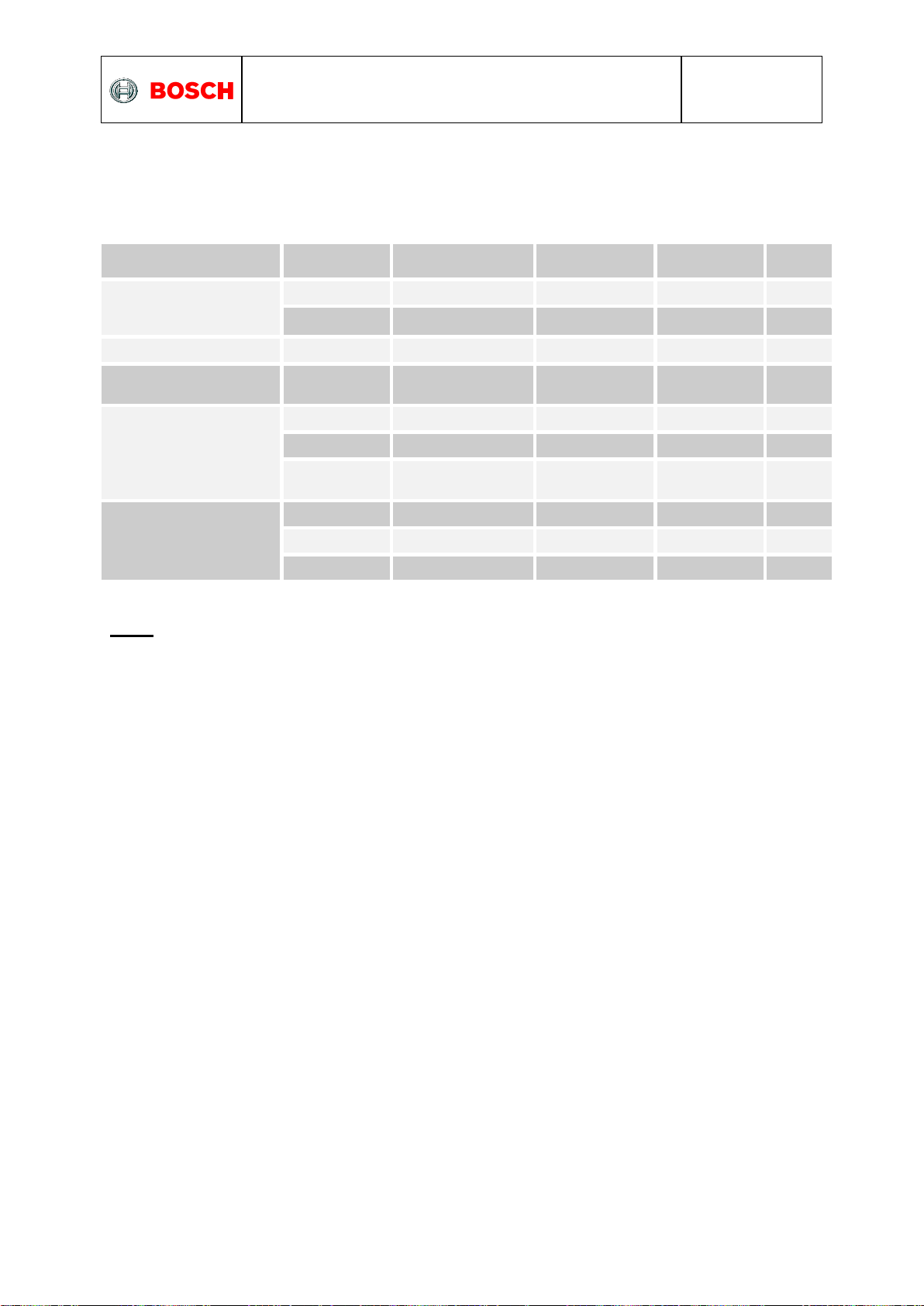

OPERATING CONDITIONS BNO055

Parameter

Symbol

Condition

Min

Typ

Max

Unit

Supply Voltage

(only Sensors)

VDD

--

2.4

--

3.6

V

Supply Voltage

(µC and I/O Domain)

V

DDIO

--

1.7

--

3.6

V

Voltage Input

Low Level (UART, I2C)

V

DDIO_VIL

V

DDIO

= 1.7-2.7V

--

--

0.25 V

DDIO

V

V

DDIO

= 2.7-3.6V

--

--

0.3 V

DDIO

V

Voltage Input

High Level (UART, I2C)

V

DDIO_VIH

V

DDIO

= 1.7-2.7V

0.7 V

DDIO

--

--

V

V

DDIO

= 2.7-3.6V

0.55 V

DDIO

--

--

V

Voltage Output

Low Level (UART, I2C)

V

DDIO_VOL

V

DDIO

> 3V , I

OL

=20mA

--

0.1 V

DDIO

0.2 V

DDIO

V

Voltage Output

High Level (UART, I2C)

V

DDIO_VOH

V

DDIO

> 3V , I

OH

=10mA

0.8 V

DDIO

0.9 V

DDIO

-- V POR Voltage threshold

on VDDIO-IN rising

V

DDIO_POT+

V

DDIO

falls at 1V/ms or slower

--

1.45

-- V POR Voltage threshold

on VDDIO-IN falling

V

DDIO_POT-

--

0.99

--

V

Operating Temperature

TA

--

-40

--

+85

°C

Total supply current

normal mode at TA

(9DOF @100Hz output

data rate)

I

DD

+ I

DDIO

VDD = 3V, V

DDIO

= 2.5V

--

--

12.3

mA

Total supply current

Low power mode at TA

I

DD_LPM

VDD = 3V, V

DDIO

= 2.5V

0.33

2.72# mA

Total supply current

suspend mode at TA

I

DD_SuM

VDD = 3V, V

DDIO

= 2.5V

--

--

0.04*

mA

Specification

If not stated otherwise, the given values are over lifetime and full performance temperature

and voltage ranges, minimum/maximum values are ±3 sigma.

