Bosch 1613, 1614, 1613EVS, 1614EVS Instruction Manual

0

1613

2

50

40

30

1

20

10

0

0

0 601 613 0 . .

1614

0 601 614 0 . .

0

RPM

23000

22000

19500

17000

14500

12000

4

3

5

2

6

2

50

40

30

1

20

10

0

0

1

1613EVS

0 601 613 7 . .

1614EVS

0 601 614 7 . .

Before use - Read this instruction manual.

Lisez attentivement la présente notice avant l'emploi.

Lea estas instrucciones de manejo antes de la utilización del aparato.

BM 2610967928 1/97 12/7/98, 10:29 AM1

1

8

9

5

6

4

3

2

2

1

15

3

4

10

11

5

12

6

13

7

14

26

16

17

18

10

BM 2610967928 1/97 12/7/98, 10:29 AM2

19

20

2

Product Data - Plunge Router

Model number 1613 1613EVS.

Identification number 0 601 613 0 . . 0 601 613 7 .

Router bit capacity 1-5/8" dia. max. 1-5/8" dia. max.

Collet capacity 1/4", 3/8", & 1/2" shanks 1/4", 3/8", & 1/2" shanks

Model number 1614 1614EVS.

Identification number 0 601 614 0 . . 0 601 614 7 .

Router bit capacity 1-5/8" dia. max. 1-5/8" dia. max.

Collet capacity 1/4" shank 1/4" shank

NOTE: This tool is designed for use with alternating current (AC) only.)

Accessory Listing

1613 & 1613EVS 1614 & 1614EVS

1/4" Collet chuck* 1/4" Collet chuck*

3/8" Collet chuck 3/4" Collet wrench*

1/2" Collet chuck* Deluxe router guide

15/16" Collet wrench* Vacuum attachment

Deluxe router guide Vacuum hose

Vacuum attachment Hose/vacuum adaptor

Vacuum hose Carrying case

Hose/vacuum adaptor

Carrying case

(* = standard equipment)

