Banner S18U User Manual

U-GAGE™ S18U Series Sensors with Analog Output

18 mm Ultrasonic Sensors with TEACH-mode programming

Features

Right-Angle Housing

Straight Housing

•Fast, easy-to-use TEACH-Mode programming; no potentiometer adjustments

•Short dead zone

•Scalable output automatically distributes the output signal over the width of the programmed sensing window

•Two bi-colored status LEDs

•Rugged encapsulated design for harsh environments

•Choose 2 meter or 9 meter unterminated cable, or 5-pin Euro-style QD connector

•Wide operating range of -20° to +60°C (-4° to +140°F)

•Choose either straight or right-angle housing

•Temperature compensation

•Selectable response times of 2.5 or 30 ms

•Select analog models with either 0-10V dc or 4-20 mA output

|

|

|

|

|

|

Ultrasonic |

|

|

|

|

|

|

|

|

|

Models |

|

|

|

|

|

|

|

|

|

|

|

Model |

Sensing |

Cable* |

|

Supply |

Output |

Housing |

Number |

Range |

|

Voltage |

Configuration |

||

|

|

|

||||

S18UUA |

|

5-wire, 2 m (6.5') cable |

|

|

0 to 10V dc |

|

|

|

|

|

|

|

|

S18UUAQ |

|

5-pin Euro style QD |

|

|

Straight |

|

|

|

|

|

|||

|

|

|

|

|

|

|

S18UIA |

|

5-wire, 2 m (6.5') cable |

|

|

4 to 20 mA |

|

|

|

|

|

|||

|

|

|

|

|

|

|

S18UIAQ |

30 to 300 mm |

5-pin Euro style QD |

|

10 to 30V dc |

|

|

|

|

|

||||

S18UUAR |

(1.2" to 11.8") |

5-wire, 2 m (6.5') cable |

|

0 to 10V dc |

|

|

|

|

|

||||

S18UUARQ |

|

5-pin Euro style QD |

|

|

Right-Angle |

|

|

|

|

|

|||

|

|

|

|

|

|

|

S18UIAR |

|

5-wire, 2 m (6.5') cable |

|

|

4 to 20 mA |

|

|

|

|

|

|||

|

|

|

|

|

|

|

S18UIARQ |

|

5-pin Euro style QD |

|

|

|

|

|

|

|

|

|

||

*9 m cables are available by adding suffix “W/30” to the model number of any cabled sensor (e.g., S18UUA W/30). A model with a QD connector requires a mating cable; see page 10.

Information about discrete models is available on Banner’s website: www.bannerengineering.com

!Never use these products as sensing devices for personnel protection. Doing so could lead to serious injury or death.

These sensors do NOT include the self-checking redundant circuitry necessary to allow their use in personnel safety applications. A sensor failure or malfunction can cause either an energized or de-energized sensor output condition.

Consult your current Banner Safety Products catalog for safety products which meet OSHA, ANSI and IEC standards for personnel protection.Not To Be Used for Personnel ProtectionWARNING . . .

Printed in USA |

02/05 |

P/N 110738 rev. A |

U-GAGE™ S18U Series Sensor — Analog Output

Principles of Operation

Ultrasonic sensors emit one or multiple pulses of ultrasonic energy, which travel through the air at the speed of sound. A portion of this energy reflects off the target and travels back to the sensor. The sensor measures the total time required for the energy to reach the target and return to the sensor. The distance to the object is then calculated using the following formula:

D = |

ct |

D = |

distance from the sensor to the target |

||

c |

= |

speed of sound in air |

|||

2 |

|||||

|

t |

= |

transit time for the ultrasonic pulse |

||

To improve accuracy, an ultrasonic sensor may average the results of several pulses before outputting a new value.

Temperature Effects

The speed of sound is dependent upon the composition, pressure and temperature of the gas in which it is traveling. For most ultrasonic applications, the composition and pressure of the gas are relatively fixed, while the temperature may fluctuate.

In air, the speed of sound varies with temperature according to the following approximation:

C |

= 20 √273 + T |

Cm/s = speed of sound in meters per second |

m/s |

C |

TC = temperature in °C |

Or, in English units: |

||

Cft/s = 49 √460 + TF |

Cft/s = speed of sound in feet per second |

|

|

|

TF = temperature in °F |

Temperature Compensation

Changes in air temperature affect the speed of sound, which in turn affects the distance reading measured by the sensor. An increase in air temperature shifts both sensing window limits closer to the sensor. Conversely, a decrease in air temperature shifts both limits farther away from the sensor. This shift is approximately 3.5% of the limit distance for a 20° C change in temperature.

