Bosch 3-500, 8-1100, 30-290, 40-220, 30-300 Operating/safety Instructions Manual

...

1

IMPORTANT: IMPORTANT : IMPORTANTE:

Read Before Using Lire avant usage Leer antes de usar

For English Version Version française Versión en español

See page 2 Voir page 18 Ver la página 34

Operating/Safety Instructions

Consignes de sécurité/d’utilisation

Instrucciones de funcionamiento y seguridad

1-877-BOSCH99 (1-877-267-2499) www.boschtools.com

Call Toll Free for

Consumer Information

& Service Locations

Pour obtenir des informa-

tions et les adresses de nos

centres de

service après-vente,

appelez ce numéro gratuit

Llame gratis para

obtener información

para el consumidor y

ubicaciones de servicio

30-300

40-220

50-210

60-120

23-380

30-290

3-500

8-1100

15-500

160992A3VR.indb 1 3/7/17 12:22 PM

2

Read all safety warnings and all instructions. Failure to follow the warnings and instructions may result in electric shock, fire and/or serious injury.

SAVE ALL WARNINGS AND INSTRUCTIONS FOR FUTURE REFERENCE

The term “power tool” in the warnings refers to your mains-operated (corded) power

tool or battery-operated (cordless) power tool.

Work area safety

Keep work area clean and well lit. Cluttered

or dark areas invite accidents.

Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases or dust. Power

tools create sparks which may ignite the dust

or fumes.

Keep children and bystanders away while

operating a power tool. Distractions can

cause you to lose control.

Electrical safety

Power tool plugs must match the outlet. Never modify the plug in any way. Do

not use any adapter plugs with earthed

(grounded) power tools. Unmodified plugs

and matching outlets will reduce risk of electric shock.

Avoid body contact with earthed or

grounded surfaces such as pipes, radiators, ranges and refrigerators. There is an

increased risk of electric shock if your body is

earthed or grounded.

Do not expose power tools to rain or wet

conditions. Water entering a power tool will

increase the risk of electric shock.

Do not abuse the cord. Never use the cord

for carrying, pulling or unplugging the

power tool. Keep cord away from heat, oil,

sharp edges or moving parts. Damaged or

entangled cords increase the risk of electric

shock.

When operating a power tool outdoors,

use an extension cord suitable for outdoor

use. Use of a cord suitable for outdoor use

reduces the risk of electric shock.

If operating a power tool in a damp location

is unavoidable, use a Ground Fault Circuit

Interrupter (GFCI) protected supply. Use of

an GFCI reduces the risk of electric shock.

Personal safety

Stay alert, watch what you are doing and

use common sense when operating a power tool. Do not use a power tool while you

are tired or under the influence of drugs,

alcohol or medication. A moment of inatten-

tion while operating power tools may result in

serious personal injury.

Use personal protective equipment. Always wear eye protection. Protective equip-

ment such as dust mask, non-skid safety

shoes, hard hat, or hearing protection used

for appropriate conditions will reduce personal

injuries.

Prevent unintentional starting. Ensure the

switch is in the off-position before connecting to power source and / or battery

pack, picking up or carrying the tool. Carry-

ing power tools with your finger on the switch

or energizing power tools that have the switch

on invites accidents.

Remove any adjusting key or wrench before turning the power tool on. A wrench

or a key left attached to a rotating part of the

power tool may result in personal injury.

Do not overreach. Keep proper footing and

balance at all times. This enables better con-

trol of the power tool in unexpected situations.

Dress properly. Do not wear loose clothing or jewelry. Keep your hair, clothing

and gloves away from moving parts. Loose

clothes, jewelry or long hair can be caught in

moving parts.

If devices are provided for the connection

of dust extraction and collection facilities,

ensure these are connected and properly

used. Use of dust collection can reduce dust-

related hazards.

Power tool use and care

Do not force the power tool. Use the correct power tool for your application. The

correct power tool will do the job better and

safer at the rate for which it was designed.

Do not use the power tool if the switch

does not turn it on and off. Any power tool

that cannot be controlled with the switch is

dangerous and must be repaired.

Disconnect the plug from the power source

and/or the battery pack from the power tool

General Power Tool Safety Warnings

160992A3VR.indb 2 3/7/17 12:22 PM

3

before making any adjustments, changing

accessories, or storing power tools. Such

preventive safety measures reduce the risk of

starting the power tool accidentally.

Store idle power tools out of the reach of

children and do not allow persons unfamiliar with the power tool or these instructions to operate the power tool. Power tools

are dangerous in the hands of untrained users.

Maintain power tools. Check for misalignment or binding of moving parts, breakage

of parts and any other condition that may

affect the power tool’s operation. If damaged, have the power tool repaired before

use. Many accidents are caused by poorly

maintained power tools.

Keep cutting tools sharp and clean. Prop-

erly maintained cutting tools with sharp cutting

edges are less likely to bind and are easier to

control.

Use the power tool, accessories and tool

bits etc. in accordance with these instructions, taking into account the working conditions and the work to be performed. Use

of the power tool for operations different from

those intended could result in a hazardous

situation.

Battery tool use and care

Recharge only with the charger specified

by the manufacturer. A charger that is suit-

able for one type of battery pack may create

a risk of fire when used with another battery

pack.

Use power tools only with specifically designated battery packs. Use of any other bat-

tery packs may create a risk of injury and fire.

When battery pack is not in use, keep it

away from other metal objects like paper

clips, coins, keys, nails, screws, or other

small metal objects, that can make a connection from one terminal to another.

Shorting the battery terminals together may

cause burns or a fire.

Under abusive conditions, liquid may be

ejected from the battery; avoid contact.

If contact accidentally occurs, flush with

water. If liquid contacts eyes, additionally

seek medical help. Liquid ejected from the

battery may cause irritation or burns.

Service

Have your power tool serviced by a qualified repair person using only identical replacement parts. This will ensure that the

safety of the power tool is maintained.

Safety Rules for Industrial Cordless Angle Wrenches

Hold power tool by insulated gripping

surfaces, when performing an operation

where the fastener may contact hidden

wiring or its own cord. Fasteners contacting

a “live” wire may make exposed metal parts of

the power tool “live” and could give the operator an electric shock.

Use appropriate detectors to determine

if utility lines are hidden in the work area

or call the local utility company for assistance. Contact with electric lines can lead to

fire and electric shock. Damaging a gas line

can lead to explosion. Penetrating a water line

causes property damage.

Switch off the power tool immediately

when the tool insert jams. Be prepared for

high reaction torque that can cause kickback. The tool insert jams when:

— the power tool is subject to overload or

— it becomes wedged in the workpiece.

Hold the tool with a firm grip. High reaction

torque can briefly occur while driving in and

loosening screws.

Secure the workpiece. A workpiece clamped

with clamping devices or in a vice is held more

secure than by hand.

Always wait until the tool has come to a

complete stop before placing it down. The

tool insert can jam and lead to loss of control

over the power tool.

Before any work on the tool (e. g., maintenance, tool change, etc.) as well as during

transport and storage, set the rotational

direction switch to the centre position. Un-

intentional actuation of the On/Off switch can

lead to injuries.

Avoid unintentional switching on. Ensure

the On/Off switch is in the off position before inserting battery pack. Carrying the

power tool with your finger on the On/Off

switch or inserting the battery pack into power

tools that have the switch on invites accidents.

Use only flawless tool bits that are not

worn. Defective tool bits can break, for exam-

ple, and cause injury or damage.

When working with an application tool, pay

160992A3VR.indb 3 3/7/17 12:22 PM

4

Additional Safety Warnings

Some dust created by

power sanding, sawing,

grinding, drilling, and other construction

activities contains chemicals known to

cause cancer, birth defects or other reproductive harm. Some examples of these

chemicals are:

• Lead from lead-based paints,

• Crystalline silica from bricks and cement and

other masonry products, and

• Arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you do this type of work.

To reduce your exposure to these chemicals:

work in a well ventilated area, and work with

approved safety equipment, such as those

dust masks that are specially designed to filter

out microscopic particles.

attention that the application tool is firmly

seated on the tool holder. When the applica-

tion tool is not firmly connected with the tool

holder, it can come loose again and not be

controlled.

Be careful when long screws are screwed

in. Depending on the type of screw and the

tool bit used, there is a danger of slipping.

Long screws are often difficult to control and

the danger exists that the tool bit may slip off

the fastener head and cause injury.

Pay attention to the direction of rotation

that is set before switching on the power

tool. For example, when a screw is to be loos-

ened and the direction of rotation is set so

that the screw is tightened, this can lead to a

strong torque reaction of the power tool.

Do not use this tool as a drill. Tools equipped

with shutoff clutches are not designed for drilling applications. The clutch can shut off automatically and without warning.

Do not open the battery. Danger of shortcircuiting.

