Page 1

Service Manual

R Series

®

April 2016 9650-0903-01 Rev. L

Page 2

0123

ZOLL Medical Corporation

269 Mill Road

Chelmsford, MA USA

01824-4105

ZOLL International Holding B.V.

Newtonweg 18

6662 PV ELST

The Netherlands

© 2016 ZOLL Medical Corporation. All rights reserved. R Series, CodeNet, SurePower, OneStep and ZOLL are trademarks or registered trademarks of

ZOLL Medical Corporation in the United States and/or other countries. Masimo is a registered trademark of Masimo Corporation in the United States

and/or other countries. All other trademarks are the property of their respective owners.

Warranty (U.S. Only)

(a) ZOLL Medical Corporation warrants to the original equipment purchaser that beginning on the date of installation, or thirty (30) days after the date of shipment from ZOLL Medical Corporation's facility,

whichever first occurs, the equipment (other than accessories and electrodes) will be free from defects in material and workmanship under normal use and service for the period of one (1) year. During such

period ZOLL Medical Corporation will, at no charge to the customer, either repair or replace (at ZOLL Medical Corporation's sole option) any part of the equipment found by ZOLL Medical Corporation to

be defective in material or workmanship. If ZOLL Medical Corporation's inspection detects no defects in material or workmanship, ZOLL Medical Corporation's regular service charges shall apply. (b)

ZOLL Medical Corporation sh all not be responsible for any equipment defect, the failure of the equipment to perform any functio n, or any other nonconformance of the equipment, caused by or attributable

to: (i) any modification of the equipment by the customer, unless such modification is made with the prior written approval of ZOLL Medical Corporation; (ii) the use of the equipment with any associated

or complementary equipment, (iii) installation or wiring of the equipment other than in accordance with ZOLL Medical Corporation's instructions. (c) This warranty does not cover items subject to normal

wear and burnout during use, including but not limited to lamps, fuses, batteries, patient cables and accessories. (d) The foregoing warranty constitutes the exclusive remedy of the customer and the exclusive

liability of ZOLL Medical Corporation for any breach of any warranty related to the equipment supplied hereunder. (e) Limitation of Liability: ZOLL shall not in any event be liable to Purchaser, nor shall

Purchaser recover, for special, incidental or consequential damages resulting from any breach of warranty, failure of essential purpose, or under any other legal theory including but not limited to lost pr ofits,

lost savings, downtime, goodwill, damage to or replacement of equipment and property, even if ZOLL has been advised of the possibility of such damages.

THE WARRANTY SET FORTH HEREIN IS EXCLUSIVE AND ZOLL MEDICAL CORPORATION EXPRESSLY DISCLAIMS ALL OTHER WARRANTIES WHETHER WRITTEN, ORAL,

IMPLIED, OR STATUT ORY, INCLUDING BUT NOT LIMITED TO ANY WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

For additional information, please call ZOLL Medical Corporation at 1-800-348-9011 (in Massachusetts 1-978-421-9655). International customers should call the nearest authorized ZOLL Medical

Corporation service center.

Software License

Read this License agreement carefully before operating any of the R Series® products.

Software incorporated into the system is protected by copyright laws and international copyright treaties as well as other intellectual property laws and treaties. This software is licensed, not sold. By taking

delivery of and using this system, the Purchaser signifies agreement to and acceptance of the following terms and conditions:

Grant of License: In consideration of payment of the software license fee which is part of the price paid for this product ZOLL Medical Corporation grants the Purchaser a non-exclusive license, without right

to sublicense, to use the system software in object-code form only.

Ownership of Software/Firmware: Title to, ownership of and all rights and interests in the system software and all copies thereof remain at all times vested in the manufacturer, and Licensors to ZOLL

Medical Corporation and they do not pass to Purchaser.

Assignment: Purchaser agrees not to assign, sub-license or otherwise transfer or share its rights under the license without the express written permission of ZOLL Medical Corporation.

Use Restrictions: As the Purchaser, you may physically transfer the products from one location to another provided that the software/firmware is not copied. You may not disclose, publish, translate, release

or distribute copies of the software/firmware to others. You may not modify, adapt, translate, reverse engineer, decompile, crosscompile, disassemble or create derivative works based on the software/

firmware.

No Implied License

Possession or purchase of this device does not convey any express or implied license to use the device with replacement parts which would, alone, or in combination with this device, fall within the scope of

one or more of the patents relating to this device.

Page 3

TABLE OF CONTENTS

Preface

Safety Considerations...................................................................................................................................................i

Additional Reference Material ............................... ... ... ... .... ... ... ... .... ... ... ... ... .... ... ... ... .... ... ... .........................................ii

Conventions..................................................................................................................................................................ii

Service Policy Warranty..............................................................................................................................................iii

Technical Service.........................................................................................................................................................iii

Technical Service Outside of the United States........................................................................................................iv

Ch a p t er 1 Maintenance Tests

Overview.................................................................................................................................................................... 1-1

Before You Begin the Maintenance Tests............................................................................................................... 1-2

Equipment You Need to Perform the Maintenance Tests...................................................................................... 1-2

Physical Inspection of the Unit ............................................................................................................................. 1-4

Front Panel Button Test ....................................................................................................................................... 1-6

3 and 5 Leads Test .............................................................................................................................................. 1-8

Power Supply Test (Optional) .............................................................................................................................. 1-9

Leakage Current Test ........................................................................................................................................ 1-14

Paddles Test ...................................................................................................................................................... 1-15

Heart Rate Display Test ..................................................................................................................................... 1-16

Calibrating Pulses on Strip Chart Test ............................................................................................................... 1-17

Notch Filter Test ................................................................................................................................................ 1-18

Heart Rate Alarm Test ....................................................................................................................................... 1-19

Defibrillator Self Test ......................................................................................................................................... 1-21

Synchronized Cardioversion Test ......................... ....................................... ...................................................... 1-23

Synchronized Cardioversion for Remote ECG Monitoring Test (Optional)........................................................ 1- 24

Shock Test ......................................................................................................................................................... 1-25

Summary Report Test ........................................................................................................................................ 1-27

Advisory Message Test (Manual/Advisory Units) .... ... .... ... ....................................... ... ... ... .... ... ......................... 1-28

Pacer Test ......................................................................................................................................................... 1-29

SpO2 Monitor Test (for SpO2 Option) ............................................................................................................... 1-31

EtCO2 Monitor Test (for EtCO2 Option) ............................................................................................................ 1-33

Barometric Pressure Calibration Check .............................................................................................................. 1-34

CO2 Accuracy Check (for EtCO2 Option) .......................................................................................................... 1-35

9650-0903-01 Rev. L iii

Page 4

NIBP Volume Leak Test ..................................................................................................................................... 1-37

NIBP Transducer Calibration Test ...................................................................................................................... 1-39

NIBP Monitor Test .............................................................................................................................................. 1-41

Ch a p t e r 2 Troubleshooting

Overview.................................................................................................................................................................... 2-1

ZOLL R Series Error Messages............................................................................................................................... 2-1

Ch a p te r 3 Disassembly Procedures

Required Equipment................................................................................................................................................. 3-1

Safety Precautions.................................................................................................................................................... 3-2

Removing the Cable Caddy ............................ ......................................................................................................... 3-3

Removing the Handle............................................................................................................................................... 3-6

Removing the Recorder, 3-

AC Charger and Battery Well....... ... ... .... ...................................... .... ... ... ... ... .... ... ... ... .... ... ... ... .................................. 3-7

Removing the Front Panel Assembly ................................................................................................................... 3-12

Front Panel Disassembly................... .... ... ... ... .... ... ... ... ... ....................................... ... .... ... ... ... ................................ 3-14

Removing the Side Panels........... ... ... .... ... ... .......................................................................................................... 3-16

Removing the Connector Panel and Bezel..................................................................... ... ... .... ... ... ... ................... 3-18

Removing the ECG Input Connector..................................................................................................................... 3-20

Removing the NIBP Assembly............................................................................................................................... 3-21

Removing the System Brick Assembly ................................................................................................................ 3-23

Disassembly of the System Brick Assembly ....................................................................................................... 3-28

Discharging Capacitor............................................................................................................................................ 3-34

Removing the Communication Module ............................................................................................................... 3-35

iv 9650-0903-01 Rev. L

Page 5

TABLE OF CONTENTS

Ch a p te r 4 Replacement Parts

List of Replacement Parts........................................................................................................................................ 4-2

Diagrams...................................................................................................................................................................4-11

Disassembling the System Brick Assembly ........................................................................................................ 4-41

Ch a p t e r 5 Functional Description

AC Charger.......... ... .... ... ... ... ... .... ... ....................................... ... ... ... .... ... ... .................................................................. 5-1

SurePower Battery.................................................................................................................................................... 5-1

Parameter Power Supply (SpO2, EtCO2, NIBP)..................................................................................................... 5-2

Digital System Board................................................................................................................................................ 5-2

Analog System Board................................ ... ... .... ... ... ... ... .... ... ... ... .... ... ... ... ... .... ........................................................ 5-3

Pace/Defib Core Engine ........................................................................................................................................... 5-4

Front Panel Controls .......................... .... ... ....................................... ... ... ... ... .... ........................................................ 5-4

Peripherals ................................................................................................................................................................ 5-4

Accessories............................................................................................................................................................... 5-5

Power Management Support Functions................................................................................................................. 5-5

WiFi ............................................................................................................................................................................ 5-6

Appendix

Interconnect Diagram for the R Series Biphasic Unit ................................................................ ...........................A-2

Delivered Energy at Every Defibrillator

Setting into a Range of Loads.................................................................................................................................A-3

Sync Connector Diagrams.......................................................................................................................................A-4

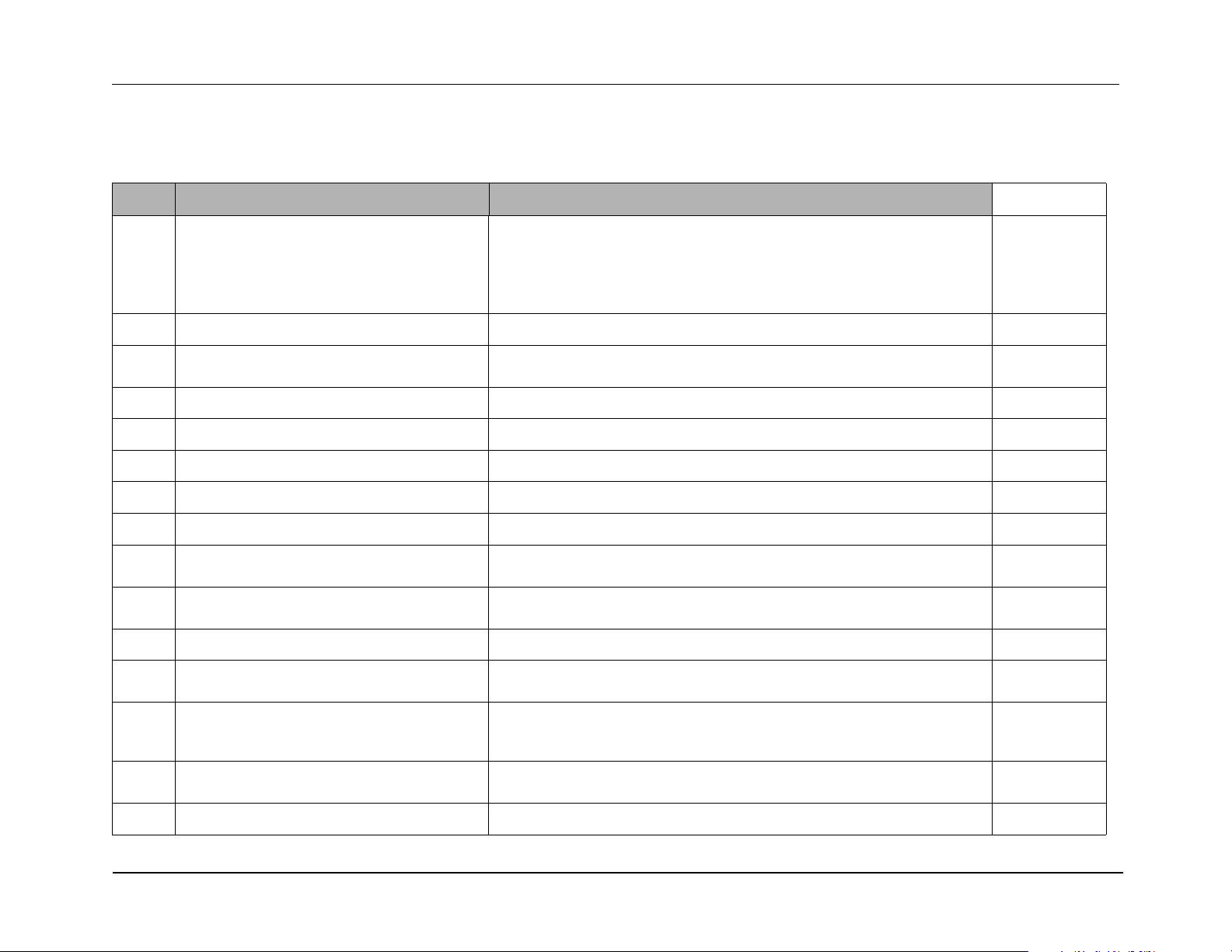

Maintenance Test Checklist.....................................................................................................................................A-5

9650-0903-01 Rev. L v

Page 6

vi 9650-0903-01 Rev. L

Page 7

R Series Service Manual

Preface

ZOLL® Medical Corporation’ s R Seri es® Service Manual is intended for the service tech nician whose responsibilit y is to maintain and inspect the R Series

defibrillators. The ZOLL R Series Service Manual has five main sections and one appendix.

