Carrier 38GS User Manual

Number One

Airconditioning

Mater

Syracuse New York

Air-Cooled Condensing Units

g DIAM KOS FOR

CONTROL WIRING

SUCTION LINE CONN

SUCTION LINE

VALVE

4'-0" OVERHEAD SPACE REQ'D

FOR SERVICE AND AIR FLOW

3 -0 (BOTH SIDES)

LIQUID LINE VALVE

LIQUID LINE CONN

CONCRETE

MOUNTING

TRANSPORTATION DAMAGE

File claim with shipping company if shipment is

damaged or incomplete.

Unpackaging Unit — Move condensing unit to final

location. Open carton at end marked “compressor

end.” Slide unit from carton taking special care to

not damage service valves or grilles.

PRELIMINARY SURVEY

Consult local building codes and National

Electrical Code (NEC) for special installation

requirements.

When installing unit, allow sufficient space for

air flow clearance, wiring, refrigerant piping and

servicing unit. Position unit so water from roof or

eaves does not flow directly on top of unit.

Install unit on a solid, level mounting pad. Unit

can be attached to pad with a mastic adhesive or

by drilling holes in base pan for 1/4-in. mounting

bolts. Do not block base pan water drainage holes.

38GS,CC,CE Condensing Units Connected to

Carrier Matched Evaporators with Carrier Acces

sory Tubing — Check system refrigerant charge

when tubing lengths are above or below 25 feet.

See Refrigerant Charging (page 10) for details.

