Page 1

Motors | Automation | Energy | Transmission & Distribution | Coatings

Soft-Starter

Arrancador Suave

Soft-Starter

SSW-07

User's Manual

Manual del Usuario

Manual do Usuário

Page 2

SOFT-STARTER

USER’S MANUAL

MANUAL DEL

USUARIO DEL

ARRANCADOR

SUAVE

English

Español

MANUAL DO

USUÁRIO DA

SOFT-STARTER

Series: SSW-07

Document: 0899.5832 / 10

English - Español - Português

Português

07/2012

Page 3

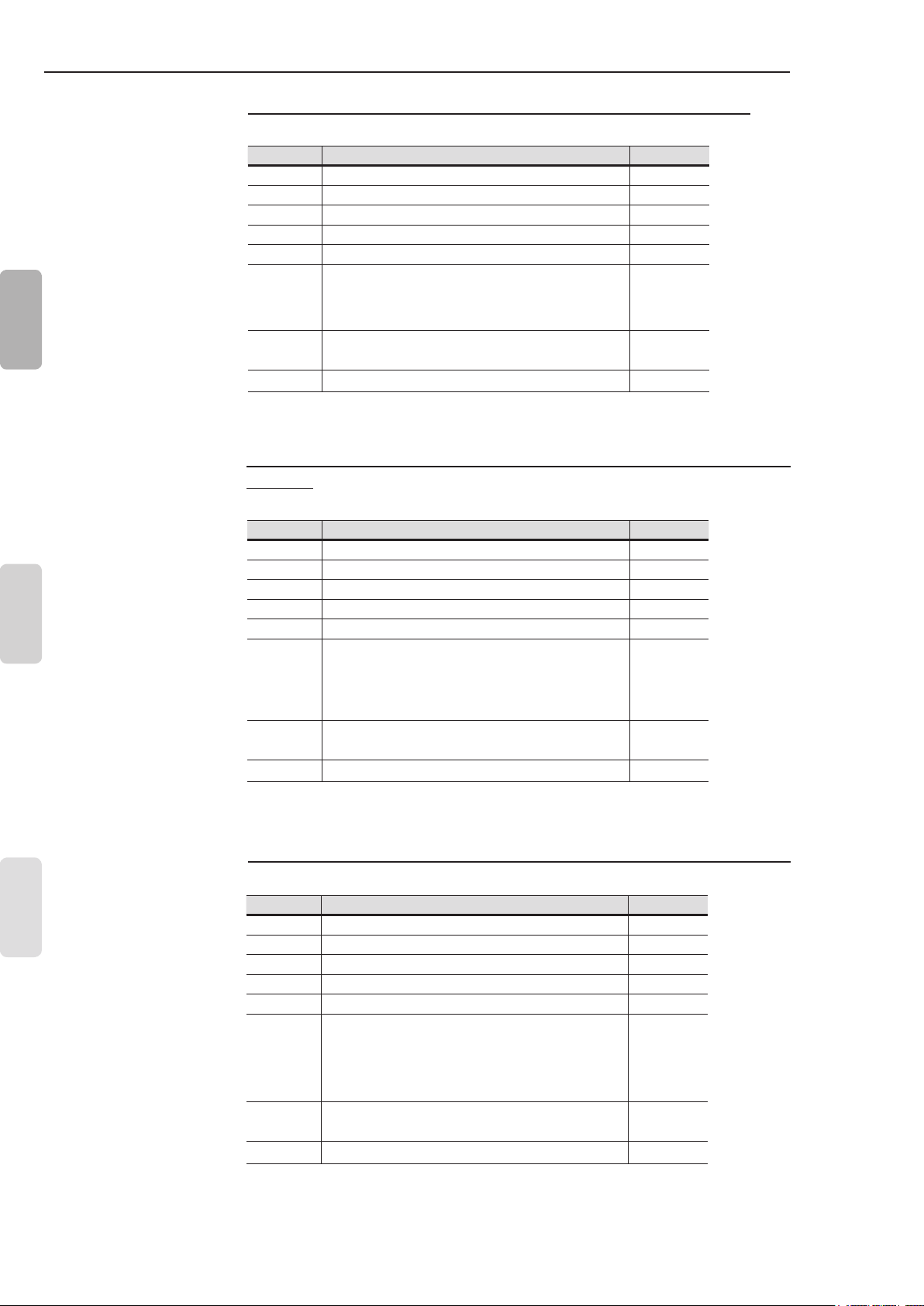

Summary of revisions / Sumario de las revisiones / Sumário das revisões

The information below describes the revisions in this manual.

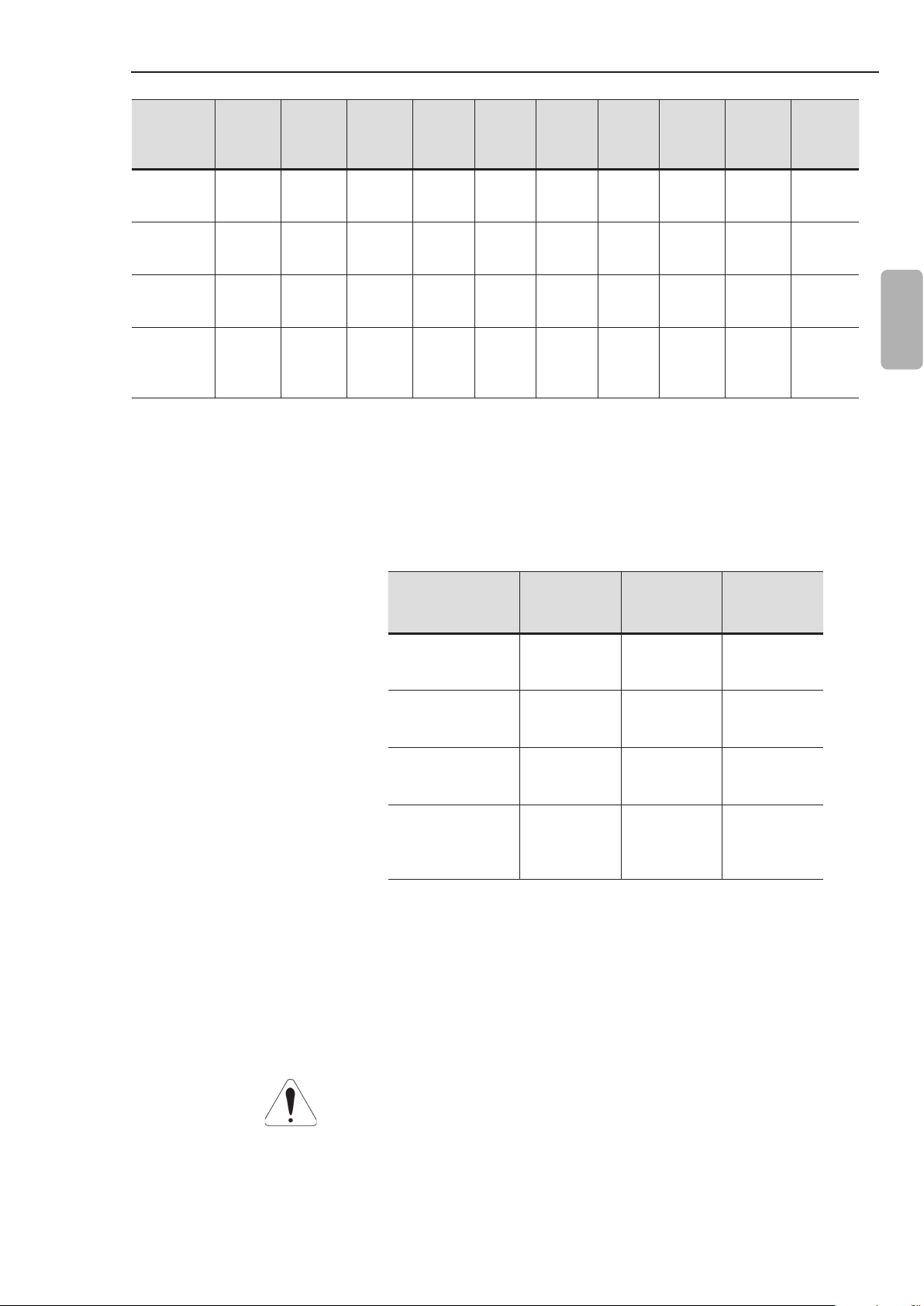

Revision Description Chapter

1 First Edition 2 General Revision 3 General Revision 4 Size 4 Included -

5 and 6 Table 3.1 and 8.2 corrected 3 and 8

English

Revision after the Size 4 UL certication.

7

Changed: item 3.2.3; 3.2.4.1; 3.2.4.2; 3.2.7;

4.8; 5.2; E77 in the table 6.1; table 8.1

8

9 General Revision -

Included new functions of

software version V1.4x

3, 4, 5, 6

and 8

3,4

and 5

La información abajo describe las revisiones ocurridas en este

manual.

Español

Português

Revisión Descripción Capítulo

1 Primer Edición 2 Revisión General 3 Revisión General 4 Inclusión Mecánica 4 -

5 y 6 Correción de las tablas 3.1 y 8.2 3 y 8

Corrección luego de la certicación UL de la

Mecánica 4. Modicado: ítem 3.2.3; 3.2.4.1;

7

8

9 Revisión General -

3.2.4.2; 3.2.7; 4.8; 5.2; E77 en la tabla 6.1;

tabla 8.1

Inclusión de las nuevas funciones de la

version de software V1.4x

3, 4, 5, 6

y 8

3, 4 y 5

A informação abaixo descreve as revisões ocorridas neste manual.

Revisão Descrição Capítulo

1 Primeira Edição 2 Revisão Geral 3 Revisão Geral 4 Inclusão da mecânica 4 -

5 e 6 Correções das tabelas 3.1 e 8.2 3 e 8

Correção depois da certicação UL da

7

8

9 Revisão Geral -

Mecânica 4. Alterado: item 3.2.3; 3.2.4.1;

3.2.4.2; 3.2.7; 4.8; 5.2; E77 na tabela 6.1;

tabela 8.1

Inclusão das novas funções da versão

de software V1.4x

3, 4, 5,

6 e 8

3, 4 e 5

Page 4

Summary

CHAPTER 1

Safety Instructions

1.1 Safety Notices in the Manual ................................................5

1.2 Safety Notices on the Product ..............................................5

1.3 Preliminary Recommendations .............................................5

CHAPTER 2

General Information

2.1 About this Manual ................................................................7

2.2 About the Soft-Starter SSW-07 ............................................7

2.3 Soft-Starter SSW-07 Identication Plate ............................8

2.4 Receiving and Storage .......................................................11

CHAPTER 3

Installation and Connection

3.1 Mechanical Installation .......................................................12

3.1.1 Environmental Conditions ............................................12

3.1.2 Soft-Starter SSW-07 Dimensions ................................12

3.1.3 Mounting Specications ...............................................13

3.1.3.1 Mounting Inside a Panel .....................................14

3.1.3.2 Mounting on Surface ..........................................15

3.2 Electrical Installation ...........................................................15

3.2.1 Power Terminals ...........................................................16

3.2.2 Location of the Grounding, Control and Power

Connections ..................................................................17

3.2.3 Recommended Power and Grounding Cables ............18

3.2.4 Power Supply Connection to the Soft-Starter SSW-07 18

3.2.4.1 Power Supply Capacity .......................................19

3.2.4.2 Recommended Fuses .........................................19

3.2.4.3 Recommended Contactors .................................20

3.2.5 Soft-Starter SSW-07 Connection to the Motor .............20

3.2.5.1 Standard Three-Wire Connection .......................21

3.2.6 Grounding Connections ...............................................21

3.2.7 Control and Signal Connections ...................................22

3.3 Recommended Set-ups ......................................................23

3.3.1 Recommended Set-up with Command via Two-wire

Digital Inputs and Isolation Contactor ..........................24

3.3.2 Recommended Set-up with Command via Three-wire

Digital Inputs and Circuit-Breaker ................................24

3.3.3 Recommended Set-up with Command via Two-wire

Digital Inputs and Direction of Rotation .......................25

3.3.4 Recommended Set-up with Command via Two-wires

Digital Inputs and DC-Braking .....................................26

3.3.5 Symbols .......................................................................27

English

Page 5

Summary

English

CHAPTER 4

Setting the SSW-07

4.1 Control Type Setting ...........................................................28

4.2 Kick Start ............................................................................29

4.3 Initial Voltage Setting ..........................................................29

4.4 Current Limit Setting ...........................................................30

4.5 Acceleration Ramp Time Setting ........................................31

4.6 Deceleration Ramp Time Setting ........................................31

4.7 Motor Current Setting .........................................................32

4.8 Motor Electronic Overload Protection ................................33

4.9 Reset ..................................................................................36

4.10 DI2 Digital Input Setting ....................................................36

4.11 Output Relay Operation ....................................................37

4.12 Relay Output RL1 Programming ......................................37

CHAPTER 5

Programming Information and Suggestions

5.1 Applications and Programming ...........................................38

5.1.1 Voltage Ramp Starting .................................................39

5.1.2 Current Limit Starting ...................................................40

5.1.3 Starting with Pump Control (P202 = 2) ........................40

5.1.4 Programming the control type in pump control ............42

5.2 Protections and Programming ............................................43

5.2.1 Suggestion on How to Program the Thermal Class .....43

5.2.2 Service Factor ..............................................................45

CHAPTER 6

Solution and Troubleshooting

6.1 Faults and Possible Causes ...............................................47

6.2 Troubleshooting ..................................................................50

6.3 Preventive Maintenance .....................................................51

CHAPTER 7

Options and Accessories

7.1 IP20 Kit ...............................................................................52

CHAPTER 8

Technical Characteristics

8.1 Nominal Powers and Currents According to UL508 ...........53

8.2 Nominal Powers and Currents for Standard IP55,

IV Pole Weg Motor .............................................................53

8.3 Power Data .........................................................................54

8.4 Electronics and Programming Data ....................................54

Page 6

CHAPTER 1

SAFETY INSTRUCTIONS

This Manual contains the necessary information for the correct use

of the Soft-Starter SSW-07.

It was written to be used by qualied personnel with suitable training

or technical qualications to operate this type of equipment.

1.1 SAFETY NOTICES IN THE MANUAL

1.2 SAFETY NOTICES ON THE PRODUCT

The following safety notices will be used in the text.

DANGER!

The nonobservance of the procedures recommended in this warning

can lead to death, serious injuries and considerable material damage.

ATTENTION!

Failure to observe the recommended procedures in this notice may

lead to material damage.

NOTE!

The text intents to supply important information for the correct

understanding and good operation of the product.

The following symbols may be attached to the product as a safety

notice.

English

1.3 PRELIMINARY RECOMMENDATIONS

High Voltages.

Components are sensitive to electrostatic discharge.

Do not touch them.

Mandatory connection to ground protection (PE).

DANGER!

Only personnel with suitable qualication and familiar with the

Soft-Starter SSW-07 and associated equipment should plan or

implement the installation, start-up, operation and maintenance of

this equipment.

These personnel must follow all safety instructions in this manual

and/ or dened by local regulations.

Failure to follow these safety instructions may result in personnel

injury and/or equipment damage.

5

Page 7

CHAPTER 1 - SAFETY INSTRUCTIONS

NOTE!

In this Manual, qualied personnel are those trained to:

1. Install, ground, power-up, and operate the Soft-Starter SSW-07

according to this manual and the required safety procedures;

2. Use protection equipment according to established regulations;

3. Give First Aid.

DANGER!

Always disconnect the general power supply before touching any

electrical component associated to the Soft-Starter SSW-07.

English

High voltage may be present even after the power supply is

disconnected. Wait at least 3 minutes for the total discharge of the

capacitors.

Always connect the equipment’s heatsink to the protection ground

(PE), at the proper connection point.

ATTENTION!

All electronic boards have components that are sensitive to

electrostatic discharges. Do not touch these components or

connectors directly.

If necessary, rst touch the grounded metallic heatsink or use a

suitable grounded wrist strap.

Do not apply any high voltage test on the Soft-Starter SSW-07!

If necessary, contact the manufacturer.

NOTE!

Soft-Starters SSW-07 may interfere with other electronic equipment.

Follow the measures in Chapter 3 to reduce these effects.

NOTE!

Read this manual completely before installing or operating the

Soft-Starter SSW-07.

