Yaesu ft 450 schematic

HF/50 MHz TRANSCEIVER

FT-450

Technical Supplement

©2007 VERTEX STANDARD CO., LTD.

Introduction

This manual provides technical information necessary

for servicing the FT-450 HF/50 MHz Transceiver.

Servicing this equipment requires expertise in handling

surface-mount chip components. Attempts by non-qualified persons to service this equipment may result in permanent damage not covered by the warranty, and may

be illegal in some countries.

EH024H90A

VERTEX STANDARD CO., LTD.

4-8-8 Nakameguro, Meguro-Ku, Tokyo 153-8644, Japan

VERTEX STANDARD

US Headquarters

10900 Walker Street, Cypress, CA 90630, U.S.A.

YAESU EUROPE B.V.

P.O. Box 75525, 1118 ZN Schiphol, The Netherlands

YAESU UK LTD.

Unit 12, Sun Valley Business Park, Winnall Close

Winchester, Hampshire, SO23 0LB, U.K.

VERTEX STANDARD HK LTD.

Unit 5, 20/F., Seaview Centre, 139-141 Hoi Bun Road,

Kwun Tong, Kowloon, Hong Kong

VERTEX STANDARD (AUSTRALIA) PTY., LTD.

Normanby Business Park, Unit 14/45 Normanby Road

Notting Hill 3168, Victoria, Australia

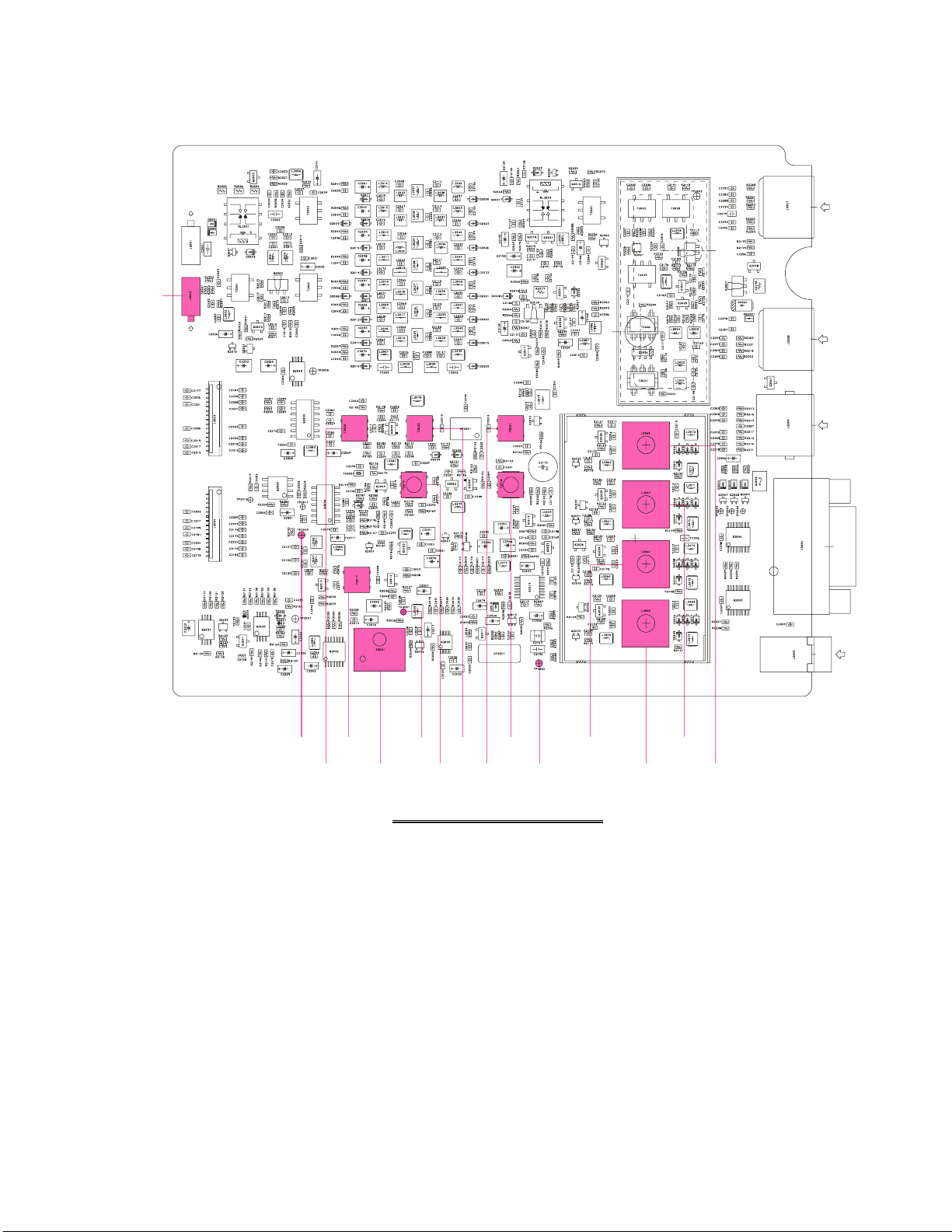

Two PCB layout diagrams are provided for each doublesided circuit board in the Transceiver. Each side of is referred to by the type of the majority of components installed on that side (“leaded” or “chip-only”). In most

cases one side has only chip components, and the other

has either a mixture of both chip and leaded components

(trimmers, coils, electrolytic capacitors, ICs, etc.), or leaded components only.

While we believe the technical information in this manual to be correct, VERTEX STANDARD assumes no liability for damage that may occur as a result of typographical or other errors that may be present. Your cooperation

in pointing out any inconsistencies in the technical information would be appreciated.