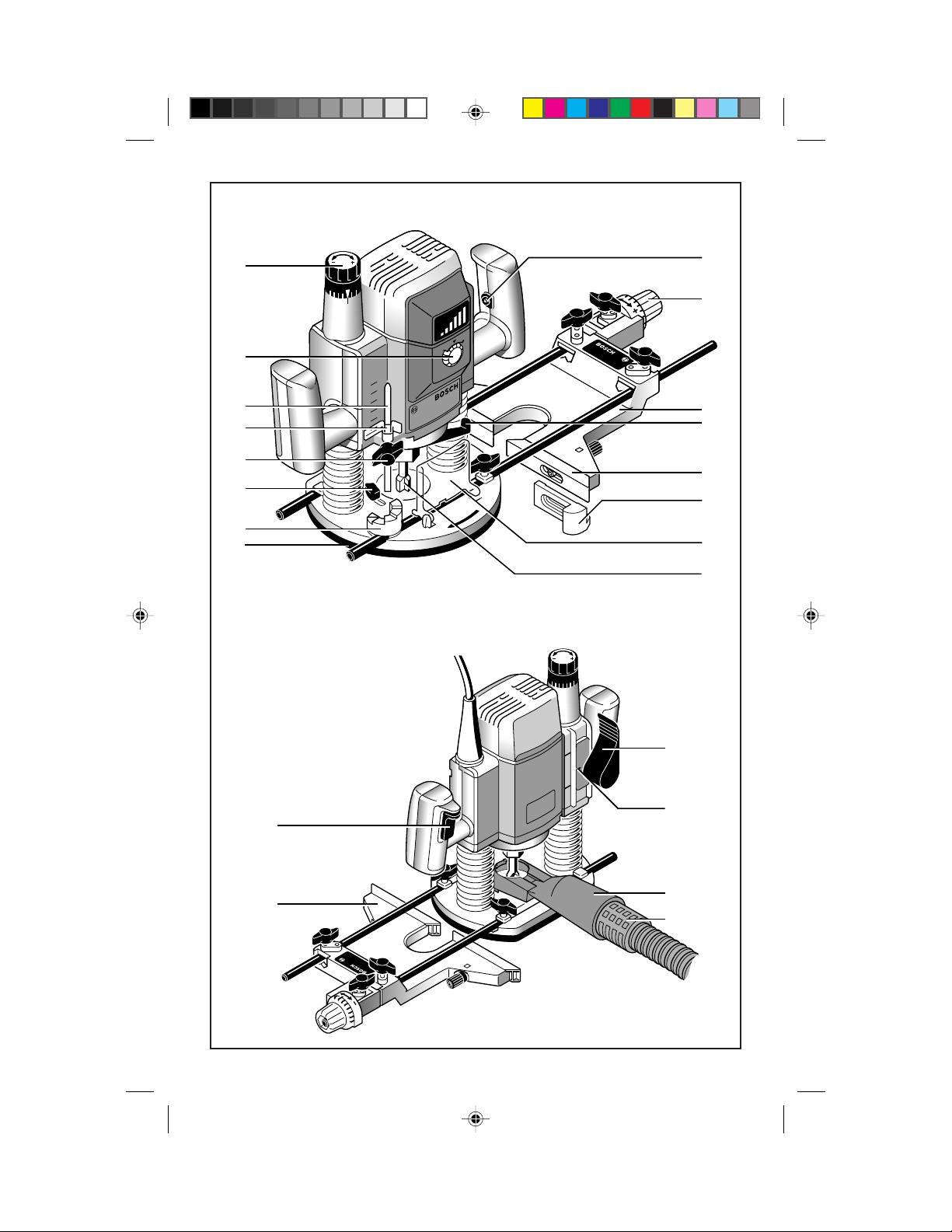

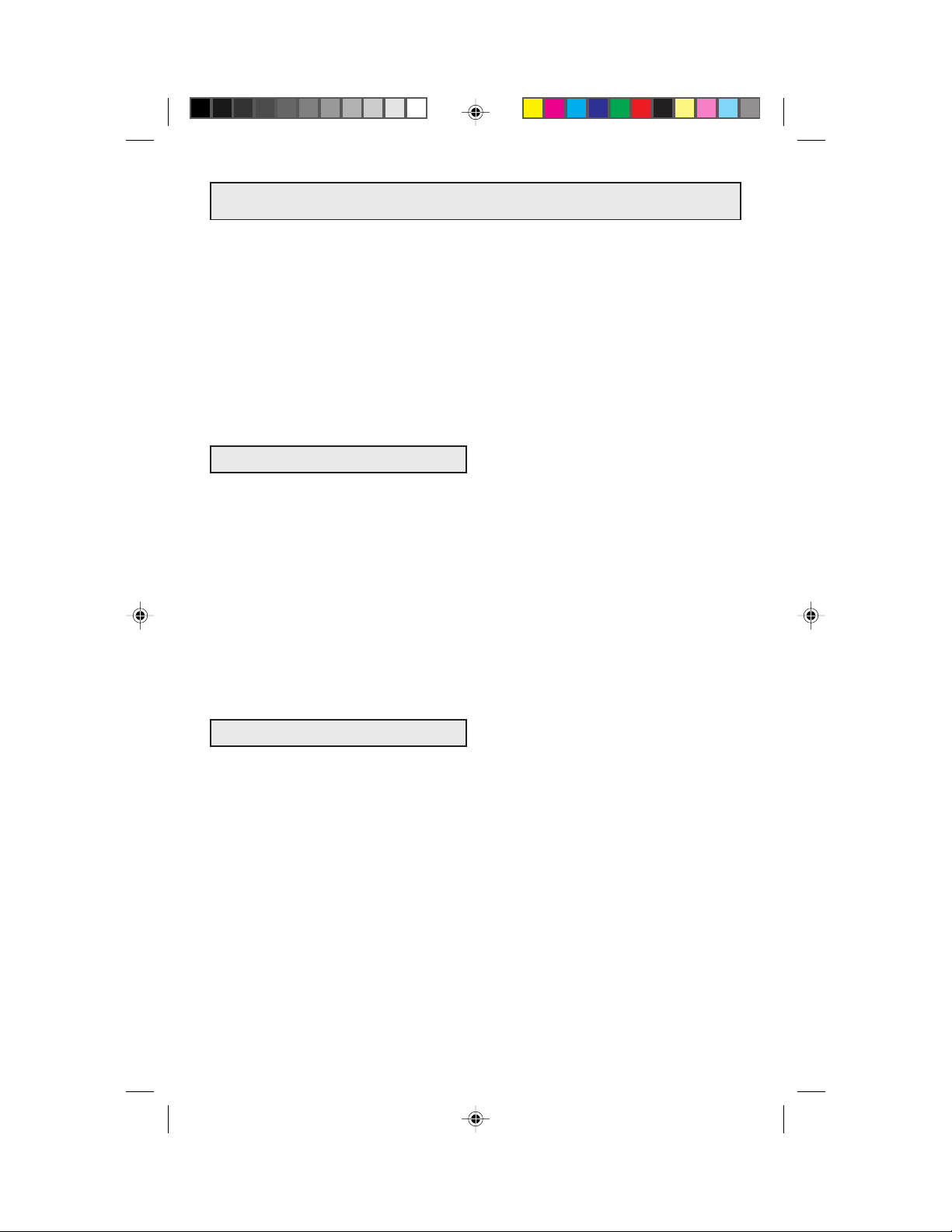

Router Components

1. Fine adjust knob 14. Chip deflector

2. Variable speed dial (1613EVS & 1614EVS) 15. Subbase

3. Depth indicator rod 16. Plunge lock/release lever

4. Depth indicator 17. Index marker

5. Depth indicator lock/release knob 18. Trigger switch

6. Templet guide lock/release lever 19. Vacuum attachment

7. Revolving depth turret 20. Vacuum hose

8. "Lock-ON" button 21. Retaining ring

9. Router guide adustment knob 22. Collet

10. Deluxe router guide 23. Collet nut

11. Spindle lock 24. Templet guide

12. Guide plate 25. Collet chuck assembly

13. Guide plate 26. Router bit

27. Template pattern

(NOTE: Router components not illustrated on page 2 are illustrated elsewhere in this manual)

3

BM 2610967928 1/97 12/7/98, 10:29 AM3

WARNING! “READ ALL INSTRUC-

TIONS”. Failure to follow the SAFETY RULES

identified by the BULLET (•) symbols listed

BELOW and other safety precautions, may

result in serious personal injury. Keep these

operating instructions with this product.

