Yaesu FT-1802M Service Manual

FMTRANSCEIVER

FT-1802M

TechnicalSupplement

©2005VERTEXSTANDARDCO.,LTD. |

EH023N90A |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

VERTEXSTANDARDCO.,LTD.

4-8-8Nakameguro,Meguro-Ku,Tokyo153-8644,Japan

VERTEXSTANDARD

USHeadquarters

10900 Walker Street, Cypress, CA 90630, U.S.A.

YAESUEUROPEB.V.

P.O. Box75525, 1118 ZN Schiphol,The Netherlands

YAESUUKLTD.

Unit 12, Sun Valley Business Park, Winnall Close Winchester, Hampshire, SO23 0LB, U.K.

VERTEXSTANDARDHKLTD.

Unit5,20/F.,SeaviewCentre,139-141HoiBunRoad, KwunTong,Kowloon,HongKong

INTRODUCTION

This manual provides technical information necessary for servicing the FT-1802M FM Transceiver.

Servicing this equipment requires expertise in handling surface-mount chip components. Attempts by nonqualified persons to service this equipment may result in permanent damage not covered by the warranty, and may be illegal in some countries.

Two PCB layout diagrams are provided for each double-sided circuit board in the Transceiver. Each side of is referred to by the type of the majority of components installed on that side (“leaded” or “chip-only”). In most cases one side has only chip components, and the other has either a mixture of both chip and leaded components (trimmers, coils, electrolytic capacitors, ICs, etc.), or leaded components only.

While we believe the technical information in this manual to be correct, VERTEX STANDARD assumes no liability for damage that may occur as a result of typographical or other errors that may be present. Your cooperation in pointing out any inconsistencies in the technical information would be appreciated.

