Delta R18448, R18224 User Manual

T

E

F

L

O

N

ASME A112.18.1 / CSA B125.1

®

®

U

P

C

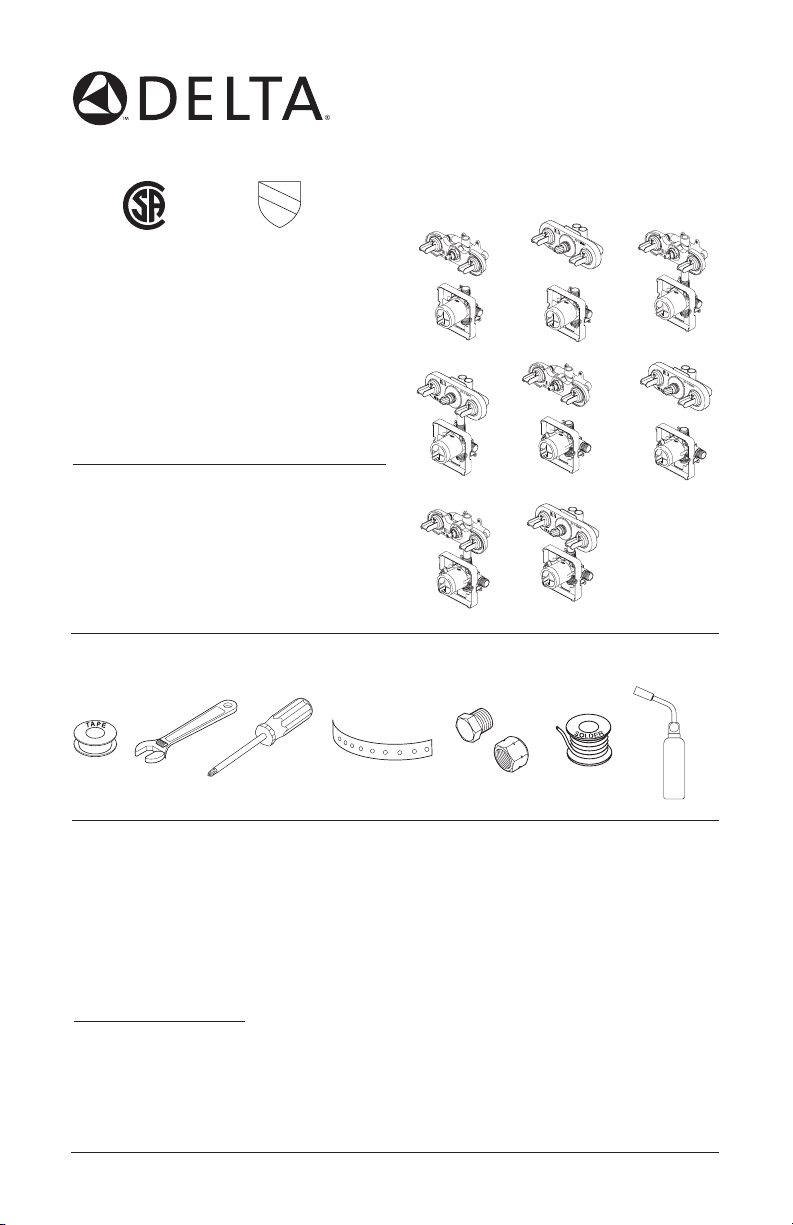

Models

R18222, R18224,

R18442 & R18448

Series

Write purchased model number here.

You may need the following tools:

SINGLE HANDLE

MULTICHOICE™ UNIVERSAL

JETTED SHOWER™ &

JETTED SHOWER XO™

ROUGH-IN VALVE BODY

For easy installation of your Delta® faucet you will need:

• To READ ALL the instructions completely before beginning.

• To READ ALL warnings, care, and maintenance information.

THIS ROUGH-IN BODY MEETS OR EXCEEDS THE FOLLOWING STANDARDS:

ANSI A112.18.1 &

ASME A112.18.1 / CSA B125.1

.

NOTICE TO INSTALLER: CAUTION!–As the installer of this rough-in body, it is your

responsibility to properly INSTALL this rough-in body per the instructions given.

YOU MUST inform the owner/user of this requirement by following the instructions.

If you or the owner/user are unsure how to properly install this rough-in body, please refer

to the instructions supplied and if still uncertain, call us at 1-800-345-DELTA. Leave this

Instruction Sheet for the owner's/user's reference.

6/27/07

1

51045 Rev B

TABLE OF CONTENTS:

Warranty -- - -- --- - - -- --- - - -- --- - - -- --- - - -- --- - - -- --- - - -- --- - - -- --- - - -- Page 2

Installation Instructions - - -- - --- -- -- - -- - -- -- - -- - -- -- - -- - --- -- -- - -- - -- -- Pages 3 -9

Replacement Parts - - --- -- -- - -- - -- -- - -- - -- -- - -- - --- -- -- - -- - -- -- - -- - -- Pages 1 0- 13

Lifetime Faucet and Finish Limited Warranty

All parts and finishes of the Delta® faucet are

warranted to the original consumer purchaser to

be free from defects in material & workmanship

for as long as the original consumer purchaser

owns their home. Delta Faucet Company

recommends using a professional plumber for all

installation & repair.