6

Page 8

GENERAL INFORMATION

Tampa para

Trifásica

Opcionais Plug-In

Ajustes e Habilitar as

Proteções

DIP Swith para

LED's para Indicação

Entrada de Alimentação

de Status da SSW-07

Saída para Motor

Saida a Relé

(13,14/23 e 24)

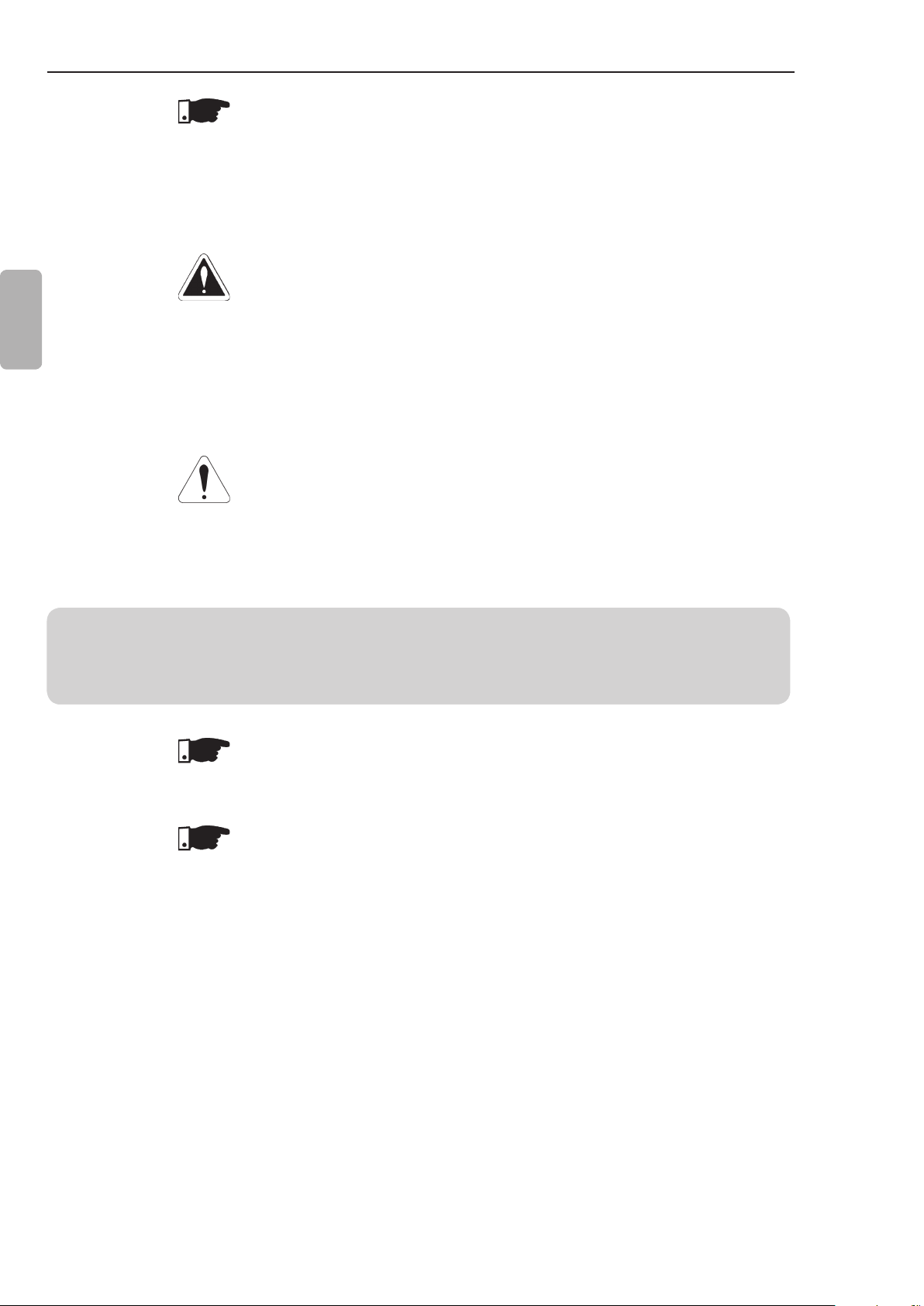

CHAPTER 2

2.1 ABOUT THIS MANUAL

2.2 ABOUT THE

SOFT-STARTER

SSW-07

This manual presents the Soft-Starter installation, how to start it up,

its main technical characteristics and how to identify and correct the

most common problems. The manuals listed next must be consulted

in order to get more information regarding the functions, accessories

and working conditions:

Programming Manual, with a detailed description of the

parameters and its functions;

RS232 / RS485 Communication Manual.

DeviceNet Communication Manual.

These manuals are supplied in electronic format on the CD-ROM

that accompanies the Soft-Starter, or can be obtained at WEG’s

web site: http://www.weg.net.

The Soft-Starter SSW-07 is a high performance product that permits

the start control of the three phase AC induction motors. Thus, it

prevents mechanical shocks on the load and current peaks in the

supply line.

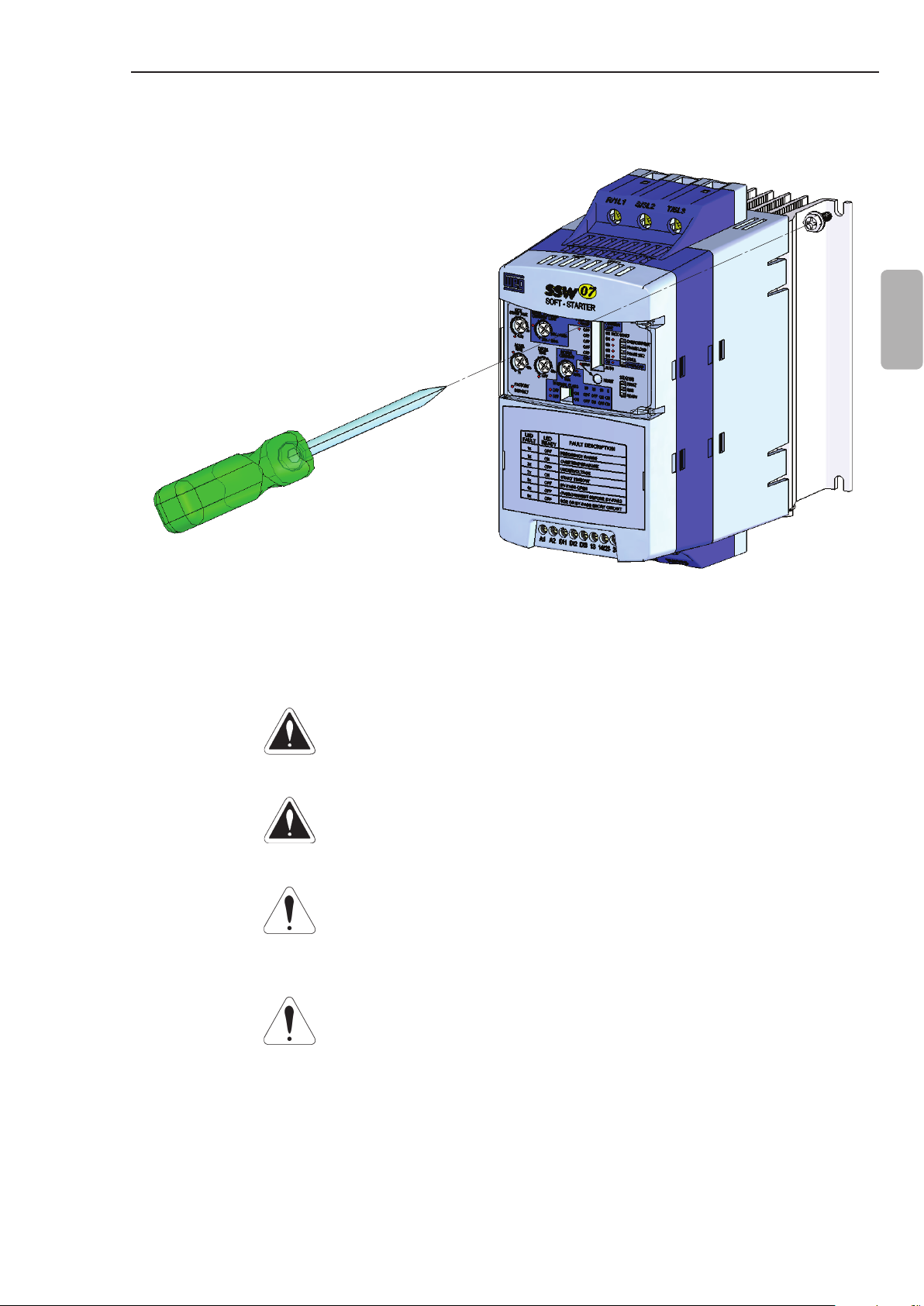

Three-phase

Power Supply

English

Trimpots to adjust

DIP switch to adjust

the Thermal Class

Electronic Power Supply

(A1 and A2)/

Start/Stop Command

of the Motor (D1) and

Reset (DI2 and DI3)

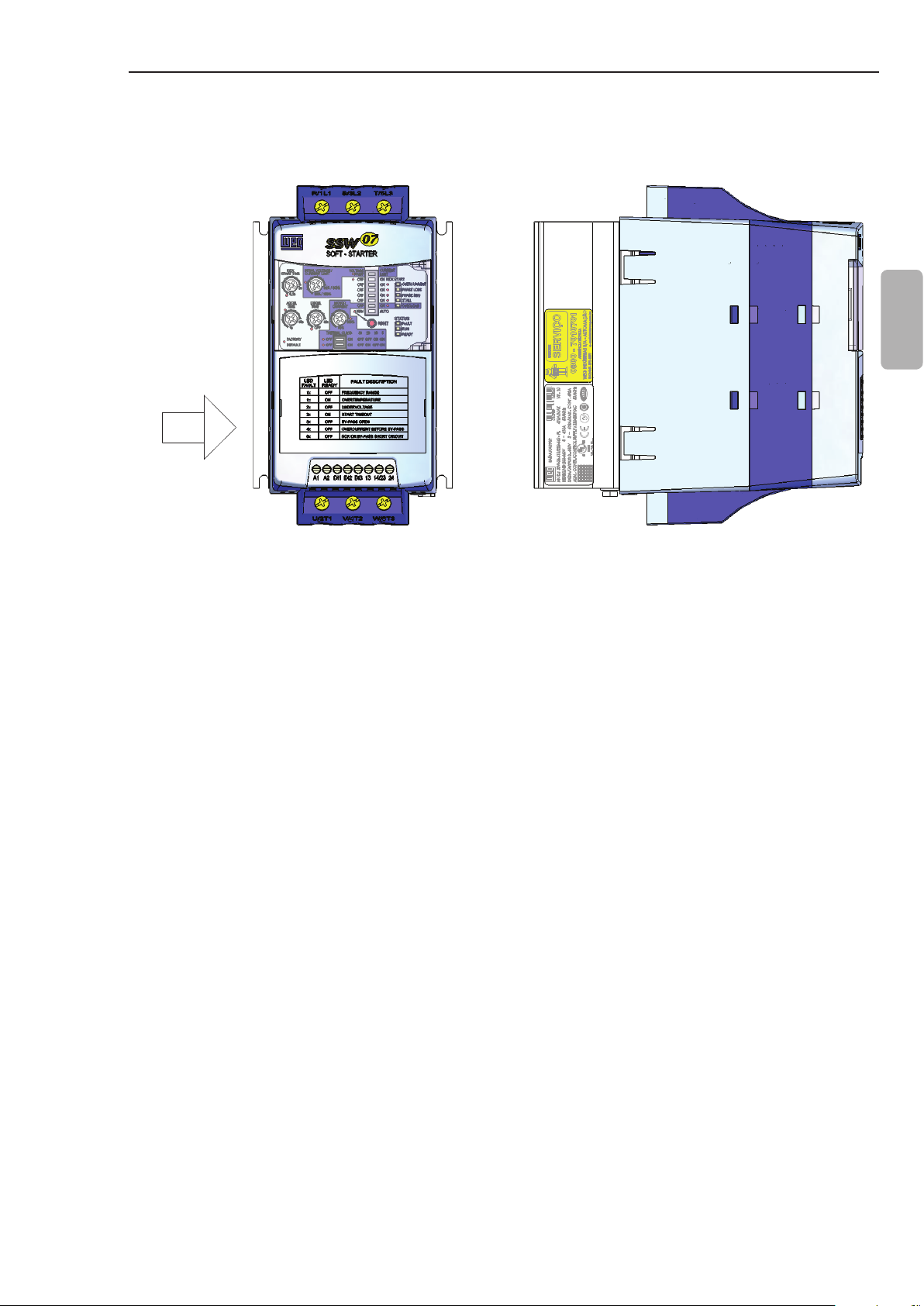

Figure 2.1 - Frontal view of the SSW-07

DIP Switch for

Soft-Starter adjustment

and protection enabling

Status Indication LEDs

of the SSW-07

Lid for optional Plug-in

Modules

Relay Output

(13, 14/23 and 24)