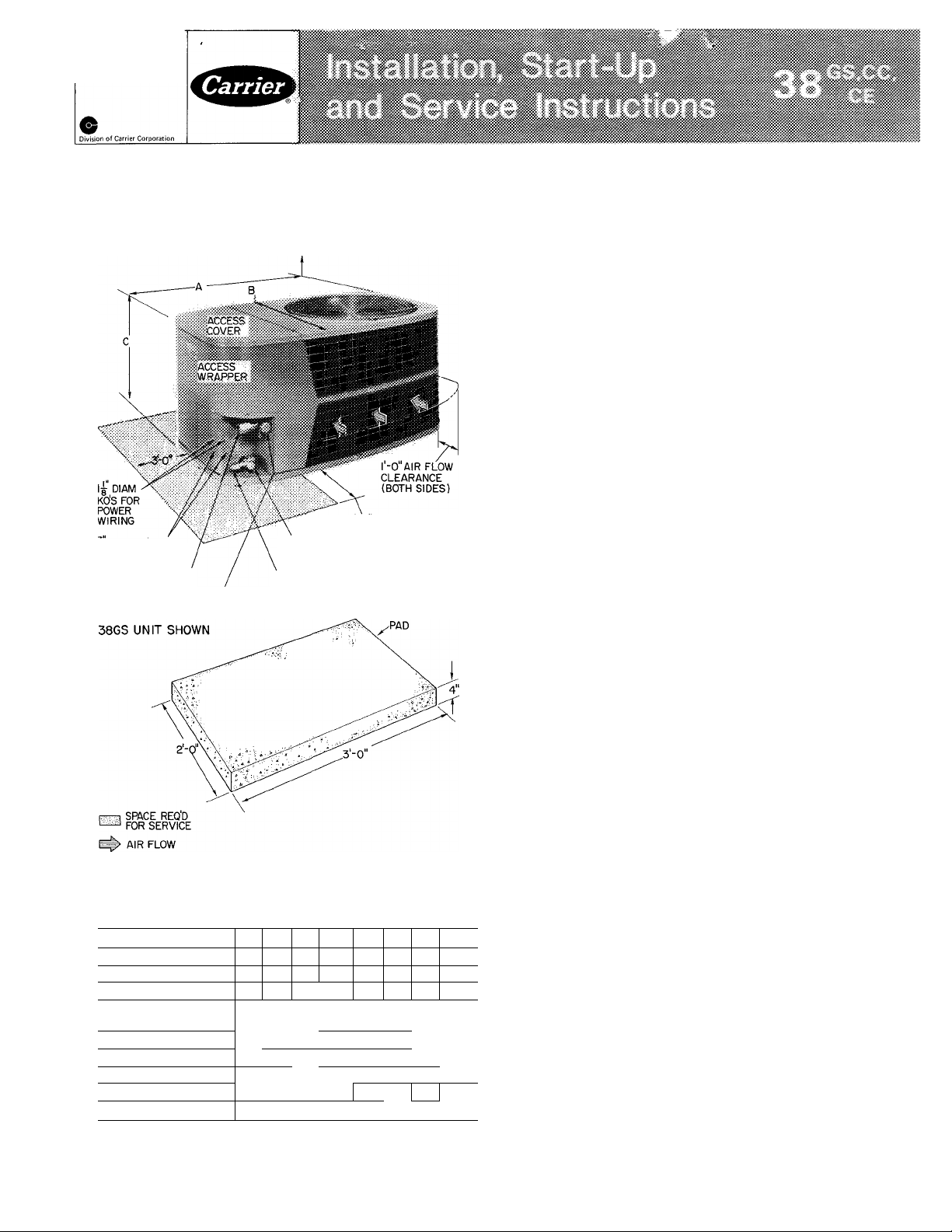

Fig. 1 — Dimensions, Connections and Mounting Pad

38GS,CC,CE Unit

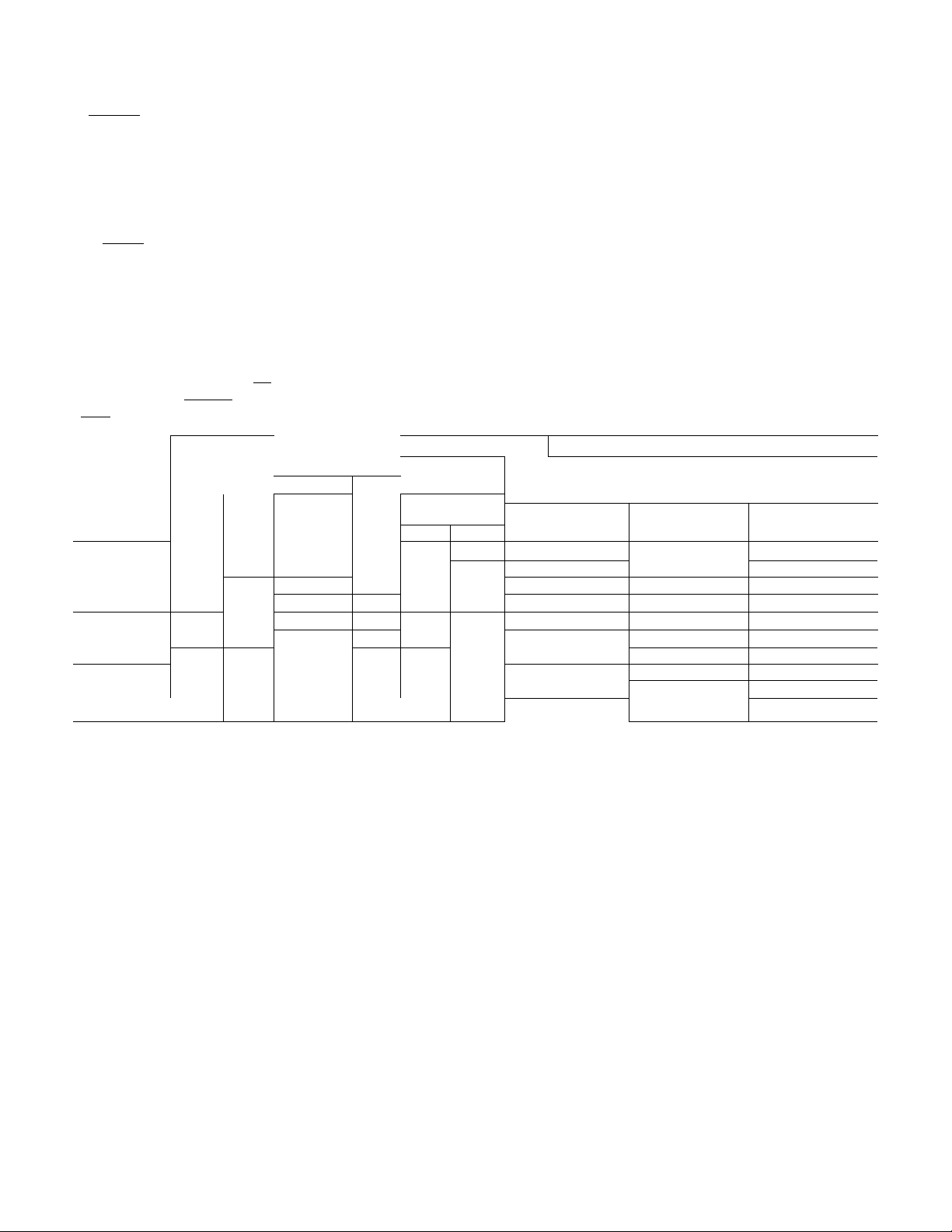

Table 1 — Installation Data

38GS

014

COND UNIT 38CC

OPER WT (lb) 130 135

UNIT DIM. (ft-in.)

