Banner EZ-SCREEN User Manual

EZ-SCREEN™Grid

Instruction Manual

Printed in USA

09/01 P/N 68410

9714 10th Avenue North • Minneapolis, MN 55441

Phone: 763.544.3164 • http://www.bannerengineering.com

Email: sensors@bannerengineering.com

Section Contents

Section 1 Introduction Overview . . . . . . . . . . . . . . . . . .Page 4

Section 2 System Components and Specifications . . . .Page 10

Section 3 Installation and Alignment . . . . . . . . . . . . . .Page 16

Section 4 System Operation . . . . . . . . . . . . . . . . . . . .Page 40

Section 5 Troubleshooting and Maintenance . . . . . . . .Page 45

Section 6 Periodic Checkout Procedures . . . . . . . . . . .Page 51

EZ-SCREEN Features

• Non-contact safety device for perimeter and

access guarding from dangerous machinery

• Diverse-redundant and self-checking design to

achieve control reliability and meet IEC 61496-1

type 4 requirements

•Choose models with 2, 3, or 4 beams, beam

spacing from 300 to 584 mm (12" to 23")

• Self-contained two-part system is optically

synchronized:

Needs no external controller

Needs no extra synchronization wire

Easy and economical to install

• Operating range 0.8 to 20 m or 15 to 70 m

(2.6' to 65' or 49' to 230')

• Selectable external device monitoring

• Selectable trip or latch output

• Fast 24 millisecond output response time for all

models

• Easy-to-use removable terminal blocks or quickdisconnect options speed and simplify wiring

• Compact, robust housing

•Multiple mounting options

• Optional accessory interface module available

for ac or larger dc loads

• Configuration settings accessible from the front,

with supplied tool. Sensor settings can be

changed while sensor remains mounted.

US

LISTED

page 2

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

EZ-SCREEN Grid

Instruction Manual

Important ... read this page before proceeding!

In the United States, the functions that Banner EZ-SCREEN™Systems are intended to perform are

regulated by the Occupational Safety and Health Administration (OSHA). However, whether or not

any particular EZ-SCREEN System installation meets all applicable OSHA requirements depends

upon factors that are beyond the control of Banner Engineering Corp. These factors include the

details of how the EZ-SCREEN System is applied, installed, wired, operated, and maintained.

Banner Engineering Corp. has attempted to provide complete application, installation, operation,

and maintenance instructions. In addition, we suggest that any questions regarding application or

use of EZ-SCREEN Systems be directed to the factory applications department at the telephone

number or addresses shown at the bottom of this page.

Banner EZ-SCREEN Systems can guard against accidents only when they are properly installed

and integrated into the machine, properly operated, and properly maintained. See Section 3 of this

manual for installation procedures, considerations, and precautions. See Sections 4 and 5 for

operating and maintenance information. It is the responsibility of the purchaser and/or user to

apply this EZ-SCREEN System in full compliance with OSHA regulations.

In addition to OSHA regulations, several other organizations provide informational material on the

use of machine guard devices. The user is referred to the American National Standards Institute

(ANSI), the Robotics Industries Association (RIA), the Association for Manufacturing Technology

(AMT), and others. Banner Engineering Corp. makes no claim regarding a specific recommendation of any organization, the accuracy or effectiveness of any information provided, or the

appropriateness of the provided information for a specific application.

The user has the responsibility to ensure that all local, state, and national laws, rules, codes, and

regulations relating to the use of this machine guarding system in any particular application are

satisfied. Extreme care is urged to ensure that all legal requirements have been met and that all

installation and maintenance instructions contained in this manual are followed.

Caution!!

Banner EZ-SCREEN Systems are for use only on machinery that can be stopped immediately after

a stop signal is issued. They may be used with part-revolution clutched machines that have the

ability to stop at any point in their stroke. Under no circumstances may the EZ-SCREEN System

be used on full-revolution clutched machinery. Banner EZ-SCREEN Systems may not be used as

tripping devices to initiate machine motion (PSDI applications) on mechanical power presses, per

OSHA regulation 29 CFR 1910.217.

Appropriate Applications

The Banner EZ-SCREEN Grid System

may be used in access-guarding and

perimeter-guarding applications only

with machinery that can be stopped

immediately after a stop signal is issued.

It may be used with part-revolution

clutched machines that have the ability

to stop at any point in their stroke.

Under no circumstances may the EZSCREEN Grid System be used to guard

full-revolution clutched machinery. The

Banner EZ-SCREEN Grid Systems may

not be used as tripping devices to

initiate machine motion (PSDI

applications) on mechanical power

presses, per OSHA regulation 29 CFR

1910.217.

The Banner EZ-SCREEN Grid System is

typically used in access-guarding or

perimeter-guarding applications for the

following types of machines:

• Assembly stations

• Manufacturing cells

• Automated production equipment

• Robotic work cells

The Banner EZ-SCREEN Grid System

may not be used in the following types

of applications:

• For hand or finger detection in pointof-operation guarding (see Section

3.1)

• In non-vertical area-guarding

applications

•To guard any machine that cannot be

stopped immediately after a stop

signal is issued, such as single-stroke

(or “full-revolution”) clutched

machinery

•To guard any machine with inadequate

or inconsistent machine response

time and stopping performance

•To guard any machine that ejects

materials or component parts through

the light grid

• In any environment that is likely to

adversely affect photoelectric sensing

system efficiency. For example,

corrosive chemicals or fluids or

unusually severe levels of smoke or

dust, if not controlled, may degrade

the efficiency of the safety light grid

Banner Engineering Corp.

9714 - 10th Avenue No.

Minneapolis, MN 55441

Email: sensors@bannerengineering.com

U.S. Standards Applicable to Use of EZ-SCREEN™ Systems

ANSI B11 Standards Safeguarding of Machine Tools

ANSI/RIA R15.06 Safety Requirements for Robot Systems

NFPA 79 Electrical Standard for Industrial Machinery

See pages 62 and 63 for information on these and other applicable standards,

and where to acquire copies.

page 3

Banner Engineering Corp. • Minneapolis, U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

Table of Contents

EZ-SCREEN Grid

Instruction Manual

Table of Contents

1. Introduction — Overview . . . . . . . . . . . . . . . . . . . . . page 4

1.1 System Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2 Applications and Limitations . . . . . . . . . . . . . . . . . . . . . . . 6

1.3 Control reliability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.4 Operating features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2. System Components and Specifications . . . . . . . . . . . Page 10

2.1 Models Available . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.2 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.3 Replacement parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.4 Literature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.5 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.6 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3. Installation and Alignment . . . . . . . . . . . . . . . . . . . Page 16

3.1 Appropriate applications . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.2 Security Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.3 Mechanical Installation Considerations . . . . . . . . . . . . . . 18