The S18U series ultrasonic sensors are temperature compensated. This reduces the error due to temperature by about 90%. The sensor will maintain its window limits to within 1.8% over the -20° to +60° C range.

NOTES:

•Exposure to direct sunlight can affect the sensor’s ability to accurately compensate for changes in temperature.

•If the sensor is measuring across a temperature gradient, the compensation will be less effective.

•The temperature warmup drift upon power-up is less than 1.7% of the sensing distance. After 10 minutes, the apparent distance will be within 0.3% of the actual position. After 25 minutes, the sensing distance will be stable.

|

|

Banner Engineering Corp. • Minneapolis, MN U.S.A. |

2 |

P/N 110738 rev. A |

www.bannerengineering.com • Tel: 763.544.3164 |

U-GAGE™ S18U Series Sensor — Analog Output

Sensor Programming

Two TEACH methods may be used to program the sensor:

• Teach individual minimum and maximum limits, or

• Use Auto-Window feature to center a sensing window around the taught position.

The sensor may be programmed either via its push button, or via a remote switch. Remote programming also may be used to disable the push button, preventing unauthorized personnel from adjusting the programming settings. To access this feature, connect the gray wire of the sensor to 0 - 2V dc, with a remote programming switch between the sensor and the voltage.

Power/ |

|

TEACH/ |

NOTE: The impedance of the Remote Teach input is 12 kΩ. |

Signal Strength |

PWR OUT |

Output Indicator |

Programming is accomplished by following the sequence of input pulses (see |

LED |

|

LED |

|

|

|

TEACH |

programming procedures starting on page 4). The duration of each pulse |

|

TEACH |

Push Button |

(corresponding to a push button “click”), and the period between multiple pulses, are |

|

|

defined as “T”: |

|

|

|

|

|

0.04 seconds < T < 0.8 seconds |

|

|

|

|

|||

Minimum |

Near |

|

Far |

|

|

Maximum |

|

|

Operating |

|

|

|

Operating |

|

|||

Figure 1. Sensor features |

Range |

Setpoint |

|

Setpoint |

|

|

Range |

|

Dead Zone |

Target |

|

Target |

|

Target |

|

Target |

|

|

Power |

Output |

Power |

Output |

Power |

Output |

Power |

Output |

|

ON: |

OFF |

ON: |

ON: |

ON: |

OFF |

ON: |

OFF |

|

Green |

|

Green |

Yellow |

Green |

|

Red |

|

Figure 2. TEACH Interface

|

Status Indicators |

|

|

Power ON/OFF LED |

Indicates |

OFF |

Power is OFF. |

|

|

ON Red |

Target is weak or outside sensing range. |

ON Green |

Sensor is operating normally, good target. |

|

|

|

|

Output/Teach LED |

Indicates |

OFF |

Target is outside window limits. |

|

|

Yellow |

Target is within window limits. |

|

|

ON Red (solid) |

In Teach Mode, waiting for first limit. |

|

|

ON Red (flashing) |

In Teach Mode, waiting for second limit. |

Banner Engineering Corp. • Minneapolis, MN U.S.A. |

|

www.bannerengineering.com • Tel: 763.544.3164 |

P/N 110738 rev. A 3 |

U-GAGE™ S18U Series Sensor — Analog Output

Teaching Minimum and Maximum Limits

General Notes on Programming

•The sensor will return to Run mode if the first Teach condition is not registered within 120 seconds.

•After the first limit is taught, the sensor will remain in Program mode until the Teach sequence is finished.

•To exit Program mode without saving any changes, press and hold the programming push button > 2 seconds (before teaching the second limit). The sensor will revert to the last saved limits.