Protect the battery against heat, e. g.,

against continuous intense sunlight, fire,

water, and moisture. Danger of explosion.

In case of damage and improper use of the

battery, vapours may be emitted. Ventilate

the area and seek medical help in case of

complaints. The vapours can irritate the re-

spiratory system.

Use the battery only in conjunction with

your Bosch power tool. This measure alone

protects the battery against dangerous overload.

Use only original Bosch batteries with the

voltage listed on the nameplate of your

power tool. When using other batteries, e.g.

imitations, reconditioned batteries or other

brands, there is danger of injury as well as

property damage through exploding batteries.

The battery can be damaged by pointed

objects such as nails or screwdrivers or

by force applied externally. An internal short

circuit can occur and the battery can burn,

smoke, explode or overheat.

160992A3VR.indb 4 3/7/17 12:22 PM

5

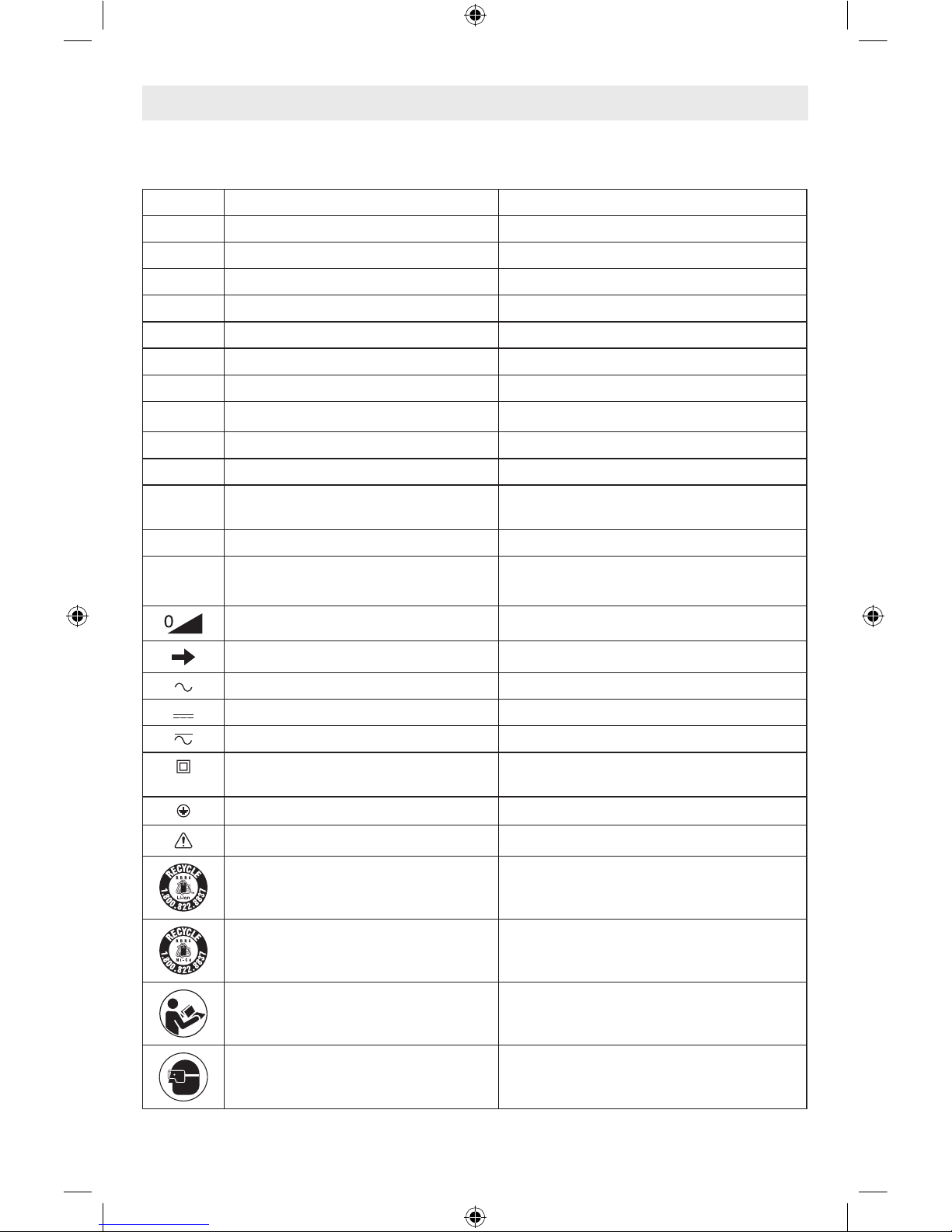

Symbols

IMPORTANT: Some of the following symbols may be used on your tool. Please study them and

learn their meaning. Proper interpretation of these symbols will allow you to operate the tool

better and safer.

Symbol Name Designation/Explanation

V Volts Voltage (potential)

A Amperes Current

Hz Hertz Frequency (cycles per second)

W Watt Power

kg Kilograms Weight

min Minutes Time

s Seconds Time

⌀

Diameter Size of drill bits, grinding wheels, etc.

n

0

No load speed Rotational speed, at no load

n Rated speed Maximum attainable speed

.../min Revolutions or reciprocation per min-

ute

Revolutions, strokes, surface speed, orbits etc. per minute

0 Off position Zero speed, zero torque...

1, 2, 3, ...

I, II, III,

Selector settings Speed, torque or position settings. Higher

number means greater speed

Infinitely variable selector with off Speed is increasing from 0 setting

Arrow Action in the direction of arrow

Alternating current Type or a characteristic of current

Direct current Type or a characteristic of current

Alternating or direct current Type or a characteristic of current

Class II construction Designates Double Insulated Construc-

tion tools.

Earthing terminal Grounding terminal

Warning symbol Alerts user to warning messages

Li-ion RBRC seal Designates Li-ion battery recycling pro-

gram

Ni-Cad RBRC seal Designates Ni-Cad battery recycling pro-

gram

Read manual symbol Alerts user to read manual

Wear eye protection symbol Alerts user to wear eye protection

160992A3VR.indb 5 3/7/17 12:22 PM

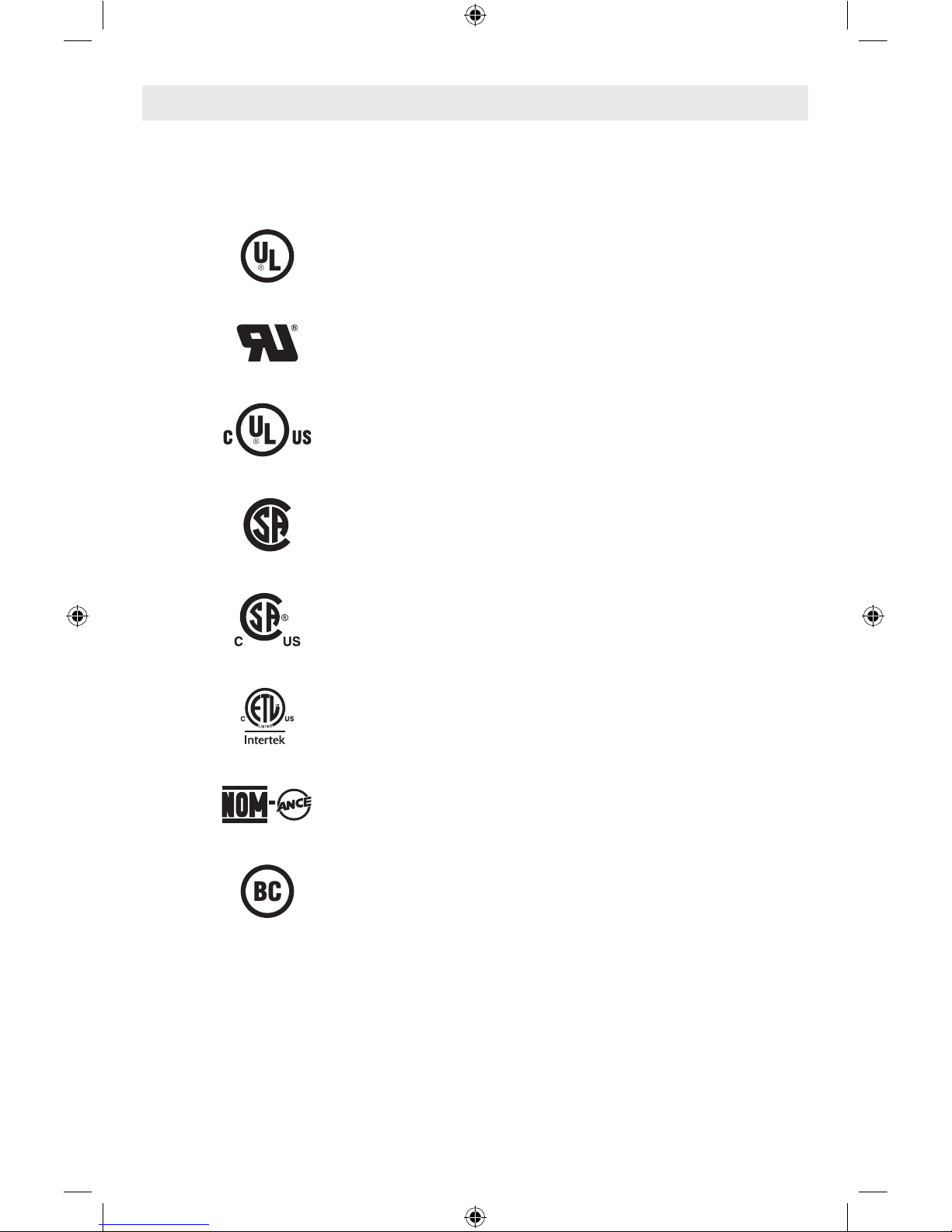

6

Symbols (continued)

IMPORTANT: Some of the following symbols may be used on your tool. Please study them and

learn their meaning. Proper interpretation of these symbols will allow you to operate the tool

better and safer.