Contents

Specifications

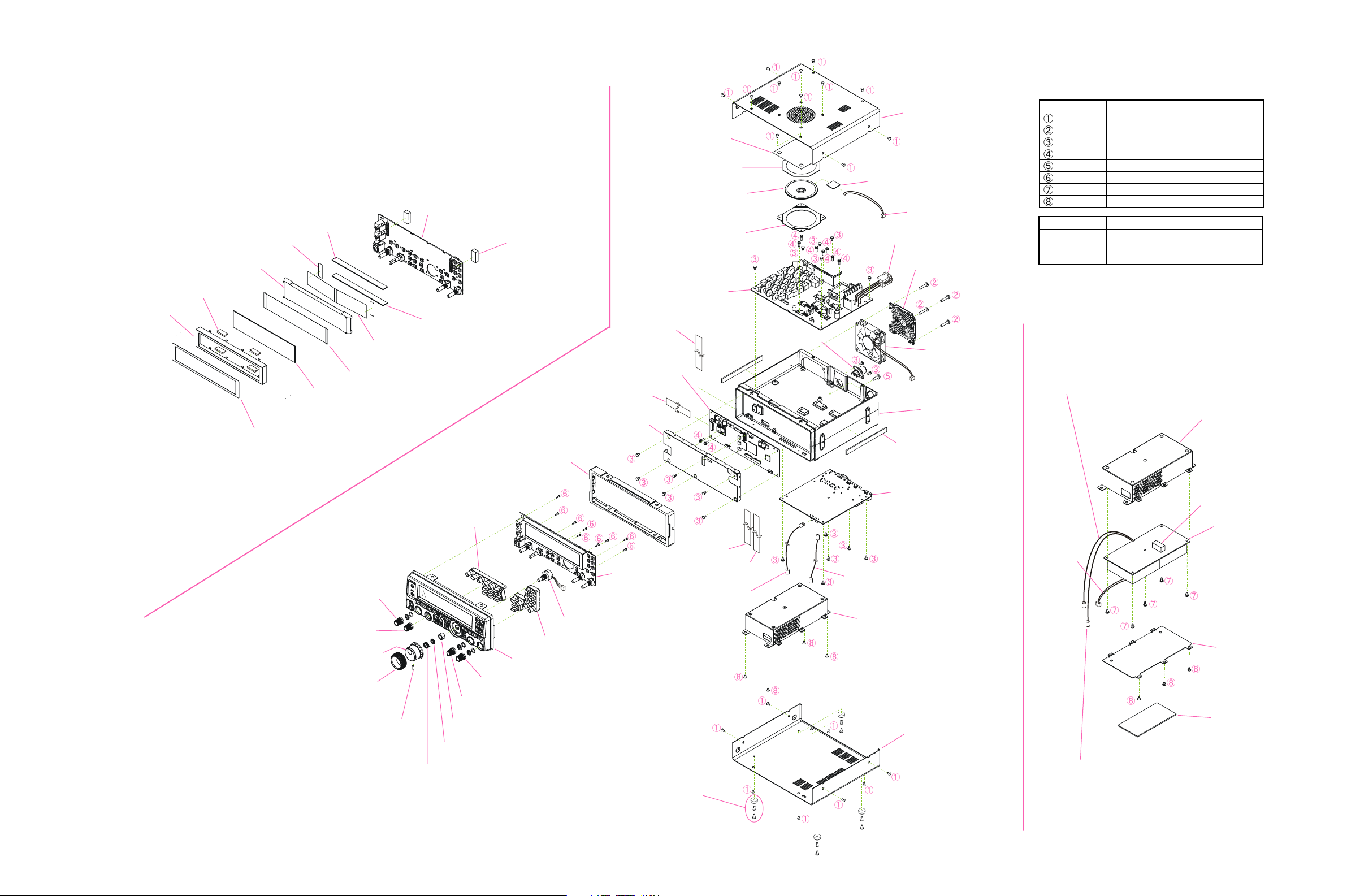

Exploded View & Miscellaneous Parts

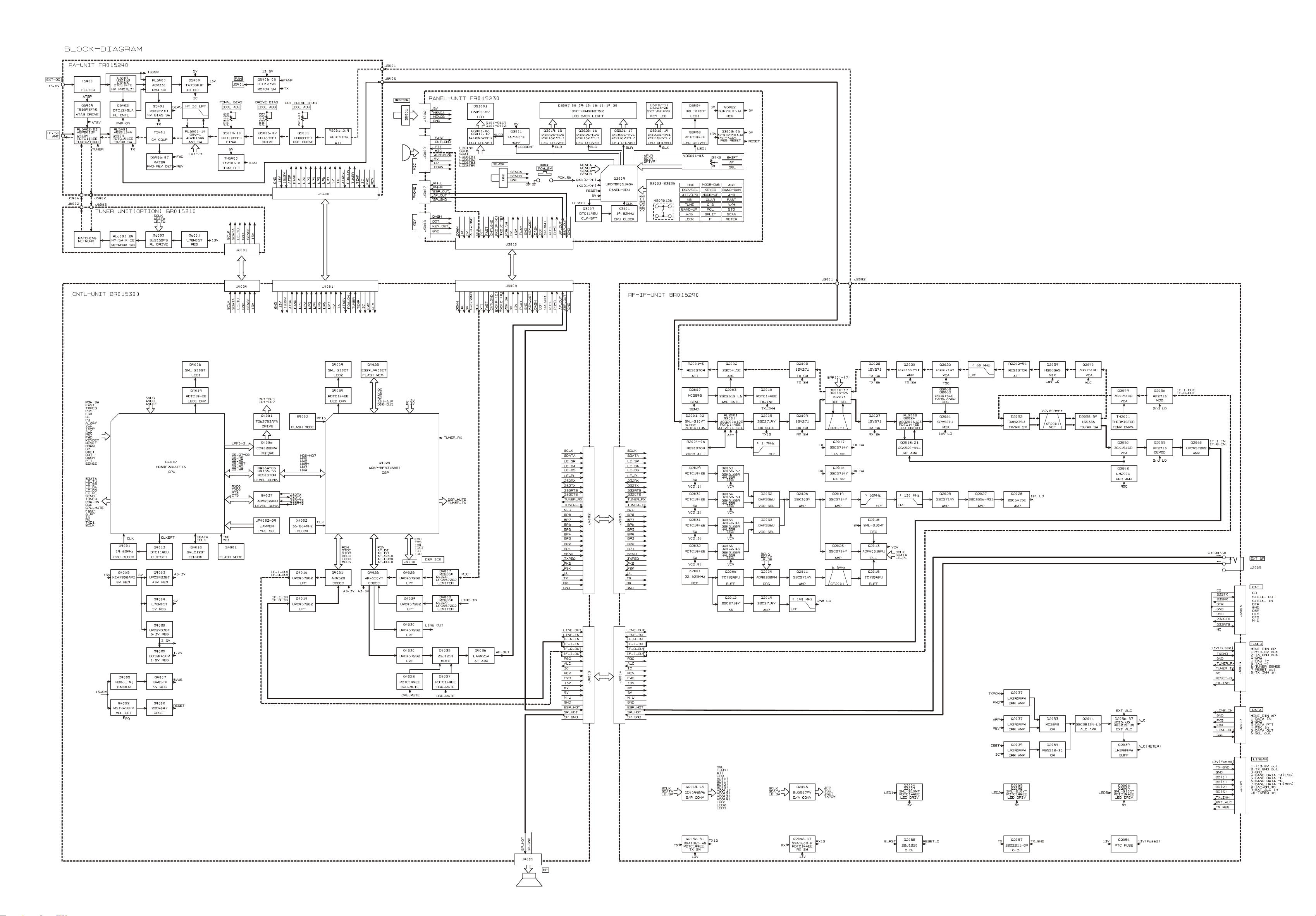

Block Diagram

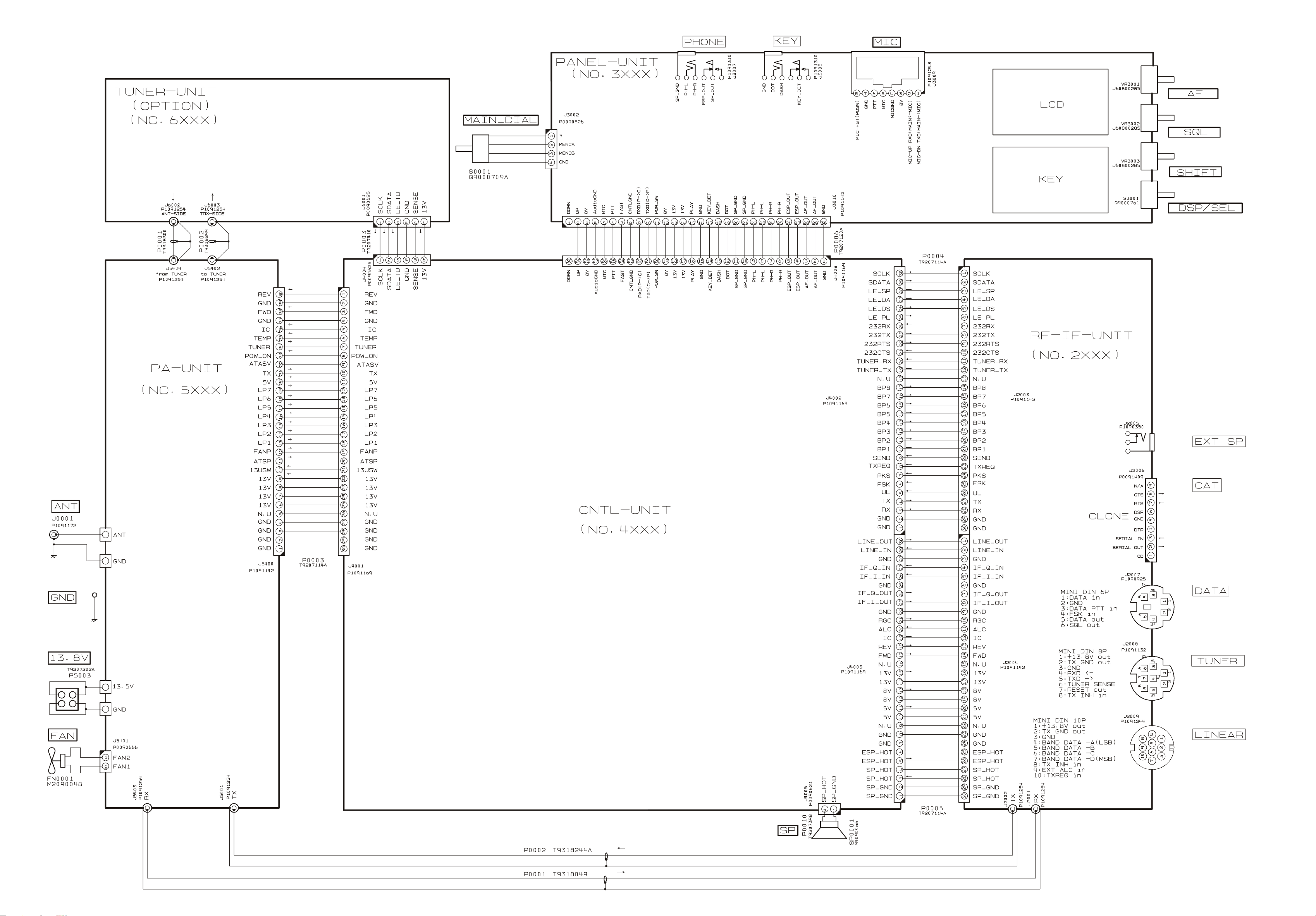

Connection Diagram

Alignment

Board Unit (Schematics, Layouts & Parts)