Length A

Width B

Height G

REFRIG CONN.(in.)

Suction (ODF)

Liquid (ODF)

*5/8-in suction connection on 38CE002

t38CE045,005 and 38GS.CC060 are factory supplied with 3/4- to

1 1/8-in suction valve adapter (field installed) for 1 1/8-in

suction line

© Carrier Corporation 1975

38CB

- - -

- - -

'l-4

% lYsT '/b I

018

1-4

024

142|149

N4

Com

036 042

030

030 036

002* 003 004 045 005

158 191

2-10V4

1-10

1-4 1 1-4 (2-0

DOtible Fittings

%

'8

048 060t

042 048 060t

193 200

----

2-0 2-0

-----

'/4t

38GS,CC,CE Condensing Units Connected to NonCarrier Evaporators — Check refrigerant charge

when condensing unit is added to a system in

which other than a Carrier approved evaporator is

being used or where the evaporator has been

previously installed. Field-supplied refrigerant pip

ing must be in accordance with Field-Supplied

Piping Data, Table 3.

Where indicated on Table 3 for 38GS,CE units,

install a liquid line filter-drier and accessory crank

case heater on condensing unit. (Filter-drier is

factory supplied on CE045,005 units.) Accessory

start capacitor and relay also required on 38GS

units, but not normally required on 38CE units.

See Compressor Service (page 7). All above items

are standard or not required for 38CC units.

Use an evaporator coil with a bleed-type ex

pansion device. If coil does not have a bleed-type

expansion device it may be necessary to add an

accessory start capacitor and relay to condensing

unit. This would require removing compressor start

thermistor (PTC device) on units so equipped.

Form 38GS-13SI

Table 2 — Accessories

PART

NUMBER

HH01AD040

HH93AZ040

JHH51AR00J[^

HH07AT070,

HH07AT074

H N93^076

HH0iAD042”

HH93AZ042

HH01YA092

HH_93_YZ094

32LT900301

(200-3 Ph)

32LT900601

(460-3 Ph)

38GS900102

38GS900212

38GS900112

38GS900292

38GS900172

38GS900182

38GC900031 10

38GC900071 10

38GC900041

38GC900081

38GS900221

38GC900091

38GC900061 35

38GC900101

38GC900191 50 %

38GC900ni

Low-Voltage Control — Honeywell Deluxe Thermostat

Thermostat Subbase

Comfort Control Center (Use with HH01AD040)

Low-Voltage Control — Honeywell Thermostat

Thermostat Subbase (with Automatic Changeover)

Low-Voltage Control ~ Honeywell Thermostat

Thermostat Subbase

Low-Voltage Control — Grayson Thermostat

Thermostat Subbase

Solid State Head Pressure Control

Indoor Fan Relays (^¡x HN61KJ210)

40VA Low-Voltage Control Transformers

(24 V - Six 38GS900Q9])

Crankcase Heaters (Six 38GS900131)

Crankcase Heaters (Six 38GS900281)

Start Capacitor and Relay Package (Six 38GS900041)

Start Capacitor

Tubing Pa

Liqui d

Lgth

(ft)

18

18

25

25

35

50

(in.)

r 5/^

OD

%

%

%

% :

%

V

D6

V

V

4

Tube End

OD (in.)

DESCRIPTION

and Relay F^ackage (Six 38GS900051

ckages

Suction*

OD

(in.)

^8

^8

y« ,

%

%

%

%

%

T ubeODFnd

in.)