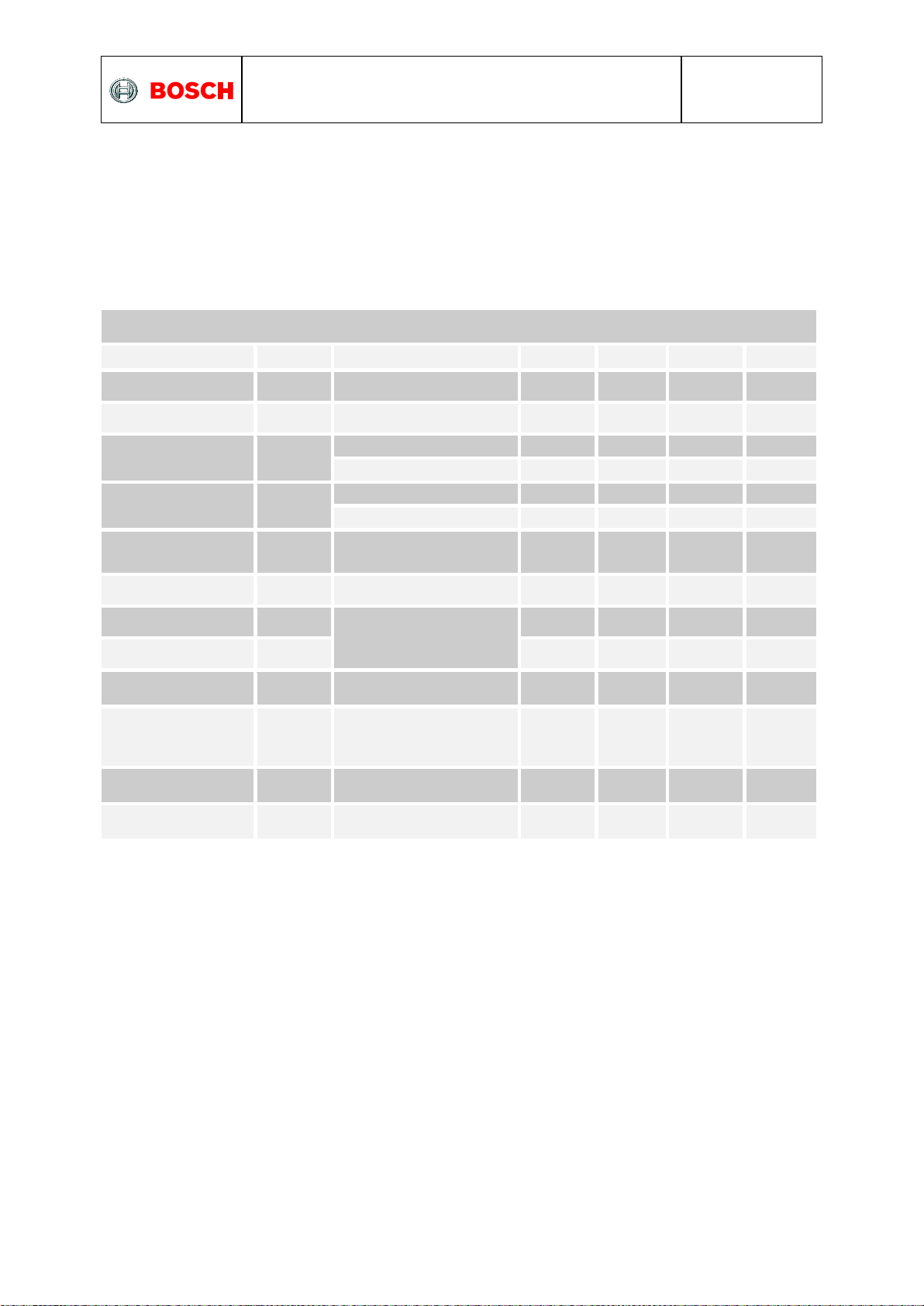

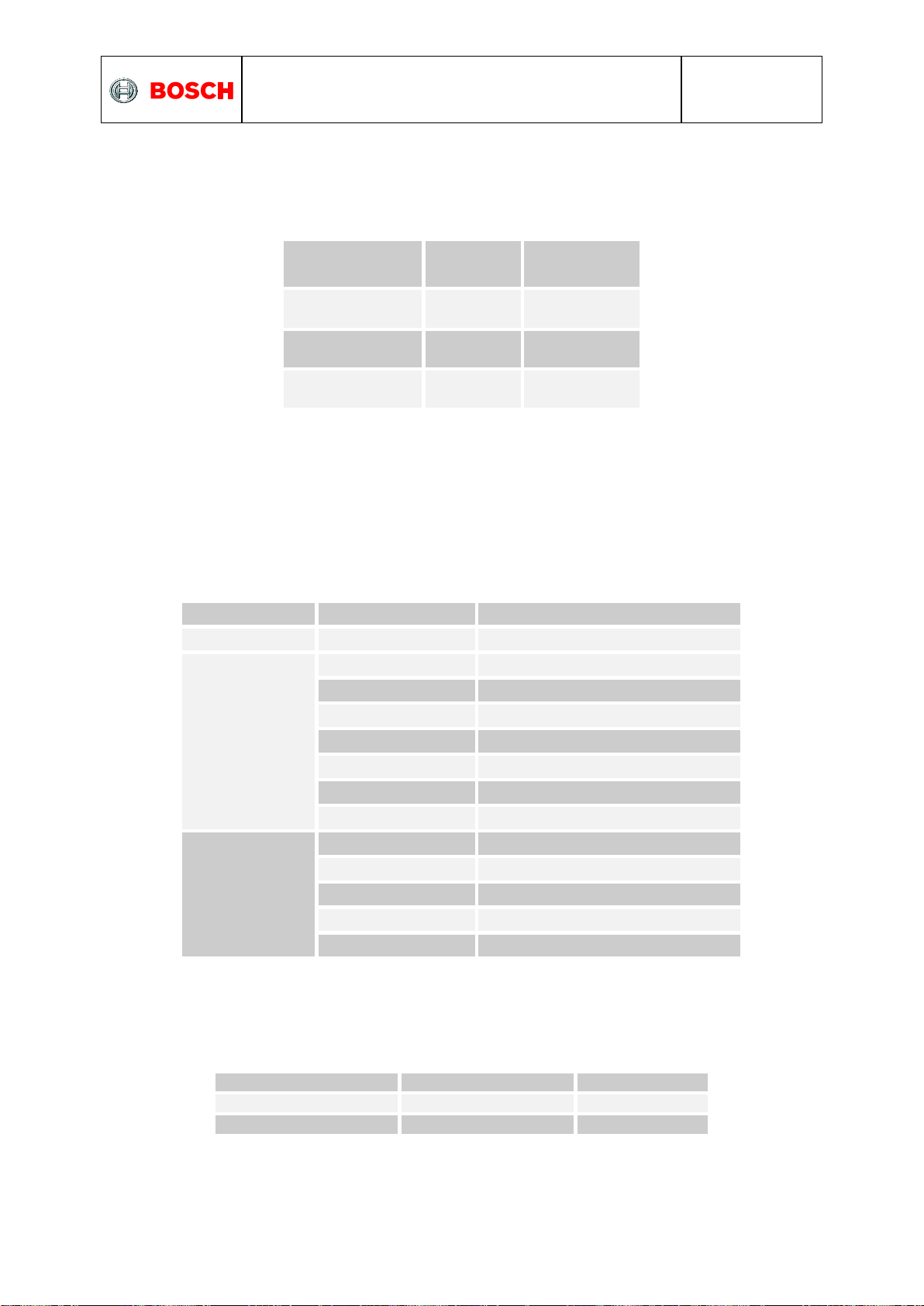

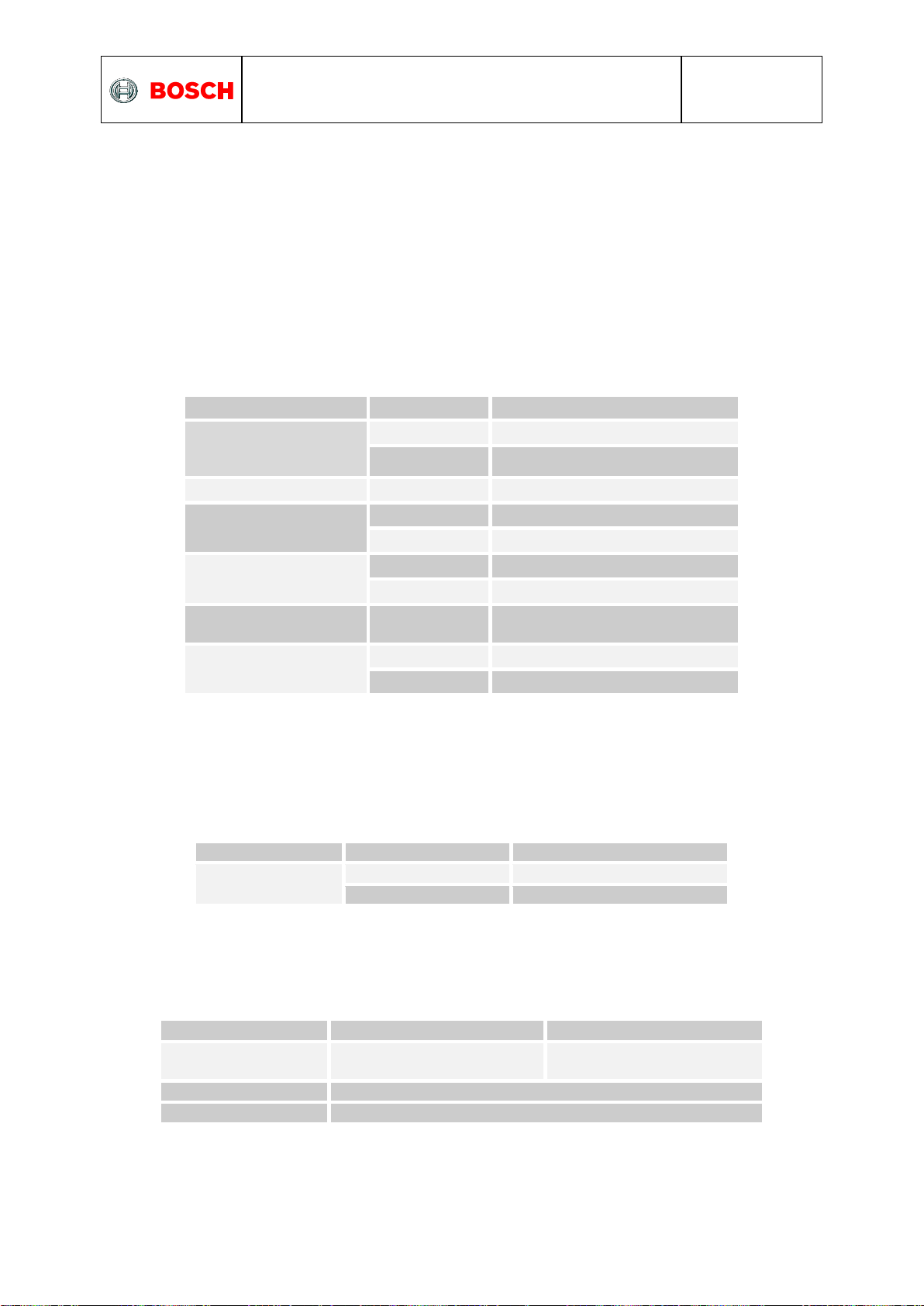

1.1 Electrical specification

Table 0-1: Electrical parameter specification

# 80% suspend mode and 20% normal mode with 9DOF @100Hz output data rate

* using I2C as communication protocol

BST-BNO055-DS000-14 | Revision 1.4 | June 2016 Bosch Sensortec

© Bosch Sensortec GmbH reserves all rights even in the event of industrial property rights. We reserve all rights of disposal su ch as copying and passing on

to third parties. BOSCH and the symbol are registered trademarks of Robert Bosch GmbH, Germany.

Note: Specifications within this document are subject to change without notice.

