Banner R58 Registration Mark Sensors User Manual

R58E Series Expert ™ Registration Mark Sensors

Registration Mark Sensor with Three-Color Light Source

Features

•Ultra-fast 10 kHz switching frequency

•Red, green, and blue LEDs evaluated during TEACH to optimize application contrast, with the best color automatically selected by the sensor; sensing beam colors also may be individually disabled

•Outstanding color contrast sensitivity; detects 16 levels of gray scale

•Smart gain-control algorithm to maximize performance in low-contrast or high-gloss applications

•Easy-to-set, automatic Expert-style configuration options include Static and Dynamic TEACH, plus Manual Adjust for fine tuning

•Easy-to-read 8-segment bargraph display indicator for TEACH and signal strength readout, plus indicators for continuous readout of output status and setup

•Fixed-convergent sensing at 10 mm ±3 mm (0.39" ±0.12")

•Rectangular 1.2 mm x 3.8 mm (0.05" x 0.15") sensing image at 10 mm (0.39") from the lens

•Parallel or perpendicular sensing image, depending on model (see below)

•Rugged zinc alloy die-cast housing with high-quality acrylic lens suitable for food processing applications; rated IP67, NEMA 6

•Easy selection of Light/Dark Operate (LO/DO), 30 ms pulse stretcher (OFF-delay), and 30 ms ON-delay, via push buttons or a remote input wire

Models

Models |

Cable* |

Focus |

Supply Voltage Output Type |

Sensing Image Orientation |

|

R58ECRGB1 |

5-wire 2 m (6.5') |

|

|

|

Parallel to sensor length |

R58ECRGB1Q8 |

5-pin Euro-style integral QD |

|

|

|

|

R58ECRGB1Q |

5-pin Euro-style QD pigtail |

10 mm |

|

Bipolar |

|

|

|

10 to 30V dc |

|

||

R58ECRGB2 |

|

(0.39") |

NPN/PNP |

|

|

5-wire 2 m (6.5') |

|

|

|||

|

|

|

Perpendicular to sensor length |

||

|

|

|

|

|

|

R58ECRGB2Q8 |

5-pin Euro-style integral QD |

|

|

|

|

R58ECRGB2Q |

5-pin Euro-style QD pigtail |

|

|

|

|

*9 m cables are available by adding suffix “W/30” to the model number of any cabled sensor (e.g., R58ECRGB1 W/30). A model with a QD connector requires a mating cable; see page 10.

WARNING . . . Not To Be Used for Personnel Protection

Never use these products as sensing devices for personnel protection. Doing so could lead to serious injury or death.

These sensors do NOT include the self-checking redundant circuitry necessary to allow their use in personnel safety applications. A sensor failure or malfunction can cause either an energized or de-energized sensor output condition. Consult your current Banner Safety Products catalog for safety products which meet OSHA, ANSI and IEC standards for personnel protection.

Printed in USA |

03/09 |

P/N 122928 rev. C |

R58 Expert™ Registration Mark Sensors

Overview

R58 Expert (R58E) sensors offer maintenance-free solid-state reliability for typical color contrasts found in product and material registration applications. Fast 50-microsecond sensing response produces excellent registration repeatability, even in ultra-high-speed applications. This fast response, coupled with the small 1.2 x 3.8 mm (0.05" x 0.15") sensing image, allows the detection of even small and inconspicuous registration marks.

R58E sensors feature TEACH mode sensitivity adjustment by presenting two sensing conditions to the sensor. TEACH mode has two options: Static TEACH and Dynamic TEACH.

Static TEACH is used to position the two sensing conditions individually. Dynamic TEACH provides a means for teaching a series of conditions on-the-fly; the R58E samples the sensing events and automatically sets the switchpoint between the lightest and darkest conditions. The sensor then determines which sensing condition is present for the shortest time and assigns the Output ON condition to that event (therefore, LO/DO selection is automatic). The LO/DO setting can then be reversed in SETUP mode.