Motor Output

7

Page 9

CHAPTER 2 - GENERAL INFORMATION

English

Three-Phase

Power Supply

R S

U

V W

Three-Phase Motor

Programmable

Digital Inputs

Dl1

Dl2

Dl3

T

Control

Power Supply

A1

A2

3 x

Digital Signal

2 x

Processor

DSP

PE

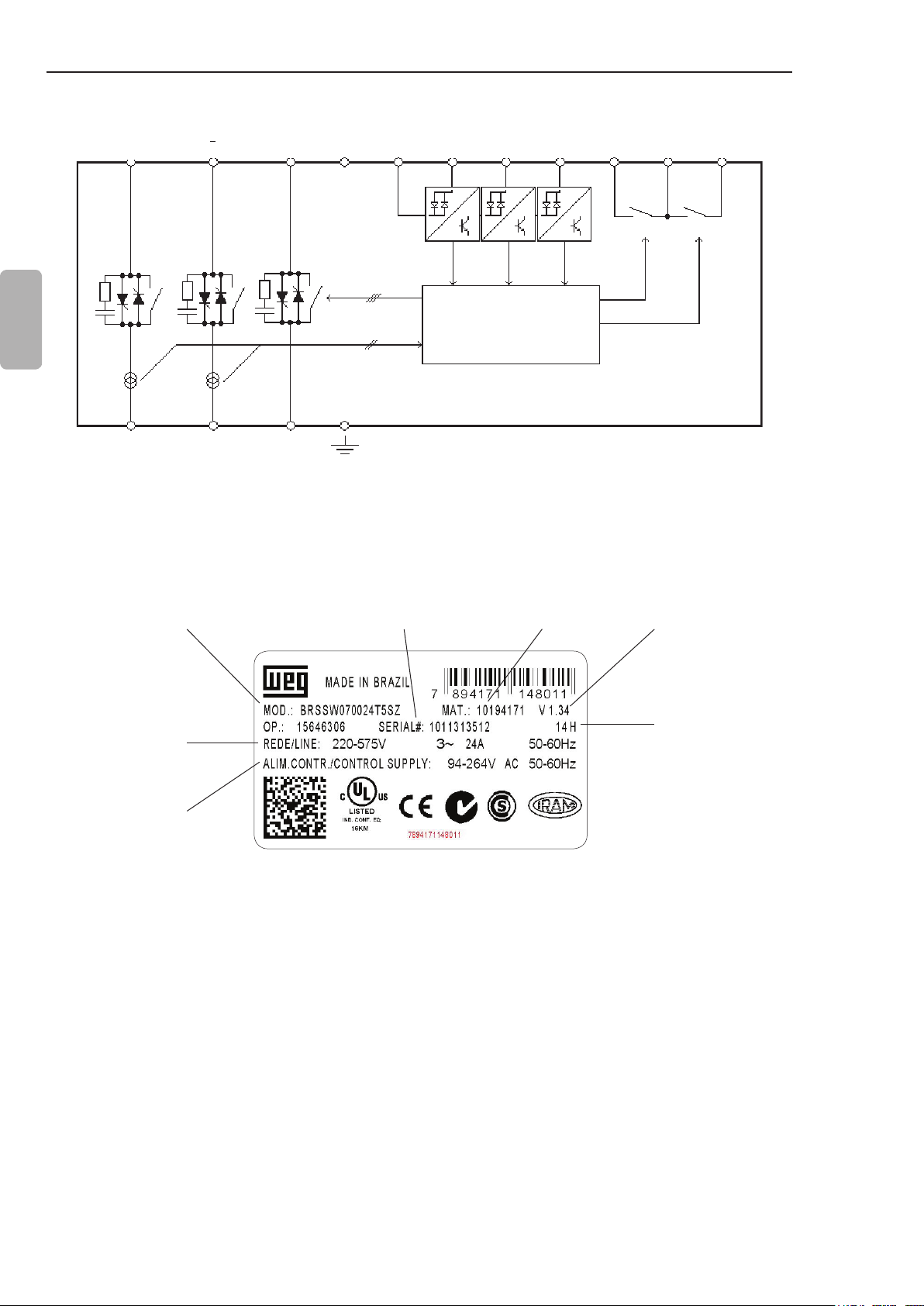

Figure 2.2 - Soft-Starter SSW-07 block diagram

Programmable Digital

Outputs

13

14/23 24

RL1

RL2

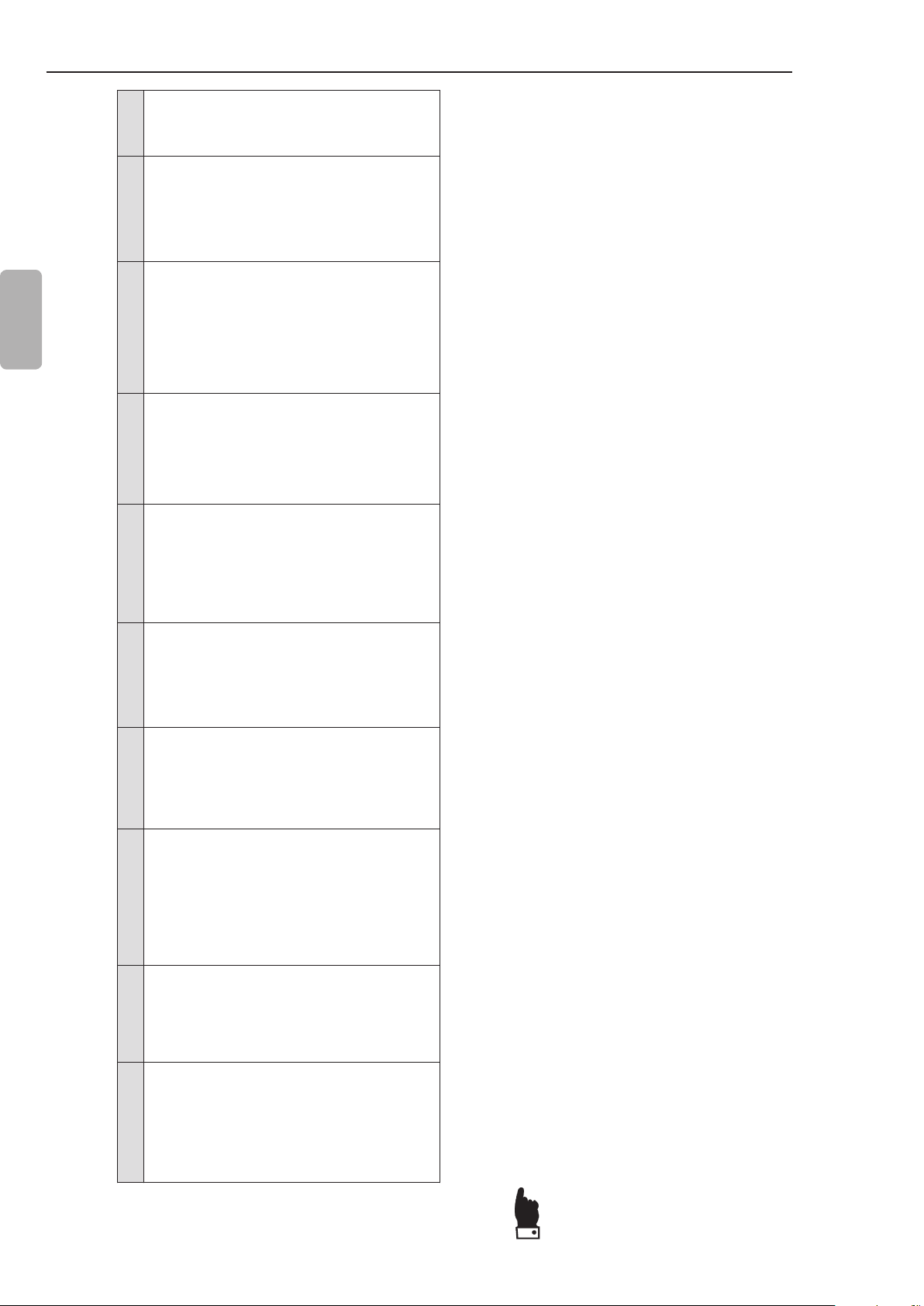

2.3 SOFT-STARTER SSW-07 IDENTIFICATION PLATE

WEG Stock

SSW-07 Model

Input Data (Voltage,

Number of Phases,

Current and Frequency)

Control Power Supply

Data (Voltage, Frequency)

Serial Number

Figure 2.3 - Soft-Starter SSW-07 identication plate

Item Number

Software

Version

Manufacturing date

(14 corresponds to

week and H to year)

8

Page 10

CHAPTER 2 - GENERAL INFORMATION

VISTA FRONTAL

VISTA DE X

Position of the Identication Plate on the Soft-Starter SSW-07:

FRONTAL VIEW X VIEW

English

X

Figure 2.4 - Location of the labels

9

Page 11

CHAPTER 2 - GENERAL INFORMATION

End of

Code

Special

Software

Blank =

Standard

S1 = Special

Software

English

Special

Hardware

Blank =

Degree of

Protection

Blank =

S = Standard

O = with

220-575 Vac Optional:

(2)

Standard

H1 = Electronics

supply: 110 to

130 Vac

H2 = Electronics

(1)

Standard

IP=IP20

Optional

(2)

supply: 208 to

240 Vac

10

HOW TO SPECIFY THE SSW-07 MODEL:

Three-

Phase

SSW-07

Nominal Current

WEG Soft-

Starter

EX SSW-07 0017 T 5 S _ _ _ _ _ _ Z

Market

Power

Supply

0017 = 17 A

0024 = 24 A

0030 = 30 A

Series

SSW-07

BR = Brazil

EX = Export

0045 = 45 A

0061 = 61 A

0085 = 85 A

0130 = 130 A

0171 = 171 A

0200 = 200 A

0255 = 255 A

0312 = 312 A

0365 = 365 A

0412 = 412 A

(1) Only for models 130 A to 412 A.

(2) Only for the 255 A to 412 A models.

NOTE!

The option eld (S or O) denes if the Soft-Starter SSW-07 will be a standard version or if it will include any optional. If standard, the

code ends here.

Always put the letter Z at the end. For example:

EXSSW070017T5SZ = Standard Soft-Starter SSW-07 with 17 A and 220 V to 575 V to three-phase input with the User’s Guide in

English, Spanish and Portuguese.

If there is any optional, the elds must be lled out in the correct sequence until the code is completed with the letter Z.

The standard product as dened by this code is described as:

Degree of Protection: IP20 from 17 A to 85 A and IP00 from 130 A to 412 A.

Page 12

CHAPTER 2 - GENERAL INFORMATION

2.4 RECEIVING AND STORAGE

The Soft-Starter SSW-07 is supplied in a cardboard box. On the

outside of the package there is an identication plate which is

identical to the one placed on the Soft-Starter SSW-07.

To open the package:

1- Put it on a table;

2- Open the package;

3- Take out the Soft-Starter.

Check if:

The Identication plate of the Soft-Starter SSW-07 matches the

model purchased:

Damage has occurred during transport. If so, contact the carrier

immediately.

If the Soft-Starter SSW-07 is not installed immediately, store it in

its package in a clean and dry place with temperature between

-25 °C (-13 °F) and 65 °C (149 °F). 1 hour at -40 °C (-40 °F) is

permitted.

English

SSW-07

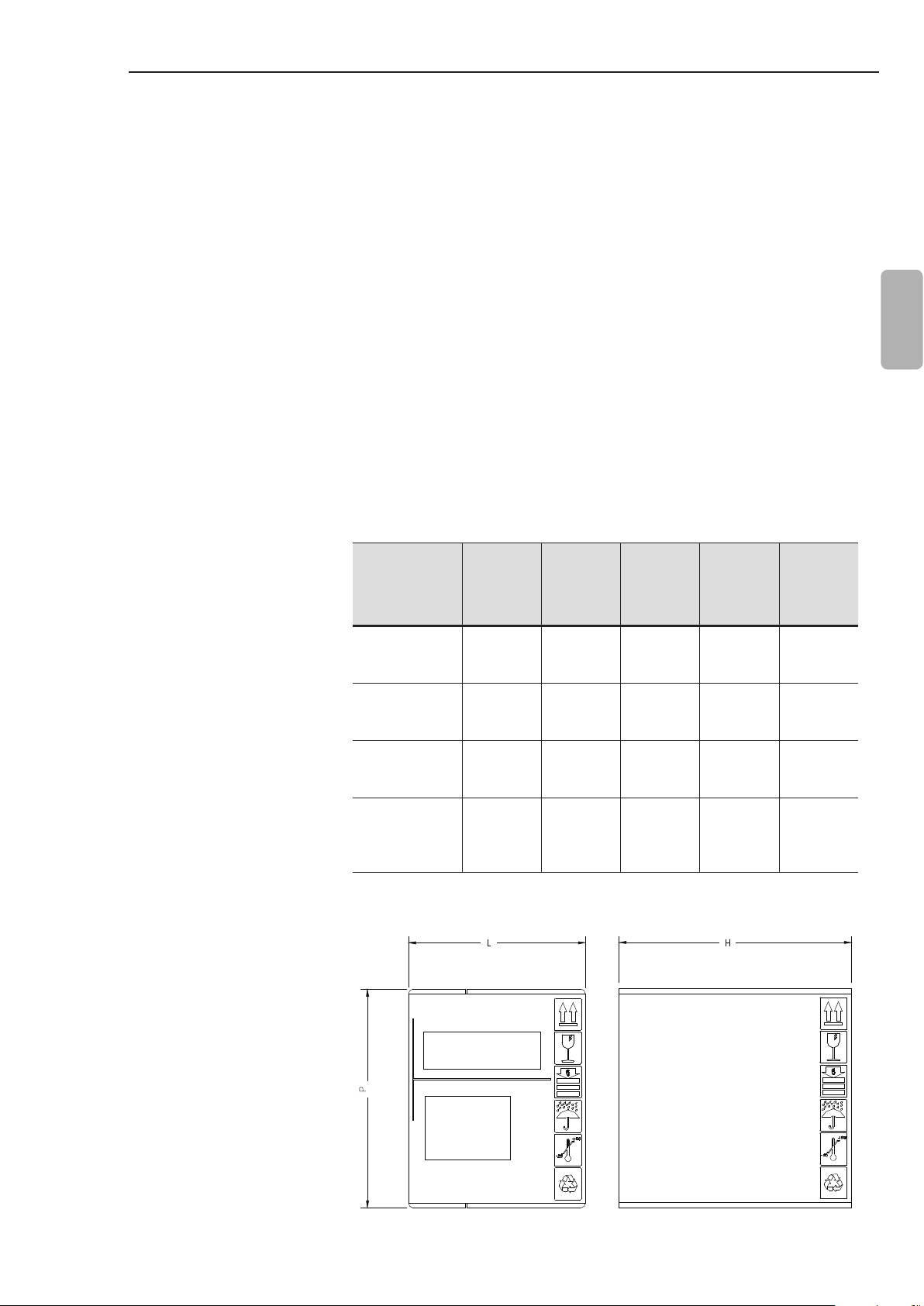

Model

17 A

24 A

30 A

45 A

61 A

85 A

130 A

171 A

200 A

255 A

312 A

365 A

412 A

Height

H

mm

(in)

221

(8.70)

260

(10.24)

356

(14.02)

415

(16.34)

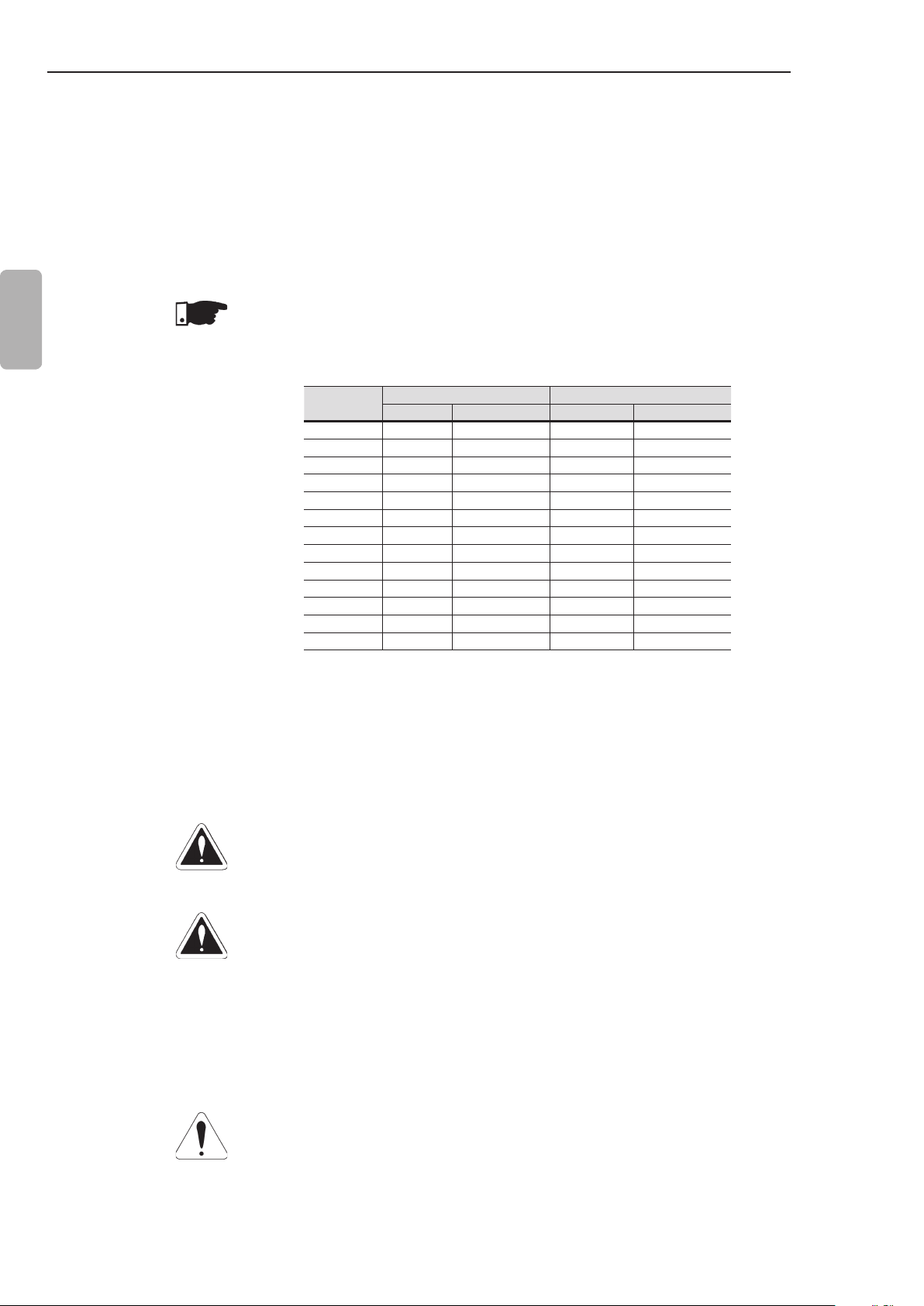

Table 2.1 - Dimensions of the package in mm (in)

Width

L

mm

(in)

180

(7.09)

198

(7.80)

273

(10.75)

265

(10.43)

Depth

P

mm

(in)

145

(5.71)

245

(9.65)

295

(11.61)

320

(12.6)

Volume

3

cm

(in3)

5768

(352.2)

12613

(770.8)

28670

(1750)

35192

(2147)

Weight

kg

(lb)

1.65

(3.64)

3.82

(8.42)

8.36

(18.43)

12.8

(28.2)

Figure 2.5 - Dimensions of the package

11

Page 13

C

A

B

P

L

3.1 MECHANICAL INSTALLATION

CHAPTER 3

INSTALLATION AND CONNECTION

This chapter describes the procedures for the electrical and

mechanical installation of the Soft-Starter SSW-07. The guidelines

and suggestions must be followed for the correct operation of the

Soft-Starter SSW-07.

3.1.1 Environmental

English

Conditions

The location of the Soft-Starters SSW-07 is an important factor to

assure the correct operation and high product reliability.

Avoid:

Direct exposure to sunlight, rain, high moisture and sea air ;

Exposure to explosive or corrosive gases and liquids;

Exposure to excessive vibration, dust or any metallic and/or oil

particles in the air.

Allowed Environmental Conditions:

Surrounding air Temperature: 0 ºC to 55 ºC (32 ºF to 131 ºF) -

nominal conditions.

Relative air moisture: 5 % to 90 %, with no-condensation.

Maximum altitude: 1,000 m (3,300 ft) above sea level - nominal

conditions.

From, 1,000 m to 4,000 m (3,300 ft to 13,200 ft) above sea level -

current reduction of 1 % for each 100 m (330 ft) above 1,000 m

(3,300 ft).

From 2000 m to 4000 m (6,600 ft to 13,200 ft) above sea level -

voltage reduction of 1.1 % for each 100m (330 ft) above 2,000 m

(6,600 ft).

Pollution degree: 2 (according to the UL508).

Normally, only non conductive pollution. Condensation must not

cause conduction in the particles in the air.

3.1.2 Soft-Starter SSW-07 Dimensions

B

D

D

C

12

The external dimensions and mounting holes are shown in gure

3.1 and table 3.1 below.

A

Figure 3.1 - SSW-07 dimensions

L

H

H

P

Page 14

CHAPTER 3 - INSTALLATION AND CONNECTION

Height

SSW-07

Model

17 A

24 A

30 A

45 A

61 A

85 A

130 A

171 A

200 A

255 A

312 A

365 A

412 A

H

mm

(in)

162

(6.38)95(3.74)

208

(8.19)

276

(10.9)

331

(13.0)

* IP20 with optional.

3.1.3 Mounting

Specications

Width

L

mm

(in)

144

(5.67)

223

(8.78)

227

(8.94)

Depth

P

mm

(in)

157

(6.18)85(3.35)

203

(7.99)

220

(8.66)

242

(9.53)

A

mm

(in)

132

(5.2)

208

(8.19)

200

(7.87)

B

mm

(in)

120

(4.72)5(0.20)4(0.16) M4

148

(5.83)6(0.24)

210

(8.27)

280

(11.0)15(0.59)9(0.35)

C

mm

(in)

7.5

(0.3)

D

Mounting

mm

(in)

3.4

(0.13) M4

5

(0.2) M5

Screw

M8

Weight

kg

(lb)

1.3

(2.9) IP20

3.3

(7.28) IP20

7.6

(16.8)

11.5

(25.4)

Table 3.1 - Installation data with dimensions in mm (in)

To install the Soft-Starter SSW-07 leave at least the free spaces

surrounding the Soft-Starter as in gure 3.2 below. The dimensions

of these free spaces are described in table 3.2.