Delta will replace, FREE OF CHARGE, during

the warranty period, any part or finish that proves

defective in material and/or workmanship under

normal installation, use & service. Replacement

parts may be obtained by calling 1-800-345DELTA (in the U.S. and Canada) or by writing to:

In the United States:

Delta Faucet Company

Product Service

55 E. 111th Street

Indianapolis, IN 46280

In Canada:

Delta Faucet Canada

Technical Service Centre

420 Burbrook Place

London, ON N6A 4L6

This warranty is extensive in that it covers

replacement of all defective parts and even

finish, but these are the only two things that

are covered. LABOR CHARGES AND/OR

DAMAGE INCURRED IN INSTALLATION,

REPAIR, OR REPLACEMENT AS WELL AS ANY

OTHER KIND OF LOSS OR DAMAGES ARE

EXCLUDED. Proof of purchase (original sales

receipt) from the original consumer purchaser

must be made available to Delta for all warranty

claims. THIS IS THE EXCLUSIVE WARRANTY

BY DELTA FAUCET COMPANY, WHICH DOES

NOT MAKE ANY OTHER WARRANTY OF ANY

KIND, INCLUDING THE IMPLIED WARRANTY

OF MERCHANTABILITY.

This warranty excludes all industrial, commercial

& business usage, whose purchasers are

hereby extended a five year limited warranty

from the date of purchase, with all other terms

of this warranty applying except the duration of

the warranty. This warranty is applicable to Delta

faucets manufactured after January 1, 1995.

Some states/provinces do not allow the exclusion

or limitation of incidental or consequential

damages, so the above limitation or exclusion

may not apply to you. Any damage to this faucet

as a result of misuse, abuse, or neglect, or any

use of other than genuine Delta® replacement

parts WILL VOID THE WARRANTY.

This warranty gives you specific legal rights, and

you may also have other rights which vary from

state/province to state/province. It applies only

®

faucets installed in the United States of

for Delta

America, Canada, and Mexico.

