Page 1

Turbidity and Suspended Solids Transmitter

Turbidity and Suspended

Solids Transmitter

Installation and User Manual

1EN 5.10 SuSix Manual 1406

FW: 841013-005/843003-001

Page 2

Turbidity and Suspended Solids Transmitter

CE CERTIFICATE OF CONFORMITY

This product complies with the requirements concerning electromagnetic compatibility (EMC)

stipulated in Council directive no. 89/336/EEC of 3rd may 1989, alteret at directive no.

92/31/EEC, on the approximation of the laws of the member states relating to electromagnetic compatibility.

CE approvals

We declare that the SuSix® transmitter and ultrasonic sensors comply with the values stipulated

in EN-61010-1 and EN 61326-1.

Ex approval

The SuSix® sensor is approved for mounting in explosive amospheres: Ex II G3.

2EN 5.10 SuSix Manual 1406

FW: 841013-005/843003-001

Page 3

Turbidity and Suspended Solids Transmitter

Table of Contents

1. Introduction 7

About this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Operating Principles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2. Safety, Repair and Product Identification 11

Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Physical Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Product Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3. Sensor Installation 12

Motion in the liquid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Mounting / position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Mechanical installation of a submerged sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Position of submerged sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Mechanial installation of sensor in a tube (in-line) . . . . . . . . . . . . . . . . . . . . . . . . . .16

Mounting guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Installation / Removal using Insertion Fitting 155210 . . . . . . . . . . . . . . . . . . . . . . .20

Required Tools and Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Preparing the Insertion Fitting before welding to tube . . . . . . . . . . . . . . . . . . . . . . . .20

Installation of the Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Removal of the Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4. Sensor Calibration 23

Turbidity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Suspended Solids . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Calibration Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Delete Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

5. Converter 29

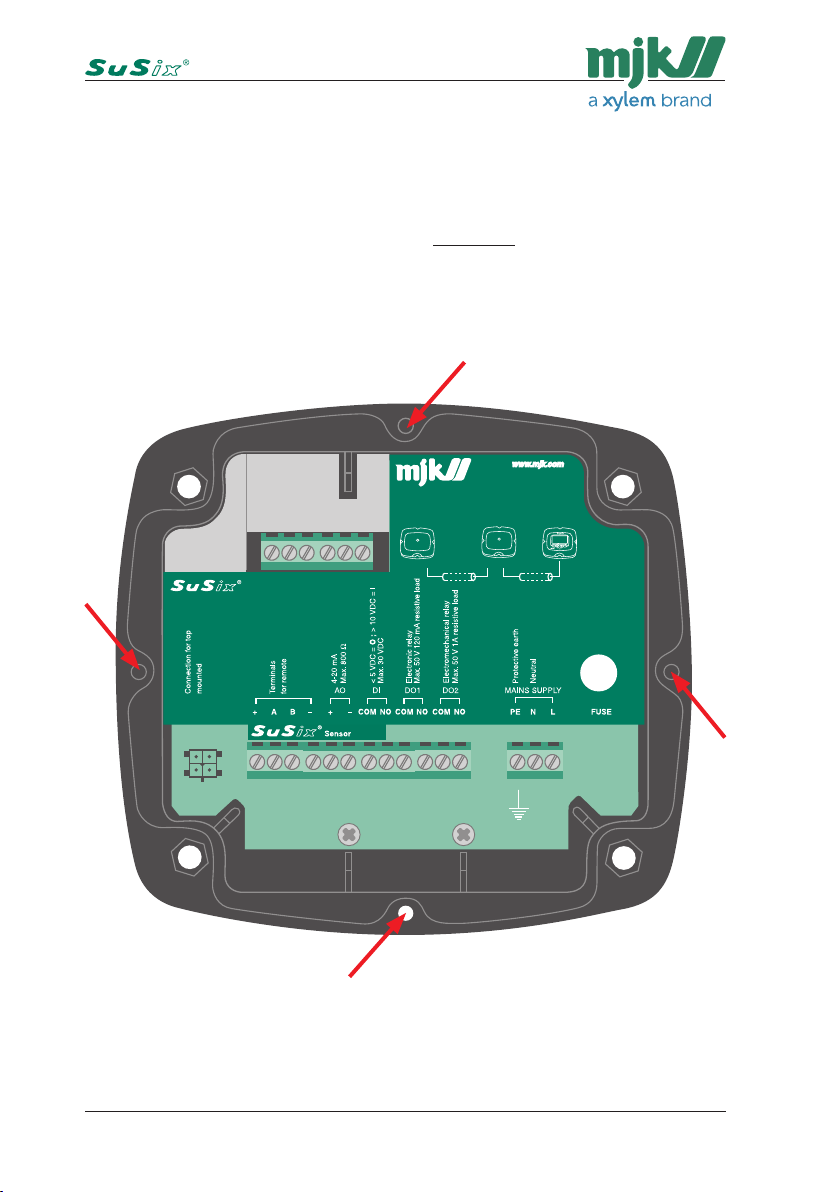

Electrical Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Changing the Power Supply Voltage 230/115 V AC . . . . . . . . . . . . . . . . . . . . . . . . .31

Analogue Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Digital Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Converter Terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Sensor and Mounting Kit / Connection Board Terminals . . . . . . . . . . . . . . . . . . . . . .36

6. System Configuration Examples 37

Magflux® with Blind Lid and SuSix® with Display Unit . . . . . . . . . . . . . . . . . . . . . . . 38

Wiring Schematic #1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

SuSix® with Blind Lid, Magflux® with Blind Lid and a Remote Display . . . . . . . . . .40

Wiring Schematic #2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

EN 5.10 SuSix Manual 1406

3

FW: 841013-005/843003-001

Page 4

Turbidity and Suspended Solids Transmitter

7. Startup 43

Initial Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

Initial Measurement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

Language Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Display Read-out, one connected unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

Display Read-out, several connected units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

Display Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

8. SuSix® Menus 47

Main Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Specify Main Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

Data Logger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

Graph Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Password . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Set Sensor Name . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Converter Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Sensor Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

Averaging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

mA Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Solid curve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

High alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Low alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Sensor error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66

Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

Factory settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Service Menu - Digest . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Service Menu - Detailed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70

Display Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .78

Language . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Set clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80

Modbus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Factory settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Display SW version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

9. Mechanical Dimensions 85

Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85

Converter and Display Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Immersion Fitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

Insertion Fitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

10. Maintenance 89

Cleaning the Sensor - Once a Month . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Cleaning the Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

4EN 5.10 SuSix Manual 1406

FW: 841013-005/843003-001

Page 5

Turbidity and Suspended Solids Transmitter

Functional Tests - Once a Year . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Electronics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .89

Replacing Wipers and Gaskets - Every Two Years . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Maintenance interval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Required materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .90

Remove the used wiper and gasket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .91

Install the new gasket and wiper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Appendix A. Pop-up and Error Messages 95

Appendix B. MJK-Field Link Software 99

Important Notes! . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .99

A. Connect a PC to the SuSix® . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

B. Save Log Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

C. Upgrade Display Firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .101

D. Upgrade Converter Firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .103

E. Install/Add Languages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Appendix C. Front Panel Cut-out Drawing 105

Appendix D. Log Files 107

Appendix E. Digital Input/Output Connections 111

Main Menu Overview 112

Converter Setup Menu Overview 114

Service Menu Overview 122

Display Configuration Menu Overview 126

Index Index-1

EN 5.10 SuSix Manual 1406

5

FW: 841013-005/843003-001

Page 6

Turbidity and Suspended Solids Transmitter

This page intentionally left blank.

6EN 5.10 SuSix Manual 1406

FW: 841013-005/843003-001

Page 7

Turbidity and Suspended Solids Transmitter

1. Introduction

Thank you for choosing the MJK SuSix® Turbidity and Suspended Solids

Transmitter. We have done our utmost to design and manufacture a quality

transmitter that satisfies your requirements.

The SuSix® Transmitter, consisting of a sensor, a converter and a display,

is easy to install, calibrate and put into service. However, read this manual

first to get familiar with the SuSix® Transmitter and all its features.

The equipment must be handled and operated as instructed by the

manufacturer, MJK Automation to ensure stable operation and accurate

measurements.

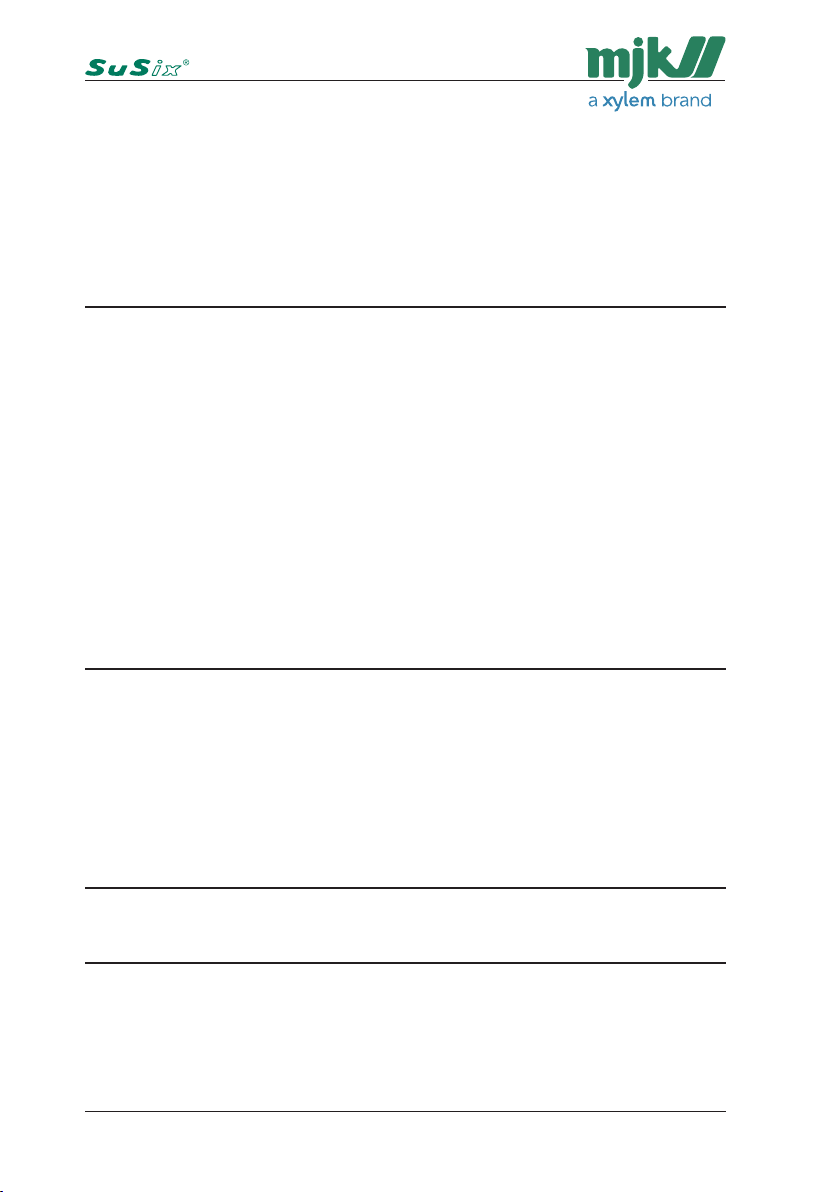

The SuSix® sensor is equipped with two light-emitting diodes (LEDs,

transmitters) and four emitter diodes (receivers). The readout is based on

several measurements utilizing all the diodes to compensate for errors like

dirt adhesion, worn diodes or scratches on the lenses.

SuSix® is available in two versions – a sensor with or without a dirt wiper

and a screw thread for submerged installation in tanks or a fitting for installation in tubes. The principles for use are identical for both versions.

You can always contact your local representative or the MJK hot lines for

advice and guidance:

• Europe Tel.: +45 45 56 06 56 E-mail: mjk@mjk.com

• Denmark Tel.: +45 45 56 06 56 E-mail: mjk@mjk.dk

Visit our web sites at www.mjk.com to learn more about MJK Automation,

our other products and the people behind them.

SuSix® is a registered trademark of MJK Automation A/S, Denmark.

MJK Automation is a Xylem Brand

EN 5.10 SuSix Manual 1406

7

FW: 841013-005/843003-001

Page 8

Turbidity and Suspended Solids Transmitter

About this Manual

This manual is divided into a table of contents, ten chapters, five appendices, four fold-out pages and one index.