Degree

of

Protection

IP00 *

English

IP00 *

SSW-07 Model

17 A

24 A

30 A

45 A

61 A

85 A

130 A

171 A

200 A

A

mm

(in)

50

(2)

80

(3.2)

100

(4)

B

mm

(in)

50

(2)

80

(3.2)

100

(4)

C

mm

(in)

30

(1.2)

30

(1.2)

30

(1.2)

255 A

312 A

365 A

150

(6)

150

(6)

30

(1.2)

412 A

Table 3.2 - Recommended free spaces

Install the Soft-Starter SSW-07 in the vertical position according to

the following recommendations:

1) Install on a reasonably at surface;

2) Do not put heat sensitive components immediately above the

Soft-Starter SSW-07.

ATTENTION!

If a Soft-Starter SSW-07 is installed on top of another use the

minimum distance A + B and diverge from the top Soft-Starter the

hot air that comes from the one beneath it.

13

Page 15

CHAPTER 3 - INSTALLATION AND CONNECTION

ATTENTION!

Independent conduits or cable trays must be planned for physic

separation of signal, control and power cables. (Refer to item 3.2

Electrical Installation).

A

A

English

SAIDA

Air Flow

FLUXO DE AR

Outlet

C

C

3.1.3.1 Mounting Inside a Panel

SSW-07

Model

130 A 12 117 129

171 A 12 154 166

200 A 12 180 192

255 A 12 230 242

312 A 12 281 293

365 A 12 329 341

412 A 12 371 383

Air Flow

B

B

Figure 3.2 - Free spaces for ventilation

ENTRADA

FLUXO DE AR

Inlet

For Soft-Starters SSW-07 installed in panels or closed metallic

boxes exhaustion/cooling is required so the temperature does not

exceed the maximum allowed. Refer to dissipated nominal power

in table 3.3.

Average Power

Dissipated Power

in the electronics

(W)

17 A 12 15.3 27.3

24 A 12 21.6 33.6

30 A 12 27 39

45 A 12 41 53

61 A 12 55 67

85 A 12 77 89

dissipated

10 starts/h

3 x In @ 30 s

(W)

Total Average Power

dissipated

10 starts/h

3 x In @ 30 s

(W)

14

Table 3.3 - Dissipated power for ventilator panel dimensioning

Page 16

CHAPTER 3 - INSTALLATION AND CONNECTION

3.1.3.2 Mounting on Surface

Figure 3.3 shows the installation of the Soft-Starter SSW-07 on the

surface of a mounting plate.

English

Figure 3.3 - Installation procedures of the Soft-Starter SSW-07 on a surface

3.2 ELECTRICAL

INSTALLATION

DANGER!

The Soft-Starter SSW-07 cannot be used as an emergency stop

device.

DANGER!

Be sure that the AC input power is disconnected before making any

terminal connection.

ATTENTION!

The information below may be used as a guide to achieve a proper

installation. Follow also the applicable local standards for electrical

installations.

ATTENTION!

If a power isolating contactor or circuit breaker with minimum voltage

coil is not used at the rst power on, then power up the electronics

rst, adjust the trimpots that are necessary to put the SSW-07 into

operation and only after this energize the power section.

15

Page 17

CHAPTER 3 - INSTALLATION AND CONNECTION

Circuit-breaker

T

S

R

Line

English

Fuses

R/1L1 S/3L2 T/5L3

3.2.1 Power Terminals

U/2T1 V/4T2 W/6T3 PE

Figure 3.4 - Standard power/grounding connections

PE

PE

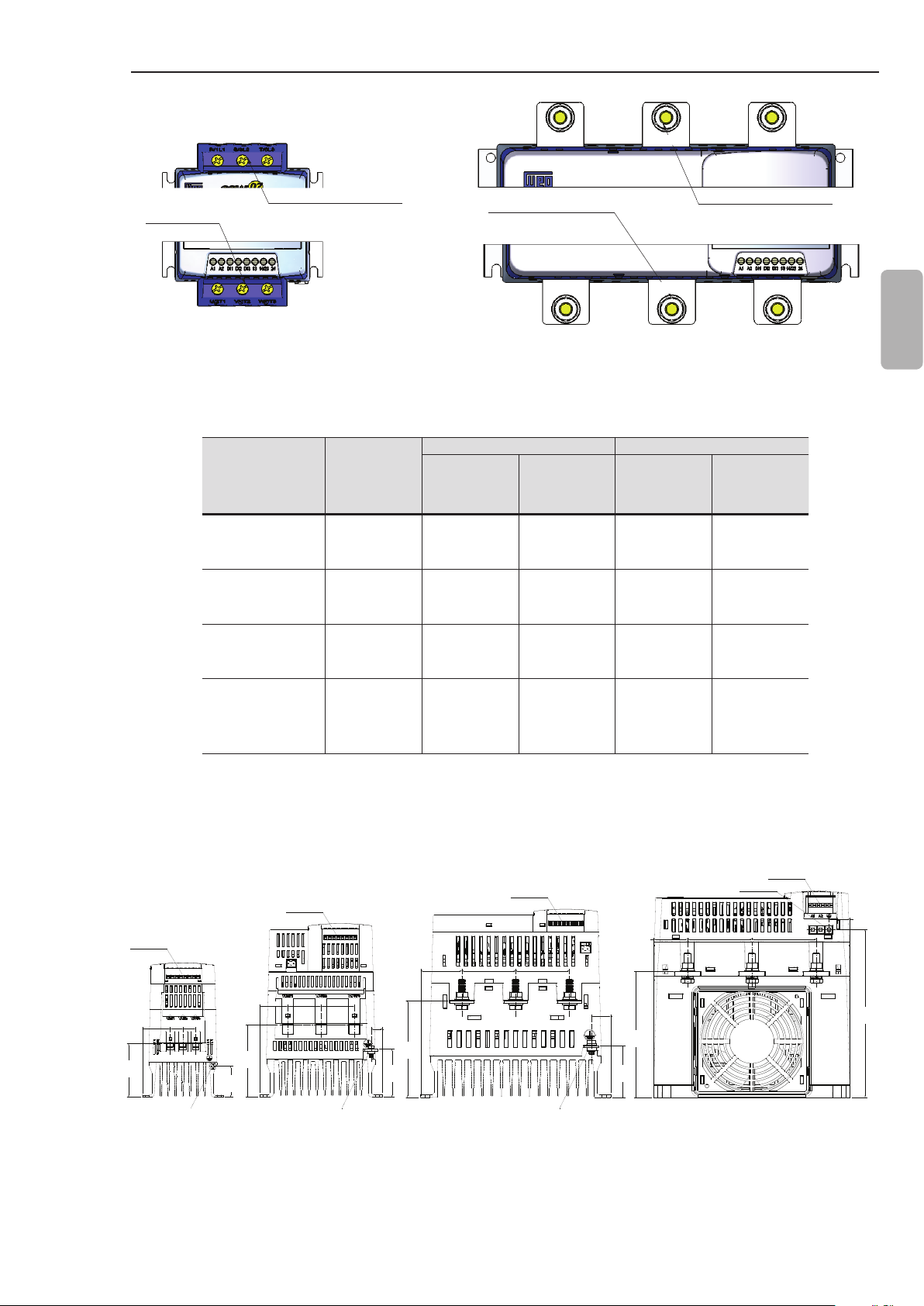

The power terminal blocks vary in size and conguration, depending

on the SSW-07 soft-starter model, as can be observed at the gures

3.5 and 3.6.

Terminals:

R / 1L1, S / 3L2 and T / 5L3: AC supply line.

U / 2T1, V / 4T2 and W / 6T3: Motor connection.

16

Page 18

CHAPTER 3 - INSTALLATION AND CONNECTION

R/1L1 S/3L2 T/5L3

Output Power

BORNE DE SAIDA

POTENCIA

Terminal

Models 17 A to 85 A Models 130 A to 412 A

Input

BORNE DE ENTRADA

Power Terminal

POTENCIA

SSW-07

Model

17 A

24 A

30 A

45 A

61 A

85 A

130 A

171 A

200 A

255 A

312 A

365 A

412 A

Figure 3.5 - Power terminals

Enclosure

Size

Screw/

Terminal

Size 01 Terminal

Size 02 Terminal

Size 03

Size 04

M8

(5/16”)

M10

(3/8”)

R/1L1

Output

BORNE DE SAIDA

POTENCIA

Power Terminal

U/2T1

S/3L2

V/4T2

Input

BORNE DE ENTRADA

POTENCIA

Power Terminal

Line / Motor Grounding

Torque

Nm

Screw

(in lb)

3

(27)

5.5

(49)

19

(168)

37

(328)

M4

(5/32”)

M5

(3/16”)

M6

(1/4”)

Terminal

T/5L3

W/6T3

English

Torque

Nm

(in lb)

4.5

(40)

6

(53)

8.3

(73)

0.5

(4.5)

Table 3.4 - Maximum torque for power connection

3.2.2 Location of the Grounding, Control and Power Connections

Control

Control

CONTROLE

Control

CONTROLE

48.2

(1.90)

39.0

(1.54)

ATERRAMENTO

39.0

(1.54)

13.3

(0.52)

114

(4.48)

56.3

(2.22)

62.8

(2.48)

32.7

(1.29)

ATERRAMENTO

33.0

36.3

84,8

(3.34)

(1.30)

14.8

14.8

(0.59)

(0.59)

(1.43)

Grounding Grounding Grounding

Dimensions in mm (in).

Figure 3.6 - Location of the grounding, control and power connections

CONTROLE

63.0

(2.48)

(2.48)

ATERRAMENTO

63.0

22.7

(0.89)

60.5

(2.38)

39.7

(1.56)

148

(5.81)

Grounding

ATERRAMENTO

75.5

(2.97)

Control

CONTROLE

75.5

(2.97)

25.1

(0.99)

197

(7.75)

17

Page 19

CHAPTER 3 - INSTALLATION AND CONNECTION

3.2.3 Recommended Power and Grounding Cables

English

The described specications in table 3.5 are valid only for the

following conditions:

Copper wires for 70 ºC (158 ºF) with PVC insulation for ambient

temperature of 40 ºC (104 ºF), installed in perforated and not

agglomerated conduits.

Naked or silver coated copper busbars with round edges with 1

mm radius with ambient temperature of 40 ºC (104 ºF) and bus

temperature of 80 °C (176 °F).

NOTE!

For correct cable dimensioning, consider the installation condition

and the maximum permitted line voltage drop.

SSW-07

Model

17 A 4 12 4 12

24 A 6 10 6 10

30 A 6 10 6 10

45 A 10 8 6 10

61 A 16 6 10 8

85 A 25 4 10 8

130 A 50 1 25 4

171 A 70 2/0 35 2

200 A 95 3/0 50 1

255 A 120 250 kcmil 2.5 14

312 A 185 350 kcmil 2.5 14

365 A 240 500 kcmil 2.5 14

412 A 300 600 kcmil 2.5 14

Power Cable Grounding Cable

2

) AWG (mm2) AWG

(mm

3.2.4 Power Supply Connection to the Soft-Starter SSW-07

18

Table 3.5 - Minimum cable gauge specication

DANGER!

The AC input must be compatible with the voltage range of the

Soft-Starter SSW-07.

DANGER!

Provide a power supply disconnecting switch for the Soft-Starter

SSW-07. This disconnecting switch must disconnect the AC input

voltage to the Soft-Starter SSW-07 whenever necessary (for

example: during maintenance services).

If a disconnected switch or a contactor is inserted in the motor supply

line never operate these devices with the motor running or when

the Soft-Starter SSW-07 is enabled.

ATTENTION!

The overvoltage control in the line that feeds the soft-starter must

be done using overvoltage suppressors with a clamping voltage of

680 Vac (phase-to-phase connection) and an energy absorption

capability of 40 joules (17 A to 200 A models) and 80 joules (255 A

to 412 A models).

Page 20

CHAPTER 3 - INSTALLATION AND CONNECTION

NOTE!

Use the wire sizes and fuses recommended in tables 3.5 and 3.7.

The connector tightening torque is indicated in table 3.4. Use only

copper wires 70 °C (158 °F).

3.2.4.1 Power Supply Capacity

The Soft-Starter SSW-07 is suitable to be used in a circuit capable

of supplying not more than X (according to table 3.6) symmetrical

rms amperes, Y maximum volts when protected by ultra-rapid fuses.

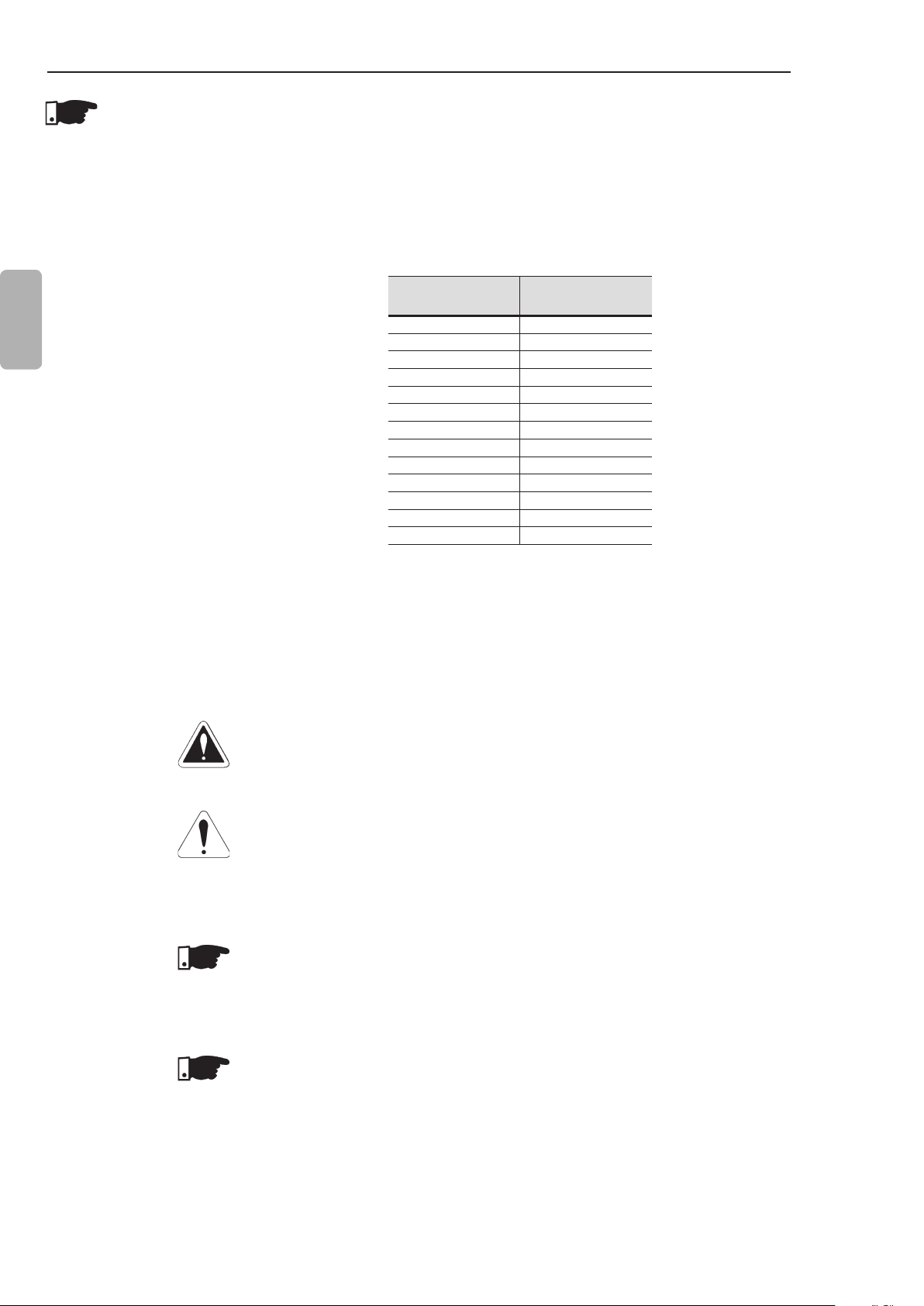

SSW-07 Model

17 A 5

24 A 5

30 A 5

45 A 5

61 A 5

85 A 10

130 A 10

171 A 10

200 A 10

255 A 25

312 A 25

365 A 25

412 A 25

Table 3.6 - Maximum current capacity of the power supply

Y = 220-575 V

X (kA)

The SSW-07 can be installed on power supplies with a higher

fault level, if it is protected by ultra-rapid fuses with an adequate

2

interrupting current and an I

t according to item 3.2.4.2.

English

3.2.4.2 Recommended Fuses

The fuses to be used on the input must be high speed semiconductor

fuses with l2t lower or equal to 75 % of the SCR value indicated in

2

table 3.7 (A

s). The fuse rated current should preferably be equal or

greater than the motor starting current to avoid cyclic overloads and

fuse opening in the forbidden region of the Time x Current curve.

These fuses will protect the SSW-07 in case of a short-circuit.

Normal fuses can also be used, instead of the high speed, which will protect

the installation from short-circuits, but the SSW-07 will not be protected.

For the electronic supply protection of the SSW-07 must be used

fuse type D, or circuit breaker type C as specied in table 3.7.