BNO055

Data sheet

Page 13

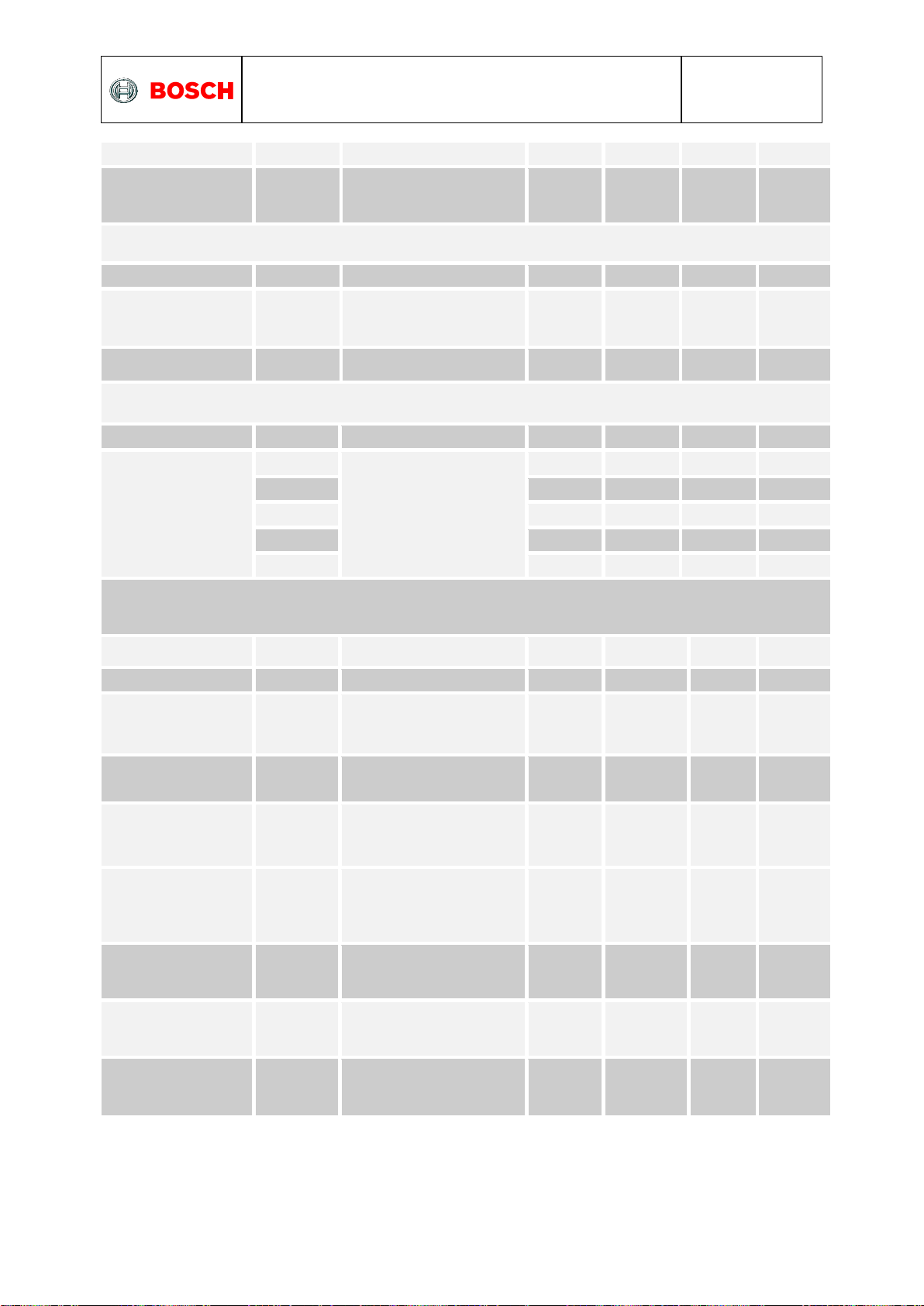

OPERATING CONDITIONS BNO055

Parameter

Symbol

Condition

Min

Typ

Max

Unit

Start-Up time

T

Sup

From Off to configuration

mode

400 ms

POR time

T

POR

From Reset to Config mode

650 ms

Data Rate

DR

s. Par. Fusion Output data rates

Data rate tolerance

9DOF @100Hz output

data rate

(if internal oscillator is

used)

DR

tol

±1 %

OPERATING CONDITIONS ACCELEROMETER

Parameter

Symbol

Condition

Min

Typ

Max

Units

Acceleration Range

g

FS2g

Selectable

via serial digital interface

±2 g

g

FS4g

±4 g

g

FS8g

±8 g

g

FS16g

±16 g

OUTPUT SIGNAL ACCELEROMETER

(ACCELEROMETER ONLY MODE)

Parameter

Symbol

Condition

Min

Typ

Max

Units

Sensitivity

S

All g

FSXg

Values, TA=25°C

1

LSB/mg

Sensitivity tolerance

S

tol

Ta=25°C, g

FS2g

±1

±4

%

Sensitivity Temperature

Drift

TCS

g

FS2g

,

Nominal VDD supplies,

Temp operating conditions

±0.03

%/K

Sensitivity

Supply Volt. Drift

S

VDD

g

FS2g

, TA=25°C,

V

DD_min

≤ VDD ≤ V

DD_max

0.065

0.2

%/V

Zero-g Offset (x,y.z)

Off

xyz

g

FS2g

, TA=25°C, nominal VDD

supplies, over life-time

-150

±80

+150

mg

Zero-g Offset

Temperature Drift

TCO

g

FS2g

,

Nominal VDD supplies

±1

+/-3.5

mg/K

Zero-g Offset Supply

Volt. Drift

Off

VDD

g

FS2g

, TA=25°C,

V

DD_min

≤ VDD ≤ V

DD_max

1.5

2.5

mg/V

Bandwidth

bw

8

2nd order filter, bandwidth

programmable

8

Hz

bw16 16 Hz

bw31 31 Hz

bw63 63 Hz

bw

125

125 Hz

bw

250

250 Hz

bw

500

500 Hz

bw

1000

1,000 Hz

1.2 Electrical and physical characteristics, measurement performance

Table 0-2: Electrical characteristics BNO055

BST-BNO055-DS000-14 | Revision 1.4 | June 2016 Bosch Sensortec

© Bosch Sensortec GmbH reserves all rights even in the event of industrial property rights. We reserve all rights of disposal su ch as copying and passing on

to third parties. BOSCH and the symbol are registered trademarks of Robert Bosch GmbH, Germany.

Note: Specifications within this document are subject to change without notice.

BNO055

Data sheet

Page 14

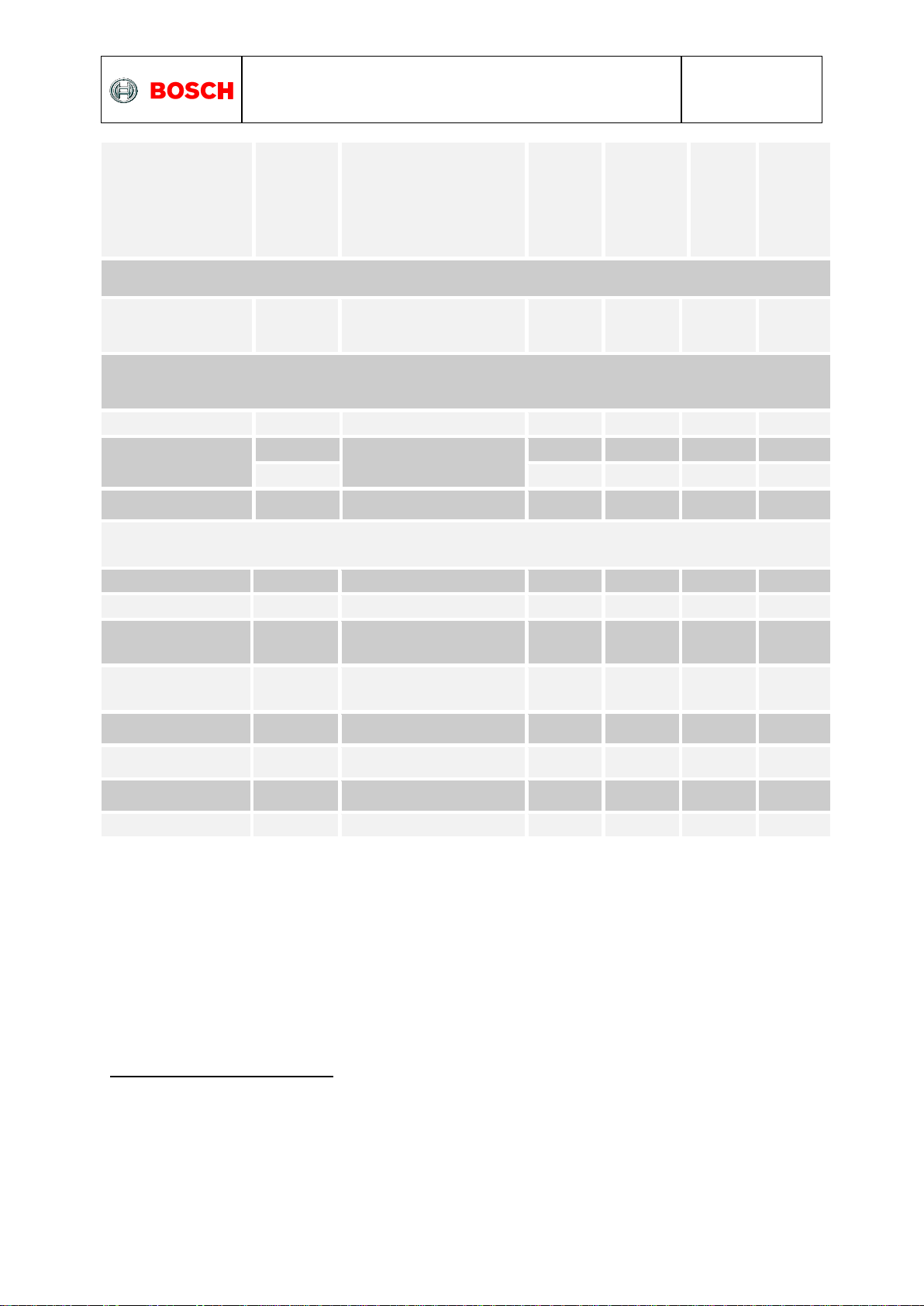

Nonlinearity

NL

best fit straight line, g

FS2g

0.5 2 %FS

Output Noise Density

n

rms

g

FS2g

, TA=25°C

Nominal VDD supplies

Normal mode

150

190

µg/Hz

MECHANICAL CHARACTERISTICS ACCELEROMETER

Parameter

Symbol

Condition

Min

Typ

Max

Units

Cross Axis Sensitivity

CAS

relative contribution between

any two of the three axes

1 2

%

Alignment Error

EA relative to package outline

0.5 2 °

OPERATING CONDITIONS GYROSCOPE

Parameter

Symbol

Condition

Min

Typ

Max

Unit

Rate Range

R

FS125

Selectable

via serial digital interface

125 °/s

R

FS250

250 °/s

R

FS500

500 °/s

R

FS1000

1,000 °/s

R

FS2000

2,000 °/s

OUTPUT SIGNAL GYROSCOPE

(GYRO ONLY MODE)

Sensitivity via register

Map

S

Ta=25°C

16.0

900

LSB/°/s

rad/s

Sensitivity tolerance

S

tol

Ta=25°C, R

FS2000

--

±1

±3

%

Sensitivity Change over

Temperature

TCS

Nominal VDD supplies -40°C

≤ TA ≤ +85°C R

FS2000

±0.03

±0.07

%/K

Sensitivity

Supply Volt. Drift

S

VDD

TA=25°C,

V

DD_min

≤ VDD ≤ V

DD_max

<0.4

%/V

Nonlinearity

NL

best fit straight line

R

FS1000, RFS2000

±0.05

±0.2

%FS

Zero-rate Offset

Off x

y and

z

Nominal VDD supplies

TA=25°C,

Slow and fast offset

cancellation off

-3

±1

+3

°/s

Zero- Offset Change

over Temperature

TCO

Nominal VDD supplies -40°C

≤ TA ≤ +85°C R

FS2000

±0.015

±0.03

°/s per K

Zero- Offset Supply

Volt. Drift

Off

VDD

TA=25°C,

V

DD_min

≤ VDD ≤ V

DD_max

0.1

°/s /V

Output Noise

n

rms

rms, BW=47Hz

(@ 0.014°/s/√Hz)

0.1

0.3

°/s

BST-BNO055-DS000-14 | Revision 1.4 | June 2016 Bosch Sensortec

© Bosch Sensortec GmbH reserves all rights even in the event of industrial property rights. We reserve all rights of disposal su ch as copying and passing on

to third parties. BOSCH and the symbol are registered trademarks of Robert Bosch GmbH, Germany.