1. Introduction

Contains a presentation of the MJK SuSix® Turbidity and Suspended

Solids Transmitter, the structure of this manual and the operating principles.

2. Safety, Repair and Product Identification

Provide answers to issues regarding safety, mounting, repair,

restrictions and product identification.

3. Sensor Installation

Contains installation guidelines such as correct and wrong positioning

of the sensor in the liquid, min. and max. distances to walls and other

solid faces, and installation in tubes.

4. Sensor Calibration

Turbidity measurements require no calibration, but detailed calibration

procedures and flow charts for suspended solids calibration are available.

5. Converter

Describes the physical specifications and installation rules for the con-

verter such as power supply, in- and outputs, sensor/converter/

display configurations, etc.

6. System Configuration Examples

Illustrate how SuSix® Turbidity and Suspended Solids Transmitters can

be interconnected with for example MJK MagFlux® flow meters in reallife scenarios.

7. Startup

Describes important checks and basic settings to get started including

the display and keyboard user interface.

8. SuSix® Menus

Contains a comprehensive description of the SuSix® menus, options

and utilities.

9. Mechanical Dimensions

Lists the SuSix® Turbidity and Suspended Solids Transmitter dimen-

sions and specifications.

8EN 5.10 SuSix Manual 1406

FW: 841013-005/843003-001

Page 9

Turbidity and Suspended Solids Transmitter

10. Maintenance

Procedures for cleaning the sensor, the converter, replacing wipers and

functional test are described.

* * * * *

Appendix A. Pop-up Events / Error Messages

Lists possible pop-up messages, explains their meaning and offer

solutions to error conditions.

Appendix B. MJK-Field Link Software Upgrade

Describes in detail how to utilise the unique and intuitive MJK-Field Link

software program to upload new display and converter firmware

versions.

Appendix C. Front Panel Cut-out Drawing

A 1:1 scale drawing of the front panel outline and cut-out area for

installation and mounting purposes.

Appendix D. Log Files

An example log file illustrates the format and explains the entries.

Appendix E. Digital Input/Output Connections

Illustrates how the digital in- and outputs can be interconnected.

* * * * *

Main Menu Overview

A continuous presentation of the main menu structure

Converter Setup Menu Overview

A continuous presentation of the converter setup menu structure

Service Menu Overview

A continuous presentation of the service menu structure

Display Configuration Menu Overview

A continuous presentation of the display configuration menu structure

EN 5.10 SuSix Manual 1406

9

FW: 841013-005/843003-001

Page 10

Turbidity and Suspended Solids Transmitter

Operating Principles

The SuSix® transmitter is an instrument for measuring turbidity and suspended solids. The transmitter consists of a sensor, a converter and a

display unit.

Operating principles

The SuSix® sensor uses a patented 6-channel, multi-beam, pulsed infrared light system providing a single sensor for both turbidity and suspended

solids measurement. The turbidity measurement complies with ISO standard 7027.

The advanced optical system is combined with a patented progressive algorithm using neural logic to generate a reliable high quality measurement.

All of the optical systems within the transmitter is fitted with automatic

self-diagnostics that ensure accurate measurements. The optical algorithm

compensates for errors due to fouling or aging of the optical array, and

an additional feature is a system that compensates for gas bubbles in the

sample media.

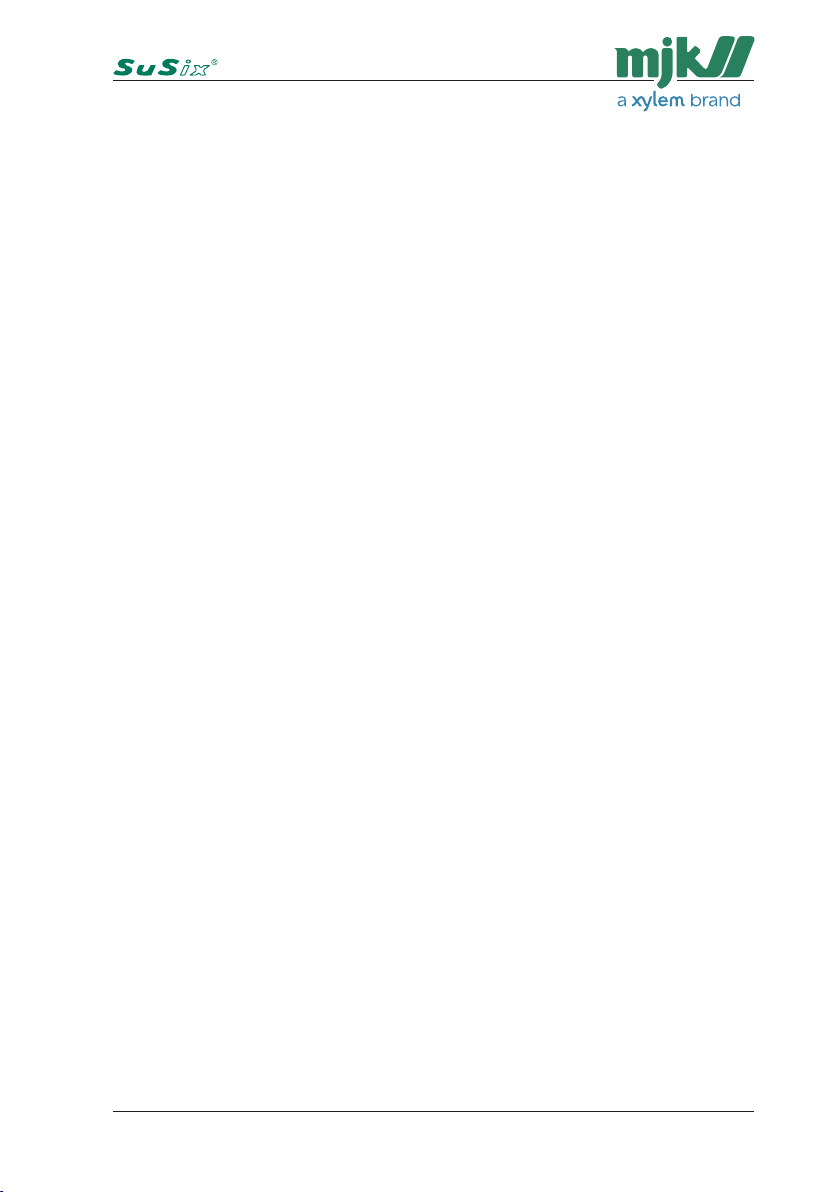

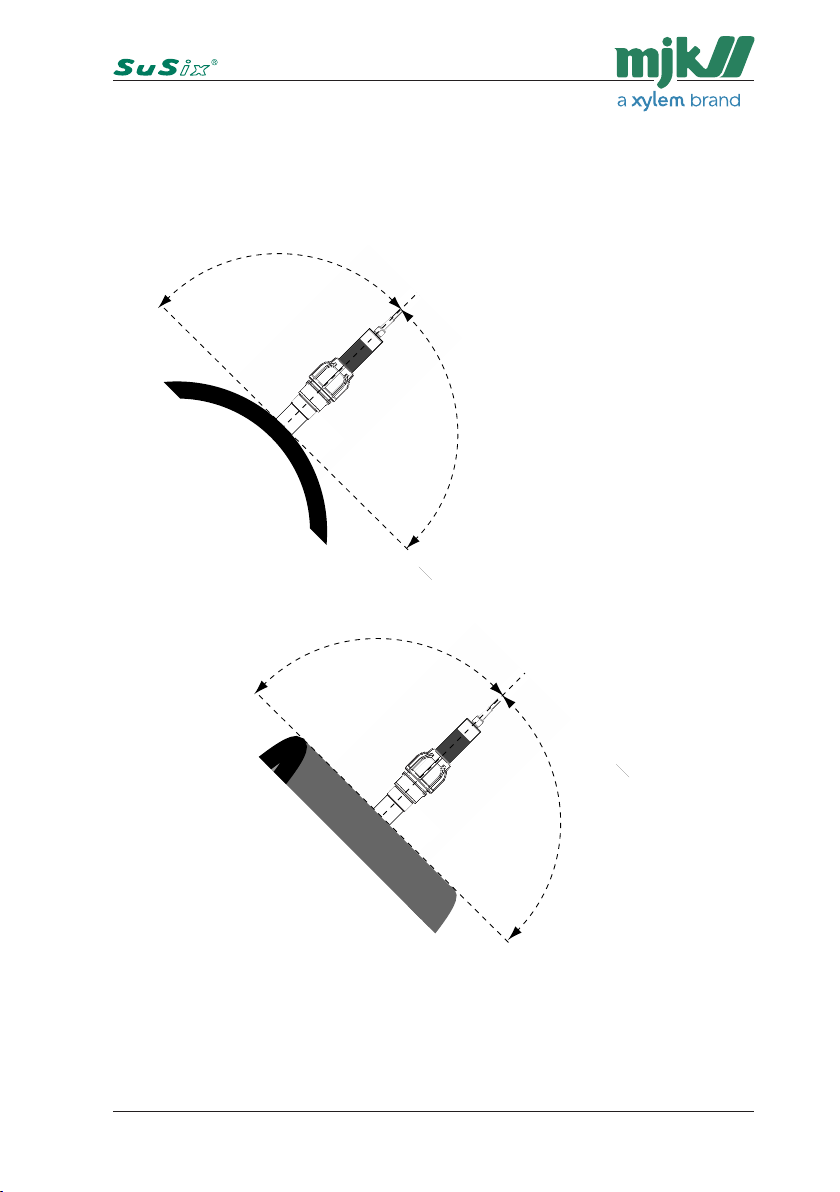

Sensor with wiper Effect of wiper

Physical fouling of the sensor head can be eliminated by an optional sensor wiper system (see pictures above).

10EN 5.10 SuSix Manual 1406

FW: 841013-005/843003-001

Page 11

Turbidity and Suspended Solids Transmitter

2. Safety, Repair and Product Identification

Safety instructions

• Read this manual carefully.

• Pay attention to the environment on the installation site.

• Wear necessary protective equipment and follow all current safety

regulations.

• SuSix® can invoke a start signal for dangerous machinery. Always

ensure that connected machinery and other equipment are effectively

put out of service (that is to remove the main fuses and lock main and

security switches in off-position) before commencing configuration,

fault finding, servicing, maintenance work, etc.

• WARNING: There is a risk of lethal, electrical shock from the "Mains

supply" terminals "N" and "L". Be careful not to touch these terminals

while the SuSix® is being serviced.

• WARNING: Incorrect installation or use can lead to body injury and/or

material damage!

Physical Mounting

The SuSix® converter/display unit must not be mounted in explosion

hazardous areas!

SuSix® may only be installed and commissioned by authorized MJK personnel, and all national and local regulations must be complied with.

Repair

Repair must only be made by authorized MJK personnel or by a service

representative approved by MJK.

Product Identification

A delivery will usually consist of a SuSix® sensor and a SuSix® converter

with or without a display unit.

Check that the item(s) delivered corresponds to the ordered item(s). The

part number is printed on an identification label sticked onto the converter

shipping box and on a label on the converter itself.

EN 5.10 SuSix Manual 1406

11

FW: 841013-005/843003-001

Page 12

Turbidity and Suspended Solids Transmitter

3. Sensor Installation

Important!

To ensure safe and optimal functionality of the SuSix® transmitter,

the instructions below must be followed closely.

• The sensor must be mounted in a location where it is possible to per-

form a representative suspended solids measurement.

• If the suspended solids transmitter is mounted in open air, protect it

against the influence of the elements using for example a rain roof.

• Fittings and mountings must be capable of carrying the transmitter’s

weight (approx. 5 kg), and vibrations from for example pumps and

other equipment must be avoided.

• The system should be installed to facilitate access to the suspended

solids transmitter operator panel and sensor without risking personal

injury during normal operation, maintenance, cleaning of sensor, etc.

• The suspended solids transmitter must be connected to a mains outlet

that complies with national and local regulations.

• All cables must be installed, connected and mounted to minimize me-

chanical impact and electrical influence from other installations.

• The sensor cable’s maximum tensile load is adjusted to the sensor

weight.

• The sensor is a mechanical instrument. Be careful not to damage the

sensor windows. The accuracy will deteriorate, if the optics is subject

to heavy pollution, or if a steel brush is used for cleaning.

• All fuses are located on the suspended solid transmitter’s motherboard.