3.3.1 Minimum Separation Distance (Ds) . . . . . . . . . . . . . . 18

3.3.2 Supplemental Safeguarding . . . . . . . . . . . . . . . . . . . . 21

3.3.3 Emitter/Receiver Orientation . . . . . . . . . . . . . . . . . . . 22

3.3.4 Adjacent Reflective Surfaces . . . . . . . . . . . . . . . . . . . 23

3.3.5 Use of Corner Mirrors . . . . . . . . . . . . . . . . . . . . . . . . 24

3.3.6 Avoiding Electrical and Optical Noise . . . . . . . . . . . . . 25

3.3.7 Multiple-System Applications . . . . . . . . . . . . . . . . . . 25

3.4 Mechanical Mounting Procedure . . . . . . . . . . . . . . . . . . . 26

3.5 Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3.6 Light Grid Initial Checkout and

Optical Alignment Procedure . . . . . . . . . . . . . . . . . . . . . . 30

3.7 Electrical Interface to the Guarded Machine

(Permanent Hookup) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

3.7.1 OSSD Output Connections . . . . . . . . . . . . . . . . . . . . . 33

3.7.2 FSD Interfacing Connections . . . . . . . . . . . . . . . . . . . 33

3.7.3 Machine Primary Control Elements and

EDM Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

3.7.4 Remote Test Input . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

3.8 Preparing for System Operation . . . . . . . . . . . . . . . . . . . . 36

4. System Operation . . . . . . . . . . . . . . . . . . . . . . . . . Page 40

4.1 System Configuration Settings . . . . . . . . . . . . . . . . . . . . . 40

4.2 Reset Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

4.2.1 Receiver Resets . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

4.2.2 Emitter Resets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

4.3 Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

4.4 Normal Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

4.5 Periodic Checkout Requirements . . . . . . . . . . . . . . . . . . . 44

5. Troubleshooting and Maintenance . . . . . . . . . . . . . . Page 45

5.1 Troubleshooting Lockout Conditions . . . . . . . . . . . . . . . . . 45

5.1.1 Receiver Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . 46

5.1.2 Emitter Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . 48

5.2 Electrical and Optical Noise . . . . . . . . . . . . . . . . . . . . . . . 49

5.3 Test Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

5.4 Servicing and Maintenance . . . . . . . . . . . . . . . . . . . . . . . 50

6. Checkout Procedures . . . . . . . . . . . . . . . . . . . . . . . Page 51

6.1 Schedule of Checkouts . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

6.2 Trip Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

6.3 Commissioning Checkout . . . . . . . . . . . . . . . . . . . . . . . . . 53

6.4 Daily Checkout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

6.5 Semi-Annual Checkout . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Appendix –

QD Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 57

QD Model Accessories . . . . . . . . . . . . . . . . . . . . . .Page 58

Accessory Bracket Dimensions . . . . . . . . . . . . . . . . . Page 59

Glossary of Safety Terms . . . . . . . . . . . . . . . . . . . . . . . Page 60

Safety Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 62

page 4

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

System Introduction

EZ-SCREEN Grid

Instruction Manual

1. Introduction — Overview

1.1 System Description

The Banner EZ-SCREEN™ Grid System is an optically synchronized,

microprocessor-controlled, opposed-mode optoelectronic “light grid.” This

economical two-part system consists of an emitter and receiver. The system

requires no external controller or sync wire between the emitter and receiver; the

microprocessors are located within the receiver. The receiver has two solid-state

safety outputs to control 24V dc loads. If an ac-powered MPCE or other load is

required, an accessory interface module may be used to convert the EZ-SCREEN

dc outputs to isolated, forced-guided relay contacts. (See Section 2.2 and Figures

3-17 and 3-18 for more information.)

Figure 1-1. EZ-SCREEN Models

SG..2-500

2 beams

500 mm (19.7")

Spacing

SG..3-400

3 beams

400 mm (15.7") Spacing

SG..3-533

3 beams

533 mm (21") Spacing

SG..4-300

4 beams

300 mm (11.8") Spacing

SG..2-584

2 beams

584 mm (23") Spacing

Each EZ-SCREEN Grid System

needs only an emitter and a receiver.

Optional Interface Module is available for

switching ac or larger dc loads. (See

Section 2.2 for more information on the

Interface Module.)

See pages 57-58 for quick-disconnect options.

Dots on

housing

indicate beam

placement

(dot size is

exaggerated

for visibility).

page 5

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

System Introduction

EZ-SCREEN Grid

Instruction Manual

Five sensor configurations are available, with two, three or four beams; emitters

have short-range and long-range versions. (Receivers are the same for both

long-range and short-range operation.) Beam spacing ranges from 300 mm to

584 mm (12" to 23"), depending on the model. The configuration (the overall

length and beam spacing) required for an application is determined by the

application and the safety standards being followed. Models SG..E/R2-584 and

SG..E/R3-533 are based on recommendations in ANSI/RIA R15.06 and ANSI B11

standards. Models SG..E/R4-300, SG..E/R3-400, and SG..E/R2-500 are based on

recommendations in EN 999. See pages 60 and 61 for a list of applicable safety

standards. Emitters and receivers do not need matching serial numbers to work

together; any emitter may be used with any receiver of the same length and beam

configuration. Figure 1-1 shows the sizes and beam configurations of the models

available.

The emitter/receiver beams feature a narrow effective aperture angle (EAA) for

effective long-range sensing — up to 70 meters, depending on model. The EAA

satisfies IEC 61496-2 (type 4), including requirements for extraneous reflections

and misalignment.

Cabling is accomplished in one of two ways. User-supplied cable may be hardwired into the emitter and receiver housings, using the removable terminals in

the end cap of each sensor, or Mini-style quick-disconnect models are available

for easier installation; see pages 57-58. See Section 2.5 for cable specifications

and Section 3.7 for wiring instructions.

Banner EZ-SCREEN Grid components may be purchased individually or in kits.

Kits include one emitter, one receiver, a keyed reset switch, and standard

mounting hardware for both sensors. When purchased separately, the emitter

and receiver each include one cable gland, mounting hardware for one sensor,

plus the accessory spanner wrench. The Key Reset switch also is available

separately, or the user may provide other means to reset the system (see

specifications in Section 2.5 for switch requirements).

The OSSD (solid-state safety outputs) are capable of performing a “handshake”

communication with the Muteable Safety Stop Interface (MSSI) or Universal

Safety Stop Interface (USSI) that are found on other Banner Engineering safety

products. The handshake protocol is satisfied by any Banner Engineering Safety

Category 4 (per ISO 13849-1/EN954-1) device with OSSD outputs or MSSI/USSI

inputs.

To ensure a Safety Category 4 (per ISO 13849-1/EN954-1) interface between the

two devices, the MSSI/USSI provides a “handshake request” that Banner

Engineering safety devices with OSSD solid-state outputs are capable of

responding to. This handshake verifies that the interface between the two devices

is capable of detecting certain unsafe failures that may occur, such as a shortcircuit to a secondary source of power or to the other channel, high input

resistance or loss of signal ground.

page 6

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

System Introduction

EZ-SCREEN Grid

Instruction Manual

1.2 Applications and Limitations

The Banner EZ-SCREEN Grid System is designed for use in access-guarding and

perimeter-guarding applications. It is designed to be mounted vertically, in order

to detect a body or torso (rather than a hand or an arm) as a person enters a

hazardous area. It is not intended nor designed for hand or finger detection in

point-of-operation guarding or for area-guarding applications.