I²t of

SSW-07

Model

17 A 720 63 FNH1-63-K-A 10806688 50 6.6URD30TTF0050 170M2611

24 A 4000 80 FNH00-80-K-A 10705995 80 6.6URD30TTF0080 170M1366

30 A 4000 100 FNH00-100-K-A 10707110 80 6.6URD30TTF0080 170M1366

45 A 8000 125 FNH00-125-K-A 10707231 100 6.6URD30TTF0100 170M1367

61 A 10500 160 FNH00-160-K-A 10701724 125 6.6URD30TTF0125 170M1368

85 A 51200 250 FNH00-250-K-A 10711445 200 6.6URD30TTF0200 170M1370

130 A 97000 400 FNH1-400-K-A 10815073 315 6.6URD31TTF0315 170M1372

171 A 168000 500 FNH2-500-K-A 10824109 450 6.6URD32TTF0450 170M3170

200 A 245000 630 FNH2-630-K-A 10824110 500 6.6URD32TTF0500 170M3171

255 A 90000 500 FNH3-500-K-A 10833056 400 6.6URD32TTF0400 170M5158

312 A 238000 710 FNH3-710-K-A 10833591 500 6.6URD33TTF0500 170M3171

365 A 238000 710 FNH3-710-K-A 10833591 550 6.6URD33TTF0550 170M5161

412 A 320000 2 x 500 A FNH3-500-K-A 10833056 700 6.6URD33TTF0700 170M6161

the

SCR

(A²s)

WEG Fuses with CE Certication Fuses with UL Certication (A)

Fuse

Nominal

Current

(A)

Fuse Model

(Blade Contacts)

Part

Number

WEG

Fuse

Nominal

Current

(A)

Ferraz Shawmut/

Mersen

Flush End Contacts

Cooper

Bussmann

Bolted

Contacts

Control

Fuse

2 A

(D Type)

or

2 A

Circuit

Breakers

(C Type)

Table 3.7 - Recommended fuses

19

Page 21

CHAPTER 3 - INSTALLATION AND CONNECTION

NOTE!

The maximum I2t of the SSW-07 255 A fuse is smaller than 200 A

because of the thyristor constructive type used on this soft-starter.

3.2.4.3 Recommended Contactors

English

3.2.5 Soft-Starter

SSW-07

Connection to

the Motor

When the SSW-07 is used in applications that require an isolator

contactor, according to the gure 3.10 (K1), the use of WEG

contactors is recommended.

SSW-07 Model WEG Contactor

17 A CWM18

24 A CWM25

30 A CWM32

45 A CWM50

61 A CWM65

85 A CWM95

130 A CWM150

171 A CWM180

200 A CWM250

255 A CWM250

312 A CWM300

365 A CWME400

412 A CWME400

Table 3.8 - Recommended contactors

DANGER!

Power factor correction capacitors must never be installed at the

output of the Soft-Starter SSW-07. (U / 2T1, V / 4T2 and W / 6T3).

ATTENTION!

To ensure that the protections based on the current reading and

display operate correctly, for example the overload, the motor

nominal current must not be lower than 50 % of the nominal SoftStarter SSW-07 current.

NOTE!

Use the wire sizes and fuses recommended in tables 3.5, 3.6 and

3.7. The connector tightening torque is indicated in table 3.4. Use

only copper wires.

NOTE!

The Soft-Starter SSW-07 is provided with electronic protection

against motor overload. This protection must be set according to

the specic motor. When several motors are connected to the same

Soft-Starter SSW-07 use individual overload relays for each motor.

20

Page 22

CHAPTER 3 - INSTALLATION AND CONNECTION

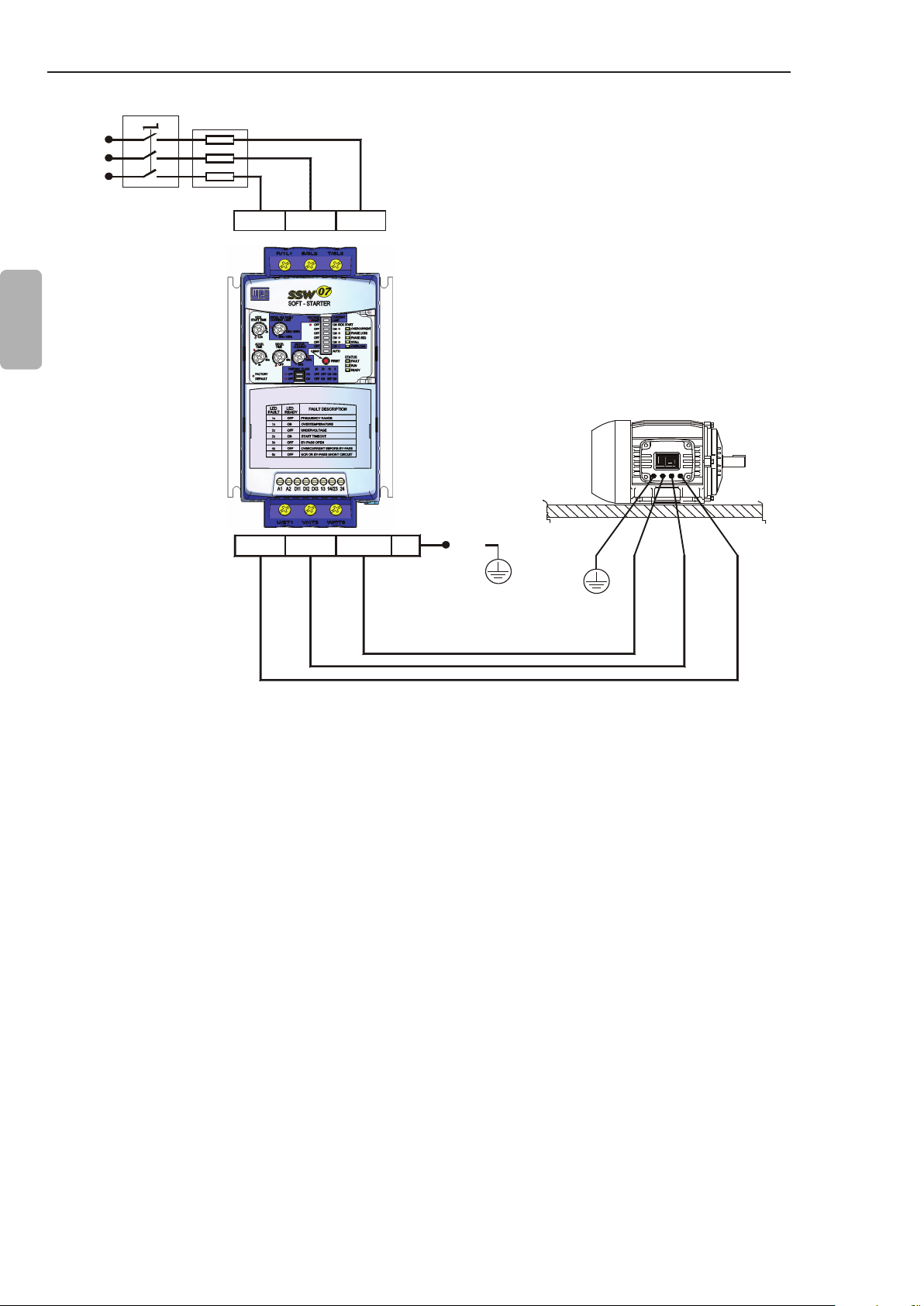

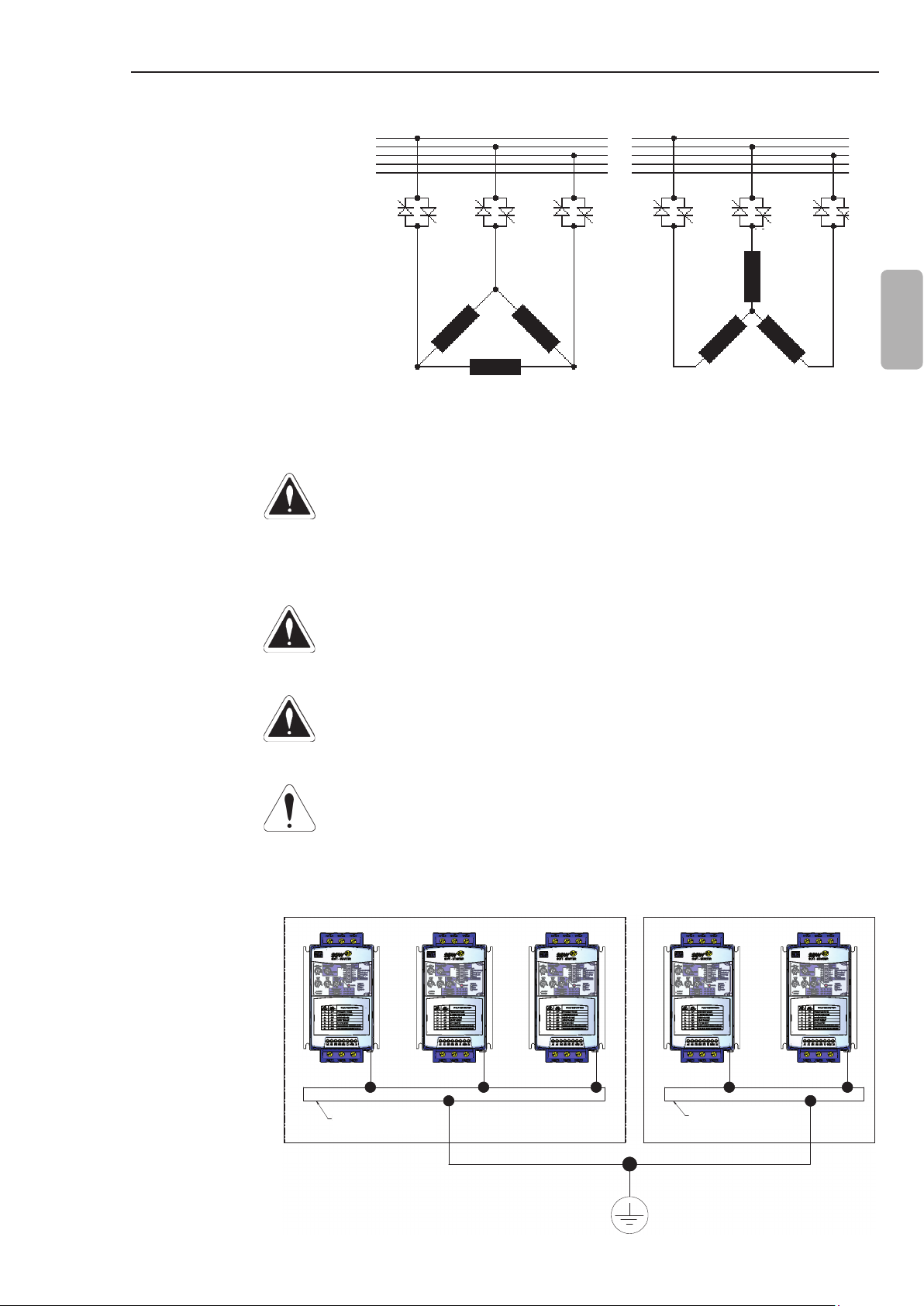

3.2.5.1 Standard Three-Wire Connection

3.2.6 Grounding

Connections

Line current of the Soft-Starter SSW-07 is equal to the motor current.

R

S

T

N

PE

R

U

1/U1

S

V

4/U2

6/W2

3/W1

T

2/V1

5/V2

Figure 3.7 - Soft-Starter SSW-07 with standard connection

R

S

T

N

PE

R

W

U

1/U1

2/V1

4/U2

S

5/V2

6/W2

T

WV

3/W1

DANGER!

The Soft-Starter must be grounded for safety purposes (PE).

The ground connection must comply with the local regulations.

Make the ground connection to a grounding bar or to the general

grounding point (resistance ≤10 ohms).

English

DANGER!

The AC input for the Soft-Starter SSW-07 must have a ground

connection.

DANGER!

Do not use the neutral conductor for grounding purpose. Use

dedicated ground conductor.

ATTENTION!

Do not share the ground wiring with other equipment that operate

with high current (for examples: high voltage motors, welding

machines, etc.). When several Soft-Starters SSW-07 are used,

observe the connections in the gure 3.8.

GROUNDING BAR

BARRA DE ATERRAMENTO

INTERNAL TO THE PANEL

INTERNA AO PAINEL

GROUNDING BAR

BARRA DE ATERRAMENTO

INTERNAL TO THE PANEL

INTERNA AO PAINEL

Figure 3.8 - Grounding connections for more than one Soft-Starter SSW-07

21

Page 23

CHAPTER 3 - INSTALLATION AND CONNECTION

EMI - Electronic Interference

The Soft-Starter SSW-07 is developed to be used in industrial

systems (Class A) according to Standard EN60947-4-2.

It’s necessary to have a distance of 0.25 m (10 in) between the

Soft- Starter SSW-07 control cables and motor cables.

Example: PLC wiring, temperature controllers, thermocouple cables, etc.

Grounding of the Motor frame

Always ground the motor frame. The Soft-Starter SSW-07 output

wiring to the motor must be installed separately from the input wiring

as well as from the control and signal wiring.

English

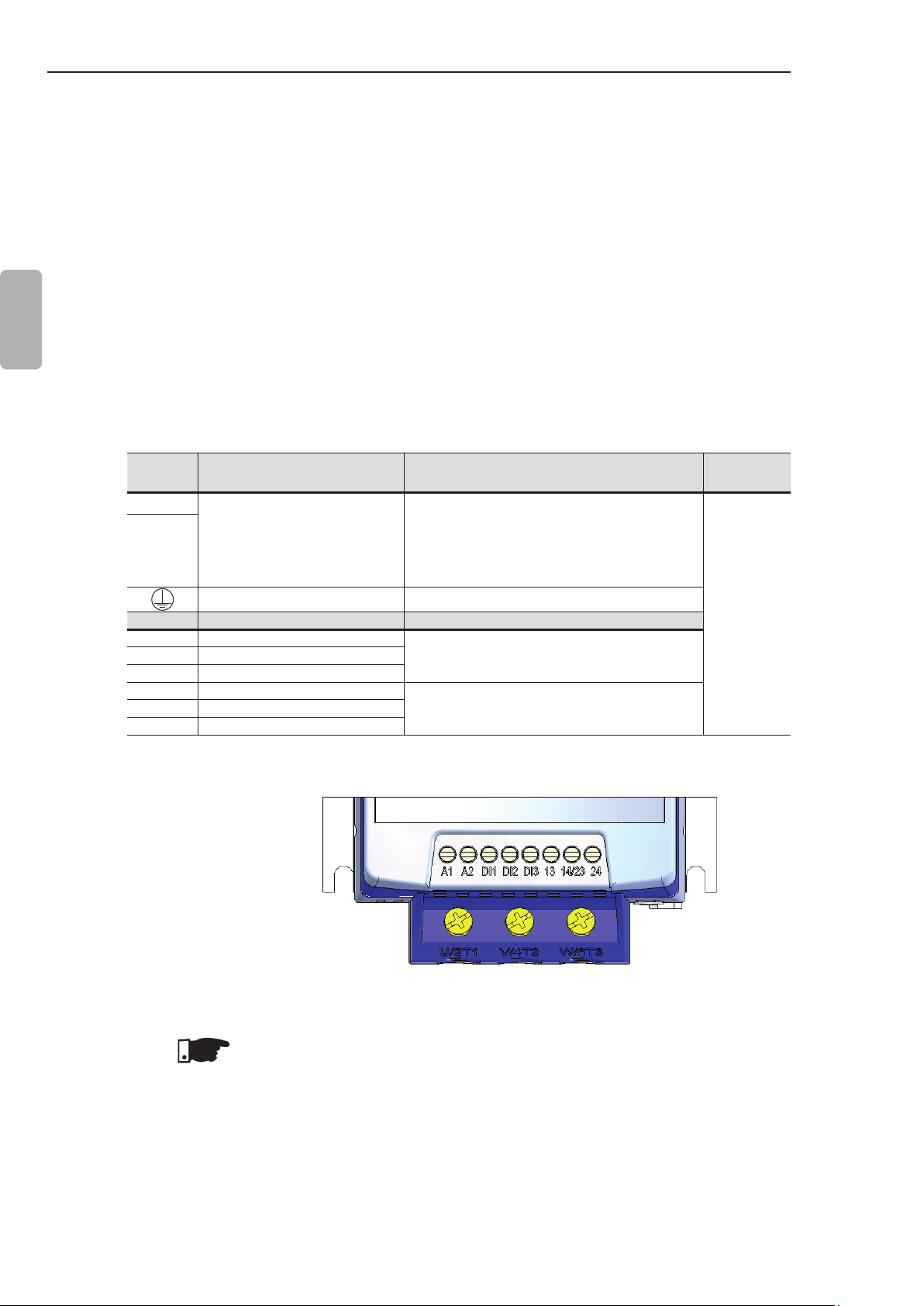

3.2.7 Control and Signal Connections

Terminal Description Specications

A1

A2

Terminal Factory Default Specications

DI1 Starts/Stops Motor

DI2 Fault reset

DI3 Fault reset

13 Relay 1 output - Operation

14/23 Relay common point

24 Relay 2 output - Full voltage

The control connections (digital inputs and relay outputs) are made

through the terminals (refer to gure 3.9).

Voltage: 110 to 240 Vac (-15 % to +10 %)

(models from 17 A to 200 A)

Electronics Supply

Grounding Only for the 255 to 412 A models

Table 3.9 - Description of the control connector pins

110 to 130 Vac or 208 to 240 Vac

(-15 % to 10 %) (models from 255 A

to 412 A).