WARNING!

The suspended solids transmitter must not be powered until the

transmitter is correctly mounted and connected!

WARNING!

Connections to the suspended solids transmitter must not be

disconnected while the transmitter is powered.

12EN 5.10 SuSix Manual 1406

FW: 841013-005/843003-001

Page 13

Turbidity and Suspended Solids Transmitter

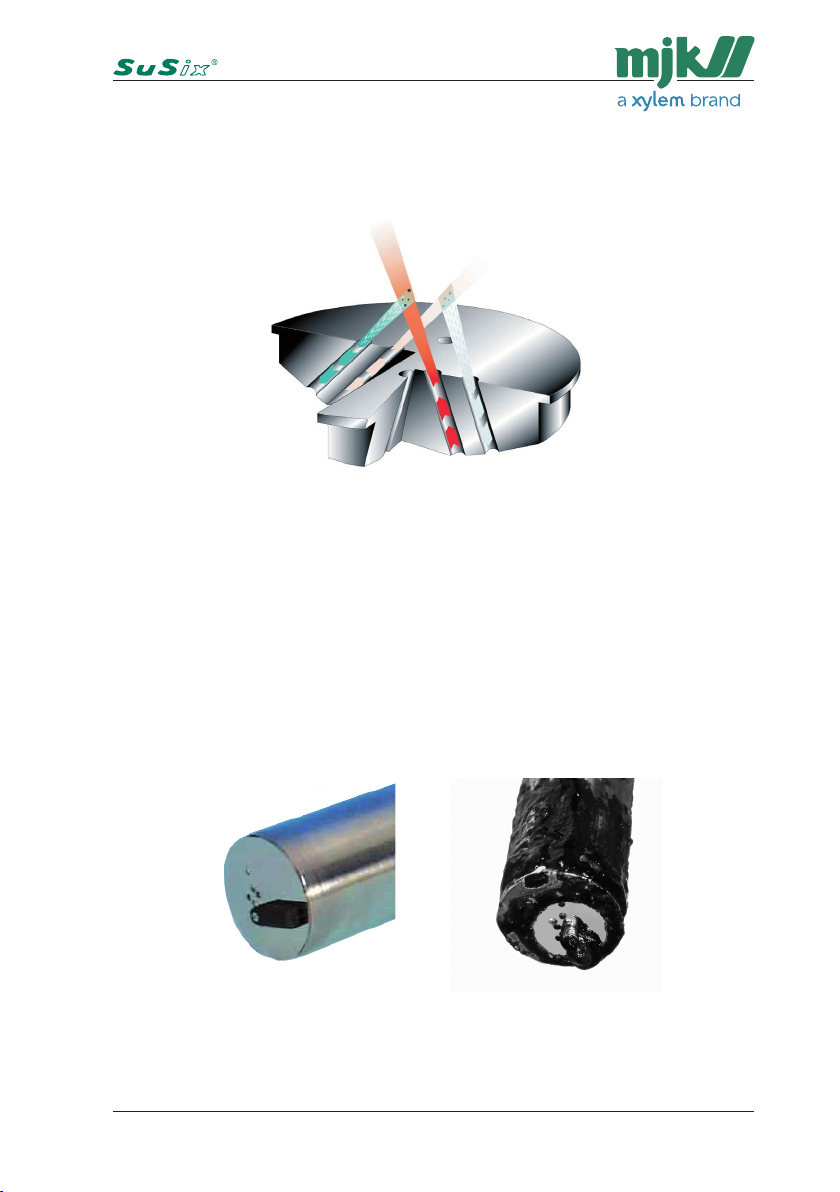

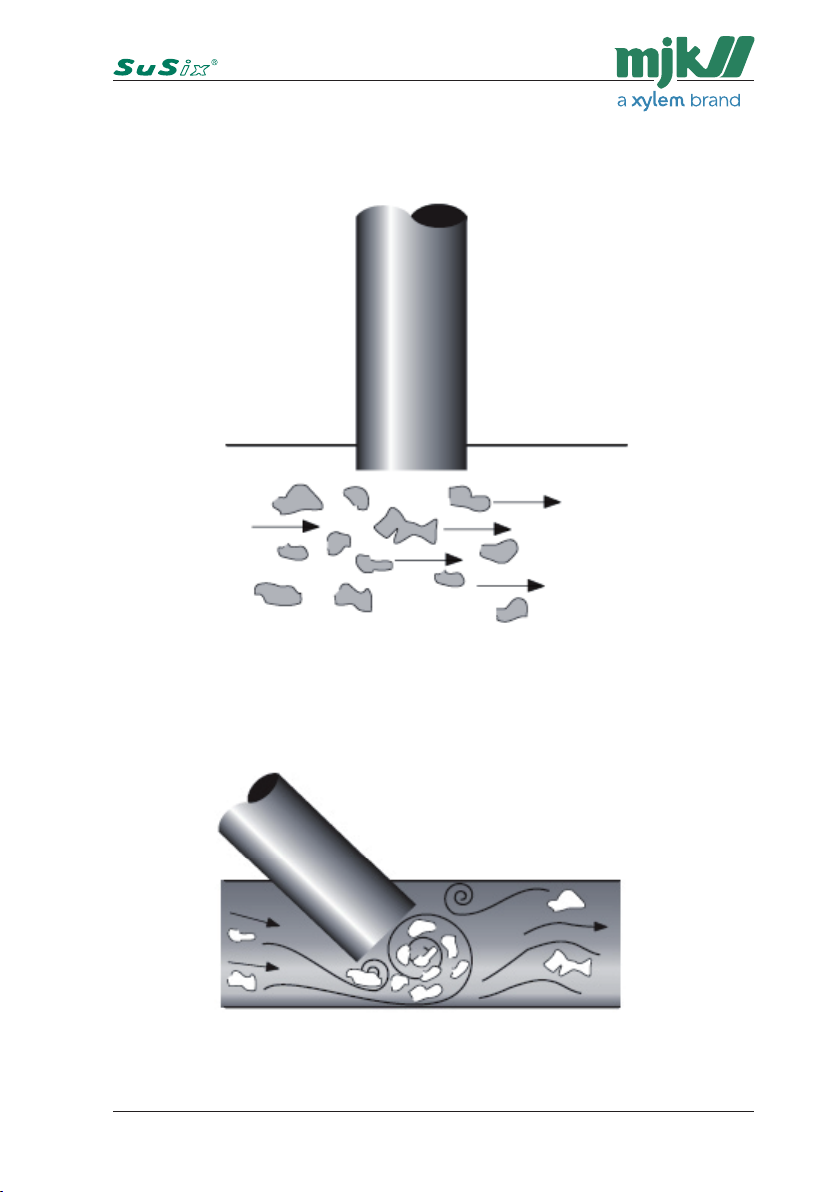

Motion in the liquid

The liquid has to remain in motion and mixed. It is possible to achieve this

by constantly circulating the liquid, or by installing the sensor at a place

with a constant flow.

Faulty measurement due to stagnant liquid

As soon as the liquid becomes stagnant, and the suspended solids start

for sedimentation, the sensor does not recognize the suspended solids

anymore. For calibration in a sample bucket it is necessary to stir gently

the liquid, or to constantly move the sensor in order to achieve reliable

measuring results. Observe that you keep the minimum distances from the

bucket walls.

EN 5.10 SuSix Manual 1406

13

FW: 841013-005/843003-001

Page 14

Turbidity and Suspended Solids Transmitter

Mounting / position

The flow direction should be parallel to the sensor surface. This prevents

turbulences at the sensor head.

Correct installation

In case of low suspended solids concentration, whirls and turbulences can

falsify the measuring result.

Incorrect installation!

14EN 5.10 SuSix Manual 1406

FW: 841013-005/843003-001

Page 15

Turbidity and Suspended Solids Transmitter

Mechanical installation of a submerged sensor

Preparation

Select an easy-to-get-to position for a measuring point which can produce

a valid and representative measuring value.

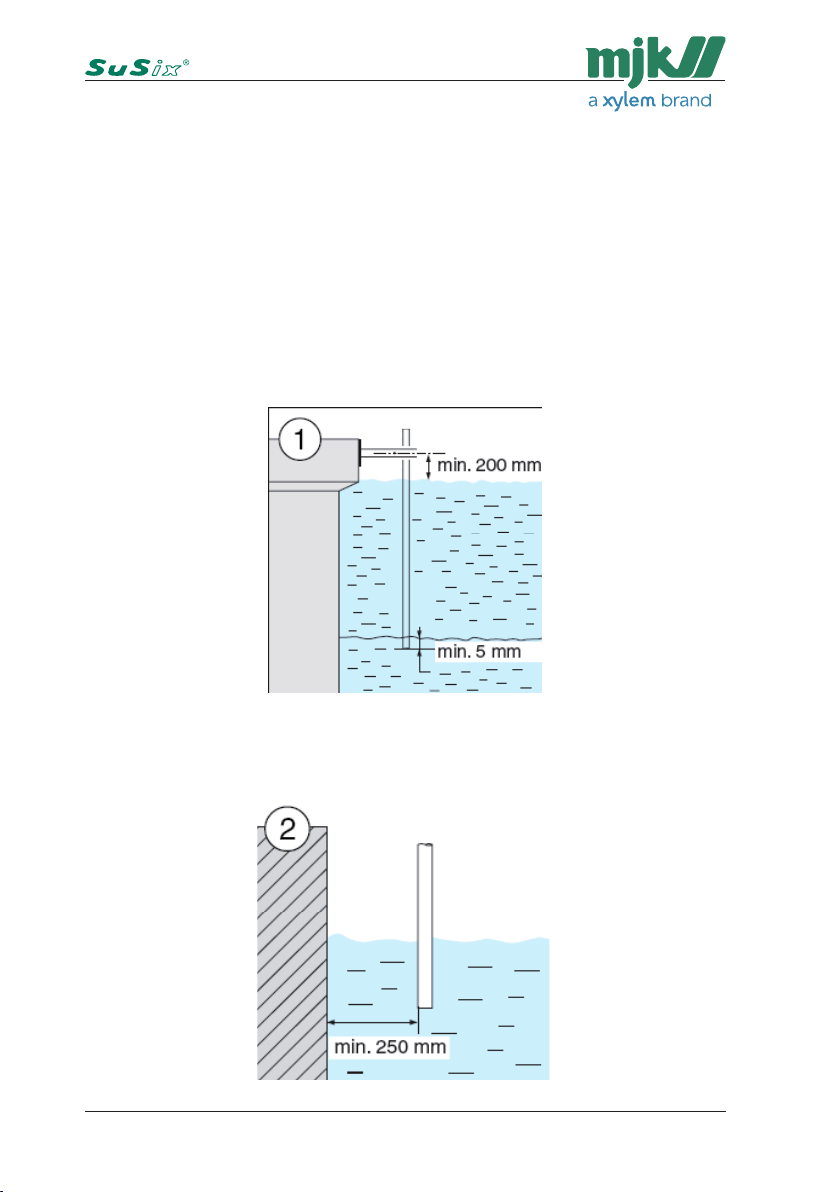

Position of submerged sensor

The following three steps are of vital importance for getting optimal measuring values.