In perimeter-guarding and access-guarding applications, the light grid is vertical

or nearly vertical. In these applications, personnel typically can pass through the

light grid (which removes or stops the hazard), then may continue into the

hazardous area.

A recommended set of beam placement positions has become accepted in the

United States and Europe. The standards (ANSI/RIA R15.06, ANSI B11 and

EN 999) recommend a safe beam placement, in order to hinder personnel from

crawling over, under or through the light grid, and into the hazardous area,

without detection. For more information, refer to Section 3.3.1.

WARNING . . .

Not for Point-ofOperation or Area

Guarding

Do not use the EZ-SCREEN Grid

System for point-of-operation or

non-vertical area guarding.

CAUTION . . .

Proper Model

Selection

Ensure proper

selection of emitter models,

with respect to range (operating

distance) between emitter and

receiver, to minimize the

possibility of optical short circuits

(see Sections 2.1 and 3.3.4).

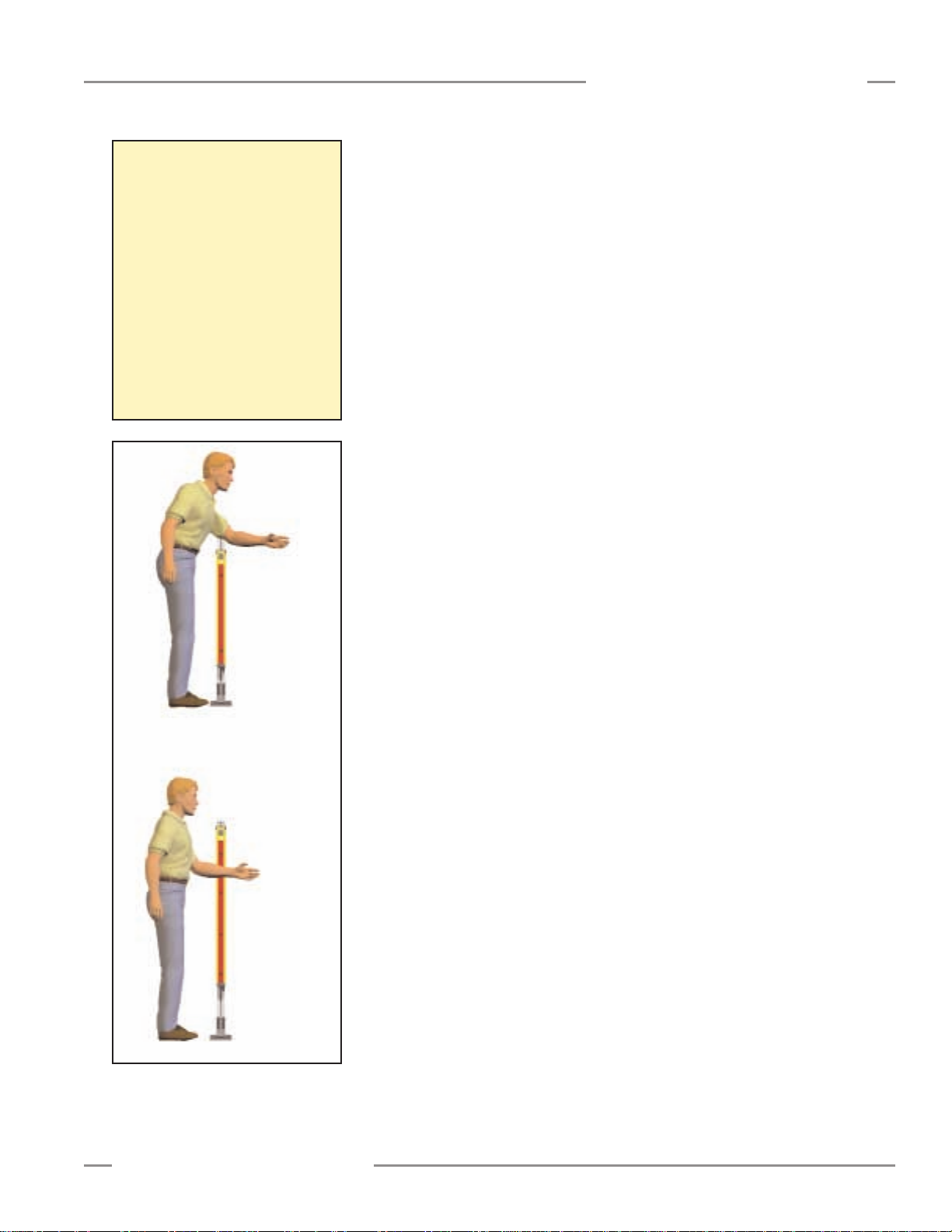

Figure 1-2. EZ-SCREEN perimeter-guarding application

Figure 1-3. Selecting the proper

emitter

Emitter

Receiver

Mirror #1

Mirror #2

!

!

Emitter Receiver

Short-Range

Emitters

0.8 to 20 m

(2.6' to 65')

Emitter Receiver

Long-Range

Emitters

15 to 70 m

(49' to 230')

page 7

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

System Introduction

EZ-SCREEN Grid

Instruction Manual

Pass-through hazards: Perimeter- and access-guarding applications must be

designed to prevent pass-through hazards. A pass-through hazard occurs when

an individual is allowed to cross the safeguard (which issues a stop command to

remove the hazard). Subsequently, the person may cross into the hazardous area

but their presence is no longer detected. A danger arises because the machine’s

dangerous motion may resume while personnel are within the safeguarded area.

Several measures can be taken to prevent a pass-through hazard, which include,

but are not limited to:

•A latching output on the safety light grid guarding the access or perimeter to

the hazardous area, which requires a manual reset procedure before machine

motion can be re-initiated. The reset switch has several requirements,

including its placement outside of the guarded area, and out of reach of

anyone inside the guarded area. In addition, the reset switch operator must

have full view of the entire guarded area during the reset procedure.

• Supplemental safeguarding, such as described by the ANSI B11 series of

safety requirements or other appropriate standards, to prevent personnel

from standing undetected within the guarded area.

In addition, hard guarding should be installed around the hazardous area to

prevent personnel from entering the guarded area, undetected by the safety light

grid, or other safeguarding means.

Because the EZ-SCREEN Grid has a selectable (latch or trip) output, it must be

installed and configured to prevent hazardous motion from occurring while

personnel are within the guarded area. See Section 4.1 for more information.

EZ-SCREEN Grid may be used to guard many types of machines, including

those for packaging, palletizers, roll formers and many types of work cells,

including robot cells. The guarded machine(s) must be capable of stopping at

any point in their motion; see page 2 for a complete list of requirements for

machines that may be guarded by this system.

WARNING . . .