This symbol designates that this tool is listed by Underwriters Laboratories.

This symbol designates that this component is recognized by Underwriters Laboratories.

This symbol designates that this tool is listed by Underwriters Laboratories, to United States and Canadian

Standards.

This symbol designates that this tool is listed by the Canadian Standards Association.

This symbol designates that this tool is listed by the Canadian Standards Association, to United States and Canadian Standards.

This symbol designates that this tool is listed by the Intertek Testing Services, to United States and Canadian

Standards.

This symbol designates that this tool complies to NOM

Mexican Standards.

This symbol designates that this tool complies with CEC

California Energy Commision energy efficiency requirements.

160992A3VR.indb 6 3/7/17 12:22 PM

7

9

13

11 10

4

5

6

28

7 8

12

1

2

3

7 8

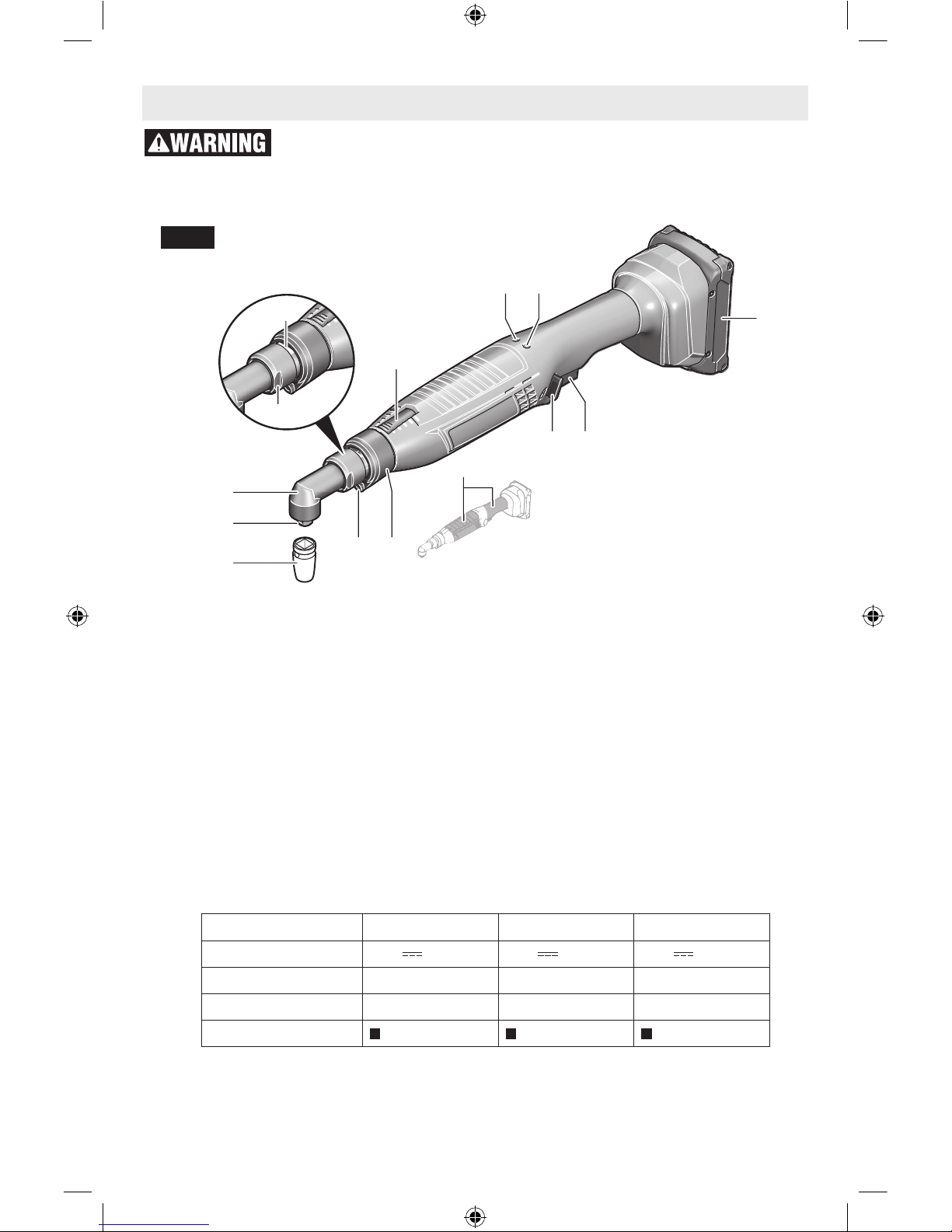

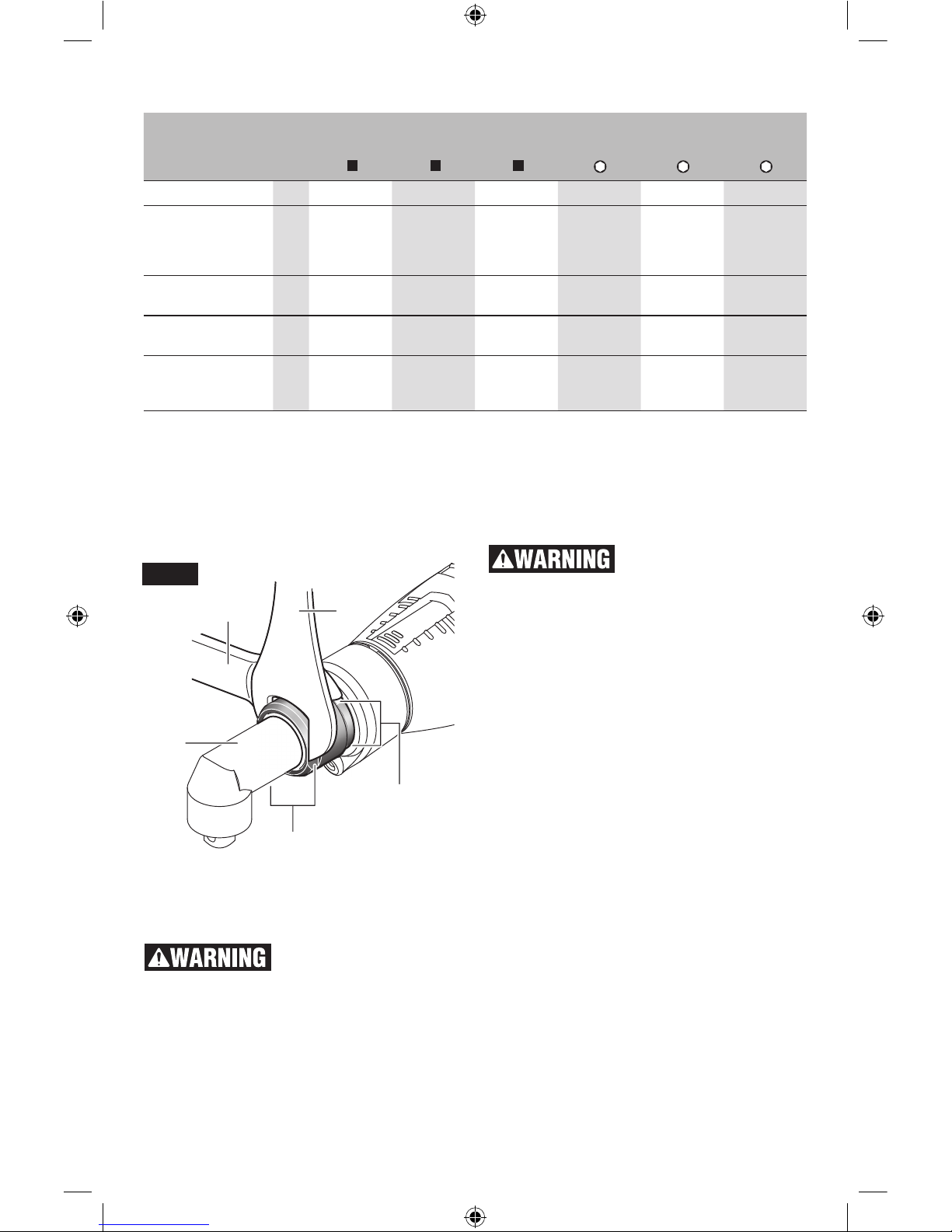

Functional Description and Specifications

Disconnect battery pack from tool before making any assembly, ad-

justments or changing accessories. Such preventive safety measures

reduce the risk of starting the tool accidentally.

