Banner EZ-SCREEN User Manual

EZ-SCREEN® Safety Light Screen

Original

Features

•An optoelectronic safeguarding device

•Standard and cascadeable models available

•Compact package for smaller production machines, robust for large power presses

•Creates a screen of synchronized, modulated infrared sensing beams. Choose from two resolutions, sized in 150 mm (6″) increments:

14 mm (0.55″) resolution models with defined areas from 150 mm to 1.8 m (6″ to 71″)

30 mm (1.18″) resolution models with defined areas from 150 mm to 2.4 m (6″ to 94.5″)

•Optional remote Test input terminals for simulating a “blocked” condition (available on some emitter models)

•Easily configured Reduced Resolution (Floating Blanking)

•Three-digit display provides diagnostic information and indicates number of beams blocked

•Zone indicators identify blocked beams

•FMEA tested to ensure control reliability

•Receiver LEDs provide system status and emitter/ receiver alignment indications

•Highly immune to EMI, RFI, ambient light, weld flash, and strobe light

•Two-piece design with External Device Monitoring

•Aux. output option to monitor the state of the OSSDs

•Vibration-tolerant, factory burned-in emitter and receiver circuitry for toughness and dependability

•Up to four pairs of emitters and receivers of different lengths can be cascaded (SLSC.. models)

•Safety PLC input compatible (per OSSD specifications)

C R  US

US

Section Contents

Section 1 |

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. Page 1 |

Section 2 System Components and Specifications . . . . . . |

. Page 6 |

|

Section 3 |

Installation and Alignment . . . . . . . . . . . . . . . . . . |

Page 21 |

Section 4 |

System Operation . . . . . . . . . . . . . . . . . . . . . . . . |

Page 41 |

Section 5 Troubleshooting and Maintenance . . . . . . . . . . . |

Page 46 |

|

Section 6 |

Checkout Procedures . . . . . . . . . . . . . . . . . . . . . |

Page 51 |

Section 7 |

Cascadeable EZ-SCREEN . . . . . . . . . . . . . . . . . |

Page 53 |

|

|

|

Printed in USA |

03/13 |

P/N 112852 rev. H |

Table of Contents |

EZ-SCREEN |

|

|

|

Instruction Manual |

1. System Overview . . . . . . . . . . . . . . . . |

. |

|

page 1 |

Important ... |

|||

|

|||||||

1.1 |

Introduction . . . . . . . . . . . . . . . . . |

1 |

|

||||

1.2 |

Applications and Limitations . . . . . . . . . . . |

. |

. . |

. . |

2 |

read this page before proceeding! |

|

1.3 |

Control Reliability: Redundancy and Self-Checking . . |

. |

. . |

. . |

2 |

||

|

|||||||

1.4 |

Operating Features . . . . . . . . . . . . . . |

. |

. . |

3 |

|

||

2.System Components and Specifications . . . . . . . . . Page 6

2.1Emitter and Receiver Models – 14 mm . . . . . . . . . . . . 7

2.2Emitter and Receiver Models – 30 mm . . . . . . . . . . . . 8

2.3 |

Cables . . . . . . . . . . . . . |

. |

. . |

. |

|

|

|

|

9 |

|

2.4 |

Accessories . . . . . . . . . . . |

. |

. . |

. |

. |

. |

|

|

|

10 |

2.5 |

Replacement Parts . . . . . . . . |

. |

. . |

. |

. |

. . |

. . |

|

16 |

|

2.6 |

Literature . . . . . . . . . . . . |

. |

. . |

. |

. |

|

|

|

|

16 |

2.7 |

Specifications . . . . . . . . . . |

. |

. . |

. |

. . |

|

. |

|

|

17 |

3. Installation and Alignment . . . . . . . . . . . . . . Page 21

3.1Mechanical Installation Considerations . . . . . . . . . . . . 21

3.2 |

Mechanical Mounting Procedure . . . . . . . . . . . . . . |

28 |

3.3 |

Initial Electrical Connections . . . . . . . . . . . . . . . |

. 29 |

3.4Light Screen Initial Checkout . . . . . . . . . . . . . . . . 30

3.5Electrical Interface to the Guarded Machine (Permanent

Hookup) . . . . . . . . . . . . . . . . . |

34 |

3.6 Preparing for System Operation . . . . . . . . . . . . . . |

38 |

3.7Sensor “Swapability” and the Optional Emitter Hookup . . . . . .38

4. System Operation . . . . . . . . . . . . . . . . . Page 41

4.1 |

Security Protocol . . . . . . . . . . . . . . . |

. |

. |

|

41 |

4.2 |

System Configuration Settings . . . . . . . . . . . . . . . 41 |

||||

4.3 |

Reset Procedures . . . . . . . . . . . . . . . |

. |

. |

|

42 |

4.4 |

Status Indicators . . . . . . . . . . . . . . . |

. |

. |

|

43 |

4.5 |

Normal Operation . . . . . . . . . . . . . . . |

. |

. |

|

46 |

4.6 |

Periodic Checkout Requirements . . . . . . . . . |

. |

. |

. . . |

46 |

5.Troubleshooting and Maintenance . . . . . . . . . . . Page 47

5.1Troubleshooting Lockout Conditions . . . . . . . . . . . . . 47

5.2 |

Test Mode . . . . . . . . . . . . . . . . . |

50 |

5.3 |

Electrical and Optical Noise . . . . . . . . . . . . . . . . |

51 |

5.4 |

Servicing and Maintenance . . . . . . . . . . . . . . . . |

51 |

6. Checkout Procedures . . . . . . . . . . . . . . . . |

|

Page 52 |

|||

6.1 |

Schedule of Checkouts . . . . . . . . . . . . . . |

. |

. |

. |

52 |

6.2 |

Commissioning Checkout . . . . . . . . . . . . . |

. . . . 52 |

|||

6.3 |

Shift/Daily Checkout . . . . . . . . . . . . . . . |

. |

. |

|

53 |

6.4 |

Semi-Annual (Six-Month) Checkout . . . . . . . . . |

. |

. |

. . |

53 |

7. Cascadeable EZ-SCREEN . . . . . . . . . . . . . . . Page 54

7.1 Overview of Cascading . . . . . . . . . . . . . . . . . 54

7.2Cascadeable Emitter and Receiver Models – 14 mm . . . . . . 55

7.3Cascadeable Emitter and Receiver Models – 30 mm . . . . . . 56

7.4Determining Interconnect Cable Lengths . . . . . . . . . . . 57

7.5Response Time for Cascaded Light Screens . . . . . . . . . 59

7.6Cascaded Sensor Configuration Settings . . . . . . . . . . . 61

7.7Programming for Cascaded Operation . . . . . . . . . . . . 61

7.8E-Stop Buttons and Rope/Cable Pulls . . . . . . . . . . . . 62

7.9Positive-Opening Safety Interlock Switches . . . . . . . . . . 63

Glossary of Terms . . . . . . . . . . . . . . . . . Page 65 Safety Standards and Regulations . . . . . . . . Inside Back Cover

In the United States, the functions that EZ-SCREEN is intended to perform are regulated by the Occupational Safety and Health Administration (OSHA). Outside of the United States, these functions are regulated by other agencies, organizations, and governments. Whether or not any particular EZ-SCREEN installation meets all applicable requirements depends upon factors that are beyond the control of Banner Engineering Corp. These factors include the details of how the EZ-SCREEN is applied, installed, wired, operated, and maintained. It is the responsibility of the purchaser and user to apply this EZ-SCREEN System in full compliance with all relevant applicable regulations and standards.