Use of Trip Output

Application of power

to the EZ-SCREEN

Grid System MUST NOT initiate

dangerous machine motion.

Machine control circuitry must be

designed so that one or more

initiation devices must be engaged

(i.e. a conscious act) to start the

machine in addition to the EZSCREEN Grid System going into

RUN mode.

Failure to follow these instructions

could result in serious bodily

injury or death.

CAUTION . . .

Other Applications

For applications not

covered in this manual,

contact

a factory applications engineer

before installing or using the EZSCREEN System.

Figure 1-4. EZ-SCREEN access-guarding application

Emitter

Receiver

Hard Guarding

Hard Guarding

Hard Guarding

!

!

page 8

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

System Introduction

EZ-SCREEN Grid

Instruction Manual

1.3 Control Reliability

In addition to physical location requirements, safety standards require a safety

system such as the EZ-SCREEN Grid to fulfill some internal requirements. For

example, for an optical safety system to be used in a Safety Category 4

application (per ISO 13849-1/EN954-1), it must be third-party certified to the

type 4 requirements of IEC 61496-1 and -2.

EZ-SCREEN Grid’s microprocessor-based circuitry features a “diverse-redundant”

design, in which two microprocessors of different design, running from different

instruction sets, constantly check all system components, including each other.

In addition, EZ-SCREEN Grid is extensively FMEA (Failure Mode and Effects

Analysis) tested to establish an extremely high probability that no system

component will ever (even if it does fail) cause a failure to danger.

1.4 EZ-SCREEN Grid Operating Features

The Banner EZ-SCREEN Grid System features several selectable functions: trip or

latch output, external device monitoring (EDM), and scan code setting. These

settings are configured within the sensors, behind the threaded access port on

the front of each sensor and in the sensor wiring configuration; see Section 4.1

for more information.

Selectable Trip/Latch Output

The setting for latch or trip output also determines whether the System will enter

Run mode automatically or require a manual reset (see Section 4.1). If the

system is set for trip output, other measures must be taken to prevent a passthrough hazard; see Section 3.3.2 for more information.

Figure 1-5. EZ-SCREEN features

Trip/Latch and EDM

Select DIP Switches

r

i

d

.

,

US

A

E

D

M

T

1

3

4

L

2

S

S

T

T

A

A

T

T

U

U

S

S

Scan Code

Select Switch

EZ-SCREEN Grid

BANNER ENGINEERING CORP., USA

888.373.6767

2

SCAN

CODE

1

1

2

BEAMS

S

R

T

E

A

STATUS

S

T

E

U

T

S

Status Indicator –

Bi-color Red/Green

7-Segment

Diagnostic Display

Scan Code

Select Switch

Wiring Chamber

End Cap

rid

A

G

N

US

,

.

E

RP

O

C

RE

G

C

RIN

7

6

E

S

7

E

-

6

.

IN

3

G

7

3

N

.

EZ

E

8

8

R

8

E

N

N

BA

2

N

A

C

S

E

D

O

1

C

S

1

T

A

T

2

S

R

U

M

A

E

E

S

B

TUS

S

A

ST

E

T

Configuration

Access Port

EZ

-

S

C

BA

RE

N

N

E

R

E

E

N

N

GI

N

G

E

8

E

8

R

8

.

ING

3

7

3

.

C

6

7

O

6

RP

7

E

2

S

D

C

A

N

O

C

M

N

T

O

D

1

E

1

1

1

2

L

2

1

2

B

E

A

M

S

R

E

S

E

T

EZ-SCREEN Grid

BANNER ENGINEERING CORP., USA

888.373.6767

E

E

D

D

M

M

2T1T1

SCAN

CODE

1L2L2

1

2

BEAMS

S

R

T

E

A

S

T

E

U

T

S

Beam Status Indicators

(One for Each Beam) –

Bi-color Red/Green

7-Segment

Diagnostic Display

Reset Indicator –

Yellow

Status Indicator –

Bi-color Red/Green

ReceiverEmitter

page 9

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

System Introduction

EZ-SCREEN Grid

Instruction Manual

If trip output is selected, the OSSD outputs will turn ON after power is applied,

and the receiver passes its internal self-test/synchronization and recognizes that

all beams are clear. The trip output will also automatically reset after all

interruptions of one or more beams are cleared. If latch output is selected, the

EZ-SCREEN requires a manual reset for the OSSD outputs to turn ON, after

power is applied and all beams are clear (see Section 4.2.1).

External Device Monitoring (EDM)

This feature allows the EZ-SCREEN Grid to monitor the status of external devices,

such as MPCEs. The choices are one- or two-channel monitoring, or OFF. EDM is

used when the EZ-SCREEN Grid OSSD outputs directly control the energizing and

de-energizing of the MPCEs or other external devices; see Sections 3.7.3 and 4.1

for more information.

Remote Test Input

A pair of terminals is provided at the emitter (see Section 3.7.4) for an external

switch, typically a normally open contact held closed. Opening a switch

connected between these two terminals “turns off” the emitter, simulating an

interruption of one or more light beams. This remote test input may be useful for

EZ-SCREEN Grid system setup and to verify machine control circuit operation.

Scan Code Configuration

The emitter and receiver may be configured to one of two scan code positions (1

or 2). Scan codes enable a receiver to recognize beams only from an emitter with

the same scan code setting. This helps minimize the effects of crosstalk between

multiple emitter/receiver pairs, and allows multiple pairs to operate in close

proximity in certain situations. See Section 3.3 for proper mounting

configurations. The scan code is set using the selection switch in each sensor’s

configuration port; see Section 4.1 for more information. Both the emitter and its

corresponding receiver must be set to the identical setting.

Status Indicators

A variety of status indicators on both the system emitter and receiver are clearly

visible on each sensor’s front panel.

• Emitter: A single bi-color red/green Status indicator shows whether power

is applied, and whether the emitter is in Run mode, Test mode, or

Lockout mode. A 7-segment diagnostic display indicates specific

error or configuration conditions.

• Receiver: A bi-color red/green Beam Status indicator for each beam shows

whether that beam is aligned and clear with a strong signal, clear

but with a weak signal, or is blocked and/or misaligned. A yellow

Reset indicator shows when the system is in Run mode or is

waiting for a reset. A bi-color red/green Status indicator shows

when outputs are ON or OFF, or the system is in Lockout mode. A

7-segment diagnostic display indicates specific error or

configuration conditions.

See Section 4.3 for more information about specific indicator and diagnostic

display code meanings.

page 10

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

System Components and Specifications

EZ-SCREEN Grid

Instruction Manual

2. System Components and Specifications

2.1 Models Available

Banner EZ-SCREEN Grid components may be purchased individually or in kits.

Kits (as indicated below) include one emitter, one receiver, a keyed reset switch,

two cable glands, two spanner wrenches, a test piece, and standard mounting

hardware for both sensors. When purchased separately, the emitter and receiver

each include mounting hardware for one sensor, one cable gland, a test piece,

and a spanner wrench. Keyed reset switches are also available separately.