Note: Specifications within this document are subject to change without notice.

BNO055

Data sheet

Page 15

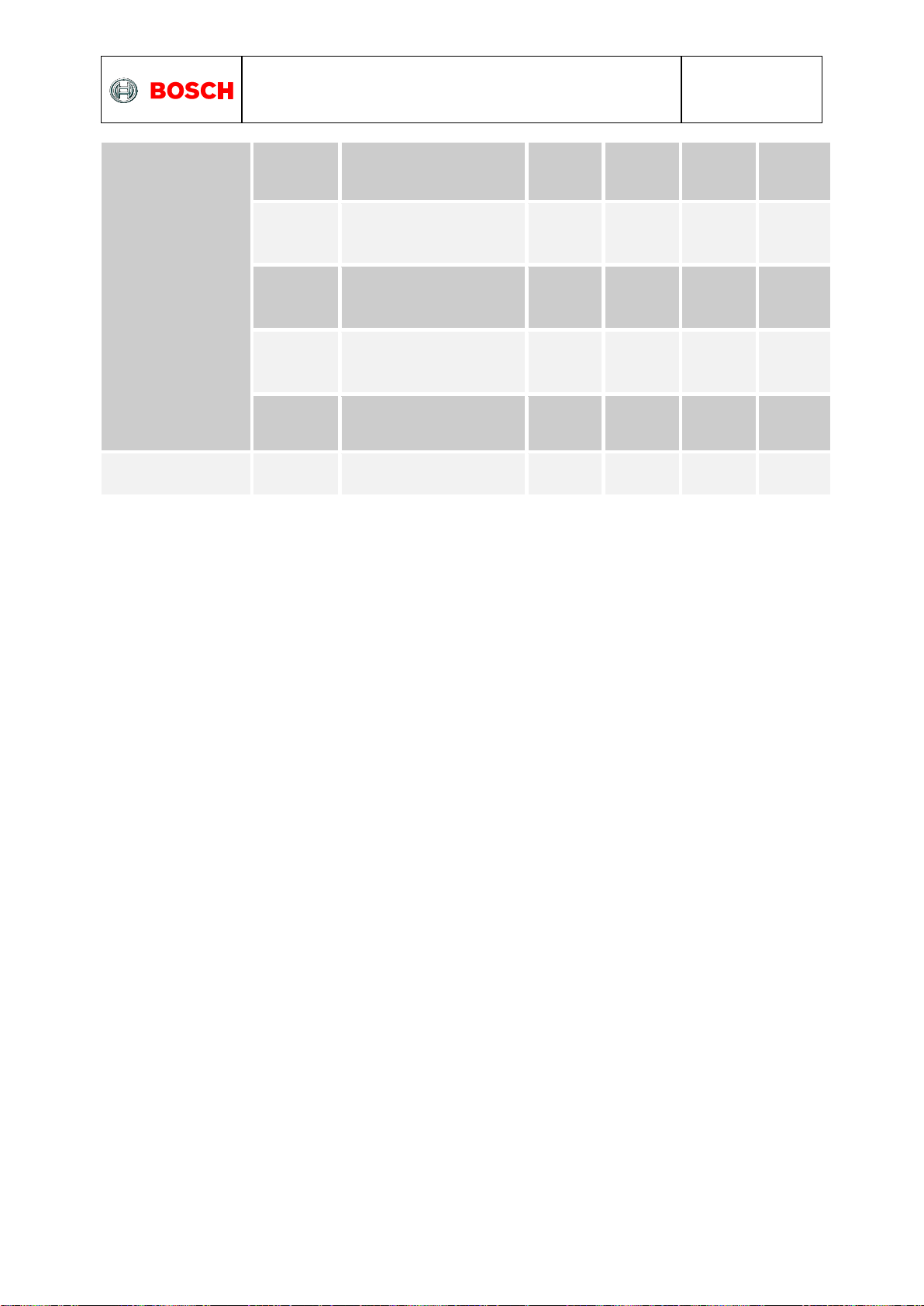

Bandwidth BW

f

-3dB

523

230

116

64

47

32

23

12

Hz

MECHANICAL CHARACTERISTICS GYROSCOPE

Cross Axis Sensitivity

CAS

Sensitivity to stimuli in

non-sense-direction

±1

±3

%

OPERATING CONDITIONS MAGNETOMETER

(MAGNETOMETER ONLY MODE)

Parameter

Symbol

Condition

Min

Typ

Max

Units

Magnetic field range1

Brg,xy

TA=25°C

±1200

±1300 µT

Brg,z

±2000

±2500 µT

Magnetometer heading

accuracy2

As heading

30µT horizontal geomagnetic

field component, TA=25°C

±2.5

deg

MAGNETOMETER OUTPUT SIGNAL

Parameter

Symbol

Condition

Min

Typ

Max

Unit

Device Resolution

D

res,m

TA=25°C

0.3 µT

Gain error3

G

err,m

After API compensation

TA=25°C

Nominal VDD supplies

±5

±8

%

Sensitivity Temperature

Drift

TCSm

After API compensation

-40°C ≤ TA ≤ +85°C

Nominal VDD supplies

±0.01

±0.03

%/K

Zero-B offset

OFFm TA=25°C

±40 µT

Zero-B offset4

OFF

m,cal

After calibration in fusion mode

-40°C ≤ TA ≤ +85°C

±2 µT

Zero-B offset

Temperature Drift

TCOm

-40°C TA +85°C

±0.23

±0.37

µT/K

Full-scale Nonlinearity

NL

m, FS

best fit straight line

1

%FS

1

2

3

4

Full linear measurement range considering sensor offsets.

The heading accuracy depends on hardware and software. A fully calibrated sensor and ideal tilt

compensation are assumed.

Definition: gain error = ( (measured field after API compensation) / (applied field) ) – 1

Magnetic zero-B offset assuming calibration in fusion mode. Typical value after applying calibration

movements containing various device orientations (typical device usage).

BST-BNO055-DS000-14 | Revision 1.4 | June 2016 Bosch Sensortec

© Bosch Sensortec GmbH reserves all rights even in the event of industrial property rights. We reserve all rights of disposal su ch as copying and passing on

to third parties. BOSCH and the symbol are registered trademarks of Robert Bosch GmbH, Germany.

Note: Specifications within this document are subject to change without notice.

BNO055

Data sheet

Page 16

Output Noise

n

rms,lp,m,xy

Low power preset

x, y-axis, TA=25°C

Nominal VDD supplies

1.0 µT

n

rms,lp,m,z

Low power preset

z-axis, TA=25°C

Nominal VDD supplies

1.4 µT

n

rms,rg,m

Regular preset

TA=25°C

Nominal VDD supplies

0.6 µT

n

rms,eh,m

Enhanced regular preset

TA=25°C

Nominal VDD supplies

0.5 µT

n

rms,ha,m

High accuracy preset

TA=25°C

Nominal VDD supplies

0.3 µT

Power Supply Rejection

Rate

PSRRm

TA=25°C

Nominal VDD supplies

±0.5

µT/V

BST-BNO055-DS000-14 | Revision 1.4 | June 2016 Bosch Sensortec

© Bosch Sensortec GmbH reserves all rights even in the event of industrial property rights. We reserve all rights of disposal su ch as copying and passing on

to third parties. BOSCH and the symbol are registered trademarks of Robert Bosch GmbH, Germany.

Note: Specifications within this document are subject to change without notice.

BNO055

Data sheet

Page 17

Parameter

Symbol

Condition

Min

Max

Units

Voltage at Supply Pin

VDD Pin -0.3

4.2

V

V

DDIO

Pin

-0.3

3.6

V

Voltage at any Logic Pin

V

non-supply

Pin

-0.3

V

DDIO

+0.3

V

Passive Storage Temp.

Range

Trps

≤ 65% rel. H.

-50

+150

°C

Mechanical Shock

MechShock

200µs

Duration ≤ 200µs

10,000

g

MechShock

1ms

Duration ≤ 1.0ms

2,000

g

MechShock

freefall

Free fall

onto hard surfaces

1.8

m

ESD

ESD

HBM

HBM, at any Pin

2

kV

ESD

CDM

CDM

500

V

ESDMM

MM

200

V

2. Absolute Maximum Ratings

Table 2-1: Absolute maximum ratings (preliminary target values)

Note:

Stress above these limits may cause damage to the device. Exceeding the specified

electrical limits may affect the device reliability or cause malfunction.

BST-BNO055-DS000-14 | Revision 1.4 | June 2016 Bosch Sensortec

© Bosch Sensortec GmbH reserves all rights even in the event of industrial property rights. We reserve all rights of disposal su ch as copying and passing on

to third parties. BOSCH and the symbol are registered trademarks of Robert Bosch GmbH, Germany.

Note: Specifications within this document are subject to change without notice.