GENERAL SAFETY RULES

for all Power Tools

Work Area

• KEEP WORK AREAS CLEAN. Cluttered

areas and benches invite accidents.

• AVOID DANGEROUS ENVIRONMENT.

Don’t use power tools in damp or wet locations.

Do not expose power tools to rain. Keep work

area well lit.

• AVOID GASEOUS AREAS. Do not operate portable electric tools in explosive atmospheres in presence of flammable liquids or

gases. Motors in these tools normally spark,

and the sparks might ignite fumes.

• KEEP CHILDREN AWAY. Do not let

visitors contact tool or extension cord. All

visitors should be kept away from work areas.

Personal Safety

• GUARD AGAINST ELECTRIC SHOCK.

Prevent body contact with grounded surfaces

such as pipes, radiators, ranges and refrigerator

enclosures. Rubber gloves and non-skid footwear are recommended when working outdoors, where damp or wet ground may be

encountered. A Ground Fault Circuit Interrupter protected power line must be used for

these conditions.

• DRESS PROPERLY. Do not wear loose

clothing or jewelry. They can be caught in

moving parts. Wear protective hair covering to

contain long hair.

• USE SAFETY EQUIPMENT. WEAR

SAFETY GOGGLES or glasses with side

shields. Wear hearing protection during extended use of power tools and dust mask for

dusty operations.

• STAY ALERT. USE COMMON SENSE.

Watch what you are doing. Do not operate tool

when you are tired or under influence of drugs.

•

REMOVE ADJUSTING KEYS AND

WRENCHES.

keys and adjusting wrenches are removed from

Form habit of checking to see that

tool before turning it on.

• AVOID ACCIDENTAL STARTING. Don’t

carry plugged in tool with finger on switch. Be

sure the switch is OFF before being plugged in.

• DON’T OVERREACH. Keep proper footing and balance at all times.

• BEFORE CONNECTING THE TOOL to a

power supply (receptacle, outlet, etc.) be sure

the voltage supplied is the same as that specified on the tool’s nameplate. A power supply

with voltage greater than that specified for the

tool can result in serious injury to the user - as

well as damage to the tool. If in doubt, DO NOT

PLUG IN THE TOOL. Using a power supply

with voltage less than the nameplate rating is

harmful to the motor.

“Volts AC” designated tools are for Alternating

Current 50-60 Hz only. “Volts DC” designated

tools are for Direct Current. Do not use AC

designated tools with DC power supply. Do not

use electronic speed controlled tools with DC

power supply.

Tool Use and Care

• DON’T FORCE TOOL. It will do the job

better and safer at the rate for which it was

designed.

• USE RIGHT TOOL. Don’t force small tool

or attachment to do the job of a heavy-duty tool.

Don’t use tool for purpose not intended - for

example; don’t use a circular saw for cutting

tree limbs or logs.

• SECURE WORK. Use clamps or a vise to

hold work. It’s safer than using your hand and

it frees both hands to operate the tool.

• DON’T ABUSE CORD. Never carry tool by

cord or yank it to disconnect from receptacle.

Keep cord from heat, oil, and sharp edges.

Always keep cord away from the spinning

blade, bits or any other moving part while the

tool is in use.

• OUTDOOR USE EXTENSION CORDS.

When tool is used outdoors, use only extension

cords suitable for use outdoors and marked with

suffix W-A (for UL), or W (for CSA). Refer to

section “Extension Cords”, for proper cord use.

• DISCONNECT TOOLS. When not in use,

before servicing, or when changing blades,

bits, cutters, etc.

• STORE IDLE TOOLS. When not in use,

tools should be stored in dry, high or locked up

place - out of the reach of children.

4

BM 2610967928 1/97 12/7/98, 10:29 AM4

• DO NOT ALTER OR MISUSE TOOL.

These tools are precision built. Any alterations

or modifications not specified is misuse and

may result in a dangerous condition.

• THE USE OF ANY ACCESSORIES not

specified in this manual may create a hazard.

• MAINTAIN TOOLS WITH CARE. Keep

tools sharp and clean for better and safer performance. Follow instructions for lubricating and

changing accessories. Inspect tool cords periodically and if damaged, have repaired by authorized service facility. Inspect extension

cords periodically and replace if damaged. Keep

handles dry, clean and free from oil and grease.

• CHECK DAMAGED PARTS. Before further use of the tool, a guard or other part that is

damaged should be carefully checked to determine that it will operate properly and perform

its intended function. Check for alignment of

moving parts, binding of moving parts, breakage of parts, mounting, and any other conditions that may affect its operation. A guard or

other part that is damaged should be promptly

and properly repaired or replaced. Have defective switches replaced. Do not use tool if switch

does not turn it on or off.

• ALL REPAIRS, ELECTRICAL OR MECHANICAL, should be attempted only by

trained repairmen. Contact the nearest Bosch

Factory Service Center, or Bosch Authorized

Service Center or other competent repair center. Use only Bosch replacement parts, any

other may create a hazard.

Safety Rules for Routers

• If router bit is protruding through the base,

never lay the router down until the motor has

come to a complete standstill.

• Never hold the workpiece in one hand and

the router in other when in use. Always clamp

the material and hold the router securely with

both hands.