Short-Range Models*

(0.8 m - 20 m)

Long-Range Models*

(15 m - 70 m)

Overall

Length

Number

of Beams

SGE2-584 Emitter

SGR2-584 Receiver

SGP2-584 Kit

SGXLE2-584 Emitter

SGR2-584 Receiver

SGXLP2-584 Kit

768 mm

(30.2")

2

SGE3-533 Emitter

SGR3-533 Receiver

SGP3-533 Kit

SGXLE3-533 Emitter

SGR3-533 Receiver

SGXLP3-533 Kit

1251 mm

(49.3")

3

SGE2-500 Emitter

SGR2-500 Receiver

SGP2-500 Kit

SGXLE2-500 Emitter

SGR2-500 Receiver

SGXLP2-500 Kit

684 mm

(26.9")

2

SGE3-400 Emitter

SGR3-400 Receiver

SGP3-400 Kit

SGXLE3-400 Emitter

SGR3-400 Receiver

SGXLP3-400 Kit

984 mm

(38.7")

3

SGE4-300 Emitter

SGR4-300 Receiver

SGP4-300 Kit

SGXLE4-300 Emitter

SGR4-300 Receiver

SGXLP4-300 Kit

1084 mm

(42.7")

4

300 mm

(11.8")

400 mm

(15.7")

500 mm

(19.7")

533 mm

(21")

584 mm

(23")

Beam

Spacing

900 mm

(35.4")

800 mm

(31.5")

500 mm

(19.7")

1066 mm

(42")

584 mm

(23")

Protected

Height

EN 999

ANSI/RIA R15.06

ANSI B11

EN 999

EN 999

ANSI/RIA R15.06

ANSI B11

ANSI/RIA R15.06

ANSI B11

Application Standard

2.2 Accessories

LAT-1 52150 Laser Alignment Tool with adapter clip

EZA-LAT-1 66027 Clip-on retroreflective target

BT-1 26809 Beam Tracker

SI-QS-CG13 48564 Pg13.5 cable gland

SI-QM-13 48559 Adapter, 1/2" NPT to Pg13.5

Interface Modules provide

isolated safety contacts for a

Primary Safety Device (the

EZ-SCREEN Grid System).

See data sheet p/n 62822 for

more information.

* Hard-wired models only are listed. Add the suffixes listed below for quick-disconnect models; see pages 57-58

for more information.

Emitter suffix Q3: 3-pin Mini-style QD, Test input jumpered

Emitter suffix Q5: 5-pin Mini-style QD, Test input available

Receiver suffix Q8: 8-pin Mini-style QD

BRT-THG-2-100 26620 50 mm (2") wide reflective tape, 2.5 m (100") long

SI-QM-13-M20 66579 Adapter, M20 to Pg13.5

CAUTION . . .

Proper Model

Selection

Ensure proper

selection of emitter models,

with respect to range (operating

distance) between emitter and

receiver, to minimize the

possibility of optical short circuits

(see Section 3.3.4).

IM-T-9A 61425

Interface Module (3 normally open redundant-output

contacts)

IM-T-11A 61424

Interface Module (2 normally open redundant-output

contacts plus 1 normally closed auxiliary output contact)

!

page 11

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

System Components

EZ-SCREEN Grid

Instruction Manual

Model

Part

Number Fits EZ-SCREEN Models

EZS-684 61949 SG..E/R2-500

EZS-768 61950 SG..E/R2-584

EZS-984 61951 SG..E/R3-400

EZS-1251 61952 SG..E/R3-533

EZS-1084 61953 SG..E/R4-300

1084 mm

1251 mm

984 mm

768 mm

684 mm

Length

Lens Shields

NOTE: The total range decreases by approximately 10% per shield.

Mirrors

NOTE: The total range decreases by approximately 8% per mirror.

Accessory Mounting Brackets

NOTE: EZA-MBK-1 Standard end cap bracket kit is included with emitter and receiver.

See Appendix page 59 for accessory bracket dimensions.

Model

Part

Number

Fits EZ-SCREEN

Models

SSM-550 61895 SG..2-500

SSM-675 61896 SG..2-584

SSM-975 61898

SG..3-400

SG..4-300

SSM-1175 61899 SG..3-533

1175 mm

(46.3")

975 mm

(38.4")

675 mm

(26.6")

550 mm

(21.7")

Length

Y L3L2L1

603 mm

(23.7")

628 mm

(24.7")

661 mm

(26")

728 mm

(28.7")

753 mm

(29.6")

786 mm

(31")

1028 mm

(40.5")

1053 mm

(41.5")

1086 mm

(42.8")

1228 mm

(48.3")

1253 mm

(49.3")

1286 mm

(50.6")

61947

Adapter Bracket Kit for MSA Series

Stands

61980 Side-Swivel Bracket Kit

62771

Retrofit Bracket Kit

(to replace SICK/Leuze Grid systems)

66013 Adjustable Bracket Kit

Part

Number

Description

L1

L3

L2

Y

101.2 mm

(3.98")

100 mm

(3.94")

115 mm

(4.53")

M6 x 19 mm screw

(4 supplied)

M5 x 10 mm screw

(4 supplied)

EZA-MBK-2

EZA-MBK-3

EZA-MBK-8

EZA-MBK-9

Model

page 12

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

System Components

EZ-SCREEN Grid

Instruction Manual

2.3 Replacement Parts

2.4 Literature

MGA-KS0-1 30140 Keyed reset switch (same as that included in kits)

MGA-K-1 28513 Replacement key for switch MGA-KS0-1

EZA-AP-1 62859 Access port plug with o-ring

EZA-CP-13 62860 Pg13.5 plug with o-ring

EZA-ECR-1 62857

Receiver wiring chamber end cap (with gasket, captive

screws, 3 plugs with o-rings, terminal block)

Model

Part

Number Description

EZA-ECE-1 62858

Emitter wiring chamber end cap (with gasket, captive

screws, 3 plugs with o-rings, terminal block)

EZA-TBE-1 62861 Emitter terminal block

EZA-TBR-1 62862 Receiver terminal block

EZA-SW-1 62863 Spanner wrench

EZA-MBK-1 60630 Standard end cap bracket kit (with hardware)

STP-3 43958 Test Piece, 1.75" dia.

60632 Manual

60633 Daily Checkout Card

60634 Semi-Annual Checkout Card

MSA Series Stands

MSA-S42-1 43175 42"

MSA-S66-1 43176 66"

SSM-550, SSM-675

SSM-975, SSM-1175

To Fit Mirror ModelsModel

Part

Number

Height

SG..2-584, SG..2-500

SG..3-533, SG..3-400,

SG..4-300

To Fit Sensor Models

SMA-MBK-1 61933 SSM Series Mirror Bracket Kit

NOTE: One EZA-MBK-2 Adaptor Bracket Kit required per sensor

Usable

Stand

Height

6.4 mm (0.25")

Pole

40 mm

(1.58") Square

(4) M10 Bolt

Base

EZ-SCREEN Grid System Specifications

page 13

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

Specifications

EZ-SCREEN Grid

Instruction Manual

2.5 Specifications

EDM Input

+24V dc signals from external device contacts can be monitored (single-channel, dualchannel or no monitoring) via EDM1 and EDM2 terminals in the receiver (see Section 3.7.3).