Preface—Contains safety warnings and an overview of the manual’s contents. Be sure to review this section thoroughly before attempting to use or service

the R Series unit.

Chapter 1—Maintenance Tests explains how to check the defibrillator’s performance using a series of recommended checkout procedures to be

conducted every 12 months.

Chapter 2—Troubleshooting provides a listing of the procedures and error messages to help the service technician detect faults and repair them.

Chapter 3—Disassembly Procedures describes step-by-step procedures for removing assemblies and subassemblies from the R Series unit

Chapter 4—Replacement Parts List displays a complete list of ZOLL part numbers for field replaceable parts available for the R Series unit, allowing

the service person to identify and order replacement parts from ZOLL.

Chapter 5—Functional Description provides technical descriptions for the R Series major subassembly modules.

Appendix—R Series interconnect diagram; table for delivered energy loads; maintenance checklists.

Safety Considerations

The following section describes general warnings and safety considerations for operators and patients. Service technicians should review the safety

considerations prior to servicing any equipment and read the manual carefully before attempting to disassemble the unit. Only qualified personnel should

service the R Series unit.

Federal (U.S.A.) law restricts this unit for use by or on the order of a physician.

Safety and effectiveness data submitted by ZOLL Medical Corporation to the Food and Drug Administration (FDA) under section 510(K) of the Medical

Device Act to obtain approval to market is based upon the use of ZOLL accessories such as disposable electrodes, patient cables and batteries. The use of

external pacing/defibrillation electrodes and adapter units from sources other than ZOLL is not recommended. ZOLL makes no representations or

warranties regarding the performa nce or ef fectivenes s of its product s when used in conjunction with pacing/d efibrillation elect rodes and adapter units fro m

other sources. If unit failure is attributable to pacing/defibrillation electrodes or adapter units not manufactured by ZOLL, this may void ZOLL's warranty.

Only qualified personnel should disassemble the R Series unit.

9650-0903-01 Rev. L i

Page 8

R Series Service Manual

WARNING! This unit can generate up to 2,850 volts with sufficient current to cause lethal shocks.

All persons near the equipment must be warned to STAND CLEAR prior to discharging the defibrillator.

Do not discharge the unit’s internal energy more than three times in one minute or damage to the unit may result.

Do not discharge a battery pack except in a ZOLL SurePower

TM

Battery Charger Station.

Do not use the R Series in the presence of flammable agents (such as gasoline), oxygen-rich atmospheres, or flammable anesthetics. Using the unit near

the site of a gasoline spill may cause an explosion.

Do not use the unit near or within puddles of water.

Additional Reference Material

In addition to this guide, there are several other components to the ZOLL R Series documentation. They include:

• ZOLL R Series Operator’s Guide - describes all the user tasks needed to operate the R S eries.

• ZOLL R Series Configuratio n Guide - describes the R Series features and functions whose operation can be customized by authorized users.

• ZOLL R Series Operator’s Guide - Pulse Oximetry (SpO

• ZOLL R Series Operator’s Guide - Non-Invasive Blood Pressure (NIBP) Insert - describes all the user tasks needed to operate the R Series NIBP

option.

• ZOLL R Series Operator’s Guide - End Tidal Carbon Dioxide (EtCO

option.

) Insert - describes all the user tasks needed to operate the R Series Pulse Oximetry option.

2

) Insert - describes all the user tasks needed to operate the R Series EtCO2

2

Conventions

WARNING! Warning statements describe conditions or actions that can result in personal injury or death.

Caution Caution statements describe conditions or actions that can result in damage to the unit.

Note: Notes contain additional information on using the defibrillator.

ii 9650-0903-01 Rev. L

Page 9

R Series Service Manual

Service Policy Warranty

In North America: Consult your purchasing agreement for terms and conditions associated with your warran ty. Outside of North America, consult ZOLL

authorized representative.

In order to maintain this warranty, the instructions and procedures contained in this manual must be strictly followed. For additional information, please

call the ZOLL Technical Service Department 1-800-348-9011 in North America.

Technical Service

If the ZOLL R Series unit requires service, contact the ZOLL Technical Service Department:

Telephone: 1-978-421-9655; 1-800-348-9011

Fax 1-978-421-0010

Email: techsupport@zoll.com

Have the following information available for the Technical Service representative:

• Unit serial number

• Description of the problem

• Department where equipment is used

• Purchase Order to allow tracking of loan equipment

• Purchase Order for a unit with an expired warranty

• Sample chart recorder strips documenting the problem, if applicable

• Full disclosure file from the unit, if applicable (.FUL extension)

• Ready code file from the unit, if applicable (.DCK extension)

• Activity log file from the unit, if applicable (.RAL extension)

If the unit needs to be sent to ZOLL Medical Corporation, obtain a Service Request number from the Technical Service representative. Return the unit in

its original container to:

ZOLL Medical Corporation

269 Mill Road

Chelmsford, Massachusetts 01824-4105

9650-0903-01 Rev. L iii

Page 10

R Series Service Manual

Attn: Technical Service Department, SR# XXXXXX

Telephone: 1-800-348-9011; 1-978-421-9655 FAX: 978-421-0010

Technical Service Outside of the United States

Customers outside of the United States sh ould return the u nit in its original co ntainer to the nearest authorized ZOLL Medical Corporation Se rvice Center.

To locate an authorized service center, contact the International Sales Department at ZOLL Medical at the above address.

iv 9650-0903-01 Rev. L

Page 11

R Series Service Manual

Chapter 1

Maintenance Tests

Overview

The R Series has two checkout procedures: the R Series Operator’s Guide defibrillator testing checklist and the extensive 12-month maintenance test

checkout procedures.

Because the R Series units must be maintained ready for immediate use, regular readiness testing is required. It can either be performed manually or

automatically. Refer to the R Series Operator’s Guide for details.

A qualified biomedical technician must perform a more thorough maintenance test checkout every 12 months to ensure that the functions of the R Series

unit work properly. This chapter describes the step by step procedures for performing the 12 month maintenance test checkout. Use the checklist at the

back of this document (ZOLL R Series Maintenance Test Checklist) to record your results of the maintenance tests.

This chapter describes the following maintenance tests:

• 1.0 Physical Inspection of the Unit

• 2.0 Front Panel Button Test

• 3.0 3 and 5 Leads Test

• 4.0 Power Supply Test (Optional)

• 5.0 Leakage Current Test

• 6.0 Paddles Test

• 7.0 Heart Rate Display Test

• 8.0 Calibrating Pulses on Strip Chart Test

• 9.0 Notch Filter Test

• 10.0 Heart Rate Alarm Test

• 11.0 Defibrillator Self Test

• 12.0 Synchronized Cardioversion Test

• 13.0 Synchronized Cardioversion for Remote ECG Monitoring Test (Optional)

• 14.0 Shock Test

• 15.0 Summary Report Test

9650-0903-01 Rev. L 1-1

Page 12

R Series Service Manual

• 16.0 Advisory Message Test (Manual/Advisory Units)

• 17.0 Pacer Test

• 18.0 SpO2 Monitor Test (for SpO2 Option)

• 19.0 EtCO2 Monitor Test (for EtCO2 Option)

• 20.0 Barometric Pressure Calibration Check

• 21.0 CO2 Accuracy Check (for EtCO2 Option)

• 22.0 NIBP Volume Leak Test

• 23.0 NIBP Transducer Calibration Test

• 24.0 NIBP Monitor Test

Before You Begin the Maintenance Tests

• Assemble the tools or specialized testing equipment listed in the “Equipment You Need to Perform the Maintenance Tests” section shown below.

• Keep an extra fully charged ZOLL SurePower defibrillator battery available.

• Schedule an hour to conduct the entire maintenance test.

• Photocopy the checklist at the back of this document and use the copy to record your results. As you conduct each step of a procedure, mark the Pass/

Fail/NA check boxes on your checklist and then save it for your maintenance file.

• Perform the tests in the order presented.

• Perform all the steps of each test procedure.

• Complete all the steps of the procedure before evaluating the test results.

Equipment You Need to Perform the Maintenance Tests

This section lists equipment that we use to perform the maintenance tests that we describe in this chapter. You can substitute an equivalent device for a

listed device; however, not all simulators and analyzers will produce the same results. Be sure to follow the manufacturer’s recommendations for

conducting the maintenance tests.

We recommend the use of the following equipment when performing R Series Maintenance Tests

• ZOLL Medical Electrode Adapter from Fluke Biomedical (DNI part number 3010-0378).

• Fluke Impulse 4000 Defibrillator Analyzer with 1.06 software or higher.

• Fluke Biomedical International Safety Analyzer.

• 2 red miniature alligator to miniature alligator leads.

1-2 9650-0903-01 Rev. L

Page 13

• 2 black miniature alligator to miniature alligator test leads.

• DC power supply (15 Amp minimum).

• 0.1resistor (¼W or greater).

• 1000 1% ¼W resistor.

• Fluke 75 multimeter or equivalent.

• Fluke Biomedical

• SpO

• Fluke BP Pump 2 NIBP simulator (if NIBP option is installed).

• CAPNOSTAT 5 Mainstream cable with airway adapter (if EtCO

• Stop watch.

• Paddles.

• Printer paper.

• Battery.

• AC line cord.

• 3 lead adapter (part # 8009-0762-XX) or 3 lead ECG cable, and 5 lead ECG cable.

• Gas Regulator (if EtCO2 option is installed).

• Calibration Gas (if EtCO2 option is installed).

cable and sensor (if option is installed).

2

Index 2PFE SpO2 Simulator or equivalent (if option is installed).

option is installed).

2

R Series Service Manual

9650-0903-01 Rev. L 1-3

Page 14

R Series Service Manual

1.0 Physical Inspection of the Unit

Tools Needed: None.

Test Setup: None.