Cordless Angle Wrench

Fig. 1a

Model number 3-500 8-1100 15-500

Voltage rating 18V

18V 18V

No load speed n

0

50-520/min 110-1100/min 50-520/min

Torque 0.7-3 Nm 2-8 Nm 2-15 Nm

Angle head

3/8" 3/8" 3/8"

Battery Packs/Chargers

Please refer to the Charger Manual included with your tool.

NOTE: For tool specifications refer to the nameplate on your tool.

1. Tool socket*

2. Square drive*

3. Angle head*

4. Spanner flats on the angle head flange*

5. Spanner flats on the sleeve nut

6. Torque setting window/cover

7. LED indicator, tightening control

8. Battery charge status indicator

9. Battery pack*

10. On/Off switch

11. Rotational direction switch

12. LED holder

13. Worklight

28. Protective covers

* Accessories shown or described are not

part of the standard delivery scope of the

product. A complete overview of accessories can be found in our accessories program.

160992A3VR.indb 7 3/7/17 12:22 PM

8

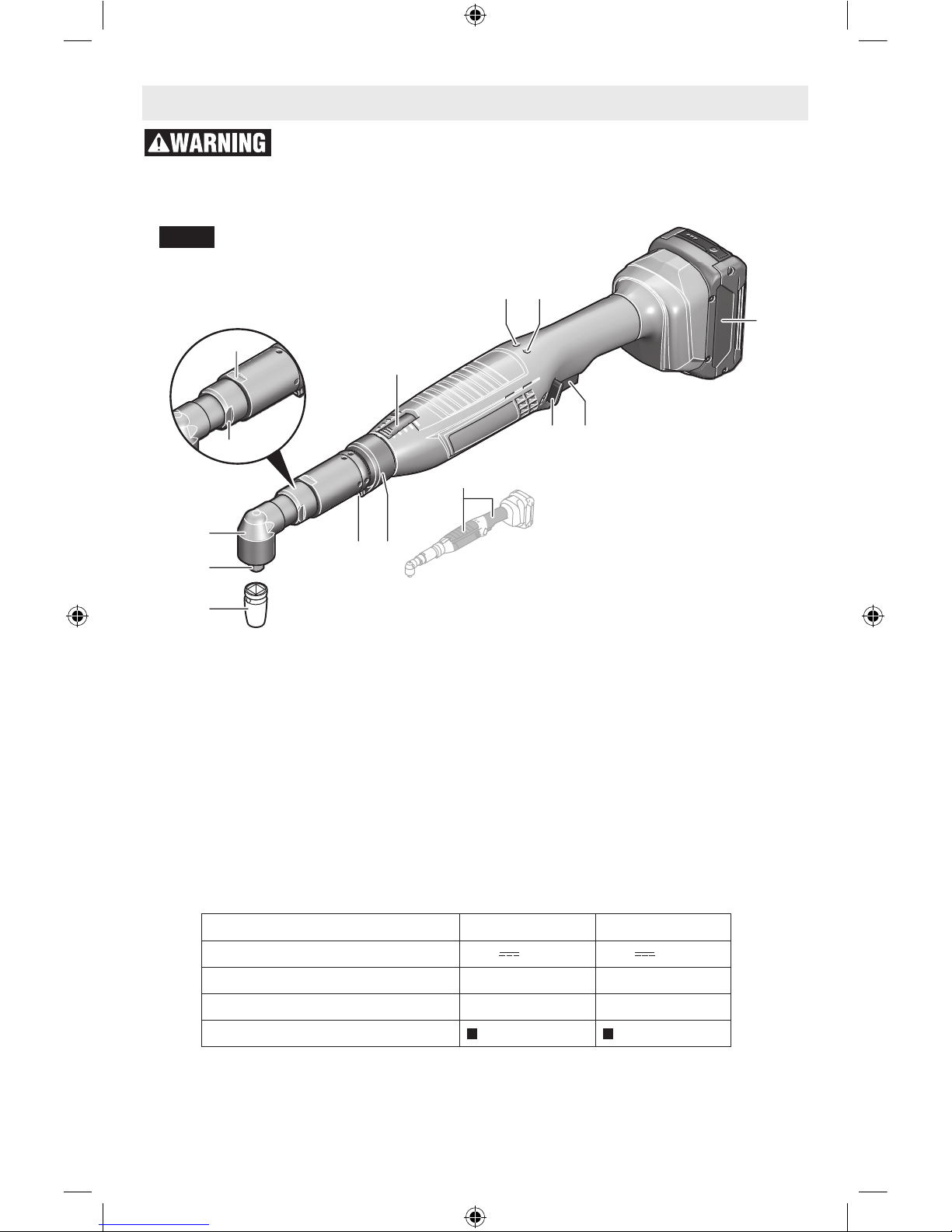

Functional Description and Specifications

Disconnect battery pack from tool before making any assembly, ad-

justments or changing accessories. Such preventive safety measures

reduce the risk of starting the tool accidentally.

Cordless Angle Wrench

Fig. 1b

Model number 23-380 30-290

Voltage rating 18V

18V

No load speed n

0

38-380/min 29-290/min

Torque 10-23 Nm 10-30 Nm

Angle head

3/8" 3/8"

Battery Packs/Chargers

Please refer to the Charger Manual included with your tool.

NOTE: For tool specifications refer to the nameplate on your tool.

9

9

9

13

11 10

4

5

4

5

6

28

7 8

12

1

2

3

1

2

3

6

6

7 8

7 8

13

11 10

12

28

1. Tool socket*

2. Square drive*

3. Angle head*

4. Spanner flats on the angle head flange*

5. Spanner flats on the sleeve nut

6. Torque setting window/cover

7. LED indicator, tightening control

8. Battery charge status indicator

9. Battery pack*

10. On/Off switch

11. Rotational direction switch

12. LED holder

13. Worklight

28. Protective covers

* Accessories shown or described are not

part of the standard delivery scope of the

product. A complete overview of accessories can be found in our accessories program.