EZ-SCREEN can guard against accidents only when it is properly installed and integrated into the machine, properly operated, and properly maintained. Banner Engineering Corp. has attempted to provide complete application, installation, operation, and maintenance instructions. In addition, please direct any questions regarding application or use of EZ-SCREEN to the factory applications department at the telephone number or addresses shown on the back cover.

In addition to OSHA regulations, several other organizations provide information about the use of safeguarding devices. Refer to the American National Standards Institute (ANSI), the Robotics Industries Association (RIA), the Association for Manufacturing Technology (AMT), and others (see below). Banner Engineering Corp. makes no claim regarding a specific recommendation of any organization, the accuracy or

effectiveness of any information provided, or the appropriateness of the provided information for a specific application.

The user has the responsibility to ensure that all local, state, and national laws, rules, codes, and regulations relating

to the use of this safeguarding system in any particular application are satisfied. Extreme care is urged to ensure that all legal requirements have been met and that all installation and maintenance instructions contained in this manual are followed.

U.S. Standards Applicable to Use of EZ-SCREEN

OSHA 29CFR1910 Occupational Safety and Health Standards ANSI B11 Standards Safeguarding of Machine Tools ANSI/RIA R15.06 Safety Requirements for Robot Systems NFPA 79 Electrical Standard for Industrial Machinery

See inside back cover for information pertaining to applicable U.S., European and International standards, and where to acquire copies.

Banner Engineering Corp. • Minneapolis, U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

EZ-SCREEN

Instruction Manual

Overview

1. System Overview

1.1 Introduction

The Banner EZ-SCREEN provides a redundant, microprocessorcontrolled, opposed-mode optoelectronic “curtain of light,” or “safety light screen.” It typically is used for point-of-operation safeguarding, and is suited to safeguard a variety of machinery.

EZ-SCREEN is extensively FMEA (Failure Mode and Effects Analysis) tested to establish an extremely high degree of confidence that when properly installed, no system component will (even if it should fail) cause a failure to danger.

In typical operation, if any part of an operator’s body (or any opaque object) of more than a pre-determined cross section is detected, the OSSD solid-state safety outputs will turn off.

These safety outputs are connected to the guarded machine’s Final Switching Devices (FSDs) that control the primary control elements (MPCEs), which immediately stop the motion of the guarded machine.

The OSSD (Output Signal Switching Device) safety outputs are capable of performing a “handshake” communication with the Muteable Safety Stop Interface (MSSI) or Universal Safety

Stop Interface (USSI) found on other Banner Engineering safety products.

Banner EZ-SCREEN is a two-piece (“two-box”) system – comprising an emitter and a receiver, but no external controller. The External Device Monitoring (EDM) function ensures the fault detection capability required by U.S. Control Reliability and ISO13849-1 Categories 3 and 4 without a third box, a controller or a “smart” (i.e., self-checking) safety module required of systems without EDM.

An auxiliary (aux.) output may be used to signal the state of the OSSDs to a process controller; see Section 1.4.3.

Emitters have a row of synchronized modulated infrared (invisible) light-emitting diodes (LEDs) in a compact rectangular metal housing. Receivers have a corresponding row of synchronized photodetectors. The dimensions of the light screen created by the emitter and receiver are called the “defined area”; its width and height are determined by the length of the sensor pair and the distance between them. The maximum range is dependent on the resolution; range decreases if corner mirrors are used. Emitter and receiver pairs with 14 mm (0.55") resolution have a maximum range of 6 m (20'), and pairs with 30 mm (1.18") resolution have a maximum range of 18 m (60').

Electrical connections are made through M12 (or Euro-style) quick-disconnects. Some emitter models have a 5-pin connector for power and the Test function. Other emitters and all receivers have an 8-pin connector for power, ground, inputs and outputs.

Functions such as Trip/Latch select, Display Invert, Cascading, Fixed Blanking, Reduced Resolution (Floating Blanking), Scan Code select, and External Device Monitoring are described in Section 1.4. All models require a supply voltage of +24V dc ±15%. See Section 2.4 for interfacing solutions.

Both emitter and receiver feature 7-segment Diagnostic Displays and individual LEDs to provide continuous indication of the EZ-SCREEN’s operating status, configuration and error conditions. See Section 1.4.7 for more information.

This manual contains numerous WARNING and CAUTION statements. Warnings refer to situations that could lead to significant or serious personal injury or death. Cautions refer to situations that could lead to slight personal injury or potential damage to equipment.

Figure 1-1. A typical EZ-SCREEN application: weld cell

Banner Engineering Corp. • Minneapolis, U.S.A.