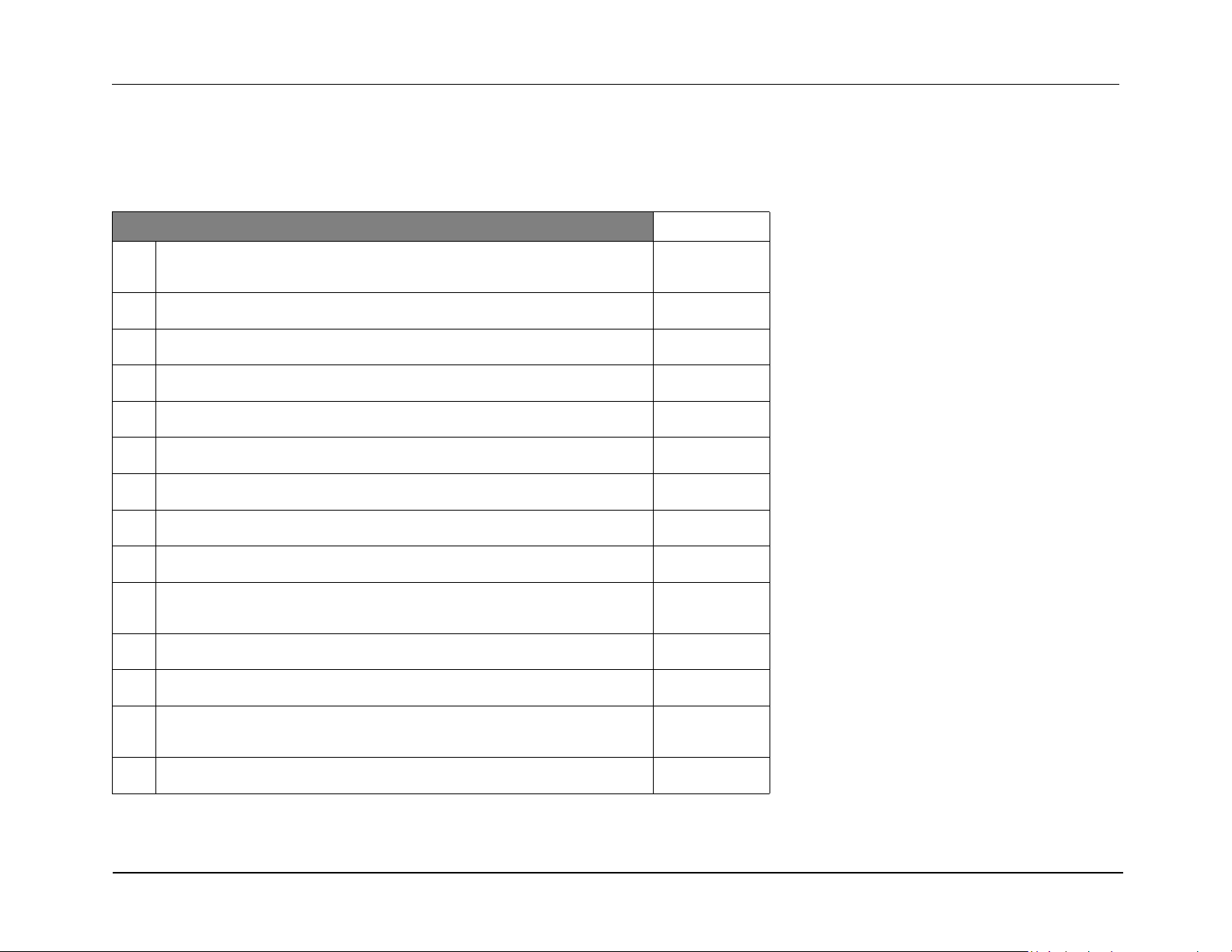

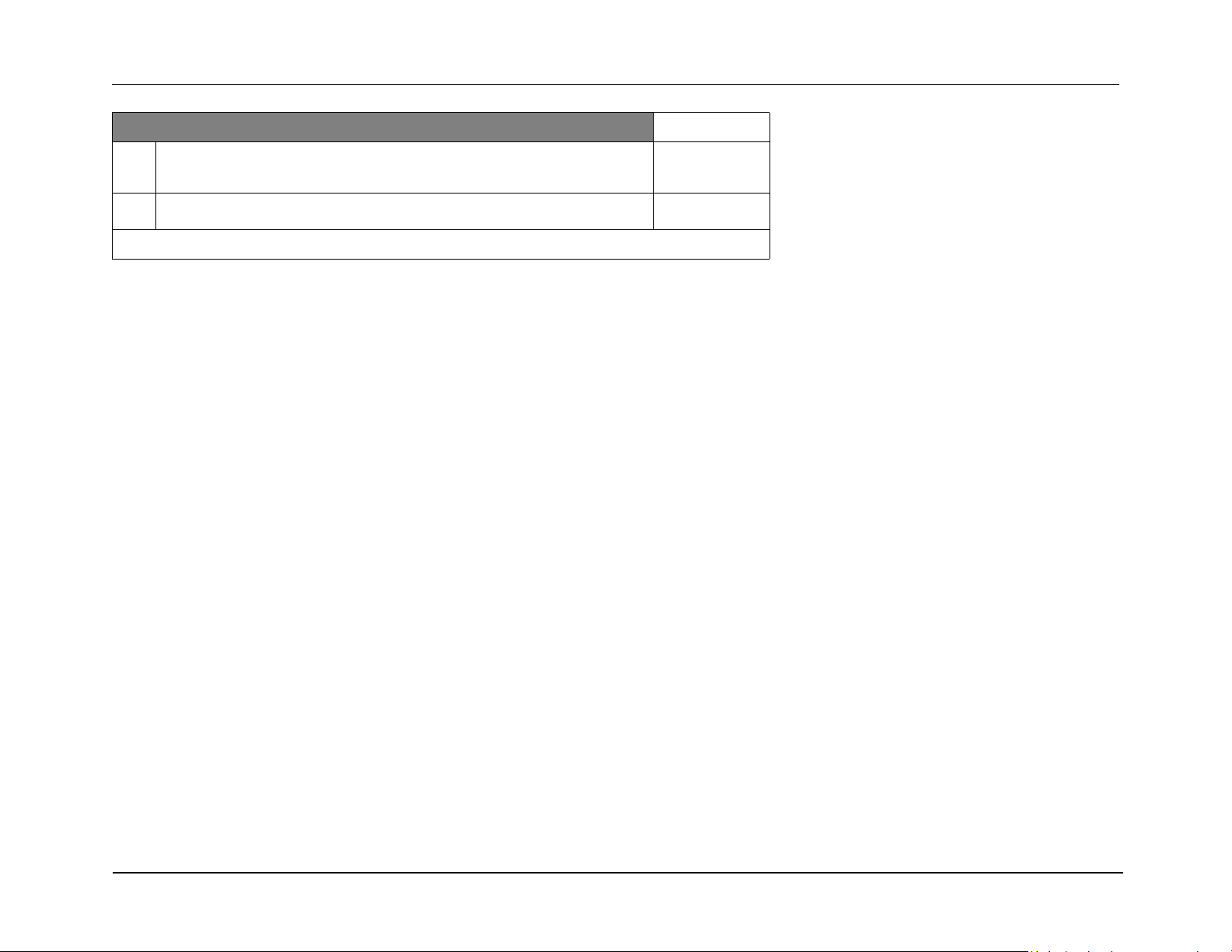

Observe this... Pass/Fail/NA

1.1 Housing

Is the unit clean and undamaged?

1.2 Does the unit show signs of excessive wear?

1.3 Is the handle undamaged?

1.4 Does the recorder door open and close properly?

1.5 Are input connectors clean and undamaged?

1.6 Are there any cracks in the housing?

1.7 Do the front panel or keypad buttons have any damage or cracks?

1.8 Are there any loose housing parts?

1.9 Do the paddle latches work properly?

1.10 Paddles

Do the adult and pedi plates have major scratches or show signs of damage?

1.11 Do the adult shoes slide on and off easily to expose the covered pedi plates?

1.12 Are the paddles clean (e.g., free of gel) and undamaged? (if applicable)

ooo

ooo

ooo

ooo

ooo

ooo

ooo

ooo

ooo

ooo

ooo

ooo

1.13 Cables

Are all cables free of cracks, cuts, exposed or broken wires?

1.14 Are all bend/strain reliefs undamaged and free of excessive cable wear?

1-4 9650-0903-01 Rev. L

ooo

ooo

Page 15

Observe this... Pass/Fail/NA

1.15 Battery

Place battery in battery well.

R Series Service Manual

1.16 Is the battery seated in the battery well correctly?

Record your results on the Maintenance Test Checklist.

ooo

9650-0903-01 Rev. L 1-5

Page 16

R Series Service Manual

2.0 Front Panel Button Test

Tools Needed: Fluke Impluse 4000.

Test Setup:

1. Install strip chart paper into the printer compartment.

2. Install a fully charged battery in the unit or connect the A/C power cord to the unit and then plug the cord into an electrical outlet.

3. Connect the OneStep

(or equivalent).

Do this... Observe this... Pass/Fail/NA

TM

cable and ECG cable (3 lead adapte r (part #8009-0762-XX), 3 lead cable, or 5 lead cable) to the Fluke Biomedical 4000 Analyzer

2.1 Turn the selector switch to MONITOR. (for AED

units, turn the selector switch to ON and select

Manual mode.)

2.2 Press the LEAD button; three times for the 3

lead cable and seven times for the 5 lead cable.

2.3 Set the Impulse 4000 to NSR of 120 BPM.

Press the LEAD button until Lead II displays. To

check the size of the ECG waveform, press the

SIZE button.

2.4 Press the ALARM SUSPEND button. Bell changes from disabled to enabled. If the alarm sounds, press the ALARM

2.5 Press the RECORDER button. The strip chart paper moves out of the unit from the printer compartment.

2.6 Open the printer door.

Press RECORDER button.

Listen for 4 beep tones. PADS and MONITOR display on the monitor.

NOTE: PADS is a factory default setting.

Each time you press the LEAD button, a different lead number appears under

the LEAD heading on the display.

PADS, I, II, III will display if a 3 lead ECG cable is connected or no ECG cable

is connected.

PADS, I, II, III, AVR, AVL, AVF, V1 will display if a 5 lead ECG cable is

connected.

As you press the SIZE button five times (0.5, 1.0, 1.5, 2.0, 3.0), note that the

size of the ECG waveform appropriately changes on the display.

SUSPEND button to turn it off. The alarm will only be suspended for 90

seconds at this point. Press and hold the ALARM SUSPEND button for 3

seconds to disable alarms.

Check that the correct time, date, ECG lead annotation and waveform are

recorded on the paper. (Set Time and Date, if necessary.)

CHECK RECORDER message appears on the monitor.

ooo

ooo

ooo

ooo

ooo

ooo

1-6 9650-0903-01 Rev. L

Page 17

R Series Service Manual

Do this... Observe this... Pass/Fail/NA

2.7 Close the printer door.

Press RECORDER button.

2.8 Press RECORDER button. Strip chart paper stops flowing out of printer compartment.

2.9 Connect A/C current and install a fully charged

battery. Turn the unit off.

2.10 Remove the battery. Observe that the battery LED alternates between green and amber.

2.1 1 Replace the battery and turn the selector switch

to MONITOR (for AED units, turn to ON.)

2.12 Press the ANALYZE button (if available). The SELECT DEFIB MODE message appears on the monitor. (For manual

2.13 Move the selector switch to DEFIB (for AED

units leave in the ON position.) Select 2J. Press

the CHARGE button.

2.14 Press and hold the ENERGY SELECT down

arrow.

2.15 Press and release the ENERGY SELECT up

arrow 18 times.

Strip chart paper flows out of printer compartment. Verify that the CHECK

RECORDER message no longer displays.

The AC Power LED should be illuminated.

The battery LED will be green or amber.

NOTE: If the battery LED alternates between green and amber, no battery is

installed or there is a battery charging fault.

Note that the battery indicator is green or amber.

devices.)

The display shows that the unit is charging. The SHOCK button lights when the

unit is charged. Ready tone for DEFIB sounds.

Unit discharges internally and selected energy decrements to 1J.

Verify the following settings: 2, 3, 4, 5, 6, 7, 8, 9, 10, 15, 20, 30, 50, 75, 100,

120, 150, 200J.

ooo

ooo

ooo

ooo

ooo

ooo

ooo

ooo

ooo

2.16 Press the CHARGE button. Note the display shows the unit charged up to 200J and the SHOCK button

lights.

2.17 Press the SHOCK button. The unit discharges and the SHOCK button is no longer lit. A 15 second strip

chart automatically prints, displaying the number of joules delivered (if

configured to print post shock).

2.18 (AED UNITS ONLY) Turn selector switch to the

OFF position.Wait a minimum of 10 seconds

and turn selector switch back to the ON

position.

9650-0903-01 Rev. L 1-7

Verify on the front panel that the green AED LED is illuminated.

ooo

ooo

ooo

Page 18

R Series Service Manual

Do this... Observe this... Pass/Fail/NA

2.19 Press the MANUAL MODE softkey, then select

the CONFIRM softkey.

2.20 Turn selector switch to the OFF position. Verify the unit turns off.

Record your results on the Maintenance Test Checklist.

Verify the green AED LED turns off.

ooo

ooo

1-8 9650-0903-01 Rev. L

Page 19

R Series Service Manual

3.0 3 and 5 Leads Test

Tools Needed: Impulse 4000,3 lead adapter (part # 8009-0762-XX) or 3 lead cable, and 5 lead cable. If applicable, test each cable separately.

Test Setup:

1. The R Series unit must be configured to display ECG LEAD OFF message.

2. Connect the lead wires appropriate to each test to the Fluke Biomedical 4000 or equivalent.

Do this... Observe this... Pass/Fail/NA

3.1 Turn the selector switch to MONITOR (for AED

units turn to ON.) Select leads.