Evap

%

^8

% 1 % %

^8

%

%

V

/4

I V4t

%

%

Cond

^41 I

%

%t

%t %

% ^/4

%t

%

y —

/4 k4

38CC — (Fan motor suitable for 32LT)

38GS

V

014,018,024

4

3/ H

030,036,042,048

/4

V

014,018,024

/8

030,036,042,048

014,018,024

030,036,042,048

014,018,024

=/8

V

030,036,042,048

/4

014,018,024 -

%

030,036,042,048

USAGE

38GS,CC,CE

38GS,CC,CE

38GS,CC,CE

38GS (except 38G5014), 38CE

38GS0Ì4

38GS (except 38GSÒ42), 38CE

38GS042

UNIT

38CC

-

030,036,042,048

-

030,036,042,048

-

030,036,042,048

-

030,036,042,048

030,036,042,048

38CE

002

003,004,045,005

002

003,004,045,005

002

“0Ü3%O470457O0r^

002

003,004,045,005

002

003,004,045,005

*AII suction lines have a 90° bend at one end

tForb/8-in evaporator connection, cut off 3/4-in end

PIPING CONNECTIONS

Condensing units can be connected to evap

orator sections using Carrier accessory tubing

package or field-supplied tubing of refrigerant

grade. (Accessory tubing not available for

38GS060, 38CC060.) See Table 2 for accessory

tubing sizes and Table 3 for recommended fieldsupplied tubing sizes. Where evaporator is 20 ft or

more below condensing unit, reduce liquid line size

one diameter (min 1/4-in. OD).

A capacity reduction will result if accessory

tubing is used in 38CE045,005 systems. For

example, when a 25 ft accessory tubing package is

used, there will be a capacity reduction of 3 3/4%

on 38CE045 and 5% on 38CE005 systems. For

maximum capacity from these systems, use tubing

sizes shown in Table 3.

When other than 25 ft of interconnecting

tubing is used, follow special requirements de

scribed in Refrigerant Charging. Do not use less

than 10 ft of liquid line. Do not cut 5/16-in. or

1/4-in. liquid line. Bend or coil to fit.

Do not use damaged or contaminated tubing. If

accessory tubing package or evaporator section has

been open for more than 15 seconds per connec

tion, evacuate or purge evaporator coil and tubing

system (use field-supplied refrigerant, not unit

refrigerant). Always evacuate or purge if fieldsupplied tubing is used.

Before Connecting Unit Piping, consider the

following:

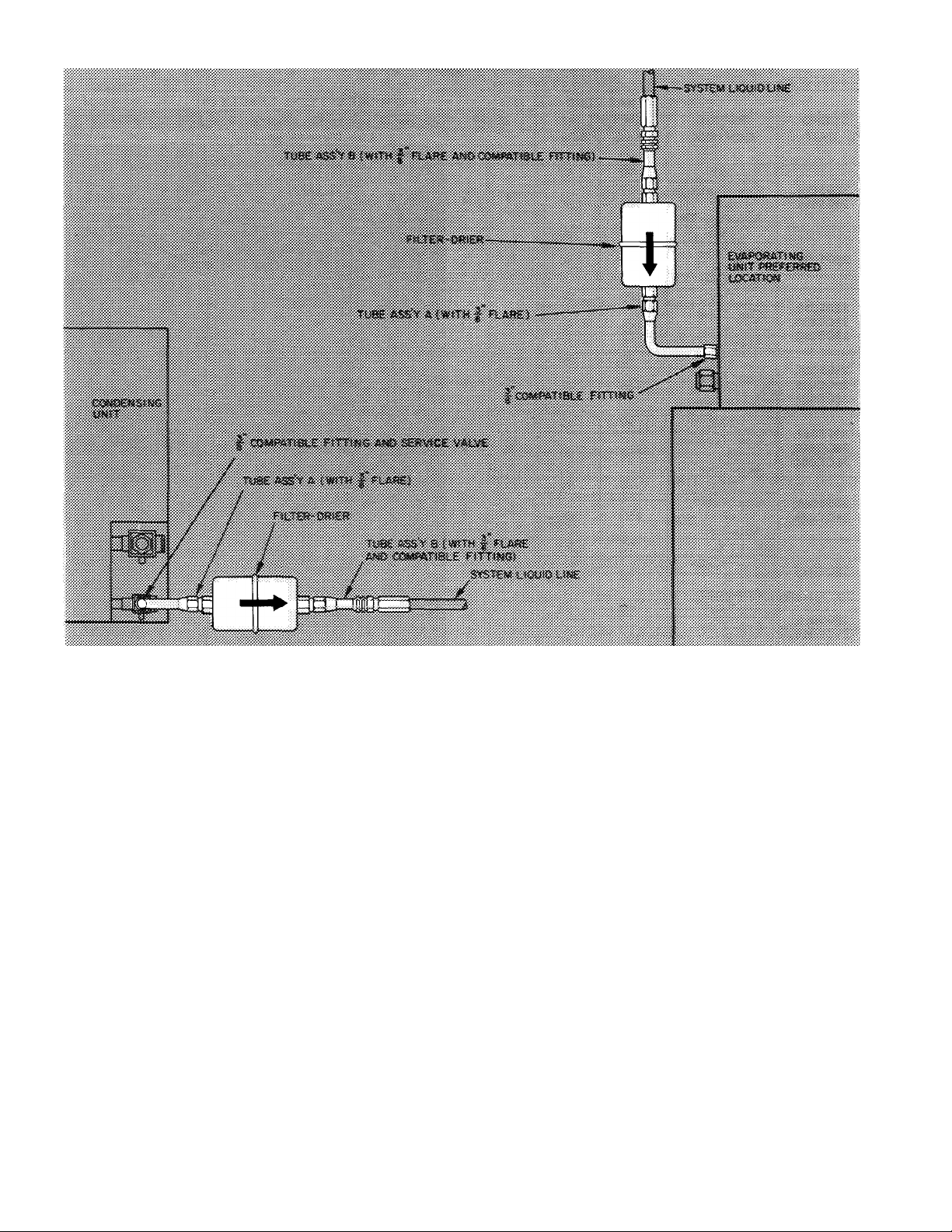

38CE045,005 AND 38CC UNITS - A filter-drier

package is shipped with these units. Included with

filter-drier are 2 short length tubing assemblies that

are equipped with flare and/or Compatible Fit

tings. Use tubing assemblies to install filter-drier

into system liquid line at evaporator or condensing

unit. See Fig. 2. Connect tubing assembly A (90°

assembly) to evaporator or condensing unit liquid

line Compatible Fitting. Complete the filter-drier

installation as shown.