BNO055

Data sheet

Page 18

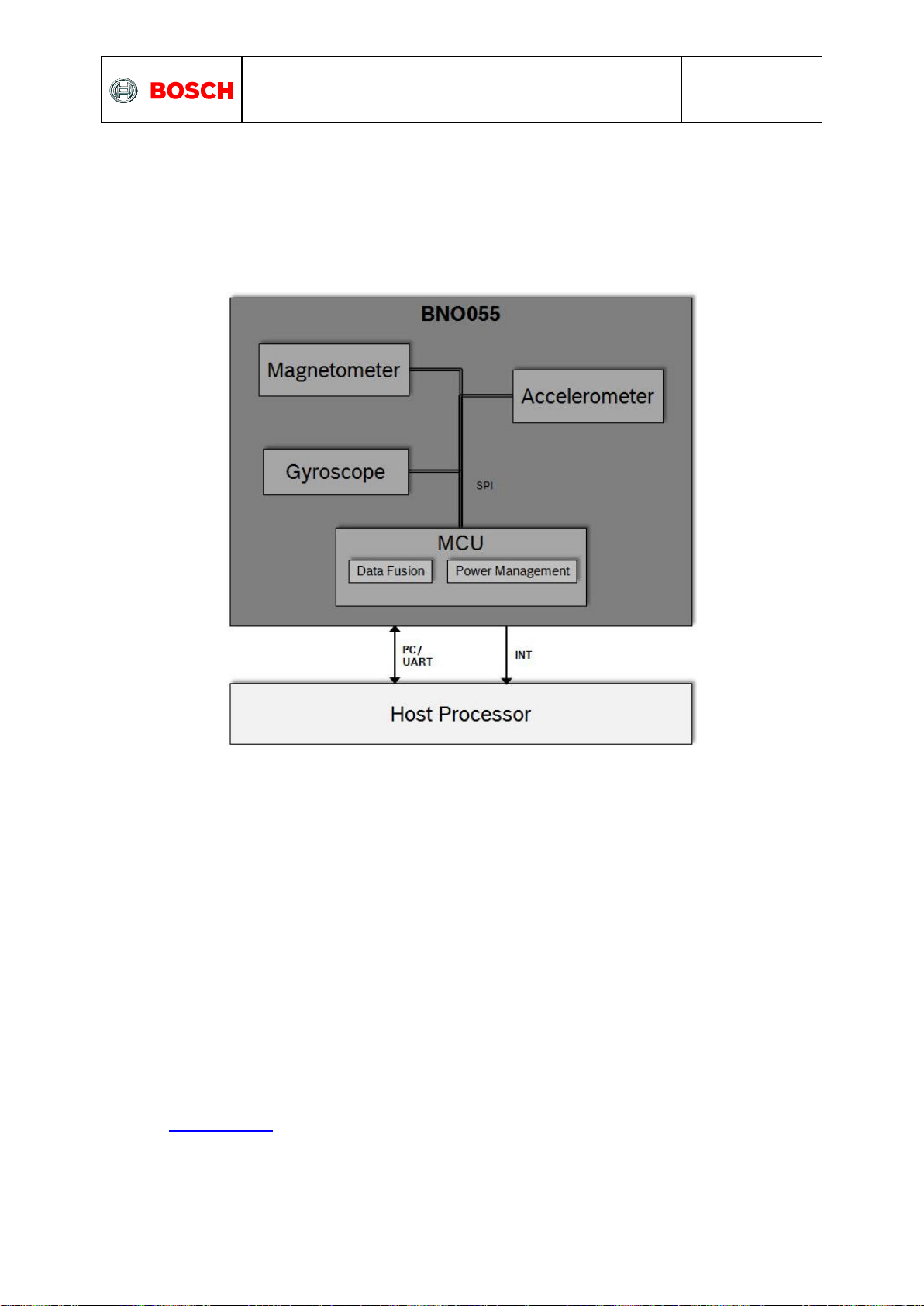

3. Functional Description

3.1 Architecture

The following figure shows the basic building blocks of the BNO055 device.

Figure 1: system architecture

3.2 Power management

The BNO055 has two distinct power supply pins:

• VDD is the main power supply for the internal sensors

• V

For the switching sequence of power supply VDD and VDDIO it is mandatory that VDD is powered

on and driven to the specified level before or at the same time as VDDIO is powered ON.

Otherwise there are no limitations on the voltage levels of both pins relative to each other, as

long as they are used within the specified operating range.

The sensor features a power-on reset (POR), initializing the register map with the default

values and starting in CONFIG mode. The POR is executed at every power on and can also

be triggered either by applying a low signal to the nRESET pin for at least 20ns or by setting

the RST_SYS bit in the SYS_TRIGGER register.

The BNO055 can be configured to run in one of the following power modes: normal mode,

low power mode, and suspend mode. These power modes are described in more detail in

section Power Modes

is a separate power supply pin used for the supply of the µC and the digital interfaces

DDIO

BST-BNO055-DS000-14 | Revision 1.4 | June 2016 Bosch Sensortec

© Bosch Sensortec GmbH reserves all rights even in the event of industrial property rights. We reserve all rights of disposal su ch as copying and passing on

to third parties. BOSCH and the symbol are registered trademarks of Robert Bosch GmbH, Germany.

Note: Specifications within this document are subject to change without notice.

BNO055

Data sheet

Page 19

Parameter

Value

[Reg Addr]: Reg Value

Power Mode

Normal Mode

[PWR_MODE]: xxxxxx00b

Low Power Mode

[PWR_MODE]: xxxxxx01b

Suspend Mode

[PWR_MODE]: xxxxxx10b

Description

Parameter

Value

Reg Value

Restriction

Entering to

sleep:

NO Motion

Interrupt

Detection

Type

No Motion

[ACC_NM_SET] : xxxxxxx1b

n/a

Detection Axis

[ACC_INT_Settings] : bit4-bit2

Shares common

bit with Any Motion

interrupt axis

selection

Params

Duration

[ACC_NM_SET] : bit6-bit1

n/a

Threshold

[ACC_NM_THRE] : bit7-bit0

n/a

Description

Parameter

Value

Reg Value

Waking up: Any

Motion Interrupt

Detection Type

Detection Axis

[ACC_INT_Settings] : bit4-bit2

Params

Duration

[ACC_INT_Settings] : bit1-bit0

Threshold

[ACC_AM_THRES] : bit7-bit0

Power Modes

The BNO055 support three different power modes: Normal mode, Low Power Mode, and

Suspend mode.

The power mode can be selected by writing to the PWR_MODE register as defined in the

table below. As default at start-up the BNO055 will run in Normal mode.

Table 3-1: power modes selection

3.2.1 Normal Mode

In normal mode all sensors required for the selected operating mode (see section 3.3) are

always switched ON. The register map and the internal peripherals of the MCU are always

operative in this mode.

3.2.2 Low Power Mode

If no activity (i.e. no motion) is detected for a configurable duration (default 5 seconds), the

BNO055 enters the low power mode. In this mode only the accelerometer is active. Once

motion is detected (i.e. the accelerometer signals an any-motion interrupt), the system is

woken up and normal mode is entered. The following settings are possible.

Table 3-2: Low power modes - Interrupts

Additionally, the interrupt pins can also be configured to provide HW interrupt to the host.

The BNO055 is by default configured to have optimum values for entering into sleep and

waking up. To restore these values, trigger system reset by setting RST_SYS bit in

SYS_TRIGGER register.

There are some limitations to achieve the low power mode performance:

Only No and Any motion interrupts are applicable and High-G and slow motion

interrupts are not applicable in low power mode.

Low power mode is not applicable where accelerometer is not employed.

BST-BNO055-DS000-14 | Revision 1.4 | June 2016 Bosch Sensortec

© Bosch Sensortec GmbH reserves all rights even in the event of industrial property rights. We reserve all rights of disposal su ch as copying and passing on

to third parties. BOSCH and the symbol are registered trademarks of Robert Bosch GmbH, Germany.

Note: Specifications within this document are subject to change without notice.

BNO055

Data sheet

Page 20

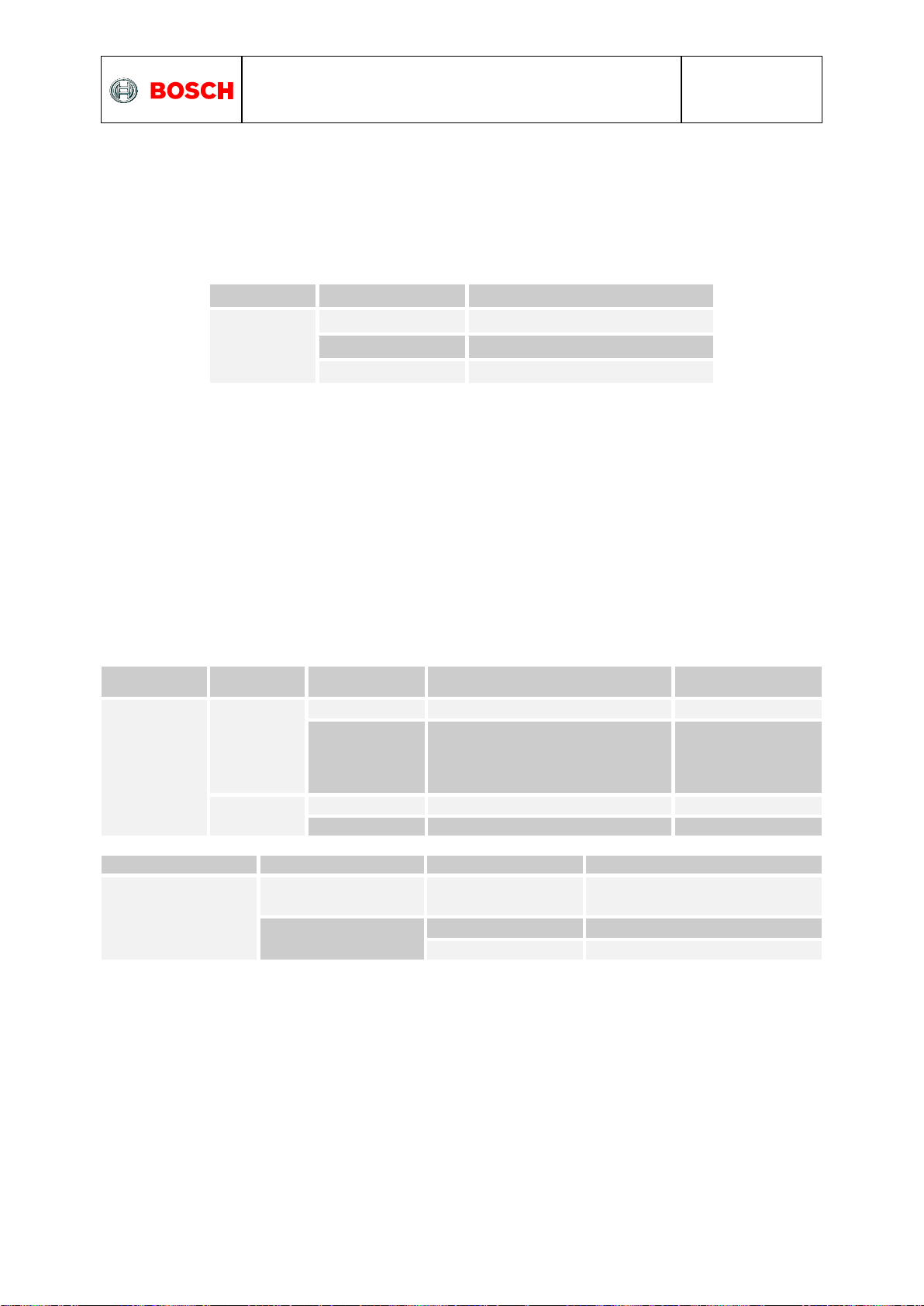

Operating Mode

Available sensor signals

Fusion Data

Accel

Mag

Gyro

Relative

orientation

Absolute

orientation

CONFIGMODE

- - - - -

Non

-fusion

modes

ACCONLY

X - - - -

MAGONLY

- X - - -

GYROONLY

- - X - -

ACCMAG

X X - - -

ACCGYRO

X - X - -

MAGGYRO

- X X - AMG

X X X - -

Fusion modes

IMU

X - X X -

COMPASS

X X - - X

M4G

X X X -

NDOF_FMC_OFF

X X X - X

NDOF

X X X - X

3.2.3 Suspend Mode

In suspend mode the system is paused and all the sensors and the microcontroller are put

into sleep mode. No values in the register map will be updated in this mode. To exit from

suspend mode the mode should be changed by writing to the PWR_MODE register (see

Table 3-1).