®

© 2007 Masco Corporation of Indiana

2

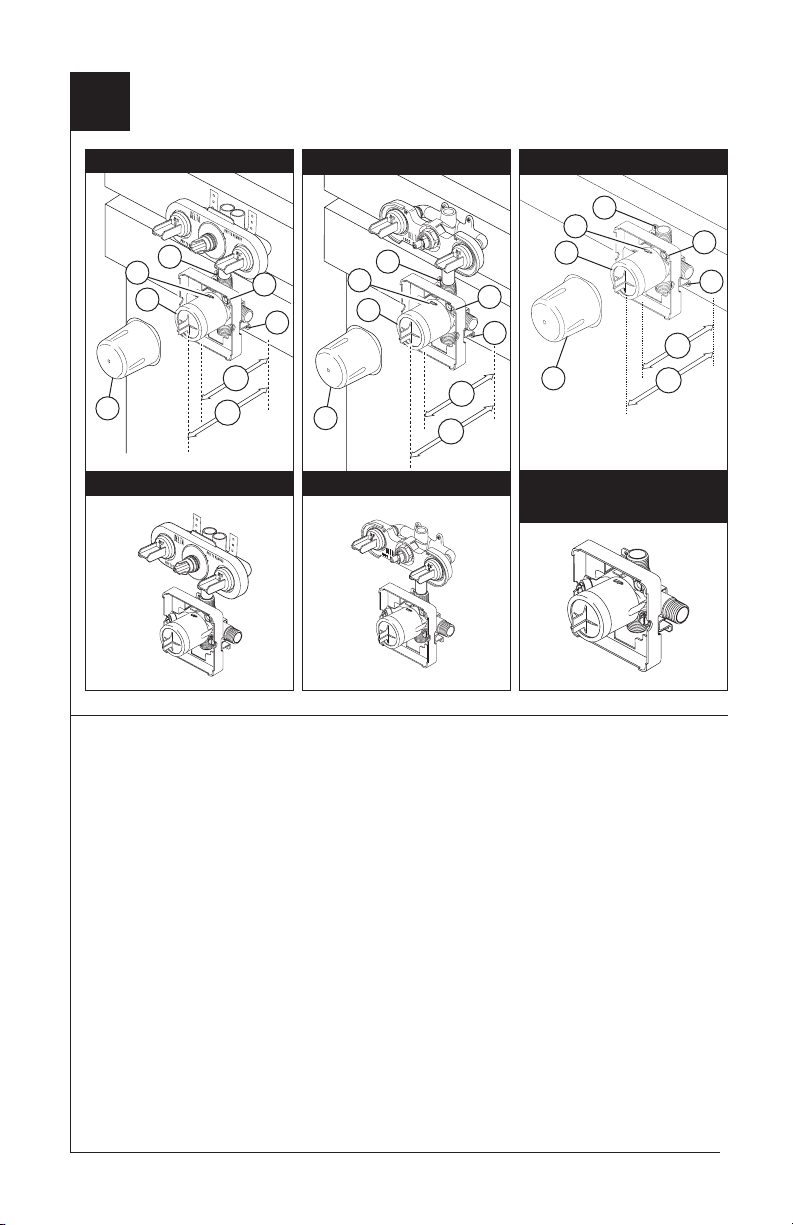

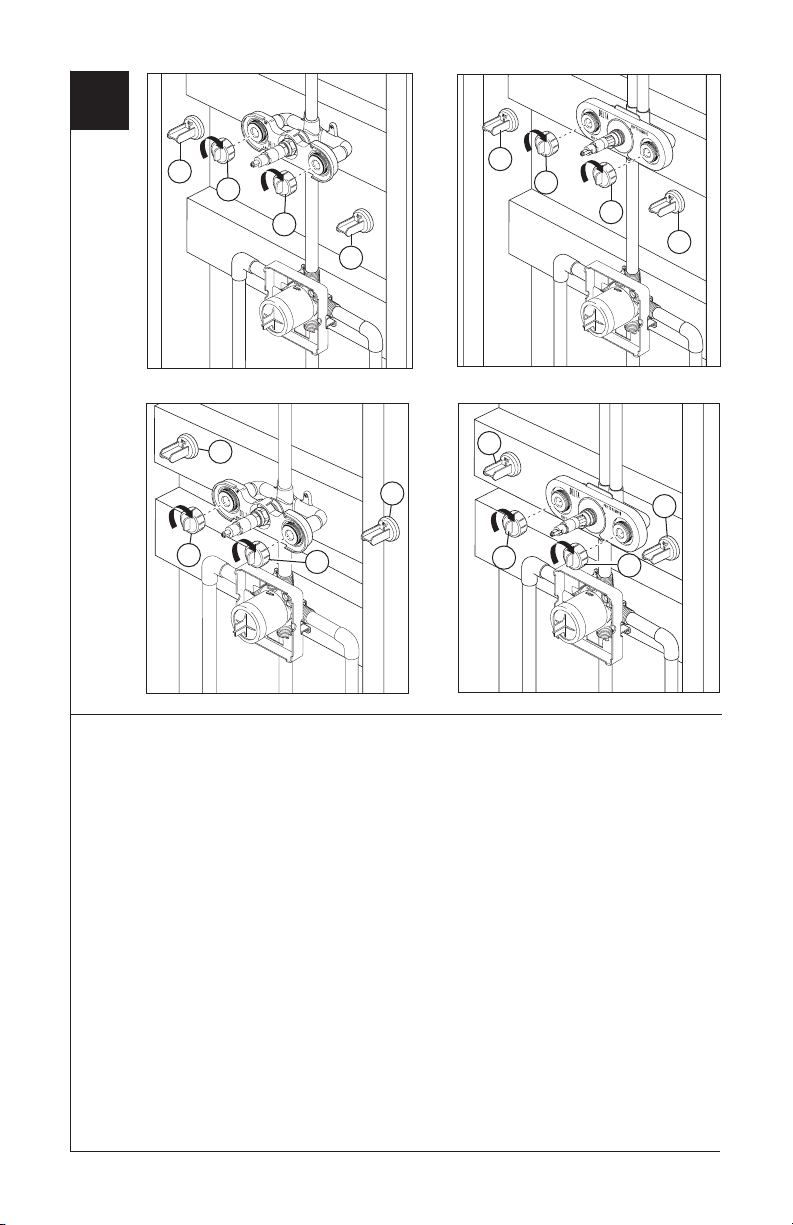

1

R18222

5

1

4

R18222-WS

R18224

3

2

3

A

B

4

3

5

1

A

B

R18224-WS

R18442 & R18448

5

1

2

3

4

R18442-WS &

3

2

3

A

B

R18448-WS

Jetted Shower™ and Jetted Shower XO™ Installation

Description:

Jetted Shower™ valves turn the body

jets on and off only. Jetted Shower XO™

valves divert the water to the jets, the

showerhead, an extra port or any

combination of two, making it a 3 port, 6

function diverter. The black stem

extender (without the stop) must be used

if using all outlets. If a 2 port, 3 function

diverter is desired, jets only, combination

jets & showerhead and showerhead

only, the plug must be soldered in as

shown and the blue stem extender with

the stop must be used.

Installation Instructions:

Shut off water supplies. Consider the

type and thickness of your finished wall

before placing your stringer back plate.

Mount the valve to desired height. We

recommend 52" from the base of the

enclosure to the center line of the jets.

Install the body (1) so the surface of the

finished wall is flush with the front of the

plasterguard (2), using the two stringer

mounting holes (3) on the bracket. Note:

Remove cover (4) to access mounting

holes. Make sure the word “UP” (5) is on

top of the valve body when installing.

Distance (A) from the stringer to the

front of the plasterguard is 2.8" (71 mm).

Distance (B) from the stringer to the front

of the bonnet is 3.9" (99 mm).

If a thin wall is used, be sure to have the

plasterguard behind the wall, otherwise

the wall should always be flush with the

front of the plasterguard. Note: For thin

wall mounting, use included template

for hole location.