RF-IF Unit

PANEL Unit

CNTL Unit

PA Unit

TUNER Unit ATU-450 (Option)

Specifications

General

Rx Frequency Range: 30 kHz - 56 MHz (operating)

160 - 6 m (specified performance, Amateur bands only)

Tx Frequency Ranges: 160 - 6 m (Amateur bands only)

Frequency Stability: ±1 ppm/hour (@+25 °C, after warmup)

Operating Temperature Range: –10 °C ~ +50 °C

Emission Modes: A1A (CW), A3E (AM), J3E (LSB, USB), F3E (FM), F2D (DTMF TONE)

Frequency Steps: 10 Hz (SSB & CW), 100 Hz (AM & FM)

Antenna Impedance: 50 Ohms, unbalanced

Power Consumption: Rx (signal present) 1.5 A

Tx (100 W) 22 A

Supply Voltage: DC 13.8 V ± 10%

Dimensions (WxHxD): 9” x 3.3” x 8.5” (229 x 84 x 217 mm)

Weight (approx.): 7.9 lb (3.6 kg)

Transmitter

Power Output: 100 watts (25 watts AM carrier)

Modulation Types: J3E (SSB): Balanced,

A3E (AM): Low-Level (Early Stage),

F3E (FM): Variable Reactance

Maximum FM Deviation: ±5.0 kHz / ±2.5 kHz

Harmonic Radiation: Better than –60 dB (160 - 10m Amateur bands)

Better than –70 dB (6m Amateur band)

SSB Carrier Suppression: At least 60 dB below peak output

Undesired Sideband Suppression: At least 60 dB below peak output

Audio Response (SSB): Not more than –6 dB from 400 to 2600 Hz

3rd-order IMD: –31 dB @14 MHz 100 watts PEP

Microphone Impedance: 600 Ohms (200 to 10 kOhms)

SPECIFICATIONS-1

Receiver

Circuit Type: Double-conversion superheterodyne

Intermediate Frequencies: 67.899 MHz / 24 kHz

Sensitivity (IPO “OFF”, ATT: OFF): SSB (2.4 kHz, 10 dB S+N/N)

0.25 µV (1.8 - 2.0 MHz)

0.25 µV (3.5 - 30 MHz)

0.20 µV (50 - 54 MHz)

AM (6 kHz, 10 dB S+N/N, 30 % modulation @400 Hz)

2.00 µV (1.8 - 2.0 MHz)

2.00 µV (3.5 - 30 MHz)

1.00 µV (50 - 54 MHz)

FM (BW: 15 kHz, 12 dB SINAD)

0.50 µV (28 - 30 MHz)

0.30 µV (50 - 54 MHz)

There is no specification in frequency ranges not listed.

Squelch Sensitivity: SSB/CW/AM

(IPO “OFF”, ATT: OFF) 2.50 µV (1.8 - 30 MHz)

1.00 µV (50 - 54 MHz)

FM

0.32 µV (28 - 30 MHz)

0.16 µV (50 - 54 MHz)

There is no specification in frequency ranges not listed.

Selectivity (–6/–60 dB): Mode –6 dB –60 dB

CW 0.5 kHz or better 2.0 Hz or less

SSB 2.2 kHz or better 4.5 kHz or less

AM 6 kHz or better 20 kHz or less

FM 15 kHz or better 30 kHz or less

FM-N 9 kHz or better 25 kHz or less

Image Rejection: 80 dB or better (160 - 10m Amateur bands)

65 dB or better (6m Amateur band)

Maximum Audio Output: SSB/CW 1.5 W into 8 Ohms with 10% THD

AM/FM 0.6 W into 8 Ohms with 10% THD

Audio Output Impedance: 4 to 16 Ohms (8 Ohms: nominal)

Conducted Radiation: Less than 4000 µµW

Specifications

Specifications are subject to change, in the interest of technical improvement, without notice or obligation, and are guaranteed only within the

amateur bands.

SPECIFICATIONS-2

Specifications

Note

SPECIFICATIONS-3

Exploded View & Miscellaneous Parts

RA0899500

LCD HOLDER

RA0931100 (X2 pcs)

LIGHT SHEET

RA089970A

LIGHT GUIDE

RA0940000 (X4 pcs)

TAPE

RA0900000

INTER CONNECTOR

RA089960A

SPONGE (LCD)

LCD

RA089980C

REFLECTOR SHEET

RA094710A

SHEET

PANEL Unit

RA0900000

INTER CONNECTOR

RA0951800 (X 2pcs)

PAD

RA0898800

SHIELD COVER (CTRL)

RA089870A

RUBBER PACKING

T9207114A

WIRE ASSY

T9207120A

WIRE ASSY

CNTL Unit

RA089840A

SP NET

RA0924900

SPONGE (SP)

M4090066

SPEAKER

RA0898600

SP HOLDER

PA Unit

P1091172

RF CONNECTOR

RA0898200

TOP CASE

S6000427

CLAMP

T9207202A

WIRE ASSY

RA0925700 (X2 pcs)

SPONGE (CHASSIS)

T9207398A

WIRE ASSY

RA0898900

FAN COVER

M2090048

FAN

RA0898000

CHASSIS

No. VXSTD P/N Decription Qty.

U31306007 OVAL HEAD SCREW M3X6B 20

U20420007 BINDING HEAD SCREW M4X20B 4

U24306002 BIND HEAD TAPTITE-B M3X6NI 20

U03310002 SEMS SCREW ASM3X10NI 9

U04410002 SEMS SCREW HSM4X10NI 1

U24108002 BIND HEAD TAPTITE-B M2X8NI 9

U20306002 BINDING HEAD SCREW M3X6NI 5

U30305002 FLAT HEAD SCREW M3X5NI 7

VXSTD P/N Decription Qty.

Q0000074 BLADE FUSE 25A 1

M3090122A MICROPHONE MH-67A8J W/CLIP 1

T9023725 DC CABLE 04P 25AX2 3000MM 1

TUNER Unit ATU-450 (Option)

T9318299

WIRE ASSY (GRN 250 TMP/TMP)

RA0901500

SHIELD CASE ASSY

RA0900800

KNOB

RA0900700

KNOB

RA0900100

KNOB MAIN ASSY

RA0900400

RUBBER RING

U91408007

HEX SOCKET SCREW

RA090090A

RUBBER KNOB

RA0900800

KNOB

R6144801

NUT

R3135000A

WASHER

R0136380

COIL SPRING

RA089920A

PANEL ASSY

RA0900800

KNOB

Q9000709A

ROTARY ENCODER

RA090100A

RUBBER KNOB

T9207114A

WIRE ASSY

PANEL Unit

T9318244A

WIRE ASSY (GRA 250 TMP/TMP)

S4000043 (X4 pcs)

CASE LEG

T9207114A

WIRE ASSY

RF-IF Unit

T9318049

WIRE ASSY (GRN 500 TMP/TMP)

ANT TUNER ASSY

RA0898500

BOTTOM CASE

T9207410

WIRE ASSY

T9318300

WIRE ASSY(GRA 320 TMP/TMP)

RA0951800

PAD

TUNER Unit

RA0901700

SHIELD PLATE

RA0901800

SPONGE RUBBER

FT-450 Technical Supplement

Exploded View-1

Exploded View & Miscellaneous Parts

Note

Exploded View-2

FT-450 Technical Supplement

Block Diagram

BLOCK DIAGRAM-1FT-450 Technical Supplement

Connection Diagram

CONNECTION DIAGRAM-1 FT-450 Technical Supplement

Alignment

Introduction and Precautions

The following procedures cover adjustments that are

not normally required once the transceiver has left

the factory. However, if a problem occurs during

normal operation due to component failure; realignment may be required after the faulty components

have been replaced.