160992A3VR.indb 8 3/7/17 12:22 PM

9

9

9

9

13

11 10

4

5

4

5

6

28

7 8

12

1

2

3

1

2

3

1

2

3

6

6

7 8

7 8

13

11 10

12

13 12

11 10

28

28

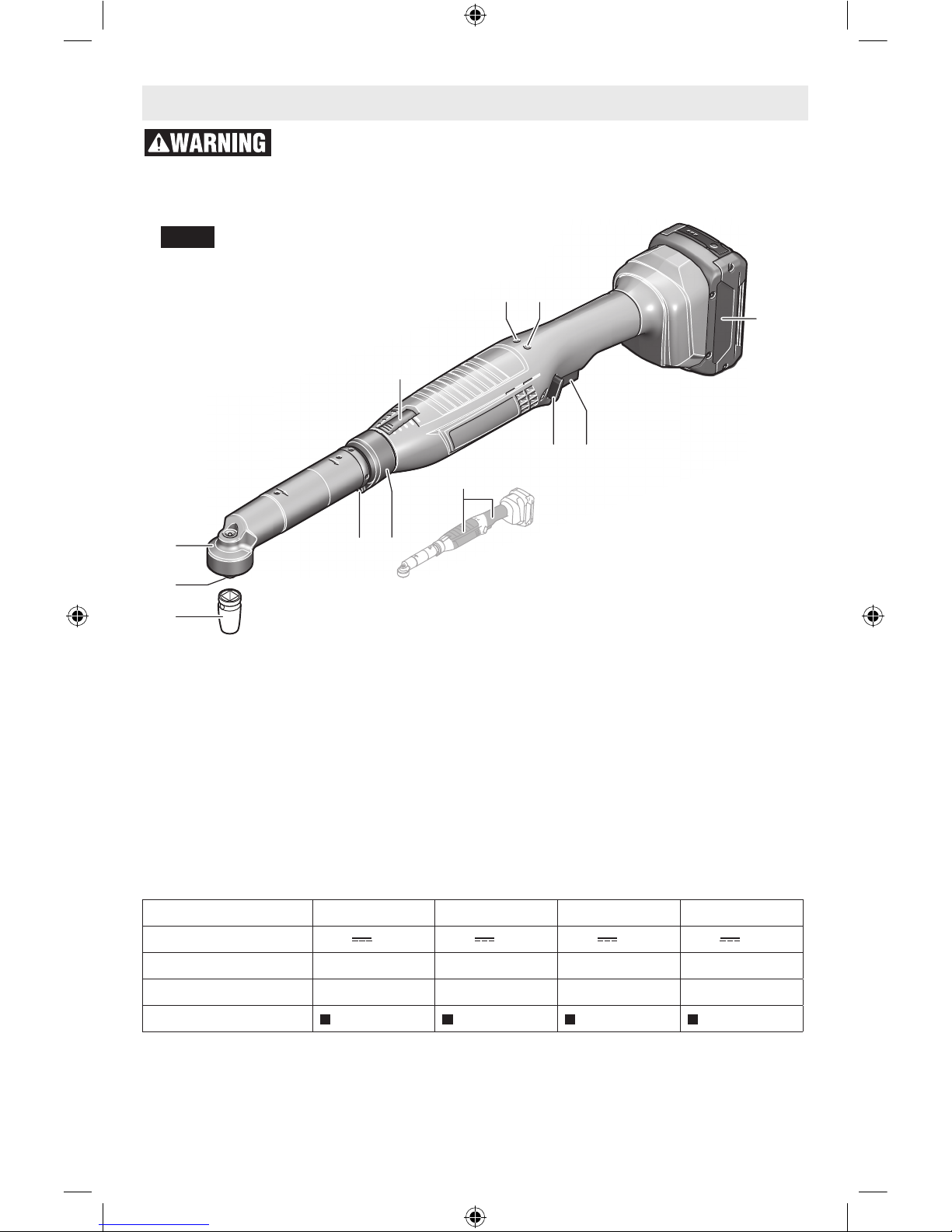

Functional Description and Specifications

Disconnect battery pack from tool before making any assembly, ad-

justments or changing accessories. Such preventive safety measures

reduce the risk of starting the tool accidentally.

Cordless Angle Wrench

Fig. 1c

Model number 30-300 40-220 50-210 60-120

Voltage rating 18V

18V 18V 18V

No load speed n

0

30-300/min 22-220/min 21-180/min 12-120/min

Torque 10-30 Nm 15-40 Nm 15-50 Nm 20-60 Nm

Angle head

3/8" 3/8" 3/8" 3/8"

Battery Packs/Chargers

Please refer to the Charger Manual included with your tool.

NOTE: For tool specifications refer to the nameplate on your tool.

1. Tool socket*

2. Square drive*

3. Angle head*

6. Torque setting window/cover

7. LED indicator, tightening control

8. Battery charge status indicator

9. Battery pack*

10. On/Off switch

11. Rotational direction switch

12. LED holder

13. Worklight

28. Protective covers

* Accessories shown or described are not

part of the standard delivery scope of the

product. A complete overview of accessories can be found in our accessories program.

160992A3VR.indb 9 3/7/17 12:22 PM

10

Disconnect battery pack

from tool before making

any assembly, adjustments or changing

accessories. Such preventive safety mea-

sures reduce the risk of starting the tool accidentally.

Recharge only with the

charger specified for the

Bosch recommended batteries. For specific charging instructions, read the operator’s manual supplied with your charger

and battery. Failure to follow the warnings

and instructions may result in electric shock,

fire and/or serious injury.

Note: The battery is supplied partially

charged. To ensure full capacity of the battery,

completely charge the battery in the battery

charger before using your power tool for the

first time.

The lithium-ion battery can be charged at any

time without reducing its service life. Interrupting the charging procedure does not damage

the battery.

The lithium ion battery is protected against

deep discharging by the “Electronic Cell Protection (ECP)”. When the battery is empty, the

tool is switched off by means of a protective

circuit: The drive socket or bit no longer rotates.

Do not continue to press

the On/Off switch after

the tool has been automatically switched

off. The battery can be damaged.

The battery is equipped with a NTC temperature control which allows charging only within

a temperature range of between 0 °C and 45

°C (32 and 113 °F). A long battery service life

is achieved in this manner.

Observe the notes for disposal.

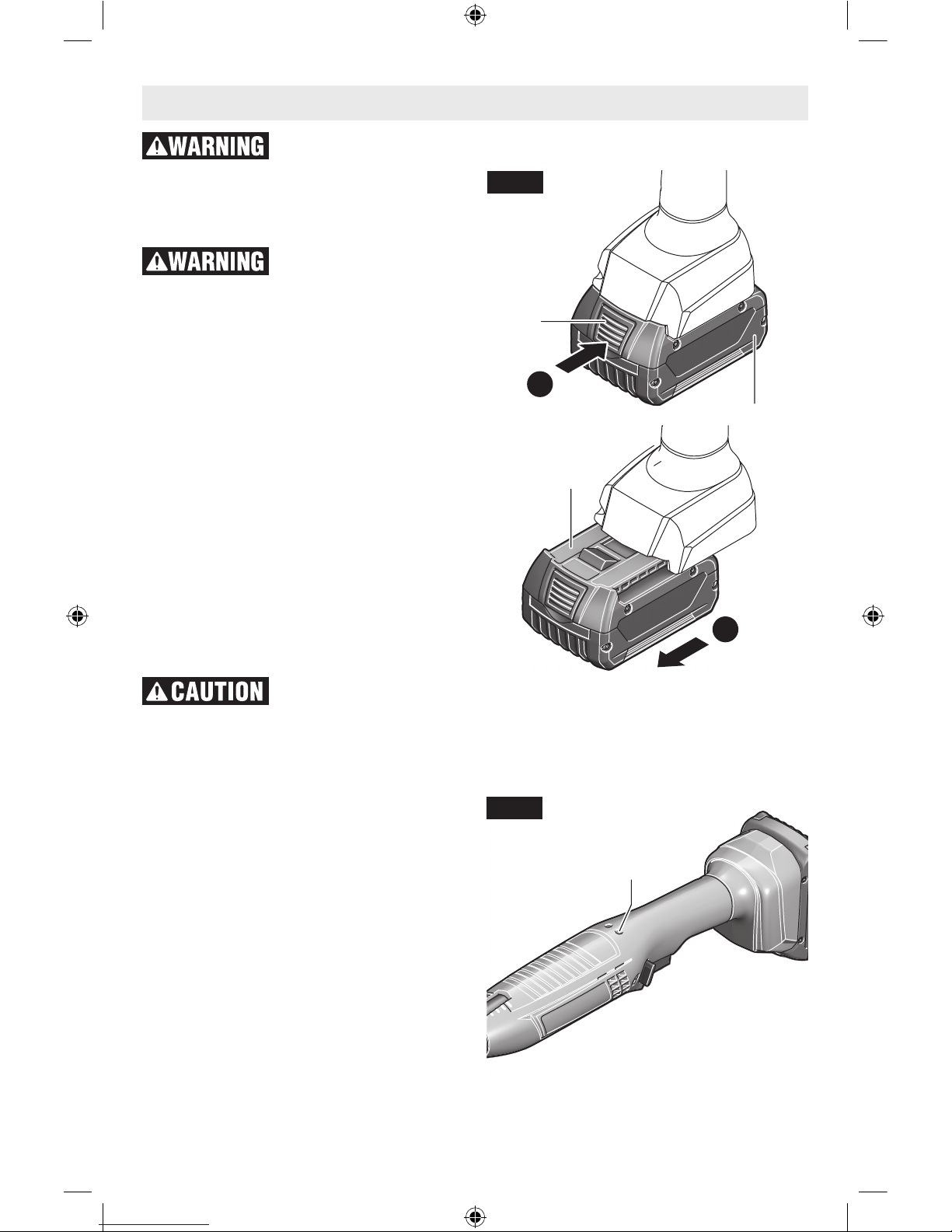

RELEASING AND INSERTING BAT-

TERY PACK

The battery 9 is equipped with two locking levels that should prevent the battery from falling

out when pushing the battery unlocking button

14 unintentionally (Fig. 2). As long as the battery is inserted in the power tool, it is held in

position by means of a spring.

– To remove the battery 9, press the unlock-

ing button 14 and pull out the battery toward

the front (Fig. 2). Do not exert any force.

– To insert battery, align battery and slide bat-

tery pack into tool until it locks into position.

Do not force.

BATTERY CHARGE STATUS

INDICATION (YELLOW LED)

Your tool is equipped with charge status indicator light 8 (Fig. 3). The indicator lights shows

the charge status of the battery

Assembly

9

9

14

2

1

Fig. 2

8

Fig. 3

160992A3VR.indb 10 3/7/17 12:22 PM

11

Battery charge

status indication

Meaning

Flashing light +

audio signal

Battery Charging:

Only 6 –8 more

screwdriving operations possible.

Continuous light Capacity no longer

sufficient for a new

screwdriving operation or the tool was

subject to overload.