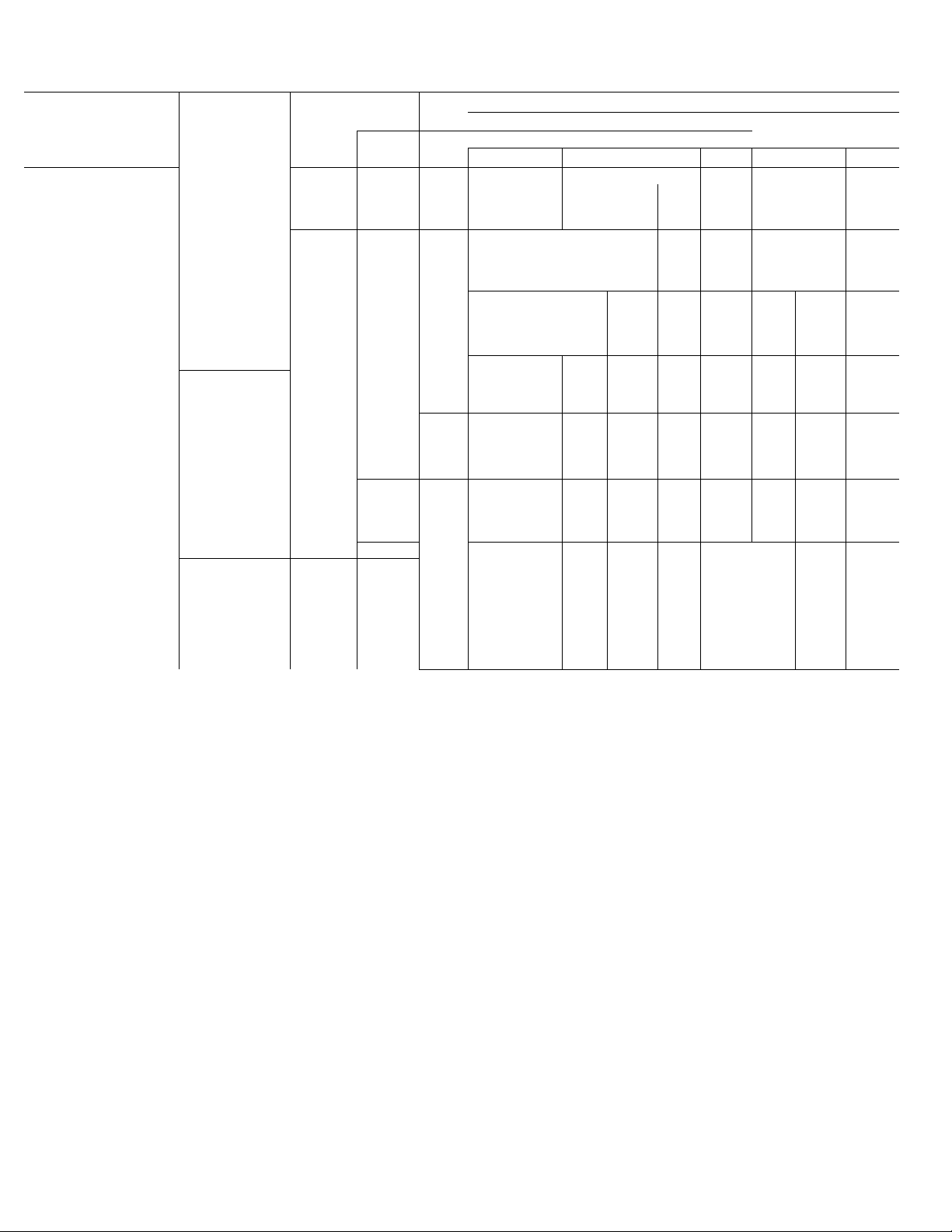

Table 3 — Field-Supplied Piping Data

MAX COND

COND

X-

f 3 UNIT

38GS014,

38GS018

38GS024

38GS030,

38CC030,

38CE002

38GS036,

38CC036,

38CE003

38GS042,

38CC042,

38CE004

38GS048,

38CC048

38CE045

38GS06 0,

38CC060,

38CE005

Cap. Tube

TXV

NOTES

REFRIG

CONTROL

TXV

Cap. Tube

or

AccuRater'*'^

TXV

Cap. Tube

AccuRater

Cap. Tube

or

AccuRater

TXV

Cap. Tube

or

AccuRater

TXV

Cap Tube

or

AccuRater

TXV

Cap Tube

or

AccuRater

TXV

Cap. Tube

or

AccuRater

L^y

Cap. Tube

or

AccuRater

Crankcase heater and liquid line filter-drier required

on 38GS and 38CE units Accessory start capacitor

with relay also required on 38GS unit, but not

normally required on 38CE units See Compressor

Service Reduce liquid line diameter by 1/8-in OD

(min 1/4-in OD) when evaporator is 20 ft or more

below condensing unit

■ Capillary Tube

- Thermal Expansion Valve

1 The following system modifications are required adjust

refrigerant charge on systems with over 25 ft separation

UNIT HT (ft)

Above

Evap

90

150

yo

150

150

90

150

90

150

90 ■

150

90

150

90

150

Be low

Evap

90

50

90

50 %

__

50

90

50

90

50

90

50

90

50

90

50

25- 50 51» 7S 7&~ 1

Suet Liq

V

'8 V» 'x iiiiii lili

%

%

%

%

1%

IV»

Vs

V» T

V»

/4

% liM

% Iliiii

V»

REFRIGERANT LINE LENGTH (ft)

Line Diameter (in* OD)

'

IIBI

ilM

iiiiiiiiiii

wmmmmmmm

N s

T %

k

between condensing unit and evaporator (See Refrigerant

Charging ) Adjust system oil charge as described in Note 2

Oil charge adjustment add 1% of nominal oil charge in

system (Table 7) for each 10 ft of refrigerant line length

above 50 feet Eor example, a system that has a 50-oz oil

charge with 1 50 ft of interconnecting piping requires 5 oz of

additional oil as shown below:

V

iÄiii

MB

ISl

*

150 ft - 50 ft = 100 ft

100 ft -E 10 ft = 10 ft

Litj 1 LEíj

iiiiii

IH

■

ilBi %

■

11»

Äiii

10x1% = 10% ( 10)

10 X 50 oz = 5 oz

Do not permit condensing unit to short cycle, particularly on

applications with long vertical line lengths Correct short

cycling condition immediately

m

¡Mil

Í.