3.3 Operation Modes

The BNO055 provides a variety of output signals, which can be chosen by selecting the

appropriate operation mode. The table below lists the different modes and the available

sensor signals.

Table 3-3: Operating modes overview

The default operation mode after power-on is CONFIGMODE.

When the user changes to another operation mode, the sensors which are required in that

particular sensor mode are powered, while the sensors whose signals are not required are

set to suspend mode.

BST-BNO055-DS000-14 | Revision 1.4 | June 2016 Bosch Sensortec

© Bosch Sensortec GmbH reserves all rights even in the event of industrial property rights. We reserve all rights of disposal su ch as copying and passing on

to third parties. BOSCH and the symbol are registered trademarks of Robert Bosch GmbH, Germany.

Note: Specifications within this document are subject to change without notice.

BNO055

Data sheet

Page 21

Sensor

Range

Bandwidth

Accelerometer

4G

62.5 Hz

Magnetometer

NA

10 Hz

Gyroscope

2000 dps

32 Hz

Parameter

Value

[Reg Addr]: Reg Value

CONFIG MODE

CONFIGMODE

[OPR_MODE]: xxxx0000b

Non-Fusion

Mode

ACCONLY

[OPR_MODE]: xxxx0001b

MAGONLY

[OPR_MODE]: xxxx0010b

GYROONLY

[OPR_MODE]: xxxx0011b

ACCMAG

[OPR_MODE]: xxxx0100b

ACCGYRO

[OPR_MODE]: xxxx0101b

MAGGYRO

[OPR_MODE]: xxxx0110b

AMG

[OPR_MODE]: xxxx0111b

Fusion Mode

IMU

[OPR_MODE]: xxxx1000b

COMPASS

[OPR_MODE]: xxxx1001b

M4G

[OPR_MODE]: xxxx1010b

NDOF_FMC_OFF

[OPR_MODE]: xxxx1011b

NDOF

[OPR_MODE]: xxxx1100b

From

To

Switching time

CONFIGMODE

Any operation mode

7ms

Any operation mode

CONFIGMODE

19ms

The BNO055 sets the following default settings for the sensors. The user can overwrite these

settings in the register map when in CONFIGMODE.

Table 3-4: Default sensor settings

In any mode, the sensor data are available in the data register based on the unit selected.

The axis of the data is configured based on the axis-remap register configuration.

The operating mode can be selected by writing to the OPR_MODE register, possible register

values and the corresponding operating modes are shown in the table below.

Table 3-5: operating modes selection

Table 3-6 below shows the time required to switch between CONFIGMODE and the other

operating modes.

Table 3-6: Operating mode switching time

BST-BNO055-DS000-14 | Revision 1.4 | June 2016 Bosch Sensortec

© Bosch Sensortec GmbH reserves all rights even in the event of industrial property rights. We reserve all rights of disposal su ch as copying and passing on

to third parties. BOSCH and the symbol are registered trademarks of Robert Bosch GmbH, Germany.

Note: Specifications within this document are subject to change without notice.

BNO055

Data sheet

Page 22

3.3.1 Config Mode

This mode is used to configure BNO, wherein all output data is reset to zero and sensor

fusion is halted. This is the only mode in which all the writable register map entries can be

changed. (Exceptions from this rule are the interrupt registers (INT and INT_MSK) and the

operation mode register (OPR_MODE), which can be modified in any operation mode.)

As being said, this mode is the default operation mode after power-on or RESET. Any other

mode must be chosen to be able to read any sensor data.

3.3.2 Non-Fusion Modes

3.3.2.1 ACCONLY

If the application requires only raw accelerometer data, this mode can be chosen. In this

mode the other sensors (magnetometer, gyro) are suspended to lower the power

consumption. In this mode, the BNO055 behaves like a stand-alone acceleration sensor.

3.3.2.1 MAGONLY

In MAGONLY mode, the BNO055 behaves like a stand-alone magnetometer, with

acceleration sensor and gyroscope being suspended.

3.3.2.2 GYROONLY

In GYROONLY mode, the BNO055 behaves like a stand-alone gyroscope, with acceleration

sensor and magnetometer being suspended.

3.3.2.3 ACCMAG

Both accelerometer and magnetometer are switched on, the user can read the data from

these two sensors.

3.3.2.4 ACCGYRO

Both accelerometer and gyroscope are switched on; the user can read the data from these

two sensors.

3.3.2.5 MAGGYRO

Both magnetometer and gyroscope are switched on, the user can read the data from these

two sensors.

3.3.2.6 AMG (ACC-MAG-GYRO)

All three sensors accelerometer, magnetometer and gyroscope are switched on.

3.3.3 Fusion modes

Sensor fusion modes are meant to calculate measures describing the orientation of the

device in space. It can be distinguished between non-absolute or relative orientation and

absolute orientation. Absolute orientation means orientation of the sensor with respect to the

earth and its magnetic field. In other words, absolute orientation sensor fusion modes

calculate the direction of the magnetic north pole.

In non-absolute or relative orientation modes, the heading of the sensor can vary depending

on how the sensor is placed initially.

All fusion modes provide the heading of the sensor as quaternion data or in Euler angles

(roll, pitch and yaw angle). The acceleration sensor is both exposed to the gravity force and

to accelerations applied to the sensor due to movement. In fusion modes it is possible to

separate the two acceleration sources, and thus the sensor fusion data provides separately

linear acceleration (i.e. acceleration that is applied due to movement) and the gravity vector.

BST-BNO055-DS000-14 | Revision 1.4 | June 2016 Bosch Sensortec

© Bosch Sensortec GmbH reserves all rights even in the event of industrial property rights. We reserve all rights of disposal su ch as copying and passing on

to third parties. BOSCH and the symbol are registered trademarks of Robert Bosch GmbH, Germany.

Note: Specifications within this document are subject to change without notice.

BNO055

Data sheet

Page 23

3.3.3.1 IMU (Inertial Measurement Unit)

In the IMU mode the relative orientation of the BNO055 in space is calculated from the

accelerometer and gyroscope data. The calculation is fast (i.e. high output data rate).

3.3.3.2 COMPASS

The COMPASS mode is intended to measure the magnetic earth field and calculate the

geographic direction.

The earth magnetic field is a vector with the horizontal components x,y and the vertical z

component. It depends on the position on the globe and natural iron occurrence. For heading

calculation (direction of compass pointer) only the horizontal components x and y are used.

Therefore the vector components of the earth magnetic field must be transformed in the

horizontal plane, which requires the knowledge of the direction of the gravity vector. To

summarize, the heading can only be calculated when considering gravity and magnetic field

at the same time.

However, the measurement accuracy depends on the stability of the surrounding magnetic

field. Furthermore, since the earth magnetic field is usually much smaller than the magnetic

fields that occur around and inside electronic devices, the compass mode requires calibration

(see chapter 3.10)

3.3.3.3 M4G (Magnet for Gyroscope)

The M4G mode is similar to the IMU mode, but instead of using the gyroscope signal to

detect rotation, the changing orientation of the magnetometer in the magnetic field is used.

Since the magnetometer has much lower power consumption than the gyroscope, this mode

is less power consuming in comparison to the IMU mode. There are no drift effects in this

mode which are inherent to the gyroscope.

However, as for compass mode, the measurement accuracy depends on the stability of the

surrounding magnetic field.

For this mode no magnetometer calibration is required and also not available.

3.3.3.4 NDOF_FMC_OFF

This fusion mode is same as NDOF mode, but with the Fast Magnetometer Calibration

turned ‘OFF’.

3.3.3.5 NDOF

This is a fusion mode with 9 degrees of freedom where the fused absolute orientation data is

calculated from accelerometer, gyroscope and the magnetometer. The advantages of

combining all three sensors are a fast calculation, resulting in high output data rate, and high

robustness from magnetic field distortions. In this mode the Fast Magnetometer calibration is

turned ON and thereby resulting in quick calibration of the magnetometer and higher output

data accuracy. The current consumption is slightly higher in comparison to the

NDOF_FMC_OFF fusion mode.

BST-BNO055-DS000-14 | Revision 1.4 | June 2016 Bosch Sensortec

© Bosch Sensortec GmbH reserves all rights even in the event of industrial property rights. We reserve all rights of disposal su ch as copying and passing on

to third parties. BOSCH and the symbol are registered trademarks of Robert Bosch GmbH, Germany.

Note: Specifications within this document are subject to change without notice.