Monitored devices must respond within 200 milliseconds of an output change.

Outputs

(See Warnings on page 33.)

Two diverse-redundant solid-state 24V dc, 0.5 A max. sourcing OSSD (Output Signal

Switching Device) safety outputs. (Use optional interface modules for ac or larger dc loads.)

Capable of the Banner “Safety Handshake” (see Section 1.1).

ON-State voltage: ≥Vin-1.5V dc

OFF-State voltage: 1.2V dc max.

Max. load resistance: 1000 ohm

Max. load capacitance: 0.1µF

Controls and Adjustments

Emitter:

Scan code selection: 2-position switch (code 1 or 2). Factory default position is 1.

Receiver:

Scan code selection: 2-position switch (code 1 or 2). Factory default position is 1.

Trip/latch output selection: redundant switches. Factory default position is L (latch).

EDM/MPCE monitor selection: redundant switches select between 1- or 2-channel

monitoring. Factory default position is 2.

Supply Voltage (V in)

24V dc ±15%, 10% maximum ripple

Emitter: 150 mA max.

Receiver: 500 mA max., exclusive of OSSD1 and OSSD2 loads (up to an additional 0.5A each)

Short Circuit Protection

All inputs and outputs are protected from short circuits to +24V dc or dc common

(except Emitter AUX power connections; see Section 3.5)

Response Time 24 milliseconds or less from interruption of light grid beam to safety outputs going to OFF-state

Safety Rating Type 4 per IEC 61496-1, -2; Category 4 per ISO 13849-1/EN 954-1

Reset Input

The Reset input must be high (10 to 30V dc at 30 mA) for 0.25 to 2 seconds and then low

(less than 3V dc) to reset the receiver.

Remote Test Input

Test mode is activated either by applying a low signal (less than 3V dc) to emitter TEST1

terminal for a minimum of 50 milliseconds, or by opening a switch connected between

TEST1 and TEST2 terminals for a minimum of 50 milliseconds. Beam scanning stops to

simulate a blocked condition. A high signal (10 to 30V dc, 35 mA inrush, 10 mA max.) at

TEST1 terminal de-activates Test mode and allows the emitter to operate normally. TEST1 and

TEST2 are factory jumpered. (See Section 3.7.4 for more information.)

Emitter/Receiver Operating Range

(See Caution on page 6.)

Short-range models: 0.8 m to 20 m (2.6' to 65')

Long-range models: 15 m to 70 m (49' to 230')

Range decreases with use of mirrors and/or lens shields; see Section 2.2.

Beam Spacing

(See dimension drawing, Figure 2-1,

for beam locations.)

Model SG...4-300: 300 mm (11.8")

Model SG...3-400: 400 mm (15.7")

Model SG...2-500: 500 mm (19.7")

Model SG...3-533: 533.4 mm (21")

Model SG...2-584: 584.2 mm (23")

Beam Diameter 25 mm (1")

Ambient Light Immunity > 10,000 lux at 5° angle of incidence

Strobe Light Immunity Totally immune to one Federal Signal Corp. “Fireball” model FB2PST strobe

Emitter Elements Infrared LEDs, 880 nm at peak emission

EZ-SCREEN Grid System Specifications (continued)

page 14

Specifications

EZ-SCREEN Grid

Instruction Manual

Effective Aperture Angle

(EAA)

Meets Type 4 requirements per IEC 61496-2, Section 5.2.9

Short-range models: ±2.5°@ 3 m

Long-range models: ±2.5°@ 15 m

Shock and Vibration

EZ-SCREEN systems have passed vibration and shock tests according to IEC 61496-1 and -2.

This includes vibration (10 cycles) of 10-55 Hz at 0.35 mm (0.014") single amplitude

(0.70 mm peak-to-peak) and shock of 10 g for 16 milliseconds (6,000 cycles).

Enclosure

Size: See Figure 2-1

Materials: Extruded aluminum housings with yellow polyester powder finish and well-sealed,

rugged molded PBT end caps, acrylic lens cover

Rating: NEMA 4, 13; IEC IP65

Operating conditions

Temperature: 0° to +50° C (+32° to 122°F)

Max. Relative Humidity: 95% maximum relative humidity (non-condensing)

Status Indicators

7-Segment Diagnostic Indicators, Both Emitter and Receiver

Dash (–) = System is OK

Error Codes = See Section 5.1 for code definitions and recommended action

Scan code setting = Appears during power-up or after scan code is changed.

(C1 or C2) (Temporary indication; normal display resumes within a few

seconds.)

Emitter: One bi-color (red/green) Status indicator

Green steady = RUN mode

Green single flashing = TEST mode

Red single flashing = Lockout (see Section 5.1.2)

OFF = No power to sensor

Receiver: Two system Status indicators, plus one bi-color (red/green) Beam Status indicator

for each beam

Yellow Reset Indicator

ON steady = RUN mode

Double flashing = Waiting for manual reset after power-up

Single flashing = Waiting for manual latch reset

OFF = No power to sensor or system is not ready for operation

Bi-Color (Red/Green) Status Indicator

Green steady = Outputs ON

Red steady = RUN mode, outputs OFF

Red single flashing = Lockout (see Section 5.1.1)

OFF = No power to sensor or system is not ready for operation

Bi-Color (Red/Green) Beam Status Indicators

Green steady = Clear beam, strong signal

Green flickering = Clear beam, weak signal

Red steady = Beam blocked

OFF = No power to sensor or no scanning

See Figure 1-5 for indicator locations.

Mounting Hardware

Emitter and receiver each are supplied with a pair of swivel end mounting brackets. Mounting

brackets are 8-gauge cold-rolled steel, black zinc finish.

Cables and Connections

Cables are user-supplied. Wiring terminals accommodate one 22 to 16 ga. wire or two wires

up to 18 ga.; Pg13.5 wiring chamber access port capacity varies, depending on cable gland

or strain relief fitting used. Supplied cable gland is for a cable diameter of 6 to 12 mm

(0.236" to 0.472").

