Page 1

Installation Instructions

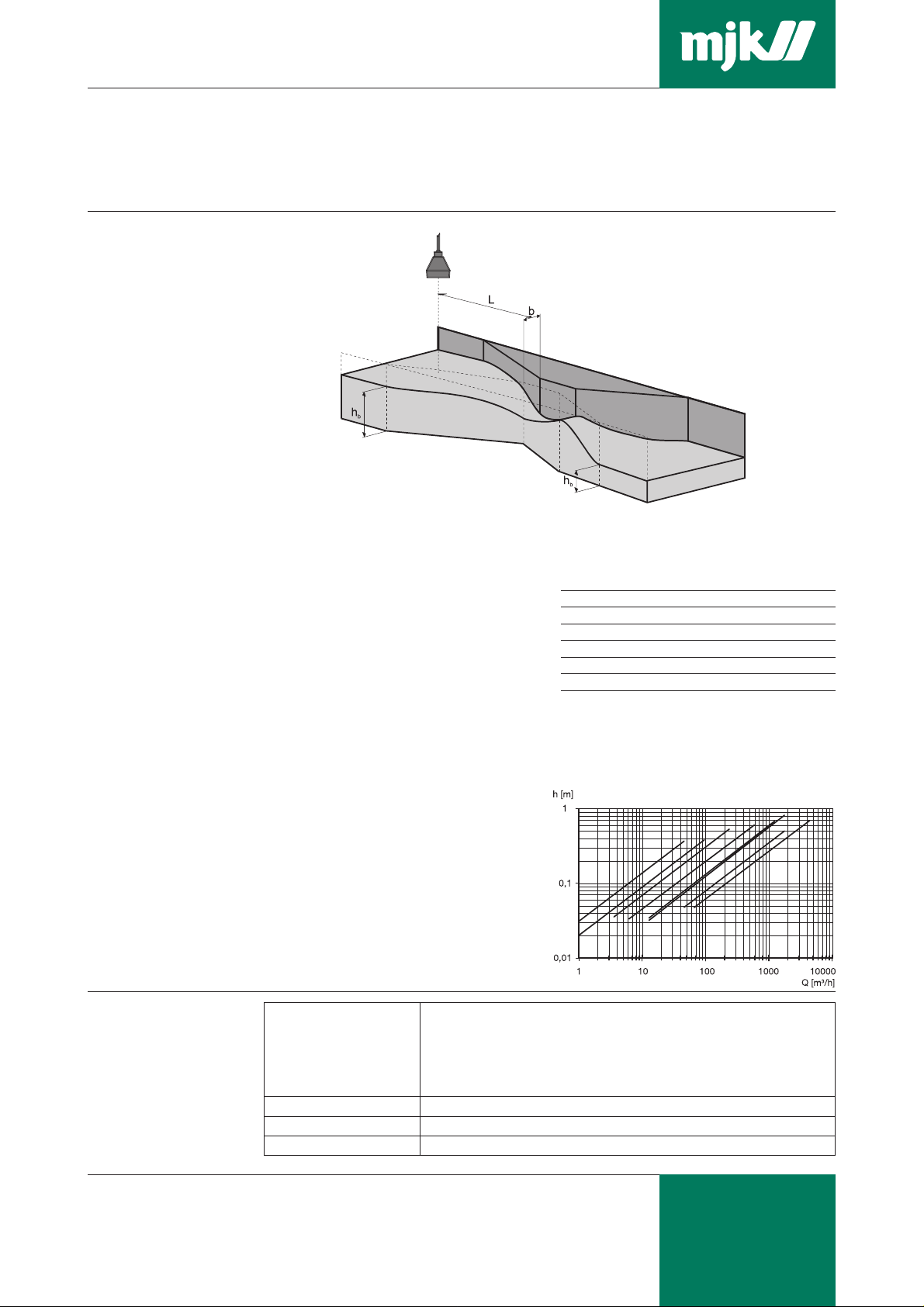

Parshall flumes

Note!