3.2 Disconnect one lead from the Impulse 4000. The ECG LEAD OFF message displays within 3 seconds (if configured).

3.3 Reconnect the lead. Repeat step 3.2 with the

remaining leads.

3.4 If applicable, repeat 3.2 and 3.3 for the

remaining cable(s).

Record your results on the Maintenance Test Checklist.

ECG LEAD OFF message is not displayed.

Wait for ECG LEAD OFF message to clear from the display (if configured).

NOTE: If heart rate alarm sounds, press and hold the ALARM SUSPEND

button for 3 seconds to disable the alarms.

ooo

ooo

ooo

ooo

9650-0903-01 Rev. L 1-9

Page 20

R Series Service Manual

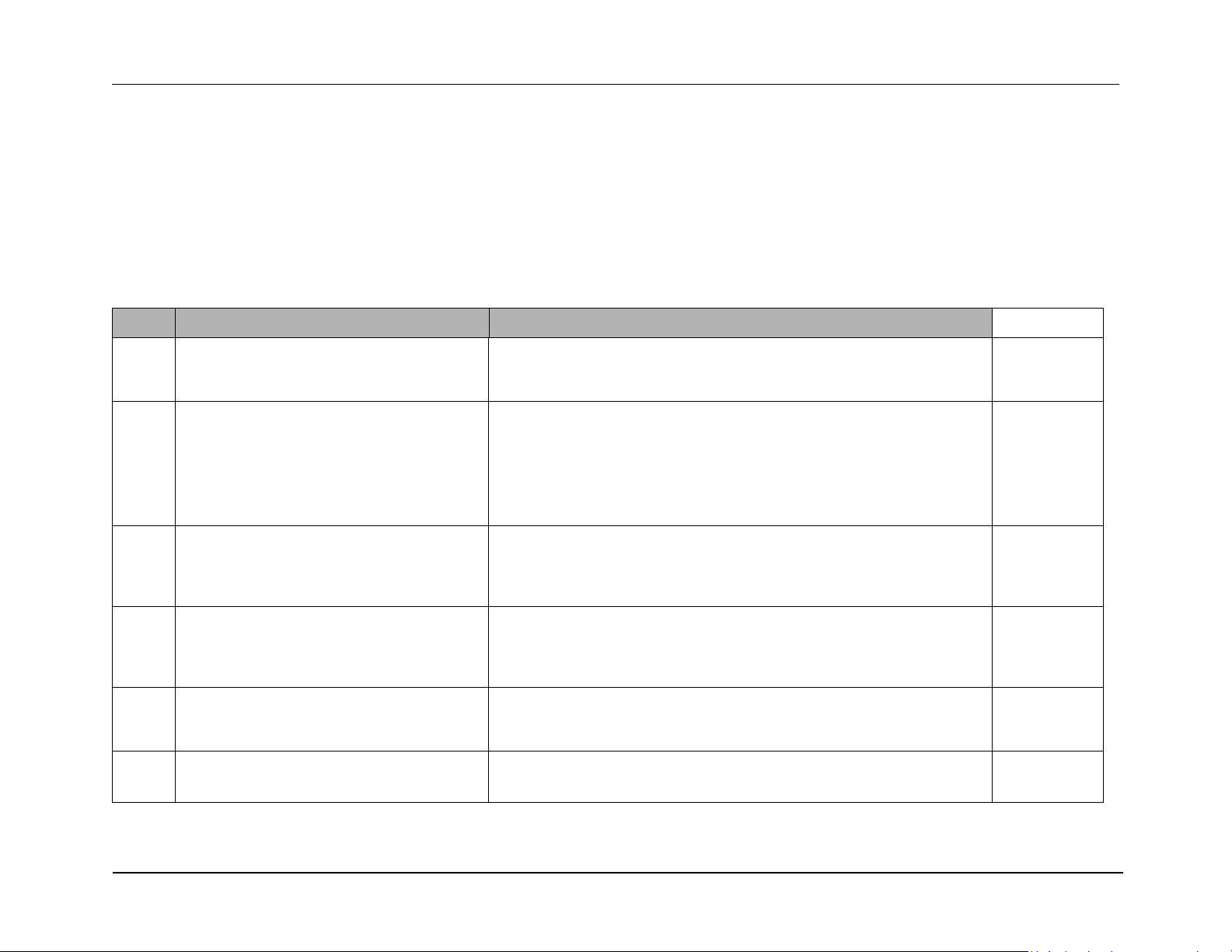

4.0 Power Supply Test (Optional)

Note: Tests in this section will produce battery errors due to the use of a power supply in place of a SurePower Battery.

Tools Needed:

• 2 red miniature alligator to miniature alligator leads.

• 2 black miniature alligator to miniature alligator test leads.

• DC power supply (15 Amp minimum).

• 0.1resistor (¼W or greater).

• 1000 1% ¼W resistor.

• Fluke 75 multimeter or equivalent.

Test Setup:

1. Disconnect the AC line cord from the unit.

2. Make sure the unit and power supply are turned off.

3. Connect one end of the black lead to the “-” terminal in the battery well.

4. Connect the other end of the black lead to the “-” terminal of the power supply.

5. Connect the red lead to “+” terminal socket of the battery well. Use the middle pin with the plasti c guard around it. Connect t he other end of the red lead

to the “+” terminal of the power supply.

6. Set the power supply voltage to 7V.

Caution Be sure to connect the power supply properly to the R Series battery well terminals or damage to the unit may result. Do NOT raise the

power supply voltage above 15V.

1-10 9650-0903-01 Rev. L

Page 21

R Series Service Manual

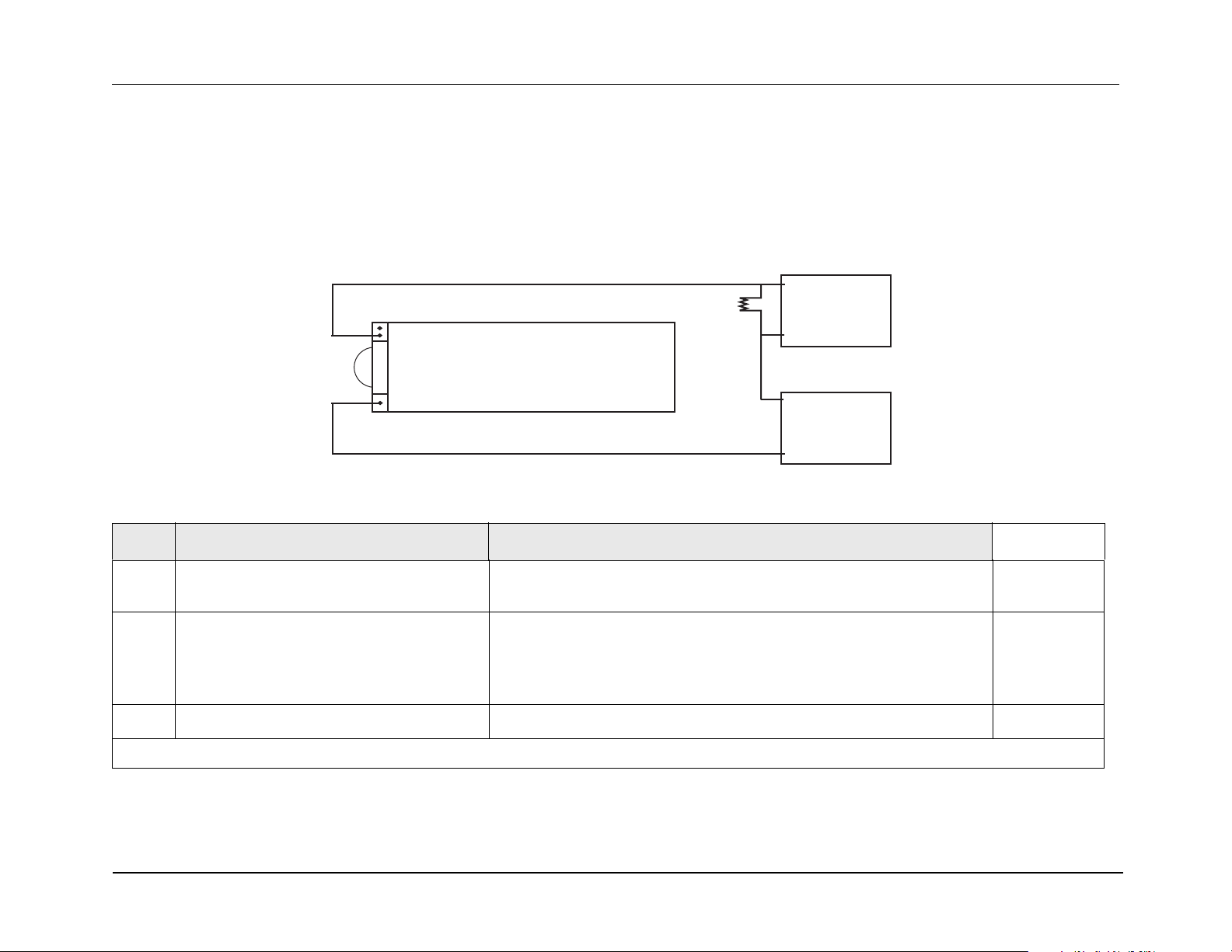

?

Battery Well

15 Amp

Supply

?

Red

Black

Do this... Observe this... Pass/Fail

4.1 Turn the selector switch to MONITOR (for AED

units turn to ON.)

4.2 Turn th e un i t off.

4.3 Adjust the power supply voltage to 10.8V and

turn the selector switch to MONITOR.

4.4 Low Battery Test

Set voltage to 10.5V.

4.5 Set voltage to 10.2V. REPLACE BATTERY message displays within 30 seconds.

4.6 Turn th e un i t off.

Record your results on the Maintenance Test Checklist.

The unit should not turn on.

The unit should turn on.

No LOW BATTERY message displays.

LOW BATTERY message disp lays within 30 seconds.

oo

oo

oo

oo

9650-0903-01 Rev. L 1-11

Page 22

R Series Service Manual

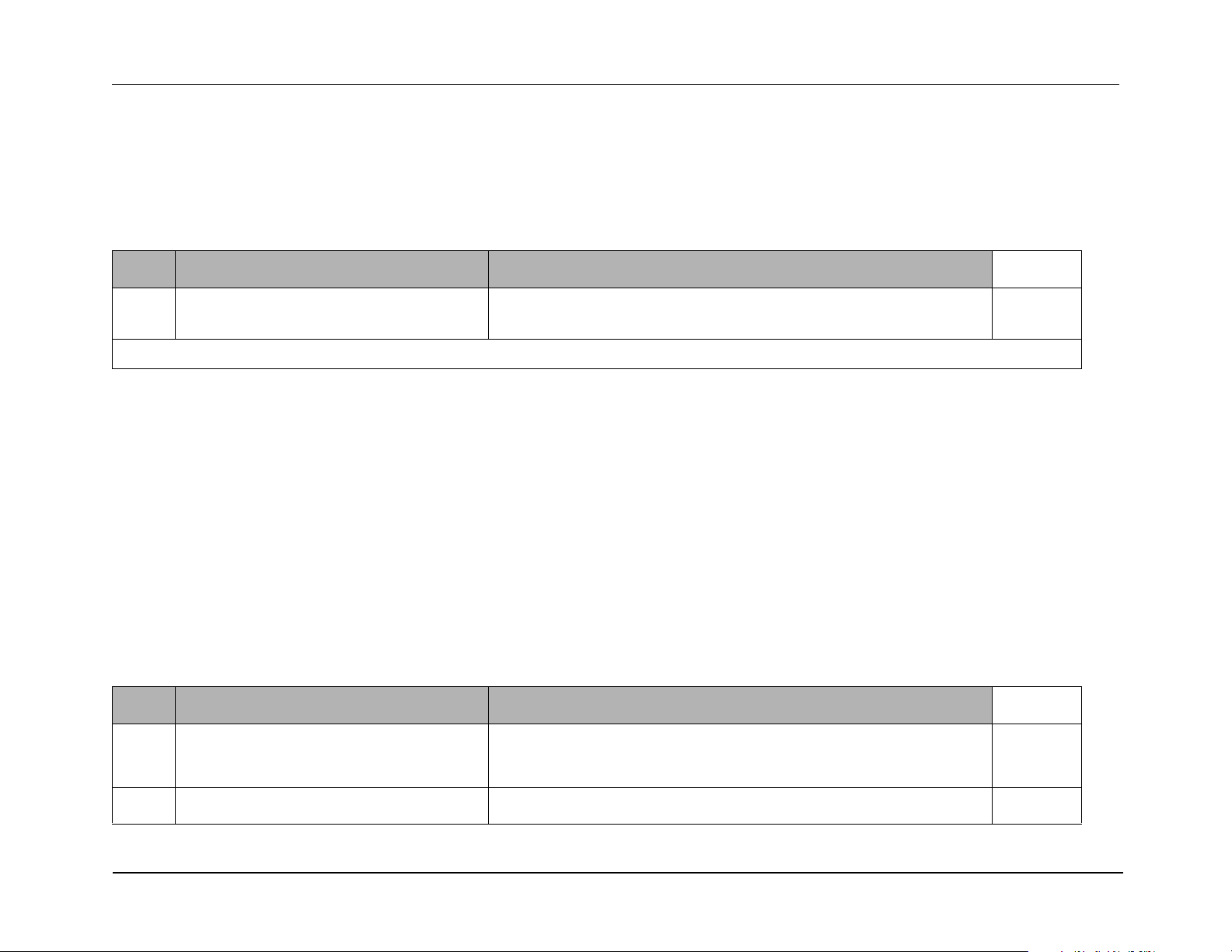

15 Amp

Supply

?