We recommend that authorized Vertex Standard

Technicians, who are experienced with the circuitry

and fully equipped to repair and align our products,

perform repairs. If a fault is suspected, contact the

selling dealer for instructions regarding repair. Authorized Vertex Standard Technicians have the latest information to align all circuits and make complete performance checks to ensure compliance with

factory specifications after repairs.

Those who undertake the following alignments are

cautioned to proceed at their own risk. Problems

caused by unauthorized attempts at realignment are

not covered by the warranty policy.

Vertex Standard must reserve the right to change

circuits and alignment procedures in the interest of

improved performance, without notifying owners.

Under no circumstances should any alignment be

attempted unless the normal functions and operation of the transceiver are clearly understood, the

cause of the malfunction has been clearly identified

and all faulty components replaced. The need for

realignment should be determined to be necessary.

The following test equipment (and a thorough familiarity with its correct use) is necessary for correct

alignment. Most steps do not require all of the equipment listed. The interactions of some adjustments

may require that several adjustments be performed

in a sequence. Do not attempt to perform only a single step unless it is clearly isolated electrically from

all other steps. Have all test equipment ready before

beginning, and follow all of the steps in a section in

the order they are presented.

Required Test Equipment

RF Signal Generator

AF Signal Generator

Spectrum Analyzer good to at least 1 GHz.

Frequency Counter

SINAD Meter

RF Millivoltmeter

Digital DC Voltmeter (high-Z, 1 M-Ohm/V)

DC Voltmeter

DC Ammeter (20 A)

Ohmmeter

50-Ohm Dummy Load (100 watts)

16.6-Ohm Dummy Load (100 watts)

In-Line Wattmeter (100 watts, 50-Ohm)

Linear Detector

RF Coupler

4-Ohm AF Dummy Load (3 watts)

Alignment Preparation & Precautions

A 50-ohm RF Dummy load and in-line wattmeter

must be connected to the "ANT" jack in all procedures that call for transmission, except where specified otherwise. Correct alignment is not possible with

an antenna.

After completing one step, read the following step

to determine whether the same test equipment will

be required. If not, remove the unneeded test equipment before proceeding (except the dummy load and

wattmeter).

Correct alignment requires that the ambient temperature be maintained constant between 68 °F ~ 86 °F

(20 °C ~ 30 °C). When the transceiver is brought into

the shop from a hot or cold environment, it should

be allowed time to come to room temperature before alignment. Also, the test equipment must be

thoroughly warmed up before beginning.

Whenever possible, alignments should be made with

oscillator shields and circuit boards firmly affixed in

place.

Note: Signal levels in dB referred to in this proce-

dure are based on 0 dBµ = 0.5 µV (closed circuit).

ALIGNMENT-1

Alignment

Reference Frequency

Connect the Frequency Counter to TP2001 on the

RF-IF-Unit.

Adjust X2001 so that the Frequency Counter read-

ing is 22.625 MHz ±10 Hz.

2nd Local Carrier Output Level

Connect the RF millivoltmeter to TP2009 on the

RF-IF-Unit.

Adjust T2017 on the RF-IF-Unit for maximum

deflection on the RF millivoltmeter (more than

25 mVrms).

PLL VCV Voltage

Connect the Digital DC voltmeter (high-Z) to

TP2006 on the RF-IF-Unit.

Set the [MODE] switch to FM.

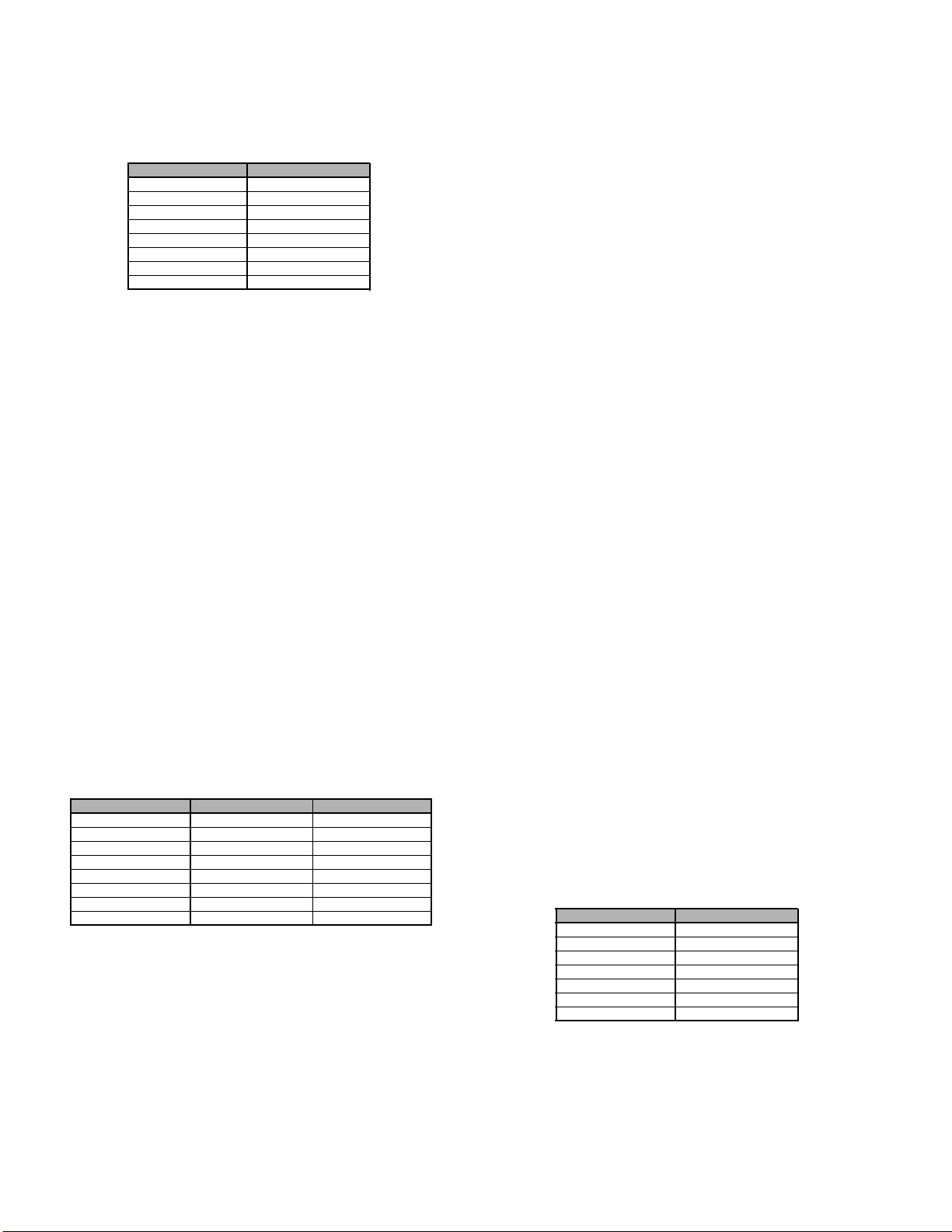

Referring to the table below, adjust the listed com-

ponents for the required voltage, or confirm that

the correct voltage is present on each frequency

listed.