• Never use bits that have a cutting diameter

greater than the opening in the base.

• After changing the bits or making any adjustments, make sure the collet nut and any other

adjustment devices are securely tightened before using the router.

• The direction of feeding the router into the

material is very important and it relates to the

direction of bit rotation. When viewing the

router from the top, the bit rotates clockwise.

When the router is located between your body

and the material, the feed direction must be to

the right. If the material is located between your

body and the router, then the feed direction

must be to the left. Feeding the router in the

wrong direction causes the cutting edge of the

bit to climb out of the work and pull the router

in the direction of this feed.

Double Insulated Tools

• Double Insulation is a design concept

used in electric power tools which eliminates

the need for the three wire grounded power cord

and grounded power supply system. It is a

recognized and approved system by

Underwriter’s Laboratories, CSA and Federal

OSHA authorities.

• Never start the router when the bit is engaged

in the material. The bit’s cutting edge may grab

the material causing the router to get out of

control. Always hold the router with two hands

during start-up. The reaction torque of the

motor can cause the router to twist.

• Always make sure the workpiece is free from

nails and other foreign objects which can cause

the bit and router to jump and damage the bit.

• Always wear safety goggles. If router has a

removable chip deflector, keep it in place when

routing.

• Never touch the router bit or other moving

part during use. After use the router bit is too

hot to be touched by bare hands.

BM 2610967928 1/97 12/7/98, 10:29 AM5

IMPORTANT: Servicing of a tool with

double insulation requires care and knowledge

of the system and should be performed only by

a qualified service technician. WHEN SERVICE IS REQUIRED USE ONLY IDENTICAL REPLACEMENT PARTS.

POLARIZED PLUGS: If your tool is equipped

with a polarized plug (one blade is wider than

the other), this plug will fit in a polarized outlet

only one way. If the plug does not fit fully in the

outlet, reverse the plug. If it still does not fit,

contact a qualified electrician to install the

proper outlet. To reduce the risk of electric

shock do not change the plug in any way.

5

Extension Cords

• Replace damaged cords immediately. Use of

damaged cords can shock, burn or electrocute.

• If an extension cord is necessary, a cord with

adequate size conductors should be used to

prevent excessive voltage drop, loss of power

or overheating. The table below shows the

correct size to use, depending on cord length

and amperage rating on the tool’s nameplate. If

in doubt, use the next heavier gauge. Always

use U.L. and CSA listed extension cords.

Ampere Rating (shown on nameplate)

0- 2.1- 3.5- 5.1- 7.1- 12.1-

2.0 3.4 5.0 7.0 12.0 16.0

25' 18 18 18 18 16 14

50' 18 18 16 16 14 12

75' 18 18 16 14 12 10

100' 18 16 14 12 10

Cord Length

150' 16 14 12 12 Wire Gauge

Note: The smaller the gauge number, the larger

the wire is in the cord.

"SAVE THESE INSTRUCTIONS"

Operating the Tool

Variable Speed with Dial Setting

(1613EVS & 1614EVS)

Your router is also equipped with a variable

speed dial 2. The router bit speed can be preset

from 12,000 to maximum nameplate RPM by

rotating the dial to the desired setting. The dial

may be set on or between any of six positions (1

= low through 6 = high). The "Lock-ON"

button may also be used with any setting of the

dial.

The following speeds generally apply, but precise settings are largely determined by

experience with the material being cut. Momentary speed variation is normal when starting

the router until the electronic regulator takes

control.

Dial 1613EVS 1614EVS

Setting RPM RPM Material

1 12,000 12,000 nonferrous metals,

2 14,000 14,500 larger diameter router

3 16,000 17,000 bits and cutters.

4 18,000 19,500 Softwoods, plastics,

5 20,000 22,000 counter tops, smaller

6 22,000 23,000 diameter router bits

and cutters.

"Soft Start" Feature

(1613EVS & 1614EVS )

The router is equipped with the "soft start"

feature which gradually increases the starting

speed and torque, reducing the stress that occurs from a high torque start.

Trigger Switch with "Lock-ON"button

Your tool can be turned "ON" or "OFF" by

squeezing or releasing the trigger. Your tool is

also equipped with "Lock-ON" button, located

on the left side of the trigger handle, that allows

for continuous operation without holding the

trigger.

TO LOCK SWITCH "ON": Squeeze trigger,

depress button and release trigger.

TO UNLOCK THE SWITCH: Squeeze trigger

and release it without depressing the "LockON" button.

WARNING! If the "Lock-ON" button is con-

tinuously being depressed, the trigger cannot

be released.

BM 2610967928 1/97 12/7/98, 10:29 AM6

Start the tool before applying to work and let

the tool come to full speed before contacting

the workpiece. Lift the tool from the work

before releasing the switch. DO NOT turn the

switch "ON" and "OFF" while the tool is under

load; this will greatly decrease the switch life.

Router Bit Installation and Removal

WARNING! Always disconnect the tool

from the power supply before installing router

bits, accessories or making any adjustments.

Installing a Router Bit

Turn the armature shaft to align the flats with

the spindle lock 11, and press the spindle lock

firmly down to engage it. Next, use the wrench

supplied to loosen the collet chuck assembly.