DMM

?

?

Battery Well

Red

Black

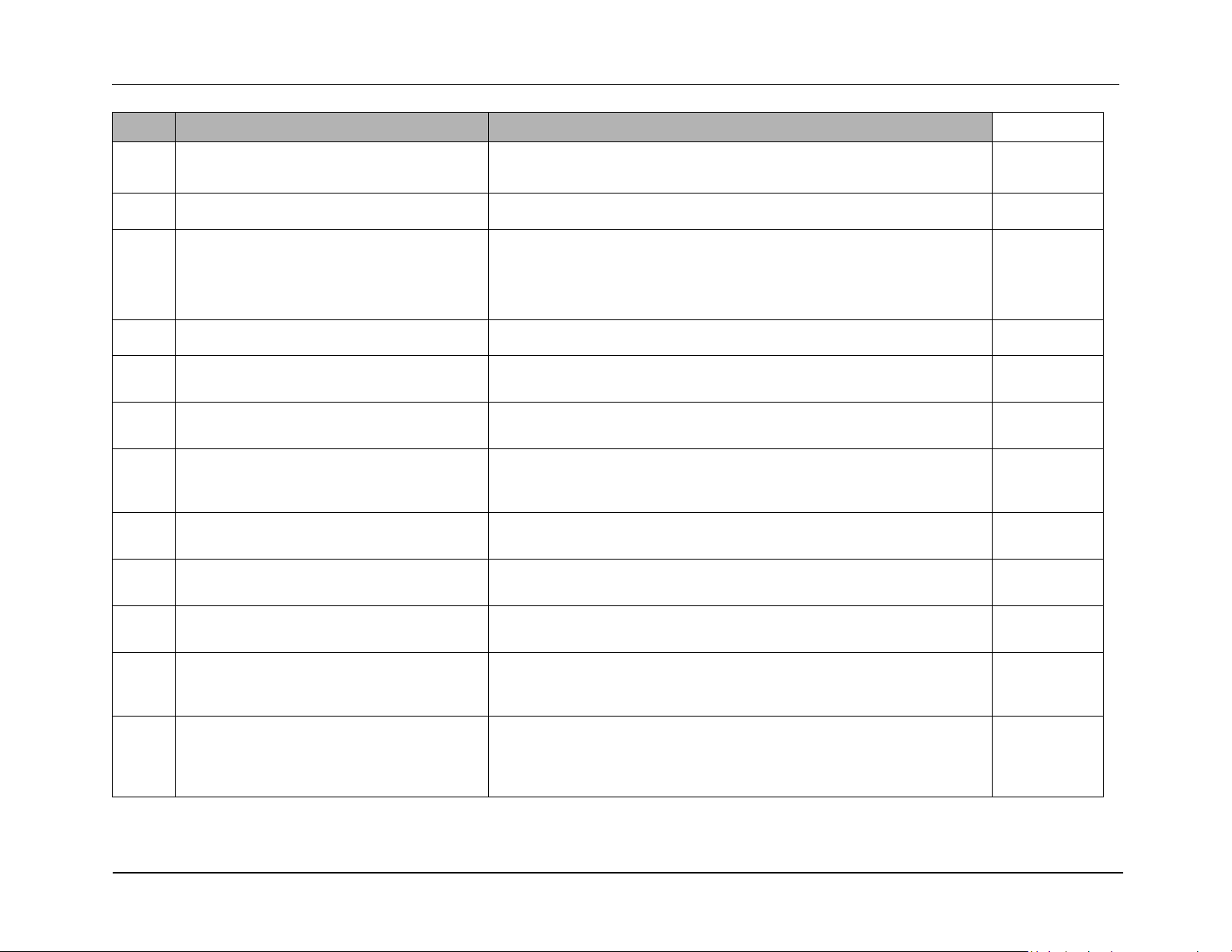

Test Setup:

1. Remove red lead from power supply and connect to 0.1

2.

Connect other end of resistor to “+” terminal of power supply using a second red lead.

resistor.

3. Connect multimeter across the resistor.

4. Set voltage scale (if DVM is not autoranging) to 220 mV.

Do this... Observe this... Pass/Fail/NA

4.7 System Current Test

Set power supply to 10.8V.

4.8 Turn the selector switch to MONITOR. Voltage across resistor should be 145 mV or less (<1.2A of ON current).

NOTE: Without optional parameters.

All devices with SpO

4.9 Turn unit off.

Record your results on the Maintenance Test Checklist.

1-12 9650-0903-01 Rev. L

, EtCO2 or NIBP <160mV

2

ooo

ooo

Page 23

Test Setup for Off Current Test:

R Series Service Manual

1. Remove 0.1

2. Connect DMM across resistor.

3. Set voltage scale to DCV.

4. Measure voltage across resistor.

4.10 Off Current Test

Record your results on the Maintenance Test Checklist.

resistor and replace with 1K.

Do this... Observe this... Pass/Fail

Voltage should be less than 270 mV (<270 A of current).

Measure across resistor with unit turned off.

Charger Test

Tools Needed: 2-Post Battery Fixture (9100-0575-TF), DVM, 2 Test Leads, Impulse 4000, Stopwatch.

Test Setup:

Set DVM to read DC Volts.

Connect Postive lead to positive post of the R Series charger load fixture.

Connect negative lead to negative post of the R Series charger load fixture.

Verify the unit is plugged into AC Power.

oo

Do this... Observe this... Pass/Fail

4.1 1 Set front panel switch to DEFIB or ON, (for BLS

units, press MANUAL MODE, then press

CONFIRM).

4.12 Install Charger T est Fixture.

9650-0903-01 Rev. L 1-13

Page 24

R Series Service Manual

Do this... Observe this... Pass/Fail

4.13 Observe the voltage. Verify the charger voltage is 11.97V-12.43V.

4.14 On the Test Fixture set the switch to 20 Ohms. Verify the charger voltage is 9.50V-11.87V.

4.15 On the Test Fixture set the switch to 27 Ohms. Verify the charger voltage is 11.97V-12.43V.

4.16 Remove the charger load Test Fixture.

4.17 Connect the universal cable to the Impulse

4000.

4.18 Press the ENERGY SELECT UP ARROW

button until 200J is displayed.

4.19 Press the CHARGE button and start timing with

a stopwatch. Stop timing when the SHOCK

button illuminates.

4.20 Press the ENERGY DOWN ARROW button. Verify the unit internally discharged.

Record your results on the Maintenance Test Checklist.

Verify 200J is displayed.

Verify charge time is between 3-10 seconds.

oo

oo

oo

oo

oo

oo

1-14 9650-0903-01 Rev. L

Page 25

R Series Service Manual

5.0 Leakage Current Test

Tools Needed: See the manufacturer’s instructions or supplied specifications for the leakage tester you use.

Test Setup: See the manufacturer’s instructions or supplied specifications for the leakage tester you use. Repeat leakage test with applicable accessories:

OneStep Cable, external paddles, internal paddles, and anterior/posterior paddles.

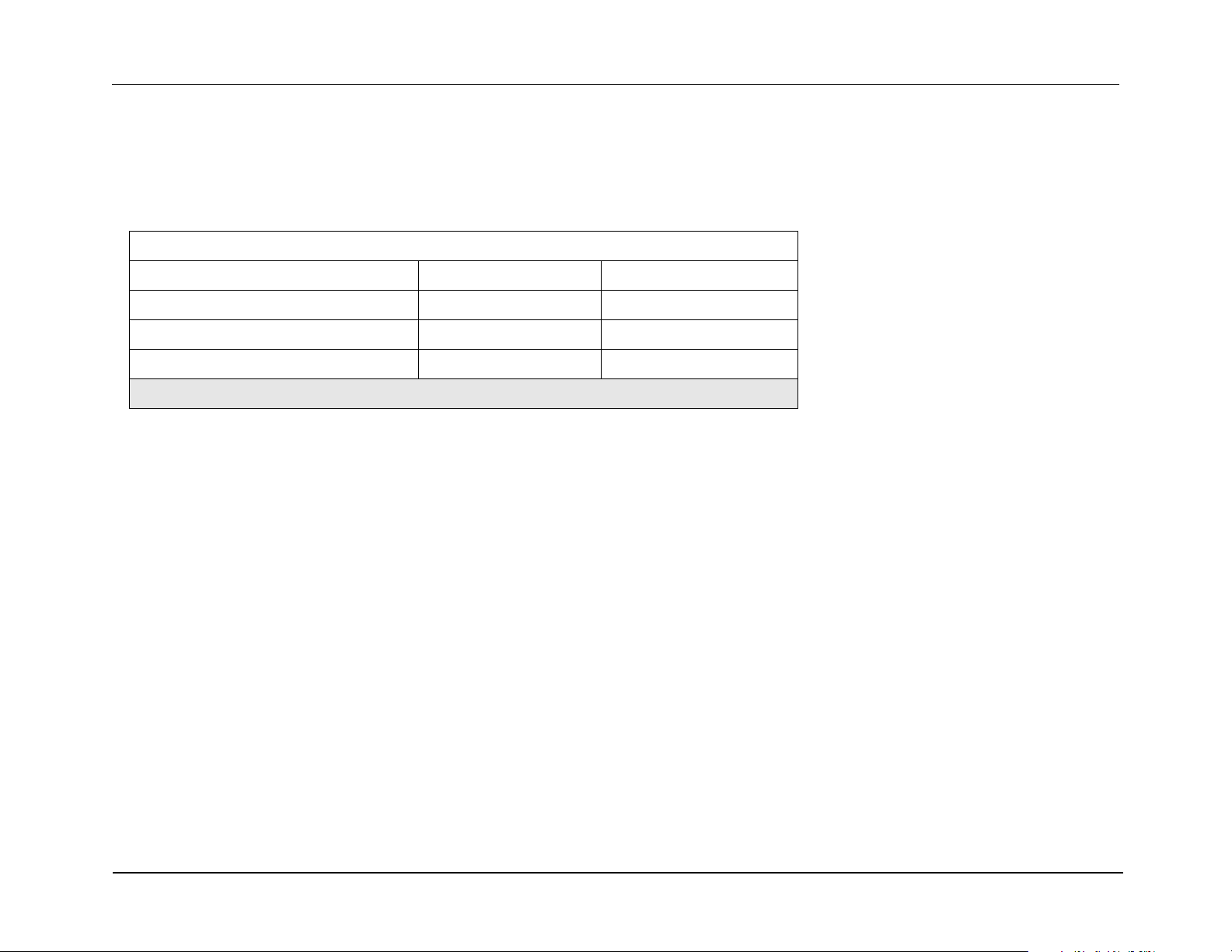

Maximum Leakage Acceptance Limits

Normal Condition Single Fault Condition*

Lead ECG 10 50

Hands Free Electrodes and Paddles (MFE) 10 100

Earth 500 1000

*Single fault considered AC mains on applied part.

9650-0903-01 Rev. L 1-15

Page 26

R Series Service Manual

6.0 Paddles Test

Tools Needed: None.

Test Setup: If applicable, connect the OneStep cable to the paddles and place the paddles in paddle wells.

Do this... Observe this... Pass/Fail/NA

6.1 Turn the selector switch to DEFIB (for AED

units, turn the selector switch to ON, and

select Manual Mode.) Press and hold the

ENERGY DOWN button on the sternum paddle.

6.2 Press and release the ENERGY UP button on

the sternum paddle for each setting.