The tool can no longer be switched on.

– Remove the battery and replace

with a fully charged

one.

Flashing light The tool is over-

heated and out of

operation:

– Before restarting

the operation of the

tool, wait until the

flashing automatically stops after a

short period.

OPERATING AND STORAGE ENVI-

RONMENT

The device is suitable exclusively for operation

at enclosed work sites.

For proper operation, the allowable ambient

temperature should be between 0 °C and +45

°C (32 and 113 °F) at an allowable relative humidity between 20 and 95 %, free of moisture

condensation.

SUSPENSION DEVICE

With the utility clip 15, the tool can be attached

to a suspension device.

– Fasten the utility clip 15 to the tool by en-

gaging it into the fastening slots 16 (Fig 4).

Depending on the tool’s centre of gravity, either the front or rear slots can be used.

Regularly check the condition of the utility clip

and the hook of the suspension device.

ADJUSTING THE WORKLIGHT

– Press off the marking ring 17 with a thin

screwdriver blade, a knife, or similar (Fig. 5).

– Using snap-ring pliers, slide the snap ring

18 toward the rear onto the housing shell.

The two shell halves of the LED holder 12,

which enclose the worklight 13, can now be

adjusted to any desired position.

– Pay attention not to damage the worklight

cable and, without kinking or bending it,

slide it into the cavity 19 intended for it in

the housing shell.

– Enclose the worklight 13 again with the two

housing shells of LED holder 12.

– Press the snap ring 18 and the marking ring

17 back to their initial positions.

16

15

Fig. 4

13 12

19

17 18

12

Fig. 5

160992A3VR.indb 11 3/7/17 12:22 PM

12

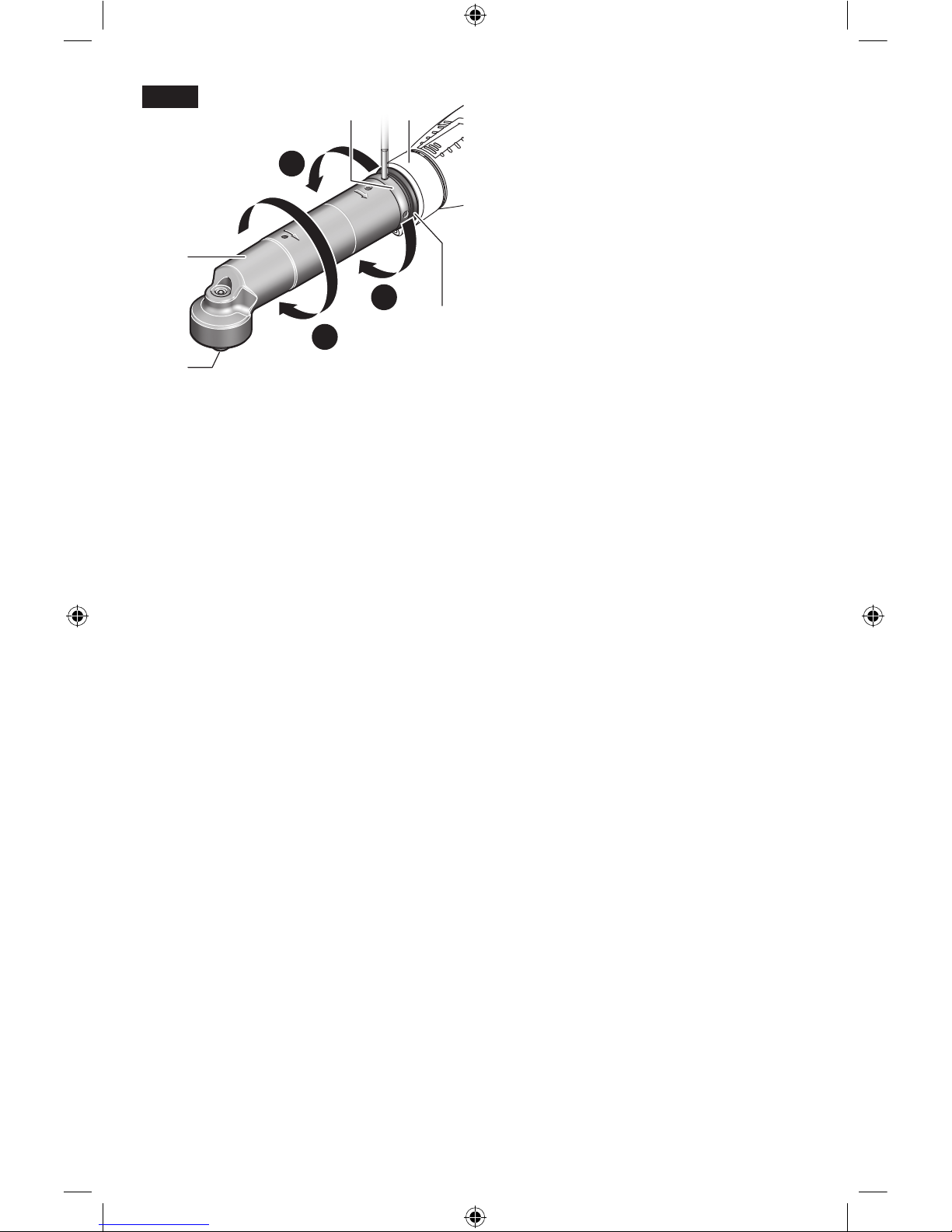

MOUNTING THE ANGLE HEAD

Applies for the following types: ANGLE

EXACT ION 3-500, 8-1100, 15-500, 23-380,

30-290.

On these industrial cordless angle wrenches,

a fitting angle head (see “ANGLE HEADS”,)

has to be mounted first.

– Hold the power tool with the open-end

spanner 21 by the spanner flats 4 of the

angle head flange (Fig. 6).

Never clamp the tool by

the housing shells!

– Mount the angle head 3 onto the flange

in the requested position and tighten the

sleeve nut with the open-end spanner 20

via the spanner flats 5.

Hold the angle head flange with the open-end

spanner 21 to prevent turning.

ADJUSTING THE ANGLE HEAD

The angle head 3 can be adjusted to a total of

eight positions.

– Hold the power tool with the open-end

spanner 21 by the spanner flats 4 of the

angle head flange.

Never clamp the tool by

the housing shells!

– Loosen the sleeve nut with the open-end

spanner 20 by the spanner flats 5. Adjust

the angle head 3 in 45° steps to the desired

position and retighten the sleeve nut again

with the open-end spanner 20 by the spanner flats 5. Hold the angle head flange with

the open-end spanner 21 to prevent turning.

ADJUSTING AND REMOVING THE

ANGLE HEAD

Applies for the following types: ANGLE EX-

ACT ION 30-300, 40-220, 50-210, 60-120.

The angle head 3 with tool bit holder 2 can

be continuously adjusted around 360° (Fig. 7).

– Loosen the lock nut 22 by inserting an ap-

propriate tool into an opening of the lock nut

and turning the lock nut in the direction of

the arrow a (left thread).

– Fix the angle head 3 in this position by turn-

ing the lock nut 22 in the direction of the

arrow c against the angle head. Tighten the

lock nut 22 with a tightening torque of max.

50 Nm again.

– Turn the angle head 3 in arrow direction b

until the desired work angle is reached, but

not more than once by 360°.

The angle head 3 can also be removed completely, e. g. when it is required to replace the

20

21

3

4

5

Fig. 6

Angle head Straight

drive head

1/4" 3/8" 3/8"

1/4" QC 1/4" QC 1/4"

Bosch part number

0607453617 0607453620 0607451618 0607453618 0607453630 0607453 631

Maximum torque,

hard screwdriving

application according

to ISO5393 Nm 20 25 30 20 20 6

Tightening torque at

the flange Nm 20 20 25 20 20 10

Accessories for

ANGLE EXACT ION 15-500 15-500 30-300 15-500 15-500 15-500

Weight according

to EPTA-Procedure

01/2003 kg 0.2 0.2 0.2 0.2 0.2 0.2

ANGLE HEADS

160992A3VR.indb 12 3/7/17 12:22 PM

13

marking ring 17 by one with another colour or

to adjust the worklight. Adjust the worklight to

the desired position first (see “Adjusting the

Worklight”, page 11) before adjusting the angle

head.

– Loosen the lock nut 22 by inserting an ap-

propriate tool into an opening of the lock nut

and turning the lock nut in the direction of

the arrow a (left thread).

– Unscrew the angle head 3 in arrow direction

b until it can be removed.

– Unscrew the lock nut 22 from the motor

housing 23 in arrow direction a.

Now, the marking ring can be exchanged or

the worklight can be adjusted.

– Turn the lock nut 22 in arrow direction c

onto the motor housing 23 and screw on the

angle head again turning in arrow direction

b.

– Lock the angle nutrunner head by screwing

the lock nut 22 in arrow direction c.