CONTENTS

Specifications..................................................... |

2 |

BoardUnit(Schematics,Layouts&Parts) |

|

ExplodedView&MiscellaneousParts........... |

3 |

MAINUnitCircuitDiagram................................. |

13 |

BlockDiagram |

5 |

MAINUnitPartsLayout....................................... |

15 |

MAINUnitPartsList............................................ |

17 |

||

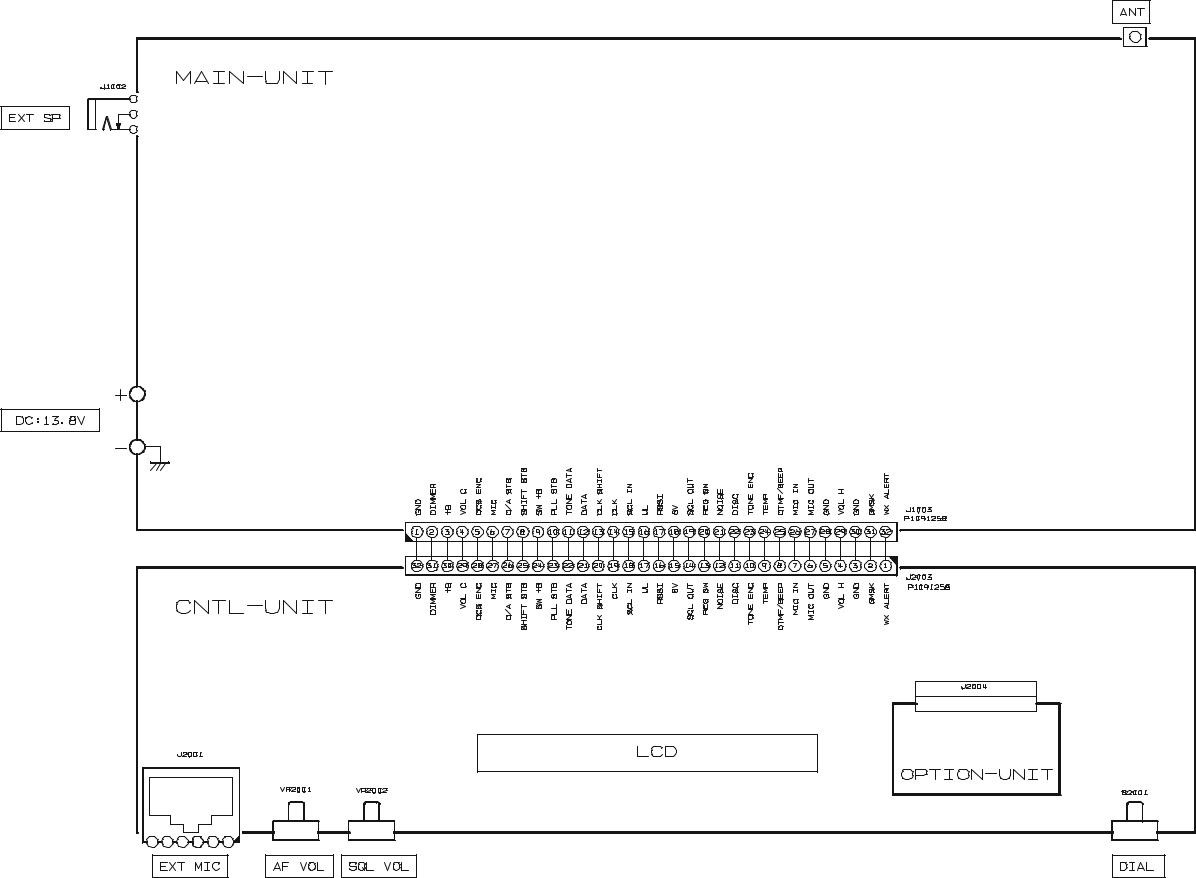

ConnectionDiagram......................................... |

6 |

CNTLUnitCircuitDiagram................................. |

27 |

CircuitDescription........................................... |

7 |

CNTLPartsLayout............................................... |

28 |

|

|

CNTLPartsList.................................................... |

29 |

Alignment.......................................................... |

9 |

|

|

1

Specifications

General

FrequencyRange: |

Tx 144 - 146 MHz or 144 - 148 MHz |

|

Rx 144 - 146 MHz or 136 - 174 MHz |

ChannelStep: |

5/10/12.5/15/20/25/50/100 kHz |

StandardRepeaterShift: |

±600 kHz |

FrequencyStability: |

Better than ±10 ppm [–4 °F to +140 °F (–20 °C to +60 °C)] |

ModesofEmission: |

F2/F3 |

AntennaImpedance: |

50 Ohms, unbalanced |

Supplyvoltage: |

13.8 V DC ±15%, negative ground |

CurrentConsumption(typical): |

Rx: less than 0.7 A, less than 0.3 A (squelched) |

|

Tx: 10 A (50 W) /7 A (25 W) /5 A (10 W) /4 A (5 W) |

OperatingTemperatureRange: |

–4° F to +140° F (–20° C to +60° C) |

CaseSize(WxHxD): |

5.5” x 1.6” x 5.7” (140 x 40 x 146 mm) (w/o knobs) |

Weight(Approx.): |

2.6 lb (1.2 kg) |

Transmitter

OutputPower: |

50 W/25 W/10 W/5 W |

ModulationType: |

Variable Reactance |

MaximumDeviation: |

±5 kHz/±2.5 kHz |

SpuriousRadiation: |

Better than –60 dB |

MicrophoneImpedance: |

2000 Ohms |

Receiver

CircuitType: |

Double Conversion Superheterodyne |

Ifs: |

21.7 MHz & 450 kHz |

Sensitivity(for 12dB SINAD): |

Better than 0.2 µV |

Selectivity(–6/–60dB): |

12 kHz/28 kHz |

IFRejection: |

Better than 70 dB |

ImageRejection: |

Better than 70 dB |

MaximumAFOutput: |

3 W into 4 Ohms @10 % THD |

Specificationssubjecttochangewithoutnoticeorobligation.SpecificationsguaranteedonlywithinAmateurband.

Frequencyrangesandfunctionswillvaryaccordingtotransceiverversion;checkwithyourdealer.