3 isolated digital inputs

Voltage: 110 to 240 Vac (-15 % to +10 %)

Current: 2 mA Max.

Contact capacity:

Voltage: 250 Vac

Current: 1 A

Torque Nm

(in lb)

0.5 (4.5)

22

Figure 3.9 - Control terminals of the Soft-Starter SSW-07

NOTE!

It is recommended to use shielded cables for the Dix inputs when

using long cables (above 30 m) in noisy environments. The metallic

shield and A2 must be grounded.

Page 24

CHAPTER 3 - INSTALLATION AND CONNECTION

3.3 RECOMMENDED SET-UPS

Some recommended set-ups are shown here and they can be

completely or partly used.

The main warning notes for all the recommended set-ups are

shown below and are described in the schemes by their respective

numbers.

NOTES!

The use of fuses or circuit breakers at the input circuit is

1

necessary for the entire installation protection. It is not necessary

to use ultra-fast fuses for the SSW-07 operation; however, their

use is recommended for the soft-starter complete protection.

The transformer “T1” is optional and must be used when there

2

is a difference between the line voltage and the electronic power

voltage.

In case that damage at the SSW-07 Soft-Starter power circuit

3

keeps the motor running (e.g., shorted thyristors), the motor

protection is obtained with the use of the power isolating

contactor (K1) or circuit breaker (Q1).

English

Start push-button.

4

Stop push-button.

5

Start/Stop switch. Bear in mind that when using two-wire digital

6

input command (normally open switch with retention), in case

of a power interruption, upon return of power, the motor will be

started immediately if the switch remains closed.

In case of maintenance of the Soft-Starter SSW-07 or the motor

7

it is necessary to remove the input fuses or disconnect the power

supply to ensure the complete equipment disconnection from

the power supply.

The emergency stop can be used by disconnecting the

8

electronics power supply.

Undervoltage release for the Q1 power isolation circuit breaker.

9

23

Page 25

CHAPTER 3 - INSTALLATION AND CONNECTION

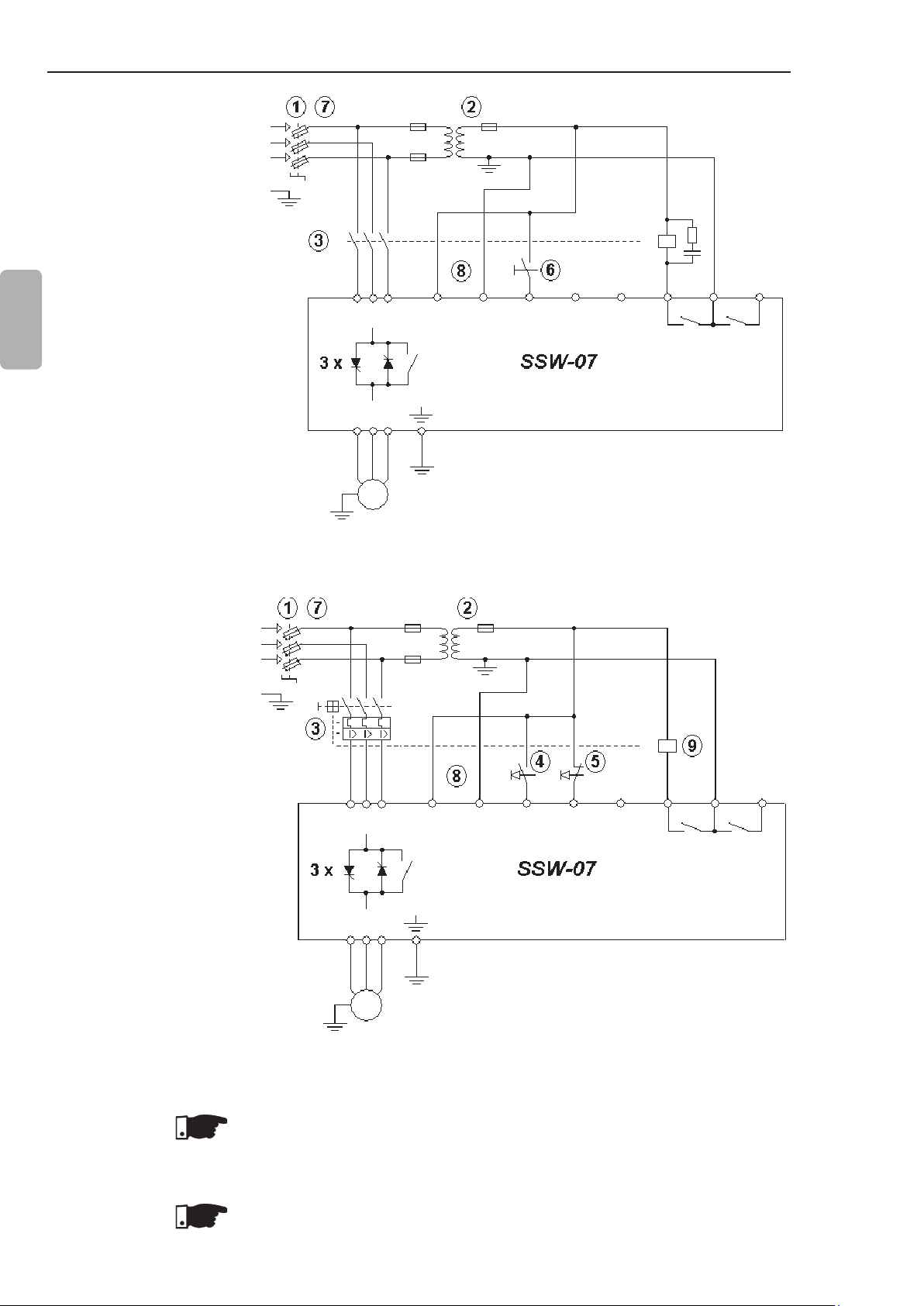

3.3.1 Recommended Set-up with Command via Two-wire Digital Inputs and Isolation Contactor

English

Refer to notes in item 3.3.

R

S

T

PE

K1

R S T

U V W

M

3~

T1

K1

RL1

23

14

24

RL2

DI1A2A1

DI2

DI3

13

Figure 3.10 - Recommended set-up with commands via two-wire digital inputs

and isolation contactor

3.3.2 Recommended

Set-up with

Command

via Threewire Digital

Inputs and

Circuit- Breaker

Refer to notes in item 3.3.

R

S

T

PE

Q1

R S T

U V W

M

3~

T1

Q1

DI1A2A1

DI2

DI3

13

14

23

RL1 RL2

24

24

Figure 3.11 - Recommended set-up with commands via three-wire digital

inputs and a circuit-breaker

NOTE!

It’s necessary to program the digital input DI2 for the three-wire

command function. Refer to item 4.10.

NOTE!

The RL1 shall be set to the “No fault” function. Refer to item 4.12.

Page 26

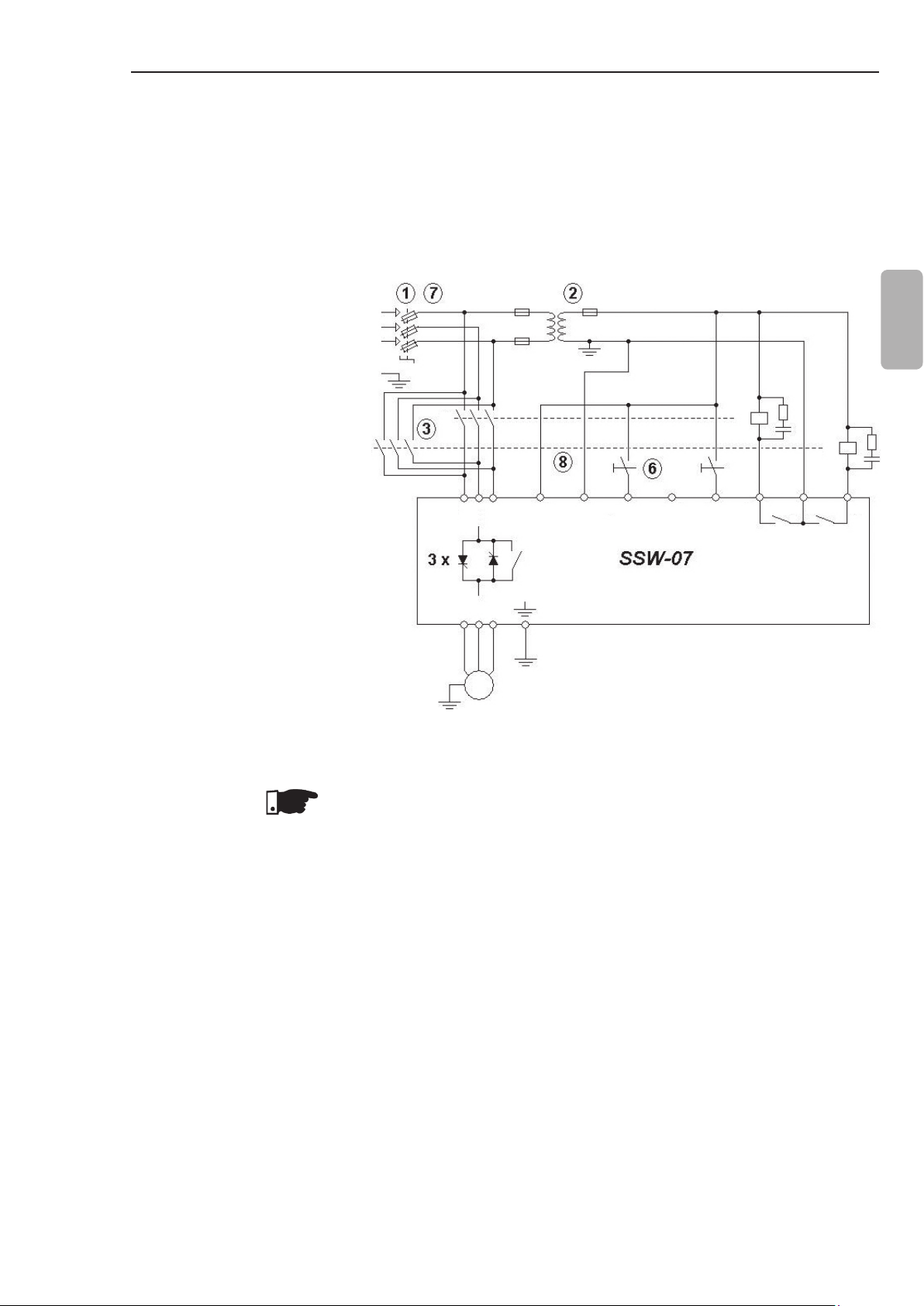

3.3.3 Recommended Set-up with Command via Two-wire Digital Inputs and Direction of Rotation

P220 = 1

P230 = 1

P263 = 1 (DI1 = Start/Stop two

wires)

P265 = 4 (DI3 = Rotation

Direction)

P277 = 4 (RL1 = FWD/REV - K1)

P278 = 4 (RL2 = FWD/REV - K2)

CHAPTER 3 - INSTALLATION AND CONNECTION

R

S

T

PE

K1

K2 K2

T1

K1

English

Refer to notes in item 3.3.

Figure 3.12 - Recommended Set-up with Command via Two-wire Digital

NOTE!

To program the parameters shown above, is necessary the use of

keypad or serial communication. See the Programming Manual for

more information.

R S T

U V W

M

3~

DI1A2A1

Inputs and Direction of Rotation

DI2

DI3

RL1

23

14

24

RL2

13

25

Page 27

CHAPTER 3 - INSTALLATION AND CONNECTION

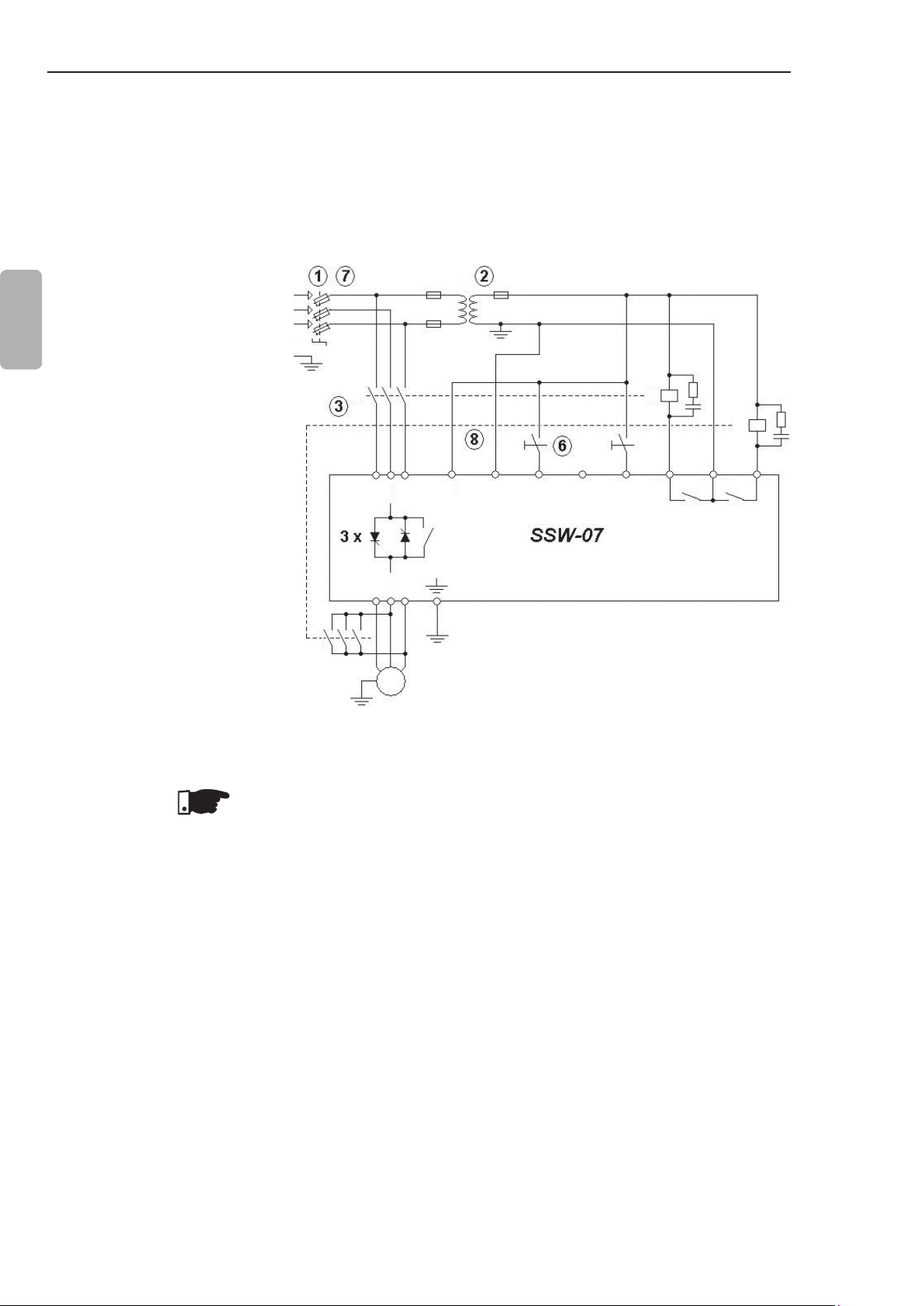

3.3.4 Recommended

Set-up with

Command via

Two-wires Digital

Inputs and DCBraking

P220 = 1

P230 = 1

P263 = 1 (DI1 = Start/Stop two

wires)

English

P265 = 5 (DI3 = Brake Off)

P277 = 1 (RL1 = Running)

P278 = 5 (RL2 = DC-Braking)

P501 ≥ 1 (DC Braking Time ≥ 1s)

R

S

T

PE

K1

T1

K1

K2

Refer to notes in item 3.3.

NOTE!

To program the parameters shown above, is necessary the use of

keypad or serial communication. See the Programming Manual for

more information.