– Retighten lock nut 22 again with a tighten-

ing torque of approx. 50 Nm.

CONFIGURING THE POWER TOOL

With the BOSCH EXACT Configurator software, different power tool settings (e. g.,

speed, driving stages, repeat protection) can

be configured. For this, the power tool must

be connected to a PC via the USB data port.

Note: Observe all safety warnings and instructions in the software instruction manual.

23

3

2

22

17

b

a

c

Fig. 7

160992A3VR.indb 13 3/7/17 12:22 PM

14

1

2

3

1

2

24

1

2

3

1

2

Fig. 8 Fig. 9 Fig. 10

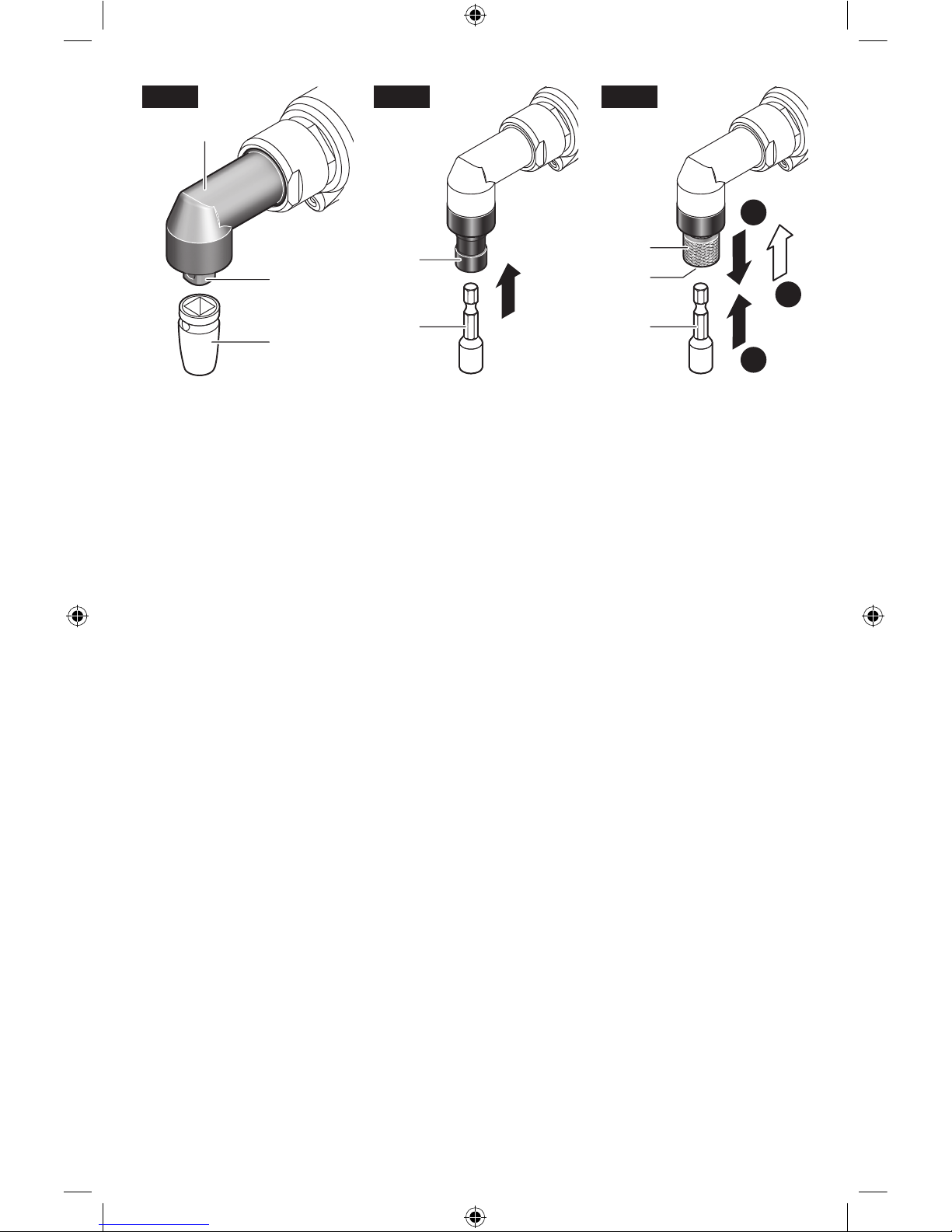

CHANGING DRIVE

SOCKET ON THE

ANGLE HEAD WITH

EXTERNAL SQUARE

DRIVE

Inserting

– Press in the pin on the

square drive of the angle

head 2, e. g. using a small

screwdriver, and slide the

drive socket 1 over the

square drive. Pay attention

that the pin engages in the

recess of the tool bit (Fig.

8).

Removing

– Press in the pin on the

square drive through the

hole on the side of the

drive socket, then pull the

socket off the square drive

of the angle head 2 (Fig. 8).

CHANGING DRIVE

BIT ON THE ANGLE

HEAD WITH INTERNAL

HEXAGON

Inserting

– Insert the tool bit 1 into the

internal hex socket of the

tool holder 2 until it can be

felt to engage (Fig. 9).

Removing

– Pull the tool bit 1 off of the

tool holder 2 with the aid of

pliers, if necessary (Fig. 9).

CHANGING DRIVE BIT

ON THE ANGLE HEAD

WITH QUICK-CHANGE

CHUCK

Inserting

Use only insertion tools with

fitting end pieces (1/4” hexagonal) .

– Pull the sleeve of quick-

change chuck 24 to the

front and hold (Fig. 10).

– Insert tool bit 1 into tool

holder 2 and release the

quick-change chuck (Fig.

10).

Removing

– Pull the sleeve of quick-

change chuck 24 to the

front and hold (Fig. 10).

– Remove tool bit 1 from tool

holder 2 and release the

quick-change chuck (Fig.

10).

160992A3VR.indb 14 3/7/17 12:22 PM

15

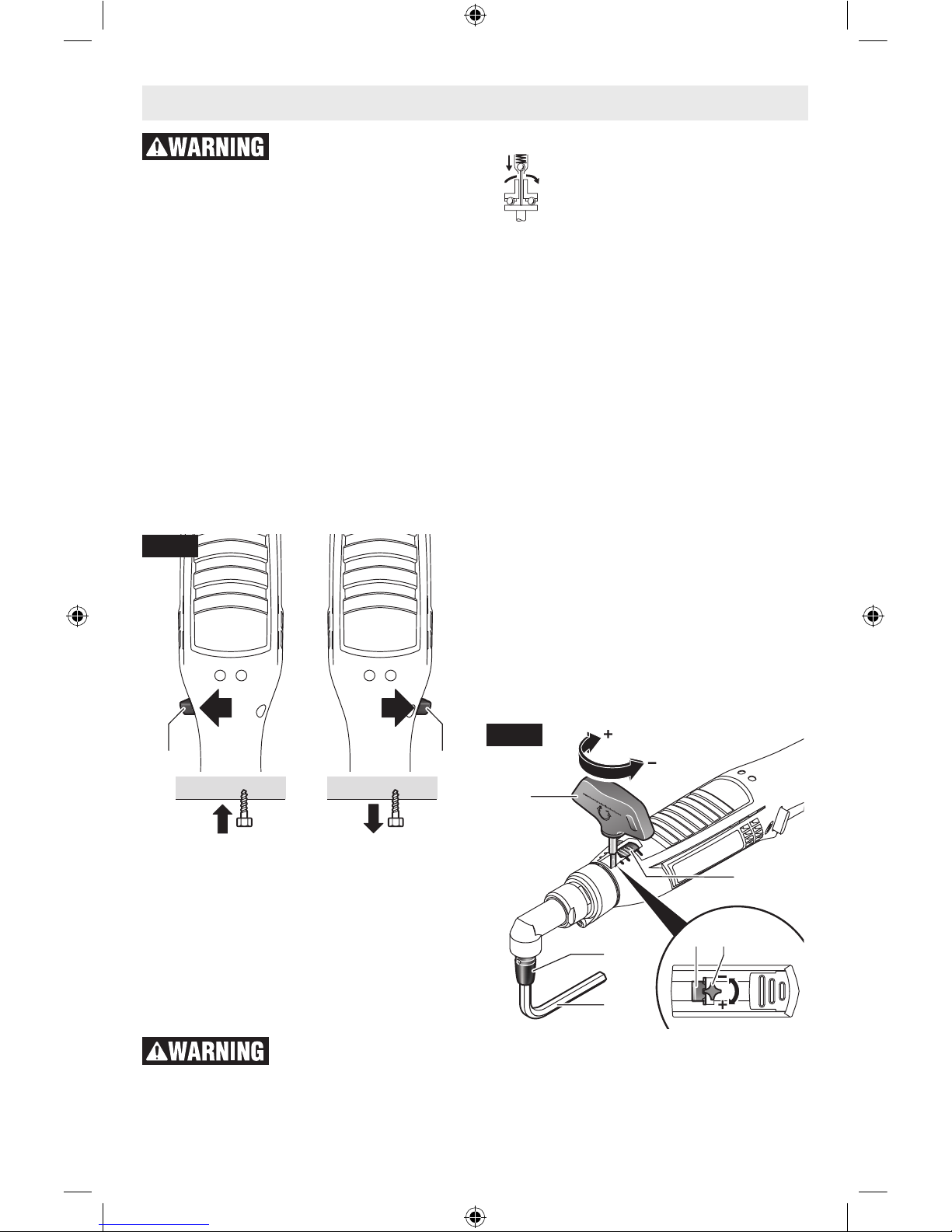

Operating Instructions

Disconnect battery pack

from tool before making

any assembly, adjustments or changing

accessories. Such preventive safety mea-

sures reduce the risk of starting the tool accidentally.