www.bannerengineering.com • Tel: 763.544.3164 |

P/N 112852P/N133487 |

1 |

|

|

|

Overviei w |

|

|

|

|

|

|

EZ-SCREEN |

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

Instruction Manual |

|

|

|

|

1.2 Applications and Limitations |

|

|

|

||||||

|

|

|

WARNING . . . Read this Section Carefully |

|

|||||||

|

The Banner EZ-SCREEN is intended for point-of-operation |

|

Before Installing the System |

|

|||||||

|

|

|

|

|

|

|

|

||||

|

machine guarding applications and other safeguarding |

|

The user is responsible for satisfying all local, state, and national |

|

|||||||

|

applications. It is the user’s responsibility to verify whether the |

|

laws, rules, codes, or regulations relating to the installation and |

|

|||||||

|

safeguarding is appropriate for the application and is installed, |

|

use of this control system in any particular application. Take |

|

|||||||

|

as instructed by this manual, by a Qualified Person. |

|

extreme care to meet all legal requirements and follow all installation |

|

|||||||

|

Before installing the EZ-SCREEN, read this manual in its |

|

and maintenance instructions contained in this manual. |

|

|||||||

|

|

The user has the sole responsibility to ensure that the |

|

||||||||

|

entirety, paying particular attention to this section and all of |

|

|

||||||||

|

Section 3. The EZ-SCREEN’s ability to perform its safeguarding |

|

EZ-SCREEN is installed and interfaced to the guarded machine |

|

|||||||

|

function depends upon the appropriateness of the application |

|

by Qualified Persons in accordance with this manual and |

|

|||||||

|

and upon its proper mechanical and electrical installation |

|

applicable safety regulations. |

|

|||||||

|

and interfacing to the guarded machine. If all mounting, |

|

Carefully read this manual in its entirety, paying particular attention to |

|

|||||||

|

installation, interfacing, and checkout procedures are not |

|

Section 1.2 and all of Section 3, before installing the System. Failure |

|

|||||||

|

followed properly, the EZ-SCREEN cannot provide the |

|

to follow these instructions could result in serious bodily injury |

|

|||||||

|

protection for which it was designed. |

|

or death. |

|

|

|

|

|

|||

|

EZ-SCREEN is typically used, but is not limited to, the |

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

||||

|

following applications: |

|

WARNING . . . Install EZ-SCREEN Only on |

|

|||||||

|

• Small assembly equipment |

|

Appropriate Applications |

|

|||||||

|

|

• Molding and power presses |

|

|

|||||||

|

|

|

|

|

|

|

|

|

|||

|

|

•Automated production equipment |

|

Banner EZ-SCREEN is for use only on machinery that can be |

|

||||||

|

|

• Robotic work cells |

|

stopped immediately after a stop signal is issued at any point in |

|

||||||

|

|

•Assembly and packaging machines |

|

the machine’s stroke or cycle, such as part-revolution clutched |

|

||||||

|

|

• Lean manufacturing systems |

|

machines. Under no circumstances may EZ-SCREEN be used |

|

||||||

|

|

EZ-SCREEN may NOT be used with the following machinery |

|

on full-revolution clutched machinery or in unsuitable applications |

|

||||||

|

|

|

as those listed at left. If there is any doubt about whether or |

|

|||||||

|

|

or unsuitable applications: |

|

|

|||||||

|

|

|

not your machinery is compatible with EZ-SCREEN, contact |

|

|||||||

|

|

•Any machine that cannot be stopped immediately after a stop |

|

|

|||||||

|

|

|

Banner’s Application Engineers at the factory. |

|

|||||||

|

|

signal is issued, such as single-stroke (or “full-revolution”) |

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|||

|

|

clutched machinery. |

|

1.3 Control Reliability: Redundancy and Self-Checking |

|

|

|||||

|

|

•Any machine with inadequate or inconsistent machine |

|

|

|||||||

|

|

response time and stopping performance. |

|

Redundancy requires that EZ-SCREEN System circuit |

|

||||||

|

|

•Any machine that ejects materials or component parts through |

|

|

|||||||

|

|

|

components be “backed up” to the extent that, if the failure of |

|

|||||||

|

|

the defined area. |

|

a single component will prevent effective machine stopping |

|

||||||

|

|

• In any environment that is likely to adversely affect |

|

action when needed, that component must have a redundant |

|

||||||

|

|

photoelectric sensing efficiency. For example, corrosive |

|

counterpart which will perform the same function. The |

|

||||||

|

|

chemicals or fluids or unusually severe levels of smoke or |

|

EZ-SCREEN is designed with redundant microprocessors. |

|

||||||

|

|

dust, if not controlled, may degrade sensing efficiency. |

|

Redundancy must be maintained for as long as the EZ-SCREEN |

|

||||||

|

|

•As a tripping device to initiate or reinitiate machine motion |

|

is in operation. Because a redundant system is no longer |

|

||||||

|

|

(PSDI applications), unless the machine and its control system |

|

redundant after a component has failed, EZ-SCREEN is |

|

||||||

|

|

fully comply with the relevant standard or regulation (see |

|

designed to monitor itself continuously. A component failure |

|

||||||

|

|

OSHA 29CFR1910.217, ANSI/NFPA 79, ANSI B11, ANSI/ |

|

detected by or within the self-checking system causes a |

|

||||||

|

|

RIA R15.06, ISO 12100, IEC 60204-1, IEC 61496, or other |

|

“stop” signal to be sent to the guarded machine and puts the |

|

||||||

|

|

appropriate standard). |

|

EZ-SCREEN into a Lockout condition. |

|

||||||

|

|

If an EZ-SCREEN is installed for use as a perimeter guard |

|

Recovery from this type of Lockout condition requires: |

|

||||||

|

|

(i.e., where a pass-through hazard may exist), the dangerous |

|

replacement• |

of the failed component (to restore redundancy) |

|

|||||

|

|

machine motion can be initiated by normal means only |

|

|

|||||||

|

|

|

and |

|

|

|

|

|

|||

|

|

after the safeguarded area is clear of individuals and the |

|

|

|

|

|

|

|||

|

|

|

the appropriate• |

reset procedure (see Section 1.4.8). |

|

||||||

|

|

EZ-SCREEN has been manually reset. See Section 3.1.2. |

|

|

|||||||

|

|

|

|

|

|

The Diagnostic Display is used to diagnose causes of a Lockout |

|

||||

|

|

|

|

|

|

condition (see Section 5.1). |

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Banner Engineering Corp. • Minneapolis, U.S.A. |

|

|

2 |

|

P/N 133487 |

|

|

|

|

|

www.bannerengineering.com • Tel: 763.544.3164 |

|

||

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

EZ-SCREEN |

|

|

Overview |

||

|

|

|

|

||

Instruction Manual |

|

|

|

|

|

|

1.4 Operating Features |

|

1.4.2 Emitter QD and Hookup Options |

|

|

The Banner EZ-SCREEN models described by this manual feature several standard selectable functions:

•Reduced Resolution (Floating Blanking),

•Trip or Latch Output,

•External Device Monitoring (EDM),

•Auxiliary Output,

•Scan Code setting,

•Fixed Blanking,

•Inverted Display, and

•Cascading (available on SLSC.. models).

These functions are configured within the sensors, behind the access cover on the front of each sensor and in the sensor wiring configuration; see Sections 3 and 4.2 for more information and configuration DIP switches.

The resolution and the maximum range can be determined by the model number on the emitter and receiver. See Section 2 for a list of model numbers.

1.4.1 Selectable Trip/Latch Output

The setting for Trip or Latch Output also determines whether the System will enter RUN mode automatically or if it will require a manual reset first (see Sections 1.4.8 and 4.2). If the System is set for Trip Output, other measures must be taken to prevent a pass-through hazard; see Section 3.1.2 and the warning below for more information.

An EZ-SCREEN emitter with an 8-pin connector can be connected to its own power supply or to the receiver cable color-for-color (see Figures 3-19 and 3-20). The color-for- color hookup allows the emitter and receiver positions to be interchanged without rewiring.

NOTE: An EZ-SCREEN emitter with 5-pin connector and Test function (see Section 1.4.4) is not capable of the color- for-color hookup.

1.4.3 External Device Monitoring (EDM)

This feature allows the EZ-SCREEN System to monitor the status of external devices, such as MPCEs. The choices are

1- or 2-channel monitoring, or no monitoring. EDM is used when the EZ-SCREEN OSSD outputs directly control the MPCEs or other external devices; see Sections 3.5.3 and 4.2 for more information.