The sensor uses a tri-color LED during either teach process and automatically selects a red, green, or blue sensing beam, based on the contrast between the registration mark and its background. For applications where the user wishes to select the sensing beam color, individual colors may be enabled/disabled in SETUP mode.

Sensitivity may be fine-tuned at any time by simply clicking the “+” or “-” buttons on the sensor. The eight-element bargraph display clearly displays the relative received signal strength.

The discrete bipolar (one NPN and one PNP) outputs may be configured in SETUP mode to include a 30-millisecond ON-delay and/or OFF-delay, if required.

TEACH and SETUP configuration may be accomplished either by using the push button on the sensor, or by supplying input pulses via the remote TEACH input. The push buttons may be diabled via the remote input.

The construction of the R58E is extremely robust, with a die-cast metal housing, plastic optics, and IP67 and NEMA 6 leakproof design for harsh sensing environments.

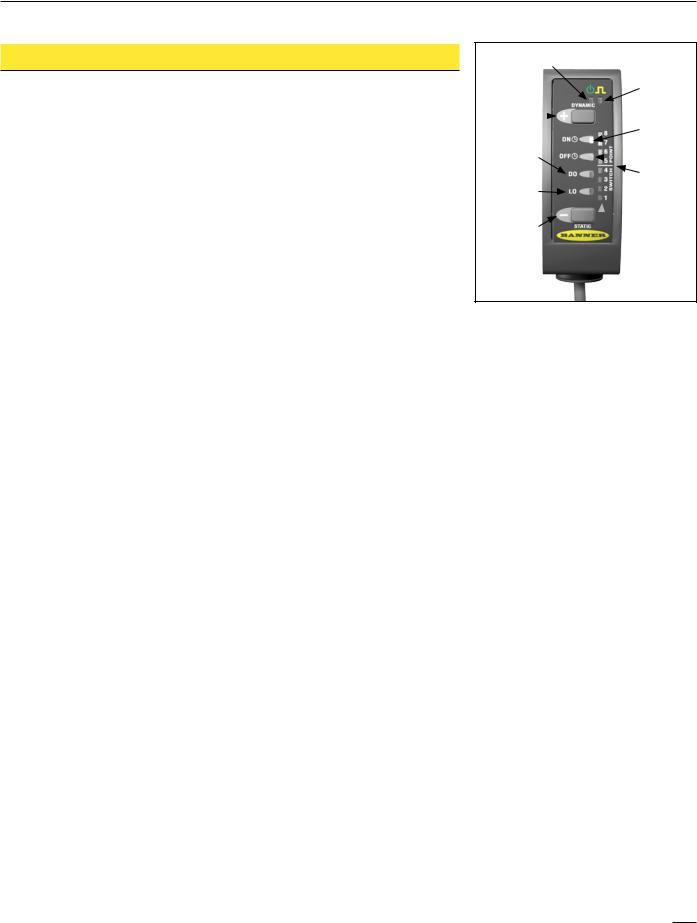

Power LED |

|

|

|

|

|

|

|

|

|

|

|

|

Output LED |

Dynamic (+) |

|

|

|

|

ON-Delay |

|

Push Button |

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

LED |

Dark |

|

|

|

|

OFF-Delay |

|

Operate |

|

|

|

|

LED |

|

(DO) LED |

|

|

|

|

Switchpoint |

|

Light |

|

|

|

|

||

|

|

|

|

|

||

Operate |

|

|

|

|

|

|

(LO) LED |

|

|

|

|

|

|

Static (-) |

|

|

|

|

8-Segment |

|

|

|

|

|

|||

|

|

|

|

|||

|

|

|

|

Bargraph |

||

Push Button |

|

|

|

|

Display |

|

Figure 1. Sensor features

|

|

|

|

Banner Engineering Corp. • Minneapolis, MN U.S.A |

|

2 P/N 122928 rev. C |

||

www.bannerengineering.com • Tel: 763.544.3164 |

||

|

|

R58 Expert™ Registration Mark Sensors

Sensor Configuration

The R58E is pre-set to power up in RUN mode and sense the most recently taught registration mark. The sensitivity of the R58E may be quickly optimized by using one of two available

TEACH modes: Static TEACH or Dynamic TEACH.