K2

R S T

U V W

M

3~

DI1A2A1

DI2

DI3

13

RL1

23

14

24

RL2

Figure 3.13 - Recommended Set-up with Command via Two-wires Digital

Inputs and DC-Braking

26

Page 28

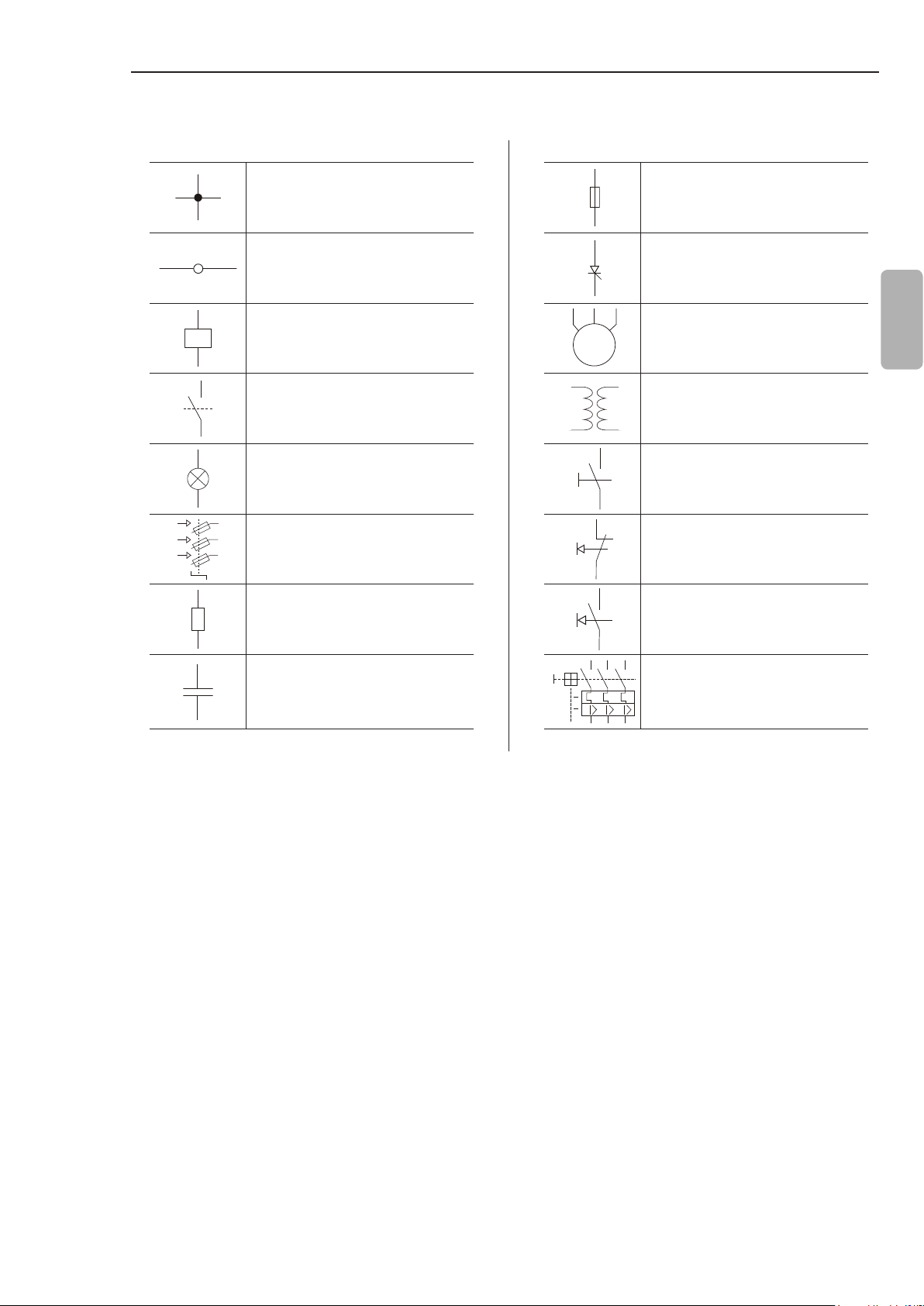

3.3.5 Symbols

CHAPTER 3 - INSTALLATION AND CONNECTION

Electrical connection between

two signals

Connection terminals Thyristor/SCR

Relay or contactor coil

M

3~

Normally open contact (NO) Transformer

Indicator light N.O Contact (with retention)

Circuit-breaker

(opens under load)

Resistor Normally open (NO)

Fuse

Three-phase motor

Normally closed (NC)

push-button

push-button

English

Capacitor Circuit-breaker with

undervoltage release

27

Page 29

CHAPTER 4

SETTING THE SSW-07

This chapter describes how to make the necessary settings for the

correct functioning of the SSW-07.

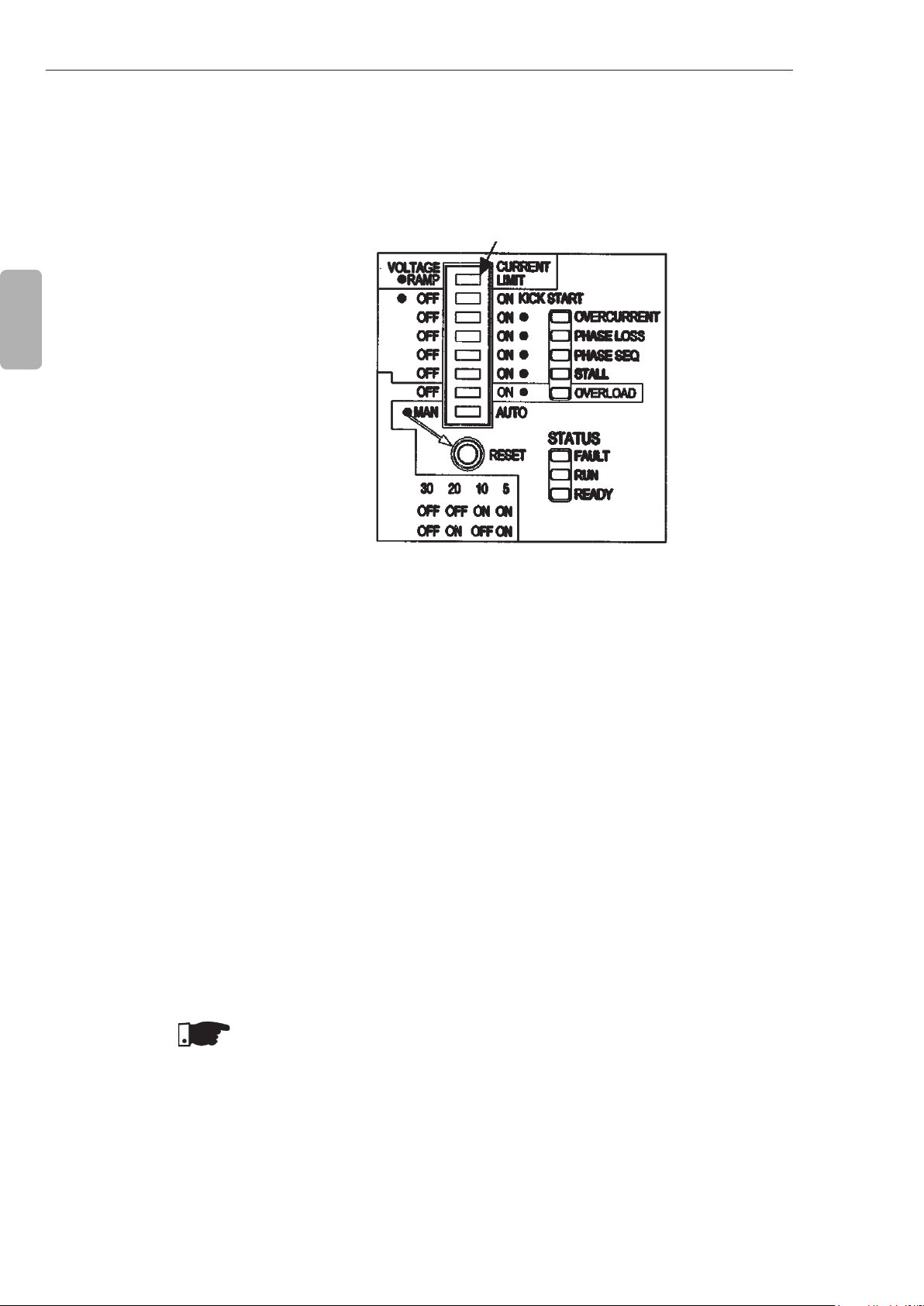

4.1 CONTROL TYPE SETTING

English

DIP Switch Control

Type Setting

Figure 4.1 - Control type setting

Select the type of starting control that best adapts to the application.

Voltage Ramp Starting:

This is the most commonly used method. Very easy to program

and set.

The Soft-Starter SSW-07 imposes the voltage applied to the motor.

Generally applied to loads with a lower initial torque or a square

torque.

This kind of control can be used as an initial working test.

Current Limit Starting:

The maximum current level is maintained during the start, being set

according to the application necessities.

Generally applied to loads with a higher initial torque or a constant

torque.

This kind of control is used to adapt the start to the capacity limits

of the supply network.

NOTES!

1. The Current Ramp control type, is only programmed using keypad

or serial communication. See the Programming Manual for more

details.

2. To program the control type in Pump control, see the Programming

Manual or item 5.1.4.

28

Page 30

CHAPTER 4 - SETTING THE SSW-07

4.2 KICK START

Kick Start Enabling

DIP Switch

English

Figure 4.2 - Kick Start enabling

Soft-Starter SSW-07 offers a Kick Start function for loads that

present a large initial resistance to movement.

This function is enabled through the Kick Start DIP Switch. The

duration of the voltage pulse is set through the trimpot Kick Start

Time.

The voltage pulse applied is of 80 % Un during the programmed

trimpot Kick Start Time.

4.3 INITIAL VOLTAGE SETTING

NOTE!

Use this function only for specic applications and where necessary.

Set the initial voltage to a value that the motor starts to run as soon

as the start command is given to the SSW-07.

Initial Voltage

Setting Trimpot

The dot indicates

the factory default

setting

Figure 4.3 - Initial voltage setting

29

Page 31

CHAPTER 4 - SETTING THE SSW-07

NOTE!

The Initial Voltage trimpot has an initial voltage setting function only

when the kind of control is programmed to start with a voltage ramp.

4.4 CURRENT LIMIT SETTING

English

This setting denes the maximum limit of the current during motor

starting in percentage of the nominal current of the Soft-Starter.

If the current limit is reached during the start of the motor, SoftStarter SSW-07 will maintain the current at this limit until the motor

reaches nominal speed.

If the current limit is not reached, the motor will start immediately.

The current limitation should be set to a level that the motor

acceleration can be observed, otherwise the motor will not start.

Current Limit

Setting Trimpot

Figure 4.4 - Current limit setting

NOTES!

If at the end of the acceleration ramp (set at the Trimpot Acceleration

Time), full voltage is not reached, a start timeout Fault will be shown.

This fault is indicated through the Fault LED ashing twice with the

Ready LED on.

The trimpot Current Limit has a Current Limit setting function only

when the kind of control is programmed to start with a Current Limit.

30

Page 32

CHAPTER 4 - SETTING THE SSW-07

4.5 ACCELERATION RAMP TIME SETTING

When Soft-Starter SSW-07 is programmed to Voltage Ramp control,

this is the voltage increment ramp time.

When Soft-Starter SSW-07 is programmed to Current Limit control,

this time is used as the maximum starting time, working as a

protection against blocked rotors.

English

Acceleration Ramp

Time Setting Trimpot

Figure 4.5 - Acceleration ramp time setting

NOTE!

The programmed acceleration time is not the exact motor

acceleration time, but the time of the voltage ramp or the maximum

starting time. The motor acceleration time depends on the motor

characteristics and the load.

4.6 DECELERATION RAMP TIME SETTING

Please consider that in cases where the relation of the SSW-07

current and the motor nominal current is 1.00, the maximum time

that the SSW-07 can work with 3 x In is 30 seconds.

Enables and sets the time of voltage decrease.

This setting should be used only for the deceleration of pumps to

reduce the water hammer. This setting must be made to achieve

the best pump performance.

NOTE!

This function is used to lengthen the normal deceleration time of a

load and not to force a lower time than that imposed by the load itself.

31

Page 33

CHAPTER 4 - SETTING THE SSW-07

English

Deceleration Ramp

Time Setting Trimpot

Figure 4.6 - Deceleration ramp time setting

4.7 MOTOR CURRENT SETTING

This setting denes the ratio of the SSW-07 current and the motor

current. The value of the setting is very important since it denes

the protection of the motor driven by the SSW-07. The setting of

this function interferes directly in the following motor protections:

-Overload;

-Overcurrent;

-Stall;

-Phase loss.

Calculation Example:

SSW-07 Used: 30 A

Motor Used: 25 A

Trimpot for the Motor Current Setting

Motor Current Setting = I

motor

I

SSW-07

Motor Current Setting = 25 A

30 A

32

Motor Current Setting = 0.833

Therefore it must be set at 83 %

Page 34

CHAPTER 4 - SETTING THE SSW-07

Motor Current

Setting Trimpot

Figure 4.7 - Motor current setting

English

4.8 MOTOR ELECTRONIC OVERLOAD PROTECTION

The motor electronic overload protection simulates the heating and

cooling of the motor, also known as thermal image. This simulation

uses as input data the True rms current.

When the thermal image passes the limit, the overload protection

trips and turns the motor off.

The adjustment of the thermal class is based on the motor locked

rotor current and locked rotor time. With this data it is possible to

nd a point in the gure to determine, which thermal class protects

the motor. Please refer to gure 4.8 for cold stall time or to gure

4.9 for hot stall time. The thermal classes below the point protect

the motor.

33

Page 35

CHAPTER 4 - SETTING THE SSW-07

Time t(s)

10000

1000

English

100

10

1

S.F.=1 1x 2x 3x 4x 5x 6x 7x 8x 9x

S.F.=1,15 1x 2x 3x 4x 5x 6x 7x 8x 9x 10x

Class 30

Class 25

Class 20

Class 15

Class 10

Class 5

x In motor

current

Figure 4.8 - Thermal classes of motor protection in cold condition

Time t(s)

1000

100

34

10

Class 30

Class 25

Class 20

Class 15

1

0.1

1x 2x 3x 4x 5x 6x 7x 8x 9x S.F.=1

Class 10

Class 5

x In motor

Current

Figure 4.9 - Motor protection thermal classes in hot condition at 100 % ln

Page 36

CHAPTER 4 - SETTING THE SSW-07

Overload Protection

Enabling DIP Swicth

Thermal class adjustment DIP Switches

Figure 4.10 - Overload protection Enabling and Adjustment

NOTES!

Adjust the motor current according to chapter 4.7 for the correct

function of the overload protection;

This protection is based on Three Phase IP55 Standard WEG

motors. If your motor is different, we recommend to adjusting a

lower thermal class. For more details refer to chapter 5.2;

When SSW-07 is without the electronic supply voltage (A1 and

A2), the thermal image is saved internally. When the supply (A1

and A2) is reestablished, the thermal image returns to the value

prior to the electronic supply loss;

The RESET of the electronic overload protection can be set to

manual function (man). In this case the RESET must be made

via digital input 2 (DI2) or through the RESET key. If the RESET

setting is automatic (auto), the fault condition will automatically

be reset after the cooling time;

The thermal image is set to zero, when the overload protection

is disabled.

English

35

Page 37

CHAPTER 4 - SETTING THE SSW-07

4.9 RESET

English

A fault condition can be reset using the RESET key at the front of

the SSW-07 or through a push-button (0.5 seconds) at DI3 (digital

input for RESET). Another way to reset the SSW-07 is by switching

Off/On the electronic power supply (A1 and A2).

NOTE!

The SSW-07 also allows for the possibility of automatic RESET by

enabling this function through the DIP Switch (auto):

Automatic RESET occurs after 15 minutes in the following

conditions:

-Overcurrent;

-Phase loss;

-Stall;

-Overcurrent before By-pass;

-Frequency out of range;

-Contact of the internal By-pass relay is open;

-Power control supply undervoltage;

-External fault.

For incorrect phase sequence there is no automatic RESET.

For electronic overload of the motor there is a specic algorithm

for the automatic RESET time.

4.10 DI2 DIGITAL INPUT SETTING

In the factory default, the DI2 digital input has its function programmed

for the reset of faults. DI2 can also be programmed to work as a

three wire control.

The three wire control allows the Soft-Starter to be commanded

through two digital inputs, DI1 as an ON input and DI2 as an OFF

input. This allows for the direct placement of two push buttons.

Refer to item 3.3.2.

To change the DI2 digital input, follow the instructions below:

1. To enter in programming mode, maintain the reset key at the

front of the SSW-07 pressed for 5 seconds. Maintain the reset

key pressed during programming;

2. When in programming mode, two LEDs will turn on (overcurrent

and phase loss), indicating that DI2 is programmed for fault Reset.

When three LEDs turn on (overcurrent, phase loss and phase

sequence), it indicates that the DI2 is programmed for three wire

commands;

3. To change the programming to three wire commands, move the

overcurrent DIP Switch and return to the previous position. The

three LEDs will turn on, indicating that DI2 is programmed for

three wire commands;

4. To change the DI2 programming to fault Reset, move the Kick

Start DIP Switch and return to the previous position. Two LEDs

will turn on, indicating that the DI2 is programmed for fault Reset;

5. Programming is concluded when the reset key is released.

36

Page 38

CHAPTER 4 - SETTING THE SSW-07

4.11 OUTPUT RELAY OPERATION

Operation Function

The relay of the Operation Function closes its N.O. contact

(13-14/23) every time the SSW-07 receives the enable command.

This contact is only opened at the end of the deceleration ramp

(when it is set via trimpot) or when the SSW-07 receives the

disable command.

The relay of the Full Voltage Function closes the N.O. contacts

(14/23-24) every time the SSW-07 applies 100 % of the voltage to

the driven motor. This contact opens when the SSW-07 receives

the disable command.

(Motor Voltage)

U

N

100 %

t

(13- 14/23)

t

Relay on

English

4.12 RELAY OUTPUT RL1 PROGRAMMING

Full Voltage Function

(14/23-24)

In the factory default programming, the relay output RL1 has its

function programmed for “Operation”. RL1 (13/14) can be also be

programmed for the “No Fault” function. This function allows the

installation of a circuit breaker with an undervoltage release at the

SSW-07 input. Refer to gure 3.3.2. In order to change the relay

output RL1 programming follow these instructions:

1. To enter in programming mode keep the reset key, at the SSW-07

front cover, pressed during 5 seconds, keeping it also pressed

throughout the programming;

2. When in the programming mode two LEDs turn on (Overcurrent

and Phase Loss), indicating that DI2 is programmed for Error

Reset. If three LEDs turn on (Overcurrent, Phase Loss and Phase

Sequence), it indicates that DI2 is programmed for three-wire

command. If the Overload LED turns on, then the RL1 function

is “No Fault”, otherwise the function is “Operation”;

3. To modify the RL1 function change the Overload DIP Switch

and put it back in the previous position. The Overload LED will

indicate the new programmed function:

- Overload LED off: Operation function;

- Overload LED on: No Fault function.

t

Figure 4.11 - Output relay operation

37

Page 39

5.1 APPLICATIONS AND PROGRAMMING

English

CHAPTER 5

PROGRAMMING INFORMATION AND SUGGESTIONS

This chapter helps the user to set the types of starting controls

according to their applications.