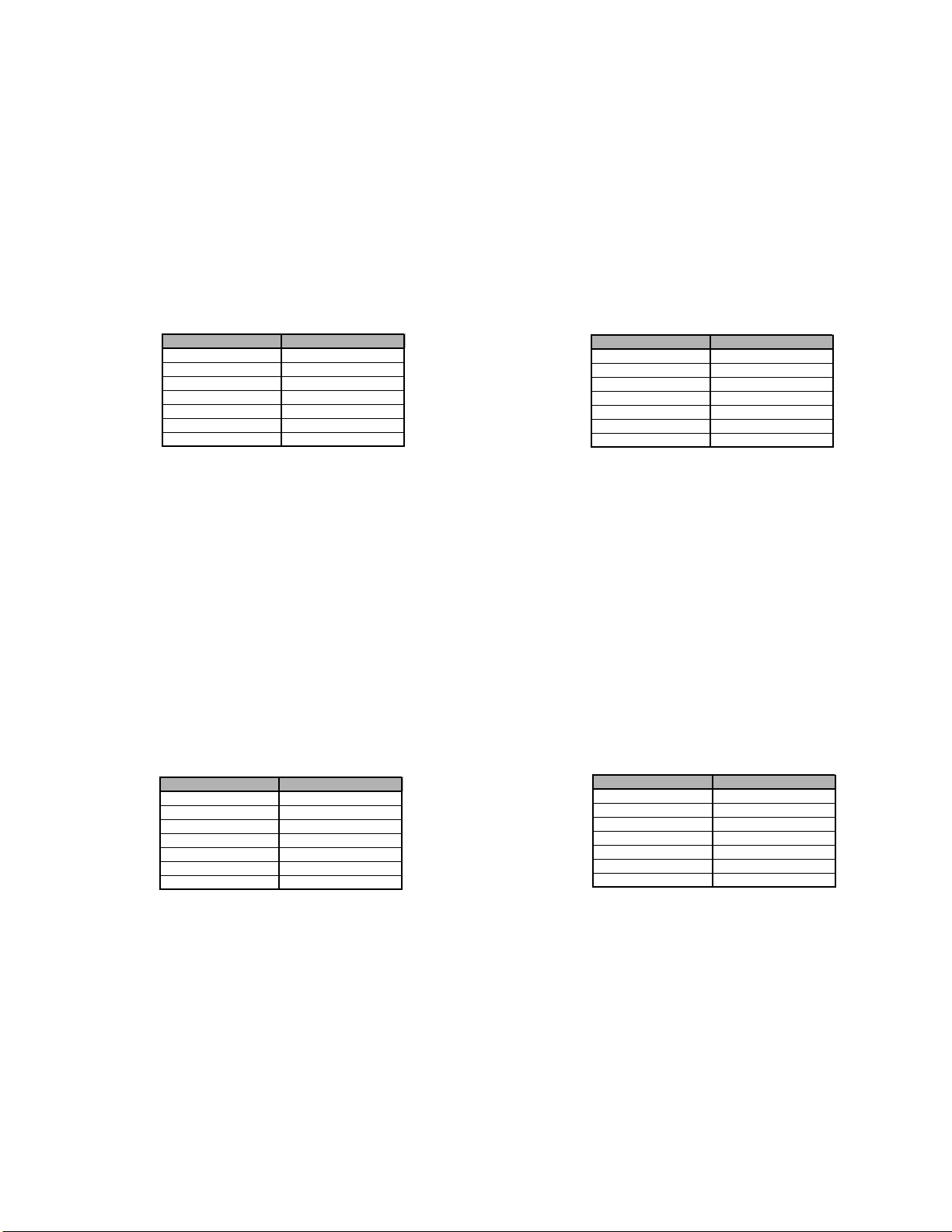

VFO-A FREQUENCY

13.499 MHz

0.030 MHz

29.999 MHz

13.500 MHz

44.499 MHz

30.000 MHz

55.999 MHz

44.500 MHz

ADJUST / CONFIRM

Adjust L2065

Confirm

Adjust L2066

Confirm

Adjust L2067

Confirm

Adjust L2068

Confirm

DC VOLTMETER

5.2 V ± 0.1 V

At least 0.5 V

5.2 V ± 0.1 V

At least 0.5 V

5.2 V ± 0.1 V

At least 0.7 V

5.2 V ± 0.1 V

At least 0.7 V

TX IF Circuit (SSB/CW)

Connect the 50-Ohm Dummy Load and Wattme-

ter to the "ANT" jack.

Disconnect the TMP plug from J2002 on the RF-

IF-Unit, and then connect the RF millivoltmeter

and 50 Ohm dummy load to J2002.

Inject the 1 mV, 1 kHz audio signal to pin 5 of

MIC jack.

Set the transceiver to 7.000 MHz, USB mode.

Press the PTT button; adjust T2018, T2019, T2021,

and T2022 on the RF-IF-Unit for maximum deflection on the RF millivoltmeter.

Disconnect the RF millivoltmeter and 50 Ohm

dummy load from J2002 on the RF-IF-Unit, then

re-connect the TMP plug to J2002.

RX IF Circuit (SSB/CW)

Set the following controls as indicated:

[IPO]: OFF

[ATT ]: OFF

[RF GAIN] knob: Fully clockwise

Connect the AF millivoltmeter and 4 Ohm

dummy load to the EXT SPKR jack.

Connect the RF Signal Generator to the "ANT"

jack, and then set the output level to 0 dBµV at

the 51.995 MHz.

Set the transceiver to 51.995 MHz in the CW

mode.

Adjust T2020 on the RF-IF-Unit for maximum

deflection on the AF millivoltmeter.

RX IF Circuit (FM)

Set the following controls as indicated:

[IPO]: OFF

[ATT ]: OFF

[RF GAIN] knob: Fully clockwise

Connect the SINAD meter and 4-Ohm dummy

load to the EXT SPKR jack.

Connect the RF Signal Generator to the "ANT"

jack, and then set the RF Signal Generator to

51.995 MHz at the level of 0 dBµV, ± 3.0 kHz deviation with a 1 kHz audio tone.

Set the transceiver to 51.995 MHz in the FM mode.

Adjust T2021 and T2022 on the RF-IF-Unit for

maximum deflection on the SINAD meter.

ALIGNMENT-2

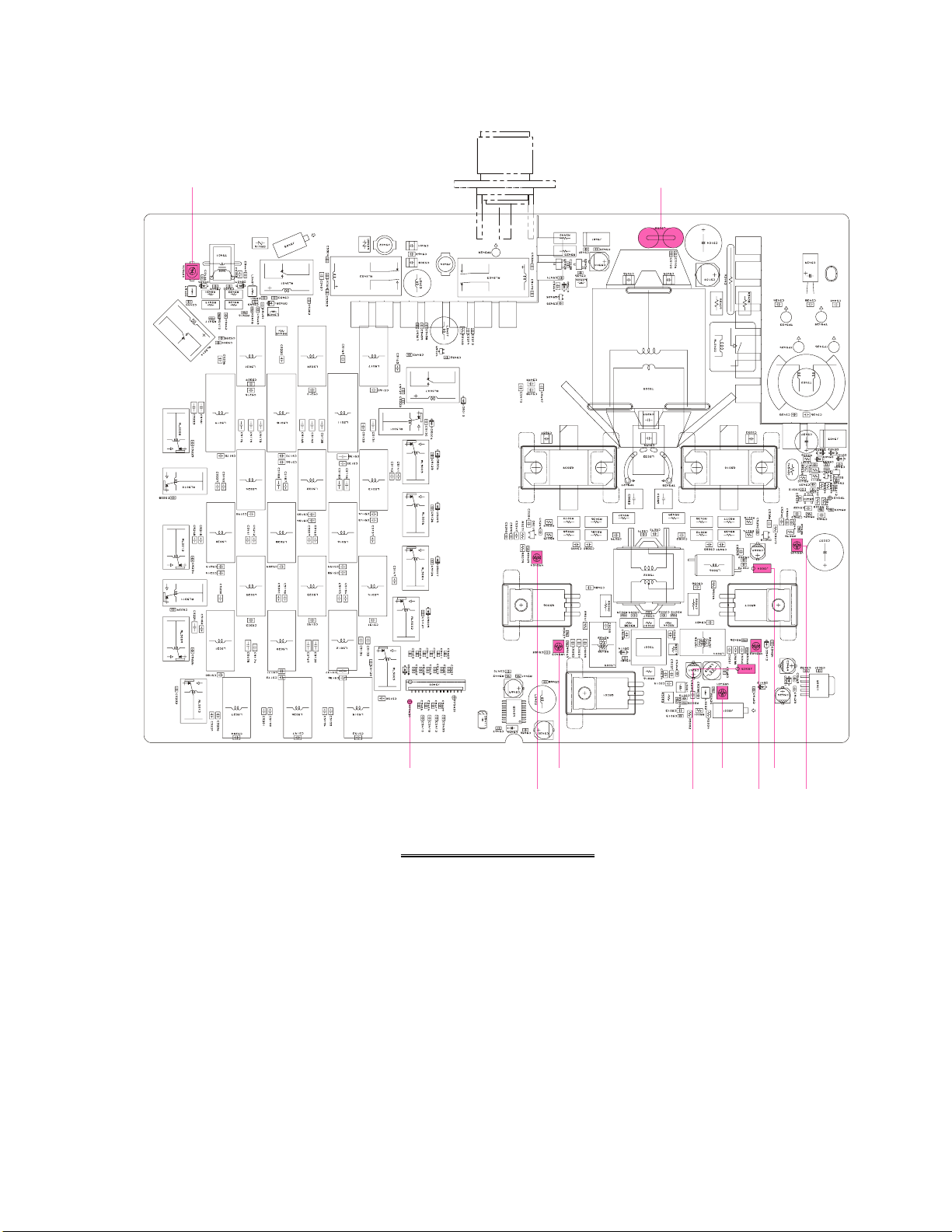

J2002

Alignment

T2020

T2021

T2018

TP2006

TP2001TP2009 T2017

X2001 T2019

T2022

RF-IF UNIT ALIGNMENT POINTS

L2066

L2065

L2067

L2068

ALIGNMENT-3

Alignment

PA Unit

Preparation

Connect the 50-Ohm Dummy Load and Wattme-

ter to the "ANT" jack.