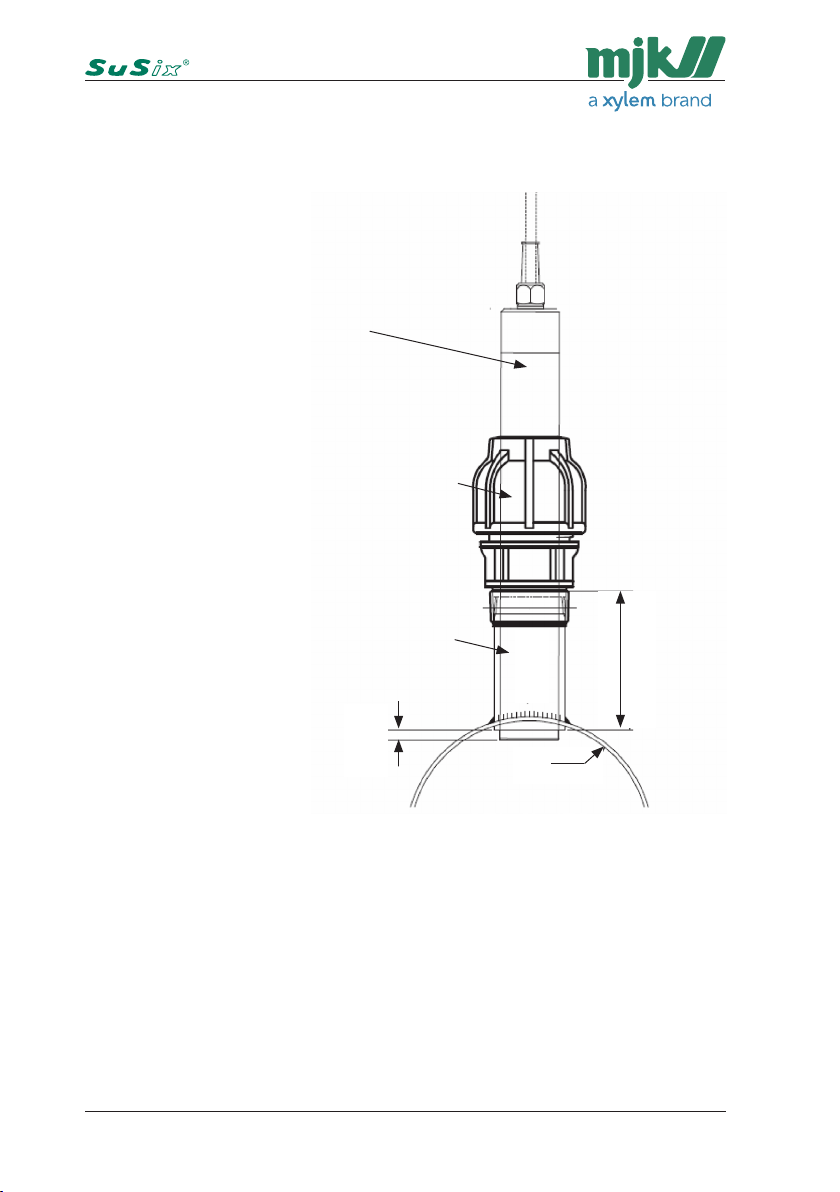

1. The sensor (the optics) must be submerged at least 5 mm in the liquid.

2. The sensor to wall distance must be at least 250 mm.

EN 5.10 SuSix Manual 1406

15

FW: 841013-005/843003-001

Page 16

Turbidity and Suspended Solids Transmitter

3. The distance from the sensor head (the optics) to solid faces (for exam-

ple bottom and walls) must be at least 30 - 80 mm (depending on the

liquid’s concentration).

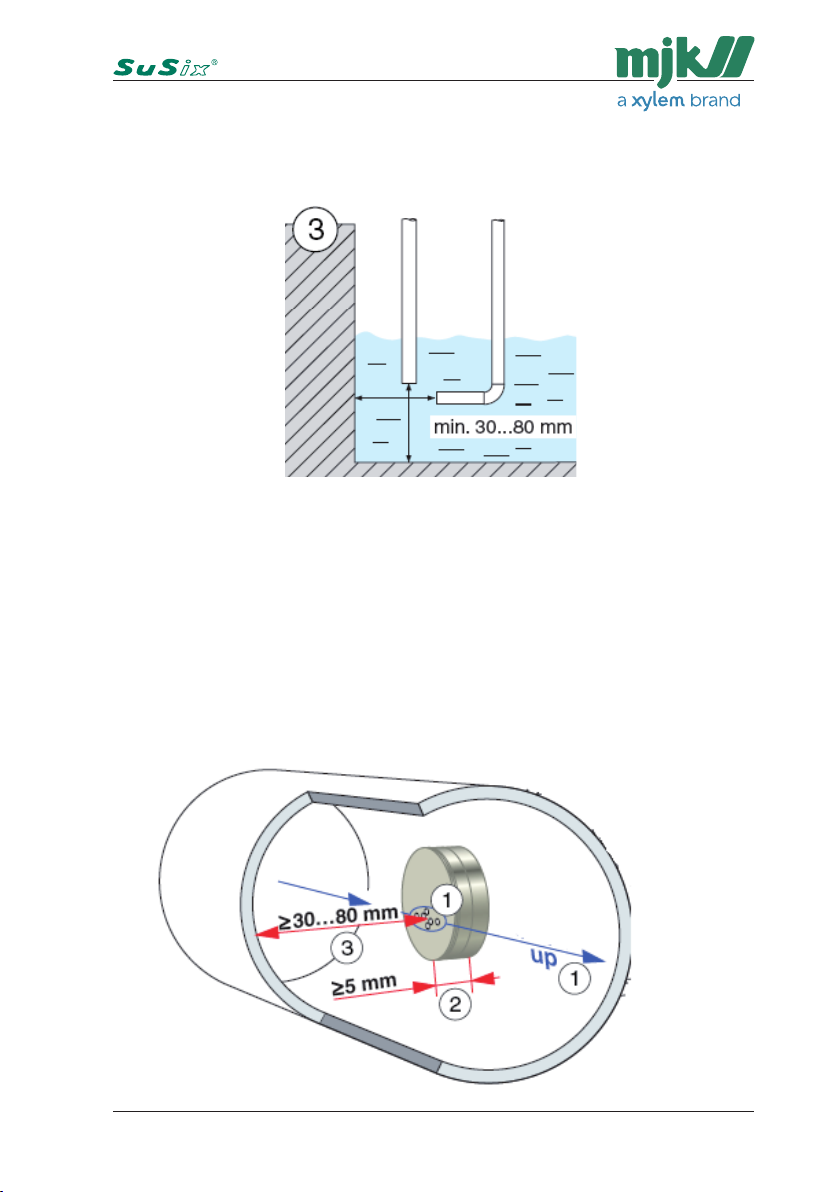

Mechanial installation of sensor in a tube (in-line)

Mounting guidelines

1. The optical windows row have to be arranged lengthwise to the me-

dium flow direction (1).

2. Keep the minimal insertion depth >5 mm (2).

3. Control the minimum distance to the opposite wall. Must be >30 …80

mm depending on the concentration (3).

16EN 5.10 SuSix Manual 1406

FW: 841013-005/843003-001

Page 17

Turbidity and Suspended Solids Transmitter

✔

✘

✔

✘

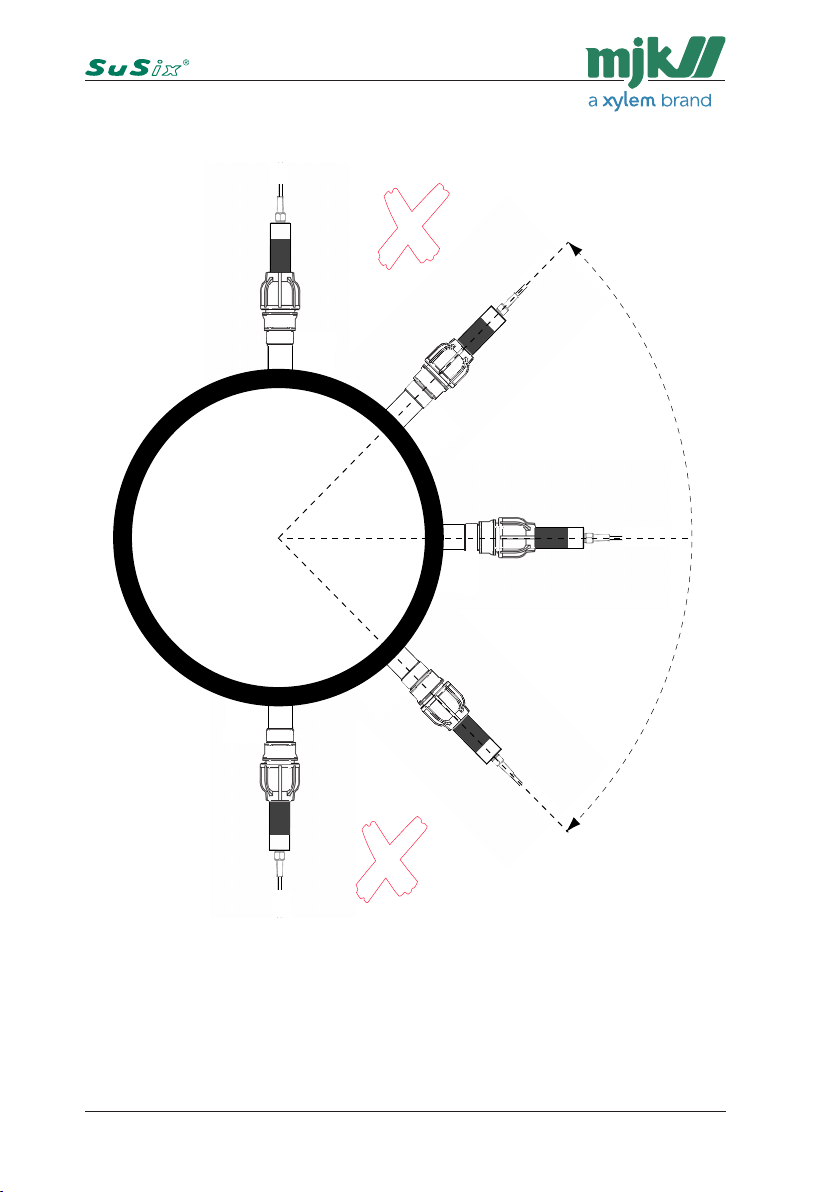

4. Make sure that the sensor is mounted within ± 45 degrees from the

horizontal plane (see below).

- 45 degrees

0

+ 45 degrees

EN 5.10 SuSix Manual 1406

17

FW: 841013-005/843003-001

Page 18

Turbidity and Suspended Solids Transmitter

5. An in-line welding stud must be welded to the tube at an angle of 90

degrees in all directions (see below).

90 degrees

18EN 5.10 SuSix Manual 1406

FW: 841013-005/843003-001

Page 19

Turbidity and Suspended Solids Transmitter

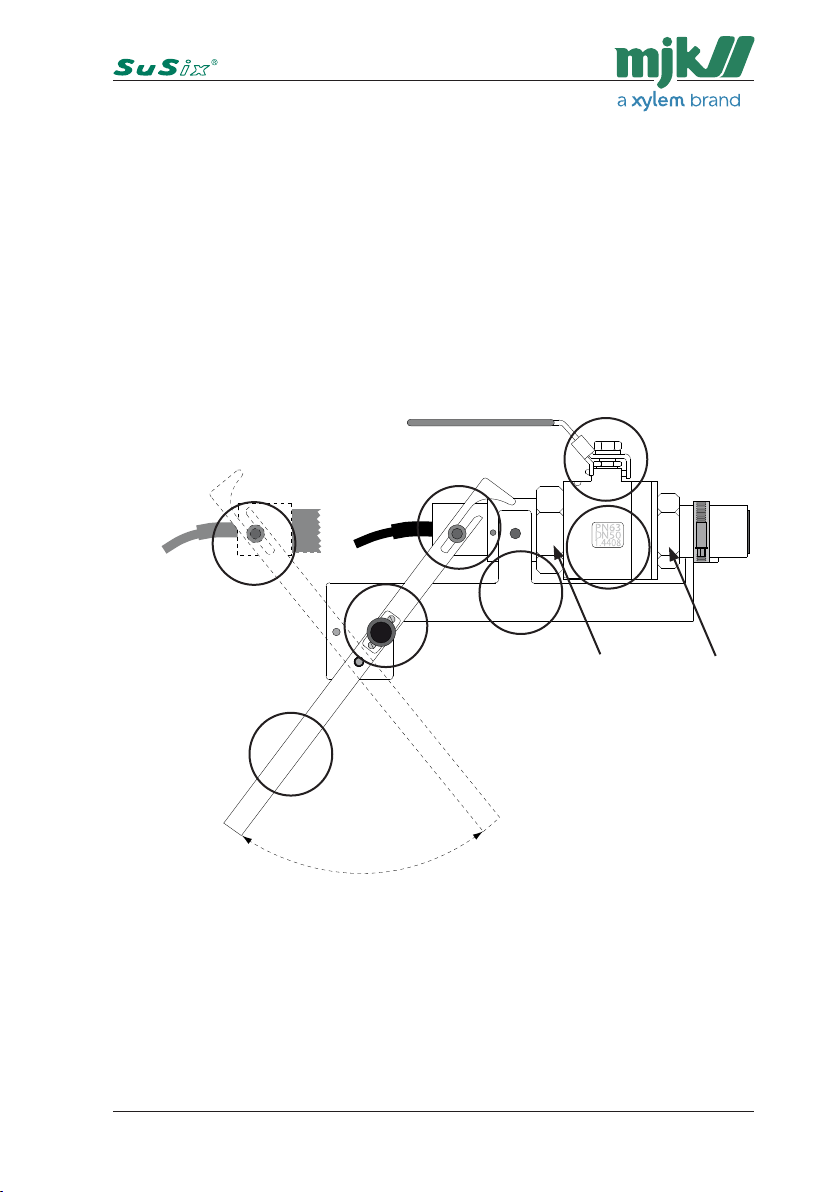

6. This drawing below illustrates a SuSix® sensor installed in an in-line

clamp fitting with parts and dimensions.