2

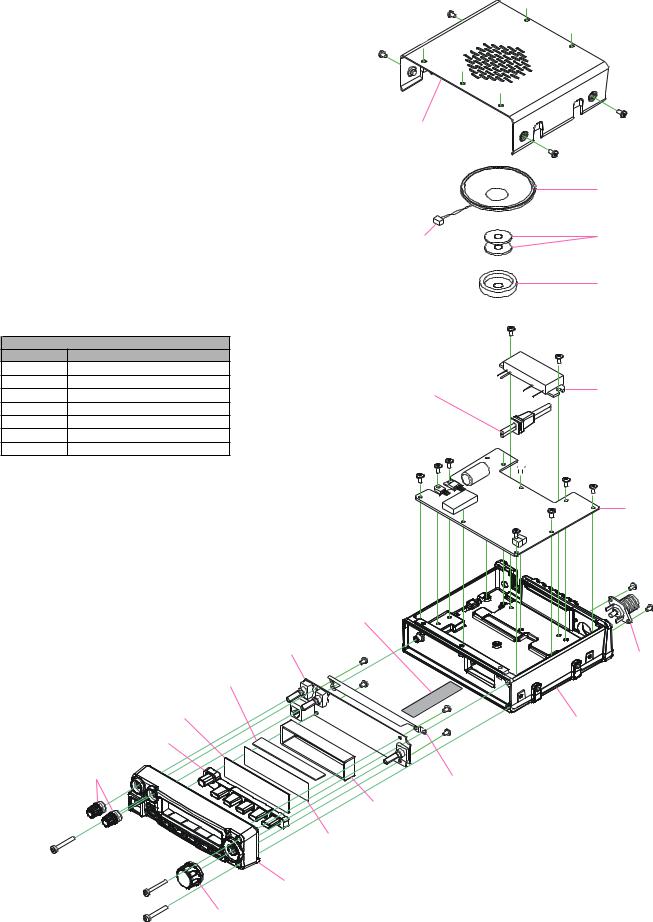

ExplodedView&MiscellaneousParts

CP8422001

CASE ASSY

w/SP NET: S8002087

M4090178

SPEAKER

S8002118 (2 pcs) T9206438A CUSHION WIRE ASSY

S8002063

CAP-SP

ACCESSORIES

VXSTDP/N DESCRIPTION

AAA43X001 MICROPHONE(MH-48A6J)

T9021715 DC CABLE(FT-1802M)

T9022815 DC CABLE(FT-1802E)

Q0000081 SPARE FUSE (15 A: FT-1802M)

Q0000075 SPARE FUSE (15 A: FT-1802E)

D6000055 BRACKET(MMB-36)

CB0297000 SCREW SET

REF. |

VXSTDP/N |

DESCRIPTION |

QTY. |

|

|

U03310002 |

SEMS SCREW |

ASM3X10NI |

4 |

|

U24112002 |

TAPTITE SCREW |

M2X12NI |

4 |

|

U24308002 |

TAPTITE SCREW |

M3X8NI |

11 |

|

U36206007 |

TAPTITE SCREW |

M2.6X6B |

9 |

|

U51320007 |

HEXA SOCKET BOLT |

M3X20B |

3 |

Non-designatedpartsareavailableonlyas partofadesignatedassembly.

T9206876(FT-1802M)

T9206955 (FT-1802E)

WIRE ASSY

T9207248

WIRE ASSY

|

CNTL UNIT |

|

|

|

|

RA0754500 |

|

|

INTER CONNECTOR |

||

|

||

G6090169 |

|

|

LCD |

|

G1094220

RA60H1317M1

|

|

MAIN UNIT |

|

|

|

|

|

P1091172

CONNECTOR

RA0753800 |

|

RA0753400 |

RUBBER KNOB |

|

|

|

CHASSIS |

|

|

|

RA0754100

KNOB (VOL/CQL)