Insert the shank of the router bit into the collet

chuck as far as it will go, then back the shank

6

out until the cutters are approximately 1/8" to

1/4" away from the collet chuck face. With the

router bit inserted and the spindle lock fully

engaged, tighten the collet chuck assembly

firmly in a clockwise direction, (viewed from

under the router), with the wrench supplied. To

avoid damaging the collet chuck, never tighten

the collet chuck unless a router bit of proper

shank size is inserted into the collet.

To ensure proper gripping of the router bit and

minimize run-out, the shank of the router bit

should always be inserted at least 5/8".

CAUTION! To prevent damage to tool. Do

not tighten collet without a bit. NOTE: The bit

shank and chuck should be clean and free of

dust, wood, residue and grease before assembling.

CAUTION! Do not use router bits greater

than 1-5/8" in diameter as they will not fit

through the base casting.

Removing the Router Bit

Use the spindle lock and wrench as described

above, and turn the collet chuck assembly in a

counter-clockwise direction. Once the collet

chuck assembly is loosened, continue to turn

the collet chuck until it pulls the collet free

from its taper, and the router bit can be removed.

NOTE: The collet chuck is self-extracting; it is

NOT necessary to strike the collet chuck to free

the bit.

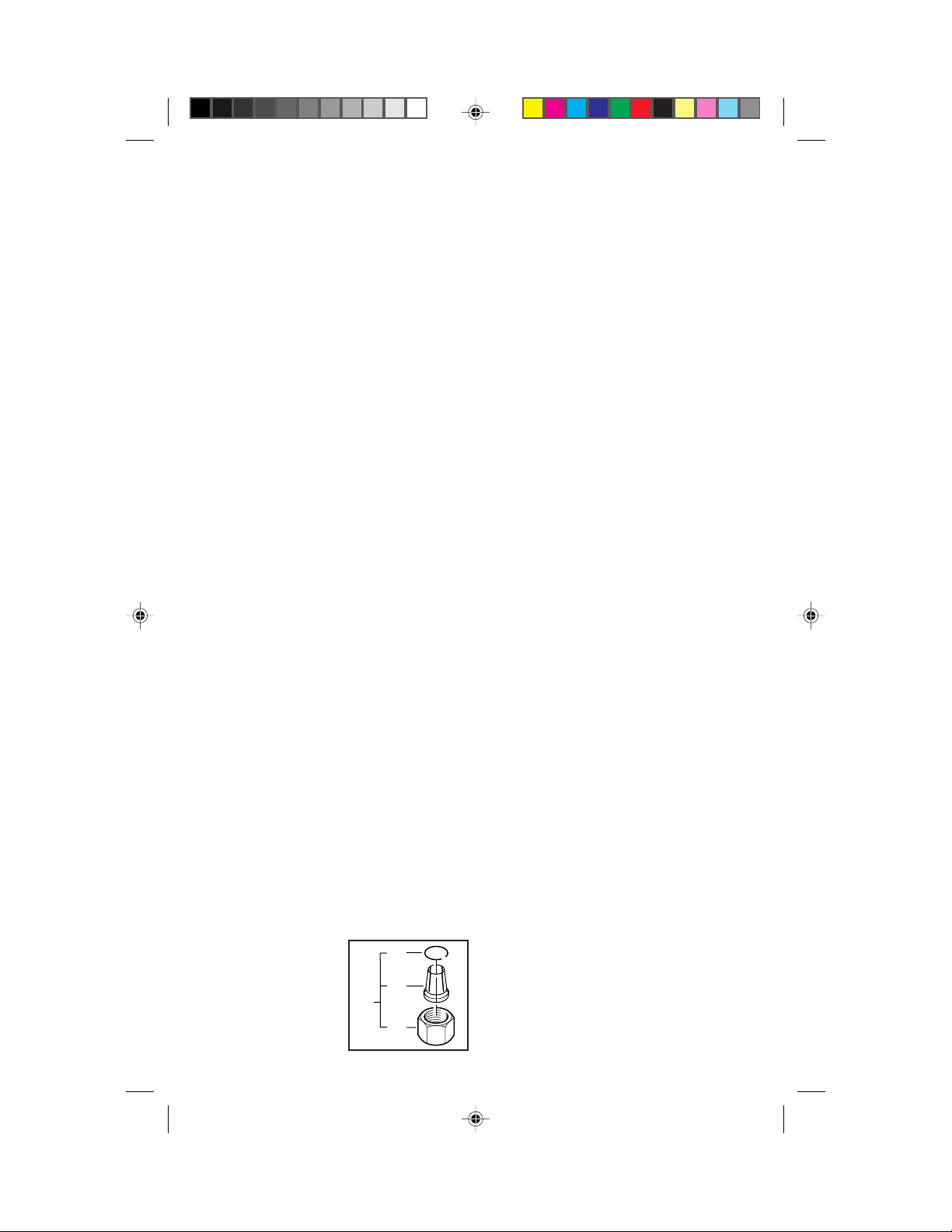

Collet Chuck Care

With the router bit removed, continue to turn

the collet chuck counter-clockwise until it is

free of the shaft. To assure a firm grip, occasionally blow out the collet chuck with compressed air, and clean the taper in the armature

assembly shaft with a tissue or fine brush. The

collet chuck is made up of three component

parts as illustrated;

check to see that the retaining ring 21 is properly located around the

collet 22 and seated in

the inner groove of the

collet chuck nut 23 and

21

22

25

23

lightly thread the collet chuck back onto the

armature shaft. Replace worn or damaged

collet chucks immediately.