6.3 Press and release the RECORDER button on

the sternum paddle.

6.4 Press and release the RECORDER button

again.

6.5 Select 30J using the paddle ENERGY button.

Press the CHARGE button on the Apex paddle.

6.6 Press and release the APEX SHOCK button. No discharge.

6.7 Press and release the STERNUM SHOCK

button.

6.8 Press and hold both paddles SHOCK buttons. The unit discharges. The 30J TEST OK message displays and the red LED

Record your results on the Maintenance Test Checklist.

The energy selection decreases to 1J.

Verify the energy levels increment through the following: 1-10, 15, 20, 30, 50,

75, 100, 120, 150, 200J.

The recorder turns on.

Verify the recorder turns off.

The unit charges to 30J, then the red LED charge indicator illuminates and the

charge tone sounds. (Note that the front panel shock button does not

illuminate).

No discharge.

turns off. The recorder runs.

ooo

ooo

ooo

ooo

ooo

ooo

ooo

ooo

1-16 9650-0903-01 Rev. L

Page 27

7.0 Heart Rate Display Test

Tools Needed:

• Impulse 4000

• ECG Cable (3 or 5 leads).

Test Setup:

1. Turn the selector switch to MONITOR (for AED units turn to ON.) Press LEAD button until “I” displays.

2. Connect the ECG leads to the Fluke Biomedical 4000 or equivalent.

3. Connect the ECG cable to the unit.

Do this... Observe this... Pass/Fail/NA

R Series Service Manual

7.1 Set the Impulse 4000 to 120BPM. The Heart Rate displays as 120 +/- 2 bpm.

Record your results on the Maintenance Test Checklist.

ooo

9650-0903-01 Rev. L 1-17

Page 28

R Series Service Manual

8.0 Calibrating Pulses on Strip Chart Test

Tools Needed: None.

Test Setup: None

8.1 Press the RECORDER button.

8.2 Press and hold SIZE button to activate the

Record your results on the Maintenance Test Checklist.

.

Do this... Observe this... Pass/Fail/NA

calibration signal.

The strip chart displays a signal of 300 ppm with an amplitude of 10 mm

+/- 1 mm. The signal also appears on the video display. (You can verify that the

rate is 300ppm by measuring 5mm from the left edge of one pulse to the left

edge of the following pulse.)

ooo

1-18 9650-0903-01 Rev. L

Page 29

9.0 Notch Filter Test

Tools Needed: Impulse 4000 (or equivalent).

Test Setup:

1. Connect the ECG cable to the Impulse 4000.

2. Connect the ECG cable to the unit.

Do this... Observe this... Pass/Fail/NA

9.1 Turn the selector switch to MONITOR mode (for

AED units turn to ON.)

9.2 Select lead I, size 3x.

Select 60Hz sine wave (or 50 Hz for a 50Hz

unit) on the Fluke 4000.

R Series Service Manual

9.3 Press RECORDER button. Verify that the waveform amplitude on the strip chart is less than 1.5 mm.

9.4 Turn th e un i t off.

Record your results on the Maintenance Test Checklist.

ooo

9650-0903-01 Rev. L 1-19

Page 30

R Series Service Manual

10.0 Heart Rate Alarm Test

Tools Needed:Impulse 4000.

Do this... Observe this... Pass Fail/NA

10.1 Turn the selector switch to MONITOR mode( for

AED units turn to ON.)

Connect the ECG leads to the Impulse 4000.

Set the simulator to 120 BPM and the

defibrillator to lead II.

10.2 Press ALARMS softkey. The alarm menu displays.

10.3 Press NEXT PARAM softkey until ECG HR

displays.

10.4 Press CHANGE VALUE softkey.

10.5 Press INC> softkey for state. Cursor scrolls through ENABLE, AUTO and DISABLE.

10.6 Press DEC< softkey for state. Cursor scrolls through ENABLE, DISABLE, AND A UTO.

10.7 Press INC> softkey until ENABLE displays. ENABLE displays.

10.8 Press ENTER softkey.

10.9 Press NEXT FIELD softkey to select the heart

rate limit.

10.10 Press CHANGE VALUE softkey and press

INC> or DEC< to set low heart rate limit to 30.

10.11 Press ENTER softkey.

10.12 Press NEXT FIELD softkey to select the high

heart rate limit.

10.13 Press CHANGE VALUE and press INC< or

DEC> softkey and set high heart rate limit to

150.

10.14 Press ENTER softkey, then press RETURN

softkey.

10.15 Press ALARM SUSPEND button. No alarm sounds.

Lead II waveform displayed on monitor.

NSR ECG at 120 BPM +/- 2 displayed.

Cursor scrolls through parameters.

Cursor scrolls to Low field.

Cursor scrolls to High field.

ooo

ooo

ooo

ooo

ooo

ooo

ooo

ooo

ooo

ooo

ooo

ooo

ooo

ooo

ooo

1-20 9650-0903-01 Rev. L

Page 31

R Series Service Manual

Do this... Observe this... Pass Fail/NA

10.16 Remove a lead wire from the Impulse 4000. The bell symbol flashes and the heart symbol stops flashing. The ECG LEAD

OFF alarm tone sounds and the Heart Rate Value is highlighted. Recorder

prints a stripchart showing a low heart rate, if enabled.

10.17 Reattach ECG Lead wire to Impulse 4000 and

hold the ALARM SUSPEND button on unit for 4

seconds.

10.18 Press the ALARM SUSPEND button. Alarm is enabled. Bell symbol (without “X”) displays.

10.19 Set simulator to 160 BPM or higher. Heart Rate Value is highlighted, alarm tone sounds, the bell and the heart

10.20 Press the ALARM SUSPEND button in the unit. Alarm is suspended for 90 seconds. The bell symbol has an “X” through it. The

10.21 Press and hold ALARM SUSPEND for

3 seconds to disable alarms.

Record your results on the Maintenance Test Checklist.

The bell symbol has an “X” through it.

The heart symbol flashes with each QRS wave.

symbol both flash.

heart symbol flashes with each QRS wave and the Heart Rate Value is

highlighted.

Verify the Heart Rate value is not highlighted, and the bell symbol displays with

an “X” through it and is not flashing.

ooo

ooo

ooo

ooo

ooo

ooo

9650-0903-01 Rev. L 1-21

Page 32

R Series Service Manual

11.0 Defibrillator Self Test

SHOCK HAZARD!

TAKE THE NECESSARY PRECAUTIONS TO GUARD AGAINST SHOCK OR INJURY BEFORE YOU START

CONDUCTING THE DEFIBRILLATO R TESTS.

Keep hands and all other objects clear of the multi-function cable connections an d defibrillator analyzer when discharging

the defibrillator.

Before you discharge the defibrillator, warn everyone near the equipment to STAND CLEAR.

Caution Do NOT internally discharge the unit more than 3 times in 1 minute. Note that multiple rapidly repeating in tern al d ischarges at more than

30 Joules may damage the unit.

Tools Needed:

• ZOLL Medical Electrode Connector (Fluke Biomedical Part Number 3010-0378 or equivalent).

• Impulse 4000 or equivalent defibrillator anal yzer.

• ECG Cable.

• Stop watch.

Test Setup:

1. Ensure the unit is turned off.

2. Ensure the ECG cable is connected to the R Series unit and the defibrillator analyzer.

Note: The OneStep cable should not be connected to any equipment at the beginning of this test.

Do this... Observe this... Pass/Fail

11.1 Turn the selector switch to DEFIB mode (For

AED units, turn to ON, and select MANUAL

MODE.)

Set leads to PADS.

11.2 Connect the OneStep cable to the test port on

the right side of the R Series.

1-22 9650-0903-01 Rev. L

CHECK PADS/POOR PAD CONTACT message displays.

DEFIB PAD SHORT message displays.

oo

oo

Page 33

R Series Service Manual

Do this... Observe this... Pass/Fail

11.3 Select energy level of 100J and press the

CHARGE button.

11.4 Press the SHOCK button. Unit does not discharge. DEFIB PAD SHORT message displays.

11.5 Set energy level to 30J. Unit internally discharges.

11.6 Press the CHARGE button. Unit charges to 30J and displays DEFIB 30J READY. The charge ready tone

11.7 Press and hold SHOCK button. Unit discharges. 30J TEST OK message displays. The message at the top of

Record your results on the Maintenance Test Checklist.

The charge time is >2 second and <10 seconds and SELECT 30J FOR TEST

is displayed.

sounds.

the printed strip chart reads as follows:

30 JOULES TEST OK. TEST_CUR=10-14A DEFIB_IMPED=0.

The impedance value may range from 0 to 5.

oo

oo

oo

oo

oo

9650-0903-01 Rev. L 1-23

Page 34

R Series Service Manual

12.0 Synchronized Cardioversion Test

Tools Needed: Impulse 4000 or equivalent defibrillator analyzer.

Test Setup:

1. Connect the OneStep cable via the adapter (D.N.I #3010-0378) to the defibrillator analyzer.

2. Select cardioversion on analyzer. Input 1mV ECG signal at 60 BPM.

Do this... Observe this... Pass/Fail

12.1 Press LEAD button to select PADS and Size

X1.

12.2 Press the SYNC softkey on the defibrillator.

Enter synchronized cardioversion timing test

mode on the defibrillator analyzer.

NOTE: Press the SYNC softkey again if the unit

is configured for Remote Sync.

12.3 Select 200J.

12.4 Press the CHARGE button. When the SHOCK

button lights, press and hold the SHOCK

button.

Record your results on the Maintenance Test Checklist.

Sync appears on display.

Sync markers display on the monitor. The sync marker appears as a down

arrow over the ECG R-wave peaks on strip chart and display.

Defibrillator discharges.

Observe that the R-wave to energy delivered (sync delay) is less than 60

milliseconds on the analyzer display.

oo

oo

oo

1-24 9650-0903-01 Rev. L

Page 35

R Series Service Manual

13.0 Synchronized Cardioversion for Remote ECG Monitoring Test (Optional)

If applicable, the R Series may be configured to receive defibrillation synchronization pulses from a remote ECG monitoring device (see the R Series

Configuration Manual). Remote Sync should be tested as a complete system that includes the remote monitor and R Series defibrillator. Be sure that the

remote device is connected to the Sync In/Marker Out c onnector on the R Series unit. The remote device must have a sync out connector and you must use

a cable to connect the two devices. Ensure the remote device conf orms with the Sy nc In /Marke r Out sp ecifi catio ns described in Appendix A: Defibrillator

Specifications of the R Series Operator’s Guide.

Tools Needed: Fluke Biomedical 4000 or equivalent defibrillator analyzer.

Test Setup:

1. Connect the OneStep cable via the adapter (D.N.I #3010-0378) to the defibrillator analyzer.

2. Select cardioversion on analyzer. Input 1mV ECG signal at 60 -120 BPM.

Do this... Observe this... Pass/Fail

13.1 Connect the remote monitor’s ECG lead cable

to the defibrillator analyzer. Connect the

R Series OneStep cable via the adapter (D.N.I.

#3010-0378) to the defibrillator analyzer.

13.2 Select Defib Mode. Press the SYNC ON/OFF

softkey. Press the REMOTE SYNC softkey.

13.3 Select 200J on the R Series. Enter

synchronized cardioversion timing test mode on

the defibrillator analyzer.

13.4 Press the CHARGE button. When the SHOCK

button lights, press and hold the SHOCK

button.

Record your results on the Maintenance Test Checklist.

9650-0903-01 Rev. L 1-25

The words REMOTE SYNC are displayed in place of the ECG trace, and a

REMOTE SYNC XXXJ SEL. message appears on the display. The ECG

heartbeat indicator will flash with each synchronization pulse received from the

remote monitoring device. On the remote device’s display, verify that sync

markers coincide with each R-wave as described in the remote device’s user

manual.

The defibrillator discharges. Observe that the R-wave to shock delay (sync

delay) is less than 60 milliseconds on the analyzer display.

oo

oo

oo

Page 36

R Series Service Manual

14.0 Shock Test

Tools Needed: Fluke Biomedical 4000 or equivalent defibrillator analyzer and a stop watch

Test Setup:

1. Connect the OneStep cable via the adapter (D.N.I #3010-0378) to the defibrillator analyzer.

2. Ensure that a fully charged battery is installed in the unit.

3. Select Defib/Energy mode on analyzer.

Do this... Observe this... Pass/Fail/NA

14.1 Turn the selector switch to DEFIB mode.(for

AED units, turn to ON, and select MANUAL

MODE).