3

2

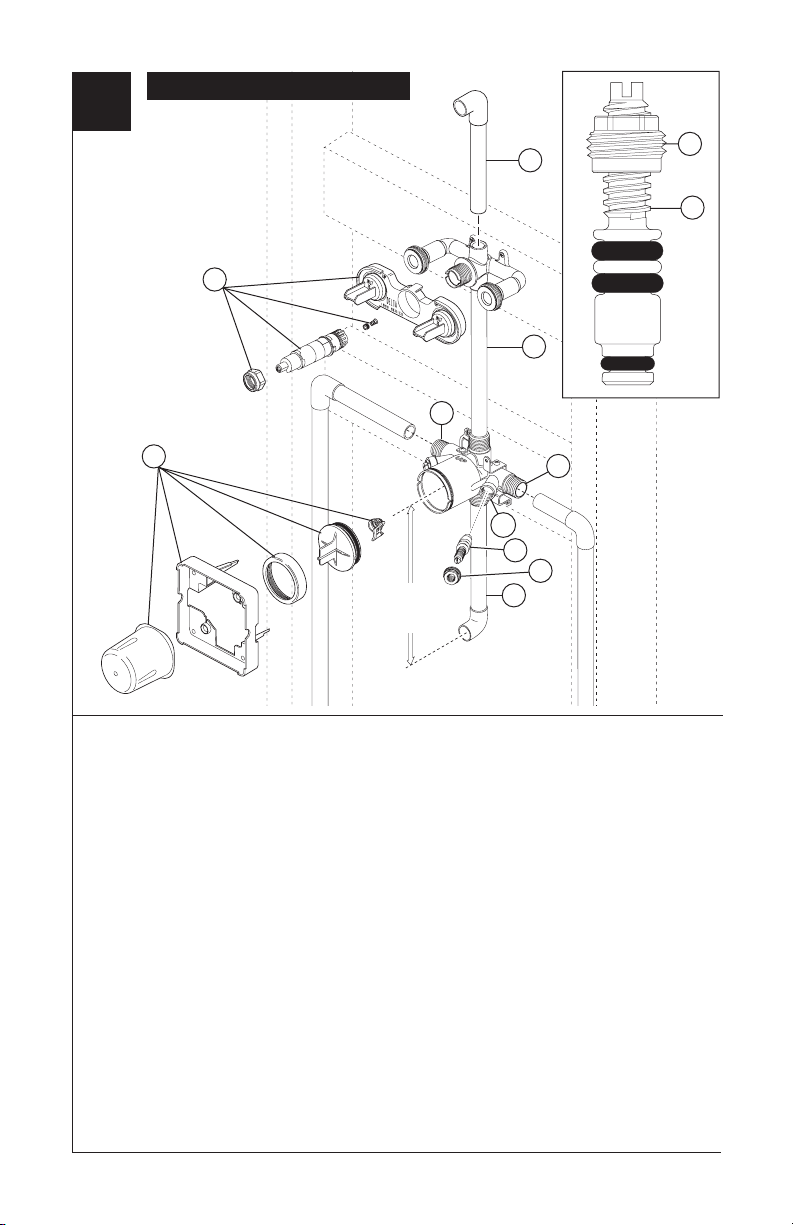

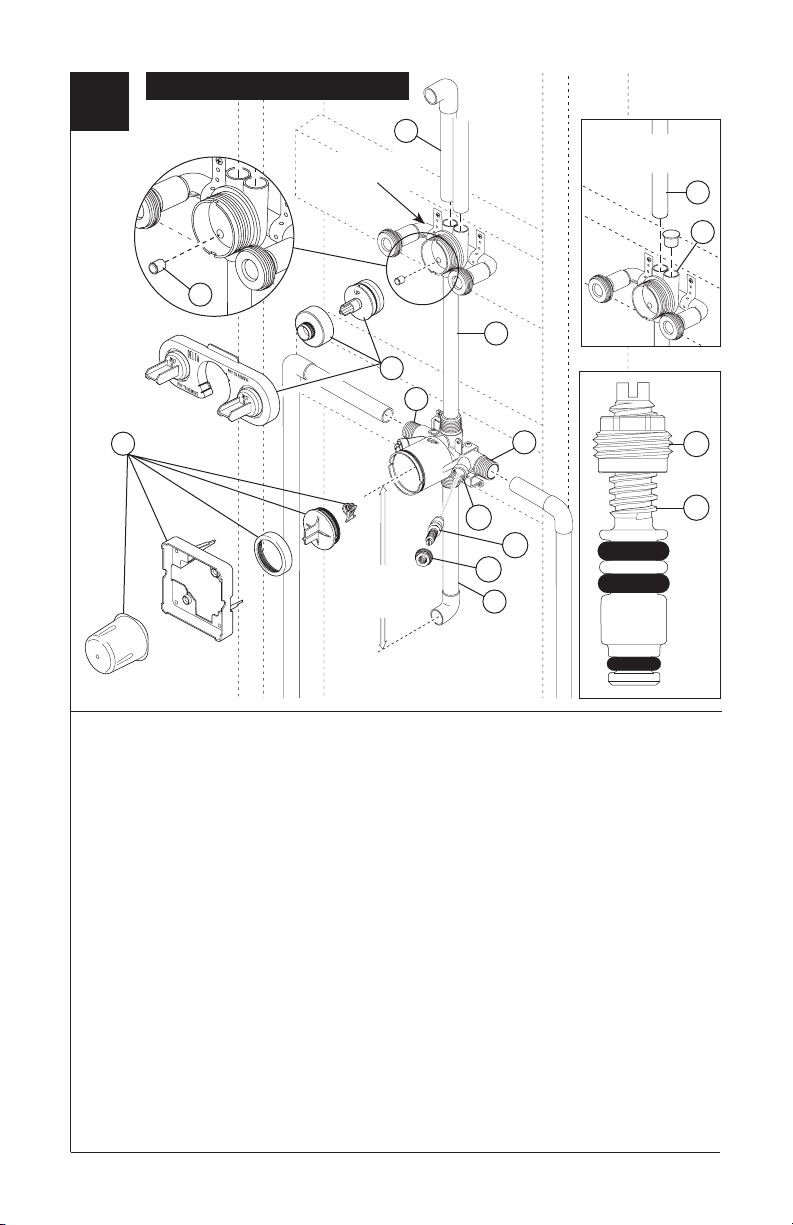

R18448 & R18448-WS

8

6

9

1

5

4

2

16"

(406 mm)

Max

R18448 & R18448-WS Installation

Remove the bonnet nut, stem and stem

extender, seat, spring, and plasterguard

(1), plus, the screen, test cap, bonnet nut,

plasterguard and cover (2) before soldering.