Certifications

LISTED

US

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

Other certifications pending; contact factory for further information

page 15

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

Specifications

EZ-SCREEN Grid

Instruction Manual

Figure 2-1. EZ-SCREEN dimensions (standard end-cap brackets shown) and EZA-MBK-1 mounting bracket dimensions

Model

Beam

Spacing

L4

Housing

Length

SG..2-584

584 mm

(23")

768 mm

(30.8")

SG..3-533

533 mm

(21")

1251 mm

(49.2")

SG..2-500

500 mm

(19.7")

684 mm

(26.9")

SG..3-400

400 mm

(15.7")

984 mm

(38.7")

Distance Between

Brackets

L1 L2 L3

1017 mm

(40.1")

717 mm

(28.2")

1284 mm

(50.6")

802 mm

(31.6")

743 mm

(29.3")

1226 mm

(48.3")

659 mm

(25.9")

959 mm

(37.8")

SG..4-300

300 mm

(11.8")

1084 mm

(42.7")

1117 mm

(44")

1059 mm

(41.7")

74.2 mm

(2.92")

4.2 mm

(0.17")

25.0 mm

(0.98")

60.0 mm

(2.36")

40 mm

(1.57")

ø 32.0 mm

(1.26")

ø 43.0 mm

(1.69")

2x 30.0°

2x 60.0°

4x 5.8 mm

(0.23")

5.0 mm

(0.20")

15.0 mm

(0.59")

3x 7.0 mm

(0.28")

15.8 mm

(0.62")

31.5 mm

(1.24")

C

L

C

L

EZ-SCREEN

Standard Mounting Bracket

EZA-MBK-1

See page 11 for information

about other accessory brackets.

NOTE: QD models have identical mounting dimensions.

Allow additional height for QD fitting:

69 mm (2.7” for emitters (3- or 5-pin)

89 mm (3.5”) for receivers (8-pin)

2.6 Dimensions

Figure 2-1 shows the dimensions of the five basic configurations, including the

placement of the individual beams. Note that beam spacing varies from model to

model; the beam spacing selected depends on the specific standard(s) being

satisfied for the individual application.

12.5 mm (0.50")

Minimum Bend Radius

L1

16.7 mm

(0.66")

26 mm

(1.02")

107.0 mm

(4.21")

L4

EZ-SCREEN Grid

BANNER ENGINEERING CORP., USA

888.373.6767

1

2

BEAMS

R

E

S

E

T

See Notes

Below

EZ-SCREEN Grid

BANNER ENGINEERING CORP., USA

888.373.6767

52 mm

S

T

A

T

U

S

L2

25 mm

(1.0")

(2.0")

1

2

BEAMS

S

R

T

E

A

S

T

E

U

T

S

55 mm

(2.1")

L3

60.0 mm

(2.36")

74.2 mm

(2.92")

page 16

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

Installation and Alignment

EZ-SCREEN Grid

Instruction Manual

3. Installation and Alignment

Read Section 3 in its entirety before installing the Banner EZ-SCREEN Grid

System. The Banner EZ-SCREEN Grid System’s ability to perform its safety

guarding function depends upon the appropriateness of the application and upon

its proper mechanical and electrical installation and interfacing to the guarded

machine. If all mounting, installation, interfacing, and checkout procedures are

not followed properly, the EZ-SCREEN Grid System cannot provide the protection

for which it was designed. Installation must be performed by a Qualified Person,

as defined in the Safety Glossary in this manual. See Warning at right.

3.1 Appropriate Applications

The Banner EZ-SCREEN Grid System may be used to guard only machinery that

can be stopped immediately after a stop signal is issued. It may be used with

part-revolution clutched machines that have the ability to stop at any point in

their stroke. Under no circumstances may the EZ-SCREEN Grid System be used

to guard full-revolution clutched machinery. Banner EZ-SCREEN Grid Systems

may not be used as tripping devices to initiate machine motion (PSDI

applications) on mechanical power presses, per OSHA regulation 29 CFR

1910.217.

The Banner EZ-SCREEN Grid System is typically used in access-guarding or

perimeter-guarding applications for the following types of machines:

• Assembly stations

• Manufacturing cells

• Automated production equipment

• Robotic work cells

The Banner EZ-SCREEN Grid System may not be used in the following types of

applications:

• For finger or hand detection in point-of-operation guarding; its beam spacing is

larger than that allowed for finger or hand detection in these applications,

• For non-vertical area-guarding applications,

•To guard any machine that cannot be stopped immediately after a stop signal

is issued, such as single-stroke (or “full-revolution”) clutched machinery,

•To guard any machine with inadequate or inconsistent machine response

time and stopping performance,

•To guard any machine that ejects materials or component parts through the

area protected by the EZ-SCREEN Grid, or

• In any environment that is likely to adversely affect photoelectric sensing

system efficiency. For example, corrosive chemicals or fluids or unusually

severe levels of smoke or dust, if not controlled, may degrade the efficiency of

the safety light grid.

WARNING . . .

Read this Section

Carefully Before

Installing the

System

The user is responsible for

satisfying all local, state, and

national laws, rules, codes, or

regulations relating to the

installation and use of this control

system in any particular

application. Extreme care should

be taken to meet all legal

requirements and follow all

technical installation and

maintenance instructions contained

in this manual.

The user has the sole

responsibility to ensure that the

Banner EZ-SCREEN Grid System is

installed and interfaced to the

guarded machine by Qualified

Persons in accordance with this

manual and applicable safety

regulations.

Read all of Section 3 of this

manual carefully before installing

the system. Failure to follow these

instructions could result in serious

bodily injury or death.

CAUTION . . .

Install System Only

on Appropriate

Applications

In order for the machinery guarded

by the EZ-SCREEN Grid system to

be stopped as described, that

machinery must be capable of

stopping at any point in its

machine cycle. This means that the

EZ-SCREEN Grid system cannot be

used with certain types of

machinery (see listing at left).

If there is any doubt about whether

or not your machinery is

compatible with the EZ-SCREEN

Grid system, contact a Banner

factory application engineer.

!

!

page 17

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

Installation and Alignment

EZ-SCREEN Grid

Instruction Manual

3.2 Security Protocol

Certain procedures for installing, maintaining and operating the EZ-SCREEN Grid

system must be performed by either Designated Persons or Qualified Persons.

A Designated Person is identified and designated in writing, by the employer, as

being appropriately trained and qualified to perform the specified checkout

procedures on the EZ-SCREEN Grid system. A machine operator so designated

may be a Designated Person. The Designated Person is empowered to:

• Perform manual resets and hold possession of the reset key, and

• Perform the Daily Checkout Procedure (see Section 6).

A Qualified Person, by possession of a recognized degree or certificate of

professional training, or by extensive knowledge, training and experience, has

successfully demonstrated the ability to solve problems relating to the installation

of the EZ-SCREEN Grid System and its integration with the guarded machine. In

addition to everything for which the Designated Person is empowered, the

Qualified Person is empowered to:

• Install the safety light grid system,

• Perform all safety light grid checkout procedures (see Section 6),

• Have access and make changes to the internal light grid configuration settings

and hold possession of the Banner spanner wrench that opens the

configuration access port plug, and

• Reset the system following a lockout condition.

Resetting the System

System resets are performed using an external Reset switch. This switch must be

located outside the guarded area, and not within reach of anyone inside the

guarded area (see Section 3.4). Its location should provide a clear view of the

entire safeguarded area. If any hazardous areas are not within view from the

switch location, additional means of safeguarding must be provided.

The switch should be protected from accidental or unintended actuation (e.g.,

through the use of rings or guards).