Auxiliary (Aux.) Output

An aux. output function is available when the receiver is configured for 1-channel EDM (for receivers with date code 0834 or newer). This current sourcing (PNP) solid-state output (75 mA max.) is used for control functions that are not safetyrelated. A typical use is to signal the state of the OSSDs to a programmable logic controller (PLC). The aux. output follows the state of the OSSDs. Pin 2 (orange/black) supplies the connection; see Section 3.5.5 and Figure 3-23.

If Trip Output is selected, the OSSD outputs will turn ON after power is applied, and the receiver passes its internal self-test/ synchronization and recognizes that all beams are clear. The Trip Output will also automatically reset after all beams are cleared. If Latch Output is selected, the EZ-SCREEN requires a manual reset for the OSSD outputs to turn ON, after power is applied and all beams are clear (see Section 4.5).

WARNING . . . Use of Trip/Latch Output

WARNING . . . Use of Trip/Latch Output

Application of power to the EZ-SCREEN components, the clearing of the defined area, or the reset of a Latch condition MUST NOT initiate dangerous machine motion. Machine control circuitry must be designed so that one or more initiation devices must be engaged (i.e., a conscious act) to start the machine – in addition to the EZ-SCREEN going into RUN mode. Failure to follow these instructions could result in serious bodily injury or death.

1.4.4 Remote Test Input

On 5-pin EZ-SCREEN emitter models (model numbers SLSE..-.. Q5; see Tables 2.1 and 2.2), a Test function is provided. A pair of wires is connected from the emitter (see Section 3.5.6) to an external switch, typically a normally open contact, held closed. Opening a switch connected between these two terminals “turns off” the emitter, simulating an interruption of one or more light beams. This remote Test input may be useful for EZ-SCREEN System setup and to verify machine control circuit operation.

1.4.5 Scan Code Configuration

The emitter and receiver may be configured to one of two Scan Code positions (1 or 2). Scan codes enable a receiver to recognize beams only from an emitter with the same Scan Code setting. This helps minimize the effects of crosstalk between multiple emitter/receiver pairs, and allows multiple pairs to operate in close proximity in certain situations. See Sections 3.1.5 and 3.1.8 for proper mounting configurations. The Scan Code is set using the selection switch in each sensor’s configuration port; see Section 4.2 for more information. Both the emitter and its corresponding receiver must be set to the identical setting.

Banner Engineering Corp. • Minneapolis, U.S.A.

www.bannerengineering.com • Tel: 763.544.3164 |

P/N 133487 |

3 |

|

|

|

Overviei |

w |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

EZ-SCREEN |

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Instruction Manual |

|

|||||

|

|

1.4.6 Reduced Resolution (Floating Blanking) |

Resolution directly affects the minimum allowable distance |

|

||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

between the defined area of a light screen and the nearest |

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

|

Reduced Resolution increases the minimum diameter of an |

hazard point (separation distance, see Section 3.1.1). The |

|

|||||||||||||||||||||||||||||||||

|

object that the light screen can reliably detect anywhere within |

green status indicator on the receiver flashes when Reduced |

|

|||||||||||||||||||||||||||||||||

|

its defined area. Reduced Resolution is generally used to allow |

Resolution is enabled. The ignored object size and resultant |

|

|||||||||||||||||||||||||||||||||

|

one or more objects (usually workpiece materials) to move |

Reduced Resolution are listed in Section 3.4.2. |

|

|

|

|

|

|

||||||||||||||||||||||||||||

|

through the defined area, at any point, without tripping the |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||

|

OSSD safety outputs. |

1.4.7 Status Indicators |

|

|

|

|

|

|

||||||||||||||||||||||||||||

|

Selecting two-beam Reduced Resolution will reduce the overall |

|

|

|

|

|

|

|||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||

|

minimum object sensitivity, which allows multiple objects to |

Status indicators on both the emitter and receiver are clearly |

|

|||||||||||||||||||||||||||||||||

|

move through the defined area (see Section 3.4.2). The effect |

visible on each sensor’s front panel. |

|

|

|

|

|

|

||||||||||||||||||||||||||||

|

is that every two consecutive beams (except for the sync beam) |

• Emitter: |

|

|

|

|

|

|

||||||||||||||||||||||||||||

|

can be blocked, but not cause the OSSDs to turn OFF. This is |

Bi-color red/green Status indicator – shows whether power is |

|

|||||||||||||||||||||||||||||||||

|

also called “Multiple-Point Floating Blanking.” |

|

||||||||||||||||||||||||||||||||||

|

applied, and whether the emitter is in RUN mode, TEST mode, |

|

||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

or Lockout condition. |

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1-Digit Diagnostic Display – indicates specific error or |

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

configuration conditions. |

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

Beams of |

|

|

|

|

|

|

• Receiver: |

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

Defined Area |

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Bi-color red/green Zone indicators – show status of a group of |

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

beams: |

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

- aligned and clear (green ON), or |

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

- blocked and/or misaligned (red ON), or |

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

- fixed blanked area (flashing green). |

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Yellow Reset indicator – shows System status: |

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

- RUN mode (ON) or |

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

- waiting for a reset (flashing). |

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Bi-color red/green Status indicator – shows System status: |

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

- Reduced Resolution enabled (flashing green), |

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

- outputs are ON or OFF (green ON or red ON), or |

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

- the System is in Lockout condition (flashing red). |

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Workpiece |

|

|

|

|

|

|

|||||||||||||||

|

|

|

|

|

|

Press Break |

|

|

|

|

|

|

|

|

3-Digit Diagnostic Display – indicates specific error, |

|

||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||

|

|

|

|

|

|

|

Die |

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

configuration conditions, or total number of blocked beams. |

|

|||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

|

Figure 1-2. Reduced Resolution |

|

See Sections 4.4 and 5.1 for more information about specific |

|

||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

indicator and Diagnostic Display code meanings. |

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||

|

|

|

Receiver |

|

|

|

|

Emitter |

|

|

|

|

|

|

|

|

||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3-digit |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1-digit |

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Diagnostic |

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Diagnostic |

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Display |

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Display |

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Zone Indicators |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

(each shows |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

status of approx. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

1/8 of the total |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Yellow Reset |

|

|

|

|

|

|

|||||||||||

|

|

beams) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Indicator |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Status Indicator |

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Status Indicator |

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(Red/Green) |

|

|

|

(Red/Green) |

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

Zone 1 Indicator |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

(indicates beam synchronization status) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Figure 1-3. EZ-SCREEN emitter and receiver status indicators |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Banner Engineering Corp. • Minneapolis, U.S.A. |

|

||||||

4 |

|

P/N 133487 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

www.bannerengineering.com • |

Tel: 763.544.3164 |

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

EZ-SCREEN

Instruction Manual

1.4.8 Manual Resets and Lockout Conditions |

1.4.10 Inverted Display |

Overview

Reset Routine

The EZ-SCREEN requires a manual reset to clear a PowerUp Lockout or Latch condition, and after correcting the cause of a Lockout condition. This function is designed to provide a “monitored manual reset” (i.e., open-closed-open action), such

that a shorted or tied-down button cannot cause a reset. When a key-operated switch is used, this is typically called a key reset.