MJK, 206310-12 SuSix® sensor

GPA, ZFP 040-R040

PP- d40 x 1½” inner RG

1½” welding stud, 1½” outer thread RG

122 mm

EN 5.10 SuSix Manual 1406

5 mm

19

1½”

nippel

Min. Ø100 mm

90 degrees

FW: 841013-005/843003-001

Page 20

Turbidity and Suspended Solids Transmitter

Installation / Removal using Insertion Fitting 155210

Warnings : Max. operating pressure is 6 bar (720 N).

Max. residual pressure when changing sensor is 1 bar (120 N).

The sensor guide (2) is not a safety component

The inser tion fitting is not fully assembled from the factory

Be careful when dealing with corroding and toxic substances

Be careful when dealing with lines under pressure

Required Tools and Materials

• 5 mm hex key

• LOCTITE® 577 sealant

4

2

3

T

6

1

5

A B

7

Measure position Service position

Preparing the Insertion Fitting before welding to tube

The nuts on the ball valve housing (see A and B arrows) have not been

tightened and secured with a sealant from the factory. This allows the

customer to rotate, position and secure the ball valve as required on the

installation site.

1. Loosen/remove the A and B nuts, and rotate the ball valve to its final

position.

20EN 5.10 SuSix Manual 1406

FW: 841013-005/843003-001

Page 21

Turbidity and Suspended Solids Transmitter

2. Apply Loctite 577 around the male threads (skipping the leader),

tighten the A and B nuts, and allow the sealant to cure for about 72

hours (3 days) to achieve full strenght.

3. Weld the Insertion Fitting to the tube (see also pages 17 - 19).

Installation of the Sensor

1. Set the sensor guide handle (7) in "Service" position.

2. Open the air relief valve on the underside (1) with a 5 mm hex key.

3. Carefully insert the sensor into the insertion fitting's built-in gasket

(inside 6) and lead the other end into the sensor guide (2).

4. Close the air relief valve on the underside (1) with a 5 mm hex key.

5. Make sure that the residual, in-line pressure is max. 1 bar !

6. Support the sensor end piece (3) and slowly open the ball valve (4).

Note: Rebounds may occur at this point !

7. Release (pull out) the safety lock (5), and at the same time pull the sensor guide handle (7).

8. When the end piece (3) touches the insertion fitting body (6), the sensor

guide handle (7) has reached its "Measure" position, and the safety

lock (5) engages (falls into place) with audible click.

9. Make sure that the safety lock (5) has been engaged (in locked position).

Removal of the Sensor

1. Make sure that the residual, in-line pressure is max. 1 bar !

2. Release (pull out) the safety lock (5), and at the same time push the

sensor guide handle (7) forwards to extract the sensor from the insertion fitting body (6).

Note: Rebounds may occur at this point !

3. The sensor guide handle (7) is in "Service" position, when the safety

lock (5) engages with a click.

4. Close the ball valve (4).

5. Open the air relief valve (1).

6. Support the sensor end piece (3), and carefully lift the sensor out of the

sensor guide (2).

7. Close the air relief valve (1).

8. Remove the sensor.

EN 5.10 SuSix Manual 1406

21

FW: 841013-005/843003-001

Page 22

Turbidity and Suspended Solids Transmitter

This page intentionally left blank.

22EN 5.10 SuSix Manual 1406

FW: 841013-005/843003-001

Page 23

Turbidity and Suspended Solids Transmitter

4. Sensor Calibration

Turbidity

The SuSix® sensor is factory calibrated for turbidity measurements. No

further calibration is required.

Suspended Solids

Calibration is required prior to using the SuSix® for suspended solids

measurements.

Important!

Suspended solids calibration must be carried out at fixed

intervals.

If a distinct change in composition and/or colour of the process appears,

the SuSix® must be re-calibrated immediately.

Note: Representative measuring values can only be expected if the

calibration point is obtained at a sludge concentration of more

than 50% of the application’s nominal range.

Calibration may be 1-point, 2-point or 3-point as required. Normally a

1-point calibration will be sufficient.

Zero-point calibration is not required!

Calibration Procedures

1. Take out the SuSix® sensor and clean it according to the directions in

the section about cleaning the sensor during maintenance.

2. Extract a sample from the actual process.

The necessary volume must be at least 10 litres. The sample is analyzed at a laboratory, and the content of suspended solids can be

determined. This value must be kept as it is required later on.

EN 5.10 SuSix Manual 1406

23

FW: 841013-005/843003-001

Page 24

Turbidity and Suspended Solids Transmitter

3. Dip the SuSix® sensor in the sample stirring continuously, or leave it in

the fluid in which the suspended solids measurement is going to take

place.

Ensure sure that the extracted sample does not sediment (deposit) by

stirring continuously.

Important!

If the signal from the suspended solids sensor changes very

slowly on the display, make sure that the signal attenuation is not

set too high. Check likewise in the “Averaging” menu that the

response time is not set too high.

The recommended response time is 5 seconds.

24EN 5.10 SuSix Manual 1406

FW: 841013-005/843003-001

Page 25

Turbidity and Suspended Solids Transmitter

Converter Setup

accordingly

Adjust samples

Adjust sample

1 Measured 10,2 g/l

2 Measured 8,11 g/l

3 Measured 5,87 g/l

Back Select OK

Clear ”Measurement sample”

No

Yes

Back Select Ok

Clear ”Measurement sample”

4. Proceed to “Sensor Calibration” in the “Converter Setup” menu (see

below).

Note that the options "Sensor Calibration", "Cleaning" and "Solid

curve" will be marked with an "NA" (not applicable), if they cannot be

selected (for example if wrong units have been chosen).

Sensor Calibration

Averaging

Units

mA output

Cleaning

Solid curve

High Alarm

Low Alarm

Sensor error

Status

Factory settings

Service menu

Back Select OK

Sensor Calibration

Sensor Calibration

Measurement samples

Adjust samples

Clear ”Measurement sample”

Clear ”Adjust samples”

Back Select OK

Measurement samples

Select sample

1. point Measured

2. point Measured

3. point Measured

Back Select OK

5. Select “Measurement samples”, “1. point” and close with OK.

EN 5.10 SuSix Manual 1406

25

FW: 841013-005/843003-001

Page 26

Turbidity and Suspended Solids Transmitter

accordingly

Sensor Calibration

Adjust samples

Adjust

1. point

00010,2 g/l

Back Select >

Adjust sample

1 Measured 10,2 g/l

2 Measured 8,11 g/l

3 Measured 5,87 g/l

Back Select OK

Next

Adjust

2. point

00008,11 g/l

Back Select >

Adjust

3. point

00005,87 g/l

Sensor Calibration

Measurement samples

Adjust samples

Clear ”Measurement sample”

Clear ”Adjust samples”

Back Select OK

Measurement samples

Select sample

1. point Measured

2. point Measured

3. point Measured

Back Select OK

Clear ”Adjust samples”

Clear ”Adjustment sample”

No

Yes

Back Select Ok

2. point

1. point

3. point

Next

Ok

Ok

Select point

Select point

Clear ”Measurement sample”

No

Yes

Back Select Ok

Clear ”Measurement sample”

1./2./3. point

Start sample?

Progress

[ 0% ]

Exit Start

6. Press “Start” to start loading of the actual sample’s values.

During this process a bar graph is displayed indicating the progress

from 0-100 %.

Start point

1./2./3. point

Measureing

Progress

[||||||||||||||||| ] 45%

Cancel

Measure point 1/2/3

Done

Progress

[ 100% ]

Exit Next

26EN 5.10 SuSix Manual 1406

FW: 841013-005/843003-001

Page 27

Turbidity and Suspended Solids Transmitter

Averaging

Quality improvement

No

Yes

Back Select >

accordingly

Averaging

(from 1 sek to 120 min)

Back Select >

Adjust calibration

Adjust samples

Clear ”Adjust samples”

Clear ”Adjustment sample”

No

Yes

Back Select Ok

Clear ”Measurement sample”

Clear ”Measurement sample”

7. After data loading is finished, a realignment of the measured value with

respect to the previously measured laboratory value is required.

Select ” Adjust samples” in the “Sensor Calibration” menu, select ”1.

point” and close with OK.

Adjust sample

1 Measured 10,2 g/l

2 Measured 8,11 g/l

3 Measured 5,87 g/l

Back Select OK

Adjust

1. point

1. point

Back Select >

Ok

Select point

No

Yes

Back Select Ok

00010,2 g/l

Next

8. Select ”Adjust” in ”1. point” and enter the value from the analyzed laboratory sample.

If a 2- or 3-point calibration is required, repeat the previous steps replacing “1. point” with “2. point” and/or “3. point”.

EN 5.10 SuSix Manual 1406

27

FW: 841013-005/843003-001

Page 28

Turbidity and Suspended Solids Transmitter

Averaging

Quality improvement

No

Yes

Back Select >

NTU (Turbidity)

FTU (Turbidity)

FNU (Turbidity)

EBC (Turbidity)

% (Suspended solids)

mg/l (Suspended solids)

g/l (Suspended solids)

Kg/l (Suspended solids)

Back Select OK

accordingly

Averaging

0001 sec

(from 1 sek to 120 min)

Back Select >

Yes

Clear ”Adjust samples”

Clear ”Adjustment sample”

No

Yes

Back Select Ok

Clear ”Measurement sample”

Averaging

Units

Quality improvement

No

Yes

Back Select >

20 mA output

Units

NTU (Turbidity)

FTU (Turbidity)

FNU (Turbidity)

EBC (Turbidity)

% (Suspended solids)

mg/l (Suspended solids)

g/l (Suspended solids)

Kg/l (Suspended solids)

Back Select OK

4mA output

4 mA = 00.00 g/l

Back Select OK

accordingly

Use mA output

Yes

No

Back Select OK

Averaging

0001 sec

(from 1 sek to 120 min)

Back Select >

Yes

Clear ”Adjust samples”

Delete Calibration

If you want to delete a calibration point (the measured value), you can do it

from the ”Clear "Measurement sample"” menu.

Clear ”Measurement sample”

No

Yes

Back Select Ok

If you want to delete an alignment point (the entered value), you can do it

from the ”Clear "Adjustment samples"” menu.

Clear ”Adjustment sample”

No

Yes

Back Select Ok

28EN 5.10 SuSix Manual 1406

FW: 841013-005/843003-001

Page 29

Turbidity and Suspended Solids Transmitter

5. Converter

Electrical Mounting

Warning!

The SuSix® converter/display unit must not be mounted in

explosion hazardous areas!

Loosen the four screws (positions indicated by arrows) and remove the

display unit to gain access to the terminals.

Max. four MJK converters with Modbus

can be connected to one display unit:

Display unitConverter #4Converter #1

+DC GND A B

Pink

Grey

Shield

Brown

display unit

display unit

+ +A B C2 N02C NO N01 PE N L

- -

-mA- -D02--D01--DI--Display-

shielded cable.

521269

C1

2 wire

4 wire

shielded cable.