BNO055

Data sheet

Page 24

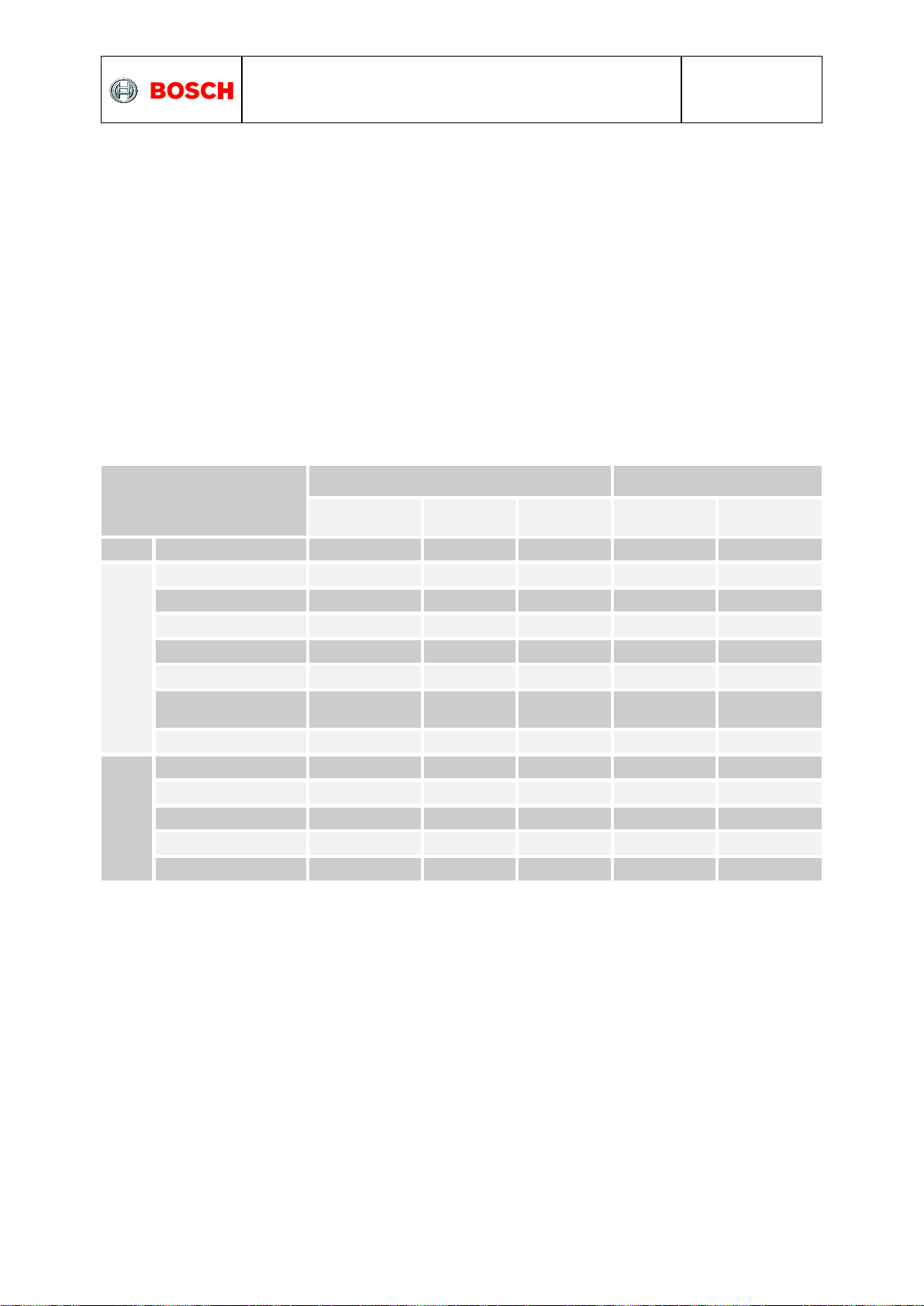

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

Reserved

Remapped Z axis value

Remapped Y axis

value

Remapped X axis

value

Value

Axis Representation

00

X - Axis

01

Y - Axis

10

Z- Axis

11

Invalid

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

Reserved

Remapped

X axis sign

Remapped

Y axis sign

Remapped

Z axis sign

Value

Sign

0

Positive

1

Negative

Z; Ωz; z

X; Ωx; x

Y; Ωy; y

Accel; Gyro; Magnet

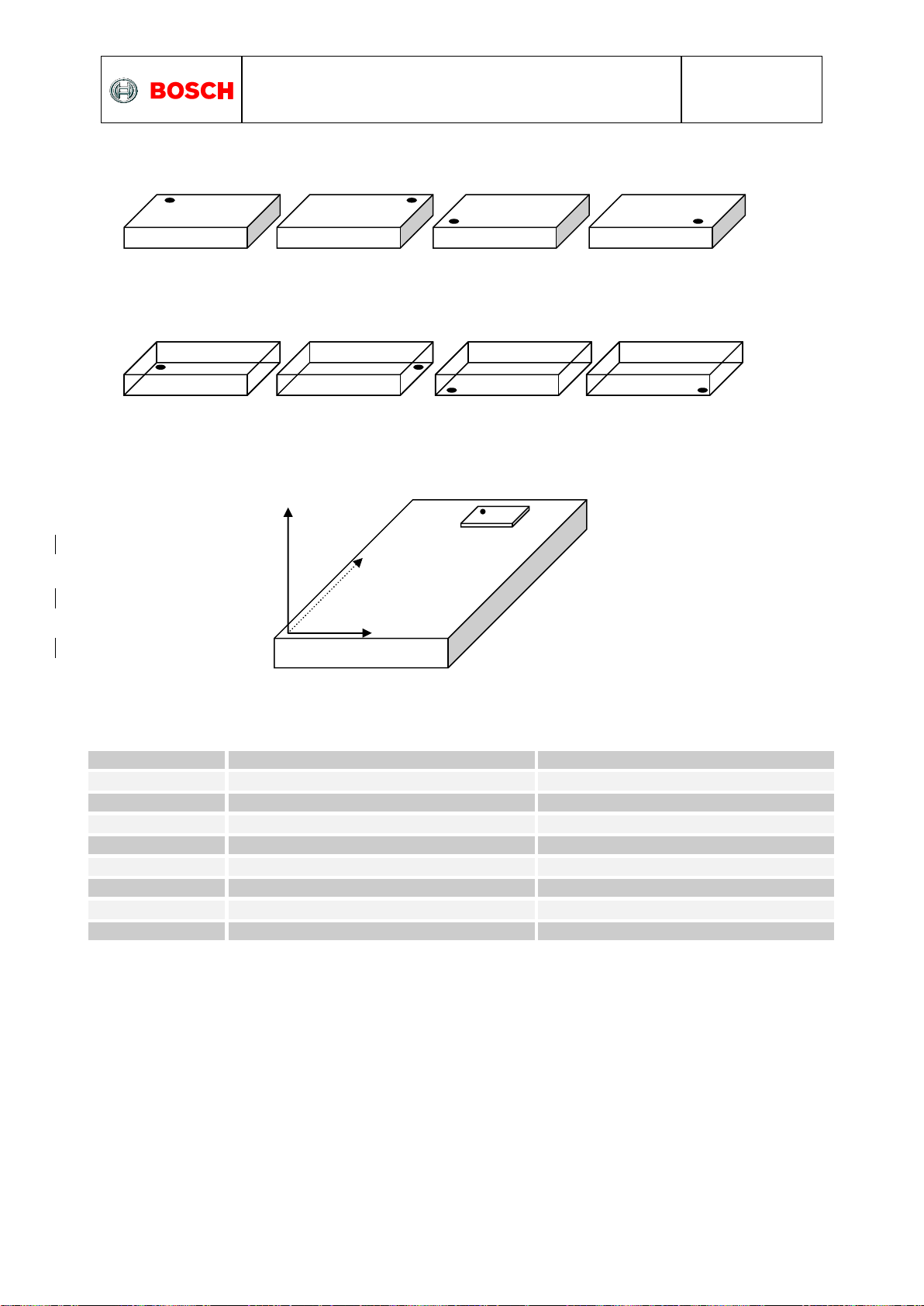

3.4 Axis remap

The device mounting position should not limit the data output of the BNO055 device. The

axis of the device can be re-configured to the new reference axis.

Axis configuration byte: Register Address: AXIS_MAP_CONFIG

There are two bits are used to configure the axis remap which will define in the following

way,

Also, when user try to configure the same axis to two or more then BNO055 will take this as

invalid condition and previous configuration will be restored in the register map. The default

value is: X Axis = X, Y Axis = Y and Z Axis = Z (AXIS_REMAP_CONFIG = 0x24).

Axis sign configuration byte: Register Address: AXIS_MAP_SIGN

The default value is 0x00.

The default values correspond to the following coordinate system

BST-BNO055-DS000-14 | Revision 1.4 | June 2016 Bosch Sensortec

© Bosch Sensortec GmbH reserves all rights even in the event of industrial property rights. We reserve all rights of disposal su ch as copying and passing on

to third parties. BOSCH and the symbol are registered trademarks of Robert Bosch GmbH, Germany.

Note: Specifications within this document are subject to change without notice.

BNO055

Data sheet

Page 25

Placement

AXIS_REMAP_CONFIG

AXIS_REMAP_SIGN

P0

0x21

0x04

P1 (default)

0x24

0x00

P2

0x24

0x06

P3

0x21

0x02

P4

0x24

0x03

P5

0x21

0x01

P6

0x21

0x07

P7

0x24

0x05

TOP VIEW

BOTTOM VIEW

ZYX

P0

P1

P2

P3

P4

P5

P6

P7

P0

Some example placement for axis vs. register settings:

For the above described placements, following would be the axis configuration parameters.

BST-BNO055-DS000-14 | Revision 1.4 | June 2016 Bosch Sensortec

© Bosch Sensortec GmbH reserves all rights even in the event of industrial property rights. We reserve all rights of disposal su ch as copying and passing on

to third parties. BOSCH and the symbol are registered trademarks of Robert Bosch GmbH, Germany.

Note: Specifications within this document are subject to change without notice.