Connect valve body to water supplies using

er fittings. Note: (3) is the cold

the prop

inlet port and (4) is the hot inlet port.

Solder a copper tube (5) from the valve

body to the jet module so the jets are at

the desired height. Solder another tube (6)

onto the top of the jet module to the shower

arm elbow to the desired height. It is

recommended to mount valves to stringers

as shown.

The pipe (7) between valve & tub spout

must be a minimum of 1/2" (13 mm) copper

pipe or 1/2" (13 mm) iron pipe in a straight

drop no less than 8" (203 mm) but no more

than 16" (406 mm) long with only one 90

degree elbow to the spout nipple. If any

outlet port is to be unused, seal the port with

a pipe plug.

If you are making a back to back or reverse

installation (hot on right and cold on left)

install the valve body as described, but

reverse the water supply lines.

After soldering, reinstall all parts in reverse

order; ensure bonnet nuts are tightened

securely. Then install the stops into the body;

be careful not to overtighten the nuts.

Note: Install stops in the w/stops version as

follows: Thread nut (8) on stem (9) as shown.

Then press stem and nut assembly into body

(10) and tighten using a 3/8", 6 point, deep

well socket. With a flat head screwdriver, adjust

stem clockwise to close and counterclockwise

to open.

3

10

9

8

7

4

2

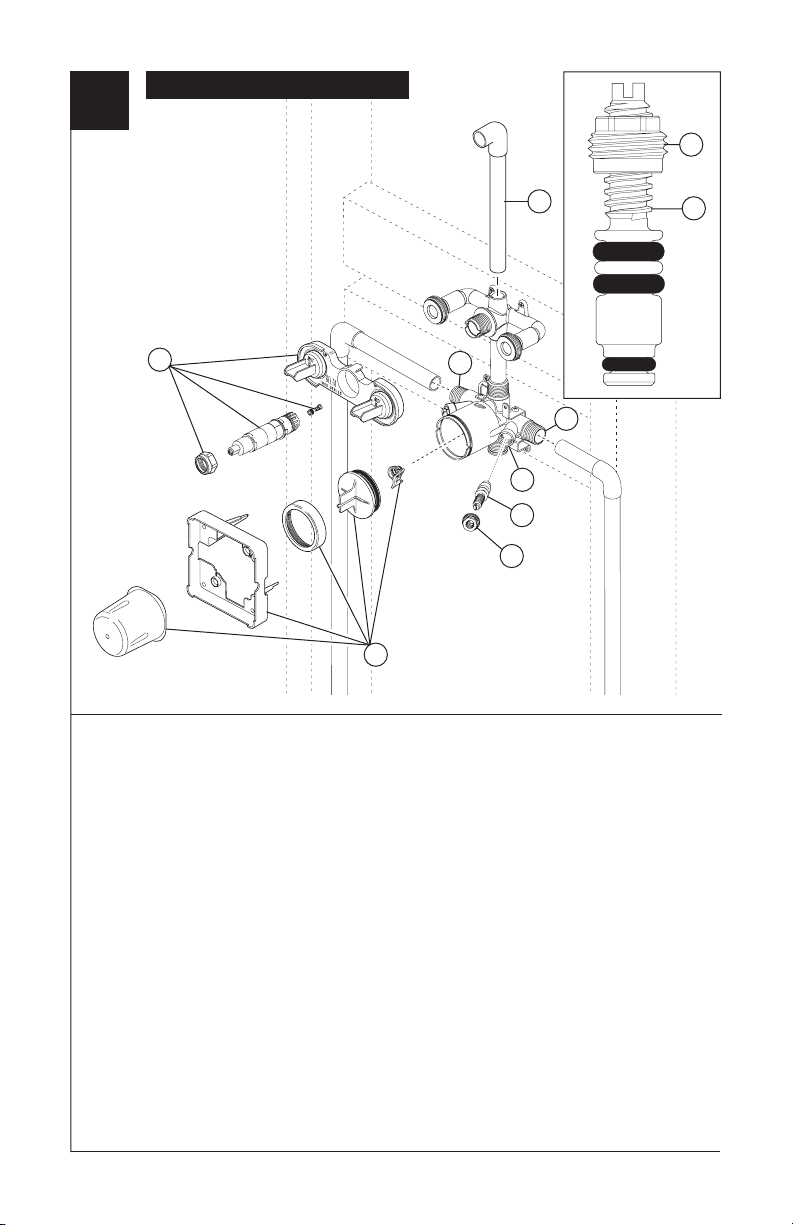

R18442 & R18442-WS

3 Port, 6 Function

Installation

9

7

5

1

4

2 Port, 3 Function

Installation

7

6

2

16"

(406 mm)

Max

R18442 & R18442-WS Installation

Remove the bonnet nut, cartridge and

plasterguard (1), plus, the screen, test cap,

bonnet nut, plasterguard and cover (2) before

soldering. Connect valve body to water

supplies using the prop

er fittings. Note: (3)

is the cold inlet port and (4) is the hot

inlet port.