If supervisory control of the Reset switch is required, a key switch may be used,

with the key kept in the possession of a Designated or Qualified Person. Using a

key switch will also provide some level of personal control, since the key may be

removed from the switch. This will hinder a reset while the key is under the

control of an individual, but must not be relied upon solely to guard against

accidental or unauthorized reset. Spare keys in the possession of others or

additional personnel entering the safeguarded area unnoticed may create a

hazardous situation.

Reset Routine

The EZ-SCREEN requires a manual reset to clear a latch condition and resume

operation following a stop command. To perform a manual reset, close the

normally open Reset switch for a least 1/4 second, but not longer than 2

seconds, and then re-open the switch. Internal lockout conditions also require a

manual reset to return the system to RUN mode after the failure has been

corrected and the input correctly cycled.

page 18

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

Installation and Alignment

EZ-SCREEN Grid

Instruction Manual

3.3 Mechanical Installation Considerations

Two factors have the greatest influence on the mechanical installation of the

EZ-SCREEN System:

• The required separation (safety) distance, and

• The presence of hard guarding.

3.3.1 Minimum Separation Distance (Ds)

Minimum Separation (Safety) Distance (Ds) is the minimum distance required

between the light grid and the closest reachable hazard point. Separation distance

is calculated so that the EZ-SCREEN Grid System will send a stop signal to the

machine when an object or a person is detected (by blocking a sensing beam),

allowing the machine to come to a stop by the time the person can reach any

machine hazard point.

After the Dsis determined, record the calculated distance in Section 6.4 (step

2) of this manual, and/or on the Daily Checkout Card.

Figure 3-1. Separation distance

D

s

D

s

D

s

Hazard

page 19

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

Installation and Alignment

EZ-SCREEN Grid

Instruction Manual

Calculation of separation distance takes into account several factors, including a

calculated human speed, the total system stopping time (which itself has several

components), and the depth penetration factor. The formula used to calculate

separation distance is:

Ds= K x(Ts+ Tr) + D

pf

where:

D

s

= the separation distance, in inches;

K = 63" per second (or 1600 mm per second), the OSHA-recommended (or

EN 999-recommended) hand-speed constant1;

T

s

= the overall stop time of the machine (in seconds) from the initial “stop”

signal to the final ceasing of all motion (including stop times of all

relevant control elements, and measured at maximum machine

velocity)2. See the Warnings on page 20, and the Notice Regarding

MPCEs (at left).

This measurement must take into account the slower of the two MPCE

channels, and the response time of all devices or controls (such as

interface modules) that react to stop the machine. If all devices are not

included, the calculated separation distance (Ds) will be too short and

serious injury could result.

T

r

= 0.024 seconds, the maximum response time of the EZ-SCREEN Grid

System; and

D

pf

= 36" or 48", the added distance due to depth penetration factor (for U.S.

applications, prescribed in ANSI/RIA R15.06 and ANSI B11). Because the

beam spacing of the EZ-SCREEN Grid is larger than 2.5" but less than

24", Dpfis either 36" or 48":

•Dpfis 36" if the top beam is 48" or higher and the bottom beam is

12" or less from the floor (a reach-through hazard).

•Dpfis 48" if the top beam is 36" to 48" above the floor and the

bottom beam is 12" or less from the floor (a reach-over hazard).

In European applications, Dpfis 850 mm, prescribed in EN 999.

NOTES:

1) The OSHA-recommended hand speed constant K has been determined by

various studies, and although these studies indicate speeds of 63"/second to

more than 100"/second, they are not conclusive determinations. The user

should consider all factors, including the physical ability of the operator,

when determining the value of K to be used.

2) Tsis usually measured by a stop-time measuring device. If the machine

manufacturer’s specified stop time is used, at least 20% should be added to

allow for possible clutch/brake system deterioration.

Figure 3-2. Determining Dpf(reach-

through versus reach-over

hazards per ANSI/RIA

R15.06)

Notice Regarding

MPCEs

Each of the two Machine Primary

Control Elements (MPCE 1 and

MPCE2) must be capable of

immediately stopping the dangerous

machine motion, irrespective of the

state of the other. These two channels

of machine control need not be

identical, but the stop time

performance of the machine (Ts, used

to calculate the separation distance)

must take into account the slower of

the two channels.

Reaching Over

Beam 1

Beam 2

Reaching Through

Beam 1

Beam 2

Beam 3

Beam 4

page 20

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

Installation and Alignment

EZ-SCREEN Grid

Instruction Manual

U.S. Applications:

Using the formula,

Ds= K x(Ts+ Tr) + D

pf

separation distance for a model SG..3-533 EZ-SCREEN Grid System

(42" protected height with 3 beams, 21" apart) is calculated (per ANSI/RIA

R15.06):

K = 63"/second

T

s

= 0.32 (0.250 second is specified by the machine manufacturer; plus

20% safety factor; plus 20 ms for interface module IM-T-9A response)

T

r

= 0.024, the maximum response time of the EZ-SCREEN Grid System

in seconds; and

D

pf

= 36"

Ds= 63 x(0.32 + 0.024) + 36

Ds= 58"

In this example, the EZ-SCREEN Grid emitter and receiver must be mounted

so that no part of the light grid will be closer than 58" from the closest

reachable hazard point of the guarded machine.

European Applications:

Using the same formula, separation distance for a model SG..3-400 EZSCREEN Grid System (800 mm protected height with 3 beams, 400 mm

apart), is calculated (per EN 999):

K = 1600 mm/second

T

s

= 0.32 (0.250 second is specified by the machine manufacturer; plus

20% safety factor; plus 20 ms for interface module IM-T-9A response)

T

r

= 0.024, the maximum response time of the EZ-SCREEN Grid System

in seconds; and

D

pf

= 850 mm

Ds= 1600 x(0.32 + 0.024) + 850

Ds= 1400 mm

In this example, the EZ-SCREEN Grid emitter and receiver must be mounted

so that no part of the light grid will be closer than 1400 mm from the closest

reachable hazard point of the guarded machine.

Figure 3-3. Calculating separation distance, two examples

NOTE: Other machine standards may require different

separation factors from those illustrated. Also,

workers’/operators’ abilities, plant procedures and other

factors may affect Ds.

CAUTION . . .

Position Components

Carefully

The emitter and receiver must be

positioned so that the hazard

cannot be accessed by reaching

over, under, around or through the

sensing field. Supplemental

safeguarding may be required; see

Section 3.3.2.

!

CAUTION . . .

Adequate Separation

Distance

The emitter and receiver must be

positioned a safe distance from

hazardous areas, as described by

OSHA standards in Section

1910.217 (c)(3)(iii)(e). Also see

Section 3.3 of this manual.

Failure to do so could result in

serious bodily injury or death.

CAUTION . . .

Determining Correct

Stop Time

Be sure to include the stop time of

all relevant devices and controls in

your calculations. Failure to do so

could result in serious bodily

injury or death.

!

!

Loading...

Loading...