..............

Connection Procedure — When making tubing

connections, be sure to provide clearance at unit

for electrical connections.

Connect refrigerant liquid and suction lines to

condensing unit, Fig. 1. Unit Compatible Fittings

permit 2 methods of refrigerant line connection;

mechanical (quick connect) or sweat connection.

Make suction line connection first.

38CE045,005, 38GS060 AND 38CC060 UNITS Remove suction line adapter taped to compressor

suction line. Connect 3/4-in. end of adapter to unit

suction line Compatible Fitting. Sweat connect

refrigerant suction line to 1 1/8-in. end of adapter.

Connect liquid refrigerant line to unit.

MECHANICAL CONNECTION (Mate one set of

connections at a time.)

1. Loosen nut on Compatible Fitting one turn. Do

not remove.

Remove plug and be sure 0-ring is in the groove

2.

inside the Compatible Fitting.

Cut tubing to correct length.

3.

Use gage on tag attached to service valve to

4.

mark tube end for correct insertion depth.

Insert tube into Compatible Fitting until it

bottoms. (Tube should be inserted at least as

far as mark on tubing.)

Tighten nut until it bottoms on back coupling

5.

flange.

c

Fig. 2 — Filter-Drier Assembly Installation (38CC, 38CE045 and 005)

SWEAT CONNECTION (Use refrigerant grade

tubing.)

1. Remove locking nut, rubber 0-ring and

Schrader core from valve.

2. Cut tubing to correct length.

3. Insert tube into Compatible Fitting. Wrap top

and bottom of service valves in wet cloth to

prevent damage by heat. Solder with low

temperature (450 F) silver alloy solder.

4. Replace Schrader core.

5. Evacuate or purge system with field-supplied

refrigerant.

ELECTRICAL DATA AND WIRING

Field wiring must comply with local and

national fire, safety and electrical codes. Voltage to

unit must be within ± 10% of voltage indicated on

nameplate. Contact local power company for

correction of improper line voltage.

of ifolt ois tmpro|>er Ime

When making electrical connections, provide

clearance at unit for refrigerant piping connections.

See Table 4 for recommended wire and fuse sizes.

Install a Branch Circuit Fused Disconnect of

adequate size to handle unit starting current.

Locate disconnect within sight of and readily

accessible from the unit, per section 440-14 of

National Electrical Code (NEC).

Bring Line Power Leads Into Unit — Extend leads

from fused disconnect thru hole provided in service

embossment (Fig. 1) and thru 7/8-in. hole into

control box.

Connect Ground Lead to a Ground Lug in Control

Box for safety. Connect power wiring. See Fig. 3.

Splice line power leads to red and violet pigtails on

38GS,CE units or to yellow pigtails (3) on 38CC

units. Use wire nuts supplied with unit. Tape each

connection. Wire nuts are suitable for copper or

aluminum wire since they contain joint compound.

Control Power (24 v) wiring is brought thru hole in

service embossment and spliced to yellow pigtails

on all units. See Fig. 4.

Furnace or fan-coil transformer must be used as

24-v supply for system as shown in Fig. 4 (At least

a 40-va transformer is recommended.) Current

38GS048,060 and 38CC048,060 units are equip

ped with a low-voltage transformer used to power

contactor thru unit control circuit. This trans

former must not be used for powering the indoor

thermostat control circuit.