Solder a copper tube (5) from the valve

body to the jet module so the jets are at the

desired height. Determine whether a three

or six function configuration is desired. For

2 port, 3 function; solder plug into auxiliary

port (6) in casting. Solder tube (7) into the

main port of the jet module to the shower

arm elbow to the desired height. For 3 port,

6 function; all outlet ports are used. It is

recommended to mount valves to stringers

as shown.

The pipe (8) between valve & tub spout must

be a minimum of 1/2" (13 mm) copper pipe

or 1/2" (13 mm) iron pipe in a straight drop

no less than 8" (203 mm) but no more than 16"

(406 mm) long with only one 90 degree elbow

to the spout nipple. If any outlet port is to be

unused, seal the port with a pipe plug.

If you are making a back to back or reverse

installation (hot on right and cold on left) install

the valve body as described, but reverse the

water supply lines.

After soldering press the detent (9) into proper

hole as shown, reinstall all parts in reverse

order; ensure bonnet nuts are tightened

securely. Then install the stops into the body;

be careful not to overtighten the nuts.

Note: Install stops in the w/stops version as

follows: Thread nut (10) on stem (11) as shown.

Then press stem and nut assembly into body

(12) and tighten using a 3/8", 6 point, deep

well socket. With a flat head screwdriver, adjust

stem clockwise to close and counterclockwise

to open.

3

12

11

10

8

10

11

5

2

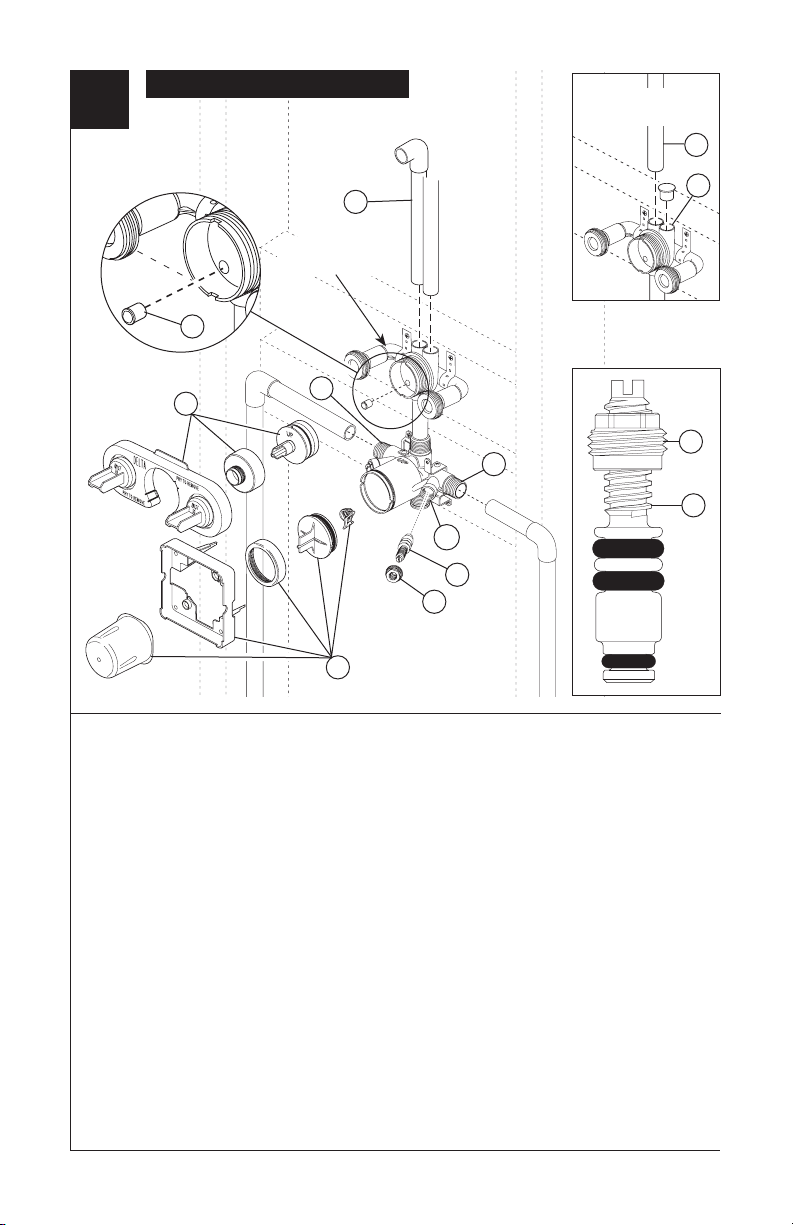

R18224 & R18224-WS

6

1

2

4

R18224 & R18224-WS Installation

Remove the bonnet nut, stem and stem

extender, seat, spring, and plasterguard

(1), plus, the screen, test cap, bonnet nut,

plasterguard and cover (2) before soldering.

Connect valve body to water supplies using

er fittings. Note: (3) is the cold

the prop

inlet port and (4) is the hot inlet port.

Solder a tube (5) onto the top of the jet

module to the shower arm elbow to the

desired height. If any outlet port is to be

unused, seal the port with a pipe plug. It

is recommended to mount unit to stringers

as shown.

If you are making a back to back or reverse

installation (hot on right and cold on left),

install the valve body as described, but

reverse the water supply lines.