14.2 Press the ENERGY SELECT down arrow until

5J displays.

14.3 Press the CHARGE button. Wait for the

SHOCK button to illuminate.

14.4 Press the SHOCK button. Unit discharges 3J-7J into the simulator.

14.5 Press the ENERGY SELECT up arrow until 50J

displays.

14.6 Press the CHARGE button. Wait for the

SHOCK button to illuminate.

14.7 Press the SHOCK button. Verify that the unit discharges 46J-62J into the simulator.

14.8 Press the ENERGY SELECT up arrow until

100J displays.

14.9 Press the CHARGE button. Wait for the

SHOCK button to illuminate.

14.10 Press the SHOCK button. Verify the unit discharges 93J-125J into the simulator.

DEFIB 5J SEL displays.

DEFIB 5J RDY displays.

Verify that DEFIB 50J SEL is displayed

Verify that DEFIB 50J RDY is displayed.

Verify that DEFIB 100J SEL is displayed.

Verify that DEFIB 100J RDY is displayed.

ooo

ooo

ooo

ooo

ooo

ooo

ooo

ooo

ooo

1-26 9650-0903-01 Rev. L

Page 37

R Series Service Manual

Do this... Observe this... Pass/Fail/NA

14.11 Press the ENERGY SELECT up arrow until

200J displays.

14.12 Press the CHARGE button. Wait for the

SHOCK button to illuminate.

14.13 Press the SHOCK button. Verify the unit discharges 196J-264J into the simulator.

14.14 Press the CHARGE button and start timing with

a stopwatch. Stop timing when the SHOCK

button illuminates.

14.15 Press the SHOCK button. V erify that the Patient Current is between 23.9-25.9A and Defib Impedance is

14.16 Press the CHARGE button, when the SHOCK

button Illuminates, press the ENERGY SELECT

DOWN ARROW.

14.17 Set Energy level to 200 Joules. Press the

CHARGE button. When the SHOCK button

illuminates, start timer.

14.18 Disconnect the cable from the analyzer. CHECK PADS audio prompt.

Record your results on the Maintenance Test Checklist.

Verify that DEFIB 200J SEL is displayed.

Verify that DEFIB 200J READY is displayed.

Observe and record the value of the charge time on the stop watch.

Charge time 1.0-7.0 sec.

between 46-54 Ohms on the strip chart.

Verify that no fault messages are displayed, and no discharge energy is

displayed on the Impulse 4000.

Verify the unit holds the energy for 60 seconds (15 seconds for AED units), and

that when the unit discharges internally, that there are no fault messages

displayed.

ooo

ooo

ooo

ooo

ooo

ooo

ooo

ooo

9650-0903-01 Rev. L 1-27

Page 38

R Series Service Manual

15.0 Summary Report Test

Tools Needed: Impulse 4000.

Test Setup:

1. Connect the OneStep cable to the Impulse 4000

2. If you are using paddles, place the paddles on the analyzer’s discharge plates.

Do this... Observe this... Pass/Fail

15.1 Press the Report Data * softkey, press Erase,

then Erase All.

15.2 Set selector switch to DEFIB (for AED units turn

to ON, and select MANAUL MODE.) Select

200J using the ENERGY SELECT button, and

press the CHARGE button. When charged,

press the SHOCK button to discharge into the

defibrillator analyzer.

15.3 Wait 18 seconds, then press the Code Marker

softkey. Press the CPR softkey. Wait 20

seconds and turn unit off. (This will allow code

marker to be saved in the summary.)

15.4 Ver if y tha t th e un i t ha s be e n off for a minimum

of 10 seconds and then turn the unit on. Press

the Report Data * softkey, then press Print

Chart, then Print All.

* For software versions 3.0 or earlier, the unit displays Report instead of Report Data.

Record your results on the Maintenance Test Checklist.

ERASING REPORT displays. Wait for the message to clear.

The unit successfully discharges and if configured to do so, prints a strip chart.

The Code Markers display. (After CPR Code Marker is selected, the unit

automatically exits the Code Marker options menu.)

Summary report prints. The report displays the correct date, time, the shock

delivered, and Code Marker event.

oo

oo

oo

oo

1-28 9650-0903-01 Rev. L

Page 39

16.0 Advisory Message Test (Manual/Advisory Units)

Tools Needed: Impulse 4000

Test Setup:

1. Connect the OneStep cable via the adapter (D.N.I #3010-0378) to the defibrillator analyzer.

Do this... Observe this... Pass/Fail

16.1 Connect OneStep cable to the simulator.

Turn the selector switch to DEFIB mode (for

AED units turn to ON, and select MANUAL

MODE.)

R Series Service Manual

16.2 Select VF (ventricular fibrillation) on the Impulse

4000, then press the ANALYZE button.

16.3 Press the SHOCK button. Unit discharges.

16.4 Select the NSR (normal sinus rhythm) on the

simulator, then press the ANALYZE button.

Record your results on the Maintenance Test Checklist.

ANALYZING ECG message displays.

STAND CLEAR message displays.*

SHOCK ADVISED message displays.

PRESS SHOCK message displays*+

*Advisory audio prompts are user configurable.

+If configured for auto charge. PRESS CHARGE message displays if not

configured to auto charge.

ANALYZING ECG message.

STAND CLEAR message.*

NO SHOCK ADVISED message.*

*Advisory audio prompts are user configurable.

oo

oo

oo

9650-0903-01 Rev. L 1-29

Page 40

R Series Service Manual

?

17.0 Pacer Test

Tools Needed: Impulse 4000 Analyzer (software 1.06 or higher) with optional external pl ug in pacing module (TQA-17) or equivalent.

Note: The following tests are to be performed only on R Series units equipped with the optional pacing function.

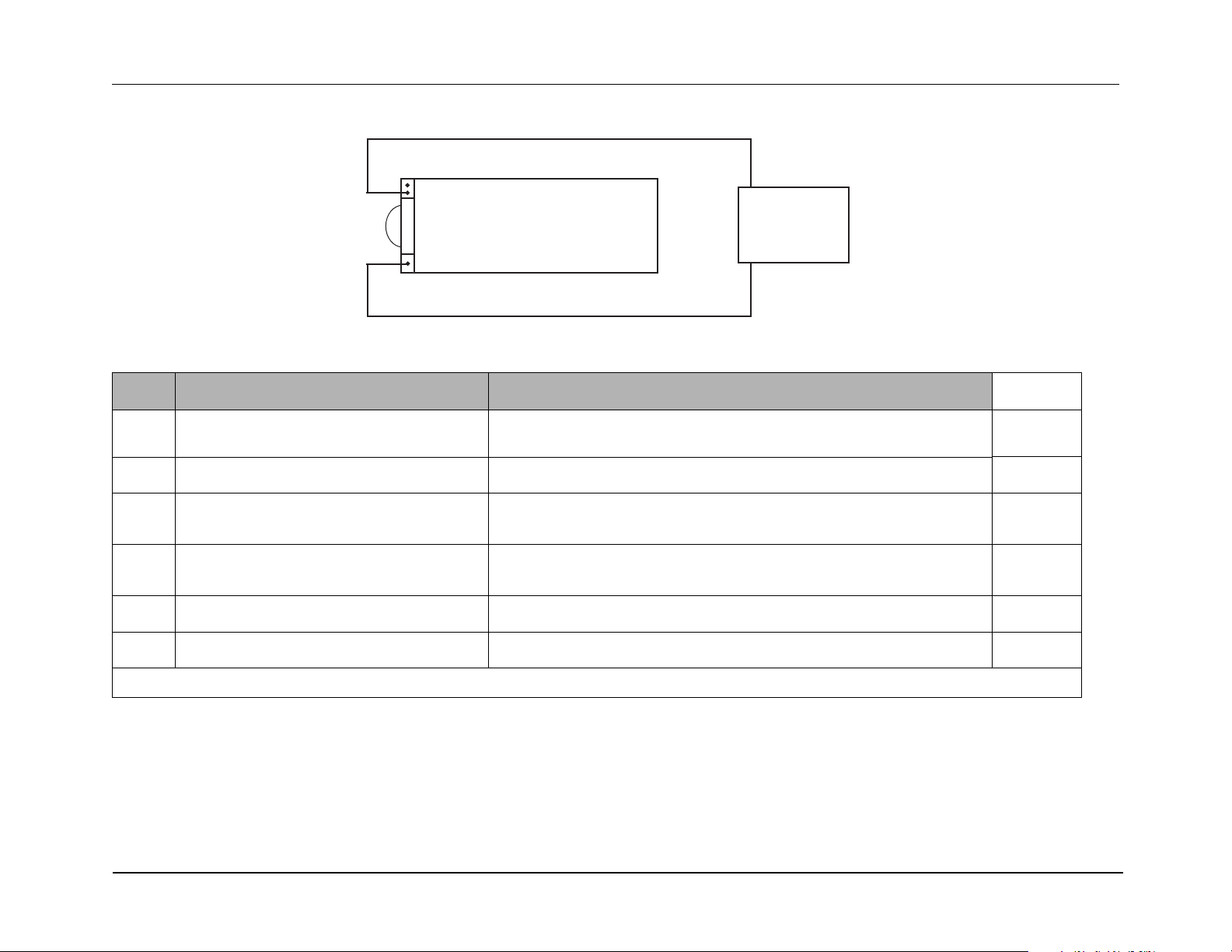

The pacer output can be measured using an oscilloscope set to DC coupling connected across a load resistor. (See above diagram for OneStep cable

connector polarity.) The load resistor is a 100 ohm, 5 watt or greater. The pacer output is a positive going pulse, 40 +/- 2 ms duration with an amplitude of

0.1 volt per milliamp of selected output (e.g., 4 0 milliamps of sel ected outp ut has an ampl itude of 4 +/- 0.5 volts of t he spec ified tole rance displ ayed on th e

oscilloscope).

If an external non-invasive pacer analyzer is being used, then follow the manufacturer’s guidelines for measuring the frequency (ppm), output (mA) and

the pulse width measured in milliseconds. Note that the analyzer pace load resistor must be less than 250 ohms.

Test Setup:

1. Connect the One Step cable from the R Series to the External Pacer Load (TQA-17) of the Impulse 4000.

2. Turn the Main Selector knob of the R Series to the Pacer mode.

3. Enter the pacer function on the analyzer.

Note: Do not connect ECG cable to Pacer Analyzer or ECG simulator.

Do this... Observe this... Pass/Fail

17.1 Set the PACER OUTPUT to 14 mA and

disconnect MFC connector from the Impulse

4000.

17.2

17.3 Set rate to 180 ppm; output to 0mA. No output appears on the Impulse 4000.

17.4 Increase the output to 40mA. Output on the Impulse 4000 is 40mA +/- 5mA.

1-30 9650-0903-01 Rev. L

Reconnect the

4000. Press Clear Pace Alarm softkey.

universal cable to the Impulse

CHECK PADS and POOR PAD CONTACT messages display . The pace alarm

is active.

CHECK PADS and POOR PAD CONTACT messages disappear. The pace

alarm is cleared.

oo

oo

oo

oo

Page 41

R Series Service Manual

Do this... Observe this... Pass/Fail

17.5 Increase the output to 80mA Output on the Impulse 4000 is 80mA or +/- 5mA.

17.6 Increase the output to 120mA. Output on the Impulse 4000 is 120mA or +/- 6mA.

17.7 Increase the output to 140mA. Output on the Impulse 4000 is 140mA or +/- 7mA. Pulse width is 40mS +/-

2mS. Pacer rate on Impulse 4000 is 177-183 ppm.

17.8 Decrease the output to 60mA.

Decrease the rate to 30 ppm.

17.9 Connect the ECG cable to the R Series and

Impulse 4000. Select the ECG at 60 BPM on

the Impulse 4000. Increase the pacer rate on

the unit to 58ppm.

17.10 Press the Async Pace softkey. ECG at 60 BPM seen on the display with the pace stimulus markers displayed.

17.11 Turn off Impulse 4000. Set Pacer Rate to

100ppm. Press the RECORDER ON button.

17.12 Press and hold 4:1 button. Observe the pace stimulus markers every 60 mm+/- 1.5 mm.

Record your results on the Maintenance Test Checklist.

Pacer rate on Impulse 4000 is 29-31 ppm.

ECG at 60 BPM is seen on the display and no stimulus markers.

Async pace message displays.