RA0754400

RA0754300 GROUND PLATE

REFLECTOR

|

RA0754600 |

|

DIFFUSER |

RA0753600

FRONT PANEL

|

RA0754200 |

|

ENCODER KNOB |

||

|

3

Note

4

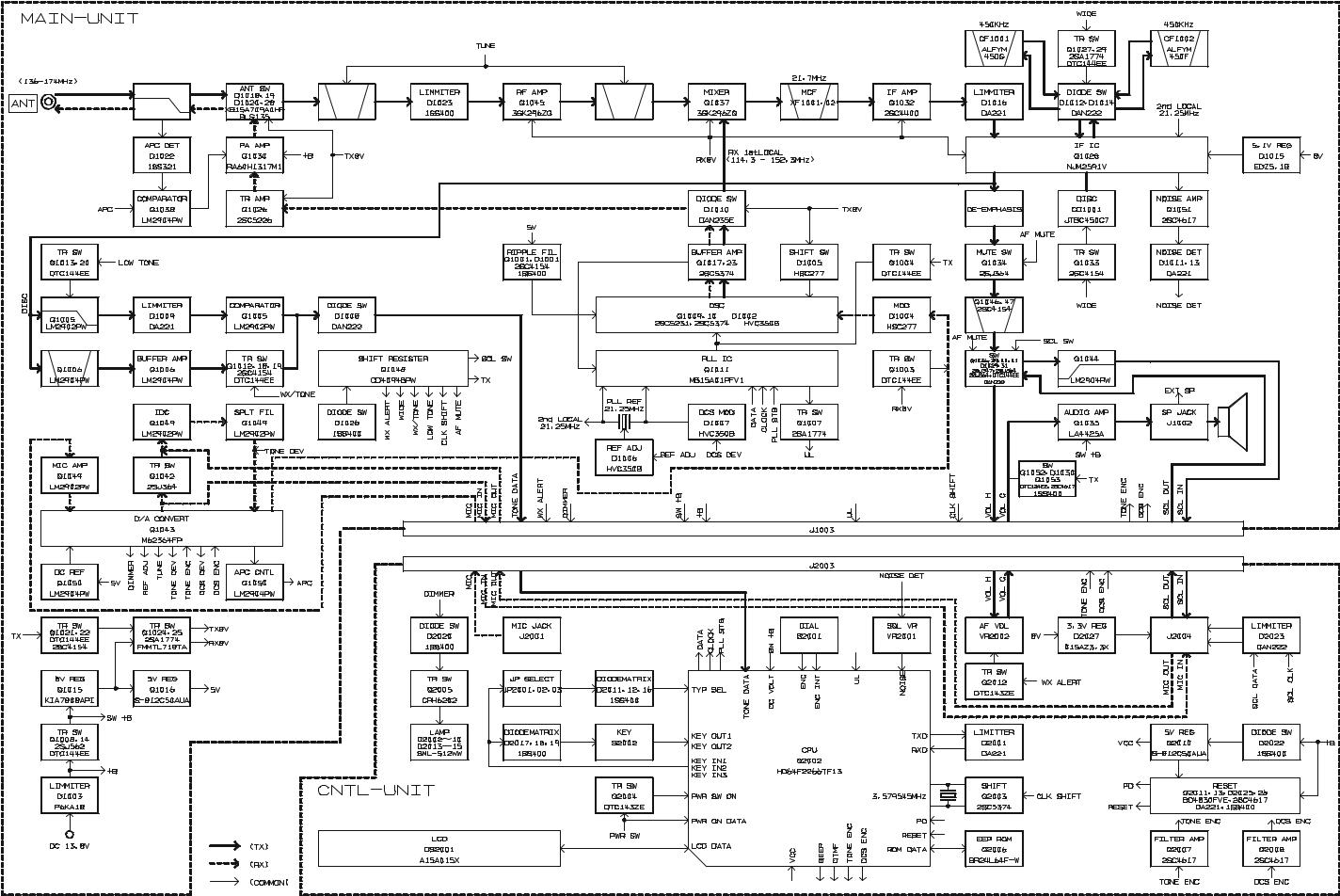

BlockDiagram

5

ConnectionDiagram

6

ReceiveSignalPath

Incoming RF signal is from the antenna jack is deliveredtotheMainUnitandpassed throughthe lowpass filter network consisting capacitors C1213, C1236, C1239, & C1241 and coils L1017, L1018, & L1019, antenna switching diode D1020 and D1028 (both RLS135), and varactor-tuned band-pass filter consisting of capacitors C1248, C1249, C1250, C1251, C1252, & C1268, coils L1020, L1021, & L1024, and diodes D1024 and D1025 (both HVC350B), before delivery to the RF amplifier Q1045(3SK296ZQ). The amplified RF signal is passed through the another varactor-tuned band-pass filter consisting of capacitorsC1198,1199,1200,&1218,coilsL1012andL1015, and diodes D1017and D1021(both HVC350B), then applied to the 1st mixer Q1037(3SK296ZQ) along with the first local signal from the PLL circuit.

The first local signal is generated between 114.3 MHz and 152.3 MHz by the VCO, which consists of Q1009 (2SC5231) and varactor diode D1002 (HVC350B) according to the receiving frequency.

IFandAudioCircuits

The 21.7 MHz first IF signal is applied to the monolithic crystal filters XF1001and XF1002which strip away unwanted mixer products, and the IF signal is applied to the first IF amplifier Q1032 (2SC4400). The amplified first IF signal is then delivered to the FM IF subsystem IC Q1028(NJM2591V), which contains the second mixer, limiter amplifier, noise amplifier, and FM detector.