ATTENTION!

Suggestions and important notes for each type of starting control.

ATTENTION!

To know the correct programming of the parameters, have your

load data on hand and use the WEG (Soft-Starter) Dimensioning

Software available at WEG’s home page (http://www.weg.net).

If you are unable to use the software mentioned above, you can

follow some practical concepts described in this chapter.

Shown below are some characteristic curves with current and

starting torque behavior according to some kinds of control.

I/In

T/Tn

Current

Torque

Tn

I/In

T/Tn

38

Tn

Current

Torque

Figure 5.1 - Characteristic curves of torque and current in a direct on-line start

and by voltage ramp

Page 40

CHAPTER 5 - PROGRAMMING INFORMATION AND SUGGESTIONS

I/In

T/Tn

5.1.1 Voltage Ramp Starting

Current

Torque

Figure 5.2 - Characteristic curves of torque and current in a

current limitation start

Tn

1) Set the value of the initial voltage to a low value;

2) When a load is applied to the motor, set the initial voltage to a

value that makes the motor rotate smoothly from the instant it is

started.

3) Set the acceleration time with the necessary start time, initially

with short times, 10 to 15 seconds, and afterwards try to nd the

best starting condition for the used load.

U(V)

Start

100 %Un

English

0

Enable

Figure 5.3 - Voltage ramp starting

Voltage Ramp

t(s)

Disable

NOTES!

With long starting times, or when the motor is without a load,

vibration can occur during the start of the motor, therefore lower

the starting time;

If faults occur during the start, check all the connections from the

Soft-Starter to the supply network, motor connections, supply

network voltage levels, fuses and circuit breakers.

39

Page 41

CHAPTER 5 - PROGRAMMING INFORMATION AND SUGGESTIONS

5.1.2 Current Limit Starting

English

1) To start with a current limitation it is necessary to start with a load.

Initial test without load can be done with a voltage ramp;

2) Set the acceleration time with the necessary starting time, initially

with short times, 20 to 25 seconds. This time will be used as the

stall time in case the motor does not start;

3) Set the current limit according to the conditions that your electric

installation allows, as well as to the values that supply enough

torque to start the motor. It can initially be programmed with values

between 2x and 3x the nominal current of the motor (ln of the motor).

I(A)

Start

I Limitation

I Nominal

Maximum Time

0

Enable

Current Limitation

t(s)

Disable

5.1.3 Starting with Pump Control (P202 = 2)

Figure 5.4 - Current limit starting

NOTES!

If the current limit is not reached during the start, the motor will

start immediately;

Very low Current Limit values do not provide sufcient torque to

start the motor. Always keep the motor rotating once it is started.

For loads that need a higher initial starting torque, the Kick Start

function can be used;

If faults occur during the start, check all the connections from the

Soft-Starter to the supply network, motor connections, supply

network voltage levels, fuses and circuit breakers.

1) To start with pump control a load is necessary. No-load tests can

be done with voltage ramp;

2) The starting parameters setting depend mainly on the types of

hydraulic installations. Thus we recommend optimizing factory

settings, if possible.

3) Check if the motor rotation direction is an indicated on the pump

frame. If not, connect the phase sequence as indicated at P620;

40

Figure 5.5 - Direction of rotation of a hydraulic centrifugal pump

Page 42

CHAPTER 5 - PROGRAMMING INFORMATION AND SUGGESTIONS

4) Set the initial voltage - P101 – so the motor starts smoothly as

soon as it is enabled.

5) Set the acceleration time according to the application, and, that

the motor is able to start the load smoothly, but the required

acceleration is not exceeded. If acceleration times are set too

long, this may result in vibration or harmful motor overheating;

6) To check the correct starting process, always use a manometer

in the hydraulic installation. Pressure increase should not result

in sudden oscillations. Thus the pressure increase should be as

linear as possible;

English

U(V)

P101

0

Figure 5.6 - Manometer showing pressure increase

P102

Enable

100%UnStart

Pump Control

7) Program the deceleration initial voltage (P103) only when no

pressure drop is detected at the deceleration begin. With this

deceleration initial voltage you can improve the linear pressure

drop during the deceleration;

8) Set the deceleration time according to the application, and,

ensuring that the pump stops smoothly within the expected

limits. The set of excessively long times may result in vibrations

or harmful motor overheating;

U(V)

Figure 5.7 - Manometer showing the pressure drop

100%Un

0

P103

Parada

P104

Pára

P105

t(s)

9) Generally, the current increases at the end of the deceleration ramp

and in this case the motor requires more torque to achieve a smooth

water ow stop. When the motor has already stopped, but is still

enabled, the current will increase too much. To prevent this condition,

set P105 to a value that as soon it stop it is also disabled;

41

Page 43

CHAPTER 5 - PROGRAMMING INFORMATION AND SUGGESTIONS

10)Set P610 and P611 to current and time levels that prevent the

hydraulic pump from running without a load.

English

U(V)

P101

Start

0

Pump Control

Figure 5.8 - Start with pump control

100%Un

P103

DisableEnable

Stop

P104P102

P105

t(s)

NOTES!

1) If the hydraulic piping is not tted with a manometer, the water

hammer can be noted at the pressure relief valves;

2) Please, consider that sudden line voltage drops results in motor

torque drops. Thus, ensure that the power supply line characteristics

are within the characteristics required for motor operation;

3) If errors are detected during the motor start, check all connections

of the Soft-Starter to the power line, the motor connections, the

voltage levels of the power line, the fuses, circuit-breakers and

disconnecting switches.

5.1.4 Programming the control type in pump control

Is recommended program the control type in pump control using

keypad or serial communication, see the Programming Manual

for more details. In special cases, when is not available keypad or

serial communication, is also possible to program the control type

in pump control following these instructions:

1) To enter in programming mode, keep the reset key at the SSW-07

front cover pressed during 5 seconds, keeping it also pressed

throughout the programming;

2) When in the programming mode, LEDs will turn on indicating the

actual parameterization. See item 4.10 and 4.12;

3) To modify the control type, change the Stall DIP Switch and put

it back in the previous position. The Stall LED will indicate the

new programmed control type:

- LED Stall off: P219=0. Control type dened through Voltage

Ramp/Current Limit DIP Switch.

- LED Stall on: P219=2. Control type in Pump Control and

parameterization through Trimpots and DIP Switches.

42

Page 44

CHAPTER 5 - PROGRAMMING INFORMATION AND SUGGESTIONS

5.2 PROTECTIONS AND PROGRAMMING

5.2.1 Suggestion on

How to Program

the Thermal

Class

For each application exists a range of thermal classes, which might

be set. The overload protection should not trip during normal starting.

Therefore it is necessary to know the starting time and current, to

determine the minimum thermal class. The maximum thermal class

depends on the motor limit.

Determine the minimum thermal class:

1) Initially start at the standard thermal class, sometimes, but without

the motor overheating;

2) Determine the correct starting time and nd an average of the

current using a multimeter with a current probe to measure it; A

current average can be found for any type of starting control;

For example:

Starting an 80 A motor using a voltage ramp. The current starts at

100 A and goes to 300 A, returning afterwards to the nominal value

in 20 seconds.

(100 A + 300 A)/2 = 200 A

200 A/80 A = 2.5 x ln of the motor

Therefore: 2.5 x ln @ 20 seconds.

English

U(V) Start

Initial Voltage

P101

Figure 5.9 - Typical current curve during a voltage ramp start

100 A

0

Enable

P102

Accel Time

100 % Un

300 A

Motor

Current

t(s)

20 s

3) Use this time to nd the minimum class necessary to start the

motor in cold condition. In the item 4.8 Motor Electronic Overload

Protection it is possible to check the thermal class curves of the

motor in cold condition.

43

Page 45

CHAPTER 5 - PROGRAMMING INFORMATION AND SUGGESTIONS

t(s)

Cold

English

20 s

0

2.5 x ln of the

motor

Figure 5.10 - Checking the minimum class of curves in cold condition

F.S.=1

15

10

5

xln

Therefore the minimum class necessary to start the cold motor is

Class 10. Class 5 will trip during starting.

NOTE!

If the motor must start in the hot condition, class 10 will trip during

the second start. In the case a higher thermal class must be set.

Determine the maximum thermal class:

To correctly program the Thermal Class that will protect your motor it

is essential to have in hand the motor locked rotor current and locked

rotor time. This information is available in the motor manufacturer’s

catalogue. Put these values into gure 4.8, in case of the cold stall

time or into gure 4.9, in case of hot stall time.

For example:

Stall Current = 6,6 x ln

Hot Stall Time = 6s

t(s)

Hot

6 s

0

6.6 x ln of the

motor

Figure 5.11 - Checking the maximum class of curves in hot condition

Class 25 is the highest class that protects the motor.

30

25

20

xln

44

Page 46

CHAPTER 5 - PROGRAMMING INFORMATION AND SUGGESTIONS

NOTE!

Remember that this protection has as a standard the Three Phase

IP55 Standard WEG Motor, therefore if your motor is different, then

do not program the thermal class to its maximum, instead, program

it near its minimum thermal class to start.

Example of how setting the thermal class:

Motor data:

Power: 50 hp

Voltage: 380 V

Nominal Current (ln): 71 A

Service Factor (S.F.): 1.00

lp/ln: 6.6

Stall time: 12 s in hot condition

Speed: 1770 rpm

Motor + load starting data:

Starting by Voltage Ramp, starting current average:

3 x the nominal current of the motor during 17 s (3 x ln @ 17 s).

1) In the graph, gure 4.8 in cold condition, one can see the minimum

Thermal Class that will allow the start with a reduced voltage:

For 3 x ln of the motor @17 s, the next highest is adopted: Class 10.

2) In the graph, gure 4.9 in hot condition, one can see the maximum

Thermal Class that the motor can stand due to the stall time in hot

condition:

For 6.6 x ln of the motor @ 12 s, the next lowest is adopted. Class 30.

English

5.2.2 Service Factor

One now knows that Thermal Class 10 allows a start and Thermal

Class 30 is the maximum limit. Thus, a Thermal Class between the

two should be adopted, according to the quantity of starts per hour

and the interval of time between Off/On procedures the motor.

The closer to Class 10, the more protected the motor will be, the

fewer the starts per hour and the greater the interval of time must

be between Off/On procedures the motor.

The closer to Class 30, the closer it gets to the maximum limit of the

motor, thus there can be more starts per hour and lower intervals of

time between Off/On procedures the motor.

When the Service Factor (S.F.) is different from 1.00 and if there is

the need to use it in the application, this must be considered in the

setting of the overload protection. To avoid tripping of the overload

protection, when the service factor is used, the nominal motor current

set at the SSW-07 must be readjusted. If an acessorie with parameter

access is used, the service factor can be set directly in the P406,

avoiding the readjustment of the nominal currrent.

45

Page 47

CHAPTER 5 - PROGRAMMING INFORMATION AND SUGGESTIONS

Example of readjustment of the nominal current:

I

I

SSW-07

MOTOR

= 30 A

= 25 A

S. F. = 1.15

English

Setting of the Motor Current = I

MOTOR

x S.F. / I

= 25 A x 1.15 /

SSW-07

30 A = 96 %

ATTENTION!

The increased motor current has direct impact on the maximum

thermal class, that protects the motor, even if the S.F. parameter is

set.

Determine the maximum thermal class, considering the service

factor:

Stall Current = 6.6 x ln

Hot Stall Time = 6 s

Service Factor = 1.15

Before the maximum thermal class is veried in gure 4.9, the stall

current must be divided by the service factor.

Stall Current / S.F. = 6.6 / 1.15 = 5.74

t(s)

Hot

6 s

25

20

15

0

5.74 x In of the motor

Figure 5.12 - Checking of the maximum thermal class, considering the S.F.

xln

Class 20 is the highest class that protects the motor, if the service

factor is used.

46

Page 48

SOLUTION AND TROUBLESHOOTING

CHAPTER 6

6.1 FAULTS AND POSSIBLE CAUSES

Protection

Description and

Fault Display

Phase loss or

Undercurrent

E03

(LED Phase

Loss)

Flashing

When an error is detected, the Soft-Starter is blocked (disabled)

and the LED’s indicate this error by means of intermittent ashes.

In order that the Soft-Starter operates normally again after an error

trip, it is necessary to reset it. This procedure is performed in the

following ways:

Disconnecting and reapplying the AC power (power-on RESET);

Pressing the “RESET” key in the SSW-07 front panel (RESET

key);

Automatically by the automatic RESET. Enable this function via

DIP Switch (auto);

Via digital input DI2 or DI3.

Activation Description Probable Causes Reset

At starting: It occurs when there

is no voltage in the power supply

terminals (R/1L1, S/3L2 and

T/5L3) or when the motor is

disconnected.

With the motor running: It trips

when the current stays below

the programmed value longer

than the programmed time.

Referring to the nominal motor

current.

When the parameters are set

with the factory default values,

then this protection trips after

elapsing 1 second with phase

loss either at the input or at the

output (motor). It trips when the

current circulating through the

SSW-07 is less than 20 % of

the value adjusted at the Motor

Current trimpot.

In hydraulic pump applications, it may

be running with no load.

Phase loss in the three-phase

network.

Short-circuit or fault at the thyristor or

By-pass.

Motor not connected.

Motor connection is incorrect

Loose contact in the connections.

Starting problems with the input

contactor.

Input fuses are blown.

Incorrect programming of the Motor

Current trimpot.

Motor current consumption lower

than required for phase loss

protection to work.

English

Power-on.

Reset key.

Auto-reset.

DIx.

Over

temperature

in the power

section

E04

(LED Fault)

Flashes once

(LED Ready)

On

When the heatsink temperature

is superior to the limit.

Also trips when the temperature

sensor is not connected.

Table 6.1 - Faults and possible causes

Shaft load too high.

Elevated number of successive

starts.

Internal temperature sensor not

connected.

Starting cycle requires ventilation kit

(models from 45 A to 200 A).

Power-on.

Reset key.

Auto-reset.

DIx.

47

Page 49

CHAPTER 6 - SOLUTION AND TROUBLESHOOTING

Protection

Description and

Fault Display

Activation Description Probable Causes Reset

motor overload

(LED Overload)

English

Start timeout

during current

Flashes twice

(LED Ready)

Electronic

E05

Flashing

limit starting

E62

(LED Fault)

On

When the times given by the

programmed thermal class

curves exceed the limit.

When the starting time is

longer than the time set in the

acceleration ramp trimpot. Active

only with current limit starting.

Incorrect setting of the "Motor

Current" trimpot (motor current set).

The set value is too low for the motor

being used.

Starting sequence greater than

allowed.

Programmed thermal class too low.

Time between Off/On procedures

lower than that permitted by the

motor power refrigeration time.

Load on the motor shaft too high.

Thermal protection value saved when

the control is turned off and brought

back when turned back on.

Programmed time for the acceleration

ramp inferior to what is needed.

Value of the programmed current

limitation too low.

Motor locked, rotor blocked.

Power-on.

Reset key.

Auto-reset.

DIx.

Power-on.

Reset key.

Auto-reset.

DIx.

Stall

E63

(LED Stall)

Flashing

Overcurrent

E66

(LED

Overcurrent)

Flashing

Incorrect phase

sequence

E67

(LED Phase

Seq.)

Flashing

Activates before full voltage, if

the current is greater than twice

the nominal motor current.

It is only monitored when the

SSW-07 is at full voltage. When

the parameters are set with

the factory default values this

protection trips when the motor

current exceeds 2 times the

value adjusted in the trimpot

(Motor Current) for a time longer

than 1 second.

When the sequence of

synchronism signals

interruptions does not follow the

RST sequence.

Programmed acceleration ramp time

lower than the actual acceleration

time.

Motor shaft is locked

The transformer that supplies the

motor can be saturating and taking

too much time to recover from the

starting current.

Momentary motor overload.

Motor shaft is locked, rotor blocked.

Network phase sequence inverted at

the input.

May have been changed in another

place of the supply network.

Motor connection is incorrect.

Power-on.

Reset key.

Auto-reset.

DIx.

Power-on.

Reset key.

Auto-reset.

DIx.

Power-on.

Reset key.

DIx.

48

Table 6.1 - Faults and possible causes (cont.)

Page 50

Protection

Description and

Fault Display

CHAPTER 6 - SOLUTION AND TROUBLESHOOTING

Activation Description Probable Causes Reset

Undervoltage

in the control

supply

E70

(LED Fault)

Flashes twice

(LED Ready)

Off

Internal

By-pass relay

contact Open

E71

(LED Fault)

Flashes 3 times

(LED Ready)

Off

Overcurrent

before the

By-pass

E72

(LED Fault)

Flashes 4 times

(LED Ready)

Off

Frequency out

of tolerance

E75

(LED Fault)

Flashes once

(LED Ready)

Off