A push button, located under the access cover, can be used to invert the display. This is desirable when an emitter and receiver are mounted with the QD connector ends up. A replacement access cover with an inverted label is included with each emitter and receiver to accommodate inverted mounting. (See Section 4.4).

To perform a manual reset, close the normally open switch for at least 1/4 second, but no longer than 2 seconds, and then re-open the switch. See Sections 3.1.3 and 4.3 for further information.

A Lockout condition will cause the EZ-SCREEN OSSD outputs to turn OFF. A Lockout condition is indicated by a flashing Red Status indicator and an error number displayed on the Diagnostic Display. Internal Lockout conditions require a manual reset routine to return the system to RUN mode after

the failure has been corrected and the input has been correctly cycled. A description of possible lockouts, their causes, and troubleshooting hints are listed in Section 5.

Trip Output/Auto Reset

While the use of a reset switch is recommended, it is not required for receivers configured for Trip Output (automatic reset). Cycling the supply power (OFF for > 2 seconds, then ON) will also clear lockouts if their cause has been corrected. If a reset switch is not used, leave pin 8 (violet wire) not connected (open) and secure it against shorting to a source of power or ground.

1.4.9 Fixed Blanking

The fixed blanking feature allows for a stationary object(s), such as tooling, to be ignored while it remains positioned in the defined area. A flashing Green Zone indicator denotes the location of a blanked area. If the object is moved or removed, the System goes into a lockout mode. This ensures that an unexpected hole in the sensing field is not created.

Fixed blanking is easily programmed, simply by positioning the objects, flipping two DIP switches and resetting the System, as described in Section 3.4.3.

1.4.11 Cascadeable Models

Emitter and receiver models SLSC..* (see Section 7) are capable of interconnecting up to four emitter/receiver pairs – regardless of the resolution, the total number of beams, or the size of the defined area. EZ-SCREEN cascadeable models can also be used individually as stand-alone systems.

Special cabling is not required, but the double-ended 22 awg cordsets listed in Section 2.3 are recommended. See Section 7.4 for maximum cable lengths. Pigtail QD models may be used to reduce the number of required cables.

Response time is dependent on the number of beams in the light screen, and the light screen’s position in the cascade. Maximum system response time can be calculated easily for these cascaded systems, in two ways:

•Individually for each light screen in the cascade (separation distance is calculated for each light screen in the cascade), or

•Based on the worst-case maximum for the entire cascade (all light screens in the cascade have the same separation distance).

See Section 7.5 for more information.

*Models SLSC..-150.. not available.

Banner Engineering Corp. • Minneapolis, U.S.A.

www.bannerengineering.com • Tel: 763.544.3164 |

P/N 133487 |

5 |

|

ComponentsOverview andSpecifications

2. Components and Specifications

EZ-SCREEN

Instruction Manual

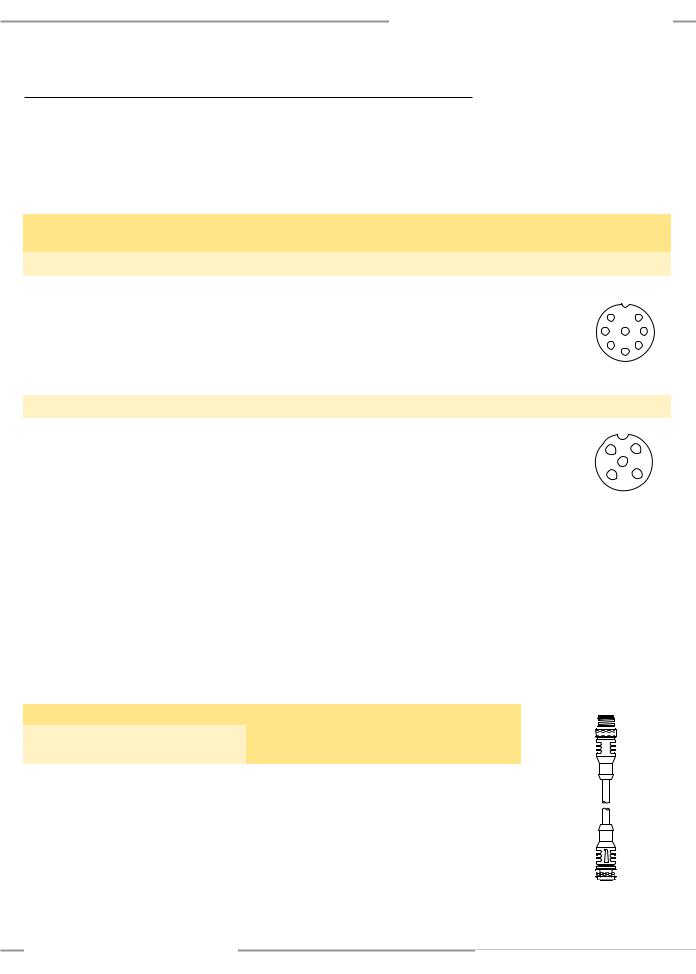

An EZ-SCREEN System includes a compatible emitter and receiver (equal length and resolution; available separately or in pairs), and two cables. Mounting hardware is included with each emitter and receiver. Interfacing solutions include IM-T-.. modules, redundant positively guided contactors, or an optional muting module; see Section 2.4.

Standard models (as listed in the following tables) feature a yellow painted aluminum housing. Other housing finishes are also available, including black, white, and silver (nickel-plated); contact the factory for more information.

Standard models are listed with integral QD fitting; for a 300 mm (12") pigtail with M12/ Euro-style 8-pin QD fitting, replace the “Q” in the model number with “P”. The 13 mm (0.5") minimum bend radius accommodates low-clearance installations. When used in a cascade installation, the pigtail models can reduce the number of cables and improve clearance and cable management.

Electro-static Dissipative Models

Electro-static dissipative (ESD-safe) versions with nickel-plated housing are also available, with a static-dissipative polymer coating which protects nearby components from damaging ESD voltages.

NOTE: ESD-safe models are not available with the pigtail QD option.