General

It is very important for the overall measuring

accuracy to comply with the installation

instructions on the next page.

At free flow, only the level ha is measured.

The location of the sensor is important and

must be carried out as illustrated below. It is

important to have a laminar flow (horizontal

streaming calm water with no whirls) at the

outlet and inlet from the flume, and the outlet

must be unobstructed.

The flume must extend upstream at least ten

times the width of the inlet section of the

flume. On the outlet side the only demand is

that the water should run freely.

The flow is calculated from the formula:

Q = k × h

where: Q = flow in m

b = throat width

h

a

h

b

L = distance to the sensor = 3 to 4 × h

n

a

3

= water level before the throat [m]

= water level in the throat [m]

a max

The factor k and exponent n are constants. The

formula complies to free flow, hb

< 0,7 × h

max

a max

T able for determination of the constants k, n and the distance

to the sensor .

bb

b

bb

kk

k

kk

nn

n

nn

LL

L

LL

2" 425 1,548 0,27

3" 630 1,548 0,30

6" 1310 1,574 0,41

9" 1851 1,528 0,58

12" 2407 1,519 0,89

Q/h diagram for Parshall flumes, the height ha is

shown as a function of the flow Q.

9” 12”

1” 2”

3”

6”

24”

36”

Specifications

MPARGB0204

Size Q

min

2 inch 50 mm 10 m

3 inch 75 mm 27,5 m

6 inch 150 mm 60 m

9 inch 225 mm 12 m

12 inch 300 mm 20 m

3

/h 100 m3/h 393 mm 10.3 kg

3

/h 275 m3/h 591 mm 16.5 kg

3

/h 600 m3/h 609 mm 33.0 kg

3

/h 1200 m3/h 753 mm 43.5 kg

3

/h 2000 m3/h 885 mm 100.0 kg

Q

max

H

max

Material Fibre glass

pH range pH 3 - 10

Temperature range - 20 … +30 °C, for short periods up to 90 °C

As our products are developed continuously,

we reserve the right to make any changes without prior notice.