I-PHASE

CONN. TO

FUSED

DISCONNECT

3-PHASE

CONN. TO

FUSED

DISCONNECT

SPLICE

------------

FACTORY WIRING

------------

FIELD WIRING

p

—

--I3D GROUND LUG

386S,CEC0NDUNIT

-YEL-

-YEL-

-YEL-

-------I3D GROUND LUG

38CC CONO UNIT

Fig. 3 — Line Power Connections

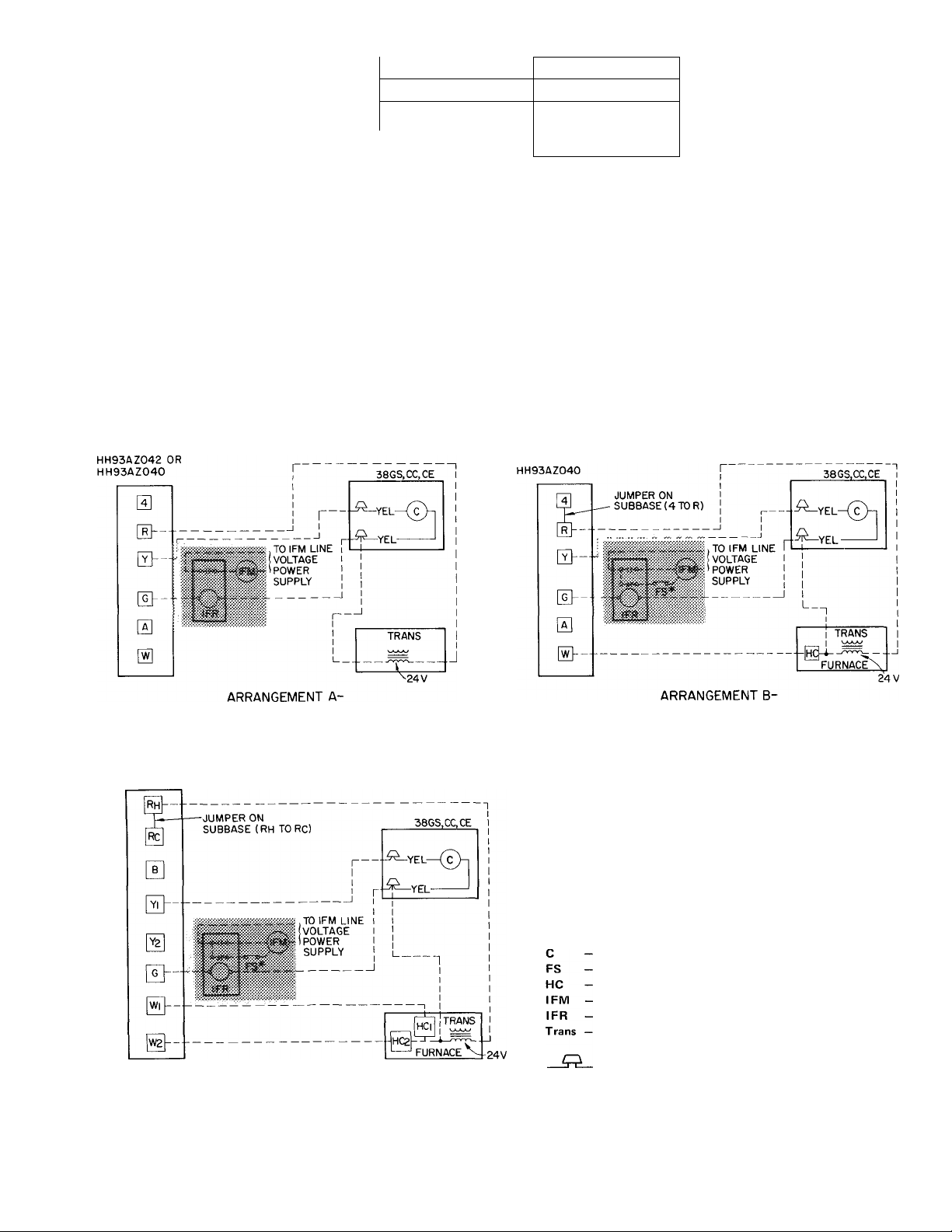

THERMOSTAT SUBBASE

THERMOSTAT SUBBASE

HH93AZ076

(COOLING ONLY)

THERMOSTAT SUBBASE

HH93AZ042 OR

ONE TRANSFORMER

(COOLING AND ONE-STAGE HEATING)

^CONNECT FS TO LOW-SPEED INDOOR FAN TERMINAL

WHEN 2-SPEED FAN IS USED

IFR, FS and IFM are located in furnace on heating-cooling

applications If accessory IFR is required for cooling only

applications, locate (IFR) in fan coiI

ARRANGEMENT C-

ONE TRANSFORMER

(COOLING AND 2-STAGE HEATING)

^CONNECT FS TO LOW-SPEED INDOOR FAN TERMINAL

WHEN 2-SPEED FAN IS USED

Fig. 4 -- Control Circuit Connections

Control Relay (10 va) or Contactor

Fan Switch

Heating Control

I ndoor Fan Motor

I ndoor Fan Relay

Transformer

Field Splice

---------------

Field Wiring

---------------- Factory Wiring

5

Loading...

Loading...