Receiver

Specified Test Piece

(2 diameters supplied

with each receiver)

Emitter

Status indicators |

|

and configuration |

Defined |

switches behind |

|

clear access panel |

Area |

QD Fitting

QD Cordsets

Figure 2-1. Banner EZ-SCREEN: emitter, receiver, and two interconnecting cables

6 P/N 11285233487 rev. F

Banner Engineering Corp. • Minneapolis, U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

EZ-SCREEN

Instruction Manual

Components and SpecificationsOverview

2.1 Standard Emitter and Receiver Models (Non-Cascadeable) – 14 mm Resolution

Order one 8-pin cable for each 8-pin emitter or receiver, or one 5-pin cable for each 5-pin emitter; see Table 2.3. For cascadeable emitter and receiver models, see Sections 7.2 and 7.3.

|

|

Standard 14 mm Resolution Models† |

|

||

Defined |

|

0.1 m to 6 m (4" to 20') range |

|

|

|

Area Height |

Emitter (8-pin)† |

Receiver |

Emitter/Receiver |

Number |

Response |

|

Pair† |

of Beams |

Time (Tr) |

||

|

|

|

|||

150 mm (5.9") |

SLSE14-150Q8 |

SLSR14-150Q8 |

SLSP14-150Q88 |

20 |

11 ms |

|

|

|

|

|

|

300 mm (11.8") |

SLSE14-300Q8 |

SLSR14-300Q8 |

SLSP14-300Q88 |

40 |

15 ms |

|

|

|

|

|

|

450 mm (17.7") |

SLSE14-450Q8 |

SLSR14-450Q8 |

SLSP14-450Q88 |

60 |

19 ms |

|

|

|

|

|

|

600 mm (23.6") |

SLSE14-600Q8 |

SLSR14-600Q8 |

SLSP14-600Q88 |

80 |

23 ms |

|

|

|

|

|

|

750 mm (29.5") |

SLSE14-750Q8 |

SLSR14-750Q8 |

SLSP14-750Q88 |

100 |

27 ms |

|

|

|

|

|

|

900 mm (35.4") |

SLSE14-900Q8 |

SLSR14-900Q8 |

SLSP14-900Q88 |

120 |

32 ms |

|

|

|

|

|

|

1050 mm (41.3") |

SLSE14-1050Q8 |

SLSR14-1050Q8 |

SLSP14-1050Q88 |

140 |

36 ms |

|

|

|

|

|

|

1200 mm (47.2") |

SLSE14-1200Q8 |

SLSR14-1200Q8 |

SLSP14-1200Q88 |

160 |

40 ms |

|

|

|

|

|

|

1350 mm (53.1") |

SLSE14-1350Q8 |

SLSR14-1350Q8 |

SLSP14-1350Q88 |

180 |

43 ms |

|

|

|

|

|

|

1500 mm (59") |

SLSE14-1500Q8 |

SLSR14-1500Q8 |

SLSP14-1500Q88 |

200 |

48 ms |

|

|

|

|

|

|

1650 mm (65") |

SLSE14-1650Q8 |

SLSR14-1650Q8 |

SLSP14-1650Q88 |

220 |

52 ms |

|

|

|

|

|

|

1800 mm (70.9") |

SLSE14-1800Q8 |

SLSR14-1800Q8 |

SLSP14-1800Q88 |

240 |

56 ms |

|

|

|

|

|

|

†Only standard 8-pin QD models are listed; 8-pin emitters/receivers feature “swapable” hookup; see Sections 3.3 and 3.7.

For other models:

5-pin emitters with Test input: Replace suffix “Q8” with “Q5”, (e.g., SLSE14-150Q5), and for the pair replace “Q88” with “Q85” (e.g., SLSP14-150Q85).

Pigtail QD (8-pin models only): Replace the “Q” in the model number with “P” (e.g., SLSE14-150P8).

ESD-safe models: Add “N” to the model number, prior to the QD option designation (e.g., SLSE14-150NQ8). ESD-safe models are not available with the pigtail QD option.

Optional housing finishes: Prior to the QD designation in the model number,

add “A” for a clear (brushed) anodized aluminum finish, black endcaps (e.g., SLSE14-150AQ8), add “S” for a nickel-plated (“silver”) finish, black endcaps (e.g., SLSE14-150SQ8),

add “B” for a black painted finish, black endcaps (e.g., SLSE14-150BQ8), add “W” for a white painted finish, black endcaps (e.g., SLSE14-150WQ8), or

add “SO” for a “safety orange” painted finish, black endcaps (e.g., SLSE14-150SOQ8).

Banner Engineering Corp. • Minneapolis, U.S.A.

www.bannerengineering.com • Tel: 763.544.3164 |

P/N 112852P/N133487rev. F |

7 |

|

|

|

Overview |

|

EZ-SCREEN |

|

|

andSpecifications |

||

|

|

|||

|

|

Instruction Manual |

||

|

|

Components |

||

|

|

|

|

|

2.2 Standard Emitter and Receiver Models (Non-Cascadeable) – 30 mm Resolution

Order one 8-pin cable for each 8-pin emitter or receiver, or one 5-pin cable for each 5-pin emitter; see Table 2.3. For cascadeable emitter and receiver models, see Sections 7.2 and 7.3.

