Delta DVP-ES2 User Manual

2011-04-12

5011685804-E204

DVP-1130070-02

………………………………………………………………… ENGLISH …………………………………………………………………

Thank you for choosing Delta’s DVP-ES2 series PLC. DVP-ES2 series provides 16~ 60 points MPU and 8 ~ 32 points digital I/O module. The maximum I/O points including those on the MPU are 256 points. DVP-ES2 can be used for various applications with different I/O points, power supply, digital I/O and analog I/O modules.

This instruction sheet provides only information on the electrical specification, general functions, installation and wiring. For detailed program design and applicable instructions for DVP-ES2, please refer to “DVP-ES2 Operation Manual: Programming”. For details on the optional peripheral, please refer to the instruction sheet enclosed in the package.

DVP-ES2 series PLC is an OPEN TYPE device and therefore should be installed in an enclosure free of airborne dust, humidity, electric shock and vibration. The enclosure should prevent non-maintenance staff from operating the device (e.g. key or specific tools are required for operating the enclosure) in case danger and damage on the device may occur.

DO NOT connect the input AC power supply to any of the I/O terminals; otherwise serious damage may occur. Check all the wiring again before switching on the power. Make sure the ground terminal  is correctly grounded in order to prevent electromagnetic interference.

is correctly grounded in order to prevent electromagnetic interference.