Weight

MJK Automation A/S

Byageren 7

DK-2850 Nærum

Denmark

Tel.: (+45) 45 56 06 56

Fax: (+45) 45 56 06 46

mjk@mjk.dk

www.mjk.dk

Page 2

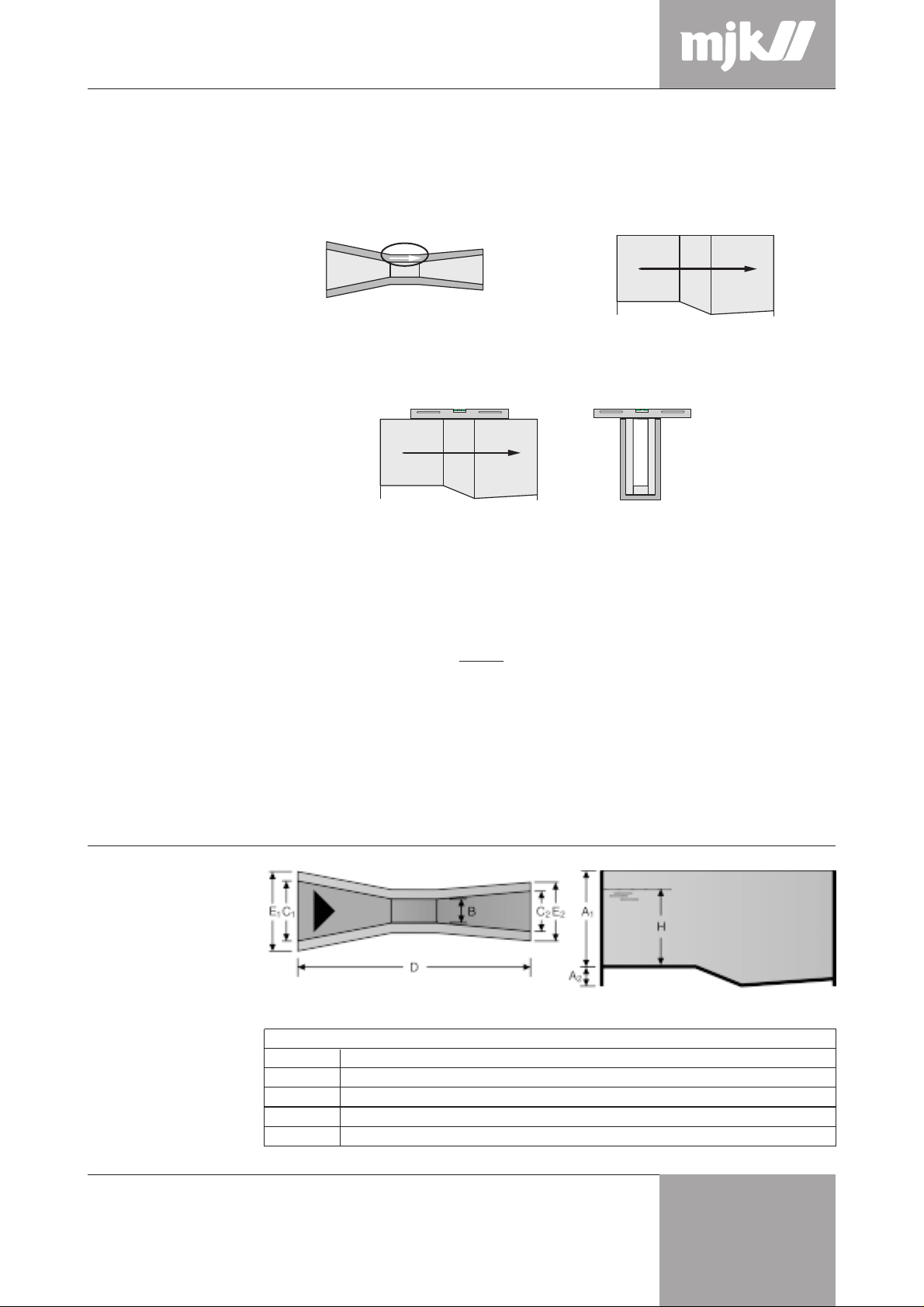

Installation instructions

Mounting of the flume

Sensor distance

The flume is designed to be moulded into concrete. Concrete with a low content of water

should be used - a plasticizer can be mixed in.

1 Position the flume correctly in relation to the flow direction. Observe the flow direction as

indicated with an arrow on the top edge of the flume:

Flow direction!

2 Fix the flume in the shuttering and make sure it is precisely leveled in both directions.

Levelled both laterally and longitudinally!

3 Cover inlet and outlet with plywood board or similar and put a piece of wood inside the

flume to support its sides.

4 Fill concrete into the shuttering until it lies a little higher than the bottom of the flume and

vibrate, so that the concrete becomes well distributed under the flume.

NB! Let the concrete harden before filling the sides of the shuttering, so the flume will be

firmly secured in the concrete.

5 Fill both sides with concrete.

Do not vibrate the concrete at the sides of the flume!

6 A 10 mm elastic infill along both sides of the flume is recommended to prevent water

penetration and possible frost fracture.

7 Mount the sensor bracket so that the sensor will be located at a distance ‘L’ from the

flume throat as explained on the front page.

Dimensions

Size A1 A2 B C1 C2 D E1 E2

2 inch 410 58 50.8 214 135 774 334 255

3 inch 610 75 76.2 259 178 914 379 298

6 inch 610 155 152.4 397 394 1525 517 514

9 inch 762 143 228.6 575 381 1626 695 501

12 inch 914 270 304.8 845 610 2867 965 730

All measurements in mm

2

MJK Automation A/S

Byageren 7

DK-2850 Nærum

Denmark

Tel.: (+45) 45 56 06 56

Fax: (+45) 45 56 06 46

mjk@mjk.dk

www.mjk.dk

Loading...

Loading...