|

|

Standard 30 mm Resolution Models† |

|

|||

Defined |

|

0.1 m to 18 m (4" to 60') range |

|

|

||

Area Height |

Emitter (8-pin)† |

Receiver |

Emitter/Receiver |

|

Number |

Response |

|

Pair† |

|

of Beams |

Time (Tr) |

||

|

|

|

|

|||

150 mm (5.9") |

SLSE30-150Q8 |

SLSR30-150Q8 |

SLSP30-150Q88 |

|

10 |

9 ms |

|

|

|

|

|

|

|

300 mm (11.8") |

SLSE30-300Q8 |

SLSR30-300Q8 |

SLSP30-300Q88 |

|

20 |

11 ms |

|

|

|

|

|

|

|

450 mm (17.7") |

SLSE30-450Q8 |

SLSR30-450Q8 |

SLSP30-450Q88 |

|

30 |

13 ms |

|

|

|

|

|

|

|

600 mm (23.6") |

SLSE30-600Q8 |

SLSR30-600Q8 |

SLSP30-600Q88 |

|

40 |

15 ms |

|

|

|

|

|

|

|

750 mm (29.5") |

SLSE30-750Q8 |

SLSR30-750Q8 |

SLSP30-750Q88 |

|

50 |

17 ms |

|

|

|

|

|

|

|

900 mm (35.4") |

SLSE30-900Q8 |

SLSR30-900Q8 |

SLSP30-900Q88 |

|

60 |

19 ms |

|

|

|

|

|

|

|

1050 mm (41.3") |

SLSE30-1050Q8 |

SLSR30-1050Q8 |

SLSP30-1050Q88 |

|

70 |

21 ms |

|

|

|

|

|

|

|

1200 mm (47.2") |

SLSE30-1200Q8 |

SLSR30-1200Q8 |

SLSP30-1200Q88 |

|

80 |

23 ms |

|

|

|

|

|

|

|

1350 mm (53.1") |

SLSE30-1350Q8 |

SLSR30-1350Q8 |

SLSP30-1350Q88 |

|

90 |

25 ms |

|

|

|

|

|

|

|

1500 mm (59") |

SLSE30-1500Q8 |

SLSR30-1500Q8 |

SLSP30-1500Q88 |

|

100 |

27 ms |

|

|

|

|

|

|

|

1650 mm (65") |

SLSE30-1650Q8 |

SLSR30-1650Q8 |

SLSP30-1650Q88 |

|

110 |

30 ms |

|

|

|

|

|

|

|

1800 mm (70.9") |

SLSE30-1800Q8 |

SLSR30-1800Q8 |

SLSP30-1800Q88 |

|

120 |

32 ms |

|

|

|

|

|

|

|

1950 mm (76.8") |

SLSE30-1950Q8 |

SLSR30-1950Q8 |

SLSP30-1950Q88 |

|

130 |

34 ms |

|

|

|

|

|

|

|

2100 mm (82.7") |

SLSE30-2100Q8 |

SLSR30-2100Q8 |

SLSP30-2100Q88 |

|

140 |

36 ms |

|

|

|

|

|

|

|

2250 mm (88.6") |

SLSE30-2250Q8 |

SLSR30-2250Q8 |

SLSP30-2250Q88 |

|

150 |

38 ms |

|

|

|

|

|

|

|

2400 mm (94.5") |

SLSE30-2400Q8 |

SLSR30-2400Q8 |

SLSP30-2400Q88 |

|

160 |

40 ms |

|

|

|

|

|

|

|

† Only standard 8-pin QD models are listed; 8-pin emitters/receivers feature “swapable” hookup; see Sections 3.3 and 3.7.

For other models:

5-pin emitters with Test input: Replace suffix “Q8” with “Q5”, (e.g., SLSE30-150Q5), and for the pair replace “Q88” with “Q85” (e.g., SLSP30-150Q85).

Pigtail QD (8-pin models only): Replace the “Q” in the model number with “P” (e.g., SLSE30-150P8).

ESD-safe models: Add “N” to the model number, prior to the QD option designation (e.g., SLSE30-150NQ8). ESD-safe models are not available with the pigtail QD option.

Optional housing finishes: Prior to the QD designation in the model number,

add “A” for a clear (brushed) anodized aluminum finish, black endcaps (e.g., SLSE30-150AQ8), add “S” for a nickel-plated (“silver”) finish, black endcaps (e.g., SLSE30-150SQ8),

add “B” for a black painted finish, black endcaps (e.g., SLSE30-150BQ8), add “W” for a white painted finish, black endcaps (e.g., SLSE30-150WQ8), or

add “SO” for a “safety orange” painted finish, black endcaps (e.g., SLSE30-150SOQ8).

Banner Engineering Corp. • Minneapolis, U.S.A.

8 |

P/N 11285233487 rev. F |

|

www.bannerengineering.com • Tel: 763.544.3164 |

|

|

||

|

|

|

|

EZ-SCREEN

Instruction Manual

2.3 Cables

Components and SpecificationsOverview

Machine interface cables provide power to the first emitter/receiver pair. Sensor interconnect cables provide power to subsequent emitters and receivers in the cascade.

Single-Ended (Machine Interface) Cables (one cable for each emitter and receiver)

Overmold and cables are PVC-jacketed. Cables are unterminated on one end to interface with guarded machine.

Model |

Length |

Wire |

Termination |

|

Banner Cable |

|

European M12 |

|

Connector |

||||

Number |

Pinout/Color Code |

|

Specification* |

|

(female face view) |

||||||||

|

|

|

|

|

|||||||||

For 8-Pin Emitters and Receivers** |

|

Pin |

Color |

Function |

Pin |

Color |

Function |

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

Bn |

+24V dc |

1 |

Wh |

+24V dc |

|

|

|

|

QDE-815D |

4.5 m (15') |

|

8-pin Euro- |

2 |

Or/Bk |

EDM #2 (Aux) |

2 |

BN |

EDM #2 (Aux) |

|

1 |

2 |

|

|

3 |

Or |

EDM #1 |

3 |

Gn |

EDM #1 |

|

||||||

QDE-825D |

8 m (25') |

22 |

style female |

|

8 |

|

|||||||

4 |

Wh |

OSSD #2 |

4 |

Ye |

OSSD #2 |

7 |

3 |

||||||

QDE-850D |

15 m (50') |

connector on |

|

||||||||||

QDE-875D |

23 m (75') |

gauge |

one end; cut |

5 |

Bk |

OSSD #1 |

5 |

Gy |

OSSD #1 |

|

|

|

|

|

6 |

Bu |

0V dc |

6 |

Pk |

0V dc |

|

6 |

4 |

||||

QDE-8100D |

30 m (100') |

|

to length |

|

|||||||||

|

7 |

Gn/Ye |

Gnd/Chassis |

7 |

Bu |

Gnd/Chassis |

|

||||||

|

|

|

|

|

5 |

|

|||||||

|

|

|

|

8 |

Vi |

Reset |

8 |

Rd |

Reset |

|

|

|

|

For 5-Pin Emitters and Receivers*** |

|

Pin |

Color |

Function |

Pin |

Color |

Function |

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

QDE-515D |

4.5 m (15') |

|

5-pin Euro- |

1 |

Bn |

+24V dc |

1 |

Bn |

+24V dc |

1 |

|

2 |

|

QDE-525D |

8 m (25') |

22 |

style female |

2 |

Wh |

Test #2 |

2 |

Wh |

Test #2 |

5 |

|||

QDE-550D |

15 m (50') |

connector on |

3 |

Bu |

0V dc |

3 |

Bu |

0V dc |

|

|

|

||

gauge |

|

|

|

||||||||||

QDE-575D |

23 m (75') |

one end; cut |

4 |

Bk |

Test #1 |

4 |

Bk |

Test #1 |

4 |

|

3 |

||

|

|

||||||||||||

QDE-5100D |

30 m (100') |

|

to length |

5 |

Gn/Ye |

Gnd/Chassis |

5 |

Shield |

Gnd/Chassis |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

*The European M12 Specification pin assignment and color codes are listed as a customer courtesy. The user must verify suitability of these cables for each application.

**8-pin Systems require two 8-pin QD cables. Only pins 1, 6, and 7 are connected on 8-pin emitters (see Figure 3-16).

***5-pin EZ-SCREEN emitter, model numbers SLSE..-..Q5 (see Table 2.1) with Test function (see Figure 3-17). One 5-pin and one 8-pin QD cable required for complete system.

Double-Ended (Sensor Interconnect) Cables

Double-ended cables are generally used to interconnect multiple emitters (8-pin or 5-pin) or receivers (8-pin) within a cascaded system. They are also useful for extending either the branch or trunk cables of a model CSB splitter cordset (see page 10). When combining cables in a multiple-light-screen cascade, refer to Section 7.4 for maximum cable lengths.