Starting operation

When starting the power tool, you should first

select the direction of rotation with the rotational direction switch 11 since the power tool

starts only when the rotational direction switch

11 is not in the middle position (switch-on lock)

(Fig. 1).

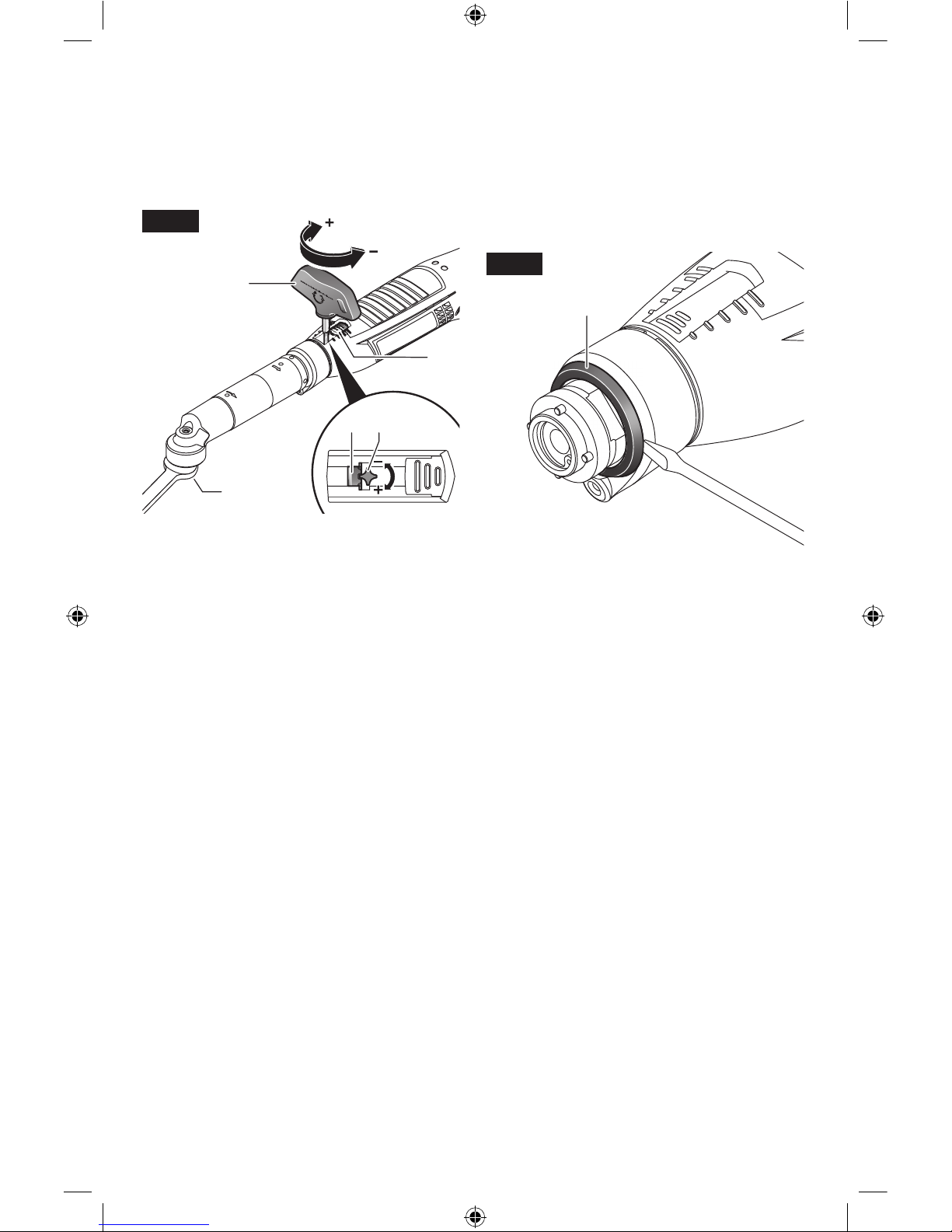

Reversing the rotational direction

– Right rotation: For driving in screws, push

the rotational direction switch 11 left to the

stop (Fig. 11).

– Left Rotation: For loosening or unscrewing

screws, push the rotational direction switch

11 right to the stop (Fig. 11).

Switching On the Worklight

The work area illumination 13 makes possible

the lighting of the screwing position for unfavorable light conditions. The work area illumination 13 is switched on by lightly pressing

the on/off switch 10. When the on/off switch

is firmly pressed, the power tool is switched

on and the work area illumination continues

to light.

Do not look directly into

the work area illumination – your sight can be temporarily degraded!

Switching On and Off

The screwdriver has a shut-off

clutch that can be set for a torque in

a given range. It responds when the

torque that is set is reached.

– To start the tool press the on/off switch 10 to

the stop (Fig. 1).

– The tool switches off automatically as soon

as the preset torque is reached.

When the on/off switch 10 is released prematurely, the preset torque is not reached.

To save energy, only switch the power tool on

when using it.

Working Advice

Apply the power tool to the screw/nut only

when it is switched off. Rotating tool inserts can slip off.

Setting the Torque

The tightening torque is dependent on the

spring pretension of the shut-off clutch. The

shut-off clutch responds in right as well as left

rotation when the torque setting is reached.

For setting the individual tightening torques,

use only the adjustment tool 25 provided.

– Push the torques setting cover 6 on the

power tool completely back.

Applies for the following types: ANGLE

EXACT ION 3-500, 8-1100, 15-500, 23-380,

30-290.

– Insert an Allen key 26 into tool bit 1 and turn

it slowly (Fig. 12).

– When a small indentation (adjusting dial 27)

is visible in the clutch, insert the adjustment

11 11

Fig. 11

6

25

1

26

27 25

Fig. 12

160992A3VR.indb 15 3/7/17 12:22 PM

16

tool 25 into the indentation and turn it (Fig.

12).

Applies for the following types: ANGLE EXACT ION 30-300, 40-220, 50-210, 60-120.

– Slowly turn the tool holder 2 using an open-

end spanner (Fig. 13).

– When a small indentation (adjusting dial 27)

is visible in the clutch, insert the adjustment

tool 25 into the indentation and turn it.

Turning in the clockwise direction results in a

higher torque, in the counterclockwise direction, a lower torque.

– Remove the adjustment tool 25. Shut the

torques setting cover 6 again to protect the

clutch against contamination.

Note: The required adjustment is dependent

on the type of threaded connection and can

be best determined by practical trials. Check

the trial fastenings with a torque wrench.

Set the torque only in the specified performance range, otherwise the shut-off clutch

will no longer respond.

Marking the Torque Setting

Always use the power tool with a marking ring

to insure that the housing body is sealed from

dust and dirt.

Applies for the following types: ANGLE EXACT ION 30-300, 40-220, 50-210, 60-120.

For these industrial cordless angle wrenches,

the angle head must be removed first, see “Adjusting and Removing the Angle head”, page

12.

The torque can be marked now as described

below.

Applies for the following types: ANGLE EXACT ION 3-500, 8-1100, 15-500.

To identify individually adjusted tightening

torques, the marking ring 17 can be replaced

with a marking ring of another color.

– Press off the marking ring 17 with a thin

screwdriver blade, a knife, or similar (Fig.

14).

Tightening Fastener Indicator

(green/red LED)

When the preset torque is reached, the shut

off coupling responds. The LED indicator 7

lights green (Fig. 1).

If the preset torque is not reached, the LED

indicator 7 lights red and an acoustical signal

sounds. The tightening fastener must be performed again.

Repeat Protection

When the shut-off coupling responds for a

tightened fastener, the motor shuts off. Switching on again is possible only after a 0.7 second delay. In this manner, an unintentional

re-tightening of an already seated screw is

avoided.

25

2

6

27 25

Fig. 13

17

Fig. 14

160992A3VR.indb 16 3/7/17 12:22 PM

Loading...

Loading...