Cut the lead of L5008 on the PA Unit.

Set VR5401, VR5402, VR5403, and VR5404 on the

PA Unit to fully counter clockwise position.

Set the transceiver to 14.150 MHz in the USB

mode.

Pre-Drive Stage Idling Current

Disconnect the jumper plug from J5003 on the

PA Unit, and then connect the DC ammeter to

J5003.

Press the PTT button; adjust VR5401 on the PA

Unit so the DC ammeter reading is 100 mA ± 10

mA.

Release the PTT button.

Drive Stage Idling Current

Disconnect the jumper plug from J5004 on the

PA Unit, and then connect the DC ammeter to

J5004.

Press the PTT button; adjust VR5402 on the PA

Unit so that the DC ammeter reading is 0.5 A ± 50

mA.

Release the PTT button.

Press the PTT button; adjust VR5403 on the PA

Unit so the DC ammeter reading is 1.0 A ± 50 mA.

Release the PTT button.

Final Stage Idling Current

Connect the DC ammeter to the lead of L5008.

Press the PTT button; adjust VR5404 on the PA

Unit so the DC ammeter reading is 1.0 A ± 100

mA.

Release the PTT button.

Press the PTT button; adjust VR5405 on the PA

Unit so the DC ammeter reading is 2.0 A ± 100

mA.

Release the PTT button.

Concluding

Re-connect the jumper plugs to J5003 and J5004,

and then solder the lead of L5008.

CM Coupler Balance

Connect the DC voltmeter between TP5430 (+

lead) on the PA Unit and Chassis (- lead).

Set the transceiver to 29.200 MHz in the CW

mode.

Press the PTT switch; adjust TC5400 on the PA

Unit for minimum deflection on the DC voltmeter (less than 0.1 V).

Release the PTT switch.

ALIGNMENT-4

Alignment

TC5400

L5008

TP5430

VR5403

PA U NIT ALIGNMENT POINTS

J5003

VR5401

J5004

VR5402VR5404 VR5405

ALIGNMENT-5

Alignment

Software Adjustment

Preparation

Set the VFO frequency for each band as indicated:

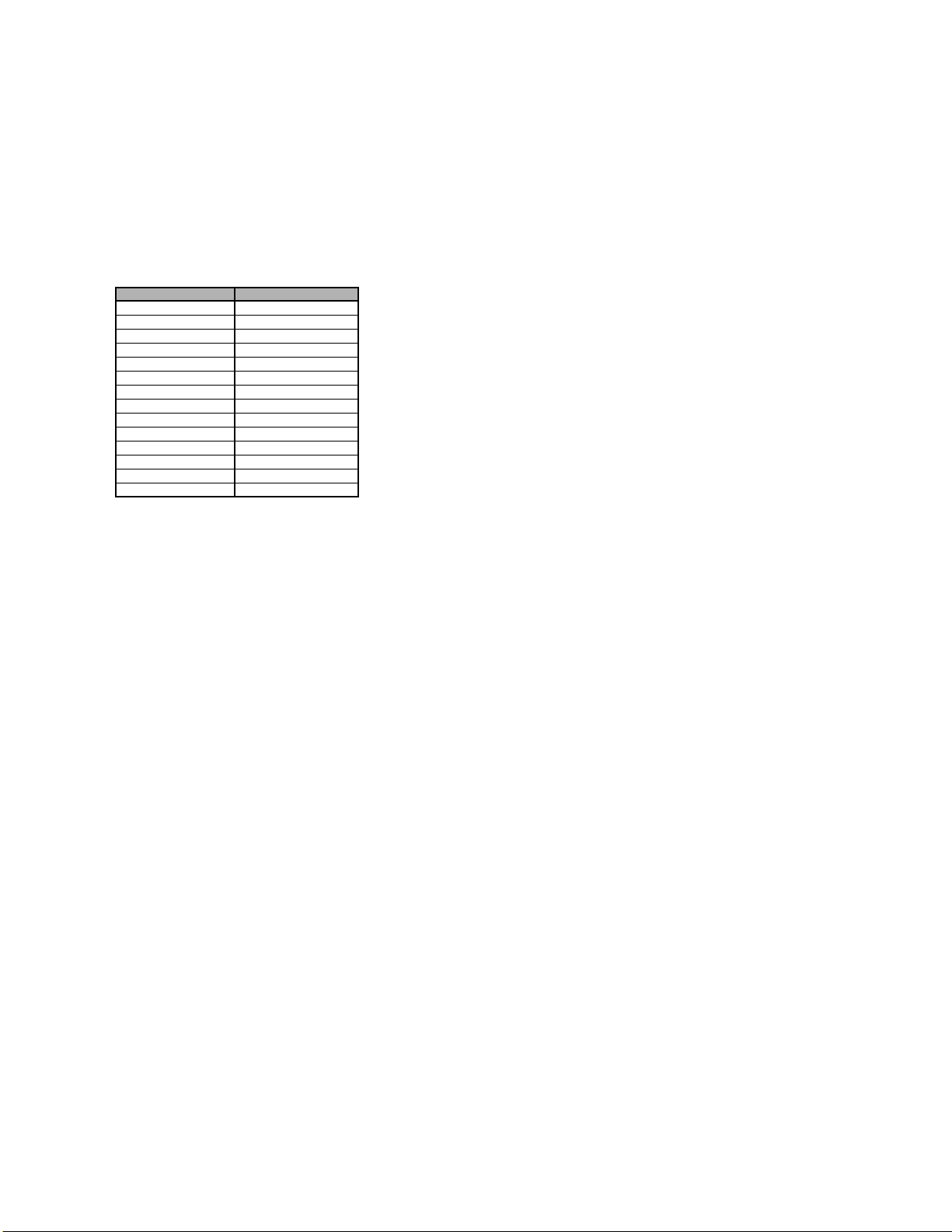

OPERATING BAND

General Band

1.8 MHz Band

3.5 MHz Band

7 MHz Band

14 MHz Band

21 MHz Band

28 MHz Band

50 MHz Band

Set the following controls as indicated:

[IPO] button: OFF

[ATT ] button: OFF

[AGC] button: AUTO

[SHIFT] knob: 12-o'clock position

[AF GAIN] knob: 12-o'clock position

[RF GAIN] knob: Fully clockwise

MODE: CW

CONTOUR: OFF

NOTCH: OFF

DNR: OFF

S-meter Adjustment

Connect the RF Signal Generator to the "ANT"

jack.

Press and hold in the [ATT/IPO], [NB], and [AGC]

buttons, while turning the radio on, to enter the

alignment mode.

Select the appropriate "Alignment Parameter"

using the [DSP/SEL] knob per the chart below,

then set the RF Signal Generator output to each

level, and adjust the [MAIN DIAL] knob for the

corresponding S-meter deflection.

ALIGNMENT PARAMETER

SMADJ0

SMADJ1

SMADJ2

SMADJ3

SMADJ4

SMADJ5

SMADJ6

SMADJ

RF SIGNAL GENERATOR

1.200 MHz, 32 dBµ

1.900 MHz, 12 dBµ

3.750 MHz, 12 dBµ

7.150 MHz, 12 dBµ

14.175 MHz, 12 dBµ

21.255 MHz, 12 dBµ

28.850 MHz, 12 dBµ

52.000 MHz, 12 dBµ

Press and hold in the [F] button for 2 seconds to

save the new settings and exit from the alignment

mode.