The second local signal is generated by 21.25 MHz crystal X1001, produces the 450 kHz second IF signal when mixed with first IF signal within Q1028

(NJM2591V).

The 450 kHz second IF signal is applied to the ceramic filter CF1001(for Narrow FM) or CF1002(for Wide FM) which strip away unwanted mixer products to the ceramic discriminator CD1001which removes any amplitude variations in the 450 kHz IF signal before detection of speech.

The detected audio from the Q1028 (NJM2591V) passes through the de-emphasis circuit consisting of resistors R1082 & R1113, and capacitors C1120 & C1122, to the audio mute gate Q1034(2SJ364)

CircuitDescription

The audio signal passes through a band-pass filter consisting of Q1046and Q1047(both 2SC4154), and the audio mute gate Q1039 (2SJ347), to the audio VR which adjusts the audio sensitivity to compensate for audio level variations. The adjusted audio signal is delivered to the audio amplifier Q1035 (LA4425A) which provides up to 3 Watts, to the external speaker jack or a 4-Ohm loudspeaker.

SquelchControl

When no carrier received, the noise signal from Q1028 (NJM2591V) is amplified by Q1051 (2SC4617), and is detected by D1011 and D1013 (both DA221). The resulting DC voltage passes through the SQL knob to main CPU Q2002 (HD64F2266TF13). While no carrier is received, main CPU Q2002(HD64F2266TF13) control Q1048 (CD4094BPWR), thus, audio mute gate Q1034 (2SJ364) and Q1039(2SJ347) turns “OFF” to disable the audio output from the speaker.

TransmitSignalPath

The speech signal from the microphone is amplified by Q1049(LA2902PWR). The amplified speech signal is subjected to the low-pass filter network Q1049 (LA2902PWR) to deviation controlled by Q1043

(M62364FP).

The adjusted speech signal from Q1043(M62364FP) is delivered to VCO Q1009 (2SC5231) which frequency modulates the transmitting VCO made up of D1004(HSC277).

The modulated transmit signal passes through buffer amplifier Q1010and Q1023(both 2SC5374).

The transmit signal applied to the drive amplifier Q1026(2SC5226), then finally amplified by power amplifier module Q1030 (RA60H1317M) up to 50 Watts. The APC circuit controls the Q1030 (RA60H1317M) power amplifier’s gain.

The 50 Watts RF signal passes through low-pass filter network consisting of Capacitors C1210 and C1211 and coil L1013, antenna switch D1018 and D1019(both XB15A709), and another low-pass filter network consisting capacitors C1213, C1236, C1239, & C1241 and coils L1017, L1018, & L1019, and then deliver to the ANT jack.

7

CircuitDescription

TXAPCCircuit

A portion of the power amplifier module output is rectified by D1022(1SS321), then delivered to APC Q1038(LM2904PWR), as a DC voltage which is proportional to the output level of the power amplifier module.

The APC Q1038(LM2904PWR) is compared the rectified DC voltage from the power amplifier module and the reference voltage from the main CPU Q2002 (HD64F2266TF13), to produce a control voltage, which regulates supply voltage to the power amplifier module Q1030 (RA60H1317M), so as to maintain stable output power under varying antenna loading condition.

PLL

A portion of the output from the VCO Q1009 (2SC5231) passes through the buffer amplifier Q1010 and Q1017 (both 2SC5374), then delivered to the programmable divider section of the PLL IC Q1011(MB15A01PFV1), which divided according

to the frequency dividing data that is associated with the setting frequency input from the main CPU Q2002(HD64F2266TF13). It is then sent to the phase comparator section of the PLL IC Q1011

(MB15A01PFV1).

The 21.25 MHz frequency of the reference oscillator circuit made up of X1001is divided by the reference frequency divider section of Q1011(MB15A01PFV1) into 4250 or 3400 parts to become 5 kHz or 6.25 kHz comparative reference frequencies, which are utilized by the phase comparator section of Q1011

(MB15A01PFV1).

The phase comparator section of Q1011 (MB15A01PFV1) compares the phase between the frequency-divided oscillation frequency of the VCO circuit and comparative frequency and its output is a pulse corresponding to the phase difference. This pulse is integrated by the charge pump and loop filter into a control voltage (VCV) to control the oscillation frequency of the VCO Q1009(2SC5231).