Plunge Mechanism

To release the plunge mechanism, grasp the

router handles firmly with both hands and press

the plunge lock/release lever 16 with the thumb

of the left hand. The motor may then be raised

or lowered to the desired position. The plunge

lock/release lever is spring-loaded, and will

hold the router motor in position when pressure

on the lock lever is released. When plunging,

always apply uniform firm pressure to both

handles to avoid cocking the motor on the

posts.

Indicator Rod and Turret

The depth indicator rod 3 and the revolving

depth turret 7 are used to control cutting depth

as follows;

With the bit installed, gently lower the motor

until the tip of the router bit just contacts the

level surface the router is sitting on. This is the

“zero” position, from which further depth adjustments can be accurately made. To set a

desired depth of cut, rotate revolving depth

turret until the lowest step is aligned with the

depth indicator rod. Loosen depth indicator

lock/release knob 5 and lower the depth indicator rod until it contacts the lowest step of the

turret. Slide the depth indicator 4 until the red

line indicates zero on the depth scale, indicating

the point at which the bit just contacts the work.

To set a desired cutting depth, slide the depth

indicator rod up until the red depth indicator

line attains the desired cutting depth, and secure the rod in position by firmly tightening the

depth indicator lock/release knob. The desired

depth of cut may now be achieved by plunging

the router until the depth indicator rod contacts

the selected stop on the revolving depth turret.

To be certain that your depth settings are accurate, you may want to make test cuts in scrap

material before beginning work. Once the desired final depth has been set on the lowest

depth turret setting with the depth indicator

rod, it is possible to make progressively deeper

cuts by starting with a higher flat on the depth

turret and after each cut, rotating the revolving

7

BM 2610967928 1/97 12/7/98, 10:29 AM7

depth turret to progressively lower stops as

desired, until the final depth (lowest step or

flat) is reached.

Fine adjustment

The router is equipped with a true micrometertype fine adjustment mechanism, which can be

used in any plunge position and provides precise adjustment of the router bit position for

unmatched accuracy. When the tool is plunged

to the approximate position desired, this device

may be adjusted to precisely set the final cutter

position.

To use the fine adjustment, turn the fine adjust

knob 1 clockwise to lower the router bit or

counter-clockwise to raise it, as indicated by

the arrow molded into the top of the knob. To

allow precise settings, the indicator ring is

graduated in English and Metric increments,

and each line is equal to 1/10 mm or .004". The

indicator ring may be reset to zero without

moving the fine-adjust knob, to allow the user

to begin the adjustment from any reference

point desired.

The fine adjustment mechanism has a total

adjustment range of 5/8", which is indicated by

the two lines printed on back of the housing.

Whenever the fine adjustment is used, be certain that the index marker 17 is positioned

between these two lines to ensure that there will

be enough travel in the desired direction after

the router is plunged into position. Note that

when the router is plunged to maximum depth

or is fully retracted to the top of the posts, the

fine adjustment mechanism will not move the

motor further down or up, as the full extension

of the travel has been reached at these points.

Similarly, the fine adjustment cannot lower the

bit when the depth indicator rod is tightened

against the depth turret.