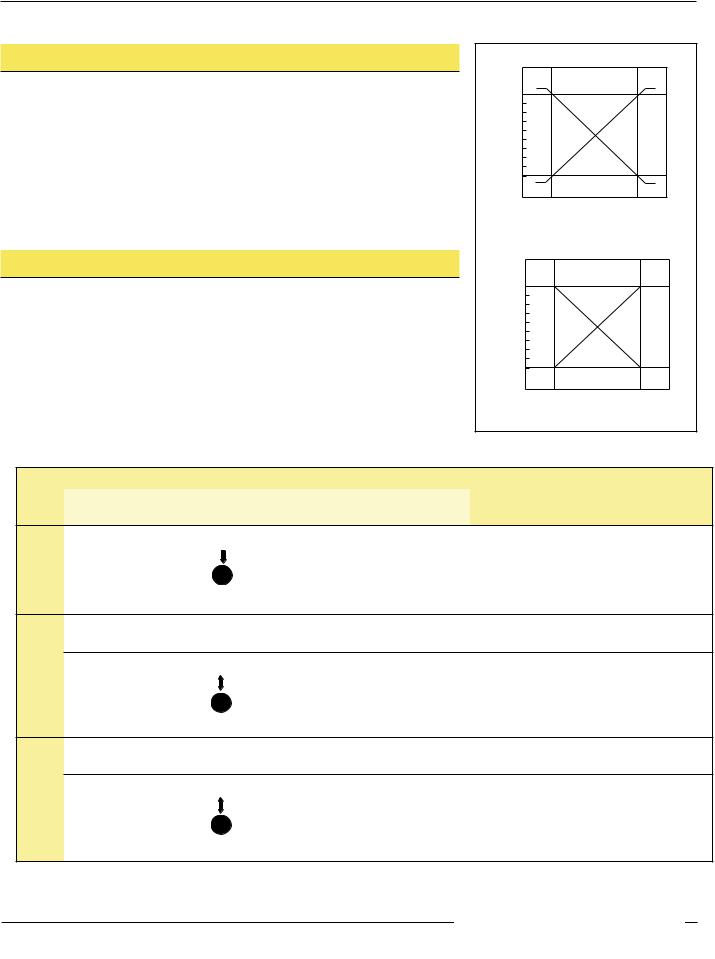

Analog Output Slope:

The U-GAGE S18U sensor may be programmed for either a positive or a negative output slope, based on which limit is taught first (see Figure 3). If the Near limit is taught first, the slope will be positive. If the Far limit is taught first, the slope will be negative. Banner’s scalable output automatically distributes the output signal over the width of the programmed sensing window.

In the event of signal loss, the analog output goes to 3.6 mA or 0V dc, which may be used to trigger an alarm.

|

|

|

Procedure |

|

|

|

||

|

|

Push Button |

|

Remote Wire |

|

|

|

|

Programming |

|

0.04 < “click” < 0.8 sec. |

|

0.04 sec. < T < 0.8 sec. |

|

|

|

|

Mode |

• Push and hold the |

|

• No action required; sensor is ready for |

|||||

|

|

|

||||||

|

|

push button |

|

1st limit teach |

|

|

|

|

|

|

• Position the target for |

|

• Position the target for the first limit |

||||

|

|

the first limit |

|

|||||

Teach FirstLimit |

|

|

|

|

|

|

||

• “Click” the push button |

|

• Single-pulse the remote line |

|

T |

|

|

||

|

|

|

|

|

|

|||

|

|

• Position the target for |

|

|

|

|

|

|

|

|

|

• Position the target for the second limit |

|||||

Teach SecondLimit |

the second limit |

|

||||||

|

|

|

|

|

|

|||

• “Click” the push button |

|

• Single-pulse the remote line |

|

T |

||||

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Current-Sourcing Models

20 |

|

Analog Output (mA) |

Positive |

Slope |

|

|

|

4 |

|

Near |

Far |

Window |

Window |

Target Position

Voltage-Sourcing Models

10 |

|

dc) |

Positive |

Slope |

|

Analog Output (V |

|

0 |

|

Near |

Far |

Window |

Window |

Target Position

Figure 3. Analog output slope

Result

Output LED: ON Red

Power LED: ON Green (good signal) or ON Red (no signal)

Power LED: Must be ON Green

Teach Accepted

(Sensor learns the 0V dc or 4 mA limit) Output LED: Flashing Red

Teach Unacceptable Output LED: ON Red

Power LED: Must be ON Green

Teach Accepted

(Sensor learns the 10V dc or 20 mA limit) Output LED: Yellow or OFF

Teach Unacceptable Output LED: Flashing Red

|

|

Banner Engineering Corp. • Minneapolis, MN U.S.A. |

4 |

P/N 110738 rev. A |

www.bannerengineering.com • Tel: 763.544.3164 |

Loading...

Loading...