Product Profile & Dimension

POWER, RUN, ERROR & COM indicators |

|

I/O point indicators |

|

I/O terminal No. |

|

|

|

Run/Stop switch |

|

|

I/O module |

|

|

|

|

COM1 Communication |

DVP40ES2 |

R |

connection port |

port (RS-232C) |

24 DI / 1 6D O |

Output type |

|

|

|

|

|

I/O terminal No. |

|

|

Mounting slot |

Model Name |

|

|

|

|

|

(35mm) |

|

COM2/COM3 (RS-485) |

I/O module clip |

|

|

DIN rail clip |

Direct mounting hole |

|

|

|

Removable I/O terminal block |

|

[ Figure 1 ] |

|

|

|

90 |

98 |

106 |

110 |

|

|

|

|

|

L1 |

|

|

|

|

61.5 |

|

|

|

|

L |

|

|

|

|

78 |

|

[ Figure 2 ] |

|

|

|

Unit: mm |

|

|

|

|

||

Model |

16ES2 |

24ES2 |

32ES2 |

|

40ES2 |

60ES2 |

20EX2 |

32ES2 |

|

name |

00R/T |

00R/T |

00R/T |

|

00R/T |

00R/T |

00R/T |

11T |

|

L |

105 |

125 |

145 |

|

165 |

225 |

145 |

145 |

|

L1 |

97 |

117 |

137 |

|

157 |

217 |

137 |

137 |

|

|

|

|

|

- 1 - |

|

|

|

|

|

Electrical Specifications

|

Model |

|

16ES2 |

24ES2 |

32ES2 |

40ES2 |

60ES2 |

|

20EX2 |

32ES2 |

|

|

Item |

|

00 |

00 |

00 |

00 |

00 |

|

00 |

11T |

|

|

Power supply |

|

|

100 ~ 240VAC (-15% ~ 10%), 50/60Hz ±5% |

|

24VDC |

|||||

|

voltage |

|

|

|

(-15~+20%) |

||||||

|

|

|

|

|

|

|

|

|

|||

|

Connector |

|

European standard removable terminal block (Pin pitch: 5mm) |

|

|||||||

|

|

ES |

|

DVP-ES2 starts to run when the power rises to 95 ~ 100VAC and stops |

|||||||

|

|

|

when the power drops to 70VAC. If the power is suddenly cut off, the MPU |

||||||||

|

Operation |

200 |

|

will continue running for 10ms. |

|

|

|

|

|

||

|

ES |

|

DVP-ES2 starts to run when the power rises to 20.4VDC~28.8VDC and |

||||||||

|

|

|

|||||||||

|

|

|

stops when the power drops to 17.5VDC. If the power is suddenly cut off, |

||||||||

|

211 |

|

the MPU will continue running for 10ms. |

|

|

|

|

||||

|

Power supply |

|

|

|

2A/250VAC |

|

|

|

2.5A / |

||

|

|

|

|

|

|

|

30VDC, |

||||

|

fuse |

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

Polyswitch |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

Power |

|

30VA |

30VA |

30VA |

30VA |

30VA |

|

30VA |

1.8W |

|

|

consumption |

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

||

|

DC24V current |

|

500mA |

500mA |

500mA |

500mA |

500mA |

|

500mA |

|

|

|

output |

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

||

|

Power supply |

|

DC24V output short circuit protection |

|

|

|

|

||||

|

protection |

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

||

|

Voltage |

|

1,500VAC (Primary-secondary), 1,500VAC (Primary-PE), |

|

|||||||

|

withstand |

|

500VAC (Secondary-PE) |

|

|

|

|

|

|||

|

Insulation |

|

> 5MΩ at 500VDC (between all I/O points and ground) |

|

|

||||||

|

resistance |

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

ESD: 8KV Air Discharge |

|

|

|

|

|

||

|

Noise immunity |

|

EFT: Power Line: 2KV, Digital I/O: 1KV, Analog & Communication I/O: 1KV |

||||||||

|

|

|

|

RS: 26MHz ~ 1GHz, 10V/m |

|

|

|

|

|

||

The diameter of grounding wire shall not be less than that of L, N terminal of Grounding the power supply. (When many PLCs are in use at the same time, please

make sure every PLC is properly grounded.)

|

Environment |

Operation: 0°C~55°C (temperature), 50~95% (humidity), pollution degree 2 |

|||||||||||||

|

Storage: -25°C~70°C (temperature), 5~95% (humidity) |

|

|

||||||||||||

|

|

|

|

|

|||||||||||

|

Agency |

UL508 |

|

|

|

|

|

|

|

|

|

|

|

||

|

European community EMC Directive 89/336/EEC and Low Voltage Directive |

||||||||||||||

|

approvals |

||||||||||||||

|

73/23/EEC |

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Vibration/shock |

International standards: IEC61131-2, IEC 68-2-6 (TEST Fc)/ IEC61131-2 & |

|||||||||||||

|

immunity |

IEC 68-2-27 (TEST Ea) |

|

|

|

|

|

|

|

|

|||||

|

Weight |

R: 377g |

|

R: 414g |

|

R: 489g |

R: 554g |

|

R: 696g |

R: 462g |

|

T: 321g |

|||

|

T: 351g |

|

T: 387g |

|

T: 432g |

T: 498g |

|

T: 614g |

T: 442g |

|

|||||

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Input Point |

|

|

|

|

|

|

||

|

Input No. |

ES200, EX200 |

|

X0, X2 |

|

X1, X3 ~ X7 |

|

X10 ~ X17, X20 ~#1 |

|||||||

|

|

ES211 |

|

X0 ~ X3 |

|

|

X4 ~ X7 |

|

|||||||

|

|

|

|

|

|

|

|

|

|

||||||

|

type |

|

|

|

|

|

|

Digital input |

|

|

|

|

|||

|

Input type |

|

|

|

|

|

DC (SINK or SOURCE) |

|

|

||||||

|

Input current |

|

|

|

|

|

|

24VDC, 5mA |

|

|

|

|

|||

|

Input impedance |

|

|

|

|

|

|

|

4.7KΩ |

|

|

|

|

||

|

Max. frequency |

|

|

|

100kHz |

|

|

10kHz |

|

|

60Hz |

||||

|

Action level |

Off → On |

|

|

|

|

|

>15VDC |

|

|

|

|

|||

|

On → Off |

|

|

|

|

|

< 5VDC |

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

Response time |

Off → On |

|

< 2.5μs |

|

|

< 20μs |

|

|

< 10ms |

|||||

|

On → Off |

|

< 5μs |

|

|

< 50μs |

|

|

< 15ms |

||||||

|

|

|

|

|

|

|

|

||||||||

|

Filter time |

X0 ~ X7 |

Adjustable within 0 ~ 20ms in D1020 (Default: 10ms) |

||||||||||||

|

|

|

|

|

|

- 2 - |

|

|

|

|

|

|

|

|

|

Output Point

|

Output point type |

Relay-R |

|

Transistor-T |

||

|

Output point number |

All |

Y0, Y2 |

Y1, Y3 |

Y4~Y17, Y20~#1 |

|

|

Voltage specification |

< 250VAC, 30VDC |

|

5 ~ 30VDC #2 |

||

|

Max. frequency |

1Hz |

100kHz |

10kHz |

1kHz |

|

|

|

Resistive |

2A/1 point (5A/COM) |

0.5A/1 point (4A/COM) #4 |

||

|

Maximum load |

Inductive |

#3 |

|

15W (30VDC) |

|

|

|

|

||||

|

|

Lamp |

20WDC/100WAC |

|

2.5W(30VDC) |

|

|

Response time |

Off → On |

Approx .10ms |

< 2μs |

< 20μs |

< 100μs |

|

On → Off |

< 3μs |

< 30μs |

< 100μs |

||

|

|

|

||||

#1: Please refer to “I/O Terminal Layout” for the max. X/Y No. on each model.

#2: UP, ZP must work with external auxiliary power supply 24VDC (-15% ~ +20%), rated consumption approx. 1mA/point.