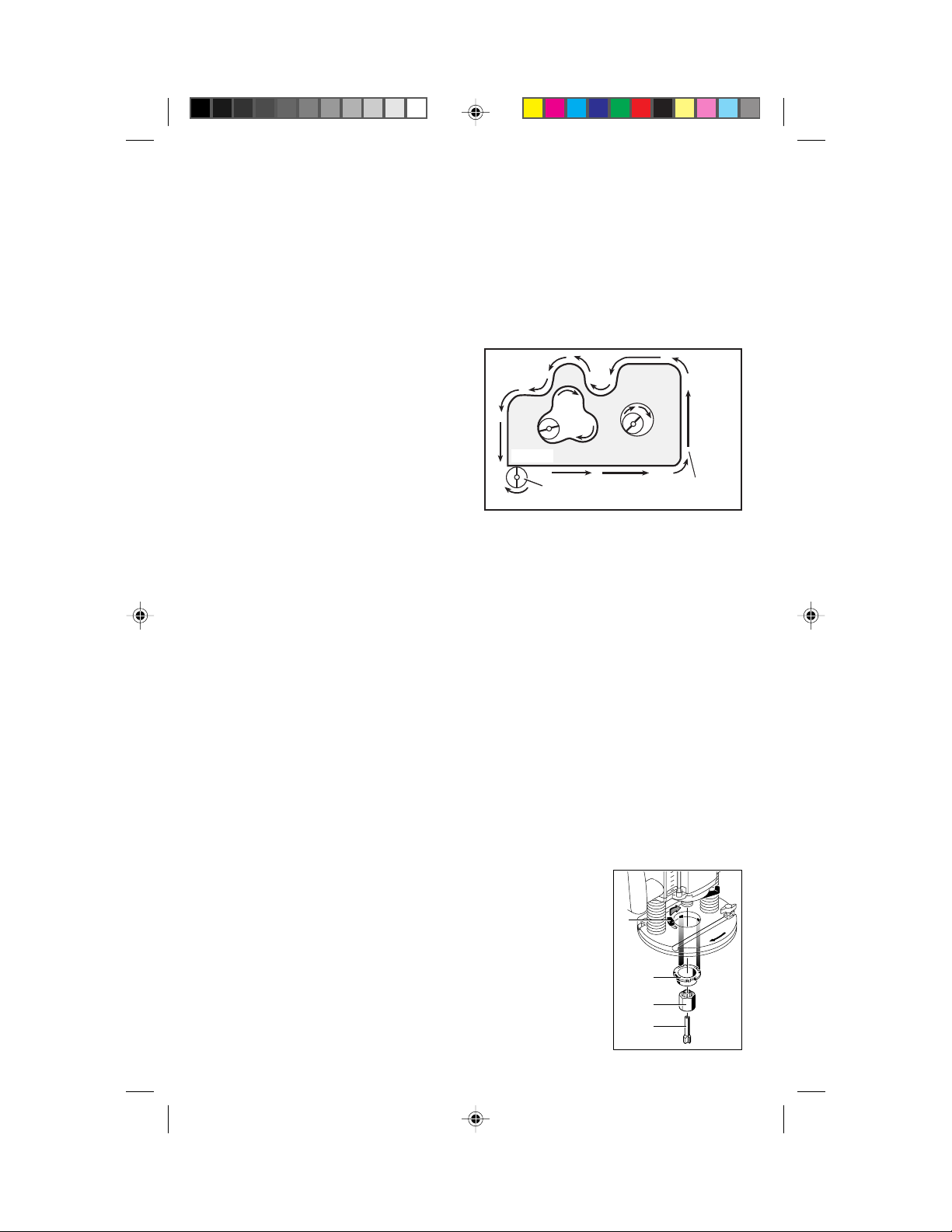

Direction of Feed

The router rotates in a clockwise direction, as

viewed from the top of the router. The correct

relationship between direction of router bit or

cutter rotation and router feed is shown below.

It is very important to move the router in the

proper direction or router bit chatter and rough

cutting will be the result. As an example, to

rout a decorative edge on the front of a table top,

you would move the router from left to right to

perform the operation, or counter-clockwise

around the workpiece. If you were cutting an

opening in the center of a panel, you would feed

the router in a clockwise direction, so that the

edge of the opening would be cut against the

rotation of the router bit as described, and have

a smooth finish. Whenever you are cutting

completely around a workpiece, it is advisable

to cut across the grain first, so any corner

tearout may be smoothed by cutting with the

grain on the second pass.

WORK

CUTTER

DIRECTION

OF FEED

Rate of Feed

When routing or doing related work in wood

and plastics, the best finishes will result if the

depth of cut and feed rate are regulated to keep

the motor operating at high speed. Feed the

router at a moderate rate. Soft materials require

a faster feed rate than hard materials.

The router may stall if improperly used or

overloaded. Reduce the feed rate to prevent

possible damage to the tool. Always be sure the

collet nut is tightened securely before use.

Always use router bits with the shortest cutting

length necessary to produce the desired cut.

This will minimize router bit run-out and chatter.