Observe the pace stimulus markers every 15mm +/-1mm.

oo

oo

oo

oo

oo

oo

oo

oo

9650-0903-01 Rev. L 1-31

Page 42

R Series Service Manual

18.0 SpO2 Monitor Test (for SpO2 Option)

Tools Needed:

• Masimo

• Masimo

• Fluke Biomedical Index 2XLFE SpO

Test Setup:

1. Connect the OneStep cable to the test port.

2. DO NOT connect the ECG cable to the simulator.

3. Install the Masimo

4. Connect the Masimo

5. Place a fully charged battery into the battery well or connect to AC power.

6. Ensure that the SpO

Reusable Sensor.

Patient Cable.

Simulator (or equivalent) .

2

Patient Cable and attach the Masimo sensor to the patient cable.

sensor to the finger simulation post.

Simulator is off.

2

Do this... Observe this... Pass/Fail

18.1 Turn the selector switch to MONITOR(for AED

units turn to ON, and select MANUAL MODE.)

18.2 Wait ten seconds.

Turn on the SpO

softkey on the Index SpO2 Simulator. Press the

MAN softkey.

18.3 Press the 02+ or 02- softkey of the simulator

until the SpO

18.4

1-32 9650-0903-01 Rev. L

Using the Index

BPM+ or BPM- softkey until the heart rate is

230 BPM.

simulator. Press the SIM

2

output is at 98%.

2

SpO

Simulator, press the

2

The SpO

The SpO

The R Series

Note that you may need to wait up to 2 minutes for the information to appear on

the ZOLL display.

The SpO2 rate 230 BPM displays on the simulator screen.

Note that you may need to wait up to 2 minutes for the information to appear on

the ZOLL display.

The

The heart

saturation percentage appears as a dashed line on the monitor.

2

PULSE SEARCH message displays.

2

SpO

reading of 98 +/- 1% appears on the R Series monitor.

2

SpO

saturation of 96-100% appears on the R Series display.

2

rate of 226-234 BPM displays on the R Series monitor.

oo

oo

oo

oo

Page 43

R Series Service Manual

Do this... Observe this... Pass/Fail

18.5

18.6

18.7 Press the OPTIONS softkey. Press TRACES.

18.8 Press RECORDER. The plethysmographic waveform prints on the strip chart paper.

18.9 Press RECORDER to stop printing. Verify that the recorder stops.

18.10

18.11 Press RECORDER. Verify th at the wavefo rm is printed at the correct rate.

18.12

Record your results on the Maintenance Test Checklist.

Using the Index

BPM- softkey until the heart rate is 50 BPM.

Using the Index

softkey until the SpO

Press TRACE 2. Select

Using the Index

BPM- softkey until the heart rate is at 230 BPM.

Press RECORDER. Remove the Masimo

patient cable.

SpO

Simulator, press the

2

SpO

Simulator, press the 02+

2

output is at 72%.

2

SpO

.

2

SpO

Simulator, press the

2

The SpO2 saturation of 96-100% displays on the unit.

The heart rate of 46-54 BPM displays on the R Series monitor.

The

SpO2 saturation of 69-74% displays on the unit.

The heart rate of 46-54 BPM displays on the R Series monitor.

Plethysmographic waveform appears on the ZOLL display.

The SpO2 saturation rate of 69-74% displays on the unit.

The heart rate in the heart position of 226-234 BPM displays on the monitor.

Press RECORDER to stop printing.

Verify that the recorder stops.

oo

oo

oo

oo

oo

oo

oo

oo

oo

o o

9650-0903-01 Rev. L 1-33

Page 44

R Series Service Manual

19.0 EtCO2 Monitor Test (for EtCO2 Option)

Tools Needed: CAPNOSTAT 5 Mainstream cable with airway adapter.

Test Setup:

1. Install the battery.

Do this... Observe this... Pass/Fail

19.1 Connect the CAPNOSTAT 5 CO2 Mainstream

cable with airway adapter attached to the yellow

connector at the back of the R Series.

19.2 Set the front panel switch to MONITOR or ON.

For AED units, enter Manual Mode.

19.3 When the WARM UP message disappears,

press the Param softkey, then select EtCO2.

19.4 Press the ZERO softkey, then wait for the

ZERO DONE message.

19.5 Press the Return softkey.

19.6 Press the following softkeys to display the CO

waveform, Options, Traces, Trace 2, then

EtCO2,

19.7 Breathe normally into the airway adapter. A capnogram waveform appears.

Record your results on the Maintenance Test Checklist.

NOTE: Make sure the airway adapter is installed in the CO

WARM UP message appears on the display.

NOTE: Warming up may take up to 3 minutes.

The ZERO DONE message appears.

A flat baseline CO2 waveform appears.

2

cable.

2

oo

oo

oo

oo

1-34 9650-0903-01 Rev. L

Page 45

20.0Barometric Pressure Calibration Check

Tools Needed: None.

Test Setup: None

Do this... Observe this... Pass/Fail/NA

R Series Service Manual

20.1 Connect the CAPNOSTAT 5 CO

yellow connector at the back of the R Series

unit, and connect an airway adapter to the

sensor.

20.2 While pressing and holding the second softkey

from the left, turn the selector switch to Monitor

(ON for AED units).

20.3 Wait for the sensor to warm up. The message WARM UP is displayed. (Warming up may take up to 3 minutes.)

20.4 Obtain the local barometric pressure in mmHg.*

20.5 Press the Baro Pr. softkey to enter the

Barometric Pressure Calibration screen.

20.6 Use the Inc> and Dec< softkeys to set the

second value on the pressure display line equal

to your local barometric pressure.

20.7 Press the Return softkey to store the offset and

return to the main EtCO

Record your results on the Maintenance Test Checklist.

*The barometric pressure can be obtained from a calibrated barometer, or from the National Weather Service at www.nws.noaa.gov Note that the barometric

pressure is in inches of mercury, multiply it by 25.4 to convert to mmHg.

Calibration screen.

2

Sensor to the

2

The unit displays EtCO2 Calibration screen.

ooo

9650-0903-01 Rev. L 1-35

Page 46

R Series Service Manual

21.0 CO2 Accuracy Check (for EtCO2 Option)

Tools Needed: Gas regulator, calibration gas (see note on page 37).

Test Setup: None

Do this... Observe this... Pass/Fail/NA

21.1 Connect the CAPNOSTAT 5 CO

yellow connector at the back of the R Series

unit, and connect an airway adapter to the

sensor.

21.2 While pressing and holding the second softkey

from the left, turn the selector switch to Monitor

(ON for AED units).

21.3 Wait for the sensor to warm up. The message WARM UP is displayed (Warming up may take up to 3 minutes.)

21.4 Obtain current room temperature in

Centigrade (Cº).

21.5 Press the Select Gas T emp softkey to enter the

CO

Accuracy screen

2

21.6 Use the Prev, Next, Inc and Dec softkeys to set

each digit of the gas temperature parameter in

the CAPNOSTAT 5 CO2 Sensor until Gas

Degrees C is equal to the room temperature.

21.7 Press the Return softkey to store the

temperature and return to the main EtCO

Calibration screen.

21.8 Press the Zero softkey to zero the mainstream

CAPNOSTAT 5 CO2 Sensor/Airway Adapter.

Sensor to the

2

2

The unit displays EtCO2 Calibration screen.

ooo

ooo

21.9 Attach a regulated flowing gas mixture of 5%

CO2, balance Nitrogen (N2) to the airway

adapter.

1-36 9650-0903-01 Rev. L

The gas flow rate should already be preset to 2 to 5 liters per minute.

Page 47

Do this... Observe this... Pass/Fail/NA

21.10 Set the Gas Balance settings of the

CAPNOSTAT 5 CO2 Sensor to that of the

calibration gas mixture (N

The default gas balance is N2.

, N2O, or He).

2

R Series Service Manual

21.11 Allow a few seconds for the gas mixture to

stabilize and observe the CO2 Percent value.

21.12 Press the Return softkey to return to the main

EtCO2 Calibration screen.

21.13 Turn the device off when calibration is

complete.

Record your results on the Maintenance Test Checklist.

The expected value is 5% ± 0.2%.

ooo

Note: The calibration gas mixture and regulator are available from most medical gas supply companies. You can also try Scott Medical products at

www.scottmedicalproducts.com.

9650-0903-01 Rev. L 1-37

Page 48

R Series Service Manual

22.0 NIBP Volume Leak Test

The volume leak test verifies the integrity of the pneumatic system on the R Series NIBP module. This test should be performed annually or every 10,000

readings, whichever comes first.

Tools Needed: NIBP simulator (the values and procedure provided in this manual are specific to the BP Pump 2)

Test Setup:

1. Connect the simulator hose to the NIBP connector on the R Series unit.

2. Configure the NIBP simulator for the volume leak test. For example, on the BP Pump 2:

• Press the MODE button three times to go into Tests mode.

• Press the SELECT button twice to access the volume leak test.

3. Make sure the ECG cable is not connected to the R Series unit.

4. If the SpO

option is installed, make sure that the SpO2 patient cable is NOT connected to the R Series unit.

2

Do this... Observe this... Pass/Fail

22.1 Turn the Selector Switch to OFF.

After 10 seconds, press and hold the fourth

softkey from the left and turn the Selector

Switch to MONITOR (ON for AED units).

22.2 Press the Leak Test softkey. The R Series displays the NIBP Leak Test Screen.

22.3 On the NIBP simulator, set the pressure

parameter to 200 mmHg.

22.4

1-38 9650-0903-01 Rev. L

On the

R Series unit, press the Close Valves

softkey.

The R Series powers on in the NIBP Service Mode.

The NIBP simulator displays a pressure reading of 200 mmHg.

The Valves status changes from OPEN to CLOSED.

oo

Page 49

R Series Service Manual

Do this... Observe this... Pass/Fail

22.5 On the NIBP simulator, press the START TEST

softkey.

Note: You must press the START TEST

softkey within 30 seconds of closing the

valves on the R Series unit.

22.6 On the NIBP simulator, press the STOP TEST

softkey.

22.7 On the R Series unit, press the EXIT softkey

twice.

Record your results on the Maintenance Test Checklist.

After approximately 1 minute, a number appears in the upper middle area of

the NIBP simulator display.

If the simulator:

• displays a Volume Leak reading <55, then the R Series unit has passed the

test.

• displays a Volume Leak reading >5

test.

• displays no Volume Leak reading, but maintains a stable pressure reading

at or above 200 mmHg, then the R Series unit has passed the test; there is

no volume leak.

In addition, the R Series displays the simulator’s pressure reading in the “Cuff

Pressure” field.

After approximately 3 minutes, the valves on the R Series unit open.

The NIBP simulator terminates the Volume Leak Test.

The R Series returns to the main NIBP Service Mode screen, then to normal

Monitor mode operation.

6

, then the R Series unit has failed the

oo

oo

5

If you are using the Fluke® Biomedical CuftLink Simulator, the volume leak reading should be <10.

6

If you are using the Fluke® Biomedical CuftLink Simulator, the volume leak reading for a failure should be >10.

9650-0903-01 Rev. L 1-39

Page 50

R Series Service Manual

23.0NIBP Transducer Calibration Test

The NIBP module’s pressure transducers are factory-calibrated prior to shipment. However, you can perform a two-point calibration procedure

periodically to ensure accurate pressure measurements.

This test should be performed annually or every 10,000 readings, whichever comes first.

Tools Needed: NIBP simulator (The values and procedure provided in this manual are specific to the BP Pump 2)

Test Setup:

1. Connect the simulator’s hose to the NIBP connector on the R Series unit.

2. Configure the NIBP simulator to simulate cuff pressure. For example, on the BP Pump 2

• Press the MODE button three (3) times to go into Tests mode.

• Press the SELECT button once to access the Pressure Simulator screen.

3. Make sure the ECG cable is not connected to the R Series unit.

4. If the SpO

7

These instructions apply to the BP Pump 2; for equivalent devices, follow the manufacturer's instructions.

option is installed, make sure that the SpO2 patient cable is NOT connected to the R Series unit.

2

7

:

Do this... Observe this... Pass/Fail

23.1 Turn the Selector Switch to OFF.

After 10 seconds, press and hold the fourth

softkey from the left and turn the Selector

Switch to MONITOR.(AED units to ON)

23.2 Press the NIBP Calib softkey. The R Series displays the NIBP Transducer Calibration Screen.

23.3 On the NIBP simulator, set the pressure

parameter to 0 mmHg.

23.4 On the R Series unit, press the Set Low softkey

to calibrate the transducer to a 0 mmHg

pressure reading.

23.5 On the NIBP simulator, set the pressure