8

Introduction

The FT-1802M is carefully aligned at the factory for the specified performance across the amateur band. Realignment should therefore not be necessary except in the event of a component failure. Only an authorized Vertex Standard representative should perform all component replacement and service, or the warranty policy may be void.

The following procedures cover the adjustments that are not normally required once the transceiver has left the factory. However, if damage occurs and some parts subsequently are replaced, realignment may be required. If a sudden problem occurs during normal operation, it is likely due to component failure; realignment should not be done until after the faulty component has been replaced.

We recommend that servicing be performed only by authorized Vertex Standard service technicians who are experienced with the circuitry and fully equipped for repair and alignment. If a fault is suspected, contact the dealer from whom the transceiver was purchased for instructions regarding repair. Authorized Vertex Standard service technicians realign all circuits and make complete performance checks to ensure compliance with factory specifications after replacing any faulty components.

Those who do undertake any of the following alignments are cautioned to proceed at their own risk. Problems caused by unauthorized attempts at realignment are not covered by the warranty policy. Also, Vertex Standard reserves the right to change circuits and alignment procedures in the interest of improved performance, without notifying owners.

Under no circumstances should any alignment be attempted unless the normal function and operation of the transceiver are clearly understood, the cause of the malfunction has been clearly pinpointed and any faulty components replaced, and realignment determined to be absolutely necessary.

Alignment

RequiredTestEquipment

The following test equipment (and familiarity with its use) is necessary for complete realignment. Correction of problems caused by misalignment resulting from use of improper test equipment is not covered under the warranty policy. While most steps do not require all of the equipment listed, the interactions of some adjustments may require that more complex adjustments be performed afterwards.

Do not attempt to perform only a single step unless it is clearly isolated electrically from all other steps. Have all test equipment ready before beginning and, follow all of the steps in a section in the order presented.

RF Signal Generator with calibrated output level at 200 MHz

Deviation Meter (linear detector)

In-line Wattmeter with 5% accuracy at 200 MHz

50-Ohm 50-W RF Dummy Load

8-Ohm AF Dummy Load

Regulated DC Power Supply adjustable from 6 to 15 VDC, 10A

FrequencyCounter:0.2-ppmaccuracyat200MHz

AF Signal Generator

AC Voltmeter

DC Voltmeter: high impedance

VHF Sampling Coupler

SINAD Meter

9

Alignment

AlignmentPreparation&Precautions

A 50-Ohm RF load and in-line wattmeter must be connected to the antenna jack in all procedures that call for transmission; alignment is not possible with an antenna. After completing one step, read the next step to see if the same test equipment is required. If not, remove the test equipment (except dummy load and wattmeter, if connected) before proceeding.

Correct alignment requires that the ambient temperature be the same as that of the transceiver and test equipment, and that this temperature be held constant between 68 °F ~ 86 °F (20 °C ~ 30 °C). When the transceiver is brought into the shop from hot or cold air, it should be allowed some time to come to room temperature before alignment. Whenever possible, alignments should be made with oscillator shields and circuit boards firmly affixed in place. Also, the test equipment must be thoroughly warmed up before beginning.

NOTE: Signal levels in dB referred to in the alignment procedure are based on 0dBµ = 0.5µV.

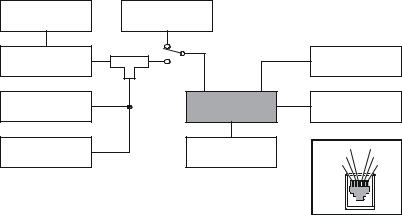

TestSetup

Set up the test equipment as shown below for transceiver alignment.

EnteringtheAlignmentMode

Alignment of the FT-1802M is performed using a front panel software-based procedure. To perform alignment of the transceiver, it must first be placed in the “Alignment Mode,” in which the adjustments will be made and then stored into memory.

To enter the Alignment mode, press and hold in the [REV(DW)] and [D/MR(MW)] keys while turning the radio on. Once the radio is on, release these two key. The transceiver is now in the “Alignment Mode.”

PLLReferenceFrequency

Rotate the DIALknob to set the alignment parameter to “148.000 rF.”

Press the [D/MR(MW)] key to enable adjustment of the “PLL Reference Frequency.”

Press the PTTswitch to activate the transmitter, adjust the DIAL knob so that the counter frequency reading is 148.000 MHz (±100 Hz).

Press the [D/MR(MW)] key.

RFFront-endTuning

Inject a 145.100 MHz signal at a level of –10 dBµ (with 1 kHz modulation @±3.5 kHz deviation) from the RF signal generator.