After soldering reinstall all parts in reverse

order; ensure bonnet nuts are tightened

securely. Then install the stops into the body;

be careful not to overtighten the nuts.

Note: Install stops in the w/stops version as

follows: Thread nut (6) on stem (7) as shown.

Then press stem and nut assembly into body

(8) and tighten using a 3/8", 6 point, deep well

socket. With a flat head screwdriver, adjust

stem clockwise to close and counterclockwise

to open.

5

3

8

7

6

7

6

2

R18222 & R18222-WS

2 Port, 3 Function

Installation

5

5

3 Port, 6 Function

Installation

7

1

4

10

9

8

2

R18222 & R18222-WS Installation

Remove the bonnet nut, cartridge and

plasterguard (1), plus, the screen, test

cap, bonnet nut, plasterguard and cover

(2) before soldering.

to water supplies using the prop

Note: (3) is the cold inlet port and (4) is

the hot inlet port.

Solder a tube (5) from main outlet of the

jet module to the shower arm elbow to the

desired height.

or six function configuration is desired. For

2 port, 3 function; solder plug into auxiliary

port (6) in casting. For 3 port, 6 function;

all outlet ports are used. It is recommended

to mount valves to stringers as shown.

If you are making a back to back or reverse

installation (hot on right and cold on left)

Connect valve body

er fittings.

Determine whether a three

install the valve body as described, but

reverse the water supply lines.

After soldering press in the detent (7) into

proper hole as shown, reinstall all other parts

in reverse order; ensure bonnet nuts are

tightened securely.

into the body; be careful not to overtighten

the nuts.

Note: Install stops in the w/stops version as

follows: Thread nut (8) on stem (9) as shown.

Then press stem and nut assembly into body

(10) and tighten using a 3/8", 6 point, deep

well socket. With a flat head screwdriver, adjust

stem clockwise to close and counterclockwise

to open.

6

8

3

9

Then install the the stops

7

3

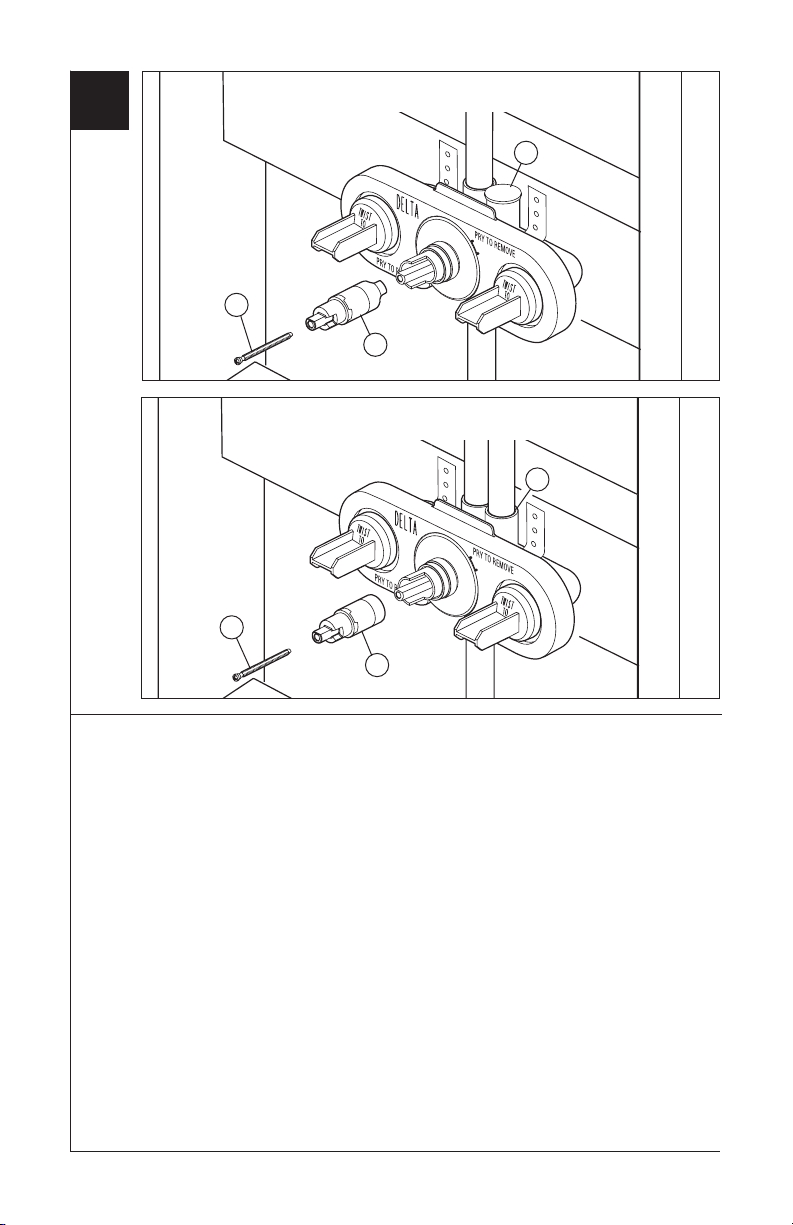

Blue Stem Extender -

2 Port, 3 Function Installation

3

1

2

Black Stem Extender -

3 Port, 6 Function Installation

3

1

4

Stem Extender Installation

Be sure to install the proper stem

extender for your installation.

required stem extender onto brass stem.

Install the blue stem extender (2) if the

Place

installation does not use the auxillary port (3).