BNO055

Data sheet

Page 26

Sensors

Parameters

Value

Accelerometer

Power Mode

NORMAL

Range

+/- 4g

Bandwidth

62.5Hz

Resolution

14 bits

Gyroscope

Power Mode

NORMAL

Range

2000 °/s

Bandwidth

32Hz

Resolution

16 bits

Magnetometer

Power Mode

FORCED

ODR

20Hz

XY Repetition

15

Z Repetition

16

Resolution x/y/z

13/13/15 bits

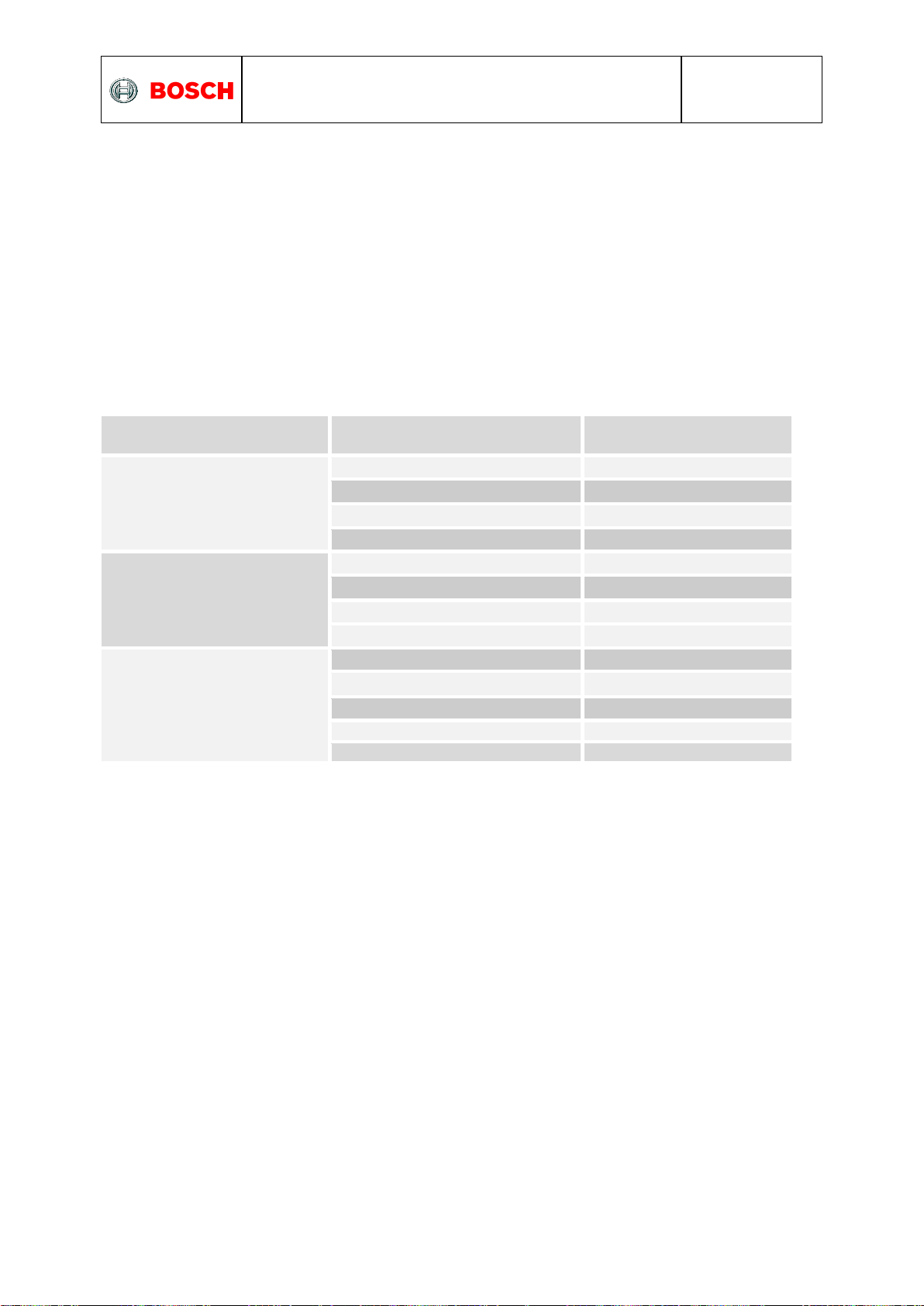

3.5 Sensor Configuration

The fusion outputs of the BNO055 are tightly linked with the sensor configuration settings.

Due to this fact, the sensor configuration is limited when BNO055 is configured to run in any

of the fusion operating mode. In any of the non-fusion modes the configuration settings can

be updated by writing to the configuration registers as defined in the following sections.

3.5.1 Default sensor configuration

At power-on the sensors are configured with the default settings as defined in Table 3-8

below.

Table 3-7: Default sensor configuration at power-on

BST-BNO055-DS000-14 | Revision 1.4 | June 2016 Bosch Sensortec

© Bosch Sensortec GmbH reserves all rights even in the event of industrial property rights. We reserve all rights of disposal su ch as copying and passing on

to third parties. BOSCH and the symbol are registered trademarks of Robert Bosch GmbH, Germany.

Note: Specifications within this document are subject to change without notice.

BNO055

Data sheet

Page 27

Parameter

Values

[Reg Addr]: Reg Value

Restrictions

G Range

2G

[ACC_Config]: xxxxxx00b

Auto controlled in fusion

mode

4G

[ACC_Config]: xxxxxx01b

8G

[ACC_Config]: xxxxxx10b

16G

[ACC_Config]: xxxxxx11b

Bandwidth

7.81Hz

[ACC_Config]: xxx000xxb

15.63Hz

[ACC_Config]: xxx001xxb

31.25Hz

[ACC_Config]: xxx010xxb

62.5Hz

[ACC_Config]: xxx011xxb

125Hz

[ACC_Config]: xxx100xxb

250Hz

[ACC_Config]: xxx101xxb

500Hz

[ACC_Config]: xxx110xxb

1000Hz

[ACC_Config]: xxx111xxb

Operation Mode

Normal

[ACC_Config]: 000xxxxxb

Suspend

[ACC_Config]: 001xxxxxb

Low Power 1

[ACC_Config]: 010xxxxxb

Standby

[ACC_Config]: 011xxxxxb

Low Power 2

[ACC_Config]: 100xxxxxb

Deep Suspend

[ACC_Config]: 101xxxxxb

3.5.2 Accelerometer configuration

The fusion outputs of the BNO055 are tightly linked with the accelerometer sensor settings.

Therefore the configuration possibilities are restricted when running in any of the fusion

operating modes. The accelerometer configuration can be changed by writing to the

ACC_Config register, Table below shows different Accelerometer configurations

Table 3-8: Accelerometer configurations

The accelerometer sensor operation mode is not configurable by user when BNO power

mode is configured as low power mode. BNO rewrites the user configured value to Normal

mode when switching from config mode to any BNO operation mode. This used to achieve

the BNO low power mode performance.

BST-BNO055-DS000-14 | Revision 1.4 | June 2016 Bosch Sensortec

© Bosch Sensortec GmbH reserves all rights even in the event of industrial property rights. We reserve all rights of disposal su ch as copying and passing on

to third parties. BOSCH and the symbol are registered trademarks of Robert Bosch GmbH, Germany.

Note: Specifications within this document are subject to change without notice.

BNO055

Data sheet

Page 28

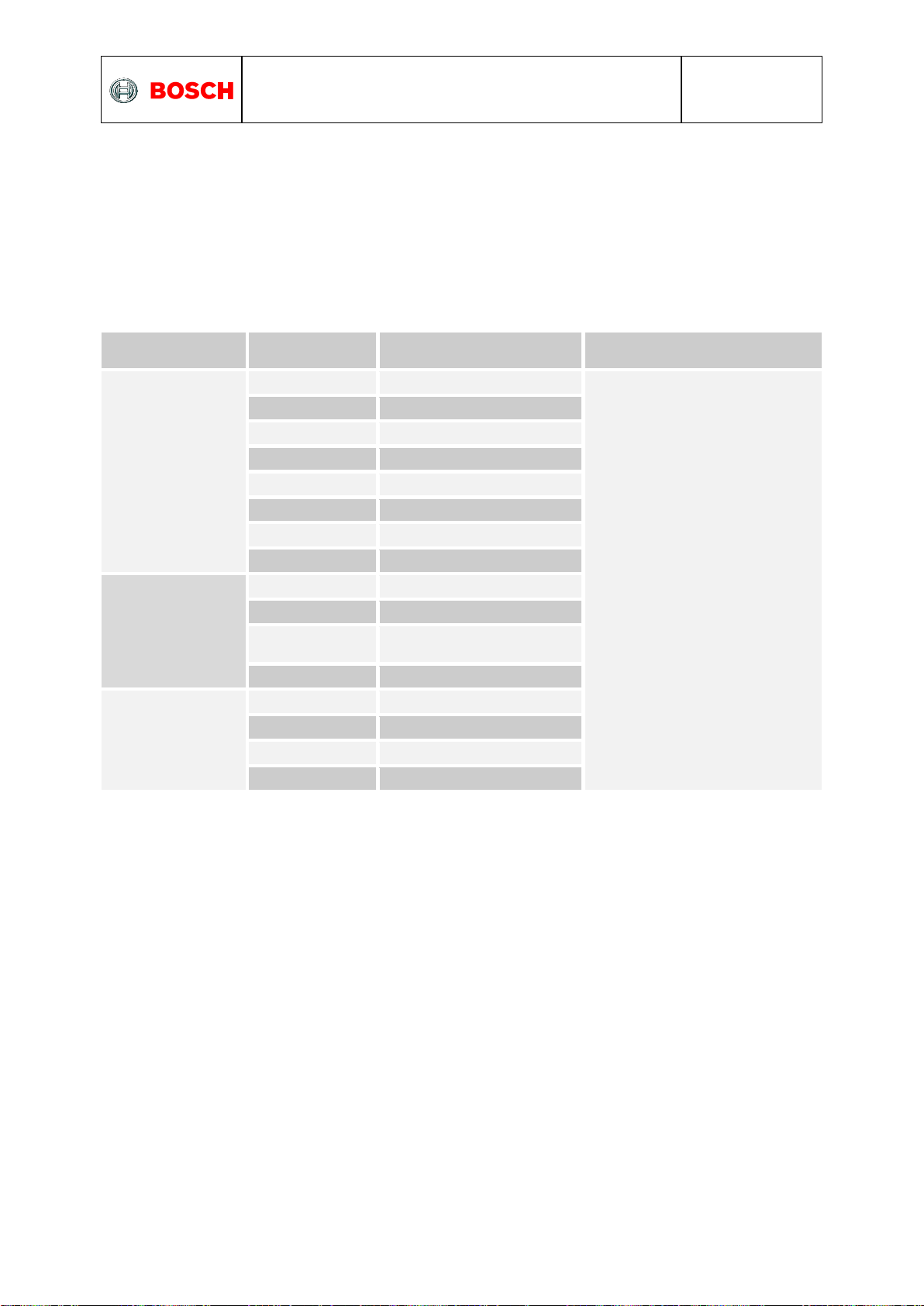

Parameter

Values

[Reg Addr]: Register value

Restrictions

Range

2000 dps

[GYR_Config_0]: xxxxx000b

Auto controlled in fusion mode

1000 dps

[GYR_Config_0]: xxxxx001b

500dps

[GYR_Config_0]: xxxxx010b

250 dps