Rotate the DIALknob to set the alignment parameter to “145.100 tn.”

Press the [D/MR(MW)] key to enable adjustment of the “RF Front-end Tuning.”

Adjust the DIAL knob so that the maximum SINAD.

Press the [D/MR(MW)] key.

50-Ohm |

RF |

|

|

|

Dummy Load |

Signal Generator |

|

|

|

|

RF Sampling |

|

|

|

Inline |

Coupler |

|

RF |

|

|

|

|

||

Wattmeter |

|

|

Signal Generator |

|

|

ANT |

DC INPUT |

|

|

Deviation Meter |

FT-1802M |

EXT SP |

SINAD Meter |

|

|

|

|

|

|

|

MIC |

|

|

|

Frequency |

AF |

|

GND |

+8V |

Counter |

Signal Generator |

PTT/CLONE |

MIC SW2 |

|

|

|

|

MIC INPUT |

MIC SW1 |

TEST EQUIPMENT SETUP

10

SquelchThresholdLevel

Inject a 145.100 MHz signal at a level of –14 dBµ (with 1 kHz modulation @±3.5 kHz deviation) from the RF signal generator.

Rotate the SQLknob to the 10-o’clocl position.

Rotate the DIALknob to set the alignment parameter to “145.100 tL.”

Press the [D/MR(MW)] key to enable adjustment of the “Squelch Threshold Level.”

Press the [D/MR(MW)] key three times.

Press the [D/MR(MW)] key.

S-meterLevel(S-1)

Inject a 145.100 MHz signal at a level of –5 dBµ (with 1 kHz modulation @±3.5 kHz deviation) from the RF signal generator.

Rotate the DIALknob to set the alignment parameter to “145.100 S1.”

Press the [D/MR(MW)] key to enable adjustment of the “S-meter Level (S-1).”

Press the [D/MR(MW)] key three times.

Press the [D/MR(MW)] key.

S-meterLevel(S-9)

Inject a 145.100 MHz signal at a level of +20 dBµ (with 1 kHz modulation @±3.5 kHz deviation) from the RF signal generator.

Rotate the DIALknob to set the alignment parameter to “145.100 S9.”

Press the [D/MR(MW)] key to enable adjustment of the “S-meter Level (S-9).”

Press the [D/MR(MW)] key three times.

Press the [D/MR(MW)] key.

TXPower(High)

Rotate the DIALknob to set the alignment parameter to “145.000 HP.”

Press the [D/MR(MW)] key to enable adjustment of the “TX Power (High).”

Press the PTTswitch to activate the transmitter, adjust the DIALknob so that the RF Power Meter reading is 50 W (±2.0W).

Press the [D/MR(MW)] key.

Alignment

TXPower(Low3)

Rotate the DIALknob to set the alignment parameter to “145.000 L3.”

Press the [D/MR(MW)] key to enable adjustment of the “TX Power (Low 3).”

Press the PTTswitch to activate the transmitter, adjust the DIALknob so that the RF Power Meter reading is 25 W (±1.5 W).

Press the [D/MR(MW)] key.

TXPower(Low2)

Rotate the DIALknob to set the alignment parameter to “145.000 L2.”

Press the [D/MR(MW)] key to enable adjustment of the “TX Power (Low 2).”

Press the PTTswitch to activate the transmitter, adjust the DIALknob so that the RF Power Meter reading is 10 W (±1.0 W).

Press the [D/MR(MW)] key.

TXPower(Low1)

Rotate the DIALknob to set the alignment parameter to “145.000 L1.”

Press the [D/MR(MW)] key to enable adjustment of the “TX Power (Low 1).”

Press the PTTswitch to activate the transmitter, adjust the DIALknob so that the RF Power Meter reading is 5 W (±0.5 W).

Press the [D/MR(MW)] key.

TXDeviation

Inject a 1 kHz, 50 mV signal from theAudio Generator.

Rotate the DIALknob to set the alignment parameter to “145.000 dU.”

Press the [D/MR(MW)] key to enable adjustment of the “TX Deviation.”

Press the PTTswitch to activate the transmitter, adjust the DIALknob so that the Deviation Meter reading is 4.2 kHz (±0.1 kHz) (EXP version: 4.5 kHz ± 0.1 kHz).

Press the [D/MR(MW)] key.

11

Loading...

Loading...