#3: Life curves

|

3,000 |

|

120VAC Resistive |

|

|

|

|

|

|

30VDC Inductive(t=7ms) |

|

||||

|

2,000 |

|

|

||||

|

|

|

240VAC Inductive(cosψ=0.4) |

|

|||

|

1,000 |

|

|

|

|||

|

|

|

120VAC Inductive(cosψ=0.4) |

|

|||

) |

500 |

|

|

|

|||

03 |

|

|

|

|

|

|

|

1X( |

300 |

|

|

|

|

|

|

no |

200 |

|

|

|

|

|

|

ita |

100 |

|

|

|

|

|

|

re |

30VDC |

|

|

|

|||

|

|

|

|

||||

pO |

50 |

Inductive |

|

|

|

||

|

30 |

|

(t=40ms) |

|

|

|

|

|

|

|

|

|

|

|

|

|

20 |

|

|

|

|

Contact |

|

|

|

|

|

|

|

[ Figure 3 ] |

|

|

0.1 |

0.2 |

0.3 |

0.5 0.7 1 |

2 |

Current(A) |

|

#4: ZP for NPN COM, UP for PNP COM.

A/D and D/A Specifications (For EX2 Model Only)

Items |

Analog Input (A/D) |

Analog Output (D/A) |

|||||||

|

Voltage |

|

Current |

Voltage |

Current |

||||

Analog I/O range |

±10V |

|

±20mA |

|

4 ~ 20mA#1 |

±10V |

0 ~ 20mA |

4 ~ 20mA#1 |

|

Digital conversion |

±2,000 |

|

±2,000 |

|

0 ~ +2,000 |

±2,000 |

0 ~ +4,000 |

0 ~ +4,000 |

|

range |

|

|

|||||||

|

|

|

|

|

|

|

|

||

Resolution #2 |

|

|

|

|

12-bit |

|

|

||

Input impedance |

> 1MΩ |

|

|

250Ω |

|

- |

|

||

Output impedance |

|

|

- |

|

|

|

0.5Ω or lower |

||

Tolerance carried |

|

|

- |

|

|

> 5KΩ |

< 500Ω |

||

impedance |

|

|

|

|

|||||

|

|

|

|

|

|

|

|

||

|

Non-linear accuracy: ±1% of full scale within the range of PLC operation |

||||||||

Overall accuracy |

temperature |

|

|

|

|

|

|

||

|

Maximum deviation: ±1% of full scale at 20mA and +10V |

|

|||||||

Response time |

2ms (set up in D1118) #3 |

|

2ms #4 |

|

|||||

Absolute input |

±15V |

|

±32mA |

|

- |

|

|||

range |

|

|

|

||||||

|

|

|

|

|

|

|

|

||

Digital data format |

2’s complement of 16-bit, 12 significant bits |

|

|

||||||

Average function |

Provided (set up in D1062) #5 |

|

- |

|

|||||

Isolation method |

No Isolation between digital circuit and analog circuit |

|

|||||||

Protection |

Voltage output has short circuit protection, but a long period of short |

||||||||

circuit may cause internal wire damage and open circuit of current output. |

|||||||||

|

|||||||||

#1: V1.2 and above supports this mode. Please refer to the detailed explanation of D1115. - 3 -

#2: Resolution formula

|

Analog Input (A/D) |

|

|

Analog Output (D/A) |

|

||

Voltage |

Current |

Voltage |

Current |

||||

(5mV = |

20V ) |

(10μΑ = |

40mA ) |

(5mV = |

20V ) |

(5μΑ = |

20mA ) |

|

4000 |

|

4000 |

|

4000 |

|

4000 |

#3: When the scan period is longer than 2ms or the set value, the setting will follow the scan period.

#4: When the scan period is longer than 2ms, the setting will follow the scan period. #5: When the sampling range is “1”, the present value will be read.

Installation

Please install the PLC in an enclosure with sufficient space around it to allow heat dissipation, as shown in the figure.

y Direct Mounting: Please use M4 screw according to the dimension of the product.

yDIN Rail Mounting: When mounting the PLC to

35mm DIN rail, be sure to use the retaining clip to stop any side-to-side movement of the PLC and reduce the chance of wires being loose. The retaining clip is at the bottom of the PLC. To secure the PLC to DIN rail, pull down the clip, place it onto the rail and gently push it up. To remove the PLC, pull the retaining clip down with a flat screwdriver and gently remove the PLC from DIN rail.

Wiring

1.Use the 12-24 AWG single-core bare wire or the multi-core wire for the I/O wiring. The PLC terminal screws should be tightened to 3.80 kg-cm (3.30 in-lbs) and please use 60/75°C copper conductor only.

2.DO NOT wire empty terminal. DO NOT place the input signal wire and output power wire in the same wiring circuit.