•Static TEACH: Both the Output ON and Output OFF conditions are presented, and sensitivity can be adjusted manually via the push buttons.

•Dynamic TEACH: The registration mark is presented during actual sensing conditions, and the sensitivity can be adjusted manually via the push buttons.

Remote TEACH

The sensor may be configured either via its push buttons, or via a remote switch. Remote configuration also may be used to enter SETUP mode to set ONand OFF-delay, and to disable the push buttons to prevent unauthorized adjustment of the configuration settings. To access this feature, connect the gray wire of the sensor to 0V dc, with a remote switch between the sensor and 0V dc.

Configuration is accomplished by following the sequence of input pulses (see following procedures). The duration of each pulse (corresponding to a push button “click”), and the period between multiple pulses, are defined as “T”:

0.04 seconds ≤ “T” ≤ 0.8 seconds

Status Indicators

LED |

Indicates |

|

|

|

|

Power |

ON Green: RUN mode |

|

OFF: TEACH or SETUP mode |

||

|

||

|

|

|

Output |

ON Yellow: Output is conducting, or TEACH Output ON condition |

|

OFF: Output is not conducting, or TEACH Output OFF condition |

||

|

||

|

|

|

Light Operate |

ON Green: Light Operate (LO) operation |

|

|

|

|

Dark Operate |

ON Green: Dark Operate (DO) operation |

|

|

|

|

OFF-Delay |

ON Green: 30 ms pulse stretcher (OFF-delay) is active |

|

OFF: No OFF-delay |

||

|

||

|

|

|

ON-Delay |

ON Green: 30 ms ON-delay is active |

|

OFF: No ON-delay |

||

|

||

|

|

|

|

ON Red: RUN mode — Indicates signal strength with respect to the |

|

|

sensing threshold (switchpoint); higher segment number for |

|

8-Segment Bargraph |

higher sensing contrast |

|

TEACH mode — Indicates relative contrast |

||

Display |

||

SETUP mode — Displays sensing beam LED color (see |

||

|

||

|

Figure 5) |

|

|

OFF: TEACH or SETUP mode — Sensor configuration active |

|

|

|

Banner Engineering Corp. • Minneapolis, MN U.S.A |

P/N 122928 rev. C 3 |

www.bannerengineering.com • Tel: 763.544.3164 |

R58 Expert™ Registration Mark Sensors

Static TEACH

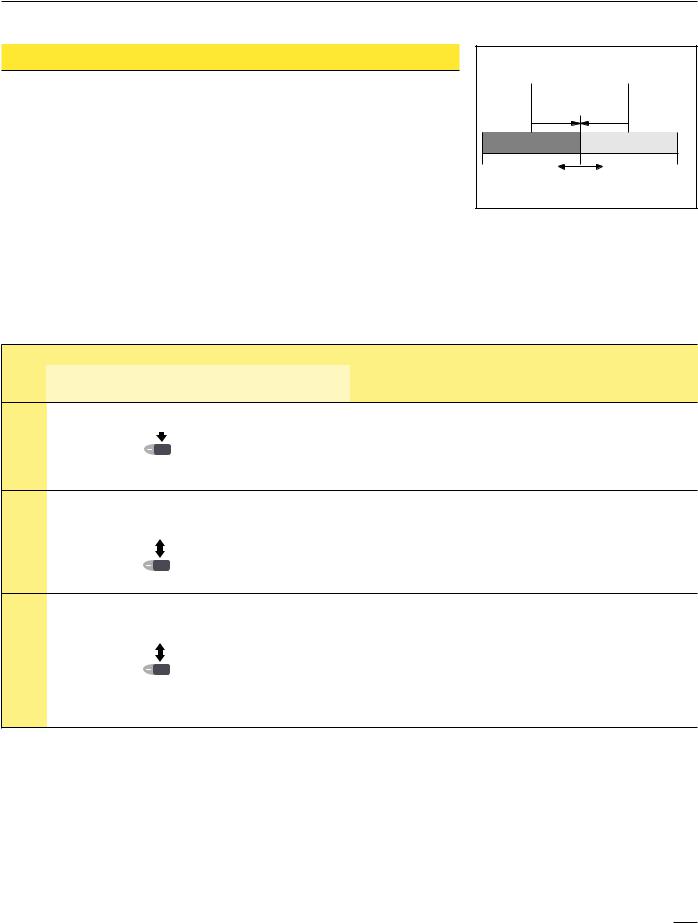

In Static TEACH mode, the sensor learns two sensing conditions after each is presented one time. The sensor automatically positions the switchpoint midway between the two conditions. See Figure 3.

NOTE: The sensor will return to RUN mode if either TEACH condition is not registered within

60 seconds. TEACH mode may be cancelled by pressing and holding the Static push button for ≥ 2 seconds. In either case, the sensor will revert to the previous conditions taught (i.e., exit without save).