Mains

supply

521268

Fuse 24V AC: 500mA T

Fuse 115V AC: 125mA T

Fuse 230V AC: 63mA T

Line

EN 5.10 SuSix Manual 1406

29

FW: 841013-005/843003-001

Page 30

Turbidity and Suspended Solids Transmitter

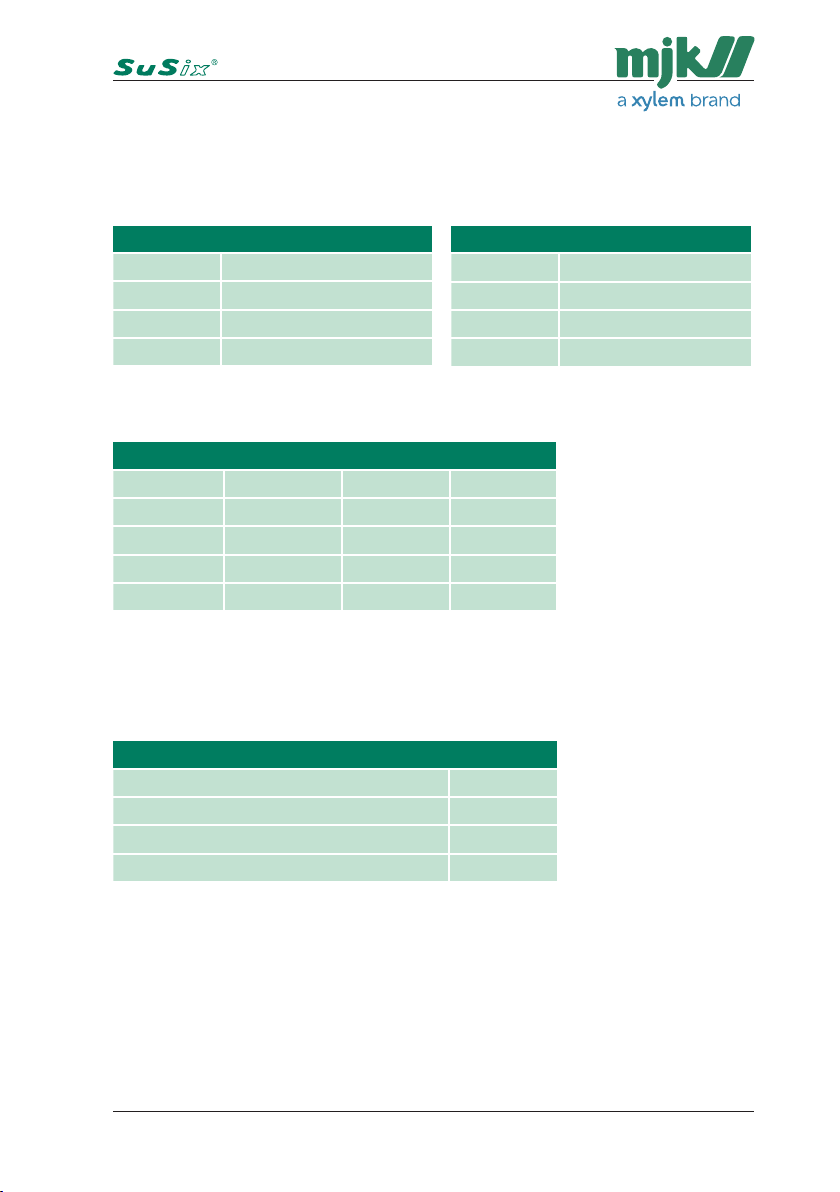

Power Supply

The flow converter must be supplied from a properly fused mains outlet, a

24 volt AC outlet, or a 10 - 30 V DC power supply/battery.

Power Supply 230 V AC, 115 V AC or 24 V AC

Terminal Designation

PE Protective ground

N 230 / 115 / 24 V AC neutral

L 230 / 115 / 24 V AC live

Power Supply 10 - 30 V DC

Terminal Designation

PE Protective ground

— DC neutral

+ DC live

The internal fuse ratings are:

Internal Fuse Ratings

Voltage Rating Order no. Dimension

230 V AC 0.063 mA T 550030 5 x 20 mm

115 V AC 0.125 mA T 550035 5 x 20 mm

24 V AC 0.5 mAT 550049 5 x 20 mm

10 - 30 V DC 1.0 AT 550051 5 x 20 mm

The technical specifications/requirements for a 10 - 30 V DC power

supply/battery are:

Technical Specifications for 10 - 30 V DC Power Supply

Power consumption without display < 5 W

Power consumption with display < 8 W

Peak start current @12 V DC,1 second Approx. 1,5 A

Peak start current @24 V DC,1 second Approx. 1 A

30EN 5.10 SuSix Manual 1406

FW: 841013-005/843003-001

Page 31

Turbidity and Suspended Solids Transmitter

Changing the Power Supply Voltage 230/115 V AC

To change the input mains voltage from 230 V AC to 115 V AC (or vice

versa) proceed as follows:

1. Loosen the four screws on the front and lift out the display (see also

page 29).

2. Note down the color and position of the wires in the terminal blocks,

and then loosen the terminal screws.

3. Unscrew the two screws that hold the metal cover and then remove it.

4. Unscrew the four screws that hold the mother PCB (the printed circuit

board with all the electrical components).

5. Remove the mother PCB and look at the back side.

This is what you should expect to see for a 230 V AC configuration:

230 V AC single jumper position

6. Unsolder and remove the jumper indicated by the arrow.

EN 5.10 SuSix Manual 1406

31

FW: 841013-005/843003-001

Page 32

Turbidity and Suspended Solids Transmitter

7. See on the following picture where two jumpers must be inserted for a

115 V AC configuration:

115 V AC dual jumper positions

8. Insert and solder 2 jumpers (wires) in the positions indicated by the

black arrows.

9. Turn around the PCB and replace the 63 mAT fuse on the right side

with a 125 mAT fuse ( or vice versa going from 115 VAC to 230 VAC).

10. Re-insert the PCB and re-assemble the converter (see also steps 4, 3,

2 and 1).

32EN 5.10 SuSix Manual 1406

FW: 841013-005/843003-001

Page 33

Turbidity and Suspended Solids Transmitter

Analogue Output

The analogue output is an active output with a maximum load of 800Ω.

Analogue Output

Terminal Designation

AO + 4-20 mA

AO

-

4-20 mA

The analogue output can be programmed for indication of primary units.

See details on page 61.

Digital Output

SuSix® has two digital outputs - DO1 with an opto (light triggered) relay

and DO2 with an electro-mechanical relay.

They can both be programmed for the following functions:

- Sensor error

- High and low alarms

Opto Relay

Terminal Designation

DO1 Com Max. 50 V DC /120 mA

DO1 NO

Electro-mechanical relay

Terminal Designation

DO2 Com Max. 50 V DC /1 A

DO2 NO

DO1 shares the common terminal (Com) with DI.

See also application examples in Appendix E. Digital Input/Output Connections on page 111.

EN 5.10 SuSix Manual 1406

33

FW: 841013-005/843003-001

Page 34

Turbidity and Suspended Solids Transmitter

Digital Input

SuSix® has one digital input which can be activated with a voltage higher

than 10 V DC and de-activated with a voltage lower than 5 V DC.

Digital Input

Terminal Designation

DI Com

DI Max. 30 V DC

The digital input (DI) can be programmed for the following functions:

- start and pause cleaning function

- Solid curve

DI shares the common terminal (Com) with DO 1.

See also application examples in Appendix E. Digital Input/Output Connections on page 111.

34EN 5.10 SuSix Manual 1406

FW: 841013-005/843003-001

Page 35

Turbidity and Suspended Solids Transmitter

Converter Terminals

Max. four MJK converters with Modbus

can be connected to one display unit:

Display unitConverter #4Converter #1

shielded cable.

+DC GND A B

Pink

Grey

display unit

+ +A B C2 N02C NO N01 PE N L

Brown

display unit

- -

-mA- -D02--D01--DI--Display-

Shield

521269

C1

2 wire

4 wire

shielded cable.

Mains

supply

Line

521268

Fuse 24V AC: 500mA T

Fuse 115V AC: 125mA T

Fuse 230V AC: 63mA T

SuSix® converter terminals

Flip the green label with "SuSix®" printed on it (see arrow) to the right to

gain access to the sensor connection terminals (see next page).

EN 5.10 SuSix Manual 1406

35

FW: 841013-005/843003-001

Page 36

Turbidity and Suspended Solids Transmitter

www.mjk.com

Sensor and Mounting Kit / Connection Board Terminals

Connect the sensor wires to the SuSix converter (or to Mounting Kit

207030 PCB 510252 or to Connection Board 207030 PCB 510252-004)

with the wires coming from the sensor as shown below (see arrow).

Terminals

Wires from sensor Converter terminals

Mounting Kit 207030

PCB 510252

Pink +DC E1 2

Grey DC GND E2 3

Brown A L1 4

White B L2 5

Shield Shield GND GND 1

Max. four MJK converters with Modbus

can be connected to one display unit:

Connection Board 207030

PCB 510252-004

Display unitConverter #4Converter #1

2 wire

shielded cable.

+DC GND A B

Pink

Grey

+ +A B C2 N02C NO N01 PE N L

Brown

- -

Shield

521269

-mA- -D02--D01--DI--Display-

C1

4 wire

shielded cable.

DK: +45 45 56 06 56

NO: +47 69 2 0 60 70

SE: +46 53 3 1 77 50

NL: +31 2 51 672171

USA: +1 847 482 8655

AUS: +61 3 9758 8533

Mains

supply

SuSix® converter terminals

36EN 5.10 SuSix Manual 1406

FW: 841013-005/843003-001

Line

521268

Fuse 24V AC: 500mA T

Fuse 115V AC: 125mA T

Fuse 230V AC: 63mA T

Page 37

Turbidity and Suspended Solids Transmitter

6. System Configuration Examples

MJK SuSix® transmitters share communication protocols with other MJK

products like the MJK Magflux® flow meter and the MJK Connect data

transmitter, and can also share display units. This section illustrates two

configuration examples and includes cable connections and part numbers.

Magflux® with Blind Lid and SuSix® with Display Unit

SuSix® with Blind Lid, Magflux® with Blind Lid and a Remote Display

EN 5.10 SuSix Manual 1406

37

FW: 841013-005/843003-001

Page 38

Turbidity and Suspended Solids Transmitter

Magflux® with Blind Lid and SuSix® with Display Unit

Configuration: Magflux® flow sensor/converter with a blind lid connected to a SuSix® transmitter with display unit

Part numbers for this configuration:

2x7xxx MagFlux® Flow Sensor

2x7791x MagFlux® Connverter with blind lid

579035 MagFlux® Gel Potting Kit IP68

2-wire, shielded, twisted cable (Magflux® <-> SuSix®)

20631x SuSix® Sensor

206305-6 SuSix® Connverter with Display Unit

38EN 5.10 SuSix Manual 1406

FW: 841013-005/843003-001

Page 39

Turbidity and Suspended Solids Transmitter

Mains

supply

-D02--D01-

C2 N02

NO N01 PE N L

C1

Line

2 wire

shielded cable.

4 wire

shielded cable.

Fuse 24V AC: 500mA T

Fuse 115V AC: 125mA T

Fuse 230V AC: 63mA T

Display unitConverter #4Converter #1

Max. four MJK converters with Modbus

can be connected to one display unit:

521268

www.mjk.com

DK: +45 45 56 06 56

NO: + 47 69 20 60 70

SE: +46 53 31 77 50

NL: +31 251 67217 1

USA: +1 847 482 8655

AUS: +61 3 9758 8533

Wiring Schematic #1

for " Magflux® with Blind Lid and SuSix® with Display Unit" from the opposite page (page 38).

SuSix® with Display Unit

2-wire, shielded twisted cable

1. Connect lead "1" to slot "Display A"

2. Connect lead "2" to slot "Display B"

3. Connect the twisted shield to slot

"Display -"

Magflux® with Blind Lid

2-wire, shielded twisted cable

1. Connect lead "1" to slot "Display A"

2. Connect lead "2" to slot "Display B"

3. Connect the twisted shield to slot

"Display -"

+DC GND A B

Pink

Grey

Shield

Brown

521269

+ +A B

12Shield

12Shield

- -

C

-mA-

-DI--Display-

EN 5.10 SuSix Manual 1406

39

FW: 841013-005/843003-001

Page 40

Turbidity and Suspended Solids Transmitter

SuSix® with Blind Lid, Magflux® with Blind Lid and a

Remote Display

Configuration: A SuSix® transmitter with a blind lid connected to a

Magflux® flow sensor with a blind lid and common remote Display

Unit.

Part numbers for this configuration:

20631x SuSix® Sensor

206305-6 SuSix® Converter

2x7xxx MagFlux® Flow Sensor

2x791x MagFlux® Converter with blind lid

579035 MagFlux® Gel Potting Kit IP68

207930 Wall Mounting Kit

2-wire, twisted shield cable (SuSix® <-> Magflux®)

4-wire, twisted shield cable (Magflux® <-> Display Unit)

40EN 5.10 SuSix Manual 1406

FW: 841013-005/843003-001

Page 41

Turbidity and Suspended Solids Transmitter

Mains

supply

-D02--D01-

C2 N02

NO N01 PE N L

C1

Line

2 wire

shielded cable.