3.DO NOT drop tiny metallic conductor into the PLC while screwing and wiring.

y Please attach the dustproof sticker to the PLC before the installation to prevent conductive objects from dropping in.

y Tear off the sticker before running the PLC to ensure normal heat dissipation.

Power Supply

The power input type for DVP-ES2 model is AC input. When operating DVP-ES2, please note the following points:

1.The range of the input voltage should be 100 ~ 240VAC. The power supply should be connected to L and N terminals. Please note that wiring AC110V or AC220V to +24V output terminal or digital input points will result in serious damage on the PLC.

2.The AC power inputs for the MPU and the digital I/O module should be ON or OFF at the same time.

3.Use 1.6mm wire (or longer) for the grounding of the PLC.

4.The power shutdown of less than 10ms will not affect the operation of the PLC. However, power shutdown time that is too long or the drop of power supply voltage will stop the running of the PLC, and all outputs will go “OFF”. When the power returns to normal status, the PLC will automatically resume operation. (Care should be taken on the latched auxiliary relays and registers inside the PLC when programming.)

5.The +24V output is rated at 0.5A from MPU. DO NOT connect other external power

-4 -

supplies to this terminal. Every input terminal requires 5 ~ 7mA to be driven; e.g. the 16-point input will require approximately 100mA. Therefore, +24V terminal cannot give output to the external load that is more than 400mA.

Safety Wiring

In PLC control system, many devices are controlled at the same time and actions of any device could influence each other, i.e. breakdown of any device may cause the breakdown of the entire auto-control system and danger. Therefore, we suggest you wire a protection circuit at the power supply input terminal. See the figure below.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

○1 |

AC power supply:100 ~ 240VAC, 50/60Hz |

○2 |

Breaker |

|

|||||||||||||||||||||

○3 |

Emergency stop: This button cuts off the system power supply when accidental |

|

|||||||||||||||||||||||

|

emergency takes place. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

○4 |

Power indicator |

○5 |

AC power supply load |

|

|||||||||||||||||||||

○6 |

Power supply circuit protection fuse (2A) |

○7 |

DVP-PLC (main processing unit) |

|

|||||||||||||||||||||

○8 |

DC power supply output: 24VDC, 500mA |

○9 |

Grounding resistance: < 100Ω |

|

|||||||||||||||||||||

○10 |

DC power supply: 24VDC |

○11 |

Digital I/O module (DC supply) |

|

|||||||||||||||||||||

○12 |

Digital I/O module (AC supply) |

○13 |

Analog I/O module (DC supply) |

|

|||||||||||||||||||||

○14 |

DC power supply: 20.4VDC~28.8VDC |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

I/O Point Wiring

There are 2 types of DC inputs, SINK and SOURCE. (See the example below. For detailed point configuration, please refer to the specification of each model.)

y DC Signal IN – SINK mode Input point loop equivalent circuit

+24V |

24G |

S/S |

X0 |

X1 |

[ Figure 5 ] |

y DC Signal IN – SOURCE mode Input point loop equivalent circuit

+24V |

24G |

S/S |

X0 |

X1 |

[ Figure 6 ] |

- 5 -

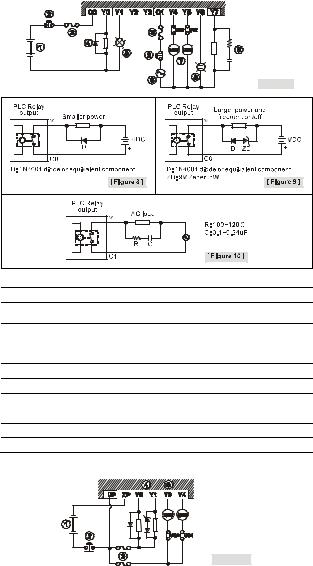

y Relay (R) output circuit wiring

[ Figure 7 ] |

○1 DC power supply

○2 Emergency stop: Uses external switch

○3 Fuse: Uses 5 ~ 10A fuse at the shared terminal of output contacts to protect the output circuit

○4 Transient voltage suppressor: To extend the life span of contact.

1.Diode suppression of DC load: Used when in smaller power (Figure 8)

2.Diode + Zener suppression of DC load: Used when in larger power and frequent On/Off (Figure 9)

○5 Incandescent light (resistive load)

○6 AC power supply

○7 Manually exclusive output: For example, Y4 and Y5 control the forward running and reverse running of the motor, forming an interlock for the external circuit, together with the PLC internal program, to ensure safe protection in case of any unexpected errors.

○8 Neon indicator

○9 Absorber: To reduce the interference on AC load (Figure 10)

y Transistor (T) output circuit wiring

[ Figure 11 ]

- 6 -

Loading...

Loading...