FREQUENCY

1.200 MHz

1.900 MHz

3.750 MHz

7.150 MHz

14.175 MHz

21.255 MHz

28.850 MHz

52.000 MHz

S-METER

S-1 (3 dots)

S-1 (3 dots)

S-1 (3 dots)

S-1 (3 dots)

S-1 (3 dots)

S-1 (3 dots)

S-1 (3 dots)

S-1 (3 dots)

ALC Adjustment

Connect the 50-Ohm Dummy Load and Wattme-

ter to the "ANT" jack.

Press and hold in the [ATT/IPO], [NB], and [AGC]

buttons, while turning the radio on, to enter the

alignment mode.

Rotate the [DSP/SEL] knob to select the align-

ment parameter "I-ALC1".

Press the PTT switch, then rotate the [MAIN DIAL]

knob for 140 W ± 10 W on the Wattmeter. Note

the alignment value which is displayed on the

frequency display area of the LCD.

Release the PTT switch.

Rotate the [DSP/SEL] knob to select the align-

ment parameter "I-ALC2".

Press the PTT switch, then rotate the [MAIN DIAL]

for 110 W ± 5 W on the Wattmeter.

Release the PTT switch.

Rotate the [DSP/SEL] knob to select the align-

ment parameter "I-ALC3".

Rotate the [MAIN DIAL] knob to set an alignment

value to same value, which was noted in the previous step ("I_ALC1").

Press and hold in the [F] button for 2 seconds to

save the new setting and exit from the alignment

mode.

Power Adjustment (100 W)

Connect the 50-Ohm Dummy Load and Wattme-

ter to the "ANT" jack.

Press and hold in the [ATT/IPO], [NB], and [AGC]

buttons, while turning the radio on, to enter the

alignment mode.

Select the appropriate "Alignment Parameter"

using the [DSP/SEL] knob per the chart below,

and adjust the [MAIN DIAL] knob for the corre-

sponding Wattmeter deflection while pressing

the PTT switch.

ALIGNMENT PARAMETER

1PO100

2PO100

3PO100

4PO100

5PO100

6PO100

7PO100

WATTMETER

100 W ±2 W

100 W ±2 W

100 W ±2 W

100 W ±2 W

100 W ±2 W

90 W ±2 W

100 W ±2 W

ALIGNMENT-6

Press and hold in the [F] button for 2 seconds to

save the new settings and exit from the alignment

mode.

Alignment

Power Adjustment (50 W)

Connect the 50-Ohm Dummy Load and Wattme-

ter to the "ANT" jack.

Press and hold in the [ATT/IPO], [NB], and [AGC]

buttons, while turning the radio on, to enter the

alignment mode.

Select the appropriate "Alignment Parameter"

using the [DSP/SEL] knob per the chart below,

and adjust the [MAIN DIAL] knob for the corre-

sponding Wattmeter deflection while pressing

the PTT switch.

ALIGNMENT PARAMETER

1PO 50

2PO 50

3PO 50

4PO 50

5PO 50

6PO 50

7PO 50

WATTMETER

50 W ±2 W

50 W ±2 W

50 W ±2 W

50 W ±2 W

50 W ±2 W

50 W ±2 W

50 W ±2 W

Press and hold in the [F] button for 2 seconds to

save the new settings and exit from the alignment

mode.

Power Adjustment (20 W)

Connect the 50-Ohm Dummy Load and Wattme-

ter to the "ANT" jack.

Press and hold in the [ATT/IPO], [NB], and [AGC]

buttons, while turning the radio on, to enter the

alignment mode.

Select the appropriate "Alignment Parameter"

using the [DSP/SEL] knob per the chart below,

and adjust the [MAIN DIAL] knob for the corre-

sponding Wattmeter deflection while pressing

the PTT switch.

ALIGNMENT PARAMETER

1PO 20

2PO 20

3PO 20

4PO 20

5PO 20

6PO 20

7PO 20

WATTMETER

20 W ±2 W

20 W ±2 W

20 W ±2 W

20 W ±2 W

20 W ±2 W

20 W ±2 W

20 W ±2 W

Power Adjustment (10 W)

Connect the 50-Ohm Dummy Load and Wattme-

ter to the "ANT" jack.

Press and hold in the [ATT/IPO], [NB], and [AGC]

buttons, while turning the radio on, to enter the

alignment mode.

Select the appropriate "Alignment Parameter"

using the [DSP/SEL] knob per the chart below,

and adjust the [MAIN DIAL] knob for the corre-

sponding Wattmeter deflection while pressing

the PTT switch.

ALIGNMENT PARAMETER

1PO 10

2PO 10

3PO 10

4PO 10

5PO 10

6PO 10

7PO 10

WATTMETER

10 W ±1 W

10 W ±1 W

10 W ±1 W

10 W ±1 W

10 W ±1 W

10 W ±1 W

10 W ±1 W

Press and hold in the [F] button for 2 seconds to

save the new settings and exit from the alignment

mode.

Power Adjustment (5 W)

Connect the 50-Ohm Dummy Load and Wattme-

ter to the "ANT" jack.

Press and hold in the [ATT/IPO], [NB], and [AGC]

buttons, while turning the radio on, to enter the

alignment mode.

Select the appropriate "Alignment Parameter"

using the [DSP/SEL] knob per the chart below,

and adjust the [MAIN DIAL] knob for the corre-

sponding Wattmeter deflection while pressing

the PTT switch.

ALIGNMENT PARAMETER

1PO 5

2PO 5

3PO 5

4PO 5

5PO 5

6PO 5

7PO 5

WATTMETER

5 W ±1 W

5 W ±1 W

5 W ±1 W

5 W ±1 W

5 W ±1 W

5 W ±1 W

5 W ±1 W

Press and hold in the [F] button for 2 seconds to

save the new settings and exit from the alignment

mode.

Press and hold in the [F] button for 2 seconds to

save the new settings and exit from the alignment

mode.

ALIGNMENT-7

Alignment

TX Gain Adjustment

Connect the 50-Ohm Dummy Load and Wattme-

ter to the "ANT" jack.

Connect the Audio Generator to pin 5 of the MIC

jack (pin 7: GND), then set the output level to 1

mV @1 kHz.

Press and hold in the [ATT/IPO], [NB], and [AGC]

buttons, while turning the radio on, to enter the

alignment mode.

ALIGNMENT PARAMETER

TXG1H

TXG2H

TXG3H

TXG4H

TXG5H

TXG6H

TXG7H

TXG1L

TXG2L

TXG3L

TXG4L

TXG5L

TXG6L

TXG7L

WATTMETER

50 W ±10 W

50 W ±10 W

50 W ±10 W

50 W ±10 W

50 W ±10 W

50 W ±10 W

50 W ±10 W

10 W ±2 W

10 W ±2 W

10 W ±2 W

10 W ±2 W

10 W ±2 W

10 W ±2 W

10 W ±2 W

Press and hold in the [F] button for 2 seconds to

save the new settings and exit from the alignment

mode.

AM Carrier Level Adjustment

Connect the 50-Ohm Dummy Load and Wattme-

ter to the "ANT" jack.

Press and hold in the [ATT/IPO], [NB], and [AGC]

buttons, while turning the radio on, to enter the

alignment mode.

Set the [MODE] switch to "AM".

Rotate the [DSP/SEL] knob to select the align-

ment parameter "AM-CAR".

Press the PTT switch, then rotate the [MAIN DIAL]

knob for 25 W±2 W on the Wattmeter.

Release the PTT switch.

Press and hold in the [F] button for 2 seconds to

save the new setting and exit from the alignment

mode.

ALC Meter Adjustment

Connect the 50-Ohm Dummy Load and Wattme-

ter to the "ANT" jack.

Press and hold in the [ATT/IPO], [NB], and [AGC]

buttons, while turning the radio on, to enter the

alignment mode.

Rotate the [DSP/SEL] knob to select the align-

ment parameter "ALCM L".

Press the PTT switch, then press the [STO] but-

ton.

Connect the Audio Generator to pin 5 of the MIC

jack (pin 7: GND), then set the output level to 4

mV @1 kHz.

Rotate the [DSP/SEL] knob to select the align-

ment parameter "ALCM H".

Press the PTT switch, then press the [STO] button.

Press and hold in the [F] button for 2 seconds to

save the new setting and exit from the alignment

mode.

Reverse ALC Adjustment

Connect the 16.6-Ohm Dummy Load (parallel

connections of the three 50-Ohm Dummy Loads)

to the "ANT" jack.

Press and hold in the [ATT/IPO], [NB], and [AGC]

buttons, while turning the radio on, to enter the

alignment mode.