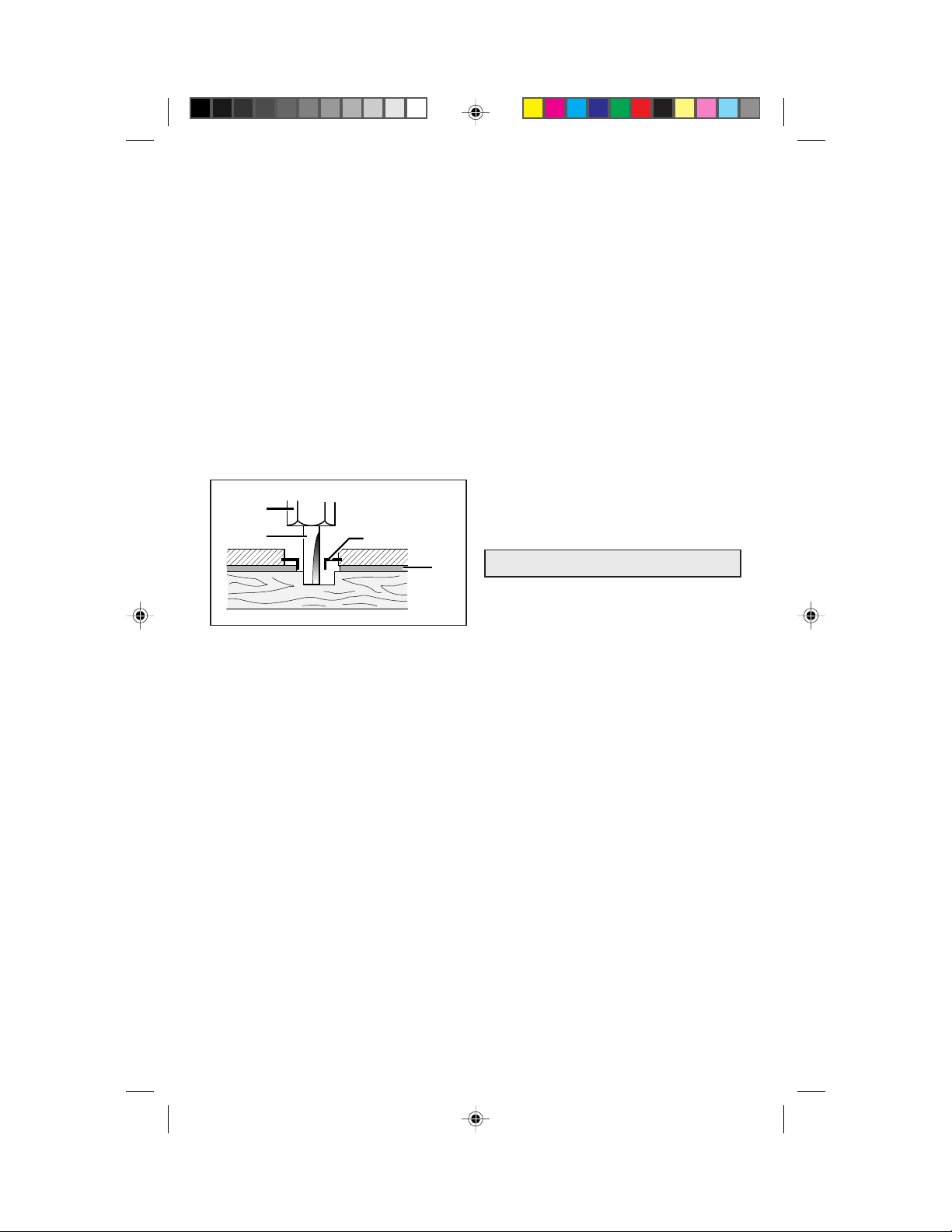

Templet Guides

The router is equipped with an exclusive quickchange templet guide mechanism, which firmly

grips the guides with a spring-loaded ring built

into the base. To insert or change the

templet guide 24, retract the templet

6

guide lock/release

lever 6. Align any

two of the four cutaway tabs on the

templet guide to the

two cast-in bosses in

the templet guide re-

24

23

26

cess of the base.

8

BM 2610967928 1/97 12/7/98, 10:29 AM8

Insert the templet guide and release the lock

lever to grip the templet guide in place.

Templet guides are used with a number of

special accessories, such as hinge templets and

dovetail fixtures which are listed in your

BOSCH catalog. In addition, special templets

are easily prepared for cutting repeated patterns, special designs, inlays, and other

applications. A templet pattern may be made of

plywood, hardboard, metal or even plastic, and

the design can be cut with a router, jigsaw, or

other suitable cutting tool. Remember that the

pattern will have to be made to compensate for

the distance between the router bit and the

templet guide 24, as the final workpiece will

differ in size from the templet pattern 27 by that

amount, due to the cutter position.

23

26

24

27

Deluxe Router Guide

For routing operations such as grooving or

dadoing, it is often necessary to guide the tool

in a line parallel to a straight edge. One method

of obtaining a straight cut is to securely clamp

a board or other straightedge to the work surface, and guide the edge of the router sub-base

along this path. It is best to keep the router in one

position as it is moved along the guide, as this

will produce the straightest cut.

The Bosch deluxe router guide is an accessory

that will guide the router parallel to a straight

edge or around a curved surface. The deluxe

router guide is supplied with two rods and a

series of wing nuts and screws to fasten the

guide and adjust its position relative to the bit.

With the guide installed and adjusted, the router

should be fed normally, keeping the guide in

contact with the edge of the workpiece at all

times. The deluxe router guide may also be

positioned under the router base for operations

where a limited amount of bit exposure is desired.

The Bosch deluxe router guide includes a

fine-adjustment mechanism for extra precision,

and removable face plates for guiding the router

along straight or curved surfaces. For proper

operation, please refer to the instructions which

are included with this accessory.

Chip Extraction

Your router may be fitted with optional chip

extraction accessories, which are available from

your Bosch dealer. Chip extraction is most

effective on grooving, dadoing, and other flatsurface operations where flying chips can be

controlled. It is less effective on edge forming

or when template guides are used as the vacuum

efficiency is greatly diminished in such circumstances.

WARNING! Use of any accessory not speci-

fied in this manual or the BOSCH catalog for

use with this tool may create a hazard.

Maintenance and Service

WARNING! Preventive maintenance per-

formed by unauthorized personnel may result

in misplacing of internal wires and components

which could cause serious hazard. We recommend that all tool service be performed at a

Bosch Factory Service Center.

Tool Lubrication

Your Bosch tool has been properly lubricated

and is ready for use. We recommend, that tools

with gears be regreased with a special gear

lubricant every time the brushes are changed.

Carbon Brushes

The brushes and commutator in your Bosch

tool have been engineered for many hours of

dependable service. To maintain peak efficiency of the motor, we recommend that every

two to six months the brushes be examined.

Only genuine Bosch replacement brushes specially designed for your tool should be used.

Bearings

After about 300-400 hours of operation, or at

every second brush change, the bearings should

be replaced at a Bosch Factory Service Center.

Bearings which become noisy (due to heavy

load or very abrasive material cutting) should

be replaced at once to avoid overheating and

motor failure.

9

BM 2610967928 1/97 12/7/98, 10:29 AM9

Loading...

Loading...