Static TEACH and Manual Adjust

Sensitivity may be adjusted at any time when the sensor is in RUN mode by clicking the “+” and “-” buttons. Each click translates to 1/2 segment on the signal strength bargraph display. For best sensing reliability, both sensing conditions should register equally distant from the switchpoint on the signal strength bargraph display.

2nd Taught |

1st Taught |

Condition |

Condition |

|

Sensor positions |

|

threshold midway |

between taught conditions |

|

Output OFF |

Output ON |

|

Position |

|

adjusted by |

|

Manual Adjust |

Figure 2. Static TEACH (Light Operate shown)

Access TEACH |

Mode |

Teach 1st Sensing |

Condition |

Teach 2nd Sensing |

Condition |

Procedure |

|

|||||||||

|

|

|

|

|

|

|

|

|

|

Result |

Push Button |

|

Remote Line |

||||||||

0.04 sec. ≤ “click” ≤ 0.8 sec. |

0.04 sec. ≤ “T” ≤ 0.8 sec. |

|

||||||||

• Push and hold the Static |

• No action required; sensor |

(push button only) |

||||||||

push button for |

is ready for the 1st sensing |

LO and DO: Alternately flash Green |

||||||||

> 2 seconds. |

condition. |

Output: ON Yellow (indicating ready to teach 1st sensing condition) |

||||||||

|

|

|

|

|

|

|

|

|

|

Bargraph display: Goes OFF |

• Present the 1st sensing |

• Present the 1st sensing |

LO and DO: Alternately flash Green |

||||||||

condition. |

condition. |

Output: OFF (indicating ready to teach 2nd sensing condition) |

||||||||

• “Click” the Static push |

• Single-pulse the remote line. |

Bargraph display: Remains OFF |

||||||||

button. |

• Wait at least 0.8 seconds. |

|

||||||||

|

|

|

|

T |

|

|

|

|||

|

|

|

|

|

|

0.8 seconds |

|

|||

|

|

|

|

|

|

|

|

|

Teach Accepted |

|

• Present the 2nd sensing |

• Present the 2nd sensing |

|||||||||

condition. |

condition. |

• Bargraph display flashes one segment for three seconds to indicate |

||||||||

• “Click” the Static push |

• Single-pulse the remote line. |

relative contrast (see contrast table on page 5). |

||||||||

button. |

|

|

|

|

T |

• Sensor enters RUN mode. |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Teach Unacceptable |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

• Pairs of bargraph display segments flash for three seconds to indicate low |

|

|

|

|

|

|

|

|

|

|

contrast. |

|

|

|

|

|

|

|

|

|

|

• Sensor returns to TEACH 1st sensing condition. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Banner Engineering Corp. • Minneapolis, MN U.S.A |

|

4 P/N 122928 rev. C |

||

www.bannerengineering.com • Tel: 763.544.3164 |

||

|

|

Loading...

Loading...