4 wire

shielded cable.

Fuse 24V AC: 500mA T

Fuse 115V AC: 125mA T

Fuse 230V AC: 63mA T

Display unitConverter #4Converter #1

Max. four MJK converters with Modbus

can be connected to one display unit:

521268

www.mjk.com

DK: +45 45 56 06 56

NO: + 47 69 20 60 70

SE: +46 53 31 77 50

NL: +31 251 67217 1

USA: +1 847 482 8655

AUS: +61 3 9758 8533

Wiring Schematic #2

for "SuSix® with Blind Lid and a Magflux® with Blind Lid connected to a

common wall mounted Display Unit" on the opposite page (page 40).

SuSix® with Blind Lid

2-wire, shielded twisted cable

1. Connect lead "1" to slot "Display A"

2. Connect lead "2" to slot "Display B"

3. Connect the twisted shield to slot

"Display -"

®

Magflux

with Blind Lid

2-wire, shielded twisted cable

1. Connect lead "1" to slot "Display A"

2. Connect lead "2" to slot "Display B"

3. Connect the twisted shield to slot

"Display -".

4-wire, shielded twisted cable

1. Connect lead "1" to slot "Display +"

2. Connect lead "2" to slot "Display A"

3. Connect lead "3" to slot "Display B"

4. Connect the twisted shield to slot

"Display -".

+DC GND A B

Pink

Grey

+ +A B

12Shield

12Shield

1

2

3

Brown

- -

Shield

-mA-

521269

C

-DI--Display-

Wall Mounted Display Unit

4-wire, shielded twisted cable

1. Connect lead "1" to slot "Display +"

2. Connect lead "2" to slot "Display A"

3. Connect lead "3" to slot "Display B"

4. Connect the twisted shield to slot

"Display -".

EN 5.10 SuSix Manual 1406

41

1

FW: 841013-005/843003-001

4 and

shield

2

3

Page 42

Turbidity and Suspended Solids Transmitter

This page intentionally left blank.

42EN 5.10 SuSix Manual 1406

FW: 841013-005/843003-001

Page 43

Turbidity and Suspended Solids Transmitter

7. Startup

Initial Checks

Before switching on power the following steps must be checked.

1. The local mains power supply voltage corresponds to the voltage

printed on the identification label of the transmitter.

2. All electrical connections are made in accordance with the electrical

connection diagram shown on page 34.

3. All terminal screws are tightened.

4. All cable glands are tightly secured.

5. All grounding connections are made in accordance with the instructions in this manual (see page 23).

Initial Measurement

1. Make sure that the sensor is completely covered by liquid.

2. Turn on power to the transmitter and wait one minute before taking the

initial measurement.

Language Selection

1. The default display language is English. If another language is required,

proceed with step 2.

2. Select "Display Setup" from the Main Menu.

3. Select "Language" from the Display Setup menu and chose the required language (see page 79).

EN 5.10 SuSix Manual 1406

43

FW: 841013-005/843003-001

Page 44

Turbidity and Suspended Solids Transmitter

Specify Main Screen

Data Logger

Password

Set Sensor Name

Converter Setup

Display Setup

Back Select OK

Select line

Linie 1 - Sensor name

Linie 2 - Meas.

Linie 3 -

Linie 4 -

Linie 5

Back Select OK

Specify Main Screen

Select line content

SuSix1 [X]

Meas.

FTU

Select Setup

Main Menu

Converter Top Display

SuSix1 [X]

Meas.

FTU

Select Setup

Converter Top Display

Specify Main Screen

Data Logger

Password

Set Sensor Name

Converter Setup

Display Setup

Back Select OK

Main Menu

Display Read-out, one connected unit

All SuSix® display read-outs are illustrated and described in this manual.

Chapter 6. SuSix® Menus (on page 47) gives a detailed description of

the 5-line LCD screen displays shown during setup, configuration and

normal operation.

The display shown above will in the remaining part of this manual be stylized to appear like this:

Display and keyboard for reading and programming

SuSix1 [X]

Prim.

Second 0.1%

mg/l

Select Setup

44EN 5.10 SuSix Manual 1406

FW: 841013-005/843003-001

Page 45

Turbidity and Suspended Solids Transmitter

Oxix1

Oxygen

% SAT

Converter Overview Menu

Converter Overview Menu

Specify Main Screen

Data Logger

Password

Set Sensor Name

Converter Setup

Display Setup

Back Select OK

Select line

Linie 1 - Sensor name

Linie 2 - Meas.

Linie 3 -

Linie 4 -

Linie 5

Back Select OK

Specify Main Screen

Select line content

SuSix1 [X]

Meas.

FTU

Select Setup

Main Menu

Converter Top Display

SuSix1 [X]

Meas.

FTU

Select Setup

Converter Top Display

Specify Main Screen

Data Logger

Password

Set Sensor Name

Converter Setup

Display Setup

Back Select OK

Main Menu

Display Read-out, several connected units

When several MJK units are interconnected, for example an Oxix® dissolved oxygen transmitter and a SuSix® turbidity and suspended solids

transmitter with different names and Modbus ID numbers, a "Display Overview Menu" is available at top level (press "Back" repeatedly):

Oxix1 91.9 %

Susix1 578 mg/L

Back Select Display

All connected units are displayed and sorted by their ID numbers, and

consequently each unit can be selected and set up as required:

Oxix1

Oxygen

Important:

More connected units can only by managed as described above, if

each unit have been assigned a unique name and Modbus ID number. See page 81 for details.

Display Keys

The keys and the soft keys (variable key functions determined by the

display firmware) are used for initial programming and normal operation of

the flow meter.

The function(s) of the four available keys is displayed at the bottom of the

display. The symbols and actual functions are described in detail in the

sections that describe the individual menus.

Select Set up

% SAT

or

SuSix1 [X]

Prim.

Second 0.1%

Select Setup

mg/l

EN 5.10 SuSix Manual 1406

45

FW: 841013-005/843003-001

Page 46

Turbidity and Suspended Solids Transmitter

Contrast Adjustment

Adjust the display contrast by pressing the two outmost keys simultaneously (indicated by the keys) and press the up/down keys as required.

Save the new setting by pressing the two outmost keys simultaneously.

System Reset

You can reset and refresh all system displays and key combinations by

pressing all four keys simultaneously.

This feature is especially useful during for example a service call, where the

display language (Dutch, Danish, etc.) cannot be understood by the local

service person. A system reset immediately sets the display language to

English.

The system reset must not be confused with the ultimate "Recover factory

settings" (see page 68) which deletes all local configurations/settings and

replaces them with default factory settings.

46EN 5.10 SuSix Manual 1406

FW: 841013-005/843003-001

Page 47

Turbidity and Suspended Solids Transmitter

SuSix1 [X]

Meas.

FTU

Select Setup

Converter Top Display

Converter Top Display

Specify Main Screen

Data Logger

Password

Set Sensor Name

Converter Setup

Display Setup

Back Select OK

Select line

Specify Main Screen

SuSix1 [X]

Meas.

FTU

Select Setup

Main Menu

Converter Top Display

SuSix1 [X]

Meas.

FTU

Select Setup

Converter Top Display

Main Menu

8. SuSix® Menus

All the SuSix® menus and sub menus are shown and described in the

following sections.

Continous overviews of the menu and sub-menu structures are presented

at the end of this manual:

• Main Menu Overview (page 112)

• Converter Setup Menu Overview (page 114)

• Service Menu Overview (page 122)

• Display Setup Menu Overview (page 126)

Main Menu

1. Press the "Setup" key on the SuSix® display (see below) to enter the

SuSix® Main Menu.

SuSix1 [X]

The SuSix® Main Menu contains a number of sub menus (see figure

below).

2. Press the up/down keys to highlight the required menu line

(here: Specify main screen) and then press OK to select it.

EN 5.10 SuSix Manual 1406

Meas.

Select Setup

Specify Main Screen

Data Logger

Password

Set Sensor Name

Converter Setup

Display Setup

Back Select OK

47

FTU

FW: 841013-005/843003-001

Page 48

Turbidity and Suspended Solids Transmitter

Login

Activate/deactivate

Change password

Back Select OK

Set log interval

0010 sec

Back Select >

Data Logger

Set Sensor Name

SuSix1

Back Select >

Set Sensor Name

Specify Main Screen

Password

Type password

0000

Back Select >

Change password

Back Select >

Activate

Deactivate

Back Select OK

Login

Activate/

Deactivate

Change password

Specify Main Screen

The "Specify Main Screen" menu allows you to customize the SuSix®

display to suit your requirements. You can add and remove five available

display lines and name/configure them individually.

1. Press the up/down keys to highlight the required menu line and then

press OK to select it.

2. Press the up/down keys to highlight the required option and press OK.

The available options are:

Not in use

The line not used. The freed space will be used by the other lines.

Meas.

Meas. (Measurement) displays the measured values in time in the pre-

defined unit (NTU, FTU, FNU or EBC for turbidity and mg/l, g/l, kg/l or

% for suspended solids).

Linie 1 - Sensor name

Select line

Linie 2 - Meas.

Linie 3 Linie 4 Linie 5

Back Select OK

Select line content

Not in use

Meas.

Homogeneity

Solid curve

Clock

Back Select OK

48EN 5.10 SuSix Manual 1406

FW: 841013-005/843003-001

Page 49

Turbidity and Suspended Solids Transmitter

Note: The units are defined later on in the "Converter setup/Units" menu

on page 60.

Homogeneity

Displays the homogeneity of the measurement. The value informs

about the composition of the liquid, not the quality of the measurement.

0% indicates full homogeneity.

100% indicates full non-homogeneity.

Solid curve

A liniarization curve can be selected depending on the application. It

only applies in suspended solids mode.

Clock

Time and date

The size of the display lines will automatically increase or decrease as the

number of display lines is removed or added to maximize the field of view

for the measured values

EN 5.10 SuSix Manual 1406

49

FW: 841013-005/843003-001

Page 50

Turbidity and Suspended Solids Transmitter

Specify Main Screen

Data Logger

Password

Set Sensor Name

Converter Setup

Display Setup

Back Select OK

Specify Main Screen

SuSix1 [X]

Meas.

FTU

Select Setup

Main Menu

Converter Top Display

SuSix1 [X]

Meas.

FTU

Select Setup

Converter Top Display

Main Menu

Login

Activate/deactivate

Change password

Back Select OK

Data Logger

Set Sensor Name

SuSix1

Back Select >

Set Sensor Name

Converter Setup

Sensor Calibration

Averaging

Units

mA output

Cleaning

Solid curve

Password

Data Logger

SuSix® provides a data logger with a capacity of approx. 20,000 entry

points. See Appendix D on page 107 for examples and descriptions of log

files.

The data logger operates after the FIFO principle (First In, First Out). If the

data logger is full and new data are coming in, the oldest data are discarded.

1. Press the up/down keys to highlight the required menu line

(here: Data Logger) and then press OK to select it.

Specify Main Screen

Data Logger

Password

Set Sensor Name

Converter Setup

Display Setup

Back Select OK

2. Press the up/down keys to change the highlighted digit, and then press

the right-key (>) to proceed to the next digit.

3. Continue until all digits have been set and press OK.

The log interval can be set in intervals from 10 seconds up to 9999

seconds.

Set log interval

Back Select >

50EN 5.10 SuSix Manual 1406

0010 sec

FW: 841013-005/843003-001

Page 51

Turbidity and Suspended Solids Transmitter

The data log contains:

• Date

• Time

• Flow values

In case of a power failure, the data logger continues when power returns.

If more converters are connected to one Display Unit, each converter has

its own individual log interval and can be sorted.

All converters share the same memory of 20.000 entry points.

The log data can be shown on the Display Unit or be stored in an external

CSV file. MJK-Field Link software is needed for transfer of data into CSV

file format via the USB port in the display unit. The format can be read in

for example Microsoft® Excel® (see Appendix D on page 107 for details).

An example of the log capacity of one sensor versus the time interval is

shown in the following table.