Rotate the [DSP/SEL] knob to select the align-

ment parameter "1-RALC".

Press the PTT switch, then rotate the [MAIN DIAL]

knob for 50 W on the PO meter of the FT-450.

Release the PTT switch.

Rotate the [DSP/SEL] knob to select the align-

ment parameter "2-RALC".

Press the PTT switch, then rotate the [MAIN DIAL]

knob for 50 W on the PO meter of the FT-450.

Release the PTT switch.

Rotate the [DSP/SEL] knob to select the align-

ment parameter "3-RALC".

Press the PTT switch, then rotate the [MAIN DIAL]

knob for 50 W on the PO meter of the FT-450.

Release the PTT switch.

Rotate the [DSP/SEL] knob to select the align-

ment parameter "50RALC".

Press the PTT switch, then rotate the [MAIN DIAL]

knob for 50 W on the PO meter of the FT-450.

Release the PTT switch.

Press and hold in the [F] button for 2 seconds to

save the new settings and exit from the alignment

mode.

ALIGNMENT-8

Alignment

Voltmeter Adjustment

Press and hold in the [ATT/IPO], [NB], and [AGC]

buttons, while turning the radio on, to enter the

alignment mode.

Adjust the DC Power Supply voltage is exactly

13.8 V.

Rotate the [DSP/SEL] knob to select the align-

ment parameter "VM-ADJ".

Press the [STO] button.

Press and hold in the [F] button for 2 seconds to

save the new setting and exit from the alignment

mode.

ATAS Controller Adjustment

Connect the Digital DC voltmeter (high-Z) to the

"ANT" jack.

Press and hold in the [ATT/IPO], [NB], and [AGC]

buttons, while turning the radio on, to enter the

alignment mode.

Rotate the [DSP/SEL] knob to select the align-

ment parameter "ATAS DN".

Press the [STO] button, then rotate the [MAIN

DIAL] knob for 8.0 V on the DC Voltmeter.

Rotate the [DSP/SEL] knob to select the align-

ment parameter "ATAS BK".

Press the [STO] button, then rotate the [MAIN

DIAL] knob for 9.5 V on the DC Voltmeter.

Rotate the [DSP/SEL] knob to select the align-

ment parameter "ATAS UP".

Press the [STO] button, confirm that the DC Volt-

meter reading is more than 10.5 V.

Press and hold in the [F] button for 2 seconds to

save the new settings and exit from the alignment

mode.

ALIGNMENT-9

Alignment

Note

ALIGNMENT-10

RF-IF Unit

Circuit Diagram

FT-450 Technical Supplement

RF-IF-1

RF-IF Unit

Note

RF-IF-2

FT-450 Technical Supplement

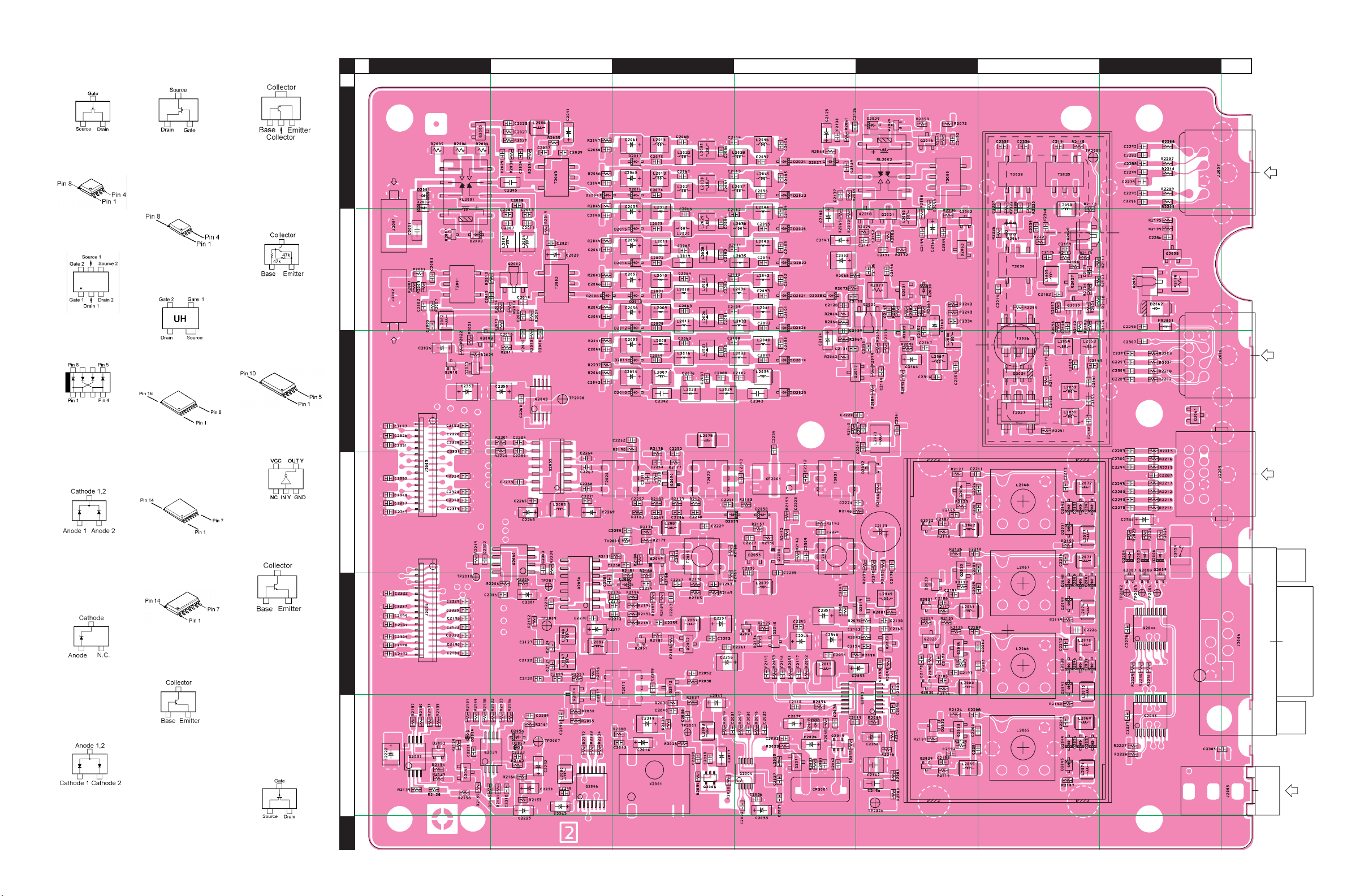

Parts Layout (Side A)

A B C D E

RF-IF Unit

F

HG

2SK520 (K41)

(Q 2018,Q 2021)

UPC4572G2

(Q2060)

SPM5001

(Q 2061)

HSB88WS

(D 2034)

2SK302Y (TY)

(Q2026)

2SK210 (YG)

(Q2033, 2034,

2035, 2036)

LM2904PWR

(Q2037, 2039, 2043)

3SK151GR

(Q2040, 2049, 2050)

ADF4001BRUZ

(Q2013)

CD4094BPWR

(Q2044, 2045)

2SC5415E (EA)

(Q2002, 2028)

2SC3357 (RK)

(Q2020)

2SD2211 (DQR)

(Q 2057)

PDTC144EE (08)

(Q2001, 2007, 2008,

Q2009, 2010, 2024,

Q2029, 2030, 2031,

Q2032, 2047, 2051)

AD9833BRMZ

(Q2004)

1

2

3

MC2848

(D2007, 2053)

DAN235U

(D 2052)

HZM7.5NB3

(D2031, 2055)

HZM5.6NB2

(D2063)

HZM27WA

(D 2061)

DAP236U

(D2032, 2033)

BU2507FV

(Q2046)

RF2713

(Q2055, 2056)

2SA1602A (MF)

(Q2048)

ISA1602AM1(Lot.9-)

(Q2048)

TC7S04FU (E5)

(Q2006, 2015)

2SC2812NL6

(Q2003, 2041)

2SC2714Y

(Q2005, 2011, 2012,

2014, 2016, 2017, 2019,

2022, 2023, 2025)

2SC3356 (R24)

(Q2027)

2SA1365

(Q2052)

2SC4154 (E)

(Q2062)

2SJ125D

(Q 2058)

4

5

6

7

FT-450 Technical Supplement

RF-IF-3

Loading...

Loading...