Install the black stem extender (4) if the

installation uses all of the outlet ports. Use

screw (1) to secure.

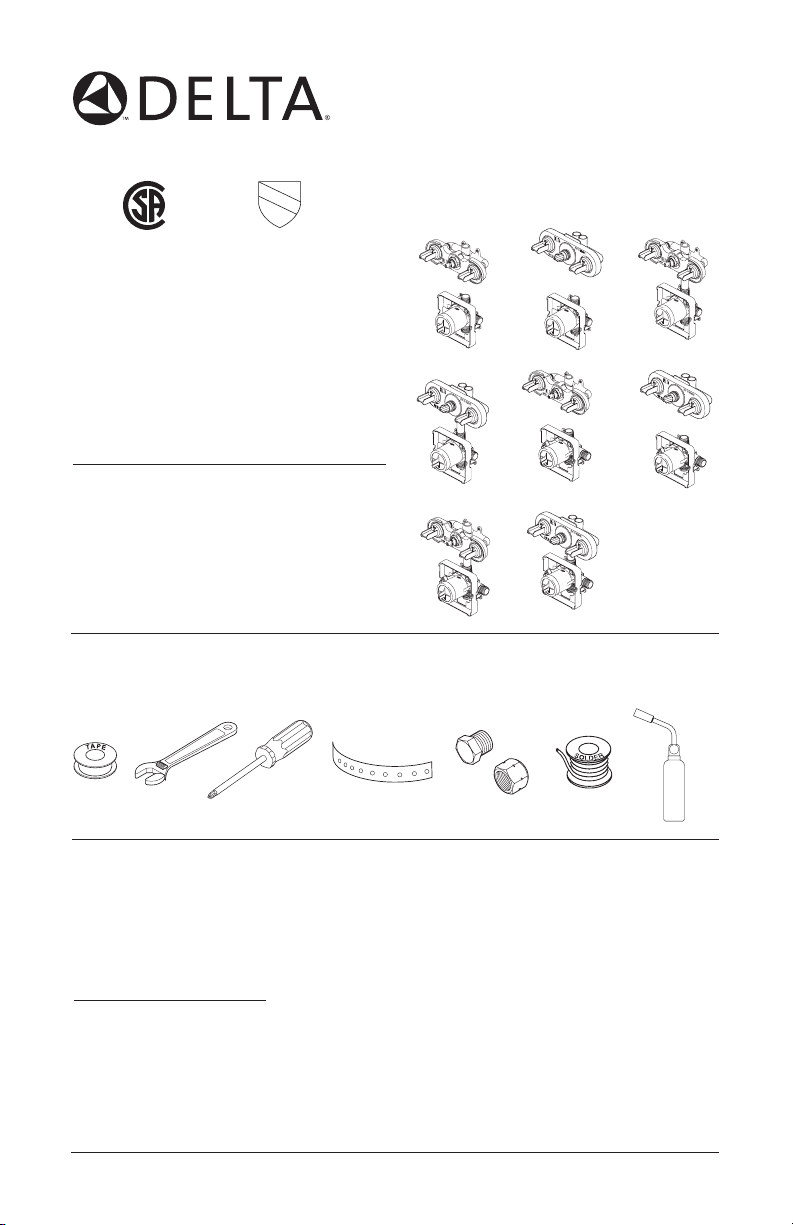

8

4

1

2

2

1

1

1

2

2

1

2

2

1

1

1

2

2

Pressure Testing & Flushing the Installation

Prior to testing, break off plasterguard caps

(1) and completely thread on the pressure

testing caps (2). Ensure the bonnet nuts

are properly tightened, and plug both

outlets with proper fittings. Check for leaks.

After testing remove shower and/or tub spout

plug and flush system. After flushing remove

filter screen (see step 2) and reinstall cap,

bonnet and cover.

9

Notes / Notas / Notes

T

E

F

L

O

N

ASME A112.18.1 / CSA B125.1

®

®

U

P

C

Modelos

R18222, R18224,

R18442 & R18448

Series

Escriba aquí el número del modelo comprado.

CUERPO DE LA VÁLVULA PARA

LA INSTALACIÓN PRELIMINAR

DE LAS REGADERAS DE

UNA MANIJA MULTICHOICE™

UNIVERSAL JETTED SHOWER™

Y JETTED SHOWER XO™

Usted puede necesitar:

Para instalación fácil de su llave Delta® usted necesitará:

• LEER TODAS las instrucciones completamente antes de empezar

• LEER TODOS los avisos, cuidados, e información de mantenimiento.

ESTA VALVULA CUMPLE O EXCEDE LAS SIGUIENTES NORMAS: ANSI A112.18.1 y

ASME A112.18.1 / CSA B125.1

AVISO AL INSTALADOR: ¡PRECAUCIÓN!- Como instalador de la tubería interna -

dentro de la pared/piso, es su responsabilidad INSTALAR esta pieza correctamente

como se describe en las instrucciones que le damos. USTED DEBE informarle al

propietario/usuario, siguiendo las instrucciones dadas, de este requisito. Si usted o el

propietario/usuario no están seguros como se instalan correctamente las tuberías internas,

por favor refiérase a las instrucciones proporcionadas y si todavía no está seguro, llámenos

al 1-800-345-DELTA. Deje esta hoja de instrucciones como referencia para el

propietario/usuario.

6/27/07

.

1

51045 Rev B

Loading...

Loading...