Log interval Log capacity

Seconds Minutes Hours Days

10 - 55,56 2,31

30 - 166,67 6,94

- 1 333 14

- 5 1667 69

- 10 3333 139

- 30 10000 417

- 60 20000 833

EN 5.10 SuSix Manual 1406

51

FW: 841013-005/843003-001

Page 52

Turbidity and Suspended Solids Transmitter

10000.00000MG/L

2007-08-21

15:25:42 1.31200MG/L

<< >>< >

SuSix1

Measurement

2312 mg/L

Select Graph

Graph Display

The content of the Data Logger can displayed on the Display Unit by

pressing the up/down keys, highlighting "Measurements" and selecting

"Graph"

SuSix1

2312 mg/L

Measurement

Select Graph

The Display Unit then shows the Graph screen. To return to the Main

Menu display screen, select "esc" by pressing the up/down keys simultaneously.

The Y axis is automatically scaled according to the maximum value of the

mA output.

Double-arrow keys jump forward and backward one screen frame at a

time. Single-arrow keys move the cursor forward and backward on the

screen.

The actual values at the cursor position is shown at the bottom of the

screen.

52EN 5.10 SuSix Manual 1406

FW: 841013-005/843003-001

Page 53

Turbidity and Suspended Solids Transmitter

Specify Main Screen

Data Logger

Password

Set Sensor Name

Converter Setup

Display Setup

Back Select OK

Specify Main Screen

SuSix1 [X]

Meas.

FTU

Select Setup

Main Menu

Converter Top Display

SuSix1 [X]

Meas.

FTU

Select Setup

Converter Top Display

Main Menu

Data Logger

Set Sensor Name

Converter Setup

Sensor Calibration

Averaging

Units

mA output

Cleaning

Solid curve

High Alarm

Low Alarm

Sensor error

Status

Factory settings

Service Menu

Back Select OK

Password

Password

A password provides (and prevents) access to all the settings in the

Display and Converter unit. The code consists of a numeric 5-digit code

between 0 and 65535. If your current password is lost or forgotten, the

password protection can be overruled with the code "01750".

1. Press the up/down keys to highlight the required menu line

(here: Password) and then press OK to select it.

Specify Main Screen

Data Logger

Password

Set Sensor Name

Converter Setup

Display Setup

Back Select OK

2. Press the up/down keys to highlight the required option and then press

OK to select it.

Set log interval

Back Select >

Login

Type password

Back Select >

EN 5.10 SuSix Manual 1406

0010 sec

Login

Activate/deactivate

Change password

Back Select OK

Activate/

Deactivate

Activate

0000

Deactivate

Back Select OK

53

Set Sensor Name

SuSix1

Back Select >

Change password

Change password

Back Select >

0000

FW: 841013-005/843003-001

Page 54

Turbidity and Suspended Solids Transmitter

The available options are:

Login

Use the up/down keys to set the digits one by one. Continue with >

until all digits have been set and then press OK.

Activate/deactivate

Write protection. Selecting "Activate" means that a password must

be entered to change vital settings. "Deactivate" disables password

protection.If your current password is lost or forgotten, the password

protection can be overruled with the code "01750".

Change password

The present 5-digit password can be changed as required.

54EN 5.10 SuSix Manual 1406

FW: 841013-005/843003-001

Page 55

Turbidity and Suspended Solids Transmitter

Specify Main Screen

Data Logger

Password

Set Sensor Name

Converter Setup

Display Setup

Back Select OK

Select line

Specify Main Screen

SuSix1 [X]

Meas.

FTU

Select Setup

Main Menu

Converter Top Display

SuSix1 [X]

Meas.

FTU

Select Setup

Converter Top Display

Main Menu

Set Sensor Name

A unique name and/or number, a function or a location can be assigned

for a sensor (here: "SuSix1"). It is consequently shown on the main display

with up to 4 display lines.

1. Press the up/down keys to highlight the required menu line

(here: Set Sensor Name) and then press OK to select it.

2. To change the default sensor name (SuSix1), press the left/right keys to

highlight the wanted character.

EN 5.10 SuSix Manual 1406

Specify Main Screen

Data Logger

Password

Set Sensor Name

Converter Setup

Display Setup

Back Select OK

55

FW: 841013-005/843003-001

Page 56

Turbidity and Suspended Solids Transmitter

Set Sensor Name

Converter Setup

Language

Set Clock

Modbus

Factory settings

Display SW version

Display Setup

Sensor Calibration

Averaging

Units

mA output

Cleaning

Set Sensor Name

SuSix1

Back Select >

3. Press the up/down keys to change the highlighted character and then

press > to proceed to the next character.

4. Continue with > until all numeric and alphabetical characters have been

set to.

5. Press OK.

The available characters depend on the chosen language. English, for

example, provides the following character set:

a b c d e f g h i j k l m n o p q r s t u v w x y z A B C D E F G H I J K L M N

O P Q R S T U V W X Y Z <space> 1 2 3 4 5 6 7 8 9 and 0.

56EN 5.10 SuSix Manual 1406

FW: 841013-005/843003-001

Page 57

Turbidity and Suspended Solids Transmitter

Specify Main Screen

Data Logger

Password

Set Sensor Name

Converter Setup

Display Setup

Back Select OK

Select line

Specify Main Screen

SuSix1 [X]

Meas.

FTU

Select Setup

Main Menu

Converter Top Display

SuSix1 [X]

Meas.

FTU

Select Setup

Converter Top Display

Main Menu

Converter Setup

Language

Set Clock

Modbus

Factory settings

Display SW version

Back Select OK

Display Setup

Converter Setup

"Converter Setup" provides configuration options for calibration, alarms,

units, etc. See detailed descriptions in the following sections, and a continuous fold-out overview on page Gf-2 at the end of this manual.

1. Press the up/down keys to highlight the required menu line

(here: Converter Setup) and then press OK to select it.

Specify Main Screen

Data Logger

Password

Set Sensor Name

Converter Setup

Display Setup

Back Select OK

2. Press the up/down keys to highlight the required option and then press

OK to select it.

The available options are described in detail in the following sections.

EN 5.10 SuSix Manual 1406

Sensor Calibration

Averaging

Units

mA output

Cleaning

Solid curve

High Alarm

Low Alarm

Sensor error

Status

Factory settings

Service Menu

Back Select OK

57

FW: 841013-005/843003-001

Page 58

Turbidity and Suspended Solids Transmitter

Averaging

Quality improvement

No

Yes

Back Select >

accordingly

Sensor Calibration

Averaging

0001 sec

(from 1 sek to 120 min)

Back Select >

Yes

Adjust calibration

Select point to adjust

1 point Done

2 point Adjust

3 point

Back Select OK

1

point

Sensor Calibration

The "Sensor Calibration" option sets the signal outlets, and the analogue

outputs and the limit values are «frozen» during the calibration process.

Sensor Calibration

Measurement samples

Adjust samples

Clear ”Measurement sample”

Clear ”Adjust samples”

Back Selec t OK

Measurement samples

1. point Measured

2. point Measured

3. point Measured

Back Select OK

1./2./3. point

Start sample?

Progress

[ 0% ]

Exit Start

1./2./3. point

Measureing

Progress

[||||||||||||||||| ] 45%

Cancel

Measure point 1/2/3

Done

Progress

[ 100% ]

Exit Next

Select sample

Start point

Select point

Adjust samples

Adjust sample

1 Measured 10,2 g/l

2 Measured 8,11 g/l

3 Measured 5,87 g/l

Back Select OK

1. point

Select point

2. point

Select point

3. point

Select point

Clear ”Measurement sample”

Clear ”Measurement sample”

No

Yes

Back Select Ok

Adjust

1. point

Back Selec t >

Ok

Adjust

2. point

Back Selec t >

Ok

Adjust

3. point

Back Selec t >

Ok

00010,2 g/l

Next

00008,11 g/l

Next

00005,87 g/l

Clear ”Adjust samples”

Clear ”Adjustment sample”

No

Yes

Back Select Ok

See page 23 for detailed calibration procedures.

58EN 5.10 SuSix Manual 1406

FW: 841013-005/843003-001

Page 59

Turbidity and Suspended Solids Transmitter

Averaging

Units

mA output

Units

NTU (Turbidity)

FTU (Turbidity)

FNU (Turbidity)

EBC (Turbidity)

% (Suspended solids)

mg/l (Suspended solids)

g/l (Suspended solids)

Kg/l (Suspended solids)

Back Select OK

Fortsætter på side 5

4mA output

4 mA = 00.00 g/l

Back Select OK

accordingly

Yes

Use mA output

Yes

No

Back Select OK

Turbidity calibration

A complete, normalized linearization curve of the probe is installed by the

manufacturer. No further calibration is possible (or required).

Suspended solids calibration

There are no calibration standards pre-defined for the system. Each measurement must be calibrated individually, and it is possible to define two

suspended solids curves for use in different liquids.

Suspended solids calibration requires a sample to be evaluated in a

laboratory in order to set the relation between the measured point and the

actual value of the sample.

Averaging

The "Averaging" option sets the time period within which the measurements are smoothed and averaged.

The current measured value is compared with the standard deviation of

the previous measured values. This feature ensures that a sudden deviation in the liquid composition is eliminated in the measurement

Quality improvement

No

Yes

Back Select >

Yes

(from 1 sek to 120 min)

Back Select >

1. Select "Yes" in the "Quality improvement" window.

EN 5.10 SuSix Manual 1406

Averaging

0001 sec

59

FW: 841013-005/843003-001

Page 60

Turbidity and Suspended Solids Transmitter

Units

mA output

Fortsætter på side 5

4mA output

4 mA = 00.00 g/l

accordingly

Yes

Use mA output

Yes

No

Back Select OK

2. Select the digits one by one with the left/right keys and set the value

with the up/down keys.

3. Press OK to save the final setting.

Units

The "Units" option sets the unit for turbidity and suspended solids. The

available units are shown below.

NTU (Turbidity)

FTU (Turbidity)

FNU (Turbidity)

EBC (Turbidity)

% (Suspended solids)

mg/l (Suspended solids)

g/l (Suspended solids)

Kg/l (Suspended solids)

Back Select OK

Units

1. Press the up/down keys to highlight the required unit and then press

OK to select it.

60EN 5.10 SuSix Manual 1406

FW: 841013-005/843003-001

Page 61

Turbidity and Suspended Solids Transmitter

mA output

Fortsætter på side 5

mA Output

When a SuSix® is connected to a power supply for the first time, the

mA output is automatically set to provide 4 mA at zero and 20 mA at the

theoretical maximum value.

Changes in the mA setting will not affect the relay output settings.

Note: Both values can be set in the range 10 % to 120 %, making it

possible to increase or decrease the mA signal.

Use mA output

Yes

No

Back Select OK

Yes

4mA output

4 mA = 00.00 g/l

Back Select OK

20 mA output

20 mA = 20.00 g/l

Back Select OK

The mA output is an active output, and the maximum load is 800 Ohm.

The upper limit for the mA output is 20,5 mA

3,75 mA indicates the mA output is not in use

3,5 mA indicates values under 4 mA level

20,5 mA indicates value higher than 20 mA level.

EN 5.10 SuSix Manual 1406

61

FW: 841013-005/843003-001

Page 62

Turbidity and Suspended Solids Transmitter

Cleaning

Menu is only

shown if sensor

hardware includes

the cleaning

device

Select curve

Curve 1

Curve 2

Back Selec t OK

Manual

Cleaning

If the sensor is the wiper type, the "Cleaning" menu is automatically available, and you may set the cleaning intervals as required.

Interval

Use DI to clean

Clean now

Maintenance

Back Select OK

Interval

Interval

Off

On

Back Select OK

Select cleaning interval

(20 - 255 Min)

Back Select >

060 Min

Use DI to clean

No

Yes

Back Select Ok

Delay

Back Select >

DI function

NO

NC

Back Select Ok

DI

00100 ms

Clean now

Yes

No

Back Select OK

Maintenance

Runtime 1000 hour

Count 500

Back Select OK

Reset Maintenance

Yes

No

Back Select OK

Cleaning may be determined by a fixed time interval, by a digital input

signal (DI), by manual interaction (Clean now), or by a number of runtime

hours.

MaintenanceClean now

62EN 5.10 SuSix Manual 1406

FW: 841013-005/843003-001

Page 63

Turbidity and Suspended Solids Transmitter

Solid curve

Solid curve

It is possible to define two calibration curves for measuring suspended

solids in different liquids.

The calibration (liniarization) curves each requires a sample to be evaluated

in a laboratory in order to set the relation between the measured point and