Model Number |

Length |

Wire |

Termination |

|

|

|

|

|

|

|

|

|

|||||

For 8-Pin Emitters |

For 5-Pin Emitters |

|

|

|

|

|||

and Receivers |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

DEE2R-81D |

DEE2R-51D |

0.3 m (1') |

|

|

|

|

|

|

|

|

|

|

|

|

|||

DEE2R-83D |

DEE2R-53D |

1 m (3') |

|

5- or 8-pin |

|

|

|

|

DEE2R-88D |

DEE2R-58D |

2.4 m (8') |

|

Double-ended |

|

|

|

|

DEE2R-815D |

DEE2R-515D |

4.5 m (15') |

22 gauge |

cables, M12/Euro- |

|

|

|

|

DEE2R-825D |

DEE2R-525D |

8 m (25') |

style connectors, |

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

||||

DEE2R-850D |

DEE2R-550D |

15 m (50') |

|

female to male |

|

|

|

|

DEE2R-875D |

DEE2R-575D |

23 m (75') |

|

(rotateable) |

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

||||

|

|

|

|

|

||||

DEE2R-8100D |

DEE2R-5100D |

30 m (100') |

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

Banner Engineering Corp. • Minneapolis, U.S.A.

www.bannerengineering.com • Tel: 763.544.3164 |

P/N 112852P/N133487rev. F |

9 |

|

|

|

Overview |

|

EZ-SCREEN |

|

|

andSpecifications |

||

|

|

|||

|

|

Instruction Manual |

||

|

|

Components |

||

|

|

|

|

|

Splitter Cordsets

Model CSB splitter cordsets allow easy interconnection between an EZ-SCREEN 8-pin receiver and its 8-pin emitter, providing a single “homerun” cable for the optional “swapable” hookup (see Figure 3-16). The model DEE2R-.. double-ended cables described on page 8 may be used to extend the lengths of the QD trunk, branch #1, or branch #2. (Branch #1 and branch #2 cable sections are 300 mm/1' long.) The model QDE-8..D single-ended cables may be used to extend the QD trunk for cut-to-length applications.

Model Number |

Trunk Length |

Wire |

|

|

|

Pinout |

|||||||

|

|

|

Pin #1 (+24V dc) |

|

|

|

|

|

|

|

|

|

Pin #1 (+24V dc) |

|

|

|

Pin #2 (EDM#2) |

|

|

|

|

|

|

|

|

|

Pin #2 (EDM#2) |

|

|

|

Pin #3 (EDM#1) |

|

|

|

|

|

|

|

|

|

Pin #3 (EDM#1) |

CSB-M1281M1281 |

0.3 m (1') |

|

Pin #4 (OSSD#2) |

|

|

|

|

|

|

|

|

|

Pin #4 (OSSD#2) |

|

Pin #5 (OSSD#1) |

|

|

|

|

|

|

|

|

|

Pin #5 (OSSD#1) |

||

CSB-M1288M1281 |

2.4 m (8') |

|

Pin #6 (0V dc) |

|

|

|

|

|

|

|

|

|

Pin #6 (0V dc) |

CSB-M12815M1281 |

4.5 m (15') |

|

Pin #7 (GND) |

|

|

|

|

|

|

|

|

|

Pin #7 (GND) |

CSB-M12825M1281 |

8 m (25') |

22 |

Pin #8 (RESET) |

|

|

|

|

|

|

|

|

|

Pin #8 (RESET) |

M12 Male |

|

|

|

|

|

|

|

|

|

M12 Female |

|||

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

gauge |

or |

|

|

|

|

|

|

|

|

|

Pin #1 (+24V dc) |

|

|

unterminated |

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

Pin #2 (EDM#2) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Pin #3 (EDM#1) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Pin #4 (OSSD#2) |

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Pin #5 (OSSD#1) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CSB-UNT825M1281 |

8 m (25') |

|

|

|

|

|

|

|

|

|

|

|

Pin #6 (0V dc) |

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

Pin #7 (GND) |

||

(unterminated) |

|

|

|

|

|

|

|

|

|

|

|

Pin #8 (RESET) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

M12 Female |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

300 mm (1.0')

see table

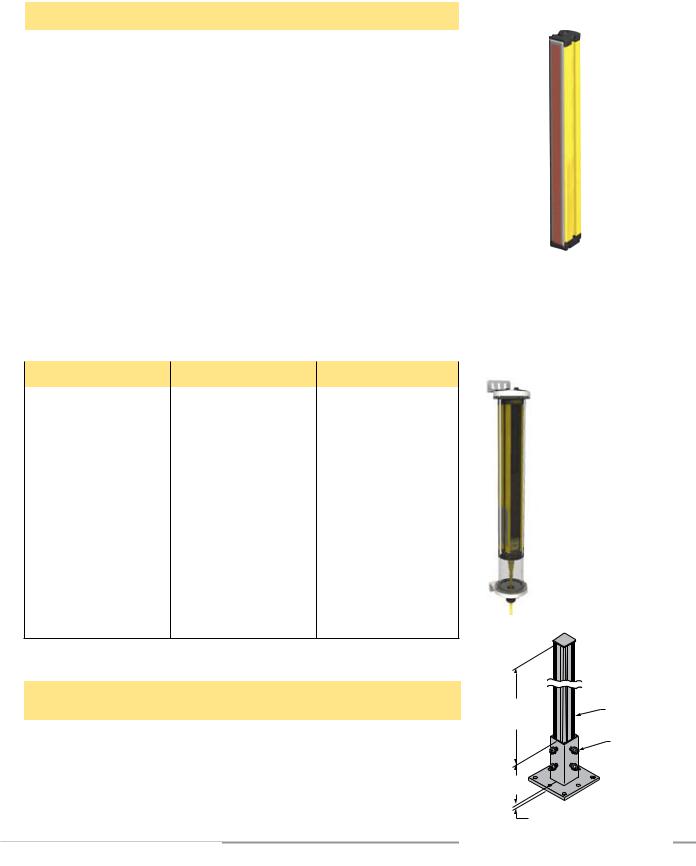

Bulkhead Connector

Model Number |

Description |

PMEF-810D |

Connector for panel connection of EZ-SCREEN emitter and receiver |

cables. 8-pin Euro-style female connector with 3 m (10') wires cut to |

|

|

length (Banner color code); 22 gauge. |

|

|

3 m |

21.5 mm |

|

ø 18.0 mm |

(9.8') |

(0.85") |

13.0 mm |

(0.71") |

7.0 mm |

|

|

|

|

(0.51") |

|

|

(0.28") |

|

|

|

1/4-18NPT |

|

M12 x 1 |

|

O-Ring |

|

|

|

2.4 Accessories

Additional interfacing solutions and accessories continue to be added; refer to

www.bannerengineering.com for a current list.

Interface Modules

Provide forced-guided, mechanically-linked relay (safety) outputs for the EZ-SCREEN.

See Banner data sheet p/n 62822 and Figure 3-23 for more information.